LifeSafety Power FlexPower C4, FlexPower C4P, FlexPower C8, FlexPower C8P Installation Manual

C4/C4P, C8/C8P Installation Manual

LifeSafety Power, Inc. | PH 888.577.2898 | TechSupport@LifeSafetyPower.com

P03-006 Rev A15

C4,C4P / C8, C8P Installation Manual

Table of Contents

Description .....................................1

Specifications ...................................1

Regulatory Information ............................1

Mounting the Power Control Modules ................1

Power Control Accessory Overview. ..................2

Connecting the Power Control Modules ...............4

Input and Output Wiring ...........................5

Common Jumper Settings .........................6

C4/C4P Application Example ........................7

C8/C8P Application Example ........................8

Description

The C4/C4P/C8/C8P power control modules add 4 or 8 zones

respectively, to an FPO power supply system. The C4/C4P/

C8/C8P accept either one or two voltage sources, either of

which are selectable for output on a zone-by-zone basis. Each

zone is fully controllable via a zone input which accepts a voltage, relay contact, or open collector input. Each zone output is

selectable for FAI operation, fail-safe or fail-secure, and voltage or relay contact output. The suffix "P" added to the model

number denotes Class 2 Power Limited outputs.

Regulatory Information

The equipment discussed within this manual has been tested

to the following standards:

• UL294, UL603, UL1076

• ULC S318, ULC S319

• CSA C22.2 #205

• CSFM Approved

Mounting the C4/C4P/C8/C8P Power Control Modules

Mounting of the board to an enclosure is via the four

snap-in standoffs supplied.

1. Locate the appropriate mounting holes in the enclosure

and snap the standoffs into the holes.

2. Align the board mounting holes with the standoffs (be

sure the PC board is properly oriented) and snap the

board onto the standoffs.

C4

Specifications

Power Input

Zone Input

Zone Output

Fuse

Size

Weight

Voltage 12 or 24VDC nominal

Current 12A maximum

Standby Current 350mA (C4)

Voltage Input 12 or 24VDC

Max Current 10mA

Voltage Same as input

C4/C8 Current

C4P/C8P Current

3A ATM automotive style (C4/C8 only)

C4/C4P

C8/C8P

C4/C4P 0.20lb (0.10kg)

C8/C8P 0.35lb (0.16kg)

700mA (C8)

All lock control relays active

3.0A resistive

2.5A resistive (Class 2 Power Ltd)

4.00" x 2.50" x 1.0"

(102mm x 64mm x 25 mm)

6.00" x 4.00" x 1.0"

(152mm x 64mm x 25 mm)

C8

Class 2 power limited wiring must be seperated from non-power limited

wiring by a minimum of 1/4 inch and must use seperate knockouts.

• The installation and all wiring methods shall be in accordance with ANSI/

NFPA70 and all local codes.

For ULC compliance, installation and all wiring methods shall be in accordance with the Canadian Electrical Code, C22.1, Part I, Section 32 .

All input wiring to the module shall be located within the same room (3 m).

2 3

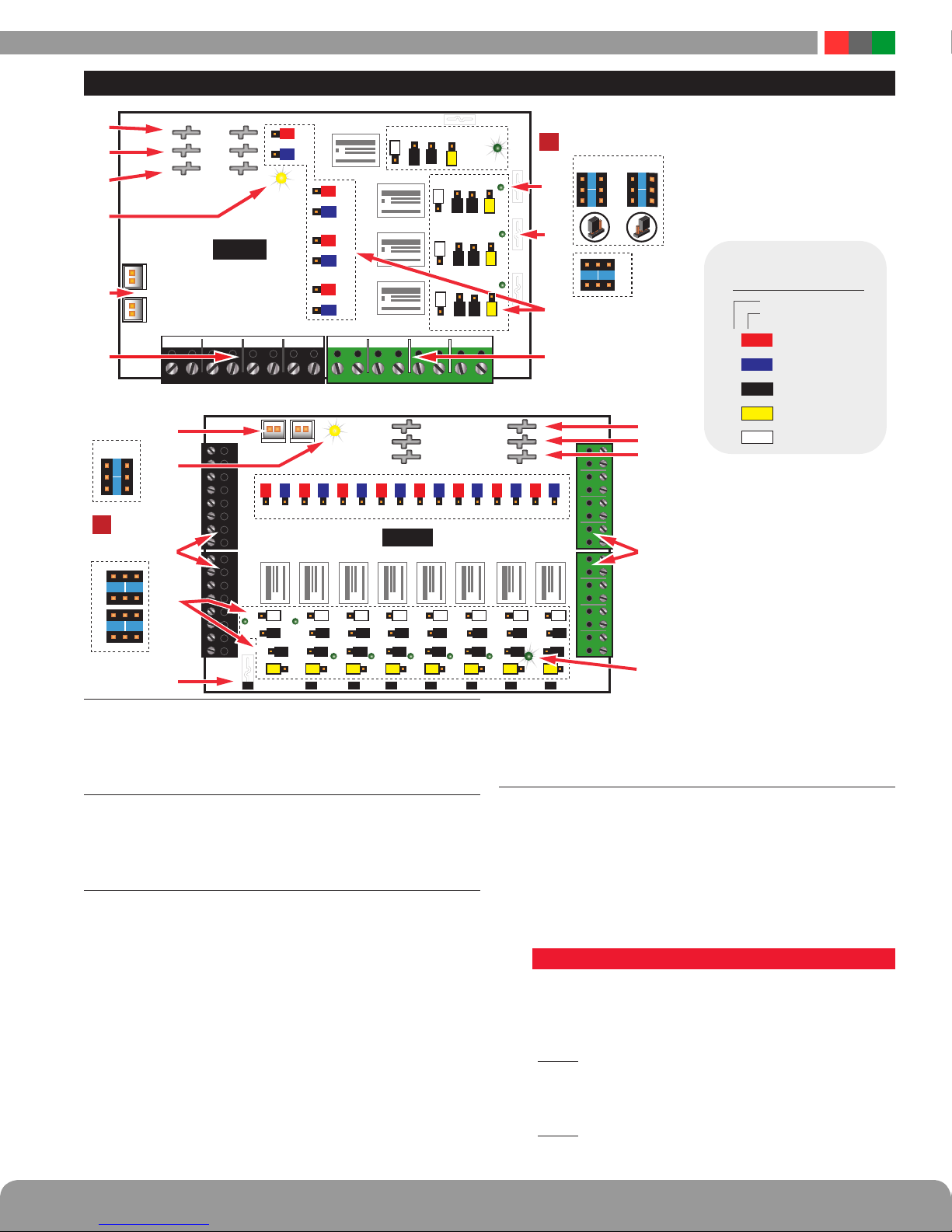

Power Control Accessory Overview

R

B1

B2

1A

2

1

BL

1B

BR

FAULTFAULT

C4/C4P

FlexIOFlexIO

INPUT FIELD WIRING 1–4 OUTPUT FIELD WIRING 1–4

2A

2

1

2B

BL

3A

R

2

1

3B

BL

4A

R

2

1

4B

BL

O1A+

A B

1

2

Note Jumper

Position

I

Orientation

F

1 2

E

C

1 2

INPUT FIELD WIRING

D

FlexIO Connectors

1

These connectors pass the FAI and Fault signals to and

from the C4/C4P/C8/C8P board and pass the FlexIO buss on

to other accessory boards in the system.

Fault LED (FLT) – Yellow

2

This LED lights when the C4/C4P/C8/C8P detects a ruptured

output fuse. This fault condition also transmits to the FPO

power supply.

Zone Inputs (IN1 – IN4/IN8)

3

These are the zone input terminal strips. These terminal strips

are removable and accept wire sizes from AWG14 – AWG22.

The terminals are labeled on the PC board near the terminal

strip. See the Input Wiring section of this manual for more

information.

• When using a relay contact input, the contact is connected

across the A and B terminals. When configured for a relay

contact input, it is normal to measure a voltage across these

two terminals. This voltage is current limited and will not

damage the activation contact.

• When using a voltage input, the voltage is connected to

the B terminal. The activation voltage must be common

grounded with the system voltage. The activation voltage

must be between 12 and 24VDC nominal.

FlexIOFlexIO

1

R

8A 8B

8F 7F 6F 5F 3F 2F 1F

8E 7E 6E 5E 4E 3E 2E 1E

F8

1

BL R BL R BL R BL R BL R BL R BL R BL

2

2

7A 7B

6A 6B

RL8 RL7 RL6 RL5 RL4 RL3 RL2 RL1

W W W W W W W W

21 21 21 21 21 2121

k Bk

B

7C8C 6C 5C 4C 3C 2C 1C

Bk Bk Bk Bk Bk Bk Bk Bk

21 21 21

7D8D 6D 5D 4D 3D 2D 1D

Y Y Y Y Y Y Y Y

F7 F6 F5 F4 F3 F2 F1

1F 1E

1

W

B

k

2

O2A+

O1B-

O2B-

O3A+ O3B- O4A+ O4B-IN1A IN1B IN2A IN3A IN3B IN4A IN4BIN2B

FAULTFAULT

1

1

2

2

5A 5B

4A 4B

C8/C8P

W

Bk Bk Bk Bk Bk Bk

21 21 21 21 21

1

Bk

2

2F 2E

W

3F 3E 3D3C

W

4F 4E 4D4C

W

B1

B2

BR

1

2

1D1C

Y

1

1

Bk

2

1

B

2

1

2

3A 3B

Important: Note Jumper

I

Position Orientation

F E

2D2C

1

B

k

Y

2

1

1

k

Bk

Y

2

1

1

B

B

k

k

Y

2

B1

B2

BR

1

1

2

2A 2B

1

2

2

1A 1B

1

2

2 1

C D

1

2

A

B

WIRING 5-8

OUTPUT FIELD

JUMPER

PROGRAMMING

Reference

Jumper Color

RED

A FAI

BLUE

B

C&E

D

F

INVERT input

BLACK

WET/DRY output

YELLOW

V SELECT

WHITE

INVERT output

I

Note: The relay contact output

has a suppression diode across

it, and cannot be used to switch

AC voltage.

To switch DC voltage with these

contacts, Terminal “B” should

WIRING 1–4

OUTPUT FIELD

be positive, “A” negative.”

• When using an open collector (transistor) input, place a jumper

across the A and B terminals and connect the open collector

to the B terminal. Note that the input source must be common

grounded with the C4/C4P or C8/C8P board’s power source.

Configuration Jumpers (xA–xF)

4

These jumpers program the zone’s input, output, and FAI

operation. Jumpers are color coded for ease of programming and jumper numbers correspond with the zone

number (e.g. 1A is jumper A for Zone 1).

OBSERVE JUMPER ORIENTATION CAREFULLY - See the

Common Jumper Settings Chart for more information.

Jumpers and their possible settings are as follows:

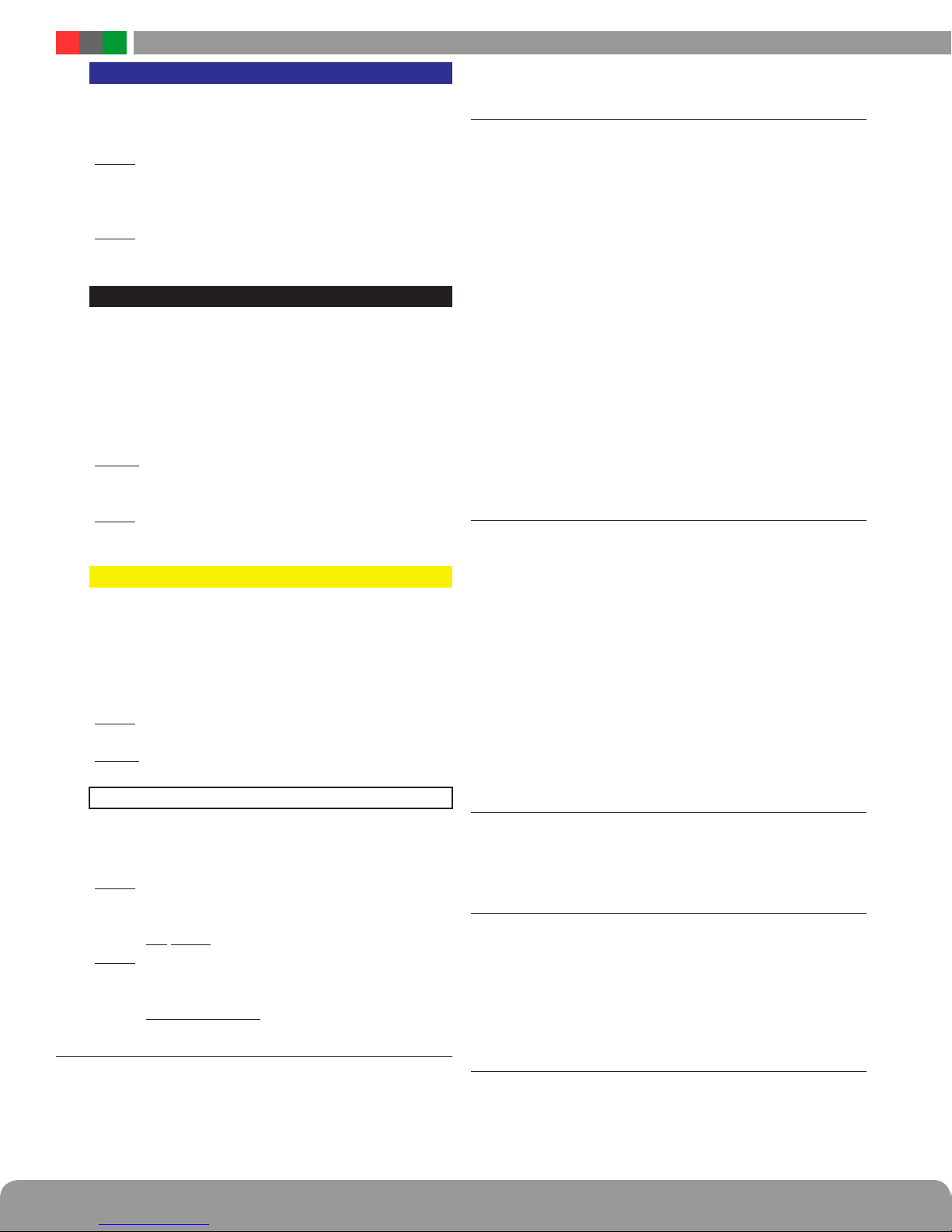

• Jumper A - RED (Zone FAI Enable)

This jumper enables or disables FAI for the selected zone.

The FAI control input is on the FPO power supply board.

See Appendix A of the FPO manual for more information

on the FAI Input.

Pos. 1 (FAI Enabled) When this jumper is placed in posi-

tion 1, the zone's output will invert when the input

is active. This is typically used to drop power to

maglocks on a fire alarm condition.

Pos. 2 (FAI Disabled) When this jumper is in position 2,

FAI will have no effect on the zone's output.

C4,C4P / C8, C8P Installation Manual

Jumper B - BLUE (Input Invert)

This jumper is used to select a fail-safe or fail-secure input.

Adjust this jumper so that the zone's output LED is FLASHING when the door is unlocked.

Pos. 1 (Fail Safe) Use this position for a NC contact input

(contact OPENS to unlock door) or for a voltage

input where the voltage is REMOVED to unlock

the door.

Pos. 2 (Fail Secure) Use this position for a NO contact input

(contact CLOSES to unlock door) or for a voltage input where the voltage is APPLIED to unlock the door.

Jumpers C & E - BLACK (Wet or Dry Output Selection)

These jumpers select whether the output is a relay contact output or a voltage output. BOTH jumpers must be

set to the same position for proper operation.

I The outputs of the C4 and C8 have built-in reverse protection di-

odes across each output. If a delay is present on lock release, or when

using as a dry relay contact output, the diode can be removed from the

circuit. See page 6 for more information.

Pos. 1 (Relay Contact Output) By placing both jumpers

in Position 1, the zone's output is set as a relay

contact output.

Pos. 2 (Voltage Output) By placing both jumpers in posi-

tion 2, the zone's output is set to output the voltage of the buss selected by Jumper D (See below).

Jumper D - YELLOW (Voltage Buss Selection)

The C4 and C8 can each accept up to two power supply

inputs connected to B1 and B2. This jumper selects which

of the two power supply inputs are used for the zone's

output. If only a single power supply is being used, set

this jumper for Position 1. (Note: if the zone's output is

set as a relay contact output, this jumper has no effect.)

Pos. 1 (B1 Buss) This position selects the power supply

connected to the B1 input of the C4 or C8 board.

Pos. 2 (B2 Buss) This position selects the power supply

connected to the B2 input of the C4 or C8 board.

Jumper F - WHITE (Output Invert)

This jumper is used to select a fail-safe or fail-secure

output. Adjust this jumper so that the door is UNLOCKED

when the zone output LED is flashing (Zone Active).

Pos. 1 (NO / Voltage when input is activated) When in Po-

sition 1, the output terminals will connect through

the NC contact if set for a relay contact output or

will output a voltage when the input is activated.

Pos. 2 (NC / Voltage when input is deactivated) When in

Position 2, the output terminals will connect through

the NO contact if set for a relay contact output or will

not output a voltage when the input is activated. This

position is typically used for Mag Locks.

Output Fuses (F1 – F8) – Optional

5

When using the fused version of the C4/C8, these are the

fuses for each zone output. Fuse numbers correspond with

the zone number (e.g. F1 is the fuse for OUT1). When using

the PTC version of the C4/C8, the fuse will be replaced with

a soldered-in PTC. Fuses or PTCs are not in the circuit when

the zone is configured as a relay contact output.

Output LEDs (01 – 08) – Green

6

These LEDs indicate the status of the output. LED numbers

correspond with the zone number (e.g. O1 is for Output 1).

• On SteadyDoor Locked (Fuse or PTC Intact)

• FlashingDoor Unlocked (Either due to Zone Input or FAI)

• OffFuse or PTC open

These LEDs are bi-color and indicate the output voltage for

each output as follows:

• Green – 12V Output

• Blue – 24V Output

I

NOTE LED colors are range based. Voltage Less than 13V

will show Green. Voltage above 20V will show Blue. Voltage

between 13 and 20 may show either voltage or a combination

Green & Blue. Always verify voltage with a voltmeter.

I Note that if an Output LED is operating opposite from

expected (flashing in normal state, steady when the input is activated), but the output terminals are behaving

as expected, then jumpers B and F should be placed

into the opposite position.

Zone Outputs (01 – 04/08)

7

These are the output terminal strips. These terminals are

removable and accept wire sizes from AWG14 – AWG22.

The terminals are labeled on the PC board near the terminal

strip. See the Output Wiring section for more information.

• Relay Contact Outputs are across the A and B terminals. The

selection for NO or NC is made by jumper F

• Voltage (Wet) Outputs are across the A and B terminals.

– Positive is terminal B

– DC Common is terminal A

IThe C4 and C8 have reverse protection diodes across

each output. If a delay is present on lock release, or when

using as a dry relay contact output, the diode can be re-

moved from the circuit. See page 6 for more information.

BR Connectors (J4 & J5)

8

The DC Common buss in the system. All DC boards in

the system must have their BR fastons wired together for

proper operation.

B2 Connectors (J6 & J7)

9

These are for connection to the B2 buss in the system. The

voltage on the B2 buss comes from an FPO power supply or a

B100 secondary supply in dual voltage systems. This voltage

will be directed to any outputs whose yellow jumper (Jumper

D) is set in the B2 position. If the C4/C8 is being used in a

single voltage system, these fastons can be left unused.

B1 Connectors (J2 & J3)

bk

These are for connection to the B1 buss in the system. The

voltage on the B1 buss comes from an FPO power supply.

This voltage will be directed to any outputs whose yellow

jumper (Jumper D) is set in the B1 position.

4 5

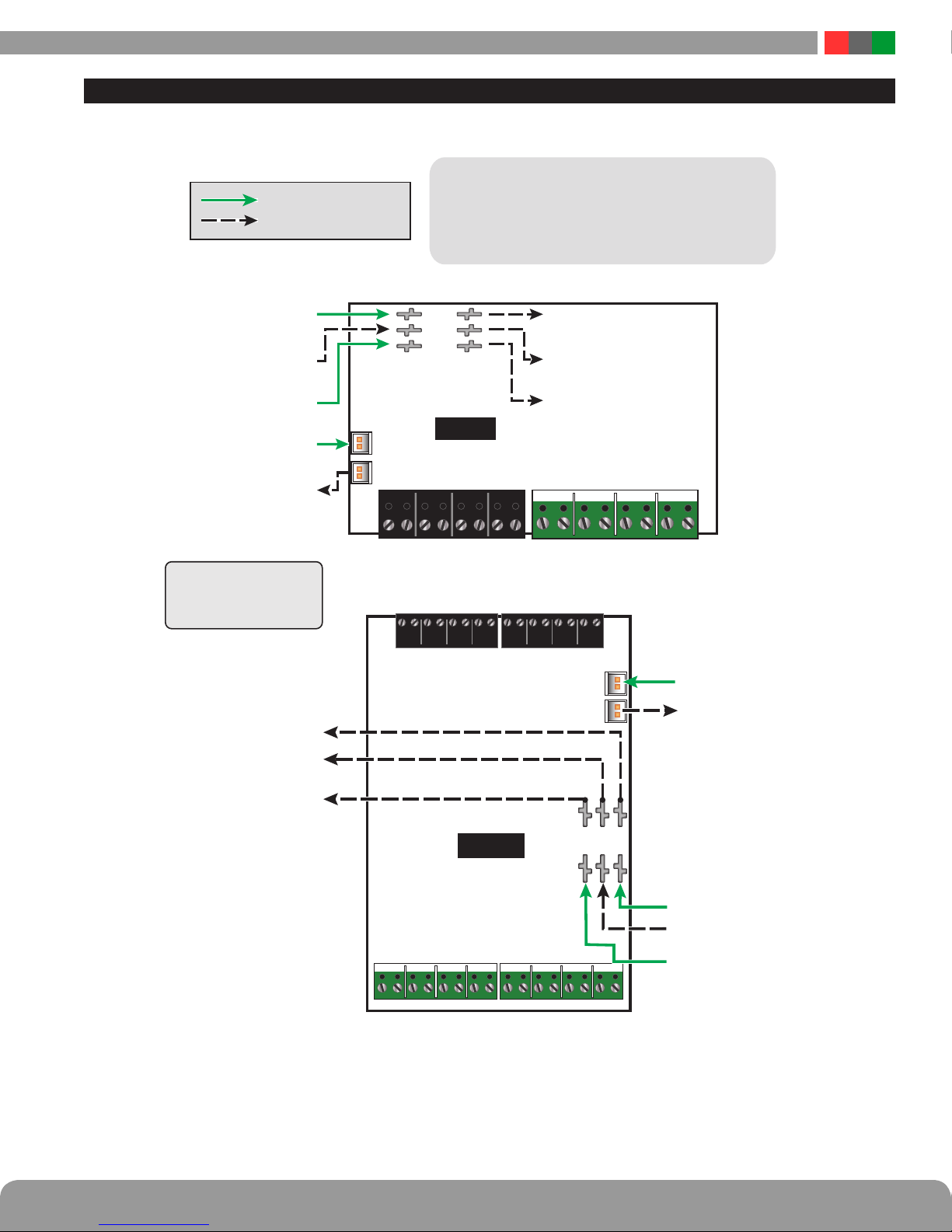

Connecting the Power Control Module

Remove all AC and battery power from the FPO system before adding or replacing a power control board.

h

Each of the B1, B2, BR, and FlexIO busses has two connectors.

Required Connections

Optional Connections

Input from Main

DC voltage source

Input from Second

DC source (optional)

These connectors may be used interchangeably.

For example: FlexIO from the power supply may be connected

to either of the C4/C8's FlexIO connectors, the Main DC voltage

source may connect to either B1 terminal, etc.

B1

B2

BR

Main DC voltage continues

to other accessories

Second DC Source continues

to other accessories

BR in from System

FlexIO in from System

FlexIO continues to

other accessories

Note:

B1 terminals are interconnected

B2 terminals are interconnected

BR terminals are interconnected

Main DC voltage continues

to other accessories

Second DC Source continues

other accessories

BR continues to

other accessories

BR continues to

C4/C4P

other accessories

FLEXIOFLEXIO

INPUT FIELD WIRING 1–4 OUTPUT FIELD WIRING 1–4

O1A

O1B

O2A

O2B

O3A O3B O4A O4B

– +– +– +– +

NOTE - Output polarity has changed -

Verify polarity via markings on the PCB

INPUT FIELD WIRING 1–8

FLEXIOFLEXIO

C8/C8P

B1B2BR

FlexIO in from System

FlexIO continues to

other accessories

NOTE - Output polarity has changed -

Verify polarity via markings on the PCB

OUTPUT FIELD WIRING 1–8

O1A

O2A

O1B

O2B

O3A O3B O4A O4B

– +– +– +– +

O5A

O5B

O6A

O6B

O7A O8B

– +– +

Input from Main

DC voltage source

Input from Second

DC source (optional)

O8A

O7B

– + – +

BR in from System

Loading...

Loading...