LifeSafety Power FlexPower Vantage FPV4-R8PE1, FlexPower Vantage FPV6-R8E1, FlexPower Vantage R8 series, FlexPower Vantage FPV4-R8E1, FlexPower Vantage FPV6-R8PE1 Installation Manual

...

Smart Power Supply Chargers

R8 Access Power

Installation Guide

FPV4-R8E1

4 amp @ 12VDC or 3A/24VDC

Eight (8) Fused outputs

FPV6-R8E1

6 amp @ 12VDC or 24VDC

Eight (8) Fused outputs

FPV102-R8E1

10 amp @ 12VDC

Eight (8) Fused outputs

FPV104-R8E1

10 amp @ 24VDC

Eight (8) Fused outputs

For 230VAC input add "/E" to model number - example FPV6-R8E1/E

For larger enclosure change E1 sux to E2 in model number - example FPV6-R8E2

FPV4-R8PE1

4 amp @ 12VDC or 3A/24VDC

Eight (8) Class II Power Limited outputs

FPV6-R8PE1

6 amp @ 12VDC or 24VDC

Eight (8) Class II Power Limited outputs

FPV102-R8PE1

10 amp @ 12VDC

Eight (8) Class II Power Limited outputs

FPV104-R8PE1

10 amp @ 24VDC

Eight (8) Class II Power Limited outputs

TechSupport@LifeSafetyPower.com

LifeSafety Power, Inc.

PH 888.577.2898

P03-054

FlexPower Vantage R8 Access Power System - Installation Manual 2

Symbol Definitions

The following symbols are used throughout this manual:

This symbol is intended to alert the installer of shock

h

hazards within the enclosure. Service should only be

performed by qualified service personnel.

This symbol is intended to alert the installer of important

i

information intended to help the installer avoid personal

injury or property damage.

Warnings

Installation and service should be performed only by quali-

h

fied service personnel and should conform to all local codes.

To reduce the risk of electric shock or fire, do not

h

expose this equipment to rain or moisture.

This equipment shall be installed in a manner which

i

prevents unintentional operation by employees,

cleaning personnel, or others working in the premises, by falling objects, customers, building vibration,

or similar causes.

This equipment is not intended for use within the patient

i

care areas of a Health Care Facility.

Replace fuses only with the same type and rating as

h

indicated in the specifications section of this manual.

Batteries (if used) should be maintained at an ambient tem-

i

perature of between 32 and 120 degrees Fahrenheit (0-49

Celsius) or premature loss of battery power could occur.

Test and verify output voltage before connecting the

i

load.

R

The equipment discussed within this manual has been

tested to the following standards:

• UL294, UL603, UL1076

• ULC S318, ULC S319

• CSA C22.2 #107.1

FCC Information

Note: This equipment has been tested and found to com-

ply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules and ICES-003. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

To prevent impaired operation, ensure that all wiring is

i

routed and secured to prevent accidental open or short

circuit conditions.

The system and any batteries (if used) should be tested

i

at least once per year to ensure proper operation.

Enclosure Mounting

Mounting an Enclosure

Use the following procedure when mounting a wall-mount enclosure.

1. (Optional) Remove the enclosure’s cover.

2. Locate the top keyhole mounting holes in the back of the enclosure.

3. Mark and pre-drill the locations for the keyholes in the

mounting surface.

4. Partially install two fasteners appropriate for the surface on which the enclosure is being installed. Leave the

heads of the fasteners approximately ¼" out from the

surface. Minimum fastener size should be #10 or larger.

5. Hang the enclosure on the two fasteners and mark the

locations of the remaining mounting holes.

6. Remove the enclosure and pre-drill the locations for the

remaining mounting holes.

7. Re-hang the enclosure on the top mounting fasteners,

start the remaining fasteners and tighten all fasteners.

8. Reinstall the enclosure’s cover, if removed in step 1.

Conventions Used Within this Manual

Positional information (e.g. top, bottom, up, down, left,

right, etc.) is referenced with the board or enclosure in the

orientation shown in the illustrations in this manual.

i It is the installer’s responsibility to determine the

appropriate fastening system for use with the surface the enclosure is being mounted to.

i For UL1076 applications, after installation is com-

plete, the installer must install the two supplied 1"

long screws to the edge of the enclosure's cover

for additional security.

FPV4

FPV6, 102,

104

FlexPower Vantage R8 Access Power System - Installation Manua 3

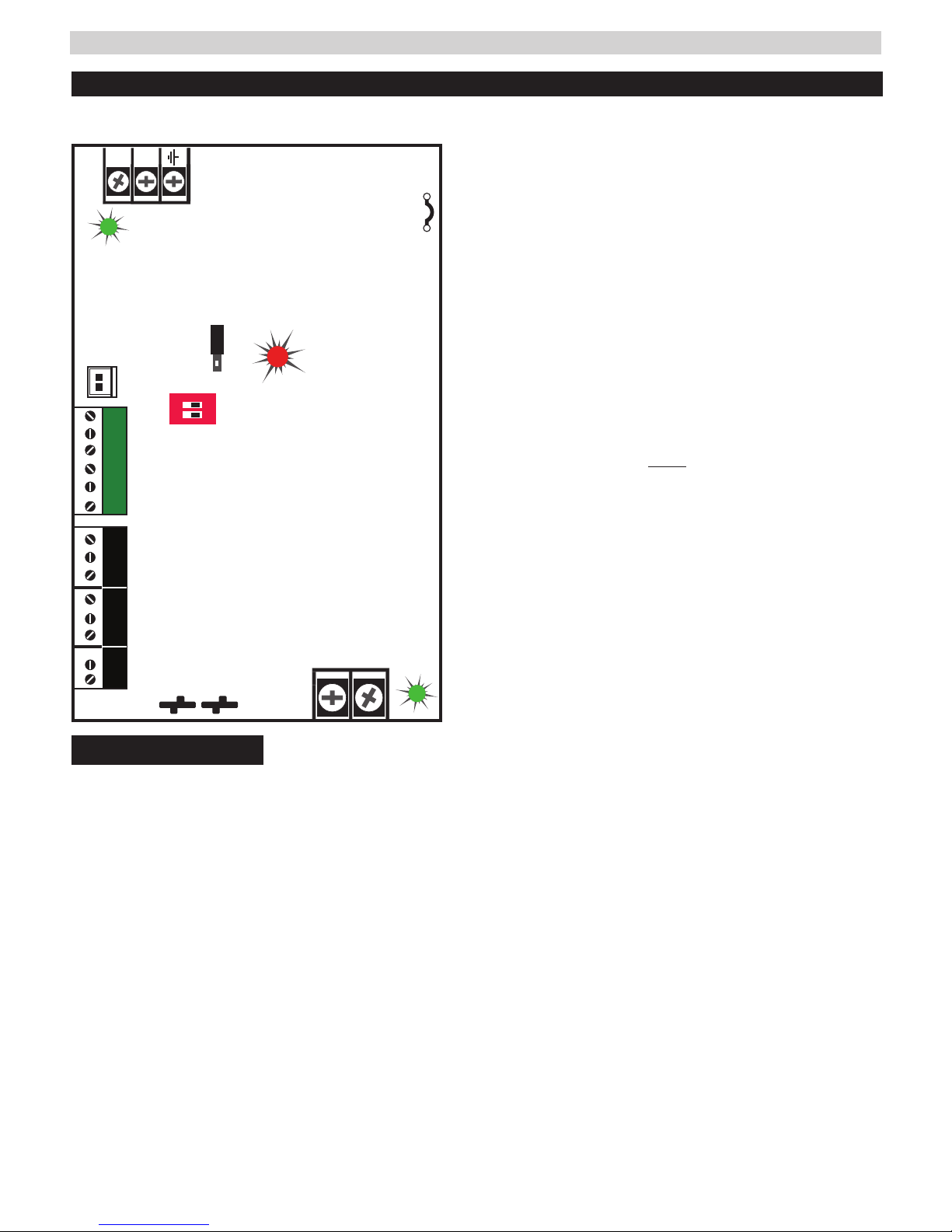

FPV4 Power Supply Overview -

This guide gives the basic information needed to install a system containing a single Vantage Power Supply for most applications.

N

L

AC ON

Voltage Select

12V

24V

ON

FAI and Charge

Current settings

FAI

FlexIO

FAI INPUTFAI INPUT

1 2

SYS FLTSYS FLT

I

Read before Power Up

1

AC Select

cut jumper for

230VAC

Leave INTACT for 120V input. CUT for 230V input.

I Failure to cut this jumper when using the FPV with a 230VAC

2

3

4

I Remove AC input power before changing the voltage select switch

5

AC Voltage Select Jumper - -

input will result in damage to the system and void the warranty.

AC Input primary AC connection.

AC LED (GREEN) indicates a valid AC input voltage is pres-

ent. Missing AC is indicated by this LED extinguishing.

H Always confirm the absence of AC power with a meter

before servicing to prevent electric shock.

Voltage Selection Jumper selects the output voltage

between 12V and 24V DC.

to avoid damaging the power supply or connected equipment.

FAI LED (RED) indicates activation of the Fire Alarm Input.

IFor FAI wiring see page 9.

FPV4

DC ON

Flex IO Connector Supplies FAI status to any accessory

6

boards. Receives fault signal from accessory boards.

FAI and Charge Current Configuration Switches

7

Switch 1 - FAI Selection

Off = Constant Output

On = Output switches on FAI

AC FLTAC FLT AUXAUX

Observe

Observe

battery polarity

battery polarity

or damage may result

or damage may result

–

i

+

ALWAYS DISCONNECT POWER BEFORE CHANGING

OUTPUT VOLTAGE TO PREVENT PS DAMAGE

I

Auxiliary Voltage is a fixed Class 2 DC output.

bl

Battery Terminal Connection for the optional

bm

battery backup. Battery set voltage must match

the DC output voltage setting.

Main DC Output of the power supply. The output

bn

can either be constant or switched based on the

configuration setting of switch.

• The DC ON LED will be green with voltage present.

Switch 2 - Charge Current

Off = High Charge Current

On = Low Charge Current

FAI Input The input from the FACP. Can be wired to accept

8

a NO, NC, Open Collector, or Voltage input.

See page 6 for FAI wiring information.

System Fault Contact - Contact labeling is adjacent to the

9

terminals and shown in the unpowered (FAULT) condition.

AC Fault Contact Contact labeling is adjacent to the

bk

terminals and shown in the unpowered (FAULT) condition.

AC fault is indicated on a missing AC Input voltage.

I For FPV6, FPV102, FPV104 - see page 4

FlexPower Vantage R8 Access Power System - Installation Manual 4

Observe battery polarity

or damage may result

Observe battery polarity

or damage may result

i

+

–

ON

1 2

For UL compliance, the AC fault contact

must be monitored by a listed control panel

N

L

FPV4

AC INPUT

AC Select

cut jumper for

230VAC

FlexIO

AC ON

DC ON

FAI and Charge

Current settings

12V 24V

SYS FLTSYS FLT

AC FLTAC FLT AUXAUX

FAI INPUTFAI INPUT

FAI

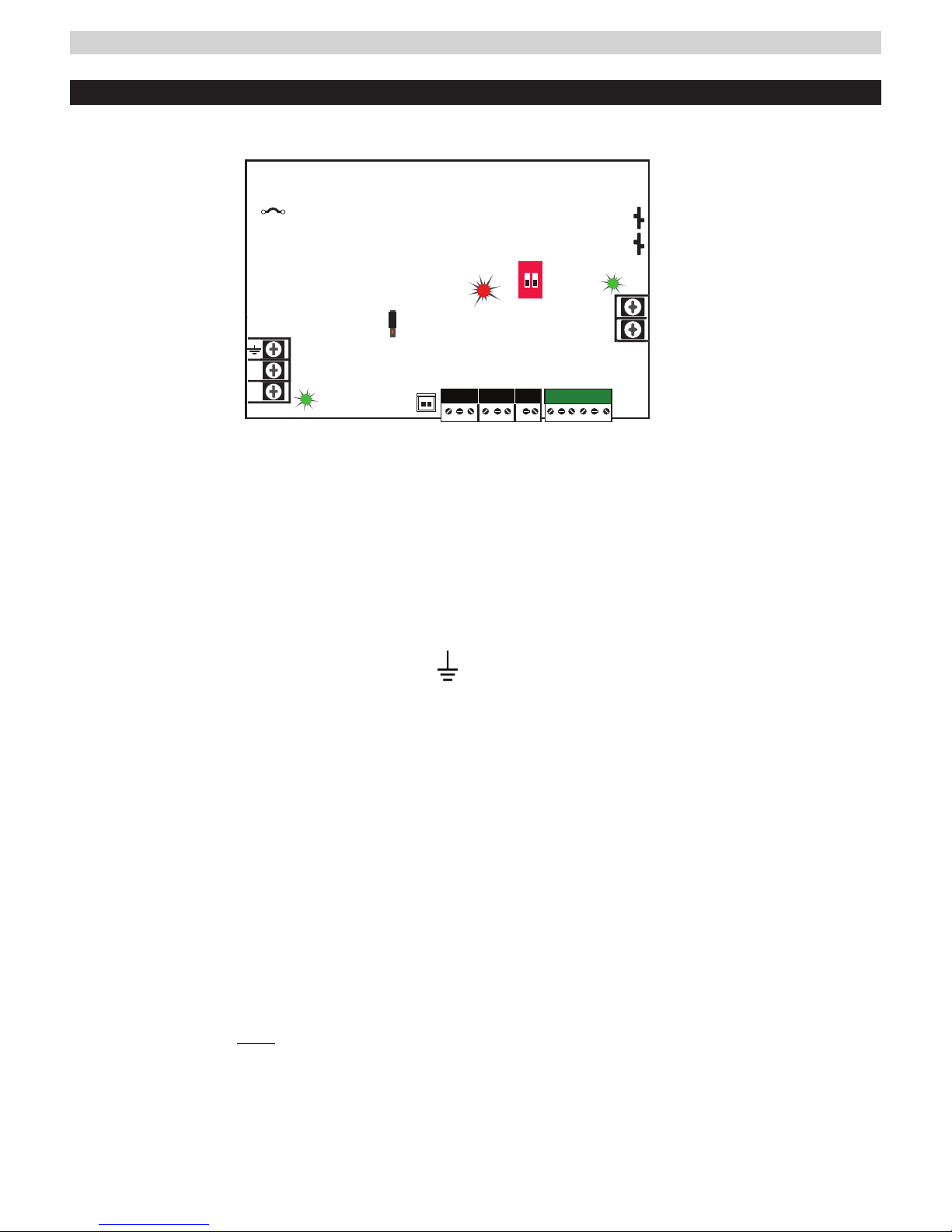

FPV6, 102, 104 Power Supply Overview -

I

Read before Power Up

This guide gives the basic information needed to install a system containing a single Vantage Power Supply for most applications.

AC Select

cut jumper for

230VAC

AC INPUT

N

L

AC Input Voltage Selection

1

Leave INTACT for 120V input. CUT for 230V input (models

ending in "/E" have jumper precut for 230VAC input).

I Failure to cut this jumper when using FPV power sup-

ply with a 230VAC input will result in damage to the system

FPV6 12/24V @ 6A

FPV102 12V @ 10A

FPV104 24V @ 10A

AC ON

12/24VDC jumper

on FPV6 only

preset to 12V

FlexIO

SYS FLTSYS FLT

For UL compliance, the AC fault contact

must be monitored by a listed control panel

+

FAI and Charge

Current settings

ON

1 2

1

AC FLTAC FLT AUXAUX

6

2

FAI INPUTFAI INPUT

Charge Current / Main output FAI Configuration Switches

Switch 1 - FAI Selection I Switch must remain Off.

FAI selection made on R8 board - page 9.

–

DC ON

Switch 2 - Charge Current

Off = High Charge Current | On = Low Charge Current

and void the warranty.

FLEX IO Connector

7

AC Input Terminal Block

2

The primary AC connection. Connect Hot Line to terminal

Supplies FAI status to any accessory boards. Receives fault

signal from accessory boards.

"L", neutral to terminal "N" and earth ground to terminal

System Fault Contact

For 230VAC input cut JP1 Jumper (see #1 above).

8

The System Fault contact output. Contact labeling is ad-

I Models ending in "/E" are factory pre-set for 230VAC input.

AC ON LED (green)

3

Indicates a valid AC input voltage is present. Missing AC is

indicated by this LED extinguishing.

H Always confirm the absence of AC power with a meter

before servicing to prevent electric shock.

jacent to the terminals. When at fault, the NO-C contact is

open, NC-C contact is closed (relay not energized).

AC Fault Contact

9

The AC Fault contact output. Contact labeling is adjacent to

the terminals. When AC is lost, the NO-C contact is open,

NC-C contact is closed (relay not energized).

FAI LED (red)

4

Indicates activation of the Fire Alarm Input.

12/24V Selection Jumper (model FPV6 only)

5

This selects the output voltage between 12V and 24V DC

on FPV6 models. The FPV power supply must be completely powered down before changing this setting. Voltage markings are printed on the PC Board adjacent to the

selector.

I Remove AC input power before changing the voltage select

jumper to avoid damaging the power supply or connected equipment.

I Models FPV102 and FPV104 are a fixed output voltage:

FPV102: 12V / 10 Amps

FPV104: 24V / 10 Amps

AUX Output

bk

The auxiliary voltage is fixed Class 2 Power Limited DC output.

FAI Input

bl

The input from the FACP. Can be wired to accept a NO, NC,

Open Collector, or Voltage input.

See page 6 for FAI wiring information.

Main Output

bm

This is the main DC output of the power supply.

Battery Terminal Connection

bn

The connection for the optional backup battery. Battery set

voltage must match the DC output voltage setting.

FlexPower Vantage R8 Access Power System - Installation Manua 5

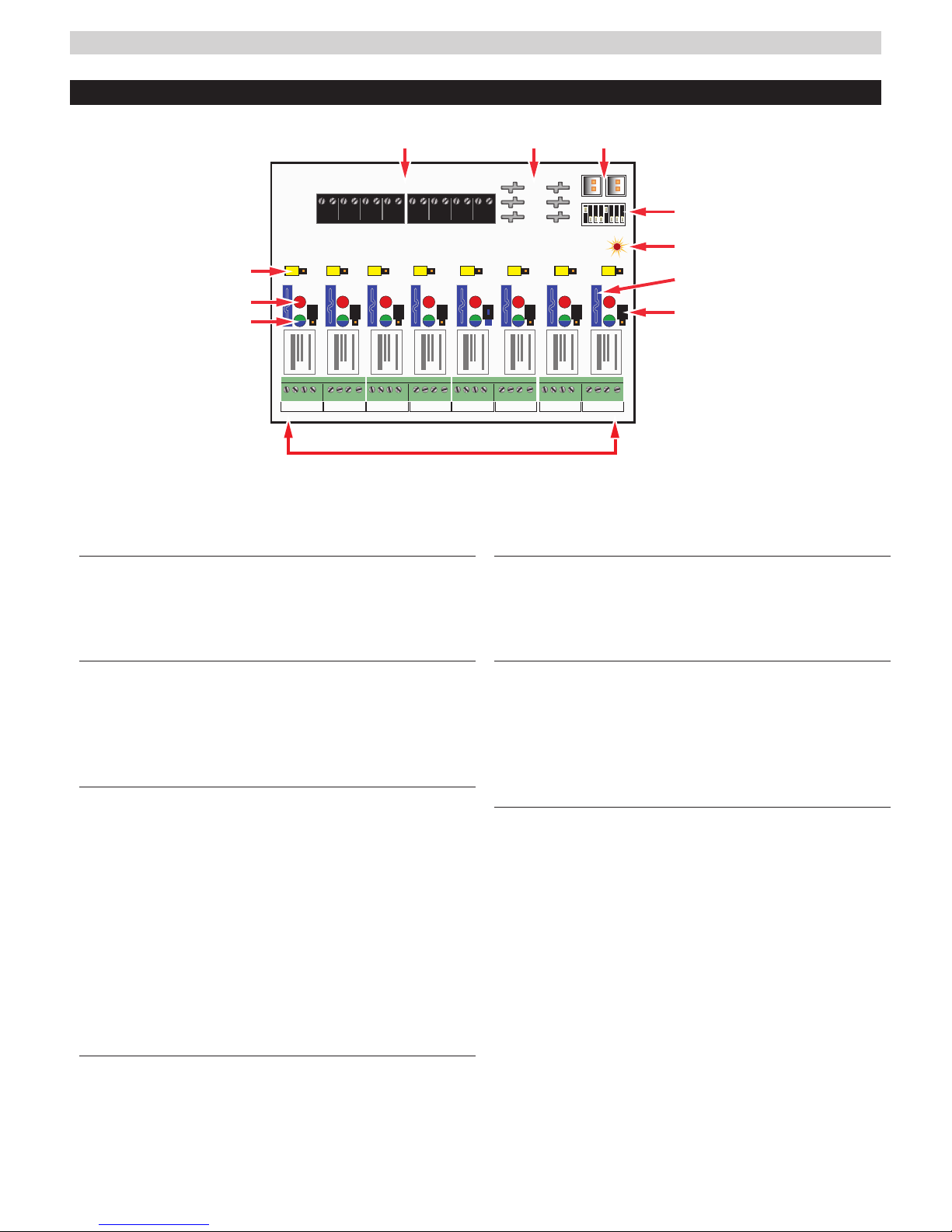

R8 Power Control Accessory Module Overview

INPUT 1 - 4 INPUT 5 - 8

GND GND GND GND

GND GND GND GND

1 2 3 4

1 2 3 4

B1 B2 B1 B2 B1 B2 B1 B2 B1 B2 B1 B2 B1 B2 B1 B2

5 6 7 8

5 6 7 8

NC C N0 COM NC C N0 COM

OUTPUT 1 OUTPUT 2

NC C N0 COM NC C N0 COM

OUTPUT 3 OUTPUT 4

I The relay contact outputs have suppression diodes across them. For a dry contact output, the output

diodes must be cut and the yellow and black jumpers removed.

FlexIO Connectors

1

These connectors pass the FAI signal to the R8/R8P

board and pass the FlexIO buss on to other accessory

boards in the system.

GND GND GND GND

GND GND GND GND

NC C N0 COM NC C N0 COM

OUTPUT 5 OUTPUT 6

B1

B2

BR

1

FAI

8

NC C N0 COM NC C N0 COM

OUTPUT 7 OUTPUT 8

Relay State LEDs (Red)

5

These LEDs indicate the state of the output relay.

The LED will be lit when the relay is active and extinguished when the relay is not active.

B1, B2, and BR Connectors

2

These connectors are the voltage inputs for the R8/R8P board.

BR is the DC Common buss in the system. B1 is the positive

voltage input for the first power supply. In dual voltage systems, B2 is the input for the second power supply.

Zone Inputs (IN1 – IN8)

3

These are the zone input terminal strips. These terminal

strips are removable and accept wire sizes from AWG14

– AWG22. The terminals are labeled on the PC board

near the terminal strip. See the Input Wiring section of

this manual for more information.

• When using a normally open relay contact input, the

contact is connected across the IN and GND terminals.

• When using an open collector (transistor) input, the

open collector it connected to the IN terminal. Note

that the input source must be common grounded

with the

Voltage Selection Jumpers (Yellow)

4

R8/R8P

board’s power source.

These jumpers select the power input to be used for

each output. For single voltage systems, this jumper

should stay in the B1 position. this jumper should be

removed on any zones where a dry contact output is

needed.

Output Voltage LEDs (Dual Color - Blue/Green)

6

These LEDs indicate the voltage of the zone’s output.

• BlueThe output is set to 24V

• GreenThe output is set to 12V

• OffFuse or PTC open or dry contact output se-

lected

Zone Outputs (01 – 08)

7

These are the zone output terminal strips. These terminal strips are removable and accept wire sizes from

AWG14 – AWG22. The terminals are labeled on the PC

board near the terminal strip. See the Output Wiring

section for more information.

• C, NC, and NO are the relay output.

– The C terminal will always have voltage present

when the yellow jumper is installed, regardless of

relay state.

– NC will have voltage when the relay is NOT ACTIVE. Use for Fail Safe locks.

– NO will have voltage when the relay is ACTIVE.

Use for Fail Secure locks.

• COM is the DC common terminal for the output

I CAUTION When powering magnetic loads such as

maglocks, door strikes, solenoids, etc, each of these

loads must have a reverse protection diode either built-

Loading...

Loading...