Lifebreath 155MAX RX, 155ECM, 200MAX RX User Manual

* LEAVE FOR HOMEOWNER

NOTE: Due to ongoing research and product development, specifications,

ratings and dimensions are subject to change without notice.

TI-84R-NE

0406

Installing Contractor

Telephone / Contact

Serial Number

Installation Date Model

TO BE COMPLETED BY CONTRACTOR AFTER INSTALLATION

OPERATION AND

INSTALLATION MANUAL

Contains

ControlAir 15

For Models:

95MAX

155MAX

155ECM

155MAXRX

200MAX

200MAXRX

MAXTOP

195DCS

300DCS

200ERV

200ERVD

CAUTION

Before

installation, careful consideration must be given to

how this system will operate if connected to any other piece

of mechanical equipment, i.e. a forced air furnace or air

handler, operating at a higher static. After

installation, the

compatibility

of the two pieces of equipment must be

confirmed by measuring the airflow’s of the Heat Recovery

Ventilator (HRV) Energy Recovery Ventilator (ERV) by

using the balancing procedure found in this manual.

It is always important to assess how the operation of any

HRV/ERV may interact with vented combustion equipment

(ie. Gas Furnaces, Oil Furnaces, Wood Stoves, etc.).

NEVER install a ventilator in a situation where its normal

operation, lack of operation or partial failure may result in

the backdrafting or improper functioning of vented combustion equipment!!!

IMPORTANT - PLEASE READ THIS

MANUAL BEFORE INSTALLING

UNIT.

2

Introduction ................................................................2

Warranty ....................................................................2

ERV Questions & Answers ........................................3

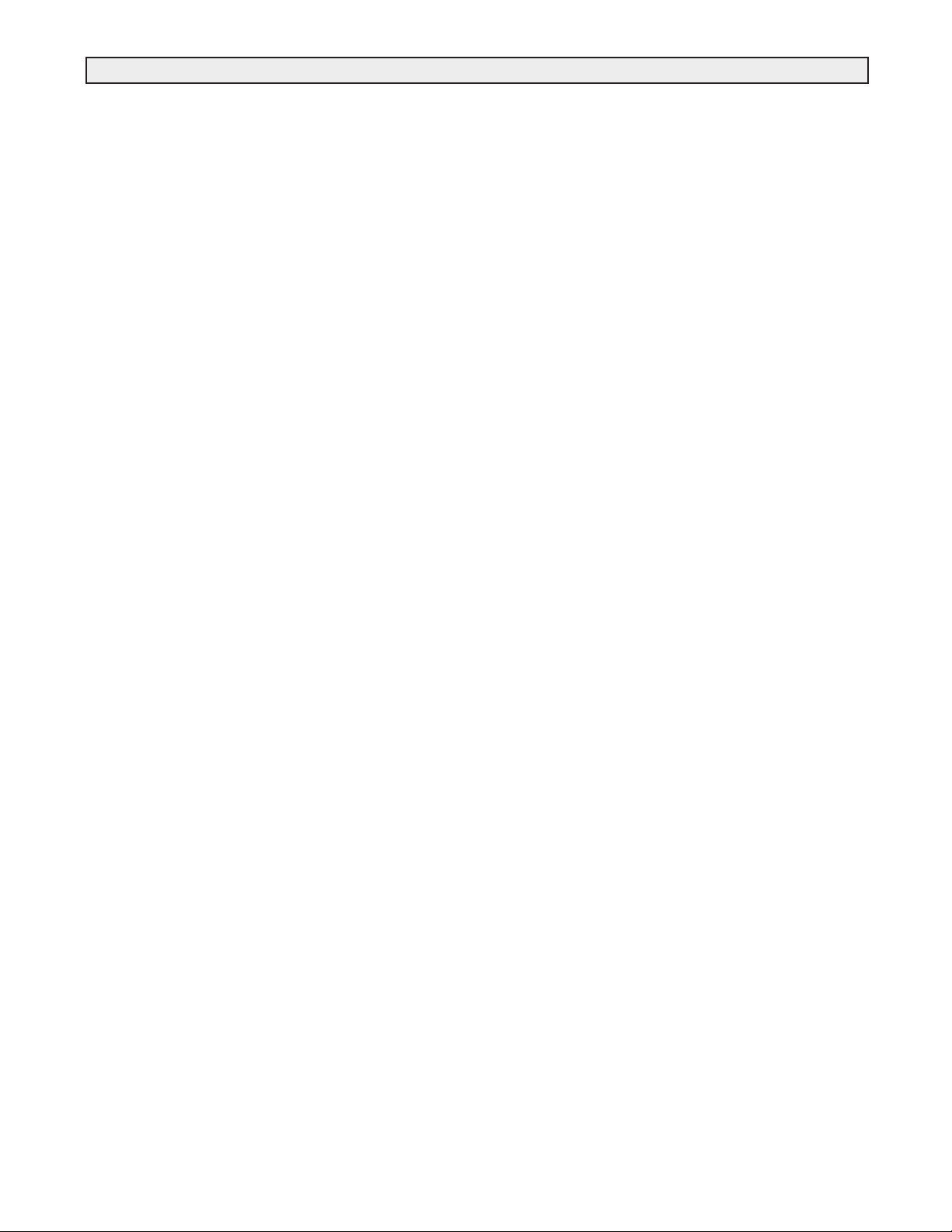

Climate Map...............................................................4

Technical Data - Model 95MAX ................................5

Technical Data - Model 155MAX ..............................6

Technical Data - Model 155ECM ..............................7

Technical Data - Model 155MAX RX ........................8

Technical Data - Model 200MAX ..............................9

Technical Data - Model 200MAX RX .....................10

Technical Data - Model MAXTOP...........................11

Technical Data - Model 195DCS.............................12

Technical Data - Model 300DCS.............................13

Technical Data - Model 200ERV.............................14

Technical Data - Model 200ERVD ..........................15

Function and Control

Operation of the ControlAir 15 .................................16

Glossary of Terms ...................................................16

Selecting Speeds and Modes of Operation .............17

The Control Pad Mounted in the Control Module ....18

Optional Remote Controls .......................................19

Using the Dehumidistat............................................20

Schematic Diagram - Model 95MAX.......................21

Installation

Installation..............................................................22

• Location

• Mounting the HRV/ERV

• Electrical

• Installing the Drain Line and "P" Trap

Installing Air Ducts ...............................................23

• Outside Weatherhoods

• Locating the Weatherhoods

• Installing Ducting from Weatherhoods to the

HRV/ERV

• Warmside Ducting

Supply Air Ducting ...................................................24

Stale Air Exhaust System ........................................24

Dampers and Grilles ................................................24

Installation Diagrams .........................................25-28

Air Flow Balancing ..................................................29

Maintenance

Maintenance Routine For HRV................................31

Maintenance Routine For ERV ................................32

Troubleshooting .......................................................33

Interlocking HRV Operation to an Airhandler/

Furnace Blower........................................................34

Wiring Diagrams .................................................35-36

HRV - Aluminum Core

A Heat Recovery Ventilator (HRV) is designed to provide fresh air into a building while exhausting an

equal amount of stale air. During the winter months,

the incoming cold fresh air is warmed by utilizing the

heat recovered from the stale air before it is exhausted to the outdoors. During summer months when the

indoor space is air conditioned, the Heat Recovery

Ventilator will help in cooling the incoming fresh air

with the stale air that is being exhausted.

ERV - Enthalpic Paper Core

An Energy Recovery Ventilator (ERV) is designed to

provide fresh air into a building while exhausting an

equal amount of stale air. An ERV is designed for use

in warm humid areas with heavy air conditioning use.

The ERV will transfer both sensible and latent heat

from the incoming fresh air to the outgoing stale air

thereby reducing the load (due to ventilation) on the

air conditioning system.

ERVs are not suitable for climates where the temperature drops below -4°C (25°F).

All Heat Recovery Ventilators carry a Lifetime

Warranty on the heat recovery core and a 5 (five)

year replacement parts warranty.

All Energy Recovery Ventilators carry a 5 (five) year

warranty on the energy recovery core and a 5 (five)

year replacement parts warranty.

During the warranty period, if any core experiences a

failure or perforation caused by normal use while

owned by the original purchaser, a replacement core

(FOB our plant) will be supplied at no expense.

Table of Contents Introduction

Warranty

3

What is the difference between an HRV

and an ERV?

The core in an HRV (Heat Recovery Ventilator) transfers heat from one air stream to the other. This is

called sensible heat. The term ERV (Energy Recovery

Ventilator) is usually used to describe a unit with an

enthalpic core that transfers moisture as well as heat

from one air stream to the other. This (moisture

transfer) is called latent heat.

Enthalpic - what does it mean?

Enthalpy is the term used to describe the energy

content of air. This energy is a combination of the sensible and latent heat. Therefore, a core which transfers

energy is called an enthalpic core.

Is an ERV better than an HRV?

NOT NECESSARILY! In cold climates such as most of

North America, an HRV works better than an ERV.

This is because the air inside the home during the winter months will be more humid than the outside air. An

ERV would transfer the latent heat (humidity) from the

exhaust air back into the incoming airstream. This will

aggravate moisture problems in the home and encourage the growth of mold and mildew. If the air in the

home is too dry for comfort, an ERV will not help. A

humidifier should be used to increase the humidity to a

comfortable level.

Where do you use an ERV instead of an HRV?

An ERV is recommended for warm, humid areas with

heavy air conditioning use. As there is no defrost in an

ERV it is not recommended for areas where the temperature drops below -4°C (25°F).

Why transfer moisture in the summer

(cooling season)?

The enthalpic core will allow moisture to be transferred

from a humid air flow to a dry air flow. This property is

useful in the cooling season if an air conditioning system is used to lower the indoor humidity. You will then

have dry, cool air in the exhaust of the ERV, and warm

humid air in the supply stream. With these conditions,

the ERV will be able to transfer the moisture and heat

of the supply air to the exhaust air. In this way, the

ERV will supply to the home air which is cooler and

drier than outside. Remember that an ERV is not a

dehumidifier, and on its own will not take moisture out

of the air.

So why use an ERV?

A properly operating air conditioner will not only lower

the temperature in your house, but will also lower the

humidity level. This prevents an uncomfortable cold

and damp situation. In fact, about 2/3 of the energy

used by the air conditioner system is to remove moisture. Therefore, when ventilating in the summer, less

moisture brought into the home means less work for

the air conditioner, and energy savings for you.

During the winter, an ERV recovers some humidity

from the exhaust air, reducing the need for humidification, if the required ventilation rate would make the

home too dry.

What's the difference between this type of core

and a rotary type?

Here's a list of characteristics of the fixed plate core.

1. No rotating parts, so maintenance is easy and the

unit lasts a long time.

2. It is very flexible in terms of installation.

3. The core can easily be changed.

4. Because the supply and exhaust air streams are

completely separate, there is very little cross leakage of any dust or germs.

Can the core become clogged with dust?

Because the surface of the core is a turbulent flow

area, dust sticks to it easily; however, because the

inside of the element is a laminar flow area, virtually no

dust sticks to it.

What is the maintenance?

About once a year you should use a vacuum cleaner

to remove the dust from the core's surface. DO NOT

WASH WITH WATER!

Is an air filter needed?

To prevent clogging of the core, an air filter should

always be installed on the supply and exhaust sides of

the core.

How much ventilation do I need?

During seasons when your windows and doors are

closed, the ERV should operate continuously when the

dwelling is occupied, and either continuously or intermittently when not occupied.

For most installations the ERV will normally be set to

operate continuously on low speed with the option of

going to high speed as the need arises. For example;

if you are entertaining and there is a large number of

people present (some may be smoking), the unit

should be switched to high speed.

Your ERV may be equipped with automatic or manual

switches, but all ERVs will have a manual speed control override.

ERV Questions and Answers

4

5

Model 95MAX

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two

airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

Each air stream has one centrifugal blower driven by a common PSC motor.

5 speed fan operation. 120 VAC, .8 Amps.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of the cabinet designed to accept PVC reinforced polyester straps that are supplied with the unit.

DEFROST

Recirculating defrost system.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resistance. Insulated to prevent exterior condensation.

Drain connections 2 - 1/2" (12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, Recirculation

mode (on compatible units), (each mode has 5 speeds). Control pad can be

removed from HRV and remotely mounted.

WEIGHT 52 lbs. (23.6 kg) Shipping Weight 56 lbs. (25.4 kg)

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept remote-

ly mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed

to accept remotely mounted Control Pad

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6”

(150 mm)

99-185 Weatherhoods, Two - 5” (125 mm) c/w 1/4” (6 mm) mesh

screen

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and a 5 year

replacement parts warranty.

TI-113-NE

0904

DIMENSIONS 95MAX inches (mm)

All units conform to

CSA and UL standards.

PERFORMANCE

HVI CERTIFIED

Net supply airflow in cfm (L/s) against external static pressure

E.S.P

(external static pressure) [cfm (L/s)]

@ 0.1" (25 Pa) 95 (45)

@ 0.2" (50 Pa) 92 (43)

@ 0.3" (75 Pa 89 (42)

@ 0.4" (100 Pa) 83 (39)

@ 0.5" (125 Pa) 76 (36)

@ 0.6" (100 Pa) 71 (34)

Maximum Temperature Recovery 88%

Sensible Effectiveness

@ 64 cfm (30 L/s) (CSA C439M) 87%

Sensible Efficiency

@ 64 cfm (30 L/s) 32°F (0°C) 74%

Sensible Efficiency

@ 64 cfm (30 L/s) -13°F (-25°C) 68%

VAC @ 60HZ 120

WATTS / Low speed 60

WATTS / High speed 150

Amp rating 0.9

18.5"

24.5"

(622 mm)

(470 mm)

Removably

Heat Recovery

Core

Drain Pan

Drain spout

FRONT TOP

knockout for

side mounting of

EXHAUST return port

6" round collar

converted to oval

minimum

18 inches (459 mm)

required for

service access

SIDE

Hanging

straps (4)

16"

(406 mm)

Threaded

inserts (4)

at corners

SUPPLY

Fresh air

from outside

5" round collar

SUPPLY

Fresh air

to building

6" round

(conv. to oval)

collar

18.5"

(470 mm)

EXHAUST

Stale Air

to outside

5" round collar

EXHAUST

Return air

from building

Choice of port location

Knockouts on top and

side of unit (use 1 only)

6" round (conv. to oval)

collar supplied

6

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two

airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

Each air stream has one centrifugal blower driven by a common PSC motor.

5 speed fan operation. 120 VAC, 1.0 Amps.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of case designed to accept four reinforced

polyester straps that are supplied with the unit.

DEFROST

Recirculating damper defrost system.

DEHUMIDISTAT

Adjustable Internal Dehumidistat.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resistance. Insulated to prevent exterior condensation. Drain connections 2 1/2" (12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, Recirculation

mode (on compatible units), (each mode has 5 speeds). Control pad can be

removed from HRV and remotely mounted.

Weight 71 lbs. (32.5 kg) Shipping Weight 73 lbs. (33.5 kg)

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept remotely

mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed to accept

remotely mounted Control Pad.

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6” (150 mm)

99-164 Duct Heater w/ Electronic SCR Thermostat, 2 Kw, 6” (150 mm)

99-186 Weatherhoods, Two - 6” (150 mm) c/w 1/4” (6 mm) mesh screen

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and a 5 year

replacement parts warranty.

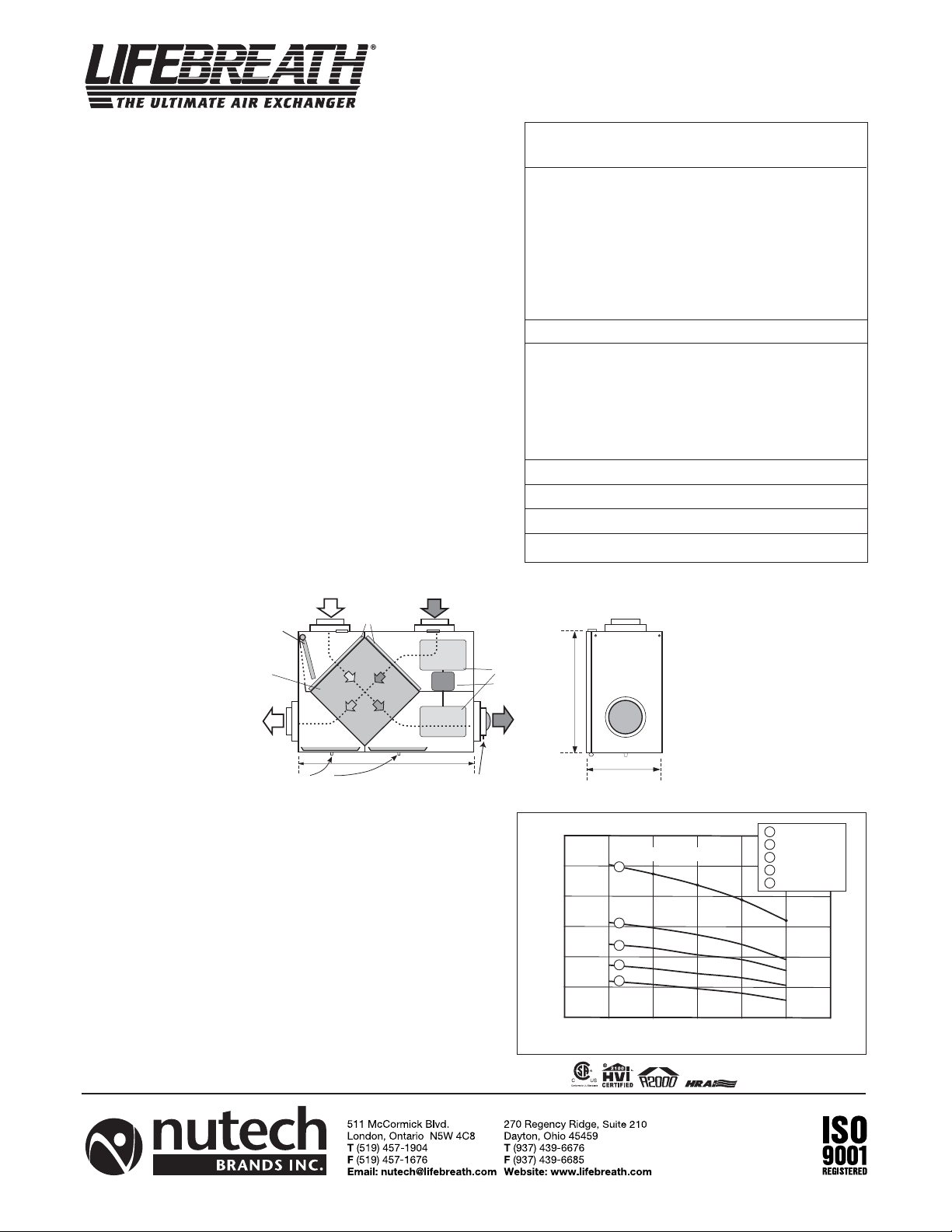

PERFORMANCE

HVI CERTIFIED

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 169 (80)

@ 0.2” (50 Pa) 161 (76)

@ 0.3” (75 Pa) 150 (71)

@ 0.4” (100 Pa) 130 (61)

@ 0.5” (125 Pa) 56 (26)

Maximum Temperature Recovery 83%

Sensible Effectiveness

@ 64 cfm (30 L/s)

(CSA C439M)

76%

Sensible Efficiency

@ 64 cfm (30 L/s) 32°F (0

O

C) 70%

Sensible Efficiency

@ 64 cfm (30 L/s) -13°F (-25

O

C)

70%

VAC @ 60HZ 120

WATTS / Low speed 49

WATTS / High speed 120

Amp rating 1.0

TI-92-NE

0904

DIMENSIONS 155MAX inches (mm

)

Model 155MAX

All units conform to CSA

and UL standards.

FRESH AIR

FROM OUTSIDE

RECIRCULATING

DEFROST

DAMPER

CORE

FILTERS

STALE AIR

FROM INSIDE

*NOTE: Front clearance of 25 inches (635 mm)

is recommended for servicing unit.

BLOWERS

MOTOR

19"

(483)

STALE AIR

TO OUTSIDE

CONDENSATE DRAINS

33 5/8"

(850mm)

*All Duct Connections 6" (150mm)

BALANCING DAMPER

FRESH AIR

TO INSIDE

14 3/4"

(375)

155MAX FANCURVE

175

Manufacturers Data

150

125

100

75

Air Flow (cfm)

50

25

0.1 0.2 0.3 0.4 0.5 0.6 0.7

*

5

4

3

2

1

Static Pressure (inH20)

5

4

3

2

1

HIGH SPEED

*

MEDIUM HIGH SPEED

MEDIUM SPEED

MEDIUM LOW SPEED

LOW SPEED

7

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two

airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

High effficiency electronic comutated ECM motor for maximum energy savings. Each air stream has one centrifugal blower. 5 speed fan operation

driven by one double shaft motor. 120 VAC, 1.0 Amps.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of case designed to accept four reinforced

polyester straps that are supplied with the unit.

DEFROST

Recirculating damper defrost system.

DEHUMIDISTAT

Adjustable Internal Dehumidistat.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resistance. Insulated to prevent exterior condensation. Drain connections 2 1/2" (12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, Recirculation

mode (on compatible units), (each mode has 5 speeds). Control pad can be

removed from HRV and remotely mounted.

Weight 71 lbs. (32.5 kg) Shipping Weight 73 lbs. (33.5 kg)

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept

remotely mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed to

accept remotely mounted Control Pad.

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6”

(150 mm)

99-164 Duct Heater w/ Electronic SCR Thermostat, 2 Kw, 6”

(150 mm)

99-186 Weatherhoods, Two - 6” (150 mm) c/w 1/4” (6 mm) mesh

screen

99-SILENCER6 6” dia. 16” long

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and a 5

year replacement parts warranty.

PERFORMANCE

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 163 (77)

@ 0.2” (50 Pa) 151 (71)

@ 0.3” (75 Pa) 140 (66)

@ 0.4” (100 Pa) 128 (60)

@ 0.5” (125 Pa) 115 (54)

@ 0.6” (150 Pa) 102 (48)

Maximum Temperature Recovery 83%

Sensible Effectiveness

@ 64 cfm (30 L/s)

(CSA C439M) 76%

Sensible Efficiency

@ 64 cfm (30 L/s) 32°F (0

O

C) 70%

Sensible Efficiency

@ 64 cfm (30 L/s) -13°F (-25

O

C) 70%

VAC @ 60HZ 120

WATTS / Low speed 17

WATTS / High speed 95

Amp rating 1.0

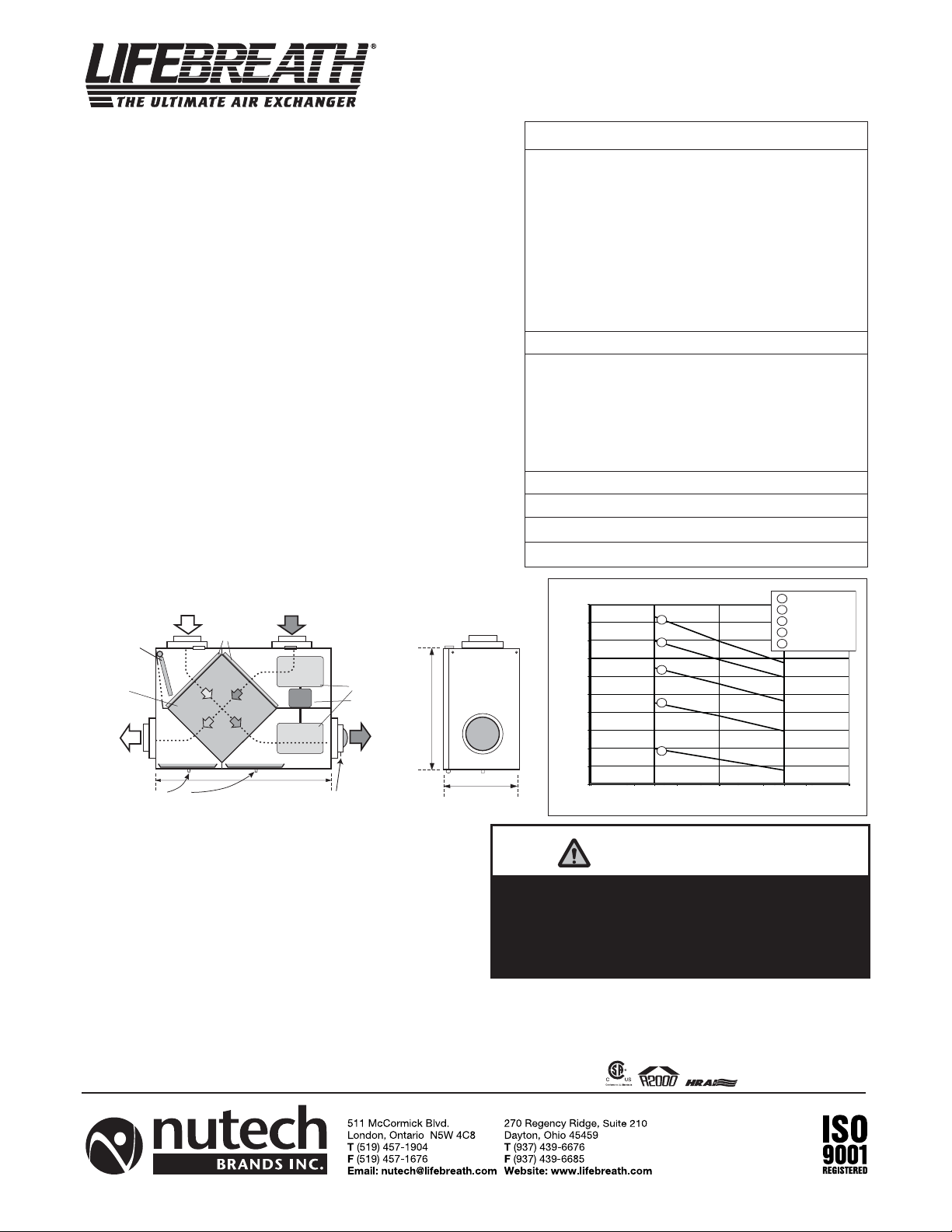

DIMENSIONS 155ECM

inches (mm)

Model 155ECM

All units conform to CSA

and UL standards.

FRESH AIR

FROM OUTSIDE

RECIRCULATING

DEFROST

DAMPER

CORE

STALE AIR

TO OUTSIDE

CONDENSATE DRAINS

FILTERS

33 5/8"

(850mm)

*All Duct Connections 6" (150mm)

STALE AIR

FROM INSIDE

BALANCING DAMPER

*NOTE: Front clearance of 25 inches (635 mm)

is recommended for servicing unit.

BLOWERS

MOTOR

FRESH AIR

TO INSIDE

19"

(483)

14 3/4"

(375)

155ECM FANCURVE

140

130

120

110

100

90

80

Air Flow (cfm)

70

60

50

40

0.3 0.4 0.5 0.6 0.7

?

Manufacturers Data

*

5

4

3

2

1

Static Pressure (in H2O)

HIGH SPEED

5

MEDIUM HIGH SPEED

4

MEDIUM SPEED

3

MEDIUM LOW SPEED

2

LOW SPEED

1

*

ATTENTION

The ECM motor produces a tone that some may

find objectionable. We recommend the

installation of the optional 99-SILENCER6 on the

‘Stale Air from Inside’ and ‘Fresh Air to Inside’

ducts.

8

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two

airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

Each air stream has one centrifugal blower driven by a common PSC motor.

5 speed fan operation. 120 VAC, 1.0 Amps.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of case designed to accept four reinforced

polyester straps that are supplied with the unit.

DEFROST

Recirculating damper defrost system.

DEHUMIDISTAT

Adjustable Internal Dehumidistat.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resistance. Insulated to prevent exterior condensation. Drain connections 2 1/2" (12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, Recirculation

mode (on compatible units), (each mode has 5 speeds). Control pad can be

removed from HRV and remotely mounted.

Weight 71 lbs. (32.5 kg) Shipping Weight 73 lbs. (33.5 kg)

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept remotely

mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed to accept

remotely mounted Control Pad.

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6” (150 mm)

99-164 Duct Heater w/ Electronic SCR Thermostat, 2 Kw, 6” (150 mm)

99-186 Weatherhoods, Two - 6” (150 mm) c/w 1/4” (6 mm) mesh screen

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and a 5 year

replacement parts warranty.

PERFORMANCE

HVI CERTIFIED

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 169 (80)

@ 0.2” (50 Pa) 161 (76)

@ 0.3” (75 Pa) 150 (71)

@ 0.4” (100 Pa) 130 (61)

@ 0.5” (125 Pa) 56 (26)

Maximum Temperature Recovery 83%

Sensible Effectiveness

@ 64 cfm (30 L/s)

(CSA C439M)

76%

Sensible Efficiency

@ 64 cfm (30 L/s) 32°F (0

O

C) 70%

Sensible Efficiency

@ 64 cfm (30 L/s) -13°F (-25

O

C)

70%

VAC @ 60HZ 120

WATTS / Low speed 49

WATTS / High speed 120

Amp rating 1.0

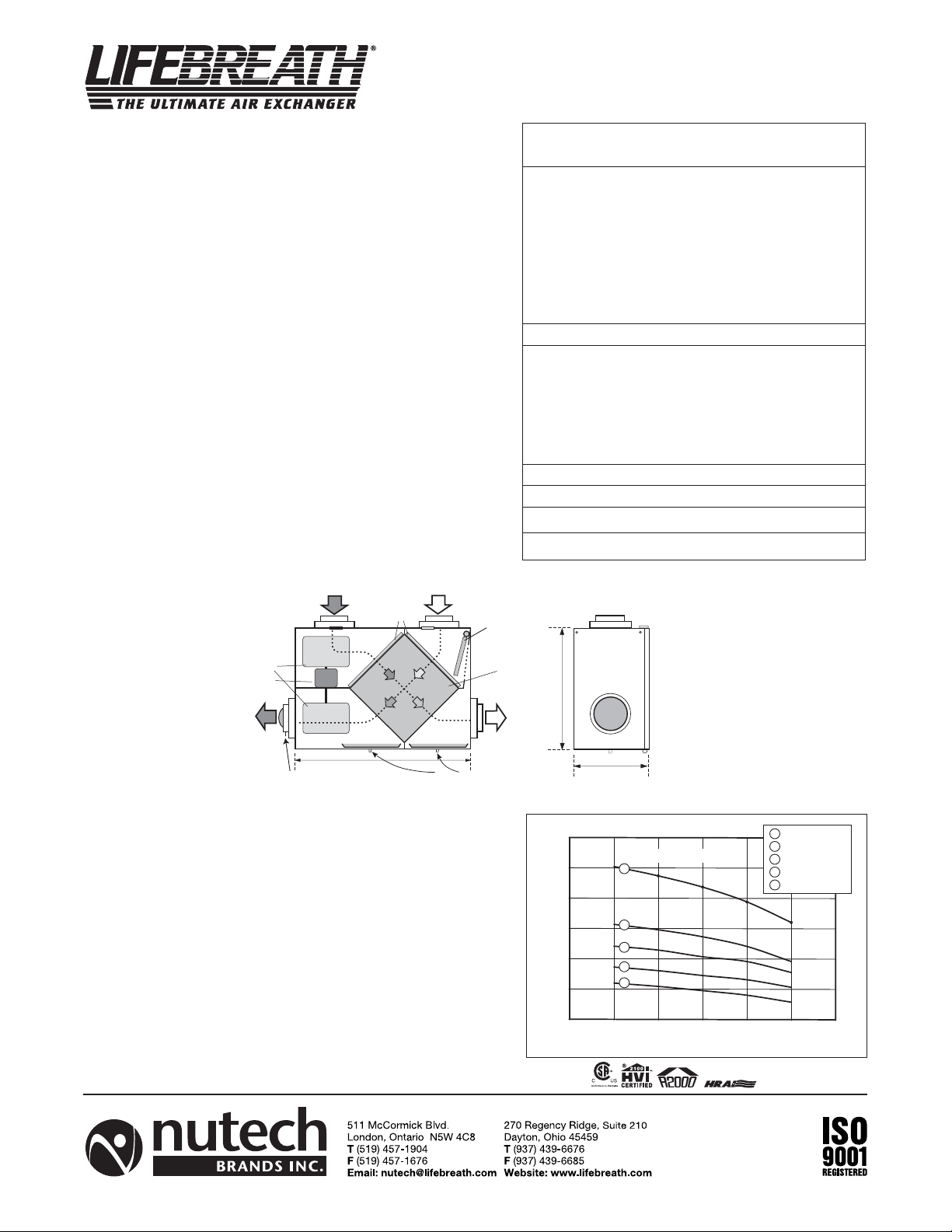

1105

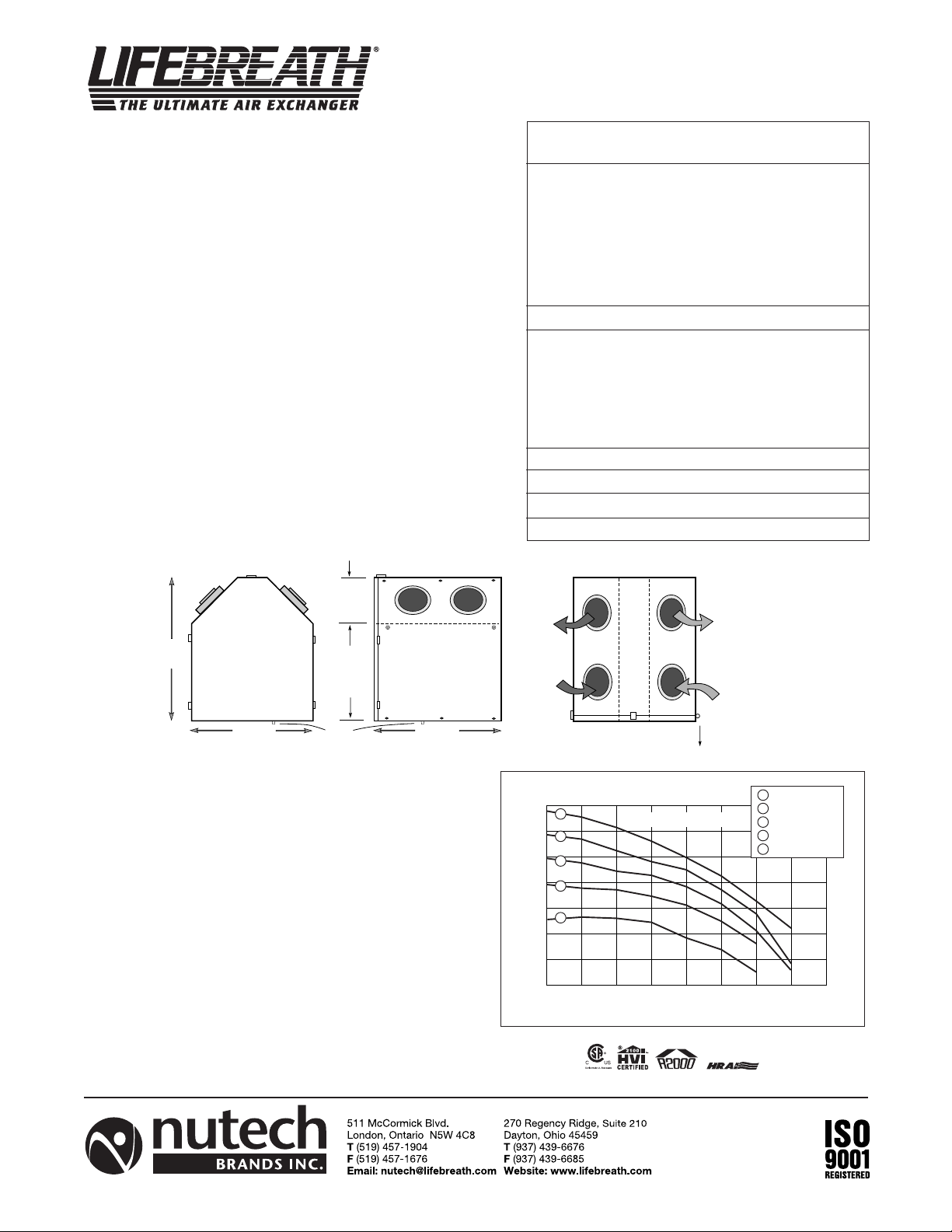

DIMENSIONS 155MAX RX inches (mm

)

Model 155MAX RX

All units conform to

CSA and UL standards.

STALE AIR

FROM INSIDE

BLOWERS

MOTOR

FRESH AIR

TO INSIDE

BALANCING DAMPER

FRESH AIR

FROM OUTSIDE

FILTERS

33 5/8"

(850mm)

*All Duct Connections 6" (150mm)

RECIRCULATING

DEFROST

DAMPER

STALE AIR

TO OUTSIDE

CONDENSATE DRAINS

CORE

19"

(483)

14 3/4"

(375)

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

155MAX FANCURVE

175

Manufacturers Data

150

125

100

75

Air Flow (cfm)

50

25

0.1 0.2 0.3 0.4 0.5 0.6 0.7

*

5

4

3

2

1

Static Pressure (inH20)

5

4

3

2

1

HIGH SPEED

*

MEDIUM HIGH SPEED

MEDIUM SPEED

MEDIUM LOW SPEED

LOW SPEED

9

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept remotely

mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed to accept

remotely mounted Control Pad.

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6” (150mm)

99-164 Duct Heater w/ Electronic SCR Thermostat, 2 Kw, 6” (150mm)

99-186 Weatherhoods, Two - 6” (150mm) c/w 1/4” (6mm) mesh screen

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and a 5 year

replacement parts warranty.

PERFORMANCE

HVI CERTIFIED

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 232 (109)

@ 0.2” (50 Pa) 223 (105)

@ 0.3” (75 Pa) 215 (102)

@ 0.4” (100 Pa) 195 (92)

@ 0.5” (125 Pa) 189 (89)

Maximum Temperature Recovery 81%

Sensible Effectiveness

@ 117 cfm (55 L/s)

(CSA C439M) 74%

Sensible Efficiency

@ 117 cfm (55 L/s) 32°F (0°C) 65%

Sensible Efficiency

@ 117 cfm (55 L/s) -13°F (-25°C) 66%

VAC @ 60HZ 120

WATTS / Low speed 87

WATTS / High speed 164

Amp rating 1.4

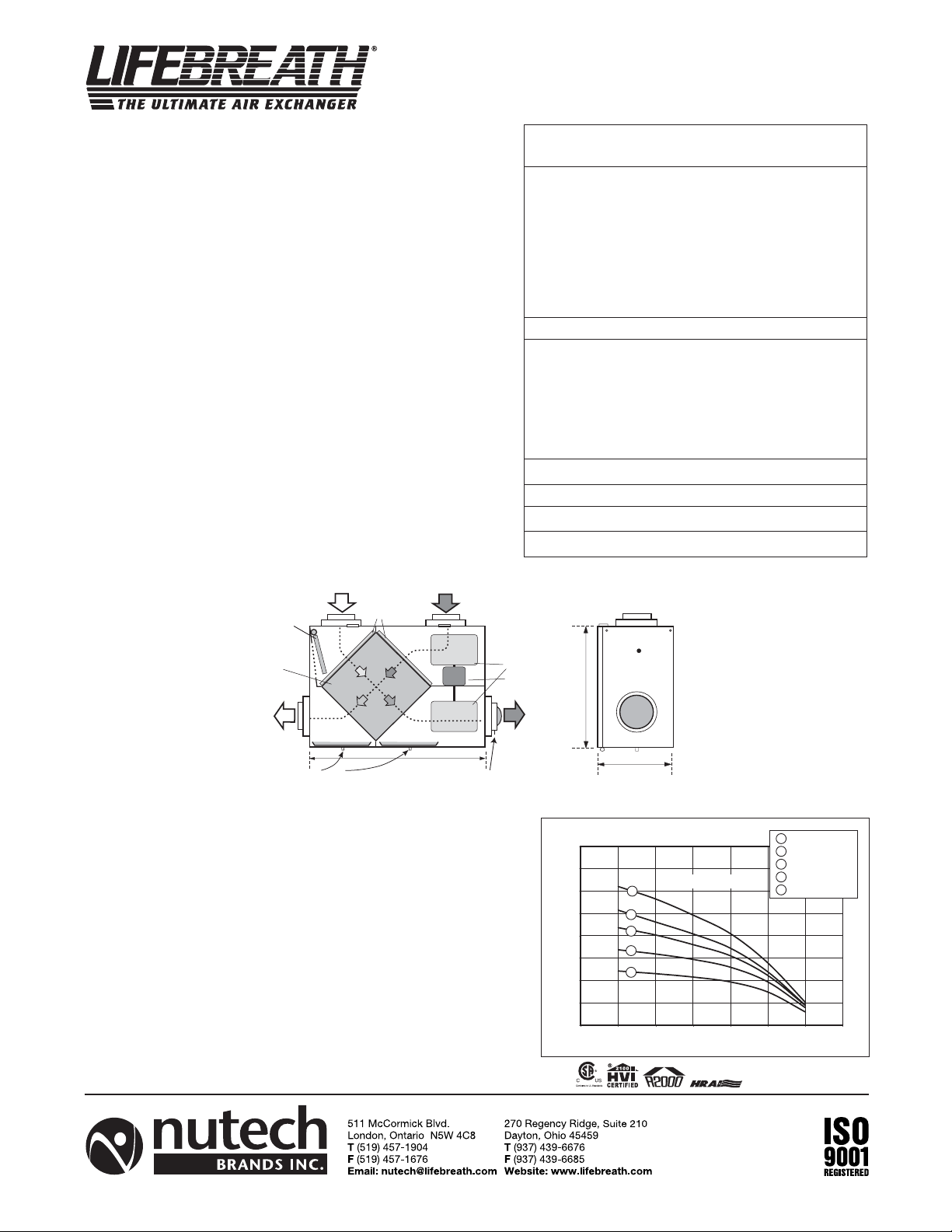

TI-99-NE

0904

Model 200MAX

DIMENSIONS 200MAX inches (mm

)

All units conform to

CSA and UL standards.

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two

airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

Each air stream has one centrifugal blower driven by a common PSC motor.

5 speed fan operation. 120 VAC, 1.4 Amps.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of case designed to accept four reinforced

polyester straps that are supplied with the unit.

DEFROST

Recirculating damper defrost system.

DEHUMIDISTAT

Adjustable Internal Dehumidistat.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated to prevent exterior condensation. Drain connections 2

- 1/2" (12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, Recirculation

mode (on compatible units), (each mode has 5 speeds). Control pad can be

removed from HRV and remotely mounted.

Weight 71 lbs. (32.5 kg) Shipping Weight 73 lbs. (33.5 kg)

FRESH AIR

FROM OUTSIDE

RECIRCULATING

DEFROST

DAMPER

CORE

STALE AIR

TO OUTSIDE

CONDENSATE DRAINS

FILTERS

STALE AIR

FROM INSIDE

33 5/8"

(850mm)

*All Duct Connections 6" (150mm)

BALANCING DAMPER

BLOWERS

MOTOR

FRESH AIR

TO INSIDE

19"

(483)

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

14 3/4"

(375)

200MAX FANCURVE

225

200

175

150

125

100

Air Flow (cfm)

75

50

25

0.3 0.4 0.5 0.6 0.7 0.8 0.9

Manufacturers Data

*

5

4

3

2

1

Static Pressure (inH20)

HIGH SPEED

5

MEDIUM HIGH SPEED

4

MEDIUM SPEED

3

MEDIUM LOW SPEED

2

LOW SPEED

1

*

1.0

10

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept remotely

mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed to accept

remotely mounted Control Pad.

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6”

(150mm)

99-164 Duct Heater w/ Electronic SCR Thermostat, 2 Kw, 6”

(150mm)

99-186 Weatherhoods, Two - 6” (150mm) c/w 1/4” (6mm) mesh screen

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and a 5 year

replacement parts warranty.

PERFORMANCE

HVI CERTIFIED

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 232 (109)

@ 0.2” (50 Pa) 223 (105)

@ 0.3” (75 Pa) 215 (102)

@ 0.4” (100 Pa) 195 (92)

@ 0.5” (125 Pa) 189 (89)

Maximum Temperature Recovery 81%

Sensible Effectiveness

@ 117 cfm (55 L/s)

(CSA C439M) 74%

Sensible Efficiency

@ 117 cfm (55 L/s) 32°F (0°C) 65%

Sensible Efficiency

@ 117 cfm (55 L/s) -13°F (-25°C) 66%

VAC @ 60HZ 120

WATTS / Low speed 87

WATTS / High speed 164

Amp rating 1.4

DIMENSIONS 200MAX RX inches (mm)

All units conform to

CSA and UL standards.

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two

airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

Each air stream has one centrifugal blower driven by a common PSC

motor. 5 speed fan operation. 120 VAC, 1.4 Amps.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of case designed to accept four reinforced

polyester straps that are supplied with the unit.

DEFROST

Recirculating damper defrost system.

DEHUMIDISTAT

Adjustable Internal Dehumidistat.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated to prevent exterior condensation.

Drain connections 2 - 1/2" (12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, Recirculation

mode (on compatible units), (each mode has 5 speeds). Control pad can

be removed from HRV and remotely mounted.

Weight 71 lbs. (32.5 kg) Shipping Weight 73 lbs. (33.5 kg)

1105

Model 200MAX RX

STALE AIR

FROM INSIDE

FILTERS

BLOWERS

MOTOR

FRESH AIR

TO INSIDE

BALANCING DAMPER

33 5/8"

(850mm)

*All Duct Connections 6" (150mm)

FRESH AIR

FROM OUTSIDE

RECIRCULATING

DEFROST

DAMPER

TO OUTSIDE

CONDENSATE DRAINS

CORE

STALE AIR

19"

(483)

14 3/4"

(375)

200MAX FANCURVE

225

200

175

150

125

100

Air Flow (cfm)

75

50

25

0.3 0.4 0.5 0.6 0.7 0.8 0.9

5

4

3

2

1

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

HIGH SPEED

5

MEDIUM HIGH SPEED

4

MEDIUM SPEED

3

MEDIUM LOW SPEED

Manufacturers Data

*

Static Pressure (inH20)

2

LOW SPEED

1

*

1.0

11

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two airstreams.

It is easily removed for cleaning or service.

MOTORS AND BLOWERS

Each air stream has one centrifugal blower driven by a common PSC motor.

5 speed fan operation. 120 VAC, 1.4 Amps.

FILTERS - Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV - Four threaded inserts at corners of case designed to

accept four reinforced polyester straps that are supplied with the unit.

DEFROST

Recirculating damper defrost system.

DEHUMIDISTAT

Adjustable Internal Dehumidistat.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resistance. Insulated to prevent exterior condensation. Drain connections 2 - 1/2"

(12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, Recirculation mode

(on compatible units), (each mode has 5 speeds). Control pad can be removed

from HRV and remotely mounted.

Weight 87 lbs. (39.5 kg) Shipping Weight 89 lbs. (40.5 kg)

PERFORMANCE

HVI CERTIFIED

Net supply airflow in cfm (L/s) against external static pressure

E.S.P cfm L/s

@ 0.1” (25 Pa) 196 (93)

@ 0.2” (50 Pa) 188 (89)

@ 0.3” (75 Pa) 178 (84)

@ 0.4” (100 Pa) 165 (78)

@ 0.5” (125 Pa) 149 (71)

Maximum Temperature Recovery 80%

Sensible Effectiveness

@ 117 cfm (55 L/s )

(CSA C439M)

72%

Sensible Efficiency

@ 117 cfm (55 L/s) 32

O

F (0°C) 64%

Sensible Efficiency

@ 67 cfm (31 L/s) -13

O

F (-25°C)

70%

VAC @ 60HZ 120

WATTS / Low speed 74

WATTS / High speed 164

Amp rating 1.4

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept

remotely mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed to

accept remotely mounted Control Pad

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6”

(150mm)

99-164 Duct Heater w/ Electronic SCR Thermostat, 2 Kw, 6”

(150mm)

99-186 Weatherhoods, Two - 6” (150mm) c/w 1/4” (6mm) mesh

screen

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and a 5

year replacement parts warranty.

TI-100-NE

0904

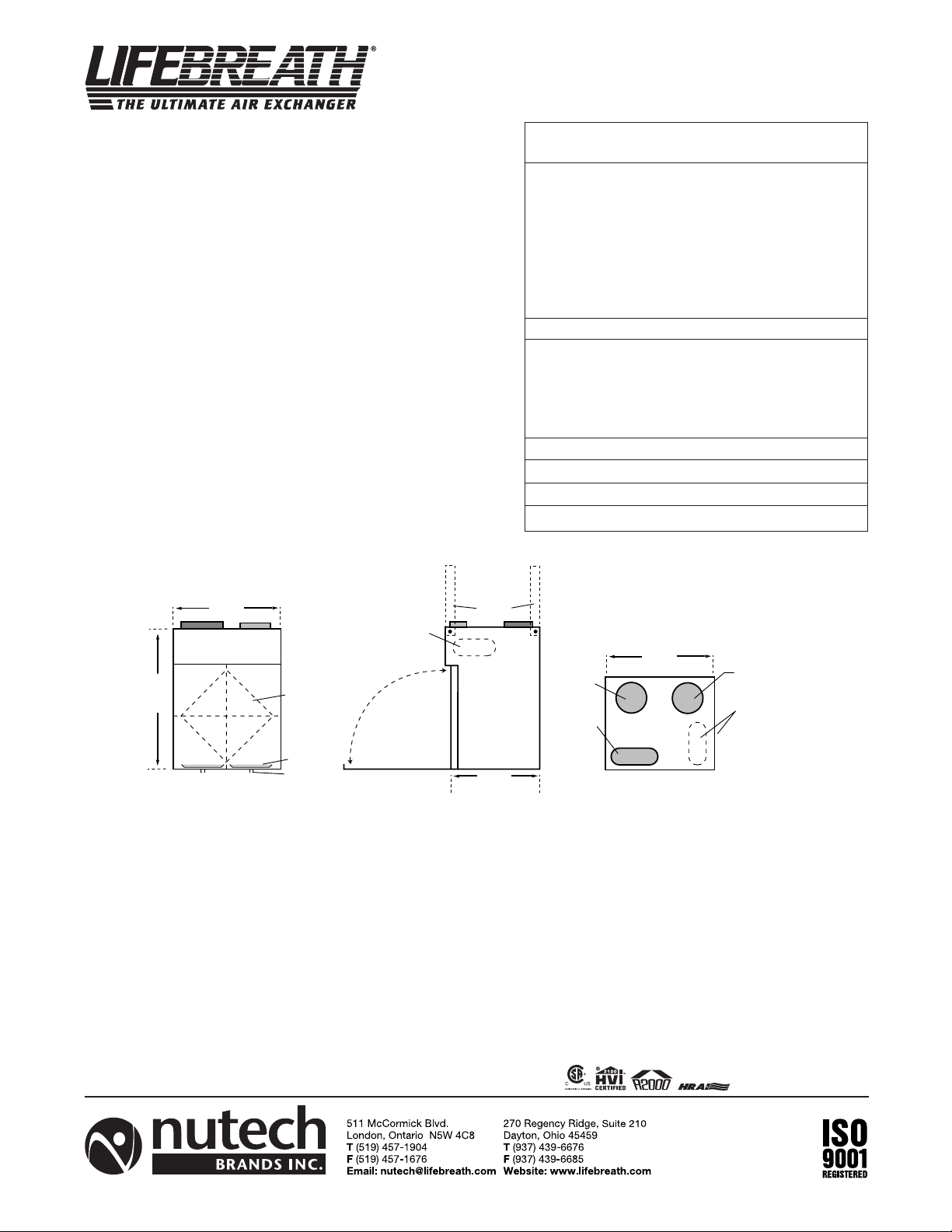

Model MAXTOP

All units conform to

CSA and UL standards.

DIMENSIONS MAXTOP

inches (mm

)

25 1/2 "

(648 mm)

CONTROLS

7 1/2"

(191 mm)

18"

(457 mm)

ALL DUCT CONNECTIONS

ARE 6" (150 mm)

STALE AIR

EXHAUST

SUPPLY OF

FRESH AIR

FRESH AIR

SUPPLY

TO BUILDING

STALE AIR

RETURN FROM

BUILDING

(572 mm)

FRONT VIEW

22 1/2"

DRAIN

CONNECTION

SIDE VIEW

26 1/2"

(673 mm)

*Service Clearance

TOP VIEW

MAXTOP FANCURVE

200

5

175

4

150

3

125

2

100

1

Air Flow (cfm)

75

50

25

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Manufacturers Data

*

Static Pressure (inH20)

25" (635 mm)

5

4

3

2

1

HIGH SPEED

*

MEDIUM HIGH SPEED

MEDIUM SPEED

MEDIUM LOW SPEED

LOW SPEED

Loading...

Loading...