Lifan 620 Maintenance Manual

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

1

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Foreword

LF620 Service Manual on common treatment of troubles is to help you correctly use and maintain

your love sedan.

This manual, with illustrative figures and easy-going words, thoroughly introduces the structure

features, use and maintenance of LF620 sedan, which will be a good guide for wide users and

maintenance technicians. Meanwhile, LF620 Spare Parts List will also be referred if necessary. For

any questions and doubts, please do not hesitate to contact the service stations of Chongqing Lifan

Passenger Vehicle Co., Ltd.

The figures, notes, specifications etc contained in the manual will take effect as of the date of printing,

which can be modified and terminated at any moment by Chongqing Lifan Passenger Vehicle Co., Ltd.

without any notice in advance.

Any comment on any thing improper in the manual shall be preferred, and no responsibility on any

thing improper shall be undertaken by Chongqing Lifan Passenger Vehicle Co., Ltd.

Without a permit from Chongqing Lifan Passenger Vehicle Co., Ltd., any unit or individual shall not be

allowed to duplicate, store, and distribute any part of the manual in any form or by any method.

Great appreciation for your support!

Compiled by: Chai Lichao

Du Tianchuan

October, 2008

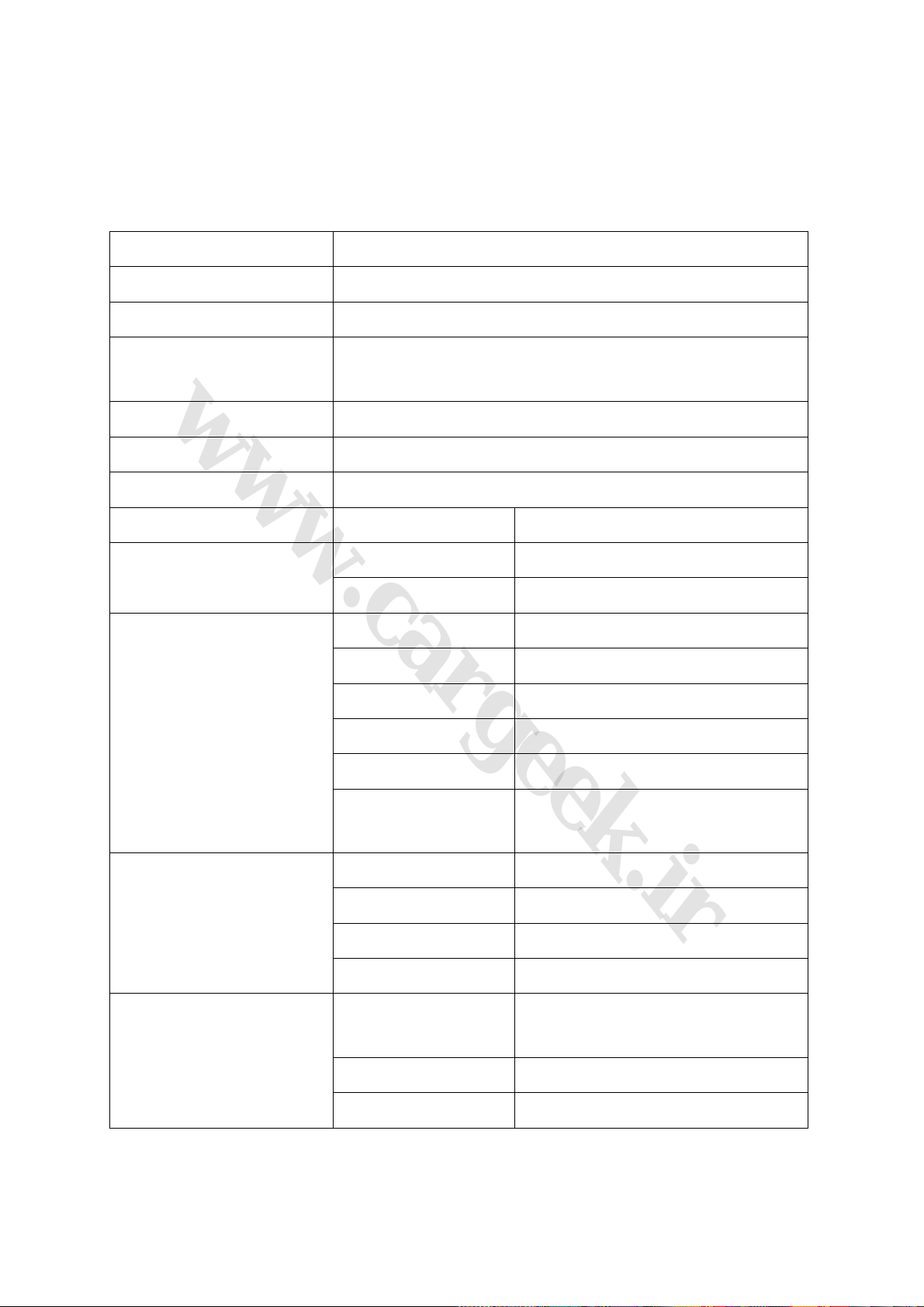

Content

2

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Foreword

Content

Part 1 Introduction

Part 2

Chapter I Electronic Injection System

Section I Introduction

Section II Principle of controlling and actuating components

Section III Steps for Trouble Diagnosis with DTC

Section IV Steps for Trouble Diagnosis Based on Engine Symptom

Section V Security Items for System Maintenance

Chapter II Chassis System

Section I Suspension and Axle

Section II Steering System

System Repair

1

2-3

4-19

20-362

20-102

21-21

22-37

38-65

66-101

102-102

103-158

103-115

116-130

Section III Brake System

Section IV Fuel System

Section V Engine Cooling System

Section VI Intake and Exhaust System

Chapter III ABS System

Section I Function and Composition of ABS

Section II Principle of ABS

Section III Removal and Installation of ABS

Section IV Fault Diagnosis and Troubleshooting

Chapter IV Electrical System

General Rules Trouble Shooting

Section I Instrument Cluster

Section II Power Window

131-151

152-153

154-156

157-158

159-190

159-159

160-162

163-166

167-190

191-269

191-195

196-208

209-215

Section III BCM Central Lock, Burglar Alarm System

3

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

216-229

Section IV Electric Side Mirror

Section V Illumination System

Section VI Wiper and Washer

Section VII Audio System

Section VIII Reverse Radar System

Section IX Power Supply and Other Electrical System

Chapter V Air Bag System

Section I Composition, Principle and Safety Rules for Maintenance

Section II Diagnosis & Fault Clearing

Section III Diagnosis of Vehicles after Collision

Section IV Removal and Installation

Section V Scrapping Tips for Air Bag Mould

Chapter VI A/C System

230-233

234-245

246-253

254-260

261-266

267-269

270-288

270-274

275-282

283-284

285-287

288-288

289-322

Section I Introduction

Section II System Layout

Section III Component Maintenance

Section IV Fault Diagnosis

Section V Precautions of Air Conditioning System

Chapter VII Auxiliary Component System

Section I Cable

Section II Windshield

Section III Safety Belt

Section IV Front Side Door

Section V Rear Side Door

Section VI Seat Assembly

Section VII Inside & Outside Decorations

289-292

293-296

297-309

310-320

321-322

323-357

323-323

324-327

328-329

330-331

332-333

334-341

342-357

Chapter VIII Vehicle Body Dimension

358-362

4

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Part1 Introduction

Chapter I Entire Vehicle Overview

5

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

LF620 sedans are devised to give expression to the human orientation with features of portable

operation, comfortable ride, spacious inner room, excellent dynamic quality and economical

efficiency. The high tech and low price endow them with the stronger market competition.

I. Engine assembly

1. Either the engine of TRITEC1.6L or LF 481Q3 is adopted, which is a single overhead camshaft

multi-point electronic injection engine with 16 valves.

II. Chassis

1. The McPherson independent suspension is applied in the front suspension; and the dependent

trailing arm suspension is adopted by the rear suspension. It also enjoys the design of the elastic

elements and the shock damper of the front and rear suspensions, director elements and stable

ones of the front sub-frame suspension.

2. Steering gear: The steering column employs the angular adjustable mode.

3. Operation system: Clutch pedal mechanism, hydraulic clutch operating device.

4. Both the front and rear brake gears are the vented disc brakes with reasonable load layout and

the Anti-Lock Brake System, namely ABS safety device. It is used to prevent sliding and dragging

on the road due to locked wheel when the vehicle brakes so as to improve the vehicle’s directional

stability, steering control ability and shorten the braking distance so that the braking will be more

efficient and safer. It greatly promotes the safety and reliability of the vehicle in various road

conditions and the reasonable distribution of the front and rear braking force.

5. 195/60R15 tires are used; the tire rim, 6J.

III. Body:

1. An integral body is adopted which has passed the frontal impact test and qualified by the state

testing institutions. Exterior design is fashionable with excellent aerodynamic performance with

streamline figure.

2. The dash board, exterior trims and lighting equipments employ the novel craftworks and

materials.

3. A/C system: It gives full expression to the ergonomic, after the filtration, offering clean and fresh

air evenly and noiselessly.

IV. Electric equipment

The electric equipment design of LF620 sedans absorbs all the electric options so as to meet

diversified customers’ needs.

1. Engine and electronic fan

The engine is equipped with a starter and a generator. Double electronic fans at two

speed-adjusting levels are arranged.

2. Power start, charging systems

The power start system mainly deals with the model and specs size confirmation of the engine,

battery and generator and voltage regulator, etc.

3. Ignition and electronic injection system

6

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

① Ignition switch: Only the mature products can be employed and the corresponding current is set

to satisfy the functional requirement.

② The engine is the mature product of the TRITEC and the electronic injection system adopts the

multi-point electronic injection system supplied and calibrated by the SUN & TECK or the Delphi.

The key components of this type’s system include the sensor, the engine control unit, the air inlet

pressure temperature sensor, the throttle valve assembly, the knock sensor, the oxygen sensor,

camshaft position sensor, crankshaft position sensor, coolant temperature sensor, weak

acceleration sensor, canCV canister control valve, fuel rail assembly, ignition coil, and the catalytic

converter etc.

4. Warning signal

The design for the control of the circuit system has been devised correspondingly to satisfy the

requirement of the entire vehicle and the state legal regulations.

The warning signal devices are used to warn and hint signals to the surrounding environment,

including the horn, steering indicator, emergent lamp switch, reversing lamp and brake lamp and

switches, front and rear fog light and so on.

5. Instrument assembly

1) Instrument cluster: Instrument cluster of the electronic odometer. The instruments include the

water thermometer, engine tachometer, speed odometer and the fuel gauge.

2)Indicators include: The battery charge indicators, engineer oil pressure indicator, brake fluid

level indicator, engine malfunction detecting indicator, handbrake indicator, safety belt indicator,

fuel warning indicator, instrument lighting light, high beam indicator, steering (emergency) light,

ABS indicator, door ajar indicator. Reverse radar display, fuel flow sensor, engine oil pressure

sensor, vehicle speed sensor, handbrake switch, door lamp switch, brake shoe sensor, safety belt

contact switch, brake fluid level sensor, parking brake (handbrake) switch etc.

6. Auxiliary electrical devices

(1) Front windshield wiper system: controlled by a combination switch handle. The wiper motor

and the connecting rod are collocated in front of the dash panel.

(2) Radio: Four speakers with adjustable high pitch function. CD player, DVD player, and backup

monitor are optional.

(3) Audio system

Single disc CD player and optional DVD on the dash board, six speakers with radio reception, disc

playing and time display functions simultaneously. This novel and nice CD, DVD player own six

interfaces respectively so six disc players are acceptable according to the customers’ needs.

(4) Cigarette lighter: one, installed for convenience, collocated according to the formative

necessity.

(5) Rear defrosting: The heating-type glass is employed for the rear window and controlled by the

switch.

(6) Self-closing four-door window functions: four-door collocation, master control at driver side and

independent control for right doors and windows, the operating switch collocated on the door

armrest.

(7) Central lock: for four doors, unified switch. Remote control, mature products selected

according to the body structure and modeling and adoption of the BCM centralized control.

(8) Electronic anti-theft device: Controlled collectively by the BCM so as to realize the function of

electronic anti-theft.

7

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

(9) A/C system: JSS-120 swinging-vane type compressor with delivery capacity 120ml/r and

excellent refrigerating effect, consisted of the condenser, evaporator, thermostat, sensor, pressure

switch and blower, etc.

7. Safe anti-theft device

(1) Air bag: The electric double air bags are located on the steering wheel and the dash board of

the co-driver room respectively.

(2) The ABS safety device of the Anti-Lock Brake System guarantees the safety and reliability of

the vehicle’s brake system.

(3) Anti-theft device (optional)

The anti-theft system is mainly controlled by the body controller BCM, connected to the engine

ECU by a communication link. When the ignition key is plugged in, if the signal detected is correct,

the ignition system will work normally; otherwise, the engine can not work. This is the anti-theft

system in common use.

8. Other electric devices:

The other electrical devices mainly include the harness, center control box, relay, safety lever,

interface, switch, corresponding fixing bracket and the strapping components.

Chapter II Main Technical Parameters of Lifan Vehicles

8

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

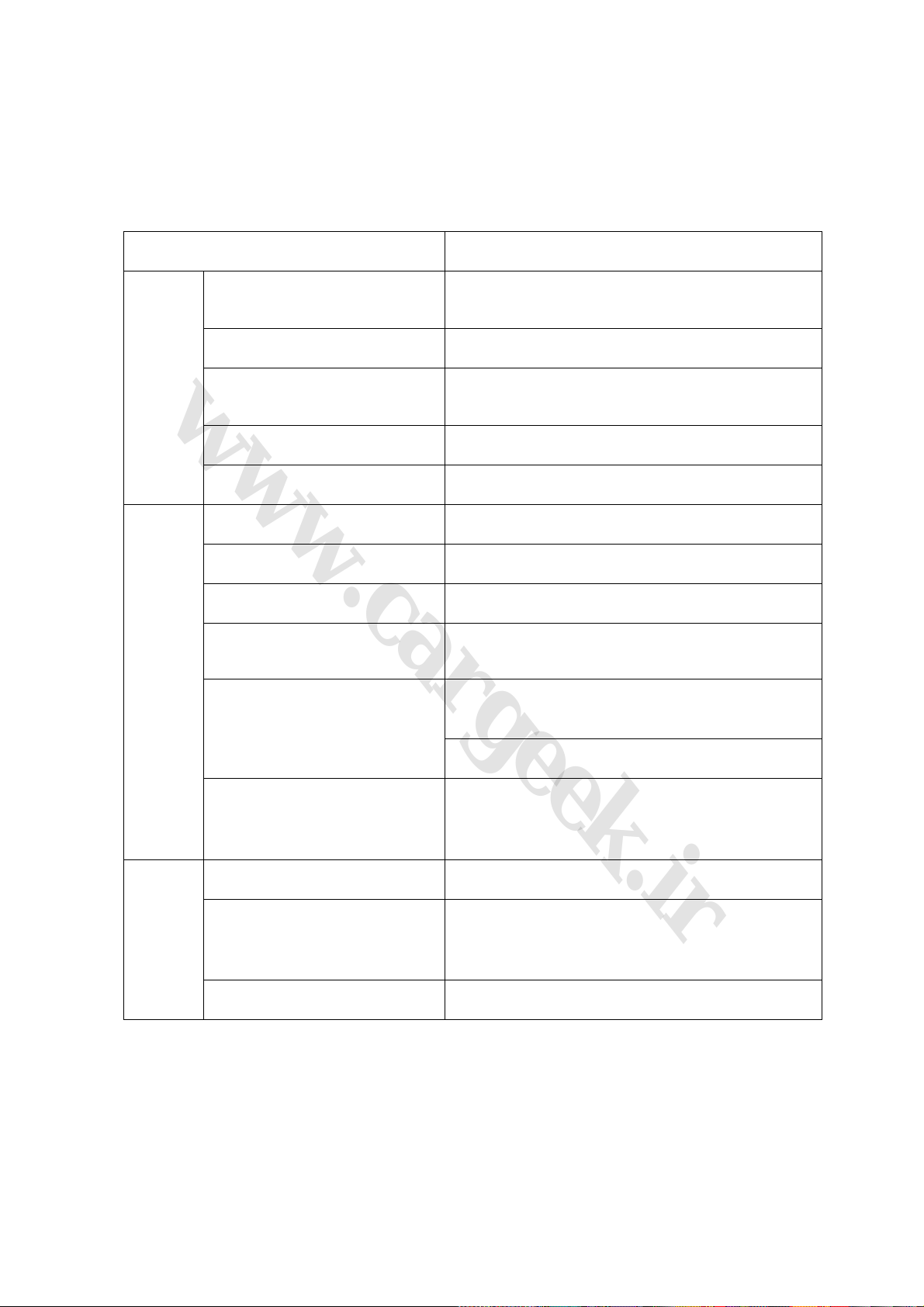

I. Basic performance parameters

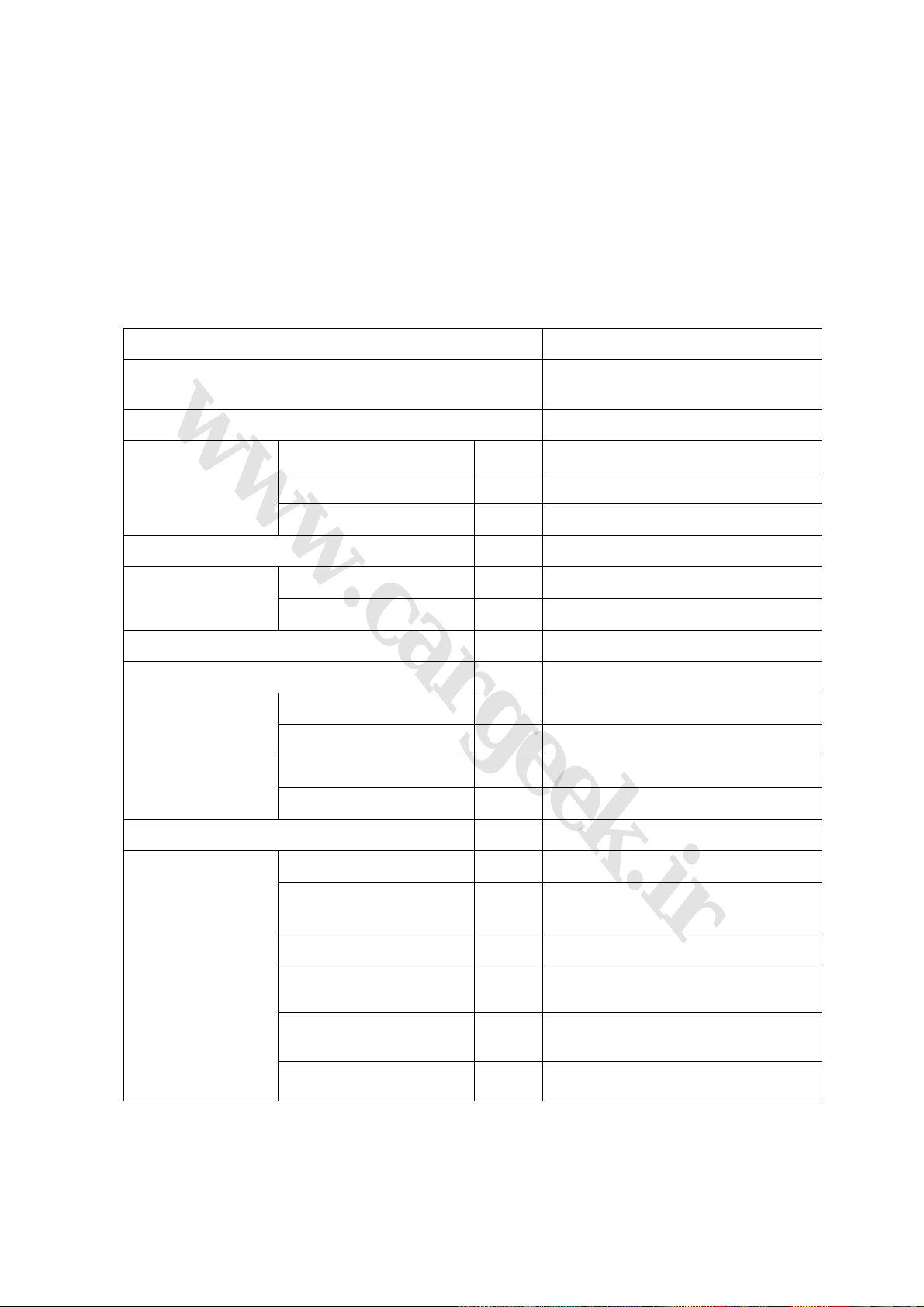

1. Complete vehicle basic parameter (Table 1)

2. Complete vehicle performance index (Table 2)

Table 1 Complete Vehicle Main Parameter

Item LF7162 sedan

Type

Drive model Front lateral engine, front-wheel drive

Length mm 4545

External dimension

Track

Trafficability

characteristic

Width mm 1705

Height (idle load) mm 1495

Wheel base mm 2605

Front track (idle load) mm 1470

Rear track (idle load) mm 1460

Front suspension mm 935

Rear suspension mm 995

Approach angle ( ° ) 20

Departure angle ( ° ) 23

Minimum ground clearance mm 170

Minimum turning radius m 10.2

3 compartments, 4 doors, 5 seats and 2

covers

Mass

Luggage boot capability L ( 300 )

Complete vehicle weight kg 1150

Axle load distribution

(front/rear)

Full load weight kg 1555

Axle load distribution

(front/rear)

Full load distribution

percentage (front/rear)

Mass center height (no/full) mm 593

kg 710/440

kg 810/745

﹪

51/49

9

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

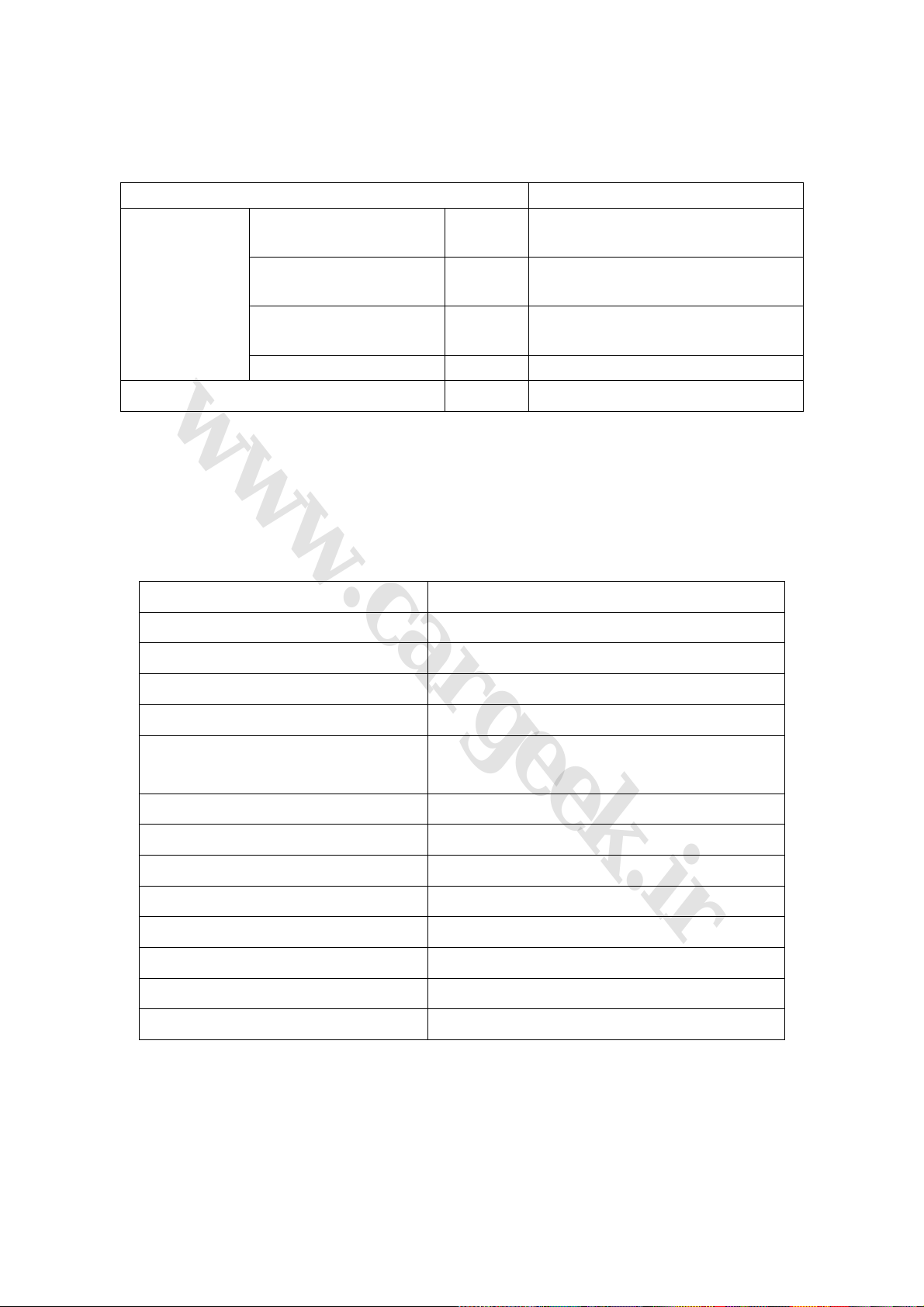

Table 2 Complete Vehicle Performance Parameter

Item LF7160

≥180km/h (BMW 1.6) ≥170km/h

(Domestic vehicle 1.6)

Performance

parameter

Maximum vehicle speed Km/h

Acceleration performance

( 0-100km )

Fuel consumption of uniform

speed traveling

Maximum climbing angle

Number of passengers People 5

s

L/90km 5.64

(﹪)

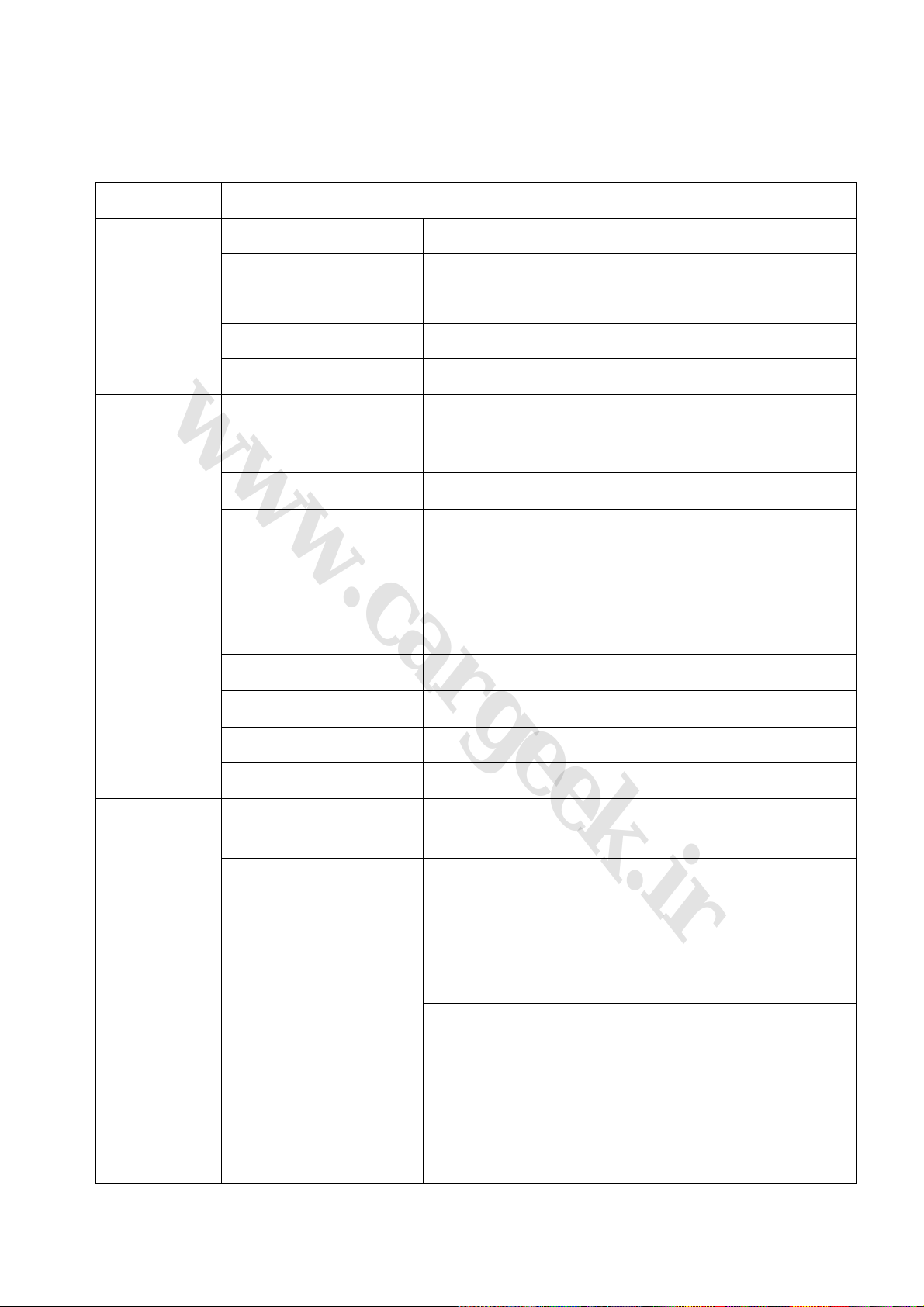

II. Structure and Parameter of Main Assemblies

1. Main technical parameters of engine assembly (Table 3, Table 4)

Table 3 Main Performance Parameter of TRITEC1.6L Engine

<15.5

≥35

Item Parameter

Engine type Four-stroke electronic gasoline injection engine

Delivery capacity 1598cc

Engine model 4 cylinders in line

Camshaft model Single overhead camshaft

Rocker arm model

Combustion chamber Single cylinder 4 valves

cylinder bore ×stroke 77mm×85.8mm

Compression ratio 10.5 : 1

Supply system Multipoint fuel injection system

Maximum torque 157Nm/4550rpm

Maximum power 87Kw/5600rpm

External dimension 440×564×670

Minimum fuel consumption 248g/Kw.h

Rocker arm shaft with midpoint support , 8mm chain

driven by hydraulic force

10

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Table 4 Main Performance Parameter of LF481Q3 Engine

Item Unit Model and parameter

Four-stroke, water cooling, 4 cylinders in line,

Model

Cylinder bore mm 81

Stroke mm 77

Total delivery capacity L 1.6

Compression ratio 9.5:1

Lubricant capacity L 4

Fuel No. 93# unleaded gasoline

Engine oil No. Not lower than SG grade (GB11121-1995)

Starting mode Electric start

16 valves, double overhead camshafts and

multipoint electronic injection

Lubricating mode Pressure and splash combined type

Cooling mode

Rated rotation speed r/min 6000

Rated power Kw 78

Maximum torque ( 3505000_r/min )

Minimum fuel consumption g/kw.h ≤270

Minimum idle load stabilized rotation

speed (idle speed)

Emission limit at idle speed

Ignition advance angle (idle speed) 5±3º

Forced circulating water cooling

N·m /rmp 137N·m / 3500rmp

r/min 800±50

Low idle

speed

High idle

speed

CO≤0.3%, HC≤80ppm

CO≤0.2%, HC≤60ppm

Intake valve clearance (cool)

Exhaust valve clearance (cool)

External

dimension

0.20~0.25

0.25~0.30

mm

Without transmission 650×605×640

With transmission

1010×605×640

11

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

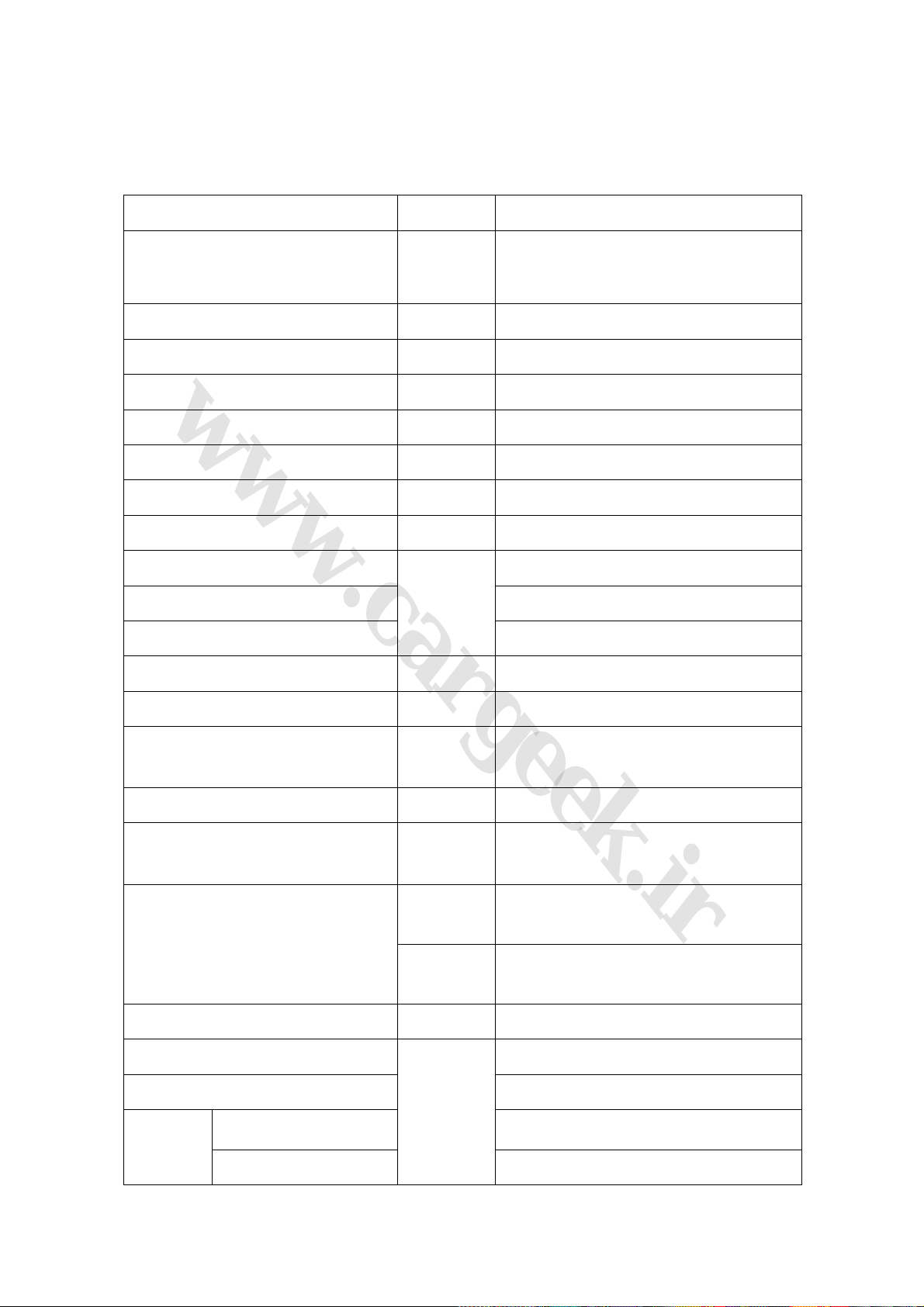

2. Model and parameter of main assemblies of chassis (Table 5)

Table 5 Model and Parameter of Main Assemblies

Name Structure and parameter

Exhaust system Three-way catalytic converter (one section) and muffler (two sections)

Intake system Intake pipeline and air cleaner

Fuel supply system

Cooling system Ribbon-tubular radiator and electronic fan

Clutch pedal force ≤140N

Clutch pedal maximum play ≤100mm

Drive shaft Model Tri-pin sliding bush end, Rzeppa fixing end

Suspension

Tire

Including fuel pump, fuel cleaner, pressure regulator, accelerator pedal,

fuel tank

Front suspension MacPherson independent suspension

Rear suspension dependent suspension with a torsion beam

Tire type Radial ply tire

Tire specification 195/60 R15

Rim specification 6J×15

Tire pressure 2.3MPA

Steering gear model Rack and pinion hydraulic power steering

Wheel alignment

Brake system

Steering equipment

Front wheel camber 0°30′±45′ (idle load)

Front wheel toe-in

Kingpin inclination angle 3º±30′ (idle load)

Kingpin caster 11°15′±45′ (idle load)

Structure model

Driving brake Disc brakes for both front and rear wheels

Parking brake Mechanical cable rear wheel rim brake

Pipe angle can be adjusted, steering wheel

external diameter 375mm

-2~2

Hydraulic dual-pipe, with vacuum booster

and ABS

12

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

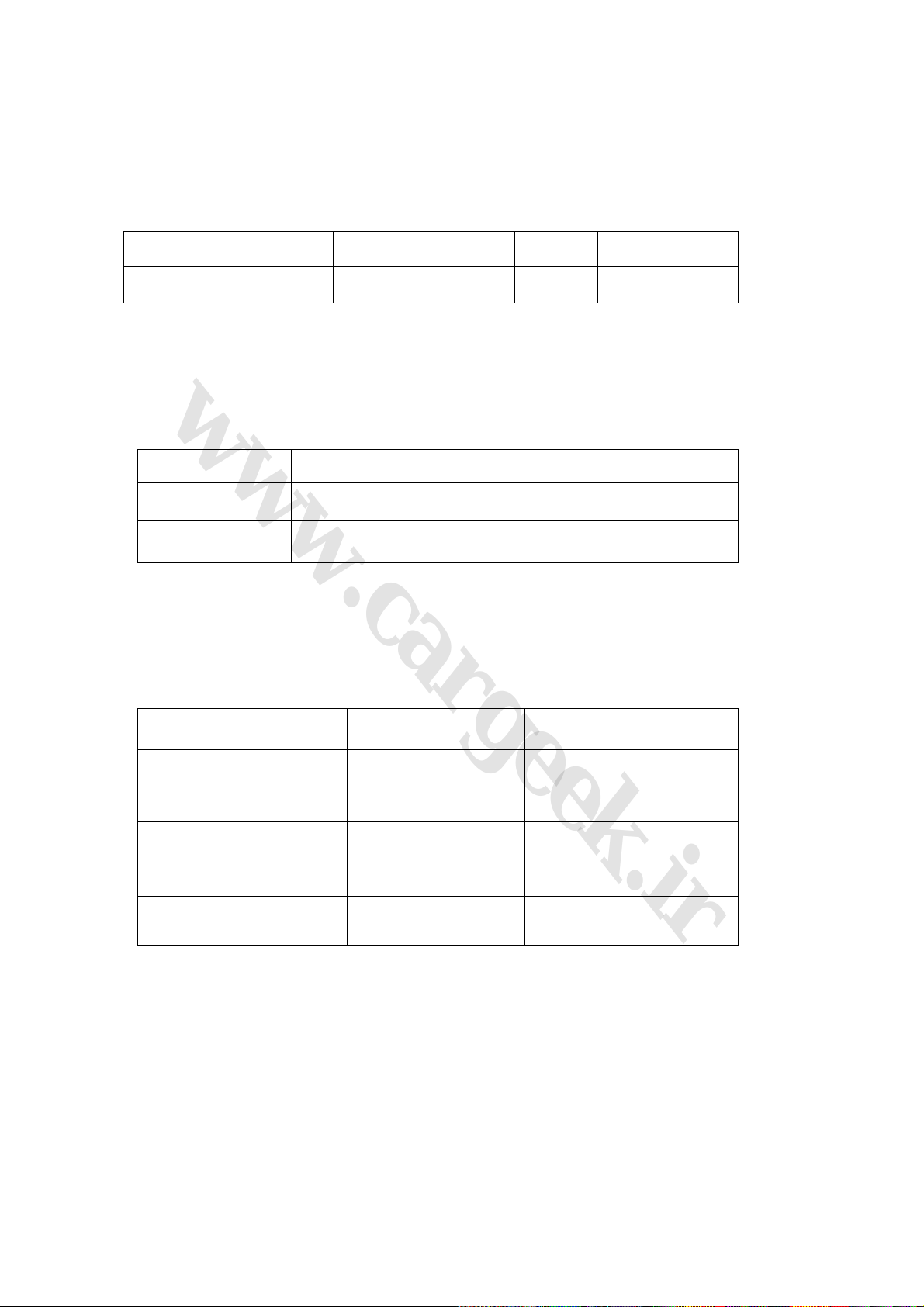

3. Vehicle body structure model and parameter (Table 6)

Table 6 Vehicle Body and Inner and Outer Trim

Name Structure and parameter

Vehicle model

Body-in-white All metal closed type structure

Vehicle

body

Inner and

outer

trims

Door assembly

Engine hood Open backward, bent arm hinge

Front and rear bumpers Injection molding

Inner trim Injection molding with surface texture

Dash board Injection molding with surface texture

A, B and C pillars and indoor shield Injection molding framework, knitted surface

Windshield

Rearview mirror

Integral body, 3 compartments, 4 doors, 2 covers and 5

seats

Framed, 4 doors open in regular direction, card lock, with

side bumper

Front windshield: laminated glass,

rear window: Toughened glass

Outer rearview mirror: Convex mirror in both left and right,

manual/automatic adjustment

Inner rearview mirror: Anti dazzle

Front seat: independent seat, adjustable back and forth

Seat

Structure model Compressive refrigeration, water heating

A/C

Operation

Refrigerant Model R134a, filling 500g ± 50g

position, backrest angle, headrest and so on; rear seat

with safe belt: dependent seat, unadjusted

Adjusted with knob to control air flow direction, to control

and adjust air flow speed, temperature and air circulation;

luxurious ones with electric adjustment

4. Structure and parameter of electrical system (Table 7)

13

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Table 7 Structure and Parameter of Electrical System

Name Structure and parameter

Wire Single wire, negative pole grounded, direct current 12V

Generator Integral type, AC, built-in voltage regulator, specification 14V/80A

Start

Illumination and

signal

Motor solenoid-operated (with generator), power 1.2kw

Electronic fan Without speed regulation single fan

Battery Maintenance-free plumbic acid battery, capacity 60Ah

Headlamp (55/55W, white, 2 lamps),

Front combination lamp

Side steering light 12V, 0.6W, amber, 2 lights

Front and rear fog lights

Rear combination lamp

Rear license plate lamp 5W, white, 2 lamps

High-mounted brake lamp LED, LED, red, 1 lamp

Inner combination roof light 5W, white, 2 lights

position lamp (0.8W, LED, white),

steering light (21W, amber, 2 lights, both combination switch)

Front fog light (55W, white, 2 lights), rear fog light (3W, LED, red,

combination switch), rear position lamp (1W, LED, red)

Brake lamp (1.2W, red, 2 lamps, contact closed switch),

Reversing lamp (21W, white, 2 lamps), steering light (21W, amber,

2 lamps, combination switch), rear position lamp (0.8W, LED, red)

Instrument

system

Electric assistant

system

Door lamp 6.2W, white, 4 lamps

Instrument cluster

Indicator

Instrument cluster with electronic odometer, including LCD water

thermostat, fuel gauge, vehicle odometer, engine rotation speed

Including battery charge indicator, engine oil pressure indicator, fuel

warning indicator, brake fluid level indicator, engine fault indicator,

handbrake indicator, anti-theft indicator, safe belt indicator,

electronic airbag indicator, instrument illumination light, high beam

indicator, fog light indicator, steering light (emergency lamp)

indicator, ABS indicator, door ajar indicator.

Brake indicator, anti-theft indicator, safe belt indicator, electronic

airbag indicator, instrument illumination light, high beam indicator,

fog light indicator, steering light (emergency lamp) indicator, ABS

indicator, door ajar indicator.

Including CD (or DVD) player, cigar lighter, rear defroster, wiper and

washer, remote door lock, anti-theft system, airbag, window

regulator.

5. Lubricant, fuel, steering fluid, brake fluid, coolant, refrigerant and capacity

14

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

(1) Lubricant

Table 8 Lubricant

Lubricant No. Weight

Bearing and button head pin Lithium base grease 7022 0.34kg

(2) Fuel

Table 9 Fuel No. and Fuel Tank Capacity

Name Performance index

Fuel No. 93# or better unleaded gasoline for vehicle

Fuel tank capacity (L) 58L

(3) Steering fluid, brake fluid, coolant and refrigerant

Table 10 Steering Fluid, Brake Fluid, Coolant and Refrigerant

Name No. Capacity or mass

Power steering fluid ESSO ATED 0.825L

Brake fluid DOT4 0.72L

Coolant Antifreeze G11 8.5L

Refrigerant R134a 500g±50g

Windshield cleaning solvent NFC-60 As necessary

Chapter III Lifan Vehicle Maintenance Routine

15

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

LF620 Maintenance Plan can make the vehicle run stably, safely and economically and

reduce faults. Maintenance interval varies according to the odometer or time interval. Please refer

to the plan. Those items that have exceeded the deadline should also be maintained in the same

interval. Rubber hoses (in cooling and heating system, brake system and fuel system) should be

specially maintained. In case of aging, cracking or damage, replace the hose. Only professional

technician can check the vehicle.

Basic maintenance items:

I. Electric equipments on vehicle body

1. Check all the inner and outer lamps and electric equipments: Instrumentation console indicator,

headlamp, front fog light, rear fog light, front position lamp, rear position lamp, front steering light,

rear steering light, brake lamp, reversing lamp, license plate lamp, luggage boot lamp, cigar lighter,

horn, power window regulator, power exterior rearview mirror and ventilation system.

2. Airbag: Visually check if its surface is damaged.

3. Self-check: Read the fault information of all systems in memorizer with Lifan special diagnostic

tools.

II. Outer vehicle body

1. Door limiter, fixed pin, door lock, engine hood, luggage boot cover hinge and buckle: Check the

function and lubricate.

2. Window: Check the function; clean the lead rail and smear special grease.

3. Wiper/cleaning equipment: Adding washing liquid; adjust the nozzle if necessary when checking

the function.

III. Engine compartment

1. Visually check if there is damage or leak for all parts.

2. Cooling system: Check the antifreeze and refill if necessary. Standard value: -25 (℃ -35℃ in

cold area)

3. Power steering system: Check if there is any leak; check the steering hydraulic oil level; and

refill if necessary.

4. Brake system: Check if there is any leak in brake pipeline; check the brake fluid level; and refill if

necessary.

5. Replace brake fluid: Every other 2 years or every 50,000km.

6. Air cleaner: Clean the filter element every 7,500km and replace the filter element every

30,000km.

7. Engine cleaner: Replace the element every 7,500km.

8. Gasoline filter: Replace it every 30,000km.

9. Battery: Check if the positive and negative poles of the battery are tightly connected; check the

electric eye.

IV. Engine and vehicle body bottom

16

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

1. Vehicle body bottom: Check if the fuel pipe, brake oil pipe and bottom protection layer are

damaged; check if the exhaust pipe leaks and if fastening is reliable.

2. Steering tie rod: Check the clearance; check if the connection is reliable and if dustproof cover

is damaged.

3. Brake lining: Check the thickness.

4. Parking brake: Check and adjust the length of cable if necessary.

5. Tire (including spare tire): Check the worn condition of tire; check the tire pressure.

6. Wheel alignment: Check with wheel aligner.

7. Wheel fixing bolt: Check according to specified torque.

8. Headlamp: Check and a.

9. Trial run: Check the performance.

Abbreviations in this manual

A

AC Alternating current

ACC Air conditioning clutch

ACMC Air conditioning magnetic clutch

ACT Air charge temperature

A/C Air conditioning

ABDC After bottom dead center

ABS Anti-lock brake system

A/D Aanalog/digit

A/F

AFS

A-ELR

ATDC After top dead center

API American Petrol Institude

ATF Automatic transmission fluid

Air/fuel ratio

Air flow meter (air flow sensor)

Automatic/emergency locking retractor (of safety belt)

ALR Automatic locking retractor (of safety belt)

ASD Automatic switching-over device

A/T Automatic transmission

B

BATT Battery

B+

BBDC Before bottom dead center

Battery positive pole

BOO Brake on-off

17

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

BTDS Before top dead center

C

CAB ABS control unit with electromagnetic coil

CANP

CMP Sensor Camshaft position sensor (crankshaft turning angle sensor)

CO Carbon monoxide

CKT Circuit

CPP Switch Clutch pedal position switch (clutch switch)

CPS Crankshaft position sensor

CPU Central processing unit

CVT Continuously variable transmission

CRS Child restraint system

CTS Coolant temperature sensor

D

DC

Canister Purge exhaust valve

Direct current

DLC Digit link connector (series data link)

DOHC Double overhead camshaft engine

DOJ Double offset joint

DRL Daytime running light

DTC Diagnostic trouble code, diagnostic code

DS Detonation sensor

E

ECA Electronic control assembly

EBCM Electronic control module (anti-lock brake module)

ECM Engine control module

ECT Engine coolant temperature

ECT Sensor

EFE Heater Early fuel evaporation heater

EFI Electronic fuel injection

Engine coolant temperature sensor

EGR Exhaust gas recirculation

EGRT Sensor EGR temperature sensor

EMI Electro magnetic interference

ELR Emergency locking retractor

18

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

EPS Electric power steering

EST Electronic spark timing

EVAP Evaporative system

EVAP Canister Evaporative system canister

F

FP Fuel pump

FPC Fuel pump control ECU

G

GEN Engine

GND Grounding

H

HC Hydrocarbon

HO2S Heated oxygen sensor

HUC Hydraulic unit control with solenoid valve

I

IAC Valve Idle air control valve

IAT Sensor Intake air temperature sensor

ICM Ignition Control Module

ICU Integrated control unit, composed of four parts

IG

In

ISC Actuator

L

L

LH

LSPV

M

Max

MAF Sensor

MAP Sensor

MFI

Ignition

Inch

Idle speed control actuator

Left

Left hand

Load sensor proportion valve

Maximum

Mass air flow sensor

Manifold absolute pressure sensor

Multipoint fuel injection

Min

19

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Minimum

MIL

M/T

N

N

Ne

NOx

O

OBD

O/D

OHC

P

P

PCM

Malfunction indicator light, engine check light

Manual transmission

Neutral

Engine rotation speed, engine efficient power

Nitrogen oxides

On-board diagnostics

Over-speed driving

Overhead camshaft

Parking

Power control module

PCV

PDC

PIM

PNP

P/N

PSPS

P/S

PSP Switch

PSW

PWR

R

R

RAM

RH

Positive crankcase vent

Power distribution control

Pressure of intake manifold

Park/neutral position

Park/neutral

Power steering pressure switch

Power steering

Power steering pressure switch

Position of throttle wide-open

Power

Right

Random memorizer

Right hand

20

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Part II System Repair

Chapter I Electronic Injection System

21

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Section I Introduction

I. Fundamentals

The electronic injection system is a multi-point fuel injection system with electronic control unit

(ECU). With various sensors installed on different parts of the engine to measure each working

parameter of the engine, the ECU can precisely control the fuel injection volume by controlling the

fuel injector according to the pre-set control program in the computer, and achieve the most

favorable air-fuel mixture for the engine under any working condition. With the control program in

the ECU and relevant actuator, such functions as fuel increase at start, fuel increase at warm-up,

fuel increase at acceleration, fuel increase at full load, fuel decrease at deceleration, fuel cut at

idle speed, and automatic idle speed control are available in this system, which can achieve

special air-fuel mixture for the engine under the special working condition. Therefore, the engine

enjoys good performances in fuel efficiency and exhaust emission, and the service performance of

the vehicle is improved at the same time. Besides, the trouble diagnostic mode in the ECU can

make the researching of troubles much easier.

II. Structure of electronic control system

The electronic control system is divided into the following three parts:

(1) Sensor---Convert various non-electrics physical quantities of the engine into electrics physical

quantities, and then send them to the ECU. The sensors on the engine include: ① Intake

pressure/temperature sensor, ② Throttle position sensor, ③ Coolant temperature sensor, ④

Heated oxygen sensor (front and rear oxygen sensor, only front oxygen senor available under

National III Emission Standard, front and rear oxygen sensor available under National III Emission

Standard+EOBD and in National IV Emission Standard), ⑤ Knock sensor, ⑥ Crankshaft position

sensor, ⑦ Weak acceleration sensor (unavailable under National III Emission Standard

(Simplified), available under National III Emission Standard +EOBD and under National IV

Emission Standard).

(2) Electronic control unit (ECU) is the “brain” for the whole electronic control system, which

analyses and processes all the information from sensors, sends orders to actuator, and makes the

engine work under the best condition.

(3) Actuator is to perform the orders from the ECU. The actuator is the “hand” and “leg” of the

electronic control system, which include: ① Fuel pump, ② Fuel injector, ③ Ignition coil, ④ Idle

speed actuator with stepper motor, ⑤ Canister control valve.

Section II Principle of controlling and actuating components

22

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

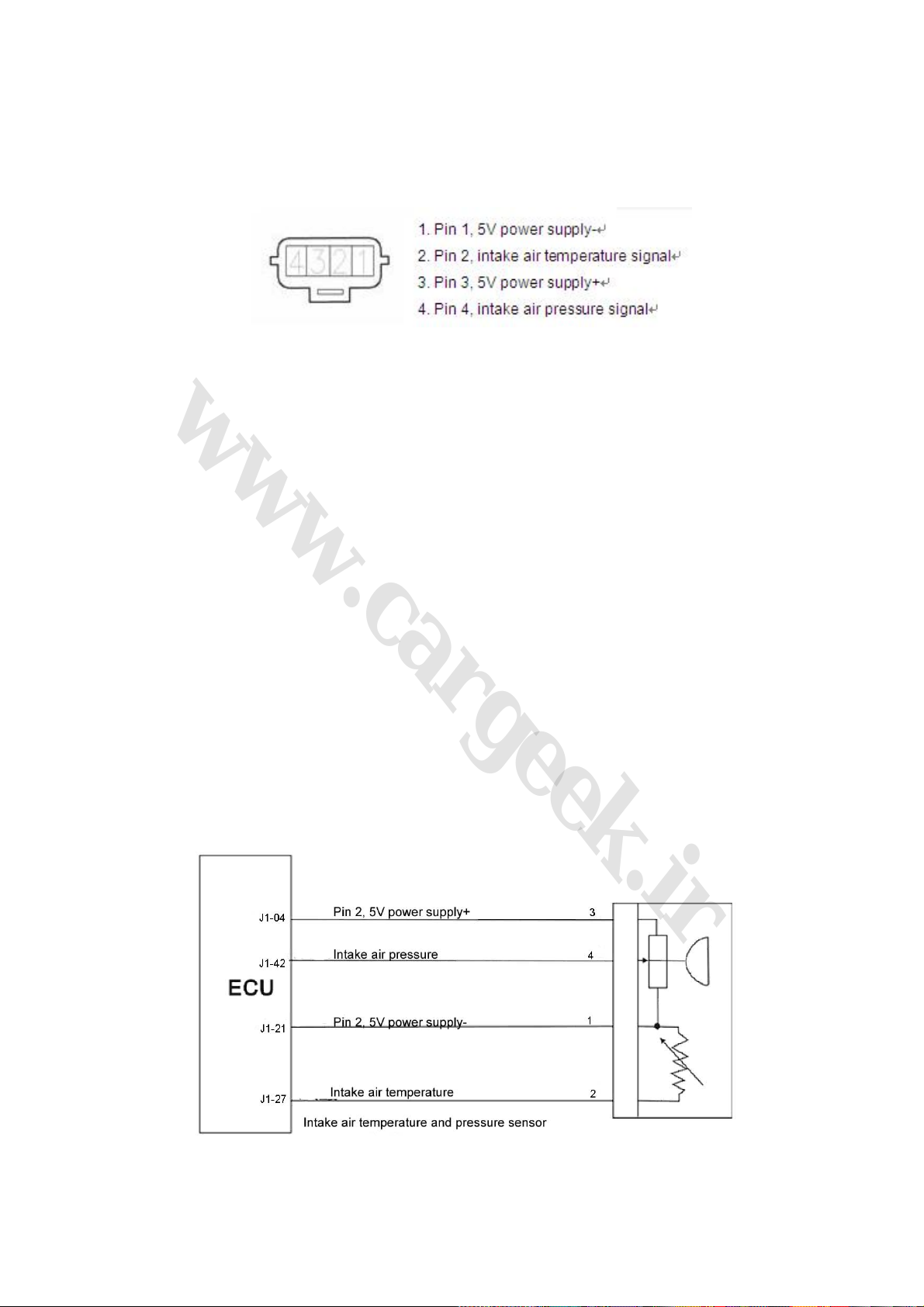

1. Intake pressure/temperature sensor (Fig. 1-1)

Fig. 1-1

(1) Function: Measure the absolute pressure of the 0.1~0.2bar intake manifold and the

temperature of the intake air flow, and provide load information for the engine.

(2) Structure and principle: The sensor consists of intake manifold absolute pressure sensor and

intake air temperature sensor, which is installed on the pressurizer tank.

(3) Intake air pressure sensor: made by a silicon chip. There is a pressure diaphragm on the

silicon chip and are 4 piezoelectric resistances on the diaphragm. The 4 piezoelectric resistances

build up a wheatstone bridge. Besides the pressure diaphragm, there is also a signal process

circuit on the chip. The silicon chip and a metal housing build up a closed referential space, in

which the absolute pressure of the air is approximately zero. Then, a microelectronic mechanical

system is established. There is a zero pressure on the active side of the silicon chip and an

absolute pressure of the intake manifold on the back side of the chip. The thickness of the silicon

chip is only several microns (μm), and the form of the chip will be mechanically changed with the

change of the absolute pressure of the intake manifold. Then, the 4 piezoelectric resistances and

their resistance values will be also changed. After treated by the signal process circuit on the chip,

the pressure signal, which is linearly related to pressure, will be formed.

(4) Intake air temperature sensor: Made by a resistance with negative temperature coefficient

(NTC). Similar to water temperature sensor, the resistance value will decrease with the increase of

the intake air temperature. The change of the intake air temperature will be supervised and

measured by a comparative electric circuit within the ECU.

(5) Connection of wiring diagram (Fig. 1-2)

Fig. 1-2

(6) Trouble diagnosis: The electronic devices of the intake air pressure sensor can diagnose

23

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

such troubles as open/short circuit and the damage of senor. When the ECU detects that the

signal output by the sensor is beyond its normal signal curve, the sensor will be in trouble. For

example, when the intake air pressure is higher or lower than its limit, the ECU will confirm that the

sensor is in trouble (The pressure lower than the limit at start will be excluded by the ECU.), then

the engine MIL will be lighted and the operation under trouble mode will be applied.

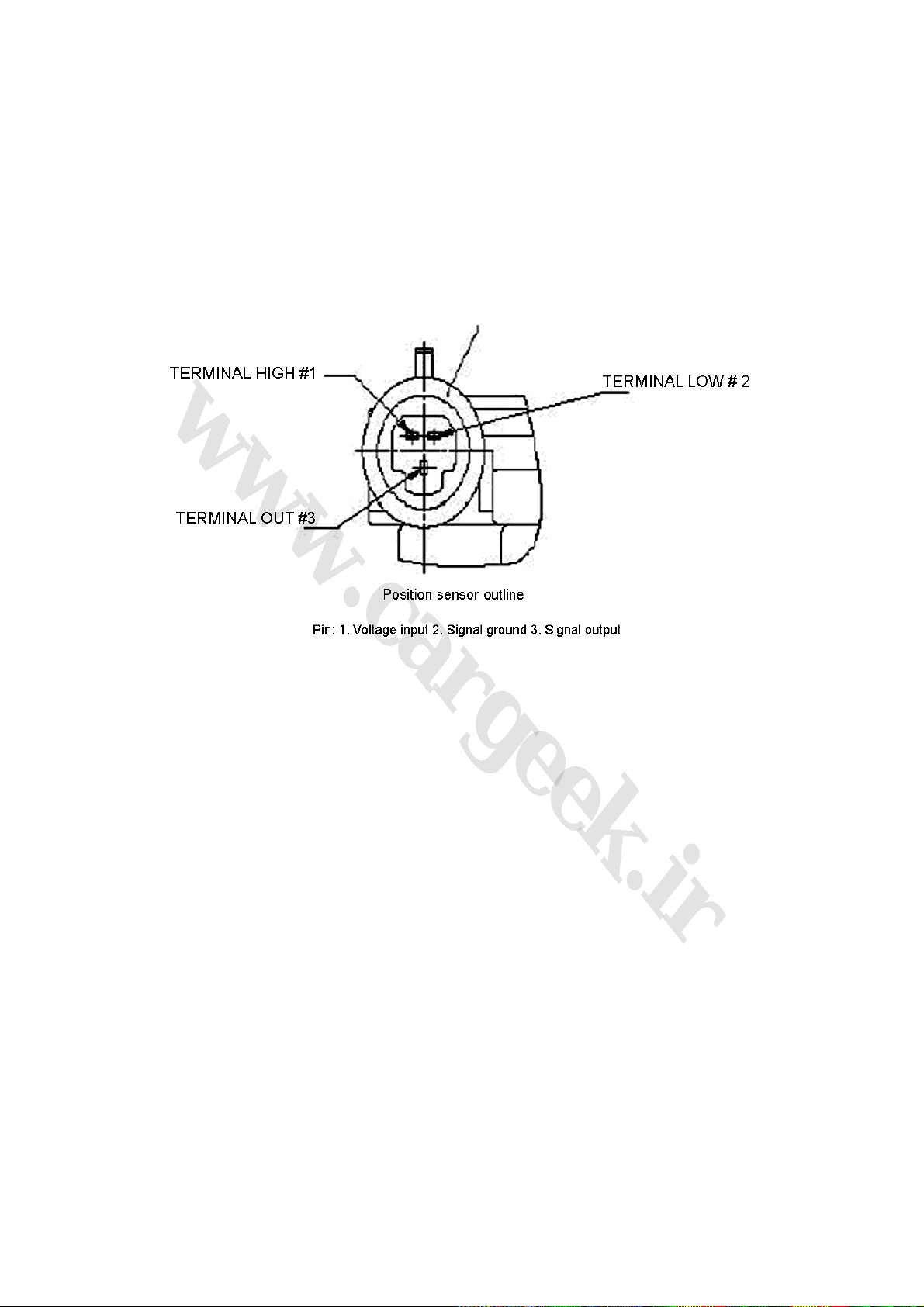

2. Throttle position sensor figure (Fig. 1-3)

Fig. 1-3

(1) Function: To provide throttle-alternator position information to the ECU. According to this

information, the ECU can obtain other information on engine load, working condition (start, idle

speed, backing, partial load, and full load), acceleration and deceleration. With the three-wire

sensor, the ECU can detect the opening of throttle through the change of pressure.

(2) Structure and principle: As an angle sensor with linear output, the sensor is made by two arc

sliding contact resistances and two sliding contact arms. The turning shaft of the sliding contact

arm shares the same axis with the throttle shaft. Power supply voltage (US) of 5V is added to the

both ends of the sliding contact resistance. When the throttle turns, the arm turns and moves on

the sliding contact resistance. Then, the electric potential (UP) at the contact point will be led out

as an output voltage. Actually, it is an angle sensor and the real value adopted by the ECU is the

value of Up/Us, and the value fluctuation of the sensor caused by the fluctuation of the generator

voltage will be avoided.

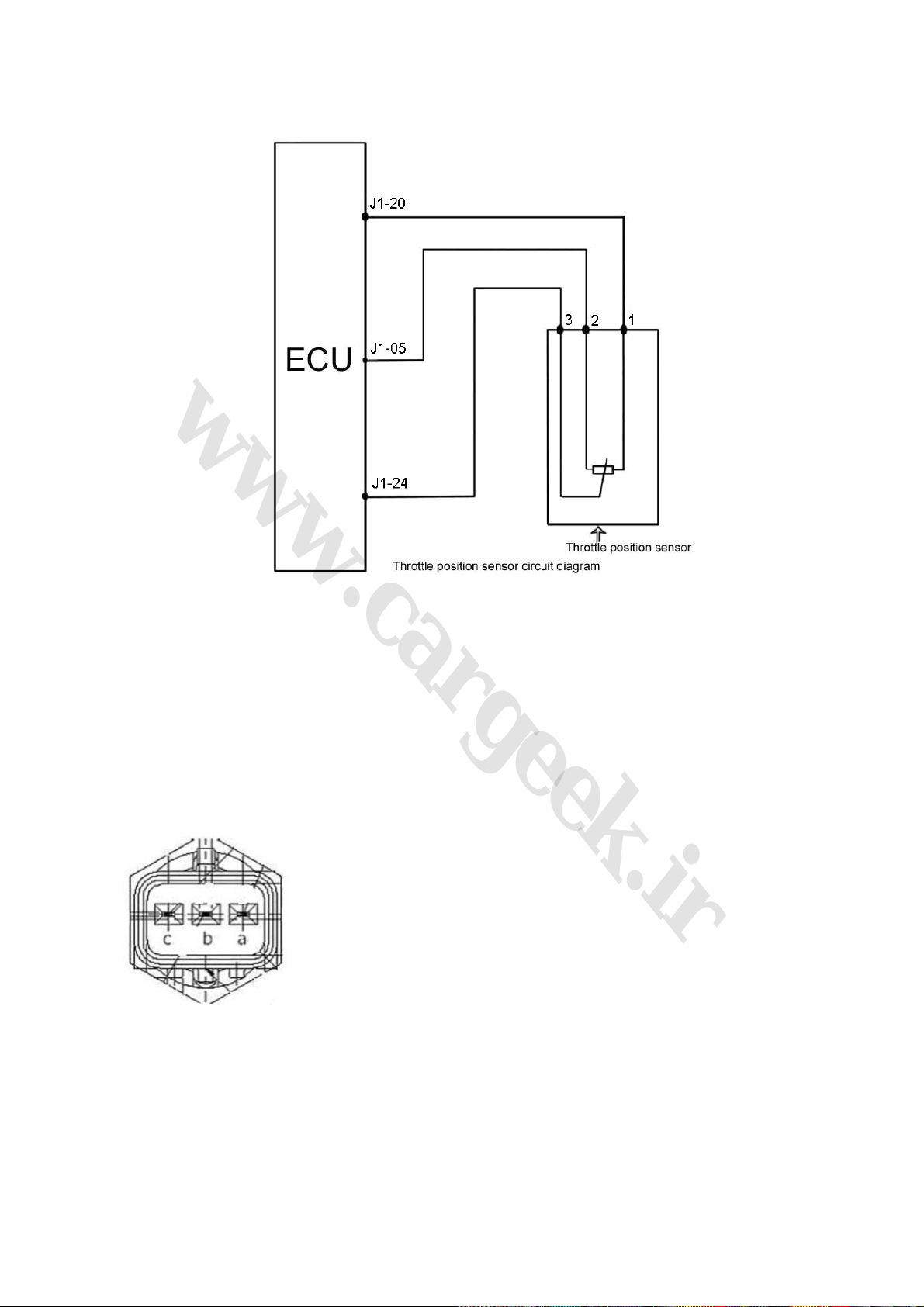

(3) Connection of wiring diagram (Fig. 1-4)

24

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Fig. 1-4

(4) Trouble diagnosis: By monitoring the throttle-alternator position, when the signal higher or

lower than its limit, the ECU will confirm that the throttle position sensor is in trouble, then the

engine operation under trouble mode will be applied, and the engine MIL will be lighted (Knock on

sensor and internal dirt will contribute to engine troubles.)

(5) Installation: Fastening torque for installation screw is 1.5N·m~2.5N·m.

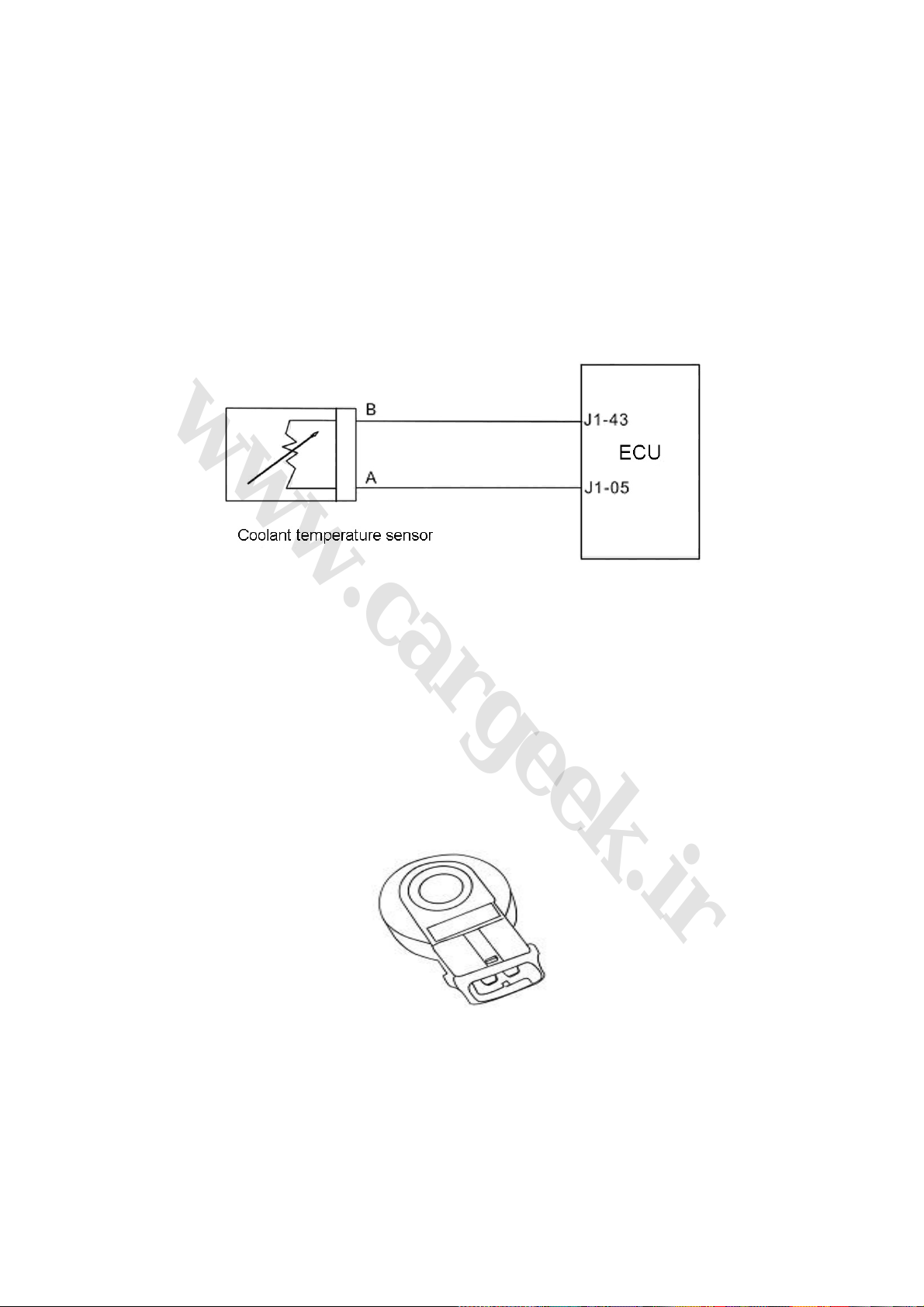

3. Coolant temperature sensor

Coolant temperature sensor

Pin: 3 pins available, equivalent.

a Electronic injection system water temperature signal pin, resistance at 20 : 2.45KΩ℃

b Instrument water temperature pin, resistance at 80 , 0.05 KΩ℃

c Signal ground

Fig. 1-5

(Fig. 1-5)

(1) Function: To provide information on coolant temperature. To provide water temperature signal

25

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

for the ECU, and to control ignition timing and fuel injection pulse width at start, idle speed, and

normal operation.

(2) Structure and principle: Made by a thermistance with NTC. The resistance value will

decrease with the increase of the coolant temperature (not a linear relation). The thermistance

with NTC is installed within a copper sleeve. With a voltage division circuit, the resistance value of

the thermistance is converted into a changing voltage and then provided to the ECU, and then the

change of water temperature can be monitored (internal structure of ECU).

(3) Connection of wiring diagram (Fig. 1-6)

Fig. 1-6

(4) Trouble diagnosis: When the coolant temperature is higher than its upper limit, or lower than

its bottom limit, the engine MIL will be lighted and the engine operation under trouble mode will be

applied. Then, the ECU will carry out the ignition and fuel injection control as per the water

temperature set under the engine water temperature trouble mode, and make the fan run at a high

speed at the same time.

(5) Limit data: 2.5±5%KΩ

(6) Installation note: Tightening torque is 15±2N·m.

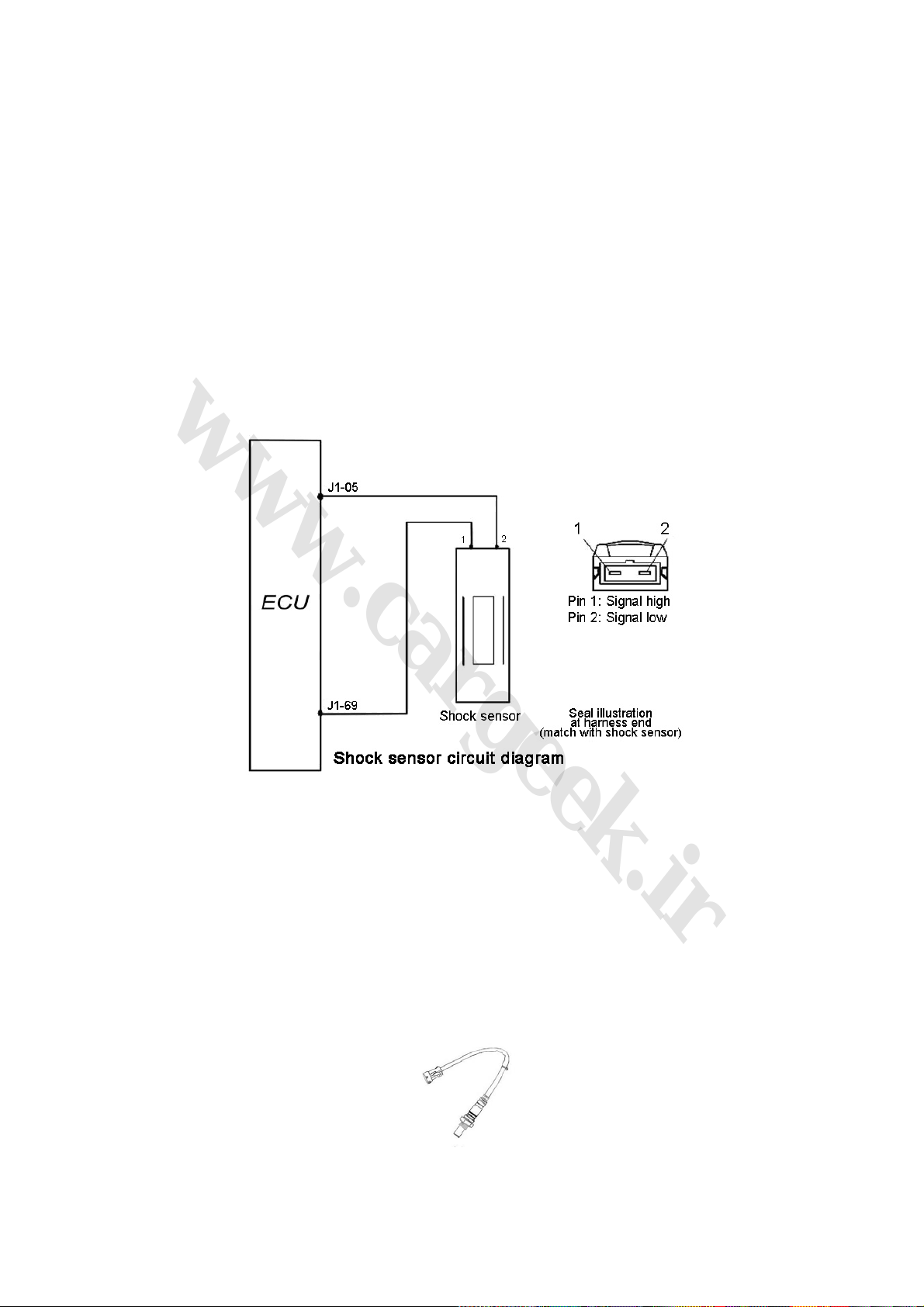

4. Shock sensor Fig. KS1-7

(1) Function: To provide engine knock information for the ECU for knock control.

(2) Structure and principle: As a vibration acceleration sensor, installed on the cylinder block of

the engine. The sense element of the sensor is a piezoelectric element. The vibration of the

cylinder block of the engine can be transferred to the piezoelectric crystal through the mass block

within the sensor. Under the mass block vibration pressure, voltage will be produced at the two

KS1-7

polars of the piezoelectric crystal, and the the vibration signal will be changed into alternately

26

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

changing voltage signal and be put out. Since the frequency of the vibration signal caused by the

engine knock is much higher than that of the vibration signal caused by normal engine shock, the

ECU can tell knock signal or non-knock signal after processing the signal with wave filtering

technology. When the load, rotation speed, and coolant temperature exceed the threshold value

and no trouble information record is available for the shock sensor, the signal of the shock sensor

will be used for shock closed loop control. When the shock closed loop control is activated, the

signal of the shock sensor will be sent to the ECU for amplification and wave filtering, and then

accumulated. If the accumulation exceeds the limit within a certain crank angle, the ECU will

confirm that shock occurs and decrease the ignition advance angle at this moment. If shock still

occurs at the next cycle, the ECU will further decrease the ignition advance angle. If no shock

occurs at the following cycles, the ECU will recover the original normal ignition advance angle.

(3) Connection of wiring diagram (Fig. 1-7)

Fig. 1-7

(4) Trouble diagnosis: The ECU will monitor the sensors, actuators, power amplifying circuit and

detecting circuit. In case of any of the following situations, like shock sensor trouble, shock control

data process circuit trouble, unreliable cylinder judgement signal, incorrect shock sensor trouble

mark level, and shock closed loop control closed, the ignition advance angle stored in the ECU will

be decreased for a safety angle. When the trouble frequency is lower than the set value, the

trouble mark level will be repositioned.

(5) Installation notes: The tightening torque for installation is 20±5N·m.

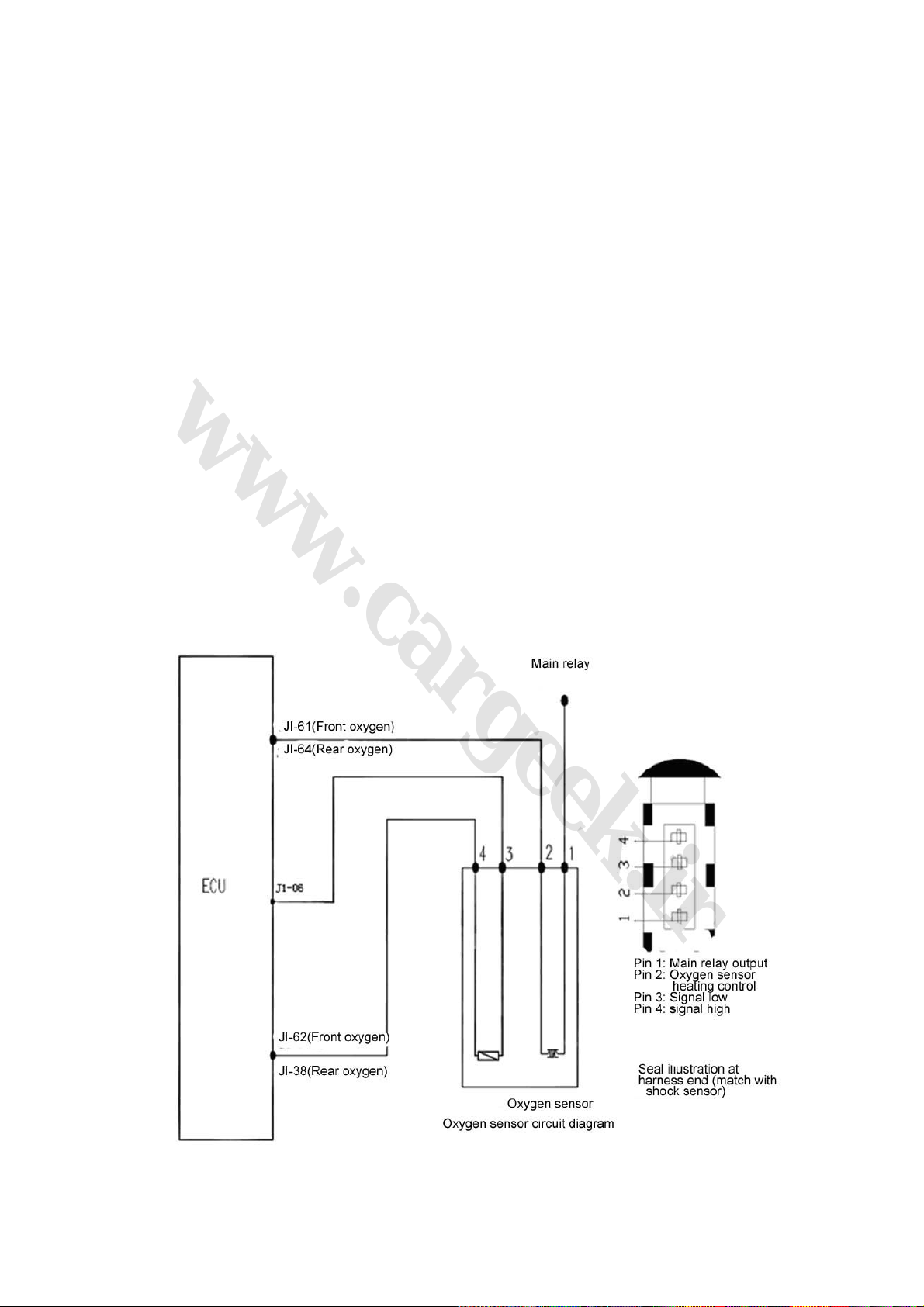

5. Oxygen sensor (Fig. 1-8)

Fig. 1-8

(1) Function: To provide the information that whether oxygen in the cylinder is too high after the

27

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

fuel is burned with the air in the cylinder. With this information, the ECU can carry out closed loop

control for the fuel ration. Therefore, the three main toxic elements (HC, CO, and NOX) of the

engine exhaust can be best converted and purified in the three-way catalytic converter.

(2) Structure and principle: The sense element of the oxygen sensor is a ceramic pipe with holes

and gaps. The pipe is surrounded by engine exhaust and the air flows within the pipe. The ceramic

pipe wall is a kind of solid electrolyte with electric heating tube inside, which begins work when the

ceramic pipe has been heated to 300℃ (a feature of a solid electrolyte). With such a special

material, the oxygen ions can freely go through the ceramic pipe. Then, the concentration

difference of the mixture will be converted into potential difference, which will be put out in the form

of electric signal. If the concentration of the mixture is relatively high, the concentration difference

of the oxygen ions inside and outside the ceramic pipe will be relatively high, and the potential

difference will be relatively high as well. At the same time, a lot of oxygen ions will move to the

outside from the inside, and the voltage output will be relatively high. If the concentration of the

mixture is relatively low, the concentration difference of the oxygen ions inside and outside the

ceramic pipe will be relatively low, and the potential difference will be relatively low as well. At the

same time, little oxygen ions will move to the outside from the inside, and the voltage output will be

relatively low. The working voltage of the oxygen sensor fluctuates from 0.1V to 0.9V, which will be

changed for 5-8 times within 10 seconds. In case of lower than the changing frequency, the

oxygen sensor shall be renewed, as it can not be repaired.

(3) Connection of wiring diagram: See oxygen sensor circuit diagram (Fig. 1-9)

Fig. 1-9

(4) Trouble diagnosis: The ECU will monitor the sensors, actuators, power amplifying circuit and

28

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

detecting circuit. In case of any of the following situations, like unreliable battery voltage,

unreliable air intake manifold absolute pressure singal, unreliable engine coolant temperature

signal, fuel injector driving stage trouble, incorrect oxygen sensor trouble mark level, and fuel

ration closed loop control closed, the fuel ration will be confirmed according to the basic fuel

injection time stored in the ECU.

(5) Installation notes: The tightening torque of the oxygen sensor is 50~60N·m. Apply anti-rust

oil to the renewed oxygen sensor to prevent difficult removal due to rust.

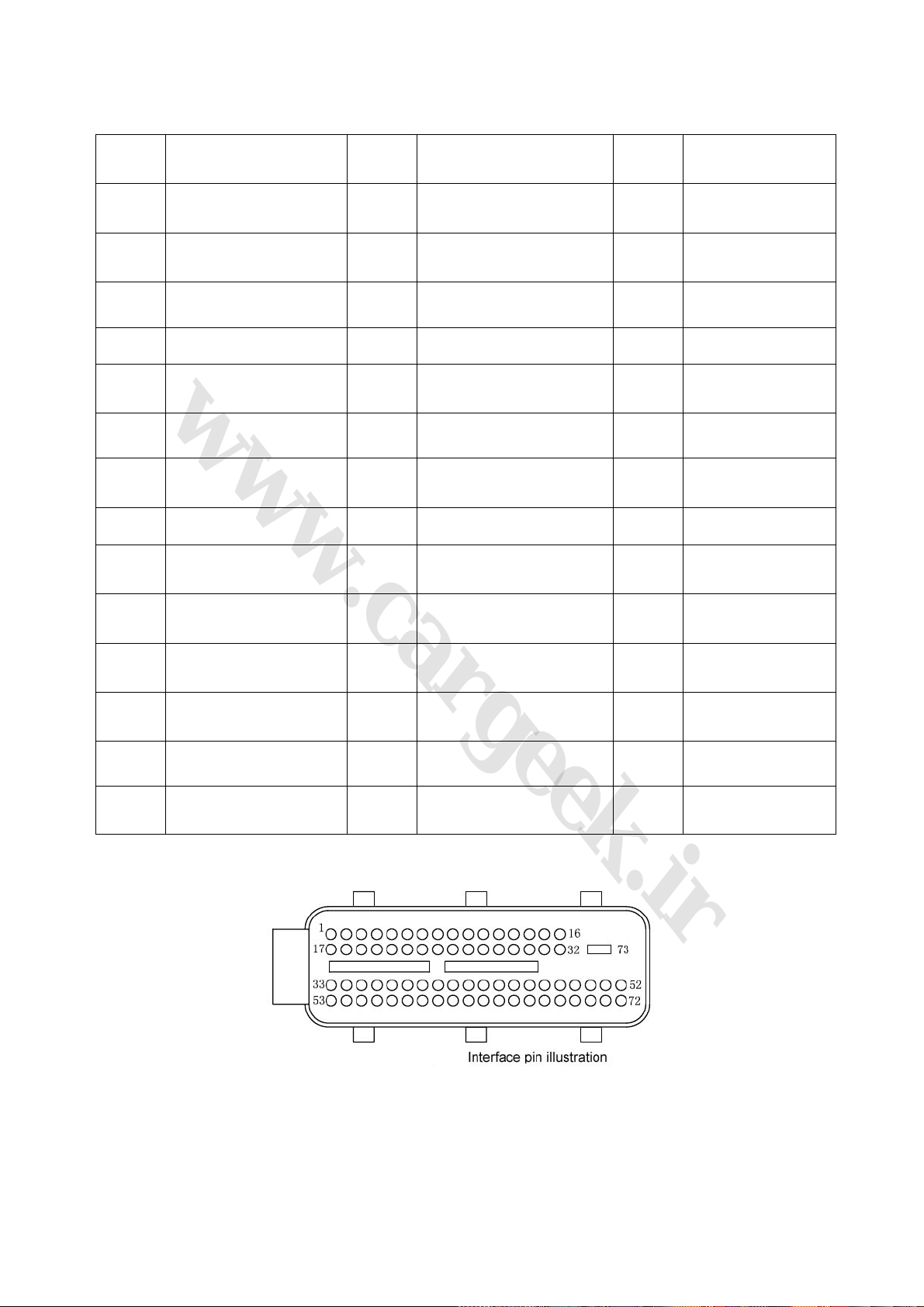

6. Electronic control unit (Fig. 1-6)

(1) Function: The ECU is the key part of the electronic control system of the engine. The sensors

provide various signals to the ECU, and the ECU calculates the signals and sends orders to the

actuators like fuel injector, ignition coil etc to control the engine.

(2) Structure: Made by a shielded housing and printed circuit board, many electronic control units

integrated on the board to control the electronic injection system.

(3) Installation: Fixed under the instrument panel sundries box with bolt, the double interfaces

ECU is adopted.

(4) LF481Q3 engine controller pin (see Table 1-1, Fig. 1-10)

Table 1-1

Pin

Number

Definition

Pin

Number

Definition

Pin

Number

Definition

J1-01 Ignition switch J1-02 Main relay rear power supply J1-03 Vehicle speed

J1-04 Pin 2, 5V power supply+ J1-05 Pin 1, 5V power supply- J1-06

J1-07 Not used J1-08 Not used J1-09

J1-10 Not used J1-11 Serial data J1-12

J1-13 Not used J1-14 CAN line negative J1-15 CAN line positive

J1-16 Not used J1-17 Power supply 1 J1-18 Power supply 2

J1-19 Not used J1-20 Pin 1, 5V power supply+ J1-21

J1-22 Trouble indicator J1-23 Not used J1-24 Throttle position

J1-25 Not used J1-26 Not used J1-27 Intake air temperature

J1-28

J1-31 Engine trouble indicator J1-32 Ignition switch A J1-33

Crankshaft 58 teeth signal

low

J1-29 Not used J1-30 Not used

Oxygen sensor signal

low

Medium-voltage

switch

Crankshaft 58 teeth

signal high

Pin 2, 5V power

supply-

Idle speed phase B

output positive

Table 1-1 (Continued)

29

www.cargeek.ir

www.CarGeek.ir

www.cargeek.ir

Pin

Number

J1-34

J1-37 Not used J1-38

J1-40 Not used J1-41 Not used J1-42 Intake air pressure

J1-43 Coolant temperature J1-44 Not used J1-45 Tachometer

Idle speed phase A output

negative

Definition

Pin

Number

J1-35 Acceleration signal J1-36 Power steering signal

Rear oxygen sensor signal

high

Definition

Pin

Number

J1-39 A/C demand (+)

Definition

J1-46

J1-49 Instrument power supply J1-50 High speed fan relay control J1-51 Not used

J1-52 Ignition coil B J1-53

J1-55 Fuel injector of cylinder 1 J1-56 Fuel injector of cylinder 3 J1-57

J1-58 Not used J1-59 Not used J1-60 Not used

J1-61

J1-64

J1-67

J1-70 Fuel injector of cylinder 2 J1-71 Fuel injector of cylinder 4 J1-72 Not used

J1-73 System ground wire

A/C compressor clutch

relay control

Front oxygen sensor

heating control

Rear oxygen sensor

heating control

Low speed fan relay

control

J1-47 Fuel pump relay control J1-48 Not used

Idle speed phase A output

negative

J1-62

J1-65 Not used J1-66 Not used

J1-68 Not used J1-69 Knock signal

Front oxygen sensor signal

high

J1-54

J1-63

Idle speed phase A

output positive

Canister solenoid

valve control

Fig. 1-10

Loading...

Loading...