Liebert POWER PROTECTION STATIC TRANSFER SWITCH User Manual

STATIC TRANSFER SWITCH 2

POWER PROTECTION

USER MANUAL

100-1000 Amp

50-60 Hz

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

OVERVIEW OF MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.0 SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.0 UNPACKING AND INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 External Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Unloading and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Handling Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.2 Unit Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Internal Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 LOCATION CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 Recommended Minimum Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Heat Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.0 LOCATING THE STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Leveling and Anchoring the Unit to the Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Leveling of the Static Switch Without Anchoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Leveling and Anchoring the Static Switch Using Floor Stand . . . . . . . . . . . . . . . . . . . . . . . . 8

5.0 POWER AND CONTROL WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.1 Input And Output Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Input Junction Box Installation (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.3 System Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.4 Control Wiring Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.5 Remote Source Selection Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.6 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.0 OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1 Programmable Relay Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.2 Optimized Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3 Distribution Cabinet With I-Line Panelboard—100-600A Units Only . . . . . . . . . . . . . . . . . 14

6.4 Input Contact Isolator Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.5 Comms Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.6 Internal Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.7 Network Interface Card (NIC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.8 LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.9 Remote Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.10 Key Lockout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.11 Redundant Output Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

i

6.12 Input Junction Boxes and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.13 Seismic Floor Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.14 Seismic Floor Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.0 INSTALLATION DRAWINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.0 INTRODUCTION TO STS2 OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.1 System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.1.1 Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.1.2 Reliability and Agency Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.1.3 Factory Backup and Service Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2 Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.1 Normal (Preferred Source) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.2 Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.3 Transfer Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2.4 Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3 Operator Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.0 THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

9.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.1.1 STS2 Static Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.1.2 Source Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.1.3 Automatic Transfer/Retransfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.1.4 Emergency Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.1.5 Load Current Transfer Inhibit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.1.6 SCR Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.1.7 On/Off Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2 Detailed Component Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2.1 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2.2 Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.2.3 SCRs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.2.4 Logic Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.2.5 Audible Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.2.6 RS-232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.0 OPERATING INSTRUCTIONS FOR THE TOUCH SCREEN INTERFACE. . . . . . . . . . . . . . . . . . . .64

10.1 Normal System Turn-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.2 Manual Transfer / Preferred Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.3 Enabling Remote Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.4 Maintenance Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.4.1 Bypass Procedures for Source 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.4.2 Bypass Procedures for Source 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.5 Normal System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.5.1 Shutdown in Static Transfer Switch Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.5.2 Shutdown in Maintenance Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

11.0 ALARM AND FAULTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.1 Event Mask. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ii

11.2 Event and History Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.2.1 Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.2.2 History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.3 Alarm Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.4 List of Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12.0 COMMUNICATION INTERFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.1 Using the RS-232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.1.1 Connecting and Using a Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

12.1.2 Configuring the STS2 via the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.1.3 Setting Bitpacked Options with the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12.1.4 Setting Event Masks with the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13.0 STS2 TOUCH SCREEN DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.1 Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.2 Menu Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.2.1 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

13.3 Mimic Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.4 Event Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.5 Event Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.6 Menu bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.6.1 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.6.2 Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

13.6.3 Source Transfers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.6.4 Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.6.5 Bypass Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.6.6 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.6.7 Logo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.7 Cleaning the LCD Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.0 OPERATING THE LED DISPLAY STS2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

14.1 LEDs and Buttons and Key Lockout Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.1.1 Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.1.2 LED and push button description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

14.1.3 Event Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.1.4 Key Lockout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.2 Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.2.1 Normal System Turn-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

14.2.2 Manual Transfer / Preferred Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.2.3 Maintenance Bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

14.2.4 Normal System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

iii

15.0 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

15.1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

15.1.1 Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

15.1.2 Input/Output Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

15.1.3 System Current Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

15.1.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.1.5 Electrical Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.1.6 Input Surge Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.1.7 Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.1.8 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15.2 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

15.2.1 Frame and Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

15.2.2 Castors, Leveling and Seismic Anchoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

15.2.3 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

15.2.4 Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.2.5 Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.2.6 Cable Entrance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.2.7 Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.2.8 Color Graphical Display or LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

15.2.9 RS-232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

15.2.10 Terminal Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

15.2.11 RS-232 Interface Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

15.2.12 Maintenance Bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

15.2.13 Fuseless Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

15.2.14 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

16.0 EVENT MESSAGE HELP TEXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

17.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

17.1 Proper Tightening of Nuts and Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

17.2 Testing the STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

17.3 Changing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

SUPPORT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

PROGRAMMABLE RELAY BOARD SETTINGS RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

INPUT CONTACT ISOLATOR SETTINGS RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

iv

FIGURES

Figure 1 Recommended derating for high altitude operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2 Maximum ambient temperature for full load operation at higher altitudes . . . . . . . . . . . . . . . . . . 7

Figure 3 Typical static transfer switch one-line diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4 Typical one-line diagram of two PDUs and a static transfer switch . . . . . . . . . . . . . . . . . . . . . . . 11

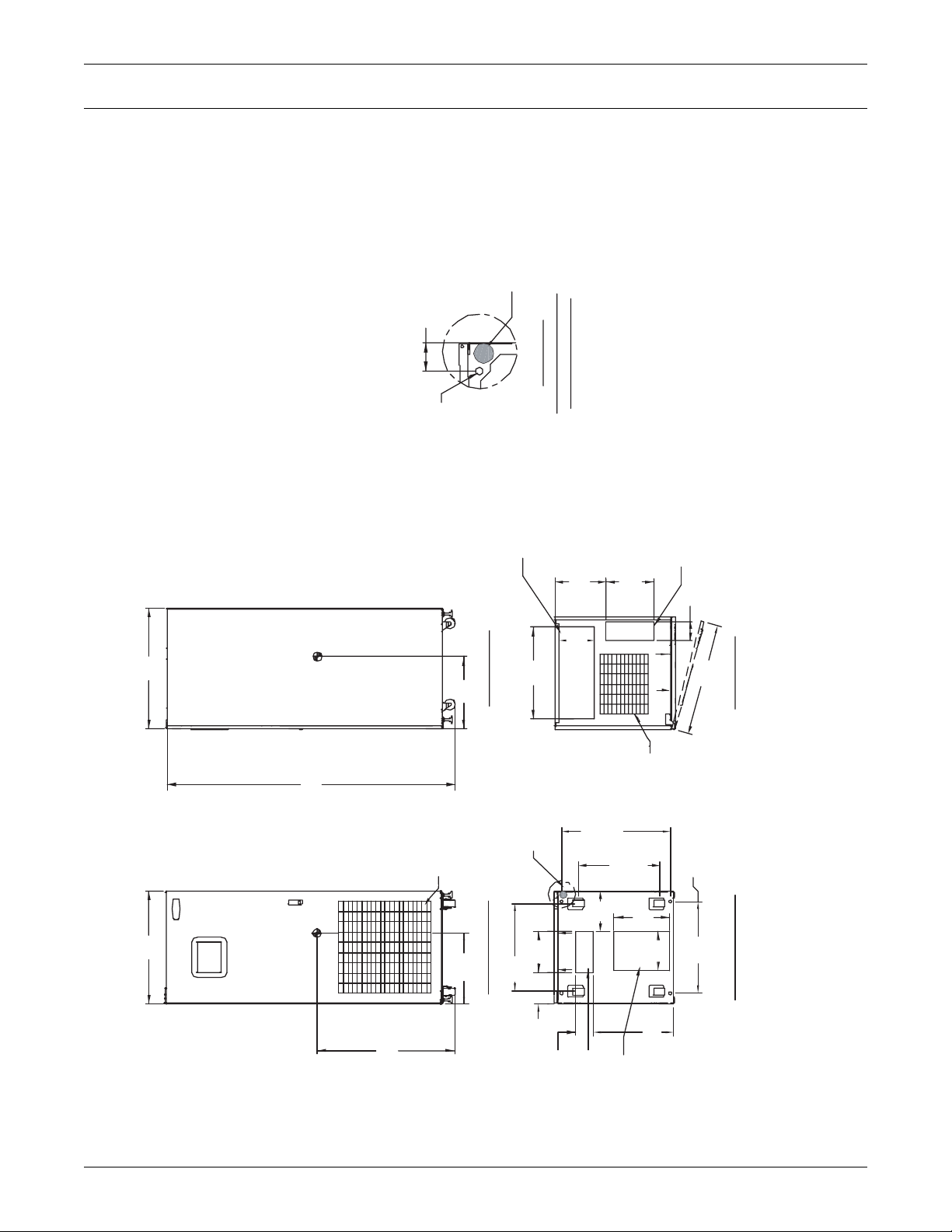

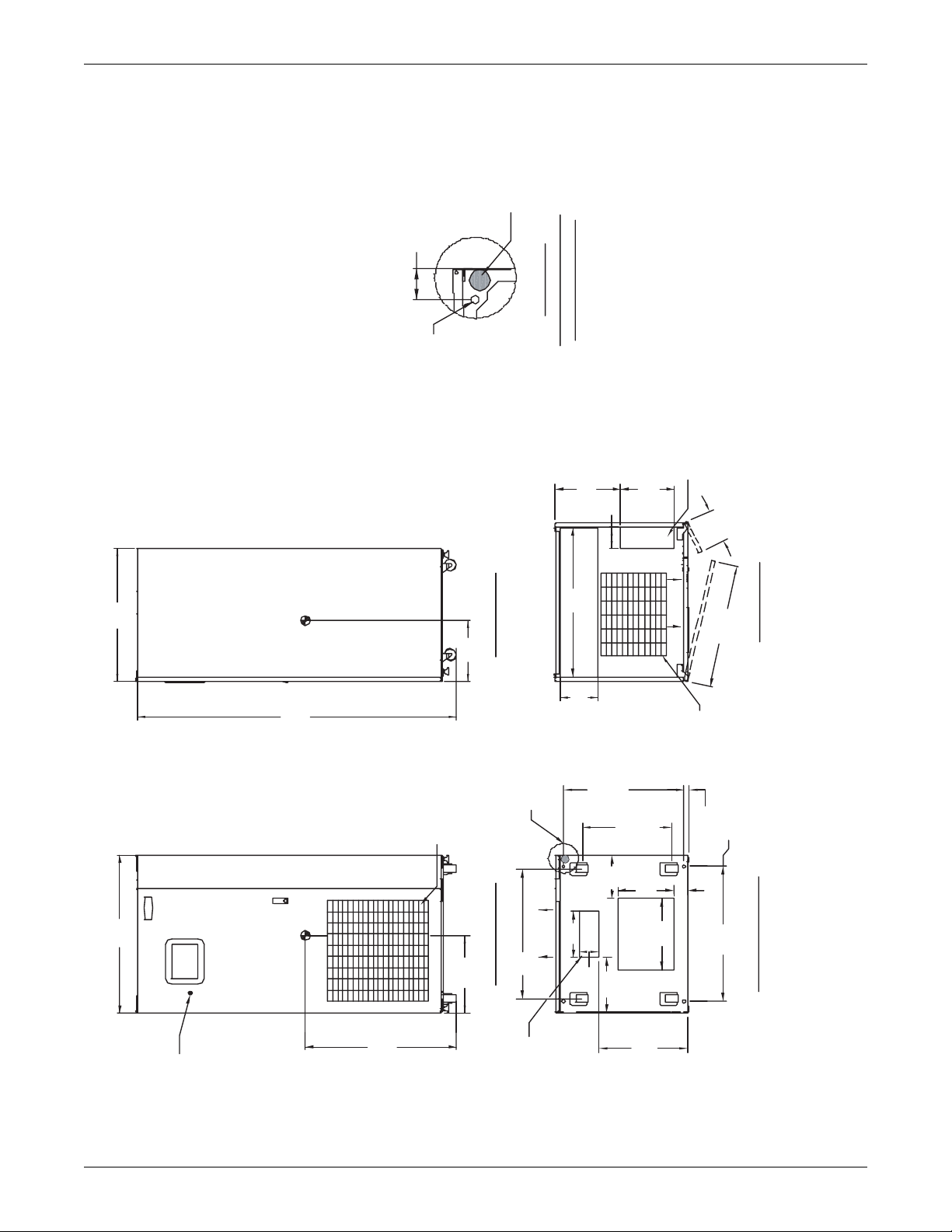

Figure 5 Outline drawing: 100 – 250 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

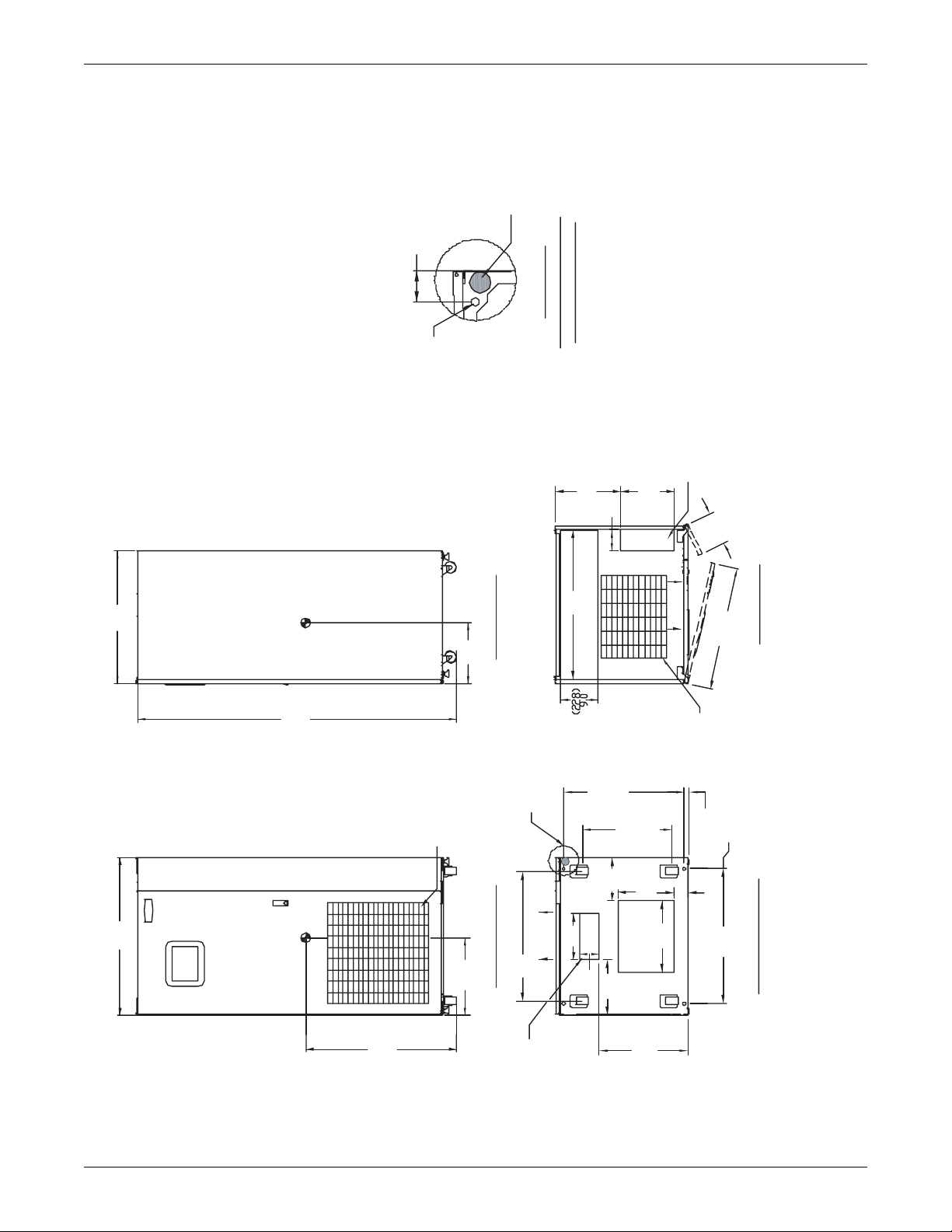

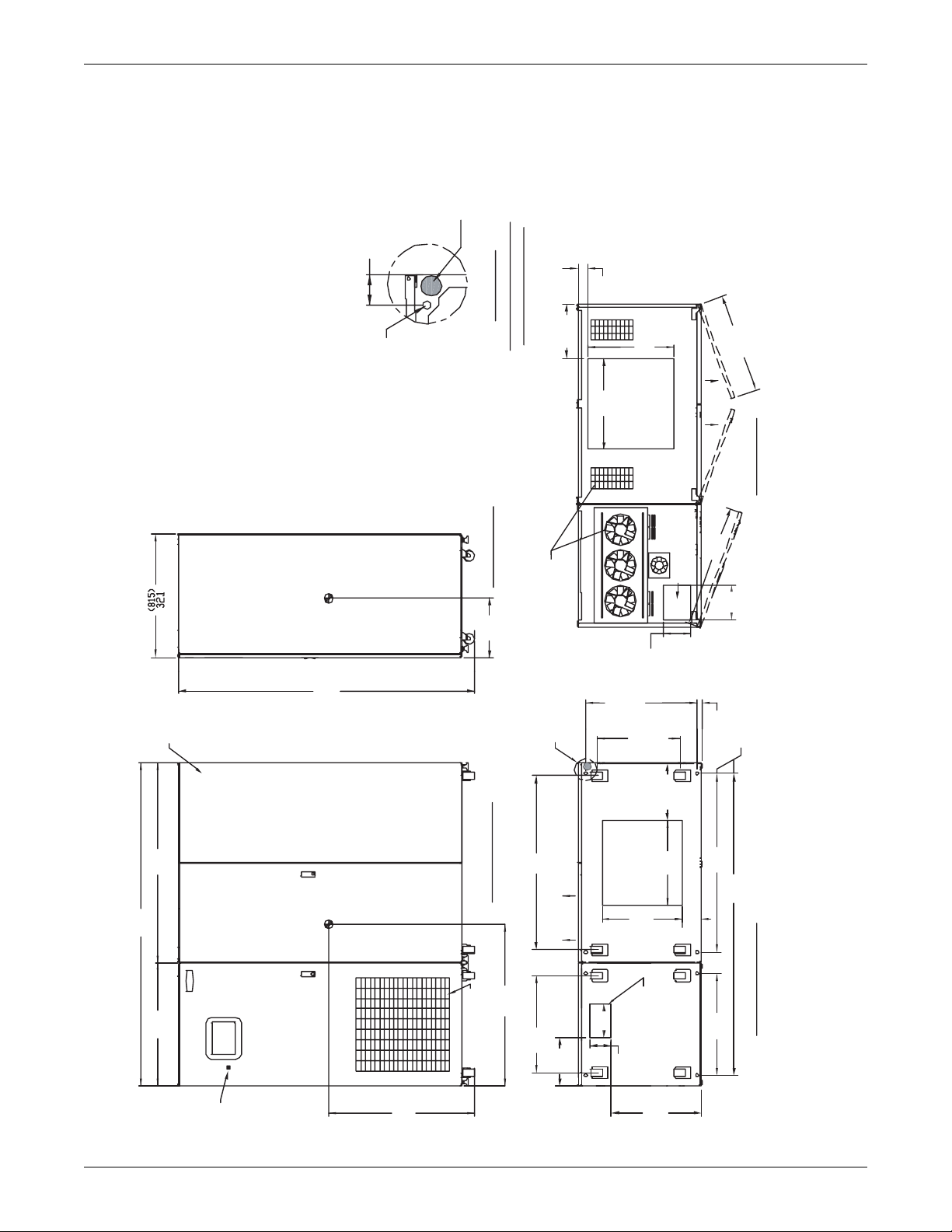

Figure 6 Outline drawing: 400 – 600 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

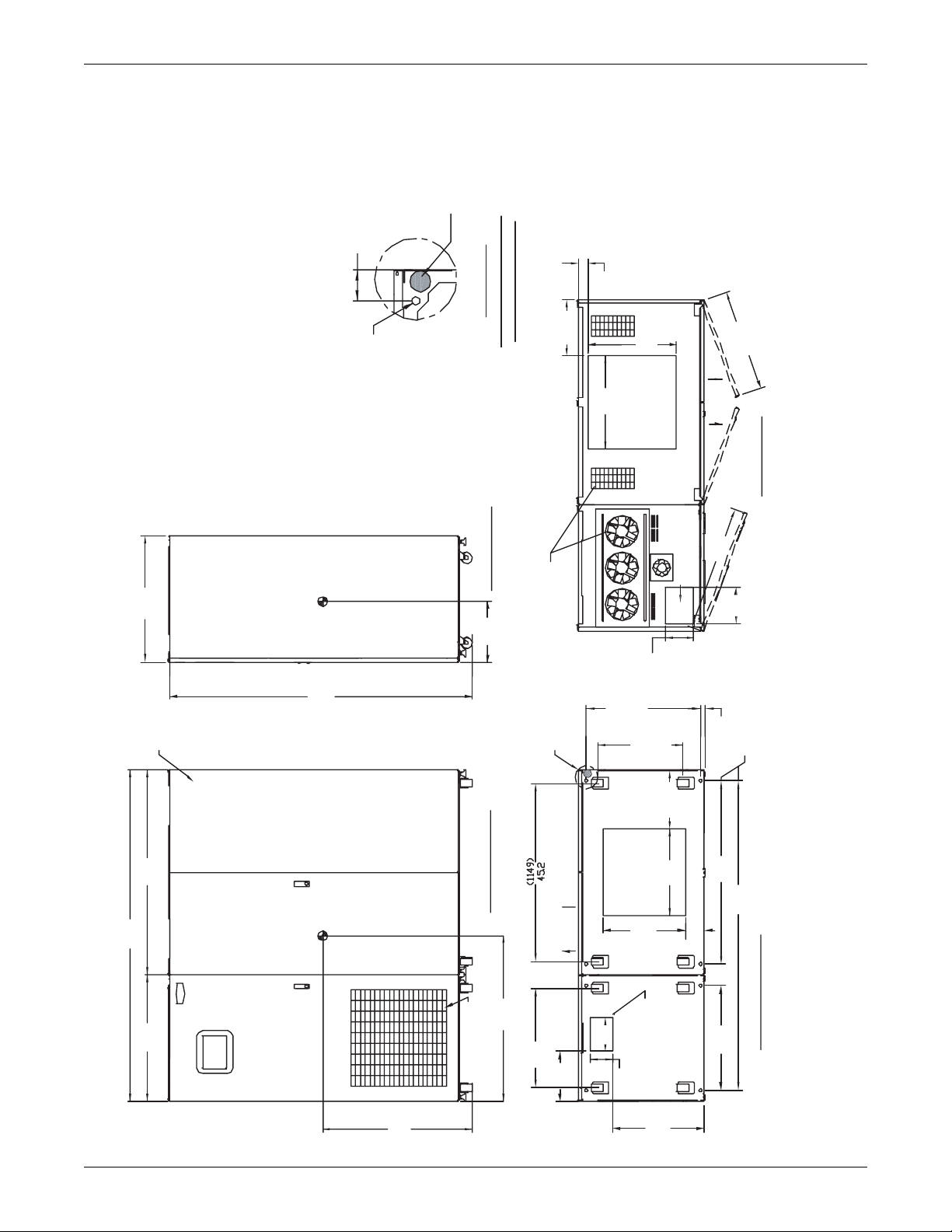

Figure 7 Outline drawing: 800 – 1000 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

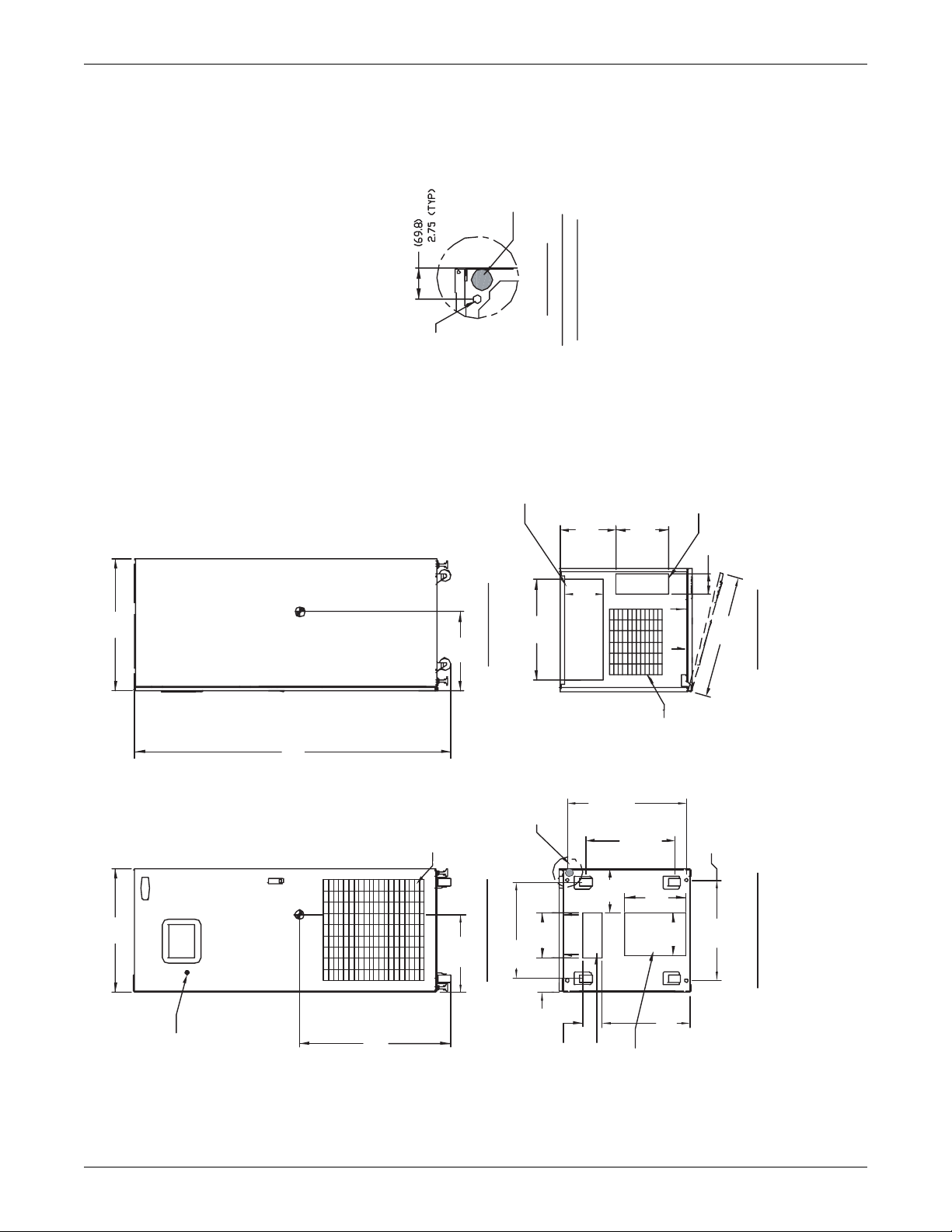

Figure 8 Outline drawing: 100 – 250amp STS2 with a key lockout switch option . . . . . . . . . . . . . . . . . . . 20

Figure 9 Outline drawing: 400 – 600 amp STS2 with a key lockout switch option . . . . . . . . . . . . . . . . . . . 21

Figure 10 Outline drawing: 800 – 1000 amp STS2 with the key lockout switch option . . . . . . . . . . . . . . . . 22

Figure 11 Seismic anchor drawing: 100 – 250 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 12 Seismic anchor drawing: 400 – 600 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 13 Seismic anchor drawing: 800 – 1000 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 14 Electrical field connections drawing: 100 – 250 amp STS2 with single output breaker. . . . . . . . 26

Figure 15 Electrical field connections drawing: 100 – 250 amp STS2 with dual output breakers . . . . . . . . 27

Figure 16 Electrical field connections drawing: 400 – 600 amp STS2 with single output breaker. . . . . . . . 28

Figure 17 Electrical field connections drawing: 400 – 600 amp STS2 with dual output breakers . . . . . . . . 29

Figure 18 Electrical field connections drawing: 800 – 1000 amp STS2 with single output breaker. . . . . . . 30

Figure 19 Electrical field connections: 800 – 1000 amp STS2 with dual output breakers . . . . . . . . . . . . . . 31

Figure 20 Circuit breaker schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 21 Control connection location diagram: 100 – 600 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 22 Control connection location diagram: 800 – 1000 amp STS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 23 Control wiring for remote source selection option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 24 Control wiring for the programmable relay board option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 25 Control wiring for the input contact isolator board option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 26 Control wiring for comms board (see Figure 27 on page 39 for internal modem wiring) . . . . . . 38

Figure 27 Control wiring for the internal modem option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 28 Control wiring for the network interface card (NIC) option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 29 Control wiring for the RS-232 port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 30 Outline drawing for input junction box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 31 Color LCD touch screen display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 32 LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 33 Installation drawing, seismic floor stand 100-250A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 34 Installation drawing, seismic floor stand 100-250A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 35 Installation drawing, seismic floor stand 100-250A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 36 Installation drawing, seismic floor stand 100-250A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 37 Installation drawing, seismic floor stand 400-600A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 38 Installation drawing, seismic floor stand 400-600A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 39 Installation drawing, seismic floor stand 400-600A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 40 Installation drawing, seismic floor stand 400-600A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 41 Installation drawing, seismic floor stand 800-1000A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 42 Installation drawing, seismic floor stand 800-1000A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 43 Installation drawing, seismic floor stand 800-1000A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 44 Installation drawing, seismic floor stand 800-1000A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 45 STS2 touch screen display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 46 STS2 touch screen display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 47 Source transfer screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 48 Gate board viewing slot locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 49 STS2 touch screen display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 50 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 51 Keyboard and keypad displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 52 Key lockout switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

v

Figure 53 Event mask dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 54 User settings dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 55 Source setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 56 Comm options dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 57 Modem dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 58 Input contact isolator dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 59 Programmable relay board dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 60 System options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 61 Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 62 History log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 63 LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 64 Key lockout switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

TABLES

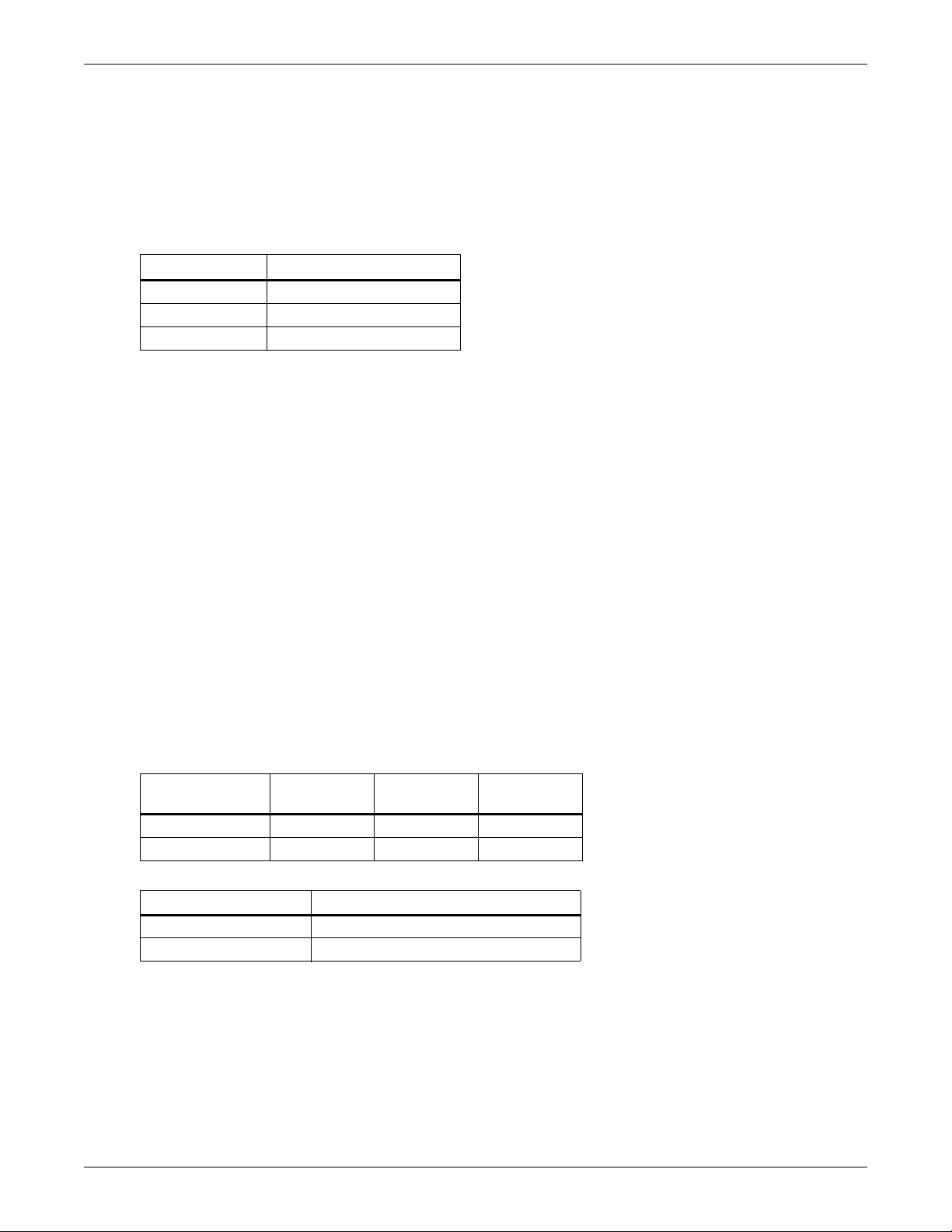

Table 1 Heat Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2 Altitude conversion—feet to meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3 Input/output conduit plate specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4 Input junction box dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 5 Input junction box terminal wire size range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 6 Remote source selection terminal block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 7 Terminal block 1 and terminal block 2 wire connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 8 Programmable relay board pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 9 Event Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 10 Terminal Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 11 Value types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 12 Group settings and values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 13 Binary-Hexadecimal Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 14 Set Point Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 15 Standard Settings for Programmable Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 16 LED and push button description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Table 17 Input/Output Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 18 System Current Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 19 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 20 Unit Short Circuit Withstand Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 21 Frame Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 22 MTA Plug Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 23 DB9 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 24 RS-232 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 25 Torque tightening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

vi

IMPORTANT SAFETY INSTRUCTIONS

Save these instructions

This manual contains important instructions that should be followed during the installation and

maintenance of the Liebert Static Transfer Switch 2 (STS2).

WARNING

!

The unit is supplied by more than one power source. the Unit contains hazardous voltages if

any of the input sources are ON, even when the unit is in bypass. To isolate the unit, turn

OFF and lock out ALL input power sources.

Verify that all input power sources are de-energized and locked out before making connections

inside unit.

Lethal voltages exist inside the unit during normal operation. Only qualified service

personnel should perform maintenance on the static switch.

NOTE

Read the entire manual before installing or operating the system. Adhere to all operating

instructions and warnings on the unit and in this manual.

Liebert Corporation neither recommends nor knowingly sells this product for use with life

support or other FDA-designated “critical” devices.

The Static Transfer Switch is suitable for indoor use only. Protect the unit from excessive

moisture and install the unit in an area free from flammable liquids, gases, or corrosive

substances.

The unit is designed to operate from solidly grounded AC power sources only. Provide input

over-current protection in accordance with the unit ratings. Wire and ground the unit

according to national and local electrical safety codes. All wiring should be installed by a

qualified electrician.

Before unit is placed into service for the first time, after equipment relocation, or after the unit

has been de-energized for an extended period of time, a thorough equipment inspection and

supervised start-up by qualified service personnel are strongly recommended.

CAUTION

!

This unit complies with the limits for a Class A digital device, pursuant to Part 15 Subpart J

of the FCC rules. These limits provide reasonable protection against harmful interference in a

commercial environment. This unit generates, uses and radiates radio frequency energy and,

if not installed and used in accordance with this instruction manual, may cause harmful

interference to radio communications. Operation of this unit in a residential area may cause

harmful interference that the user must correct at his own expense.

WARNING

!

Locate the center of gravity symbols and determine the unit’s weight before handling

the cabinet.

1

OVERVIEW OF MANUAL

The STS2 Installation, Operation and Maintenance Manual is organized in a logical progression so

that you can follow the procedures, in the order provided to get your STS2 installed and running.

Read the entire manual before proceeding with the unpacking and installation of the STS2.

The major sections are as follows:

Important Safety Instructions—review the instructions on the previous page before proceeding.

Support Information—a blank table in which you can enter pertinent data, such as the serial and

part numbers, which is needed when calling Liebert support.

Programmable Relay Board Settings Record—a blank table in which you can document your

Programmable Relay Board settings.

Input Contact Isolator Settings Record—a blank table in which you can document your Input

Contact Isolator settings.

1.0 - Safety Precautions—provides safety warnings that you must review before proceeding.

2.0 - Unpacking and Inspections—provides instructions for inspecting, unloading, handling and

removing the STS2 from the shipping pallet.

3.0 - Location Considerations—provides information regarding environmental considerations for

where the STS2 is installed.

4.0 - Locating the STS2—provides instructions for leveling the STS2 and anchoring the unit to the

floor, should that be required.

5.0 - Power and Control Wiring—provides instructions wiring the STS2 for power and control connections.

6.0 - Options—lists the options available for the STS2.

7.0 - Installation Drawings—provides outline, seismic and electrical field connection drawings

required for installing the STS2.

8.0 - Introduction to STS2 Operations—provides a system description.

9.0 - Theory of Operation—provides an overview of how the unit works, plus a brief overview of

some of the components.

10.0 - Operating Instructions for the Touch Screen Interface—provides instructions for turning the system on and off, completing a maintenance by-pass, and selecting a preferred source.

11.0 - Alarm and Faults—provides a list of event messages.

12.0 - Communication Interfaces—discusses the communication ports and provides a list of termi-

nal and modem commands.

13.0 - STS2 Touch Screen Display—provides instructions for using the HMI touch screen interface

for monitoring and managing the STS2.

14.0 - Operating the LED Display STS2—provides instructions for operating the LED Display

unit without the touch screen display.

15.0 - Specifications—provides specifications for the STS2.

16.0 - Event Message Help Text—provides the help text for the various system event messages.

This help is also available through the touch screen interface.

17.0 - Maintenance—briefly discusses routine maintenance, provides proper torque settings for nuts

and bolts, and provides the Liebert contact information.

2

1.0 SAFETY PRECAUTIONS

Read this manual thoroughly before working with the static transfer switch.

Be sure to review the warning under Important Safety Instructions on page 1.

Refer to the Handling Considerations on page 5 before attempting to move the unit.

Under typical operation and with the doors closed, only normal safety precautions are necessary. The

area around the static transfer switch should be kept free from puddles of water, excess moisture and

debris. The vent grate in the front of the system should not be obstructed in order to ensure a smooth

air flow through the unit for cooling.

ONLY qualified service personnel should perform maintenance on the static transfer switch. When

performing maintenance on any part of the equipment under power, service personnel and test equipment should be located on rubber mats. The service personnel should wear insulating shoes for isolation from direct contact with the floor.

Unless all power is removed from the input sources to the unit, one person should never work alone. A

second person should be on hand to assist and summon help, should an accident occur.

Three types of messages are used throughout this manual to stress important text. Carefully read the

information below each Warning, Caution and Note and use professional skills and prudent care

when performing the actions described in that text.

A Warning indicates the presence of a possible serious, life-threatening condition. For example:

Safety Precautions

WARNING

!

The unit is supplied by more than one power source. The Unit contains hazardous voltages if

any of the input sources is ON, even when the unit is in bypass. To isolate the unit, turn OFF

and lock out ALL input power sources.

Verify that all input power sources are de-energized and locked out before making connections

inside unit.

Lethal voltages exist inside the unit during normal operation. only qualified service personnel

should perform maintenance on the static switch.

A Caution indicates a condition that could seriously damage the equipment and possibly injure personnel. For example:

CAUTION

!

Risk of unit damage

The input sources to the static switch must be grounded-wye sources. input sources other

than solidly grounded-wye sources may cause damage to the switch.

A Note emphasizes important text. If the instructions are not properly followed, the equipment could

be damaged or may not properly operate. For example:

NOTE

Read the entire manual before installing and operating the unit.

3

2.0 UNPACKING AND INSPECTIONS

NOTE

Read the entire manual before installing and operating the unit. Upon receipt of the Static

Transfer Switch2, the installer should perform the following steps to assure a high-quality

installation.

A high-quality installation begins on the receiving dock. The STS2 and its packaging should be

inspected when the unit is delivered. If the packaging is not damaged, unpack the unit and conduct

an internal inspection before beginning the installation process. This section discusses the inspecting

and unpacking of the STS2.

2.1 External Inspections

1. While the STS2 is still on the truck, inspect the equipment and shipping container(s) for any signs

of damage or mishandling. Do not attempt to install the system if damage is apparent.

2. Upon receipt and before unpacking, inspect the shipping crate for damage or mishandling. Check

the Shock-Watch™ indicator.

• If the indicator is red, note on shipper’s receipt and check for concealed damage.

• If any damage as a result of shipping is observed, file a damage claim with the shipper within

24 hours and contact your local Liebert representative or Liebert Global Services at

1-800-543-2378 to inform them of the damage claim and the condition of the equipment.

3. Locate the bag containing the keys for the front access door. The bag is attached to the cabinet.

4. Compare the contents of the shipment with the bill of lading. Report any missing items to the

carrier and to Liebert Global Services immediately.

5. Check the nameplate on the cabinets to verify that the model numbers correspond with the one

specified. Record the model numbers and serial numbers in the front of this installation manual.

A record of this information is necessary should servicing be required.

6. If unit is to be stored before installation, it is recommended to store the unit in a dry environment

with temperatures in the range of -40°F (-40°C) to 176°F (80°C). Use original packing materials or

other suitable means to keep the unit clean. When opening the shipping crate, use care not to

puncture the container with sharp objects.

Unpacking and Inspections

2.2 Unloading and Handling

CAUTION

!

Risk of unit damage.

When moving the unit by forklift, lift the unit from the rear so as to protect the front panel.

Do not exceed a 15 degree tilt with the forklift.

Also, if you are moving the unit by forklift or pallet jack after it has been removed from the

pallet, be aware of the location of the casters and leveling feet so as not to damage them.

Most STS2 models are contained in one cabinet. The 800–1000 amp units are contained in two cabinets that are connected together and shipped on one pallet.

Because the weight distribution in the cabinet is uneven, use extreme care during handling and

transporting.

The unit can be moved by forklift or pallet jack.

See 2.2.2 - Unit Preparation on page 5 for instruction on removing the STS2 from the pallet.

4

2.2.1 Handling Considerations

The static switch is bolted to a wooden shipping pallet to allow handling by forklift equipment or a

pallet jack.

Easily Moved — The unit is furnished with integral castors that allow the unit to be rolled into place

after it has reached its location and is removed from the pallet.

WARNING

!

Exercise extreme care when handling static switch cabinets to avoid equipment damage or

injury to personnel.

The cabinet can be safely tilted 15 degrees in any direction by forklift.

If moving the unit up a ramp on its casters or a pallet jack, ensure that the incline does not

exceed fifteen (15) degrees.

Locate the center of gravity symbols and determine the unit’s weight before handling

the cabinet.

Check the unit size and weight — Refer to the cabinet drawings furnished with the unit for size

and weight. Typical cabinet dimensions are shown in Figures 5 through 7. Typical unit weights are:

100-250 amp 780 lbs. (354 kg)

400-600 amp 1200 lbs. (544 kg)

800-1000 amp 2500 lbs. (1134 kg).

Unpacking and Inspections

Plan the route — Review the route over which the unit will be transported to its installation location to ensure that all passages are large enough to accommodate the unit and support the weight.

Check for any non-negotiable corners or offsets in hallways. Before moving the unit to the intended

location, review 3.0 - Location Considerations.

2.2.2 Unit Preparation

The unit can be removed from the pallet before it is moved to its location.

Complete the following steps to properly remove the STS2 from the shipping pallet:

1. Set the pallet in a level area with enough room to maneuver and remove the unit.

2. Remove the bolts holding the unit to the shipping pallet (located in the base of the unit).

3. Remove the shipping blocks from under the frame of the unit.

4. Use a forklift to raise the unit off the pallet and onto the floor. Ensure that the forklift is clear of

the unit’s casters and leveling feet. Lift the unit from the rear.

5. Conduct an internal inspection of the unit. See the list below of inspection items.

2.3 Internal Inspections

After the STS2 has been unpacked, conduct an internal inspection:

1. Verify that all items have been received.

2. If spare parts were ordered, verify their arrival.

3. After the Static Transfer Switch has been removed from the pallet, open the door and remove

cabinet panels to check for shipping damage to internal components.

4. Check for loose connections or unsecured components in the cabinet(s).

5. Check for any unsafe condition that may be a potential safety hazard.

After the STS2 has been inspected and no problems are found, the unit can be moved to its installation location. If using a forklift, remember to lift the unit from the rear.

5

3.0 LOCATION CONSIDERATIONS

The STS2 should be placed in a clean, cool and dry location. The STS2 requires only front access for

installation and maintenance. Back or side access is not required. Adequate space is required above

the unit for conduit (if configured as such) and cooling air flow. This section provides specific information for these considerations.

The unit is designed with top and bottom cable terminations to allow maximum flexibility in its

installation. If bottom cable entry is used, sufficient cable bending space must be provided by a raised

floor or a floor stand.

For dimensions of each unit, see Figures 5, 6 and 7 in section 7.0 - Installation Drawings on

page 17. If your unit is equipped with an optional key lockout switch, see Figures 8 through 10 for

location of that switch.

3.1 Recommended Minimum Service Clearances

The recommended service clearances are at the front of the unit. The minimum service clearance

required by the National Electrical Code (NEC) Article 110-26 is 36 in. (91 cm) for units with voltages

up to 150 volts to ground and 42 in. (107 cm) for units with voltages over 150 volts to ground. Clearance of at least 18 in. (46 cm) is required above the unit for cooling air flow.

3.2 Heat Output

Location Considerations

The unit produces minimal heat during normal operation.

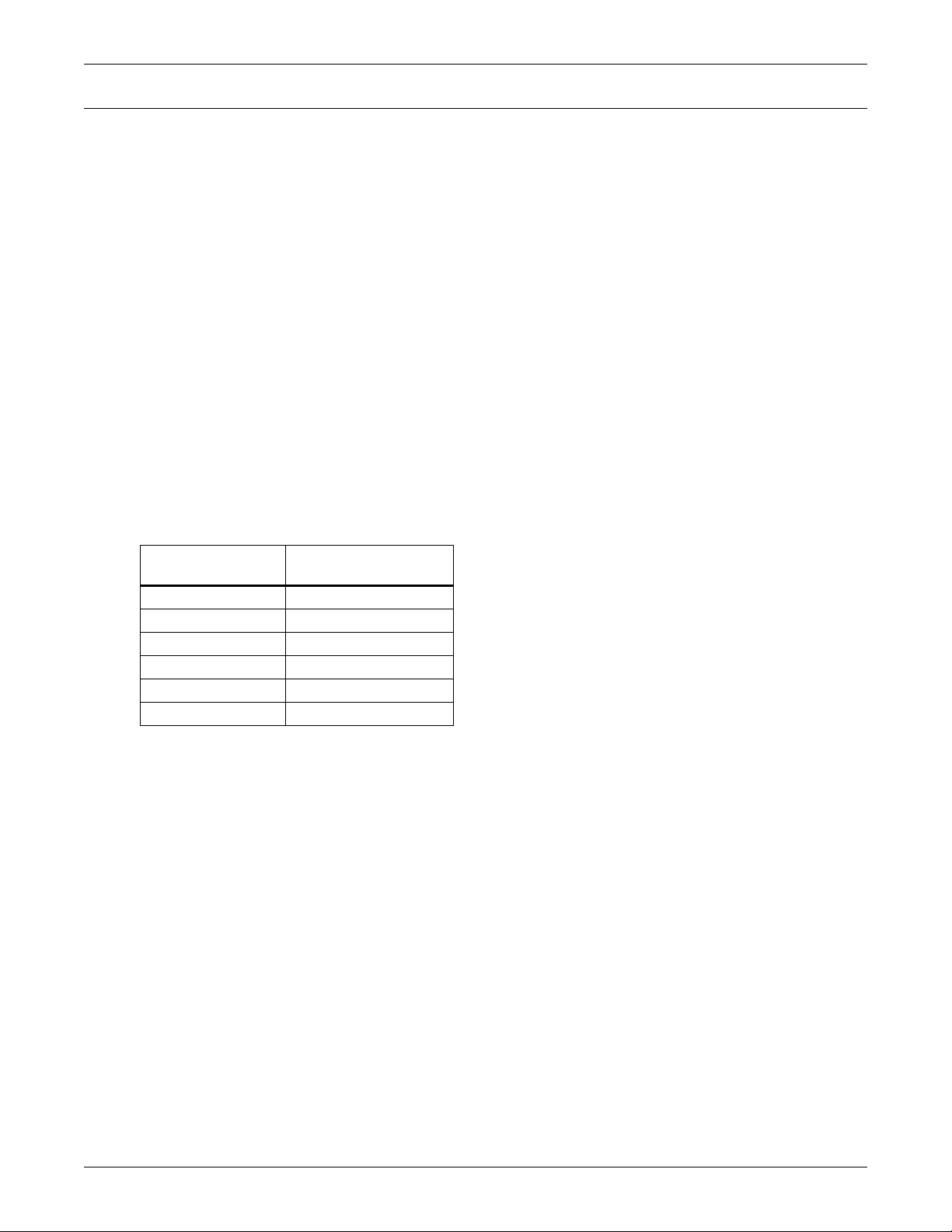

Table 1 Heat Output

Switch Size

100 amp 2,711 (0.80)

250 amp 4,680 (1.37)

400 amp 6,972 (2.04)

600 amp 10,520 (3.08)

800 amp 13,777 (4.03)

1000 amp 17,390 (5.09)

Heat Output

BTU/Hr (kW)

3.3 Operating Environment

The unit is designed to be installed indoors where the ambient air temperature is in the range of 32°

and 104°F (0°C and 40°C) with a relative humidity of 0% to 95% non-condensing, up to an altitude of

4000 feet (1200 meters).

6

3.4 Altitude

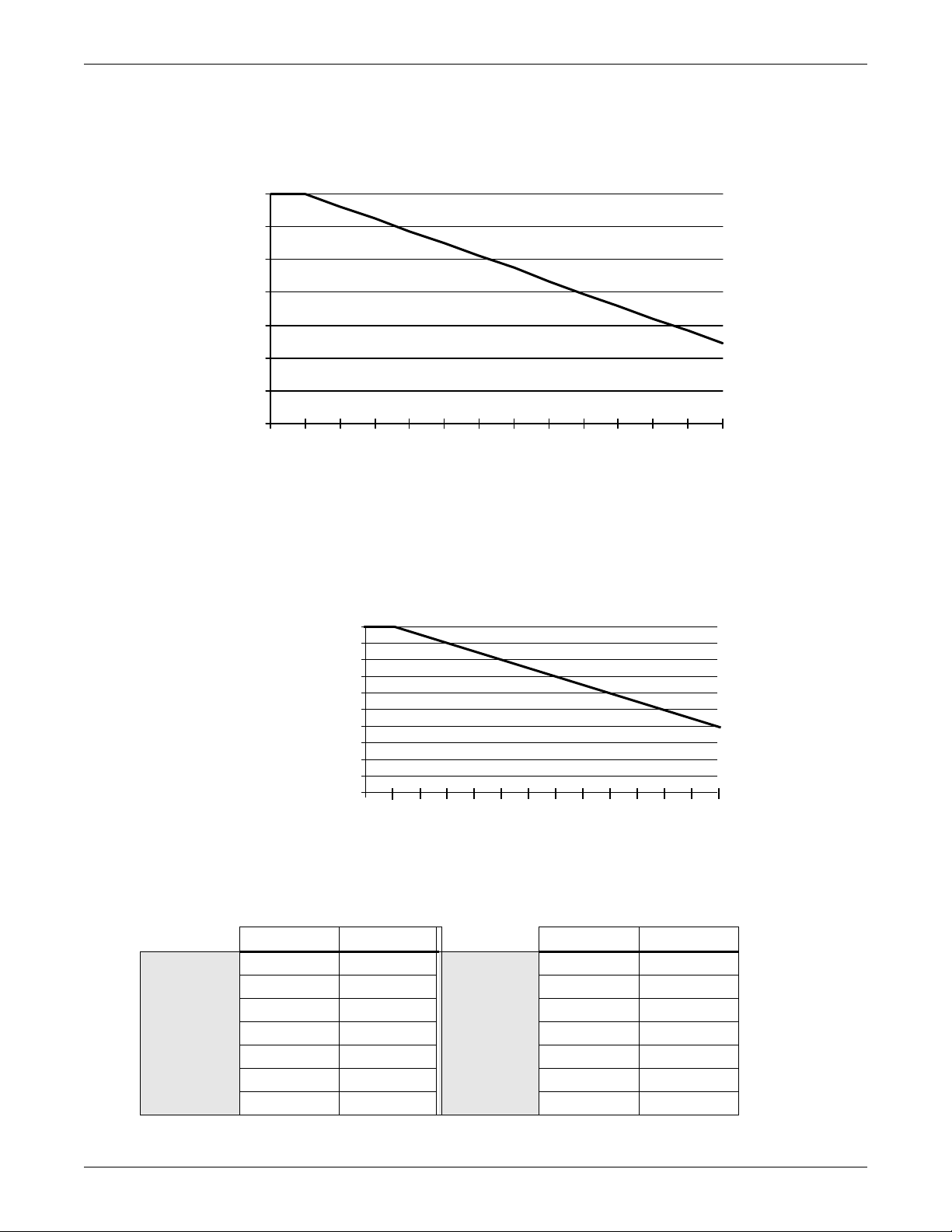

The standard units are designed for full load operation up to 4000 feet (1200 m) above sea level. See

Figure 1 for recommended deratings for altitudes greater than 4000 feet (1200 m).

Figure 1 Recommended derating for high altitude operation

100

98

96

94

92

Rating (%)

90

88

86

0

4000

4500

5000

5500

6000

6500

7000

Altitude (Feet Above Sea Level)

7500

8000

8500

Location Considerations

9000

9500

10000

Operation at full load at a higher altitude can be accommodated in ambient temperatures less than

104°F (40°C) ambient. Figure 2 shows the maximum allowable ambient temperature for full load

operation at altitudes above 4000 feet (1200 m).

Figure 2 Maximum ambient temperature for full load operation at higher altitudes

104.0 (40)

102.2 (39)

100.4 (38)

98.6 (37)

96.8 (36)

95.0 (35)

93.2 (34)

94.1 (33)

°F (°C)

89.6 (32)

87.8 (31)

86.0 (30)

0

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

Max. Ambient Temperature

9000

Altitude—Feet

Table 2 Altitude conversion—feet to meters

Feet Meters Feet Meters

Altitude

4000 1200

4500 1372 8000 2438

5000 1524 8500 2591

5500 1676 9000 2743

6000 1829 9500 2896

6500 1981 10000 3048

7000 2134

Altitude

7500 2286

9500

10000

7

4.0 LOCATING THE STS2

This section provides instructions for leveling the STS2 and anchoring the unit to the floor, should

that be required.

For leveling feet details, see Figures 5 through 10.

4.1 Leveling and Anchoring the Unit to the Floor

The STS2 can be anchored to the concrete floor to ensure stability for the unit in the event of seismic

activity.

The seismic brackets are an option for the STS2 and are shipped separately from the unit when

ordered.

See Figures 11 through 13 for instructions and details for installing seismic anchoring.

4.2 Leveling of the Static Switch Without Anchoring

The Static Transfer Switch is furnished with casters and leveling feet. After final positioning of the

unit, adjust the leveling feet located in each corner of the frame base to level and stabilize the unit.

4.3 Leveling and Anchoring the Static Switch Using Floor Stand

The STS2 can be installed using the optional floor stand to support the unit instead of using the

raised floor. The STS2 can be rolled or placed using a lift on to the floor stand.

Locating the STS2

After final positioning of the unit, adjust the leveling feet located in each corner of the frame base to

level and stabilize the unit.

The floor stand can also be used to ensure the unit’s stability in the event of seismic activity by

anchoring the STS2 to the floor stand and to the concrete floor .

The seismic floor stand is shipped separately from the unit when ordered.

See Figures 33 through 44 for instructions and details for installing seismic floor stand.

8

5.0 POWER AND CONTROL WIRING

All power and control wiring should be installed by a qualified electrician. All power and control wiring must comply with the NEC and applicable local codes. Unless otherwise labeled, use the recommended tightening torque as shown in Table 25 - Torque tightening.

The busbars are accessible through the front of the STS2 and designed to allow one-handed tightening.

Cables can be installed through the top or bottom of the unit through removable conduits plates.

See Figures 5 through 10 for wiring entrance locations.

Input wiring also can be installed under a raised floor to optional input junction boxes and cables,

when used.

5.1 Input And Output Power Connections

If the unit is furnished with input junction boxes, the input power connections are made to the input

power terminals located in the junction boxes. Input power cables, furnished with the input junction

boxes, are shipped unattached to the unit for connection between the junction boxes and the bus bars

provided inside the unit. Input junction box installation is discussed in 5.2 - Input Junction Box

Installation (Optional) on page 10.

If input junction boxes are not furnished, the input power connections are made to the bus bars provided inside the unit. These bus bars are accessible through the front of the unit.

Output power connections also are made to the bus bars provided inside the unit. These bus bars are

accessible through the front of the unit. See Figures 14 to 19 for details on the bus bars.

Power and Control Wiring

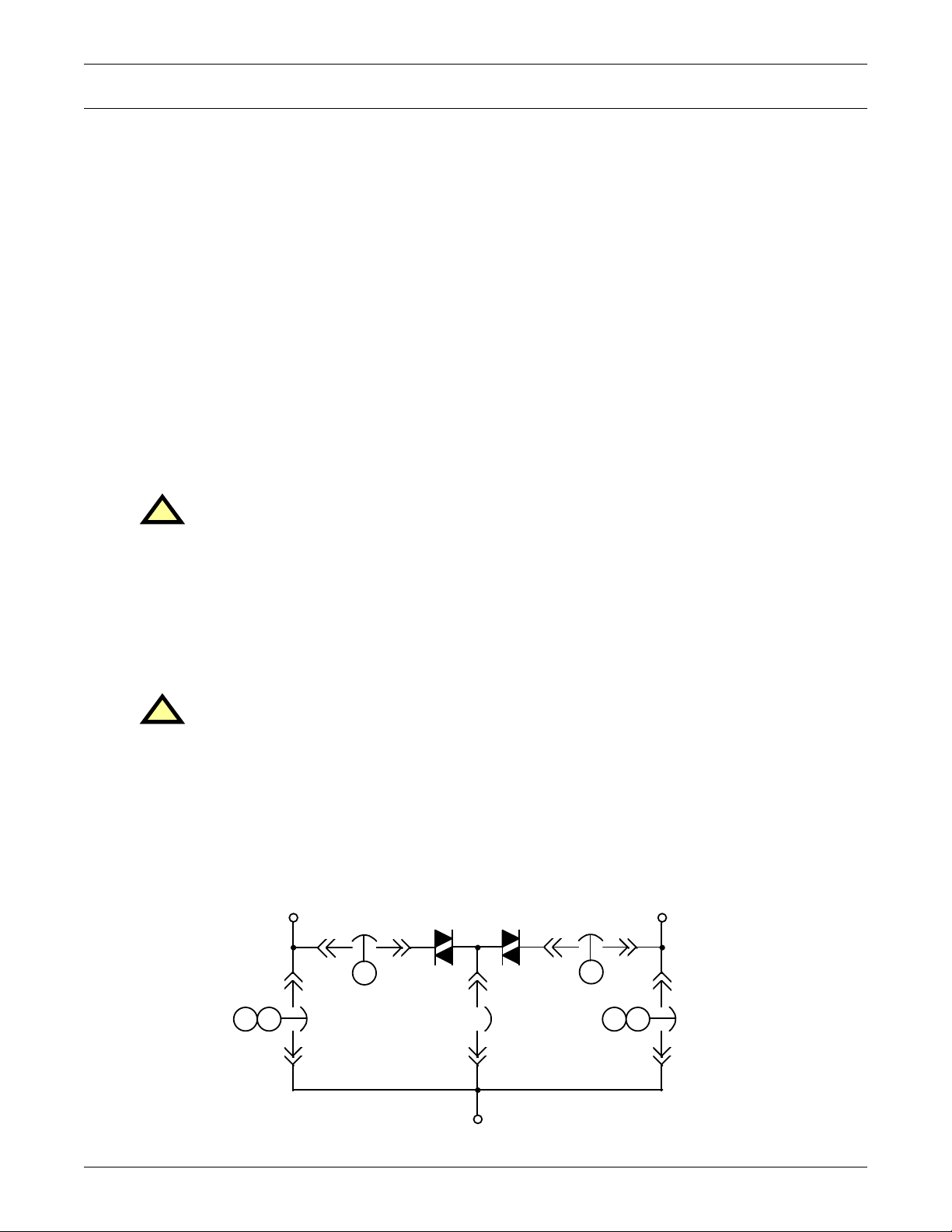

WARNING

!

Risk of electric shock

Verify that all input power and control circuits are de-energized and locked out before making

connections inside unit.

The two input power feeds (sources) to the STS2 should be from two independent sources to avoid a

common source failure.

To ensure proper operation of the STS2, the two input sources must be the same nominal voltage level

and phase rotation.

For uninterrupted automatic transfer, the two input sources should be synchronized within 15 degrees.

CAUTION

!

Risk of unit damage.

The input sources to the static switch must be grounded-wye sources. Input sources other

than solidly grounded-wye sources may cause damage to the switch.

The STS2 is designed for operation with 3 or 4-wire solidly grounded sources only.

For 4-wire operation, the common source neutral must be connected to the STS2. See Figure 3 on

page 9 for a typical one-line diagram. Refer to Figures 14 to 19 for electrical field connections on all

units, with both single and dual output breakers.

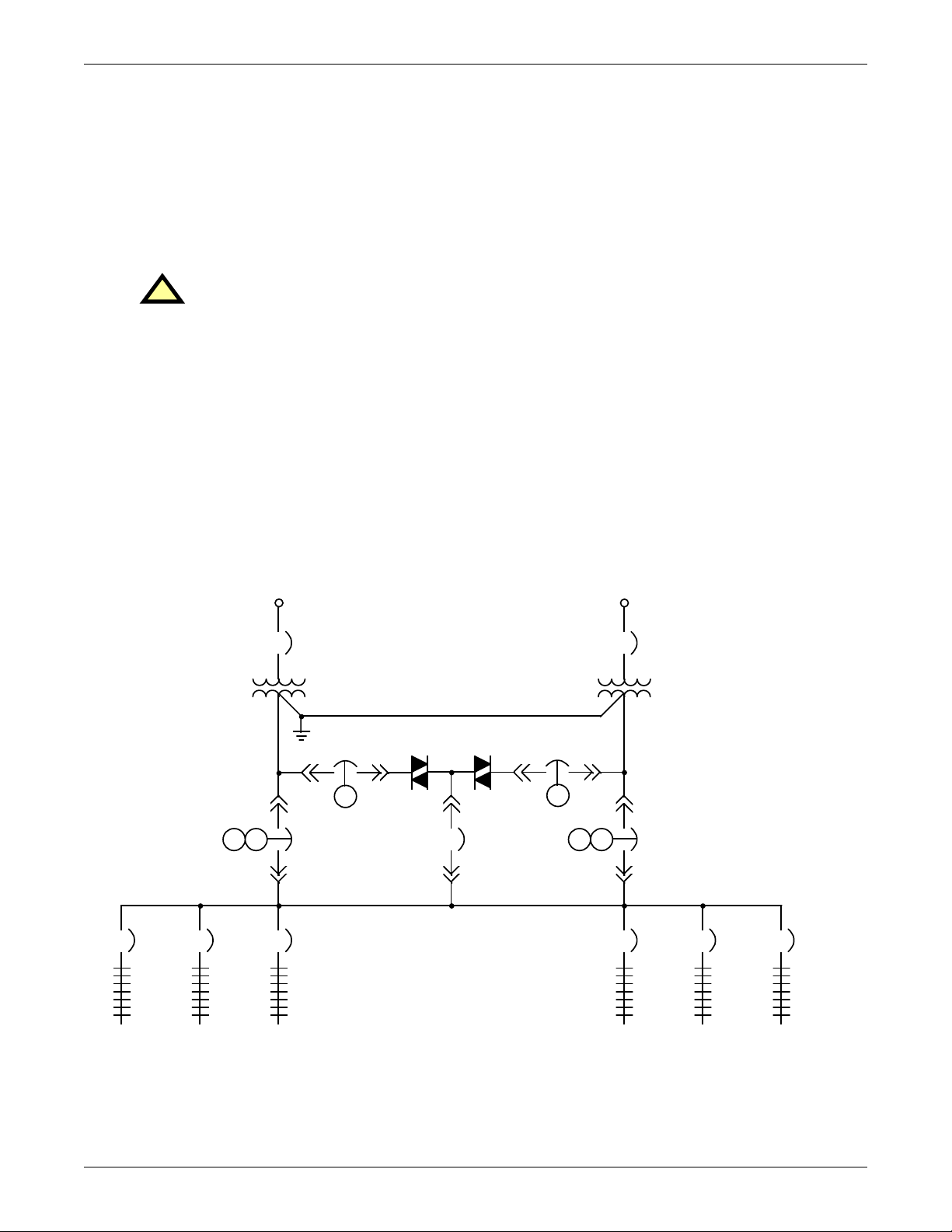

Figure 3 Typical static transfer switch one-line diagram

SOURCE 1 SOURCE 2

STS1 STS2

CB1 CB2

SS1 SS2

K1

K3K2 K3K1

OUTPUT

CB3 CB5CB4

9

K2

The input and output power wire size should be based on the upstream overcurrent protection device,

observing the NEC and local codes.

The molded case switches contained in the STS2 are typically non-automatic circuit breakers that

rely on the upstream and/or load overcurrent protection. Upstream overcurrent protection should be

rated equal to or less than the rating of the STS2 molded case switches.

The STS2 input and output power and ground and neutral bus bars accommodate a wide range of

wire sizes. The STS2 bus bars accommodates standard 2 hole lugs.

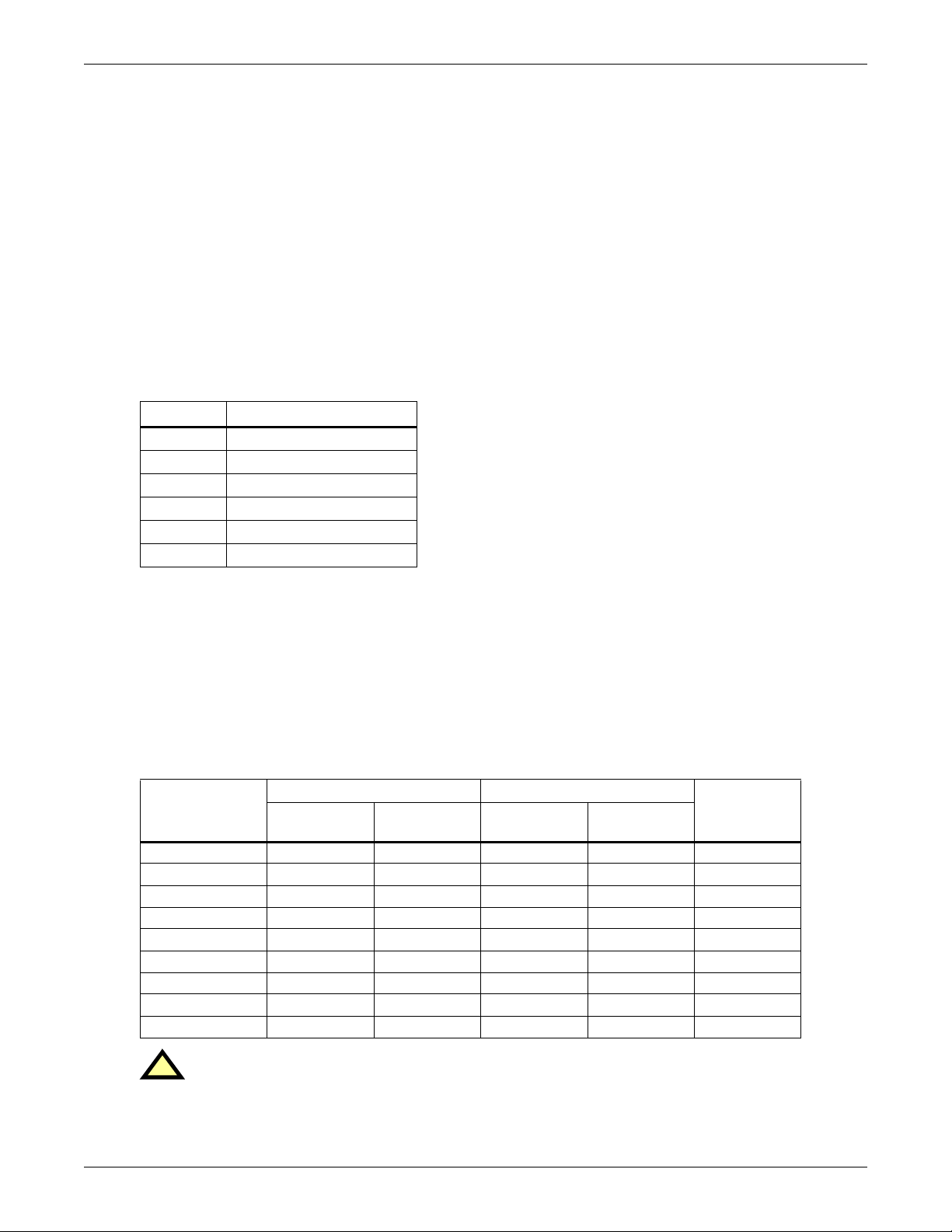

Table 3 Input/output conduit plate specifications

Rating Max. number and size

100-250A 6 — 3" conduit

400-600A 9 — 4" conduit

800-1000A 12 — 4" conduits

5.2 Input Junction Box Installation (Optional)

The input junction box option is available to simplify input connections to the STS2. Two input junction boxes and the associated flexible 10 foot long (3 meter) input cables are provided with this option.

This option is available only with bottom cable entrance, typically when the unit is located on a raised

floor.

If the input junction boxes will be used, they either can be shipped with the unit or shipped in

advance to be installed during the rough-in stage of construction.

Power and Control Wiring

Locate the junction boxes a maximum of 8 feet (2.4 meters) from the planned location of the Static

Switch.

Due to a lack of clearance for the cables below the unit, the cables are also shipped loose from the unit

for installation at the site. The input cables connect from the input junction boxes to the input power

bus bars inside the STS2.

The standard configuration for the input junction boxes and cables is for 3-wire-plus-ground feeds. If

the input neutral is required, special 4-wire-plus-ground input cables and junction boxes are required.

See Figure 30 for wiring details.

For preparation purposes, the following tables provide the dimensions and wire sizes for the input

junction boxes.

Table 4 Input junction box dimensions

Length

Switch Rating

100 amp 16 (406) 14 (356) 6 (152)

250 to 600 amp 30 (762) 16 (406) 6 (152)

Inches (mm)

Width

Inches (mm)

Height

Inches (mm)

Table 5 Input junction box terminal wire size range

Switch Rating Power and Ground Lug Wire Range

100 amp #6 to #2/0 AWG

250 to 600 amp (2) #6 AWG to (2) 500 kcmil

10

5.3 System Grounding

Equipment grounding — Grounding is primarily for equipment and personnel safety, although

proper grounding also enhances equipment performance.

All input and output power feeds must include an equipment grounding means as required by the

NEC and local codes.

An insulated equipment ground conductor is recommended to run with each input and output power

feed. The equipment ground conductors should be at least the minimum size conductor per the NEC

based on the upstream overcurrent protection device.

WARNING

!

If conduit is used as a grounding means, adequate electrical continuity must be maintained at

all conduit connections. The use of isolating bushings with a metal conduit can be a safety

hazard and is not recommended.

4-Wire-Plus-Ground Systems — When 4-wire-plus-ground input feeds are utilized, the input power

sources must be properly grounded. Because the neutral is not switched by the STS2, the neutrals of

the two power sources are solidly interconnected. The NEC prohibits grounding a power source at

more than one point. Connecting the neutrals of two grounded power sources together effectively

grounds each of the sources at more than one point, which allows neutral current to flow on the

ground system, defeats ground fault protection, creates a safety hazard, and violates the NEC.

Where possible, the two power sources should be located in close proximity and a single

neutral-to-ground bond made (as shown in Figure 4 on page 11 or as is typical with a doubleended substation).

Power and Control Wiring

Figure 4 Typical one-line diagram of two PDUs and a static transfer switch

SOURCE 1

MICB1

ISOLATION

TRANSFORMER

SS1 SS2

CB1 CB2

K1

K3K2 K3K1

225A 225A225A 225A 225A225A

STS1 STS2

CB3CB4

SOURCE 2

K2

MICB2

ISOLATION

TRANSFORMER

CB5

5.4 Control Wiring Connections

No control wiring is needed on the standard STS2. Only certain options require external control wiring. See 6.0 - Options on page 13 for details

11

5.5 Remote Source Selection Wiring

An optional Remote Source Selection board may be installed in your STS2. This board is installed in

the same bay as the communications options. See Figures 21 and 22 for the location of these options.

See Figure 23 for information on the control wiring for the Remote Source Selection option.

The Remote Source Selection allows you choose the preferred input source from a remote location.

Terminal connections allow the customer to remotely select a source to be the preferred source in the

same process as the local source transfer selection.

The unit’s preferred source selection and Remote Source Selection are active at the same time, with

the STS2 following the last request for a preferred source change, regardless of whether it was from

the local or Remote Source Selection controls.

A six pin terminal block provides the Remote Source Selection connections. Two pairs of wires are

used from the switch to trigger the source selection. You can select the type of switch used for this

remote control. Connections are made to four of the connections, using Form A dry contacts. The contacts are numbered left to right:

Table 6 Remote source selection terminal block

Contact Connection

1 Source 1

2 Isolated ground

3 Source 2

4 Isolated Ground

5 DO NOT USE

6 DO NOT USE

Power and Control Wiring

See 10.3 - Enabling Remote Source Selection for instructions on enabling the Remote Source

Selection option.

5.6 Power Supply

The STS2 is supplied with redundant power supplies that are designed to operate from a voltage

range of 200V to 600V. The unit is set at the factory to match the nameplate voltage. Field adjustments are not necessary. If the unit needs to operate at a voltage other than what is listed on the

nameplate, contact Liebert Global Service or the local Liebert representative. Table 7 provides transformer tap information.

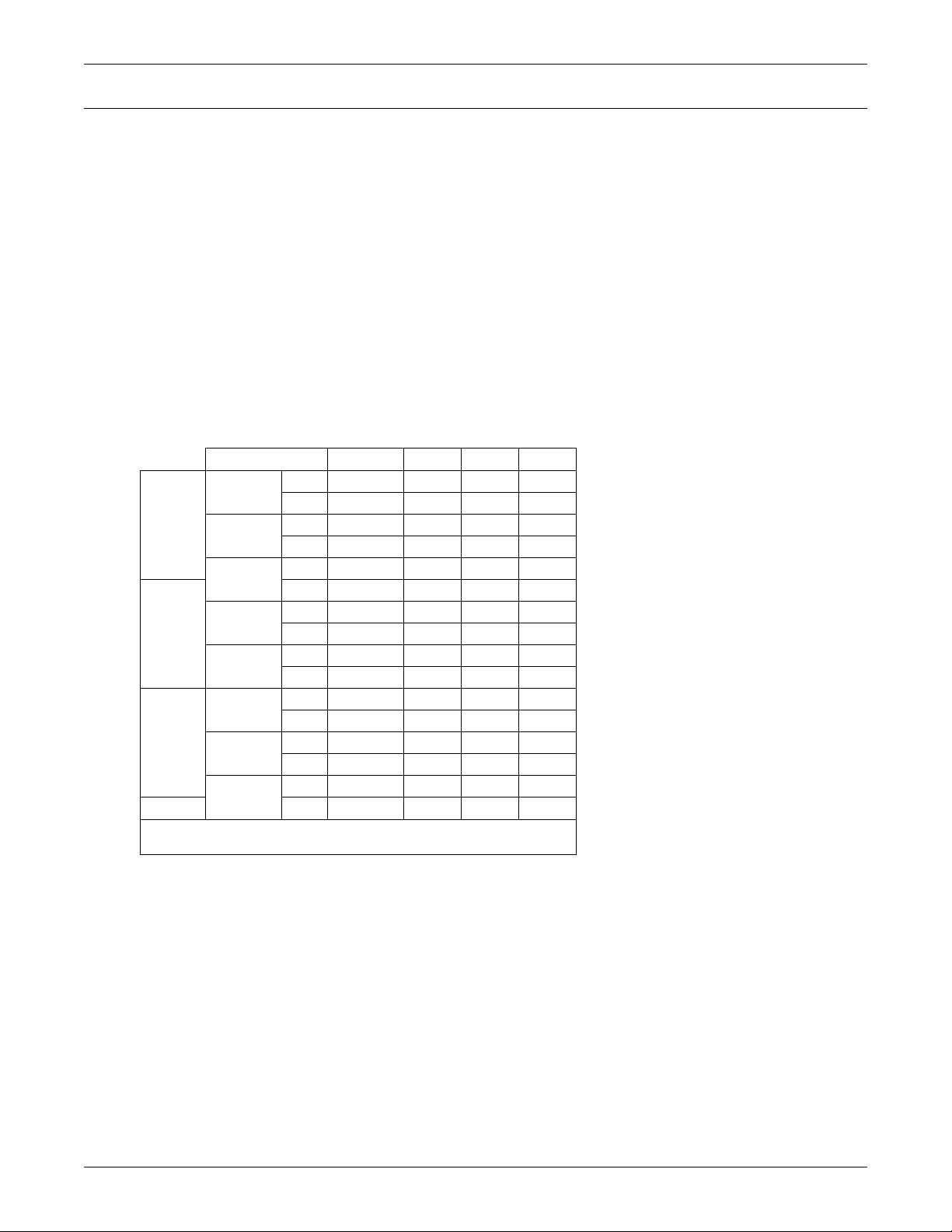

Table 7 Terminal block 1 and terminal block 2 wire connections

Voltage

200 1 9 1 9 1-7

208 1 10 1 10 1-7

220 2 12 2 12 6-8

240 1 11 1 11 1-7

380 1 8 1 8 2-7

400 1 9 1 9 3-7

415 1 10 1 10 4-7

480 1 11 1 11 5-7

600 1 12 1 12 6-7

Connect t Connect

F1

TB1-XX

F2

TB1-YY

TB2-XX

F3

F4

TB2-YY

Jumper

Between

CAUTION

!

Using Table 7, ensure that the wiring for the control transformers matches the input voltage

for the unit.

Improper wiring could result in blown fuses.

12

6.0 OPTIONS

This section discusses the options available for the STS2. The communications options are also discussed in 12.0 - Communication Interfaces.

6.1 Programmable Relay Board

The Programmable Relay Board (PRB) provides a means to trigger an external device when an event

occurs in the STS2. Each PRB has 8 channels. Each channel has two sets of Form-C dry contacts,

rated 1 Amp @ 30 VDC or 250 mAmp @ 125 VAC.

Any alarm/event can be programmed to any channel or channels. Up to ten (10) events can be programmed to a relay. If multiple events are grouped to one relay, group the events logically to simplify

troubleshooting when an event is triggered. The same alarm/event can be programmed to more than

one channel. Up to two Programmable Relay Boards can be installed in the STS2 for a total of 16

channels. Programming is performed through the touch screen display.

See Configuring the Programmable Relay Board Settings on page 97 for default settings and

instructions for reconfiguring the relays. See Figures 21 and 22 for the location of the PRB. See

Figure 24 for wiring details. Table 8 provides the PRB pinout.

Table 8 Programmable relay board pinout

Channel Pin No. C N.C. N.O.

CH1

TB1

TB2

TB3

TB4 B1-3 1 2 3

Key: N.O. = Normally Open; N/C. = Normally Closed; C = Common

Note: Pin 16 not used on TB1, TB2, and TB3.

CH2

CH3

CH4

CH5

CH6

CH7

CH8

A1-3 1 2 3

B4-6 4 5 6

A7-9 7 8 9

B 10-12 10 11 12

A 13-15 13 14 15

B1-3 1 2 3

A4-6 4 5 6

B7-9 7 8 9

A 10-12 10 11 12

B 13-15 13 14 15

A1-3 1 2 3

B4-6 4 5 6

A7-9 7 8 9

B 10-12 10 11 12

A 13-15 13 14 15

Options

6.2 Optimized Transfer

When the STS2 is used as a primary-side switch—on the primary of an isolation transformer—optimized transfer greatly reduces the transformer magnetization current during automatic transfers

through a new transfer control algorithm. The Liebert algorithm (patent pending) optimizes the

transfer timing so that the volt-seconds applied to the downstream transformer primary is balanced,

minimizing peak saturation current.

The volt-second balance is achieved by directly computing the volt-second applied to the transformer

during transfer events and determining the optimum time to turn on the alternate source SCRs in

order to balance the volt-second within specified tolerance.

Optimized transfer also seeks to minimize the voltage disturbances while still maintaining transformer flux balance. This unique flux balance algorithm does not just wait for the balance point to

occur, but will pulse fire the SCRs as soon as possible to minimize the voltage disruption. This results

in far superior voltage waveforms applied to the load.

13

6.3 Distribution Cabinet With I-Line Panelboard—100-600A Units Only

A distribution cabinet with a Square D I-Line panelboard offers space to plug in up to 10 three-pole

branch circuit breakers (100A-250A). The panelboard is rated at 600A with an overall short-circuit

rating of 100,000 AIC.

The full-height cabinet mounts on either the right or left side of the STS2 and is fully enclosed with a

keylock door and an accent cover that permits access to the panelboard without exposing other portions of the STS2.

6.4 Input Contact Isolator Board

The Input Contact Isolator Board (ICI) provides an STS2 module interface for up to eight external

user alarm or message inputs to be routed through the static transfer switch’s alarm network. The

eight contacts are normally open dry contacts. When a contact closes, an event is triggered.

The Input Contact Isolator options are configured through the Input Contact Isolator dialog box,

which is accessed from the Comm Option dialog box on the touch screen display. You also can program the alarm messages through this dialog box. See Configuring the Input Contact Isolator

Settings on page 95 for instructions on configuring the connections.

See Figures 21 and 22 for the location of the ICI. See Figure 25 for wiring details.

6.5 Comms Board

The Comms Board provides a communication interface to Liebert SiteScan, site monitoring product,

and/or an external or internal modem. SiteLink-12 or SiteLink-4 is required for SiteScan to communicate with the STS2.

The Comms Board is equipped with an RS-422 communication port for communication to a Liebert

SiteScan monitoring system using a 2-wire twisted pair for reliable communication up to 1000 meters

(3281 feet). Information available from the RS-422 port includes the present switch status information, all monitoring parameters, and all active alarms.

The Comms Board is equipped with a modem interface for remote reporting of the present switch status information, alarm history information, and the history of status screens that are triggered upon

a major alarm event. The monitoring system software also supports an auto-dial feature that allows

the system to automatically dial programmed phone numbers by way of the modem to report designated alarm conditions.

Programming the Comms Board is performed through the touch screen display. See Comm

Options on page 93 for details.

See Figures 21 and 22 for the location of the Comms Board.

See Figure 26 for information on the control wiring.

Options

6.6 Internal Modem

The Internal Modem is an option that must be ordered separately. An external modem is available

from third party sources. The Internal Modem is capable of dialing out from the STS2 or accepting

incoming calls and connecting to a remote terminal or computer. Using an ASCII Query and Answer

format the modem connection can be used to view system status and alarms. The modem provides all

information normally available on the LCD display of the STS2. No control functions are available via

the modem, such as making transfers, selecting a preferred source, or changing configurations.

The modem can also be configured to dial out two different telephone numbers (any combination of

modem or pager numbers).

The connection to this modem is through a standard RJ-11 port.

See Figures 21 and 22 for the location of the internal modem. See Figure 27 for more information

on the internal modem.

Programming the modem is performed through the touch screen display, see Configuring the

Modem on page 94 for details.

The modem commands are shown in Table 10.

14

6.7 Network Interface Card (NIC)

An OpenComms Network Interface Card (NIC) enables the STS2 to communicate to a network management system (NMS). The NIC provides the internal hardware and software to communicate, via

SNMP, to any I.P.-based Ethernet network through an RJ-45 connector using Category 5 cabling.

The NIC provides redundant paths for communications that make it possible to connect to a Building

Management System (BMS) using Modbus, while simultaneously communicating to a NMS through

SNMP. A terminal block provides the connection to Modbus.

See Figures 21 and 22 for the location of the NIC.

See Figure 28 control wiring information.

If you have questions about the NIC, refer to the OpenComms Network Interface Card Installation

and Users Guide.

6.8 LED Display

A light-emitting diode display is available to replace the standard liquid crystal display touch screen

control. The display provides monitoring and control throuh a series of LEDs and buttons. LEDs alert

you when a problem occurs. A PC running terminal emulation solfware conneted to the RS-232 port is

needed to access the data and configuration settings.

6.9 Remote Source Selection

Options

The Remote Source Selection allows the preferred input source to be chosen from a remote location. A

user supplied normally open dry contact allows the user to remotely select a source to be the preferred

source in the same process as the local source transfer selection.

The unit’s preferred source selection and Remote Source Selection are active at the same time, with

the STS2 following the last request for a preferred source change, regardless of whether it was from

the local or Remote Source Selection controls.

See 10.3 - Enabling Remote Source Selection for instructions on enabling the Remote Source

Selection.

See Figures 21 and 22 for the location of the Remote Source Selection option.

See 5.5 - Remote Source Selection Wiring on page 12 and Figure 23 for information on the control wiring.

6.10 Key Lockout Switch

The key lockout switch activates a software lockout of the touch screen display to prevent manual

transfers and configuration changes. When locked out, the touch screen becomes a read only display.

A key is needed to do manual transfers or change settings.

The alarm silence button is not disabled when in the lockout position.

The switch is located behind the front door but can be operated without opening the front door. See

Figures 8 to 10 for the key lockout location on each unit.

See 14.1.4 - Key Lockout Switch for instructions on using the key lockout switch.

6.11 Redundant Output Breaker

An output plug-in, non-automatic circuit breaker is provided which allows redundancy in the output

power path. The breaker is connected in parallel with the output plug-in non-automatic circuit

breaker.

15

6.12 Input Junction Boxes and Cables

Two input power junction boxes and interconnecting cables provide under floor connection for the two

input power feeds. Power terminal blocks are provided in each junction box for the connection of the

input power conductors and a parity-sized ground conductor. The junction boxes are NEMA 1 enclosures. A main input cable assembly is provided for connection between the unit and the junction box.

The cable length between the unit and junction box is 10 feet (3 meters) long.

See 5.2 - Input Junction Box Installation (Optional) on page 10 for more information and specifications. See Figure 30 for wiring details.

6.13 Seismic Floor Anchors

Seismic anchors are available for anchoring the unit to a concrete floor to meet seismic Zone 4

requirements. See 4.1 - Leveling and Anchoring the Unit to the Floor on page 8 for more information. Installation details are provided in Figures 11 through Figure 13 on page 25.

6.14 Seismic Floor Stand

Seismic floor stands in four heights—18", 24", 30" and 36" (457mm, 610mm, 762mm and 914mm)—

are available for the STS2. The stands can be fastened to the floor to meet seismic Zone 4 requirements. See 4.0 - Locating the STS2 and Figures 33 through 44 for instructions and details for

installing seismic floor stands.

Options

16

7.0 INSTALLATION DRAWINGS

Figure 5 Outline drawing: 100 – 250 amp STS2

(69.8)

2.75 (TYP)

THREADED

HOLE (4) TYP

12MM DIA

MOUNTING

10)

(SEE NOTES

LEVELER

DETAIL A

WITHOUT SIDE PANEL

FRONT OF UNIT SHOWN

Installation Drawings

PS211100 REV. NO. 2

NOTES:

1. ALL DIMENSIONS ARE IN INCHES AND MILLIMETERS.

2. 18” (457MM) MIN. CLEARANCE ABOVE UNIT REQUIRED FOR AIR EXHAUST.

3. INSTALLATION AND SERVICE ACCESS REQUIRED IN FRONT ONLY.

4. HEAT OUTPUT: 2710 BTU/HR (0.80 KW/HR) MAX. FOR 100A SWITCH.

4680 BTU/HR (1.37 KW/HR) MAX. FOR 250A SWITCH.

5. WEIGHT - 780 LBS. (354 KG).

6. UNIT BOTTOM IS STRUCTURALLY ADEQUATE FOR FORKLIFT HANDLING.

7. KEEP CABINET WITHIN 15 DEG. OF VERTICAL WHILE HANDLING.

8. COLOR - IBM OFF WHITE.

9. OPEN DOOR TO REPLACE AIT FILTER, DISPOSABLE TYPE, SIZE 1X25X25.

10. THREADED MOUNTING HOLES (SEE DETAIL A) ARE PROVIDED FOR SEISMIC

ANCHORING OR FLOOR STAND. MOUNTING BOLTS MUST BE THREADED INTO

THE UNIT MOUNTING HOLES FROM UNDERNEATH THE UNIT BASE. IF FLOOR

STAND IS USED, THE CASTERS MUST REST ON THE FLOOR STAND TO

CENTER

(815)

32.1

(762)

30

GRAVITY

(1956)

77.0

CENTER

GRAVITY

POWER CABLE

SUPPORT THE WEIGHT OF THE UNIT.

TOP ENTRY AREA

(326)

(736)

29.0

CENTERS

CASTER

(272)

10.7

12.8

(548)

21.6

CENTERS

(376)

(488)

19.2

SIDE VIEW

BLOCK

FILTER

AIR

AIR INTAKE AREA

DO NOT

(620)

24.4

SEE DETAIL A

(343)

(238)

13.5

9.4

12MM

FRONT

AIR

EXHAUST

14.8

TOP ENTRY AREA

CONTROL CABLE

(130)

5.1

(756)

29.8

TOP VIEW

MAX. DOOR SWING 180°

12MM CENTERS

100 - 250 AMP

OUTLINE DRAWING

CENTERS

CASTER

(477)

18.8

(594)

FRONT VIEW

(280)

23.4

11.1

FRONT

(265)

10.4

(619)

24.4

BOTTOM VIEW

STATIC TRANSFER SWITCH 2

(932)

36.7

17

(213)

8.4

(116)

4.6

(546)

21.5

POWER CABLE

CONTROL CABLE

BOTTOM ENTRY AREA

BOTTOM ENTRY AREA

Figure 6 Outline drawing: 400 – 600 amp STS2

(69.8)

1. ALL DIMENSIONS ARE IN INCHES AND (MILLIMETERS).

2. 18" (457MM) MIN. CLEARANCE ABOVE UNIT REQUIRED FOR AIR EXHAUST.

3. INSTALLATION AND SERVICE ACCESS REQUIRED IN FRONT ONLY.

4. HEAT OUTPUT: 6970 BTU/HR (2.04 KW/HR) MAX. FOR 400A SWITCH.

10520 BTU/HR (3.08 KW/HR) MAX. FOR 600A SWITCH.

5. WEIGHT - 1200 LBS. (544 KG))

6. UNIT BOTTOM IS STRUCTURALLY ADEQUATE FOR FORKLIFT HANDLING.

7. KEEP CABINET WITHIN 15 DEG. OF VERTICAL WHILE HANDLING.

8. COLOR - IBM OFF WHITE.

9. OPEN DOOR TO REPLACE AIR FILTER, DISPOSABLE TYPE, SIZE 1X25X25.

ANCHORING OR FLOOR STAND. MOUNTING BOLTS MUST BE THREADED INTO

THE UNIT MOUNTING HOLES FROM UNDERNEATH THE UNIT BASE. IF FLOOR

STAND IS USED, THE CASTERS MUST REST ON THE FLOOR STAND TO

NOTES: