Page 1

H

P

S

SERVICE MANUAL

English

Cod. 273000

Rev. 16.02.2006

Issued by T.D.Service

Page 2

Page 3

Caution

Recommendations:

S the manual is retained for the entire service life of the machine;

S the user reads the manual carefully before carrying out any operations on the machine;

S the machine is used exclusively for the purpose for which it is intended; incorrect use of the machine shall release the

manufacturer from any liability.

This manual has been prepared to enable the end ---user to carry out only the operations that can made with the panels

closed. Any operations that require the opening of doors or equipment panels must be carried out only by qualified

personnel.

Each machine is equipped with an electric isolating device which allows the operator to work in conditions of safety. This

device must always be used to eliminate risks during maintenance (electric shocks, scalds, automatic restarting, moving

parts and remote control).

The panel key supplied with the unit must be kept by the person responsible for maintenance.

For identification of the unit (model and serial no.) in case of the necessity for assistance or spare parts, read the identification

label placed on the outside and inside of the unit.

IMPORTANT:

1

4

7

10

12

14

18

19

21

23

25

This manual may be subject to modification; for complete and up---to---date information the user should

always consult the manual supplied with the machine.

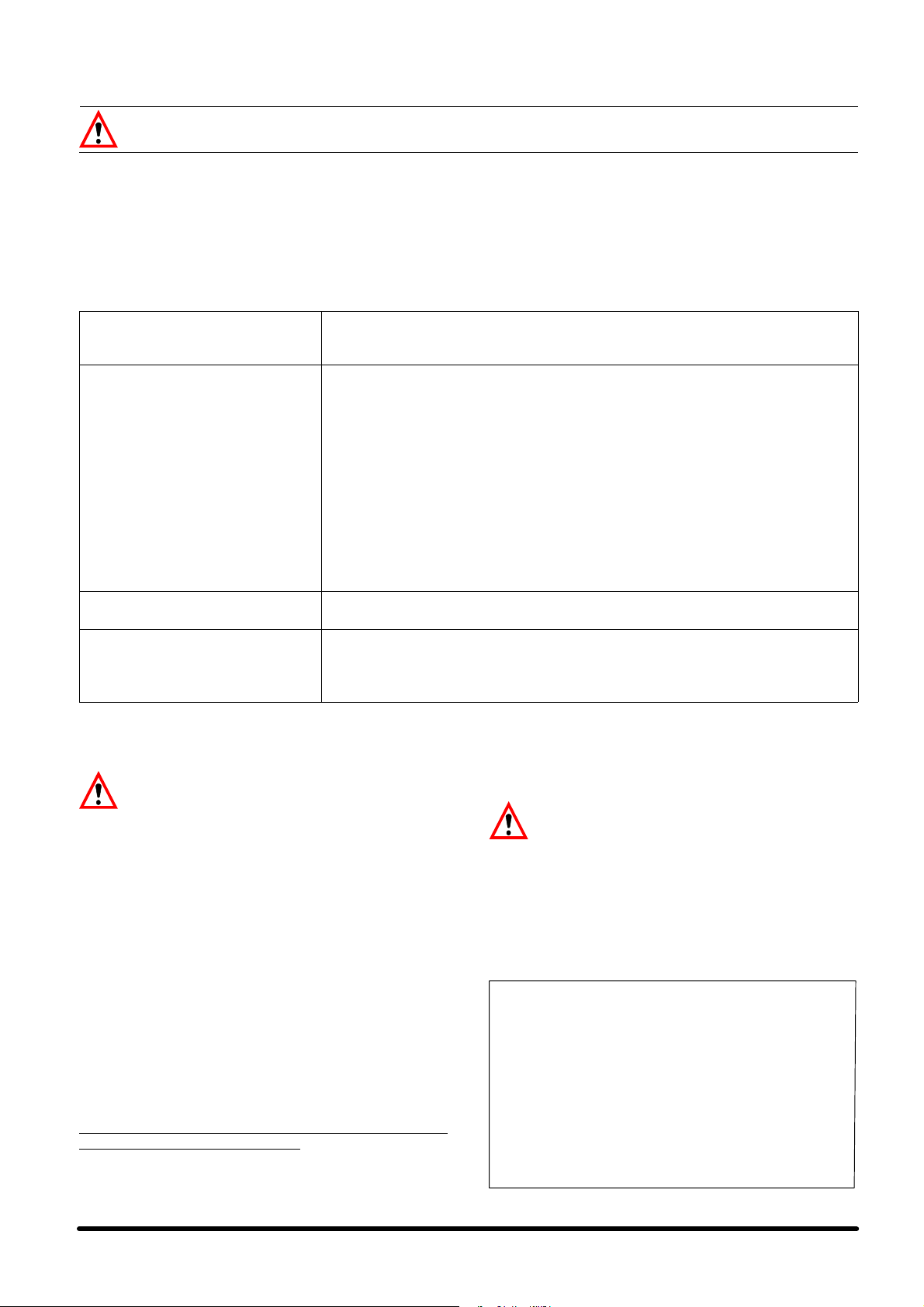

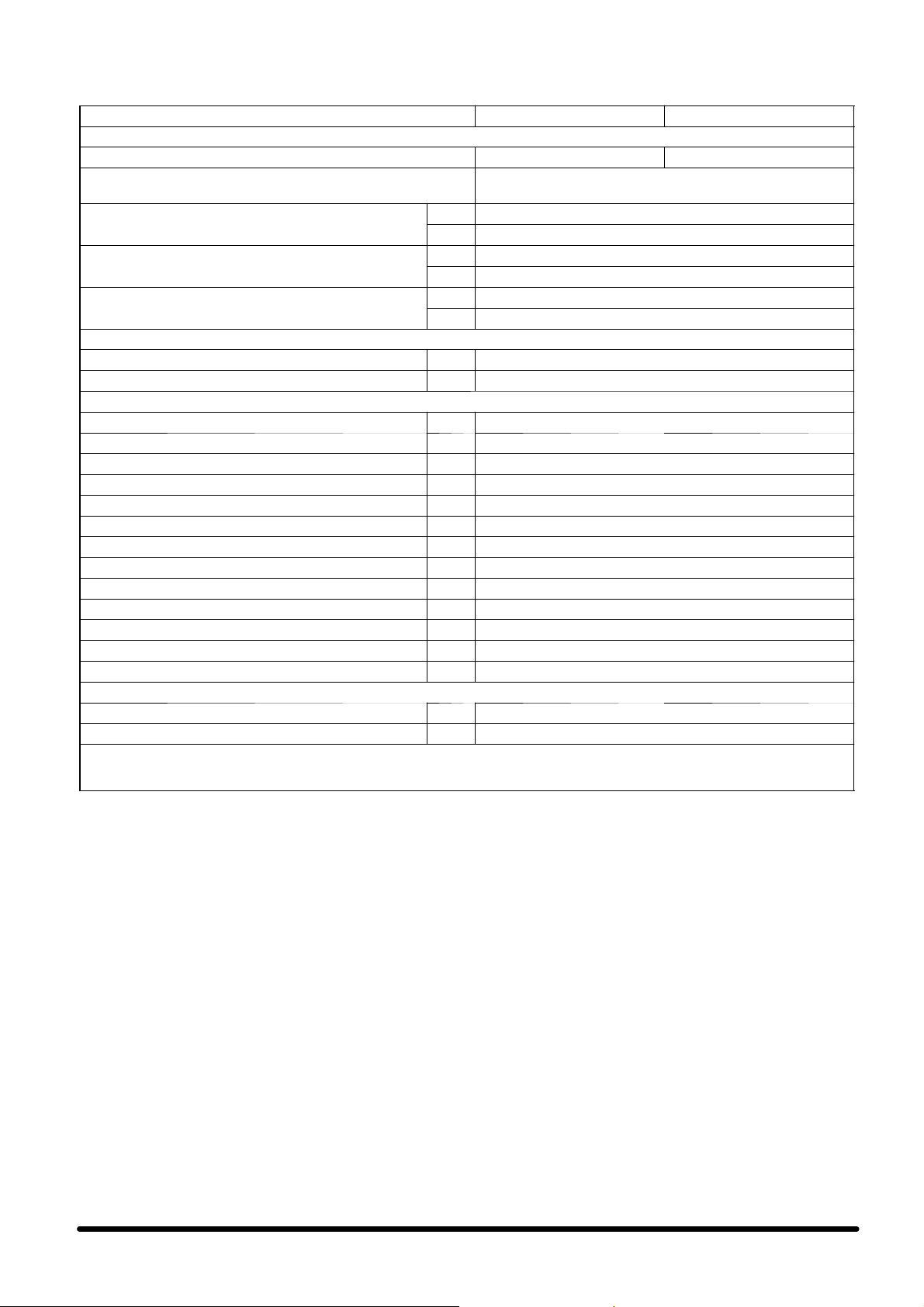

Attention: data relevant to the unit supplied

is indicated on the inboard label (see the blank facsimile below).

Data in the manual is referred to standard conditions

and can be modified without any advance notice.

POS. DESCRIPTION

1 Compressor Full Load Ampere [A]

2 Compressor Locked Rotor Ampere [A]

3 Compressor quantity

4 Evaporator fan Full Load Ampere [A]

5 Evaporator fan Locked Rotor Ampere [A]

6 Evaporator fan quantity

7 Condenser fan Full Load Ampere [A]

8 Condenser fan Locked Rotor Ampere [A]

9 Condenser fan quantity

10 Electrical heating Ampere

11 Electrical heating steps

12 Humidifier Ampere

13 Steam production capacity

14 Max. unit AC Ampere

15 Max. unit DC Ampere

16 Rated peak withstand current

17 Rated short --- time current

18 Refrigerant type

19 High pressure switch Stop

20 High pressure switch Restart

21 Low pressure switch Stop

22 Low pressure switch Restart

23 Min. room operation temperature

24 Max. room operation temperature

25 Min. room operation humidity

26 Max. room operation humidity

27 Max. refrigeration circuit pressure

15

11

2

5

8

3

6

9

13

16

17

20

22

24

26

27

Page 4

Index

1 -- Preliminary operations pag. 1...............................................................

1.1 --- Foreword pag. 1.......................................................................................

1.2 --- Check operating limits pag. 1............................................................................

1.3 -- - Check sound pressure levels pag. 1.......................................................................

1.4 --- Conditioner inspection pag. 1............................................................................

1 . 5 --- Tr a n s p o r t pag. 1.......................................................................................

1 . 6 --- S e a l i n g t h e r o o m pag. 1.................................................................................

1.7 --- Servicing areas pag. 1..................................................................................

2 -- Installation pag. 1..........................................................................

2.1 --- Overall dimensions pag. 1...............................................................................

2.2 - -- Positioning the HPSE indoor unit pag. 1...................................................................

2.3 --- Positioning two inner HPSE units pag. 1...................................................................

2.4 --- Freecooling duct connections (optional) pag. 1.............................................................

2.5 --- Positioning the HPSC condensing unit pag. 2...............................................................

2.6 --- Refrigeration connections pag. 2.........................................................................

2.7 --- Condensate drain connection pag. 3......................................................................

2.8 --- Electrical connections and wiring diagram (supplied with the unit) pag. 3.......................................

2.9 --- User interface pag. 3....................................................................................

2.10 --- Emergency cooling version (EFC 48 VDC / 230 VAC) pag. 3.................................................

2.11 --- Electrical protection pag. 3..............................................................................

3 -- Starting and stopping pag. 3................................................................

3 . 1 --- F i r s t s t a r t --- u p ( o r af t e r a l o n g ha l t ) pag. 3..................................................................

3 . 2 --- S t a r t --- u p wi t h lo w o u t s i d e t e m p e r a t u r e (o n l y o n “ H P S C x x A / L” m o d e l s ) p a g . 3...................................

3 . 3 --- S e l f te s t pag. 3.........................................................................................

3.4 --- Starting and stopping pag. 4.............................................................................

4-- Operation pag. 4............................................................................

4.1 --- Control of the condenser fan speed (“HPSCxxA/L” models only) pag. 4.........................................

4.2 --- Emergency cooling (optional) pag. 4......................................................................

5-- Operatinglogic pag. 4......................................................................

5.1 --- Cooling only unit pag. 4.................................................................................

5.2 --- Unit with electric heating pag. 4..........................................................................

5.3 --- Unit with freecooling pag. 5..............................................................................

5.4 --- LAN local network management: Stand---by and Cascade modes pag. 5.......................................

5.5 --- Alarm control pag. 5....................................................................................

6 -- Settings pag. 5.............................................................................

7 -- Maintenance / Spare parts pag. 6............................................................

7.1 --- Routine maintenance pag. 6.............................................................................

7.2 --- Extraordinary maintenance pag. 6........................................................................

7.3 --- Dismantling the unit pag. 7..............................................................................

7.4 --- Spare parts pag. 7.....................................................................................

8 -- Appendix pag. 8............................................................................

8.1 --- Check the unit after the installation pag. 8..................................................................

Ta b l e s pag. 9....................................................................................

Drawings / Circuits pag. 17.......................................................................

Page 5

1 --- Preliminary operations

1.1 --- Foreword

This manual covers the installation, operation and maintenance of HPS air conditioners, which are composed of an

evaporating unit (HPSE), positioned in the room, and a condensing unit (HPSC), positioned outside.

IMPORTANT:

Also consult the manual for the microprocessor control.

1.2 --- Check operating limits

The units are designed to operate within specific working

ranges (see Tab. 1, Tab. 2, Tab. 3, Tab. 4, Tab. 5 and Tab. 6).

These limits are referred to new machines or for those that

have been correctly installed and serviced. The warranty

clauses are no longer valid for any damage or malfunction

that may occur during or due to operation outside the application range.

1.3 --- Check sound pressure levels

Tab. 1, Tab. 2, Tab. 3, Tab. 4, Tab. 5 and Tab. 6 show the internal (HPSE) and external (HPSC) sound pressure levels for

units in standard configuration, in continuous operation, at

2m from the front surface of the machine, 1m above base

level, and referred to free field conditions.

1.4 --- Conditioner inspection

On receiving the equipment immediately inspect its condition; report any damage to the transport company at once.

(e.g. acid vapours).

S Position the internal evaporating unit (HPSE) so as to op-

timise the indoor air distribution and avoid hot spots.

S Position the indoor unit preferably in the centre of the

room ceiling.

S Fix the unit to the ceiling by inserting expansion or

through clamps (in this case ensure the clamp is sealed)

using the slots on the two side brackets (see Fig. 2a,

Fig. 2b and Fig. 2c).

S Make sure the airflow circulates freely.

S To allow the servicing of the unit, the Service Area shown

in Fig. 2a and Fig. 2b, has to be left unobstructed (in

Fig. 2a the 300 mm minimum clearance from the back of

the evaporating unit is compulsory).

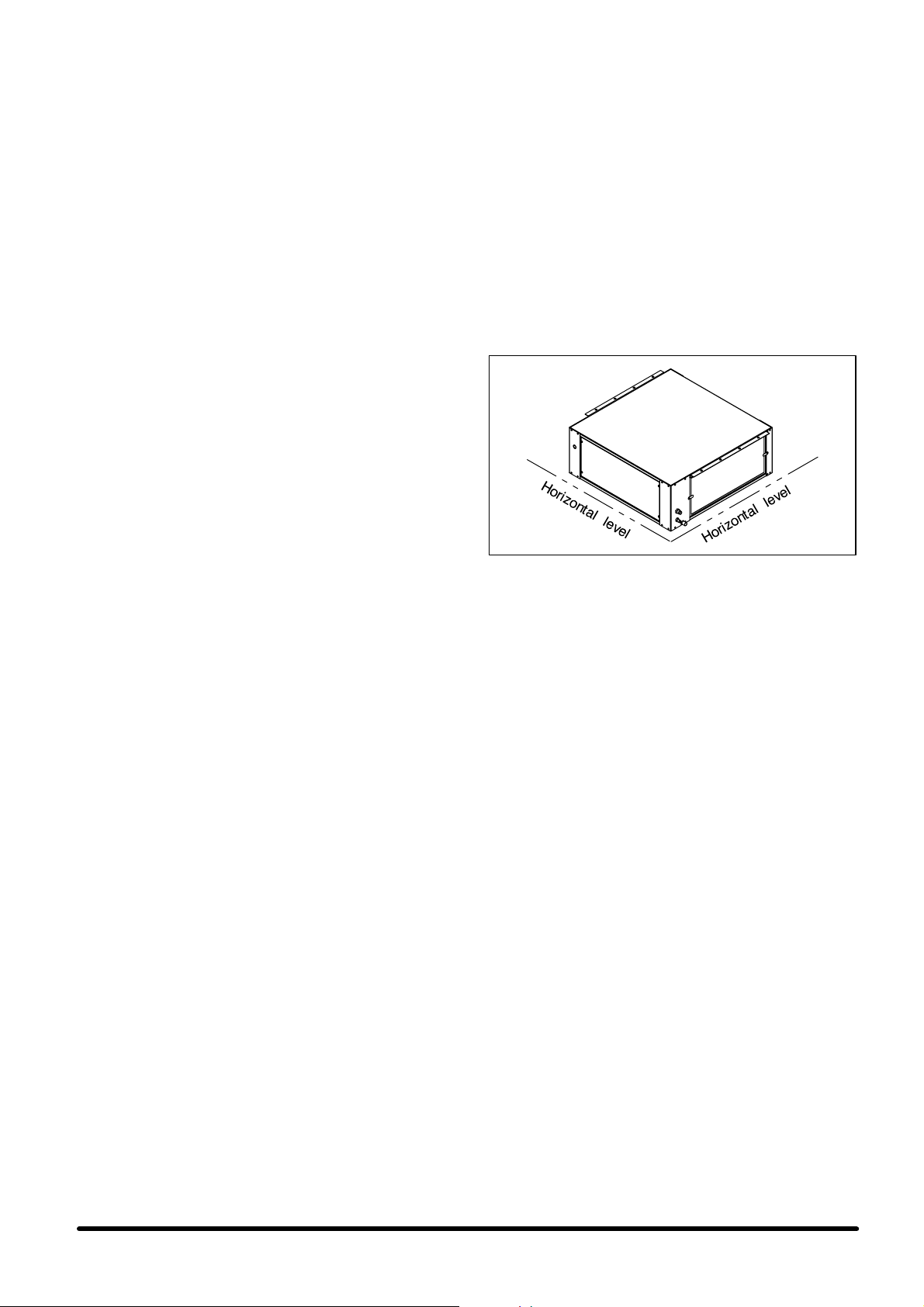

S Check if the unit is horizontal on both sides ”A” and

”B” (see. Fig. a).

Fig. a) Horizontal level control

“A” “B ”

1 . 5 --- Tr a n s p o r t

S Always keep the unit vertically upright and do not leave

it in the open.

S While carrying the unit, avoid exerting any pressure on

the upper corners of the package.

S Unpack the unit as close as possible to its installation

position. Once unpacked, avoid any impact to its internal

components.

1.6 --- Sealing the room

To create stable thermohygrometric conditions within the

room, proceed as follows:

S vapour seal the walls, floor and ceiling using an imperme-

able material;

S make sure that the room is airtight by sealing all gaps,

cable entries, etc.

1.7 --- Servicing areas

The unit must be provided with a suitable service area (see

Fig. 4).

All maintenance of the evaporating unit can be carried out as

shown in Fig. 2a and Fig. 2b.

Access to the condensing unit is provided by removable panels with screw fixings.

2 --- I n s t a l l a t i o n

CAUTION:

The evaporating unit (HPSE) must never be installed outdoors.

2.1 --- Overall dimensions

See Fig. 1a, Fig. 1b, Fig. 1c, Fig. 1d, Fig. 1e and Fig. 1f for

the overall dimensions of the evaporating unit (HPSE) and

external condensing unit (HPSC).

2.2 --- Positioning the HPSE indoor unit

S Unpack the unit as close as possible to the place where

it has to be installed. Once unpacked, avoid stress and

any impact to its internal components.

S The indoor unit can be installed in any indoor location

provided it is not exposed to an aggressive environment

2.3 --- Positioning two inner HPSE units

The ceiling installation of two units operating in the same

room must be carefully evaluated, considering the following

factors:

1) each intake side of the machine must be able to intake as

much as the other two;

2) possible ”Freecooling” function;

3) the thermal loads to be dissipated can be true hot air

flows hitting the intake sides of the machines: in this case,

the two intake sides of the two machines can be arranged

even at a short distance (up to 300 mm) to intake the thermal load where it is highest.

2.4 --- Freecooling duct connections

(optional)

The air conditioner may be supplied with an integrated Freecooling device (optional), which uses fresh air from outside to

cool the room without starting up the compressor. The device

provides the correct cooling capacity required, using a

motorised, modulating damper. In this case, the rear of the

unit is equipped with connections which draw in the outside

air, as follows:

S double circular holes, for 202 mm (HPSE 06) or 252 mm

( H P S E 0 8 --- 1 0 --- 1 2 --- 1 4 ) d i a m e t e r f l e x i b l e d u c t s t o b e

fixed with metal clamps;

S single rectangular hole with flange for 560x190 mm

(HPSE 06) or 600x250 mm (HPSE 08 --- 10 --- 12 --- 14) duct

(not supplied by Liebert --- HIROSS).

Inbothcases,theholesinthewallhavetobeprotectedby

rainproof grilles with a prefilter, to avoid water or foreign

bodies getting into the conditioner.

Outside air, taken into the room by the fan, is exhausted

through an overpressure damper, which is installed on the

wall of the room and protected by an external rainproof grille .

2.4.1 --- External air temperature probe installation

Install the external air temperature probe at the end of the

freecooling duct.

pag. 1

Page 6

IMPORTANT:

The bulb must be positioned as much outside as possible but

must not be exposed to direct sunlight or weather agents

such as rain or snow.The unit operation could be jeopardized

if these precautions are not applied.

2.5 --- Positioning the HPSC condensing

unit

Available condensing unit versions:

HPSC “0”: base version

HPSC “A”: advanced version

HPSC “L”: long piping version (see Fig. 12)

S The condensing unit must be positioned outside to en-

able its cooling (see Fig. 3).

S It is connected to the air conditioner through the re-

frigerant pipelines. Keep the refrigerant lines as short

as possible and anyway follow the indications in

Tab. a, Tab. b, Fig. 11 and Fig. 12, considering that in stallations with equivalent length of the refrigerant

pipelines over 10 m are possible only for HPSCxxL

units.

S Install the condensing unit in a level position, able to bear

its weight and vibrations and away from contaminating

agents (e.g. dust, leaves) to ensure the best efficiency

over time. Avoid any place containing flammable gases.

S If different locations are available, preferably install the

condensing unit in places sheltered from rain, with suitable air circulation and not subject to strong sun exposure; the latter precaution enables performance optimisation and compliance with the operating limits. For installationsinplaceswithwindspeedsover5m/s(e.g.

building tops) consider that such conditions can offer resistance to the air outlet from the condensing unit, reducing the air delivery and thus the heat exchange capacity,

or they can make the fan run too fast jeopardizing its operation, as well as increasing the hazard of the machine tilting if it is not properly fixed. To lessen the problem of

strong gusts of wind, position the condensing unit close

to a wind barrier (e.g. building or enclosing wall) and in

a direction perpendicular to the flow of the discharge air.

To prevent tilting ensure that the unit is securely fixed, if

necessary through additional supports or tie---rods, thus

ensuring stability even in case of earthquakes. Position

the unit so that the ejected hot air and the sound

emissions do not disturb people. In case of snow, make

sure that the unit is not completely covered and that the

inlet sections are always clear. To enable sufficient air delivery through the unit/s and to have sufficient space for

maintenance, it is necessary not to obstruct the air inlet

and discharge sections of the condensing unit, positioning it, or several machines, to maintain the minimum service areas and distances indicated in Fig. 4, for some

possible installation configurations.

S Fig. 3 shows some examples of how to install the con-

densing unit. For wall --- mounted installation the condensing unit can be supplied with an optional mounting

kit, comprising a pair of galvanised steel angle brackets,

painted with RAL9002 polyester powder with a smooth

finish; suitable elastomer anti---vibration mounts and

stainless steels fixings, including anchor screws for wall

fastening (see Fig. 2d).

NOTE: The anchor screws included in the kit are to be

used only when fastening the brackets to a concrete or

brick wall (including hollow bricks). Do not use them on

sandwich walls (e.g. a container) or walls of unknown

composition. In these cases the most suitable fastening

system for the special material must be used. If the above

mentioned optional kit is not used, suitable anti --- vibration mounts must always be fitted between the condensing unit and the mounting brackets, to avoid the transmission of vibrations. Also make sure that the brackets

used are suitable for supporting the condensing unit in all

conditions (e.g. in case of temporary abnormal loads on

the unit).

2.6 --- Refrigeration connections

THIS OPERATION MUST BE CARRIED OUT BY AN EXPERT TECHNICIAN.

The condensing and evaporating units are pre---charged

with Nitrogen and have to be charged with refrigerant (see

Chap. 7.2.2 – Refrigerant charging).

a) Pipeline positioning

Connect the air conditioner to the condensing unit using re-

frigerant lines in hard or soft copper.

S Limit the number of pre --- shaped bends. If this is not

possible, every bend must have a radius of at least 100

mm.

S The gas line must be insulated.

S The liquid line must be kept away from heat sources. If

this is not possible it has to be insulated.

S If the condensing unit is located above the evaporating

unit, the last segment of the suction line (insulated pipework) must be inclined towards the condensing unit.

If, on the other hand, the condensing unit is located below the

air conditioner it is advisable to create a trap on the suction

line.

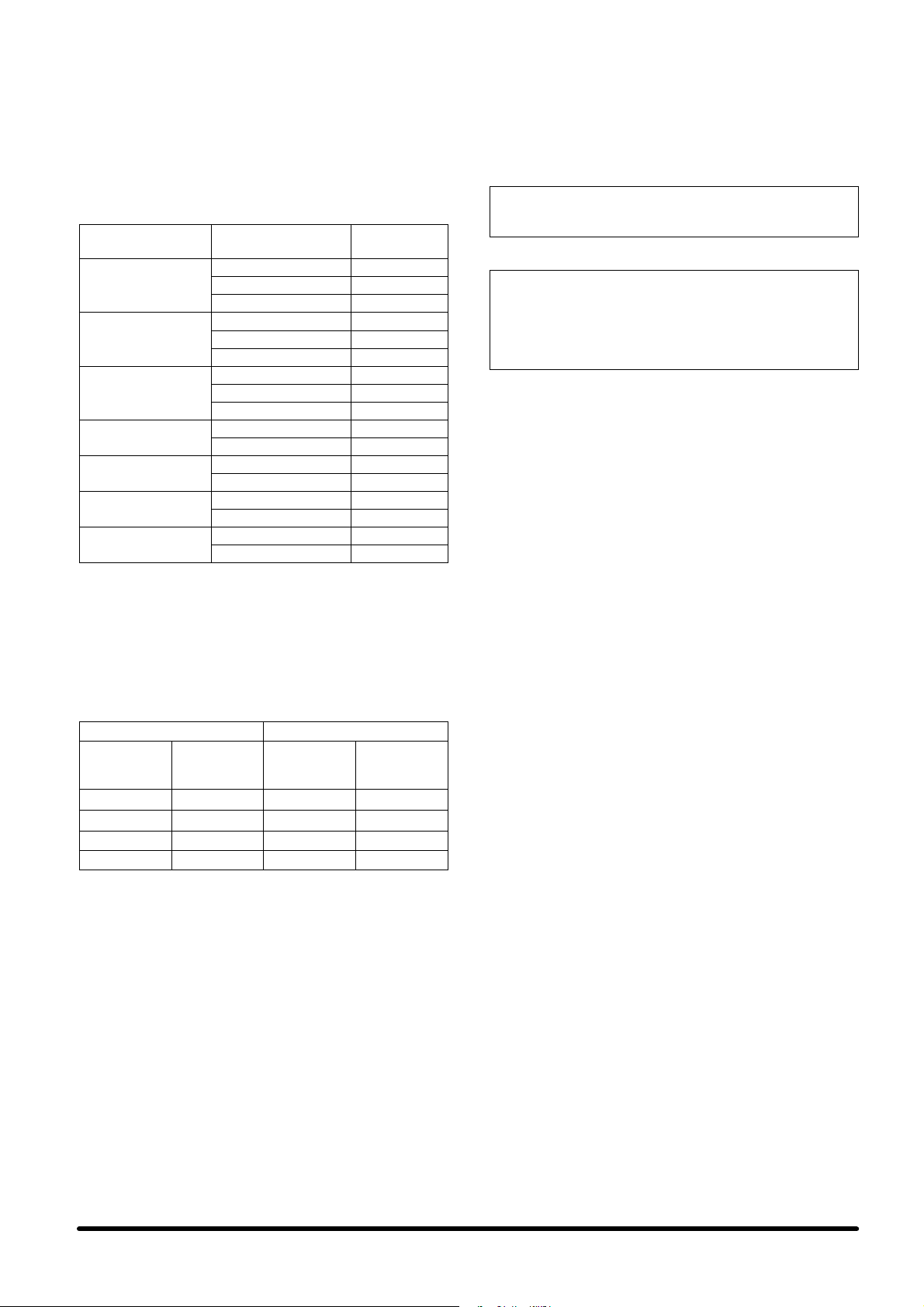

Tab. a --- HPSCxx0/A: external standard

Model

HPS060/A 2m<L≤10m φ 16 x 1 φ 12 x 1 1% with 10 m

HPS080/A 2m<L≤10m φ 16 x 1 φ 12 x 1 3% with 10 m

HPS100/A 2m<L≤10m φ 18 x 1 φ 12 x 1 2% with 10 m

HPS120/A 2m<L≤10m φ 18 x 1 φ 12 x 1 4% with 10 m

HPS140/A 2m<L≤10m φ18x1 φ 12 x 1 5% with 10 m

Tab. b --- HPSCxxL: external standard diameters

Model

HPS06L

HPS08L

HPS10L

HPS12L

HPS14L

diameters for external refrigerant

pipelines --- R407C

Equivalent

length

“L”

Gas

line

Liquid

line

Cooling capacity

drop vs. the std.

installation (2m)

for external refrigerant pipelines--- R407C

Equivalent

length

“L”

2m<L≤10m

10m<L≤20m

20m<L≤30m

30m<L≤40m

40m<L≤50m

2m<L≤10m

10m<L≤20m

20m<L≤30m

30m<L≤40m

40m<L≤50m

2m<L≤10m

10m<L≤20m

20m<L≤30m

30m<L≤40m

40m<L≤50m

2m<L≤10m

10m<L≤20m

20m<L≤30m

30m<L≤40m

40m<L≤50m

2m<L≤10m

10m<L≤20m

20m<L≤30m

30m<L≤40m

40m<L≤50m

Gas

line

φ 16 x 1

φ 16 x 1

φ 18 x 1

φ 18 x 1

φ 18 x 1

φ 16 x 1

φ 18 x 1

φ 18 x 1

φ 18 x 1

φ22 x1

φ 18 x 1

φ 22 x 1

φ22 x1

φ22 x1

φ22 x1

φ 18 x 1

φ22 x1

φ22 x1

φ22 x1

φ28 x1

φ18 x1

φ22 x1

φ22 x1

φ28 x1

φ28 x1

Liquid

φ 12 x 1

φ 12 x 1

φ 12 x 1

φ 12 x 1

φ 12 x 1

φ 12 x 1

φ 12 x 1

φ 12 x 1

φ 12 x 1

φ 16 x 1

φ 12 x 1

φ 12 x 1

φ 16 x 1

φ 16 x 1

φ 16 x 1

φ 12 x 1

φ 16 x 1

φ 16 x 1

φ 16 x 1

φ 16 x 1

φ 12 x 1

φ 16 x 1

φ 16 x 1

φ 16 x 1

φ 16 x 1

line

Cooling capacity

drop vs. the std.

installation (2m)

1% with 10 m

4% with 20 m

3% with 30 m

5% with 40 m

6% with 50 m

3% with 10 m

3% with 20 m

5% with 30 m

6% with 40 m

3% with 50 m

2% with 10 m

3% with 20 m

5% with 30 m

6% with 40 m

7% with 50 m

4% with 10 m

3% with 20 m

4% with 30 m

5% with 40 m

2% with 50 m

5% with 10 m

3% with 20 m

5% with 30 m

2% with 40 m

3% with 50 m

pag. 2

Page 7

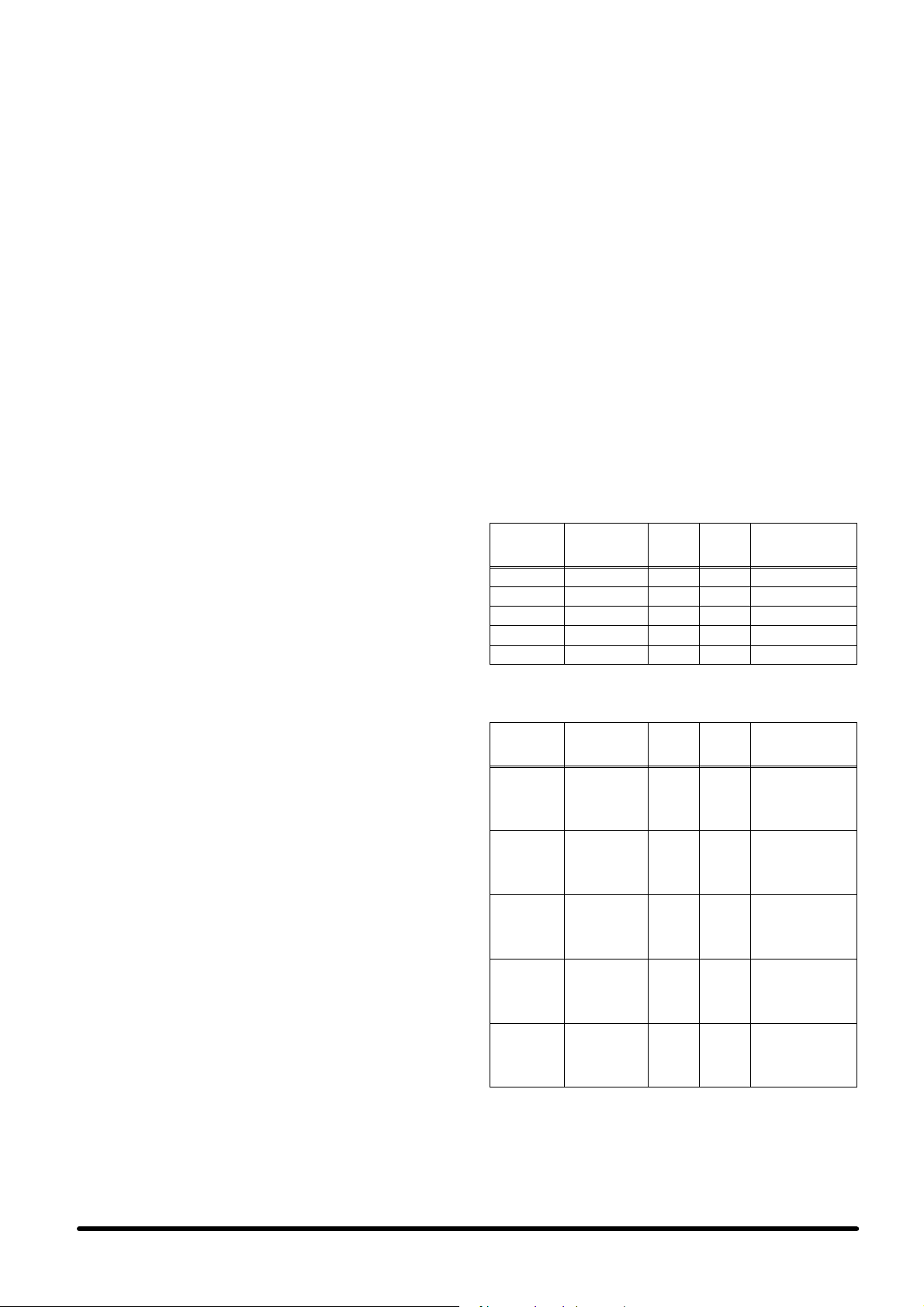

Tab. c --- Equivalent lengths (m) of: curves,

(mm

)

shut---off and non ---return valves

Nominal

diameter

(mm)

90° 45° 180° 90°

12 0.50 0.25 0.75 2.10 1.90

14 0.53 0.26 0.80 2.20 2.00

16 0.55 0.27 0.85 2.40 2.10

18 0.60 0.30 0.95 2.70 2.40

22 0.70 0.35 1.10 3.20 2.80

28 0.80 0.45 1.30 4.00 3.30

b) Evacuation of the refrigerant lines

The evacuation operation must be carried out with a special

(quality) vacuum pump, using the 1/4” SAE connectors, located on the unit on---off valves,

2.7 --- Condensate drain connection

During the cooling cycle part of the moisture in the air condenses on the evaporating coil. The condensate is collected

in the tank fitted under the coil and must be drained outside.

Tab. d --- Condensate drain connection

CONNECTOR DIMENSIONS

Condensate drain φ 21 mm

To drain the condensate:

S Use galvanized steel, PVC or flexible polythene pipe.

S CAUTION: DO NOT INTERCONNECT THE OUTLETS OF

DIFFERENT MACHINES.

S Make sure there is at least a 2% gradient towards the

drain outlet.

S There must beadraintrapplacedatleast30mmbelow

the drain tank.

S Fill the drain trap with water by pouring it into the conden-

sate tank.

2.8 --- Electrical connections and wiring

diagram (supplied with the unit)

For the electric connections of the indoor units HPSE and

outdoor units HPSC, refer to Fig. 5, Fig. 6 and Fig. 7.

Before connecting or disconnecting the fast couplers between the indoor unit and outdoor unit, make sure that the

main switch is in the “OFF” position and that:

S all electrical components are not damaged;

S allterminalscrewsaretight;

S thesupplyvoltageandfrequencyareasindicatedonthe

unit;

S there are no live components.

IMPORTANT:

The 48 Vdc supply (in the version ”Emergency Free Cooling”) must be delivered through a shielded cable, with the

connection of the shielding braid on the evaporating side.

The signal connection cable between the evaporating unit

and the condensing unit must be shielded, with the connection of the shielding braid on the evaporating side.

2.9 --- User interface

The standard control system on HPS is based on a microprocessor board mounted inside the electrical panel, which can

be connected to a user interface (remote display) that can be

positioned inside the room as required. The user interface

(remote display), when installed, is mounted in a painted

metal box and connected to the air conditioner using a

multi---pole screened cable (optional accessory).

2.10 --- Emergency cooling version

(EFC 48 VDC / 230 VAC)

When this option is used install the supply cable as described

in the electrical diagram.

In the 48VDC units respect the polarity “+” and “ --- ”.

2.11 --- Electrical protection

CAUTION: For the electrical protection of the conditioner an

adequate switch with current protection must be installed in

the power supply line. For the selection of the disconnect

switch please refer to Tab. 7.

3 --- Starting and stopping

3 . 1 --- F i r s t s t a r t --- u p

(or after a long halt)

Before starting the air conditioner check if the power supply

voltage and frequency comply with those on the identification plate of the unit. After this, it is possible to power the unit

by operating the main switch. For units equipped with PowerFace microprocessor control, it is possible to start and stop

the unit by following the instructions given below.

For units equipped with POWERFACE interface only:

S The unit is started by pressing the main switch ON.

S The unit is stopped by pressing the main switch OFF.

For units equipped with a local or remote display interface:

S The unit is started by pressing the switch with LED.

S The unit is stopped by pressing the switch with LED.

For units supplied with a HIROMATIC interface:

S Start by pressing the ON --- OFF push button on the Hiro-

matic (confirmed by SYS.ON on the display).

S Stop by pressing the ON --- OFF push button on the Hiro-

matic (confirmed by SYS.OFF. on the display).

IMPORTANT:

In both cases it is extremely important to consider the status

of the digital input to the PowerFace microprocessor control

managing the unit ON ---OFF (see relevant handbook and wiring diagram). Indeed, for the unit to start (operating on the

unit main switch, or on the ON --- OFF button of the HIROMATIC interface), the digital input must be bridged (see wiring

diagram). Check that there are no active alarms; wait until the

system reaches the standard operation and then make the

following checks:

S Check that the fans are working correctly.

S Make sure that the temperature is controlled and the

compressor and the heaters (optional) work when required.

S Make sure that the condensing unit fan speed controller

regulates the fan operation (only on “HPSCxxA/L” models).

3 . 2 --- S t a r t --- u p w i t h l o w o u t s i d e t e m p e r a -

ture (only on “HPSCxxA/L” models)

In case of low outside temperature (<0_C), the unit start---up

is helped by the delay time of the low pressure alarm, within

which the pressures in the refrigerating circuit reach the standard operation values.

3 . 3 --- S e l f t e s t

The self---test function is possible only when a unit has the remote or local display installed. The self --- test function, performs a sequential, automatic check of components such as

the compressor, fan, heaters, Freecooling damper, alarm

relay and warning relay. This eliminates the need for manual

control and leads to a remarkable decrease in the time

needed for starting the unit, with the ability to carry out a quick

check of the main components for the correct conditioner

operation.

pag. 3

Page 8

3.4 --- Starting and stopping

For the units provided with the POWERFACE control, you

can switch on/off using the main switch.

For the units provided with HIROMATIC interface:

S Start up the unit by pressing the Hiromatic ON --- OFF

push button (confirmed by SYS.ON on the display).

S Stop the unit by pressing the Hiromatic ON --- OFF push

button (confirmed by SYS.OFF on the display).

4 --- O p e r a t i o n

The unit operation is completely automatic. The sequence

below explains (with the assistance of Fig. 8 ---Operation

diagram) how the unit operates (see also Fig. 9 and Fig. 10

--- Refrigerating circuit):

1) The temperature sensor, positioned inside the HPSE

evaporating unit, informs the control about the condition

of the return air.

2) The control compares the information received with the

programmed Set Point value (= minimum indoor temperature) and Proportional Band (and Differential in the

versions with optional Freecooling), activating the conditioner’s air treatment modes as follows:

Cooling (Fig. 8a)

After switching the unit on, the evaporator fan starts immediately whereas the compressor is started only when the temperature of the room to be conditioned exceeds the set value.

In the HPSCxxA/L unit versions, the condensing unit fan

starts automatically if the condensing pressure increases

(control through Variex), while in the other versions the fan/s

is/are controlled by a pressure switch ensuring a limit lower

than the condensing pressure. The air taken in by the evaporator fan enters the unit through the side intakes, passing

through the filters, and then reaches the evaporator. The cold

refrigerant flows inside the evaporator pipes, thus cooling the

air passing through it. The treated air is conveyed into the

conditioned room through the supply outlet. The heat taken

from the room and that generated by the conditioner motor

operation is rejected through condensing coil located in the

external condensing unit and cooled with outside air by the

condenser fan. For the operation logic of the controls see

chapter 5.

Heating (optional)

Heating of the air is achieved by means of electric heaters,

located in the air flow and activated according to the logic set

on the controls (see chapter 5).

Freecooling (optional)

When the temperature of the outside air is sufficiently below

that of the inside air it is possible to use this difference to provide cooling inside the room by direct intake of the outside air,

i.e. without using the compressor. In this way it is possible to

achieve considerable energy savings. When the required

conditions occur, the servo --- motor, managed by the PowerFace control, opens the modulating damper which separates

the flow of the inside air and outside air. Outside air, drawn

into the room by the fan, is exhausted through an overpressure damper* which is installed on an outside wall of the

room and is protected by an external rainproof grille*. The

degree of opening of the damper is determined as a function

of the temperature set point and the return air temperature.

4.1 --- Control of the condenser fan speed

(“HPSCxxA/L” models only)

A sensor is positioned so as to detect the condensing pressure of the refrigeration gas. On the basis of this information,

an electronic device (Variex) modulates the fan speed in

order to keep the condensing pressure within the permitted

range. In this way, besides optimizing the compressor operation, you can have a reduction of the sound pressure level

(mainly during the night), easier start --- up of the compressor

at low temperatures and some energy saving.

For the calibration of the speed controller refer to chap. 6.

4 . 2 --- E m e r g e n c y c o o l i n g (optional)

4.2.1 --- Emergency cooling 48VDC

With the 48VDC emergency cooling option, the evaporator

fan, freecooling damper actuator and controls are always

supplied at 48VDC, while the compressor, the condenser fan

and the heaters are connected to the AC mains. If the AC

mains supply fails, the conditioner does not stop but continues to circulate the air, activating the Freecooling as soon

as the relevant conditions are reached, automatically optimized in the event of mains failure.

IMPORTANT:

For proper operation, the unit must always be fed by 48VDC.

4.2.2 --- Emergency cooling 230VAC --- 50Hz

In case of AC mains failure, the evaporator fan, freecooling

damper actuator and controls are supplied by a second

230V/1Ph/50Hz supply, arranged by the user (UPS/generator), ensuring operation in the same way as the 48VDC version.

CAUTION:

For safety reasons open the main switch.

5 --- Operating logic

The different unit versions feature different automatic operating logic, as described below.

5.1 --- Cooling only unit

5.1.1 --- Control logic

The control algorithm is based on single --- step regulation for

the mechanical cooling, i.e. compressor start/stop. The control manages all the activation delays, ensuring correct operation and extending the operating life as much as possible.

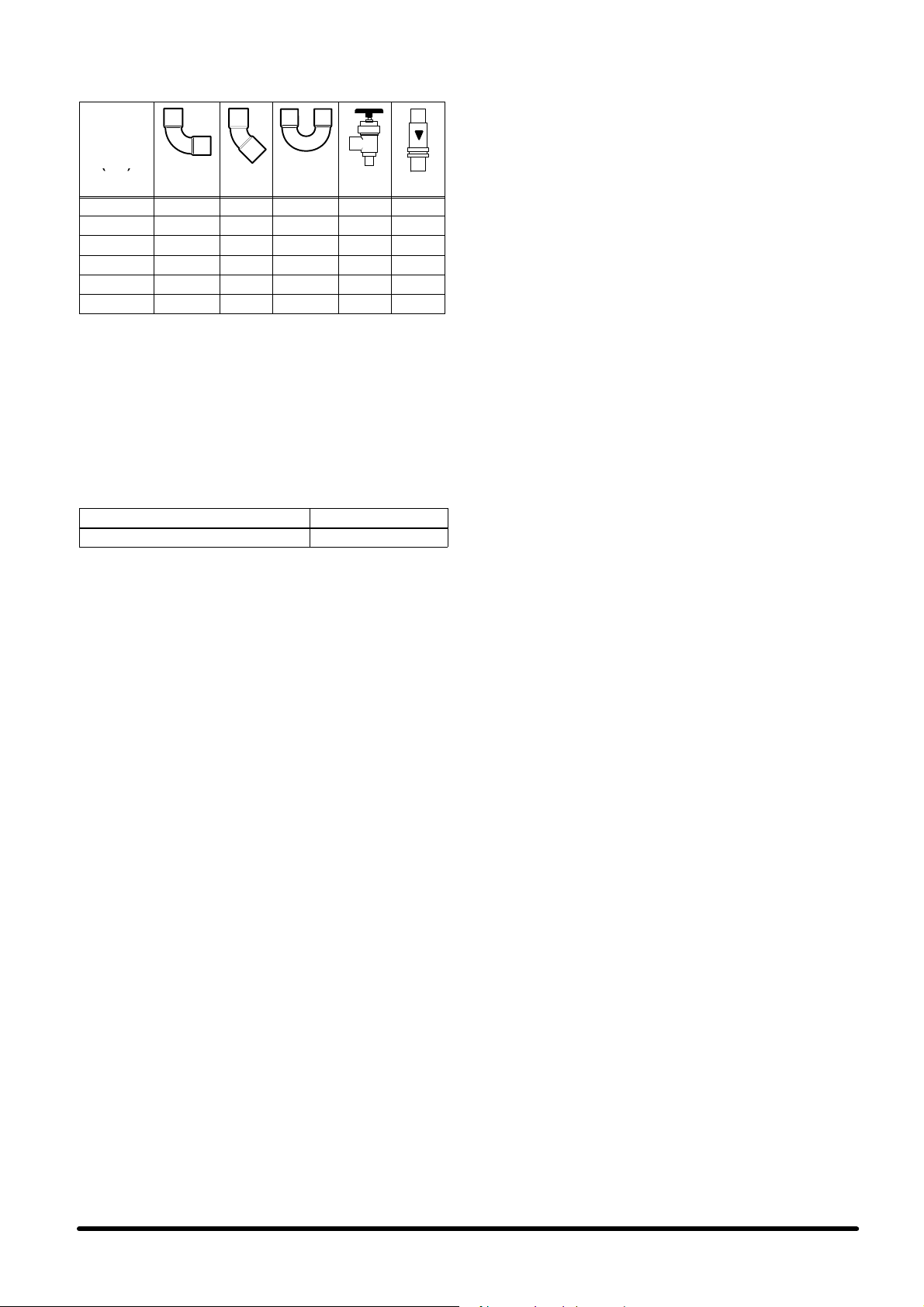

Fig. a) Operation of the cooling only unit

PBand

Cooling only

unit

Set Cooling °C

5.2 --- Unit with electric heating

5.2.1 --- Control logic

For the heating and cooling version the control algorithm is

based on single---step regulation for the electric heating and

single step regulation for the compressor (mechanical cooling). The control manages all of the compressor activation

delays as previously described, ensuring its correct operation and maximising run times.

5.2.2 --- Dead band

In this version the “Dead band” parameter, in the “optional

devices” menu of the PowerFace microprocessor control is

very important, enabling the heating semi--- band to be

shirted by inserting a non --- sensitive area (ventilation only)

between the set point temperature and the start of the heating semi --- band (see Fig. b). In this way, without having to

alter the proportional band, the electric heating can be activated at lower temperatures (according to the value set for

the dead band) compared to the standard setting, consequently reducing the energy consumption of the heaters and

optimizing their operation according to the site requirements.

pag. 4

Page 9

Fig. b) Unit operation with electrical heating

1

/2Band

1

/2Band

Dead Band

Set point CoolingHeating

PBand

Set point

1

/2Band

CoolingHeating °C

1

/2Band

Cooling and

heating unit

Cooling and

heating unit

with Dead band

°C

5.3 --- Unit with freecooling

5.3.1 --- Control logic

The control algorithm is based on single--- stage regulation

for the heating and mechanical cooling (compressor), with

modulating proportional --- integral control for the Freecooling

(see Fig. c). The control manages all of the compressor activation delays, as we have seen in the 2 previous cases, in

order to guarantee the proper operation and to extend its life.

The activation of the Freecooling mode occurs as a function

of the difference (that can be set) between the inside temperature and the outside temperature. This means that if the

difference between the two temperatures increases beyond

the set value, the unit automatically initiates the Freecooling

function; the compressor is deactivated and an analogue

output controls the 3 --- point servomotor of the damper. The

damper opening is determined as a function of the difference

between the outdoor and indoor temperatures and as a function of the intake air temperature, which cannot be lower than

a preset safety value. If the indoor temperature exceeds the

proportional band by more than 20% for over 10 minutes, the

unit reverts to compressor --- aided cooling and the Freecooling mode remains de --- activated for

1

/2hour. If the inside

temperature exceeds the proportional band by more than

50% for over 2 minutes, the Freecooling mode is de --- activated for 1 hour, and the unit reverts to cooling by means of

the refrigeration circuit.

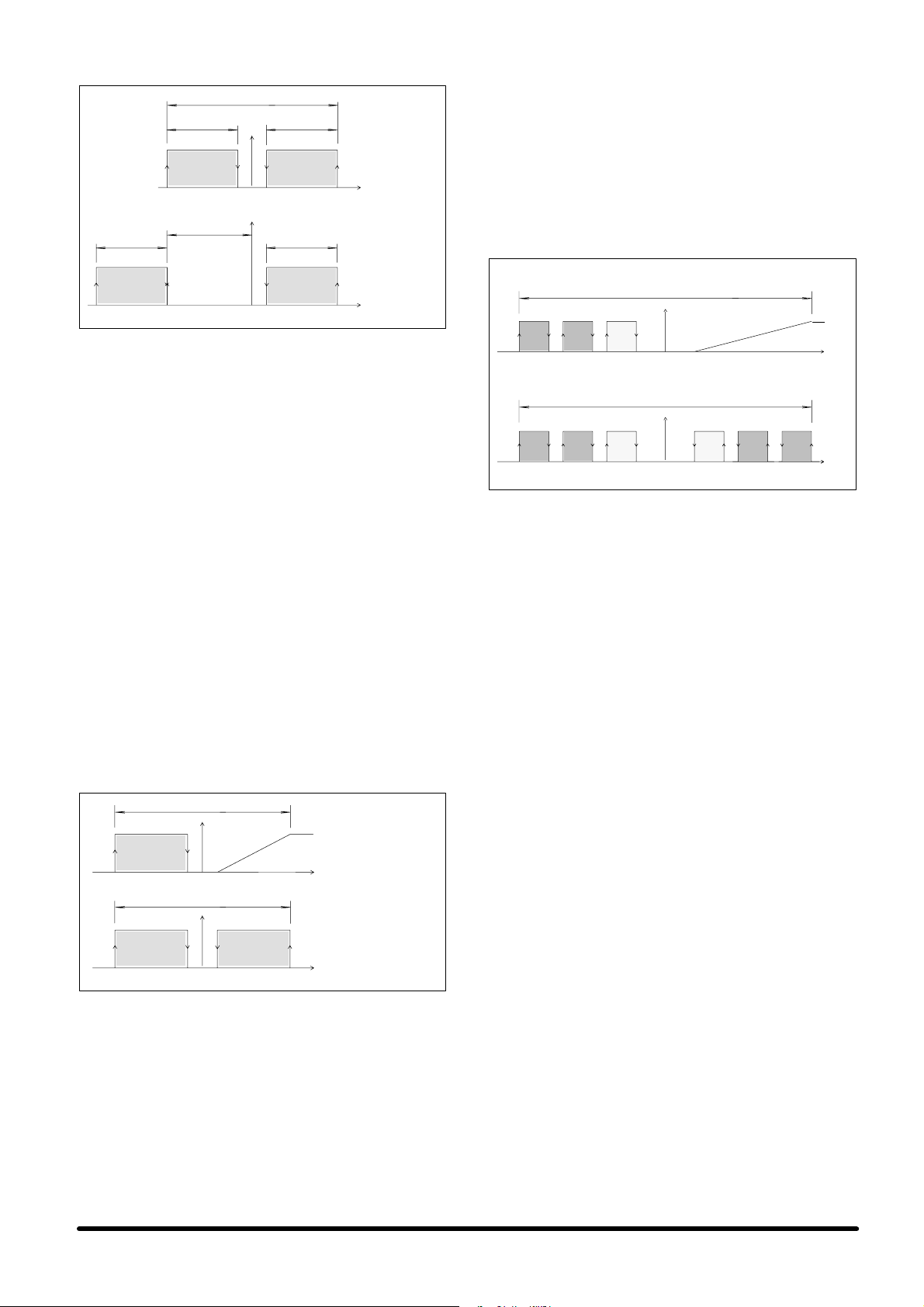

Fig. c) Compressor, heater and damper opening

operation

PBand

Set CoolingHeating

PBand

Set CoolingHeating

Freecooling

mode

_C

Compressor

cooling mode

_C

5.4 --- LAN local network management:

Stand---by and Cascade modes

The control of the units in stand ---by can be completely automatic, thanks to the possibility of connection with the PowerFace control. A unit in stand --- by is automatically activated in

case of an alarm causing the main unit to lock --- out. This also

occurs if the main unit is switched off or disappears from the

system due to a failure on the control connecting network

(bus). Rotation of the stand--- by units can be set to occur

automatically every 24 hours, so as to enable an even wear of

the system components. If the system is connected to a Hiromatic interface, it is possible to set timed daily or weekly rotation functions. When the Cascade function is activated, if sev-

eral units are simultaneously on, with the same Set Point, the

temperature used for the control is the average of those detected. In mechanical cooling mode, the proportional semi--band is divided by the number of units in the system, in order

to share the total available cooling capacity. The activation of

the Freecooling mode (if installed) is sequential on the different units forming the system, and precedes the possible activation of compressor for mechanical cooling.

Fig. d) shows an example, illustrating the operation of a system formed by three units.

Fig. d) System with 3 units in cascade ---

PowerFace control

Freecooling mode

PBand

3

3

1

2

Set _CCoolingHeating

Compressor cooling mode

PBand

11

223

Set _CCoolingHeating

5.5 --- Alarm control

Two sets of alarm contacts (each n.c. or n.o.) are available on

the terminal board of the electrical panel board for:

1) General Alarm (highest priority), including:

S Compressor alarm (high and low pressure).

S Sensor fault.

S Memory fault.

S Evaporator fan fault.

2) General Warning (lowest priority), including:

S High temperature.

S Low temperature.

A further General Warning is available in the unit equipped

with heating, signalling the following abnormal condition:

S Electrical heater fault.

NOTE:

S An alarm causes the unit to stop and the unit in stand --- by

(if available) to intervene.

S A warning does not stop the unit.

S Both the alarm and the warning activate visual and aud-

ible indication (on unit with Hiromatic).

S Both the alarm and the warning must be reset manually

on the PowerFace (or Hiromatic if installed).

Should the thermofuse intervene, the electrical heaters must

be replaced.

6 --- S e t t i n g s

S The air conditioner has already been factory --- tested and

set as described below (see Tab. 8).

S For the microprocessor control settings please refer to

the relevant manual (to avoid incorrect operation do not

use temperature and relative humidity set points or proportional bands which differ excessively from the standard settings).

pag. 5

Page 10

7 --- Maintenance / Spare parts

For safety reasons, always isolate the unit using the mains switch OFF, before opening the panels.

If installed:

AS THE MICROPROCESSOR CONTROL FEATURES AUTO-

MATIC RESTART (AFTER A SUPPLY INTERRUPTION), IT IS

RECOMMENDED THAT THIS FUNCTION IS DISABLED AND

THE MAINS SWITCH IS OPENED WHEN PERFORMING

ANY MAINTENANCE.

7.1 --- Routine maintenance

Maintenance program --- Monthly check

Check that the fan motor rotates freely without any abnormal noise, and ensure that the

FANS

AIR FILTERS

ELECTRICAL CIRCUIT

REFRIGERATION CIRCUIT

bearings are not running hot.

Also check the current absorption.

Check the conditions of the filters (3 for the recirculation air and 1 for the freecooling

air, if this option is included), if necessary, clean or replace them.

Toreplacethefiltersfortherecirculationair:

S Rotate the two filter ---locking fasteners securing each filter.

S Remove the filters.

S Fit the spare parts.

S Lock the filters by rotating the two fasteners in the opposite direction to secure each

filter.

To replace the filter for the freecooling air (if this option is included):

S Remove the unit lower panel.

S Remove the fastening bracket and pull the filter vertically downwards.

S Fit the spare part.

S Reposition the bracket and close the panel.

S Check the power supply on all phases.

S Ensure that all electrical connections are tight.

S Check the evaporating pressures (to be performed by a refrigeration technician).

S Check the compressor current absorption, the head pressure and the presence of

any unusual noise.

S Ensure that there is no ice formation on the evaporator.

S On a daily basis, check the control readings for tempera-

ture and, if shown, relative humidity.

S The Maintenance Programme described below should

be carried out by a skilled technician, preferably working

under a maintenance contract.

7.2 --- Extraordinary maintenance

CAUTION:

If you need to intervene immediately after the

unit stops, wait 5 minutes before accessing the

inner parts, as you could get burnt.

7.2.1 --- Check of the system vacuum and leaks

NOTE:

Before proceeding, recover all the refrigerant, according to

the local laws.

1) Switch the unit off (main switch on OFF).

2) Remove the panels necessary for inspecting the refriger-

ating circuit.

3) Connect a high efficiency vacuum pump to the needle

valves (Schräder) on the gas and liquid lines; also arrange a connection with a nitrogen bottle.

4) Load the circuit with nitrogen (7 bar/700 kPa). Find poss-

ible leaks in the circuit by soapy water or other specific

product (foaming agents), and repair as necessary.

5) Drain the circuit by a vacuum of 0.3 mbar absolute.

6) After 3 hours check not to have exceeded 1.3 mbar abso-

lute; this condition ensures a humidity lower than 50 ppm

inside the system. If the vacuum is not kept there are still

leaks; repeat the operations from point 4.

7.2.2 --- Refrigerant charging

After having eliminated the humidity from the refrigerating circuit (see 7.2.1), proceed as follows:

1) Make sure all the unit components are in operating order.

2) Using a charging hose, connect the cylinder to the liquid

line of the circuit. Drain the substances that cannot be

condensed from the hose.

Charge the circuit exclusively with the

refrigerant indicated on the identification

label.

Charge the quantity of refrigerant indicated in Tab. e.

3) Set the main switch on ON.

4) Start the compressor.

5) The charge operation can be considered finished when,

keeping the condensation temperature at a steady level

(~ 50_C, if necessary partially clog the condensing coil),

no more bubbles appear for at least ten minutes. Check

if the superheat in these conditions is 7---8 degrees.

Superheat calculation

a) With the unit operating in standard conditions,

measure the temperature of the suction line in the

point where the bulb of the thermal expansion valve

is fastened, in case of ”HPSCxxA/L” version unit, in the

compressor inlet, in case of other versions.

b) Detect the evaporation pressure gauge temperature

from a pressure gauge placed on the compressor

suction.

c) Subtract the obtained temperature value from the

one measured in point a).

The difference is the superheat value.

pag. 6

Page 11

7.2.3 --- R407C refrigerant units

Onl

l

ing/FC/EFC

Onl

l

i

FC/EF

C

HPSE1

0

HPSE1

0

HPSE1

2

HPSE1

4

7.2.3.1---Features of the refrigerating fluid R407C

At standard temperature and pressure it is a colourless gas

with low toxicity, non---flammable, and it has an allowed exposure limit value (AEL/TLV)corresponding to 1000 ppm (average value measured on 8 hours/day). In the event of leakage, air the room before use.

Tab. e --- R407C refrigerant charge

Internal

unit

HPSE 06

ycoo

HPSE 08

ycoo

ng

HPSE 08

HPSE 10

Only cooling

HPSE 10

FC / EFC

HPSE 12

Only cooling / FC / EFC

HPSE 14

Only cooling / FC / EFC

IMPORTANT:

The charges indicated in Tab. e refer to a 2 m length for the

gas and liquid pipes: Tab. f shows the indications for longer

measures on the additional charge in grams of refrigerant

R407C by each pipe meter of the gas and liquid lines, according to the diameters indicated in Tab. a.

External

unit

HPSC 060 2.2

HPSC 06A 2.7

HPSC 06L 3.7

HPSC 080 2.7

HPSC 08A 2.7

HPSC 08L 3.7

HPSC 080 3.0

HPSC 08A 3.0

HPSC 08L 4.0

HPSC 10A 2.7

HPSC 10L 3.7

HPSC 10A 3.0

HPSC 10L 4.0

HPSC 12A 3.6

HPSC 12L 4.6

HPSC 14A 3.6

HPSC 14L 4.6

R407C charge

(kg)

The oil to be used when topping up is EMKARATE RL

32--- 3MA or MOBIL EAL ARTIC 22CC, if it’s unavailable use

an oil with the same characteristics (see Tab. g and Tab. h).

NEVER M IX DIFFERENT OILS TOGETHER. CLEAN THE PIPING COMPLETELY BEFORE CHANGING THE TYPE OF OIL

USED.

Ta b . g --- E M K A R A T E RL 3 2 --- 3 M A o i l

viscosity at 40 _C

viscosity at 100 _C

viscosity index (ISO Grade)

:

31.2 cST

:

5.6 cST

:

32

Tab. h --- MOBIL EAL ARTIC 22CC oil

approx. specific weight (at 15_C)

flash point (C.O.C.)

pour point

viscosity index

viscosity at 40_C

viscosity at 100_C

:

0.99 kg/l

:

245 _C

:

< --- 5 4 _C

:

116

:

23.6 cST

:

4.7 cST

7.3 --- Dismantling the unit

The machine has been designed and built to ensure continuous operation.

The working life of some of the main components, such as

the fan and the compressor, depends on their maintenance.

If the unit has to be dismantled, this must be done by skilled

refrigerator technicians.

The refrigerating fluid and the lubricating oil in the circuit must

be disposed of in conformity with the laws in force in your

country.

7.4 --- Spare parts

We recommend the use of original spare parts.

When placing an order please refer to “Component List” enclosed with the machine and specify the unit model and serial

no.

Tab. f --- Additional charge in grams of refrigerant

R407C by meter of each line

Liquid line Gas line

Ø pipeline

(mm)

φ 12 x 1 85.0 φ 16 x 1 4.0

φ 16 x 1 160.0 φ 18 x 1 5.5

---

---

Add

charge

R407C g/m

--- φ 22 x 1 8.5

--- φ 28 x 1 14.5

Ø pipeline

(mm)

Add

charge

R407C g/m

pag. 7

Page 12

8 --- A p p e n d i x

8.1 --- Check the unit after the installation

The following list includes the checks to carry out to verify that HPS is intact after the installation.

IMPORTANT:

EVERY UNIT IS TESTED IN OUR PLANTS BEFORE DELIVERY.

A) STATIC CHECK

A.1) Evaporating unit HPSE

A.1.a) Sight check that the panels and rivets are in-

tact and well fixed.

A.1.b) Checkforthepresenceofacondensatedrain

for each machine and of the discharge pipe

supplied separately.

A.1.c) Check that the (optional) Freecooling air in-

take ducts (rigid or flexible) and the rainproof

external grille, with metallic prefilter (optional)

are available and fixed.

A.1.d) Check that the unit is fixed firmly to the ceiling

or to the wall, and that any fastening devices

passing along the walls of the room to be

conditioned are sealed.

A.1.e) Put the electrical board of the room in the

”OFF” position.

A.1.f) Check for the correct connection of the sup-

ply cables and of the Bus cable between the

PowerFacecardandtheremotedisplayor

between the PowerFace and Hiromatic (if installed, optional).

A.1.g) Check the fastening of cables, electronic

components and fuses.

A.1.h) Check the correct position of the air filter.

A.2) Motor ---condensing unit HPSC

A.2.a) Remove the panels of the compressor com-

partment to access the refrigerating circuit (if

the weather conditions allow this; prevent

water from entering the electric board and the

compressor compartment).

A.2.b) Check that the refrigerating circuit is intact

and that there are no oil stains in the compressor compartment and along the ducts.

A.2.c) Check the evaporating fan by turning it by

means of a screwdriver: it must be free to rotate without any abnormal noise.

A.2.d) Check that the electrical board is free from

foreign bodies, the correct connection to the

evaporating unit and that all electrical connections are tightened.

B) DYNAMIC CHECK

B.1) Check the ground connection.

B.2) Put the electrical board of the room in the

”ON” position.

B.3) Set the main switch of the indoor unit ”ON”.

B.4) Check the voltage at the main supply cables.

B.5) Check the voltage at the emergency supply

cables.

B.6) Only for the units equipped with Hiromatic re-

mote interface, set the wished system con-

figuration, such as set point, network (only for

”Advanced” versions, by assigning an

identification number for each unit), para-

meter sharing, stand --- by, freecooling differ-

entials (if installed), and so on.

B.7) Measure the current absorbed by the evapor-

ating fan only.

B.8) Start up the compressor (if necessary force

the system via the control) and wait until the

system is stable. Measure the absorbed cur-

rent,withbothfanandcompressoroperat-

ing.

B.9) Check all these values comparing them with

those shown in the machine plate.

B.10) Check the delivery temperature with a digital

thermometer.

B.11) Verify the superheating, according to par.

7.2.3.

B.12) Close the panels of the evaporating and mo-

tor---condensing units.

The unit is ready for the dynamic check.

pag. 8

Page 13

Tab. 1 -- 50 Hz Technical data for “COOLING ONLY” and “COOLING + HEATING” unit versions

(*)

(F and F + C) coupled with “HPSCxx0”

Model HPS 06 HPS 08

Operating limits

Main power supply voltage 230V ±10% / 1Ph / 50Hz 400V±10% / 3Ph+N+PE / 50Hz

Outdoor conditions

*

Indoor conditions with compressor running

Storage conditions

Sound pressure level

Outdoor sound pressure level

(1)

Indoor sound pressure level dB(A) 58.0 62.5

Standard electrical features

Compressor --- AC power input

Compressor --- AC operative current (OA)

(2)

(2)

Compressor --- AC max. current (FLA) A 11.4 5.1

Compressor --- AC starting current (LRA) A 47.0 32.0

Condenser fan --- AC power input

(2)

Condenser fan --- AC max. power input kW 0.08 0.10

Condenser fan --- AC operative current (OA)

(2)

Condenser fan --- AC max. current (FLA) A 1.4 1.4

Condenser fan --- AC starting current A 1.6 1.6

Evaporator fan --- AC power input

Evaporator fan --- AC operative current (OA)

Evaporator fan --- AC max. current (FLA)

(2)

(2)

(3)

Evaporator fan --- AC starting current A 1.3 2.7

Electric heating (optional)

Heating capacity kW 1.5 3.0

H e a t i n g --- m a x . cu r r e n t A 6.5

OA: Standard Operating Ampère

FLA: Full Load Ampère

LRA: Locked Rotor Ampère

Notes:

(*)

Maximum outdoor temperature referred to 30ûC / 35% R.H. indoor unit air suction (HPSE).

(**)

Conditions referred to the suction sections of the inner unit (HPSE); the min. indoor temperature is referred to 30% of indoor relative humidity and to the min.

outdoor temperature; for higher relative humidity and/or outdoor temperatures, the min. indoor temperature is higher than the table data.

(1)

Measured with 35ûC outdoor temperature at 2m far from the unit; free field conditions.

(2)

Indoor reference conditions: 30ûC / 35% R.H. at the HPSE indoor unit air suction sides; 35ûC outdoor. Nominal power supply.

(3)

It refers to nominal speed (Factory setting).

from: 10°C

to: 47°C 45°C

from: 24°C, 30% R.H. / 80% R.H.

(**)

to: 35°C, 40% R.H. 30°C, 40% R.H.

from: --- 4 0 °C, 5% R.H.

to: 55°C, 90% R.H.

dB(A) 50

kW 1.58 2.18

A 7.6 3.9

kW 0.08 0.10

A 0.6 0.7

kW 0.18 0.35

A 0.8 1.5

A 1.0 2.0

pag. 9

Page 14

Tab. 2 -- 50 Hz Technical data for “FREECOOLING” and “230V/1Ph/50Hz EMERGENCY FREECOOLING”

(**

)

unit versions (FC and EFC -- AC) coupled with “HPSCxx0”

Model HPS 06 HPS 08

Operating limits

Main power supply voltage 230V ±10% / 1Ph / 50Hz 400V±10% / 3Ph+N+PE / 50Hz

Emergency power supply voltage

Outdoor conditions

**

Indoor conditions with compressor running

Storage conditions

from: 10°C

to: 48°C 45°C

from: 24°C, 30% R.H. / 80% R.H.

to: 35°C, 40% R.H. 30°C, 40% R.H.

from: --- 4 0 °C, 5% R.H.

to: 55°C, 90% R.H.

Sound pressure level

Outdoor sound pressure level

(1)

dB(A) 50

Indoor sound pressure level dB(A) 59.0 62.5

Standard electrical features

Compressor --- AC power input

Compressor --- AC operative current (OA)

(2)

(2)

kW 1.57 2.18

A 7.3 3.9

Compressor --- AC max. current (FLA) A 11.4 5.1

Compressor --- AC starting current (LRA) A 47.0 32.0

Condenser fan --- AC power input

(2)

kW 0.08 0.10

Condenser fan --- AC max. power input kW 0.08 0.10

Condenser fan --- AC operative current (OA)

(2)

A 0.6 0.7

Condenser fan --- AC max. current (FLA) A 1.4 1.4

Condenser fan --- AC max. current (FLA) A 1.6 1.6

Evaporator fan --- AC power input

Evaporator fan --- AC operative current (OA)

Evaporator fan --- AC max. current (FLA)

(2)

(2)

(3)

kW 0.14 0.39

A 0.6 2.8

A 0.6 2.4

Evaporator fan --- AC starting current A 1.2 5.3

Electric heating (optional)

Heating capacity kW 1.5 3.0

H e a t i n g --- m a x . cu r r e n t A 6.5

OA: Standard Operating Ampère

FLA: Full Load Ampère

LRA: Locked Rotor Ampère

Notes:

(*)

The emergency cooling option (EFC) is required.

(**)

Maximum outdoor temperature referred to 30ûC / 35% R.H. indoor unit air suction (HPSE).

(***)

Conditions referred to the suction sections of the inner unit (HPSE); the min. indoor temperature is referred to 30% of indoor relative humidity and to the min.

outdoor temperature; for higher relative humidity and/or outdoor temperatures, the min. indoor temperature is higher than the table data.

(1)

Measured with 35ûC outdoor temperature at 2m far from the unit; free field conditions.

(2)

Indoor reference conditions: 30ûC / 35% R.H. at the HPSE indoor unit air suction sides; 35ûC outdoor. Nominal power supply.

(3)

It refers to nominal speed (Factory setting).

230V ±10% / 1Ph+PE / 50Hz

(with emergency cooling)

(*)

(***)

pag. 10

Page 15

Tab. 3 -- 50 Hz Technical data for “FREECOOLING” and “48Vdc EMERGENCY FREECOOLING” unit

(**

)

versions (FC and EFC--DC) coupled with “HPSCxx0”

Model HPS 06 HPS 08

Operating limits

Main power supply voltage 230V ±10% / 1Ph / 50Hz 400V±10% / 3Ph+N+PE / 50Hz

Emergency power supply voltage

Outdoor conditions

**

Indoor conditions with compressor running

Storage conditions

from: 10°C

to: 48°C 45°C

from: 24°C, 30% R.H.. / 80% R.H.

to: 35°C, 40% R.H. 30°C, 40% R.H.

from: --- 4 0 °C, 5% R.H.

to: 55°C, 90% R.H.

Sound pressure level

Outdoor sound pressure level

(1)

dB(A) 50

Indoor sound pressure level dB(A) 57 62

Standard electrical features

Compressor --- AC power input

Compressor --- AC operative current (OA)

(2)

(2)

kW 1.57 2.17

A 7.3 3.9

Compressor --- AC max. current (FLA) A 11.4 5.1

Compressor --- AC starting current (LRA) A 47.0 32.0

Condenser fan --- AC power input

(2)

kW 0.08 0.10

Condenser fan --- AC max. power input kW 0.08 0.10

Condenser fan --- AC operative current (OA)

(2)

A 0.6 0.7

Condenser fan --- AC max. current (FLA) A 1.4 1.4

Condenser fan --- AC max. current (FLA) A 1.6 1.6

Evaporator fan --- DC power input

Evaporator fan -- - DC operative current (OA)

Evaporator fan --- DC max. current (FLA)

(2)

(2)

(3)

kW 0.10 0.28

A 2.6 5.8

A 2.6 9.6

Evaporator fan --- DC starting current A 0.1 0.1

Electric heating (optional)

Heating capacity kW 1.5 3.0

H e a t i n g --- m a x . cu r r e n t A 6.5

OA: Standard Operating Ampère

FLA: Full Load Ampère

LRA: Locked Rotor Ampère

Notes:

(*)

The emergency cooling option (EFC) is required.

(**)

Maximum outdoor temperature referred to 30ûC / 35% R.H. indoor unit air suction (HPSE).

(***)

Conditions referred to the suction sections of the inner unit (HPSE); the min. indoor temperature is referred to 30% of indoor relative humidity and to the min.

outdoor temperature; for higher relative humidity and/or outdoor temperatures, the min. indoor temperature is higher than the table data.

(1)

Measured with 35ûC outdoor temperature at 2m far from the unit; free field conditions.

(2)

Indoor reference conditions: 30ûC / 35% R.H. at the HPSE indoor unit air suction sides; 35ûC outdoor. Nominal power supply.

(3)

It refers to nominal speed (Factory setting).

48VDC ±17%

(with emergency cooling)

(*)

(***)

pag. 11

Page 16

Tab. 4 -- 50 Hz Technical data for ”COOLING ONLY” and “COOLING + HEATING” unit versions

(*)

(F and F+C) coupled with “HPSCxxA/L”

Model HPS 06 HPS 08 HPS 10 HPS 12 HPS 14

Operating limits

Main power supply voltage

Outdoor conditions

*

Indoor conditions with compressor running

Storage conditions

Sound pressure level

Outdoor sound pressure level

(1)

dB(A) 48.5 48.5 52.5 53.5 55.0

Indoor sound pressure level dB(A) 58.0 62.5 62.5 64.0 64.0

Standard electrical features

Compressor --- AC power input

Compressor --- AC operative current (OA)

(2)

(2)

Compressor --- AC max. current (FLA) A 11.4 5.1 7.0 10.0 10.2

Compressor --- AC starting current (LRA) A 47.0 32.0 46.0 50.0 63.0

Condenser fan --- AC power input

(2)

Condenser fan --- AC max. power input kW 0.24 0.24 0.48 0.48 0.48

Condenser fan --- AC operative current (OA)

(2)

Condenser fan --- AC max. current (FLA) A 1.4 1.4 2.8 2.8 2.8

Condenser fan --- AC max. current (FLA) A 1.6 1.6 3.3 3.3 3.3

Evaporator fan --- AC power input

Evaporator fan --- AC operative current (OA)

Evaporator fan --- AC max. current (FLA)

(2)

(2)

(3)

Evaporator fan --- AC starting current A 1.3 2.7 2.7 2.7 2.7

Electric heating (optional)

Heating capacity kW 1.5 3.0 3.0 4.5 6.0

H e a t i n g --- m a x . cu r r e n t A 6.5 13.0

OA: Standard Operating Ampère

FLA: Full Load Ampère

LRA: Locked Rotor Ampère

Notes:

(*)

Maximum outdoor temperature referred to 30ûC / 35% R.H. indoor unit air suction (HPSE).

(**)

Conditions referred to the suction sections of the inner unit (HPSE); the min. indoor temperature is referred to 30% of indoor relative humidity and to the min.

outdoor temperature; for higher relative humidity and/or outdoor temperatures, the min. indoor temperature is higher than the table data.

(1)

Measured with 35ûC outdoor temperature at 2m far from the unit; free field conditions.

(2)

Indoor reference conditions: 30ûC / 35% R.H. at the HPSE indoor unit air suction sides; 35ûC outdoor. Nominal power supply.

(3)

It refers to nominal speed (Factory setting).

230V ±10%

/1Ph/50Hz

400V ±10% / 3Ph+N+PE / 50Hz

from: --- 3 0 °C

to: 51°C 50°C

from: 24°C, 30% R.H / 80% R.H.

to:

34°C,

40% R.H.

30°C, 40% R.H.

(**)

from: --- 4 0 °C, 5% R.H.

to: 55°C, 90% R.H.

kW 1.73 2.23 3.06 3.75 4.68

A 8.0 4.0 5.5 6.6 8.6

kW 0.07 0.10 0.22 0.22 0.28

A 0.6 0.7 1.5 1.5 1.7

kW 0.18 0.35 0.35 0.34 0.34

A 0.8 1.5 1.5 2.0 2.0

A 1.0 2.0 2.0 2.0 2.0

pag. 12

Page 17

Tab. 5 -- 50 Hz Technical data for “FREECOOLING” and “230V/1Ph/50Hz EMERGENCY FREECOOLING”

(**

)

unit versions (FC and EFC -- AC) coupled with “HPSCxxA/L”

Model HPS 06 HPS 08 HPS 10 HPS 12 HPS 14

Operating limits

Main power supply voltage

Emergency power supply voltage

Outdoor conditions

**

Indoor conditions with compressor running

Storage conditions

Sound pressure level

Outdoor sound pressure level

(1)

dB(A) 48.5 48.5 52.5 53.5 55.0

Indoor sound pressure level dB(A) 59.0 62.5 62.5 64.5 66.0

Standard electrical features

Compressor --- AC power input

Compressor --- AC operative current (OA)

(2)

(2)

Compressor --- AC max. current (FLA) A 11.4 5.1 7.0 10.0 10.2

Compressor --- AC starting current (LRA) A 47.0 32.0 46.0 50.0 63.0

Condenser fan --- AC power input

(2)

Condenser fan --- AC max. power input kW 0.24 0.24 0.48 0.48 0.48

Condenser fan --- AC operative current (OA)

(2)

Condenser fan --- AC max. current (FLA) A 1.4 1.4 2.8 2.8 2.8

Condenser fan --- AC max. current (FLA) A 1.6 1.6 3.3 3.3 3.3

Evaporator fan --- AC power input

Evaporator fan --- AC operative current (OA)

Evaporator fan --- AC max. current (FLA)

(2)

(2)

(3)

Evaporator fan --- AC starting current A 1.2 5.3 5.3 5.3 5.3

Electric heating (optional)

Heating capacity kW 1.5 3.0 3.0 4.5 6.0

H e a t i n g --- m a x . cu r r e n t A 6.5 13.0

OA: Standard Operating Ampère

FLA: Full Load Ampère

LRA: Locked Rotor Ampère

Notes:

(*)

The emergency cooling option (EFC) is required.

(**)

Maximum outdoor temperature referred to 30ûC / 35% R.H. indoor unit air suction (HPSE).

(***)

Conditions referred to the suction sections of the inner unit (HPSE); the min. indoor temperature is referred to 30% of indoor relative humidity and to the min.

outdoor temperature; for higher relative humidity and/or outdoor temperatures, the min. indoor temperature is higher than the table data.

(1)

Measured with 35ûC outdoor temperature at 2m far from the unit; free field conditions.

(2)

Indoor reference conditions: 30ûC / 35% R.H. at the HPSE indoor unit air suction sides; 35ûC outdoor. Nominal power supply.

(3)

It refers to nominal speed (Factory setting).

230V ±10%

/1Ph/50Hz

400V ±10% / 3Ph+N+PE / 50Hz

230V ±10% / 1Ph+PE / 50Hz

(with emergency cooling)

(*)

from: --- 3 0 °C

to: 52°C 50°C

from: 24°C, 30% R.H / 80% R.H.

to:

35°C,

40% R.H.

30°C, 40% R.H

(***)

from: --- 4 0 °C, 5% R.H.

to: 55°C, 90% R.H.

kW 1.74 2.22 3.06 3.75 4.66

A 8.1 4.0 5.5 6.6 8.5

kW 0.07 0.10 0.22 0.22 0.28

A 0.6 0.7 1.5 1.5 1.7

kW 0.14 0.39 0.39 0.45 0.48

A 0.6 2.8 2.8 2.9 2.4

A 0.7 2.4 2.4 2.4 2.4

pag. 13

Page 18

Tab. 6 -- 50Hz T echnical data for “FREECOOLING” and “48Vdc EMERGENCY FREECOOLING” unit

(**

)

versions (FC and EFC--DC) coupled with “HPSCxxA/L”

Model HPS 06 HPS 08 HPS 10 HPS 12 HPS 14

Operating limits

Main power supply voltage

Emergency power supply voltage

Outdoor conditions

**

Indoor conditions with compressor running

Storage conditions

Sound pressure level

Outdoor sound pressure level

(1)

dB(A) 48.5 48.5 52.5 53.5 55.0

Indoor sound pressure level dB(A) 57.0 62.0 62.0 67.0 68.5

Standard electrical features

Compressor --- AC power input

Compressor --- AC operative current (OA)

(2)

(2)

Compressor --- AC max. current (FLA) A 11.4 5.1 7.0 10.0 10.2

Compressor --- AC starting current (LRA) A 47.0 32.0 46.0 50.0 63.0

Condenser fan --- AC power input

(2)

Condenser fan --- AC max. power input kW 0.24 0.24 0.48 0.48 0.48

Condenser fan --- AC operative current (OA)

(2)

Condenser fan --- AC max. current (FLA) A 1.4 1.4 2.8 2.8 2.8

Condenser fan --- AC max. current (FLA) A 1.6 1.6 3.3 3.3 3.3

Evaporator fan --- DC power input

Evaporator fan -- - DC operative current (OA)

Evaporator fan --- DC max. current (FLA)

(2)

(2)

(3)

Evaporator fan --- DC starting current A 0.1 0.1 0.1 0.1 0.1

Electric heating (optional)

Heating capacity kW 1.5 3.0 3.0 4.5 6.0

H e a t i n g --- m a x . cu r r e n t A 6.5 13.0

OA: Standard Operating Ampère

FLA: Full Load Ampère

LRA: Locked Rotor Ampère

Notes:

(*)

The emergency cooling option (EFC) is required.

(**)

Maximum outdoor temperature referred to 30ûC / 35% R.H. indoor unit air suction (HPSE).

(***)

Conditions referred to the suction sections of the inner unit (HPSE); the min. indoor temperature is referred to 30% of indoor relative humidity and to the min.

outdoor temperature; for higher relative humidity and/or outdoor temperatures, the min. indoor temperature is higher than the table data.

(1)

Measured with 35ûC outdoor temperature at 2m far from the unit; free field conditions.

(2)

Indoor reference conditions: 30ûC / 35% R.H. at the HPSE indoor unit air suction sides; 35ûC outdoor. Nominal power supply.

(3)

It refers to nominal speed (Factory setting).

230V ±10%

/1Ph/50Hz

400V ±10% / 3Ph+N+PE / 50Hz

48VDC ±17%

(with emergency cooling)

(*)

from: --- 3 0 °C

to: 52°C 50°C

from: 24°C, 30% R.H. / 80% R.H.

to:

35°C,

40% R.H.

30°C, 40% R.H.

(***)

from: --- 4 0 °C, 5% R.H.

to: 55°C, 90% R.H.

kW 1.74 2.23 3.06 3.75 4.66

A 8.1 4.0 5.5 6.6 8.5

kW 0.07 0.10 0.22 0.22 0.28

A 0.6 0.7 1.5 1.5 1.7

kW 0.10 0.28 0.28 0.39 0.45

A 2.6 5.8 5.8 8.1 9.5

A 2.6 9.6 9.6 9.6 9.6

pag. 14

Page 19

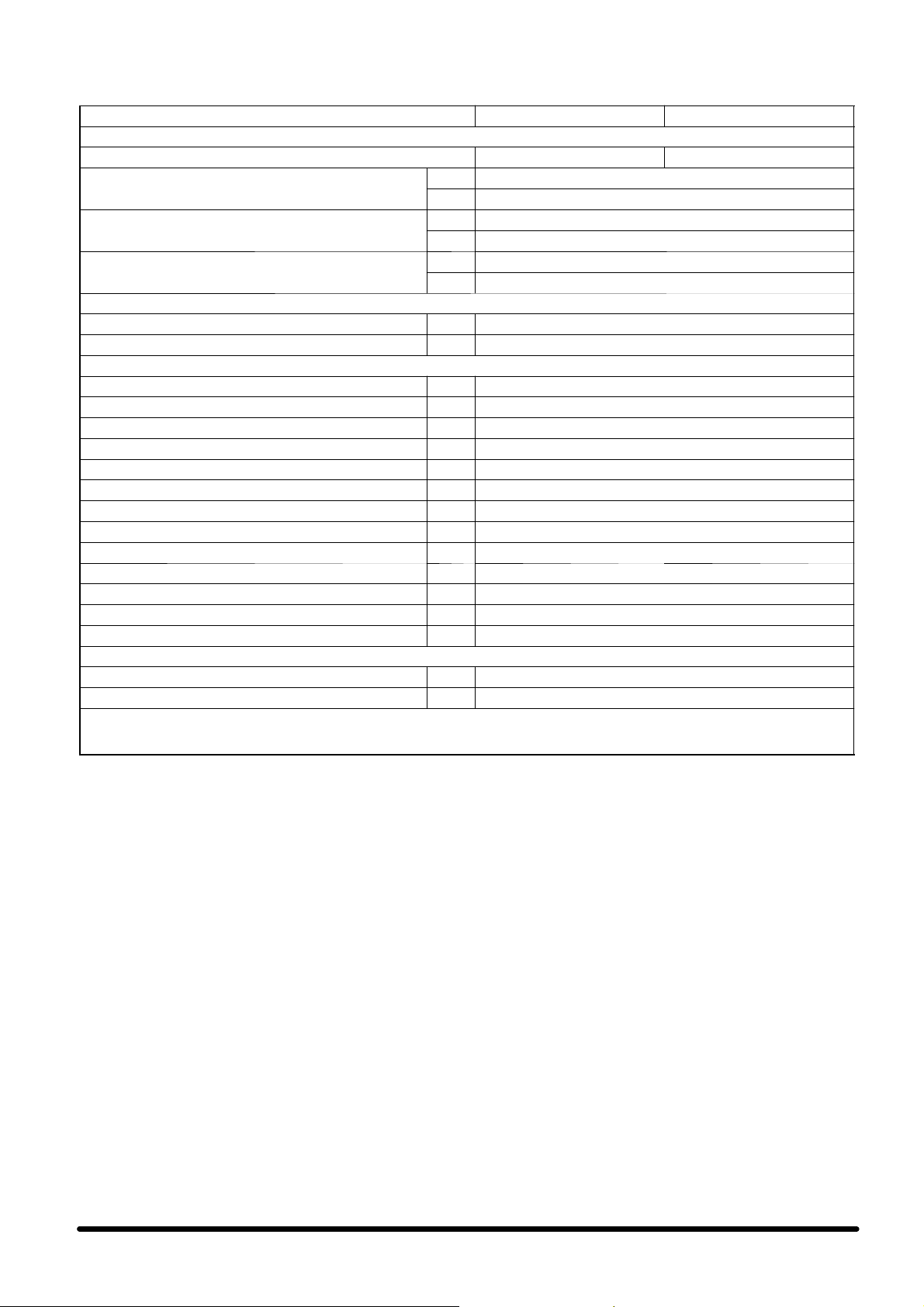

Tab. 7 -- Differential current protection switch

“

HPS08

A

HPS10

20A

2

HPS12

(Ccurve

)

g

Cablesizing

V

/

HPS08

A

HPS10

20A

4x2.5mm

+

2x2.5mm

+

HPS12

(Ccue)Tx2.5mmTx2.5m

m

48VDC

HPS08

A4x

HPS10

20A

4x2.5mm2+

2x2.5mm2+

HPS12

(Ccurve)Tx2.5mmTx

2.5mm

50Hz unit versions (”cooling only”,

“

cooling+heating” and“freecooling”)

”

“

”

Unit power supply 230V / 1Ph / 50Hz 400V / 3Ph / 50Hz + N

HPS 06

Differential current protection switch

I nn = 0.03A

2poles 4poles

20A

(”C” curve)

--- 2 x 2.5mm2+Tx2.5mm

Cable sizing

2

HPS 10

HPS 12

---

HPS 14

Emergency freecooling” unit version

230V/1Ph/50Hz

”

Main line power supply

Unit EFC ---AC line power supply

HPS 06

HPS 10

HPS 12

Differential current protection switch

I nn = 0.03A

2poles 4poles

230

main line

20A

(”C” curve)

1Ph/50Hz

E F C --- A C

line

10A

(”C” curve)

400V / 3Ph / 50Hz + N

230V / 1Ph / 50Hz + N

main line

---

HPS 14

“Emergency freecooling” unit version

48VDC

Differential current protection switch I nn = 0.03A

2poles 4poles

Main line power supply 230V / 1Ph / 50Hz 400V / 3Ph / 50Hz + N

Unit EFC ---DC line power supply 48VDC

main line

E F C --- D C

line

main line

20

(”C” curve)

4x2.5mm2+Tx2.5mm

Cable sizin

E F C --- A C

line

main line

--- 2 x 2.5mm2+Tx2.5mm

20

(”C” curve)

4x2.5mm2+ 2x2.5mm2+

T x 2.5mm

2

Cable sizing

E F C --- D C

line

main line

E F C --- A C

line

2

T x 2.5mm

E F C --- D C

line

2

HPS 06

HPS 10

HPS 12

20A

(”C” curve)6A(”C” curve)

---

--- 2 x 2.5mm2+Tx2.5mm

20

(”C” curve)

2.5mm2+ 2x2.5mm2+

T x 2.5mm

2

HPS 14

Notes:

S

The cables have to be sized in compliance with local standards and according to the type and characteristics (e.g. Amperes) of installation.

S

The specific power of the user --- installed switch, must be lower than 300.000 (A2xs).

S

Prescriptions on the differential relay required to the user:

S

for special places (healthcare facilities, etc.) comply with the local regulations;

S

For ordinary places, a low sensitivity is suggested (30 mA) coordinated with the value of the ground heater (IEC 364): Ra≤50/la(Art. 413.1.4.1, CEI 64 --- 8);

S

In case of frequent over---voltages with mains impulse, it is advisable to install a selective differential and to evaluate the need for adopting other devices.

T x 2.5mm

2

2

pag. 15

Page 20

Tab. 8 -- Settings

Component Setting Notes

Low pressure switch (LP)

High pressure switch (HP)

Fan speed controller (BV)

(only for “HPSCxxA/L” configuration unit)

STOP: 1.0 bar

START: 2.0 bar

(fixed settings)

STOP: 28.0 bar

START: 20.0 bar

(fixed settings)

SET: 25.0 bar

(for the adjustment refer to the instruc-

BANDA P: 3.8 bar

tions supplied with the machine)

Automatic reset

Manual reset pressing

the push button

Tab. 9 -- Fire proof classification of electrical/electronic components

(according to UL 94 normative --- vertical burning)

Electrical/electronic components Fire proof classification

Contactors V1

Automatic switches V1

Cables V1

PC Board (PowerFace) V0

HP and LP pressure switches V1

Clogged filter V2

Terminal block for internal unit (HPSE) V0

Terminal block for external unit (HPSC) V1

Ducts V1

Soft--- Starter V1

Connectors V0

Auxiliary relais V1

Electrical heater safety thermostat V1

Sensors V1

Servomotor V1

pag. 16

Page 21

28.528.5 803

Refrigerant

connection

LEFT SIDE VIEW

803

310

FRONT VIEW (CIRCULAR DUCTS VERSION)

251,5 300 251,5

N. 2 collars

ø200 H=35 mm

155155

310

Electrical

connection

Refrigerant

connection

803 28,528,5

FRONTVIEW(RECTANGULARDUCTVERSION)

120,5 562 120,5

Collar

190x560 H=35 mm

59 192 59

310

unit fixing

N. 8 slots 9x12 ---

70994

RIGHT SIDE VIEW

Condensate drain

TOP VIEW

150 150 125

803

228 150

Fig. 1a --- Evaporating unit HPSE 06 (version with freecooling)

14.5

13,583313,5

860

Fig. 1 --- Overall dimensions

pag. 17

Page 22

28.528.5 903

Refrigerant

connection

LEFT SIDE VIEW

903

375

Electrical

connection

903 28,528,5

276,5 350 276,5

150,7 601,6 150,7

187,5

375

187,5

FRONT VIEW (CIRCULAR DUCTS VERSION)

FRONTVIEW(RECTANGULARDUCTVERSION)

N. 2 collars

ø250 H=35 mm

Refrigerant

connection

Collar

250x600 H=35 mm

61,7 251,6 61,7

375

226,5

unit fixing

N. 8 slots 9x12 ---

81588

RIGHT SIDE VIEW

F i g . 1 b --- E v a p o r a t i n g u n i t H P S E 0 8 --- 1 0 --- 1 2 --- 1 4 (version with freecooling)

Condensate drain

14.5

903

TOP VIEW

150 150

226,5 150

13,593313,5

960

pag. 18

Page 23

Electrical

connection

LEFT SIDE VIEW

FRONT VIEW

803

310

Refrigerant

connection

803

BOTTOM VIEW

860

310

28,5 803 28,5

unit fixing

N. 8 slots 9x12 ---

70994

803

RIGHT SIDE VIEW

F i g . 1 c --- E v a p o r a t i n g u n i t H P S E 0 6 --- 0 8 --- 1 0 (version without freecooling)

Condensate drain

14.5

TOP VIEW

228 150 150 150 125

13,583313,5

pag. 19

Page 24

Electrical

connection

LEFT SIDE VIEW

FRONT VIEW

903

375

Refrigerant

connection

903

BOTTOM VIEW

960

375

28,5 903 28,5

unit fixing

N. 8 slots 9x12 ---

80994

RIGHT SIDE VIEW

Condensate drain

903

TOP VIEW

226.5 150 150 150 226.5

F i g . 1 d --- E v a p o r a t i n g u n i t H P S E 1 2 --- 1 4 (version without freecooling)

14.5

13,593313,5

pag. 20

Page 25

A

FRONT VIEW

A --- A Se c .

132 656 132

A

80535

outlet

Refrigerant

338

SIDE VIEW

inlet

Refrigerant

Electrical

connections

390

1818

354

390

840

REAR VIEW

Fig. 1e --- Conde nsing unit HPSC 06--- 08

outlet

Refrigerant

920

inlet

Refrigerant

pag. 21

Page 26

A

27

656

FRONT VIEW

27

A --- A Se c .

132 132

A

115535

outlet

Refrigerant

338

SIDE VIEW

1190

inlet

Refrigerant

Electrical

connections

390

354 1818

390

REAR VIEW

920

F i g . 1 f --- C o n d e n s i n g u n i t H P S C 1 0 --- 1 2 --- 1 4

outlet

Refrigerant

pag. 22

inlet

Refrigerant

Page 27

F i g . 2 --- I n s t a l l a t i o n

F i g . 2 a --- E v a p o r a t i n g u n i t c e i l i n g i n s t a l l a t i o n H P S E 0 6 --- 0 8 --- 1 0 --- 1 2 --- 1 4

(version without freecooling)

375 (HPSE 12--14)

310 (HPSE 06--08--10)

Service area

for electical

min. 300

board

803 (HPSE 06--08--10)

903 (HPSE 12--14)

min. 200

pag. 23

Page 28

F i g . 2 b --- E v a p o r a t i n g u n i t i n s t a l l a t i o n H P S E 0 6 --- 0 8 --- 1 0 --- 1 2 --- 1 4

(version with freecooling)

C

Service area

for electical

Service area

for Freecooling

min. 300

A

filter

board

B

min. 200

HPSE A B C

06 min. 300 803 310

0 8 --- 1 0 --- 1 2 --- 1 4 min. 320 903 375

3

5

1

4

2

3

3

ITEM DESCRIPTION

1 Electrical box accessibility

2 Support for filter

3 Air filter

4 Freecooling filter accessibility

5 Electrical box

pag. 24

Page 29

F i g . 2 c --- E v a p o r a t i n g u n i t c e i l i n g i n s t a l l a t i o n H P S E 0 6 --- 0 8 --- 1 0 --- 1 2 --- 1 4

(version with freecooling)

4

1

10

11

9

23

8

7

6

5

5

ITEM DESCRIPTION

CODE

HPSE 06

CODE

H P S E 0 8 --- 1 0 --- 1 2 --- 1 4

1 Wall plate for circular ducts 13503801 13536101

2 2 flexible ducts with fixing clamps, L = 0.5 m 270190 (Ø 202mm) 270191 (Ø 254mm)

3 Fixing clamps --- ---

4 Wall plate for rectangular duct 13501801 13536001

5 Circular / rectangular version --- ---

6 Wall hole 400 x 200mm 600 x 400mm

7 Overpressure damper 134948 134992

8 Grille for overpressure damper 270206 117832

9 Aluminium grille with metallic prefilter 270202 270219

10 Metallic prefilter (included in item 9) --- ---

11 Wall hole 550 x 210mm 590 x 230mm

pag. 25

Page 30

Fig. 2d --- Condensing unit wall installation

1

2

3

4

5

3

2

1

HPSC 06 ---08

COD. 129201

H P S C 1 0 --- 1 2 --- 1 4

ITEM

1 Nut

2 Serrated lock washer

3 Washer

4 A n t i --- v i b r a t i n g m o u n t

5 Bracket

KIT DESCRIPTION

COD. 129201