Life Fitness LC8500R, LC9100R, 90R, 95Re, R9 Service Manual

...

Lifecycle Recumbent Bikes

LC9500R, LC9100R, LC8500R,

R9, R7, 95Ri, 93Ri, 90R, and 95Re

Customer Support Services

SERVICE MANUAL

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

GENERAL CONTENTS

INTRODUCTION ...............................................................................................................ii

SPECIAL SERVICE TOOLS .............................................................................................iii

GLOSSARY (Pending) .....................................................................................................iv

COMPONENT IDENTIFICATION......................................................................................v

SECTIONAL CONTENTS

TROUBLESHOOTING 1

DIAGNOSTICS LED 2A

DIAGNOSTICS LCD 2B

HOW TO…SERVICE 3

ELECTRONICS 4

MISCELLANEOUS 5

i

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

INTRODUCTION

This service manual is applicable to Recumbent Exercise Bikes LC9500R, LC9100R, LC8500R, R9, R7, 95Ri,

93Ri, 90R, and 95Re Information represents typical configuration and may differ slightly from actual equipment.

The service manual provides recommendations for safe and efficient approaches to problem situations.

If an operating problem should arise, turn to the TROUBLESHOOTING GUIDES and attempt to isolate what is

causing the malfunction. The GUIDES are listed by symptoms and follow with suggestions as to the most probable

cause of the problem.

Once you have pinpointed the source of the problem, turn to the appropriate "How To..." section and review the

proper procedures for removing, replacing or adjusting a part. The "How To..." sections are organized by

replaceable part (or assembly) name and each page lists the “Special Tools Required“to complete the specific task.

Refer to COMPONENT IDENTIFICATION in the front part of this section to locate and identify in order service

repair parts for your machine.

If you do not have a part in stock, a form to order by FAX has been included in Section V for your convenience or

you can call Life Fitness Customer Support Services any Monday through Friday from 8:00 AM to 6:00 PM

(C.S.T.). When you place a call, in order to speed our response to your particular situation, please have the

following information available for the customer service phone technician who will be prepared to assist you:

1. The Lifecycle equipment model number

2. The serial number

3. The symptom of the problem

4. The part name and number to order

When you receive your order, review the appropriate "How To..." section and follow the step by step procedures

designed to help you install the part quickly and correctly.

If you have any questions or comments please phone, mail, or fax us at:

LIFE FITNESS COMPANY - CUSTOMER SUPPORT SERVICES

10601 Belmont Avenue, Franklin Park, IL 60131; U.S.A.

Telephone: 847-451-0036, Toll Free: 800-351-3737, FAX: 847-288-3702

ii

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

SPECIAL SERVICE TOOL REQUIREMENTS

Unless otherwise specified, only basic hand tools are required to perform service procedures

outlined in this section. Some of these standard tools should consist of: Philips and StraightBlade Screw Drivers, Torx Set, Pliers, Rubber Mallet, Pry Bar, Snap Ring Pliers (internal and

external), Standard and Metric size Socket Set (3/8 or 1/2 drive), and Standard and Metric size

Combination, open-end, or Box Wrenches.

Specialized tools will be listed after the sub-heading Special Service Tools:, which appears

below the Service Procedure heading at the top of the page. If no specialized tools are

required, then the title would read: Special Service Tools: NONE, which means that standard

hand tools should be employed to provide service to the product.

Specialized tools must be used to safely and effectively complete the service procedures.

Improvisation or attempts to use any other tool could result in unnecessary damage to the

equipment or personal injury.

iii

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

GLOSSARY

PENDING

iv

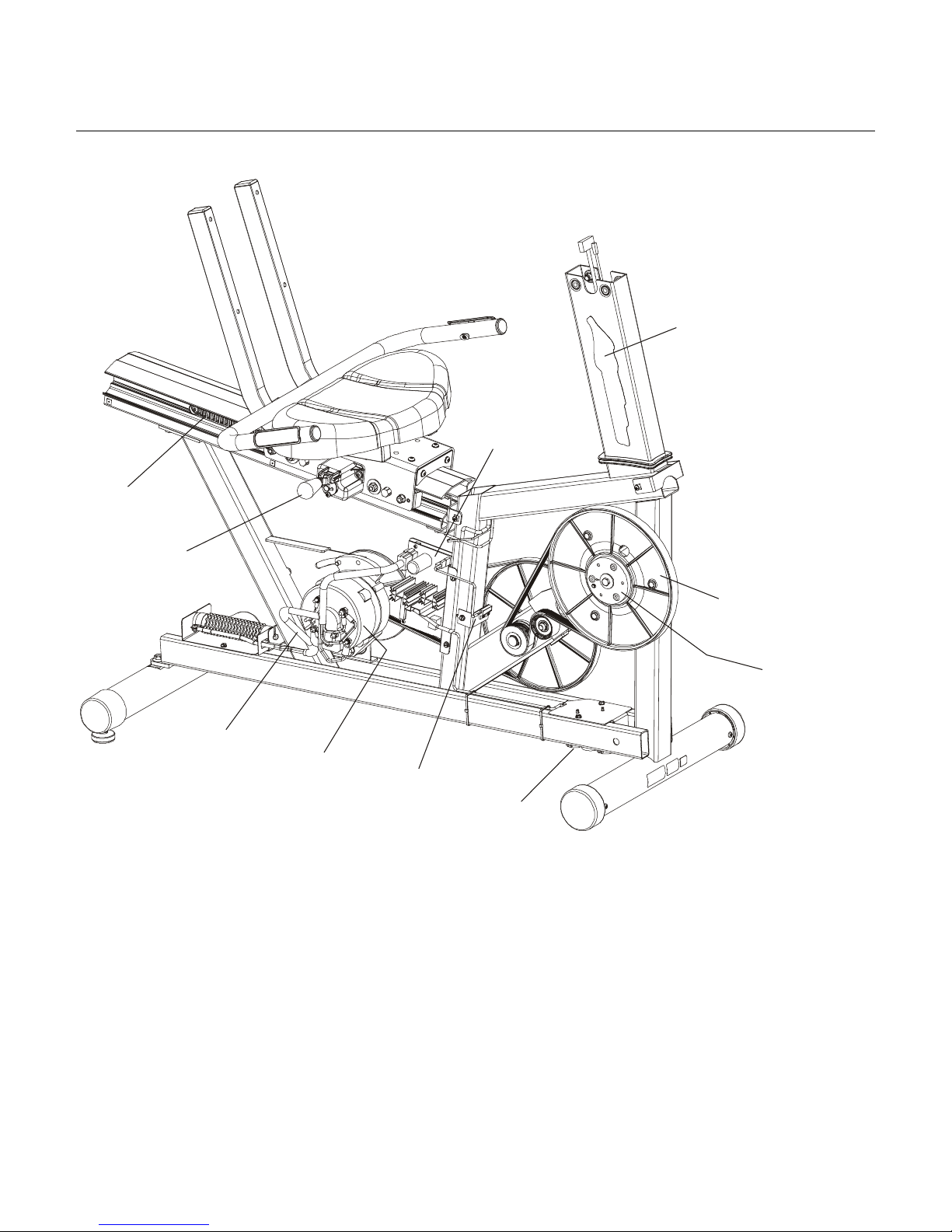

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

COMPONENT IDENTIFICATION

Console

Console

Support

Assembly

Seat Back

Handlebar

End Cap

Left Side

Shroud

Left Pedal

Seat Pad

Right

Crank Arm

Right

Pedal

Wheel

Accessory

Tray

Rear Stabilizer

Right Side

Shroud

Leveler

v

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

COMPONENT IDENTIFICATION

Heart

Rate

Cable

Left

Crank Arm

Hub

Main Cable

Seat

Assembly

Shroud

Gasket

Extrusion

Frame

Resistor

Assembly

Intermediate

Pulley

Alternator

Belt

vi

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

COMPONENT IDENTIFICATION

Decal

Power

Control

Board

Rack

Locking

Mechanism

Alternator

Cable

Alternator

Reed

Switch

Crank Arm

Pulley

Right

Crank Arm

Hub

Battery

vii

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

NOTES:

viii

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

SECTION I

TROUBLESHOOTING

GUIDES

Page

Display Console LEDs Not Illuminating............................................................................... 3

Display Console Initializes Then Fails................................................................................. 3

No Prompt ...........................................................................................................................3

LEDs Not Constant..............................................................................................................4

LEDs Do Not Extinguish...................................................................................................... 4

Prompt Flashes ...................................................................................................................4

Display Console Keys Do Not Function ..............................................................................4

Excessive Resistance is Immediate.................................................................................... 5

Excessive Resistance Loading Occurs ...............................................................................5

Resistance Varies During Manual Mode............................................................................. 5

RANDOM and HILL Resistance is Constant, No Variation .................................................6

Pedaling Is Difficult.............................................................................................................. 6

Pedaling is to Easy.............................................................................................................. 6

Inadequate Resistance During Pedaling............................................................................. 7

Battery Over-Heating...........................................................................................................7

Bike Not Stable ...................................................................................................................7

Loud Noise ..........................................................................................................................7

No Heart Rate .....................................................................................................................8

Channels Do Not Change ...................................................................................................8

Sound Does Not Change ....................................................................................................8

Faulty PCB ..........................................................................................................................8

No Sound ............................................................................................................................8

Unable to Receive Channels............................................................................................... 9

Snow and Noise ..................................................................................................................9

Screen is Blank ...................................................................................................................9

Screen Does Not Respond To Touch .................................................................................9

Wrong Buttons Activated when Touching Screen............................................................... 9

No Buttons Activated when Touching Screen..................................................................... 9

Screen Does Not Turn ON and No Audio ...........................................................................9

Testing the Inverter Board................................................................................................... 10

Testing the Power Supply Cable......................................................................................... 11

Notes...................................................................................................................................12

1

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

Notes

2

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

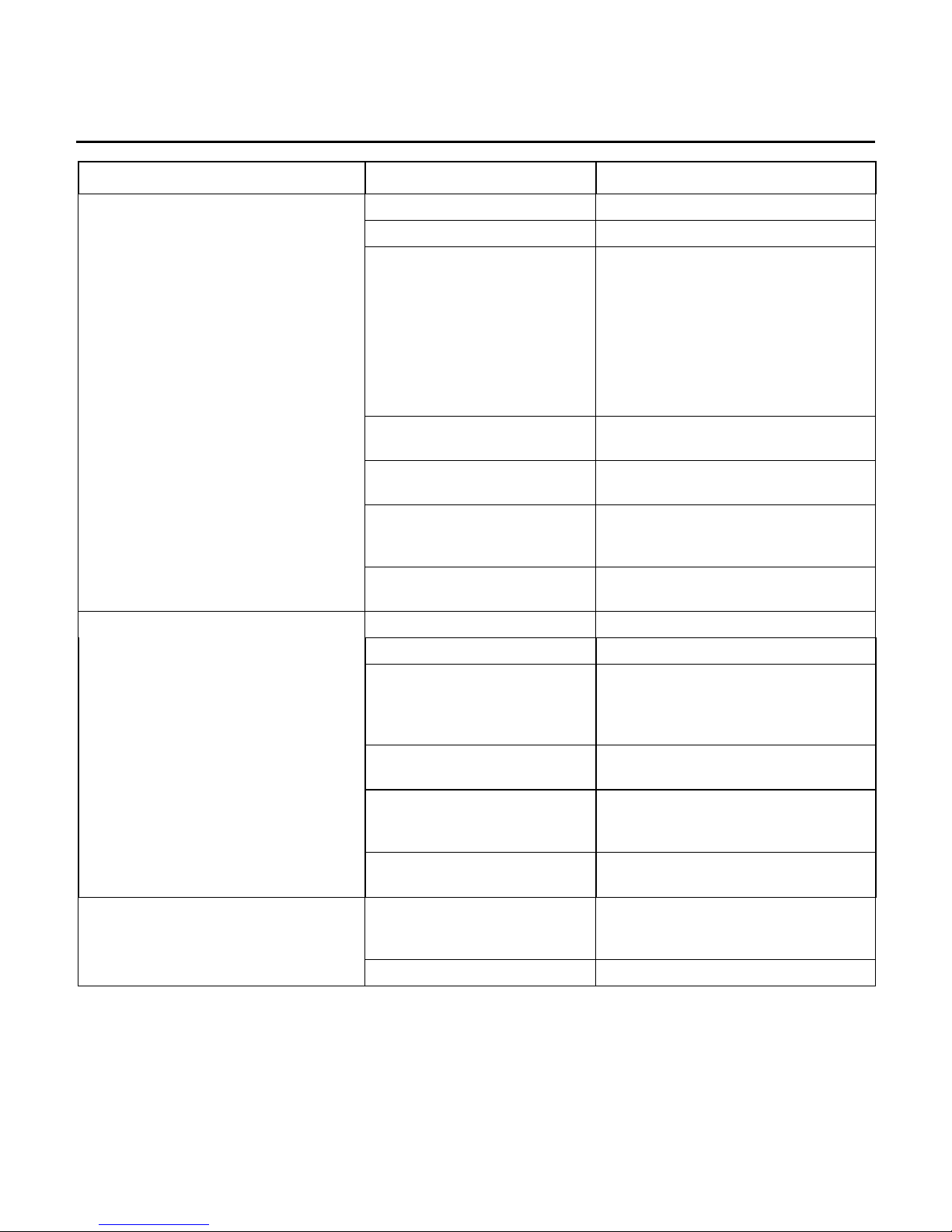

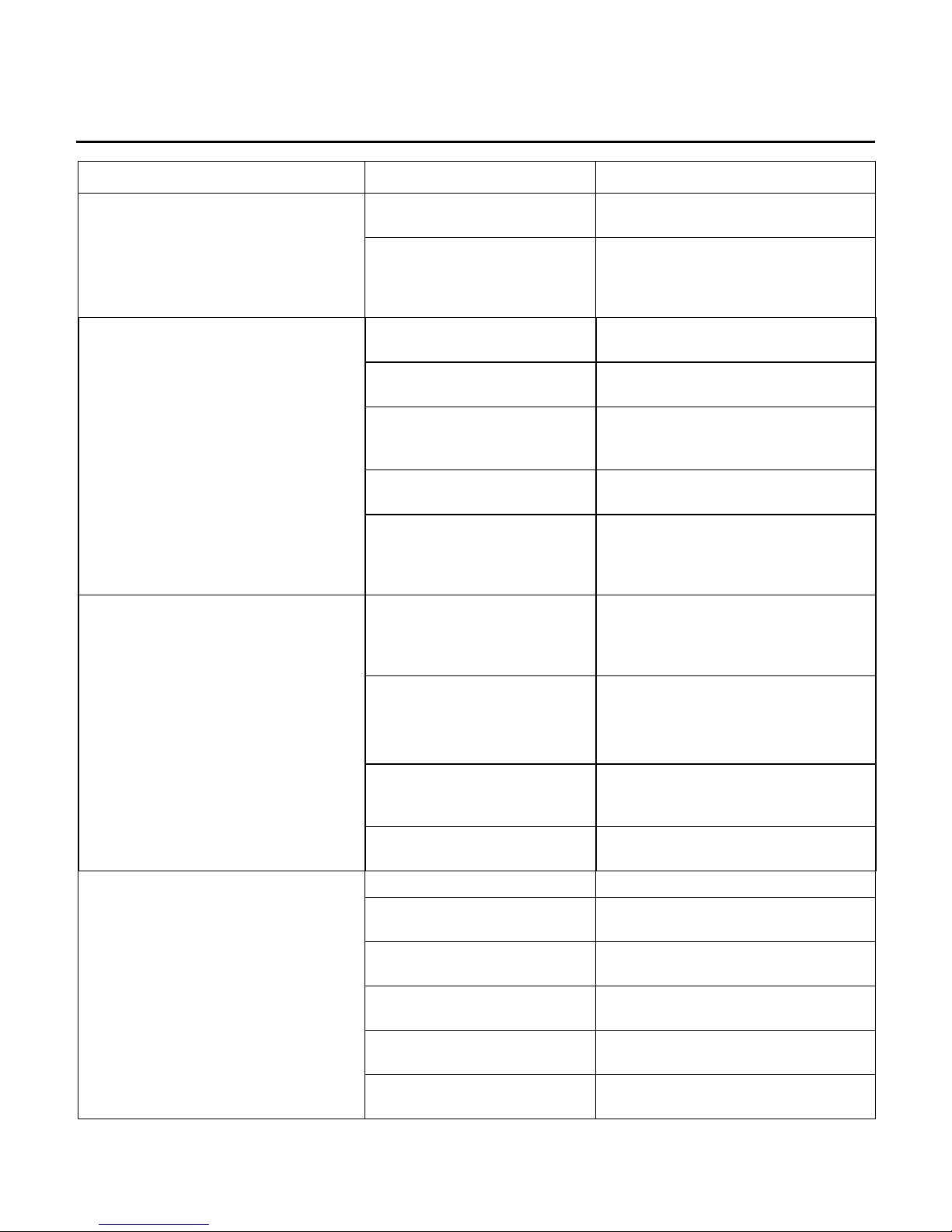

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Display Console LEDs not illuminating

Display console initializes then fails

Auto start not responding. Check auto start not responding.

Keypad not responding. Test keypad in diagnostics.

Insufficient battery voltage. Check battery voltage. The LC9500,

LC9100, and C9i have a 6VDC

battery (non-alkaline) which should

test at a minimum of 6.0 VDC. The

LC8500, and C7 has a 9VDC alkaline

battery and it should test at a

minimum of 9.0 VDC. Replace battery

if it fails to meet minimum

requirements.

Loose wire connections. Disconnect then reconnect

connections.

Worn or damaged wire

harnesses.

Malfunctioning display

console.

Malfunctioning alternator

control board (ACB).

Loose wire connections. Disconnect then secure connections.

No RPM. Enter Diagnostic and check for RPM.

Inspect wire harnesses. Replace

worn or damaged harness.

Test with substitute display console.

Replace malfunctioning display

console.

Test with substitute ACB. Replace

malfunctioning ACB.

No prompt upon release of START

key. Entry of additional information not

allowed.

Malfunctioning alternator. Test alternator output or test with

substitute alternator. Replace

malfunctioning alternator. Refer to

Alternator Voltage Test.

Malfunctioning alternator

control board.

Malfunctioning display

console.

Worn or damaged wire

harnesses.

Malfunctioning display

console.

Battery drained. Replace Battery with new one.

Test with substitute alternator control

board. Replace malfunctioning board.

Test with substitute display console.

Replace malfunctioning display

console.

Inspect wire harnesses. Replace

worn or damaged harness.

Test with substitute display console.

Replace malfunctioning display

console.

3

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

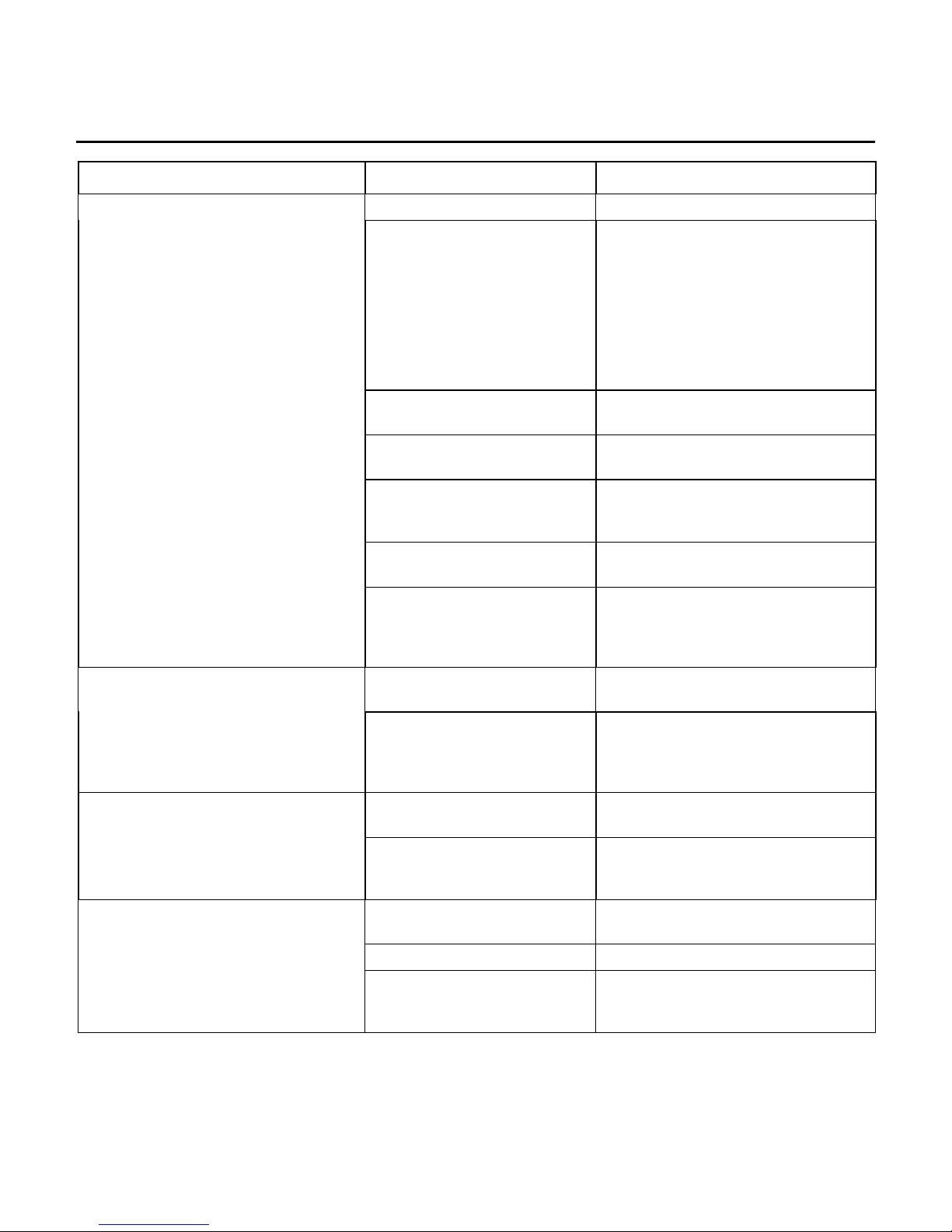

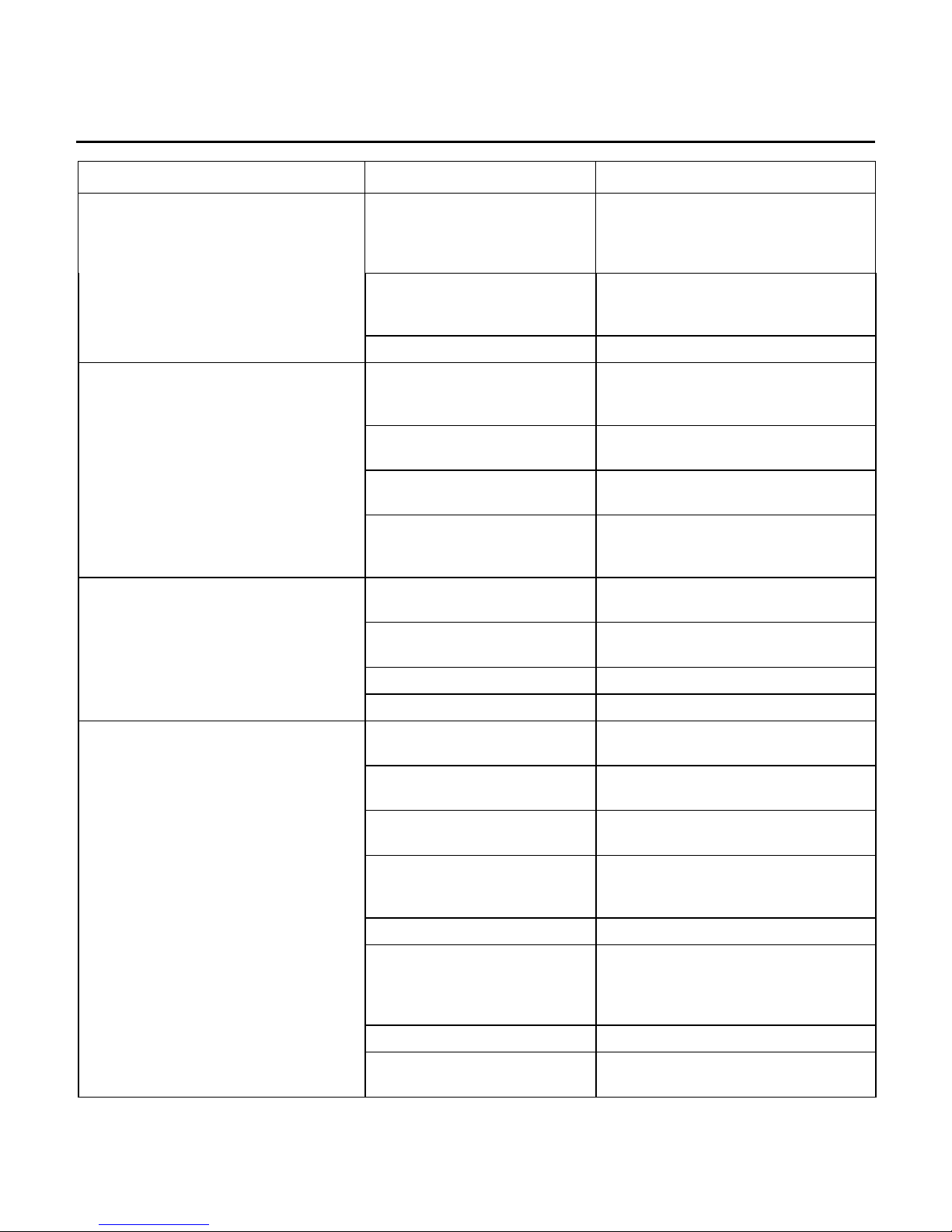

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Display Console LEDs are not

constant

Pedaling to slowly Pedal faster than 35 RPM.

Insufficient battery voltage Check battery voltage. The LC9500,

LC9100, and C9i have a 6VDC

battery (non-alkaline) which should

test at a minimum of 6.0 VDC. The

LC8500, and C7 has a 9VDC alkaline

battery and it should test at a

minimum of 9.0 VDC. Replace battery

if it fails to meet minimum

requirements.

Loose wire connections Disconnect then reconnect

connections.

Display Console LEDs do not

extinguish in timely manner at the end

of a workout, when the CLEAR key is

pressed, or when the pedaling stops.

Prompt persistently flashes and entry

of additional information is not allowed.

Display Console keys (except START

key) do not function and Exercise Bike

does not respond.

Worn or damaged wire

harnesses

Malfunctioning Display

Console

Malfunctioning Alternator

Control Board

Malfunctioning Alternator Test Alternator output or test with

Malfunctioning Alternator

Control Board

Malfunctioning Display

Console

Attempting to enter improper

duration of time

Malfunctioning Display

Console

Attempting to enter program

not available.

Malfunctioning Keypad Test Keypad in Diagnostics.

Malfunctioning Display

Console

Inspect wire harnesses. Replace

worn or damaged harnesses.

Test with substitute Display Console.

Replace malfunctioning Display

Console.

Test with substitute Alternator Control

Board. Replace malfunctioning board.

substitute Alternator. Replace

malfunctioning Alternator. Refer to

Alternator Voltage Test.

Test with substitute Alternator Control

Board. Replace defective board.

Inspect for damage or depression at

START key. Test with substitute

Display Console. Replace

malfunctioning Display Console.

Refer to Operation Manual for time

duration requirements.

Test with substitute Display Console.

Replace malfunctioning Display

Console.

Refer to Operation Manual for

program availability.

Test with substitute Display Console.

Replace malfunctioning Display

Console.

4

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

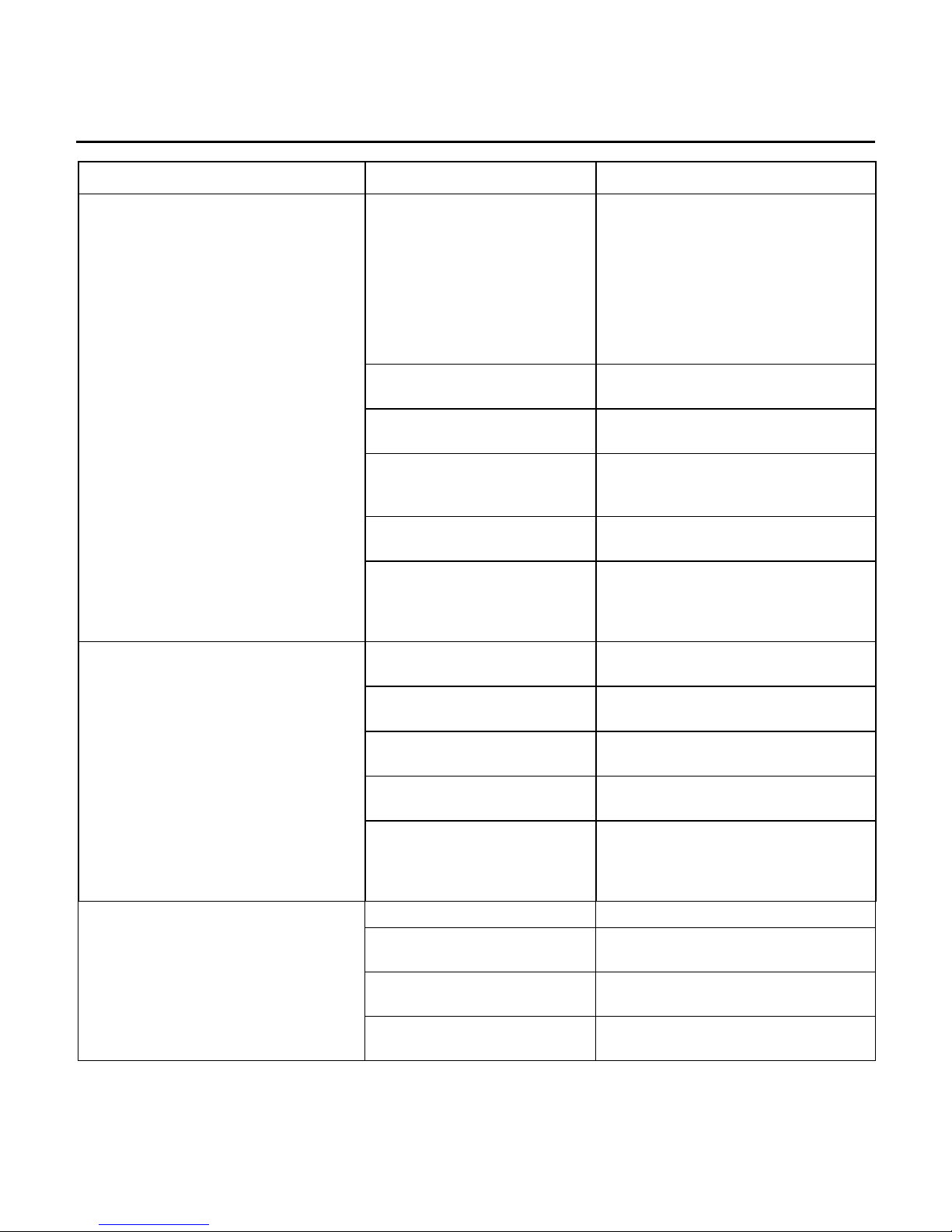

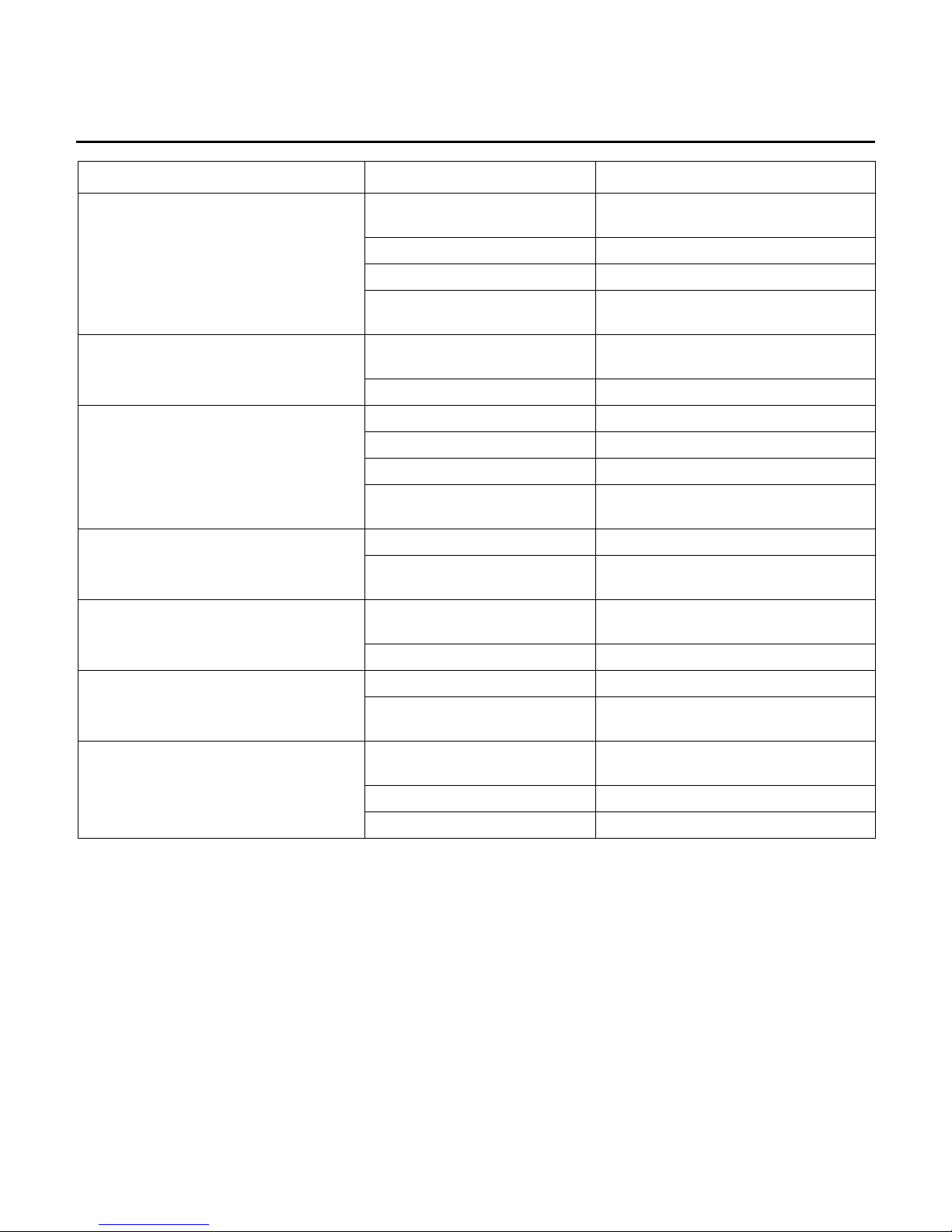

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Upon start of program, excessive

resistance load is immediate; no

normal, incremental increase from “no

load.”

Insufficient battery voltage Check battery voltage. The LC9500,

LC9100, and C9i have a 6VDC

battery (non-alkaline) which should

test at a minimum of 6.0 VDC. The

LC8500, and C7 has a 9VDC alkaline

battery and it should test at a

minimum of 9.0 VDC. Replace battery

if it fails to meet minimum

requirements.

Loose wire connections Disconnect then, reconnect

connections.

During program, excessive resistance

loading occurs.

During MANUAL program, resistance

variation occurs.

Worn or damaged wire

harnesses

Malfunctioning Display

Console

Malfunctioning Alternator

Control Board

Malfunctioning Alternator Test Alternator output or, test with

Loose wire connections Disconnect then, reconnect

Worn or damaged wire

harnesses

Malfunctioning Display

Console

Malfunctioning Alternator

Control Board (ACB)

Malfunctioning Alternator Test Alternator output or, test with

Pedaling too slowly Pedal faster than 35 RPM.

Loose wire connections Disconnect then, reconnect

Worn or damaged harnesses Inspect wire harnesses. Replace

Malfunctioning Display

Console

Inspect wire harnesses. Replace

worn or damaged harness.

Test with substitute Display Console.

Replace malfunctioning Display

Console.

Test with substitute Alternator Control

Board. Replace malfunctioning board.

substitute Alternator. Replace

malfunctioning Alternator. Refer to

Alternator Voltage Test.

connections.

Inspect wire harnesses. Replace

worn or damaged harness.

Test with substitute Display Console.

Replace Display Console.

Test with substitute ACB. Replace

malfunctioning ACB.

substitute Alternator. Replace

malfunctioning Alternator. Refer to

Alternator Voltage Test.

connections.

worn or damaged harness.

Test with substitute Display Console.

Replace Display Console.

5

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

During MANUAL program, resistance

variation occurs.

During RANDOM or HILL programs,

resistance is constant without variation

for interval training nor hill

incline/decline.

Malfunctioning Alternator

Control Board

Malfunctioning Alternator Test Alternator output or, test with

Loose wire connections Disconnect then, reconnect

Worn or damaged harnesses Inspect wire harnesses. Replace

Test with substitute Alternator Control

Board. Replace defective board.

substitute Alternator. Replace

malfunctioning Alternator. Refer to

Alternator Voltage Test.

connections.

worn or damaged harness.

Pedaling is difficult, feels restricted or,

is not possible when Exercise Bike has

not been started (START key not

pressed).

During exercise program, pedaling is

insufficiently easy, not providing

adequate resistance.

Malfunctioning Display

Console

Malfunctioning Alternator

Control Board

Malfunctioning Alternator Test Alternator output or, test with

Malfunctioning Pulley Clutch

Assembly

Alternator Belt excessively

tight

Alternator Belt Alignment is

OFF

Crank bearings worn or

corroded

Pedaling too slowly Pedal faster than 30 RPM.

Program level doesn’t

challenge user ability

Loose wire connections Disconnect then, reconnect

Worn or damaged harnesses Inspect wire harnesses. Replace

Malfunctioning Display

Console

Malfunctioning Alternator

Control Board

Test with substitute Display Console.

Replace malfunctioning Display

Console.

Test with substitute Alternator Control

Board. Replace defective board.

substitute Alternator. Replace

malfunctioning Alternator. Refer to

Alternator Voltage Test.

Inspect Clutch for free backward and

forward rotation. Replace

malfunctioning Pulley Clutch or

Freewheel.

Inspect belt deflection. Adjust as

necessary.

Alternator Belt Deflection: 1/4 inch

(6mm)

Realign alternator belt to far users left

groove of the alternator pulley, not in

the center.

Replace Crank Bearings.

Select higher level.

connections.

worn or damaged harness.

Test with substitute Display Console.

Replace malfunctioning Console.

Test with substitute Alternator Control

Board. Replace defective board.

6

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

During exercise program, pedaling is

insufficiently easy, not providing

adequate resistance.

Malfunctioning Alternator Test Alternator output or, test with

substitute Alternator. Replace

malfunctioning Alternator. Refer to

Alternator Voltage Test.

Alternator Belt excessively

loose

Drive Belt excessively loose Inspect Belt. Replace Belt.

Inspect belt deflection. Adjust as

necessary. Alternator Belt Deflection:

1/4 inch (6mm)

Battery over-heating during exercise

program.

Exercise Bike not stable upon floor.

During exercise program, loud noise

issuing from Exercise Bike.

Battery Wires incorrectly

connected

Worn Battery Wires Inspect Wires. Replace Wires or

Battery leads grounding upon

frame

Malfunctioning Display

Console

Stabilizer Foot Pads not

adjusted correctly

Floor surface not level Position Exercise Bike upon level

Wheel(s) damaged Replace damaged wheel(s).

Frame damaged Contact Customer Support Services.

Non-carpeted, hard surface

floor

Improper riding style Change style. Do not lean excessively

Crank Bearings worn Inspect Bearings. Replace as

Inspect connections: red wire to

positive (+) lead; black wire to

negative (-) lead.

harness.

Inspect leads. Replace battery.

Test with substitute Display Console.

Replace malfunctioning Display

Console.

Adjust Foot Pads.

surface.

Place Exercise Bike upon softer

surfaced floor.

to either side.

necessary.

Alternator Belt excessively

loose

Alternator Belt worn Replace Belt.

Malfunctioning Alternator Operate Exercise Bike as in normal

Drive Belt excessively loose Inspect Belt. Replace Belt.

Free-wheel Pulley Assembly Inspect clutch for free rotation.

7

Inspect belt deflection. Adjust as

necessary. Alternator Belt Deflection:

1/4 inch (6mm)

use with light and heavy load levels.

Listen for excessive noise. Replace

Alternator as necessary.

Replace defective Freewheel Pulley.

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

No heart rate or, display reads (No

Heart Rate).

No heart rate reading Executive Diagnostic Mode to verify

performance of heart rate function.

Faulty cable connection Verify heart-rate cable is properly

connected.

Using an ohmmeter, verify continuity

at the main console cable. See wiring

diagram for pin location.

Malfunctioning

Handlebar/Lifepulse Grip

Assembly (include. Worn or

damaged heart rate lead)

Life Pulse handlebar Verify that the handlebar is

Handlebar/Lifepulse Grip

Assembly

Loose or malfunctioning heart

rate lead connection at Display

Console

Malfunctioning Display

Console

Wear or damage to grip Replace the handlebar assembly.

Channels do not change.

Sound does not change.

Faulty PCB Only one channel programmed Follow the setup procedures in the

No sound.

Key pad malfunction. Run Key pad test in diagnostics.

Interface PC board defective. Replace Interface PC board.

Key pad malfunction. Run Key pad test in diagnostics.

Interface PC board defective. Replace Interface PC board.

Faulty headphones. Replace headphones.

Faulty headphone jack

assembly.

Faulty cable to Headphone

jack assembly

Air/cable setting may not be

correct

Power applied prior to video

hookup

Replace Handlebar/Lifepulse

Assembly.

functioning. See diagrams.

Using an ohmmeter, verify continuity

between Lifepulse sensor and cable

connection. See wiring diagram for

pin location.

Dry wipe sensors.

Secure connection. Replace

malfunctioning Handlebar/Lifepulse

Grip Assembly

Test with substitute Display Console.

Replace malfunctioning Display

Console.

Replace if defective.

Replace if defective.

operator manual.

Replace headphone jack assembly.

Replace Headphone jack cable.

Follow the set up procedures in the

operators’ manual.

Power down, install video, and follow

channel instruction.

8

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Unable to receive any channels when

using cable.

Snow and noise appear on the screen.

Screen is blank with audio beeps or

dark.

The wrong buttons activate when the

touch screen is touched.

screen is touched.

Screen does not turn ON and no

audio.

Air/cable setting may not be

correct.

Coax Cable may be bad. Replace Coax Cable.

Coax Cable may be unplugged Reconnect Cable.

Cable system may not be

producing clear signal

Air/cable setting may not be

correct.

Coax cable may be bad. Replace Coax cable.

LCD Back Light burned up. Replace LCD/Touch Screen.

Back Light power inverter bad Replace backlight inverter

LCD Screen failure Replace LCD/Touch Screen.

Problem on the single board

computer

Touch screen failure. Replace LCD/Touch Screen.Screen Does not respond to touch.

Problem with Single Board

Computer.

Touch Screen not calibrated

correctly

Touch Screen Damaged. Replace LCD/Touch Screen.

Touch Screen Damaged. Replace LCD/Touch Screen.No buttons activate when the touch

Failure On the single board

computer.

No power. Check Main Cable for 5 & 12VDC.

Faulty wire harness to console. Replace Wire Harness

LCD defective. Replace LCD\TOUCH screen

Follow the setup procedures in the

operator manual.

Notify installer.

Follow the setup procedures in the

operator manual.

Replace Single Board Computer.

Replace Single Board Computer.

Calibrate Touch Screen. Refer to

Diagnostics.

Replace the single board Computer.

Check wiring diagram pin locations.

9

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

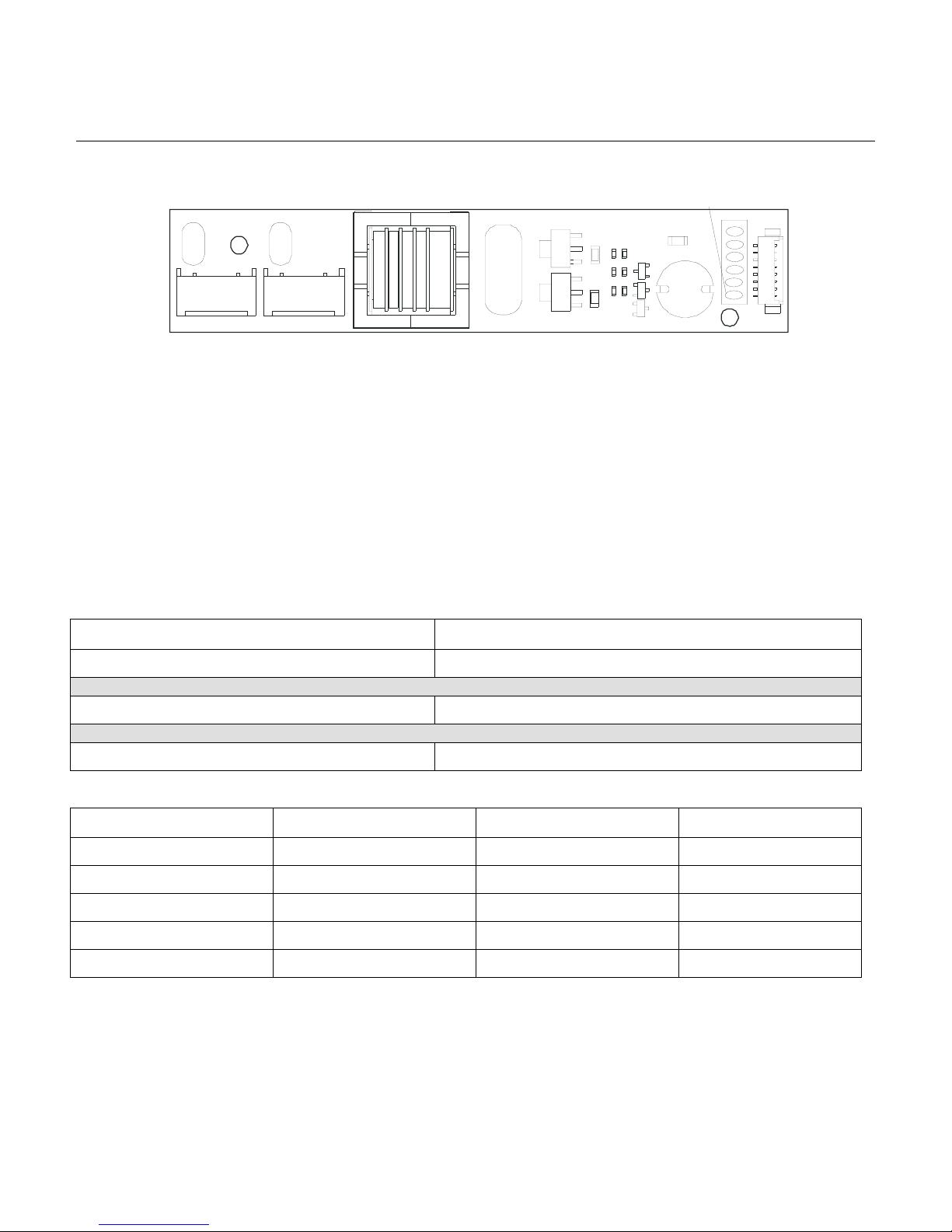

TROUBLESHOOTING GUIDE – TESTING THE INVERTER BOARD

Special Service Tools Required: Multi-meter

CAUTION! HIGH VOLTAGE ON CONNECTORS J2 AND J3

1.

J3

Remove the Integrated System Console from the Unit.

2. Remove Rear Cover from the Console Assembly.

3. Plug in Power Supply and Remote Control to the Console

4. Press the Power On Key on the Remote Control.

5. TEST NO. 1: Place the Red Lead from the multi-meter onto Test Point 1 and the Black Lead onto Test

Point 3. Voltage should be 12 Vdc (+/- .5V).

J2

Tes t Points

6

5

4

3

2

1

J1

6. TEST NO. 2: Place the Red Lead from the multi-meter onto Test Point 5 and the Black Lead to Test Point

3. Voltage should be 12 Vdc (+/- .5V)

PROBLEM SOLUTION

No Voltage on TP1 Replace Cable, Remote, or Main PC Board.

Voltage present on TP1 Replace the Inverter Board

Voltage on TP1 and TP2 but NO Voltage on TP5 Replace Cable between Inverter Board and Main PC Board

TEST POINT VOLTAGE DESCRIPTION PIN NUMBER

TP 1 & 2 12 Vdc VIN 1 & 2

TP 3 &4 0 Vdc Ground 3 & 4

5 12 Vdc Enable 5

5 0 Vdc Disable 5

6 Not Used Not Used 6/7/8

10

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE – TESTING THE POWER SUPPLY CABLE

Special Service Tools Required: Multi-meter

1. Unscrew the Retaining Nut securing the Power

Cable Plug. Remove the Cable.

2. Using a Multi-meter, touch the Red Lead to the

POSITIVE area on the Cable, which is the center

of the cable. Next touch the Black Lead to the

NEGATIVE area, which is the side of the inner

Cable. The voltage should read 12 Vdc.

Positive

Negative

Retaining nut

11

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

TROUBLESHOOTING GUIDE

Notes

12

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

SECTION IIA

DIAGNOSTIC MODES

FOR LED UNITS

Page

LC9500R ............................................................................................................................. 3

LC9100R Console............................................................................................................... 4

LC8500R Console............................................................................................................... 5

R9 Console ......................................................................................................................... 6

R7 Console ......................................................................................................................... 7

MAP..................................................................................................................................... 8

ENTRY LEVEL .................................................................................................................... 9

Test/Service - All LEDs And Keypad Test.......................................................................... 10

Test/Service - Walking LED Test ....................................................................................... 11

Test/Service - Miscellaneous 1 Test .................................................................................. 12

Test/Service - Miscellaneous 2 Test .................................................................................. 13

Test/Service - Port I/O Test................................................................................................ 14

Test/Service - Life Pulse Test ............................................................................................ 15

Test/Service - CSAFE Network Test .................................................................................. 16

Test/Service - EEPROM Test............................................................................................. 17

Test/Service - Telemetry Enable/Disable ........................................................................... 18

Test/Service - Language .................................................................................................... 19

Optional Settings - MAX Program Duration........................................................................ 20

Optional Settings - English/Metric Units............................................................................. 21

Optional Settings - WATT Display Enable/Disable............................................................. 22

Optional Settings - METS Display Enable/Disable............................................................. 23

Optional Settings - CAL/HR Display Enable/Disable.......................................................... 24

Optional Settings – WATTS Program Enable/Disable ....................................................... 25

Optional Settings - METS Program Enable/Disable........................................................... 26

Optional Settings - Statistics .............................................................................................. 27

Optional Settings – Entertainment Controls ....................................................................... 28

Optional Settings - Photo Shoot......................................................................................... 29

Notes.................................................................................................................................. 30

1

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

Notes

2

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

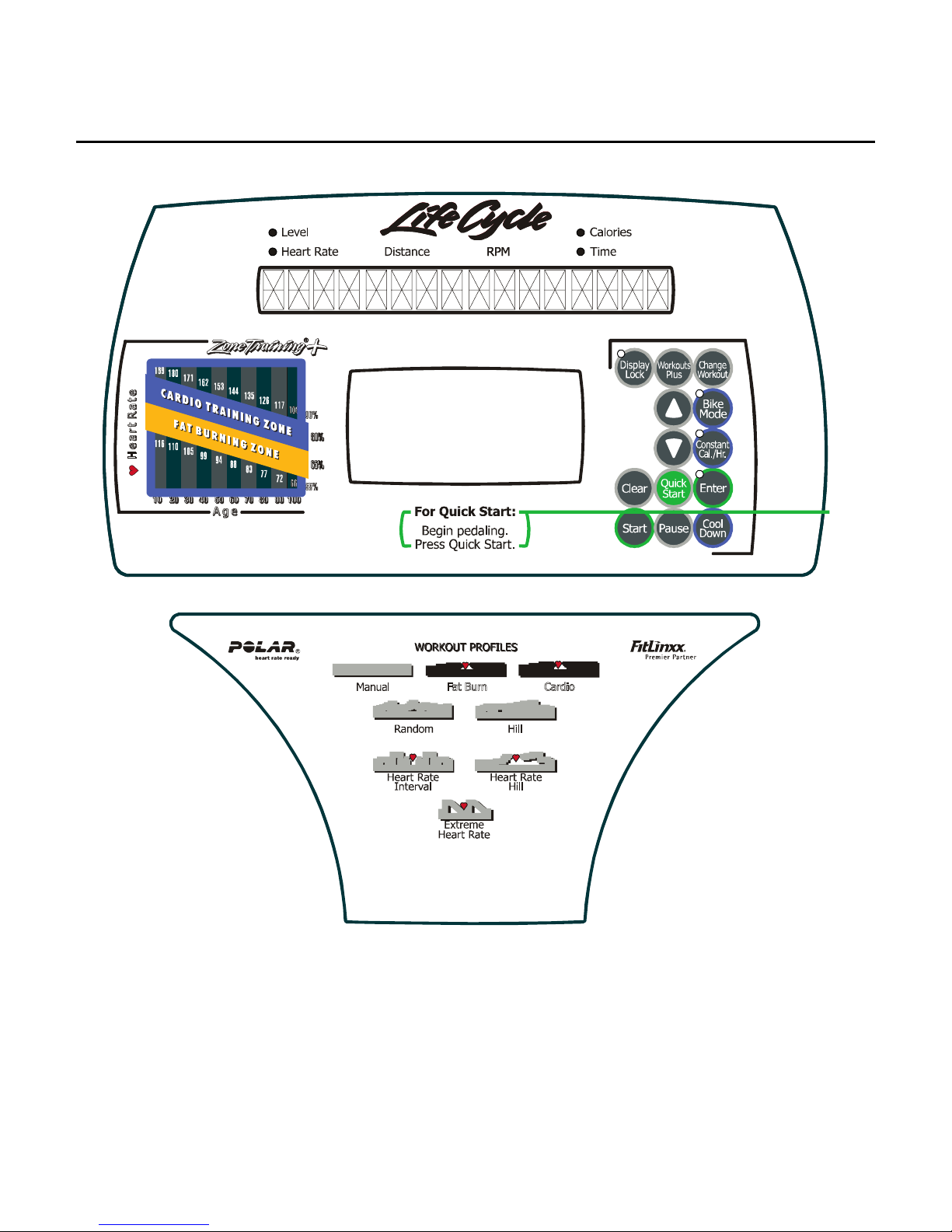

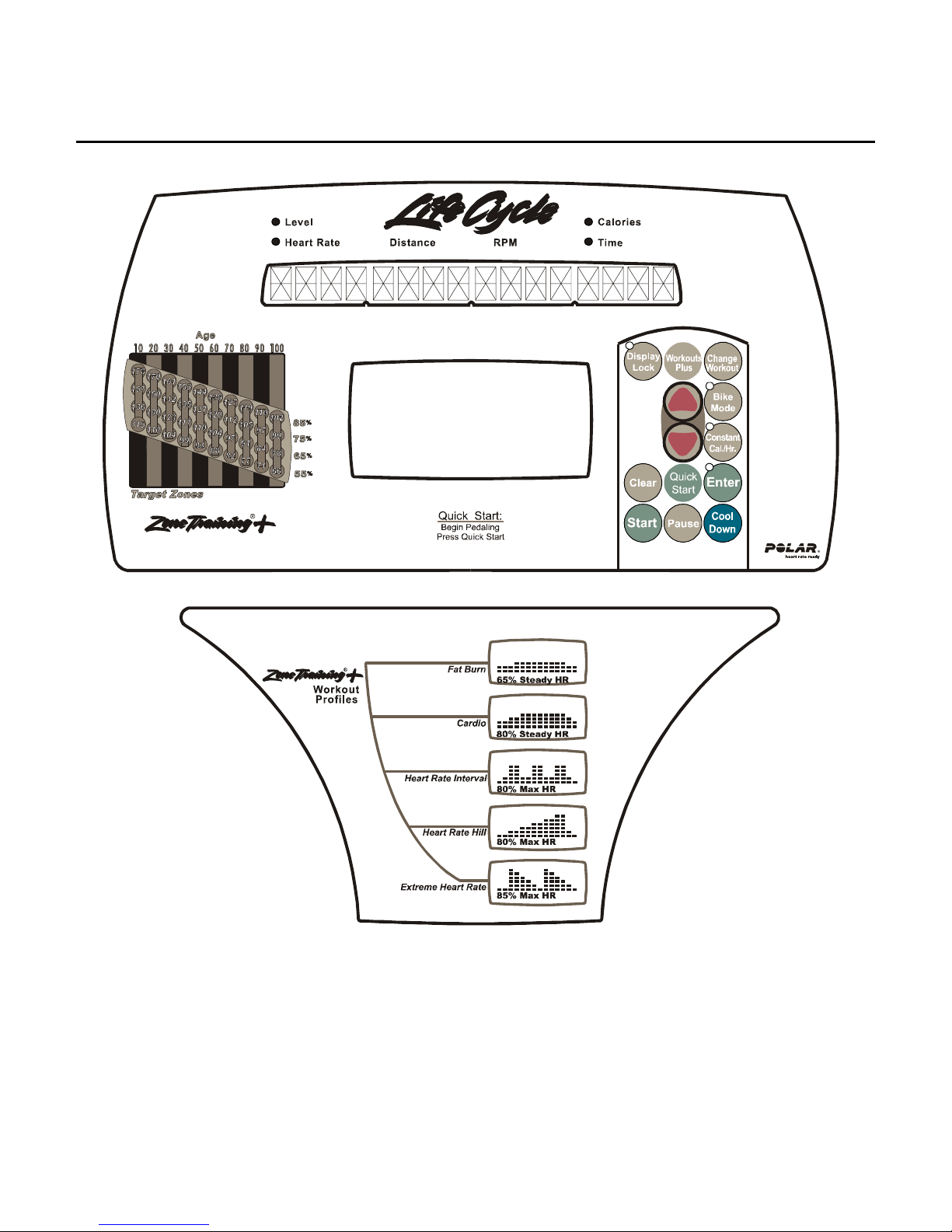

DISPLAY CONSOLE LC9500R

LC9500R

3

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

DISPLAY CONSOLE LC9100R

LC9100R

4

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

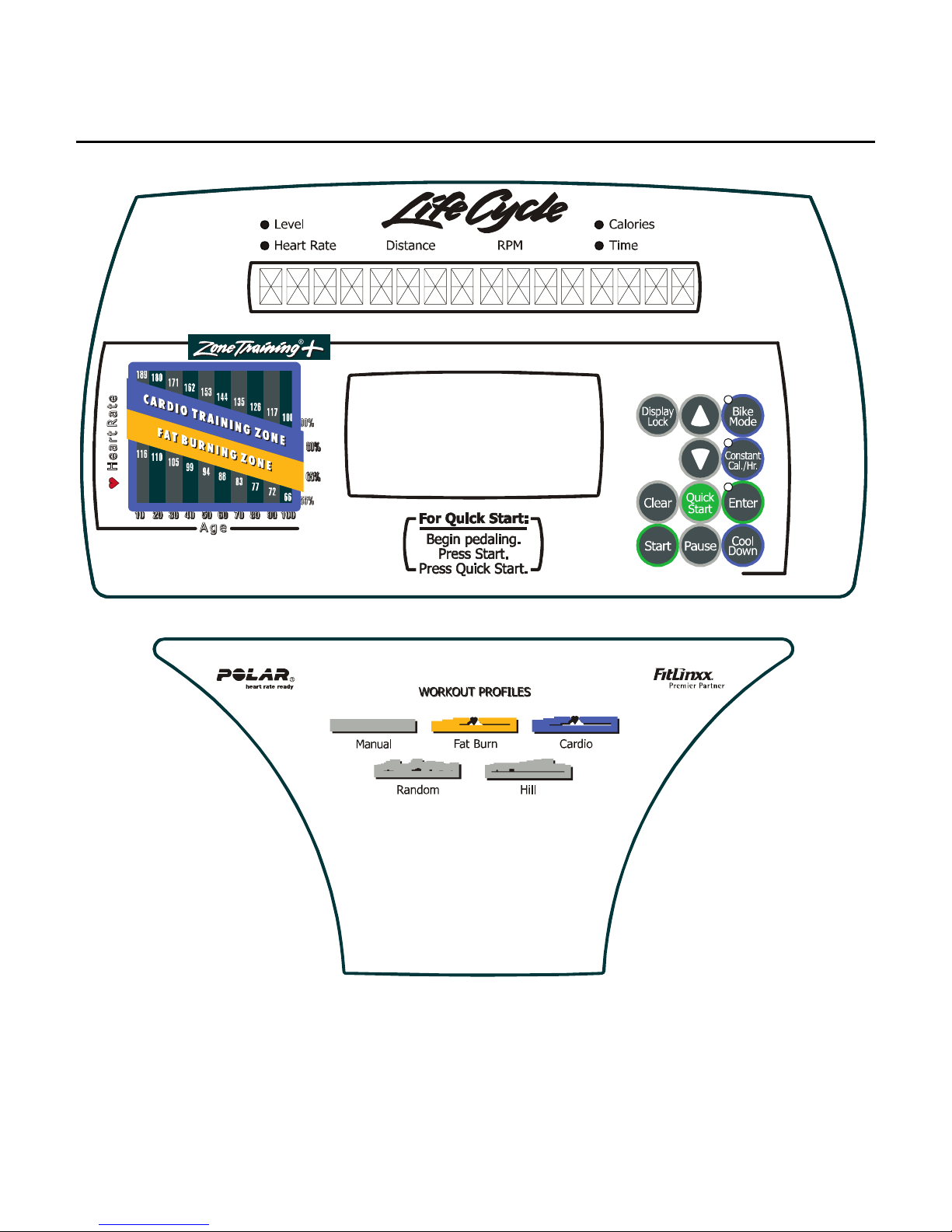

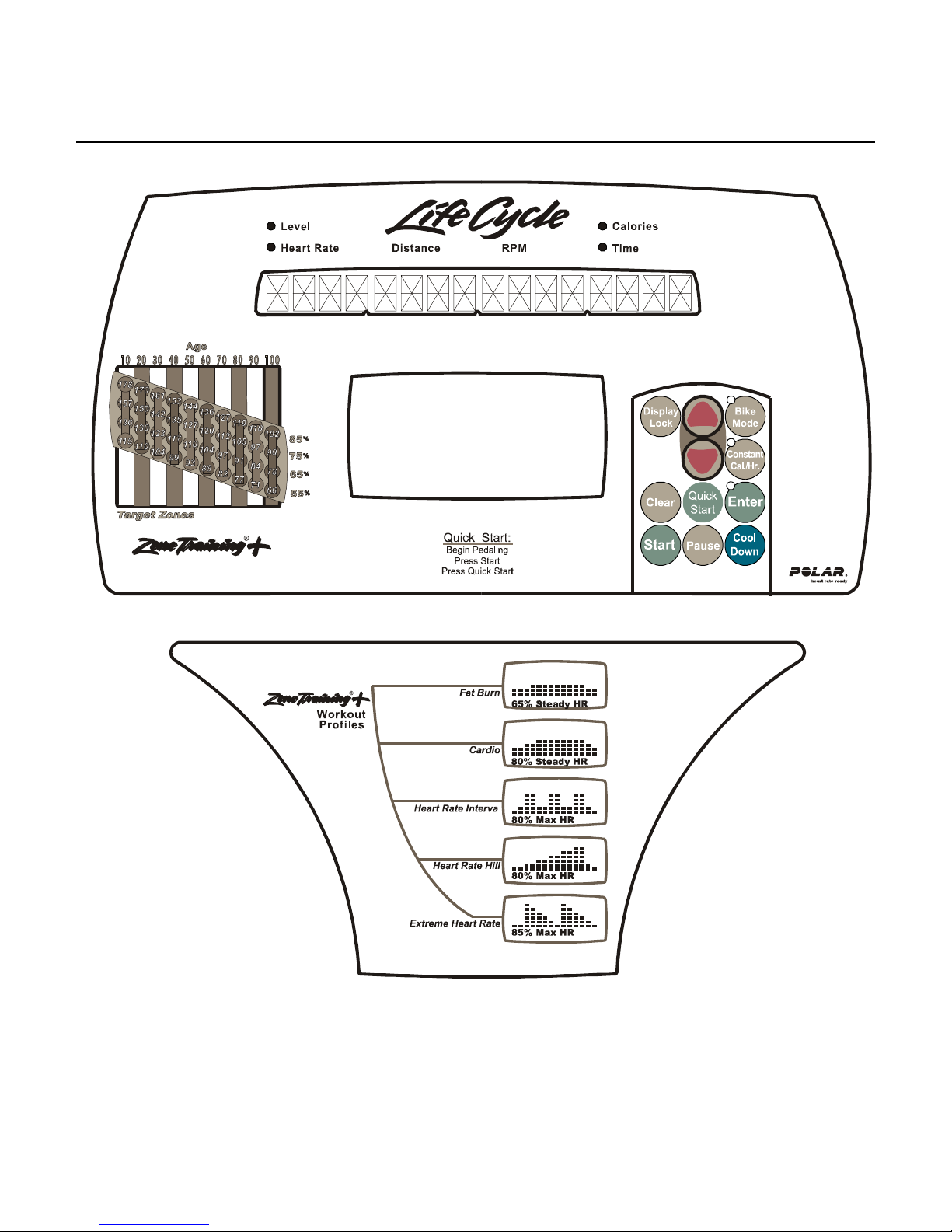

DISPLAY CONSOLE LC8500R

LC8500R

5

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

DISPLAY CONSOLE R9

R9

6

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

DISPLAY CONSOLE R7

R7

7

Lifecycle Recumbent Bikes LC95R, LC91R, LC85R, R9, R7, 95Ri, 93Ri, 90R, and 95Re

A

A

MAP

Test/service

Display Test

Walking Led

Port I/o Test

Language

All Led’s On

Keypad Test

Relay

Fld Kick

Units

lt. Voltage

lt Rpm

Entertainment

8

Loading...

Loading...