Page 1

CLEAN • FRESH • AIR

OPERATION AND

INSTALLATION MANUAL

Contains

ControlAir 15

®

For Models:

200ERV

200ERVD

500ERV

700ERV

1200ERV

TO BE COMPLETED BY CONTRACTOR AFTER INSTALLATION

ControlAir 15

ControlAir 15

ControlAir 15

Analog Controls

Analog Controls

Installing Contractor

Telephone / Contact

CAUTION

Before

given to how the system will operate if connected to

any other piece of mechanical equipment, i.e. a forced

air furnace or air handler, operating at a higher static.

After

equipment must be confirmed, by measuring the

airflow’s of the Energy Recovery Ventilator (ERV), by

using the balancing procedure in this manual

It is always important to assess how the operation of

any Energy Recovery Ventilator may interact with

vented combustion equipment (ie. Gas Furnaces, Oil

Furnaces, Wood Stoves, etc.)

NEVER install an Energy Recovery Ventilator in a situation where its normal operation, lack of operation or

partial failure may result in the backdrafting or improper

functioning of vented combustion equipment!!!

IMPORTANT - PLEASE READ THIS

MANUAL BEFORE INSTALLING UNIT

installation, careful consideration must be

installation, the compatibility of the two pieces of

Serial Number

Installation Date Model

* LEAVE FOR HOMEOWNER

NOTE: Due to ongoing research and product development, specifications,

ratings and dimensions are subject to change without notice.

TI-83C-NE

0007

Page 2

TABLE OF CONTENTS

Warranty ..................................................................................... 2

ERV Questions and Answers ..................................................... 3

Select the Correct Size ERV .......................................................5

Specifications

Model 200ERV ........................................................................... 6

200ERVD ........................................................................ 7

500ERV ........................................................................... 8

700ERV ........................................................................... 9

1200ERV ........................................................................ 10

Description of your ERV

Part 1: Function and Control

Operation of the ControlAir 15 ................................................. 12

Glossary

Optional Remote Controls ......................................................14

m

.........................

Part 2: Installation

Installation

m • Location

• Mounting the ERV

• Electrical

Installing Air Ducts

• Outside Weatherhoods

• Locating the Weatherhoods

Installing Ducting from Weatherhoods to the ERV

•

• Ducting

• Connections to Furnace Ductwork ................................... 18

• Damper and Grilles ......................................................... 18

Air Flow Balancing and Procedure

Installation Diagrams

General Installation

..............................................................................16

...........................................................11

......................

................................................................ 17

..................................................... 20 - 21

........................................................ 22 - 26

.................................. 12

...................................... 19

INTRODUCTION

The LIFEBREATH Enthalpic Core Energy

Recovery Ventilator (ERV) is designed for

warm, humid regions and it uses the vapour

transmission technology to transfer sensible

and latent heat to the cooler, drier air

stream. During the cooling season, humidity

drawn in from the outside is transferred

through the core to the exhaust air stream,

helping lower the load on the air conditioner.

It is recommended for regions where the

temperature does not drop below 25˚F (-4˚C).

WARRANTY

All LIFEBREATH Energy Recovery Ventilators

carry a five year warranty on the Energy Recovery

Core, Model 200ERV has a 5 year warranty on

replacement parts and Model 500, 700, and 1200

ERV has a 2 year warranty on replacement parts.

Maintenance

Troubleshooting Your ERV ...................................................... 27

Maintenance Routine ....................................

Wiring Diagram ..................

TFP Information ....................................................................... 32

..............................................

................

.......... 28

29 - 31

2

Page 3

ERV Questions & Answers

What is the difference between an HRV

and an ERV?

The core in an HRV (Heat Recovery Ventilator) transfers heat from one air stream to the other. This is called

sensible heat

Ventilator) is usually used to describe a unit with an

enthalpic core that transfers moisture as well as heat

from one air stream to the other. This (moisture transfer) is called

. The term ERV (Energy Recovery

latent heat

.

Enthalpic - what does it mean?

Enthalpy is the term used to describe the energy content of air. This energy is a combination of the sensible

and latent heat. Therefore, a core which transfers energy is called an enthalpic core.

Is an ERV better than an HRV?

NOT NECESSARILY!! In cold climates such as most of

North America, an HRV works better than an ERV. This

is because the air inside the home during the winter

months will be more humid than the outside air. An ERV

would transfer the latent heat (humidity) from the

exhaust air back into the incoming airstream. This will

aggravate moisture problems in the home and encourage the growth of mold and mildew. If the air in the

home is too dry for comfort, an ERV will not help. A

humidifier should be used to increase the humidity to a

comfortable level.

Where do you use an ERV instead

of an HRV?

An ERV is recommended for warm, humid areas with

heavy air conditioning use. As there is no defrost in an

ERV it is not recommended for areas where the temper-

ature drops below -4

˚C (25˚F)

Why transfer moisture in the summer

(cooling season)?

The enthalpic core will allow moisture to be transferred

from a humid air flow to a dry air flow. This property is

useful in the cooling season if an air conditioning system is used to lower the indoor humidity. You will then

have dry, cool air in the exhaust of the ERV, and warm

humid air in the supply stream. With these conditions,

the ERV will be able to transfer the moisture and heat of

the supply air to the exhaust air. In this way, the ERV

will supply to the home air which is cooler and drier than

outside. Remember that an ERV is not a dehumidifier,

and on its own will not take moisture out of the air.

damp situation. In fact, about 2/3 of the energy used by

the air conditioner system is to remove moisture.

Therefore, when ventilating in the summer, less moisture brought into the home means less work for the air

conditioner, and energy savings for you.

During the winter, an ERV recovers some humidity

from the exhaust air, reducing the need for humidification, if the required ventilation rate would make the

home too dry.

What's the difference between this type of

core and a rotary type?

Here's a list of characteristics of the fixed plate core.

1. No rotating parts, so maintenance is easy and the

unit lasts a long time.

2. It is very flexible in terms of installation.

3. The core can easily be changed.

4. Because the supply and exhaust air streams are

completely separate, there is very little cross leakage

of any dust or germs.

Can the core become clogged with dust?

Because the surface of the core is a turbulent flow

area, dust sticks to it easily; however, because the

inside of the element is a laminar flow area, virtually no

dust sticks to it.

What is the maintenance?

About once a year you should use a vacuum cleaner to

remove the dust from the core's surface. DO NOT

WASH WITH WATER!!

Is an air filter needed?

To prevent clogging of the core, an air filter should

always be installed on the supply and exhaust sides of

the core.

How much ventilation do I need?

During seasons when your windows and doors are

closed, the ERV should operate continuously when the

dwelling is occupied, and either continuously or intermittently when not occupied.

For most installations the ERV will normally be set to

operate continuously on low speed with the option of

going to high speed as the need arises. For example; if

you are entertaining and there is a large number of

people present (some may be smoking), the unit

should be switched to high speed.

So why use an ERV?

A properly operating air conditioner will not only lower

the temperature in your house, but will also lower the

humidity level. This prevents an uncomfortable cold and

Your ERV may be equipped with automatic or manual

switches, but all ERVs will have a manual speed control

override.

3

Page 4

CLEAN • FRESH • AIR

Select the correct Lifebreath to match your climate

®

Severe Conditions Moderate Conditions

HRV recommended HRV recommended

Double core high efficiency HRV

recommended for extreme conditions

Pacific Coastal Arid Zone-Dry Climate

HRV recommended HRV recommended

ERV optional* Double core high efficiency HRV optional

Extreme Area**-High Humidity

ERV recommended*

*ERV not recommended where temperatures fall below 25˚F (-4˚C) for more than 5 days.

**ERV 's are recommended in regions where high outdoor humidity is cause for operating air

conditioning/dehumidification more frequently than heating system.

The following table is used to outline total dollar ventilation costs for Heat Recovery Ventilators

(HRV's) and Energy Recovery Ventilators (ERV's) for various geographic regions in the United States and Canada.

Costs are for balanced systems using values based on electricity at $0.086 per kWh and fossil fuel at $0.72 per therm

(100, 000 BTU). It was assumed that electric heat was 100% efficient and fossil fuel heat was 80% efficient. Cooling

equipment had a SEER of 12.

Ventilation energy costs would include both fan energy use and the energy required to condition the air displaced by

the ventilation system.

Straight ventilation costs are also included to show the benefit of recovery.

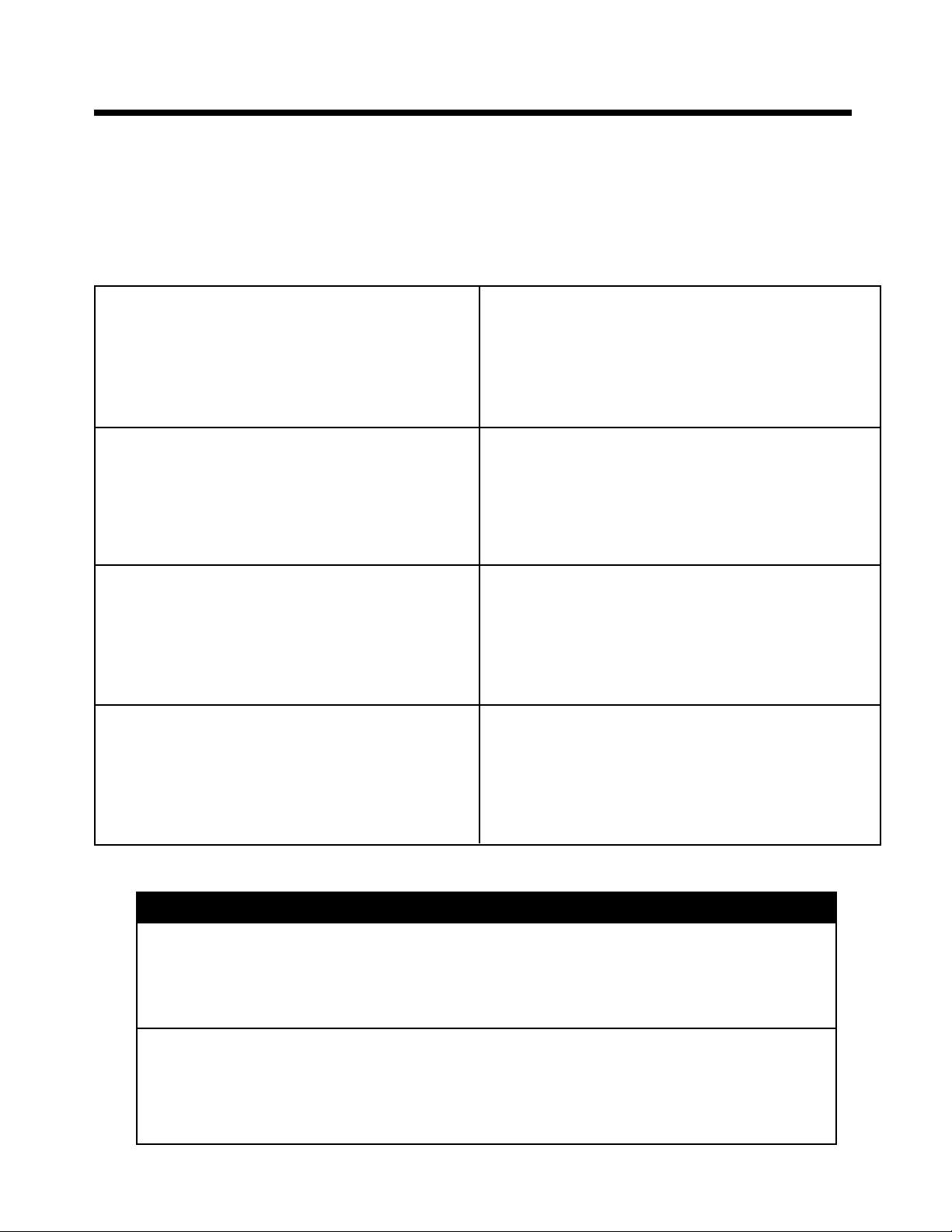

ANNUAL SAVINGS WITH BALANCED MECHANICAL VENTILATION WITH ENERGY RECOVERY

MODE LOS ANGELES MIAMI NEW YORK DETROIT MINNEAPOLIS PORTLAND, OR

HRV - ELECTRIC HEAT

ERV - ELECTRIC HEAT

HRV - FOSSIL FUEL HEAT $60.97 $124.95 $80.72 $81.73 $92.08 $66.19

ERV - FOSSIL FUEL HEAT $59.56 $104.42 $76.84 $79.37 $88.38 $65.76

VENTILATION ONLY-FOSSIL

VENTILATION ONLY-ELECTRIC

SAVINGS WITH ERV-ELECTRIC $69.86 $133.61 $179.89 $228.79 $285.22 $76.20

SAVINGS WITH HRV-ELECTRIC $65.05 $85.68 $192.65 $257.23 $322.46 $110.80

SAVINGS WITH ERV-FOSSIL $65.93 $150.51 $133.20 $156.36 $191.05 $103.28

SAVINGS WITH HRV-FOSSIL $64.52 $129.98 $129.32 $154.00 $187.35 $102.85

HRV - ELECTRIC HEAT $145.30 $155.04 $189.52

ERV - ELECTRIC HEAT $179.78 $196.74 $253.93

HRV - FOSSIL FUEL HEAT $82.72 $84.87 $93.49

ERV - FOSSIL FUEL HEAT $80.80 $83.27 $92.49

VENTILATION ONLY-FOSSIL

VENTILATION ONLY-ELECTRIC

SAVINGS WITH ERV-ELECTRIC $249.37 $276.87 $368.91

SAVINGS WITH HRV-ELECTRIC $283.85 $318.57 $433.32

SAVINGS WITH ERV-FOSSIL $166.60 $180.99 $230.41

SAVINGS WITH HRV-FOSSIL $164.68 $179.39 $229.41

$71.57 $171.66 $125.19 $138.83 $166.62 $142.18

$66.76 $123.73 $137.95 $167.27 $203.86 $176.78

$125.49 $254.93 $210.04 $253.73 $279.43 $169.04

$136.62 $257.34 $317.84 $396.06 $489.08 $252.98

TORONTO MONTREAL WINNIPEG

$247.40 $264.26 $322.90

$429.15 $473.61 $622.84

511 McCormick Blvd.

London, Ontario

Canada N5W 4C8

Phone: (519) 457-1904

Fax: (519) 457-1676

4

Page 5

Selecting the Correct Size ERV

Commercial and Institutional Requirements

For outdoor air requirements, ASHRAE has produced the Ventilation Standard 62-1989 that

is used to determine acceptable ventilation rates. This standard is referenced directly or

used as “Good Engineering Practice” in most Code documents or design criteria.

Small restaurants, Donut Shops and Fast food stores

Seats 40

Employees 5

Total 45

ASHRAE requirement 20 cfm (10L/s) per person

Ventilation required 45 x 20 = 900 cfm (450 L/s)

Bar or Tavern

Seats 50

Employees 7

Total 57

ASHRAE requirement 30 cfm (15L/s) per person

Ventilation required 57 x 30 = 1710 cfm (855 L/s)

Classroom and School Portables

Seats 29

Teacher 1

Total 30

ASHRAE requirement 15 cfm (7.5L/s) per person

Ventilation required 30 x 15 = 450 cfm (255 L/s)

Beauty Salon

Customers 12

Employees 6

Total 18

ASHRAE requirement 25 cfm (12.5L/s) per person

Ventilation required 18 x 25 = 450 cfm (255 L/s)

Bank

Customers 25

Staff 9

Total 34

ASHRAE requirement 20 cfm (10L/s) per person

Ventilation required 34 x 20 = 680 cfm (320 L/s)

Bingo Hall

Customers 180

Staff 20

Total 200

ASHRAE requirement 30 cfm (15L/s) per person

Ventilation required 200 x 30 = 6000 cfm (3000 L/s)

Print Shop, Duplicating

Square footage of shop 2000 square ft (m

ASHRAE requirement 0.5 cfm/ft2 (2.5L/s - m

per person

Ventilation required 2000 x 0.5 = 1000 cfm (500 L/s)

Swimming Pools

1 cfm per sq. ft. of the water surface area

or

0.5 cfm per sq. ft. of the water surface plus deck area

Hot Tubs

7 - 10 cfm per sq. ft. of the water surface area

2

)

2

)

MAKE UP HEAT REQUIREMENT at 1200 CFM (566L/s)

Nominal Nominal Nominal

Outdoor Temp. kW Req. for kW Req. for kW Req. for

C° F° 20°C (68°F) 25°C (77°F) 30°C (86°F)

Air Delivery Air Delivery Air Delivery

0 32 7 10 14

-10 14 10 14 17

-20 -4 12 15 19

-30 -22 15 19 22

-40 -40 17 21 24

5

Page 6

®

CLEAN • FRESH • AIR

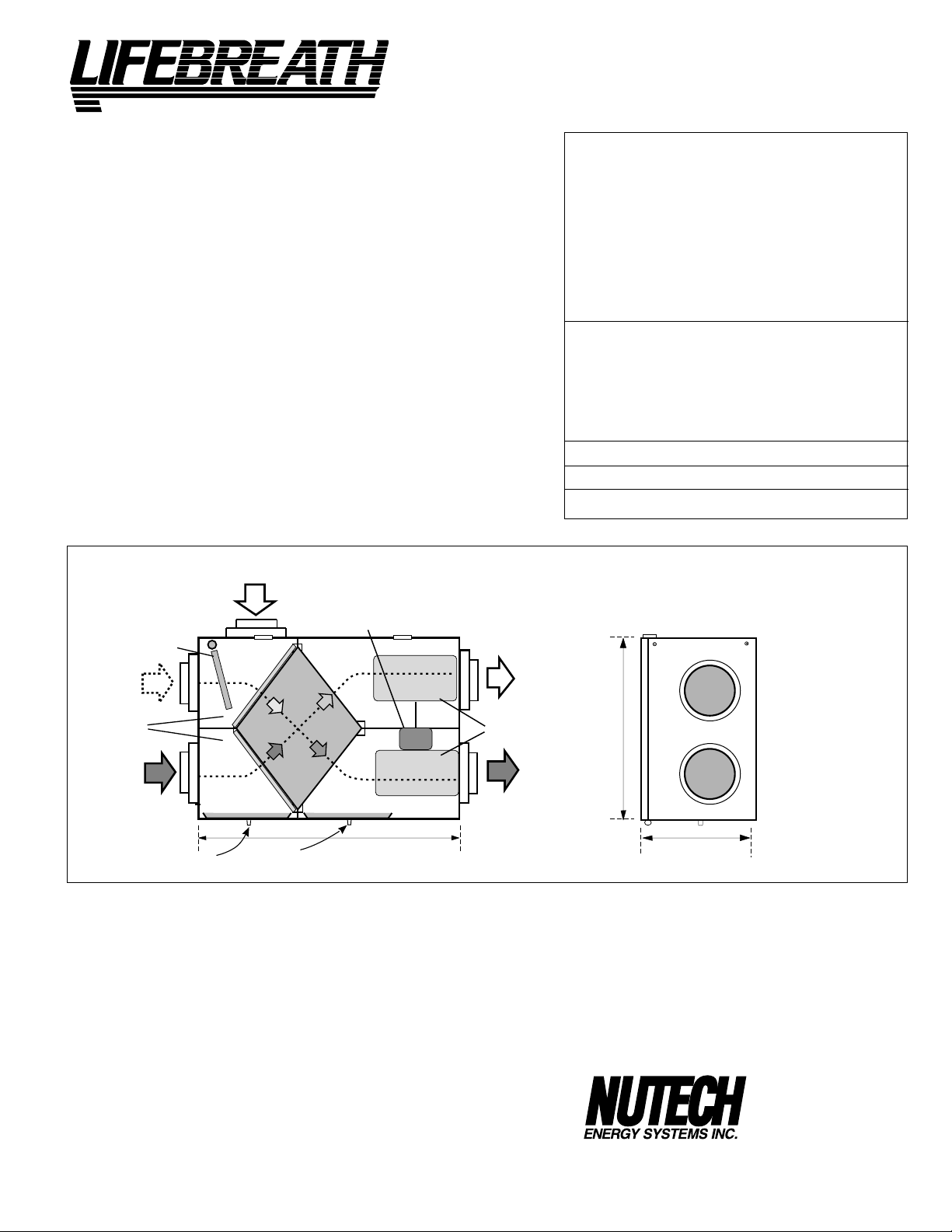

ENGINEERING DATA

LATENT RECOVERY/MOISTURE TRANSFER CORE

The cross-flow energy recovery core transfers heat and water vapour

between the two airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

driven by a common PCS motor. 5 speed fan operation.

High speed - 120 VAC, 1.4 Amps, 164 Watts.

FILTERS

- Washable air filters in exhaust and supply air streams.

MOUNTING THE ERV

corners of case designed to accept four PVC reinforced polyester straps

that are supplied with the unit.

CASE

- Twenty gauge prepainted galvanized steel (G60) for superior

corrosion resistance. Insulated to prevent exterior condensation.

CONTROLS

WEIGHT

- ControlAir 15

63 lbs. (28.7 kg)

-

Each air streams has one centrifugal blower

- Four 10/24" (10.5 mm) threaded inserts at

SHIPPING WEIGHT

65 lbs. (29.6 kg )

Model 200 ERV

PERFORMANCE

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 195 (92)

@ 0.2” (50 Pa) 185 (87)

@ 0.3” (75 Pa) 175 (83)

@ 0.4” (100 Pa) 160 (76)

@ 0.5” (125 Pa) 145 (68)

Sensible Effectiveness

@ 110 L/s (55 cfm)

Sensible Efficiency

@ 110L/s (55 cfm) @0

Sensible Efficiency

@ 110 L/s (55 cfm) @ -25

VAC @ 60HZ 120

WATTS / Low speed 80

Amp rating 1.4

HVI CERTIFIED

(CSA C439M)

O

C (32°F) 70%

O

C (-13°F)

80%

55%

DIMENSIONS 200 ERV

*

All Duct Connections 6"(150mm)

STALE AIR

FROM INSIDE

FILTERS

FRESH AIR

FROM OUTSIDE

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min. (3 wire)

99-105 Deluxe Programmable Control includes

Programmable Time Clock, Dehumidistat

and Air Sentry™

99-109 Air Sentry™ Air Quality Monitor

99-186 Weatherhoods, Two - 6” (150mm)

c/w 1/4” (6mm) mesh screen

MOTOR

31"

(787)

inches (mm)

FRESH AIR

TO INSIDE

BLOWERS

STALE AIR

TO OUTSIDE

19"

(483)

14 3/4"

(375)

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

WARRANTY

Units carry a 5 year warranty on the energy recovery core and

replacement parts.

All units are CSA and UL standards.

It is not recommended for regions where the temperature

does not drop below 25°F (-4°C)

DATE: __________________________

PROJECT: ___________________________________

MECHANICAL CONTRACTOR: __________________________

6

511 McCormick Blvd.

London, ON N5W 4C8

Phone: (519) 457-1904

Fax: (519) 457-1676

Email: nutech@lifebreath.com

TI-98E

0006

Page 7

®

CLEAN • FRESH • AIR

ENGINEERING DATA

LATENT RECOVERY/MOISTURE TRANSFER CORE

The cross-flow energy recovery core transfers heat and water vapour

between the two airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

driven by a common PCS motor. 5 speed fan operation.

High speed - 120 VAC, 1.4 Amps, 164 Watts.

FILTERS

- Washable air filters in exhaust and supply air streams.

MOUNTING THE ERV

corners of case designed to accept four PVC reinforced polyester straps

that are supplied with the unit.

DEFROST

CASE

- Damper defrost system.

- Twenty gauge prepainted galvanized steel (G60) for superior

corrosion resistance. Insulated to prevent exterior condensation.

DRAIN CONNECTIONS

CONTROLS

WEIGHT

- ControlAir 15

63 lbs. (28.7 kg)

-

Each air streams has one centrifugal blower

- Four 10/24" (10.5 mm) threaded inserts at

- Two - 1/2” (12mm) O.D.

SHIPPING WEIGHT

65 lbs. (29.6 kg )

Model 200 ERVD

PERFORMANCE

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 195 (92)

@ 0.2” (50 Pa) 185 (87)

@ 0.3” (75 Pa) 175 (83)

@ 0.4” (100 Pa) 160 (76)

@ 0.5” (125 Pa) 145 (68)

Sensible Effectiveness

@ 110 L/s (55 cfm)

Sensible Efficiency

@ 110L/s (55 cfm) @0

Sensible Efficiency

@ 110 L/s (55 cfm) @ -25

VAC @ 60HZ 120

WATTS / Low speed 80

Amp rating 1.4

HVI CERTIFIED

(CSA C439M)

O

C (32°F) 70%

O

C (-13°F)

80%

55%

FRESH AIR

FROM OUTSIDE

DAMPER

DEFROST

PORT

FILTERS

STALE AIR

FROM HOUSE

CONDENSATE DRAINS

DIMENSIONS 200 ERVD

*

All Duct Connections 6"(150mm)

MOTOR

31"

(787)

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min. (3 wire)

99-105 Deluxe Programmable Control includes

Programmable Time Clock, Dehumidistat

and Air Sentry™

99-109 Air Sentry™ Air Quality Monitor

99-186 Weatherhoods, Two - 6” (150mm)

c/w 1/4” (6mm) mesh screen

inches (mm)

STALE AIR

TO OUTSIDE

BLOWERS

FRESH AIR

TO INSIDE

19"

(483)

14 3/4"

(375)

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

WARRANTY

Units carry a 5 year warranty on the energy recovery core and

replacement parts.

All units are CSA and UL standards.

It is not recommended for regions where the temperature

does not drop below 25°F (-4°C)

DATE: __________________________

PROJECT: ___________________________________

MECHANICAL CONTRACTOR: __________________________

7

511 McCormick Blvd.

London, ON N5W 4C8

Phone: (519) 457-1904

Fax: (519) 457-1676

Email: nutech@lifebreath.com

TI-200ERVD

0006

Page 8

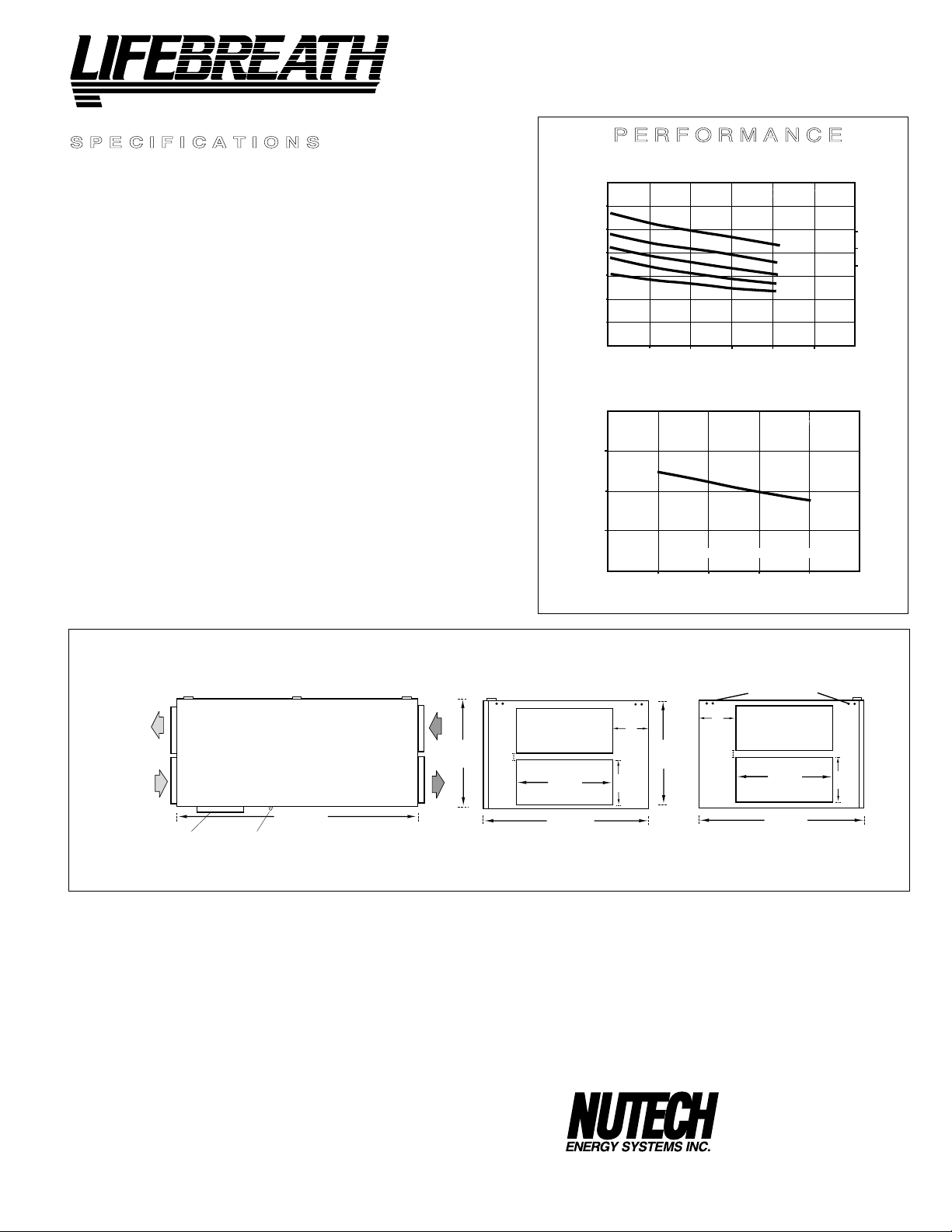

SPECIFICATIONS

CLEAN • FRESH • AIR

PERFORMANCE

®

Model 500ERV

LATENT RECOVERY (MOISTURE) TRANSFER CORES

Modular (4 section) 2- Enthalpic, 2 Aluminum arranged for high

efficiency crossflow ventilation.

MOTORS

total on high speed). HP - 1/10, 1625 RPM. Watts - total on High Speed - 610.

FILTERS

BLOWERS

Each air stream has two centrifugal blowers driven by two PSC motors.

CONNECTION DUCT SIZES

MOUNTING

type apparatus (brackets and rods not included).

DEFROST

CASE

resistance. Insulated with foil faced insulation duct liner where required to

prevent exterior condensation. Drain connection, One - 1/2" (12 mm) O.D.

CONTROLS

WEIGHT

-

Two PSC, 5 speed double shafted, 120 VAC, 3.15 Amps each (6.3

- Washable air filters in exhaust and supply air streams.

- Centrifugal type rated at 530 cfm (250 L/s) free air delivery.

Four - 14" x 8" (356 mm x 200 mm).

- Unit to be set on support brackets hung by threaded rod

- Damper defrost system.

- 20 gauge prepainted galvanized steel (G60) for superior corrosion

- ControlAir 15

178 lbs. (81 kg)

SHIPPING WEIGHT

203 lbs. (92 kg)

AIRFLOWS (Each Air Stream)

282 (600)

235 (500)

190 (400)

143 (300)

94 (200)

AIRFLOW L/s (CFM)

42 (100)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

TEMPERATURE EFFECTIVENESS

100%

90%

EFFECTIVENESS

80%

94

(200)

143

(300)

AIRFLOW IN L/s (CFM)

LIFEBREATH 500

SPEED

5

4

3

2

1

LIFEBREATH 500

NOTE: Exhaust Relative Humidity (RH) at 40%

190

(400)

235

(500)

6.3 HIGH

3.8 MED

3.1 LOW

282

(600)

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

DIMENSIONS 500 ERV

EXHAUST AIR

TO OUTSIDE

NOTE:

Service clearance

is 30 in. (760 mm)

SUPPLY AIR

FROM OUTSIDE

DEFROST

DRAIN CONNECTION

49"

(1245 mm)

FRONT VIEW

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min. (3 wire)

99-105 Programmable Ventilation Control includes

Programmable Time Clock, Dehumidistat and

Air Sentry™

99-109 Air Sentry™ Air Quality Monitor

________________

DATE:

PROJECT:

________________________________________

MECHANICAL CONTRACTOR:

UNIT SELECTED:

__________________________

EXHAUST AIR

FROM BUILDING

SUPPLY AIR

TO BUILDING

_____________

18 3/4"

(475 mm)

8

inches (mm)

MOUNTING POINTS

5 7/8"

(150 mm)

1 3/8"

(35 mm)

EXTERIOR DUCT

14"

(356 mm)

28 1/4"

(717 mm)

CONNECTION SIDE

8"

(200 mm)

1 1/4"

(32 mm

)

14"

(356 mm)

28 1/4 "

(717 mm)

INTERIOR DUCT

CONNECTION SIDE

5 7/8"

(150 mm)

8"

(200 mm)

18 3/4"

(475 mm)

All units conform to CSA and UL standards.

WARRANTY

Units carry a 5 year warranty on the energy recovery cores and

15 years on aluminum cores. Two (2) year replacement parts

warranty.

It is recommended for regions where the temperature does

not drop below 25°F (-4°C).

511 McCormick Boulevard.

London, ON N5W 4C8

Phone: (519) 457-1904

Fax: (519) 457-1676

E mail:nutech@lifebreath.com

TI-130

0006

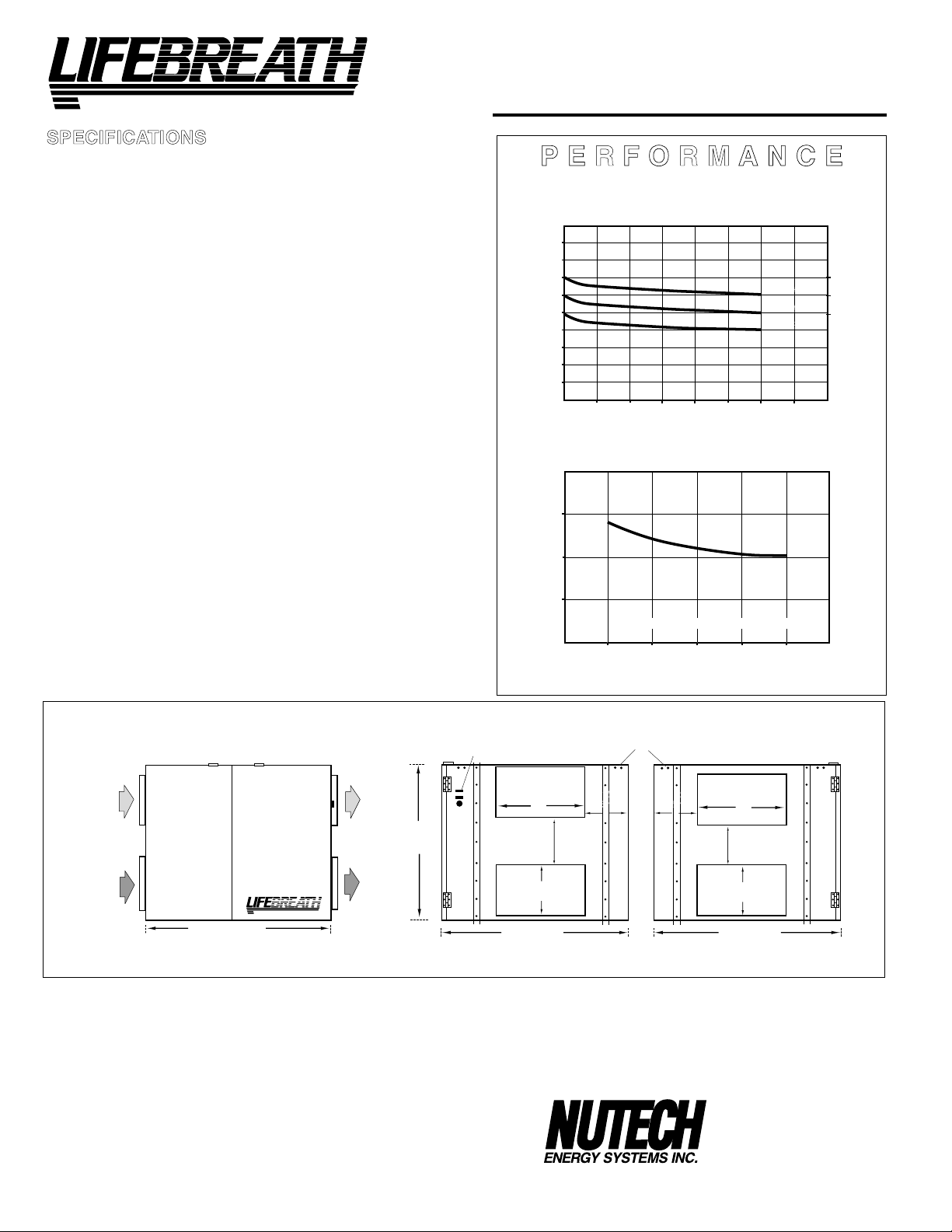

Page 9

®

SPECIFICATIONS

PERFORMANCE

CLEAN • FRESH • AIR

LATENT RECOVERY (MOISTURE) TRANSFER CORES

Modular (2 section) enthalpic (moisture) transfer cores arranged for

efficient cross-flow ventilation.

MOTORS

Two PSC, 3 speed single shafted, 120 VAC, 2.75 Amps each (5.5 total

on high speed). HP - 1/10, 1625 RPM. Watts - total on high speed - 648.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 700 CFM (329 L/s) free air delivery. Each air

stream has one single shafted motor driving a centrifugal blower.

CONNECTION DUCT SIZES

Four - 14" x 8" (356 mm x 200 mm)

MOUNTING

Unit to be set on support brackets hung by threaded rod type

apparatus (brackets and rods not provided).

CASE

20 gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated with foil faced insulation where required to prevent exterior condensation.

CONTROLS

Illuminated power switch, 3 speed blower control, low voltage (24

VAC) terminals for connection of remote controls.

WEIGHT

142 lbs (64.4 kg)

SHIPPING WEIGHT

167 lbs. (75.8 kg)

Model 700ERV

MODEL 700FD, 700DD

AIRFLOWS (Each Air Stream)

423 (900)

378 (800)

329 (700)

282 (600)

235 (500)

190 (400)

143 (300)

94 (200)

AIRFLOW L/s (CFM)

42 (100)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5) 150 (.6) 175 (.7)

EXTERNAL STATIC PRESSURE IN PASCALS (IN. W.C.)

TEMPERATURE EFFECTIVENESS

70%

60%

50%

EFFECTIVENESS

NOTE: Exhaust Relative Humidity (RH) at 40%

HIGH SPEED

MED SPEED

LOW SPEED

5.5 HIGH

5.0 MED

4.7 LOW

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

DIMENSIONS 700

SUPPLY AIR

FROM OUTSIDE

NOTE:

Service clearance

is 30 in. (760 mm)

EXHAUST AIR

FROM BUILDING

HEAT RECOVERY VENTILATORS (HRVs)

29 5/8" (753 mm)

FRONT VIEW

All units conform to CSA and UL standards.

WARRANTY

Units carry a 5 year warranty on the energy recovery cores and

2 year replacement parts warranty.

DATE:

PROJECT:

MECHANICAL CONTRACTOR:

_________________________________________

______________________________________

__________________________

EXHAUST AIR

TO OUTSIDE

®

SUPPLY AIR

TO BUILDING

625 mm

(24 5/8 ")

190

inches (mm)

CONTROLS

14"

(356 mm)

8"

(200 mm)

28 3/4"

(730 mm)

DISCHARGE SIDE

8 1/4"

(210 mm)

(165 mm)

143

(400)

(300)

AIRFLOW IN L/s (CFM)

MOUNTING POINTS

6 1/2"

6 1/2"

(165 mm)

235

(500)

282

(600)

14"

(356 mm)

6 1/4"

(159 mm)

8"

(200 mm)

28 3/4"

(730 mm)

INLET SIDE

It is recommended for regions where the temperature

does not fall below 25°F (-4°C).

511 McCormick Blvd.

London, ON N5W 4C8

Phone: (519) 457-1904

Fax: (519) 457-1676

E mail: nutech@lifebreath .com

9

329

(700˚)

TI-131

9807

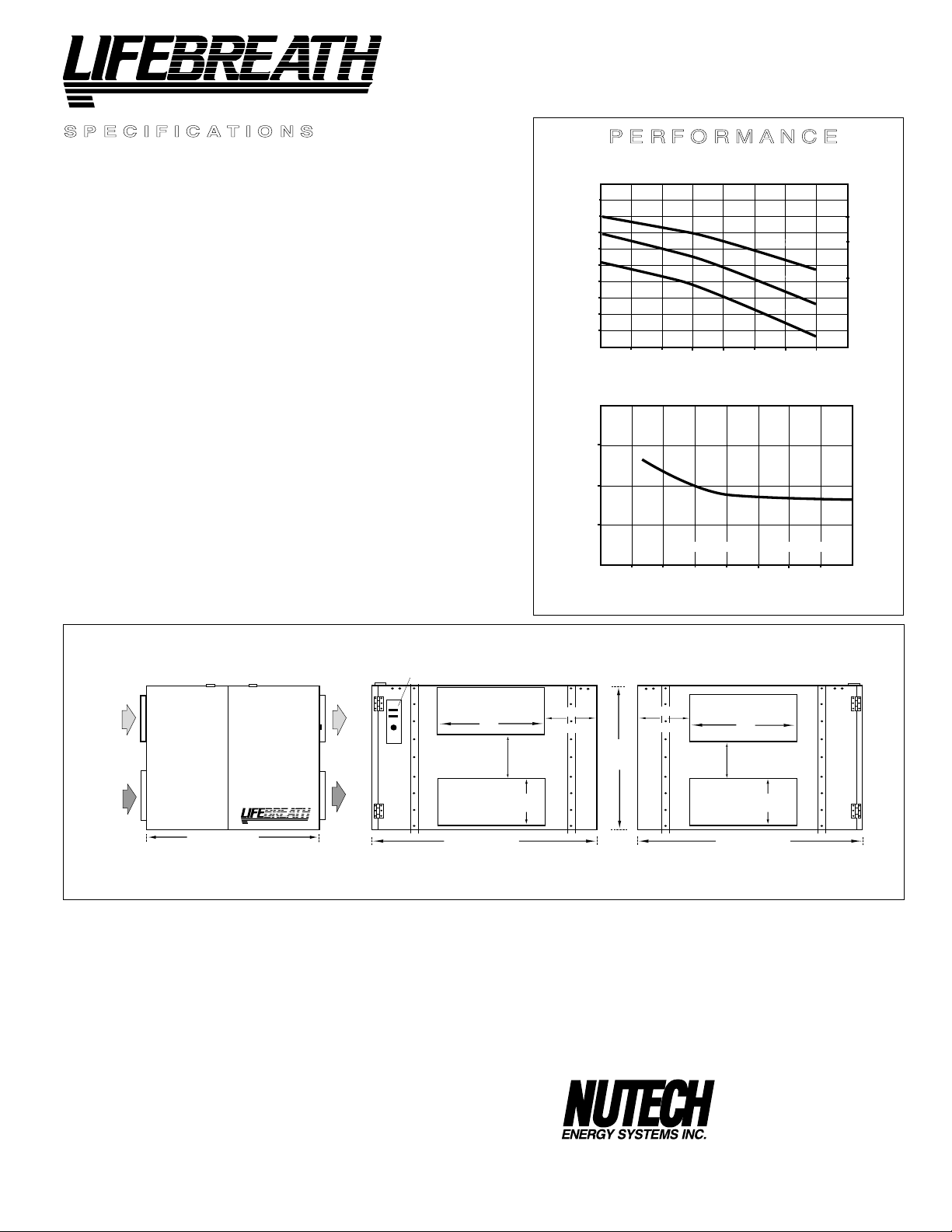

Page 10

CLEAN • FRESH • AIR

SPECIFICATIONS

PERFORMANCE

®

Model 1200ERV

LATENT RECOVERY (MOISTURE) TRANSFER CORES

Modular (3 section) latent recovery (moisture) transfer cores arranged for

efficient cross-flow ventilation.

MOTORS

Two PSC, 3 speed double shafted, 120 VAC, 4 Amps each (8.1 total on high

speed). HP - 1/4, 1625 RPM. Watts - total on high speed - 972.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 1200 cfm (566 L/s) free air delivery. Each air

stream has one double shafted motor driving a centrifugal blower.

CONNECTION DUCT SIZES

Four - 20" x 8" (508 mm x 200 mm).

MOUNTING

Unit to be set on support brackets hung by threaded rod type apparatus.

(brackets and rod not provided).

CASE

20 gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated with foil faced insulation where required to prevent

exterior condensation.

CONTROLS

Illuminated power switch, 3 speed blower control, low voltage (24 VAC)

terminals for connection of remote controls.

WEIGHT

191 lbs. (87 kg)

SHIPPING WEIGHT

215 lbs. (98 kg)

613 (1300)

566 (1200)

518 (1100)

472 (1000)

423 (900)

378 (800)

329 (700)

AIRFLOW L/s (CFM)

282 (600)

235 (500)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5) 150 (.6) 175 (.7)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

TEMPERATURE EFFECTIVENESS

70%

60%

EFFECTIVENESS

50%

500

500

(235)

(235)

AIRFLOWS (Each Air Stream)

8.1 HIGH

1100

1100

(518)

(518)

7.8 MED

7.1 LOW

1200

1200

(566)

(566)

HIGH SPEED

MED SPEED

LOW SPEED

NOTE: Exhaust Relative Humidity (RH) at 40%

700

800

900

700

(329)

(329˚)

800

(378)

(378)

600

600

(282)

(282)

AIRFLOW IN L/s (CFM)

900

(423)

(423)

1000

1000

(472)

(472)

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

DIMENSIONS 1200

SUPPLY AIR

FROM OUTSIDE

NOTE:

Service clearance

is 30 in. (760 mm)

from front

access doors.

EXHAUST AIR

FROM BUILDING

29 7/8" (759 mm)

FRONT VIEW

EXHAUST AIR

HEAT RECOVERY VENTILATORS (HRVs)

TO OUTSIDE

¤

SUPPLY AIR

TO BUILDING

OPTIONS

99-101 Sixty Minute Remote Timer

99-130 Remote Wall Mount Dehumidistat Control

24 VAC only, W (white) or B (beige)

________________

DATE:

PROJECT:

________________________________________

MECHANICAL CONTRACTOR:

UNIT SELECTED:

__________________________

CONTROLS

inches (mm)

20"

(508 mm)

6 3/4"

(172 mm)

8"

(200 mm)

41 1/2"

(1055 mm)

DISCHARGE SIDE

All units conform to CSA and UL standards.

WARRANTY

Units carry a 5 year warranty on the energy recovery cores and 2

year replacement parts warranty.

It is recommended for regions where the temperature does

not fall below 25°F (-4°C).

_____________

10 3/8"

(263 mm)

24 5/8 "

(625 mm)

10 3/8"

(263 mm)

20"

(508 mm)

5 7/8"

(159 mm)

8"

(200 mm)

41 1/2"

(1055 mm)

INLET SIDE

511 McCormick Boulevard

London, Ontario

Phone: (519) 457-1904

Fax: (519) 457-1676

E mail:nutech@lifebreath.com

10

TI-132

9807

Page 11

STALE AIR

FROM INSIDE

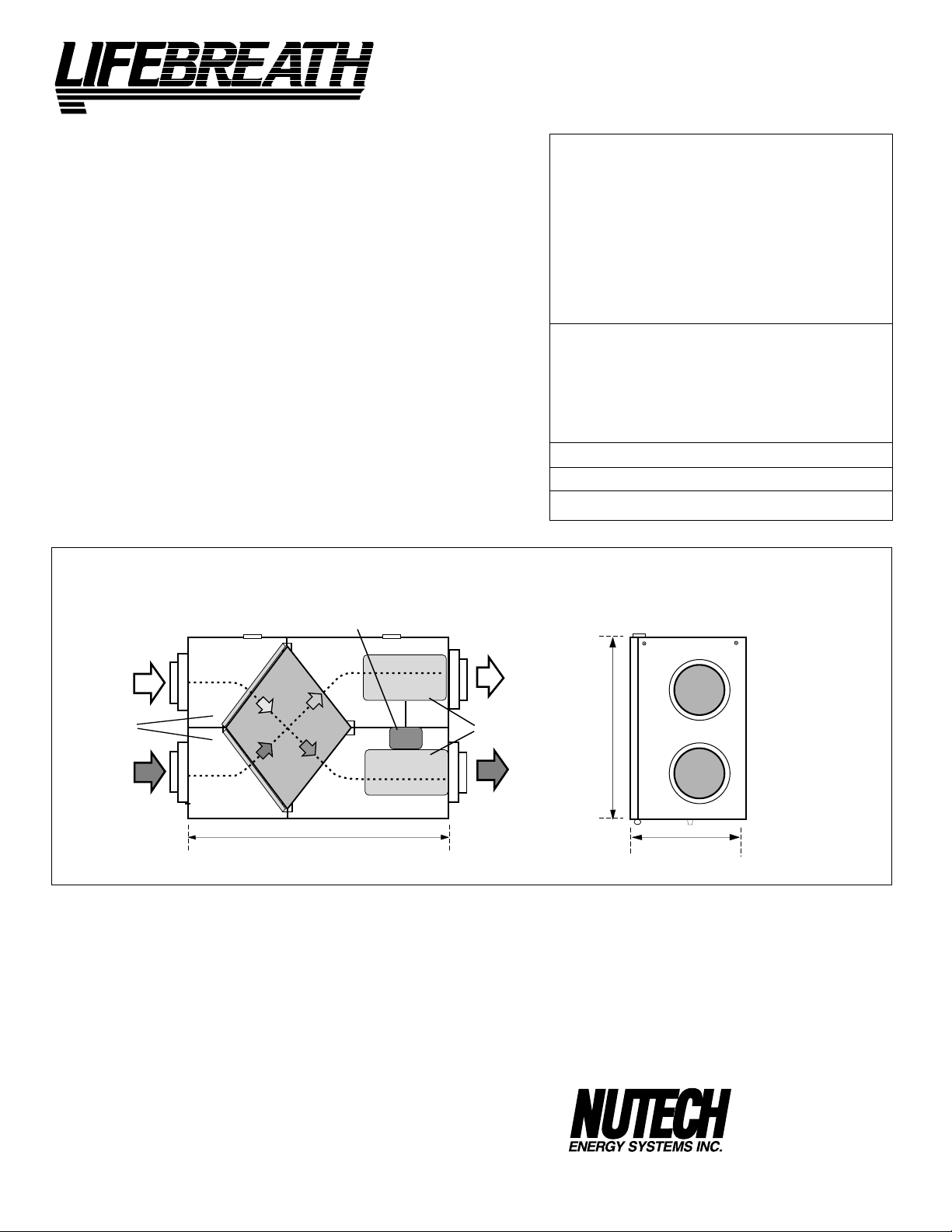

DIMENSIONS 200 ERV

*

All Duct Connections 6"(150mm)

MOTOR

FRESH AIR

TO INSIDE

inches (mm)

FILTERS

FRESH AIR

FROM OUTSIDE

31"

(787)

Figure 2

DESCRIPTION OF YOUR ERV

A) Air Circulation Fans and Motor

Inside the casing are two fans, one for exhaust air and one for

fresh air supply. Turning the fans is an efficient PSC motor.

B) Latent Recovery / Moisture Transfer Core

Cross-flow energy recovery core transfers heat and water

vapor between the two air streams, and is easily removed for

cleaning or service.

C) Air Filters

There are two permanent washable air filters. The filters lower

the amount of dust and outside particulates entering the Core

and your fresh air supply.

BLOWERS

STALE AIR

TO OUTSIDE

19"

(483)

14 3/4"

(375)

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

The Duct Ports

There are four duct ports on the ERV.

1) Fresh air intake port. It is connected to the exterior air intake hood using

insulated duct with a vapour barrier.

2) The fresh air supply port is connected to the fresh air diffuser, which

is typically located in the major living areas or connected to the return

of the HVAC forced air system.

3) Stale air return port is connected to exhaust grilles or the return of the

HVAC forced air system.

4) The exterior exhaust port is connected to the exterior exhaust hood

using insulated duct with vapour barrier.

Note:

The ERV is recommended for areas where the temperature

does not drop below 25˚F (-4˚C). The ERV does not require a

condensate drain, as the water vapour is either transmitted

through the exchanger core or is discharged outdoors.

11

Page 12

PART 1

FUNCTION & CONTROL

Models 200 & 500 Only

Operating the ControlAir 15

Plugging in the ERV energizes the unit. A self test function

will be performed every time the ERV is energized (refer to

“Self Test” for more details). After the self test has completed successfully the ERV will default to Speed 1. This is the

factory default setting. Follow the instructions found on the

ERV door to select desired mode and speed, or refer to the

instructions found on the following page.

Control Module

Control Pad

ControlAir 15

Exploded view

Self Test

Each time the ERV is powered/energized the self test function

will automatically initiate. During the self test the ERV will

cycle through all the speeds available (1-5), test the damper

motor operation and will default back to the previous

mode/speed selection, (factory default is Speed 1). Total self

test duration is approximately 1min 30 sec.

Automatic Defrost Operation

*Not on all Erv’s

The advanced technology of the digital microprocessor

automatically activates the defrost system only as it is

needed. To be an efficient heat recovery device, the ERV

must effectively provide for core defrost as well as providing

efficient heat exchange. As outdoor conditions cool, the

temperature sensor (thermistor) tracks the supply air temperature. The thermistor then sends its signal to the microprocessor (circuit board) which initiates only the defrost

cycle time required to clear the core. On recirculating

defrost models, the core is defrosted when the supply air

port is automatically blocked off and exhaust air is redirected back through the ERV. On damper defrost models, the

core is defrosted when the supply air port is automatically

blocked off and the warm air surrounding the ERV is drawn

in through the defrost port. The mode indicator will flash

RED during the defrost cycle. This dramatic advance makes

more energy available for recovery as the unit spends less

time in defrost mode. By optimizing the defrost cycle, the

ERV combines money saving performance with a well

designed and reliable control system.

Glossary

Removing and relocating the

Control Pad

The Control Pad can be removed and installed in a remote location (100’

wire length max). The Control Pad can be installed in a 2x4 box with a

“Decora” type cover plate or can be installed in the optional “Ventilation

Dehumidistat” When the Control Pad is installed in a remote location all

optional controls will still be wired to the Control Module on the ERV.

When remotely mounted on its own, the Control Pad is wired to the

Control Module by 3 wire (min. 20 gauge). When remotely mounted in the

Ventilation Dehumidistat, 4 wires are required (min. 20 gauge). Connect

the colour coded terminals from the Control Pad/Ventilation Dehumidistat

to the corresponding terminals on the Control Module.

12

DEFROST MODE (

during cold weather, the ERV will automatically cycle through its

defrost mode as needed.

ENERGY RECOVERY VENTILATOR (ERV) - a ventilation system

that recovers energy from exhaust air, also known as an air-to-air

exchanger.

RESET - whenever resetting of the ERV is required, simply disconnect the power for 30 seconds.

STANDBY MODE - the ERV is energized and waiting for fan operation to be initiated by a remote device or manual override.

THERMISTOR

electrical resistance in a known manner, as outdoor temperatures

fluctuate.

*Not on all Erv’s)

- the ERV's temperature sensor which measures

-to ensure reliable operation

Page 13

To select mode of operation for ControlAir 15

Press and hold the fan selection button on the Control Pad. After 5 seconds the control will begin

to cycle each mode holding each for 2 seconds. Release the button when the desired mode of

operation is reached.

Modes of Operation LED Indication

OFF

Standby / On S

20 On / 40 Off

Recirculation

*Note: Not available on all HRVs

No LED’s illuminated

operation.

teady Green LED and Yellow LED to indicate speed

will run at speed selected in ventilation mode. Standby mode is

indicated by no speed indicator illuminated. Optional remote

controls will override standby or selected speed into high speed.

Flashing Green LED and Yellow LED to indicate speed.

ERV will operate in ventilation mode at speed selected for

20 minutes and OFF for 40 minutes.

Steady Red LED and Yellow LED to indicate Speed.

will operate in recirculate mode at the selected speed. Optional

remote controls will override unit into high speed ventilate mode.

ERV is off, no controls will initiate

ERV

ERV

To select speed

Momentarily press fan selection button and release. ERV will move into next speed. OFF is indicated by no yellow LED illuminated. Speed 1 is the first yellow LED. Speed five is indicated by a

flashing speed 4 LED.

Automatic Defrost

During cold outdoor conditions the ERV will occasionally go into an automatic defrost function, which

will prevent ice from forming on the core. Defrost is indicated by a flashing Red LED indicator.

*

Not on all Erv’s

13

Page 14

ControlAir 15

NEW!

ControlAir 15

OPTIONAL REMOTE CONTROLS

Models 200 & 500 Only

PROGRAMMABLE VENTILATION CONTROLLER (PVC)

LOCATION: Hallway, kitchen, office

& work place

• Advanced digital remote.

• Digital dehumidistat.

• Full fan speed control.

AIR SENTRY™

•

Recirculation mode (on compatible HRVs).

•

• 7 day, 24 hour programmable timer.

• Digital display and status lights.

• 100' (30 m) maximum wire length .

PART NO. 99-105

Connects to RED, ORANGE, GREEN and YELLOW terminals.

*NOTE: This device is NOT compatible with the Air Sentry .

VENTILATION DEHUMIDISTAT

LOCATION: Central location in house.

• Dehumidistat activates high speed over-

VENTILATION

DEHUMIDISTAT

ride when humidity level in home

exceeds setting.

• Knockout designed to accept Control

Pad when remotely mounted, giving full

HRV functionality & control from remote

location.

(connect 1/unit only)

Air Quality Sensor built-in.

AIR SENTRY™ AIR QUALITY SENSOR

LOCATION: Kitchen, basement,

(connect 1/unit only).

AIR SENTRY

FAN SPEED INDICATOR

work place

TM

• Digital Air Quality Monitor.

• Status light indicates fan speed.

• Increases ventilation to remove

odours and contaminants.

• Among gases detected are

cigarette smoke and formaldehyde.

IGITAL

IR

UALITY

D

PART NO. 99-109

ENSOR

A

Q

S

• 100' (30 m) maximum wire length.

Connects to RED, GREEN and YELLOW terminals.

**NOTE:

This device is NOT compatible with the PVC.

Control Module

Control Pad

• All controls wire to

matching colour on

the Control Module.

• Control Pad can be

removed and mounted

in a remote location.

PART NO. 99-250

Connects to BLACK RED, GREEN and YELLOW terminals.

*Replaces 99-116 DVC & 99-230 VRD.

*Only compatible with ControlAir 15 electronics.

DIGITAL ELECTRONIC TIMER (DET)

LOCATION: Bathrooms & kitchen

Connect up to 8 on 300

•

If a PVC or Air Sentry is used, connect

•

up to 5 on 300

' wire max.

• Touch pad operation

• 20/40/60 minute status lights

• Compact wall mount unit

• Mounts in 2x4 box

Shown with “decora” cover plate

•

PART NO. 99-104

Connects to RED, GREEN and YELLOW terminals.

' (91 m) wire max

(99-107W)

•

Control Pad mounts

in a 2”x 4” box or can

be mounted in the

optional Ventilation

Dehumidistat.

• Full fan speed control.

•

Three Modes of Operation

- Standby/ON

- 20 ON / 40 OFF

-

Recirculation

(on compatible HRV’s)

*See individual control instructions for more details.

14

0005

Page 15

Speed Selection and Controls

Model 700 and 1200 ERV only

These models are equipped with a 3 speed control, low

medium and high, as well as a lighted on/off switch and a

4 screw terminal strip. The terminal strip can be used to

hook up any low voltage device which will then jump the

unit to high speed from whatever setting the speed control

was on. The terminal strip can also be wired to allow the

from high to low from a remote location. To wire the unit in

this configuration you would need two electrical on/off

switches to be installed at the remote location into a double gang electrical enclosure or side by side. One should

be labeled on/off and the other should be labeled

high/low.

unit to be turned off from a remote location as well as

ON

OFF

ON/OFF ONLY

LOW

HIGH

LOW/HIGH ONLY

SWITCHING FROM REMOTE LOCATION

*Supplied and Installed by Contractor*

ON

OFF

ON/OFF/LOW/HIGH

LOW

HIGH

COMMON

ON/OFF SWITCH

3 SPEED CONTROL

HIGH

ON/OFF

Optional Remote Controls

RED BLACK ORANGE

DEHUMIDISTAT VENTILATION

CONTROL (DVC)

PART NO. 99-116

•Turns ERV ON/OFF

• Dehumidistat increases

ventilation when required

DEHUMIDISTAT

PART NO. 99-130W

•Provides high speed

ventilation when humidity

level exceeds setting

Off

10

20

60

50

30

40

60 MINUTE CRANK TIMER

PART NO. 99-101

•Provides high speed

ventilation for 60 minutes

15

This style of remote switching began

approximately July 1997

Page 16

PAR T 2

INSTALLATION

Model 200 only

Location

The ERV must be located in a conditioned space where it

will be possible to conveniently service the unit. Typically

the ERV would be located in the mechanical room or an

area close to the outside wall where the weatherhoods

will be mounted. If a basement area is not convenient or

does not exist, a utility or laundry room may be used

Attic installations are not normally recommended due to:

A) the complexity of work to install

B) extreme temperatures in the attic

C) difficulty of access for service and cleaning

Sufficient clearance at the front of the access door is

required for servicing the air filters and core. A minimum

of 25" (635 mm) clearance is recommended so the door

can be opened. Four PVC reinforced polyester hanging

straps are provided for hanging the ERV from the basement floor joists.

Mounting

The hanging straps should be attached to the unit at the

top end corners (mounting screws are already located on

the ERV case). Securely fasten the other end of the straps

to the floor joists with wide head nails (not supplied), making sure the unit is level. The straps are designed to

reduce the possibility of noise, resonance or harmonics;

therefore using the full length of the strap between the

ERV and the floor joists is recommended.

WARNING:

In order to prevent electric shock when cleaning or servicing the ERV, it is extremely important to confirm the

polarity of the power line that is switched by the safety

(disconnect) switch. The hot line (black) is the proper line

to be switched. To confirm the proper polarity, use a voltmeter or test lamp to ensure there is no power after the

switch when the door is open. Check between that point

and ground (on the cabinet). This must be done as

dwellings are occasionally wired improperly. Always

make sure that the ERV is properly grounded.

Connecting Appliances to the ERV

It is not recommended that any of the following appliances be connected to the ERV:

Lint, dust or grease will collect in the ERV, damaging the unit.

• clothes dryer

• range top

• stovetop fan

• central vacuum system

Connecting any of these to the ERV will

invalidate your warranty.

Electrical

The ERV should be plugged into a standard designated

(120VAC) electrical outlet with ground. It is not recommended that an extension cord be used for this appliance.

If further wiring is required, then a licensed electrician

should make all electrical connections. It is recommended

that a separate 15 amp/120 volt circuit be used.

16

Page 17

INSTALLING AIR DUCTS

A well designed and installed ducting system will allow the

ERV to operate at its maximum efficiency.

Always try to keep duct runs as short and straight as

possible.

When installing the weatherhood, its outside perimeter

must be sealed with exterior caulking.

• At least 3' (1m) away from the corner of the building

• Not near a gas meter, electric meter or a walkway

where fog or ice could create a hazard

• Not into a garage, workshop or other unheated space

See Figures 6-9 for diagrams of various installations.

Outside Weatherhoods

The fixed covered hoods have a built-in bird screen with a

1/4" (6 mm) mesh to prevent foreign objects from entering

the ductwork.

Locating the Intake

Weatherhood

• Should be located upstream (if there are prevailing

winds) from the exhaust outlet

• At least 6' (2 m) from the exhaust weatherhood

• At least 6' (2 m) away from dryer vents and furnace

exhaust (medium or high efficiency furnaces)

• A minimum of at least 6' (2 m) from driveways, oil fill

pipes, gas meters, or garbage containers

• At least 18" (457 mm) above the ground,

or above the depth of expected snow accumulation

• At least 3' (1 m) from the corner of the building

• Do not locate in a garage, attic or crawl space

Installing the ducting from

the weatherhoods to the ERV

The inner and outer liners of the flexible insulated duct

must be clamped to the sleeve of the weatherhoods (as

close to the outside as possible) and the appropriate port

on the ERV. It is very important that the fresh air intake line

be given special attention to make sure it is well sealed. A

good bead of high quality caulking (preferably acoustical

sealant) will seal the inner flexible duct to both the ERV

port and the weatherhood prior to clamping.

To minimize air flow restriction, the flexible insulated duct

that connects the two outside weatherhoods to the ERV

should be stretched tightly and be as short as possible.

Twisting or folding the duct will severely restrict air flow. See

Figure 6 for the recommended connection of flexible insulated ducts to the the outside weatherhoods and the ERV.

Ducting

Locating the Exhaust

Weatherhood

• At least 6' (2 m) from the ventilation air intake

• At least 18" (457 mm) above ground or above the

depth of expected snow accumulation

WEATHERHOOD INSTALLATION

BELT OF OUTSIDE WALL

INSULATED FLEXIBLE

HOOD

BIRD

SCREEN

Figure 4

THERMAL COLLAR

1/ Thermal Collar slides over galvanized

sleeve of Weatherhood.

2/ Fasten Thermal Collar to Belt.

3/ Slide the Insulated Flexible Ducting over

the Weatherhood’s galvanized sleeve and

fasten it to the Thermal Collar.

4/ Hood is hinged to allow for easy access

for cleaning of bird screen.

DUCTING

To maximize airflow in the ductwork system, all ducts

should be kept short and have as few bends or elbows as

possible. Forty-five degree elbows are preferred to 90°

elbows. Use “Wye” (Y) fittings instead of "Tees" (T) whenever possible.

All duct joints must be fastened with screws, rivets or duct

sealant and wrapped with a quality duct tape to prevent

leakage. We recommend aluminum foil duct tape.

Galvanized ducting from the ERV to the living areas

in the house is recommended whenever possible, though

flexible duct can be used in moderation if so desired.

To avoid possible noise transfer through the ductwork system, a short length (approximately 12 " or 300 mm) of nonmetallic flexible insulated duct should be connected between

the ERV and the supply/ exhaust ductwork system.

The main supply and return lines connected to the ERV

must be the same diameter as the duct connections (or

larger for extensive duct runs). Branch lines to the individual rooms may be as small as 4 inches (100 mm), but 5

inch (125 mm) lines are preferred .

All ducts running through attics and unconditioned spaces

must be sealed and insulated to code.

17

Page 18

SUPPLY AIR DUCTING

In homes without a forced air furnace (see Fig. 7), fresh air should

be supplied to all bedrooms and living areas, excluding bathrooms, kitchen and utility areas. It should be supplied from high

wall or ceiling locations. Grilles that diffuse the air comfortably

such as the TECHGRILLE (Fig.5) are recommended.

If the floor is the only option available, then special care should be

taken in locating grilles. Areas such as under baseboard heaters

will help to temper the air. Also optional inline duct heaters are

available for mounting in the supply duct work to add heat if

required.

In homes with a forced air furnace, you may want to connect the

ERV to the furnace ductwork (see information below).

Dampers and Grilles

The use of balancing dampers and/or adjustable grilles to balance the flow rates into various rooms is recommended. We

suggest TECHGRILLE air diffusers available from NUTECH

(see Fig.5).

• The TECHGRILLE is a round, fully adjustable grille, which

provides superior, quiet air distribution.

• Available in 4", 5", 6" and 8" diam.(100,125,150 and 200 mm).

Direct Connection to Furnace Ductwork

Should you wish to hard duct the supply air directly into the cold

air return of the furnace (see Figures 7, 8, 9), remember to check

the air flow balance of the ERV with the furnace fan both "ON" and

"OFF" to determine that it does not imbalance the unit more than

10%. Also, it is advisable to include a short length of fabric flex

duct or other non-metallic connector in this hard ducted line in

order to keep the ERV separately grounded (electrically) from the

furnace. This will avoid a possible shock hazard to Service People

if a short to ground develops in one of the devices.

AIR FLOW

SUPPLY

Indirect Connection to Ductwork

If permitted by local codes, an indirect connection may be made

between the ERV supply duct and the return plenum of the HVAC

system. The fresh air from the unit may be directed at a grille

installed in the cold air return duct of the HVAC system. The fresh

air supply outlet from the unit should be no closer than 4 inches

(100 mm) and no more than 12 inches (300 mm) from the grille.

CAUTION: An indirect connection to the return plenum is often

prohibited by code. An opening in the return plenum within the

same space as the furnace itself, or a water heater, may create

sufficient negative pressure in the mechanical room to cause

spillage of combustion gases, which can then be drawn into the

return ducting and circulated throughout the dwelling. This method

should be used only in cases where the furnace and water heater

are directly vented appliances with 100% outside air for combustion supplied directly to the equipment.

Stale Air Exhaust System

The stale air exhaust system is used to draw air from the points in

the house where the worst air quality problems occur. It is recommended that return air ducts are installed in the bathroom, kitchen,

and laundry room. Additional return air ducts from strategic locations (i.e. greenhouse, atrium, swimming pool, sauna, etc.) may be

installed.

An alternative method with low installation cost is to connect the

ERV exhaust duct to the return duct of the HVAC system (see

Fig. 9). In this method, the exhaust air is not ducted back to the

ERV with "dedicated lines" from bathrooms, kitchens etc.

Instead the exhaust air is drawn out of the cold air return of the

forced air furnace. This method has become popular and provides good ventilation when installed in accordance with the

instructions. The furnace blower must be running when the

unit is operating for this system to be effective.

We recommend the use of high mounted wall returns with

grilles. The exhaust air duct from the kitchen should never

be connected to a range hood. Instead, the exhaust grille

should be mounted high on the wall at least 4 feet (1.2 m)

horizontally away from the stove. A "flip-up", 6" X 10" (150 X

250 mm) rectangular kitchen grille with removable grease

filter is available. (Grille: Part No. 10-002. Replacement

filter:Part No. 10-002-2).

Removable

Dampers should be located just prior to the Energy

Recovery Ventilator to balance the stale air exhausted

out of the house with a fresh air supply entering the

house. See "Air Flow Balancing".

AIR FLOW

EXHAUST

Figure 5: TECHGRILLE AIR DIFFUSERS

filter

18

Page 19

PITOT TUBE AIR FLOW BALANCING

It is necessary to have balanced air flows in an ERV. The volume of air brought

in from the outside must equal the volume of air exhausted by the unit. If the air

flows are not properly balanced, then:

• The ERV may not operate at its maximum efficiency

• A negative or positive air pressure may occur in the house

• The unit may not defrost properly

• Failure to balance ERV properly may void warranty

Excessive positive pressure

may drive moist indoor air into the external walls

of the building where it may condense (in cold weather) and degrade structural

components. May also cause key holes to freeze up.

Excessive negative pressure

may have several undesirable effects. In some

geographic locations, soil gases such as methane and radon gas may be drawn

into the home through basement/ground contact areas. Excessive negative

pressure may also cause the backdrafting of vented combustion equipment.

Read the Application Warning on the front of this manual!

Prior to balancing, ensure that:

1. All sealing of the ductwork system has been completed.

2. All of the ERV’s components are in place and functioning properly.

3. Balancing damper are fully open.

4. Unit is on HIGH speed.

5. Air flows in branch lines to specific areas of the house should be adjusted

first prior to balancing the unit. A smoke pencil used at the grilles is a good

indicator of each branch line’s relative air flow.

6. After taking readings of both the stale air to the ERV duct and fresh air to the

house duct, the duct with the lower CFM ([L/s] velocity) reading should be

left alone, while the duct with the higher reading should be dampered back to

match the lower reading.

7. Return unit to appropriate fan speed for normal operation.

BALANCING PROCEDURE

The following is a method of field balancing and ERV using a Pitot tube, advantageous in situations when flow stations are not installed in the ductwork.

Procedure should be performed with the ERV on high speed.

The first step is to operate all mechanical systems on high speed

an influence on the ventilation system, i.e. the ERV itself and the forced air furnace or air handler if applicable. This will provide the maximum pressure that

the ERV will need to overcome, and allow for a more accurate balance of the

unit.

Drill a small hole in the duct (about 3/16”), three feet downstream of any elbows

or bends. These are recommended distances but the actual installation may

limit the amount of straight duct.

The Pitot tube should be connected to a magnehelic gauge or other manometer

capable of reading from 0 to 0.25 in (0 - 62 Pa) of water, preferably to 3 digits of

resolution. The tube coming out of the top of the pitot is connected to the high

pressure side of the gauge. The tube coming out of the side of the pitot is connected to the low pressure or reference side of the gauge.

Insert the Pitot tube into the duct; pointing the tip into the airflow.

For general balancing it is sufficient to move the pitot tube around in the duct

and take an average or typical reading. Repeat this procedure in the other (supply or return) duct. (Fig. B)

Determine which duct has the highest airflow (highest reading on the gauge).

Then damper that airflow back to match the lower reading from the other duct.

The flows should now be balanced.

Actual airflow can be determined from the gauge reading. The value read on

the gauge is called the velocity pressure. The Pitot tube comes with a chart that

will give the air flow velocity based on the velocity pressure indicated by the

gauge. This velocity will be in either feet per minute or indicated by the gauge.

This velocity will be in either feet per minute or metres per second. To determine the actual airflow, the velocity is multiplied by the cross sectional area of

the duct being measured.

, which have

This is an example for determining the airflow in a 6” duct.

The Pitot tube reading was 0.025 inches of water.

From the chart, this is 640 feet per minute.

The 6” duct has a cross sectional area of = (3.14 X [6”/12]

The airflow is then 640 ft./min. X 0.2 square feet = 128 cfm

For your convenience, the cross sectional area of some common round duct is

listed below:

DUCT DIAM. (inches) CROSS SECTION AREA (sq. ft.)

5 0.14

6 0.20

7 0.27

The accuracy of the air flow readings will be affected by how close to any

elbows or bends the readings are taken. Accuracy can be increased by taking

an average of multiple readings as outlined in the literature supplied with the

Pitot tube.

19

2

)/4

= 0.2 square feet

Figure A:

Pitot Tube Air Flow Balancing Kit

c/w magnehelic gauge, Pitot tube, hose and carry case.

PART NO. 99-167

DUCT

AIR

FLOW

Pitot tube

Magnehelic gauge

MAGNEHELIC

Figure B: Pitot tube and gauge

Pitot Tube

main balancing

dampers

motors

ERV

Note: for best results, keep

Pitot tube will away from

dampers and motor turbulence

Pitot Tube

Figure C: Placement of Pitot tube

TI-74-2-ERV

9811

Page 20

Installation Diagrams (Examples Only)

ERV

Round adjustable

TECHGRILLES

Optional controls for

intermittent high speed

Optional control

Figure 6

Independent Installation

Adjustable stale

air return

Note: •

or other central location to outdoors

• ERV supplies outdoor air directly to each bedroom,

to each floor without a bedroom and to the principal living areas

• ERV shown is for illustrative purposes only. Actual port location

varies depending on model. See schematic diagrams on page 4.

ERV exhausts from kitchen and /or bathrooms

ERV access door

(on back of unit)

Adjustable fresh

air supply

Adjustable damper for

balancing air flow in and

out of the house

Stale air

exhaust hood

Flexible insulated ducting

with a vapour barrier

Fresh air

supply hood

Figure 7

20

Page 21

Installation Diagrams (Examples only)

DIRECT CONNECTION of the SUPPLY AIR STREAM to the

FURNACE COLD AIR RETURN

EXHAUST AIR from various parts of home.

i.e. bathrooms (if required), kitchens (if required).

Balancing damper*

in both air streams.

Outdoors

*Unit is normally balanced on HIGH speed

with furnace blower ON.

NOTES:

1. Furnace blower may need to operate when ERV is on to provide good air distribution.

2. No separation requirements necessary between direct connection point and furnace.

3. Weatherhood arrangement is for drawing purposes only. 6' (2 m) minimum separation required.

18" (460 mm) above grade minimum.

4. Due to the differences in pressure between the HRV and the equipment it is being connected to,

the HRV's airflow must be confirmed on site, using the balancing procedure found in this manual.

Return Air

3' min.

recommended

Cool Air

Return

Combustion

or Electric

Forced Air

Furnace

Figure 8

Outdoors

Figure 9

DIRECT CONNECTION of BOTH the ERV SUPPLY AIR STREAM and

EXHAUST AIR STREAM to the FURNACE COLD AIR RETURN

Return Air

40 inches minimum (1m) separation

Balancing damper* in both air streams.

*Unit is normally balanced on HIGH speed

with furnace blower ON.

NOTES:

1. Furnace blower is required to operate when ventilation from ERV is required.

The furnace should be set to run continuously.

2. A minimum separation of 40 inches (1m) is required between the two direct connections.

3. The exhaust air connection should be upstream of the supply air connection to prevent

exhausting any fresh air.

4. Weatherhood arrangement is for drawing purposes only. 6' (2 m) minimum separation required.

18" (460 mm) above grade minimum.

5. Due to the differences in pressure between the HRV and the equipment it is being connected to,

the HRV's airflow must be confirmed on site, using the balancing procedure found in this manual.

Return Air

3' min.

recommended

Cool Air

Return

Combustion

or Electric

Forced Air

Furnace

21

Page 22

INSTALLATION MODEL 500, 700, AND 1200 ONLY

Location for Mounting

The ERV must be located in a conditioned space

where the surrounding air temperature does not

effect the ERV or its ducting. The unit must be

mounted level horizontal. The warranty could be

void if these conditions are not met.

Typically the ERV is positioned close to an outside

wall or the roof to simplify the connections and

keep the length of insulated ducting required for

the fresh air intake to a minimum.

A minimum clearance of 36 inches (90 cm) in front

of the ERV is recommended to service the

enthalpic cores and the filters. The ERV may be

mounted on an equipment platform providing there

is sufficient space to open the doors for servicing.

The Ductwork System

A properly designed ducting system will allow the

ERV to operate at its maximum efficiency. (Air flow

will be restricted by undersized ducting, use of too

many elbows, tees, bends, etc.). Always try to

keep duct runs as short and straight as possible.

NOTE: Fully insulated ducting with an integral

vapour barrier must be used on all runs

passing through unconditioned areas in

order to avoid condensation problems and

energy losses from the air steams.

All joints must be airtight, sealed and impervious

to moisture. See specification sheets for each unit

for exact duct sizes and location.

To minimize pressure drop and noise, galvanized

metal ducts, properly sized, are recommended.

Keep ducting as short as possible and use a minimum of elbows and tees. Connecting sections and

shorter runs may be flexible ducting one size larger

than the metal equivalent. Use flexible duct connectors at the ERV to avoid noise transmission.

All duct joints must be secured with screws, rivets

or duct sealant and sealed with aluminum duct

tape to prevent leakage.

22

Page 23

Outside Weatherhoods

Stale Air Return System

The weatherhoods must have built-in “bird” screen with 1/4 in

(63.5 mm) minimum mesh to prevent birds and rodents from

entering into the ductwork. Do not

be very susceptible to plugging up. Gravity dampers at the

vents must not be used as they will restrict air flow and often

“seize up”. The preferred location of the outside weatherhoods is:

• no less than 10 ft. (3 m) apart from each other

• at least 18 in ( 46 cm) above or ground level

• away from sources of contaminants, such as

automobile exhaust fumes, gas meters, garbage

cans, containers, etc.

• not exposed to prevailing winds, whenever reasonable possible

The outside perimeter of the weatherhood must be caulked

to prevent leakage into the building.

The design and size of the weatherhoods or louvres chosen

by the installer must allow for adequate free area. Water and

debris penetration of the system is minimized when the airflow does not exceed 1000 FPM (5.08 m/s) free area velocity.

use smaller mesh as it will

Ducting from the Weatherhoods

The stale air return system is used to draw air from the

points in the building where the worst air quality problems

occur. Balancing dampers and/or adjustable grilles are recommended on all return air lines which are used during

installation to help balance the “draw” from different areas

of the building.

Alternately, the stale air may be drawn directly from the

return air duct. When this system is used, the air handler’s

blower must constantly operate. The exhaust takeoff connection must be at least a 3 ft (1 m) from a directly connected ERV supply duct if both are connected to the same

duct run. Static pressure of the air handlers return system

should be noted and compensated for if it is apparent that

the static pressure of the return in the air handler will

exceed .1 to .15” W.C.

A damper located just prior to the ERV is required to balance the stale air exhausted with the fresh air supply entering the building.

Return air suction points should be located on the opposite

side of the room from the fresh air inlet. The inlets may be

located in the ceiling or high on the walls and fitted with

inlet grilles.

Galvanized sheet metal ducting with sufficient cross section

with an integral single piece vapour barrier should be used to

connect the ERV to the weatherhoods. All ducting must

meet UL Class 1 requirements.

A minimum R value of insulation should be equal to 4

(RSI 0.75)

A good bead of high quality caulking (preferably acoustical

sealant) and taping with a high quality aluminum foil tape is

recommended to seal the duct to both the ERV and the

weatherhood.

Warmside Ducting - General

Ducting from the ERV to the different areas in the building

should be galvanized metal whenever possible.

To minimize airflow losses in the ductwork system, all ducts

should be as short as possible and with as few bends or

elbows as possible. 45° elbows are preferred to 90°

elbows. Use “Wye” (Y) fittings instead of “Tees” (T) whenever possible.

Many commercial activities produce air contaminants in the

form of dusts, fumes, mists, vapours and gases. contaminants should be controlled at the source so that they are not

dispersed through the building nor allowed to increase to

toxic concentration levels. The energy recovery ventilator

allows for economical operation of the HVAC system while

effectively removing contaminants from the space. In

designing the exhaust portion of the system the exhaust

grilles are placed so as to remove the contaminants while

not allowing them to enter the breathing zone of the occupants.

For contaminants that are lighter than air, grilles should be

located high on the wall. If contaminants are heavier than

air, a lower placement of the grilles will be required.

Information on a contaminants specific gravity and toxicity

should be available from chemical data sheets.

All duct joints mist be fastened with screws, rivets or duct

sealant and wrapped with a quality duct tape to prevent leakage. We recommend aluminum foil tape.

23

Page 24

Fresh Air Supply System

The Integrated HVAC System

The fresh air supply ductwork from the ERV may be

directly connected to the return air duct of the forced air

system. Check the air flow balance of the ERV with the

air handler blower both “ON” and “OFF” to determine that

it does not imbalance the ERV more than 10%. Also, it is

advisable to include a short length of flex duct or other

non-metallic connector in this hard ducted line in order to

keep the ERV acoustically isolated and separately

grounded (electrically) from the air handler. This will

avoid a possible shock hazard to service people if a short

to ground develops in one of the devices.

It may be necessary to install a separate fresh air supply

ductwork system if the heating is other than forced air.

When installing an ERV, the designer and installer should

be aware of local codes that may require smoke detectors and/or firestats in the HVAC or ERV ductwork.

Because an ERV is designed to bring fresh air into the

building, structures may require supply voltage interrupt

when smoke or flame sensors are triggered, or when a

central fore alarm system is activated.

Supply air grilles may be ceiling or high wall mounted.

Avoid locating incoming fresh air grilles that could cause

a direct draft on the occupants.

The use of balancing dampers or adjustable grilles to balance the flow rates into various rooms is recommended.

The use of balancing dampers or adjustable grilles as

supply air diffusers and air exhaust covers are recommended. TECHGRILLES™ are round, efficient, sound

absorbing devices available in 4”, 5”, 6” and 8” (100, 125,

150, and 200 mm) models.

The ERV has become an integral component of the

HVAC system. Figure A shows an ERV unit providing

fresh air directly to the return air plenum of a rooftop unit.

In the balanced airflow system, the ERV exhaust

removes stale room air (eg. from lunch room, storage or

copy area) and returns to the space an equal amount of

fresh outdoor air, making the use of an economizer obsolete in conjunction with an ERV.

Many buildings have ceiling return air plenum as in

Figure B. Fresh air from the ERV can be introduced

directly into the ceiling space but this should occur near

the air handler’s intake.

By operating the ERV on a 24 hour/7 day battery backed

timer the unit can be set to operate only when occupancy

or indoor conditions require the air exchange.

In installations where it is satisfactory to provide general exhaust from the space, the air to be exhausted may

be taken directly from the return air plenum to the ERV

as it is drawn back to the air handler. Fresh air supplied

by the ERV is then introduced directly into the return air

plenum but at a location closer to the air handler. The

air handler would have a constant running blower to

effectively distribute the fresh air and remove the stale

air. Balancing dampers would be located in both the

ERV supply and exhaust ducts between the return air

plenum and the ERV.

NOTE: At no time should the air handler T.E.S.P. on

the return duct exceed that of the ERV. Supply Air

T.E.S.P.

AIR FLOW

SUPPLY

AIR FLOW

EXHAUST

Figure

TECHGRILLE™ (optional) schematic

24

Page 25

ECONOMIZER (DISABLED)

ROOFTOP

UNIT

STALE AIR

EXHAUST

FRESH AIR

SUPPLY

Figure 6A

ERV UNIT

RETURN AIR DUCT or

B.D.

A

ERV FRESH

AIR SUPPLY

SUPPLY DUCT

BREATHER T

B.D.

B

STALE AIR

EXHAUST TO ERV

ECONOMIZER (DISABLED)

STALE AIR

EXHAUST

FRESH AIR

SUPPLY

Figure 6B

ROOF DECK

CEILING RETURN AIR PLENUM

ERV UNIT

25

B

A

ERV FRESH

AIR SUPPLY

ROOFTOP

UNIT

12" BREATHER

SPACE

B.D.

B.D.

STALE AIR EXHAUST

SUPPLY DUCTWORK

Page 26

Various Installation Types

Figure 7A

Saddle Installation

Hang unit with suspended rods

and "U" channel members.

Vibration Isolators

Threaded

rod and U channel

(Supplied by others)

(Supplied by others)

*NOTE:

When installing your ERV,

flexible duct connectors should

be installed between the ERV

and the galvanized ductwork.

Figure 7B

Curb Mounted

Figure 7C

Suspended

Unit Suspended using

Polyester reinforced PVC support straps.

PVC Support Straps

(Supplied by others)

Curb is wood or metal

(Supplied by others)

Mount unit on wooden or metal

curb assembly. Unit must be raised

an adequate height for installation

and slope of drain lines.

May be anchored to

floor,leaving space

for drain connections

Vibration Isolators

(Supplied by others)

26

Page 27

TROUBLESHOOTING YOUR ERV SYSTEM

Symptom

Poor air flow

Supply air inlet feels cold (a

problem if it affects the

occupant in the normal living

environment, not just cold air

at the supply grille itself

Humidity levels are too low

Cause

• Mesh on outside hood is plugged

• Filters plugged

• Cores obstructed

• House grilles closed

• Dampers closed

• Low voltage at site

• Ductwork too long, excessive number of bends

• Improper speed control setting

• Improper balancing of ERV airflows

• Poor location of air supply grilles, cause

discomfort

• Outdoor temperature below 25°F (-4°C)

• Excessive infiltration through house leakage

• ERV speed set too high

• Dehumidistat set too low

• ERV improperly balanced

• Lifestyle of occupants, generate little indoor

humidity

Solution

• Clean exterior hoods or vents

• Remove and clean filters

• Remove and clean core (vacuum or blow out;

• Open and adjust grilles

• Open and adjust dampers

• Have electrician check voltage

• Have HVAC contractor check ducting

• Increase speed setting

• Have HVAC contractor re-balance system

• Relocate air supply grilles so airflow does not

• A small duct heater may be added to the supply

• Weather-strip, caulk and seal opening through

• Lower ERV speed setting.

• Set dehumidistat higher.

• Have HVAC contractor re-balance system.

• May need to install a humidifier.

do not wash)

affect occupant. Adjust grille so that airflow is

entrained along wall or ceiling. (Note, closing the

grille too far will cause the air to be directed

downward from a ceiling, rather than along the

ceiling.

air ducting to boost temperature. If supply air is