Page 1

POWER CONVERSION/DISTRIBUTION

Precision Power Center

TECHNICAL DATA MANUAL

Three Phase

15-225 kVA

50 & 60 Hz

Page 2

Page 3

Table of Contents

NO-COMPROMISE POWER DISTRIBUTION AT LOWER INSTALLED COST . . . . . . . . . . . . . . . . . . . . . .1

LIEBERT PACKAGED POWER SYSTEM ADVANTAGES COMPARED TO CONVENTIONAL,

BUILT-UP SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CAPACITIES AND CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

STANDARD FEATURES FOR ALL SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ADDITIONAL FEATURES FOR ALL SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

HARMONICS SOLUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SYSTEM MONITORING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Power Monitor Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Monitoring Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PHYSICAL/ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

HEAT OUTPUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

SYSTEM SIZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

SERVICE ACCESS AND CLEARANCE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figures

Figure 1 Conventional built-up system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2 Liebert Precision Power Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 3 Liebert Precision Power Center—Top Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 4 Precision Power Center, 1-4 panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 5 Top Exit Precision Power Center, 1-2 panelboards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 6 Precision Power Center diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 7 Dimensions, clearances, 1 panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8 Dimensions, clearances, 2 panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9 Dimensions, clearances, 3 panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10 Dimensions, clearances, 4 panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11 Dimensions, clearances, Top Exit unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table s

Table 1 Features available by model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2 Electrical and mechanical characteristics, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3 Electrical and mechanical characteristics, 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4 Electrical and mechanical characteristics, Top Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5 Heat output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

i

Page 4

ii

Page 5

No-Compromise Power Distribution at Lower Installed Cost

NO-COMPROMISE POWER DISTRIBUTION AT LOWER INSTALLED COST

Liebert Precision Power Centers offer distribution, computer-grade grounding, and monitoring. Unlike conventional built-up systems, these Liebert packaged power systems provide easy low-cost installation, simple

relocation, security, proven design and performance, electrical isolation, and effective noise suppression.

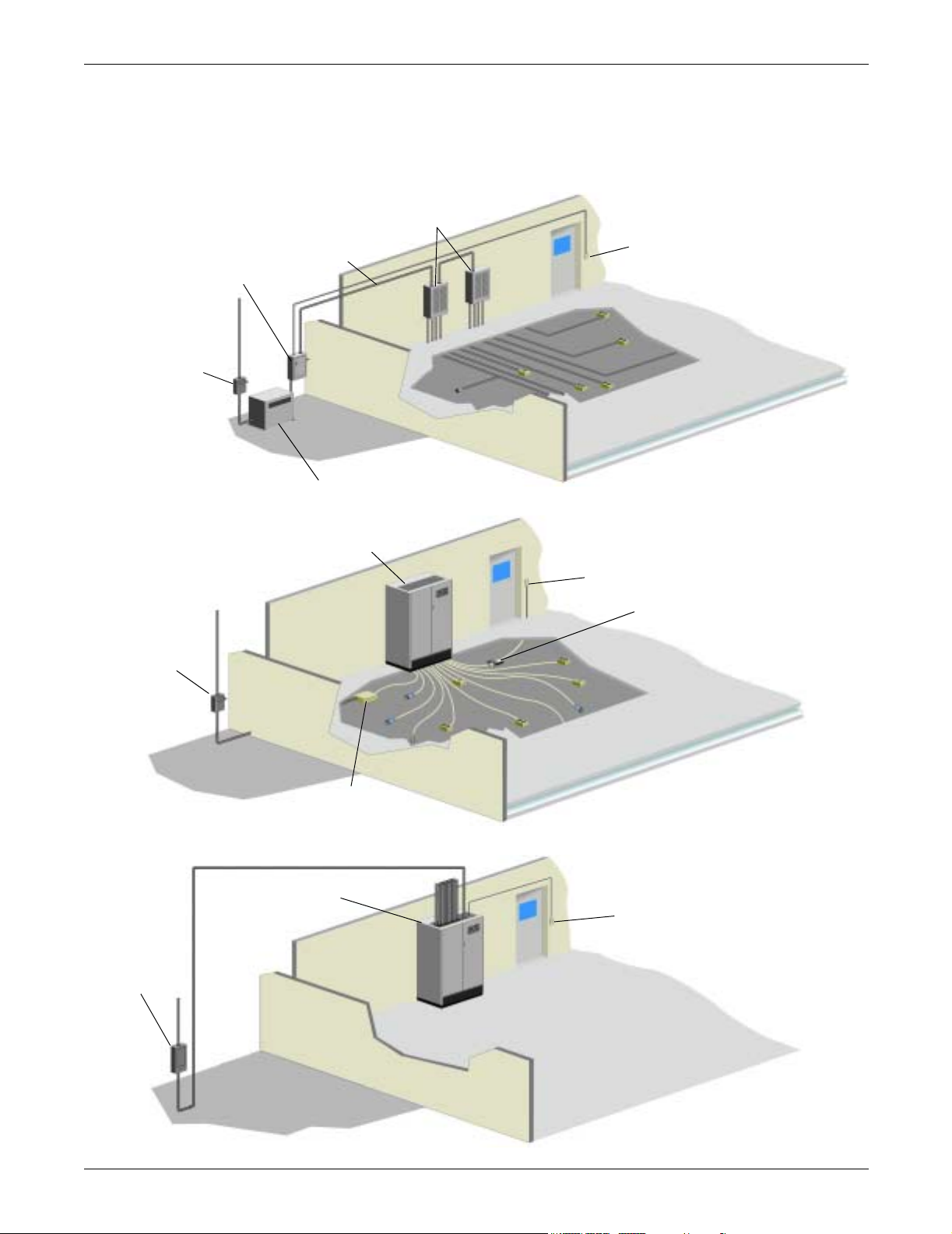

Figure 1 Conventional built-up system

Power Panels with Rigid

Conduit Distribution

Input

Circuit

Breaker

Output

Circuit

Breaker

4-wire

208/120V

Isolation Transformer

REPO

Figure 2 Liebert Precision Power Center

Power Panels with Flexible

Interconnecting Cables

Circuit

Breaker

Power J-Box

Figure 3 Liebert Precision Power Center—Top Exit

Top Exit Precision

Power Center

REPO

Control

J-Box

REPO

Circuit

Breaker

1

Page 6

Liebert Packaged Power System Advantages Compared to Conventional, Built-Up Systems

LIEBERT PACKAGED POWER SYSTEM ADVANTAGES COMPARED TO CONVENTIONAL,

UILT-UP SYSTEMS

B

Desirable Features Conventional Built-Up Systems Liebert Packaged Power System

Proven System

Design

Agency Approved

Factory Tested

Power Quality

Improvement

Computer-Grade

Grounding

Secure Distribution

Circuit Identification

Monitoring

Ease of Installation

Easy System

Expansion

Easy System

Rearrangement

Easy To Move

No. Each site is a one-of-a-kind installation.

“Design” depends on engineer and installer.

Not as a system. Even though listed

components may be used, site-fabricated

distribution is subject to acceptance by local

inspecting authorities.

No. Testing of performance is done at the site,

if at all.

Doubtful. Because of the variables in design

and installation, site-fabricated distribution

does not consistently offer computer-grade

power isolation or ground systems.

Difficult. Since site-fabricated distribution

seldom includes an isolation transformer in the

computer room, a local single point ground

system that minimizes common mode

disturbances is difficult to establish.

Possibly. Only if the entire distribution panel is

dedicated to the computer and the panel is in

the computer room.

Possibly. Circuit number and receptacle

references might be supplied, depending on

the installing electrician and available

information.

Seldom. Some add-on monitoring systems are

available, but monitoring also depends on the

installing electrician and available information.

No. All site-fabricated distribution wiring

becomes part of premises wiring.

No. Conduit installation and wire pulling is timeconsuming, and can hamper operations while

in progress.

No. Site-fabricated distribution cannot be easily

rearranged. Old conduit and wiring must be

removed and new installed.

No. New distribution must be built at the new

site and old conduit and wiring usually must be

removed from the former site.

Yes. Liebert power systems are complete,

proven-design, factory tested to ensure

consistent performance. Designed-in

distribution flexibility accommodates all

installation sites.

Yes. UL listing as a complete system is an

assurance of safety.

Yes. Factory testing the complete system

ensures performance and safety of the system.

Yes. Because packaged power systems have

shielded isolation transformers close to the

load, they offer power line noise attenuation

and controlled grounding.

Yes. The packaged power system with

isolation transformer automatically establishes

a local single-point ground for the critical load.

The power grounding point is the same as the

computer system grounding point, minimizing

common mode disturbances.

Yes. Power distribution panel is in the

computer room. Access is limited to authorized

personnel.

Yes. Identification tags adjacent to each circuit

breaker provide circuit identification and

description of load served. Each cable is

tagged with circuit number and cable length.

Yes. Built-in power parameter monitoring,

alarm, and control capabilities are standard in

packaged power systems.

Yes. A packaged system requires only a single

connection to the premises wiring.

Yes. New cable(s) can be routed quickly with

minimal disruption.

Yes. Even after major equipment

rearrangement, redistributing power from

packaged systems becomes a simple matter of

re-routing the flexible interconnecting cables.

Yes. The package is easily moved with the

computer system to the new site.

2

Page 7

Capacities and Configurations

CAPACITIES AND CONFIGURATIONS

Liebert packaged power systems provide isolation, monitoring control, conditioning, and local single-point

ground to ensure computer-grade power.

With sizes ranging from 15 kVA to 225 kVA in a wide variety of configurations, the Liebert packaged distribution and conditioning systems can meet the requirements of almost any application.

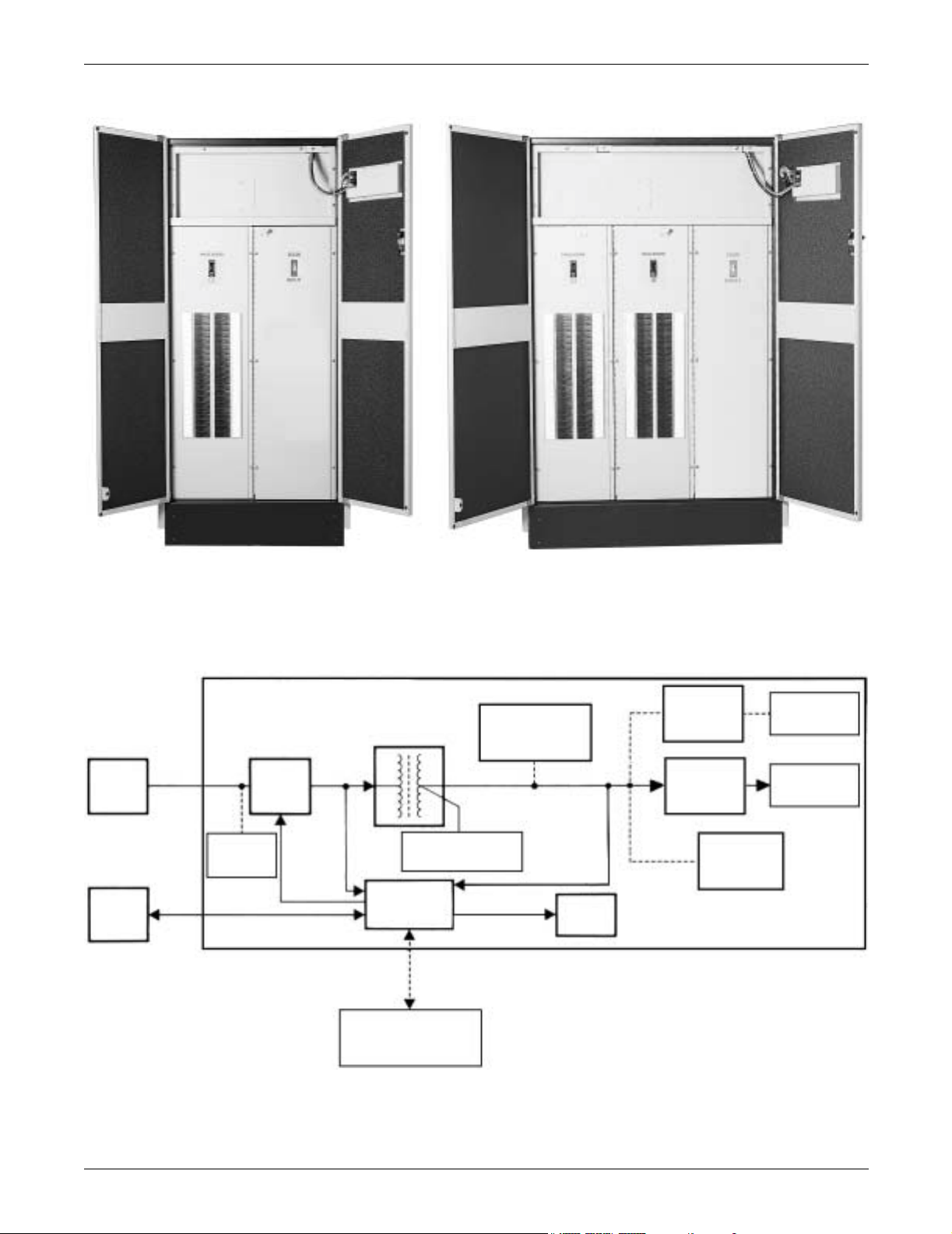

Figure 4 Precision Power Center, 1-4 panelboards

15-30 kVA, 1 panelboard 50-225 kVA, 4 panelboards

50-225 kVA, 3 panelboards 50-125 kVA, 2 panelboards

3

Page 8

Figure 5 Top Exit Precision Power Center, 1-2 panelboards

Capacities and Configurations

15-30 kVA, 1 panelboard

Figure 6 Precision Power Center diagram

Shielded

Isolation

Transformer

High

Vol tag e

J-Box

Arrester

Low

Vol tag e

J-Box

Input

Circuit

Breaker

Surge

Monitoring

Control

Remote

Monitoring

System

Single Point

Ground

and

Spike

Suppression

Module

Display

50-225 kVA, 2 panelboards

Main

Circuit

Breaker

Main

Circuit

Breaker

Subfeed

Output

Breaker

Local

Output

Panelboard

Output

Panelboard

4

Page 9

Standard Features for All Systems

STANDARD FEATURES FOR ALL SYSTEMS

Shielded Isolation Transformer Temperature Sensors Input Circuit Breaker

All Liebert distribution and conditioning systems

incorporate standard features that ensure load protection and simplify maintenance.

Precision Power Centers use quality, dry type,

shielded isolation transformers for noise reduction

up to 120 dB, with harmonic voltage distortion of

0.5 percent. Depending on kVA capacity, output

impedance is between 3 and 5.5 percent, while fullload efficiency is between 96.5 and 98 percent.

The transformer has temperature sensors in the

windings to provide an alarm if internal temperature

exceeds 180°C. It will shut down the system if internal temperature exceeds 200°C. Full Class H 220°C

transformer insulation and all copper windings are

used for long life and efficient operation.

A main input circuit breaker provides either manual

control, or automatic shutdown of the system in the

event of an overcurrent condition. The breaker is

sized for 125 percent of the system input full load

amperes. In addition to manual and thermal-magnetic trip, the input breaker can be tripped by an

electrically actuated shunt trip mechanism. As a

standard feature, the shunt trip of the input circuit

breaker is activated by the 200°C temperature sensor, local Emergency Power Off switch, and Manual

Restart circuit.

The local Emergency Power Off (EPO) switch is an

illuminated push button, easily accessible for emergency shutdown, but fully guarded by a hinged cover

to prevent accidental operation.

The manual restart circuit shunt-trips the main

input breaker whenever input power fails. This isolates the system from repetitive power applications

during fault-clearing operations by the utility, and

allows an orderly restart of the system when normal

power returns.

The manual restart circuit can be disabled by the

manual restart select switch. The auto position of the

switch defeats manual restart, and allows the conditioner to automatically restart when power returns.

Auto restart is useful for unattended remote sites

where the load can automatically restart, and in

those applications where the manual restart function

is provided elsewhere in the system.

The low-voltage shunt trip circuit also allows system

shutdown by external relays, Remote Emergency

Power Off (REPO) switches, or other remote devices.

A double-pole, double-throw (dpdt) building interface

relay is powered by a 24 VDC supply from the output

of the unit. Energized whenever the system is on, the

relay drops out if the output voltage disappears. The

relay can be used for remote alarming of system

shutdown, or shutdown interface with additional

loads such as environmental control units.

Power conditioner system components are housed in

a welded steel frame with removable panels for maximum accessibility to the interior. For safety and

security, any panels that provide access to high voltage require a tool for removal.

Panelboards

One 42-pole panelboard is provided on 15 and

30 kVA Precision Power Centers. Two 42-pole panelboards (for a total of 84 poles) are provided on 50

through 125 kVA Precision Power Centers. Three

42-pole panelboards (for a total of 126 poles) are provided on 150 through 225 kVA Precision Power Centers. (The three-panelboard configuration is not

available on Top Exit units.) Each panelboard is

enclosed for safety and has individual isolated neutral and safety ground busbars.

Each panelboard is protected by a main circuit

breaker, which also allows manual shutdown of the

entire panelboard without affecting the other panelboard(s).

Output circuits are protected by single-, two-, or

three-pole thermal-magnetic molded-case branch circuit breakers sized specifically for the load to be

served. (Standard panelboards use plug-in breakers.)

5

Page 10

ADDITIONAL FEATURES FOR ALL SYSTEMS

Additional Features for All Systems

Flexible Output Cables and Terminations

A flexible output cable

system is available for

Precision Power Centers.

Insulated cable conductors are protected by jacketed, liquid-tight, flexible

steel conduit with an integral copper shielding conductor. Each output cable

is fabricated to the specified length and type of termination to match the equipment it will be connected

to. “Add-on” UL listed cables for field installation are

also available.

Terminations include receptacles to match equipment plugs and conduit termination fittings with

conductor pigtails for hard wire connection.

Additional Pole Capacity

Additional panelboard pole capacity is available for

all power distribution units.

An additional 42-pole panelboard can be added to the

Precision Power Center for a total of 84 poles.

The Precision Power Center can have three 42-pole

panelboards for a total of 126 poles. (The three-panelboard configuration is not available on Top Exit

units.) For additional poles, distribution side sections

can be added. Each side section provides another

42-pole panelboard.

Optional Panelboard Types

Branch circuit panelboards that accept bolt-in circuit

breakers are optional, as are panelboards for plug-in

or bolt-in breakers manufactured by Square-D Company.

Subfeed Output Circuit Breaker

A subfeed output circuit

breaker, powered ahead of

the output panelboards, is

available on the Precision

Power Center to feed a

remote distribution unit,

panelboards, or other

loads. Multiple Subfeed

Output Breakers are

available upon request.

High-Voltage Junction Box With Flexible Input Cable

The high-voltage junction

box can be installed under

a raised floor system. The

junction box contains terminals for connecting the

incoming power line and

ground conductors. A

10-foot (3 m) flexible cable

is furnished for connection between the junction

box and the power conditioning system.

Low-Voltage Junction Box With Flexible Input Cable

The low-voltage junction box

can be installed under a

raised floor. It contains terminals for connection of all

building interface alarms or

controls, and all Remote

Emergency Power Off

switches. A 10-foot (3-meter)

flexible control cable for the

system is furnished for connection between the junction box and the power conditioning system.

Secondary Class Surge Arrester

A secondary class surge

arrester using high capacity utility-grade metal

oxide resistors is wired to

all three phases of the

input power to shunt voltage surges to building

ground. The arrester is

rated for a maximum

FOW spark-over of 3200 volts with maximum discharge voltage of 2.2 kV at 1500 amperes, assuming

a standard 8 x 20 microsecond waveform. The surge

arrester provides protection against high voltage

surges that can cause insulation or wiring failures.

6

Page 11

Additional Features for All Systems

Spike Suppression Module

The spike suppression module consists of AC filter

capacitors and dynamic peak limiting devices with a

response time of less than 1 nanosecond. Normal mode

high frequency noise is attenuated, while high-speed,

high-energy transients are limited to a safe level.

Transformerless System (Not Available on Top Exit Units)

The Precision Power Center can be supplied without

a transformer for use with separate power conditioning systems. If step-down and isolation are not necessary, transformerless systems provide the packaged

power system advantages of security, distribution,

monitoring, and upgrade flexibility.

Remote Emergency Power Off (REPO) Switch

Pressing the REPO push button activates the shunt trip

mechanism of the main input

circuit breaker, shutting down

the system.

The illuminated and fully

guarded REPO button is

mounted in a wall box. The

assembly includes 50 feet

(15.2m) of 3-conductor cable for

wiring to the unit. Additional

lengths of cable are available.

Floor Pedestals

In rooms without a raised

floor, the floor pedestals provide space for the bottom

entrance/exit of cables in Precision Power Center. The

height of the floor pedestals is

customer-specified. Standard

floor pedestal height range is

adjustable from 8.6 to 13.25 in. (218 to 336 mm).

Other available ranges: 6 to 8.5 in. (152 to 216 mm),

and 13.5 to 18 in. (343 to 457 mm). Non-raised floor

applications for the Precision Power Center are not

CSA approved.

Transient Suppression Plate

The transient suppression plate is a one-squaremeter plate mounted to (and bonded to) the highvoltage junction box. It reduces the effects of transients on the ground system by providing a capacitive coupling to building steel.

Phase Rotation Meter

The phase rotation meter is a hand-held instrument

with clip-on leads for connecting to the circuit under

test. The meter shows the circuit phase rotation in

“ABC” or “BAC” sequence.

The phase rotation meter can verify rotation

sequence of any circuit up to 600 volts.

Table 1 Features available by model

PPC

15-30 kVA

42 poles

Panelboards

Flexible Output Cables and

Terminations

Additional Pole Capacity

Optional Panelboard Types Optional Optional Optional Optional Optional

Subfeed Output Circuit

Breaker

High-Voltage Junction Box

with Flexible Input Cable

Low-Voltage Junction Box

with Flexible Input Cable

Secondary Class Surge

Arrester

Spike Suppression Module Optional Optional Optional Optional Optional

Transformerless System Optional Not available Optional Not available Optional

Remote Emergency Power

Off (REPO) Switch

K-20 Transformer Optional Optional Optional Optional Optional

Multi-Winding Transformer Optional Optional Optional Optional Optional

Floor Pedestals Optional Not available Optional Not available Optional

Transient Suppression Plate Optional Not available Optional Not available Optional

standard

(one 42-pole

panelboard)

Available Available Available Available Available

Optional 84

poles

Not available Not available

Standard Not available Standard Not available Standard

Optional Not available Optional Not available Optional

Optional Optional Optional Optional Optional

Optional Optional Optional Optional Optional

Top Exit

15-30 kVA

42 poles

standard

(one 42-pole

panelboard)

Optional 84

poles

PPC

50-125 kVA

84 poles

standard

(two 42-pole

panelboards)

Optional 126 or

168 poles

Optional

(up to 225 A)

Top Exit

50-150 kVA

84 poles

standard

(two 42-pole

panelboards)

Optional 126

poles

Not available

150-225 kVA

126 poles

standard

(three 42-pole

panelboards)

Optional 168 or

210 poles

Optional

(up to 400 A)

PPC

7

Page 12

HARMONICS SOLUTIONS

Harmonics Solutions

Solutions to Harmonics Problems

Precision Power Centers are available with several

harmonic solution options, along with the standard

product features, to provide flexible power distribution for today’s nonlinear loads.

The basic Precision Power Center is designed to

accommodate moderate levels of harmonic currents.

All Precision Power Center isolation transformers

provide cancellation of the load triplen harmonic currents and are designed to tolerate neutral currents

K-Factor Transformers

Shielded isolation transformers with a K-20 rating

are specially designed to minimize the heating

effects of the load’s harmonic currents and to tolerate

full harmonic loading without overheating.

Multi-Winding Transformers

Shielded isolation transformers with multiple secondary windings that are phase shifted provide cancellation of the load’s non-triplen harmonic currents.

up to 1.73 times full load. When severe levels of harmonic currents are anticipated, several additional

power center features are available.

With K-Factor

Features Comparison Basic System

Designed for nonlinear loads X X X

Neutral sized for greater than 1.73X FLA X X X

Available with multiple outputs for mainframe computers X X X

Reduces harmonic current distortion X X X

Improves harmonic power factor X X X

Cancels triplen (3rd, 9th, 15th, etc.) harmonics X X X

Tolerates higher levels of harmonic currents X X

Cancels non-triplen (5th, 7th, etc.) harmonics X

Transformer

With Multi-Winding

Transformer

SYSTEM MONITORING

Monitoring systems for Liebert power conditioners range from temperature sensing to multiple-parameter

monitoring with remote display and printout.

All units are equipped with a guarded and illuminated Local Emergency Power Off switch; provisions for connecting Remote Emergency Power Off switch; selectable auto or manual restart feature, to allow an orderly

system restart after a power failure; a summary alarm contact; and a building interface relay.

Power Monitor Panel

True RMS techniques are used to provide accurate

measurements of Precision Power Center operation,

while the high visibility Liquid Crystal Display provides clear reporting. The microprocessor-based

power monitoring system continuously monitors and

sequentially displays the following parameters:

• Input voltages, line-to-line for each phase

• Output voltages, line-to-line and line-to-neutral

for each phase

• Output currents for each phase, including neutral

and ground currents

• Output voltage THD for each phase

• Output current THD, K-factor and crest factor for

each phase

• Output power including kVA, KW, KW-hours,

power factor, percent load and output frequency

8

Page 13

System Monitoring

The monitor panel also provides warning of out-ofspec conditions through audible alarm and displayed

alarm messages. All alarmed conditions are retained

in a non-volatile memory until reset. Alarm thresholds are adjustable, to meet individual site needs.

Alarmed conditions include:

• Output overvoltage

• Output undervoltage

• Output voltage THD

• Output overcurrent

• Neutral overcurrent

• Ground overcurrent

• Transformer overtemperature

• Frequency deviation

• Phase sequence error

• Phase loss

• Five customer-specified alarm conditions

For additional application flexibility, the following

alarms can be configured to shut down the Precision

Power Center-output over/under voltage; phase

sequence error; phase loss; ground overcurrent.

Through a two-conductor communications cable, the

system can communicate alarms and monitored conditions to a Liebert SiteScan central monitoring system.

An isolated RS-232 ASCII communication port is provided for communication to other monitoring systems.

Remote Monitoring Systems

SiteScan

SiteScan is an on-line center for monitoring and controlling all support systems in a large data processing installation. SiteScan provides early warning

alarms and total site management data. A softwarebased system using a microcomputer as the central

processing center, SiteScan is programmable, menudriven, and upgradeable.

Basic Temperature Monitoring Panel

The Transformer Overtemperature alarm indicator

is a part of the 180°C transformer temperature sensing circuit. This configuration is optional on all units.

Four primary site management programs are built

into SiteScan:

• Alarm functions provide instant warning of

potential problems. A seven level selection of

options for response to each alarm offers total flexibility in designing a custom-tailored alarm system.

• Control functions allow critical setpoints and

sensitivities to be adjusted by remote control for

dynamic, single-point site management. Password

access preserves site security.

• Status functions provide complete information

on all computer support systems, including realtime status of all monitored parameters and any

alarm conditions.

• History functions offer database management

capabilities. These functions track, store and

graphically display crucial data and trends for site

management activities such as capacity analysis,

growth predictions, and energy management.

SiteScan makes full use of all features of its computer-based central processor, including RS-232

communications and other output ports and

unlimited expansion via multiplexers. For critical

data processing facilities, the SiteScan system

offers total site management capability in a virtually obsolescence-proof configuration.

9

Page 14

Physical/Electrical Data

PHYSICAL/ELECTRICAL DATA

Table 2 Electrical and mechanical characteristics, 60 Hz

Total

Output

Input

Size, kVA

15 kVA

(with transformer)

(without transformer) 208/120V 208/120V PRC015 300 (136) 42 42 60

30 kVA

(with transformer)

(without transformer) 208/120V 208/120V PRC030 300 (136) 42 83 110

50 kVA

(with transformer)

(without transformer) 208/120V 208/120V PRC050 400 (175) 84 139 175

75 kVA

(with

transformer)

(without transformer) 208/120V 208/120V PRC075 400 (175) 84 208 300

100 kVA

(with transformer)

(without transformer) 208/120V 208/120V PRC100 450 (200) 84 277 350

125 kVA

(with transformer)

(without transformer) 208/120V 208/120V PRC125 450 (200) 84 347 450

150 kVA

(with transformer)

(without transformer) 208/120V 208/120V PRC150 700 (320) 126 416 600

200 kVA

(with transformer)

225 kVA

(with transformer)

NOTES

1. All input and output ratings are three-phase.

2. Consult factory for voltages and applications not shown.

3. For extra panelboard option: 84 pole models are 32" (813 mm) wide; 126 pole models are 44" (1118 mm) wide; and 168 pole models are

62" (1575 mm) wide.

Volts

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

600V

480V

Output

Volts

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

Model

Number

PPB015C

PPA015C

PPC015C

PPB030C

PPA030C

PPC030C

PP8050C

PPA050C

PPC050C

PPB075C

PPA075C

PPC075C

PPB100C

PPA100C

PPC100C

PPB125C

PPA125C

PPC125C

PPB150C

PPA150C

PPC150C

PPB200C

PPA200C

PPB225C

PPA225C

Weight

lbs (kg)

550 (250)

550 (250)

550 (250)

700 (320)

700 (320)

700 (320)

850 (380)

850 (380)

850 (380)

1050 (470)

1050 (470)

1050 (470)

1275 (580)

1275 (580)

1275 (580)

1450 (660)

1450 (660)

1450 (660)

1750 (790)

1750 (790)

1750 (790)

2100 (950)

2100 (950)

2250 (1020)

2250 (1020)

Poles

(Standard)

42

42

42

42

42

42

84

84

84

84

84

84

84

84

84

84

84

84

126

126

126

126

126

126

126

Input

Full

Load

Amps

15

19

43

30

38

87

50

63

145

74

93

215

99

124

286

124

155

358

148

185

427

197

247

222

278

Main

Input

Circuit

Breaker

20

25

60

40

50

110

70

80

200

100

125

300

125

175

400

175

200

450

200

250

600

250

350

300

350

Dimensions

W x D x H

inches (mm)

20 x 32 x 68

(508 x 813 x 1727)

20 x 32 x 68

(508 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

Standard main input circuit breaker interrupting ratings are as follows. Other ratings available on request.

Input OPD 208V 480V 600V

Up to 250 Amps 65 kA 35 kA 22 kA

300 to 600 Amps 65 kA 35 kA 25 kA

10

Page 15

Physical/Electrical Data

Table 3 Electrical and mechanical characteristics, 50 Hz

Total

Output

Size, kVA

Input

Volts

Output

Volts

Model

Number

Weight

lbs (kg)

Poles

(Standard)

15kVA

(with transformer)

(without transformer)

415V

400V

380V

415/240V

380/220V

415/240V

400/230V

380/220V

415/240V

380/220V

PPG015G

PPU015U

PPF015F

PRG015

PRF015

600 (275)

600 (275)

600 (275)

300 (136)

300 (136)

42

42

42

42

42

30 kVA

(with transformer)

(without transformer)

415V

400V

380V

415/240V

380/220V

415/240V

400/230V

380/220V

415/240V

380/220V

PPG030G

PPU030U

PPF030F

PRG030

PRF030

775 (350)

775 (350)

775 (350)

300 (136)

300 (136)

42

42

42

42

42

50 kVA

(with transformer)

(without transformer)

415V

400V

380V

415/240V

380/220V

415/240V

400/230V

380/220V

415/240V

380/220V

PPG050G

PPU050U

PPF050F

PRGO50

PRF050

925 (420)

925 (420)

925 (420)

400 (175)

400 (175)

84

84

84

84

84

75 kVA

(with transformer)

(without transformer)

415V

400V

380V

415/240V

380/220V

415/240V

400/230V

380/220V

415/240V

380/220V

PPG075G

PPU075U

PPF075F

PRG075

PRF075

1150 (520)

1150 (520)

1150 (520)

400 (175)

400 (175)

84

84

84

84

84

100 kVA

(with transformer)

(without transformer)

415V

400V

380V

415/240V

380/220V

415/240V

400/230V

380/220V

415/240V

280/220V

PPG100G

PPU100U

PPF100F

PRG100

PRF100

1400 (630)

1400 (630)

1400 (630)

450 (200)

450 (200)

84

84

84

84

84

125 kVA

(with transformer)

(without transformer)

415V

400V

380V

415/240V

380/220V

415/240V

400/230V

380/220V

415/240V

380/220V

PPG125G

PPU125U

PPF125F

PRG125

PRF125

1575 (710)

1575 (710)

1575 (710)

450 (200)

450 (200)

84

84

84

84

84

150 kVA

(with transformer)

(without transformer)

415V

400V

380V

415/240V

380/220V

415/240V

400/230V

380/220V

415/240V

380/220V

PPG150G

PPU150U

PPF150F

PRG150

PRF150

1900 (860)

1900 (860)

1900 (860)

700 (320)

700 (320)

126

126

126

126

126

200 kVA

(with transformer)

415V

400V

380V

415/240V

400/230V

380/220V

PRG200G

PPU200U

PPF200F

2300 (1045)

2300 (1045)

2300 (1045)

126

126

126

225 kVA

(with transformer)

NOTES

1. All input and output ratings are three-phase.

2. Consult Factory for voltages and applications not shown.

3. For extra panelboard option: 84 pole models are 32" (813 mm) wide; 126 pole models are 44" (1118 mm) wide; and 168 pole models are

62" (1575 mm) wide.

415V

400V

380V

415/240V

400/230V

380/220V

PPG225G

PPU225U

PPF225F

2450 (1110)

2450 (1110)

2450 (1110)

126

126

126

Input

Full

Load

Amps

22

23

24

21

23

43

45

47

42

46

72

75

79

70

76

108

112

117

104

114

143

149

157

139

152

179

186

196

174

190

214

223

234

209

228

285

297

312

321

334

351

Main

Input

Circuit

Breaker

30

30

30

30

30

60

60

60

60

60

100

100

100

90

100

150

150

150

150

150

200

200

200

175

200

225

250

250

225

250

300

300

300

300

300

400

400

400

450

450

450

Dimensions

W x D xH

inches (mm)

20 x 32 x 68

(508 x 813 x 1727)

20 x 32 x 68

(508 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

Standard main input circuit breaker interrupting ratings (rated symmetrical ultimate breaking capacity per

IEC 947-2) are as follows. Other ratings available upon request.

INPUT OPD 380-415V

Up to 110 Amps 15 kA

125 to 600 Amps 25 kA

11

Page 16

Heat Output

Table 4 Electrical and mechanical characteristics, Top Exit

Total

Input

Size, kVA

15 kVA

30 kVA

50 kVA

75 kVA

100 kVA

125 kVA

150 kVA

200 kVA

225 kVA

NOTES

1. All input and output ratings are three-phase.

2. Consult factory for voltages and applications not shown.

3. For extra panelboard option: 84 pole models are 44" (1118 mm) wide; and 126 pole models are 62" (1575 mm) wide.

Volts

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

208V

600V

480V

600V

480V

Output

Volts

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

208/120V

Model

Number

PPB015C

PPA015C

PPC015C

PPB030C

PPA030C

PPC030C

PP8050C

PPA050C

PPC050C

PPB075C

PPA075C

PPC075C

PPB100C

PPA100C

PPC100C

PPB125C

PPA125C

PPC125C

PPB150C

PPA150C

PPC150C

PPB200C

PPA200C

PPB225C

PPA225C

Weight

lbs (kg)

600 (272)

600 (272)

600 (272)

750 (340)

750 (340)

750 (340)

900 (408)

900 (408)

900 (408)

1100 (499)

1100 (499)

1100 (499)

1325 (601)

1325 (601)

1325 (601)

1500 (680)

1500 (680)

1500 (680)

1750 (794)

1750 (794)

1750 (794)

2100 (958)

2100 (958)

2250 (1021)

2250 (1021)

Output

Poles

(Standard)

42

42

42

42

42

42

84

84

84

84

84

84

84

84

84

84

84

84

84

84

84

84

84

84

84

Input

Full

Load

Amps

15

19

43

30

38

87

50

63

145

74

93

215

99

124

286

124

155

358

148

185

427

197

247

222

278

Main

Input

Circuit

Breaker

20

25

60

40

50

110

70

80

200

100

125

300

125

175

400

175

200

450

200

250

600

250

350

200

250

Dimensions

W x D x H

inches (mm)

32 x 32 x 68

(813 x 813 x 1727)

32 x 32 x 68

(813 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

44 x 32 x 68

(1118 x 813 x 1727)

Standard main input circuit breaker interrupting ratings are as follows. Other ratings available on request.

Input OPD 208V 480V 600V

Up to 250 Amps 65 kA 35 kA 22 kA

300 to 600 Amps 65 kA 35 kA 25 kA

HEAT OUTPUT

Table 5 Heat output

kVA 1/2 Load BTU/hr (kW) 3/4 Load BTU/hr (kW) Full Load BTU/hr (kW)

15 1300 (.38) 1900 (.57) 2500 (.73)

30 2200 (.64) 3400 (1.00) 4600 (1.35)

50 3100 (.91) 4650 (1.36) 6200 (1.82)

75 4100 (1.20) 6150 (1.80) 8150 (2.39)

100 5050 (1.48) 7700 (2.26) 9900 (2.90)

125 5800 (1.70) 8700 (2.55) 11500 (3.37)

150 6300 (1.85) 9400 (2.75) 12500 (3.66)

200 7700 (2.26) 11500 (3.37) 15500 (4.54)

225 7800 (2.29) 11800 (3.46) 15800 (4.63)

Environmental Characteristics

Temperature, operating: 0°C to +40°C

Temperature, storage: 55°C to + 85°C

Relative humidity: 0% to 95% (non-condensing)

12

Page 17

SYSTEM SIZING

Sizing a power center to meet present and future

needs is a fundamental requirement.

Present Requirements

Estimating the present system size in kilovolt

amperes (kVA) is done in a number of ways. Typical

sources include computer site planning manuals,

equipment nameplate data, and electrical service

data. kVA requirements are estimated using any of

the following formulas:

V = volts pf = power factor

A = amperes • = “multiplied by”

kVA = kilovolt-amperes BTU/hr = British Ther-

mal Units per hour (heat

output)

kW = kilowatts Kcal/hr = kilocalories per

hour (heat output)

1. Power profile of equipment. (This is the most

reliable base from which to estimate present

kVA loading.)

For three-phase systems:

V A 1.73()⋅⋅

kVA

---------------------

=

kVA 1000⋅

-----------------

A

=

V1.73()⋅

1000

System Sizing

Growth Requirements

The power center should be sized to anticipate

growth. Growth rates associated with data processing centers double power requirements in a short

time. Therefore it is reasonable to size the system for

twice the present kVA load. Even in a minimum

growth environment, the power center should be

sized for 125% of the estimated kVA load.

Special Load Characteristics

For special load characteristics, factory application

engineers should be consulted for recommended system sizing.

System Grounding Considerations

The grounding of any power conditioning system is

critical to its performance. The National Electrical

Code provides for a safe electrical system. The

ground path required by the NEC for safety should

be enhanced or improved for system performance,

never defeated or eliminated. For detailed system

grounding considerations, refer to the Precision

Power Center Installation Operation and

Mainenance Manual.

For single-phase equipment:

VA⋅

kVA

A

--------

=

kVA 1000⋅

-----------------

=

1000

V

2. Kilowatts (kW) and Power Factor (pf).

kW

kVA

-----

=

pf

(If pf is not given, assume 0.8.)

3. Ampere specifications for the electrical

service feeding the site:

V A 1.73()⋅⋅

kVA

---------------------

=

1000

(for three-phase systems)

4. BTU/hr or Kcal/hr specifications:

kW

BTU hr()⁄

----------------

=

3413

kVA

=

kW

-----

=

pf

kcal hr()⁄

---------------

860

(If pf is not known, assume 0.8.)

After the present kVA requirement has been determined, the anticipated growth and the special characteristics of the load must be considered.

13

Page 18

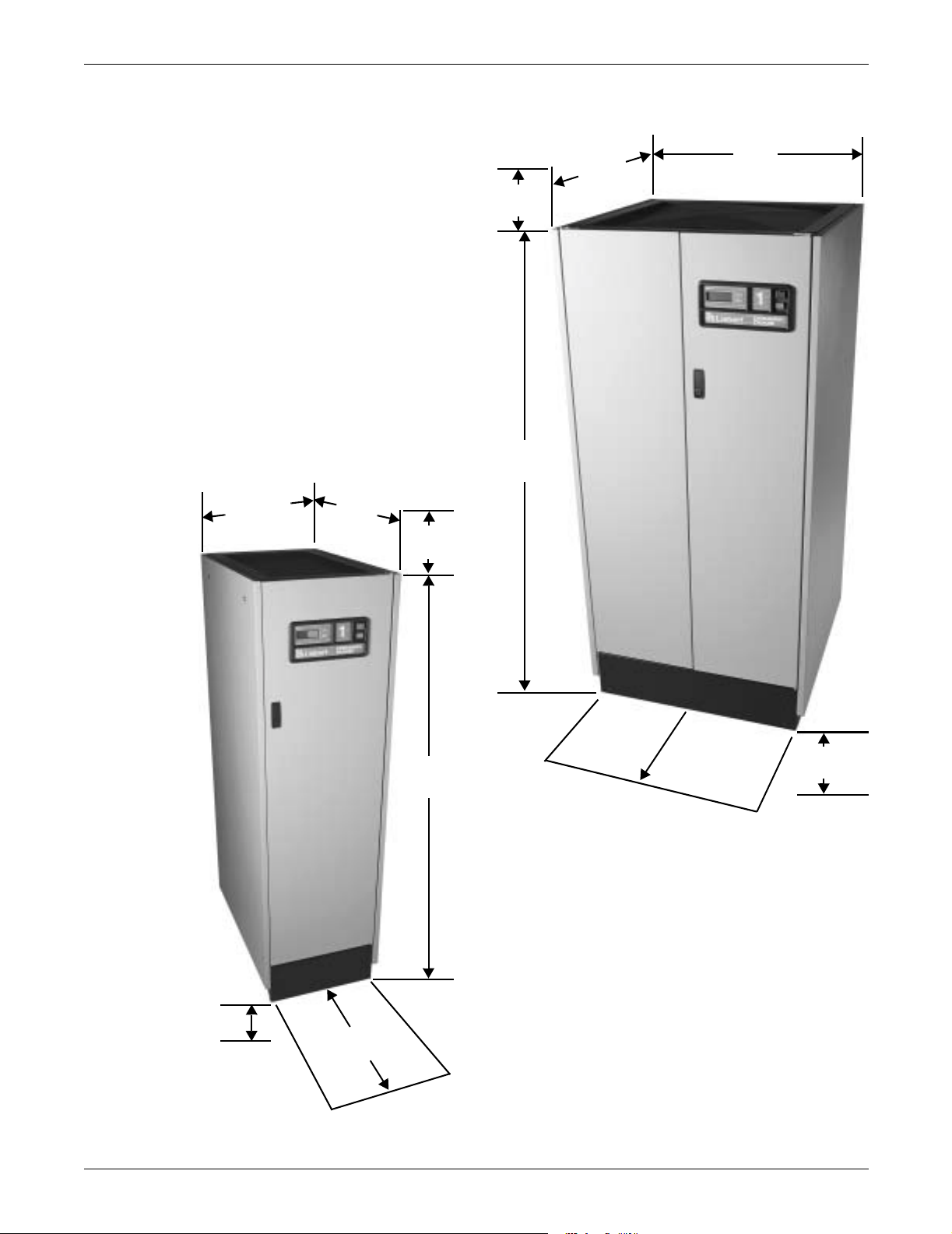

SERVICE ACCESS AND CLEARANCE REQUIREMENTS

Precision Power Centers are designed for easy servicing. Access areas and minimum clearances of each

are described below.

Precision Power Center - 15-225 kVA sizes

Recommended minimum service clearances for Precision Power Centers should be at the front and one

other side, or rear. Service clearance extends 42 in.

(1067 mm) from the unit in accordance with the

National Electrical Code. If bottom cable exit is

desired, there must be at least 6" (143 mm) clearance

at the bottom of the unit.

(NOTE: If bottom cable exit or distribution cables are

used, the unit must be installed on a raised floor or

floor pedestals must be provided. Non-raised floor

applications are not CSA approved.)

Units with a transformer require 18" (427 mm) above

the unit for cooling airflow.

Figure 7 Dimensions, clearances, 1 panelboard

Figure 8 Dimensions, clearances, 2 panelboards

18" *

(457mm)

68"

(1727mm)

Service Access and Clearance Requirements

32"

(813mm)

32"

(813mm)

20"

(507mm)

32"

(813mm)

18" *

(457mm)

68"

(1727mm)

42" **

(1067 mm)

* 16For units with transformer

** Required in front of unit plus

on one other side or in back

*** For bottom cable exit

6" ***

(152 mm)

6" ***

(152mm)

42" **

(1067mm)

14

Page 19

Figure 9 Dimensions, clearances, 3 panelboards

Service Access and Clearance Requirements

18" (457mm)

For units with

transformer

68"

(1727 mm)

32"

(813mm)

44"

(1118mm)

42" (1067 mm)

Required in front of

unit plus on one other

side or in back

15

6" (152mm)

For bottom cable exit

Page 20

Figure 10 Dimensions, clearances, 4 panelboards

Service Access and Clearance Requirements

62"

(1575mm)

18" (457mm)

For units with transformer

Note: Units are 32"

(813mm) deep

68"

(1727 mm)

42" (1067 mm)

Required in front of unit plus

on one other side or in back

16

6" (152mm)

For bottom cable exit

Page 21

Figure 11 Dimensions, clearances, Top Exit unit

44" (1118mm) for

2 panelboards

32" (813mm) for

1 panelboard

or

Service Access and Clearance Requirements

32"

(813mm)

68"

(1727 mm)

42" (1067 mm)

Required in front of unit plus

on one other side or in back

Allow 36" (914 mm) minimum

clearance on both sides or in

rear for cooling air flow

17

Page 22

Service Access and Clearance Requirements

18

Page 23

Page 24

POWER CONVERSION/DISTRIBUTION

Precision Power Center

TECHNICAL DATA MANUAL

The Company Behind the Products

With over a million installations around the globe,

Liebert is the world leader in computer protection

systems. Since its founding in 1965, Liebert has

developed a complete range of support and

protection systems for sensitive electronics:

• Environmental systems—close-control air

conditioning from 1 to 60 tons

• Power conditioning and UPS with power

ranges from 300 VA to more than 1000 kVA

• Integrated systems that provide both

environmental and power protection in a

single, flexible package

• Monitoring and control—from systems of any

size or location, on-site or remote

• Service and support through more than 100

service centers around the world and a 24/7

Customer Response Center

While every precaution has been taken to ensure

the accuracy and completeness of this literature,

Liebert Corporation assumes no responsibility and

disclaims all liability for damages resulting from

use of this information or for any errors or

omissions.

© 2002 Liebert Corporation

All rights reserved throughout the world.

Specifications subject to change without notice.

® Liebert and the Liebert logo are registered

trademarks of Liebert Corporation. All names

referred to are trademarks or registered

trademarks of their respective owners.

Technical Support

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Single-Phase UPS

800-222-5877

Outside the United States

614-841-6598

3-Phase UPS

800-543-2378

Environmental Control

800-543-2778

Italy

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD)

+39 049 9719 111

FAX: +39 049 5841 257

Asia

23F, Allied Kajima Bldg.

138 Gloucester Road

Wanchai

Hong Kong

+852 2 572 2201

FAX: +852 2 831 0114

Web Site

www.liebert.com

SL-20045 (6/02)

Loading...

Loading...