LifeSafety Power FlexPower Installation Manual

FlexPower

DC Power System Installation Manual

LifeSafety Power, Inc. | PH 888.577.2898 | TechSupport@LifeSafetyPower.com

P03-40 Rev A15

FlexPower DC Power System Installation Manual

Table of Contents

Notes and Warnings ......................................iii

Symbol Definitions ............................................................ iii

Warnings.................................................................... iii

Regulatory Information ......................................................... iii

Conventions Used Within this Manual.............................................. iii

Power Supply Quick Start ..................................iv

Section 1 – Installation and Operation .........................1

1.1 Mounting .................................................................1

1.2 Jumper / LED / Connector Descriptions ..........................................3

1.3 FAI Input Usage ............................................................6

1.4 Typical Installation & Wire Routing .............................................7

1.5 Power-Up and Basic System Verification Checklist .................................8

Section 2 – Troubleshooting and Maintenance ....................9

2.1 Troubleshooting Table .......................................................9

2.1 Troubleshooting Table (continued) .............................................10

2.2 Maintenance Instructions ....................................................10

Section 3 – Specifications ................................. 11

3.1 Electrical Specifications .....................................................11

3.2 Temperature Specifications ..................................................13

3.3 Mechanical Specifications ...................................................13

3.4 Replacement Parts .........................................................14

Appendix 1 – Tamper Switch Wiring .......................... 15

Appendix 2 – User Certificate............................... 16

Appendix 3 – UL Compliance Verification Sheet .................. 17

ii iii

Notes and Warnings

Symbol Definitions

The following symbols are used throughout this manual:

This symbol is intended to alert the installer of shock

h

hazards within the enclosure. Service should only be

performed by qualified service personnel

This symbol is intended to alert the installer of important

i

information intended to help the installer avoid personal

injury or property damage

Warnings

Installation and service should be performed only by

h

qualified service personnel and should conform to all

local codes

To reduce the risk of electric shock or fire, do not

h

expose this equipment to rain or moisture

This equipment shall be installed in a manner which

i

prevents unintentional operation by employees,

cleaning personnel, or others working in the premises, by falling objects, customers, building vibration,

or similar causes

This equipment is not intended for use within the pa-

i

tient care areas of a Health Care Facility

Replace fuses only with the same type and rating as

h

indicated in the specifications section of this manual.

Regulatory Information

The equipment discussed within this manual has been tested to the following standards:

• UL294, UL603, UL1076

• ULC S318, ULC S319

• CSA C22.2 #107.1, CSA C22.2 #205

FCC Information

Note: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Conventions Used Within this Manual

Positional information (e.g. top, bottom, up, down, left,

right, etc.) is referenced with the board or enclosure in the

orientation shown in the illustrations in this manual.

To prevent impaired operation, ensure that all wiring

i

is routed and secured to prevent accidental open or

short circuit conditions

The system and any batteries (if used) should be

i

tested at least once per year to ensure proper operation

Batteries (if used) should be maintained at an am-

i

bient temperature of between 32 and 120 degrees

Fahrenheit (0-49 Celsius) or premature loss of battery power could occur

FlexPower DC Power System Installation Manual

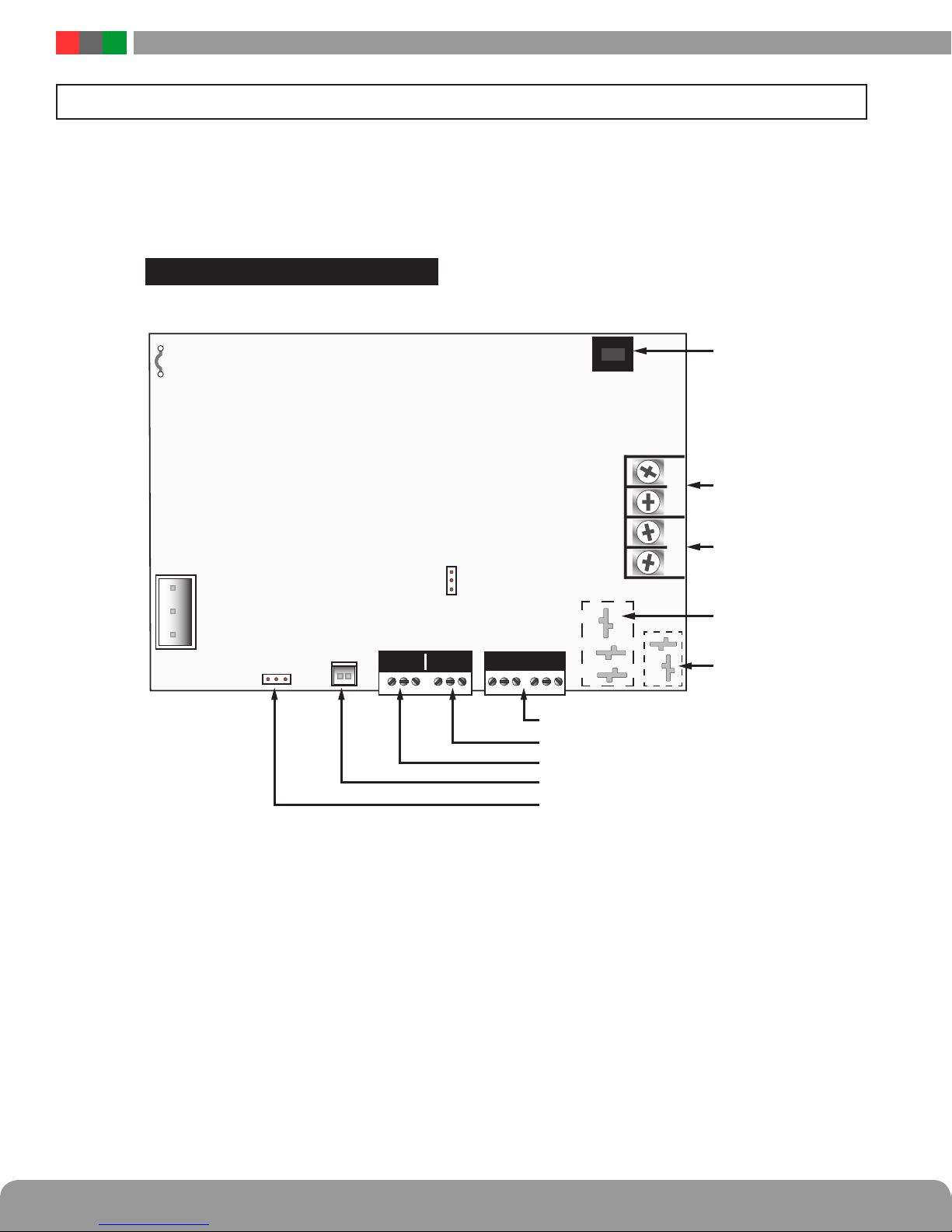

Power Supply Quick Start

This section gives a quick visual guide of installation connections and settings for installers already familiar with the FlexPower line of power supplies. For full information, please read this entire manual before installing.

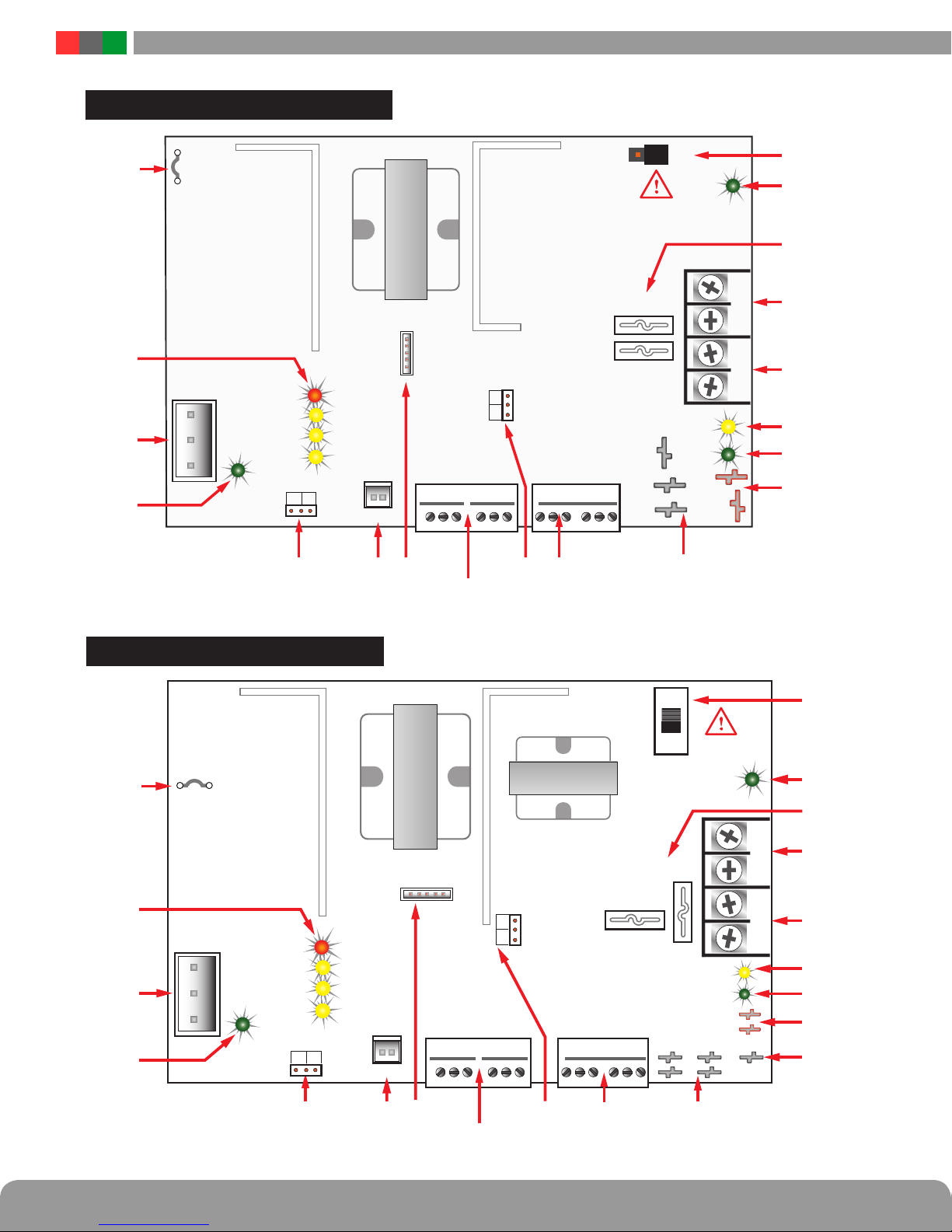

QUICK INSTAL - SECTION FINDER

Cut for

230VAC input

section 1.2 #1section 1.2 #1

AC Input

section 1.2 #3section 1.2 #3

Models ending in "/E"

are factory preset for 230VAC

with JP1 jumper already cut

E GRND

Flex

Battery

Battery

Presence Jumper

Presence Jumper

section 1.2, #9

SYS AC

+ –+ –+ –+ –

FAI

FAI Input - section 1.2 #10 & section 1.3

Fault Contacts/AC - section 1.2 #8

Fault Contacts/System - section 1.2 #8

Flex IO Connector - section 1.2 #6

Earth Ground Jumper - section 1.2 #5

12/24 V Selection

section 1.2 #20

Main Output

section 1.2 #17

FAI Controlled Output

section 1.2 #16

FlexConnect

Accessory Power

section 1.2 #11

Battery Connection

section 1.2 #13

Figure 2

iv 1

Installation and Operation

Section 1 – Installation and Operation

The following pages cover the installation, setup, and basic operation of the FPO series power supplies.

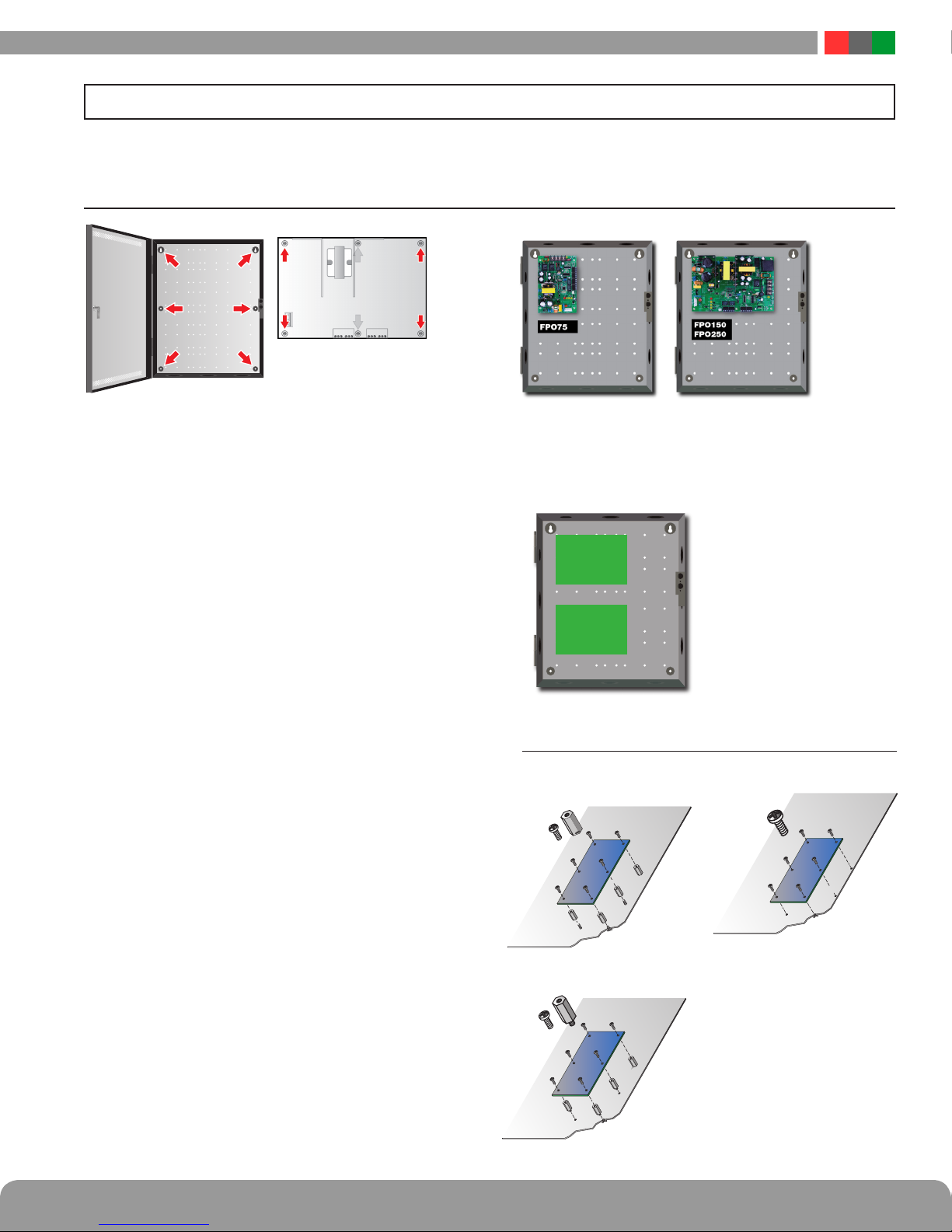

1.1 Mounting

Figure 1 Figure 2 Figure 3

Mounting an Enclosure

Use the following procedure when mounting a wall-mount enclosure

(figure 1).

1. (Optional) Remove the enclosure’s cover.

2. Locate the top keyhole mounting holes in the back of the enclosure.

3. Mark and pre-drill the locations for the keyholes in the mounting surface.

4. Partially install two fasteners appropriate for the surface on

which the enclosure is being installed. Leave the heads of the

fasteners approximately ¼" out from the surface. Minimum

fastener size should be #10 or larger.

5. Hang the enclosure on the two fasteners and mark the locations of the remaining mounting holes.

6. Remove the enclosure and pre-drill the locations for the remaining mounting holes.

7. Re-hang the enclosure on the top mounting fasteners, start

the remaining fasteners and tighten all fasteners.

8. Reinstall the enclosure’s cover, if removed in step 1.

i It is the installer’s responsibility to determine the ap-

propriate fastening system for use with the surface the

enclosure is being mounted to.

i For UL1076 applications, after installation is complete, the

installer must install the two supplied 1" long screws to the

edge of the enclosure's cover for additional security.

Mounting a Sub Assembly to an Enclosure

Third Party sub assemblies will be mounted in one of three methods

based on the supplied mounting hardware (figure 5).

FPO/FPV

larger

FPO/FPV

smaller

Figure 4

Screw

Female to female Stando

Screw mounting

Mounting an FPO PS Board to an Enclosure

Use the following procedure when mounting an FPO power supply to a LifeSafety Power enclosure (figure 2).

1. Locate the appropriate mounting holes in the enclosure and

snap the four or six standoffs provided into the holes.

2. Align the board mounting holes (mounting hole locations are

indicated in the drawing above) with the standoffs and snap the

board onto the standoffs. Be sure the board is properly oriented

before snapping the board onto the standoffs (Figure 3).

3. When two FPO/FPV boards are installed, the larger shall be

located on top (figure 4).

Screw

Male to female Stando

Figure 5

FPO75

FlexPower DC Power System Installation Manual

120/230VAC

Cut for 230VCut for 230V

AC Input

AC ON

Earth

GND DET

12V

24V

DC1

DataLinkDataLink

FAI

GND FLT

AC FLT

SYS FLT

1

2

Flex IO

2

Battery

Battery

Detect

Detect

1

AC FLTAC FLT

FAI INPUTFAI INPUTSYS FLTSYS FLT

For UL compliance, the AC fault contact

must be monitored by a Listed control panel

DC2 NODC2 NO

DC2 NCDC2 NC

DC1DC1

BRBR

DC2DC2

REV BAT

DC2

+

BB

–

BB

Observe battery polarity

Observe battery polarity

or damage may result

or damage may result

+ DC2 –+ DC2 – + DC1 –+ DC1 –

i

FPO150 / 250

120/230VAC

Cut for 230VCut for 230V

AC Input

AC ON

Earth

GND DET

12V

24V

DC1

DC2 NODC2 NO

DC2 NCDC2 NC

DC1DC1

V+V+

REV BAT

DC2

i

BRBR

+ DC2 –+ DC2 – + DC1 –+ DC1 –

–

BB

+

BB

DC2DC2

V-V-

DataLinkDataLink

2

Battery

Battery

Detect

Detect

FAI

GND FLT

AC FLT

SYS FLT

1

2

Flex IO

1

AC FLTAC FLT

Observe battery polarity

Observe battery polarity

or damage may result

or damage may result

FAI INPUTFAI INPUTSYS FLTSYS FLT

For UL compliance, the AC fault contact

must be monitored by a Listed control panel

2 3

Loading...

Loading...