Liebert Hiross Himod 65UC, Himod 27UC, Himod 80UC, Himod 85UC, Himod 90UC Service Manual

...Page 1

Himod

C Version

Service Manual

English

cod. 272631 − rev. 25.02.2005

Page 2

Page 3

Caution

We recommend that:

S the manual is retained for the entire service life of the machine;

S the user reads the manually carefully before carrying out any operations on the machine;

S the control is used exclusively for the purpose for which it is intended; incorrect use of the control shall release the manufac-

turer from any liability.

This manual has been prepared to enable the end−user to carry out only the operations that can be made with the panels closed.

Any operations that require the opening of doors or equipment panels must be carried out only by qualified personnel.

Each machine is equipped with an Electric Insulating device which allows the operator to work in conditions of safety. Switch off

the machine before any maintenance operation to eliminate risks remaining (electric shocks, scalds, automatic restarting, moving parts and remote control).

For "UNDER" units installed on raised floor: switch off the machine before removal of the floor panels within a distance of

850 mm from the machine, to avoid risks of contact with rotating devices.

The panel key supplied with the unit must be kept by the person responsible for maintenance.

For identification of the unit (model and serial no.) in case of the necessity for assistance or spare parts, locate the identification

label on the outside of the unit.

Index

1 − Preliminary operations 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 − Inspection 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 − Handling 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 − Operating limits 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 − Identification 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 − Positioning 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 − Clearance areas and main dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 − Overall dimensions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 − Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 − Air inlet and outlet 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 − Hole in raised floor 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 − Extension hood 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 − Extension hood with sound reduction cartridges (Over unit) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 − Horizontal discharge hood (Over unit) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 − Base module 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 − Base frame 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 − High efficiency filters 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 − New Air module 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 − Water connections 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 − General warnings 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 − Auxiliary water connections 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 − Chilled water connections 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 − Adding ethylene glycol 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 − Electrical connections 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 − Electrical connections 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 − Fan connections 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 − Aeraulic features 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 − Start−up 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 − First start−up (or after long standstill) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 − Starting and stopping 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 − Automatic restart 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 − Operation 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 − Chilled water valve 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

English

Page 4

8 − Calibrations 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 − Maintenance / Spare Parts 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 − Spare parts 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 − Dismantling the unit 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A − HUMIDAIR humidifier A − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.1 − Preface A − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.2 − Installation A − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.3 − Humidair components A − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.4 − Start−up and operation A − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.4.1 − Start−up A − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.4.2 − Operation A − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.5 − Maintenance A − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.5.1 − Removing the steam cylinder A − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.5.2 − Replacing the steam cylinder A − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.5.3 − Annual maintenance A − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

App. A.6 − Spare part list A − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Service Manual HIMOD can also be surfed on the Web at the address: www.HIROSS.IT/pde/TDS/Himod

This document is password−protected. Ask for the password to your Dealer/Area Manager.

English

Page 5

1 − Preliminary operations

Room conditions

Hot water heating coil

Chilled water coil

1.1 − Inspection

On receiving the equipment immediately check its

condition; report any damage to the transport company at once.

1.2 − Handling

S Always keep the unit vertically upright and do not

leave it out in the open.

S If possible transport the unit using a fork lift truck;

otherwise use a crane with belts or cables, avoiding

pressing on the top edges of the packing.

1.3 − Operating limits

The units are designed to operate within working

ranges (see Tab. 1).

These limits are referred to new machines or to those

that have been correctly installed and serviced.

The warranty clauses are no longer valid for any possible damage or malfunction that may occur during or

due to operation outside the application values.

1.4 − Identification

The air conditioner can be identified according to the

following nomenclature:

27

UC

Model

Air distribution:

U = Under (downflow)

= Over (upflow)O

Cooling circuit:

A = air−cooled

= water−cooledW

= chilled water

C

F = Freecooler

= Dualfluid (air−cooled)D

= Dualfluid (water−cooled)

H

Tab. 1 − Operating limits

Room conditions

Voltage tolerances

UNDER OVER

from: 18°C, 45% R.H.

to: 27°C, 55% R.H

standard 400V 10%/3/50

208B230V ± 10%/3/60

optional

380V ± 10%/3/60

460V ± 10%/3/60

To view the Service Manual HIMOD version

A/W/F/D/H, refer to the Manual code 272157

Hot water heating coil

Chilled water coil

Storage conditions

inlet water

temperature

water pressure max. 8.5 bar

inlet water

temperature

water pressure max. 16 bar

from: − 20°C

to: 50°C

max. 85°C

min. 5°C

English

HIMOD−C

1

Page 6

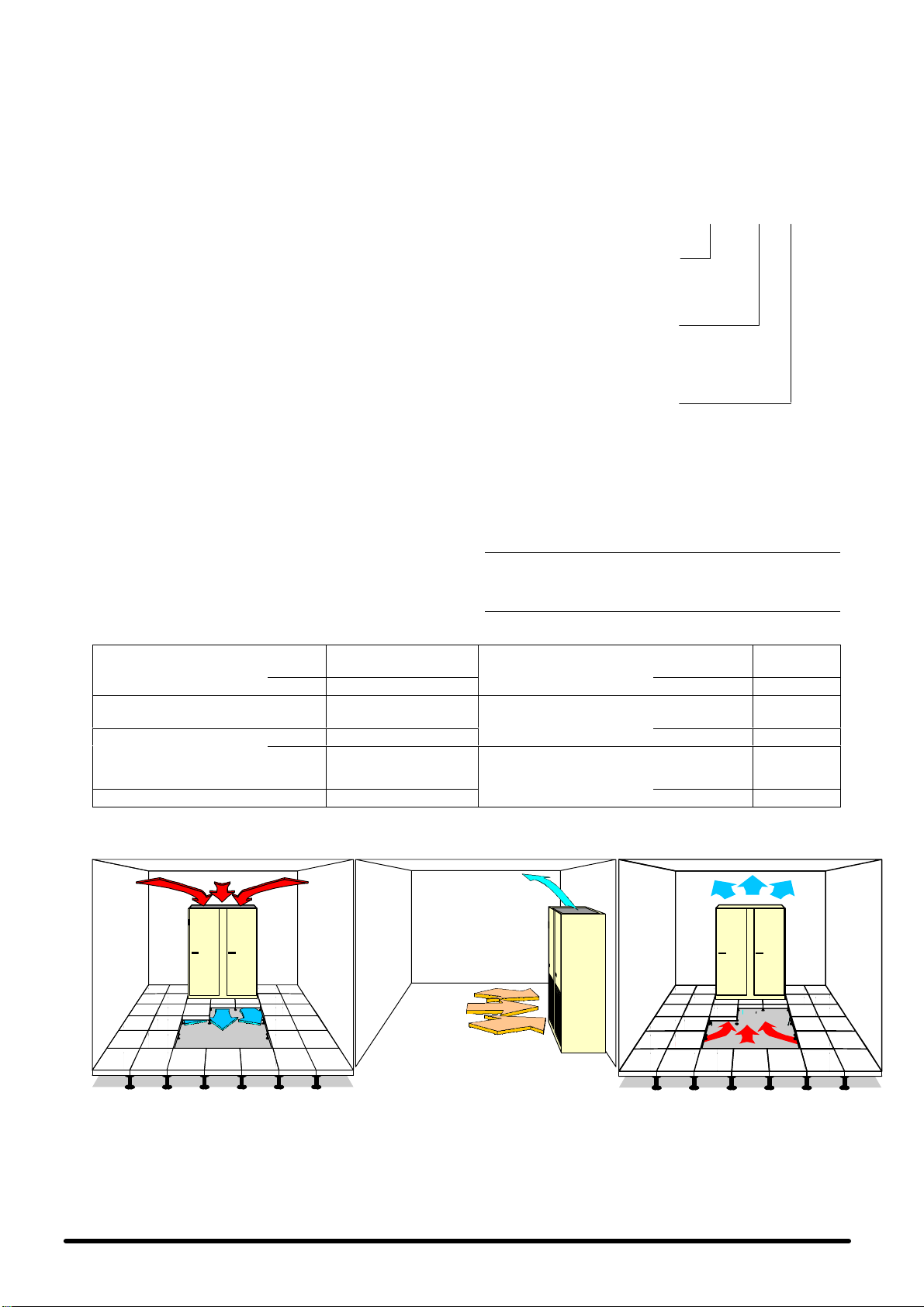

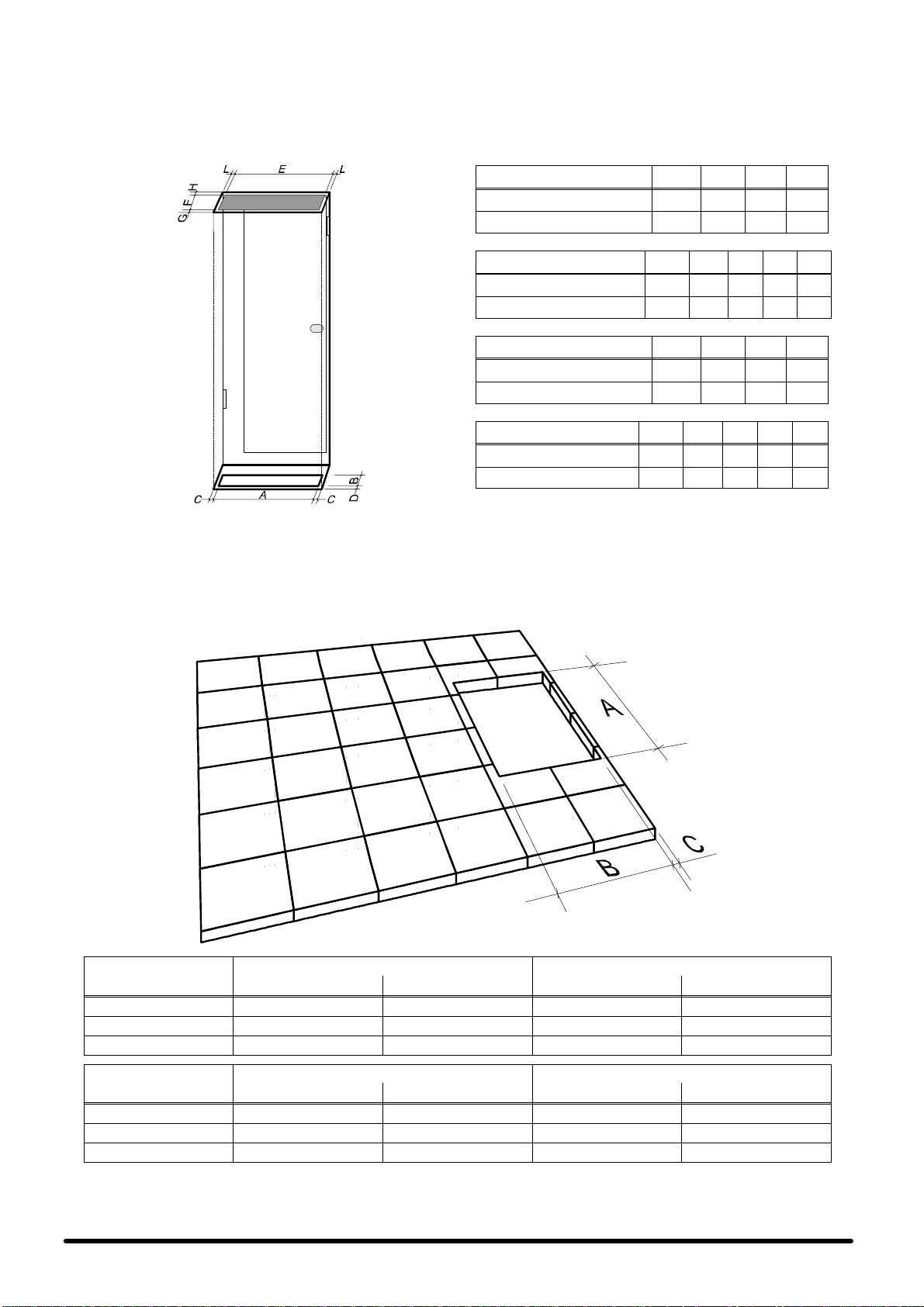

2 − Positioning

2.1 − Clearance areas and main dimensions

MODEL

27−45 O/UC 55−65−80−85 O/UC 90−10 UC 12−14 UC

A [mm] 1000 1750 2050 2550

B [mm] 1740 1740 1740 1740

C [mm] 800 800 800 800

D [mm] 890 890 890 890

E [mm] 50 50 50 50

F [mm] 1950 1950 1950 1950

MODEL WEIGHT (kg) − standard unit

27 UC 290

45 UC 340

55 UC 495

65 UC 555

80 UC 590

85 UC 610

90 UC 660

10 UC 670

12 UC 830

14 UC 840

27 OC 290

45 OC 340

55 OC 495

65 OC 555

80 OC 590

85 OC 610

2

HIMOD−C

English

Page 7

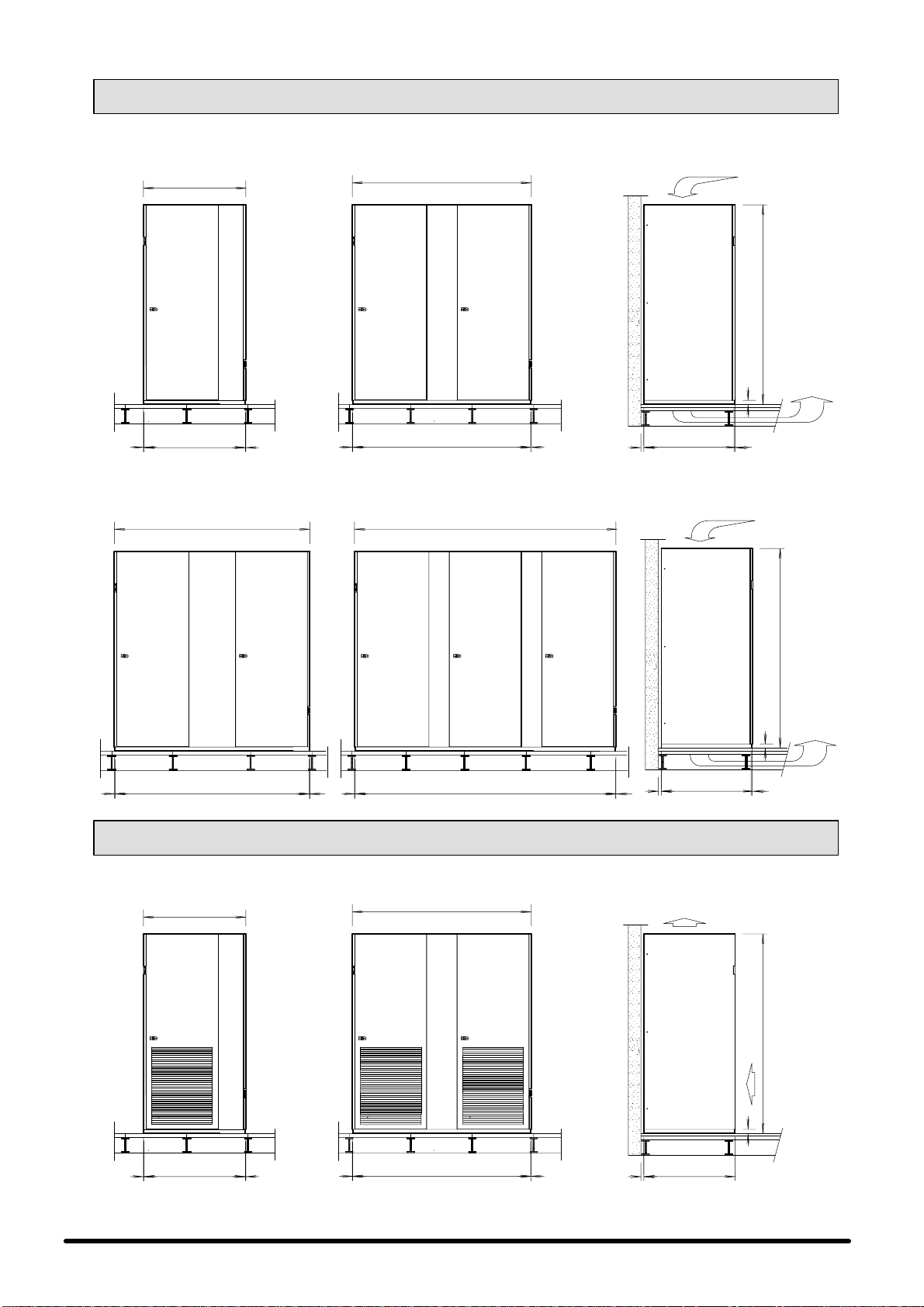

2.2 − Overall dimensions

27−45 UC 55−65−80−85 UC

Under Version

1000

5 990

90−10 UC 12−14 UC

2050

1750

1950

40

5

5

1740

2550

5

50

885

5

1950

40

5

2040

5

5

2540

50

5

885

5

Over Version

27−45 OC 55−65−80−85 OC

1000

1750

1950

English

5 990

40

5

5

1740

HIMOD−C

5

50

890

3

Page 8

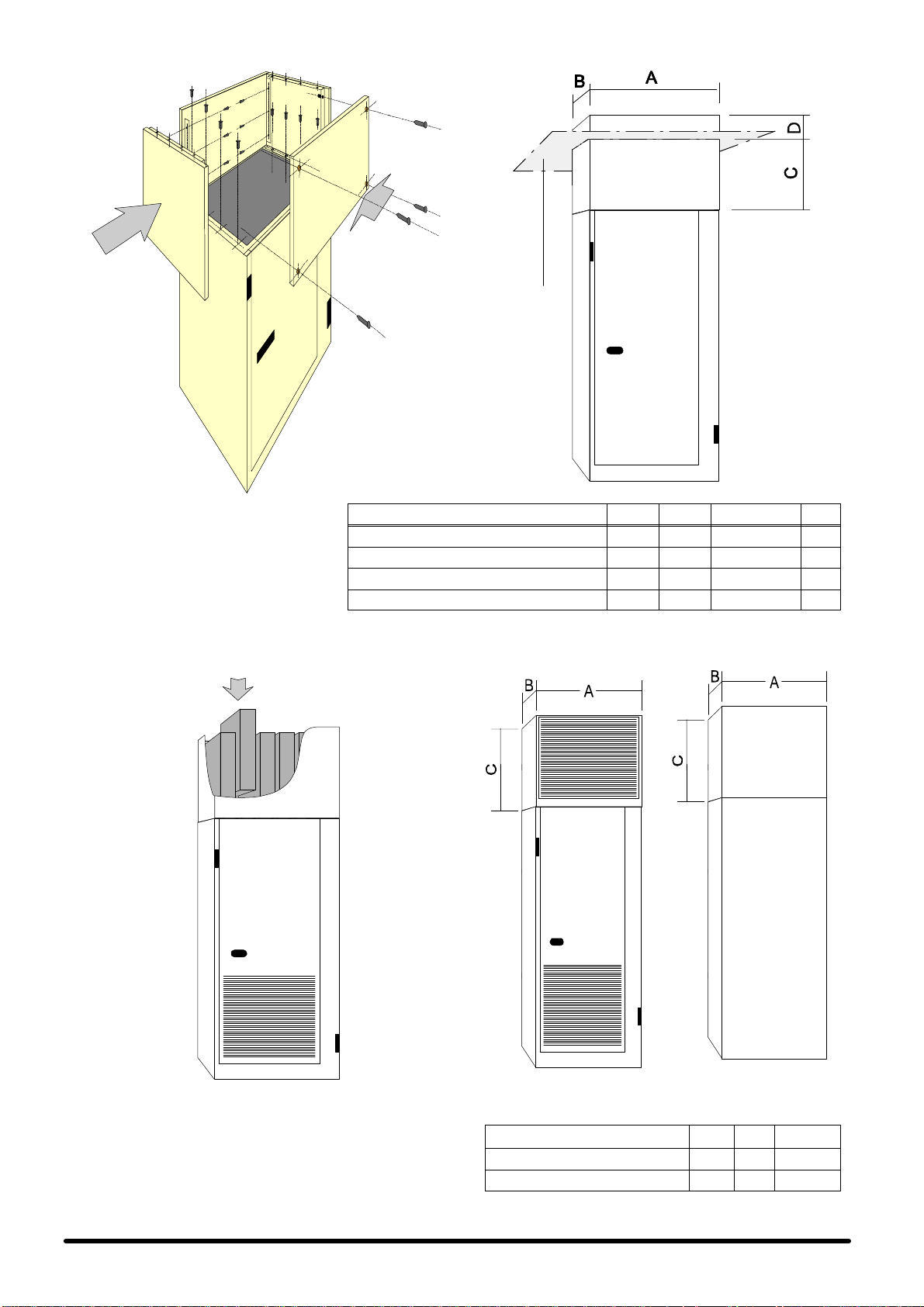

3 − Installation

ATTENTION: The conditioner must never be installed out of doors.

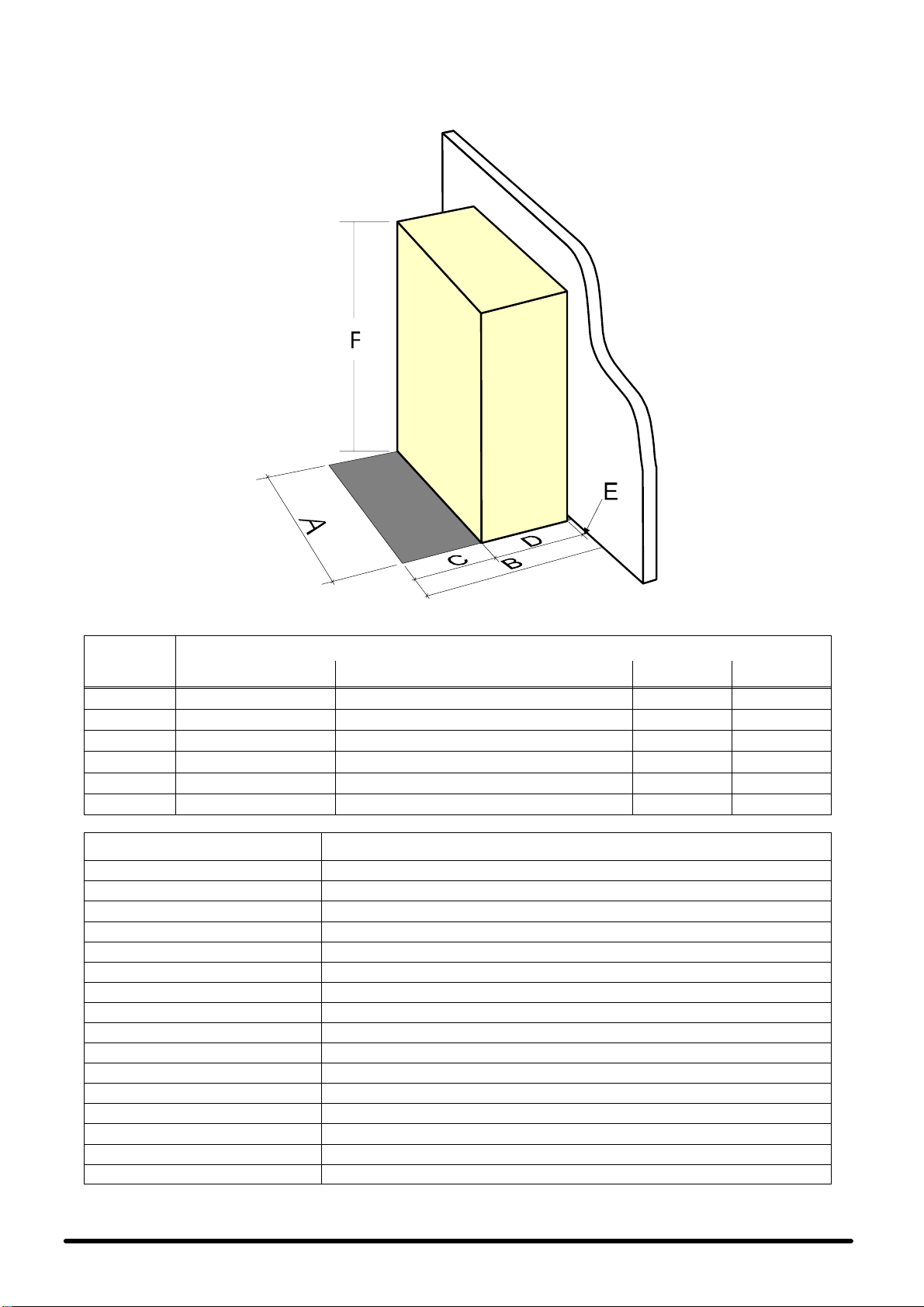

3.1 − Air inlet and outlet

27−45 C − under

55−65−80−85 C − under

27−45 C − under

55−65−80−85 C − under

90−10 C − under

12−14 C − under

90−10 C − under

12−14 C − under

A B C D

910 778 40 52

1580 778 80 52

E F G H L

910 804 43 43 45

1660 804 43 43 45

A B C D

1960 297 40 483

2460 297 40 483

E F G H L

1960 799 43 46 45

2460 799 43 46 45

Look−through rear view

ATTENTION: About the upflow (over) units, the extraordinary removal of the fan (560 mm blade diameter) is permitted only from the top of the unit.

Please keep it on mind during the possible ducting design and manufacturing.

3.2 − Hole in raised floor

27−45 C 55−65−80−85 C

without base frame with base frame without base frame with base frame

A [mm] 900 1000 1650 1750

B [mm] 810 885 810 885

C [mm] 93 48 93 48

90−10 UC 12−14 UC

without base frame with base frame without base frame with base frame

A [mm] 1970 2050 2470 2550

B [mm] 810 885 810 885

C [mm] 93 48 93 48

CAUTION: For "UNDER" units installed on raised floor, inhibit inappropriate access to the unit from the base to

not−authotized staff: i.e. fixing the floor panels up to 850 mm from the unit.

4

HIMOD−C

English

Page 9

3.3 − Extension hood

false ceiling

27−45 C

55−65−80−85 C

90−10 UC

12−14 UC

3.4 − Extension hood with sound reduction cartridges (Over unit)

A B C D

1000 890 500 / 1200 30

1750 890 500 / 1200 30

2050 890 500 / 1200 30

2550 890 500 / 1200 30

3.5 − Horizontal discharge hood (Over unit)

English

HIMOD−C

front back

A B C

27−45 C

55−65−80−85 C

1000 890 600/900

1750 890 600/900

5

Page 10

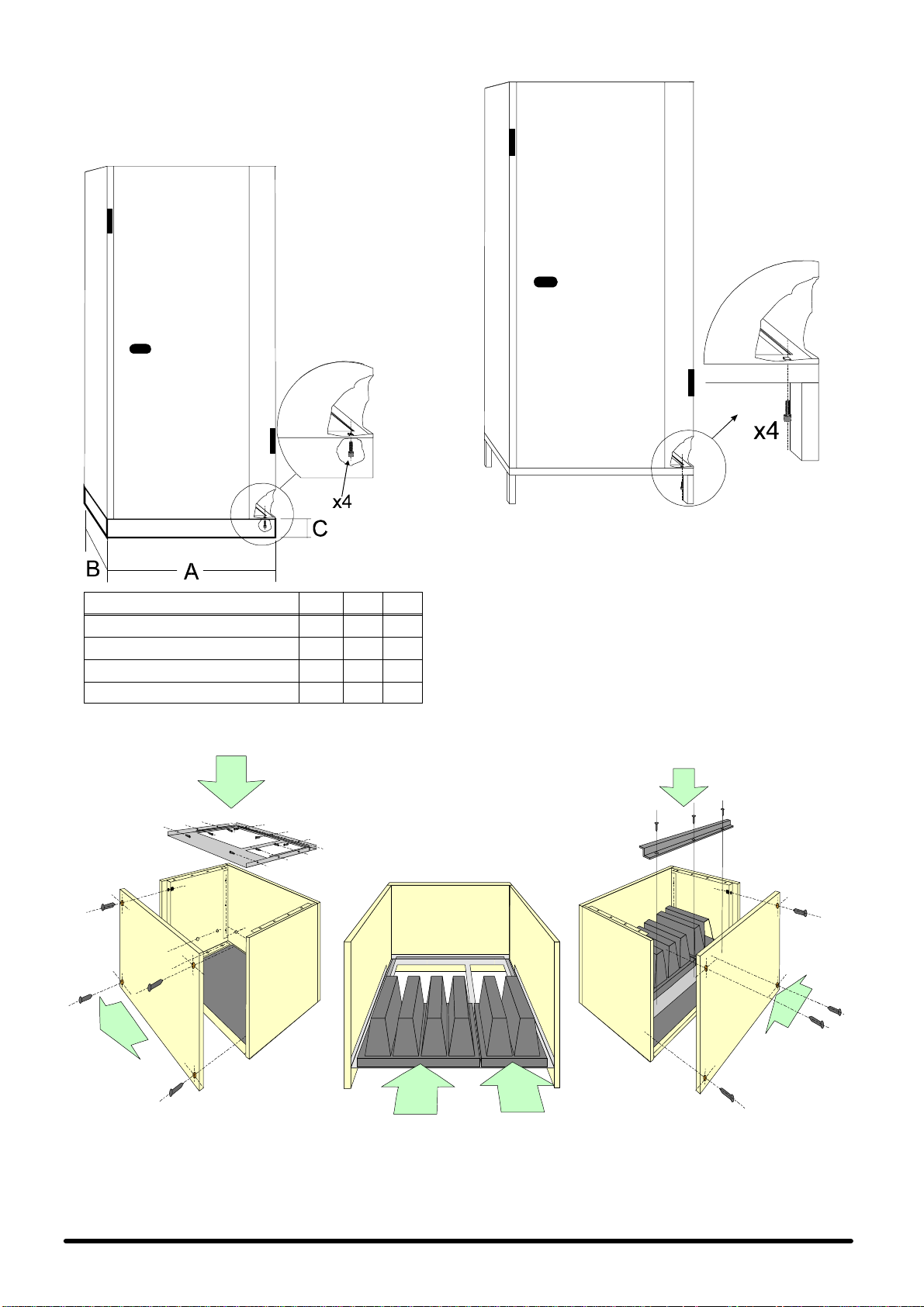

3.6 − Base module

If there is no raised floor below the unit it must be

placed on a base module to allow access to the external

connections.

The conditioner is connected to the base module by 4

screws.

3.7 − Base frame

27−45 C

55−65−80−85 C

90−10 UC

12−14 UC

3.8 − High efficiency filters

A B C

990 885 200

1740 885 200

2040 885 200

2540 885 200

6

HIMOD−C

English

Page 11

3.9 − New Air module

UNDER

(C version)

UNDER

(Mod. 90−10 − C version)

OVER

(C version)

UNDER

(Mod. 12−14 − C version)

English

HIMOD−C

7

Page 12

4 − Water connections

4.1 − General warnings

ENSURE THAT THE TUBING DOES NOT OBSTRUCT THE AIR FLOW(Under only).

IF THE TUBING IS TO RUN OUTDOORS, ADD

ETHYLENE GLYCOL TO THE CIRCUIT AS DESCRIBED IN PARA. 4.4.

4.2 − Auxiliary water connections

− Condensate drain (Fig. 1):

S Use galvanized steel, PVC or flexible polythene

tubing.

S Allow a 2% gradient towards the drain outlet.

S There must be a drain trap (1) placed at least 30

mm below the drain tray (2).

S Fill the drain trap with water (3).

Fig. 1 − Condensate drain

2

1

3

min.

30 mm

S Place shut−off ball valves (3) at the conditioner in-

let and outlet to allow easy maintenance.

S It is useful to install a thermometer (4) and a ma-

nometer (5) at the conditioner inlet and outlet.

S Install a water drain tap (6) at the lowest point in

the circuit.

S Place a control valve (7) in the outlet water tubing.

S Fill the circuit with water/glycol (see below), up to

a maximum pressure of 7 bar.

Fig. 2 − Chilled water circuit

Air

conditioner

2

1 6

4 5

7 3

BRACKET

to be

connected

by user

− Humidifier (optional): See App. A.

− Hot water (optional):

S Use copper or steel (Mannesmann) tubing.

S Insulate both tubes using Armaflex insulation.

4.3 − Chilled water connections

S Use copper or steel (Mannesmann) tubing.

S Place the tubing on supporting saddles (1).

S Insulate both tubes using Armaflex insulation (2).

4.4 − Adding ethylene glycol

Tab. 2 − Ethylene glycol to be added to water

freezing temperature

(_C)

ethylene glycol to add to

water (% in weight of

total mixture)

N.B. Values are for Shell antifreeze 402. For different brands check manufacturer’s data.

0 −5 −11 −18 −27 −39

0 10 20 30 40 50

NOTES:

S To avoid stratification run the circulation pump for

at least 30 min. after adding any glycol.

S After adding water to the water circuit, disconnect

the unit from the sanitary water piping system; in

this way the water mixed with glycol won’t return

into the same piping system.

S After any topping−up of water check the glycol

concentration and add any glycol if necessary.

S The hydraulic features of the system vary by adding

glycol. Therefore check the head and the flow rate

of the pump to be used.

8

HIMOD−C

English

Page 13

Fig. 3 − Chilled water connections

POS

CONNECTION

Himod C

under

27−45

140

125

A

B

Right side view

(DX)

120

150

Frontal view

BA

55−65−80−85

140

125

A

B

Right side view

(DX)

120

150

BA

Frontal view

DIMENSION

.

27C 45−55C 65−80−85C

A Chilled water inlet 1 " female 1 ¼" female 1 ½" female

B Chilled water outlet 1 " female 1 ¼" female 1 ½" female

English

HIMOD−C

9

Page 14

Fig. 4 − Chilled water connections

POS

CONNECTION

200

Himod C

under

90 − 10

95

A

B

Right side view

(DX)

100

180

BA

Frontal view

12−14

200

95

A

B

Right side view

(DX)

110

185

BA

Frontal view

DIMENSION

.

90−10 C 12−14 C

A Chilled water inlet 2 " male 2 ½" male

B Chilled water outlet 2 " male 2 ½" male

10

HIMOD−C

English

Page 15

Fig. 5 − Chilled water connections

POS

CONNECTION

27−45

160 / 200

Himod C

over

220

BA

55−65−80−85

150

Frontal view

300

Left side view

(SX)

A

B

90 (80−85 C)

170 (55−65 C)

220

150

BA

Frontal view

300

A

B

Left side view

(SX)

DIMENSION

.

27C 45−55C 65−80−85C

A Chilled water inlet 1 " female 1 ¼" female 1 ½" female

B Chilled water outlet 1 " female 1 ¼" female 1 ½" female

English

HIMOD−C

11

Page 16

Fig. 6 − Auxiliary water connections

Under single / double

Himod C

under/over

Frontal view

155

D

E

27−45−55−65

A

B

C

27−45

Over single / double

27−45 55−65−80−85

Left side view

80

145

E

D

80−85

A

B

C

(SX)

E

D

27−45−55−65 80−85

55−65−80−85

105

215

90

D

E

27−45

55−65−80−85

Frontal view

POS.

105

D A

E

170

B

C

CONNECTION DIMENSION

A HUMIDAIR water supply (optional) ½" G male

B HUMIDAIR water drain (optional)

C Condensate drain

D/E (small) Hot water inlet/outlet (optional)

D/E (big) Hot water inlet/outlet (optional)

12

Frontal view

D

E

HIMOD−C

105

170

Left side view

(SX)

D A

E

22 mm female

20 mm female

18 x 1 mm

22 x 1 mm

590

B

C

English

Page 17

Fig. 7 − Auxiliary water connections

90−10

135105

Himod C

under

Frontal view

12−14

90 490 85

B

A

E

Left side view

(SX)

C

D

135105

67

D

E

B

A

C

English

POS.

Frontal view

90 480 85

B

A

E

C

D

CONNECTION DIMENSION

Left side view

(SX)

A HUMIDAIR water supply (optional) ½" G male

B HUMIDAIR water drain (optional)

C Condensate drain

D/E Hot water inlet/outlet (optional)

22 mm female

20 mm female

22 x 1 mm

HIMOD−C

67

D

E

B

A

C

13

Page 18

Fig. 8 − Water circuit

Himod C

27−55−65

5

3

1

2

4

COOLING WATER INLET

COOLING WATER OUTLET

HOT WATER OUTLET

HOT WATER INLET

POS. DESCRIPTION

1 Chilled water coil

2 Reheating coil (optional)

3 ON−OFF 3−way valve (optional)

4 Chilled water 3−way valve

5 Air purge valve

14

HIMOD−C

English

Page 19

Fig. 9 − Water circuit

Himod C

45−80−85−90−10−12−14

1

5

3

1

2

4

COOLING WATER INLET

COOLING WATER OUTLET

HOT WATER OUTLET

HOT WATER INLET

POS. DESCRIPTION

1 Chilled water coil

2 Reheating coil (optional)

3 ON−OFF 3−way valve (optional)

4 Chilled water 3−way valve

5 Air purge valve

English

HIMOD−C

15

Page 20

5 − Electrical connections

5.1 − Electrical connections

1) Before proceeding with the electrical connections,

ensure that:

S all electrical components are undamaged;

S all terminal screws are tight;

S the supply voltage and frequency are as indicated

on the unit.

2) Power supply cable connections (see Fig. 10):

S Connect the cable to the Line inlet terminal

board.

S Use the cable size defined according to the flow

(see Fig. 11), the supply voltage and the installation type.

S Protect the supply using a back−up fuse.

Fig. 10 − Supply cable passage

3) Wiring connections:

4) In case of short circuit, check the sticking of the in-

S Do not fit the supply cable in the raceways inside

the machine electric board.

S Use multipolar cables with sheath (CEI20−22)

only.

S Connections for remote on−off and hot water

consent must be done by the installer.

S The General Alarm terminals allow remote

alarm signalling.

volved remote control switch and possibly replace

it.

Under unit

(Mod. 90−10 C version)

Under unit Over unit

Under unit

(Mod. 12−14 C version)

16

HIMOD−C

English

Page 21

Fig. 11 − Electrical connections

(F): Cooling

()

(F+C): Cooling + Electrical heating

() g

an(s)

heating,

humidification

Fan(s) + heating, + humidification

AUXILIARY TERMINAL BOARD

clogged

filter (CF)

remote on−off

user alarm

(or AAP)

G0

24 24 191111 50 020 3002 24 055G0GGG0 5533 102

smokestat

firestat (AAP)

water

leakage

(LWD)

fans

operating

70

NO*

C*NC*

72 73 400 401 40271

GENERAL ALARM

401 − 402: alarm signal

401 − 400: alarm off

* unit under power

Tab. 3 − Electrical data

CONFIGURATION MODELS

(F): Cooling

Fan(s)

(F+C): Cooling + Electrical heating

F

Fan(s) + heating

(F+C+H): Cooling + Electrical

heating + Humidity

+

+

27 – 45 C

55 – 65 – 80 – 85 C

90 − 10 U C

12 − 14 U C

27 – 45 C

55 – 65 – 80 – 85 C

90 − 10 U C

12 − 14 U C

27 – 45 C

55 – 65 – 80 – 85 C

90 − 10 U C

12 − 14 U C

Supply cable inlet

50 Hz

FLA

(A)

LRA

(A)

3ph / 400V

4,8 16,0 10A

9,7 32,0 16A

17,3 35,6 16A

17,3 53,4 25A

13,3 16,0 16A

26,7 32,0 32A

34,3 35,6 50A

34,3 53,4 50A

22,3 16,0 32A

35,7 32,0 50A

47,3 35,6 63A

47,3 53,4 63A

RESIDUAL−CURRENT CIRCUIT BREAKERS

Inn = 0.3A (400V)

English

HIMOD−C

17

Page 22

60 Hz

(F): Cooling

(F+C): Cooling + Electrical heating

(F): Cooling

(F+C): Cooling + Electrical heating

(F): Cooling

(F+C): Cooling + Electrical heating

CONFIGURATION MODELS

(F): Cooling

Fan(s)

(F+C): Cooling + Electrical heating

Fan(s) + heating

(F+C+H): Cooling + Electrical

heating + Humidity

Fan(s) + heating + humidification

(F): Cooling

Fan(s)

(F+C): Cooling + Electrical heating

Fan(s) + heating

(F+C+H): Cooling + Electrical

heating + Humidity

Fan(s) + heating + humidification

(F): Cooling

Fan(s)

(F+C): Cooling + Electrical heating

Fan(s) + heating

(F+C+H): Cooling + Electrical

heating +Humidity

Fan(s) + heating + humidification

3ph / 208−230V

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

27 – 45 C

55 – 65 – 80 – 85 C

FLA

(A)

8,9 35,4 16A

17,8 70,8 25A

24,3 35,4 32A

48,6 70,8 50A

33,3 33,3 63A

57,6 57,6 80A

LRA

RESIDUAL−CURRENT CIRCUIT BREAKERS

(A)

3ph / 380V

4,9 20,4 10A

9,7 40,8 16A

13,8 20,4 16A

27,5 40,8 32A

22,8 22,8 40A

36,5 36,5 50A

3ph / 460V

4,0 16,0 10A

8,0 32,0 10A

11,4 16,0 16A

22,7 32,0 25A

20,4 20,4 32A

31,7 31,7 40A

Inn = 0.3A (400V)

NOTES:

S The cables have to be sized in compliance with local standards and according to the type and characteristics (e.g. Amperes) of installation.

S The specific power the user−installed switch allows must be lower than 300,000 A2 x s.

S Prescriptions on the differential relay required to the user:

S for special places (healthcare facilities, etc...) comply with the local regulations;

S For ordinary places, a low sensitivity is suggested (300 mA) coordinated with the value of the ground heater (IEC 364): Ra v 50/Ia (Art.

413.1.4.1, CEI 64−8);

S In case of frequent over−voltages with mains impulse, it is advisable to install a selective differential and to evaluate the need for adopting

other devices.

S (Models 90−10−12−14 U C only) The value of current (Full Load Ampere) is calculated considering electric heaters running at a capacity

of 17,55 kW, configuration F+C and F+C+H.

18

HIMOD−C

English

Page 23

5.2 − Fan connections

The fan is electrically feeded by an autotransformer

that is connected by the constructor in order to obtain

the nominal air flow and the Available External Static

Pressure (AESP).

To change the factory connection proceed as follow:

− identify the unit’s graph;

− check the factory fan blocks connection ( or )

and correct if necessary (see Fig. 12);

− find the output connectors and the bridges corresponding to the graph values (see para. 5.3;

− connect the bridges and the output connectors;

− connect the 400V supply cables to the C" terminals.

− choose the curve’s point where both the air flow

and the static pressure are the most suitable for the

installation;

After a wiring modification, execute a

loadless test on the autotransformer.

Check the voltage of each wire, in order

not to damage the transformer (always

refer to the output voltage column va-

lues).

N.B. A FAN SPEED VARIATION CHANGES THE WOR-

KING CONDITION OF THE UNIT.

Fig. 12 − Example of electrical connection to the autotransformer

AUTOTRANSFORMER

In the example picture, the power supply

voltage required is 260 V, at 50 Hz.. The fan

blocks are connected.

FAN MOTOR

Reference colors:

u1 : brown v1 : light blue

w1 : black u2 : red

v2 : grey w2 : orange

klixon: white PE : yellow/green

E

E

E

260V

autotransformer

output

English

HIMOD−C

19

Page 24

Tab. 4 − Autotransformer output connections

50 Hz

autotrasformer outlet voltage

(1)

185 E A ↔ H 185 −

200 E A ↔ G 200 −

215 E A ↔ F 215 −

230 A − 230 −

245 F A ↔ E 245 −

260 G A ↔ E 260 −

275 H A ↔ E 275 160 (156)

280 E B ↔ G 280 160 (162)

295 E B ↔ F 295 170 (167)

310 B − 310 180 (179)

325 F B ↔ E 325 180 (185)

340 G B ↔ E 340 200 (196)

355 H B ↔ E 355 200 (202)

370 E C ↔ G 370 210 (214)

385 E C ↔ F 385 220 (219)

400 C − 400 230 (231)

output

connectors

output STD graph value

bridge fan connection fan connection

60 Hz

autotrasformer outlet voltage

(1) connection: fan inlet voltage = autotrasformer outlet voltage

(1)

190 E B ↔ G 190 −

208 A − 208 −

210 E B ↔ F 210 −

230 B − 230 −

250 F B ↔ E 250 −

270 G B ↔ E 270 160 (156)

290 H B ↔ E 290 170 (167)

320 E C ↔ H 320 180 (179)

340 E C ↔ G 340 200 (196)

360 E C ↔ F 360 210 (214)

380 C − 380 220 (219)

400 F C ↔ E 400 230 (231)

420 G C ↔ E 420 −

440 H C ↔ E 440 −

460 D − 460 −

connection: fan inlet voltage = autotrasformer outlet voltage multiplied by 0.577

output

connectors

output STD graph value

bridge fan connection fan connection

20

HIMOD−C

English

Page 25

Tab. 5 − Standard fan connections for HIMOD with autotransformer

50 Hz

Standard

Model

25/27U C 215

35/45U C 215

50/55U C 230

60/65U C 230

70/80U C 230

75/85U C 230

90U C 260

10U C 280

12U C 260

14U C 325

autotrasformer outlet voltage

(1)

connections output connectors bridge

E A ↔ F

E A ↔ F

A −

A −

A −

A −

G A ↔ E

E B ↔ G

G A ↔ E

F B ↔ E

25/27O C 230

35/45O C 230

50/55O C 230

60/65O C 230

70/80O C 230

75/85O C 230

Model

27U C 250

45U C 250

55U C 260

65U C 260

80U C 280

85U C 280

27O C 270

45O C 270

55O C 260

65O C 260

80O C 280

85O C 280

autotrasformer outlet voltage

(1)

A −

A −

A −

A −

A −

A −

60 Hz

Standard

connections output connectors bridge

F B ↔ E

F B ↔ E

G A ↔ E

G A ↔ E

E B ↔ G

E B ↔ G

G B ↔ E

G B ↔ E

G A ↔ E

G A ↔ E

E B ↔ G

E B ↔ G

(1) connection: fan inlet voltage = autotrasformer outlet voltage

connection: fan inlet voltage = autotrasformer outlet voltage multiplied by 0.577

English

HIMOD−C

21

Page 26

Tab. 6 − Electrical data

component

Model

27U C 4.3 4.4 16 1.4

45U C 4.3 4.4 16 1.4

55U C 2 x 4.3 2 x 4.4 2 x 16 2 x 1.5

65U C 2 x 4.3 2 x 4.4 2 x 16 2 x 1.5

80U C 2 x 4.3 2 x 4.4 2 x 16 2 x 1.5

85U C 2 x 4.3 2 x 4.4 2 x 16 2 x 1.5

90U C 2 x 5.8 2 x 6.0 2 x 17.8 2 x 2.4

10U C 2 x 5.9 2 x 6.0 2 x 17.8 2 x 2.6

12U C 3 x 5.9 3 x 6.0 3 x 17.8 3 x 2.5

14U C 3 x 5.9 3 x 6.0 3 x 17.8 3 x 3.1

27O C 4.3 4.4 16 1.5

45O C 4.3 4.4 16 1.5

55O C 2 x 4.3 2 x 4.4 2 x 16 2 x 1.5

65O C 2 x 4.3 2 x 4.4 2 x 16 2 x 1.5

80O C 2 x 4.4 2 x 4.4 2 x 16 2 x 1.6

85O C 2 x 4.4 2 x 4.4 2 x 16 2 x 1.6

OA

(A)

50 Hz

(3ph − 160 400V)

FLA

(A)

FAN

LRA

(A)

absorbed power

(kW)

60 Hz

component

Model

OA

(A)

FLA

(A)

27U C 3.4 3.5 16 1.1

45U C 3.4 3.5 16 1.2

55U C 2 x 3.3 2 x 3.5 2 x 16 2 x 1.2

65U C 2 x 3.4 2 x 3.5 2 x 16 2 x 1.2

80U C 2 x 3.2 2 x 3.5 2 x 16 2 x 1.2

85U C 2 x 3.3 2 x 3.5 2 x 16 2 x 1.2

27O C 3.3 3.5 16 1.2

45O C 3.3 3.5 16 1.2

55O C 2 x 3.3 2 x 3.5 2 x 16 2 x 1.2

65O C 2 x 3.3 2 x 3.5 2 x 16 2 x 1.2

80O C 2 x 3.3 2 x 3.5 2 x 16 2 x 1.3

85O C 2 x 3.3 2 x 3.5 2 x 16 2 x 1.3

1. The fan OA" value and the absorbed power are refered to standard air flow; Under unit with underflow air discharge and 20 Pa available external static pressure; Over unit with ducted air discharge and 50 Pa available external static pressure.

NOTE: the indicated fan currents are measured on their terminal boards; to calculate the current absorption of the fans to the machine supply

terminals multiply the indicated values by the selected transforming ratio (see Tab. 4).

FAN

(3ph − 160 460V)

LRA

(A)

absorbed power

(kW)

22

HIMOD−C

English

Page 27

Tab. 7 − Optional electrical data

9.0

5.8

C

13.0

9.0

15.0

5.8

9.0

5.8

8.0

5.8

Component ELECTRICAL HEATING HUMIDIFIER

Model FLA (A) rated power [kW] FLA (A) rated power [kW]

(400V / 3Ph / 50Hz)

27−45 U/O C 8.5 5.85

55−65−80−85 U/O C 17.0 11.70

90−10−12−14 U

Component ELECTRICAL HEATING HUMIDIFIER

Model FLA (A) rated power [kW] FLA (A) rated power [kW]

17.0 11.70

25.4 17.55

(208−230V / 3Ph / 60Hz)

27−45 U/O C 15.4 5.85

55−65−80−85 U/O C 30.8 11.70

50 Hz

60 Hz

(380V / 3Ph / 60Hz)

27−45 U/O C 8.9 5.85

55−65−80−85 U/O C 17.8 11.70

(460V / 3Ph / 60Hz)

27−45 U/O C 7.4 5.85

55−65−80−85 U/O C 14.7 11.70

5.3 − Aeraulic features

The aeraulic features, namely the values of the useful

static pressure while the voltage changes (graphs), can

be surfed on the Web at the following address:

www.HIROSS.IT/pde/TDS/Aeraulic_features

This document is password−protected. Ask for the password

to your Dealer/Area Manager.

English

HIMOD−C

23

Page 28

6 − Start−up

6.1 − First start−up (or after long stand-

still)

Start the air conditioner as follows:

1) Open all valves in the water circuit according to the

instruction label attached to the valve.

2) Check that there are no water leakages.

3) Bleed all air out of the chilled water circuit using

the bleed valve on the chilled water coil.

4) Close all MCBs on the electrical panel.

5) Check the supply voltage on all phases.

6) Start the unit by pressing ON OFF (see Fig. 13).

7) Check the electrical absorption of all components

(see Chap. 5).

8) Ensure that the fans rotate in the correct direction

(see arrow on fan).

CAUTION: risk of contact with rotating devices.

9) Ensure that all control system settings are correct

and that there are no alarms (see Control manual).

10)Verify the water flow.

11)Verify the Fresh Air Intake operation (if fitted).

12)Once the system is operating under load, check the

various components, as follows:

S Verify that the fans are operating properly.

S Ensure that the temperature and relative hu-

midity are being controlled, and that the humidifier (optional) and heating steps (optional) operate when required.

S Ensure that chilled water valve operates when

required.

6.2 − Starting and stopping

Turn on the unit operating on the ON/OFF switch placed on the left case of the unit (Fig. 13). If the ON/OFF

remote device is not installed, the green LED on the

Microface case will light up together with the LED placed below the ON/OFF switch. The fan starts immediately (the fan always works when the unit is ON); after 2 minutes the regulation is activated, so the cooling

(compressor), heating (electric heaters), humidifying

and dehumidifying devices can start.

Adjust the set−point as indicated in Control ma-

nual.

Stop the unit putting the ON/OFF switch in OFF.

S The main switch QS should only be switched off if

the unit is stopped for a long period of time.

6.3 − Automatic restart

If desired, the unit will automatically restart on the return of power after a supply interruption (see Control

manual).

Fig. 13 − On−Off switch

7 − Operation

Unit operation is completely automatic. The below sequence explains how the unit operates :

S The air, sucked in by the fan(s), enters the unit.

S The air is immediately filtered.

S The TEMPERATURE sensor or HUMITEMP (tem-

perature + rel. humidity) sensor (check type

installed), verifies the state of the inlet air, and relays

this information to the control system.

S The control system compares the relayed informa-

tion to the set point and proportional band values

programmed into its memory: it then commands the

air conditioner to treat the air as follows (see also

Control manual):

S COOLING

Chilled water flows through the chilled water

coil, thus cooling the air passing over it. The

chilled water flow is controlled by a timed modulating (3−way) valve, which regulates the flow

rate in order to obtain the exact amount of cooling required.

S HEATING

This can take one of two forms:

− electrical heating (optional): the heating elements heat the air passing over them. There are

3 heating steps.

− hot water heating (optional): if hot water is

available, this flows through the hot water coil,

thus heating the air passing over it. The hot water flow is controlled by an on−off (3−way)

valve.

S DEHUMIDIFICATION − optional

Maximum chilled water flow is requested

through the coil, whose temperature drops below the dew point of the air, thus dehumidifying

it.

If necessary, heating is used to reheat the air.

N.B.: If, during dehumidification, the ambient

temperature drops below a specified level, dehumidification will be stopped if necessary (see

LOW LIMIT intervention in Control manual).

S HUMIDIFICATION − optional

The humidifier creates steam, which is distributed into the air stream via the steam distribution pipe (see also App. A).

24

HIMOD−C

English

Page 29

S Filtered new air is injected into the air stream via

the Fresh Air Intake.

S The treated air passes through the fans, which op-

erate continuously, and is then dispersed out of the

unit.

S Under unit only: the air passes from the underfloor

void into the room via air distribution outlets.

For "UNDER" units installed on raised floor:

switch off the machine before removal of the floor

panels within a distance of 850 mm from the machine, to avoid risks of contact with rotating devices

(see Fig. 15).

N.B.: Manual control can be performed using the control

system (see Control manual).

Fig. 14 − Position of the chilled water valve actuator

3 mm

Manual adjust-

A

B

ment with 3 mm allen key

7.1 − Chilled water valve

The 3−way valve controls the chilled water flow. It operates as follows (Fig. 14):

S When the valve is fully open (i.e. max. chilled water

flow) the actuator slot is set to ’1’.

S When the valve is closed (i.e. no chilled water flow)

the actuator slot is set to ’0’.

The valve running time is set to the value specified in

the Control Manual.

Note 1: In the unlikely event of control system failure,

the valve can be manually controlled by means of a 3

mm allen key placed into the actuator slot.

NEVER PERFORM THIS OPERATION USING A

SCREWDRIVER.

Note 2: For models 90−10−12−14 UC the chilled water valve is not foreseen for the manual operation.

When actuator stem is completely down the valve is

closed (by−pass 100%), when actuator stem is completely up the valve is open (by−pass 0%) and all water

flows into the coil.

B

3

m

m

3 mm

A

Position indicator in

Position 0 = CLOSED

Valve Closed

(by−pass open)

Position indicator in

Position 1 = OPEN

Valve fully Open

(by−pass closed)

Fig. 15 − Floor panels removal on a safety way

850 mm

English

HIMOD−C

25

Page 30

8 − Calibrations

S The air conditioner has already been factory−te-

sted and calibrated as shown below.

COMPONENT SETTING NOTES

Fan differential

pressure switch

Clogged filter

differential pressure switch

(CF)

0.8 mbar

Filters G4 = 2 mbar

9 − Maintenance / Spare Parts

AS THE HIROMATIC/MICROFACE FEATURES

AUTOMATIC RESTART (AFTER A SUPPLY INTERRUPTION) IT IS ADVISED TO EITHER DISABILITATE AUTORESTART OR TO OPEN

SWITCH QS WHEN PERFORMING ANY MAINTENANCE.

Maintenance schedule − Monthly check

Check that the fan motor rotates freely without any abnormal noise, and en-

FANS

AIR FILTERS

NEW AIR FILTER

(if fitted)

CONTROL SYSTEM Verify the operation of LEDs, display and alarms.

HUMIDIFIER

(if fitted)

ELECTRICAL

CIRCUIT

CHILLED WATER

CIRCUIT

sure that the bearings are not running hot.

Also check the current absorption.

Verify the state of the filters; if necessary clean or replace them.

In very dusty ambients perform this check more frequently.

Verify the state of the filter; if necessary clean or replace it.

See App. A.

S Check the electrical supply on all phases.

S Ensure that all electrical connections are tight.

S Ensure that there are no water leaks.

S Bleed any air out of the chilled water circuit using the bleed valve situa-

ted on the top right of the chilled water coil.

S Verify the correct chilled water flow.

S Check the inlet − outlet fluid temperature and pressure using the ther-

mometers and manometers, if fitted.

S On a daily basis check the HIROMATIC/MICRO-

FACE readings for temperature and, if shown, rel.

humidity.

S The Maintenance Programme below should be car-

ried out by a qualified technician, preferably working under a maintenance contract.

calibrate

9.1 − Spare parts

It is recommended the use of original spare parts.

When placing an order refer to Component List" enclosed with the machine and quote the unit model no.

and serial no.

9.2 − Dismantling the unit

The machine has been designed and built to ensure

continuous operation.

26

The working life of some of the main components,

such as the fan and the compressor, depends on the

maintenance that they receive.

If the unit has to be dismantled, this operation must be

done by skilled refrigeration technicians.

HIMOD−C

English

Page 31

App. A − HUMIDAIR humidifier

App. A.1 − Preface

The HUMIDAIR represents the best humidifier

technology available, guaranteeing the steam as clean

as possible together with simple maintenance.

Tab. 8 − Humidair specifications

steam

HUMIDAIR KIT

model code kg/h (*) V/ph/Hz (l) (l/min.) (l/min.)

HAK 93H

HAK 93L

For humidifier current (FLA) and rated power refer to electrical features in air conditioner manual.

(*) Unit is factory−set to produce 70% of the maximum value (see Microface manual).

141103 2.7 − 9.0

141104 2.7 − 9.0

production

(variable)

humidifier

power supply

voltage

380 460 V

trifase

50−60 Hz

208 230 V

trifase

50−60 Hz

App. A.2 − Installation

The humidifier is supplied already mounted within the

air conditioner. The only necessary operations are the

connections for the supply water (Fig. 1) and drain wa-

In order to obtain optimum performance from the

HUMIDAIR it is advisable to read this manual carefully.

max. cylinder

water volume

5.34 0.6 2.5

5.34 0.6 2.5

max. supply

water quantity

ter (Fig. 2); for the positions of the supply/drain connections within the unit see Fig. 6 and Fig.7.

max. drain

water quantity

Fig. 1 − Supply water connection

SUPPLY WATER FEATURES

S The supply water temperature must never exceed 40_C.

S The supply water pressure must be between 0.3 and 6 bar.

If greater, use a pressure reducing valve set to 3−4 bar.

S Sanitary water should be used. Do not use demineralized

water or water containing impurities.

S Conductivity range : 125−1250 mS/cm.

water

supply

CUT−OFF TAP

Must be included in the

supply water tubing.

supplying limit

SUPPLY WATER TUBING

S It is supplied a 1−m−long plastic

tube, diameter 6 x 1mm with ½"

G m connections.

B

A

ALTERNATIVE SUPPLY

WATER TUBING

Unscrew the ring nut A and

connect a tube straight to

the 3/4"G Male connection

B on the humidifier.

English

A − 1

Page 32

Fig. 2 − Drain water connection

DRAIN WATER DEVICE

Dispose the drain water into

an ordinary drainage network,

using a funnel (the drainage

network must be able to withstand water temperatures up

to 100 _C).

NOTES:

1) Allow a 2% gradient towards the drain outlet.

2) Avoid back pressures in the drain piping.

WATER DRAIN TUBING

It is supplied a hose with an integral

drain trap.

K

L

DO NOT DISMANTLE THE

DRAIN TRAP.

S DO NOT DISMANTLE THE

DRAIN TRAP.

S The hose is already fitted onto

the humidifier drain outlet (K).

S Fill the drain trap with water

(L).

S The drain pipe is made of plastic

material which does not conduct electricity.

App. A.3 − Humidair components

The components of the HUMIDAIR humidifiers are

shown below.

Fig. 3 − The humidifier and its connections

DRAIN VALVE ASSEMBLY (D)

A

filling cup

H

SUPPLY VALVE (F)

F

O

overflow tube

from

humidifier

power

electrodes

steam

outlet

Y

Z

U

P

to electrical

supply

from

level sensor

to interface

L

S

level electrode

R

S

S

power electrodes

C

S

steam cylinder

A − 2

water

supply

supply valve

drain valve

G

F

V V

S

S

N

drain tank

D

S

T

E

water

drain

outlet

from

supply valve

to interface

from

supply valve

to interface

English

Page 33

App. A.4 − Start−up and operation

App. A.4.1 − Start−up

Before using the humidifier, check the following:

S Supply and drain connections.

S That the cut−off tap is open.

S All wiring.

S Earthing.

S Steam hose connection between steam cylinder

and distributor.

To start the humidifier simply switch on the air conditioner, which will in turn automatically start and stop

the humidifier as required. The (adjustable) parameters which determine humidifier operation have already been factory−preset (see HIROMATIC manual).

App. A.4.2 − Operation

Water, provided it contains even a small quantity of

salts in solution, is a conductor of electricity. Therefore, if the steam cylinder is filled with water and a potential difference is applied between the production

electrodes, the water behaves like an ordinary electrical resistance and becomes hot, thus creating steam.

The steam production rate can be controlled by varying the water level in the cylinder; the higher the water

level, the deeper the electrodes are immersed into it

and the greater the steam production.

Note 1

In case of low water conductivity the cylinder 93H (9.0

kg/h) or 53H (4.5kg/h) can be substituted with the cylinder 93L or 53L without changing the power supply.

Please remember to set the right cylinder type into the

Control system.

The steam production will remain unchanged.

Note 2

When starting with an empty cylinder, the water conductivity is normally insufficient for the HUMIDIFIER STEAM OUTPUT to be reached immediately.

Therefore the humidifier produces as much steam as

possible to fill the cylinder completely. Any evaporation water is immediately refilled.

The drain valve is kept shut and therefore, as the steam

does not contain any salts, the conductivity of the water within the cylinder slowly increases until the HUMIDIFIER STEAM OUTPUT is obtained.

The length of the start−up period depends upon the

water conductivity. For very conductive water it may

occur that the HUMIDIFIER STEAM OUTPUT is

obtained immediately.

App. A.5 − Maintenance

App. A.5.1 − Removing the steam cylinder

To remove the steam cylinder, proceed as follows (see

Fig. 3):

1) Open the General Switch relative to the humidifier.

2) Drain all the water from the cylinder by activating

"HUM. DRAIN" in the HIROMATIC Service

menu several times (see Microface manual).

3) Disconnect the steam hose (S) (made of non−conductive rubber).

4) Disconnect the power electrode wires (P) and level

sensor wire (L).

5) Undo the clip (R).

6) Pull the cylinder (C) out of its gland at the bottom

(G).

App. A.5.2 − Replacing the steam cylinder

When the steam cylinder is approaching the stage

where it needs to be replaced, warning A25 is generated (see HIROMATIC manual) to advise the user

that the cylinder must be replaced. To replace the cylinder, proceed as follows (see Fig. 3):

1) Carry out the instructions in para. Removing the

steam cylinder.

2) Using the new cylinder, carry out 4)−6) of para. 5.1

in reverse order.

3) Connect the steam hose (S); the clip on the hose

needs to be tightened only slightly.

4) Manually switch the humidifier on for 2−3 minutes

(in the HIROMATIC Service menu). Then switch

it off.

5) Drain the water as for 2) in para. Removing the

steam cylinder.

6) If the air conditioner features a HIROMATIC with

Graphic display, reset the humidifier working hours

(window no. 1 of PARAMETE R ME NU) to zero.

7) Close the General Switch relative to the humidifier.

App. A.5.3 − Annual maintenance

Annually (e.g. before any close−down period) carry

out the following service on the humidifier (see Fig. 3):

1) Carry out the instructions in para. Removing the

steam cylinder.

2) Disconnect the supply (F) and drain (D) valve wires.

3) Unscrew and remove the drain tank (T).

4) Unscrew the drain valve assembly screws (V).

5) Remove the drain valve assembly.

6) Unscrew and remove the drain valve solenoid (O).

7) Unscrew and remove the drain valve armature (A).

8) Clean all parts of the drain valve using a commercially available descaling agent (to remove any incrustations).

9) Detach the hose from the supply valve.

10)Remove the supply valve connection (N).

11)Unscrew the supply valve (F) and remove it.

12)Clean the supply valve using a jet of water.

13)Replace any hose which has become hard and

brittle.

14)Thoroughly flush the drain line (E).

15)Reassemble the humidifier by carrying out the

above instructions in reverse order.

ATTENTION

Always empty the cylinder completely before any close−down period.

English

A − 3

Page 34

App. A.6 − Spare part list

POSITION

CO

NJ

C

NJ

NJ

NJ

It is recommended the use of original spare parts.

When placing an order quote the part code, as well as

the air conditioner model no. and serial no.

POSITION

(see Fig. 3)

C

T 141200 Drain tank 1 1 1 1 1

U 141201 Filling cup 1 1 1 1 1

N 141300 Supply valve connection 1 1 1 1 1

K 2400006 Rubber gasket for drain tank 1 1 1 1 1

B 240007 Rubber gasket for supply valve connection 1 1 1 1 1

F

A 183205 Drain valve armature 1 1 1 1 1

H 183206 Drain valve housing 1 1 1 1 1

O 254001 Drain valve solenoid 1 1 1 1 1 (+)

X 254393 Connector for level electrode 1 1 1 1 1

Y 254394 Connector for production electrode 2 3 3 3 3

Z 271099 Base 1 1 1 1 1

(+) = Spare part recommended

(*) = Consumable material

DE DESCRIPTION

141070 Steam cylinder 140

141071 Steam cylinder 263

141072 Steam cylinder 243

141073 Steam cylinder 363

141074 Steam cylinder 343

183209 Complete supply valve

183204 Complete supply valve

275905 Isolator for level sensor 1 1 1 1 1

21L 53H 53L 93H 93L

1

1

INSTALLED QUANTITY

1

1

1

1 1 1 1

Notes

(*)

(*)

(*)

(*)

1

(*)

A − 4

English

Page 35

Il Fabbricante dichiara che questo prodotto è conforme alle direttive Europee:

The Manufacturer hereby declares that this product conforms to the European Union directives:

Der Hersteller erklärt hiermit, dass dieses Produkt den Anforderungen der Europäischen Richtlinien gerecht wird:

Le Fabricant déclare que ce produit est conforme aux directives Européennes:

El Fabricante declara que este producto es conforme a las directivas Europeas:

O Fabricante declara que este produto está em conformidade com as directivas Europeias:

Tillverkare försäkrar härmed att denna produkt överensstämmer med Europeiska Uniones direktiv:

De Fabrikant verklaart dat dit produkt conform de Europese richtlijnen is:

Vaimistaja vakuuttaa täten, että tämä tuote täyättää seuraavien EU-direktiivien vaatimukset:

Produsent erklærer herved at dette produktet er i samsvar med EU-direktiver:

Fabrikant erklærer herved, at dette produkt opfylder kravene i EU direktiverne:

Since the Liebert HIROSS Company has a policy of continuous

Ο ΚατασÀευαστÞj δηλþνει üτι το παÃüνπÃοΪüνεßναι ÀατασÀευασmÝνο αýmφωνα mετιj οδηγßεj τηj Ε.Ε.:

product improvement, it reserves the right to change design and

specifications without previous notice.

98/37/CE; 89/336/CEE; 73/23/CEE; 97/23/CE

Printed in Italy by Liebert HIROSS S.p A.

Issued by T.D.Service

Page 36

Zona Industriale Tognana

Via Leonardo da Vinci, 16/18

35028 Piove di Sacco (PD)

ITALY

Tel. +39 049 9719111

Telefax +39 049 5841257

Internet :

www.liebert-hiross.com

Since the Liebert HIROSS Company has a policy of continuous

product improvement, it reserves the right to change design and

specifications without previous notice.

Liebert HIROSS

is a division of

EMERSON

Printed in Italy by Liebert HIROSS S.p A.

Issued by T.D.Service

Loading...

Loading...