Operating and installation instructions

wine cooling cabinet

20190322

7088105 - 00

SWTNes / WFS 1151

Appliance at a glance

Contents

1 Appliance at a glance............................................ 2

1.1 Description of appliance and equipment.................. 2

1.2 Appliance range of use............................................. 2

1.3 Conformity................................................................ 3

1.4 Product data............................................................. 3

1.5 External dimensions of the appliance....................... 3

1.6 Saving energy.......................................................... 3

1.7 Example of food arrangement.................................. 4

1.8 Smart device ........................................................... 4

2 General safety information................................... 4

3 Controls and displays........................................... 5

3.1 Home screen............................................................ 5

3.2 Operating structure................................................... 5

3.3 Navigation................................................................ 6

3.4 Display symbols....................................................... 6

3.5 Appliance options..................................................... 6

4 Putting into operation............................................ 6

4.1 Transporting the appliance....................................... 6

4.2 Installing the appliance............................................. 7

4.3 Reversing the door................................................... 7

4.4 Water connection..................................................... 16

4.5 Insertion into a row of kitchen units........................... 17

4.6 Disposing of packaging............................................ 18

4.7 Connecting the appliance......................................... 18

4.8 Switching on the appliance....................................... 18

4.9 Inserting the FreshAir filter. ...................................... 18

4.10 Setting the clean ventilation grid timer...................... 19

5 Control.................................................................... 19

5.1 Changing the temperature unit................................. 19

5.2 Child proofing........................................................... 19

5.3 Sabbath Mode.......................................................... 19

5.4 Freezer compartment............................................... 20

5.5 Wine zone................................................................ 22

6 Maintenance........................................................... 23

6.1 Change the FreshAir filter......................................... 23

6.2 Defrosting with NoFrost............................................ 24

6.3 Cleaning the ventilation grid..................................... 24

6.4 Cleaning the appliance............................................. 24

6.5 Cleaning the IceMaker.............................................. 25

6.6 Customer service..................................................... 25

7 Malfunctions........................................................... 25

8 Messages................................................................ 26

9 Decommissioning.................................................. 27

9.1 Switching the appliance off....................................... 27

9.2 Taking the appliance out of service........................... 28

10 Disposing of the appliance................................... 28

The manufacturer works constantly on the further development

of all the types and models. Therefore please understand that

we have to reserve the right to make design, equipment and

technical modifications.

To get to know all the benefits of your new appliance, please

read the information contained in these instructions carefully.

The instructions apply to several models. Differences may

occur. Text relating only to specific appliances is marked with

an asterisk (*).

Instructions for action are marked with a , the results of

action are marked with a

.

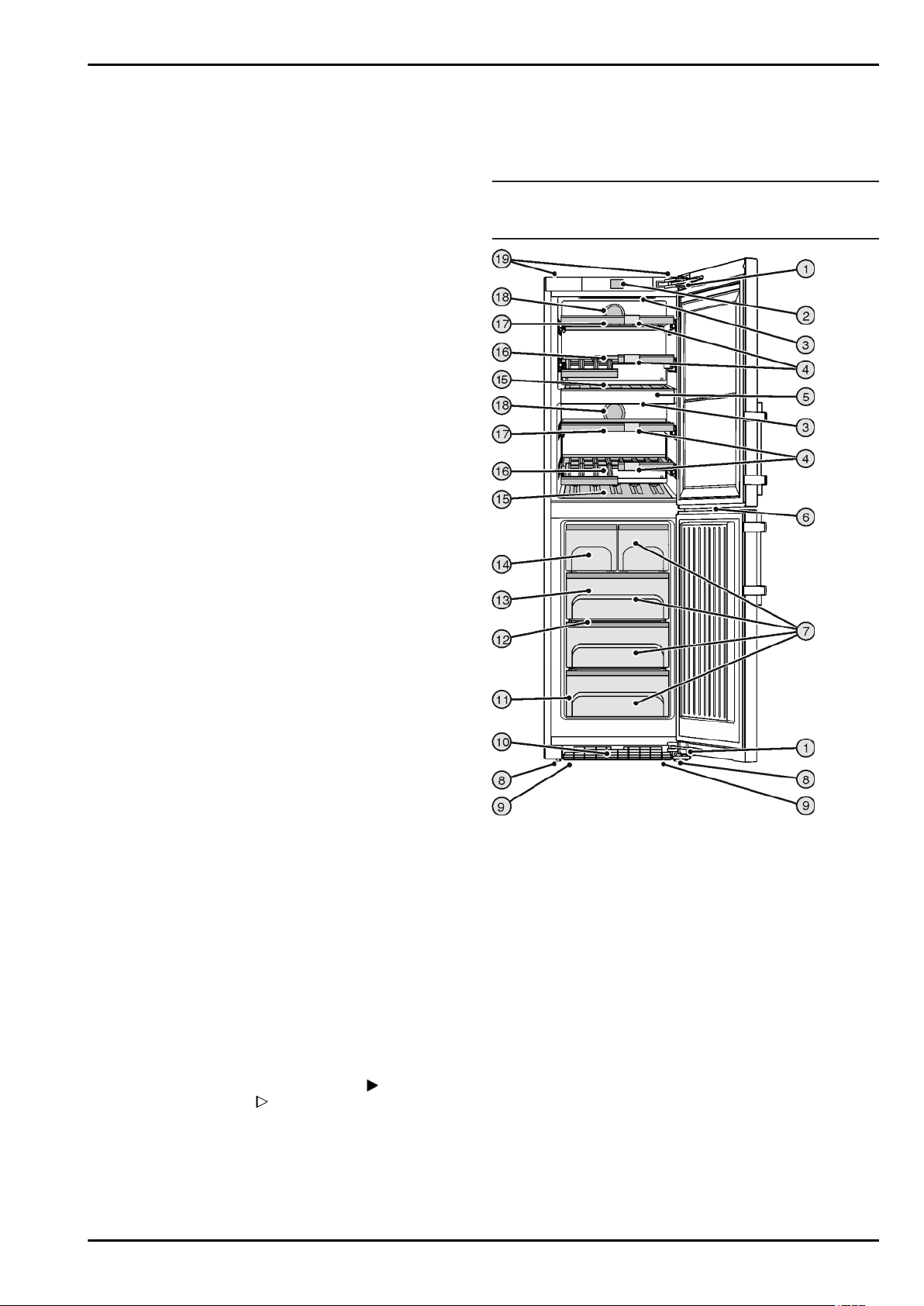

1 Appliance at a glance

1.1 Description of appliance and equipment

Note

Shelves, drawers and baskets are arranged for optimum

u

energy efficiency on delivery.

Fig. 1

(1) Soft closing fittings (11) Type plate

(2) Operating and control

elements

(3) LED interior lighting (13) Cold storage accumula-

(4) Labelling clip (14) IceMaker

(5) Divider (15) Wine rack

(6) Freezer compartment

LED light

(7) Freezer compartment (17) Wooden shelf, fixed

(8) Adjusting feet (18) Active carbon filter

(9) Front transport handles,

rear transport castors

(10) Ventilation grid

1.2 Appliance range of use

Intended use

The appliance must only be used in a domestic

or a normal household setting. Only drinks such

as wine must be stored in the wine compartment. Only frozen food must be stored in the

(12) VarioSpace

tors

(16) Wooden shelf, folding

(19) Rear transport handles

2 * Depending on model and options

Appliance at a glance

freezer compartment. This includes, for

example, using

-

in staff kitchens, bed and breakfast establishments,

-

by guests in country houses, hotels, motels

and other accommodation,

-

for catering and similar services in the wholesale trade.

All other types of use are not permitted.

Foreseeable misuse

The following applications are expressly

forbidden:

-

Storing and refrigerating medicines, blood

plasma, laboratory preparations or similar

substances and products based on the

Medical Device Directive 2007/47/EC

-

Use in outdoor areas with very high humidity.

-

Use in areas at risk of explosions

-

Use on moving substrates, such as ships, rail

travel or aeroplanes

-

Storing live animals

Misusing the appliance may lead to damage to

the goods stored or they may spoil.

Climate classifications

Depending on the climate classification the

appliance is designed to operate in restricted

ambient temperatures. The climate classification applying to your appliance is printed on the

rating plate.

Note

Keep to the specified ambient temperatures

u

in order to guarantee that the appliance works

properly.

Climate classification

SN 10 °C to 32 °C

N 16 °C to 32 °C

ST 16 °C to 38 °C

T 16 °C to 43 °C

for ambient temperatures of

1.3 Conformity

The refrigerant circuit has been tested for leaks. This appliance

complies with the applicable safety stipulations and with directives 2014/35/EU, 2014/30/EU, 2009/125/EG, 2011/65/EU and

2010/30/EU.

1.4 Product data

Product data is included with the appliance, as per Directive

(EU) 2017/1369. The complete product data sheet is available

on the Liebherr website under Downloads.

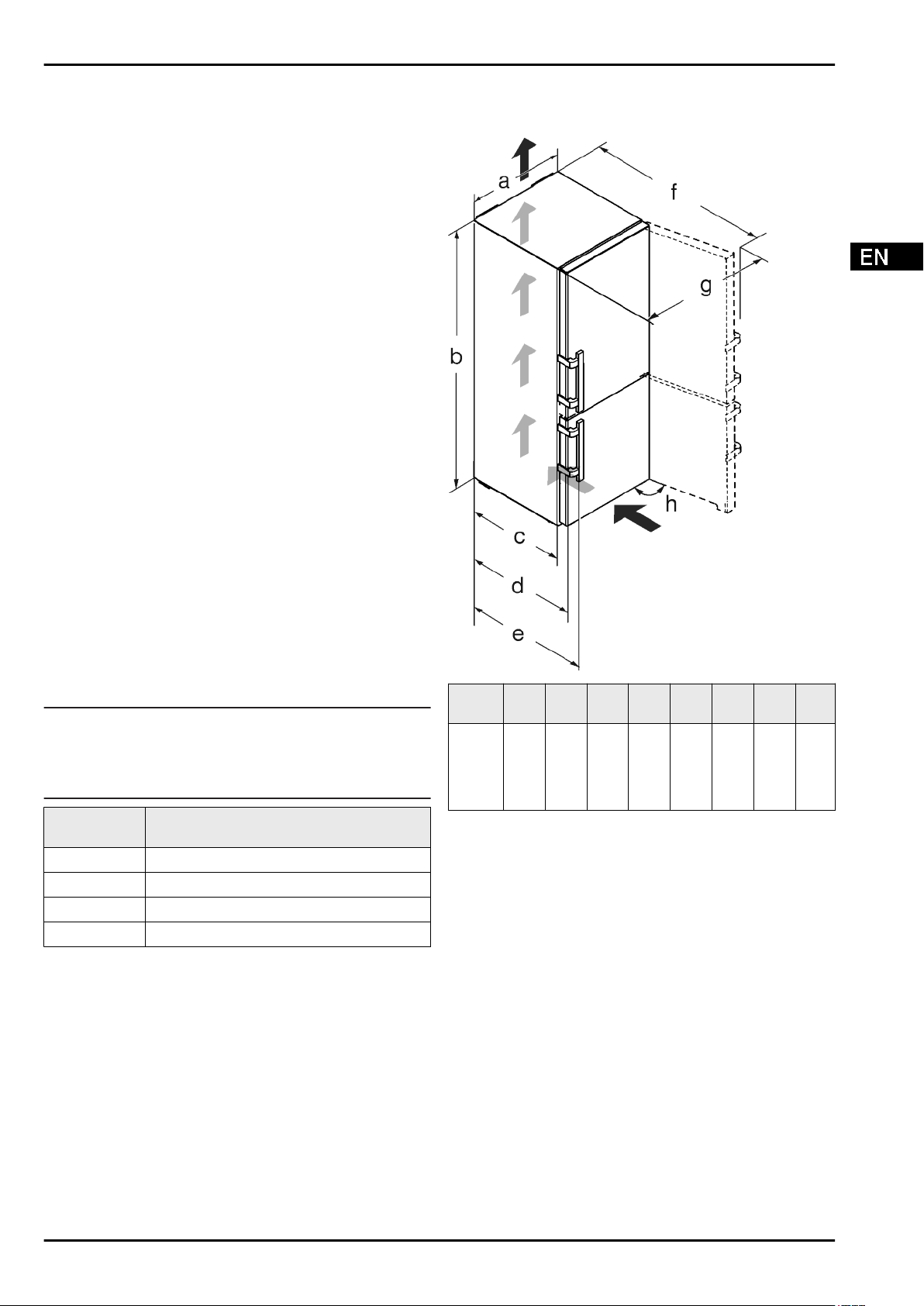

1.5 External dimensions of the appliance

Fig. 2

Model a

[mm]b [mm]c [mm]d [mm]e [mm]f [mm]g [mm]

SWTN

es

42.. /

WFS

1151

x

If you are using wall spacers, add 15 mm (see 4.2) to the

dimensions.

With the door open the dimensions apply to an opening angle

of 115° . Clearances vary depending on the opening angle.

600 1850

600 x665 x709

x

1185 x871 115

h [°]

1.6 Saving energy

Pay attention to good ventilation. Do not cover ventilation

-

holes or grids.

Always keep the fan air slits clear.

-

Do not install the appliance in direct sunlight, next to an

-

oven, radiator or similar.

Energy consumption is dependent on the installation condi-

-

tions, e.g. ambient temperature (see 1.2) . If the ambient

temperature deviates from the standard temperature of

25°C, the energy consumption may differ.

Open the appliance for as short a time as possible.

-

The lower the temperature is set the higher the energy

-

consumption.

Inserting warm food: allow to cool down to room temperature

-

first.

* Depending on model and options 3

General safety information

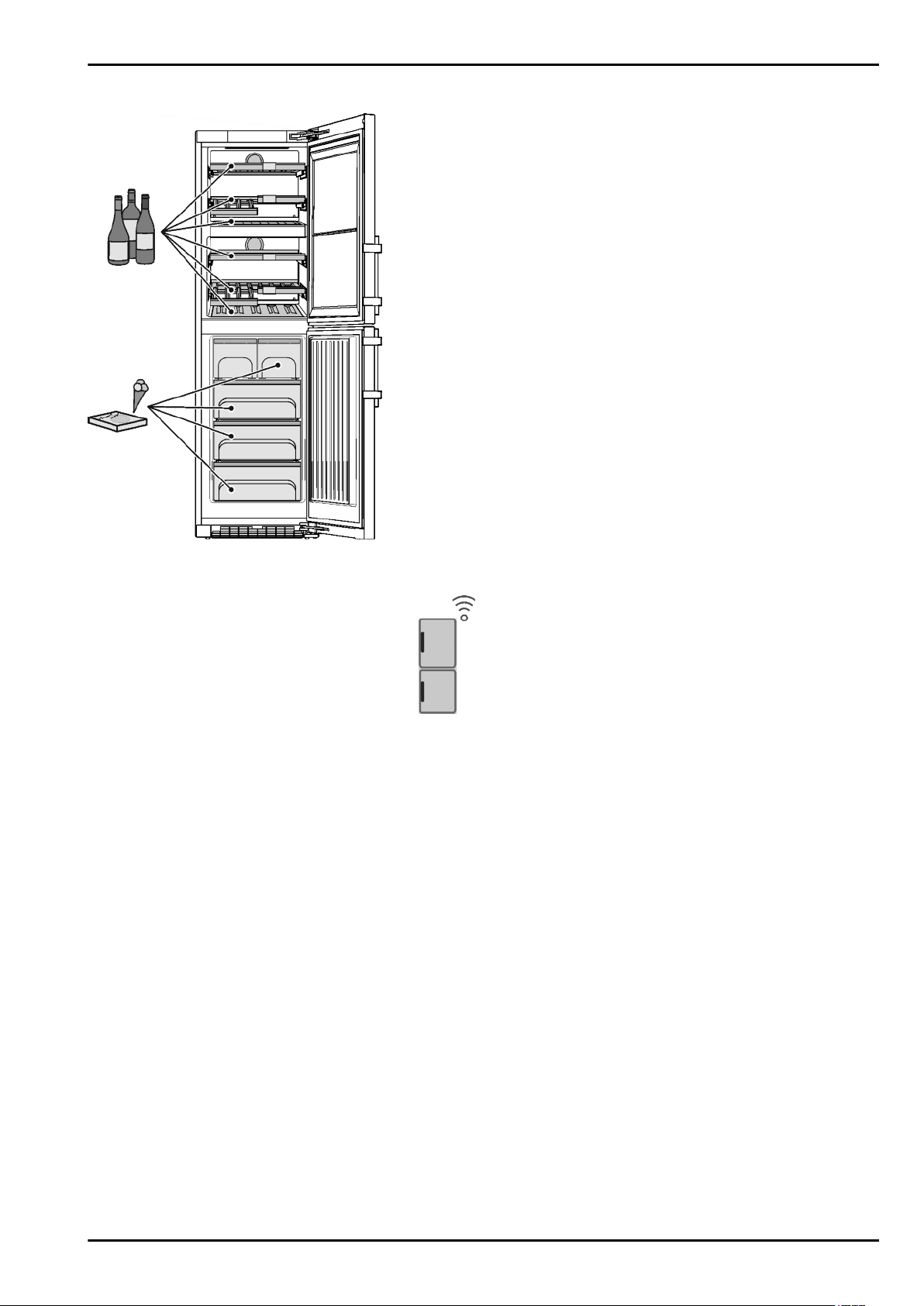

1.7 Example of food arrangement

Fig. 3

1.8 Smart device

The appliance is ready for integration into a smart

home and for extended services. Other options can

be selected with a SmartDeviceBox. This is activated via the MyLiebherr customer portal.

You will find more information about availability and pre-requisites and the individual options on the website www.smartdevice.liebherr.com.

2 General safety information

Danger for the user:

-

This device can be used by children and

people with impaired physical, sensory or

mental abilities or with a lack of experience

and knowledge provided that they are supervised or have received instruction in the safe

use of this device, and about the resulting

hazards. Children must not play with this

appliance. Cleaning and user maintenance

work must not be carried out by children

without adult supervision. Children aged

between 3 and 8 are allowed to load and

unload the appliance. Children below the age

of 3 must be kept away from the appliance

unless they are under continuous adult supervision.

-

When disconnecting the appliance from the

supply, always take hold of the plug. Do not

pull the cable.

-

In the event of a fault pull out the mains plug

or deactivate the fuse.

-

Do not damage the mains power cable. Do

not operate the appliance with a defective

mains power cable.

-

Only customer service or other specially

trained staff may repair or perform other operations on the appliance.

-

Only assemble, connect and dispose of the

appliance according to the instructions.

-

Please keep these instructions in a safe place

and pass them on to any subsequent owners.

-

All repairs to and intervention in the IceMaker

may be carried out only by service personnel

or by other skilled personnel trained for the

purpose.

-

The manufacturer is not liable for damage

caused by a faulty fixed water connection.

-

Special lights, such as LED lights on the

appliance, are used to illuminate the interior

of the appliance and are not suitable for room

lighting.

Fire hazard:

-

The coolant used (information on the model

plate) is eco-friendly but also flammable. Any

leaking coolant may ignite.

•

Do not damage the refrigerant circuit pipes.

•

Do not use an open flame or other source

of ignition inside the appliance.

•

Do not use electrical appliances inside the

appliance (e.g. steam cleaners, heaters, ice

cream makers, etc.).

•

If the refrigerant leaks: remove any naked

flames or ignition sources from the vicinity

of the leakage point. Properly air the room.

Inform customer services.

-

Do not store explosives or sprays using

combustible propellants such as butane,

propane, pentane, etc. in the appliance. To

identify these spray cans, look for the list of

contents printed on the can, or a flame

symbol. Gases possibly escaping may ignite

due to electrical components.

-

Keep burning candles, lamps and other items

with naked flames away from the appliance so

that they do not set the appliance on fire.

-

Please be sure to store alcoholic drinks or

other packaging containing alcohol in tightly

closed containers. Any alcohol that leaks out

may be ignited by electrical components.

Danger of tipping and falling:

-

Do not misuse the plinth, drawers, doors etc.

as a step or for support. This applies particularly to children.

4 * Depending on model and options

-

Danger of tipping if the door is open if the

appliance has not yet been installed properly.

Danger of food poisoning:

-

Do not consume food which has been stored

too long.

Danger of frostbite, numbness and pain:

-

Avoid lasting skin contact with cold surfaces

or refrigerated/frozen food or take protective

steps, e.g. wear gloves. Do not consume ice

cream, water ice or ice cubes immediately

and do not consume them too cold.

Danger of injury and damage:

-

Hot steam can lead to injury. Do not use electrical heating or steam cleaning equipment,

open flames or defrosting sprays to defrost.

-

Do not use sharp implements to remove the

ice.

Danger of crushing:

-

Do not hold the hinge when opening and

closing the door. Fingers may get caught.

Symbols on the appliance:

The symbol can be located on the

compressor. It refers to the oil in the

compressor and indicates the following

danger: Swallowing or inhaling can be fatal.

This is only relevant for recycling. There is no

danger in normal operation.

A sticker to this effect may be applied to the

rear of the appliance. It refers to the foampadded panels in the door and/or the

housing. This is only relevant for recycling. Do

not remove the sticker.

Please observe the specific information in

the other sections:

Controls and displays

3 Controls and displays

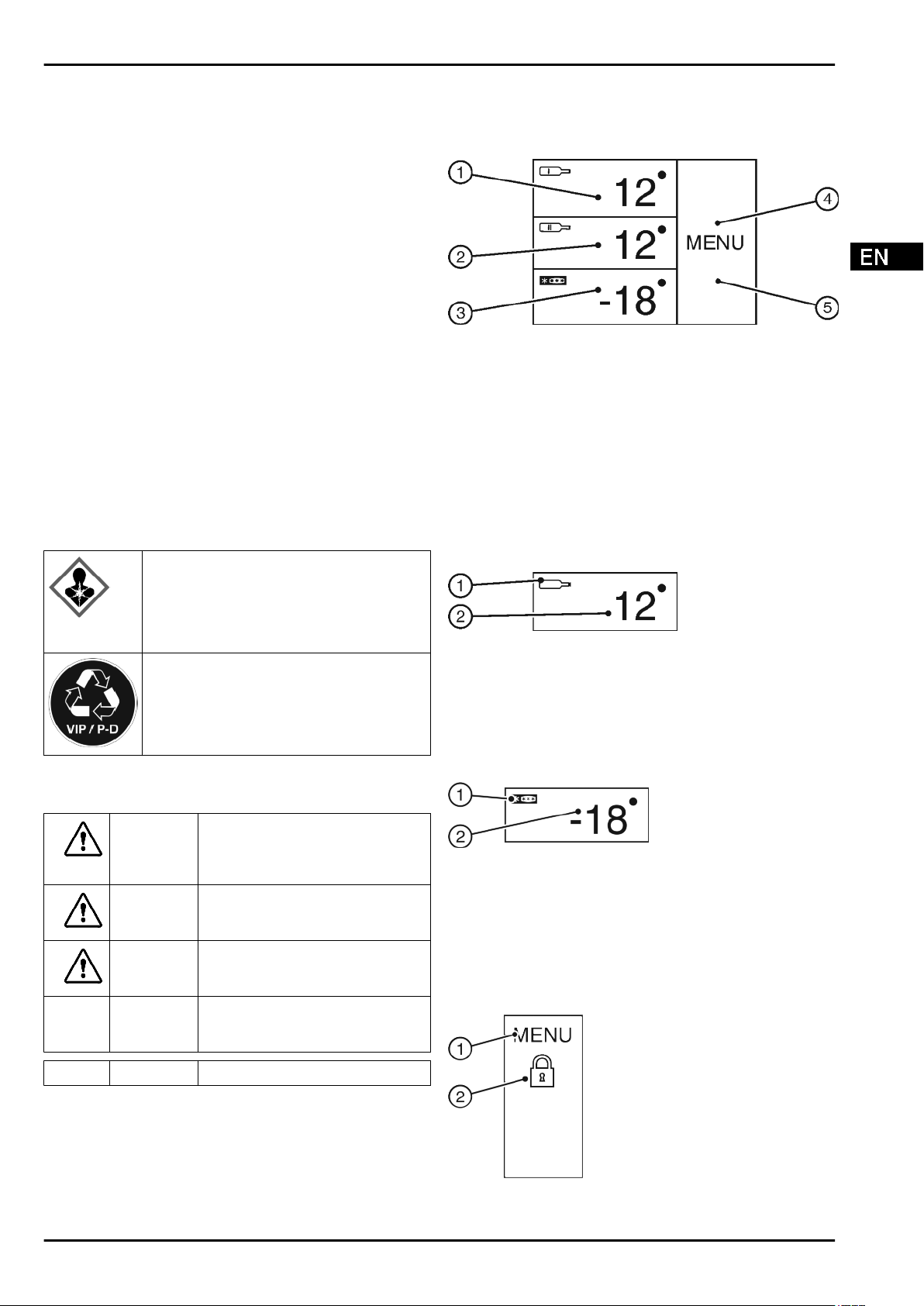

3.1 Home screen

Fig. 4

(1) Top wine cooling field (4) Menu field

(2) Bottom wine cooling

field

(3) Freezer compartment

field

The home screen is the first screen the user sees. All settings

can be made from there.

All functions can be called up by touching the screen and

values can be changed.

3.2 Operating structure

Wine cooling field

(1) Wine cooling compart-

ment symbol

The set temperature is displayed in the wine cooling field.

The following settings can be entered:

Temperature settings

-

Switching the wine cooling compartment on and off

-

Freezer compartment field

(5) Screen

Fig. 5

(2) Wine cooling compart-

ment temperature display

DANGER identifies a situation involving direct

danger which, if not obviated, may

result in death or severe bodily

injury.

WARNING identifies a dangerous situation

which, if not obviated, may result in

death or severe bodily injury.

CAUTION identifies a dangerous situation

which, if not obviated, may result in

minor or medium bodily injury.

NOTICE identifies a dangerous situation

which, if not obviated, may result in

damage to property.

Note identifies useful information and tips.

* Depending on model and options 5

(1) Freezer compartment

symbol

The freezer compartment temperature is displayed in the

freezer compartment field.

The following settings can be entered:

Temperature settings

-

Switch off appliance. Screen remains functional.

-

Menu field

Fig. 7

(1) Main menu (2) Option selected

Fig. 6

(2) Freezer compartment

temperature display

Putting into operation

The menu field gives access to the appliance options and

settings. Selected options are also displayed.

3.3 Navigation

Touch the menu to access the individual options. An audible

signal sounds after confirming an option or a setting. The

display switches to the home screen.

The appliance is operated using the following symbols:

Standby:

Switches the appliance or temperature zone on.

Menu:

Calls up options.

Minus / Plus:

Changing settings (e.g. adjusting

temperatures).

Left/right navigation arrow:

Selects options and navigates

through the menu.

You can scroll through the individual

options using the navigation arrows.

The first option is displayed again

after the last one.

Back:

Cancels the selection.

The display switches to the next

higher level or to the home screen

OK:

Confirms the selection.

After confirmation the display

switches to the home screen.

ON / OFF, START / STOP

Starts/ stops options.

After selecting or cancelling an option

the display switches to the home

screen.

RESET:

Resets timer.

Access to customer service

Standby:

The appliance or temperature zone is

switched off.

Messages:

There are active error messages and

reminders.

3.5 Appliance options

You can select or set the following options; explanations and

setting options, (see 5) :

Symbol Option

SuperFrost

Fan

SabbathMode

Dim mode

IceMaker

Child safety device

Temperature unit

x

If the option is selected, the relevant symbol is displayed in

the menu field.

If more than 6 selected options are selected only 4 options are

displayed in the menu field. The other options are displayed by

pressing the bottom navigation arrow. Pressing the navigation

arrow repeatedly takes you back to the home screen.

The symbol disappears if the option ends or is disabled.

x

x

x

x

4 Putting into operation

Note

If no selection is made after 1 minute the display switches to

the home screen.

3.4 Display symbols

Display symbols provide information on the current appliance

status:

Up arrows:

The temperature increases.

Down arrows:

The temperature reduces.

4.1 Transporting the appliance

Risk of injury and danger of damage as a result of incorrect

transport!

u

u

u

CAUTION

Transport the appliance in a packed condition.

Transport the appliance upright.

Do not transport the appliance without assistance.

6 * Depending on model and options

Risk of injury due to broken glass!

WARNING

In case of transport at an altitude of over 1500 m the glass

panes of the door may break. The fragments have sharp edges

and may cause serious injury.

Take appropriate protective action.

u

Putting into operation

Do not install the appliance without assistance.

q

The more coolant there is in the appliance, the larger the

q

room in which the appliance is installed must be. If the room

is too small, any leak may create a flammable mixture of gas

and air. For each 8 g of coolant the installation space must

be at least 1 m3. Information on the coolant is on the model

plate inside the appliance.

Remove the protective film from the outside of the appliance.

u

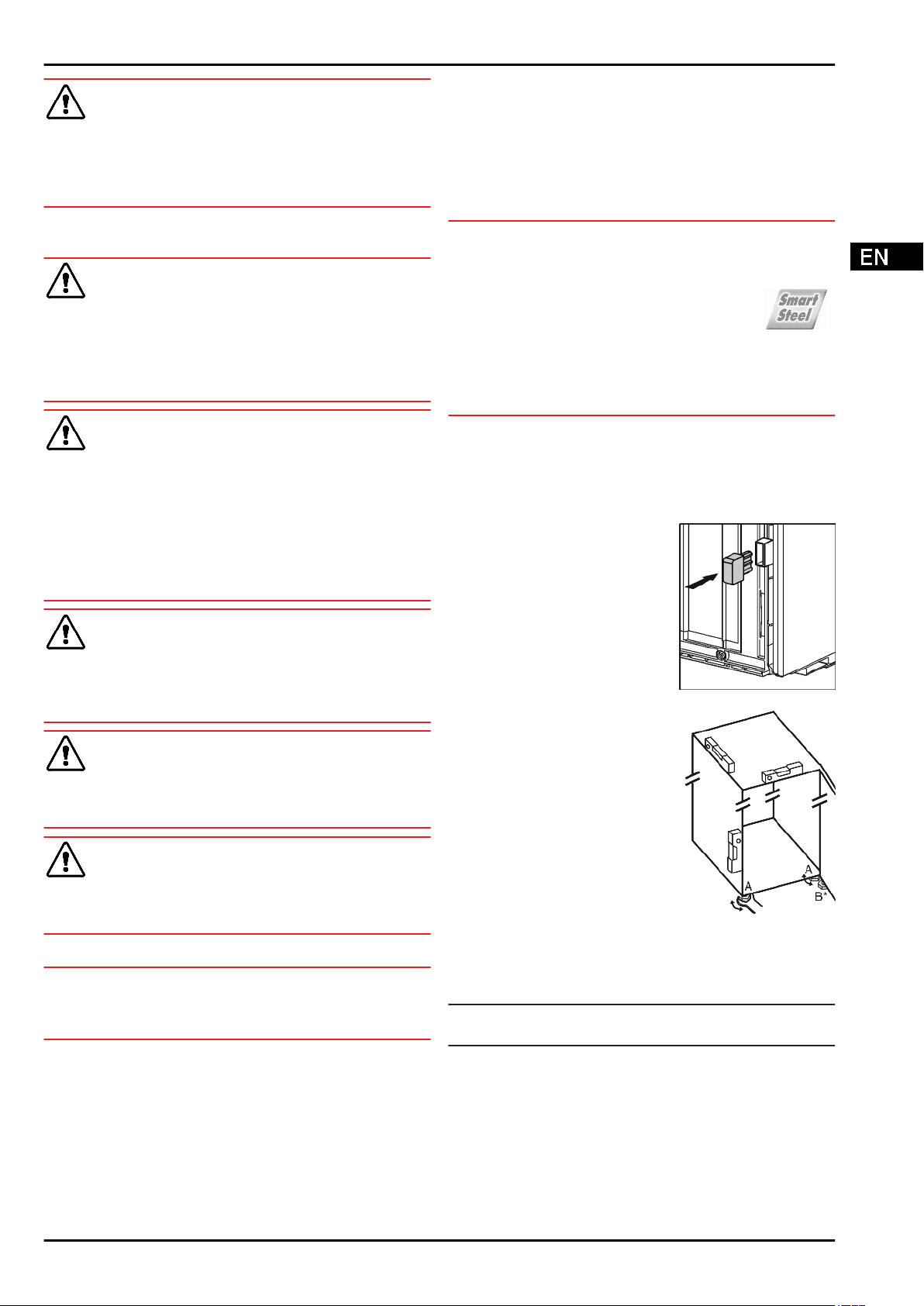

4.2 Installing the appliance

Fire hazard due to dampness!

If live parts or the mains lead become damp this may cause

short circuits.

u

Risk of fire due to short circuit!

If the mains cable/connector of the appliance or of another

appliance touch the rear of the appliance, the mains cable/

connector may be damaged by the appliance vibrations,

leading to a short circuit.

u

u

Fire hazard due to refrigerant!

The coolant used is eco-friendly but also flammable. Any

leaking coolant may ignite.

u

Fire hazard and danger of damage!

u

Blocked ventilation openings pose a risk of fire and damage!

u

If your appliance is not a side-by-side (SBS) appliance:*

NOTICE

Risk of damage due to condensate!*

u

q

q

q

q

q

q

WARNING

The appliance is designed for use in enclosed areas. Do not

operate the appliance outdoors or in areas where it is

exposed to splash water or damp conditions.

WARNING

Stand the appliance so that it is not touched by connectors

or main cables.

Do not plug the appliance or any others into sockets located

near the rear of the appliance.

WARNING

Do not damage the piping of the refrigeration circuit.

WARNING

Do not place appliances emitting heat e.g. microwaves,

toasters etc. on the appliance!

WARNING

Always keep the ventilation openings clear. Always ensure

that the appliance is properly ventilated!

Do not install the appliance directly alongside a further

refrigerator/freezer.

In the event that the appliance is damaged, contact the

supplier immediately before connecting to the mains.

The floor at the site must be flat and level.

Do not install the appliance in a location where it is exposed

to direct radiation of the sun, next to a cooker, heater and

similar.

Always stand the appliance backed directly to the wall using

the enclosed wall spacers (see below).

The appliance may be moved only when it is empty.

The surface supporting the appliance must be at the same

level as the surrounding floor.

NOTICE

Risk of damage from stainless steel care products!

The stainless steel doors and stainless steel side panels

are treated with a premium surface finish.

Stainless steel care products attack these surfaces.

Only use a soft, clean cloth to wipe down finished door

u

and side panel surfaces and painted door and side

panel surfaces. To remove heavy dirt, use a little water or

neutral detergent. Alternatively, you can use a micro-fibre

cloth.

Remove all transit supports.

u

Spacers must be used to achieve the declared energy

consumption and to prevent condensation in the event of high

surrounding humidity. This increases the appliance depth by

about 15 mm. The appliance will work perfectly well without the

spacers but will have a slightly higher energy consumption.

If your appliance comes with wall

u

spacers, mount these on the

back of the appliance, bottom left

and right.

Dispose of packaging material (see 4.6) .

u

Align the appliance so that it

u

stands firmly and on a level by

applying the accompanying

spanner to the adjustableheight feet (A) and using a

spirit level.

Then support the door:

u

Extend the adjustable foot at

the turn hinge (B) until it rests

on the floor and then make a

further 90° turn.

When a Side-by-Side appliance (S…) is fitted together with

a second appliance (as a SBS combination):*

Proceed according to the Side-by-Side combined fridge-

u

freezer installation instructions. (Accessories bag of the SBS

freezer/appliance with freezer compartment)*

Note

Clean the appliance (see 6.4) .

u

If the appliance is installed in a very damp environment,

condensate may form on the outside of the appliance.

Always see to good ventilation at the installation site.

u

4.3 Reversing the door

If necessary, you can change the way the door opens:

Ensure that the following tools are available:

Torx® 25 (T25)

q

* Depending on model and options 7

Putting into operation

Torx® 15 (T15)

q

Slotted screwdriver

q

Open-ended wrench SW10

q

Spirit level

q

Open-ended wrench supplied with the T25 tool

q

If necessary, a cordless screwdriver

q

Get a stepladder if necessary

q

If necessary, a second person for assembly

q

NOTICE

Risk of condensation damage for Side-by-Side appliances!*

Certain appliances can be set up as Side-by-Side combinations (two appliances next to each other).

If your appliance is a Side-by-Side (SBS) appliance:

Set up the SBS combination in accordance with the

u

enclosed document.

If the positioning of the devices is stipulated:

Do not change the door hinges over.

u

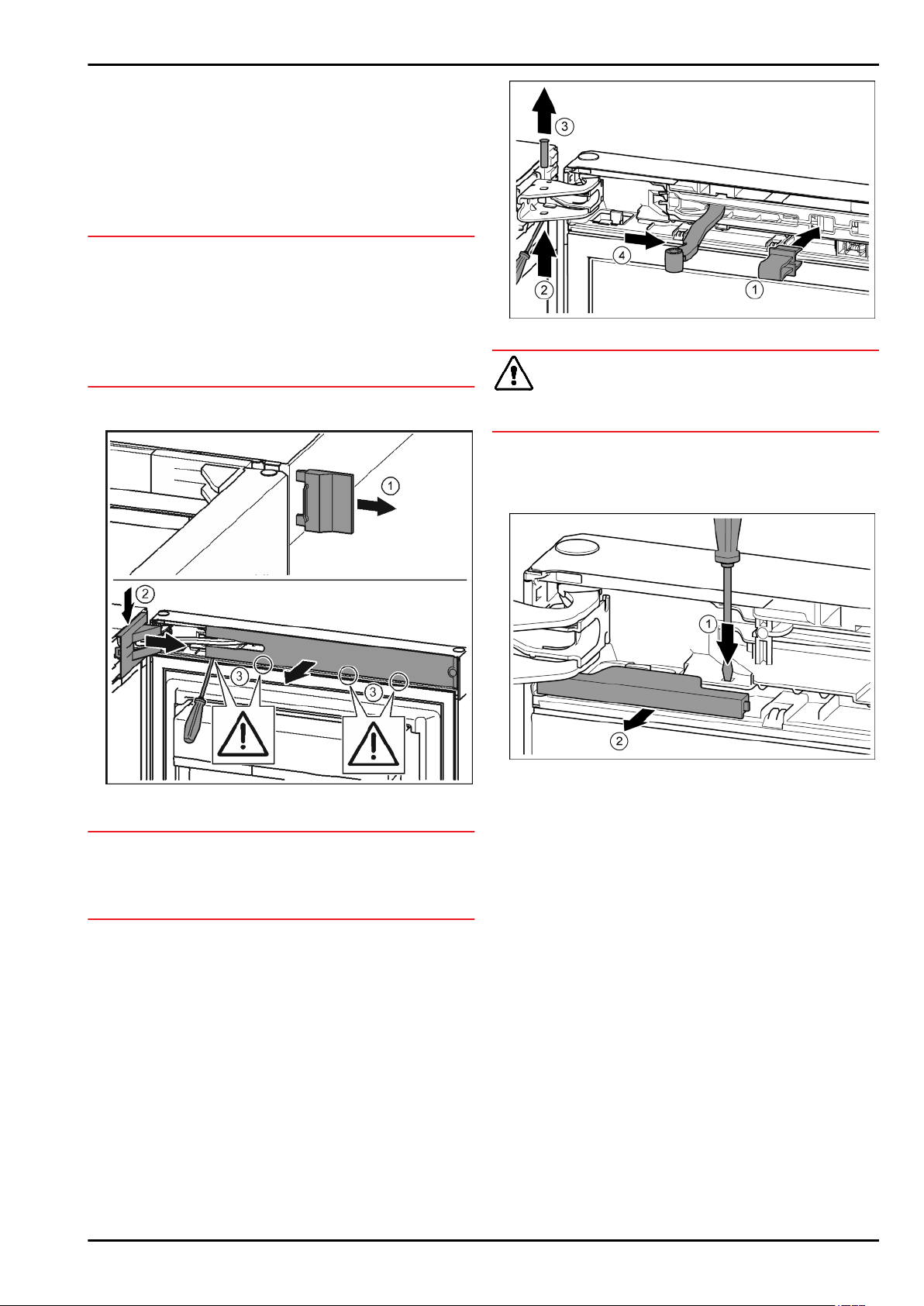

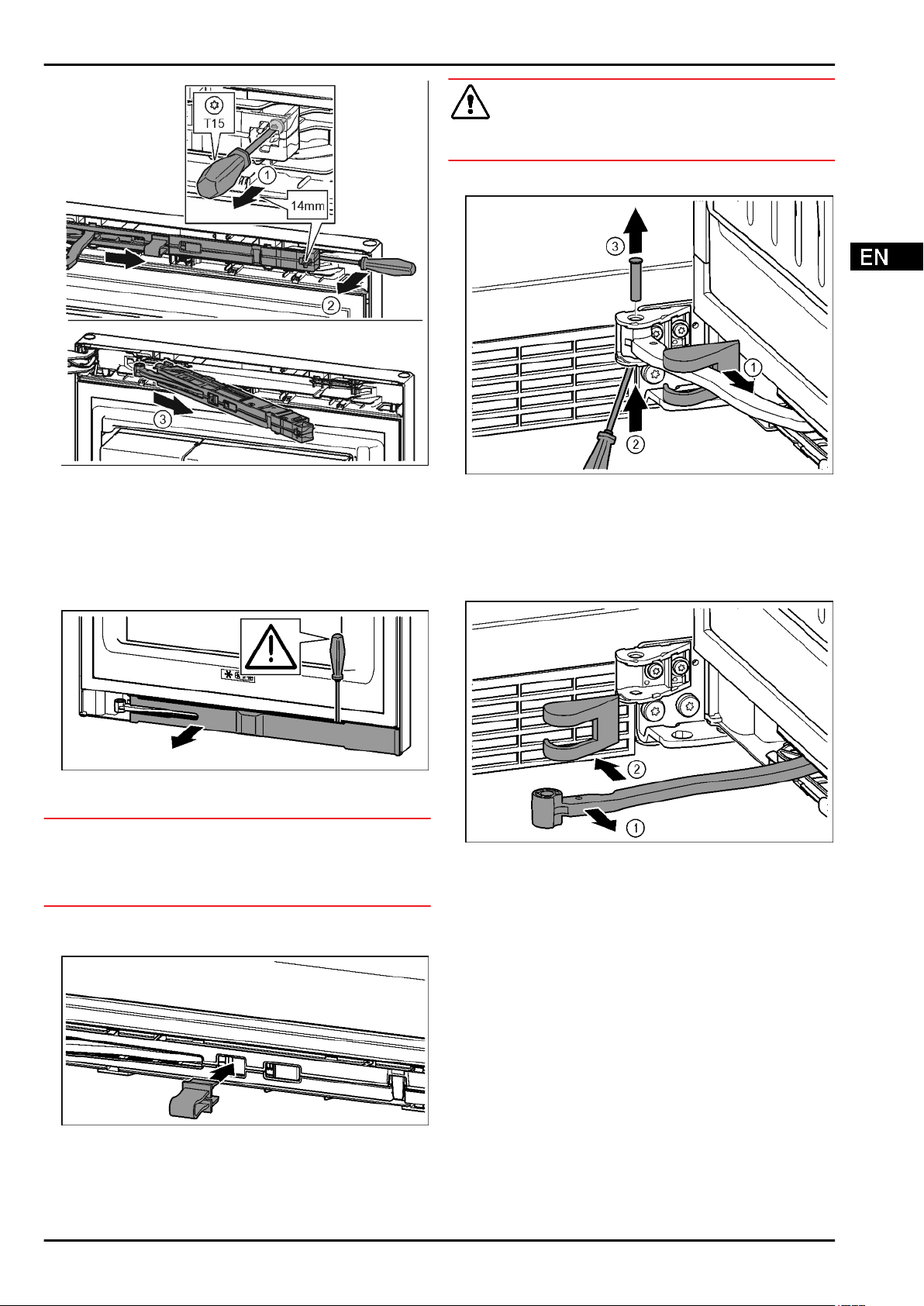

4.3.1 Remove the upper soft stop mechanism

Fig. 9

CAUTION

Crushing hazard by joint folding up!

Engage safety device.

u

Fig. 8

Open the top door.

u

NOTICE

Risk of damage!

If the door seal is damaged, the door may fail to close properly

and the cooling will be inadequate.

Do not damage the door seal with the screwdriver!

u

Engage the locking device in the opening.

u

Unscrew the bolt with a screwdriver.

u

Remove the bolt in an upward direction.

u

Turn the hinge in the direction of the door.

u

Fig. 10

Press the tab with the slotted screwdriver.

u

Pull cover out of the catch mechanism.

u

Fig. 9 (1)

Fig. 9 (2)

Fig. 9 (3)

Fig. 9 (4)

Fig. 10 (1)

Fig. 10 (2)

Remove the outer cover.

u

Disengage and release the bearing bracket cover. Remove

u

the bearing bracket cover.

Unlatch the panel with a slotted screwdriver and swivel it to

u

one side.

Fig. 8 (3)

Fig. 8 (1)

Fig. 8 (2)

8 * Depending on model and options

Putting into operation

Fig. 11

Undo the soft stop mechanism screw with a T15 screwdriver

u

approx. 14 mm.

Insert a screwdriver behind the soft stop mechanism on the

u

handle side and rotate forwards.

Remove the soft stop mechanism.

u

Fig. 11 (1)

Fig. 11 (2)

Fig. 11 (3)

4.3.2 Remove the bottom soft stop mechanism

Crushing hazard by joint folding up!

Engage safety device.

u

Engage the locking device in the opening.

u

Fig. 14

CAUTION

Remove the bearing bracket cover and push it along the

u

hinge.

Fig. 14 (1)

Lift the bolt with a finger or screwdriver from below.

u

Fig. 14 (2)

Insert the screwdriver under the bolt head and remove.

u

Fig. 14 (3)

Fig. 12

Open the bottom door.

u

NOTICE

Risk of damage!

If the door seal is damaged, the door may fail to close properly

and the cooling will be inadequate.

Do not damage the door seal with the screwdriver!

u

Unlatch the panel with a slotted screwdriver and swivel it to

u

one side.

Fig. 13

Fig. 15

Turn the hinge in the direction of the door.

u

Remove the bearing bracket cover.

u

Fig. 15 (1)

Fig. 15 (2)

* Depending on model and options 9

Putting into operation

Fig. 18

Carefully remove the grey cable from the guide in the door.

u

Fig. 18 (1)

Press the tab upwards.

u

Carefully remove the plug.

u

Fig. 18 (2)

Fig. 18 (3)

Fig. 16

Undo the screw on the soft stop mechanism about 14 mm

u

with a T15 screwdriver.

Insert the screwdriver on the handle side behind the soft

u

stop mechanism. Turn the unit forwards.

Remove the unit.

u

Set aside the soft stop mechanism.

u

Fig. 16 (1)

Fig. 16 (2)

Fig. 16 (3)

4.3.3 Remove the cable connection

Fig. 17

Carefully remove the cable over the bearing bracket from the

u

guide.

Fig. 17 (1)

Carefully pull the cable strands out of the channel.

u

Fig. 17 (2)

Press the tab upwards and carefully remove the plug.

u

Fig. 17 (3)

Fig. 19

Press the tab.

u

Remove the cable holder with its cable.

u

Fig. 19 (1)

4.3.4 Removing the top door

Fig. 19 (2)

Fig. 20

10 * Depending on model and options

Risk of injury if the door tips!

CAUTION

Take good hold of the door.

u

Set down the door carefully.

u

Putting into operation

4.3.6 Moving the upper bearing parts to the

other side

Carefully remove the protective cover.

u

Undo the bolt a little with a T15 screwdriver.

u

Hold the door and remove the bolts with your fingers.

u

Fig. 20 (1)

Fig. 20 (2)

Fig. 20 (3)

Lift the door and set it aside.

u

Carefully lift the plugs out of the door bearing bush with a

u

slotted screwdriver and remove.

Fig. 20 (4)

4.3.5 Removing the lower door

Fig. 22

Remove both screws with the T25 screwdriver.

u

Lift and remove the bearing bracket and cable.

u

Risk of injury if the door tips!

Take good hold of the door.

u

Set down the door carefully.

u

Pull out the bolts towards the top.

u

Swing the door out, pull it upwards and set it aside.

u

Fig. 21 (1)

Fig. 21 (2)

CAUTION

Fig. 21

Fig. 23

Pull the bearing bush out of the guide.

u

Swing the cable holder out.

u

Fig. 23 (2)

Fig. 23 (1)

Fig. 24

Remove the cable from the guide.

u

Fig. 24 (3)

NOTICE

Cable crushing

Pay attention to the mark when positioning the cable. The

u

shorter end of the cable is positioned from the mark in the

cable holder.

* Depending on model and options 11

Putting into operation

Fig. 25

Insert the cable mirror inverted.

u

The black mark must be positioned on the edge of the cable

w

holder.

Swing the cable holder in.

u

Click the cover into place.

u

Position the screw with a T25 screwdriver.

u

Position the upper bearing bracket.

u

Place the pins in the provided screw holes.

w

Tighten the screw.

u

Insert the screw with a T25 screwdriver and tighten.

u

Fig. 27 (3)

Fig. 27 (4)

Fig. 27 (5)

Fig. 27 (4)

Fig. 27 (6)

4.3.7 Moving the central bearing parts to the

other side

Fig. 26

Insert the bearing bush from the other side and click into

u

place.

Fig. 28

Remove the washer.

u

Remove the screws with the T25 screwdriver.

u

Remove the cover carefully.

u

Screw the bearing bracket and the film rotated 180° firmly

u

onto the other side.

Attach the cover rotated 180° onto the other side.

u

Push the washer in from the front.

u

Fig. 28 (1)

Fig. 28 (2)

Fig. 28 (3)

Fig. 28 (4)

Fig. 28 (5)

Fig. 28 (6)

4.3.8 Moving the lower bearing parts to the

other side

Fig. 29

Lift the bearing pin completely upward and remove.

u

Fig. 29 (1)

Remove the screws with the T25 screwdriver and remove

u

the soft stop connection.

Fig. 29 (2)

Release the cover and remove from the side.

u

Rotate the cover 180° and clip onto the other side from the

u

right.

Fig. 27 (2)

Fig. 27 (1)

Fig. 27

12 * Depending on model and options

Putting into operation

Undo the screws with a T25 screwdriver and remove the

u

bearing bracket

Fig. 29 (3)

Underside of door faces upwards: Turn the door.

u

Pull out the guide bush: Press the tab with a slotted screw-

u

driver and, at the same time, insert the slotted screwdriver

under the guide bush.

Slide the guide bush included in the scope of supply to the

u

other side of the housing.

Upper side of door faces upwards: Turn the door.

u

Fig. 31 (1, 2)

Fig. 31 (3)

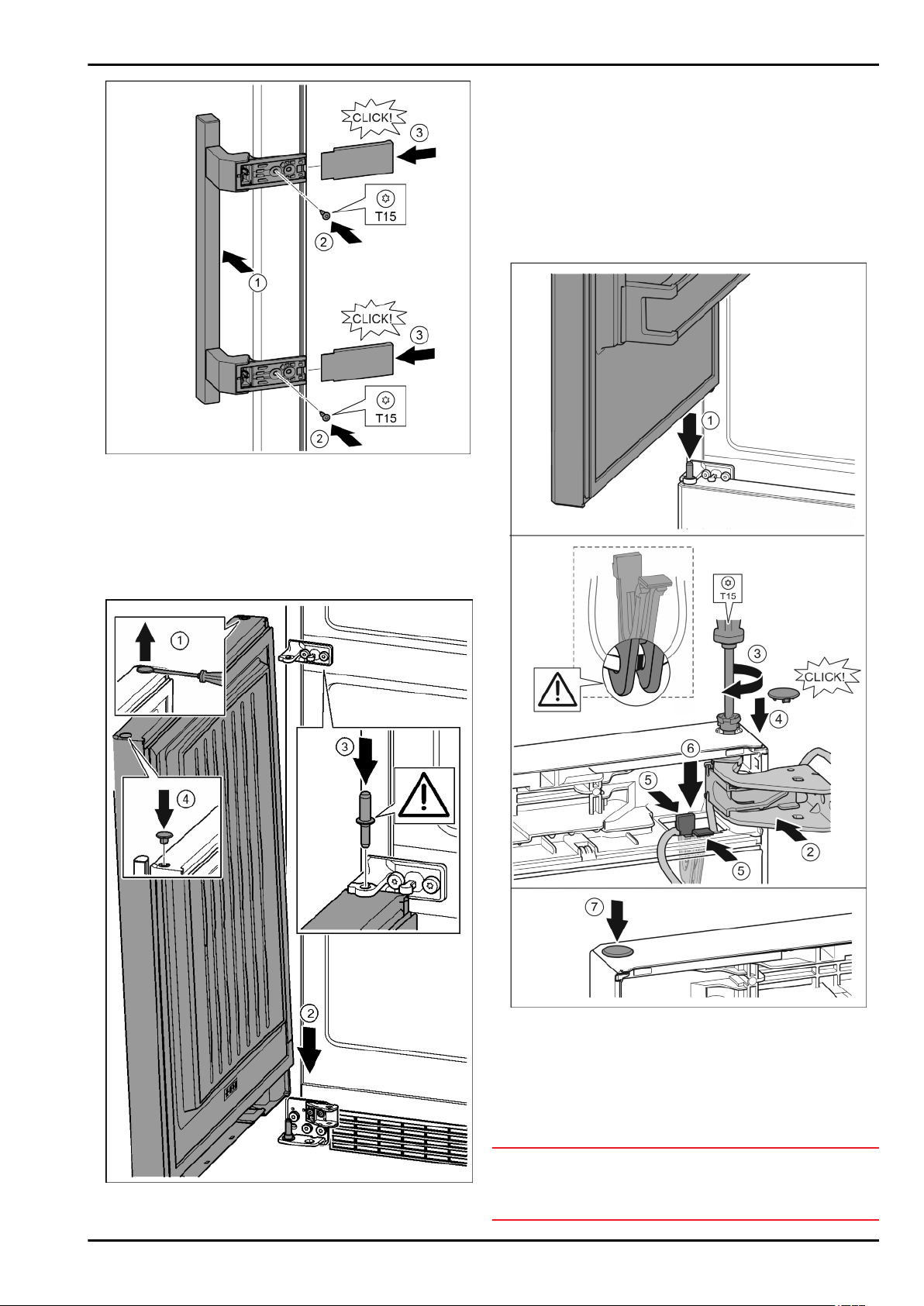

4.3.10 Moving the handles to the other side

Remove the cover and fix it on the other side.

u

Place the bearing bracket on the other side and screw in

u

with the aid of a T25 screwdriver. Start with screw 2 at the

bottom in the middle.

Screw in screws 3 and 4.

u

Rotate the soft stop connection 180°. Screw in with a T25

u

screwdriver on the other side of the bearing bracket.

Fig. 30 (2)

Fig. 30 (3, 4)

Fig. 30 (1)

Fig. 30 (5)

Insert the bearing pin completely. Make sure that the catch

u

mechanism is pointing to the rear.

Fig. 30 (6)

4.3.9 Moving the door bearing parts to the

other side

Top door

Fig. 30

Fig. 32

Pull off the cover.

u

Remove the screws with the T15 screwdriver.

u

Remove the handle.

u

Carefully lift up the side plugs with a slotted screwdriver and

u

pull them out.

Insert the plugs again on the other side.

u

Fig. 32 (1)

Fig. 32 (2)

Fig. 32 (3)

Fig. 32 (4)

Fig. 32 (5)

Fig. 31

* Depending on model and options 13

Putting into operation

Fig. 33

Position the handle on the other side.

u

The screw holes must be exactly above each other.

w

Tighten the screws with the T15 screwdriver.

u

Position the covers on the side and push in.

u

Ensure that it clicks into place.

w

Fig. 33 (1)

Fig. 33 (2)

Fig. 33 (3)

Carefully lift up the plugs with a slotted screwdriver and

u

remove them.

Position the door from above onto the lower bearing pins.

u

Fig. 34 (1)

Fig. 34 (2)

Insert the centre bearing pin through the centre bearing

u

bracket into the lower door. Make sure that the catch mechanism is pointing to the rear.

Insert the plugs again on the other side of the door.

u

Fig. 34 (3)

Fig. 34 (4)

4.3.12 Fitting the upper door

4.3.11 Fitting the bottom door

Fig. 35

Place the upper door on the centre bearing pins

u

Align the top of the door with opening in the bearing bracket.

u

Fig. 35 (1)

Fig. 35 (2)

Insert the bolt and tighten with a T15 screwdriver.

u

Fit the protective cover to protect the door: Insert the protec-

u

tive cover and check that it is attached to the door. If not,

insert the bolt fully.

Fig. 35 (4)

Fig. 35 (3)

NOTICE

Cable crushing

The mark on the cable must be centred in the holder. The

Fig. 34

u

tab with the longer opening must point forwards.

14 * Depending on model and options

Putting into operation

Insert the holder with its cable into the opening.

u

Press the holder downwards until the tab clicks into place.

u

Fig. 35 (5)

Fig. 35 (6)

Insert the plugs.

u

Fig. 35 (7)

4.3.13 Fitting the cable connection

Fig. 36

Engage the plug above the upper bearing bracket and care-

u

fully place the cable strands into the channel.

Carefully position the grey cable in the guide above the top

u

bearing bracket.

Fig. 36 (2)

Fig. 36 (1)

4.3.15 Fit the bottom soft stop mechanism

Fig. 38

Slide the soft stop mechanism on the bearing bracket side at

u

an angle into the slot as far as the limit stop.

Slide the soft stop mechanism fully into the slot.

u

The unit is positioned correctly when the rib on the soft stop

w

mechanism is in the guide.

Tighten the screw with the T15 screwdriver.

u

Push the cover over the hinge.

u

Fig. 38 (4)

Fig. 38 (1)

Fig. 38 (2)

Fig. 38 (3)

Fig. 37

Insert the grey cable into the guide in the top door.

u

Fig. 37 (1)

Engage the plug.

u

Position the remaining cable length as a loop in the guide, if

u

required.

Fig. 37 (2)

4.3.14 Aligning the doors

Risk of injury due to the door dropping out!

If the bearing parts are not screwed into place firmly enough,

the door may drop out. This may lead to severe injuries. What is

more, the door may not close and therefore the appliance may

fail to cool properly.

u

u

u

u

WARNING

Screw the turn hinges firmly into place with 4 Nm.

Check all of the screws and retighten if necessary.

Align the doors flush with the appliance housing using the

two oblong holes in the lower bearing bracket and centre

bearing bracket if needed. To do this undo the middle screw

in the bottom bearing bracket with the T25 tool supplied.

Undo the remaining screws a little with the T25 tool or with a

T25 screwdriver and align using the slotted holes. Undo the

screws in the middle bearing bracket with the T25 tool and

align the middle bearing bracket using the slotted holes.

Support the door: Take off the adjustable foot on the bearing

bracket using the open-ended wrench SW10 until it comes

into contact with the floor, then turn an additional 90°.

Fig. 39

The door is open 90°

Turn the hinge in the mount.

u

Insert the bolt with a T15 screwdriver in the mount and

u

hinge. Make sure that the catch mechanism is sitting

correctly in the groove.

Push the bearing bracket cover along the hinge and fit on

u

the mount.

Remove the locking device.

u

Position the panel on the handle side and swing it in.

u

Fig. 39 (3)

Fig. 39 (1)

Fig. 39 (2)

Fig. 39 (4)

Fig. 39 (5)

The panel is clicked into place.

w

Close the bottom door.

u

* Depending on model and options 15

Putting into operation

4.3.16 Fit the top soft stop mechanism

Fig. 40

Slide the soft stop mechanism on the bearing bracket side at

u

an angle into the slot as far as the limit stop.

Slide the unit in fully.

u

The unit is positioned correctly when the rib on the soft stop

w

mechanism is in the guide in the housing.

Tighten the screw with the T15 screwdriver.

u

Fig. 40 (1)

Fig. 40 (2)

Fig. 41

The door is open 90°.

Turn the hinge in the bearing bracket.

u

Insert the bolt in the bearing bracket and hinge. Make sure

u

that the catch mechanism is sitting correctly in the groove.

Fig. 41 (1)

Fig. 41 (2)

Remove the locking device.

u

Slide on the cover.

u

Fig. 41 (4)

Fig. 41 (3)

Fig. 42

Position the bearing bracket and engage. If necessary push

u

apart carefully.

Position the panel.

u

Swing in the panel and click into place.

u

Slide on the external cover.

u

Close the upper door.

u

Fig. 42 (1)

Fig. 42 (2)

Fig. 42 (3)

Fig. 42 (4)

Fig. 42 (5)

4.4 Water connection

Danger of electric shock!

u

u

u

Risk of poisoning!

u

u

u

WARNING

Disconnect the appliance by unplugging it before you

connect it to the water line.

Shut off the water supply before you connect the water feed

lines of the IceMaker.

The connection to the drinking water system may be carried

out only by a qualified gas fitter and plumber.

WARNING

The water quality has to comply with the drinking water ordinance of the respective country (e.g. 98/8

Connect to the drinking water supply only.

The IceMaker serves exclusively for making ice cubes in

household quantities and has to be operated with water suitable for the purpose.

Fig. 43

a b c M

~ 1100 mm ~ 700 mm ~ 110 mm Solenoid valve

- The water pressure must be between 0.15 MPa and

0.6 MPa (1.5 bar - 6 bar).

16 * Depending on model and options

Putting into operation

- Water must be supplied to the appliance through a cold

water pipe that complies with hygiene standards and can

withstand the operating pressure.

Use the stainless steel hose supplied (Length 1.5 m) Do not

reuse old hoses. A 3 m hose is available as an optional

extra. This must be professionally installed.

A filter with a seal is located in the hose connector.

- A stopcock must be placed between the hose line and the

domestic water connection to cut off the water supply, if

necessary.

- All devices and equipment used to supply water must

comply with the regulations in force in the respective

country.

- Do not damage or kink the water supply line during installation.

Open the water supply cut-off valve

u

the whole water system for leaks.

Hook the clip

u

fix it to the stainless steel pipe to store it.

Fig. 44 (5)

into the auxiliary tool

Fig. 44 (1)

Fig. 44 (6)

and check

and

4.5 Insertion into a row of kitchen units

Fig. 44

The solenoid is at the bottom on the back of the appliance. It

has a metric R3/4 connecting thread.

For specialist staff:

The back of the appliance must be accessible to connect the

stainless steel hose:

WARNING

Risk of injury.

Cuts from a broken auxiliary tool

Only use an auxiliary tool

u

Slide the nut

u

Fig. 44 (3)

Insert the filter

u

The filter

w

Fig. 44 (3)

Connect the nut

u

with the filter resting on the straight end of the hose

Fig. 44 (2)

Open the water supply cut-off valve

u

bleed the water pipe and fill it with water. Keep the hose in a

bucket.

Remove the cover

u

Slide the nut

u

Fig. 44 (8)

Moisten the seal

u

on the end of the angled hose

The seal

w

Fig. 44 (8)

Fig. 44 (4)

up to the end and secure.

Fig. 44 (2)

Fig. 44 (2)

and is easily retained.

rests flat on the straight end of the hose

Fig. 44 (4)

.

Fig. 44 (10)

Fig. 44 (7)

up to the end and secure.

Fig. 44 (9)

Fig. 44 (9)

and is easily retained.

lies flat on the angled end of the hose

Fig. 44 (6)

Fig. 44 (6)

over the straight end of the hose

into the nut

to the cut-off valve

.

over the angled end of the hose

and push into the nut

Fig. 44 (8)

.

at room temperature.

Fig. 44 (4)

.

Fig. 44 (3)

Fig. 44 (1)

temporarily to

Fig. 44 (7)

.

NOTICE

Risk of damaging the threads of the solenoid.

Locate the nut carefully and screw onto the thread.

u

Connect the nut

u

the seal resting on the

Fig. 44 (11)

Tighten connections with the auxiliary tool

u

wise until the maximum torque is reached and the auxiliary

tool

Fig. 44 (6)

Fig. 44 (7)

.

is overwound.

to the solenoid

Fig. 44 (9)

Fig. 44 (8)

angled end of the hose

Fig. 44 (6)

with

clock-

Fig. 45

A [mm] B [mm]

x

665

x

If wall spacers are used, the dimensions increase by 15 mm

(see 4.2) .

The dimensions apply for an opening angle of 90 °. Spacing

angles will vary according to the opening angle.

You can purchase a kit to limit the door opening angle to 90° on

soft closing appliances. Please contact our customer service

team.

The appliance can be built into kitchen units. A top cupboard

Fig. 45 (2)

the appliance

units.

The appliance can be installed right next to the kitchen cabinet

Fig. 45 (3)

Fig. 45 (B)

opened fully. The appliance may protrude further depending on

the depth of the kitchen cabinets and whether wall spacers are

used.

65 Min. 300 Min. 50 Min. 46

can be added above the appliance in order to bring

Fig. 45 (1)

. The appliance must stick out by the depth

from the front of the cabinet so that the doors can be

C [cm2]

up to the height of the fitted kitchen

D [mm] E [mm]

NOTICE

Danger of overheating due to insufficient air ventilation!

The compressor may be damaged if there is insufficient air

ventilation.

Take care to ensure adequate air ventilation.

u

Observe the ventilation requirements.

u

Ventilation requirements:

* Depending on model and options 17

Putting into operation

Spacer ribs on the back of the appliance provide sufficient

-

air ventilation. In the final appliance position, these must not

be placed in recesses or cut-outs.

There must be a ventilation shaft with the depth

-

at the back of the top cupboard over the entire width of the

cupboard.

The ventilation shaft

-

ceiling.

the larger the ventilation space, the more energy-saving the

-

appliance is in operation.

If the appliance is installed with the hinges next to a wall

Fig. 45 (4)

the wall must be observed. This is how far the handle protrudes

when the door is open.

the distance

Fig. 45 (C)

Fig. 45 (E)

must be observed under the

between the appliance and

Fig. 45 (D)

4.6 Disposing of packaging

Danger of suffocation due to packing material and plastic film!

u

The packaging is made of recyclable materials:

-

-

-

-

-

u

WARNING

Do not allow children to play with packing material.

corrugated board/cardboard

expanded polystyrene parts

polythene bags and sheets

polypropylene straps

nailed wooden frame with polyethylene panel*

Take the packaging material to an official collecting point.

4.7 Connecting the appliance

Failure to connect properly

Fire hazard.

u

u

NOTICE

Failure to connect properly

Damage to the electronics.

u

u

Note

Only use the power connection lead supplied.

u

WARNING

Do not use an extension cable.

Do not use distributor blocks.

Do not use a standalone inverter.

Do not use an energy saving plug.

A longer power connection lead can be ordered from

Customer Service.

- The type of current and voltage at the installation site correspond to the information on the model plate (see 1) .

- The socket is earthed according to the regulations and

fused.

- The fuse tripping current is between 10 and 16 A.

- The socket is easily accessible.

- The socket is outside the back of the appliance area in the

specified area

Check the electrical connection.

u

Insert the appliance plug

u

appliance. Ensure that it clicks into place.

Connect the power plug to the power supply.

u

The Liebherr logo appears on the screen.

w

The display switches to the standby symbol.

w

Fig. 46 (a, b, c)

Fig. 46 (G)

.

into the back of the

4.8 Switching on the appliance

Note

If the appliance is in demo mode, DEMO appears on the homescreen.

Disable demo mode (see 7) .

u

Note

The manufacturer recommends:

Store frozen produce at -18 °C or colder.

u

Connect and switch on appliance approx. 2 hours before

loading for the first time.

4.8.1 Switch on appliance

If the standby symbol is displayed over the whole screen:

Press the standby symbol.

u

The appliance is switched on. The display switches to the

w

home screen.

The appliance is set to the displayed temperatures. This is

w

shown by down arrows.

If the Standby symbol appears in the wine cooler or

freezer field:

Press the Standby symbol in the wine cooler or freezer field.

u

The appliance is switched on.

w

The appliance is set to the displayed temperatures. This is

w

shown by down arrows.

If the screen is black:

Touch the screen.

u

The standby symbol appears on the whole screen.

w

Press the standby symbol.

u

The appliance is switched on. The display switches to the

w

home screen.

The appliance is set to the displayed temperatures. This is

w

shown by down arrows.

4.8.2 Switch on the wine cooling compart-

ment.

The standby symbol is displayed in the wine cooling field.

Press the standby symbol in the wine cooling field.

u

The wine cooling zone is switched on

w

The wine cooling compartment is set to the temperatures

w

displayed. This is shown by down arrows.

4.9 Inserting the FreshAir filter.

The supplied FreshAir filter can be used for optimum air quality.

Fig. 46

a b c d G

~ 1800 mm ~ 1400 mm ~ 2100 mm ~ 200 mm Appliance

plugs

Ensure that the following conditions are met:

18 * Depending on model and options

The intake is located at the top of the appliance, (see 1)

Remove cover.

u

Fig. 47

FreshAir-Insert the filter in the cover and turn it clockwise.

u

Ensure that the filter clicks into place.

u

Replace the cover again.

u

Setting the timer

Press menu.

u

Press the navigation arrows until the FreshAir filter is

u

displayed.

Press the FreshAir filter symbol.

u

Press ON.

u

The timer is set. After the interval has expired a message

w

prompts you to change the FreshAir filter.

4.10 Setting the clean ventilation grid

timer

The ventilation grid must be cleaned at least once a year for

sufficient ventilation. The timer can be set as a reminder.

Press menu.

u

Press the navigation arrows until the ventilation grid

u

is displayed.

Press the ventilation grid symbol.

u

Press ON.

u

The timer is set. After the interval has expired a message

w

prompts you to clean the ventilation grid.

5 Control

5.1 Changing the temperature unit

The temperature display can be switched from °C to °F.

Press menu.

u

Press the navigation arrow until °C is displayed.

u

Press °F.

u

The temperature is displayed in °F.

w

Switch from °F to °C in the same way.

5.2 Child proofing

The child-proofing function enables you to make

sure that the appliance is not inadvertently

switched off by playing children.

Control

5.2.1 Switching on the child safety device

Press menu.

u

Press the navigation arrows until the child safety

u

device is displayed.

Press ON.

u

The child safety device is switched on.

w

5.2.2 Switching the child safety device off

Press menu.

u

Press the navigation arrows until the child safety

u

device is displayed.

Press OFF.

u

The child safety device is switched off.

w

5.3 Sabbath Mode

This function meets the religious requirements on the Sabbath

or Jewish feast days. When Sabbath mode is on some of the

electronic control functions are switched off. After setting

Sabbath mode you no longer need to worry about indicator

lamps, figures, symbols, displays, alarm messages and fans.

The thawing cycle only works for the specified time without

taking account of fridge use. After a power cut the appliance

automatically switches back to Sabbath mode.

There is a list of Star-K certified appliances at www.star-k.org/

appliances.

Danger of food poisoning.

If a power cut occurs when Sabbath mode is enabled, this

message is not saved. Once the power is restored the appliance continues to work in Sabbath mode. When this mode is

over no message about the power cut is displayed on the

temperature display.

If a power cut occurred during Sabbath mode:

u

-

-

-

-

-

5.3.1 Switching SabbathMode on.

u

u

u

w

SabbathMode switches off automatically after 120 hours if it

has not already been switched off manually. The display

switches to the home screen.

5.3.2 Switch off the SabbathMode

u

u

w

WARNING

Check the food for quality. Do not eat the food if it has

thawed.

All functions are blocked until Sabbath mode is switched off.

If functions such as SuperFrost, SuperCool, ventilation etc.

are selected when Sabbath mode is switched on they

remain switched on.

The IceMaker does not work.

No audible signals are emitted and the temperature display

does not indicate any warnings or settings (such as a

temperature alarm or door alarm).

The internal light is off.

Press menu.

Press the navigation arrow until SabbathMode is

displayed.

Press ON.

SabbathMode is switched on. Only the SabbathMode

symbol appears on the screen.

Touch the screen.

Press OFF.

SabbathMode is switched off.

* Depending on model and options 19

Control

5.4 Freezer compartment

You can store frozen food, make ice cubes and freeze fresh

food in the freezer compartment.

5.4.1 Freezing food

The rating plate indicates the maximum quantity of fresh food

you can freeze within 24 hours (see 1) under “Freezing

capacity ... kg/24h”.

Each drawer can hold a max. of 25 kg of frozen food.

The shelves can each be loaded with 35 kg of frozen food.

Closing the door creates a vacuum. After closing, wait for

around 1 minute, then the door will be easier to open.

Risk of injury due to broken glass!

Bottles and cans containing drinks may burst when being

frozen. This applies particularly to sparkling drinks.

u

So that the food is rapidly frozen through to the core, do not

exceed the following quantities per pack

- Fruit, vegetables up to 1 kg

- Meat up to 2.5 kg

u

5.4.2 Storage life

The values indicated for storage life are standard ones.

5.4.3 Thawing food

- in the refrigerator compartment

- in a microwave oven

- in a conventional or fan oven

- at room temperature

u

u

5.4.4 Setting the temperature

The temperature depends on the following factors:

-

-

-

The temperature can be set from -26 °C to -16 °C.

Recommended temperature setting: -18 °C

u

w

CAUTION

Do not freeze bottles and cans containing drinks!

Pack the food in portions in freezer bags, reusable plastic,

metal or aluminium containers

Standard values for the storage life of various types of food in

the freezer compartment:

Ice-cream 2 to 6 months

Sausage, ham 2 to 6 months

Bread, bakery products 2 to 6 months

Game, pork 6 to 10 months

Fatty fish 2 to 6 months

Lean fish 6 to 12 months

Cheese 2 to 6 months

Poultry, beef 6 to 12 months

Vegetables, fruit 6 to 12 months

Remove only as much food as is required. Use thawed food

as quickly as possible.

Food once thawed should be re-frozen only in exceptional

cases.

the amount of times the door is opened

the room temperature of the installation site

the type, temperature and amount of food

Press the freezer compartment field.

The following screen is displayed:

Fig. 48

Setting a higher temperature:

Press plus.

u

Setting a lower temperature:

Press minus.

u

The minus symbol is greyed out when the coldest temperature

is selected.

The plus symbol is greyed out if it is pressed again after

selecting the hottest temperature. The standby symbol is

displayed on the screen.

Confirm the required temperature with OK.

u

The display switches to the home screen.

w

The selected temperature is displayed.

w

Up or down arrows indicate the change in temperature. The

w

arrows are greyed out when the target temperature is

reached.

5.4.5 SuperFrost

With this function you can freeze fresh food

quickly through to the core. The appliance

operates with maximum refrigeration. The

noise of the refrigeration unit may be temporarily louder as a result.

You can freeze as many kilograms of fresh food within 24 hrs as

is indicated on the type plate under “Freezing capacity ... kg/

24hrs”. This maximum freezing quantity can vary depending on

model and climate class.

You have to activate SuperFrost in good time, depending on

how much fresh food is to be frozen: about 6 hours before

placing the food inside in case of small amounts and about 24

hours in advance in case of the maximum amount of food to be

frozen.

Wrap produce and spread it out as far as possible. Do not allow

produce to be frozen to touch produce that is already frozen to

prevent the latter thawing.

You do not have to activate SuperFrost in the following cases:

when placing frozen food in the freezer

-

when freezing up to approx. 1 kg fresh food daily

-

Switching SuperFrost on.

Press menu.

u

Press the navigation arrow until SuperFrost is

u

displayed.

Press ON.

u

SuperFrost is switched on.

w

The freezer temperature goes down and the appli-

w

ance works at maximum cooling capacity.

If there is a small amount of frozen food:

wait about 6 hours.

u

Place packaged food in the top drawers.

u

With the maximum amount of frozen food (see model plate):

wait about 24 hours.

u

Remove top drawers and place food directly on the upper

u

shelves.

SuperFrost switches itself off automatically after about 65

w

hours.

The SuperFrost symbol is greyed out.

w

Put the food in the drawers and close them again.

u

The appliance works in normal mode again.

w

20 * Depending on model and options

Control

Switching off SuperFrost

Press menu.

u

Press the navigation arrow until SuperFrost is

u

displayed.

Press OFF.

u

SuperFrost is switched off.

w

5.4.6 Drawers

Note

The energy consumption increases and the cooling performance reduces if the air ventilation is insufficient.

Ensure that the air slits of the fan on the rear wall are always

u

kept free!

To store frozen food directly on the shelves pull the drawer

u

forward and lift it out.

5.4.7 Shelves

Moving shelves

To remove the shelf: lift up at

u

the front and pull out.

To put the shelf back: simply

u

push in as far as it will go.

Using cold storage accumulators

Place the frozen cold

u

storage accumulators on the

frozen food in the upper front

area of the freezer compartment.

5.4.10 IceMaker

The IceMaker is located in the top drawer of the freezer on the

left-hand side.

Make certain that the following conditions are met:

The appliance is level.

-

The appliance is connected.

-

The freezer compartment is switched on.

-

The IceMaker is connected to the water supply.

-

Producing ice cubes

The production capacity depends on the freezer temperature.

The lower the temperature, the more ice cubes can be

produced in a specific period.

The ice cubes drop from the IceMaker into the drawer. When a

certain filling level has been reached, no further ice cubes are

produced. The IceMaker does not fill the drawer right up to the

brim.

Distribute the ice cubes evenly in the drawer to increase the

capacity.

If large quantities of ice cubes are needed, the complete

IceMaker drawer can be exchanged for the adjacent drawer.

When the drawer is closed, the IceMaker automatically recommences production.

Once the IceMaker has been switched on for the first time, it

may take up to 24 hours until the first ice cubes are produced.

Removing shelves

The shelves may be

u

removed for cleaning.

5.4.8 VarioSpace

You can remove the shelves

and drawers. This leaves more

room for larger food items such

as poultry, meat, large game

and tall baked goods, which

can be frozen whole before

further preparation.

Each drawer can hold max. 25 kg of frozen food.

u

The shelves can each be loaded with 35 kg of frozen food.

u

5.4.9 Cold storage accumulators

The cold storage accumulators prevent the temperature from

rising too fast in the event of power failure.

Note

When the appliance is used for the first time and if it has been

out of use for a long time, particles may collect in the IceMaker

and/or water conduit.

Do not use or consume ice cubes that have been made 24

u

hours after the first ice cubes are made.

Switch the IceMaker on.

Press Menu.

u

Press the navigation arrows until the IceMaker is

u

displayed.

Press the IceMaker symbol.

u

Press ON.

u

The IceMaker is switched on.

w

Note

The IceMaker only makes ice cubes when the drawer is

u

completely closed.

Flushing

Flushing function to rinse out the water pipe when used for the

first time.

Note

The water pipe can only be rinsed out if the temperature is

more than 0 °C.

Only use the flushing option if the temperatures in the appli-

u

ance are higher than 0 °C.

* Depending on model and options 21

Control

NOTICE

Blocked IceMaker and water outlet.

Risk of damage to the IceMaker and the drawer outlet.

Put containers with a maximum height of 12 cm in the

u

drawer under the IceMaker.

Ensure that the IceMaker drawer is empty.

Put containers with a max. height of 12 cm in the drawer

u

under the IceMaker.

Press Menu.

u

Press the navigation arrows until the IceMaker is

u

displayed.

Press the IceMaker symbol.

u

Press the navigation arrows until flushing is

u

displayed.

Press ON.

u

Water pipes are rinsed and at the same time

w

the ice cube tray ice cube tray is turned back

to the cleaning position.

Do not operate the screen during this procedure.

u

Flushing function terminated: The symbol appears.

Press OK.

u

Remove the drawer and the container.

u

Clean the drawer and, if necessary, remove excess water

u

from the drawer.

IceMaker holiday function

The IceMaker holiday function is suitable for short phases

when no ice cubes are to be made, for example, when you are

on holiday.

Switching the IceMaker holiday function on.

The IceMaker drawer must be emptied and pushed in.

Press menu.

u

Press the navigation arrows until the IceMaker is

u

displayed.

Press the IceMaker symbol.

u

Press the navigation arrows until the IceMaker

u

holiday function is displayed.

Press ON.

u

The ice cube tray moves to the cleaning position.

w

The IceMaker switches to holiday function.

The IceMaker holiday function symbol appears in

w

the menu area.

Remove the drawer.

u

Clean the ice cube tray and drawer with a soft cleaning cloth

u

and warm water. If necessary use a mild detergent. Then

rinse out.

Push the drawer in.

u

Switching the IceMaker holiday function off

NOTICE

Sickness caused by dirty ice compartment.

After the IceMaker has been switched off for a long time,

u

clean the ice cube tray.

Press OFF.

u

The ice cube tray moves to the operating position. The

w

IceMaker switches on.

The IceMaker symbol appears in the menu field instead of

w

the IceMaker holiday function symbol.

Switching off the IceMaker

If no ice cubes are required, the IceMaker can be switched off

independently of the freezer compartment.

When the IceMaker is switched off, the drawer of the IceMaker

can also be used for freezing and storing food.

Cleaning the IceMaker (see 6.5) .

u

Press Menu.

u

Press the navigation arrows until the IceMaker is

u

displayed.

Press the IceMaker symbol.

u

Press OFF.

u

The IceMaker is switched off.

w

If necessary, food can now be frozen in the drawer up to a

u

maximum height of 12 cm.

5.5 Wine zone

You can bring your wines to the ideal drinking temperature

slowly and gradually in the wine zone.

5.5.1 Storing wine bottles

48 Bordeaux bottles (0,75 l) can be stored in the wine zone.

Store white wine only in one compartment and red wine only

u

in the other, since both compartments can be set to independent temperatures.

If possible, lay bottles of the same type of wine side by side

u

on the same grid shelf.

Rearrange bottles as seldom as possible.

u

Stored open bottles

u

on the folded down

wooden grid shelf.*

To fold down the

u

wooden grid shelf:

press the lock under

the trim sideways.*

The wooden grid

w

shelf folds down.*

5.5.2 Setting the temperature of the wine

cooler

The appliance is set up for regular use by default. You can set

the temperature from 20 °C to 5 °C, we recommend 8 °C to

12 °C.

The wine cooler is divided into two compartments which you

can set at different temperatures.

Press the wine cooler field.

u

The following screen is displayed:

w

*

NOTICE

Rinse agent residue in the ice compartment and drawer.

Nausea or irritation of the mucous membrane.

Remove rinse agent residue: Discard the first three batches

u

of ice cubes.

Remove the drawer.

u

Clean the ice cube tray and drawer with a soft cleaning cloth

u

and warm water. If necessary use a mild detergent. Then

rinse out.

Push the drawer in.

u

Press Menu.

u

Press the navigation arrows until the IceMaker is

u

displayed.

Press the IceMaker symbol.

u

Setting a higher temperature:

Press plus.

u

Setting a lower temperature:

Press minus.

u

The minus symbol is greyed out when the coldest temperature

is selected.

Fig. 49

22 * Depending on model and options

Maintenance

The plus symbol is greyed out if it is pressed again after

selecting the hottest temperature. The standby symbol is

displayed on the screen.

Confirm the required temperature with OK.

u

The display switches to the home screen.

w

The selected temperature is displayed.

w

Up or down arrows indicate the change in temperature. The

w

arrows are greyed out when the target temperature is

reached.

5.5.3 Fan

When the fan runs, the relative humidity in the interior increases

so that the cork does not dry out.

When the fan is activated, the energy consumption increases.

To save energy, the fan switches off automatically when the

door is open.

Switching on the fan

Press menu.

u

Press the navigation arrows until the fan is

u

displayed.

Press ON.

u

The fan is switched on.

w

To switch off the fan

Press menu.

u

Press the navigation arrows until the fan is

u

displayed.

Press OFF.

u

The fan is switched off.

w

If the compressor is running, the ventilator runs even if it is

switched off. It switches off automatically a few minutes after

the compressor runtime.

5.5.4 Dim mode

For glazed door models you can set the dim mode of the light,

i.e. the intensity with which the light is to shine after the door

has closed.

Setting Dim mode

Note

With Dim mode on, the light dims out slowly when you close

u

the door.

There are 5 settings for the intensity of the light after the door is

closed. Settings range from having no light on in the wine

cooler, to minimum light intensity (1) up to maximum light intensity (4).

Press menu.

u

Press the navigation arrow until Dim mode appears.

u

Press the Dim Mode symbol.

u

Press plus or minus.

u

The light intensity is shown in preview.

w

After selecting the lowest level, press the minus symbol again.

The button becomes inactive. The standby symbol is displayed

on the screen.

The plus symbol is greyed out when the highest level is

selected.

Press OK to confirm your settings.

u

The display switches to the home screen.

w

The light intensity after closing the door is set.

w

5.5.5 Labelling clip

You can write which wines are stored in the respective

compartments on the label clip. You can obtain additional labelling clips from your dealer.

Using labelling clips.

Fig. 50

Note

Do not use water-resistant permanent markers.

Label with a water-soluble film pen (non-permanent).

u

5.5.6 Wooden shelf

Fig. 51

To remove the wooden shelf:

Pull the wooden shelf forward.

u

Lift the wooden shelf.

u

To insert the wooden shelf:

Place the wooden shelf on the rails.

u

6 Maintenance

6.1 Change the FreshAir filter.

The FreshAir filter guarantees optimum air quality. It should be

changed every 12 months. When the timer is set a message on

the display prompts you to change it. The FreshAir filter can be

ordered from the specialist dealer.

Change FreshAir filter is displayed.

Press the change FreshAir filter symbol

u

The display switches to the home screen.

w

The message can be displayed again by pressing on the menu

field until the filter has been changed and confirmed. (see 8) .

Fig. 52

Remove cover.

u

* Depending on model and options 23

Maintenance

Turning the timer off

If the reminder function is to be switched off the timer can be

turned off.

Press menu.

u

Press the navigation arrows until the ventilation grid

u

is displayed.

Press the ventilation grid symbol.

u

Press OFF.

u

The timer is turned off.

w

Fig. 53

Remove the FreshAir filter.

u

Insert the new filter in the reverse order.

u

Ensure that the filter clicks into place.

u

Replace the cover again.

u

Confirming the filter change

Press menu.

u

Press the navigation arrows until the FreshAir filter is

u

displayed.

Press the FreshAir filter symbol.

u

Press the navigation arrows until change FreshAir

u

filter is displayed.

Press RESET.

u

The timer is reset. The change interval starts all over

w

again.

Turning the timer off

If a new FreshAir filter is not inserted the timer can be turned off

Press menu.

u

Press the navigation arrows until the FreshAir filter is

u

displayed.

Press the FreshAir filter symbol.

u

Press OFF.

u

The timer is turned off.

w

6.2 Defrosting with NoFrost

The NoFrost system automatically defrosts the appliance.

Wine zone:

The defrost water evaporates due to the compressor heat.

Drops of water on the rear wall are perfectly normal.

Freezer compartment:

The moisture condenses on the evaporator, is periodically

defrosted and evaporates.

The appliance does not have to be manually defrosted.

u

6.3 Cleaning the ventilation grid

The ventilation grid ensures that the appliance works properly

due to optimum aeration and ventilation.

Clean the ventilation grid regularly with a vacuum cleaner.

u

Remove stubborn stains with a soft cloth.

u

When the timer is set a message on the display

prompts you to clean it. The clean ventilation grid

symbol appears on the screen.

Press the clean ventilation grid symbol.

u

The display switches to the home screen.

w

The message can be displayed again by pressing the menu

field until it has been cleaned and this has been confirmed.

(see 8) .

Confirming that the ventilation grid has been cleaned

Press menu.

u

Press the navigation arrows until the ventilation grid

u

is displayed.

Press the ventilation grid symbol.

u

Press the navigation arrows until clean ventilation

u

grid is displayed.

Press RESET.

u

The timer is reset. The cleaning interval starts all

w

over again.

6.4 Cleaning the appliance

Risk of injury and damage as a result of hot steam!

Hot steam can lead to burns and can damage the surfaces.

u

NOTICE

Incorrect cleaning damages the appliance!

u

u

u

u

u

u

u

u

u

u

u

u

NOTICE

Risk of damage from stainless steel care products!

The stainless steel doors and stainless steel side panels

are treated with a premium surface finish.

Stainless steel care products attack these surfaces.

u

Do not clean the glass door with abrasive cleaning agents or

rough cloths. Otherwise the surface and the frame may

become dull or be scratched.

u

u

u

u

Note

u

u

WARNING

Do not use any steam cleaners!

Do not use cleaning agents in concentrated form.

Do not use any scouring or abrasive sponges or steel wool.

Do not use any sharp or abrasive cleaning agents, nor any

that contain sand, chloride or acid.

Do not use chemical solvents.

Do not damage or remove the type plate on the inside of the

appliance. It is important for the customer service.

Do not pull off, bend or damage cables or other components.

Do not allow any cleaning water to enter the drain channel,

ventilation grille or electrical parts.

Please use soft cleaning cloths and a universal pH-neutral

cleaning agent.

Please use cleaning and care products suitable for contact

with foodstuffs in the appliance interior.

Empty appliance.

Pull out the power plug.

Clean plastic outer and inner surfaces with lukewarm

water and a little washing-up liquid.

Only use a soft, clean cloth to wipe down finished door

and side panel surfaces and painted door and side

panel surfaces. To remove heavy dirt, use a little water or

neutral detergent. Alternatively, you can use a micro-fibre

cloth.

Clean the glass door with a standard glass cleaning agent

and a soft cloth.

Most of the parts can be dismantled for cleaning: see the

relevant chapter.

Clean drawers by hand with lukewarm water and a little

washing up liquid.

Wipe wooden grid shelves with a dry lint-free cloth.

Do not clean wooden grid shelves with water and washingup liquid.

Clean other items of equipment by hand with lukewarm

water and a little washing-up liquid.

24 * Depending on model and options

Malfunctions

Only use a damp cloth to clean the telescopic rails. The

u

grease in the runners is for lubrication purposes and must

not be removed.

After cleaning:

Wipe dry the appliance and items of equipment.

u

Connect the appliance and switch it on again.

u

Switch on SuperFrost (see 5.4.5) .

u

When the temperature is sufficiently cold:

Put the food back inside.

u

6.5 Cleaning the IceMaker

The IceMaker drawer must be emptied and pushed in. The

IceMaker must be switched on.

Press Menu.

u

Press the navigation arrows until the IceMaker is

u

displayed.