Page 1

After Sales Service International

Service Documentation

Service Manual No. 01/2008 LHG/TKD-Ne/23.10.08

Appliance Documentation

IGN 2556 from Index 20

IGN 2566 from Index 20

with IceMaker

NoFrost freestanding freezer

IGN 2556

IGN 2566

Page 1/21 01200800SM_gb.doc

Page 2

Service Information No. 01/2008 IGN 2556/2566

Contents

1.0 Operating and control elements...............................................................................................3

2.0 Functions at a glance ................................................................................................................3

3.0 Description of appliance ...........................................................................................................4

3.1 Sensor positions, schematic diagrams 4

4.0 Main components and their functions .....................................................................................5

4.1 Electrical components and functions 5

4.1.1 General 5

4.1.2 Freezer compartment 5

4.2 Refrigeration components and functions 8

4.2.1 Freezer compartment 8

5.0 Assembly instructions / replacement of parts ........................................................................9

5.1 General 9

5.1.1 Electronic control system 9

5.1.2 Door magnet 10

5.2 Freezer compartment 11

5.2.1 Evaporator module 11

5.2.2 Evaporator sensor 12

5.2.3 Air sensor 12

5.2.4 Fan 13

5.2.5 Temperature fuse 14

5.2.6 IGN 2566 only, IceMaker 15

5.2.7 IGN 2566 only, double solenoid valve IceMaker 15

6.0 Technical data..........................................................................................................................16

6.1 General 16

6.2 Freezer compartment 16

7.0 Service menu............................................................................................................................17

7.1 Manual defrosting 17

7.2 Demo mode 17

7.3 Service mode 18

7.4 Sensor test (temperature display) and door contact test "E" 19

8.0 Error code, troubleshooting....................................................................................................19

8.1 Table of error codes 19

8.2 Troubleshooting VCC compressor / inverter 20

8.2.1 Checking the inverter and the frequency signal 20

8.2.2 Checking the compressor 21

Page 2/21

Page 3

Service Information No. 01/2008 IGN 2556/2566

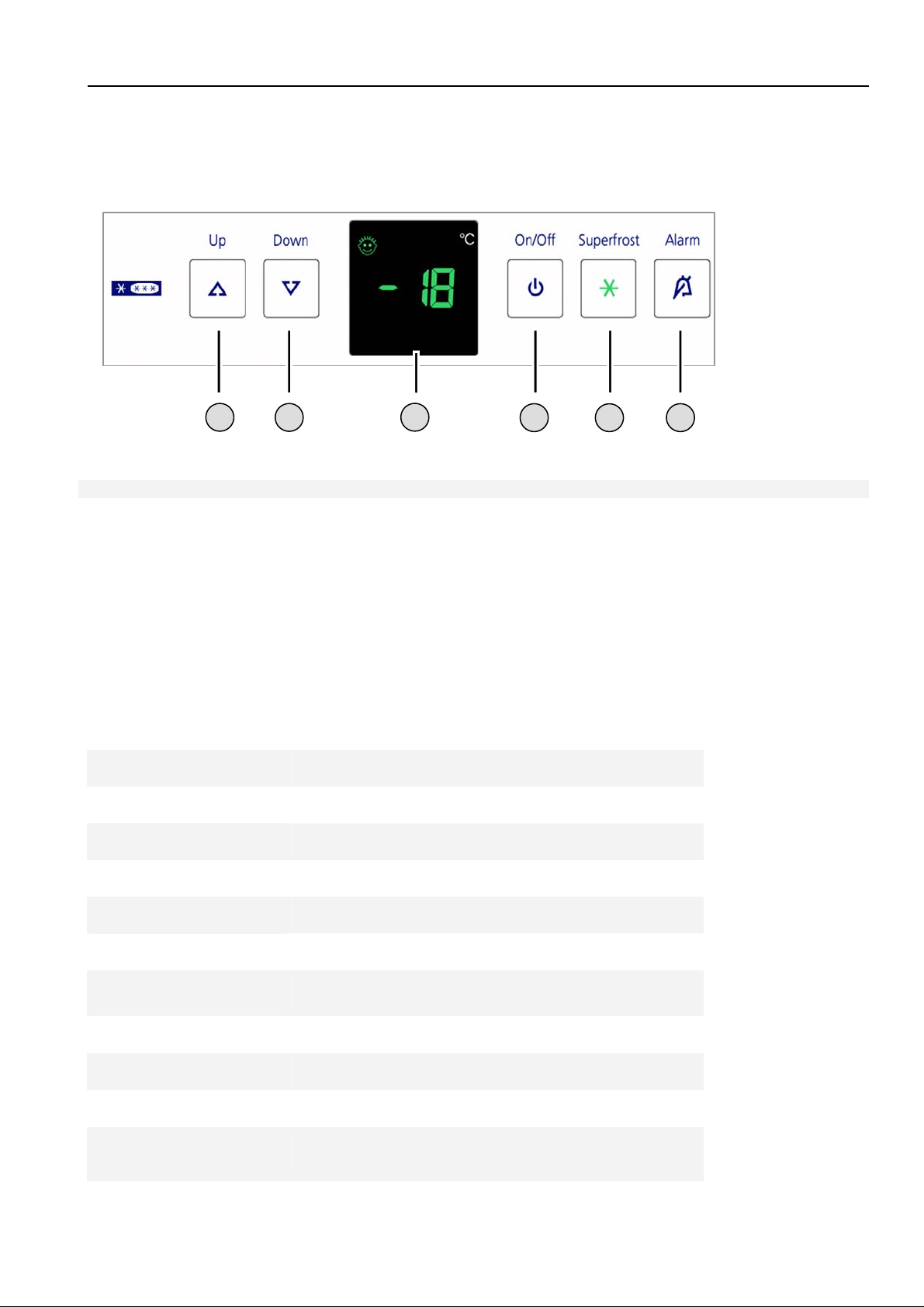

1.0 Operating and control elements

1 Up Setting button temperature higher

2 Down Setting button temperature lower

3 Temperature/function display

4 ON/OFF ON/OFF button

5 SuperFrost SuperFrost function

6 Alarm Alarm OFF button for audible alarm

1

2

3

Freezer compartment

4

5

6

2.0 Functions at a glance

Control:

Temperature display:

Temperature range:

Temperature alarm:

Door alarm:

Fan:

Defrosting:

Interior light:

Service menu:

Compressor:

Solenoid valve

refrigeration circuit:

Electronic

Actual value

-14°C to -28°C

Visual, audible

Audible

Present

Automatic

Present

Present

VCC

Not present

Page 3/21

Page 4

Service Information No. 01/2008 IGN 2556/2566

r

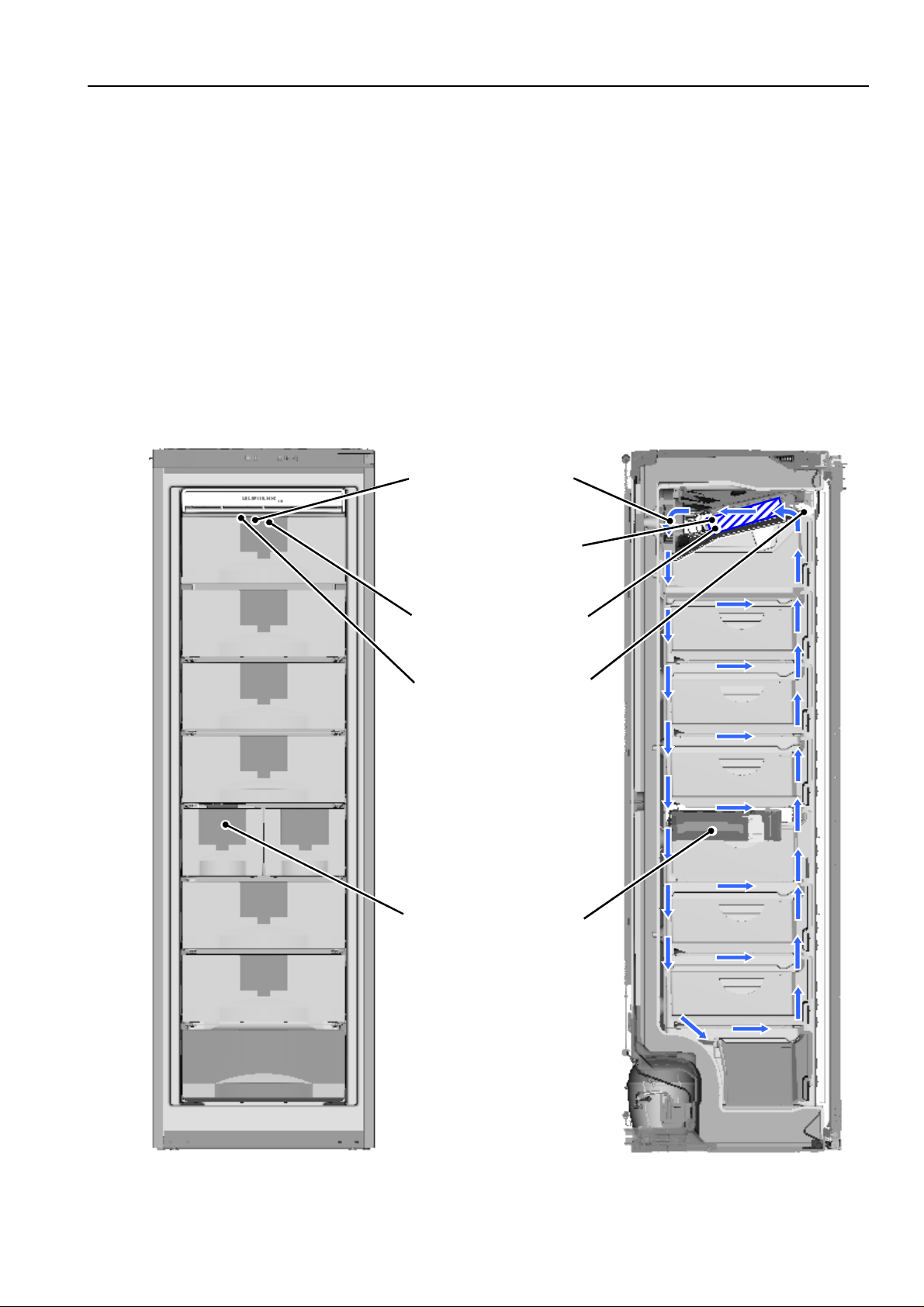

3.0 Description of appliance

The IGN 2556/2566 is a NoFrost freezer using a series 6 control system with actual value display.

The appliance has a lamellar evaporator with fan and integrated defrost heater. Two sensors, an air sensor and

an evaporator sensor, see to the control and automatic defrosting. A safety temperature limiter protects the

appliance against excessively high temperatures during the defrosting phase.

The IGN 2566 is equipped with an IceMaker.

3.1 Sensor positions, schematic diagrams

Foamed-in rear wall

Fan

evaporato

Evaporator sensor

Air sensor

IGN 2566 only:

IceMaker

Fig. 3.1 / 2 Fig. 3.1 / 1

Page 4/21

Page 5

Service Information No. 01/2008 IGN 2556/2566

4.0 Main components and their functions

4.1 Electrical components and functions

4.1.1 General

Electronic control system

Type:

Components:

Series 6 electronic control system

Electronic single-board solution

4.1.2 Freezer compartment

Electronic control system

Setting range:

Display range:

Functions

Temperature alarm:

-14°C to -28°C

0°C to -49°C

Values outside the range are indicated by a cross bar

Alarm value: 4K warmer than set value.

Warmest alarm value: -10 °C

Coldest alarm value: -20 °C

Delay: 20 minutes

Visual: Flashing alarm LED

Audible: 4 beeps (suppressed during start-up)

Defrosting:

During start-up: The temperature display flashes until the switch-off

value is reached, the audible alarm is switched OFF.

(e.g. given a set value of -18°C, a temperature of –14°C must be present for at

least 20 minutes, then a temperature alarm is raised.)

When the defrosting phase begins, the temperature alarm is suppressed for

1.5 hrs.

ON: - During start-up after 6 hours cumulative compressor

running time.

- After a cumulative compressor running time of 10 to 30 hours

maximum, depending on the number/duration of the door

openings.

When the defrosting phase begins, the compressor and the fan are

switched OFF and the defrost heater is switched ON.

Duration: The defrost heater remains switched ON until

- the freezer compartment evaporator sensor has reached +32°C

or

- a max. defrosting time of 50 minutes has been reached.

Info: After the end of the heating phase the compressor is switched ON

with a 15-minute delay. Fan ON, from -25°C.

If the SuperFrost function is activated during the defrosting phase,

this will not interrupt defrosting.

Door alarm:

When: If door is open, after 60 seconds.

Audible: 3 beeps.

Page 5/21

Page 6

Service Information No. 01/2008 IGN 2556/2566

SuperFrost:

Sensor

Air sensor:

Evaporator sensor:

Switch

Door switch:

ON: Freezer compartment sets itself to -32°C (quantity-controlled, min.

30 hrs., max. 65 hrs.)

The appliance sets itself to -32°C for at least 30 hours. In the

following 35 hours cooling by 11K to the set value must have been

reached or a total time of 65 hours must have elapsed in order that

SuperFrost is automatically ended.

OFF: The freezer compartment sets itself to the set value.

Note: If SuperFrost is actuated during a defrosting phase, the SuperFrost

function is not performed before the defrosting phase has run.

Position: Behind the front panel of the evaporator module.

Function: - Switches the compressor ON/OFF.

- Generates the display value.

Position: Slipped into the lamellar evaporator.

Function: - Switches the defrost heater OFF (ends the defrosting phase).

- Switches the fan ON/OFF.

Position: In front panel

Loads

Fan:

Type: Reed contact

Contact type: Make contact

Function: Activation via:

magnet on the door, magnet is replaceable.

Switching signal when:

door open: fan OFF

door alarm ON after 60 seconds

Position: In the evaporator module, at the back centre.

Function:

Evaporator

sensor

Switch-on

value

Switch-on

value

Switch-on

value

Switch-off

value

e.g. If the evaporator sensor has reached the switch-on value for the fan and the

compressor is ON and the door is CLOSED, then the fan is ON.

Compressor Door Fan

OFF CLOSED

ON CLOSED

OFF/ON OPEN

OFF/ON

CLOSED/

OPEN

OFF

ON

OFF

OFF

Switch-on value evaporator sensor:

a) During start-up/after defrosting: -25°C

b) In the normal mode 2K colder than air sensor

Page 6/21

Page 7

Service Information No. 01/2008 IGN 2556/2566

Defrost heater:

Compressor:

Position: Clipped into lamellar evaporator

Function: Keeps the evaporator free from ice. Activation via electronic control

system.

Defrost heater ON:

- Depending on the number and duration of door openings, the

electronic system calculates the defrost cycles between 10-30

hours cumulative compressor running time.

- Upon start-up after 6 hours cumulative

compressor running time.

Defrost heater OFF:

- When the evaporator sensor has reached +32°C

- When max. time of 50 minutes is exceeded.

Heater cannot be replaced Æonly complete evaporator module!

Type: VCC compressor, frequency-controlled.

Function: ON: Air sensor switch-on value

Note: On-delay time (8 minutes) must have elapsed.

OFF: Air sensor switch-off value.

VCC compressor, frequency-controlled.

• Compressor with 4 different speeds (1600 / 1900 / 3000 / 3600 rpm).

• The inverter electronic control is fitted directly on the compressor. The inverter

electronic control controls the compressor with a pulse-width modulated

square-wave voltage.

• For speed value input, the inverter electronic module receives a square wave

frequency signal from the power PCB.

This frequency signal is output with 56, 71, 87,100 or 117 Hz, depending on

the speed at which the compressor is to run.

Frequency in Hz Speed in rpm Operation

56 Compressor OFF Compressor OFF

71 1600 Ideal case

87 1900 Control mode

100,

0 (signal interruption),

other values than the

defined frequencies

117 3600 SuperFrost

• Runtime longer than 70 minutes:

Speed increase by one step during compressor operation.

• Runtime shorter than 40 minutes:

Speed reduction on next start-up.

3000

Start-up, signal

interruption, signal fault

For troubleshooting, see section 8.2 Troubleshooting VCC compressor / inverter

Page 7/21

Page 8

Service Information No. 01/2008 IGN 2556/2566

4.2 Refrigeration components and functions

4.2.1 Freezer compartment

Compressor

Compressor:

Frame heater

Position:

Evaporator

Type:

VCC, frequency-controlled

Foamed-in in the housing, in the contact area of the magnetic door seal.

Lamellar evaporator.

Type of installation:

Injection point:

Flow sequence:

In evaporator module on appliance ceiling

Front centre

Front to back

Page 8/21

Page 9

Service Information No. 01/2008 IGN 2556/2566

5.0 Assembly instructions / replacement of parts

5.1 General

5.1.1 Electronic control system

Covers: Disengage covers at the marked points.

Fig. 5.1.1/ 1 Left cover Fig. 5.1.1/ 2 Right cover

Front panel: Unlock locating lugs at the left and right of the front panel.

Fig. 5.1.1/ 3 Left locating lug Fig. 5.1.1/ 4 Right locating lug

PCB carrier: Draw the front panel forwards for removal and expose the cables.

Disconnect and detach group connectors.

Fig. 5.1.1/ 5 Group connector

Fig. 5.1.1/ 6 Group connector

Fig. 5.1.1/ 7 Front panel assembly

Page 9/21

Page 10

Service Information No. 01/2008 IGN 2556/2566

5.1.2 Door magnet

Magnet holder: Press marked locating lugs together and detach magnet holder upwardly.

Fig. 5.1.2 / 1

Magnet

holder

Page 10/21

Page 11

Service Information No. 01/2008 IGN 2556/2566

g

5.2 Freezer compartment

5.2.1 Evaporator module

Fig. 5.2.1/ 1 Evaporator module

Locking parts: Are snapped into place at the right and left for locking the evaporator module.

Transit support: Remove the adhesive tape as transit support of the "top polystyrene moulding", it is no

longer needed for assembly (Fig. 5.2.1/ 3).

Top polystyrene moulding: Lift off the polystyrene moulding first at the front, then at the back.

Draw the "top polystyrene moulding" forwards for removal.

. 5.2.1/ 2 Remove locking part

Fi

Locking

parts

Remove top drawers

Evaporator module

Fig. 5.2.1/ 3 Remove adhesive tape

Top polystyrene moulding

Adhesive tape

Page 11/21

Page 12

Service Information No. 01/2008 IGN 2556/2566

g

5.2.2 Evaporator sensor

Evaporator module: Dismantle the evaporator module as described below under 5.2.1 Evaporator

module.

Evaporator sensor: Is slipped inbetween the lamellas and in case of defect it has to be cut off and

repaired with the repair kit (Art. No. 9590 062).

Fig. 5.2.2/ 1 Evaporator module folded down

Temperature fuse

Evaporator

5.2.3 Air sensor

Evaporator module: Dismantle the evaporator module as described below under 5.2.1 Evaporator

module.

Front polystyrene moulding: Is situated behind the front panel is the evaporator module (is only inserted).

Acts as an air seal of the air sensor in the direction of the lamellar evaporator.

Air sensor: Is engaged behind the front panel of the evaporator module and in case of defect

it has to be cut off and repaired with the repair kit (Art. No. 9590 062).

. 5.2.3/ 1 Removal of the polystyrene

Fi

Fig. 5.2.3/ 2 Air sensor

Page 12/21

Page 13

Service Information No. 01/2008 IGN 2556/2566

5.2.4 Fan

Evaporator module: Dismantle the evaporator module as described below under 5.2.1 Evaporator

module.

Fan casing: Detach fan connector. Lift the fan casing out of the housing support, swing it down

and remove it.

Fig. 5.2.4/ 1 Fan casing

Fan: Lay the fan casing front face down, and remove the attached sealing rubber at the

Fig. 5.2.4/ 3 Fan housing, front face

Fig. 5.2.4/ 5 Fan housing, components

Fan connector

Fan casing

Fig. 5.2.4/ 2 Fan casing, swung down

rear. Detach the fan from the housing.

Sealing rubber

Fig. 5.2.4/ 4 Fan housing, rear

Page 13/21

Page 14

Service Information No. 01/2008 IGN 2556/2566

5.2.5 Temperature fuse

Evaporator module: Dismantle the evaporator module as described below under 5.2.1 Evaporator

module.

Temperature fuse: Fastened by a screw.

To be noted for replacement:

- Cut off only at the coloured wires (not heater wire!)

- Fix the wires in such a way that they do not touch the heater.

Fig. 5.2.5/ 1 Temperature fuse

Temperature fuse

Screw

Page 14/21

Page 15

Service Information No. 01/2008 IGN 2556/2566

g

g

5.2.6 IGN 2566 only, IceMaker

Holder: Press the locating lugs in the two openings of the holder inwards and draw the holder forwards

for removal (see Fig. 5.2.6/ 1).

Reed contact: The reed contact for drawer recognition is situated in the holder.

IceMaker: Draw the IceMaker forwards and lower it for removal. Disconnect the IceMaker cables.

Fig. 5.2.6/ 1 Disengaging the holder

Holder

Fig. 5.2.6/ 2 Reed contact in holder

Holder with reed

contact

Fig. 5.2.6/ 3 IceMaker

5.2.7 IGN 2566 only, double solenoid valve IceMaker

Solenoid valve - Undo marked screw (see Fig. 5.2.7/ 1).

- Remove cover.

- Detach electrical connectors.

- Undo screw fitting of water hose.

Fi

. 5.2.7 / 1

. 5.2.7 / 2

Fi

Screw fitting of

water hose

Double solenoid valve

Electrical

connection

Page 15/21

Page 16

Service Information No. 01/2008 IGN 2556/2566

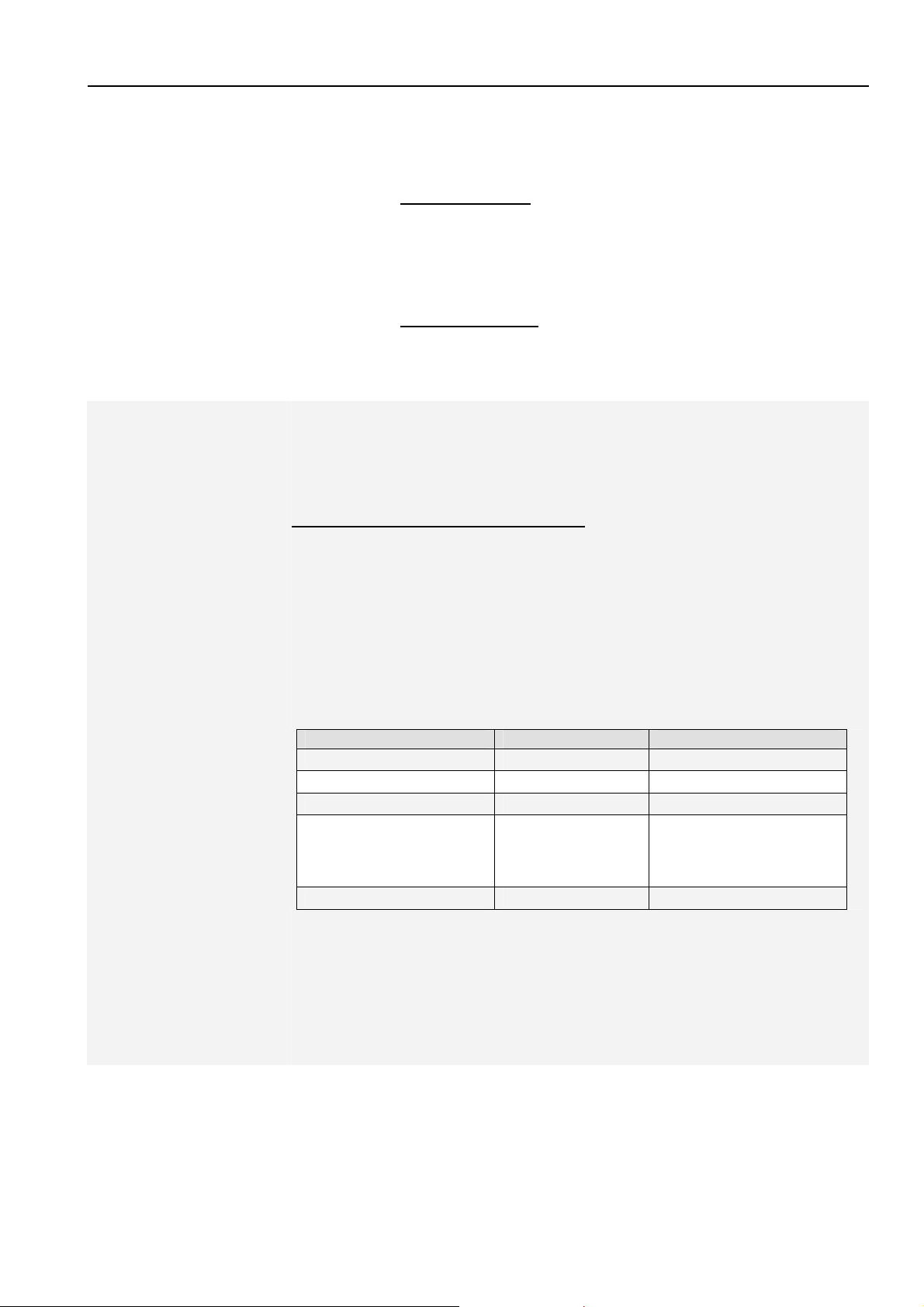

6.0 Technical data

6.1 General

Sensor values:

Air and evaporator sensors

Temperature °C Resistance value kOhm

6.2 Freezer compartment

+35 3.1

+30 3.8

+25 4.7

+20 5.9

+15 7.3

+10 9.3

+5 11.9

0 15.3

-5 19.8

-10 25.9

-15 34.1

-20 45.3

-25 60.8

-30 82.3

-35 112.8

Fan:

Defrost heater:

Temperature fuse:

Wattage: 1.6 watts

Voltage: 9 volts/DC

Wattage: 199 watts

Voltage: 230 volts/AC

Tripping temperature: +93°C

Page 16/21

Page 17

Service Information No. 01/2008 IGN 2556/2566

7.0 Service menu

The service menu may be used by service technicians only.

Activation of service menu: Press "ON/OFF" + "SuperFrost" simultaneously for about 3 seconds

Once the service menu is activated, the SuperFrost LED flashes.

7.1 Manual defrosting

Step Display Operation

Service menu start

Press "ON/OFF" and

1 Actual value

Evaporator must be cold

"H" flashes together

1

with SuperFrost LED

Manual defrosting is ended: - by switching appliance OFF/ON.

- automatically after the defrosting parameters have been reached.

(evaporator sensor +32°C or max. defrosting time 50 minutes)

"SuperFrost"

simultaneously for 3

seconds

Press "SuperFrost" "A" flashes Defrosting activated.

Display following

operation

"H" flashes with

SuperFrost LED

Testing option / Info

Service menu active.

Stepwise manual

defrosting.

7.2 Demo mode

Step Display Operation

Service menu start

Press "ON/OFF" and

1 Actual value

"H" flashes with

2

SuperFrost LED

3a

3b

Demo mode (Demo mode can be deactivated only via service menu, not by OFF/ON.)

Operation switches to the mode wanted, demo mode or normal mode, as soon as "SuperFrost" has

been actuated.

d1

d0

"SuperFrost"

simultaneously for 3

seconds

Press "Up" once

Press SuperFrost. -18°C

Press SuperFrost. Actual value

Display following

operation

"H" flashes with

SuperFrost LED

"d1" or "d0" flashes

with SuperFrost

LED

Testing option / Info

Service menu active.

Stepwise manual

defrosting.

Service menu active.

Stepwise demo mode

Demo mode ON

Demo mode OFF

Page 17/21

Page 18

Service Information No. 01/2008 IGN 2556/2566

7.3 Service mode

Step Display Operation

Display following

operation

Service menu start

Press

1 Actual value

"ON/OFF" and

"SuperFrost"

simultaneously for 3

"H" flashes with

SuperFrost LED

seconds

Service mode

-- test display LED, buttons, door contact --

"H" flashes with

1

SuperFrost LED

"L" flashes with

2

SuperFrost LED

Press "Up" twice

Press "SuperFrost" "rd" flashes Service mode activated

"L" flashes with

SuperFrost LED

All button LEDs and

3 "rd" flashes Door closed and open

display segments

shine

All button LEDs and

4

display segments

shine

Press all the buttons

- "L0" shines

- 2 seconds beep

After step 4, actuation of the last button, a beep sounds.

Service mode

-- Testing electric loads--

5 "L0" shines No operation

6 "L0" shines Press "Up"

7 "L1" shines Press "Up"

8 "L4" shines Press "Up"

9 "L7" shines Press "Up"

"L0" shines All OFF

"L1" shines

"L4" shines Defrost heater ON

"L7" shines

"L8" shines

Return to step 5 is brought about by pressing the up button again.

End Press "ON/OFF"

1) Power input = power input of the appliance in the respective testing step!

Testing option / Info

Service menu active.

Stepwise manual

defrosting.

Service mode selected

Door contact, LEDs,

display

Buttons / button actuation

is confirmed by beep

Compressor ON

low speed

Fan ON

low speed

Fan ON

high speed

Power

input1)

--

-199 watts

1.4 watts

1.6 watts

Page 18/21

Page 19

Service Information No. 01/2008 IGN 2556/2566

7.4 Sensor test (temperature display) and door contact test "E"

Step Display Operation

Service menu start

Press "ON/OFF" und

1 Actual value

Sensor test and door contact test (sensor values without offset, appliance in control mode)

"H" flashes with

1

SuperFrost LED

"E" flashes with

2

Superfrost LED

"E3" flashes

3

alternately with sensor

temperature

"E4" flashes

4

alternately with sensor

temperature

"E7" flashes

5

alternately with sensor

temperature

End Press ON/OFF twice

"SuperFrost"

simultaneously for 3

seconds

Press "Up" three times

Press "SuperFrost"

Press "Up"

Press "Up"

Press "Up"

Display following

operation

"H" flashes with

SuperFrost LED

"E" flashes with

Superfrost LED

"E3" flashes

alternately with

sensor temperature

"E4" flashes

alternately with

sensor temperature

"E7" flashes

alternately with

sensor temperature

"E8" flashes

alternately with

"1" or display is

OFF

Testing option / Info

Service menu active.

Stepwise manual

defrosting.

Sensor test mode selected

Air sensor

Evaporator sensor

Ambient sensor

Door contact

(display OFF=door closed,

1=door open)

8.0 Error code, troubleshooting

8.1 Table of error codes

Error code Defective component Emergency mode

Compressor switches OFF.

F3 Freezer compartment air sensor

F4

ru Ambient sensor

Freezer compartment evaporator

sensor

Info:

Compressor switches ON again only when the

appliance has been switched OFF and on again.

Compressor continuous operation (highest speed)

Appliance continues to operate in normal mode,

only without regard to the ambient temperature.

Info:

Is displayed only in the service mode of the service

menu, in step 2 instead of "rd".

Page 19/21

Page 20

Service Information No. 01/2008 IGN 2556/2566

8.2 Troubleshooting VCC compressor / inverter

8.2.1 Checking the inverter and the frequency signal

Connect appliance to a power meter.

Switch appliance ON.

Is the

compressor

Yes

Press SuperFrost

Does the speed

increase, higher

power input?

No

Switch appliance OFF

Does the

compressor

stay at a

standstill?

Yes

Inverter faulty

Yes

No

No

Is

the compressor

running after 90

seconds?

Yes

Frequency signal faulty / not

connected or power PCB faulty.

Inverter; power PCB and the

frequency cable are OK.

Frequency signal faulty / not

connected or power PCB faulty.

No

see 8.2.2

Attention: In case of interruption of the frequency signal, the compressor starts

only after 90 seconds!!

Page 20/21

Page 21

Service Information No. 01/2008 IGN 2556/2566

8.2.2 Checking the compressor

Fault profile: Compressor does not run (even after a waiting time of 90 seconds)

Select step 6 (compressor ON) in the service menu under "7.3 service mode". If the compressor now

starts there was probably an operator error. Otherwise proceed as described below.

At the inverter, line voltage (230V) must be applied between N and 1/C.

Pull off frequency signal connector (lilac)

from the inverter, wait 90 secs.

Replace inverter electronic module.

If the compressor still does not run,

replace the compressor.

Then replace the inverter back again.

Is voltage

applied to the

inverter?

Yes

Is the

compressor

running?

No

Is the

compressor

running?

No

No

Yes

Yes

Fault at cable connection /

connector or power PCB.

Presumably operator error.

Check speed increase!

Power PCB or inverter fault.

Page 21/21

Loading...

Loading...