Lievers K-150 Operation Manual

OPERATION MANUAL AND PART LIST

K-150

From October 2013

LIEVERS HOLLAND

Groot Mijdrechtstraat 68 – 3641 RW

Postbus 103 - 3640 AC

Mijdrecht (NL)

Tel.: 0031 – (0)297-231900 / Fax: 0031 – (0)297-231909

E-mail: info@lieversholland.nl / Internet: www.lieversholland.nl

2/15 Operation manual K-150, revision 3: 01-10-2013

CONTENT

1. PREFACE……………………………………………………………………………………………………………………………………………………………………..2

2. INTRODUCTION..…………………………………………………… ……………………………………………………………………………………………………4

3. TECHNICAL SPECIFICATIONS .........................................................................................................................................5

4. SAFETY..........................................................................................................................................................................6

4.1. SAFETY ASPECTS .................................................................................................................................................................6

4.2 SAFETY PRECAUTIONS. ......................................................................................................................................................... 6

5. USE ...............................................................................................................................................................................9

5.1. ASSEMBLING THE BULLFLOAT ................................................................................................................................................ 9

5.2 USE OF K-150 E / ER.......................................................................................................................................................... 9

5.3 USE OF K-150 WITH PETROL ENGINE ....................................................................................................................................11

6. MAINTENANCE ........................................................................................................................................................... 12

7.TROUBLESHOOTING, REPAIRS ..................................................................................................................................... 12

8.DISMANTLING, DISPOSAL ............................................................................................................................................ 13

9. PART LISTS ..................................................................................................................................................................14

10. DECLARATION OF CONFORMITY ............................................................................................................................... 23

© Lievers Holland, NL 2005

All rights are reserved. Reprints, copies, adaptations for new editions and publications in any form or through any

media, including abstract forms are not permitted unless written permissions is first obtained from Lievers Holland.

Lievers Holland may not be held responsible for any guarantees or liabilities for the contents of this publication and

points to, in this case, all implied securities for suitability of merchantability or any other purposes. Lievers Holland

further retains the right to revise this publication and to alter the contents over certain periods of time, without the

obligation to report such alterations and changes first.

3/15 Operation manual K-150, revision 3: 01-10-2013

1. Preface

This manual has been written to help you operate and maintain the K-150 safely. This manual is intended for

dealers and operators of K-150 and contains useful instructions for use, maintenance and repair. These

instructions need to be respected and followed.

Guarantee provisions

All damage to parts of this machine, occurring within 12 months after date of purchase as a consequence of material,

production or construction defects, will be replaced by the manufacturer as soon as possible.

The manufacturer declines all responsibility for unsafe situations, accidents and damage caused by:

Ignoring safety and using instructions as described on the machine or the instruction manual.

Incompetent or incorrect maintenance.

Use of the machine by unqualified personnel (employees who are unfamiliar with the content of this instruction

manual).

Storing the machine in a damp place.

Other use than the prescribed use.

Cleaning of the machine with a high pressure cleaner or by a water jet under high pressure.

Alternations of the machine carried out by other than manufacturer. This also includes assembling of non -

original parts.

(Furthermore are applicable the general terms of delivery and payment of the “METAALUNIE”)

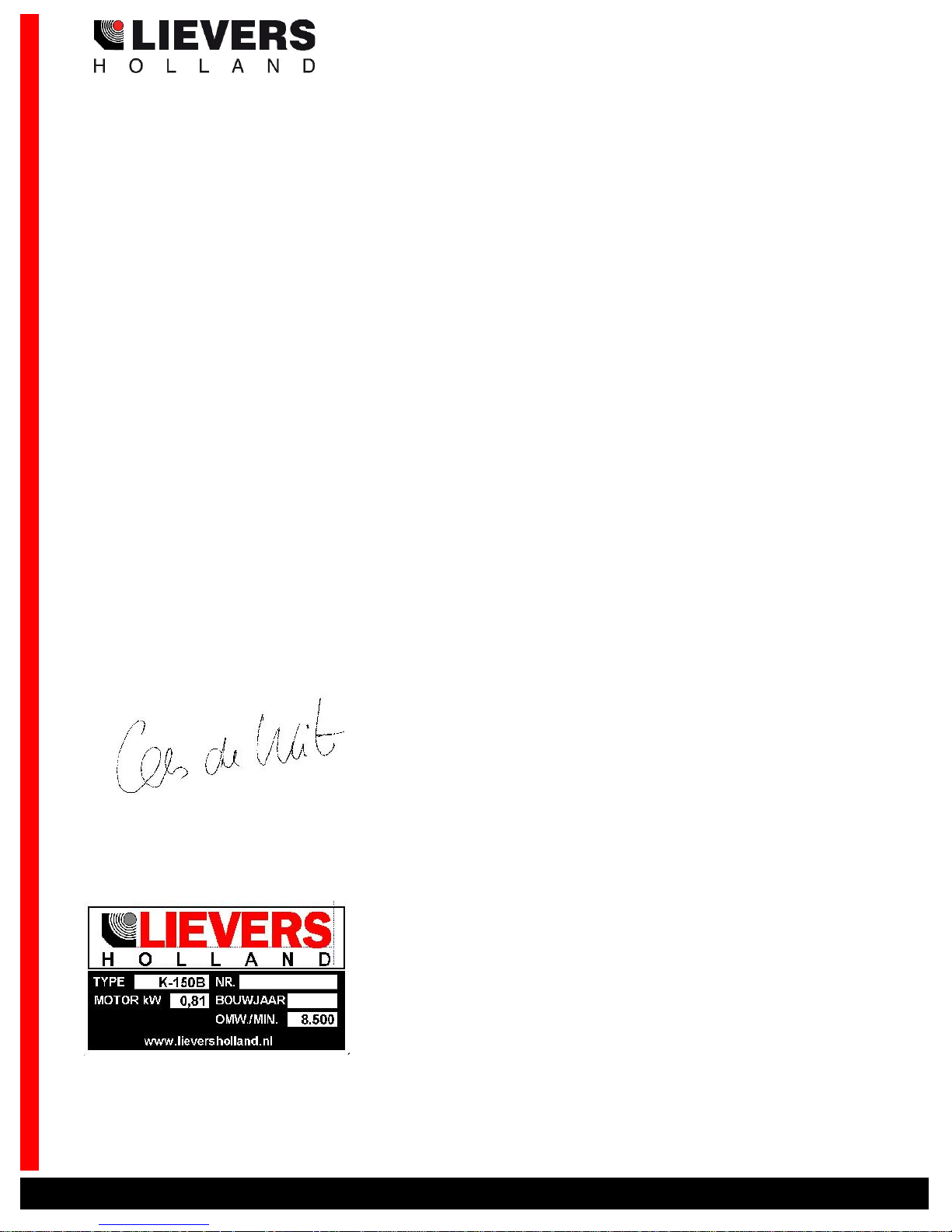

Garantiebewijs

K-150 nr. _______________________________

Date of purchase: ___________________________________

Fig. 1: Rating plate K-150

The rating plate can be found on motor mounting plate.

4/15 Operation manual K-150, revision 3: 01-10-2013

2. Introduction

Intended use

The K-150 is a light bullfloat with a blade width of 1.50 meter used for levelling freshly poured concrete floors.

.

Working

The K-150 works well without guiding rails. K-150 has an in height adjustable steering handle which is directly

connected to the blade. The specially designed shape of the blade together with the

low weight prevents ridges on the concrete surface. K-150 is driven by an electric or petrol engine.

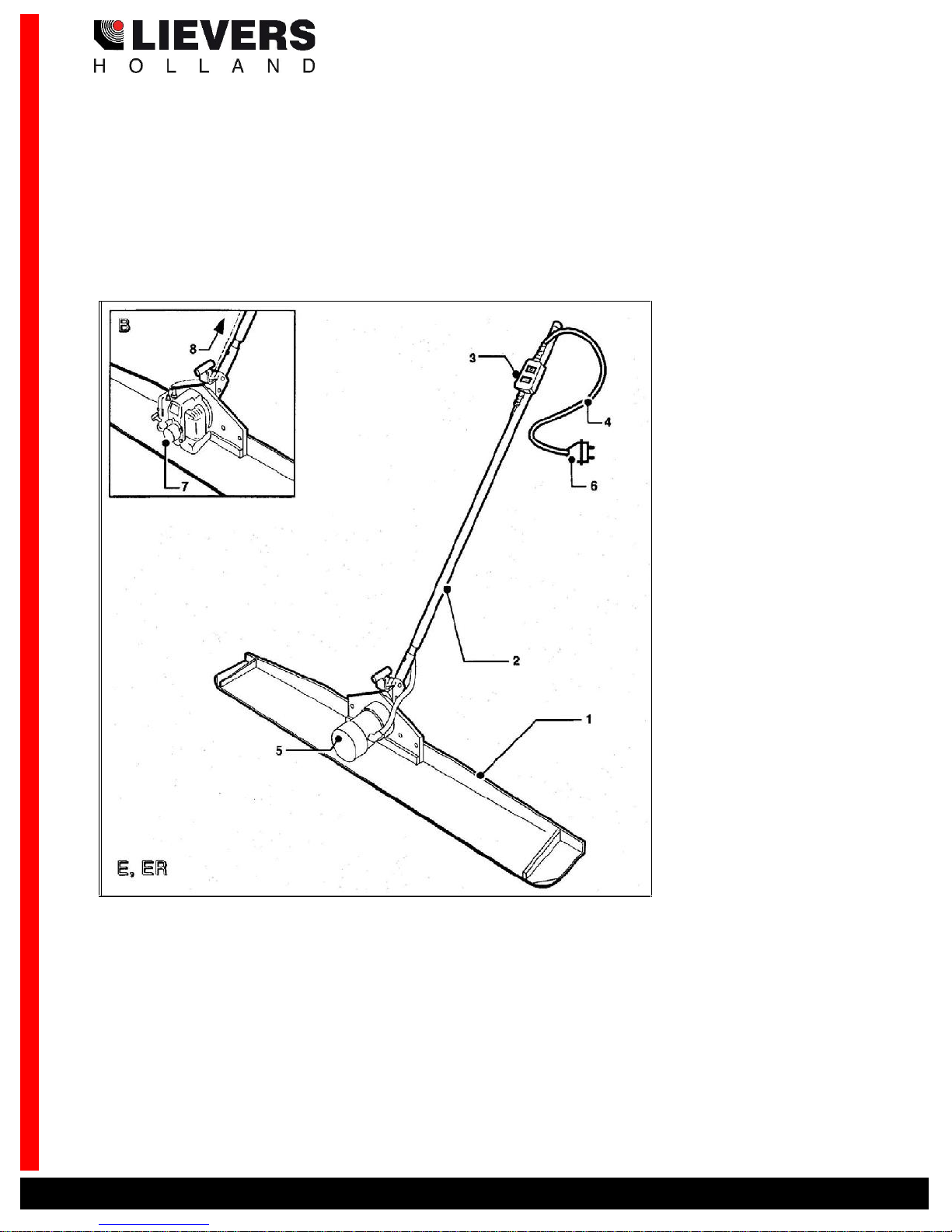

Fig. 2: Overview important components

1. Aluminium profile

2. Operation handle

3. ON/OFF switch

4. Power supply cable

5. Electrical drive unit 230V

6. Plug

7. Petrol engine

8. Gas throttle

5/15 Operation manual K-150, revision 3: 01-10-2013

3. Technical specifications

Technical data

K-150 E, ER,

( 230V / 1 phase)

K-150 B

4- stroke petrol engine

Voltage

Power

Frequency

Centrifugal force

Weight

Isolation

Motor protection

Sound pressure level ISO 6081

The weighted effective value

Of acceleration, determined

according to ISO 5349

Comfort exposure

Execution

230V. 1 phase, 50/60Hz.

350 watt

8.500 p/min.

1.800 Newton

1,5 m 10 Kg

IP 54, splashproof

Double insulated

Impact - shockproof

76 dB(A)

5.65 m/s²

=1,6hr max. 6,3hr per day

Portable

------------------------

0,81kW (1,1PK)

9.000 p/min.

1.800 Newton

1,5 m 11 Kg

IP54,splashproof

------------------------ 80 dB(A)

2.76 m/s²

= 6,6hr max. 24 hr per day

Portable

Table 1: technical data K-150 E, ER, B

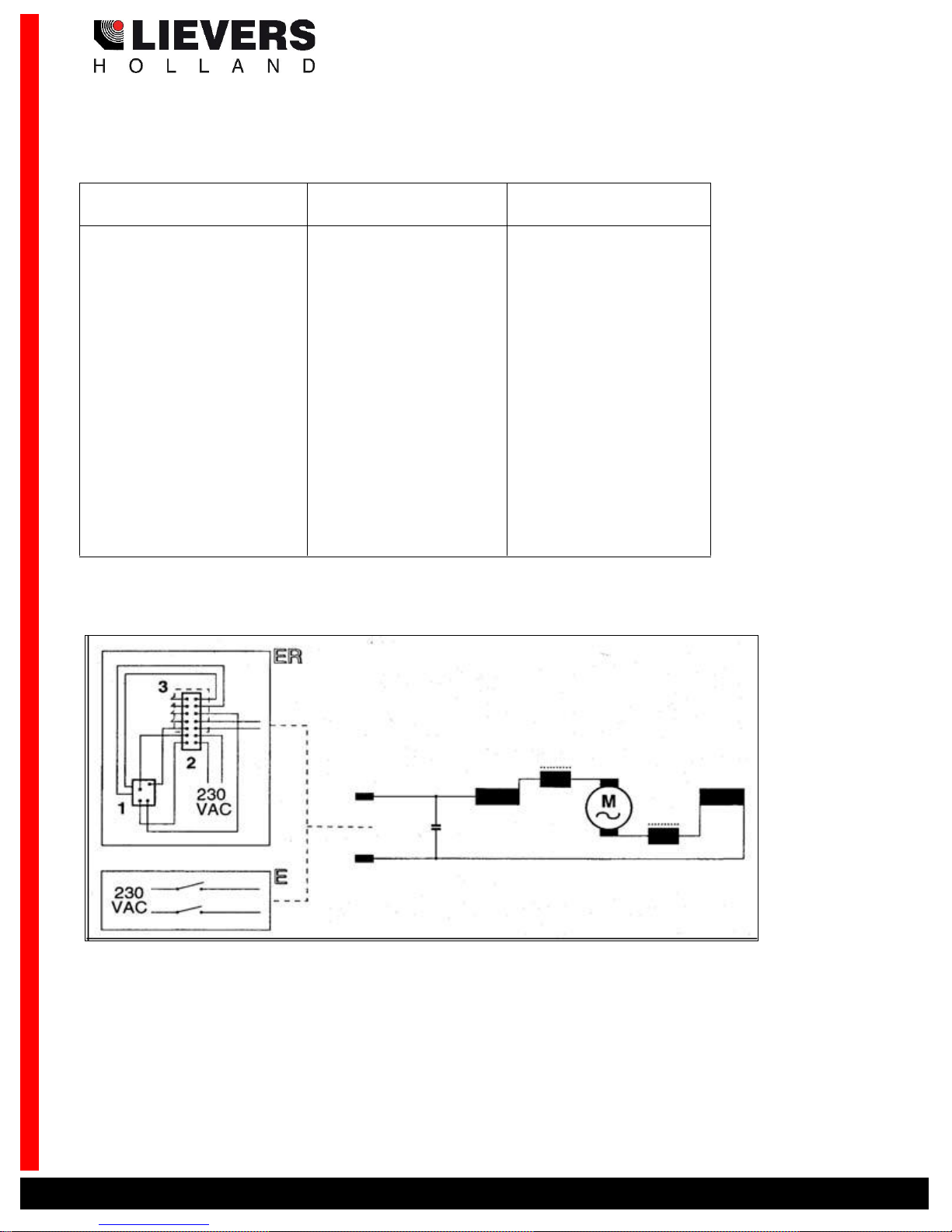

Fig. 3: Electric schedule types E and ER

6/15 Operation manual K-150, revision 3: 01-10-2013

4. Safety

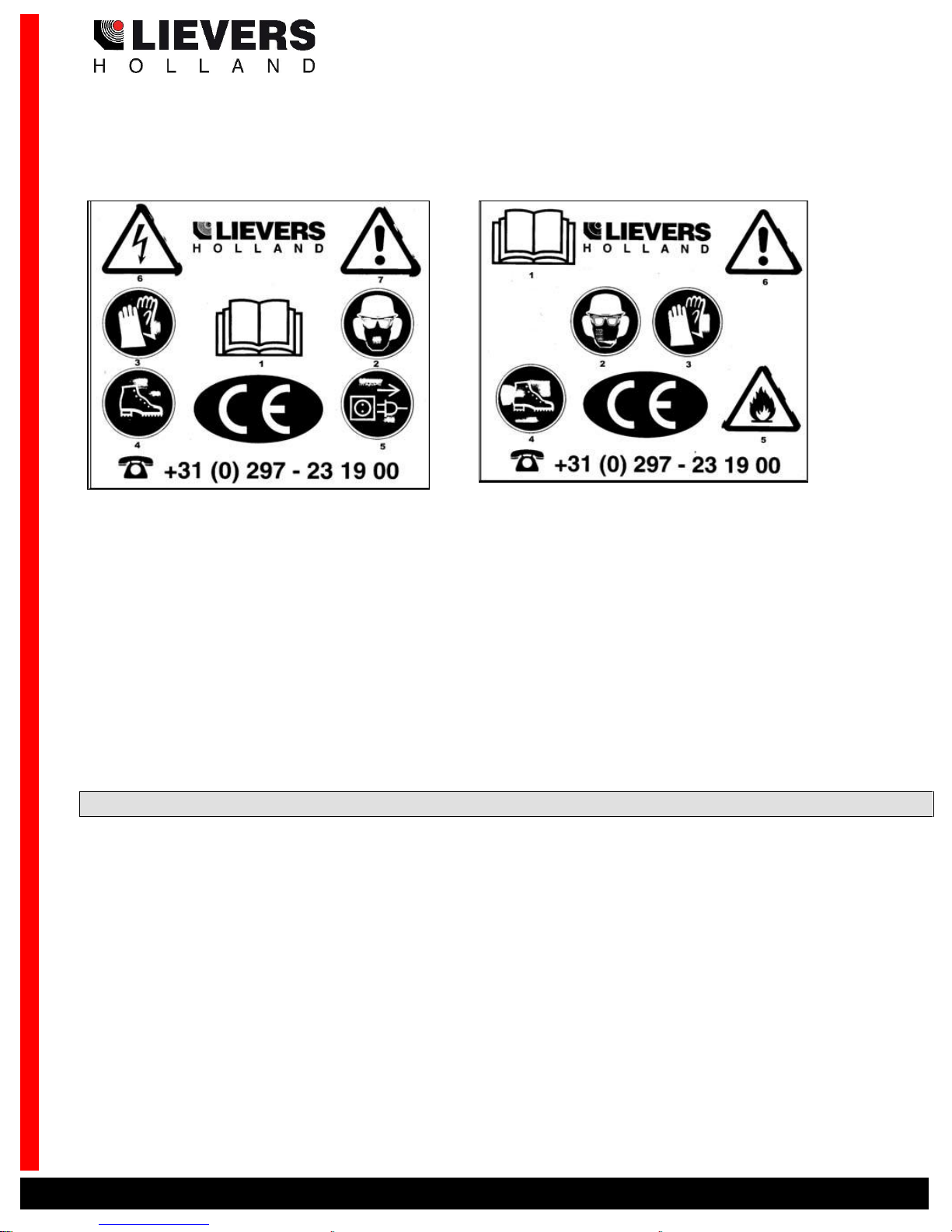

Explanation of the used safety symbols:

K-150 E / ER K-150 B

Fig. 4: Safety symbols K-150 E / ER Fig. 5: safety symbols K-150 B

ENSURE, THAT ALL SYMBOLS ON THE MACHINE, CAN ALWAYS BE CLEARLY READ.

4.1 Safety aspects

The following safety aspects apply to the machine:

Safety symbols are present on the bullfloat K-150

4.2 Safety precautions

The Lievers bullfloats have been developed and tested in accordance with the strict international safety stan dards.

Before operating these machines, make sure to have read this manual carefully. If you have any questions , do not

hesitate to contact the supplier.

Ensure that you are qualified (familiar with the contents of this manual), to operate and carry out light maintenance

work to the machine.

Wear safety shoes with extra protection (steel caps and anti-slip soles).

1. Read the instruction manual before using the

machine.

2. Safety glasses, safety helmet and ear

protection compulsory.

3. Working gloves compulsory.

4. Safety shoes with extra protection

compulsory.

5. Before opening remove the plug.

6. Dangerous electric voltage

7. Be careful.

1. Read the instruction manual before using the

machine.

2. Safety glasses, safety helmet and ear

protection compulsory.

3. Working gloves compulsory.

4. Safety shoes with extra protection

compulsory.

5. Inflammable material.

6. Be careful.

7/15 Operation manual K-150, revision 3: 01-10-2013

Wear a safety helmet and hearing protection.

Wear safety glasses, working gloves which do not conduct electricity and protective clothing.

Ensure that all symbols on the machine, can always be clearly read.

Be careful when lifting and carrying the bullfloat. Do not bend forwards when picking up the machine, but bend your

knees.

When cleaning the machine, ensure that no water or cleaning detergents get into the motorhousing.

When the machine is not being used for longer periods of time, then it must be stored in a dry and clean area.

Regular maintenance of the machine promotes safe operation.

The following safety-aspects specifically apply to those Lievers products which are equipped with an electrical drive

unit:

Place the wires between the electrical source and the work place in such a way, that they cannot be damaged and

your colleagues cannot trip over them.

Do not use the machine in an explosion endangered area.

Check that the electrical source complies with the local valid regulations.

Use an electrical source which is provided with an earth leakage switch or attach a safety transformer between the

electrical mains and the machine.

Regularly check the connections of the supply-cable to the switch.

Ensure that the wall socket and possible connections between the extension leads are protected against dampness.

Do not pull the plug out of the wall socket or extension lead by its lead.

Check the feeder cable’s outer casing and if in use extension lead’s outer casing before you connect the machine to

the electrical mains. The outer casing may not be damaged. Replace the cable if you cannot read the marks on the

outer casing anymore.

Check the machine’s cable-connections before you connect the machine to the electrical mains. The cables must be

properly connected.

Switch off the machine, when the electrical power cuts off. This prevents the machine from starting suddenly when

the electrical power comes on again.

Disconnect the electrical supply to the machine, before you start to clean or maintain the machine.

Ensure that the ventilation slots of the machine are free from dirt and moisture.

Loading...

Loading...