Page 1

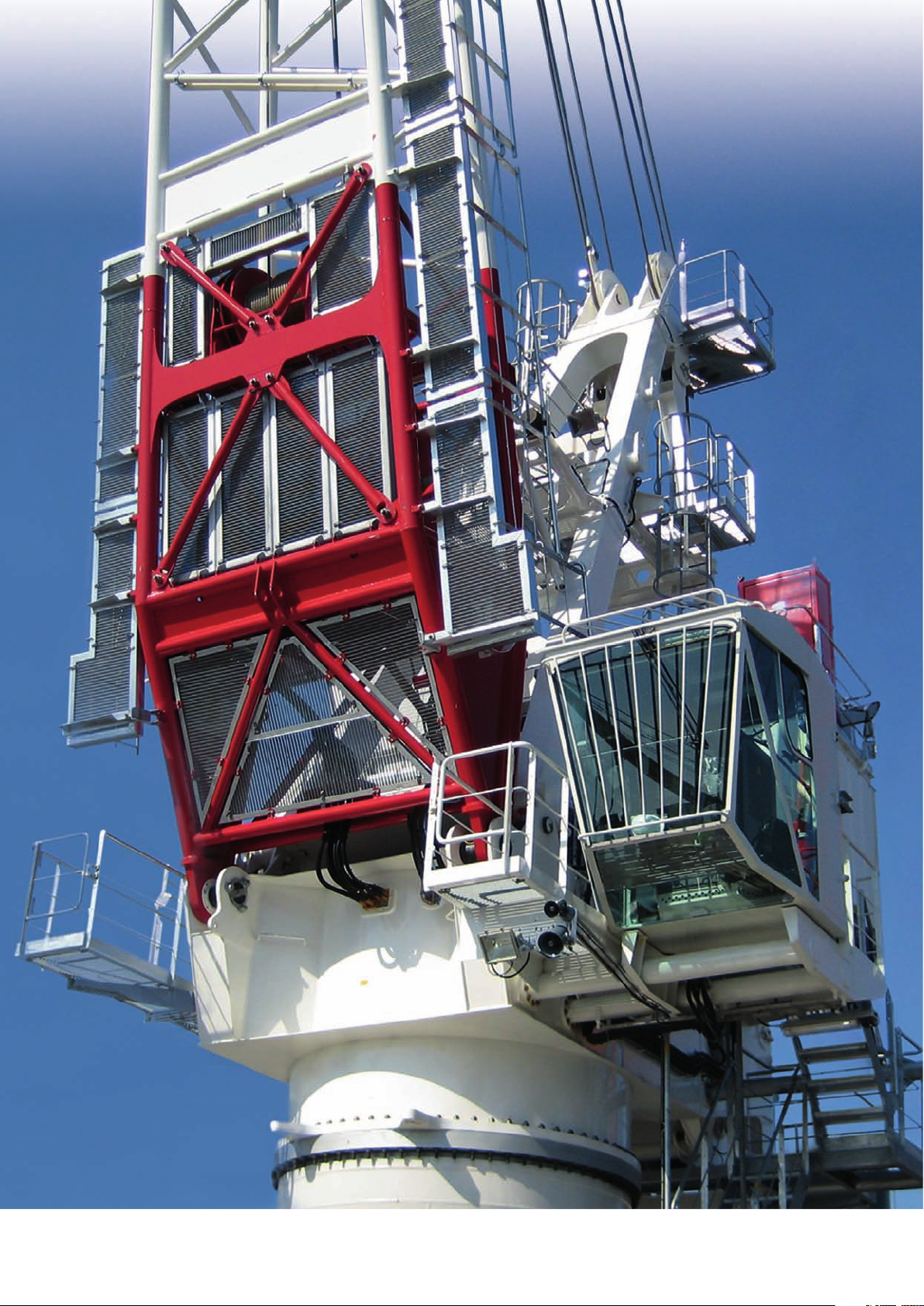

Liebherr

Offshore Cranes

© DSME

Page 2

Experience The Progress –

Liebherr Offshore Cranes

Liebherr offshore cranes are modern, sophisticated machines that benefit from the experience gained

during many years of design development and operation in the most severe environmental conditions. They

offer a wide variety of applications including load lifting and load handling, for fixed and floating production

installations, jack-up rigs, offshore construction vessels and offshore support vessels.

Up-to-date technology and excellent workmanship guarantee the high quality standards Liebherr offshore

cranes are known for.

The combination of continuous research and input from various design disciplines together with the feedback

from more than 800 cranes in the field provides Liebherr with the technology and quality leadership which

make our offshore cranes a benchmark for today's industry.

2

Page 3

1

BOS

Offshore Crane Series

2

MTC

Offshore Crane Series

The range of Liebherr BOS cranes includes rope luffing

offshore pedestal cranes with an open A-frame design and

either electro-hydraulic or diesel-hydraulic drive. Being an

offshore crane of the 3rd generation, the Liebherr BOS crane

stands for the highest manufacturing standards and for

modern, innovative offshore crane technology.

RL

3

The Liebherr ram luffing offshore crane (RL) is the result of

more than 25 years experience in the offshore industry. The

product development is a continuous process and is based on

the actual feedback from users all over the world. The compact

RL offshore cranes offer medium lifting capacities and working

outreaches as well as exemplary reliability and availability.

5

Cranes for subsea operations with Active Heave Compensation (AHC) and Subsea Winch.

Offshore Crane Series

AHC

Subsea Offshore Cranes

Instead of a slewing bearing the Liebherr MTC cranes are fitted

with a patented slewing mechanism, which supports precise

handling and trouble-free operation. The MTC range includes

modern, highly developed mast type cranes for all customers

with a preference for non-metallic slewing systems.

4

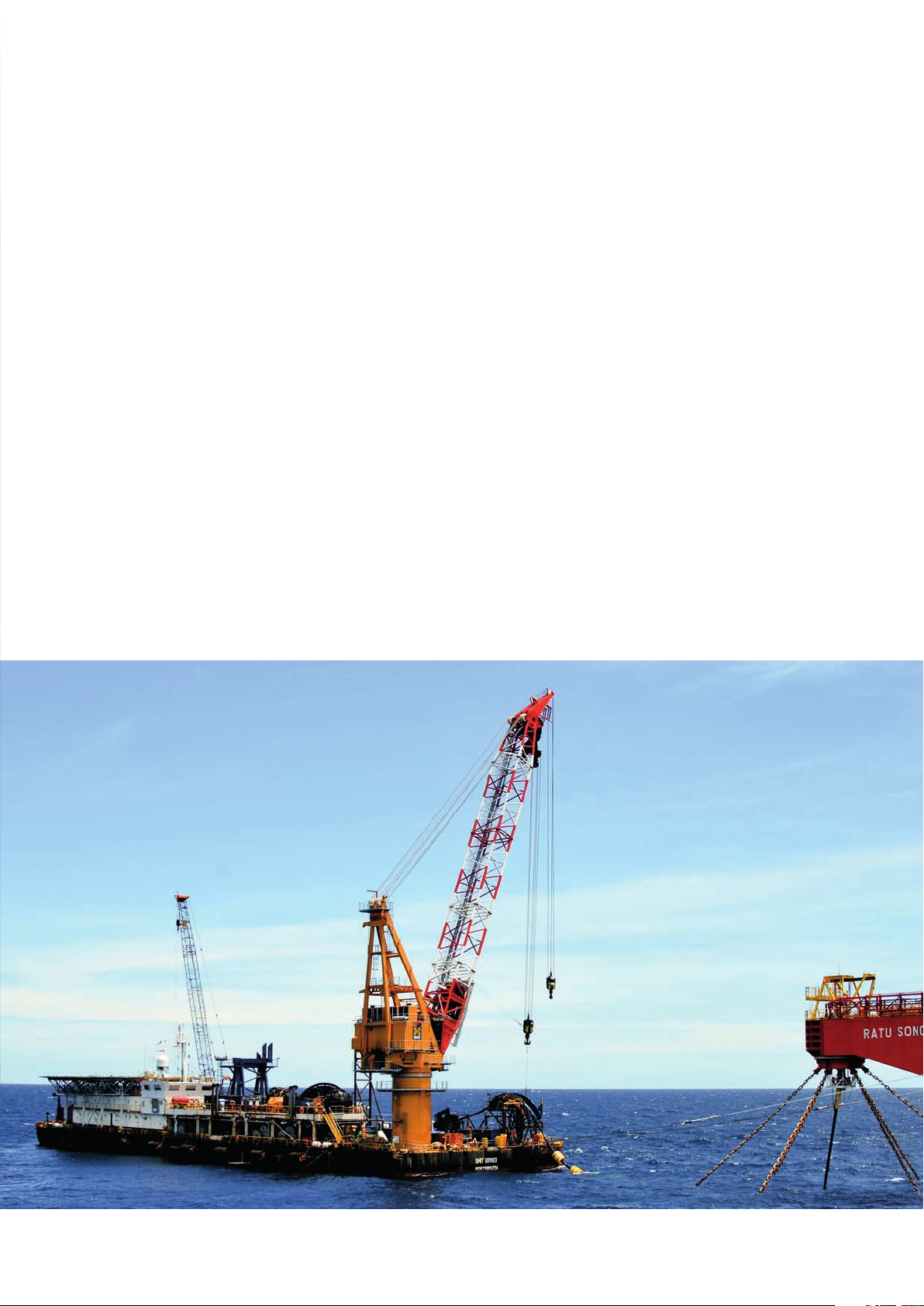

With the recently introduced heavy lift concept, Liebherr is

breaking the rules of traditional design solutions and crane

concepts. What was expected to be tomorrow’s technology

was implemented into these special machines. The current

range of cranes offers fully revolving heavy lift solutions with

lifting capacities of up to 3,000 metric tonnes and also includes

"Around-The-Leg" designs.

6

Benefit through partnership – the Liebherr service philosophy

is based on long-term partnerships and traditional values.

Guaranteed spare parts availability for the lifetime of a crane

and high level logistical service are only two examples of

the unique service support Liebherr offers its customers. A

worldwide network of service centres with 24/7 services is

another highlight which underlines Liebherr’s commitment to

first class customer support.

Heavy Lift Cranes

After Sales Service

3

Page 4

4

Page 5

Unique Selling Propositions

Experience

Today, the Liebherr group incorporates more than 32,000

employees in more than 100 manufacturing plants throughout

the world.

From the beginning Liebherr has been improving its products

and services to meet the requirements of this demanding and

steadily developing market.

Competence

Liebherr offshore cranes are sophisticated machines which are

developed and manufactured in-house and are perfectly suited

to the nature of their intended use.

Modern, well-organised workshops reflect Liebherr’s

commitment to high quality workmanship. The deployment of

a vertical range of manufacture is unique in this industry sector:

All our offshore cranes are produced in our own facilities – no

part of the manufacturing process is subcontracted.

Quality

Full traceability from the first steel plate up to the fully

assembled unit - what is a vision for others, is Liebherr's

standard for any new offshore crane.

Thanks to clearly defined working processes and Liebherr’s

dedication to quality, the cranes meet and even exceed the

requirements of customers and certification authorities.

Technology & Innovation

Liebherr is well known as a trendsetter in new technologies and

innovations.

The Litronic® system, for example, is a crane management tool

of the latest generation, which incorporates all crane controls,

system diagnosis, safeguarding and recording functions.

Additional features such as remote monitoring and remote

diagnostic services are available upon request.

The Master 4 release includes the latest developments in the

electronic industry, e. g. 64bit CANBUS technology, large

memory, touch screen functions, various data transmission

protocols and several different interface types.

Service

Benefit through partnership - Liebherr is not only the first

choice in terms of high quality offshore cranes, but also

provides unrivalled service:

An in-house training centre, guaranteed spare parts availability

for 20 years and more, 24/7 technical support and availability

of service technicians for call-off service demonstrate our

commitment towards our customers.

5

Page 6

BOS

1

The BOS rope luffing type offshore crane is the right choice for applications requiring high

lifting capacities at medium or high outreaches.

Its design supports adequate access to all inspection and

service areas, as well as maximum reliability and minimum

downtime.

Being an offshore crane of the latest generation, the Liebherr

BOS crane represents state-of-the-art technology.

The BOS cranes are available with either electric or diesel

driven prime over and can be designed for operation in either

safe or hazardous areas.

Offshore Crane Series

Standard features include:

• Modular design with standardised components for

maximum reliability

• Liebherr Litronic® CANBUS-type crane management

system

• Hoist winches mounted inside the boom (for prevention of

“two-blocking”)

• Power output regulator to avoid power pack overloading

and to ensure optimum operating efficiency

6

Page 7

789

Page 8

Page 9

MTC

2

For customers and applications requiring offshore cranes with non-metallic slewing bearings,

Liebherr offers the MTC mast-type offshore crane.

The patented slewing mechanism prevents the gantry from

"tilting" through self-alignment and also allows the gliding

pads in the upper and lower bearing to be exchanged without

the gantry having to be lifted off the mast.

The MTC cranes are available with either electric or diesel

driven prime mover and can be designed for operation in

either safe or hazardous areas.

Offshore Crane Series

Standard features include:

• LiebherrLitronic® CANBUS-type crane management system

• Patentedslewingmechanism

• Hoistwinchesmountedinsidetheboom(forprevention

of "two-blocking")

• Poweroutputregulatortoavoidpowerpackoverloading

and to ensure optimum operating efficiency

Page 10

RL

3

The RL crane is the smallest in the Liebherr offshore crane range. With an electro-hydraulic drive and safe area rating, all RL

types are available in a compact version, with the prime mover situated inside the slewing column. Alternatively the crane can be

equipped with a machinery compartment on the rear side of the crane for diesel or EX rated applications.

Offshore Crane Series

© Terminale GNL Adriatico S.r.l.

10

Page 11

The diesel-hydraulic RL cranes do not rely on an external

power source and are ideal for providing reliable and troublefree operation on unmanned platforms or installations

requiring autonomous crane operation.

Main particulars of the RL-type cranes:

• Compact design based on modular systems (with or

without machinery house)

• Liebherr Litronic

system

®

CANBUS-type crane management

• Power output regulator to avoid power pack overloading

and to ensure optimum operating efficiency

• Precise operation thanks to closed loop hydraulic systems

for hoisting and slewing

11

Page 12

4

Our fully revolving heavy lift crane provides lifting capacities of up to 2,000 metric tonnes. The MTC 78000 is the biggest heavy lift

crane worldwide using conventional anti-friction bearing technology and is capable of full 360° turns.

Besides a powerful 8x 500 kW electro-hydraulic aggregate,

this crane is equipped with a special solution for compensation of reverse power which occurs, for example,

during the hoist lowering mode. This means that no

undesired reverse power is brought into the power supply

system.

Similar to our offshore cranes, the MTC 78000 is equipped with Liebherr's own sophisticated crane management system Litronic

data recording and preventive maintenance activities.

Highest operational standards and various safety features make

this crane a prime example of modern heavy lift technology.

Heavy Lift Cranes

®

, which supports machine

12

Page 13

13

Page 14

5

For efficient subsea operations Liebherr offers cranes with Active Heave Compensation (AHC) and Subsea Winch.

Subsea offshore cranes

The revolutionary Active Heave Compensation (AHC) System

and the Subsea Winch from Liebherr have been designed for

subsea load handling from a vessel to the seabed and load

lifting from the seabed to the vessel, as well as for handling

loads under water.

The completely new design of the Subsea Winch allows our

cranes to lift up to 260 tonnes in subsea mode and up to

300 tonnes above the water surface as heavy-lift operation.

Loads can be handled in waters with a depth of up to 3,400 m.

With the innovative design concept of the winch unit (including

the support) a completely new idea is provided, which significantly extends the lifetime of the main wire rope. In

addition to the reduced life cycle costs, the main winch can be

easily adapted for the customer's site specific use.

Liebherr's AHC system is completely integrated in the wellproven Liebherr Litronic

is recognised using a completely new, in-house designed

MRU (Motion Reference Unit), which compensates the motion

with the appropriate winch rotation.

Along with the newly developed AHC system and the Subsea

Winch, Liebherr has designed a "Knuckle Boom" crane to

meet the requirements of the market.

It is based on Liebherr's proven electro-hydraulic drive

system which is controlled by the Litronic

allowing smooth operation under all working conditions.

Booms are available with outreaches between 35 m and 50 m.

®

control system. The vessel's motion

®

system

14

Page 15

6

After Sales Service

Spare Parts

•Liebherr OEM (Original Equipment Manufacturer) spare parts

assuring safe and reliable operation of the machine

•Availability of spare parts for more than 20 years

•Fast delivery by using optimized transport channels

•High stock availability (storage of more than 30,000 different

parts)

Technical Support

•24-hour hotline

•Ad hoc troubleshooting by experienced and highly

trained professionals

•Close contact with various service stations located around

the world

•Online service for computer based control systems

•

Support for special enquiries (special lifts, upgrades,

modifications, maintenance etc.)

Service

•Experienced and highly trained service engineers are posted

at service stations throughout the world (available ad hoc)

•Engineers are multi-skilled (electronics, electrics, hydraulics

and mechanics)

•All Liebherr engineers are supported by a professional team

of factory-based specialists

•Commissioning, check-ups, inspections, fault finding,

maintenance, upgrades, recommendations etc.

Repair Service

•Performed by qualified Liebherr personnel or by the

OEM supplier

•Repair of hydraulic pumps and motors, distribution

gearboxes, diesel engines, winches, slewing gears,

electronic components

Crane Upgrading

•Upgrade to latest systems and/or latest rules and standards

•Upgrade to new control system, new hydraulic system

•Upgrade of LML/SLI

•Installation of additional safety features (emergency lowering,

personnel lifting etc.)

Training

•Individually adapted technical training at Liebherr facility

or on site

•Trainers have experience in the field and are highly skilled

professionals

•Professional training is supported by simulators, cut models

of components and the use of multimedia tools

General

•Liebherr aims to support the operation and be the partner of

any Liebherr offshore crane worldwide via safe, cost-efficient

and reliable service activities

15

Page 16

Offshore Equipment Worldwide

Sunderland

•Manufacturing Sites

•Service Stations

•SalesStations

Rostock

Nenzing

Members of Liebherr-MCCtec GmbH (Offshore Division):

Liebherr-Werk Nenzing GmbH

Dr. Hans Liebherr Strasse 1

6710 Nenzing

Austria

Tel.: +43 50809 41-481

Fax: +43 50809 41-625

info.lwn@liebherr.com

Liebherr-MCCtec Rostock GmbH

Liebherrstrasse 1

18147 Rostock

Germany

Tel.: +49 381 60 06 0

Fax: +49 381 60 06 100

info.mcr@liebherr.com

Liebherr Sunderland Works Ltd.

Ayres Quay, Deptford Terrace

Sunderland

Tyne and Wear, SR4 6DD

Great Britain

Tel.: +44 191 51 43 001

Fax: +44 191 51 44 191

info.lsw@liebherr.com

Sales Stations:

Liebherr Brasil Ltda.

Av. Marechal Câmara, 271, Sala 301

Rio de Janeiro - RJ-Brasil

20020-080

Tel.: +55 21 2220 8469

Fax: +55 21 2240 3563

Liebherr Russland OOO

1 Borodinskaya Str. 5

121 059 Moscow

Russia

Tel.: +7 495 502 17 34

Fax: +7 495 933 72 23

Liebherr-Maritime Benelux B.V.

Beeldschermweg 2

P.O. Box 1690

3821 AH Amersfoort

Netherlands

Tel.: +31 33 450 0850

Fax: +31 33 450 0899

Sales Headquarter:

Liebherr-Werk Nenzing GmbH

Dr. Hans Liebherr Strasse 1

6710 Nenzing

Austria

Tel.: +43 50809 41-481

Fax: +43 50809 41-625

offshore.crane@liebherr.com

Liebherr Nenzing Crane Co.

Offshore Cranes

7075 Bennington Street

Houston, Texas 77028

USA

Tel.: +001 713 636 4070 (24 h)

Fax: +001 713 636 4073

Service Stations:

Liebherr-Nenzing Service GmbH

Am Neuländer Baggerteich 1

210 Hamburg

Germany

Tel.: +49 40 76702 200

Fax: +49 40 76587 79

Liebherr Brasil Ltda.

Rua Dr. Hans Liebherr, 1

SP 12522-640 Guarantigueta

Brazil

Tel.: +55 12 3128 4282

Fax: +55 12 3128 4322

Liebherr (HKG) Limited

86 Ping Che Road

Fanling

New Terretories

Hong Kong

Tel.: +852 3142 3113

Fax: +852 3142 3119

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing/Austria

Tel.: +43 50809 41-0

Fax: +43 50809 41-500

info.lwn@liebherr.com

www.liebherr.com

Liebherr Sunderland Works Ltd.

Ayres Quay, Deptford Terrace

Sunderland

Tyne and Wear, SR4 6DD

Great Britain

Tel.: +44 191 567 9977

Fax: +44 191 567 2723

Liebherr-Canada Ltd.

Suite 810, Atlantic Place

215 Water Street

St. John´s, NL A1C 6C9

Canada

Tel.: +001 709 748 7829

Fax: +001 709 368 6494

Liebherr-Singapore Pte. Ltd.

No. 8 Panadan Avenue

Singapore 609384

Tel.: +65 6265 2305 264

Fax: +65 6261 6485

Liebherr-Maritime Benelux B.V.

Beeldschermweg 2

P.O. Box 1690

3821 AH Amersfoort

Netherlands

Tel.: +31 33 450 0880

Fax: +31 33 450 0897

Liebherr Nenzing Crane Co.

Offshore Cranes

7075 Bennington Street

Houston, Texas 77028

USA

Tel.: +001 713 636 4071

Fax: +001 713 636 4073

Liebherr-Africa (Pty.) Ltd.

Vlakfontein Road

Fulcrum Ind. Township

P.O. Box 841

Springs/Trasnvaal 1560

Tel.: +27 11 365 2000

Fax: +27 11 817 3884

Liebherr Russland OOO

1-aya Borodinskaya UL., 5

Floor 3

121 059 Moscow

Russia

Tel.: +7 495 710 7602

Fax: +7 495 933 0771

Liebherr (HKG) Limited

Shanghai Representive Office

Suite 709

7/F. Jin Zhong Building

Shanghai, China 200031

Tel.: +86 21 6415 2148

Fax: +86 21 6473 6786

Frontline Cranes & Construction

Machinery FZE

Jebel Ali Free Zone (South)

Plot No.: 10508

P.O. Box 2540

Dubai

U.A.E

Tel.: +971 4 8860199 107

Fax: +971 4 8860324

Liebherr Offshore Cranes – 10447797 – 01/2012 – Subject to change without notice.

Loading...

Loading...