LifeSafety Power B100, FLEXPOWER B100 Installation Manual

B100 Installation Manual

Description

The B100 provides an additional voltage in a FlexPower system. This voltage can either be accessed directly via the B100's

terminals or through other FlexPower Accessory Boards. The

B100’s input is typically supplied by the B1 buss in the system,

allowing the FPO’s battery set to back up the B100’s output

voltage without the need for a second battery set. Output settings for the B100 include a fixed 12V setting and an adjustable

setting of 5 to 18V. Multiple B100s can be added to a system

for virtually unlimited voltage combinations.

Specifications

Input Voltage 8-25V (Must be at least 3V above

output voltage setting)

Current 3.5A maximum

Standby Current 35mA

Output Voltage 5-18V

Current 4A maximum

(Class 2 Power Limited)

Fuse 7.5A ATM automotive style

Size

Weight 0.20lb (0.09kg)

4.00" x 2.50" x 1.75"

(102mm x 64mm x 45 mm)

Regulatory Information

The equipment discussed within this manual has been tested

to the following standards:

• UL294, UL603, UL864, UL1076, UL1481, UL2044, UL2572

• ULC S318, ULC S319, ULC S527

• CSA C22.2 #107.1

• CSFM Approved

1.3

• z

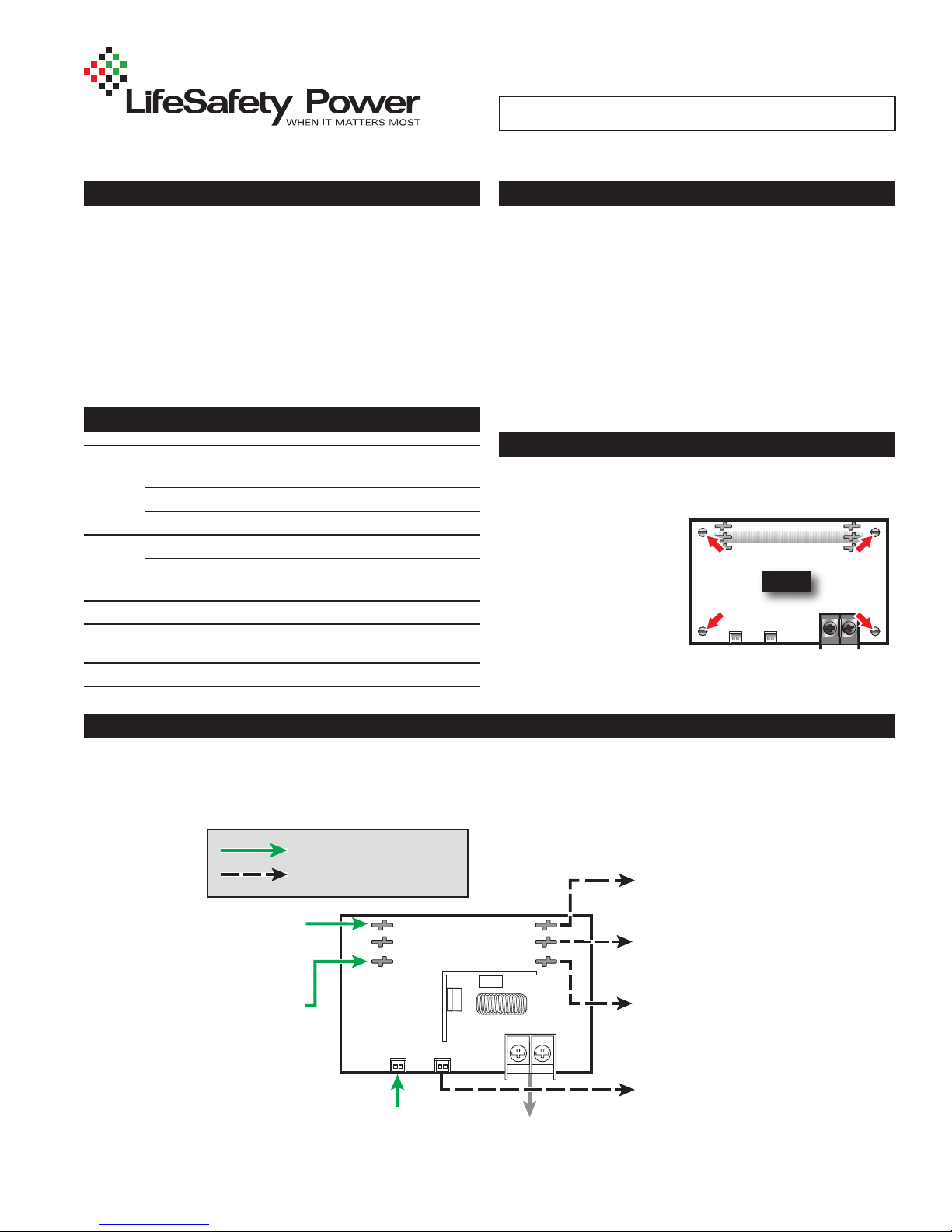

Mounting the B100 Secondary Power Supply

Mounting of the B100 Board to an enclosure is via the four

snap-in standoffs supplied.

1. Locate the appropriate

mounting holes in the

enclosure and snap

the standoffs into the

holes.

2. Align the board mounting holes with the

standoffs (be sure the PC board is properly oriented)

and snap the board onto the standoffs.

B100

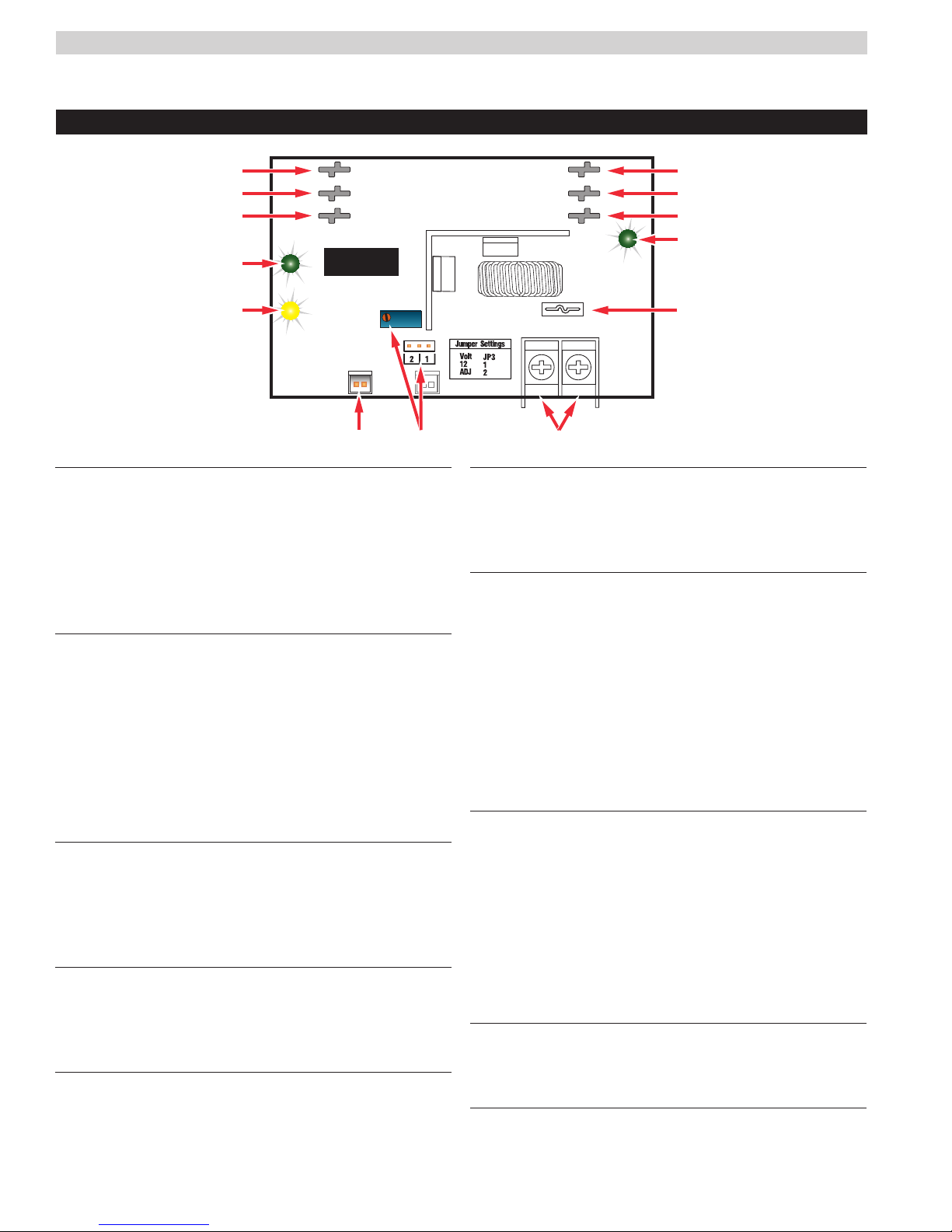

Connecting the B100 Secondary Power Supply

Remove all AC and battery power from the FPO system before adding or replacing a B100 board.

h

Observe polarity of the DCIN and BR Connections or damage to the system could occur.

h

Required Connections

Optional Connections

DC Input from System

(Typically the DC1 output

of an FPO power supply)

BR in from System

I The DC In, DC Out, and BR terminals run

through the board for daisy chaining and each

terminal set is interchangeable from a functional

standpoint.

Either DC IN may be used, either DC Out may be

used or either BR may be used interchangeably.

DC IN

DC OUT

BR

FlexIO

in from System

DC IN

DC OUT

BR

– OUT +

DC OUT terminals to

device to be powered

Input voltage continues to other

accessories (typically to B1 Buss – ensure

no other voltage sources on this buss)

B100’s output to other accessories

(typically to B2 Buss – ensure no other

voltage sources on this buss)

BR continues to other accessories

FlexIO continues to other accessories

P03-005 Rev A09

B100 INSTALL MANUAL 2

B100 – Secondary Power Supply

DC In

DC IN

DC OUT

BR

B100

Fault

DC IN Connectors (J1 & J4)

1

These fastons are the input to the B100. Either faston

may be used as the input. Two connections are provided

to allow this voltage to pass through to other accessory

boards in the system. This input voltage must always be at

least 3 volts above the output voltage setting for the B100

to maintain its output.

DC OUT Connectors (J2 & J5)

2

These fastons are the output of the B100 for connection

to other accessories in the system. This output may

be considered as an equivalent to the DC1 faston of an

FPO power supply.

Either or both DC OUT fastons may be used in the system.

I Ensure there are no other voltage sources connected

to the buss before powering the system or damage

WILL occur.

BR Connectors (J3 & J6)

3

The DC Common buss in the system. All boards in the

system must have their BR fastons wired together for

proper operation (except for between the DC and AC

sections of an FPX hybrid system).

DC IN LED (D1) – Green

4

This LED indicates the availability of voltage on the DC

IN Buss. When voltage is available on the buss, the LED

is lit.

FAULT LED (D7) – Yellow

5

This LED lights when the B100 detects a fault condition. This

fault condition also transmits to the FPO power supply

Fault conditions detected include ruptured output fuse, no

output, output overload, or output voltage out of regulation.

DC IN

DC OUT

BR

DC Out

– OUT +

FlexIO Connectors (JP1 & JP2)

6

These connectors allow the fault status of the B100 to be

transmitted to the FPO power supply and pass the FlexIO

buss on to other accessory boards in the system.

Output Voltage Selection (JP3 & VR1)

7

This jumper selects the output voltage for the B100 and

the potentiometer sets the output voltage when in the

adjustable range. In adjustable range, voltage may be

set from 5 to 18VDC.

Possible jumper settings are as follows:

• 12V Out JP3 Position 1

• Adjustable OutputJP3 Position 2

I The VR1 potentiometer will have no effect unless

the jumper is set for the adjustable range.

DC Output

8

This is the output terminal strip. This terminal strip is

non-removable and accepts wire sizes from AWG12 –

AWG22. The terminals are labeled on the PC board by

the terminal strip.

I

CAUTION When powering magnetic loads such as

maglocks, door strikes, solenoids, etc, each of these

loads must have a reverse protection diode either built-in

or external to the device.

Output Fuse (F1)

9

This fuse protects the DC Output terminals. It does not

protect the DC OUT faston.

DC OUT LED (D4) – Green

.

bk

This LED indicates the availability of voltage on the DC

OUT Buss. When voltage is available on the buss, the

LED is lit.

B100 INSTALL MANUAL 3

B100 Current Loading

Power drawn from the B100 subtracts from the power available from the FPO supplying the B100. The most accurate

way to determine the draw from the FPO is to calculate the actual power draw and factor in the efficiency of the B100.

PI = PO*1.15

Where:

PI = Input power of the B100

PO = Output power draw on the B100

B100 Current Load Examples

Example: 1

An FPO250 set for 24V is powering a B100. The B100 is set for

an output of 12V and has a 3A total load connected.

PO = 12V*3A = 36W

PI = 36W * 1.15 = 41.4W

In this example, the B100 will draw 41.4W from the FPO250

This leaves 208.6W available from the FPO250

Example: 2

What size FPO do I need to create a dual voltage power supply

providing 12V@4A and 24V@6A?

12V x 4A x 1.15 = 55.2 Watts

24V x 6A = 144 Watts

144W + 55.2W = 199.2W

The next greater FPO to 199.2 is 250

Use an FPO250 power supply with the B100 converter

Example: 3

What size FPO do I need to create a dual voltage power supply

providing 12V@1A and 24V@3A?

12V x 1A x 1.15 = 13.8 Watts

24V x 3A = 72 Watts

13.8W + 72W = 85.8W

The next greater FPO to 84 is 150

Use an FPO150 power supply with the B100 converter

Loading...

Loading...