Page 1

A 918 CompactWheeled excavator

Job Report

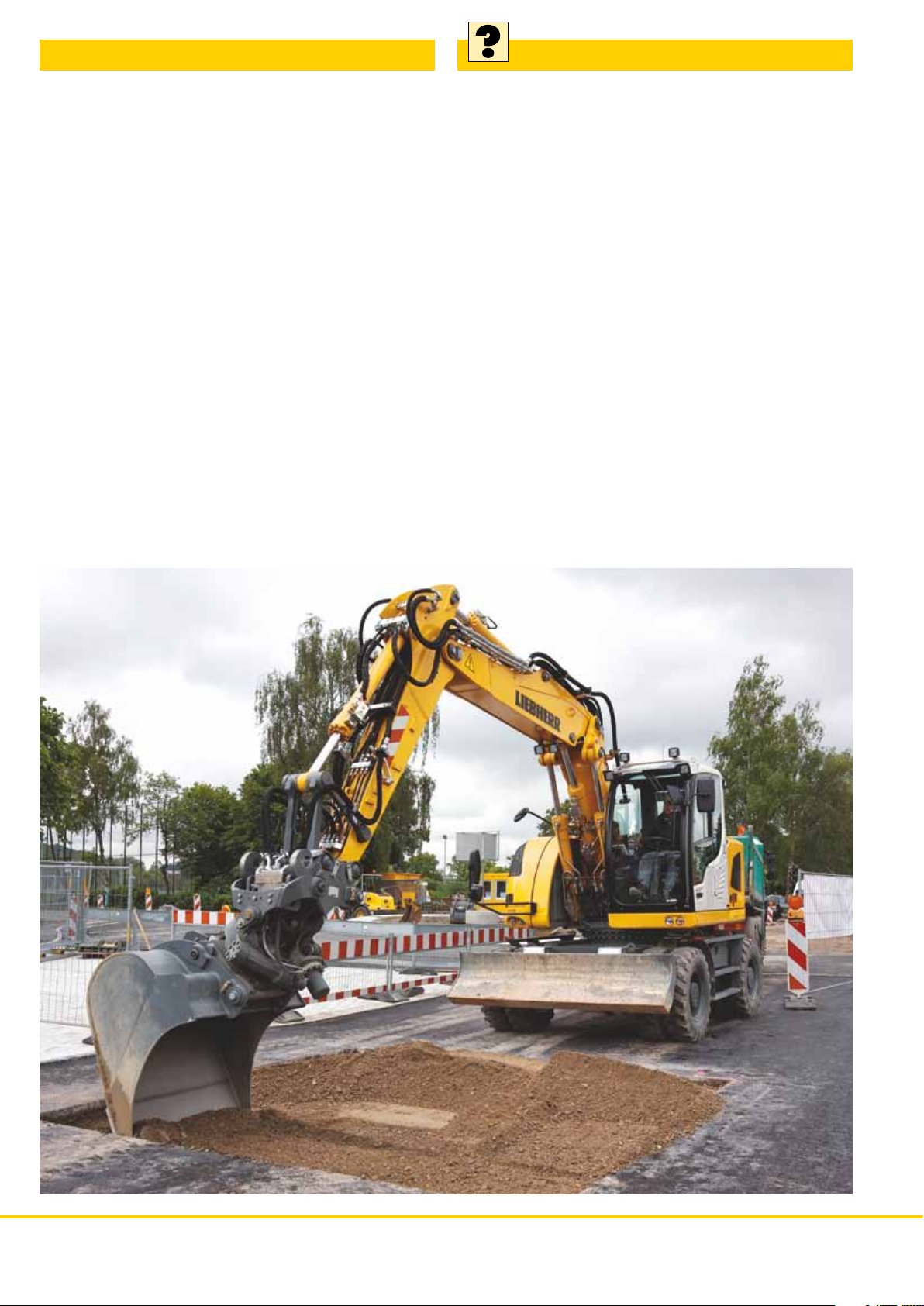

The Liebherr A 918 Compact Litronic wheeled

excavator with LIKUFIX and TR 25 tiltrotator in

service with Grüner and Mühlschlegel

Page 2

Situation Task

In 1924, Fritz Grüner founded the construction company, Grüner

und Mühlschlegel, in the southern German town of Biberach an

der Riß. The company is still based there today. The areas of

activity of this traditional family firm from Upper Swabia include

civil engineering, road and bridge building as well as garden and

landscape design. Health and safety, focussing on employees

and long-term company development are the key tenets of the

company’s philosophy. These make the medium-sized company

a reliable and firm partner for employees and customers alike.

Grüner und Mühlschlegel exclusively uses Liebherr machines

for earth moving. Amongst other machines, the fleet includes

three A 900 C Litronic wheeled excavators, an A 316 Litronic, an

R 934 C Litronic crawler excavator and five 506 stereo loaders.

The firm’s construction orders are divided half-and-half between

private companies and public clients within a radius of 100 km

of the company’s headquarters. Recently, the 90 employees of

Grüner und Mühlschlegel have worked on tasks such as new

office and administration buildings, industrial structures and

various road building projects. Under its managing director,

Andreas Braun, the company has made a name for itself in the

region through reliability, quality and technical expertise. Despite

problems in the general economic situation, the construction

company is pleased to report a good level of incoming orders

with full order books.

There is an extreme variety of earth moving tasks to be tackled, reflecting the construction company’s wide range of

activities. These include classic excavation, exposing existing

construction segments, shaping earth mounds, and compacting

incorporated material. A wheeled excavator was to be used

as before for accomplishing these tasks. When it came to

purchasing the machine, the wish list included a high lifting

capacity because of the need to unload and shift prefabricated

concrete components in addition to carrying out the groundworks. It is also highly important for the wheeled excavator to

have a short tail swing radius, because the working environment

in road building and city centre applications is often restricted.

It is necessary to use different working tools in order to accomplish the various tasks. There must be provision for exchanging

these from the operator’s cab within the shortest possible time.

The company places particular emphasis on the operating and

maintenance costs of a machine, as well as its environmental

friendliness. Therefore, the final choice came down exclusively

to wheeled excavators that meet the requirements of the current

exhaust emissions stage IIIB.

Page 3

Solution

Grüner und Mühlschlegel chose to tackle these applications with

an A 918 Compact Litronic wheeled excavator weighing about

18 tonnes, and equipped with the LIKUFIX fully hydraulic quick

coupling system. Its tail swing radius of only 1.85 m means the

excavator has a short rear end and is ideal for use in road building and city centre tasks. The machine is powered by a 110 kW /

150 PS Liebherr diesel engine developed in conjunction with

MAN. This engine meets the requirements of exhaust emissions

stage IIIB without needing to use a particle filter. All that is required for exhaust purification is an oxidation catalytic converter

which is maintenance-free when used with low-sulphur engine

oil as standard. As a result, maintenance costs are reduced. The

drive unit sets new standards in terms of fuel consumption for

this machine class. In some cases, the company’s machine operator can achieve less than 7 litres/hour, with the average figure

between 7 and 9 litres/hour. The A 918 Compact Litronic offers

a high lifting capacity, powerful excavating forces and very good

performance combined with low fuel consumption. This means

it meets the requirements of the construction company in terms

of productivity and efficiency.

Using Liebherr’s own LIKUFIX quick coupling system, the machine operator can change over from one tool to another within

15 seconds, without leaving the cab. It can use backhoe buckets, tilting buckets, a n add-on compactor and a Liebherr TR 25

tiltrotator with backhoe bucket. The Liebherr tiltrotator is being

used first for the extension to Hans-Liebherr-Strasse in Biberach, a project which also includes building a roundabout. It has

already become the most used working tool on this construction

site. Flexible use of the attached backhoe bucket significantly

reduces unproductive repositioning of the hydraulic excavator

during working; this increases the machine’s productivity.

The road extension became necessary due to building of a new

school in Biberach, which will become one of the largest educational facilities in Baden-Württemberg. Grüner und Mühlschlegel

has been given the order of completing the construction work

in this building project, and the company is doing this as part of

a consortium of contractors in which it is playing the managerial role. Liebherr tiltrotators have a tilting angle of 2 x 50° and

can rotate endlessly through 360°. The tilting cylinder is located

horizontally and is installed in a protected position. Even at the

maximum tilting angle, it does not have any protruding parts

which might be damaged when working in cramped conditions.

This ensures low service costs and makes Liebherr tiltrotators

the ideal tool for working with retaining walls or in the immediate

vicinity of structures. These jobs arise particularly frequently at

Grüner und Mühlschlegel. In this regard, the laborious job of digging by hand can be reduced to a minimum. The A 918 Compact

Litronic is equipped with the ergonomic Liebherr proportional

control, meaning that the tiltrotator can be operated quickly,

sensitively and precisely. Grüner und Mühlschlegel selected the

tiltrotator configuration recommended by Liebherr. The Liebherr

tiltrotator is equipped with the Liebherr LIKUFIX quick coupling

system on the top. This means the tiltrotator is only mounted

when it is actually needed. This reduces fuel consumption, increases the service life of the tiltrotator and makes it possible

to exploit the maximum lifting capacity of the hydraulic excavator during load lifting work. And when the job involves loading

trucks, the tiltrotator can be dropped off to allow the largest possible backhoe bucket to be mounted. As a result, a high material

loading rate is achieved with low fuel consumption. The fully automatic central lubrication system fitted as standard offers additional convenience for the operator and increased productivity

for the machine owner. Work can continue during the lubricating

process (attachment and swing ring). To protect the lubricant

tank of the central lubrication system against vandalism, it is

installed behind the left service door as standard. The machine

operator positively rates this equipment and the fact that daily

maintenance work can be performed from the ground. The efficiency of the new machine is so great compared to the old ones

that the company is now considering whether to bring forward

the originally planned renovation of the machine fleet.

Page 4

Technical Data Configuration

A 918 Compact Litronic

Operating weight

Engine output

Emission stage

Emission control system

Fuel consumption

_______________________________________________________________________________________

______________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________________

__________________________________

______________________________________________________________________________________________________________

17, 800 kg / 39,240 lbs

110 kW / 150 HP

IIIB

Oxydation catalytic converter

7-9 liters / hour

Prop-up blade

Two-piece boom

2.45 m / 8.0 ft stick

Quick coupler SW / QC 48 with LIKUFIX

Liebherr proportional control

Piston rod protection for stabilizer cylinders

Manual central lubrication for undercarriage

Electronic immobilizer

Printed in Germany by Schirmer BK LHB 11481197-1.5-06.12_enGB

Liebherr-Hydraulikbagger GmbH

Liebherrstraße 12, D-88457 Kirchdorf / Iller

+49 7354 80-0, Fax +49 7354 80-72 94

www.liebherr.com, E-Mail: info.lhb@liebherr.com

Subject to technical modifications.

Loading...

Loading...