Lifebreath 2500EFD User Manual

* LEAVE FOR HOMEOWNER

NOTE: Due to ongoing research and product development, specifications,

ratings and dimensions are subject to change without notice.

Installing Contractor

Telephone / Contact

Serial Number

Installation Date Model

TO BE COMPLETED BY CONTRACTOR AFTER INSTALLATION

CAUTION

Before

installation, careful consideration must be given to

how this system will operate if connected to any other piece

of mechanical equipment, i.e. a forced air furnace or air

handler, operating at a higher static. After

installation, the

compatibility

of the two pieces of equipment must be

confirmed by measuring the airflow’s of the Heat Recovery

Ventilator (HRV) Energy Recovery Ventilator (ERV) by

using the balancing procedure found in this manual.

It is always important to assess how the operation of any

HRV/ERV may interact with vented combustion equipment

(ie. Gas Furnaces, Oil Furnaces, Wood Stoves, etc.).

NEVER install a ventilator in a situation where its normal

operation, lack of operation or partial failure may result

in the backdrafting or improper functioning of vented

combustion equipment!!!

IMPORTANT - PLEASE READ THIS

MANUAL BEFORE INSTALLING UNIT

OPERATION AND

INSTALLATION MANUAL

TI-59

1203

For Models:

2500IFD

2500EFD

2

Introduction

These Heat Recovery Ventilators (HRVs) are designed

for commercial and industrial applications to provide

fresh air to a building while exhausting an equal

amount of stale air. During the winter months the

incoming cold fresh air is warmed by utilizing the heat

recovered from the stale air before it is exhausted to

the outdoors. During summer months when the indoor

space is air conditioned, the Heat Recovery Ventilator

will help in cooling the incoming fresh air with the stale

air that is being exhausted.

Table of Contents

Introduction .................................................................... 2

Select Correct HRV......................................................... 3

Specifications - Model 2500IFD .................................. 4

Specifications - Model 2500EFD ................................. 5

Options & Accessories ....................... 6

Operation Instructions ................................................... 7

Installation Tips ............................................................. 7

Remote Controls ........................................................... 8

User Adjustable Defrost ................................................ 8

Defrost Control .............................................................. 8

Fan Defrost ................................................................. 9

Location ...................................................................... 9

Mounting ..................................................................... 9

Drains ......................................................................... 12

Ducting ......................................................................... 12

Return and Supply ....................................................... 13

Air Flow Balancing ....................................................... 14

The Integrated HVAC System ...................................... 15

Electrical Connections ................................................. 15

Maintenance ................................................................ 15

Wiring Diagram ........................................................... 17

Ladder Diagram .......................................................... 18

Warranty .................................................................... 19

I F D

2500

Interior

mount

Fan

Defrost

E F D

2500

Exterior

(roof mount)

Fan

Defrost

3

MAKE UP HEAT REQUIREMENT at 1200 CFM (566L/s)

Nominal Nominal Nominal

Outdoor Temp. kW Req. for kW Req. for kW Req. for

C° F° 20°C (68°F) 25°C (77°F) 30°C (86°F)

Air Delivery Air Delivery Air Delivery

0 32 7 10 14

-10 14 10 14 17

-20 -4 12 15 19

-30 -22 15 19 22

-40 -40 17 21 24

Selecting the Correct Size HRV

Commercial and Institutional Requirements

For outdoor air requirements, ASHRAE has produced the Ventilation Standard 62-1989

that is used to determine acceptable ventilation rates. This standard is referenced directly or

used as “Good Engineering Practice” in most Code documents or design criteria.

Small restaurants, Donut Shops and Fast food stores

Seats 40

Employees 5

Total 45

ASHRAE requirement 20 cfm (10 L/s) per person

Ventilation required 45 x 20 = 900 cfm (450 L/s)

Bank

Customers 25

Staff 9

Total 34

ASHRAE requirement 20 cfm (10 L/s) per person

Ventilation required 34 x 20 = 680 cfm (320 L/s)

Bar or Tavern

Seats 50

Employees 7

Total 57

ASHRAE requirement 30 cfm (15 L/s) per person

Ventilation required 57 x 30 = 1710 cfm (855 L/s)

Bingo Hall

Customers 180

Staff 20

Total 200

ASHRAE requirement 30 cfm (15 L/s) per person

Ventilation required 200 x 30 = 6000 cfm (3000 L/s)

Classroom and School Portables

Seats 29

Teacher 1

Total 30

ASHRAE requirement 15 cfm (7.5 L/s) per person

Ventilation required 30 x 15 = 450 cfm (255 L/s)

Print Shop, Duplicating

Square footage of shop 2000 square ft

ASHRAE requirement 0.5 cfm / ft

2

(2.5 L/s - m2)

Ventilation required 2000 x 0.5 = 1000 cfm (500 L/s)

Beauty Salon

Customers 12

Employees 6

Total 18

ASHRAE requirement 25 cfm (12.5 L/s) per person

Ventilation required 18 x 25 = 450 cfm (255 L/s)

Swimming Pools

Refer to “Pool” Models Installation Manuals.

4

SPECIFICATIONS

AIR FLOW

2100 cfm (985 L/s) at 1.0"wg ESP

PERFORMANCE

70% effective at 2500 cfm (1172 L/s)

CORE

Modular aluminum sensible heat recovery core.

Plate-to-plate type. Slides out of either side of cabinet for

service.

MOTORS

Two single shaft PSC, 3-speed, 208/230V,5.1 amps,

1 ph, 1 hp

BLOWERS

Two direct-drive centrifugal blowers, one per air stream.

FILTERS

Two 18" X 24" 4-inch pleated filters in each air stream.

DUCT CONNECTIONS

Four 24" X 16" (610mm X 406mm)

CABINET

20 gauge powder coated galvanized steel (G60) for

superior corrosion resistance. 16 gauge galvanized

frame, insulated with1.5" fibreglass insulation to prevent

condensation.

DRAIN

Two stainless steel drain pans with 1/2" NPT drain

spouts.

MOUNTING

Unit to be set on support brackets hung by threaded rod

type apparatus. Brackets and rod not provided.

CONTROLS

24V terminal strip inside electrical box, to connect

optional remote controls (not included), obtain on/off and

high/low functions.

DEFROST

Factory set defrost time (user adjustable).

Supply motor is shut off while exhaust air defrosts core.

WARRANTY

15 year warranty on heat exchanger, and 2 years

on parts.

WEIGHT

700 lbs.

SHIPPING WEIGHT

1100 lbs.

All units conform to CSA and UL standards.

Model 2500IFD

DATE: ______________________________________________PROJECT: ______________________________________

MECHANICAL CONTRACTOR: _________________________________________________________________________

TI-91I

1203

Exhaust to Outside

Motors (2)

Exhaust to

Supply from Outside

Exhaust from Building

Supply to Building

Electrical

Service

Panel*

Heat

Exchanger

Service

Panel*

89.9"

SIDE VIEW

*NOTE: Removable service access panels on both sides of 2500IFD cabinet.

38.4"

outside

Supply to

building

24"

47"

16"

FRONT VIEW BACK VIEW

Heat Exchange Core

Drain Pans (2)

Filter

Service

Panel*

Supply from

outside

38.4"

24"

16"

Exhaust from

building

4" Filters

47"

2"

7"

6"

5

DATE: ____________________________________________PROJECT: ________________________________________

MECHANICAL CONTRACTOR:__________________________________________________________________________

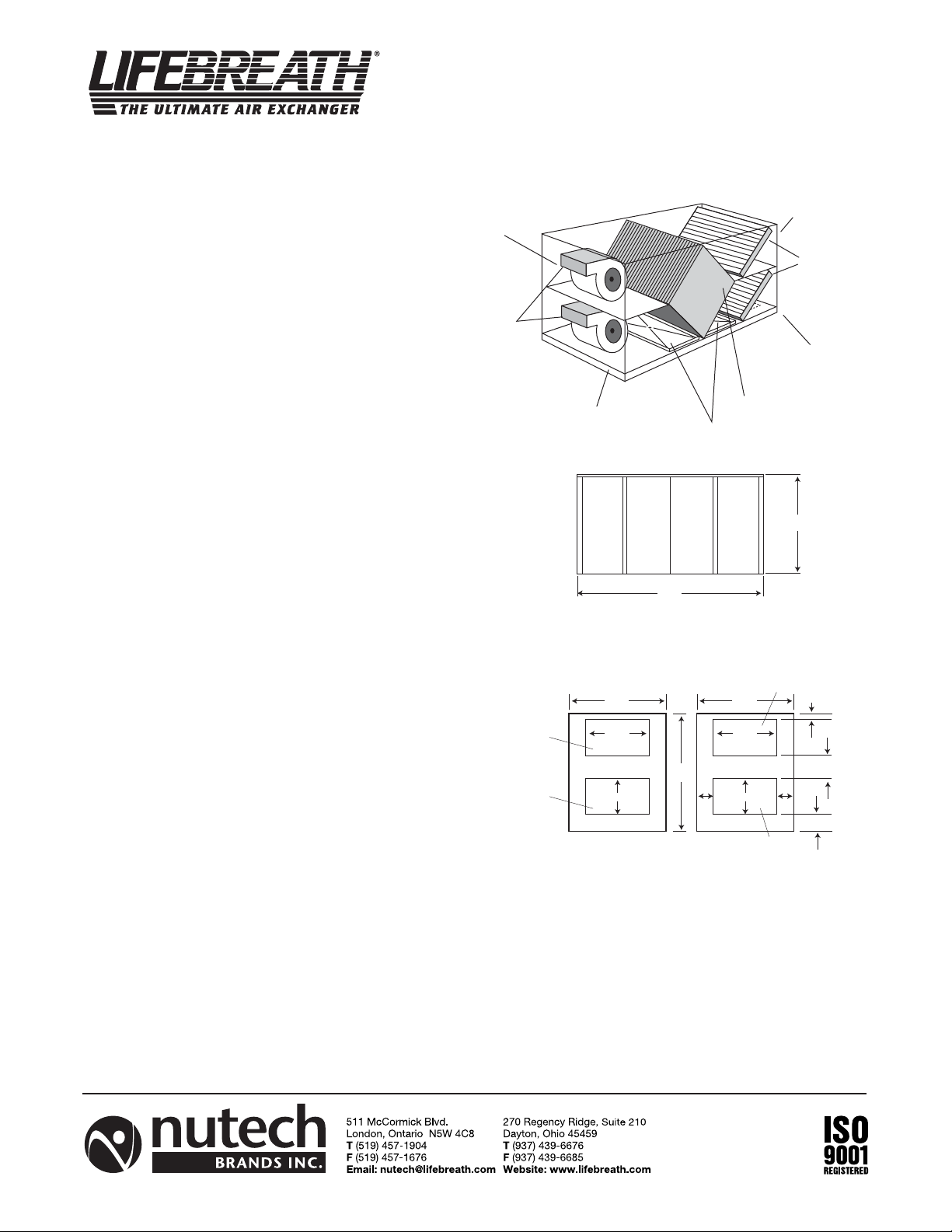

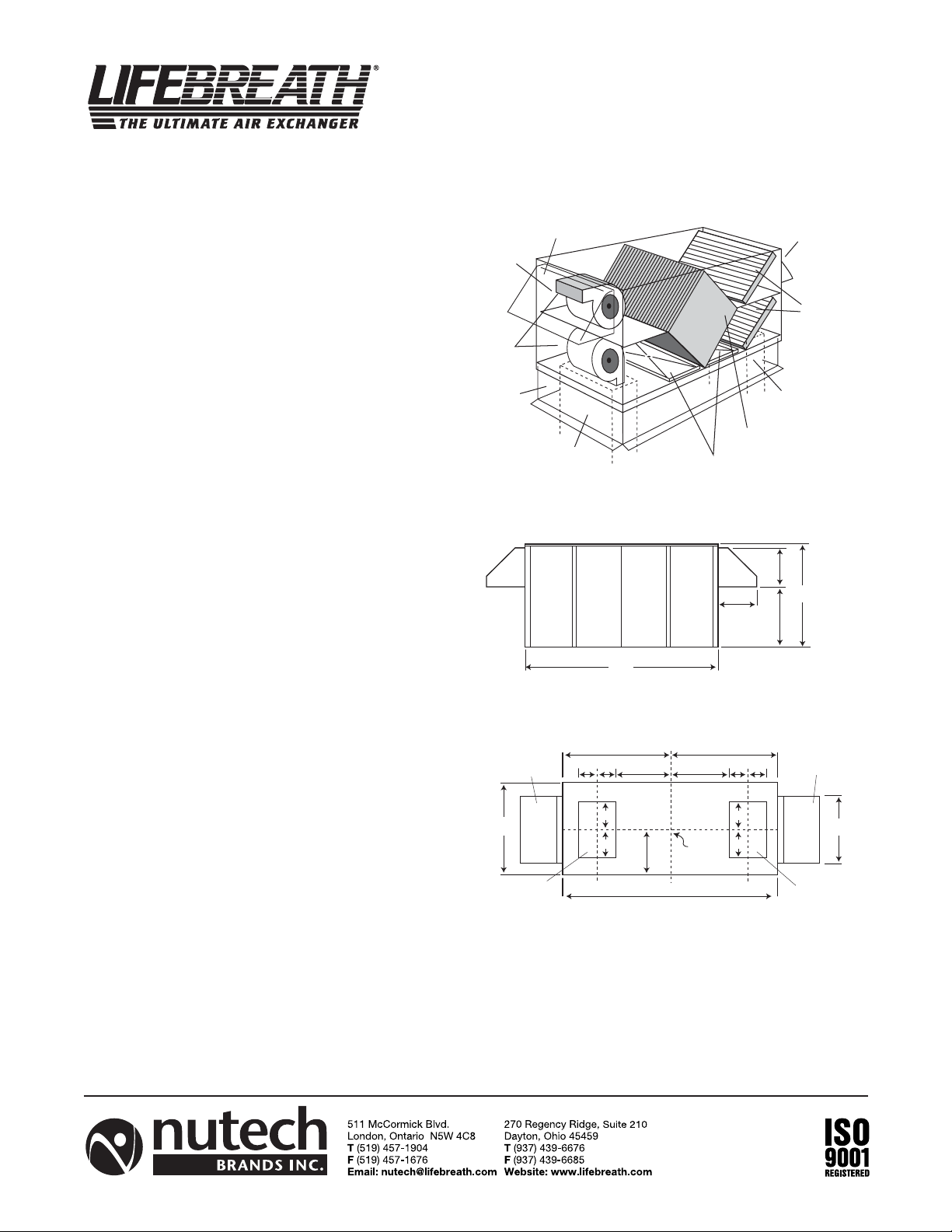

Model 2500EFD

(ROOFTOP)

TI-91E

1203

All units conform to CSA and UL standards.

SPECIFICATIONS

AIR FLOW

2100 cfm (985 L/s) at 1.0"wg ESP

PERFORMANCE

70% effective at 2500 cfm (1172 L/s)

CORE

Modular aluminum sensible heat recovery core.

Plate-to-plate type. Slides out of either side of cabinet

for service.

MOTORS

Two single shaft PSC, 3-speed, 208/230V,5.1 amps, 1 ph,

1 hp

BLOWERS

Two direct-drive centrifugal blowers, one per air stream.

FILTERS

Two 18" X 24" 4-inch pleated filters in each air stream.

DUCT CONNECTIONS

Four 24" X 16" (610mm X 406mm) to and from the building

under cabinet.

Four 28" X 18" (711mm X 457mm) hoods

included on side of cabinet with screens.

CABINET

20 gauge powder coated galvanized steel (G60) for

superior corrosion resistance. 16 gauge galvanized

frame, insulated with 1.5" fibreglass insulation to prevent condensation.

DRAIN

Two stainless steel drain pans with 1/2" NPT drain

spouts.

MOUNTING

Rooftop mounted on optional roof curb (Part No. 53-

2500)

CONTROLS

24V terminal strip inside electrical box, to connect

optional remote controls (not included), obtain on/off

and high/low functions.

DEFROST

Factory set defrost time (user adjustable).

Supply motor is shut off while exhaust air defrosts core.

WARRANTY

15 year warranty on heat exchanger, and 2 years on

parts.

WEIGHT

700 lbs.

SHIPPING WEIGHT

1100 lbs.

OPTIONAL CURB

WEIGHT 50 lbs.

Hoods (2)

c/w Bug Screen

Motors (2)

Roof Curb

*NOTE: Roof curb is one inch smaller than outside dimensions of cabinet.

*NOTE: Removable service access panels on both sides of 2500EFD cabinet.

38.4" 28"

Fresh Air

Supply

Exhaust

Hoods

Supply Duct

24"x16"

Electrical

Service

Panel*

Heat

Exchanger

Service

Panel*

89.9"

Filter

Service

Panel*

SIDE VIEW

44.95"

Hood Hood

8" 8"

12"

12"

21.8"

19.2"

89.9"

25"

Bottom duct

connections

16" X 24"

Centre

Point

44.95"

BOTTOM VIEW

Supply Hoods

Exhaust Duct

Heat Exchange Core

Drain Pans (2)

18"

18"

27"

8" 8"

12"

12"

4" Filters

24"x16"

47"

Stale Air

Return

6

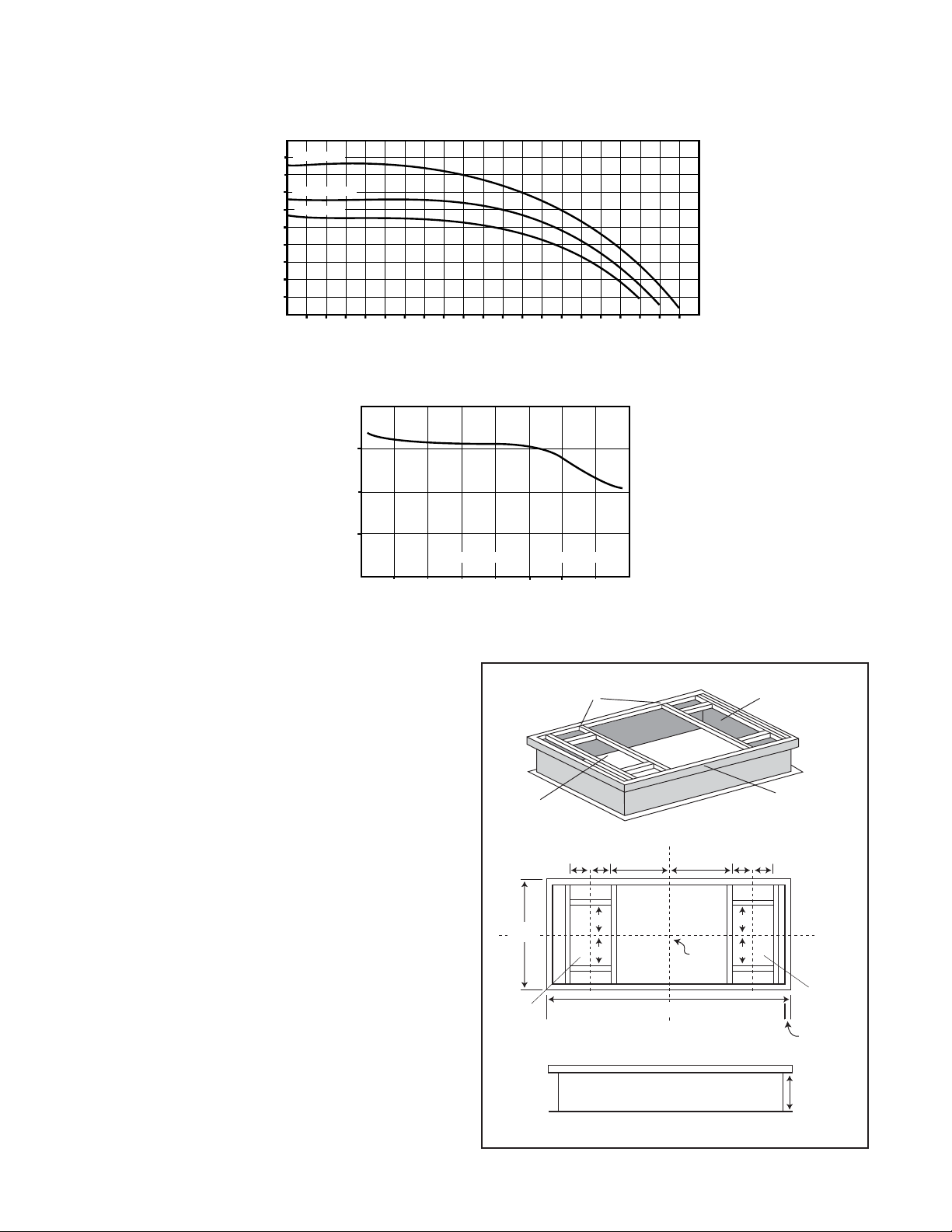

AIRFLOWS (Each Air Stream)

1316 (2800)

1175 (2500)

1034 (2200)

893 (1900)

752 (1600)

611 (1300)

470 (1000)

329 (700)

188 (400)

47 (100)

AIRFLOW L/s (CFM)

25

50 75 100 125 150 175 200 225 250 275 300 325 350 375

(

0.1

) (0.2) (0.3) (0.4) (0.5) (0.6) (0.7) (0.8) (0.9) (1.0) (1.1) (1.2) (1.3) (1.4) (1.5)

400 425 450 475 500 525 550

(1.6) (1.7) (1.8) (1.9) (2.0) (2.1) (2.2)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

70%

60%

50%

850

(1800)

944

(2000)

1039

(2200)

TEMPERATURE EFFECTIVENESS

AIRFLOW IN L/s (CFM)

NOTE: Exhaust Relative Humidity (RH) at 40%

EFFECTIVENESS

1133

(2400)

1228

(2600)

1322

(2800)

1416

(3000)

HIGH SPEEDHIGH SPEED

MEDIUM SPEEDMEDIUM SPEED

LOW SPEEDLOW SPEED

Performance

Options and Accessories

99-101: CRANK TIMER

Mechanical timer to activate high speed.

99-116: DEHUMIDISTAT VENTILATION CONTROL (DVC)

Turns unit on/off via slider switch and high/low via built-in

dehumidistat.

99-130: DEHUMIDISTAT

Activates high speed when indoor humidity

rises above set point on control.

99-140: 4" TECHGRILLE

99-141: 5" TECHGRILLE

99-142: 6" TECHGRILLE

99-148: 8" TECHGRILLE

Round, white, step-type diffusers.

53-2500: OPTIONAL ROOF CURB

Supports HRV on roof and connects

HRV to ducting below.

WEIGHT: 50lbs

Information about design-built electric make-up heat

coils available upon request.

Roof Curb (optional)

Part No. 53-2500

Duct Collar Supports

Return air

opening

8" 8"

36.5"

Fresh Air

Supply

12"

12"

21.8"

Bottom duct

connections

16" X 24"

Centre

Point

88.5"

TOP VIEW

Supply air

opening

Factory installed

perimeter wooden

nailer strip

8" 8"

25"

12"

12"

14"

Stale Air

Return

0.7"

SIDE VIEW

Loading...

Loading...