Liebherr Truck-mounted concrete pumps User Manual

Truck Mounted Concrete Pumps:

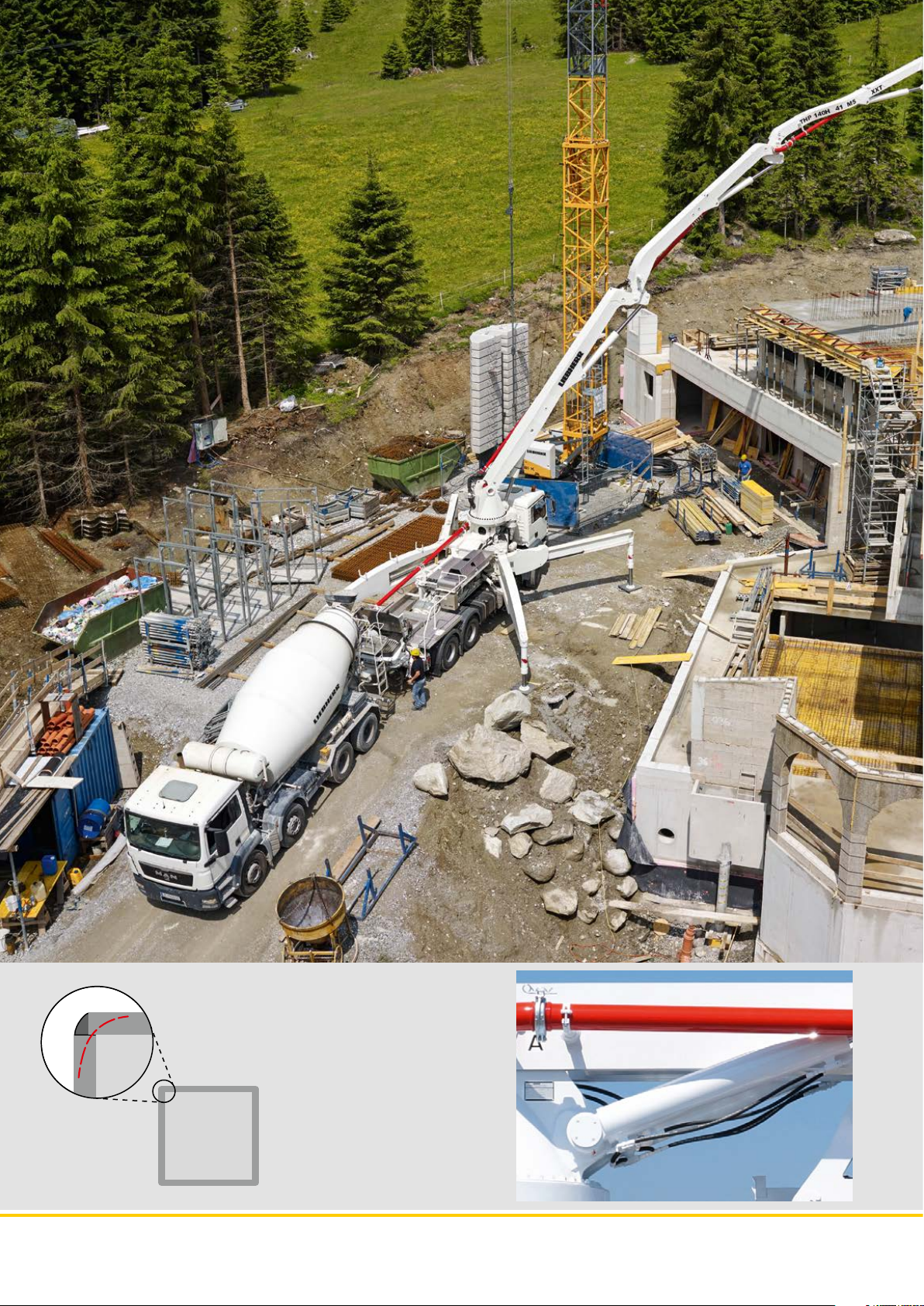

Optimum Conveyance of Concrete

The rugged design ensures reliable operation

over several years with

low operating costs.

Innovative technology, such

as the patented support

system, provides advantages

during ever yday operation.

2

More profit by way of investment

There are many reasons for choosing a Liebherr truck mounted concrete pump:

When purchasing from Liebherr, you are guaranteed high-performance „Made in

Germany“ products for the most exacting requirements. With utmost importance

attached to quality, we only install components supplied by renowned manufacturers. Extensive test series and field testing, as well as material inspections

ensure long life-expectancy of the concrete pumps. The innovative pump units,

hydraulic system and state-of-the-art control ensures cost-effective operation of

the concrete pump.

Numerous technical details simplify servicing: For example, easier and quicker

replacement of wear parts.

Over the long-term, a concrete pump from Liebherr will prove a profitable investment as the outlay for servicing and energy costs yield a positive overall balance

with regard to life cycle costs.

The higher resale value of German quality products from Liebherr proves yet another positive aspect in the total cost balance.

Various design details simplify the

replacement of wear parts, thus

optimising servicing.

Advanced structural designs and state-of-

the-art manufacturing technologies pro-

duce a dependable, sturdy construction

for the toughest of everyday applications.

3

Liebherr booms are sturdier

with improved torsional resistance due to their welding

system.

4

The distributor booms

Distributor booms from Liebherr are available in roll-fold, Z-fold or multi-fold designs (depending on the respective type) featuring three, four or five boom elements.

The balanced weight distribution resulting from alternating pipeline guidance

on the left-hand and right-hand boom side, as well as the torsional resistant

steel structure, ensures low-vibration guidance of the boom. Arrangement of the

pipeline close to the boom, combined with the large-sized pins and hydraulic

cylinders contribute to a safe and consistent guidance of the boom.

Pipe bends are predominantly the same, making the storage of wear parts easier. Due to their large radius (R=275), the pipe bends reduce resistance in the

concrete line.

High pressure filtering in the boom ensures exceptionally clean hydraulic oil to

improve operational safety. Considerably smaller particles can be filtered out in

the high-pressure range.

Reduced boom width

Largely-dimensioned hydraulic

cylinders and sturdy hinged pins

ensure even and vibration-free

movements, contributing to a

longer life-expectancy.

Reduced boom width is highly advantageous when inserting into openings

in buildings.

5

Outrigger XXH

6

Loading...

Loading...