Page 1

Laboratory

technical

sales manual

Page 2

Contents

LKPv and LGPv laboratory appliances

with Profi-Controller

Alarm, memory and safety functions

Temperature, door-open and power failure alarms

Internal system alarms

Internal memory functions

Special safety functions

Temperature and alarm documentation

External temperature and alarm monitoring connections

External alarm contact connection

Product temperature monitoring connection

Safety feature table

Temperature consistency and distribution according to NF X 15 -14

Description of the NF X 15-140 test procedure

Results according to NF X 15-140

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT

laboratory appliances with Comfort-Controller

Alarm, memory and safety functions

Temperature, door-open and power failure alarms

Internal system alarm

Internal memory functions

Special safety function

Temperature and alarm documentation

External temperature and alarm monitoring connection

External alarm contact connection

Product temperature monitoring connection

Safety feature table

Temperature consistency and distribution according to NF X 15 -140

Description of the NF X 15-140 test procedure

Results according to NF X 15-140

Loading plan:

low temperature chest freezers with kryo racks

Pharmacy refrigerators compliant to DIN 58345

2

Page 3

Doorvoermogelijkheid PT 100

Bovenin de binnenruimte is een

opening (Ø 7,6 mm) aangebracht

die de mogelijkheid biedt een

externe temperatuurvoeler of een

andere meetverbinding door te

voeren.

Verlicht tekstdisplay

Tiptoetsbediening met hygiënisch

vuilbestendig foliedisplay en toets-

blokkering. Keuze uit 5 talen (Engels,

Duits, Frans, Spaans en Italiaans).

Temperatuur wordt op 0,1°C nauw-

keurig aangegeven.

Beveiligd bij stroomuitval

Een 12V accu voorkomt dat data

verloren gaan. Gedurende 72 uur

wordt het temperatuurverloop

geregistreerd en wordt, indien

Optisch en akoestisch alarm

Een deur- en temperatuuralarm

waarschuwt bij een ongewenste

temperatuurverandering van 2K.

30 Alarmsituaties worden bewaard

en kunnen via het display of de in-

frarood interface worden uitgelezen.

Aansluiten op centale

Met een seriële interface RS 485 of

potentiaalvrij contact is aansluiten op

een centraal log- of alarmsysteem

mogelijk. Iedere 2 minuten worden

tijd, datum en temperatuur exact

geregistreerd.

Temperatuurregistratie

Iedere 4 minuten worden datum, tijd

en temperatuur, evenals eventuele

alarmmeldingen, bewaard. Na 2.800

registraties (~ 7,5 dag) worden data

LKPv and LGPv laboratory appliances with Profi-Controller

All LKPv and LGPv modells have integrated high and low internal air temperature alarms with both audio

and visual signals. The factory settings for the alarm limits are + 3 /– 2 K in relation to the set temperature.

If the set temperature is altered to meet a specific storage temperature requirement then the alarm settings

move in parallel and do not need to be adjusted separately. There is a 30 minute delay to avoid unwanted

All LKPv and LGPv modells register when doors are left open or ajar and have an integrated audio and visual

All LKPv and LGPv modells have a battery back-up which operates an audio and visual alarm immediately

upon power failure. Both the integrated temperature data logger and the optional external temperature

Alarm, memory and safety functions

Liebherr Mediline refrigerators and freezers with Profi-Controller help to protect your inventory. These cabinets offer a variety of alarm,

memory and safety features designed to greatly reduce the risk of loss of contents.

Temperature, door-open and power failure alarms

High and low temperature alarms

alarms due to e.g. door opening.

Door-open alarm

door-open alarm. This alarm has a 1 minute delay which can be adjusted.

Power failure alarm

monitoring via the RS 485 interface continue to function during power failure for up to 72 hrs.

Internal system alarms

The following alarms are related to internal self-checks of the refrigeration system and the electronic controller probes. While these might not be immediately

relevant to the everyday operation of the cabinets they do provide added security by warning probably before the air temperature probe registers an alarm condition.

They also provide a service engineer with valuable information thus allowing quicker intervention.

High condenser temperature alarm

This integrated audio and visual alarm warns of excessive condenser temperatures possibly caused by e.g.

high ambient temperatures or blocked air-flow to or from the refrigeration system.

Low evaporator temperature alarm

This integrated audio and visual alarm warns of low evaporator temperatures possibly caused by e.g.

defective air-circulation fan or blocked internal air-flow. This alarm will possibly warn much sooner than the

high or low temperature alarm.

Probe failure alarm

As a self-control system, defective probes are registered and the controller cause an audio and visual alarm

signal. In case of an air-probe error the controller has pre-defined operating modes to maintain the internal

temperature at + 5 °C.

3

Page 4

This function stores to memory details of the last 30 alarms: time and date of the start and the end of the

alarm condition, the type of the alarm condition and the maximum and minimum internal air temperatures

This function stores to the memory the internal temperature profile at 4-minute intervals. 2800 temperature

LKPv and LGPv laboratory appliances with Profi-Controller

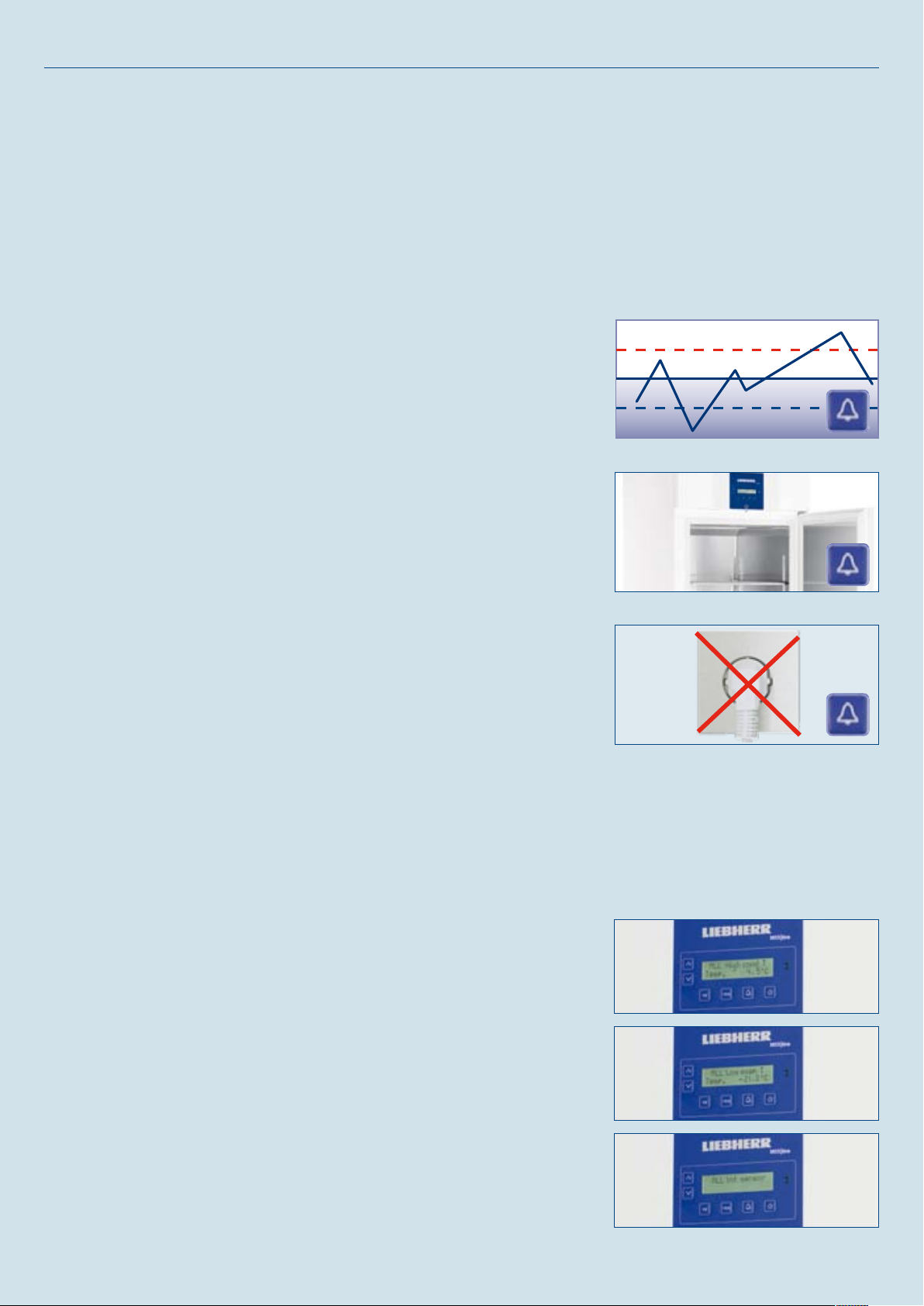

The LKPv and LGPv models all have a solid-state relay guaranteed to > 1 billion compressor start cycles. As

well as allowing very accurate temperature control this feature practically excludes the possibility of burnt

All LKPv and LGPv modells have a double internal fan arrangement so that in case of one defective fan

the cooling system continues to function at reduced capacity. The highly reliable fans Liebherr uses are

Internal memory functions

Internal alarm memory

measured during this alarm condition period are registered.

Internal temperature memory

logs are stored to memory, which corresponds to approximately a 7-day logging period.

Special safety functions

Solid-state relay for maximum reliability

relay contacts as a cause for extreme internal temperatures.

Double fan cooling

40 °C

30 °C

20 °C

10 °C

0 °C

-10 °C

-20 °C

-30 °C

16.07.2009

12:00

18:00

17.07.2009

06:0000:00 12:00 18:00

18.07.2009

06:0000:00 12:00 18:00

19.07.2009

06:0000:00 12:00 18:00

guaranteed to 80 000 hrs operating time.

4

Page 5

Liebherr

Temperature

Monitoring

Software for

Serial Interface &

Infrared key

Deutsch

English

Français

Italiano

Español

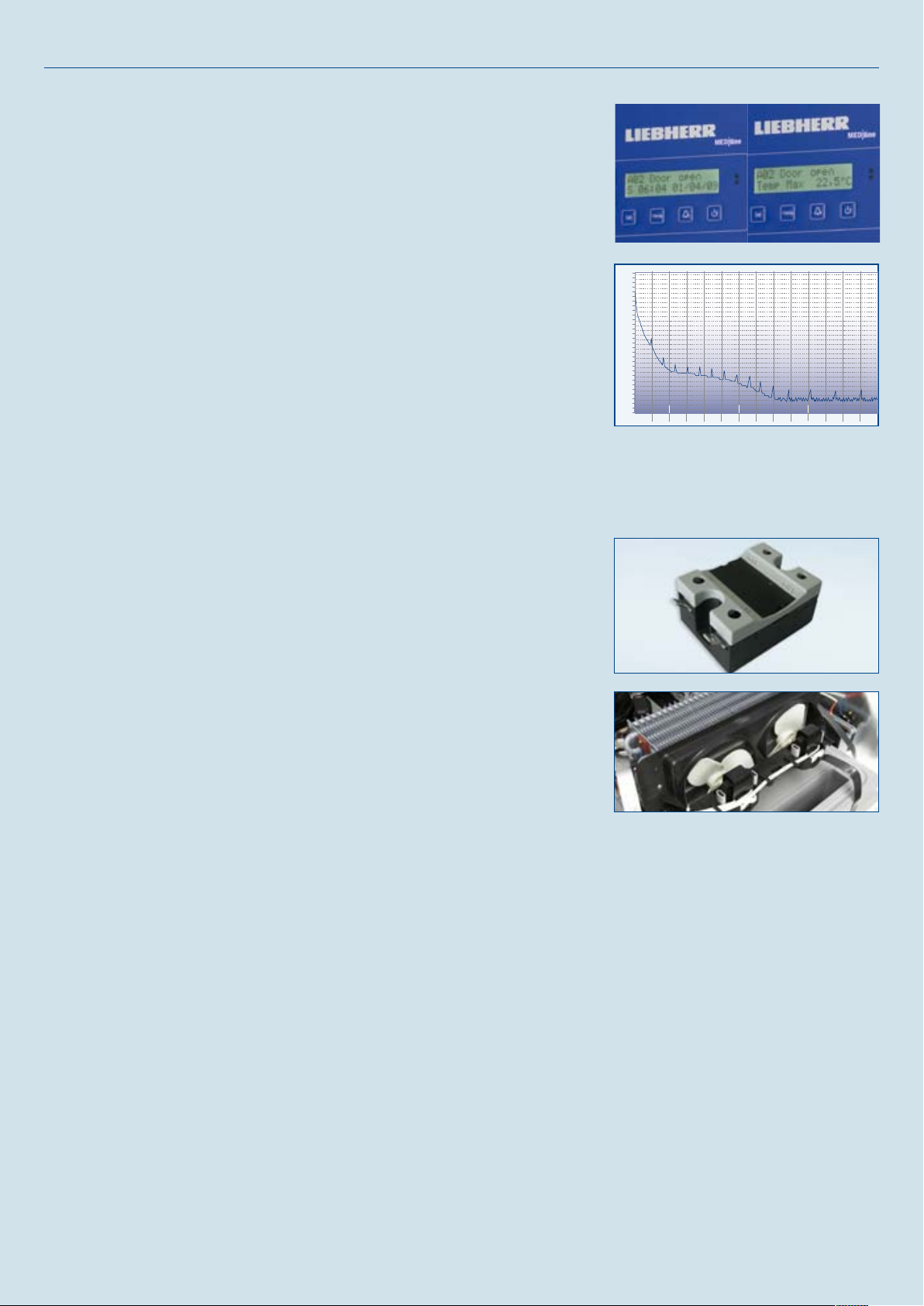

All LKPv and LGPv models have an integrated temperature data logger which stores up to 2800 air-probe

temperature values recorded at 4 minute intervals, which equals approximately 7.7 days. In order to use

red interface on the cabinet to the “infrared key”. This “key” is then connected by cable to a PC or laptop

ware allows visualisation and analysis of the temperature data in various formats including a graph. The data

LKPv and LGPv laboratory appliances with Profi-Controller

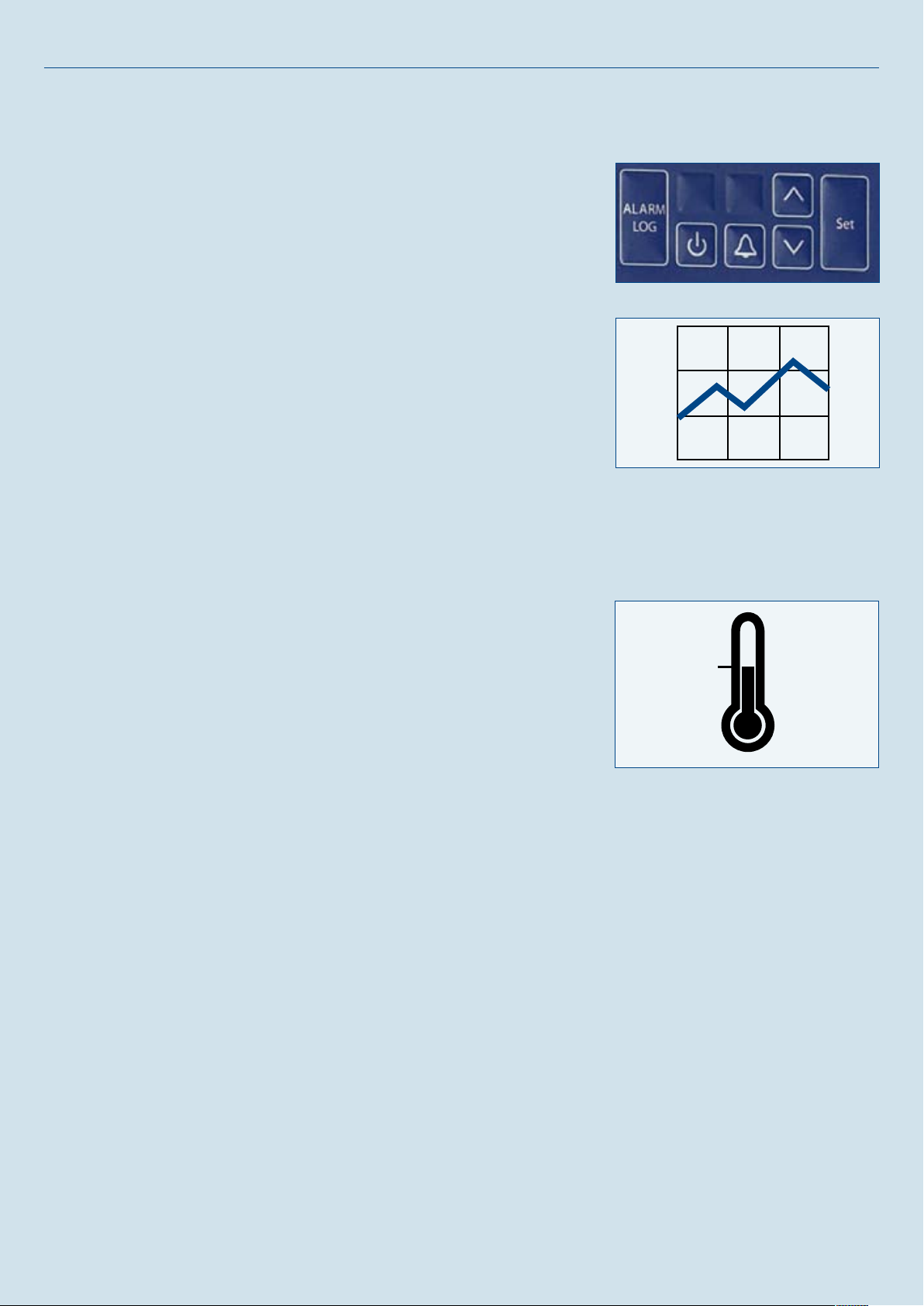

Temperature and

alarm documentation

Liebherr Mediline refrigerators and freezers with Profi-Controller help to protect your inventory. These cabinets offer a variety of features and

options designed both for external monitoring of the internal temperatures, the product temperatures and alarm conditions to greatly reduce

the risk of loss of contents.

External temperature and alarm

monitoring connections

Infrared interface and optional infrared key

this data an infrared device (“key”) is available as an optional extra. The data is transferred from the infra-

and the data is transferred onto the dedicated software on the PC. Only one set of data i.e. from one cab-

inet, can be transferred at one time.

The optional kit includes all the necessary components: key, cable and software including manual. The soft-

can also be exported to Excel, Word and other standard formats for storage or further analysis.

Example: visualisation of temperature data

40 °C

36 °C

32 °C

28 °C

24 °C

20 °C

16 °C

12 °C

8 °C

4 °C

0 °C

– 4 °C

– 8 °C

– 12 °C

– 16 °C

– 20 °C

– 24 °C

– 28 °C

16.07.2009

12:00

16.07.2009

18:00

17.07.2009

00:00

17.07.2009

06:00

17.07.2009

12:00

17.07.2009

18:00

18.07.2009

00:00

18.07.2009

06:00

18.07.2009

12:00

18.07.2009

18:00

19.07.2009

00:00

19.07.2009

06:00

Internal temperature

19.07.2009

12:00

19.07.2009

18:00

5

Page 6

Liebherr

Temperature

Monitoring

Software for

Serial Interface &

Infrared key

Deutsch

English

Français

Italiano

Español

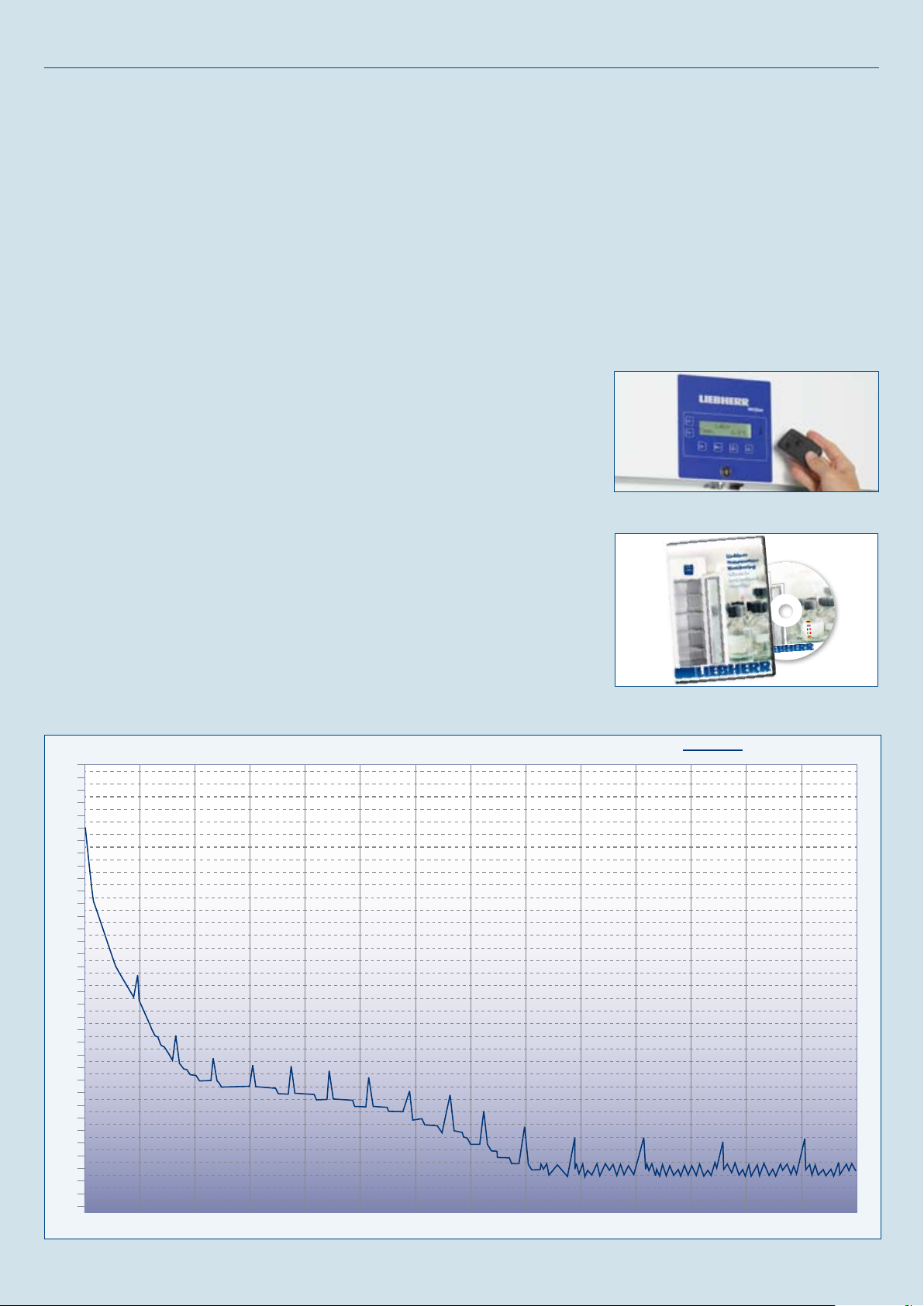

. The

maximum possible length of the data lines depends on the quality of the components used. The maximum

Dedicated software is provided in the accessory package allowing visualisation, analysis and export to other

formats for storage. The software reads the air-probe temperature at 2 minute intervals and records alarm

conditions. When an alarm condition is registered the software will warn on the PC on which the software

is running. If this PC is not supervised (e.g. at night or over weekends) then the alarm signal might not be

recognised. In order to avoid unrecognised alarms the software includes an email function, which sends an

email in case of an alarm condition to predefined email addresses. These emails can be easiliy checked with

LKPv and LGPv laboratory appliances with Profi-Controller

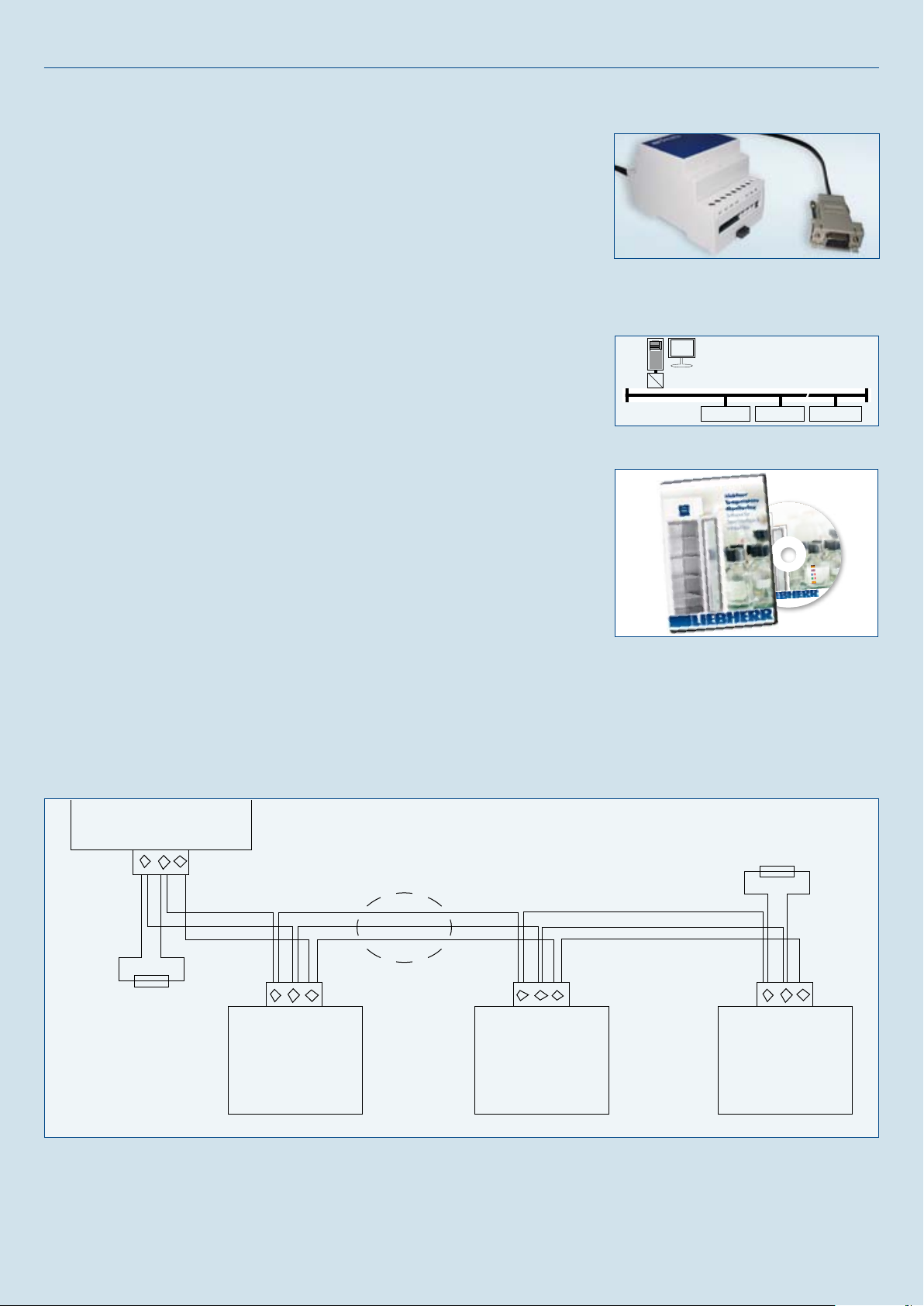

All LKPv and LGPv models have an RS 485 interface. If an RS 485 monitoring system is not already in place,

a converter kit is available as an optional extra to convert the RS 485 signal to an RS 232 signal and allow

RS 485 interface and optional signal converter

connection to a PC or laptop.

The RS 485 bus connection is made using standard shielded data cables, e.g. type LiYCY 2 x 0,14 mm

2

BUS line

range is 500 m. A maximum of 20 appliances can be wired in series.

appliance 1 appliance 2 appliance 20

a smartphone. Therefore the user will be warned without having direct access to a computer.

Networking

Both laboratory appliances with Profi-Controller as well as laboratory appliances with Comfort-Controller can be networked using the same Liebherr accessory

package “RS 485 interface converter including temperature monitoring software”.

Example: RS 485 network

RS 485

+ - s

Optimum:

Shielded Twisted Pair

Terminator

120 Ohm

- + s

- + s - + s

Address 1 Address 2 Address 3

Terminator

120 Ohm

6

Page 7

LKPv and LGPv laboratory appliances with Profi-Controller

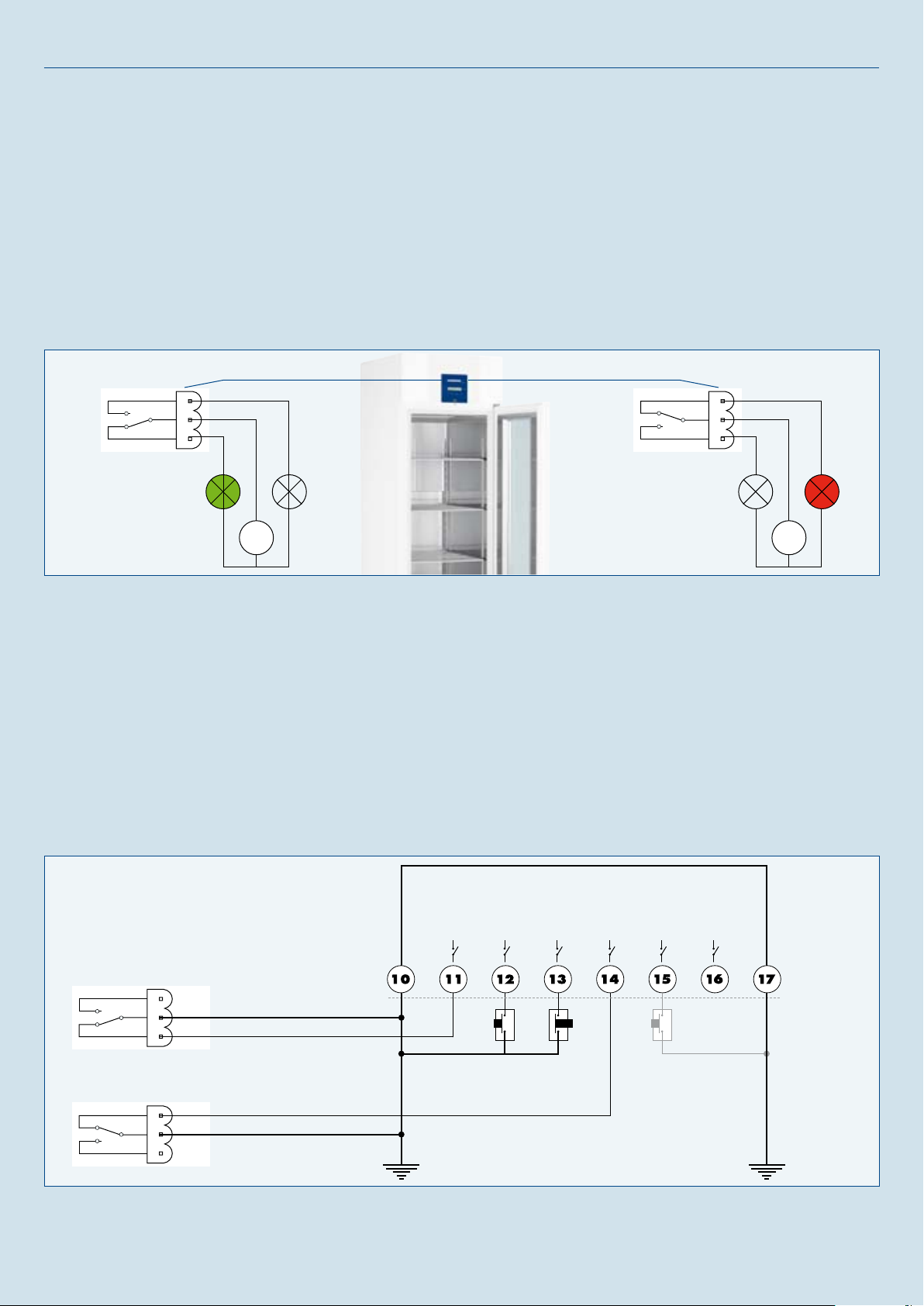

External alarm contact connection

Volt-free contact

All LKPv and LGPv models have an integrated volt-free contact. The relay contact can be wired into a warning system in the building which would advise e.g. security

personnel or a janitor outside of working hours. Warning systems with audio or visual alarms are possible.

The following example shows a circuit with a visual alarm. Either normal operation or alarm condition or both can be indicated. Either AC or DC circuits are possible,

max AC 230 V / 5 Amp.

Example: visual alarm system using volt free alarm contact

Normal operation Alarm condition

e.g. green lamp

indicating normal

opretaion

external power supply

N.O.

COM

N.C.

+

e.g. red lamp

indicating alarm

condition

-

external power supply

N.O.

COM

N.C.

+

-

Alternatively, if no internal warning system is in place and additional wiring inside the building is problematical, the volt-free contact can be used in conjunction

with e.g. a GSM alarm dialler. There are many different versions of GSM alarm dialers available on the market which either call a telephone number and/or send

a text message in case of an alarm. Depending on the specification of the alarm dialler, potentially many appliances can be connected to one dialler. Being GSM

appliances, only a SIM card and a power supply are required.

The following example shows a circuit with a GSM dialler: A change in relay setting activates the alarm function of the dialler and thus initiates either a telephone

call or an SMS to pre-defined numbers with a pre-recorded message. The dialler in the example has 6 addressed alarm inputs. This could be 6 individual appliances

or 6 rooms, each with several appliances wired in series.

Example: GSM dialler alarm system using volt free alarm contact

Alarm inputs A1– 6

GND

Open or close A1– 6 to GND

Normal operation

COM

N.C.

Alarm condition

N.O.

COM

GND

A1 A2 A3 A4 A5 A6

Any contractors

normally open or closed

GND

GND

In spite of all efforts to produce appliances of unequalled reliability, Liebherr strongly recommends that the volt-free contact is wired into some kind of independent

and external warning system. Please take a few moments to consider the value of the contents of the refrigerators and freezers under your supervision. The cost

of such a warning system is often negligible in comparison to the value of the contents.

7

Page 8

LKPv and LGPv laboratory appliances with Profi-Controller

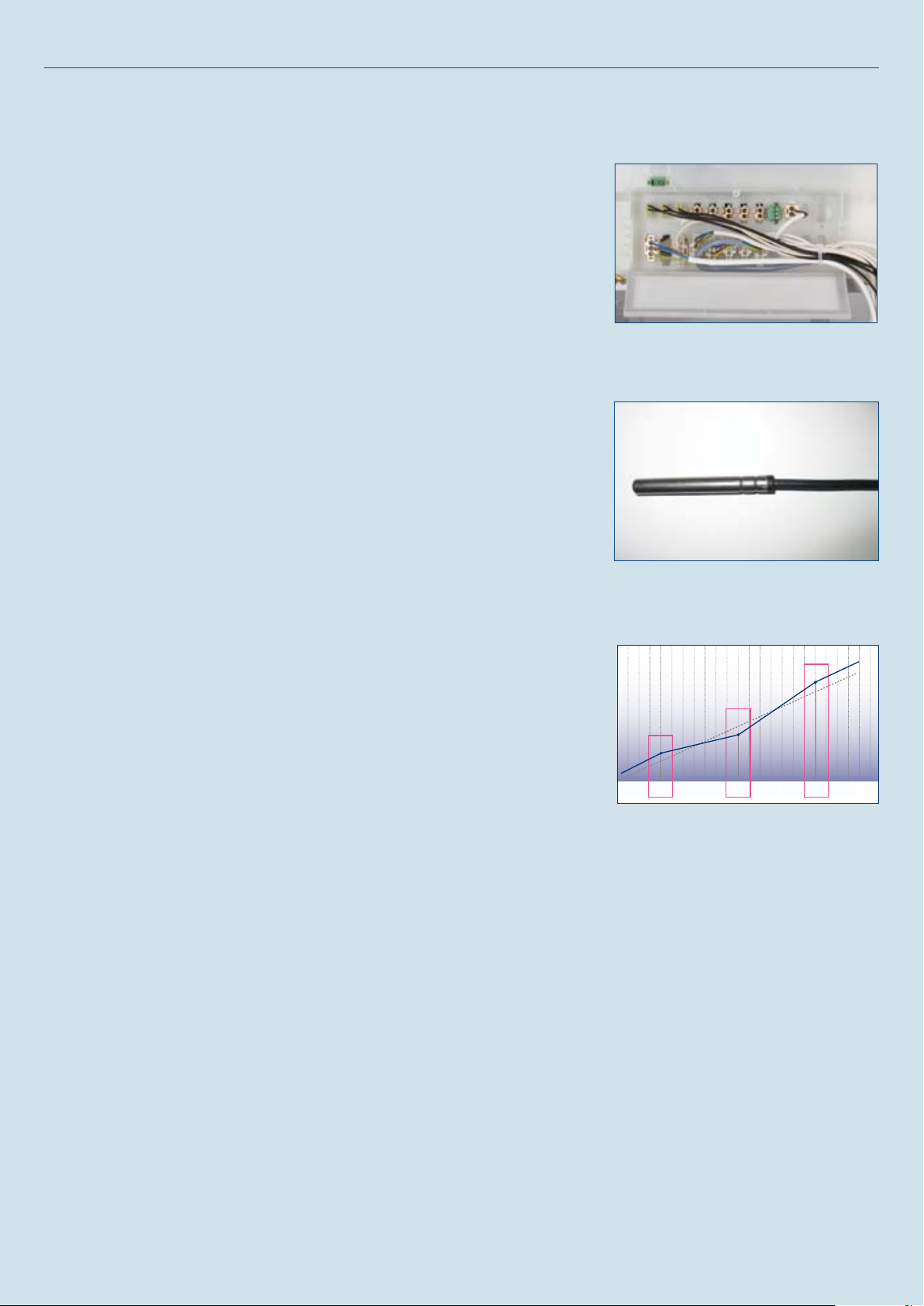

Product temperature monitoring connection

Interface for optional NTC product temperature probe

All LKPv and LGPv models have an integrated interface for connecting an optional available NTC product

temperature probe to the Profi-controller. The controller can be set to display either the internal air temper-

ature, as registered by the air probe or the temperature registered by the product probe or both. Also the

temperature alarm limits as well as the temperature alarm delay for the product temperature probe can be

adjusted by the user to suit individual requirements. In addition the product temperature can be monitored

on an external documentation system via the RS 485 interface.

Whereas the air probe is in a fixed position, the product probe will be located by the user, e.g. in a phial or

in a measurement package in order to simulate a product temperature.

The product temperature probe is water resistant and resistant to corrosion (IP 68 and AISI 316). It complies

with all relevant NSF standards.

Due to possible tolerances of the product temperature probe the temperature displayed can differ from

the product probe temperature. Using the calibration function, the temperature displayed can be aligned

with the product probe temperature at as many as three temperature points. The correction value for the

compensation of the differences can be adjusted in 0,1 °C steps.

+0.8°C

-0.4°C

+0.5°C

Cal.1 1.0°C 0.5°C Cal.2 8.0°C -0.4°C Cal.3 15.0°C 0.8°C

8

Page 9

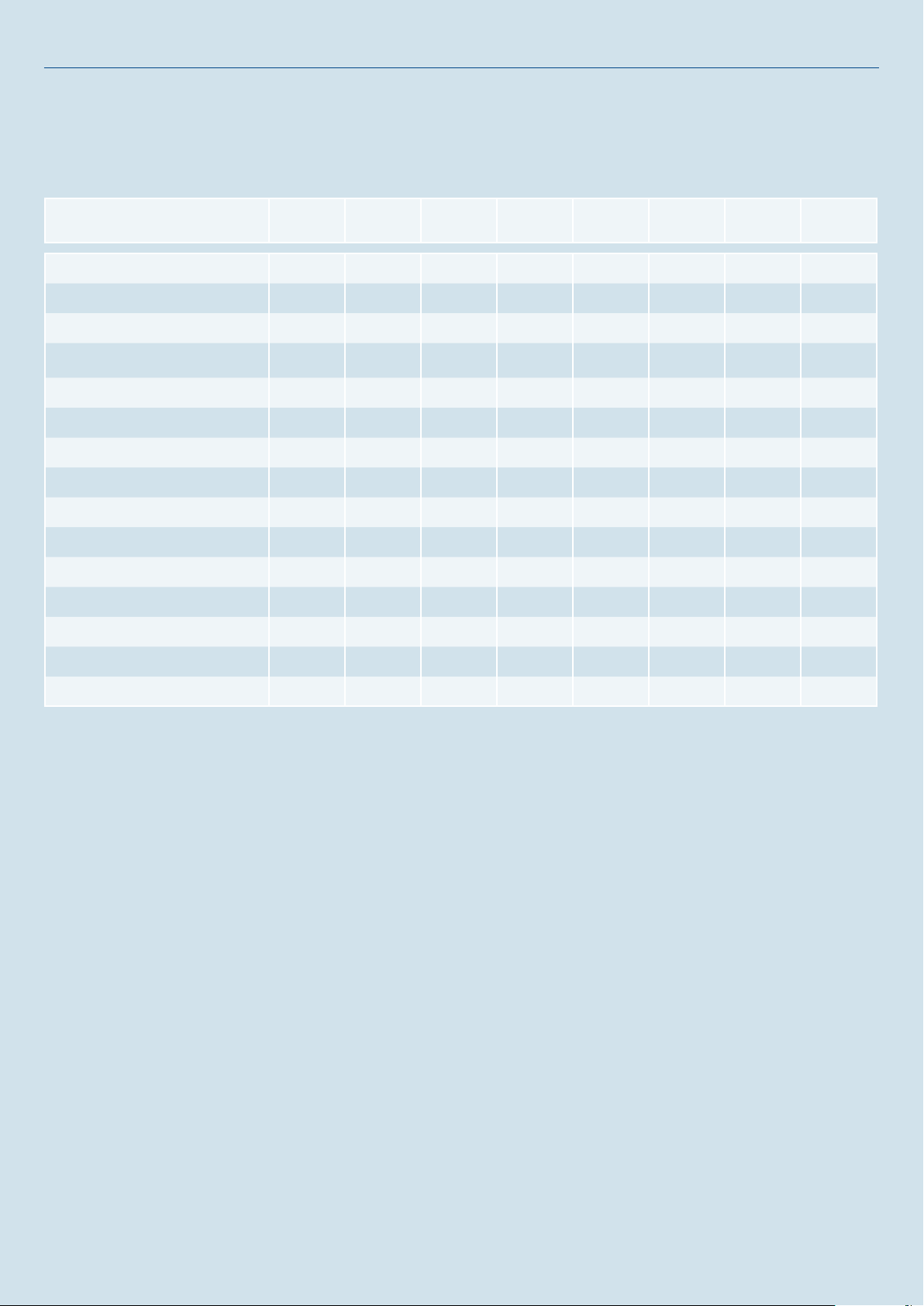

LKPv and LGPv laboratory appliances with Profi-Controller

Safety feature table

Laboratory appliances with

Profi-Controller

Spark-free interior No No No No No No No No

High / Low temperature alarm, audio and visual Yes Yes Yes Yes Yes Yes Yes Yes

Door-open alarm, audio and visual Yes Yes Yes Yes Yes Yes Yes Yes

Power failure alarm through battery backup

for 72h, audio and visual

Volt-free contact for external alarm signal Yes Yes Yes Yes Yes Yes Yes Yes

RS 485 data transfer interface Yes Yes Yes Yes Yes Yes Yes Yes

Infrared data transfer interface Yes Yes Yes Yes Yes Yes Yes Yes

Infrared data transfer key with data monitoring

software

RS 485 / RS 232 converter with data

monitoring software

NTC product temperature probe Accessory Accessory Accessory Accessory Accessory Accessory Accessory Accessory

Internal alarm memory Yes Yes Yes Yes Yes Yes Yes Yes

Min. / Max. temperature memory Yes Yes Yes Yes Yes Yes Yes Yes

Access port for e.g. PT 100 probe Yes Yes Yes Yes Yes Yes Yes Yes

Probe failure alarm Yes Yes Yes Yes Yes Yes Yes Yes

LKPv 6520 LKPv 6522 LKPv 8420 LKPv 1420 LKPv 1422 LGPv 6520 LGPv 8420 LGPv 1420

Yes Yes Yes Yes Yes Yes Yes Yes

Accessory Accessory Accessory Accessory Accessory Accessory Accessory Accessory

Accessory Accessory Accessory Accessory Accessory Accessory Accessory Accessory

Condenser and evaporator temperature alarms Yes Yes Yes Yes Yes Yes Yes Yes

9

Page 10

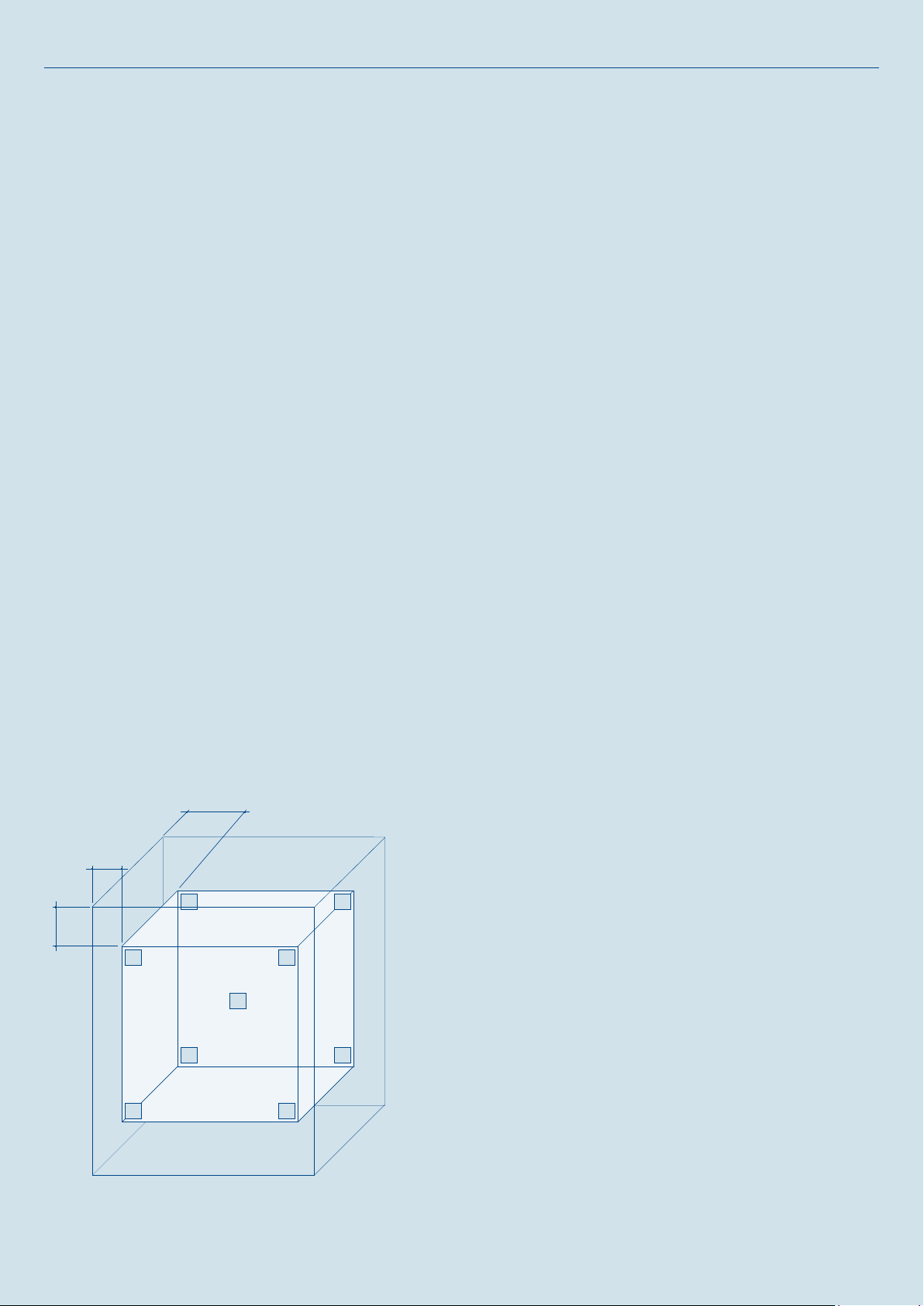

LKPv and LGPv laboratory appliances with Profi-Controller

Temperature consistency and distribution

according to NF X 15-140

The Liebherr laboratory cabinets are all tested in-house to the NF X 15-140 test procedure. Liebherr’s modern R & D facility has climate controlled test rooms

which conform to EN 23953.

Description of the NF X 15-140 test procedure

The general test conditions are as follows:

■

Ambient temperature + 25 °C

■

60 % relative humidity

■

Refrigerator set temperature + 5 °C

■

Freezer set temperature – 20 °C

Measurements are made using 9 x PT 100 air temperature probes positioned in accordance with NF X 15-140.

“Unless specifically stipulated, the temperature probes are located at equal distances from the walls of 1/10 of each of the dimensions of the internal volume

(w/h/d). The location of the probes used for characterisation forms a supposedly representative sample of the working space.”

The characterisation is performed using nine probes; one located at each corner, one in the centre of the working space.

Location of the probes used for characterisation

1/10 T

1/10 B

2 3

1/10 H

1

4

5

centred

7 8

6

9

10

Page 11

LKPv and LGPv laboratory appliances with Profi-Controller

Cabinets are tested empty over a period of 24 hrs including defrost cycles.

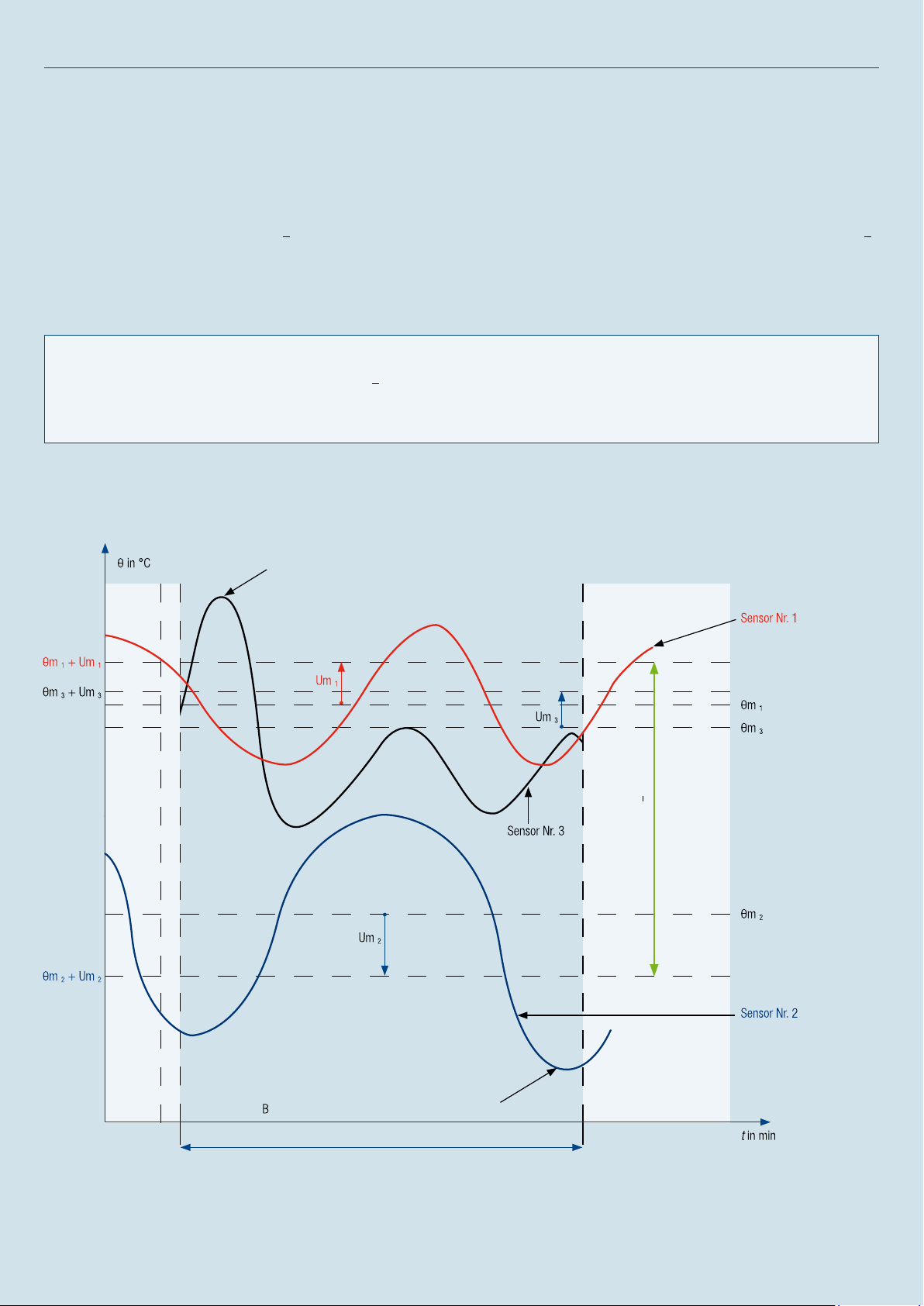

Test criteria for characterising the temperature consistency and distribution

1) Gradient or homogeneity: “The gradient H0

increased by their expanded uncertainty U

, within the working space during the measurement time.”

mj

Gradient: “Distribution of temperatures within the chamber“

max = (mean value warmest probe + expanded measurement uncertainty)

min = (mean value coldest probe – expanded measurement uncertainty)

Example: Gradient (Homogeneity)

Maximum value

is the maximum difference, obtained in an achieved environment, between the mean values of measurements 0mj

H0 = max (0

-mj+Umj) – min (0-mj-Umj)

Gradient H0

Minimum value

Measurement period

The gradient indicates the temperature distribution within the cabinets. Especially in the laboratory sector optimum temperature distribution is crucial to guarantee

the safe storage of samples or other products at any place within the unit. The lower the gradient the better is the temperature distribution within the unit.

11

Page 12

LKPv and LGPv laboratory appliances with Profi-Controller

2) Fluctuation: “The characterisation of the temperature fluctuation within the working space enables to determine the variation in maximum temperature at a

measurement point of the working space during the measurement time.”

“Maximum fluctuation: Value of the probe with the greatest difference between highest and lowest measured temperature”

The lower the maximum fluctuation the better is the temperature consistency within the units.

Example: Fluctuation

in °C

0

Sensor (j) Sensor with greatest difference

A B B

Duration of measurements

Maximum

fluctuation

m

S0

Fluctuation

of a sensor

j

S0

B

t

in min

12

Page 13

LKPv and LGPv laboratory appliances with Profi-Controller

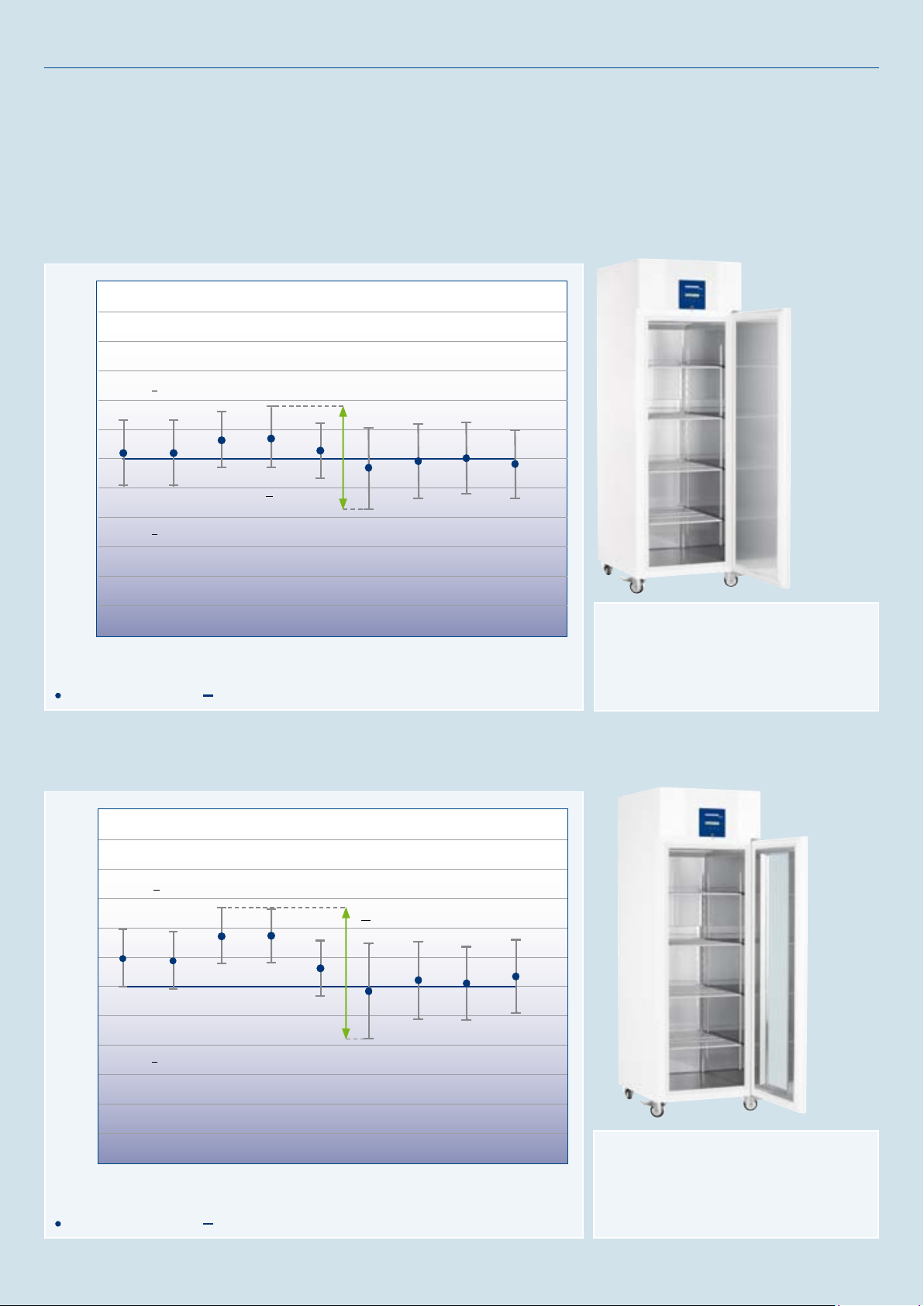

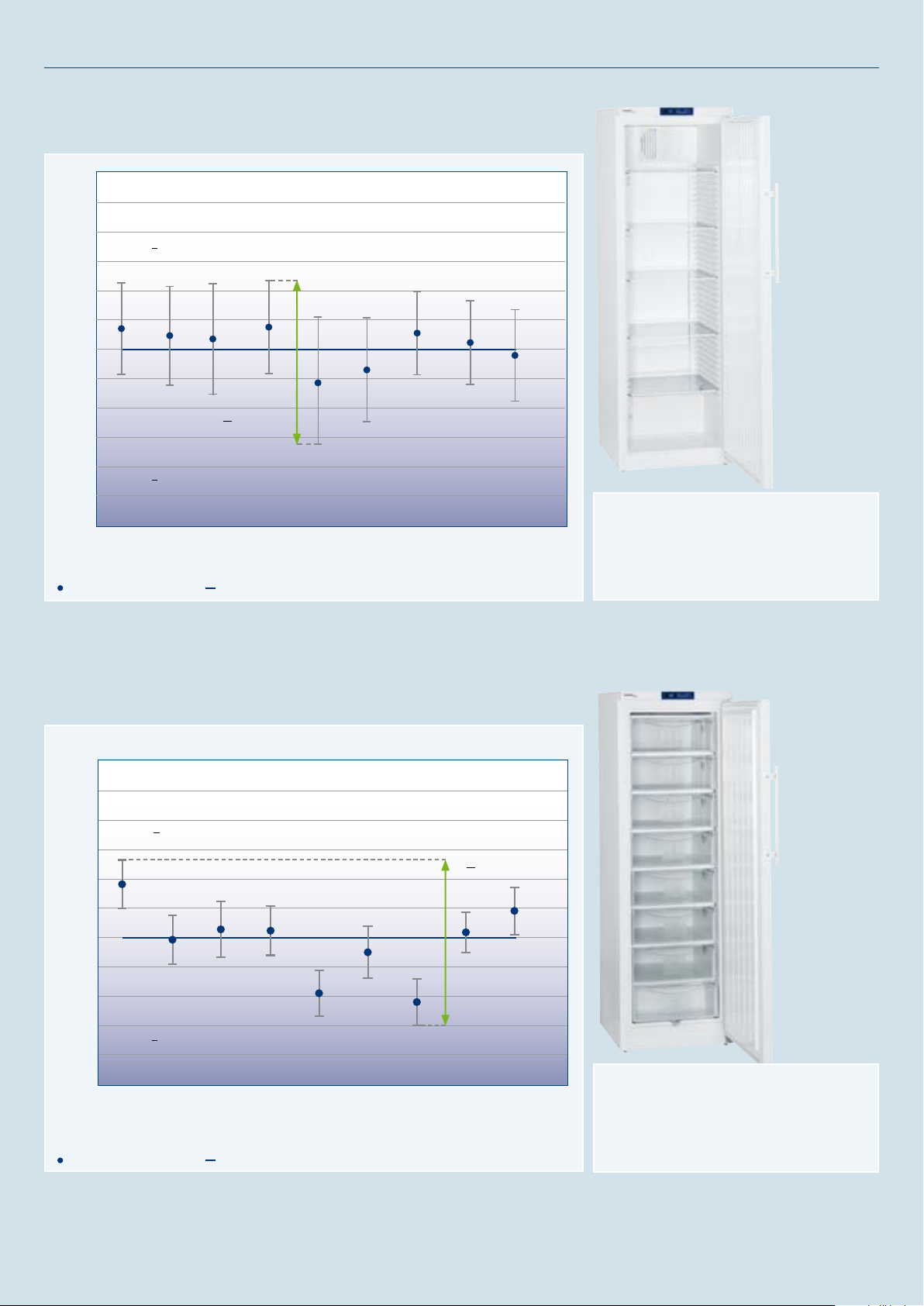

Results according to NF X 15-140

The evaluation of air temperatures of the LKPv and LGPv models according to NF X 15-140 using a PT 100 temperature probe with 25 g copper thermal mass

shows the following results:

LKPv 6520

8,0 °C

7,5 °C

7,0 °C

6,5 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

6,0 °C

5,5 °C

5,0 °C

mj

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

Average probe temperature

min (0

t1 t2 t3 t4 t5 t6 t7 t8 t9

LKPv 6522

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

max (0

H0= Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

Gradient H0- : 1.8 K (+ 0.9 K / – 0.9 K from

set temperature)

Max. fluctuation: 1.0 K

5,5 °C

5,0 °C

4,5 °C

4,0 °C

min (0

3,5 °C

3,0 °C

2,5 °C

2,0 °C

Average probe temperature

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

– Umj) = mean value coldest probe – expanded measurement uncertainty

Gradient H0- : 2.3 K (+1.4 K / – 0.9 K from

set temperature)

Probes

Max. fluctuation: 1.6 K

Set temperature

13

Page 14

LKPv and LGPv laboratory appliances with Profi-Controller

LKPv 8420

8,0 °C

7,5 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

– Umj) = mean value coldest probe – expanded measurement uncertainty

min (0

3,0 °C

mj

2,5 °C

2,0 °C

t1 t2 t3 t4 t5 t6 t7 t8 t9

Average probe temperature

H0 = Gradient

Gradient H0- : 1.74 K (+0.9 K / – 0.84 K from

set temperature)

Probes

Max. fluctuation: 1.5 K

Set temperature

LKPv 1420

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

Average probe temperature

max (0

min (0

t1 t2 t3 t4 t5 t6 t7 t8 t9

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

Gradient H0- : 2.0 K (+0.5 K / – 1.5 K from

set temperature)

Max. fluctuation: 1.2 K

14

Page 15

LKPv and LGPv laboratory appliances with Profi-Controller

LKPv 1422

8,0 °C

7,5 °C

7,0 °C

6,5 °C

max (0

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

min (0

3,0 °C

2,5 °C

2,0 °C

t1 t2 t3 t4 t5 t6 t7 t8 t9

Average probe temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

Gradient H0- : 2.6 K (+1.5 K / – 1.1 K from

set temperature)

Max. fluctuation: 1.6 K

LGPv 6520

-17.0 °C

-17.5 °C

-18.0 °C

-18.5 °C

-19.0 °C

-19.5 °C

-20.0 °C

-20.5 °C

-21.0 °C

-21.5 °C

-22.0 °C

-23.0 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

min (0

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Gradient H0- : 3.0 K (+1.75 K / –1.25 K from

set temperature)

Average probe temperature

Set temperature

Max. fluctuation: 3.6 K

15

Page 16

LKPv and LGPv laboratory appliances with Profi-Controller

LGPv 8420

– 17,0 °C

– 17,5 °C

max (0

– 18,0 °C

– 18,5 °C

– 19,0 °C

– 19,5 °C

– 20,0 °C

– 20,5 °C

– 21,0 °C

– 21,5 °C

– 22,0 °C

– 22,5 °C

min (0

– 23,0 °C

t1 t2 t3 t4 t5 t6 t7 t8 t9

Average probe temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

Gradient H0- : 3.52 K (+2.0 K / – 1.52 K from

set temperature)

Max. fluctuation: 4.3 K

LGPv 1420

–17.0 °C

–17.5 °C

–18.0 °C

–18.5 °C

–19.0 °C

–19.5 °C

–20.0 °C

–20.5 °C

–21.0 °C

–21.5 °C

–22.0 °C

–23.0 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

min (0

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Gradient H0- : 3.5 K (+1.5 K / – 2.0 K from

set temperature)

Average probe temperature

Set temperature

Max. fluctuation: 3.9 K

16

Page 17

Doorvoermogelijkheid PT 100

Bovenin de binnenruimte is een

opening (Ø 7,6 mm) aangebracht

die de mogelijkheid biedt een

externe temperatuurvoeler of een

andere meetverbinding door te

voeren.

Verlicht tekstdisplay

Tiptoetsbediening met hygiënisch

vuilbestendig foliedisplay en toets-

blokkering. Keuze uit 5 talen (Engels,

Duits, Frans, Spaans en Italiaans).

Temperatuur wordt op 0,1°C nauw-

keurig aangegeven.

Beveiligd bij stroomuitval

Een 12V accu voorkomt dat data

verloren gaan. Gedurende 72 uur

wordt het temperatuurverloop

geregistreerd en wordt, indien

Optisch en akoestisch alarm

Een deur- en temperatuuralarm

waarschuwt bij een ongewenste

temperatuurverandering van 2K.

30 Alarmsituaties worden bewaard

en kunnen via het display of de in-

frarood interface worden uitgelezen.

Aansluiten op centale

Met een seriële interface RS 485 of

potentiaalvrij contact is aansluiten op

een centraal log- of alarmsysteem

mogelijk. Iedere 2 minuten worden

tijd, datum en temperatuur exact

geregistreerd.

Temperatuurregistratie

Iedere 4 minuten worden datum, tijd

en temperatuur, evenals eventuele

alarmmeldingen, bewaard. Na 2.800

registraties (~ 7,5 dag) worden data

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

All LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT models have integrated high and low internal air temperature

alarms with both audio and visual signals. The factory settings for the alarm limits are +3 /–3 K in relation

to the set temperature: If the set temperature is altered to meet a specific storage temperature requirement

then the alarm settings move in parallel and do not need to be adjusted separately. There is a 15 minutes

delay to avoid unwanted alarms due to e.g. door opening. The alarm parameters can however be adjusted

All LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT models register when doors are left open or ajar and have an

integrated audio and visual door-open alarm. This alarm has a 1 minute delay, and can be adjusted between

All LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT models indicates a visual power failure alarm after the return of

As a self-control system, defective probes are registered and the controller causes an audio and visual

alarm signal. In case of an air-probe error the controller has pre-defined operating modes to maintain the

Alarm, memory and safety functions

Liebherr Mediline refrigerators and freezers with Comfort-Controller help to protect your inventory. These cabinets offer a variety of alarm,

memory and safety features designed to greatly reduce the risk of loss of contents .

Temperature, door-open and power failure alarms

High and low temperature alarms

by the user to suit individual requirements.

Door-open alarm

1 and 5 minutes.

Power failure alarm

the power supply. The power failure alarm remains until it is manually reset.

Internal system alarm

The following alarm is related to internal self-checks of the electronic controller probes. While this might not be immediately relevant to the every-day operation of

the cabinets it does provide added security by warning probably before the air temperature probe registers an alarm condition.

Probe failure alarm

internal temperature at + 5 °C.

17

Page 18

In order to ensure maximum reliability, the Comfort-Controller has a heavy-duty compressor relay thus

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

This function stores to memory details of the last three temperature and power failure alarms. Time and

After reaching the set temperature for the first time, the Comfort controller begins continuously to store

to memory the highest and lowest internal temperatures registered. These minimum and maximum

temperatures can be read out from the memory. After reading the min/max memory, the values can either be

reset or left in the memory. Normally the values would be noted by the user and the memory reset in order

to define the next period to be registered. The controller also registers the time elapsed since the last reset

Internal memory functions

Internal alarm memory

date of the start and the duration of the alarm conditions are registered.

Min. / max. temperature memory

Min

up to a period of ~ 40 days.

Max

Special safety function

Electro-mechanical + 2 °C safety thermostat for laboratory refrigerators with Comfort-Controller

reducing the possibility of burned relay contacts. Should however a defect occur, an additional safety ther-

mostat backs up the controller to prevent the product temperature from dropping below +2 °C.

+ 2 °C

18

Page 19

Liebherr

Temperature

Monitoring

Software for

Serial Interface &

Infrared key

Deutsch

English

Français

Italiano

Español

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

Temperature and

alarm documentation

Liebherr Mediline refrigerators and freezers with Comfort-Controller help to protect your inventory. These cabinets offer a variety of features

and options designed both for external monitoring of the internal temperatures, the product temperatures and alarm conditions to greatly

reduce the risk of loss of contents.

External temperature and alarm

monitoring connection

RS 485 interface and optional signal converter

All LK(U)v, LCv, LK(U)exv and LG(U)ex models have an integrated RS 485 interface. If an RS 485 monitoring

system is not already in place, a converter kit is available as an optional extra to convert the RS 485 signal

to an RS 232 signal and allow connection to a PC or laptop.

The RS 485 bus connection is made using standard shielded data cables, e.g. type LiYCY 2 x 0,14 mm². The

maximum possible length of the data lines depends on the quality of the components used. The maximum

range is 500m. A maximum of 20 appliances can be wired in series.

Dedicated software is provided in the accessory package allowing visualisation, analysis and export to other

formats for storage. The software reads the air-probe temperature at 2 minute intervals and records alarm

conditions. When an alarm condition is registered the software will warn on the PC on which the software

is running: if this PC is not supervised (e.g. at night or over weekends) then the alarm signal might not be

recognised. In order to avoid unrecognised alarms the software includes an email function, which sends an

email in case of an alarm condition to predefined email addresses. These emails can be easily checked with

a smartphone. Therefore the user will be warned without having direct access to a computer.

Networking

Both laboratory appliances with Profi-Controller as well as laboratory appliances with Comfort- Controller

can be networked using the same Liebherr accessory package “RS 485 interface converter including

temperature monitoring software”.

Example: RS 485 network

RS 485

+ - s

Optimum:

Shielded Twisted Pair

BUS line

appliance 1 appliance 2 appliance 20

Terminator

120 Ohm

Terminator

120 Ohm

- + s

- + s - + s

Address 1 Address 2 Address 3

19

Page 20

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

External alarm contact connection

Volt-free contact

All LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT models have an integrated volt-free contact. The relay contact can be wired into a warning system in the building which

would advise e.g. security personnel or a janitor outside of working hours. Warning systems with audio or visual alarms are possible.

The following example shows a circuit with a visual alarm. Either normal operation or alarm condition or both can be indicated. Either AC or DC circuits are possible,

max AC 230 V / 5 Amp.

Example: visual alarm system using volt free alarm contact

Normal operation Alarm condition

e.g. green lamp

indicating normal

opretaion

external power supply

N.O.

COM

N.C.

+

e.g. red lamp

indicating alarm

condition

-

external power supply

N.O.

COM

N.C.

+

-

Alternatively, if no internal warning system is in place and additional wiring inside the building is problematical, the volt-free contact can be used in conjunction

with e.g. a GSM alarm dialler. There are many different versions of GSM alarm dialers available on the market which either call a telephone number and/or send a

text message in case of an alarm. Depending on the specification of GSM alarm dialers, potentially many appliances can be connected to one dialler. Being GSM

appliances, only a SIM card and a power supply are required.

The following example shows a circuit with a GSM dialler: A change in relay setting activates the alarm function of the dialler and thus initiates either a telephone

call or an SMS to pre-defined numbers with a pre-recorded message. The dialler in the example has 6 addressed alarm inputs. This could be 6 individual appli-

ances or 6 rooms, each with several appliances wired in series.

Example: GSM dialer alarm system using volt free alarm contact

Alarm inputs A1– 6

GND

Open or close A1– 6 to GND

Normal operation

COM

N.C.

Alarm condition

N.O.

COM

GND

A1 A2 A3 A4 A5 A6

Any contractors

normally open or closed

GND

GND

In spite of all efforts to produce appliances of unequalled reliability, Liebherr strongly recommends that the volt-free contact is wired into some kind

of independent and external warning system. Please take a few moments to consider the value of the contents of the refrigerators and freezers under

your supervision. The cost of such a warning system is often negligible in comparison to the value of the contents.

20

Page 21

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

Product temperature monitoring connection

Interface for optional NTC product temperature probe

All LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT models have an integrated interface for connecting an optional

available NTC product temperature probe to the comfort controller. The controller can be set to display either

the internal air temperature, as registered by the air probe, or the temperature registered by the product

probe. Depending on this selection the temperature alarm limits are related either to the air probe or to

the product probe. In addition the product temperature can be monitored on an external documentation

system via the RS 485 interface.

Whereas the air probe is in a fixed position, the product probe will be located by the user, e.g. in a phial or

in a measurement package in order to simulate a product temperature.

The product temperature probe is water resistant and resistant to corrosion (IP 68 and AISI 316). It complies

with NSF standards.

Due to possible tolerances of the product temperature probe the temperature displayed can differ from

the product probe temperature. Using the calibration function, the temperature displayed can be aligned

with the product probe temperature. The correction value for the compensation of the differences can be

adjusted in 0,1 °C steps.

+0.5 °C

Cal. 5.0 °C + 0.5 °C

21

Page 22

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

Safety feature table

Laboratory appliances

with Comfort-Controller

Spark-free interior No No Yes Yes No No Ye s Ye s No

High / Low temperature alarm, audio and visual

Door-open alarm, audio and visual Yes Yes Yes Yes Yes Ye s Ye s Ye s Yes

Power failure warning after power

supply is returned, visual

Volt-free contact for external alarm

signal

RS 485 data transfer interface Yes Yes Yes Yes Ye s Yes Yes Yes Yes

RS 485 / RS 232 converter with

data monitoring software

NTC product temperature probe Accessory Accessory Accessory Accessory Accessory Accessory Accessory Accessory Accessory

Internal alarm memory Yes Yes Yes Yes Ye s Yes Yes Yes Yes

Min. / Max. temperature memory Yes Yes Yes Yes Yes Yes Ye s Ye s Ye s

+2°C safety thermostat Yes Yes Yes No Ye s Ye s Yes No

Access port for e.g. PT 100 probe Yes Yes Ye s Ye s Ye s Yes Yes Yes Yes

Probe failure alarm Yes Yes Yes Ye s Yes Yes Yes Yes Ye s

LKUv 1610 LKUv 1612 LKUexv 1610 LGUex 1500 LKv 3910 LKv 3912 LKexv 3910 LGex 3410 LCv 4010

Yes Yes Yes Yes Ye s Yes Yes Yes Yes

Yes Yes Yes Yes Ye s Yes Yes Yes Yes

Yes Yes Yes Yes Ye s Yes Yes Yes Yes

Accessory Accessory Accessory Accessory Accessory Accessory Accessory Accessory Accessory

For refrigerator

compartment

Low temperature freezers

to – 45 °C

Spark-free interior No No No

High / Low temperature alarm

audio and visual

Lid-open alarm,

audio and visual

Power failure warning after power

supply is returned, visual

Volt-free contact

for external alarm signal

RS 485 data transfer

interface

RS 485 / RS 232 converter with

data monitoring software

NTC product temperature probe Accessory Accessory Accessory

Internal alarm memory Yes Yes Yes

Min. / Max.

temperature memory

Access port for e.g. PT 100 probe Ye s Yes Yes

Probe failure alarm Yes Yes Yes

LGT 2325 LGT 3725

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Accessory Accessory Accessory

Yes Yes Yes

LGT 4725

22

Page 23

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

Temperature consistency and distribution

according to NF X 15-140

The Liebherr laboratory cabinets are all tested in-house to the NF X 15-140 test procedure. Liebherr’s modern R & D facility has climate controlled test rooms

which conform to EN 23953.

Description of the NF X 15-140 test procedure

The general test conditions are as follows:

■

Ambient temperature + 25 °C

■

60 % relative humidity

■

Refrigerator set temperature + 5 °C

■

Freezer set temperature – 20 °C

■

Low temperature freezer set temperature – 45 °C

Measurements are made using 9 x PT 100 air temperature probes positioned in accordance with NF X 15-140.

“Unless specifically stipulated, the temperature probes are located at equal distances from the walls of 1/10 of each of the dimensions of the internal volume

(w/h/d). The location of the probes used for characterisation forms a supposedly representative sample of the working space.”

The characterisation is performed using nine probes; one located at each corner, one in the centre of the working space.

Location of the probes used for characterisation

1/10 T

1/10 B

2 3

1/10 H

1

5

centred

4

7 8

6

9

23

Page 24

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

Cabinets are tested empty over a period of 24 hrs including defrost cycles.

Test criteria for characterising the temperature consistency and distribution

1) Gradient or homogeneity: “The gradient H0

increased by their expanded uncertainty U

, within the working space during the measurement time.”

mj

Gradient: “Distribution of temperatures within the chamber“

max = (mean value warmest probe + expanded measurement uncertainty)

min = (mean value coldest probe – expanded measurement uncertainty)

Example: Gradient (Homogeneity)

Maximum value

is the maximum difference, obtained in an achieved environment, between the mean values of measurements 0mj

H0 = max (0

-mj+Umj) – min (0-mj-Umj)

Gradient H0

Minimum value

Measurement period

The gradient indicates the temperature distribution within the cabinets. Especially in the laboratory sector optimum temperature distribution is crucial to guarantee

the safe storage of samples or other products at any place within the unit. The lower the gradient the better is the temperature distribution within the unit.

24

Page 25

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

2) Fluctuation: “The characterisation of the temperature fluctuation within the working space enables to determine the variation in maximum temperature at a

measurement point of the working space during the measurement time.”

“Maximum fluctuation: Value of the probe with the greatest difference between highest and lowest measured temperature”

The lower the maximum fluctuation the better is the temperature consistency within the units.

Example: Fluctuation

in °C

0

Sensor (j) Sensor with greatest difference

A B B

Duration of measurements

Maximum

fluctuation

m

S0

Fluctuation

of a sensor

j

S0

B

t

in min

25

Page 26

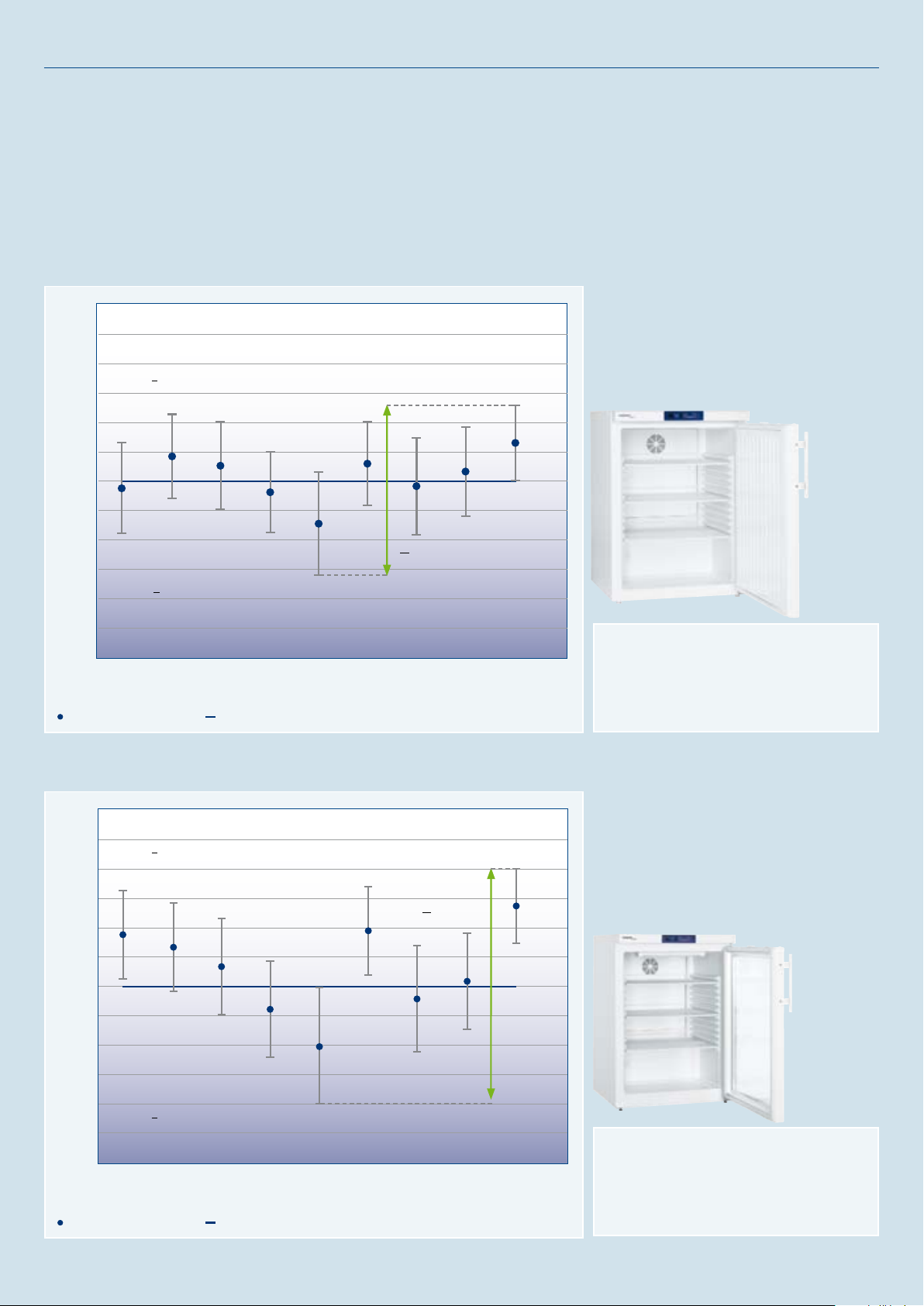

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

Results according to NF X 15-140

The evaluation of air temperatures of the LK(U)v, LCv, LK(U)exv, LG(U)ex and LGPv models according to NF X 15-140 using a PT 100 temperature probe with

25 g copper thermal mass shows the following results:

LKUv 1610

8,0 °C

7,5 °C

7,0 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

6,5 °C

6,0 °C

5,5 °C

5,0 °C

mj

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

t1 t2 t3 t4 t5 t6 t7 t8 t9

Average probe temperature

LKUv 1612

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

max (0

H0 = Gradient

min (0

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

Gradient H0- : 2.9 K (+1.3 K / –1.6 K from

set temperature)

Max. fluctuation: 2.5 K

H0 = Gradient

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

min (0

2,5 °C

2,0 °C

t1 t2 t3 t4 t5 t6 t7 t8 t9

Average probe temperature

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

Gradient H0- : 4.0 K (+2.0 K / – 2.0 K from

set temperature)

Max. fluctuation: 3.3 K

26

Page 27

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

LKUexv 1610

8,0 °C

7,5 °C

max (0

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

min (0

t1 t2 t3 t4 t5 t6 t7 t8 t9

Average probe temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

Gradient H0- : 4.1 K (+1.6 K / –2.5 K from

set temperature)

Max. fluctuation: 3.0 K

LGUex 1500

-17.0 °C

-17.5 °C

-18.0 °C

-18.5 °C

-19.0 °C

-19.5 °C

-20.0 °C

-20.5 °C

-21.0 °C

-21.5 °C

-22.0 °C

-22.5 °C

-23.0 °C

-23.5 °C

-24.0 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

min (0

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Gradient H0- : 5.7 K (+2.1 K / – 3.6 K from

set temperature)

Average probe temperature

Set temperature

Max. fluctuation: 0.80 K

27

Page 28

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

LKv 3910

9,0 °C

8,5 °C

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

1,5 °C

1,0 °C

Average probe temperature

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

min (0

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Set temperature

Gradient H0- : 3.0 K (+1.25 K / –1.75 K from

set temperature)

Max. fluctuation: 2.5 K

LKv 3912

9,0 °C

8,5 °C

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

1,5 °C

1,0 °C

Average probe temperature

max (0

min (0

t1 t2 t3 t4 t5 t6 t7 t8 t9

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

Gradient H0- : 4.2 K (+1.8 K / – 2.4 K from

set temperature)

Max. fluctuation: 3.7 K

28

Page 29

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

LKexv 3910

8,0 °C

7,5 °C

7,0 °C

max (0

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

min (0

2,5 °C

2,0 °C

t1 t2 t3 t4 t5 t6 t7 t8 t9

Average probe temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Set temperature

Gradient H0- : 2.8 K (+1.2 K / –1.6 K from

set temperature)

Max. fluctuation: 3.4 K

LGex 3410

-17.0 °C

-17.5 °C

-18.0 °C

-18.5 °C

-19.0 °C

-19.5 °C

-20.0 °C

-20.5 °C

-21.0 °C

-21.5 °C

-22.0 °C

-23.0 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

min (0

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Gradient H0- : 2.9 K (+1.4 K / – 1.5 K from

set temperature)

Average probe temperature

Set temperature

Max. fluctuation: 0.40 K

29

Page 30

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

LCv 4010 – Evaluation of refrigerator compartment

9,0 °C

8,5 °C

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

1,5 °C

1,0 °C

Average probe temperature

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

min (0

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Set temperature

Gradient H0- : 3.4 K (+1.8 K / –1.6 K from

set temperature)

Max. fluctuation: 4.0 K

LCv 4010 – Evaluation of freezer compartment

– 16,5 °C

– 17,0 °C

– 17,5 °C

– 18,0 °C

– 18,5 °C

– 19,0 °C

– 19,5 °C

– 20,0 °C

– 20,5 °C

– 21,0 °C

– 21,5 °C

– 22,0 °C

– 22,5 °C

– 23,0 °C

– 23,5 °C

– 24,0 °C

Average probe temperature

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

min (0

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Set temperature

Probes

H0 = Gradient

Gradient H0- : 6.0 K (+2.6 K / – 3.4 K from

set temperature)

Max. fluctuation: 3.4 K

30

Page 31

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

LGT 2325 *

– 41,0 °C

– 41,5 °C

– 42,0 °C

– 42,5 °C

– 43,0 °C

– 43,5 °C

– 44,0 °C

– 44,5 °C

– 45,0 °C

– 45,5 °C

– 46,0 °C

– 46,5 °C

– 47,0 °C

– 47,5 °C

– 48,0 °C

– 48,5 °C

Average probe temperature

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

min (0

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Set temperature

Gradient H0-: 4,58 K (+ 2,45 K/-2,13 K from

set temperature)

Max. fluctuation: 1,8 K

*If the cabinet is operated at -20 °C it is recommended to reduce the predefined offset of 2,7 K to 1,0 K (see user manual).

LGT 3725 *

-42,0 °C

-42,5 °C

-43,0°C

-43,5°C

-44,0°C

-44,5 °C

-45,0 °C

-45,5 °C

-46,0 °C

+ Umj) = mean value warmest probe + expanded measurement uncertainty

max (0

mj

H0 = Gradient

-46,5 °C

-47,0 °C

-47,5°C

min (0

– Umj) = mean value coldest probe – expanded measurement uncertainty

-48,0 °C

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Average probe temperature

*If the cabinet is operated at -20 °C it is recommended to reduce the predefined offset of 2,7 K to 1,0 K (see user manual).

Set temperature

Gradient H0- : 3,23 K (+ 0,82 K/-2,41 K from

set temperature)

Max. fluctuation: 0,5 K

31

Page 32

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

LGT 4725 *

-42,0 °C

-42,5 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

-43,0°C

-43,5°C

-44,0°C

H0 = Gradient

-44,5 °C

-45,0 °C

-45,5 °C

-46,0 °C

-46,5 °C

-47,0 °C

-47,5°C

– Umj) = mean value coldest probe – expanded measurement uncertainty

min (0

-48,0 °C

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Average probe temperature

*If the cabinet is operated at -20 °C it is recommended to reduce the predefined offset of 2,7 K to 1,0 K (see user manual).

Set temperature

Gradient H0-: 3,27 K (+ 0,8 K/-2,47 K from

set temperature)

Max. fluctuation: 1,1 K

32

Page 33

LK(U)v, LCv, LK(U)exv, LG(U)ex and LGT laboratory appliances with Comfort-Controller

Loading plan: low temperature chest freezers with kryo racks (height of kryo boxes 50 mm)

LGT 2325 L GT 3725

Interior dimensions (W/D/H) in mm

Number of racks: 140/140/604 mm

Number of racks: 140/140/222 mm

Number of boxes: 130/130/50 mm

Maximum height of racks:

Maximum height of racks above the compressor:

889/410/630 1170/500/650

8 18

2 3

96 210

630 mm 650 mm

375 mm 380 mm

LGT 4725

Interior dimensions (W/D/H) in mm

Number of racks: 140/140/604 mm

Number of racks: 140/140/222 mm

Number of boxes: 130/130/50 mm

Maximum height of racks:

Maximum height of racks above the compressor:

1445/500/650

24

3

276

650 mm

380 mm

33

Page 34

Pharmacy refrigerators compliant to DIN 58345

Pharmacy refrigerators compliant to

DIN 58345

In order to comply with the DIN 58345 standard, the MKv and MKUv models have the following specifications:

1) To avoid any unwanted manipulation, the set temperature is fixed at +5 °C to guarantee maximum safety

2) Likewise the offset values of the probes cannot be changed

3) Also alarm limits cannot be changed from the default values +2/+8°C

4) An additional probe is positioned at the warmest point within the unit and this temperature is displayed on the controller

5) The MKv 3912 has a load line to prevent pharmaceuticals being placed at the very top of the compartment

6) In order to prevent product loss or detriment due to incorrect storage, an integrated evaporator cover keeps products

away from the cold surface of the evaporator

7) The integrated power failure alarm gives an acoustic warning immediately upon power failure

Otherwise the MKv and MKUv models have the same features as the LKv and LKUv equivalents.

Safety feature table

Pharmacy refrigerators

compliant to DIN 58345

Spark-free interior No No No No

High / Low temperature alarm

audio and visual

Door-open alarm, audio and visual Yes Yes Yes Yes

Power failure warning immediately

upon power failure l

Volt-free contact

for external alarm signal

RS 485 data transfer

interface

RS 485 / RS 232 converter with

data monitoring software

NTC product temperature probe Accessory Accessory Accessory Accessory

Internal alarm memory Yes Yes Yes Yes

Min. / Max.

temperature memory

MK v 3910 MKv 3912

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

Accessory Accessory Accessory Accessory

Yes Yes Yes Yes

MKU v 1610 MK U v 1612

+ 2 °C safety thermostat Yes Yes Yes Yes

Access port for e.g. PT 100 probe Ye s Yes Yes Yes

Probe failure alarm Yes Yes Yes Yes

34

Page 35

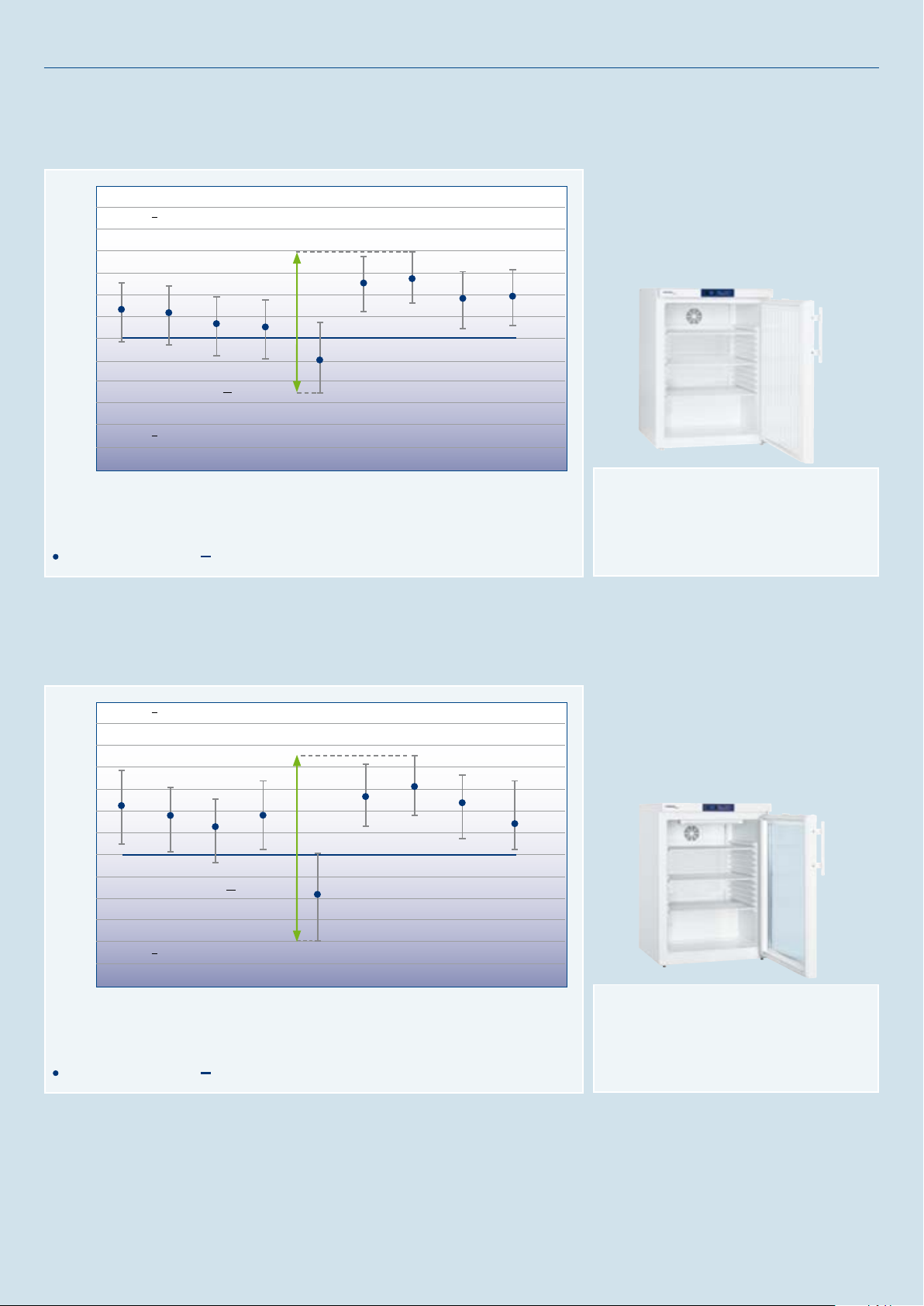

Pharmacy refrigerators compliant to DIN 58345

Results according to NF X 15-140

The evaluation of air temperatures of the MK(U)v models according to NF X 15-140 using a PT 100 temperature probe shows the following results:

MKv 3910

8,5 °C

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

min (0

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Gradient H0- : 4.20 K (+2.4 K / –1.8 K from

set temperature)

Average probe temperature

MKv 3912

8,5 °C

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

max (0

min (0

t1 t2 t3 t4 t5 t6 t7 t8 t9

Set temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0

= Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Max. fluctuation: 3.10 K

Gradient H0- : 4.46 K (+3.1 K / –1.36 K from

set temperature)

Average probe temperature

Set temperature

Max. fluctuation: 3.60 K

35

Page 36

Pharmacy refrigerators compliant to DIN 58345

MKUv 1610

8,5 °C

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

max (0

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0 = Gradient

min (0

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

t1 t2 t3 t4 t5 t6 t7 t8 t9

Probes

Gradient H0- : 3.31 K (+2.0 K / –1.31 K from

set temperature)

Average probe temperature

MKUv 1612

8,5 °C

8,0 °C

7,5 °C

7,0 °C

6,5 °C

6,0 °C

5,5 °C

5,0 °C

4,5 °C

4,0 °C

3,5 °C

3,0 °C

2,5 °C

2,0 °C

max (0

min (0

t1 t2 t3 t4 t5 t6 t7 t8 t9

Set temperature

+ Umj) = mean value warmest probe + expanded measurement uncertainty

mj

H0

= Gradient

– Umj) = mean value coldest probe – expanded measurement uncertainty

mj

Probes

Max. fluctuation: 2.70 K

Gradient H0- : 4.27 K (+2.27 K / –2.00 K from

set temperature)

Average probe temperature

Liebherr laboratory refrigerators or freezers do not comply with the German Institute for Standardisation norm DIN 58371 regarding the

requirements for the storage of conserved blood and DIN 58375 regarding the requirements for the storage of blood plasma. The MKv and

MKUv models comply with the German Institute for Standardisation norm DIN 58345 which refers to the specification of pharmacy refrigerators.

All other Liebherr refrigerators and freezers in this catalogue do not comply with this standard.

Set temperature

Max. fluctuation: 4.00 K

36

Loading...

Loading...