Page 1

Operating and installation instructions

Multi-temperature wine cabinet for integrated use, door-on-door

180210

7084026 - 01

WTI ... 6

Page 2

Appliance at a glance

Contents

1 Appliance at a glance............................................ 2

1.1 Description of appliance and equipment.................. 2

1.2 Range of appliance use............................................ 2

1.3 Conformity................................................................ 3

1.4 External dimensions of the appliance....................... 3

1.5 Saving energy.......................................................... 3

2 General safety information................................... 3

3 Controls and displays........................................... 4

3.1 Operating and control elements............................... 4

3.2 Temperature display................................................. 4

4 Putting into operation............................................ 4

4.1 Changing over door hinges...................................... 4

4.2 Installation................................................................ 5

4.3 Transporting the appliance....................................... 8

4.4 Installing the appliance............................................. 8

4.5 Disposing of packaging............................................ 8

4.6 Connecting the appliance......................................... 9

4.7 Switching on the appliance....................................... 9

5 Control.................................................................... 9

5.1 Brightness of the temperature display...................... 9

5.2 Child proofing........................................................... 9

5.3 Door alarm................................................................ 9

5.4 Temperature alarm................................................... 9

5.5 Storing wine bottles.................................................. 9

5.6 Setting the temperature in the wine zone.................. 10

5.7 Fan........................................................................... 10

5.8 Labels....................................................................... 10

5.9 Wooden shelf........................................................... 10

6 Maintenance........................................................... 10

6.1 Replacing the activated charcoal filter...................... 10

6.2 Cleaning the appliance............................................. 10

6.3 Customer service..................................................... 11

7 Malfunction............................................................. 11

8 Decommissioning.................................................. 12

8.1 Switching off the appliance....................................... 12

8.2 Taking the appliance out of service.......................... 12

9 Disposing of the appliance................................... 12

The manufacturer works constantly on the further development

of all the types and models. Therefore please understand that we

have to reserve the right to make design, equipment and technical modifications.

To get to know all the benefits of your new appliance, please read

the information contained in these instructions carefully.

Instructions for action are marked with a

action are marked with a .

, the results of

1 Appliance at a glance

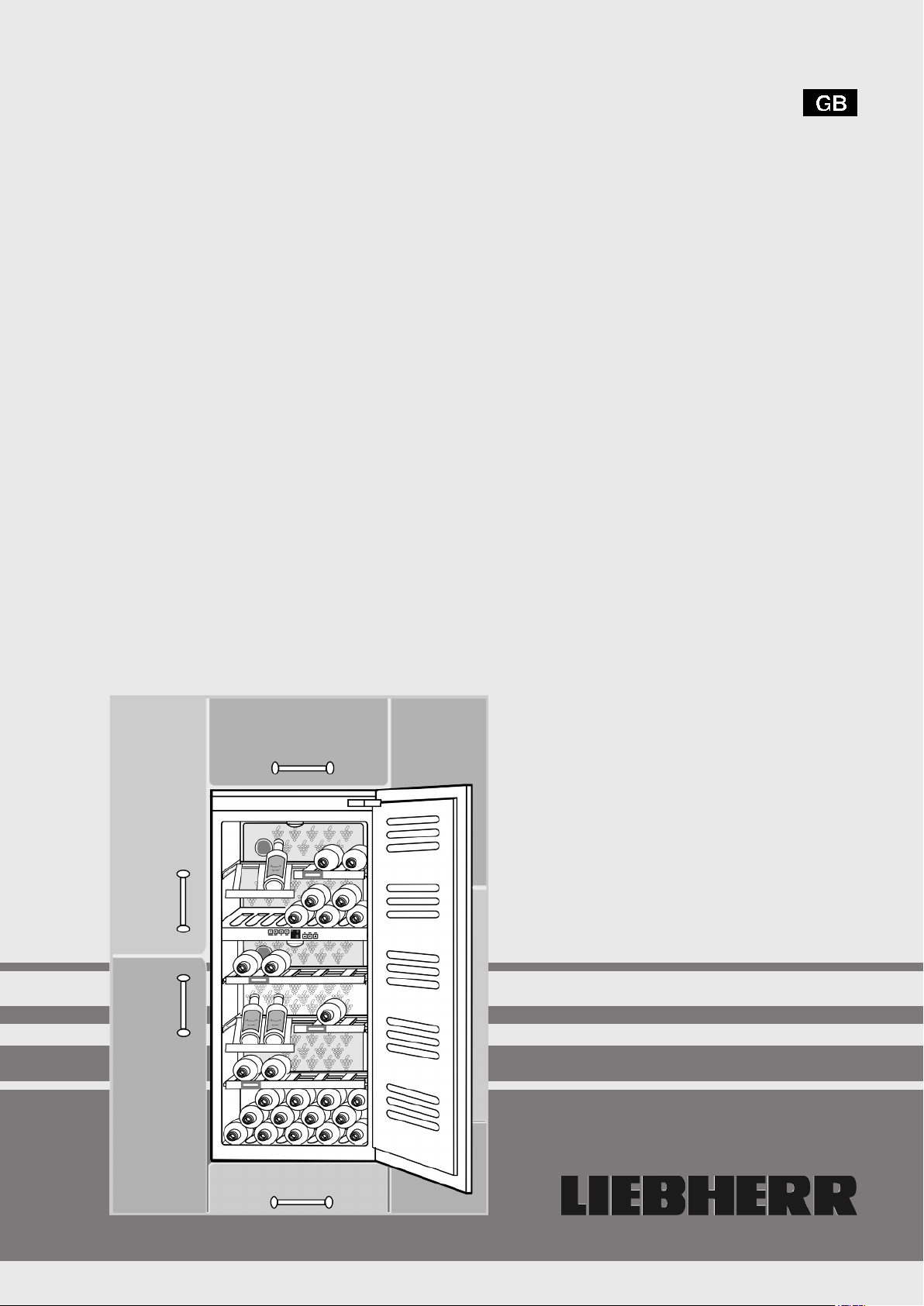

1.1 Description of appliance and equipment

Fig. 1

(1) Interior light (5) Operating and display

elements

(2) Activated charcoal filter (6) Wooden shelf

(3) Label (7) Type plate

(4) Wooden shelf, folding

1.2 Range of appliance use

The appliance is suited exclusively for storing wine.

In the case of commercial food cooling, the pertinent statutory

regulations have to be observed. The appliance is not suited for

storing and cooling pharmaceuticals, blood plasma, laboratory

preparations or similar substances and products subject to the

Medical Devices Directive 2007/47/EC. Any misuse of the appliance may result in damage to or spoilage of the stored goods.

Furthermore, the appliance is unsuited for use in areas exposed

to an explosion hazard.

The appliance is set to operate within specific ambient temperature limits according to its climate rating. The correct climate

rating for your appliance is indicated on the type plate.

Note

u

Compliance with the ambient temperatures indicated is

required, otherwise the cooling performance is reduced.

Climate

rating

SN 10 °C to 32 °C

N 16 °C to 32 °C

ST 16 °C to 38 °C

T 16 °C to 43 °C

for ambient temperatures of

2

Page 3

1.3 Conformity

The refrigerant circuit has been tested for leaks. When installed,

this appliance complies with the relevant safety provisions and

EC directives 2006/95/EC and 2004/108/EC.

As energy efficiency guidelines for multi-temperature wine cabinets are not available, wine compartments are evaluated as

cellar temperature compartments for energy efficiency class allocation.

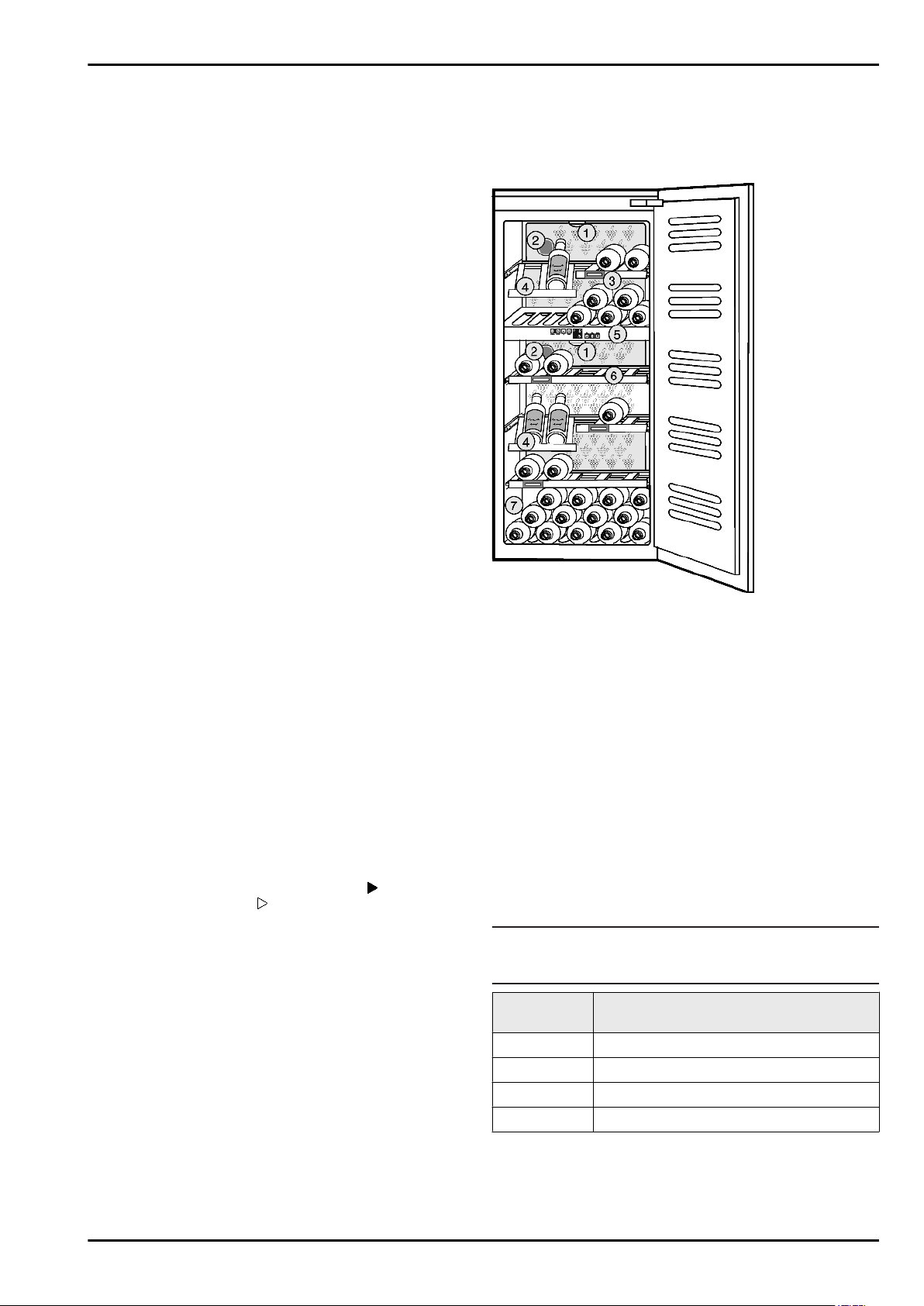

1.4 External dimensions of the appliance

General safety information

Install and connect the appliance only as instructed.

-

Please keep these instructions in a safe place and pass them

-

on to any subsequent owners.

Fire hazard:

The refrigerant R 600a is environmentally friendly but flam-

-

mable. Escaping refrigerant may ignite.

Do not damage the refrigerant circuit pipes.

•

Do not allow naked flames or ignition sources to enter the

•

appliance.

Do not use any electrical appliances in the interior (e.g.

•

steam cleaners, heaters, ice cream maker etc.).

If refrigerant escapes: eliminate naked flames or sources

•

of ignition from the vicinity. Pull out the power plug. Ventilate the area well. Notify customer service.

Do not store explosives or sprays using combustible propel-

-

lants such as butane, propane, pentane, etc. in the appliance.

Respective spray cans can be identified by reference to the

contents printed on the can or by a flame symbol. Gases

possibly escaping may ignite due to electrical components.

Only store high-percentage alcohol in tightly sealed, upright

-

containers. Alcohol possibly escaping may ignite due to electrical components.

Danger of tipping and falling:

Do not misuse the plinth, drawers, doors etc. as a step or for

-

support. This applies particularly to children.

Danger of food poisoning:

Do not consume food which has been stored too long.

-

Danger of frostbite, numbness and pain:

Avoid lasting skin contact with cold surfaces or refrigerated/

-

frozen food or take protective steps, e.g. wear gloves. Do not

consume ice cream, water ice or ice cubes immediately and

do not consume them too cold.

Risk of crushing

Do not reach into the soft stop mechanism. Fingers may be

-

trapped when the door is closed.

Please observe the specific information in the other

sections:

Fig. 2

1.5 Saving energy

Always ensure good ventilation. Do not cover ventilation

-

openings or grille.

Do not place appliance in areas of direct sunlight or next to a

-

stove, heater or similar object.

The energy consumption depends on the installation condi-

-

tions, e.g. the ambient temperature (see 1.2) .

Keep the time the appliance is open to a minimum.

-

2 General safety information

Danger for the user:

This appliance is not designed for persons (including children)

-

with physical, sensory or mental impairment or persons not

having sufficient experience and knowledge, unless they are

instructed in the use of the appliance and are initially supervised by a person responsible for their safety. Keep children

under supervision to ensure they do not play with the appliance.

In case of a fault, pull out the mains plug (not by pulling the

-

connecting cable) or switch off the fuse.

Have any repairs to or intervention in the appliance, and any

-

change of the mains power cable, carried out by the customer

service only or by other specialised personnel trained for the

purpose.

When disconnecting the appliance from the supply, always

-

take hold of the plug. Do not pull the cable.

DANGER identifies a situation involving direct

danger which, if not obviated, may

result in death or severe bodily injury.

WARNING identifies a dangerous situation

which, if not obviated, may result in

death or severe bodily injury.

CAUTION identifies a dangerous situation

which, if not obviated, may result in

minor or medium bodily injury.

NOTICE identifies a dangerous situation

which, if not obviated, may result in

damage to property.

Note identifies useful information and tips.

3

Page 4

Controls and displays

3 Controls and displays

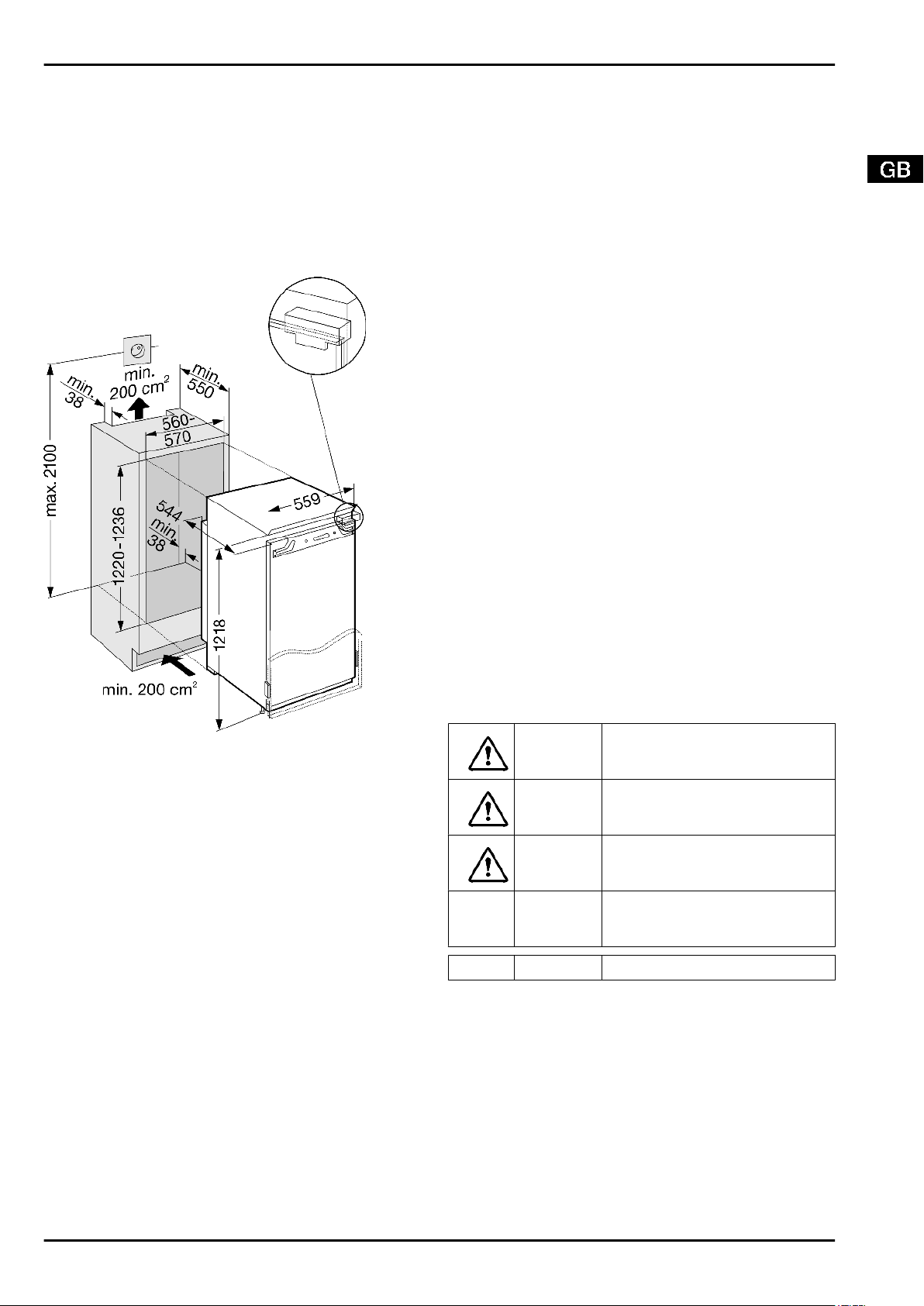

3.1 Operating and control elements

Fig. 3

(1) Lower wine zone

temperature display

(2) Up setting button, lower

wine zone

(3) Down setting button,

lower wine zone

(4) Alarm button (9) On/Off button

(5) Upper wine zone

temperature display

(6) Child-proofing symbol

(7) Down setting button, upper

wine zone

(8) Up setting button, upper

wine zone

(10) Fan button

3.2 Temperature display

The following are displayed in normal operation:

the average wine cabinet temperature

-

The temperature display flashes:

the temperature setting is being changed

-

the wine cabinet temperature is too cold/too warm

-

The following displays indicate malfunction. Possible causes and

corrective action (see Malfunction).

F0 to F5

-

4 Putting into operation

4.1 Changing over door hinges

Ensure that the following tools are to hand:

Crosstip screwdriver

q

Flat-blade screwdriver

q

Cordless screwdriver Torx 15

q

•

Cordless screwdriver Torx 20

•

Cordless screwdriver Torx 25

•

Cordless screwdriver Torx 30

•

Slide the appliance 2/3 of the way into the recess.

Pull out the power plug.

Open the door.

CAUTION

Risk of injury if soft stop contracts!

u

Detach with care.

u

Push tension spring

u

Lower soft stop mechanism

u

Unscrew holder

u

Unfasten ball stud

Fig. 4 (11)

Fig. 4 (1)

Fig. 4 (3)

outwards, using a screwdriver.

Fig. 4 (2)

.

using a spanner.

for removal.

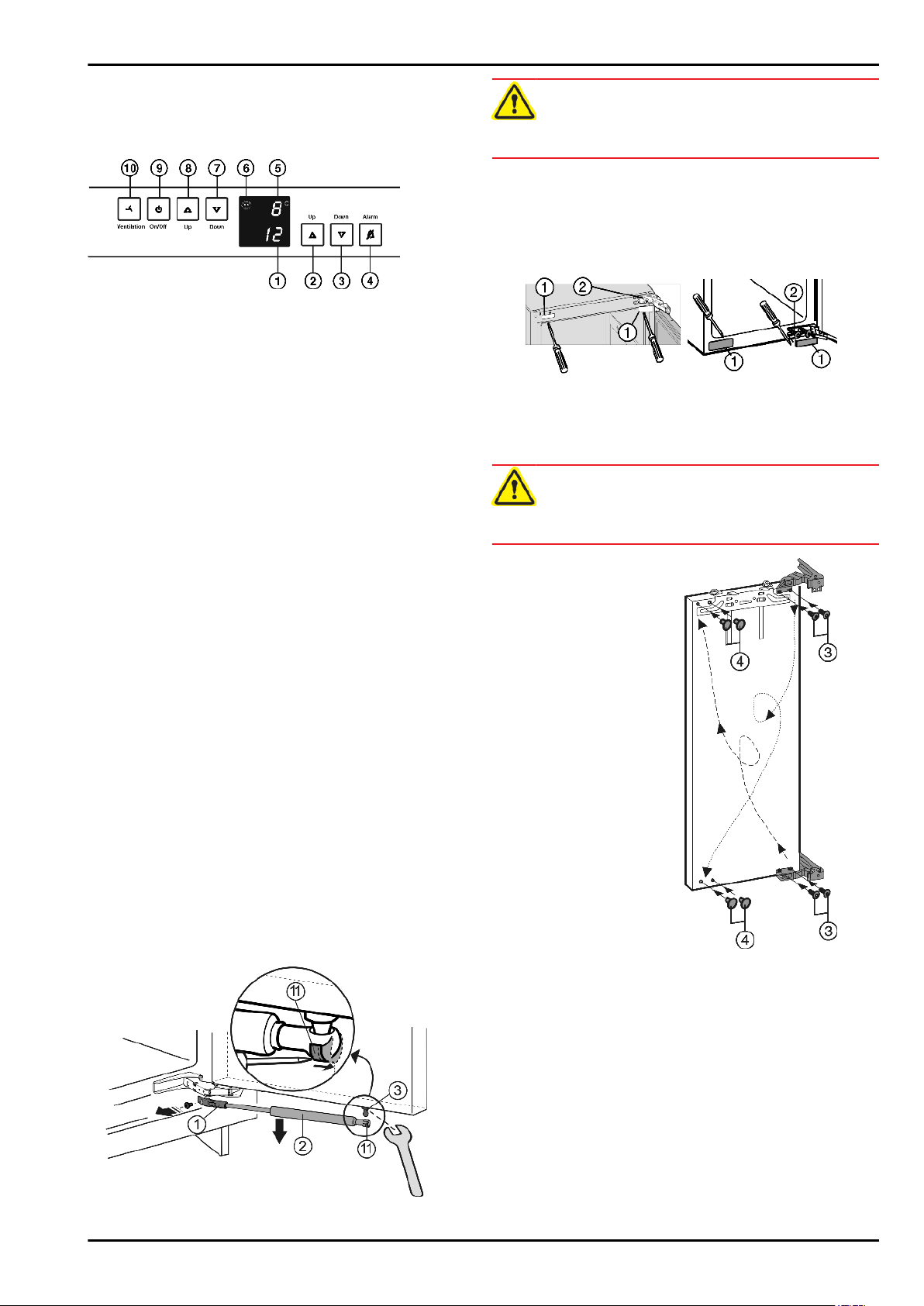

4.1.2 Demount door

u

Lift offcovers

u

Only slackenfastening screws

u

Remove door: push outwards, unhinge and set aside.

Fig. 5 (1)

.

Fig. 5 (2)

.

4.1.3 Changing bearing parts

CAUTION

Risk of injury if hinges fold!

u

Leave hinges open.

u

Transfer top and

bottomfastening screws

Fig. 5 (2)

side.

Screws are self-tapping. Use

cordless screwdriver:

u

Unscrew

hinges from the door,

transfer them and screw

them on tightly (4 Nm).

u

Close vacated fastening

holes with stoppers

Fig. 6 (4)

to the opposite

Fig. 6 (3)

.

the

Fig. 5

4.1.1 Detach the soft stop mechanism

4

Fig. 4

4.1.4 Re-fit door

u

Attach appliance door to the prefitted fastening screws

Fig. 5 (2)

u

Screw in mounting screws

u

Re-fit covers

.

Fig. 5 (1)

Fig. 5 (2)

.

tightly (4 Nm).

Fig. 6

Page 5

Putting into operation

4.1.5 Re-fit soft stop mechanism

u

Screw ball stud

mounting hole.

u

Push tension spring

u

Screw on the bracket

u

Attach soft stop mechanism

WARNING

Risk of injury due to the door dropping out!

If the fastening parts are not screwed into place firmly enough,

the door may drop out. This may lead to severe injuries. What is

more, the door may not close and therefore the appliance may

fail to cool properly.

u

Screw the hinges and the ball journal of the soft stop mechanism firmly into place, with 4 Nm.

u

Screw the holder of the soft stop mechanism firmly into place,

with at least 3 Nm.

u

Check all of the screws and retighten if necessary.

Fig. 7 (3)

Fig. 7 (11)

Fig. 7 (1)

tightly ( 4 Nm) into the new

inwards again.

tightly (3 Nm).

Fig. 7 (2)

to ball stud.

Fig. 7

The appliance can also be installed in an ordinary kitchen

cabinet. In this case detach the fittings of the unit door and recess.

They are no longer needed as the unit door is fitted to the appliance door.

Check installation dimensions:

Appliance height a Recess height b

1218 mm 1220 mm - 1236 mm

4.2 Installation

Fig. 9

Note

u

Before assembling the door of the unit, make sure that the

admissable weight of the unit door is not exceeded.

u

Otherwise damage to the hinges and resultant malfunction

cannot be ruled out.

Model Max. weight of unit

door

WTI 20 kg

Fig. 8

Ensure that the following tools are to hand:

Cordless screwdriver Torx® 15, 20, 25

q

Spanner 13

q

Screwdriver

q

The shelf and side walls of the unit must be at right-angles to one

another. Align the unit with a spirit level and an angle. If necessary, level out by building up from underneath.

5

Page 6

Putting into operation

4.2.1 Installing the appliance

For 16 mm thick unit walls = 568 mm

wide recess:

u

Remove the protective film from the cover

trim

Fig. 15 (3)

wall of the appliance on the handle side

and flush with the front and glue on.

u

If necessary, shorten the cover trim

Fig. 15 (3)

To slide in and align the appliance:

u

Slide in the appliance.

For 16 mm thick unit walls =

568 mm wide recess:

u

Let the spacers abut the side

wall of the unit.

For 19 mm thick unit walls =

562 mm wide recess:

u

Align the front edges of the

hinges so as to be flush with the

side wall of the unit.

. Apply the strip on the side

at the bottom.*

Fig. 15

Fig. 16

Fig. 17

u

Detach the connecting cable from the rear of the appliance, removing the cable holder because otherwise

there will be vibratory noise!

u

Lay the connecting cable with

the help of a string in such a way

that the appliance can be easily

connected after fitting.

u

Fit equaliser trim

with screws

the appliance.

u

Slide the appliance 2/3 of the way into the recess.

For 16 mm thick unit walls =

568 mm wide recess:

u

Clip spacer

spacer

Fig. 10 (6)

hinges.

u

Screw plastic bracket

Fig. 14 (8)

side of the appliance with

M5 screws

Fig. 12 (1)

Fig. 12 (2)

onto

Fig. 13 (5)

onto the

onto the handle

Fig. 14 (9)

.

and

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 18

In case of units with (16 mm and 19 mm) door stop

components (knobs, sealing lips etc.):

u

To allow for the extra distance (depth of door stop components): allow the hinges to protrude by the extra distance.

Fig. 19

For units without door stop components:

u

Align the plastic bracket in depth so as to be flush with the front

side of the side walls of the unit.

For units with door stop components:

u

To allow for the extra distance : align the plastic bracket

parallel to the front edge of the hinges.

For units with set back base:

u

Align plastic bracket

the front edges of the side walls of the unit, even if the bracket

projects over the base of the unit as a result.

u

Level the appliance by means of the adjustable feet using the

accompanying spanner

w

The appliance is now correctly positioned in depth. The

distance between the front edge of the side wall of the unit and

the body of the appliance is 42 mm all the way round (Allow

for door stop components, such as knobs and sealing lips.)

Note

Incorrect installation will lead to malfunction!

If the distance is not kept, the door may not close. This may lead

to icing, to condensate forming and to malfunction.

u

Be sure to keep to a spacing of 42 mm all the way round. (Allow

for door stop components, such as knobs and sealing lips.)

Fig. 19 (8)

Fig. 19 (7)

in depth so as to be flush with

.

Fig. 14

Fasten the appliance in the recess with screws:

6

Page 7

u

by screwing long Spax

screws

Fig. 20 (10)

through the top and

bottom hinge plates.

Putting into operation

u

Pre-assemble by passing a

long screw

the centre of the oblong hole in

the plastic bracket

u

Fold down the cover of the

plastic bracket

u

Close the appliance door.

Fig. 21 (8)

Fig. 21 (10)

Fig. 21 (8)

through

.

.

4.2.2 Fitting the unit doors

u

Check 8 mm presetting. (Distance between appliance door

and lower edge of crosspiece)

u

Push up assembly aids

edge ▲of the assembly aid = top edge of the unit door to be

fitted.

u

Unscrew fastening

crosspiece

Fig. 23 (12)

undoing the locknuts

Fig. 22 (14)

u

Attach the fastening

crosspiece

Fig. 23 (12)

assembly aids

Fig. 23 (11)

inside of the unit door.

u

Centre the fastening crosspiece

centre line on the unit door and put the tip of the arrow on the

crosspiece above it.

w

Distances to the outer edge are equal at the left and right.

For chipboard doors:

u

secure fastening crosspiece

screws.

For frame and panel doors:

u

secure fastening crosspiece

edge.

u

Raise the assembly aids

and insert them into the adjacent openings.

.

using the

to the

by

Fig. 22 (11)

Fig. 23 (12)

Fig. 23 (12)

Fig. 23 (12)

Fig. 23 (11)

to unit door height. Lower

: mark a short

with at least 6

with 4 screws at the

for removal, turn them

Fig. 20

Fig. 21

Fig. 22

Fig. 23

u

Attach the unit door to the adjusting bolts

loosely screw the locknuts

u

Close the door.

u

Check the gap between the door and the surrounding unit

doors.

u

To laterally align the unit door: move the unit door in the X

direction.

u

To align the unit door in height Y and in lateral inclination:

adjust the adjusting bolt

w

The unit door is flush and in alignment with the surrounding

unit fronts.

u

Tighten the locknuts

u

Screw mounting

bracket

Fig. 25 (18)

with hexagon screw

Fig. 25 (19)

pilot holes in the

appliance door.

Ensure that both metal edges are flush (symbol //):

u

Drill pilot holes in the door of the unit (possibly make preliminary hole with a bradawl).

u

Screw the appliance door to the unit door with screws

Fig. 25 (15)

Fig. 25 (18)

u

To align the unit door in depth Z: undo screws

the top, hexagon screws

the door.

u

Allow an air gap of approx. 2 mm between

the unit door and the body of the unit.

Do not allow knobs and sealing lips to

contact the door - important for function!

For large or sectioned unit doors:

u

fit a 2nd pair of mounting brackets

Fig. 25 (18)

u

Use the holes pre-drilled in the handle

area of the appliance door for this

purpose.

into the

passed through the mounting brackets

.

.

Fig. 24 (14)

Fig. 24 (17)

Fig. 24 (14)

Fig. 26 (19)

.

Fig. 24 (17)

onto them.

with a screwdriver.

Fig. 26 (20)

at the door, then move

Fig. 24

and

Fig. 25

Fig. 26

at

7

Page 8

Putting into operation

u

Check the fit of the door and readjust if necessary.

u

Tighten all screws.

u

Tighten the locknuts

Fig. 27 (21)

a screwdriver.

u

Screw the equaliser trim

screws

u

Fix the appliance in the round hole at the bottom with the

second screw

Fig. 27 (10)

u

Snap covers into place.

u

Attach top cover

and snap into place.

u

Attach side cover

Fig. 28 (24)

and then press until it audibly

snaps into place.

u

Attach covers

sideways, then draw them

forwards with a screwdriver

so that they snap into place

well.

while holding the adjusting bolts

Fig. 27 (22)

.

, push it to the limit

4.3 Transporting the appliance

Fig. 27 (14)

Fig. 27 (1)

onto the cupboard ceiling.

Fig. 27 (8)

through the plastic bracket

Fig. 28 (23)

Fig. 28 (25)

with the ring spanner

Fig. 27 (17)

from below using three

Fig. 27

, with

Fig. 28

Standard EN 378 specifies that the room in which you install your

appliance must have a volume of 1 m2 per 8 g of R 600a refrigerant used in the appliance. If the room in which the appliance is

installed is too small, a flammable gas-air mixture may form in the

event of a leakage in the refrigeration circuit. The quantity of

refrigerant used in your appliance is indicated on the type plate

on the inside of the appliance.

Fit the appliance in stable kitchen units only.

The following ventilation gaps must be observed:

The depth of the ventilation channel at the rear of the unit must

q

be at least 38 mm.

There must be a ventilation space of at least 200 cm2 in the

q

plinth and at the top of the unit.

Basically the principle applies: the larger the ventilation space,

q

the more energy-saving the appliance is in operation.

WARNING

Fire hazard due to dampness!

If live parts or the mains lead become damp this may cause short

circuits.

u

The appliance is designed for use in enclosed areas. Do not

operate the appliance outdoors or in areas where it is exposed

to splash water or damp conditions.

WARNING

Fire hazard due to refrigerant!

The refrigerant R 600a is environmentally friendly but flammable.

Escaping refrigerant may ignite.

u

Do not damage the piping of the refrigeration circuit.

WARNING

Fire hazard and danger of damage!

u

Do not place appliances emitting heat e.g. microwaves,

toasters etc. on the appliance!

u

Detach the connecting cable from the rear of the appliance,

removing the cable holder at the same time because otherwise there will be vibratory noise!

After installation:

u

Remove all transit supports.

u

Unscrew the red transport lock.

Close the vacated retaining

hole using the stopper (60).

CAUTION

Risk of injury and danger of damage as a result of incorrect transport!

u

Transport the appliance in a packed condition.

u

Transport the appliance upright.

u

Do not transport the appliance without assistance.

4.4 Installing the appliance

In the event that the appliance is damaged, contact the supplier

immediately before connecting to the mains.

The floor at the site must be flat and level.

Do not install the appliance in a location where it is exposed to

direct radiation of the sun, next to a cooker, heater and similar.

Do not install the appliance without assistance.

8

u

Dispose of packaging material (see 4.5) .

If the appliance is installed in a very damp environment, condensate may form on the outside of the appliance.

u

Always see to good ventilation at the installation site.

4.5 Disposing of packaging

WARNING

Danger of suffocation due to packing material and plastic film!

u

Do not allow children to play with packing material.

The packaging is made of recyclable materials:

corrugated board/cardboard

-

EPS moulded parts

-

polythene bags and sheets

-

polypropylene straps

-

u

Take the packaging material to an official collecting point.

Page 9

4.6 Connecting the appliance

NOTICE

Risk of damage to the electronic control system!

u

Do not use stand-alone inverters (conversion of d.c. to a.c./

three-phase) or energy saving plugs.

WARNING

Fire and overheating hazard!

u

Do not use extension cables or multiple socket outlets.

The type of current (alternating current) and voltage at the installation site have to conform with the data on the type plate (see

Appliance at a glance).

Connect the appliance only with a properly installed

socket outlet with earthing contact. The socket outlet

must be fused with 10 A or higher.

u

Check the electrical connection.

u

Clean the appliance (see 6.2) .

u

Plug in the power plug.

4.7 Switching on the appliance

u

Press On/Off button

w

The temperature display and the alarm button flash until the

set temperature is reached.

Fig. 3 (9)

.

5 Control

5.1 Brightness of the temperature display

You can adjust the brightness of the temperature display to the

light conditions of the room in which the appliance is installed.

5.1.1 Adjusting the brightness

The brightness is adjustable between h0 (no illumination) and

h5 (maximum luminosity).

u

To activate the setting mode: press the fan button

for about 5s.

w

The fan button

u

Using the Up setting button, upper wine zone

Down setting button, upper wine zone

u

To confirm: briefly press the fan button

u

To set the display brighter: press the Up setting

button, upper wine zone

u

To set the display darker: press the Down setting

button, upper wine zone

u

To confirm: briefly press the fan button

w

The brightness is adjusted to the new value.

u

To deactivate the setting mode: press the On/Off button

Fig. 3 (9)

-or-

u

Wait for 5 minutes.

w

The temperature is indicated again in the temperature display.

.

Fig. 3 (10)

flashes. The display indicates c.

Fig. 3 (7)

Fig. 3 (10)

Fig. 3 (8)

Fig. 3 (7)

.

.

Fig. 3 (10)

5.2 Child proofing

The child-proofing function enables you to make sure that the

appliance is not inadvertently switched off by playing children.

Fig. 3 (10)

Fig. 3 (8)

select h.

.

.

and

Control

u

Briefly press the fan button

u

To switch on: using the Up setting button, upper

wine zone

wine zone

u

To switch off: using the Up setting button, upper

wine zone

wine zone

u

To confirm: press the fan button

w

The child-proofing function is switched on when the childproofing symbol

u

To deactivate the setting mode: press the On/Off button

Fig. 3 (9)

-or-

u

Wait for 5 minutes.

w

The temperature is indicated again in the temperature display.

Fig. 3 (8)

Fig. 3 (7)

Fig. 3 (8)

Fig. 3 (7)

Fig. 3 (6)

.

5.3 Door alarm

If the door is open longer then 60 s, the audible alarm sounds.

5.3.1 Muting the door alarm

The audible alarm can be muted when the door is open. The

sound switch-off function is active as long as the door is left open.

u

Press alarm button

w

The door alarm is silenced.

Fig. 3 (4)

5.4 Temperature alarm

The audible alarm sounds if the wine storage temperature is too

warm or too cold.

The temperature display flashes at the same time.

The cause of the temperature being too high may be:

warm fresh food was placed inside

-

too much warm ambient air flowed in when rearranging and

-

removing food

power failure for some time

-

the appliance is faulty

-

The audible alarm is automatically silenced and the temperature

display stops flashing when the temperature is sufficiently cold/

warm again.

If the alarm status persists: (see Malfunction).

Note

Food may be spoilt if the temperature is not cold enough.

u

Check the quality of the food. Do not consume spoiled food.

5.4.1 Muting the temperature alarm

The audible alarm can be muted. When the temperature is sufficiently cold again, the alarm function is active again.

u

Press alarm button

w

The audible alarm is silenced.

Fig. 3 (4)

5.5 Storing wine bottles

64 Bordeaux bottles (0,75 l) can be stored in the wine zone.

u

Store white wine only in one compartment and red wine only

in the other, since both compartments can be set to independent temperatures.

u

If possible, lay bottles of the same type of wine side by side

on the same grid shelf.

u

Rearrange bottles as seldom as possible.

Fig. 3 (10)

or Down setting button, upper

select c1.

or Down setting button, upper

select c0.

shines.

.

.

to confirm.

Fig. 3 (10)

.

5.2.1 Setting the child-proofing function

u

To activate the setting mode: press the fan button

for about 5s.

w

The fan button flashes. The display indicates c.

Fig. 3 (10)

9

Page 10

Maintenance

u

Stored open bottles on the

folded down wooden grid

shelf.

u

To fold down the wooden grid

shelf: press the lock under

the trim sideways.

w

The wooden grid shelf folds

down.

5.6 Setting the temperature in the wine zone

The appliance is pre-set for normal operation. The temperature

can be set from 20 °C to 5 °C, the recommended temperatures

are 8 °C to 12 °C.

The wine zone is divided into two wine compartments, which can

be set to different temperatures, as needed.

u

To set the temperature warmer: press the Up setting button,

upper wine zone

zone

u

u

-or-

u

w

w

Fig. 3 (2)

To set the temperature colder: press the Down setting button,

upper wine zone

zone

Fig. 3 (3)

To change the temperature in 1 °C steps: briefly press the

button.

To change the temperature continuously: hold down the

button.

During setting the new value is displayed flashing.

The actual temperature is displayed about 5 s after the last

press of a button. The temperature slowly adjusts to the new

value.

5.7 Fan

When the fan runs, the relative humidity in the interior increases

so that the cork does not dry out.

When the fan is activated, the energy consumption increases. To

save energy, the fan switches off automatically when the door is

open.

5.7.1 Switching on the fan

u

Briefly press the fan button

w

The fan button

w

The fan always runs. The humidity is high.

5.7.2 Switch off the fan

u

Briefly press the fan button

w

The fan button

w

The fan runs only when this is necessary for temperature

control. The humidity is low.

5.8 Labels

You can note down on the labels the type of wine stored in the

respective compartment. Additional labels can be obtained from

your specialist dealer.

5.8.1 Labelling

Fig. 3 (8)

.

Fig. 3 (7)

.

Fig. 3 (10)

Fig. 3 (10)

or Up setting button, lower wine

or Down setting button, lower wine

Fig. 3 (10)

shines.

Fig. 3 (10)

does not shine.

.

.

5.9 Wooden shelf

Pay attention that the wooden

shelf does not get caught on the

rear hook.

u

To remove the folding wooden

shelf: lift it off the pull-out rail

and draw it forwards.

u

To insert the wooden folding shelf: slide it under the rear hook

and press onto the rails so that they audibly snap into place.

u

To insert other wooden

shelves: place on the rails.

6 Maintenance

6.1 Replacing the activated charcoal filter

The activated charcoal filter ensures ideal air quality and should

therefore be replaced annually. It can be ordered from a specialised dealer.

Each wine zone is equipped with an activated charcoal filter of

its own.

The activated charcoal filter is fitted at the bottom of the rear wall

of the appliance.

u

Take the activated charcoal filter by the

grip.

u

Turn the activated charcoal filter

through 90° to the right or left

Fig. 29 (1)

u

Remove

coal filter.

u

Insert the new activated charcoal filter

with the grip in an upright position.

u

Turn the new activated charcoal filter

through 90° to the right or left

Fig. 29 (1)

6.2 Cleaning the appliance

Before cleaning:

Risk of injury and damage as a result of hot steam!

Hot steam may damage the surfaces and cause burns.

u

Do not use any steam cleaners!

NOTICE

Incorrect cleaning damages the appliance!

u

Do not use cleaning agents in concentrated form.

u

Do not use any scouring or abrasive sponges or steel wool.

u

Do not use any cleaning agents containing sand, chloride,

chemicals or acid.

u

Do not use chemical solvents.

u

Do not damage or remove the type plate on the inside of the

appliance. It is important for the customer service.

u

Do not pull off, bend or damage cables or other components.

u

Do not allow any cleaning water to enter the drain channel,

ventilation grille or electrical parts.

.

Fig. 29 (2)

until it snaps into place.

CAUTION

the activated char-

Fig. 29

10

Page 11

Malfunction

u

Empty the appliance.

u

Pull out the plug.

- Use soft cleaning cloths and a multi-purpose

cleaning agent with neutral pH value.

- Only use food compatible cleaning and care agents

on the inside of the appliance.

Interior:

u

Clean the plastic surfaces, outside and inside, by hand using

lukewarm water and a little washing-up liquid.

u

Wipe the rubber lip of the

control panel with a damp

cloth and a cleaning agent

with neutral pH value.

To clean the drain opening:

u

Remove the wooden grid shelves

and detach the pull-out rails.

u

Remove the caps and screws of

the metal cover (1) and side them

aside.

u

Raise the metal cover (2) and draw

it forwards (3).

u

To clean the drain opening:

remove any deposits with a fine

instrument, e.g. a cotton bud.

Items of equipment:

u

Wipe wooden grid shelves with a dry, lint-free cloth.

Note

u

Do not clean wooden grid shelves with water and washing-up

liquid.

u

Clean other items of equipment by hand with lukewarm water

and a little washing-up liquid.

After cleaning:

u

Wipe dry the appliance and items of equipment.

u

Connect the appliance and switch it on again.

u

Put the food back inside.

6.3 Customer service

First check whether you can correct the fault yourself by reference to the list (see Malfunction). If this is not the case, please

contact the customer service whose address is given in the

enclosed customer service list.

WARNING

Risk of injury if repair work is not carried out professionally!

u

Have any repairs to and intervention in the appliance and

mains power cable, which are not expressly mentioned in the

(see Maintenance) carried out by the customer service only.

u

Read the appliance

designation

Fig. 30 (1)

No.

Fig. 30 (2)

serial No.

the type plate located

inside the appliance

on the left-hand side.

u

Notify the customer service, specifying the fault, appliance

designation

Fig. 30 (3)

w

This will help us to provide you with a faster and more accurate

service.

, service

and

Fig. 30 (3)

Fig. 30 (1)

.

off

, service No.

Fig. 30 (2)

Fig. 30

and serial No.

u

Keep the appliance closed until the customer service arrives.

w

The food will stay cool longer.

u

Pull out the mains plug (not by pulling the connecting cable)

or switch off the fuse.

7 Malfunction

Your appliance is designed and manufactured for a long life span

and reliable operation. If a malfunction nonetheless occurs

during operation, check whether it is due to a handling error. In

this case you will have to be charged for the costs incurred, even

during the warranty period. You may be able to rectify the

following faults yourself:

Appliance does not work.

The appliance is not switched on.

→

Switch on the appliance.

u

The power plug is not properly inserted in the wall socket.

→

Check power plug.

u

The fuse of the wall socket is not in order.

→

Check fuse.

u

The compressor runs for a long time.

The compressor switches to a low speed when little cold is

→

needed. Although the running time is increased as a result,

energy is saved.

This is normal in energy-saving models.

u

Excessive noise.

Speed-controlled* compressors may produce varying

→

running noise due to different speed steps.

The sound is normal.

u

A bubbling and gurgling noise.

This noise comes from the refrigerant flowing in the refriger-

→

ation circuit.

The sound is normal.

u

A quiet clicking noise.

The noise is produced whenever the refrigeration unit (motor)

→

automatically switches on or off.

The sound is normal.

u

A hum. It is briefly a little louder when the refrigeration unit

(the motor) switches on.

The refrigeration increases automatically when fresh food

→

has just been placed in the appliance or the door has been

left open for a while.

The sound is normal.

u

The ambient temperature is too high.

→

Solution: (see 1.2)

u

A low hum.

The sound is produced by air flow noise of the fan.

→

The sound is normal.

u

Mould on the wine bottles.

Similarly as with other forms of storage, a little mould may

→

form depending on the type of adhesive used for the label.

Remove residual adhesive.

u

The temperature display indicates: F0 to F5.

There is a fault.

→

Contact the customer service (see Maintenance).

u

The temperature is not cold enough.

The door of the appliance is not properly closed.

→

Close the door of the appliance.

u

Insufficient ventilation.

→

Clear ventilation grilles.

u

The ambient temperature is too high.

→

Solution: (see 1.2) .

u

The appliance was opened too frequently or for too long.

→

11

Page 12

Decommissioning

Wait until the appliance reaches the required temperature

u

itself. If not, contact the customer service. (see Maintenance).

The temperature is incorrectly set.

→

Set to a colder temperature and check after 24 h.

u

The appliance is too close to a heat source.

→

Solution: (see Putting into operation).

u

The interior light is not on.

The appliance is not switched on.

→

Switch on the appliance.

u

The door was open longer than 15 min.

→

The interior light automatically switches off if the door has

u

been open for about 15 min.

The LED lighting is defective or the cover is damaged:

→

WARNING

Risk of injury due to electric shock!

Live parts are located under the cover.

u

Have the LED interior light changed or repaired only by the

customer service or by specialized personnel trained for the

purpose.

WARNING

Danger of injury due to laser radiation, class 1M.

u

Do not look inside when the cover is open.

8 Decommissioning

8.1 Switching off the appliance

u

Press On/Off button

w

The temperature display is dark.

Fig. 3 (9)

for about 2 s.

8.2 Taking the appliance out of service

u

Empty the appliance.

u

Pull out the power plug.

u

Clean the appliance (see 6.2) .

u

Leave the door open to prevent odour.

9 Disposing of the appliance

The appliance contains some reusable materials

and should be disposed of properly - not simply with

unsorted household refuse. Appliances which are no

longer needed must be disposed of in a professional

and appropriate way, in accordance with the current

local regulations and laws.

When disposing of the appliance, ensure that the refrigeration

circuit is not damaged to prevent uncontrolled escape of the

refrigerant it contains (data on type plate) and oil.

u

Disable the appliance.

u

Pull out the plug.

u

Cut through the connecting cable.

12

Loading...

Loading...