Page 1

LIEBERT NX 1+1 SYSTEM

PRODUCT SPECIFICATION AND INSTALLATION SHEET

+

General

The Liebert NX UPS uses intelligent and reliable

decentralized technology to achieve parallel operation of two modules of the same rating.

The 1+1 system is used to:

• Increase the reliability of the system to ensure

adequate power supply to the critical load connected.

• Increase serviceability and allow the execution of

maintenance operations and reparations without

affecting the ordinary operating conditions of the

system (depending on the redundancy level).

CAUTION

!

An external maintenance cabinet is strongly

recommended to maintain the power supply to

load in case of complete maintenance.

Conditions for Parallel System

1. Each UPS module should have the same rating,

the same firmware and hardware version.

2. Each UPS module must have the same bypass

source.

3. The outputs of all UPS modules are connected

altogether.

4. The main inputs can be from different sources, but

the phase rotation sequence of main inputs,

bypass inputs and outputs must be correct and the

same.

5. The parallel logic cable and load sharing cable

must be connected in a ring correctly (See

Figure 2)

Features of Parallel System

1. The hardware and firmware for parallel UPS

module operation is standard in the Liebert NX,

and the configuration can be set up by changing

the settings in configuration software.

2. It is easy to install the parallel cables in a ring,

providing high reliability and redundancy. And

the intelligent paralleling logic provides the user

with maximum flexibility. For example, shutting

down or starting up the UPS modules in the

parallel system can be done in any sequence. If an

overload transfer occurs, the whole system can

recover automatically from bypass mode after the

overload is cleared.

3. The total load of the parallel system can be

queried from each module’s liquid crystal display

screen.

4. Optional monitoring background software can

treat the entire parallel system as a big

single-module UPS, and provide corresponding

management. It can also get the information for all

modules by connecting to just one of the modules.

1

Page 2

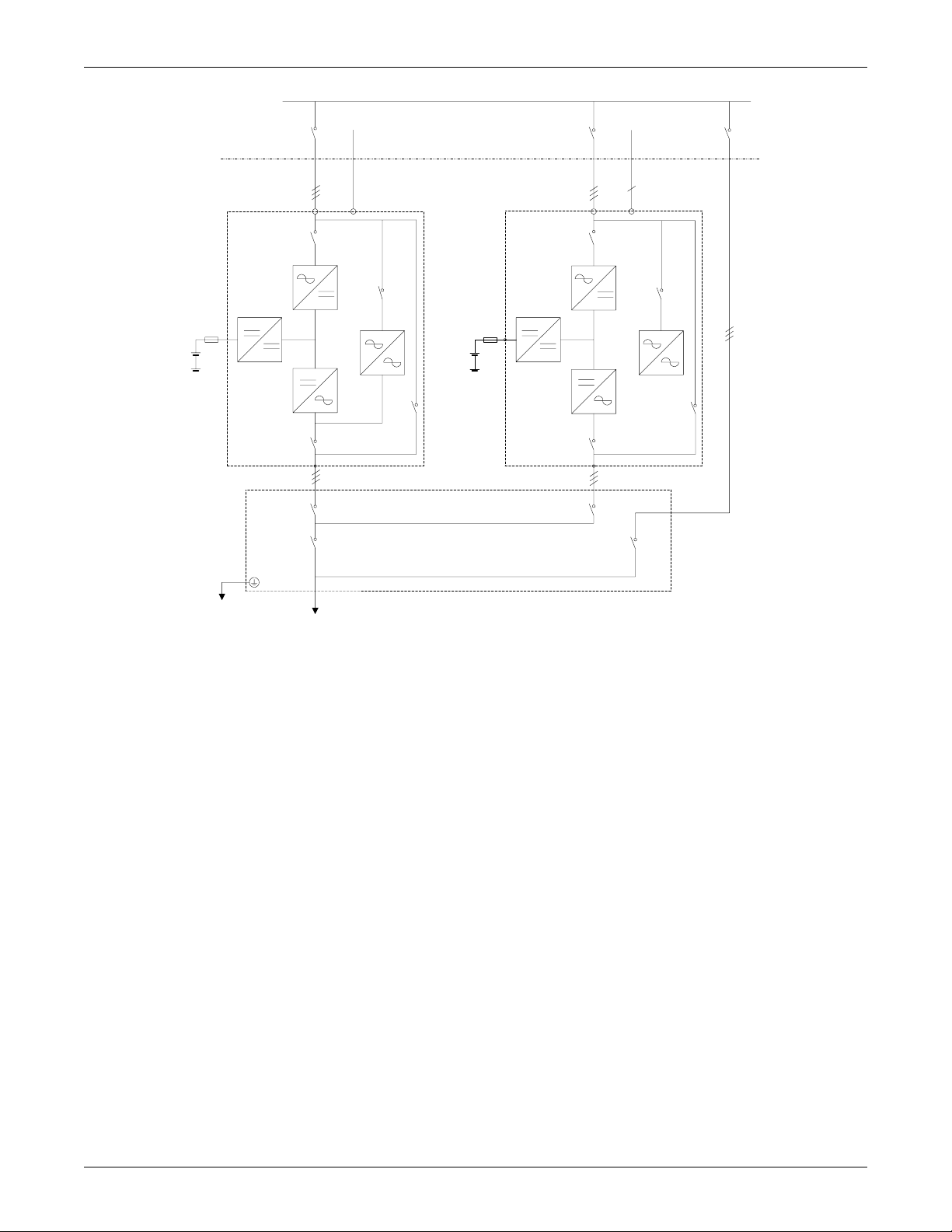

Figure 1 '1+1' System block diagram

Supplied by Others

Input Utility

Supply A B C

UPS1 UPS2

Charger Charger

Inverter Inverter

NN

CB1 CB1

SW1-C SW1-C

Static

Switch

Battery 2Battery 1

SW1-D SW1-D

SW1-A SW1-A

Q1EXT Q2EXT

Distribution Panel

Input Utility

Supply A B C

FuseFuse

RectifierRectifier

Static

Switch

A B CA B C

QBYPQUPS

To L o ad

Operating Principles

Redundancy Paralleling

The redundancy parallel system can noticeably

improve system reliability. In normal condition, neither UPS module works at full load. That means

that even if the load is increased, the system will not

transfer to bypass. And when a UPS module shuts

down due to any failure, the remaining UPS module

can still power and protect the load. When redundancy is lost due to module failure or load increase,

the parallel system will trigger an alarm.

Operation Modes Summary

The parallel system also has operation modes such

as normal, battery, bypass and maintenance bypass.

All UPS modules in the 1+1 parallel system operate

in coordination.

• Normal Mode Operation

The load is powered by the inverters of all the

UPS modules in the system. If the frequency of

bypass is within the synchronous range, the

inverter will be synchronized with the bypass.

Otherwise, the system will operate at nominal

frequency.

• Battery Mode Operation

The batteries of all UPS modules power the load

through their inverters. The system operates at

nominal frequency.

• Bypass Mode Operation

The condition to transfer to bypass mode is the

same as that for a single module system. The

bypass of all the UPS modules powers the load.

• Maintenance Bypass Mode Operation

The sequence to transfer to maintenance bypass

mode is the same as for transferring a singlemodule system. The maintenance bypass

switches should be switched on as synchronously

as possible. Thus the system can be repaired

without interrupting the power supply to critical

load.

Intermodule Control

Two kinds of signals are used for the parallel cables:

• Analog signals—UPS output unbalanced current

• Digital signals—control logic signals, parallel

cable status

Parallel control cables should be connected to the

parallel board (M3) of all modules and form a ring to

provide redundancy as shown in Figure 2.

Two types of Parallel control cables needed:

• DB9 for analog signals with one end DB9/F and

one end DB9/M

• DB25 for digital signals with one end DB25/F and

one end DB25/M

These come in lengths of 5m, 10m, &15m.

2

Page 3

Installation

The basic installation procedure of parallel system is

the same as that of single module system. The following sections only introduce the installation procedures specific to the parallel system.

Cabinet Installation

Parallel system composed of two UPS modules

The two UPS modules that will form the 1+1 system

should be placed side-by-side. Each battery cabinet

is placed next to its corresponding UPS module.

Preliminary Checks

Each UPS module should have the same rating, the

same firmware and the same hardware version.

Refer to the instructions in Conditions for Paral-

lel System on page 1.

Figure 2 Connecting 1+1 system parallel control

cables

1 2

#1 UPS Module #2 UPS Module

Parallel Board Parallel Board

X5

X4

3

X1-1 X1-1X1-2 X1-2

X4

X2-2X2-1X2-2X2-1

Protective Devices

Refer to the instructions supplied in the Liebert NX

installation manual, SL-25215.

Power cables

Wiring of power cables is similar to that of single

module system (see the Liebert NX installation manual, SL-25215). The bypass sources of all modules

should be the same, and the outputs should be connected altogether correctly.

NOTE

The length and specifications of power

cables including the bypass input cables

and UPS output cables should be the same,

thus the load can be shared evenly in

bypass mode.

Parallel Control Cables

Make the connections described below on the parallel logic board (M3) inside the Liebert NX:

• Connect one end of the DB-25 interconnecting

cable to the X2_1 connector of UPS 1 and the other

end to the X2_2 connector of UPS 2.

• Connect one end of the DB-25 interconnecting

cable the X2_2 connector of UPS 1 and the other

end to the X2_1 connector of UPS 2.

• Connect one end of the DB-9 interconnecting cable

the X1_1 connector of UPS 1 and the other end to

the X1_2 connector of UPS 2.

• Connect one end of the DB-9 interconnecting cable

the X1_2 connector of UPS 1 and the other end to

the X1_1 connector of UPS 2.

The connections are shown above in Figure 2.

4

1 2

UPS Unit

Parallel Connection Board

3

4

Interconnecting Cables

Commissioning a Parallel System

CAUTION

!

The operations in this section must be

performed by authorized electricians or

qualified technical personnel. If you have

any difficulties, contact Liebert Global

Services at 800-543-2378.

Check the input and output wiring of each UPS module. Ensure that the phase rotation sequence of the

main inputs and the bypass inputs and outputs of

each UPS module are the same. Ensure the parallel

cables are connected firmly.

It is assumed that the installation is complete, the

system has been commissioned by authorized personnel and the external power isolators are closed.

Before startup, disconnect the load.

Start the UPS modules separately and set the

parameters of each UPS module through configuration software. Pay particular attention to the parameters directly relevant to the parallel system:

• UPS Configuration: Each UPS module belonging

to the parallel system should be set as Parallel

configuration.

• UPS ID No.: Each UPS module should have a

unique identification number in the parallel system.

• Parallel system requisite UPS units: Set the minimum number of UPS modules to support the

user’s expected load. For 1+1 systems this settings

needs to be set to 1.

• Parallel system redundant UPS units: Set the

redundant number of UPS modules which will not

cause the parallel system transfer to bypass even

3

Page 4

if they get failure during operation. For 1+1 systems, this settings needs to be set to 1.

NOTE

The settings should be the same for all

modules within the parallel system, except

the UPS ID No.

System Startup

1. Start each UPS normally as described in Liebert

NX installation manual. SL-25215.

2. Turn on the inverter of each UPS module one at a

time.

3. Apply the load after the last UPS module transfers

to inverter. The total load can be determined

through the LCD of either UPS.

4. Verify the load rate of each UPS module. If the

load rates are roughly the same, then the parallel

system may be assumed to be operating normally.

Figure 3 Connecting EPO push button

NOTE

If one module cannot transfer to inverter

mode long after its inverter is on, its output

connection may not be good or its output

phase rotation may not be coincident with

other modules. At this time, the LCD for the

UPS module will display “inverter

asynchronous” and the inverter indicator

will flash continuously. If either UPS

module makes abnormal noise after it

transfers to inverter, its parallel cables may

be incorrectly connected.

Emergency Power Off (EPO)

The external emergency stop facility is identical to

that described for the single unit installation — that

an individual emergency stop button is provided for

each unit. Note that this is a Normally Open switch.

UPS2

X2

EPO-H

X2

EPO-H

EPO- L

EPO-L

Monitor board

Monitor board

EPO

Liebert Corporation

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

© 2004 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change without notice.

UPS1

Telephone: 1-800-877-9222

Facsimile: 1-614-841-6022

www.liebert.com

® Liebert and the Liebert logo are registered trademarks of

Liebert Corporation. All names referred to are trademarks or

registered trademarks of their respective owners.

SL-25246 (10/04) Rev. 0

4

Loading...

Loading...