Life Fitness SM51 User Manual

5 STACK MULTI-JUNGLE (SM51)

WITH 2 ADJUSTABLE PULLEYS

UNPACKING AND ASSEMBLY INSTRUCTIONS

M051-K50-B112 1

SM51 Unpacking & Assembly Instructions

The SM51 comes partially assembled. Follow the steps below to complete the assembly.

WARNING: COMPONENTS OF THE SM51 ARE LARGE AND HEAVY. USE CAUTION

WHEN ASSEMBLING THIS MACHINE.

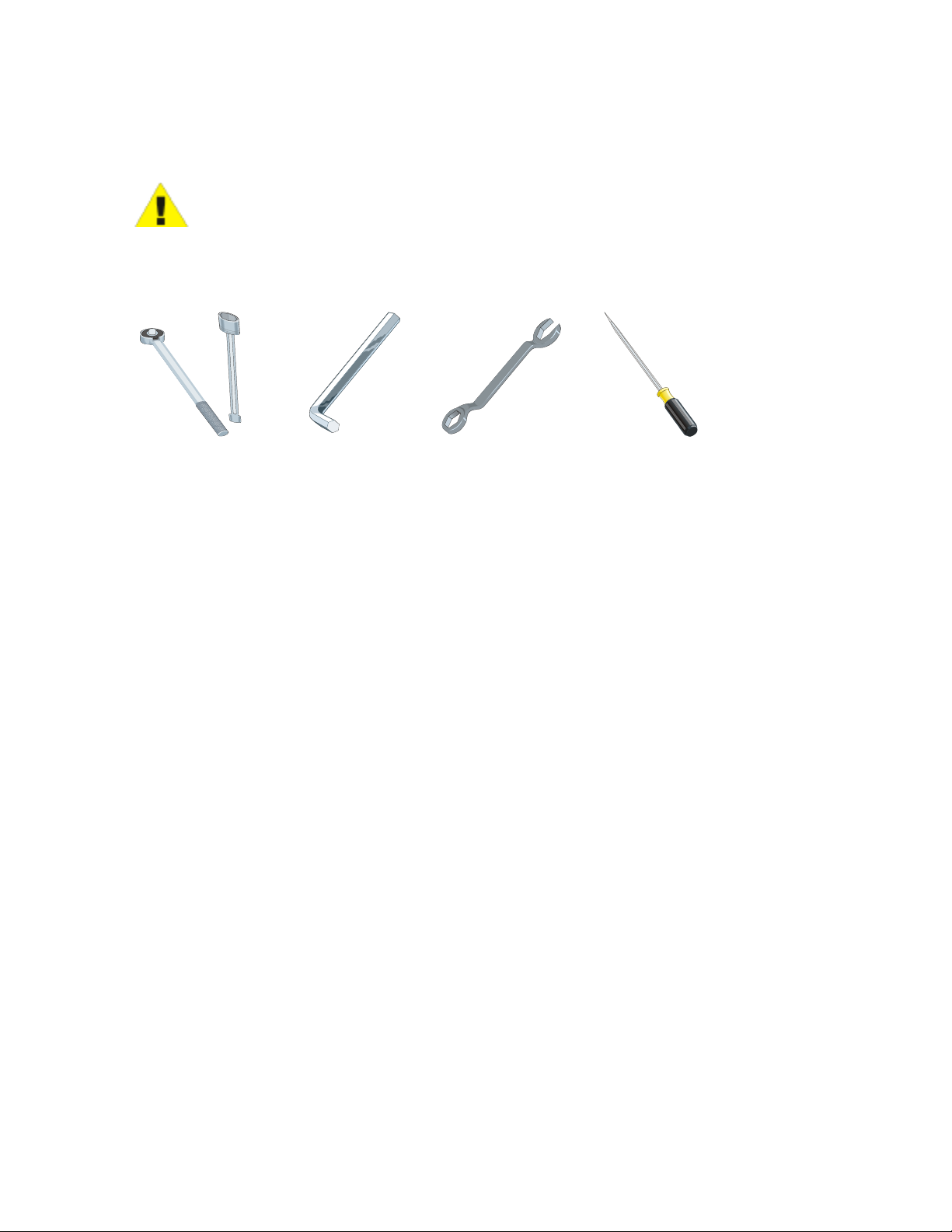

MATERIALS AND TOOLS REQUIRED FOR ASSEMBLY

1/2”, 3/8”, 5/8” & 9/16”

Socket wrench

You will also need a ladder and a piano dolly to lift and position the weight stacks.

1/8”

Hex key wrench

5/8” & 9/16”

Combination wrench

Pinch bar

ASSEMBLY TIME

Two people can accomplish this assembly in approximately 2 hours.

2

UNPACKING

Follow the steps below when unpacking the components of the SM51.

1. Cut off the shipping wrapper.

2. Remove the parts box and shipping boards.

3. Remove the items in the parts box. These items are shown in Figure 1.

A. Remove the bolts bag.

B. Remove the parts shown below. Parts that are used to build the SM51 are

described in the section HARDWARE at the end of these instructions.

SM51 Unpacking & Assembly Instructions

Figure 1. Parts box contents.

3

SM51 Unpacking & Assembly Instructions

g

)

ASSEMBLY

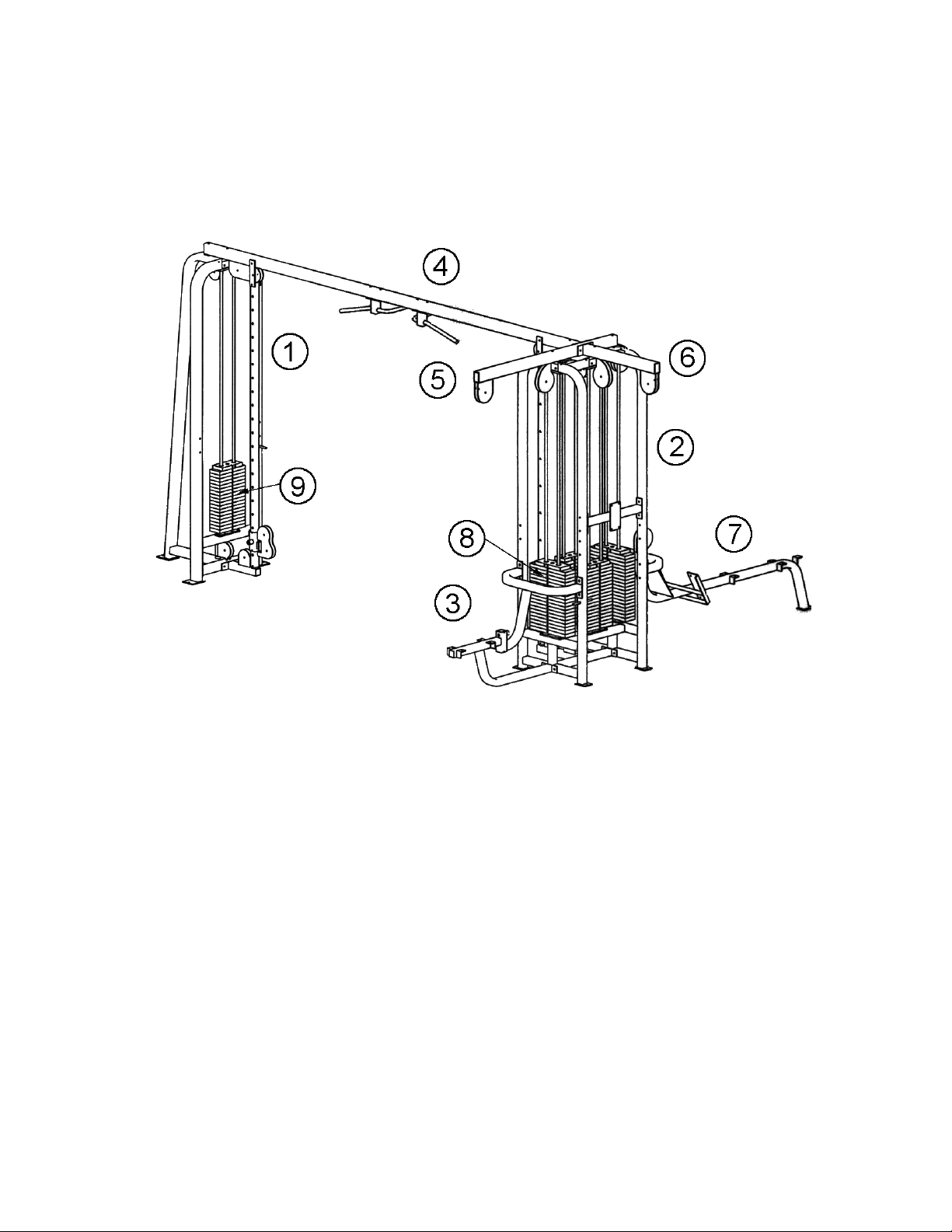

Figure 2 shows an assembled SM51.

Figure 2. SM51 main components (seats and cables removed for clarity).

1. 1 stack cell

2. 4 stack cell

3. Lat bench

4. Connecting beam

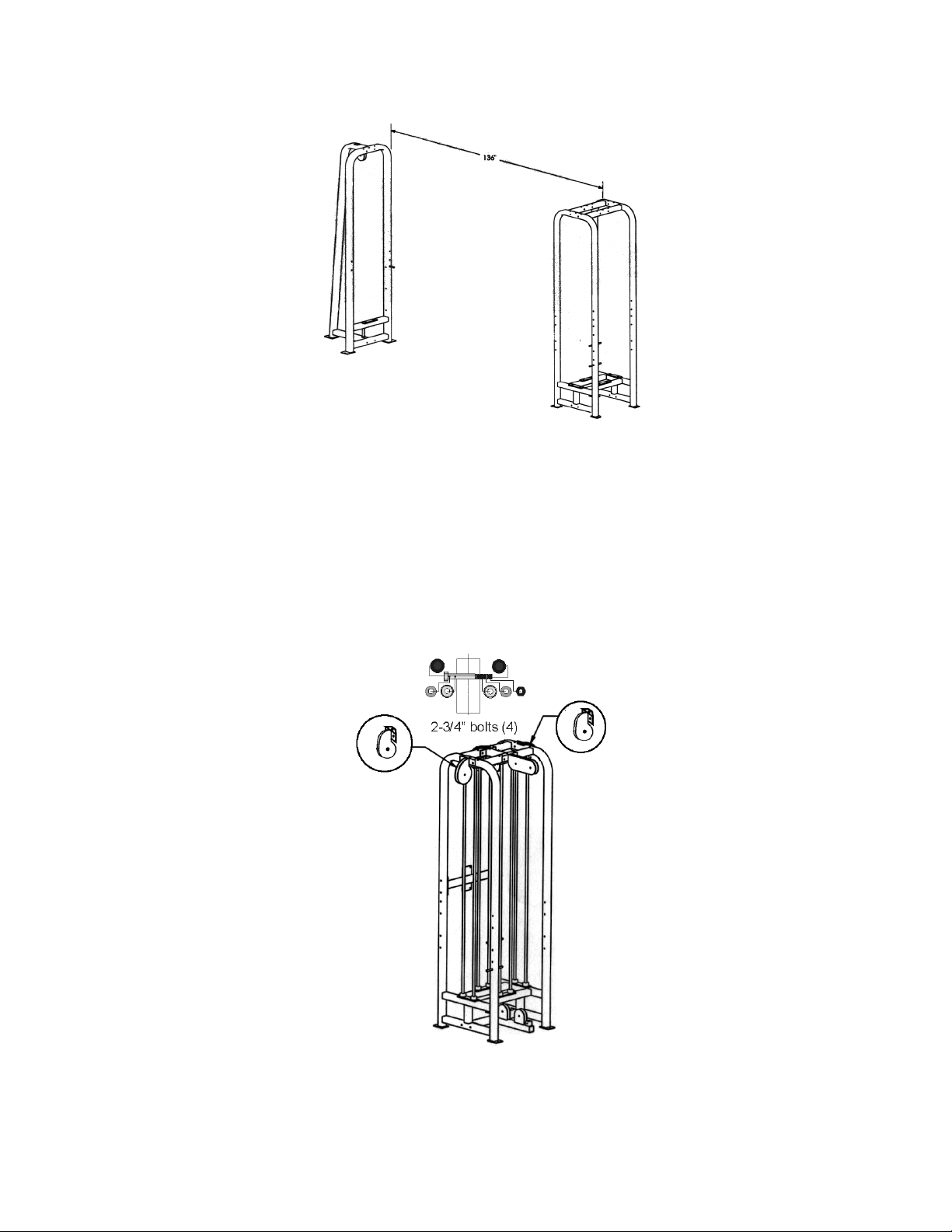

1. Place the two weight “cells” in their final resting spots. The cells will be

approximately 11’4” apart as shown in Figure 3.

4

5. Lat top

6. Tricep top

7. Low row bench

8. 300 lb. Weight stacks (2)

9. 190 lb. Wei

ht stacks (3

SM51 Unpacking & Assembly Instructions

Figure 3. Set the weight stack cells.

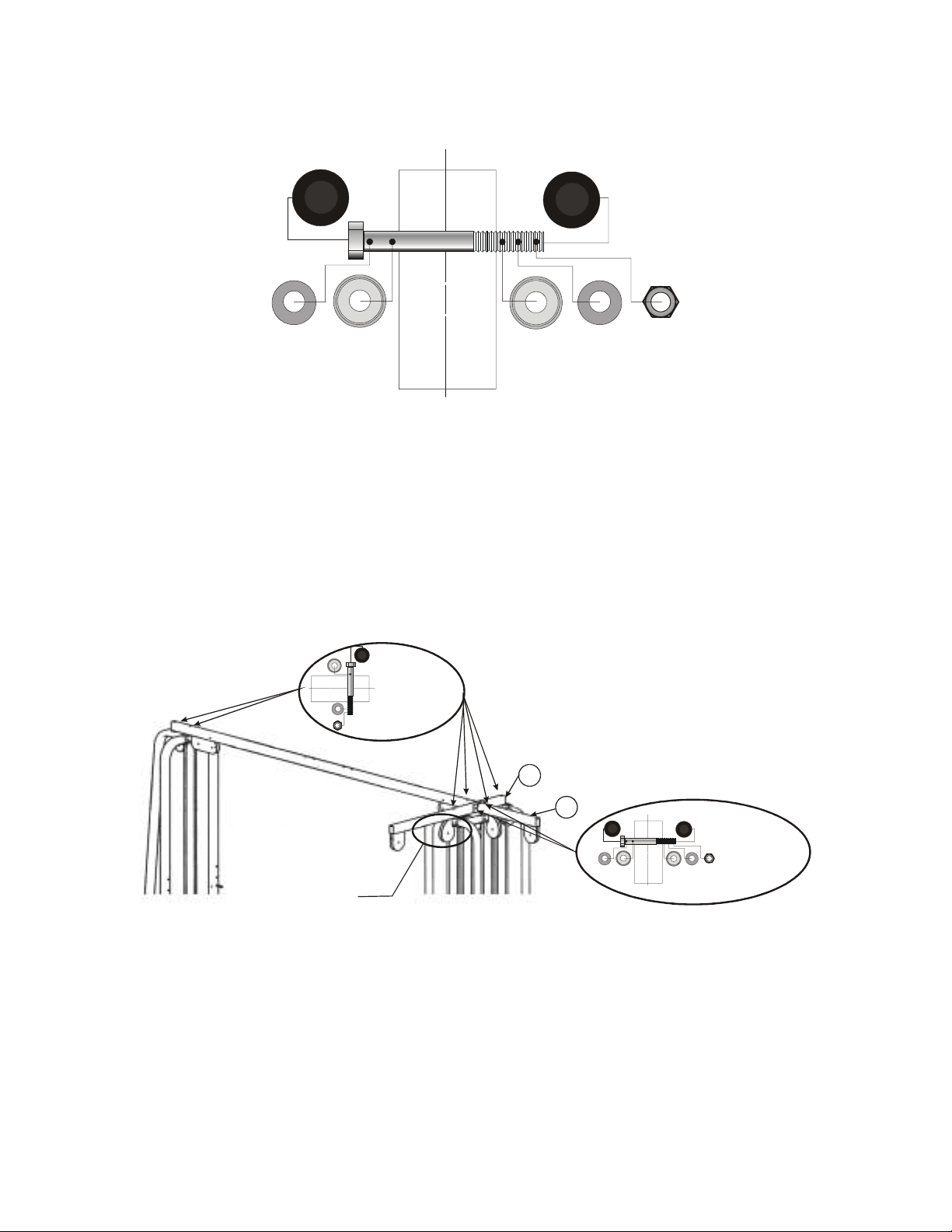

2. Bolt on the teardrop pulleys above the benches (see Figure 4) on the 4 stack cell

using two 3/8” x 2-3/4” hex head bolts (used to bolt the cross beam to the cross

members and the adjustable pulley tops to the top beams). Include the 3/8” flat

washer, end cap washers, end caps and 3/8” Nyloc (locknut). Use the bolt

configuration shown in Figure 5. You may wish to use a pinch bar to align the bolt

holes.

Figure 4. Bolt on the teardrop pulleys.

5

SM51 Unpacking & Assembly Instructions

g

Figure 5. Configuration for 2-3/4” and 3” bolts.

3. Bolt on the connecting beam (part 4 from Figure 2) using a 5/8” socket with

extension and combination wrench, to the cells using two of the large 7/16” x 6” bolts,

7/16” washers, and 7/16” nuts (parts A, B, and C in HARDWARE section at end of

these instructions), end cap washers and end caps (parts F and H in HARDWARE

section). Figure 6 shows the connected cells. You will need to remove the pulleys

from the teardrop pulley assemblies to gain clearance for the socket wrench

extension. Leave the pulleys out of the housings until the cables have been installed.

7/16” x 6” (6)mount on tops

T

U

Remove pulleys from

housings to give cleara nce

to socket extension

Figure 6. Bolt on the connecting beam, lat top, and tricep top.

3/8” x 3” (2)bolt top

beams to

ether

6

SM51 Unpacking & Assembly Instructions

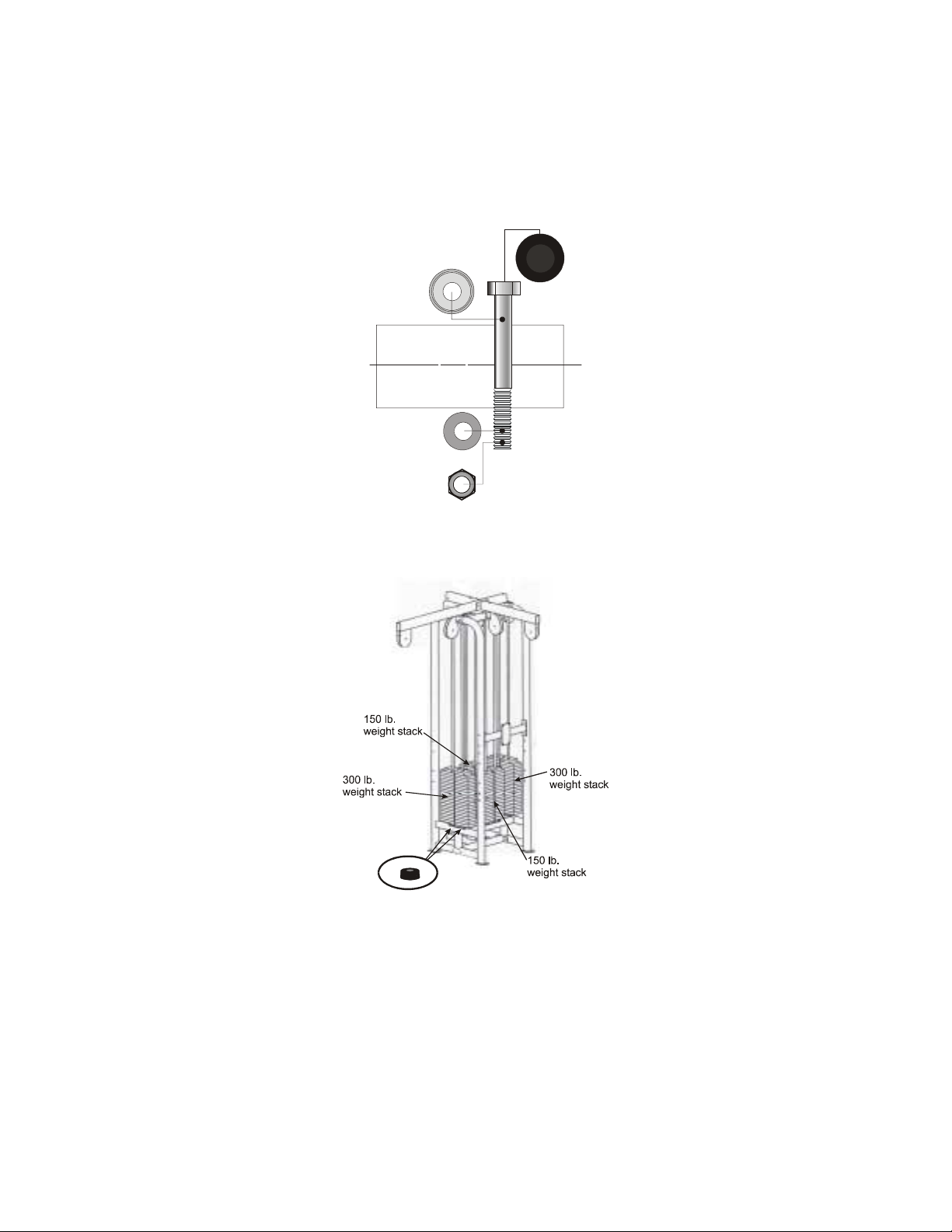

4. Mount the 56” lat top (part T from HARDWARE section) to the 4-stack cell using a

5/8” socket and combination wrench. Insert two of the large 7/16” by 6” bolts using the

hardware configuration shown in Figure 7. Mount the 29” tricep top (part U in

HARDWARE section) to the frame and connecting beam (See Figure 7).

Figure 7. Configuration for 6” bolts.

Figure 8. Mount the weight stacks.

5. Mount the weight stacks to the 4-stack cell. To do this:

A. Remove the tricep back rest bolts using a 9/16” socket and combination

wrench (see Figure 9).

B. Unbolt the top plate and remove the guide rods using a 9/16” socket and

combination wrench (see Figure 9).

7

Loading...

Loading...