Page 1

English

4 to 16 kVA

Power System

208 V / 240 V 60Hz

User Manual

Page 2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS.

This manual contains important instructions that

should be closely followed during installation

and maintenance of this UPS unit and during the

installation and replacement of power and

battery modules.

This product is designed for Commercial /

Industrial use only. This product is not intended

for use with life support and other U.S. FDA

designated “critical” devices. Maximum load

must not exceed that shown on the UPS rating

label. See Limited Warranty.

WARNING: Lethal voltages may be present

within this unit even when it is apparently not

operating. Observe all cautions and warnings in

this manual. Failure to do so MAY result in

serious injury or death. Never work alone.

Observe the following precautions when working

with batteries:

§ CAUTION: DO NOT dispose of battery

modules in a fire; the battery module may

explode.

§ CAUTION: DO NOT open or mutilate

batteries; released electrolyte is harmful to

skin and eyes, and may be toxic.

§ CAUTION: A battery can present a risk of

electrical shock and high short circuit

current. The following precautions should

be observed when working on batteries:

§ Remove watches, rings or other metal

objects.

§ Use tools with insulated handles.

§ CAUTION: Lead-acid batteries contain

hazardous toxic materials. Handle,

transport, and recycle in accordance with

local regulations.

This UPS is designed for use on a properly

grounded (earthed), 208/240 VAC, 60Hz supply,

and is to be installed by qualified personnel.

ELECTROMAGNETIC COMPATIBILITY - The

Nfinity™ UPS complies with the limits for a

Class A digital device, pursuant to Part 15 of

FCC rules. These limits provide reasonable

protection against harmful interference in a

commercial environment. This device

generates, uses, and radiates radio frequency

energy and, if not installed and used in

accordance with the instruction manual, may

cause harmful interference to radio

communications. Operating this device in a

residential area is likely to cause harmful

interference, which the user must correct at their

own expense.

Operate the UPS in an indoor environment only

in an ambient temperature range of 0°C to

+40°C (32°F to +104°F). Install it in a clean

environment, free from conductive

contaminates, moisture, flammable liquids,

gasses, or corrosive substances.

Turn the UPS off and isolate the UPS before

cleaning. Use only a soft cloth, never liquid or

aerosol cleaners. Keep the front and rear vents

free of dust accumulation that could restrict

airflow.

Never block or insert any object into the

ventilation holes or other openings.

This UPS contains user replaceable modules.

No attempts should be made to access the

interior of any module. See troubleshooting

section on module replacement.

1

Page 4

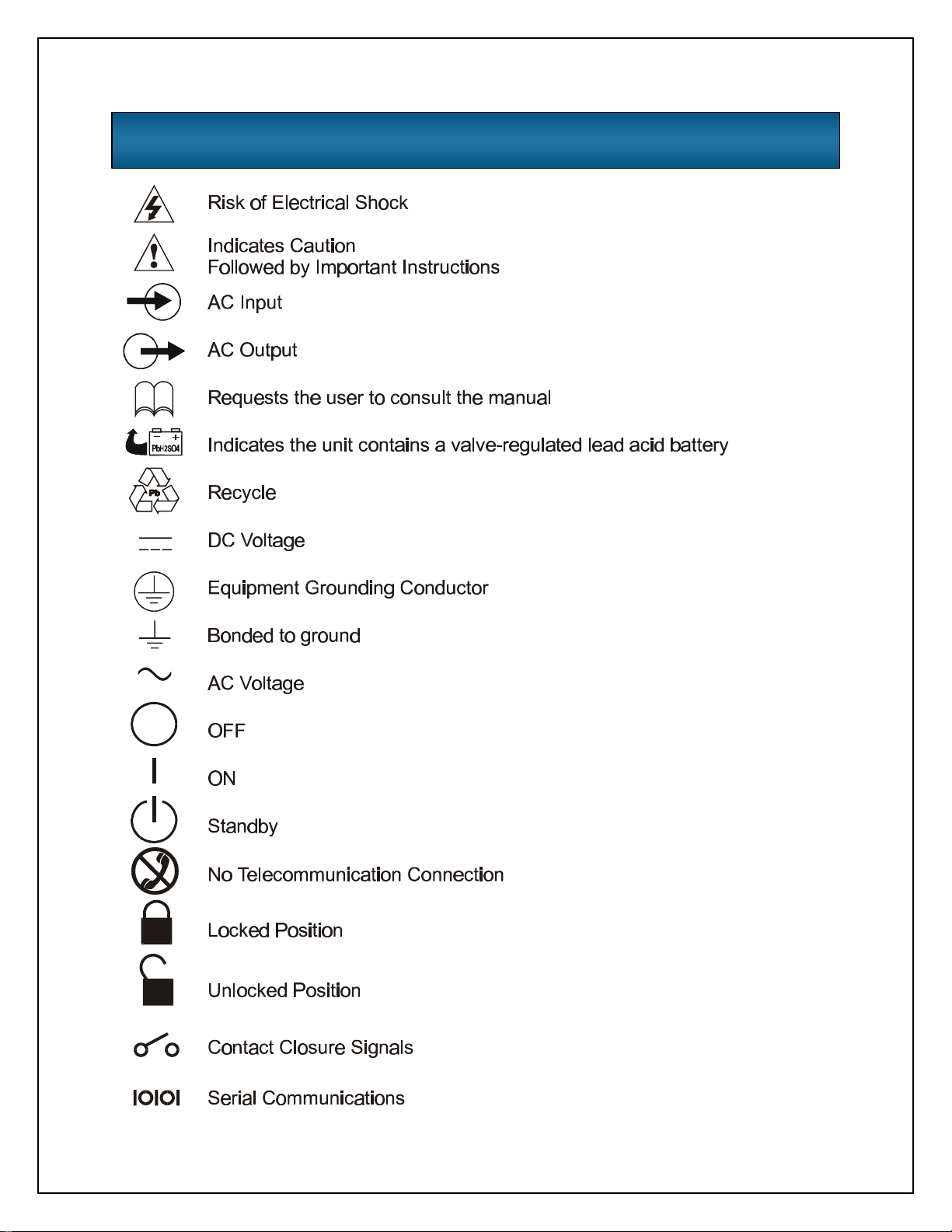

Glossary of Symbols

2

Page 5

3

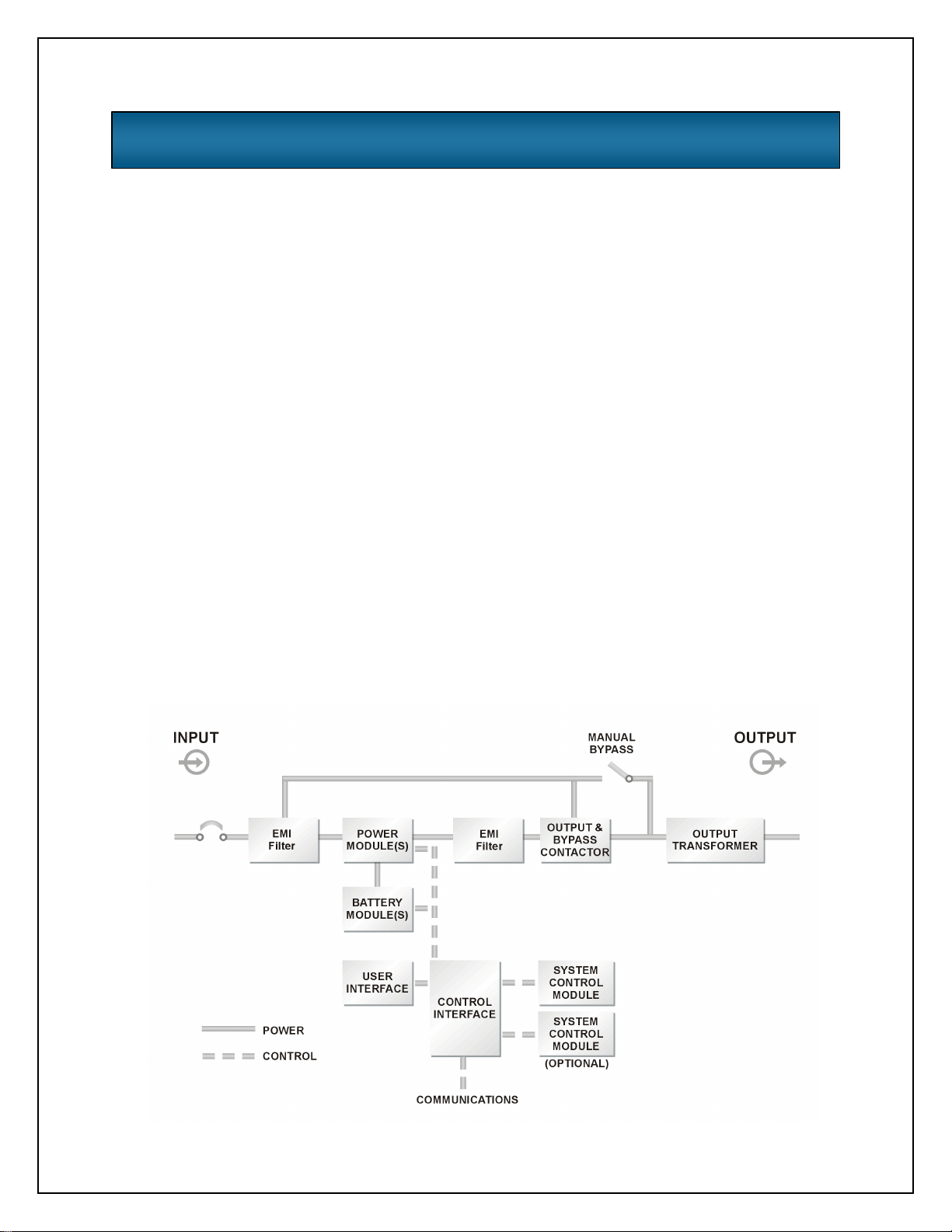

Introduction

General Description

Modes of Operation

Major Components

Page 6

General Description

Congratulations on your purchase of Liebert’s

Nfinity™ Uninterruptible Power System. As with

every Liebert product, we stand behind our

quality. If you have any questions concerning

this UPS, please feel free to contact your local

sales representative, or call the appropriate

Technical Support number listed in the back of

this manual.

To ensure proper installation and operation of

this unit, please read this manual thoroughly.

SYSTEM DESCRIPTION

The Liebert Nfinity Power System is a modular

UPS intended for use with workstations, servers,

network, telecom or other sensitive electronic

equipment. It provides continuous, high-quality

AC power to your equipment, protecting it from

any power disturbance due to blackouts,

brownouts, surges or noise interference.

The Nfinity modular UPS was designed to

provide maximum system availability to business

critical equipment. Nfinity is also an easily

adaptable UPS system. By simply installing

additional power or battery modules you can

expand your current system capacity or extend

your back-up runtime.

Nfinity has a comprehensive user interface that

can be configured according to the user’s

preference. It also informs the user of details on

the status of the UPS, and keeps a log of

events.

FEATURES:

§ Up to 16 kVA of modular back-up

power

§ Continuous power conditioning

§ A user-friendly interface for custom

configuration

§ Continuous system monitoring

§ Warning alarms and event logs

STANDARD COMPONENTS:

§ Power Modules – for power

conditioning

§ Battery Modules – for back-up power

§ System Control Modules – for system

monitoring and communications

§ LCD display for comprehensive user

indications and programmable controls

§ Output transformer for isolation

COMMUNICATIONS

§ Dry contacts

§ RS-232

§ Optional communications via

Intellislot™ communication ports

4

Page 7

5

Page 8

Modes of Operation

The Nfinity UPS is designed to operate as a true

on-line system in the following modes:

Normal Mode

The Power Module rectifiers derive power from a

utility AC source and supplies regulated DC

power to the inverter. The module’s inverter

regenerates precise AC power to supply the

connected equipment. The battery charger

maintains a float-charge on the battery.

Back-Up Mode

When AC utility fails, the connected equipment

is supplied power by the inverter, which obtains

energy from the battery modules. The output

power equipment will not be interrupted during

the failure or restoration of the AC utility source.

Auto Restart Mode

After a power outage and complete battery

discharge, once the AC utility is restored, the

UPS will automatically restart and resume

supplying power to the connected equipment.

This feature is enabled at the factory, but can be

disabled by the user. The user can also

program two auto restart delay settings:

1. Battery capacity level (%)

2. Countdown timer

Recharge Mode

When AC utility is restored, the unit will then

automatically recharge the battery modules until

they are fully charged.

Bypass Mode

The bypass provides an alternate path for power

to the connected equipment that operates in the

following manner:

Automatic

In the event of an internal failure or should

the inverter overload capacity be exceeded,

the UPS performs an automatic transfer of

the connected equipment from the inverter

to the bypass source.

Manual

Should the UPS need to be taken out of

service for limited maintenance or repair,

manual activation of the bypass will cause

an immediate transfer of the equipment from

the inverter to the bypass source.

6

Page 9

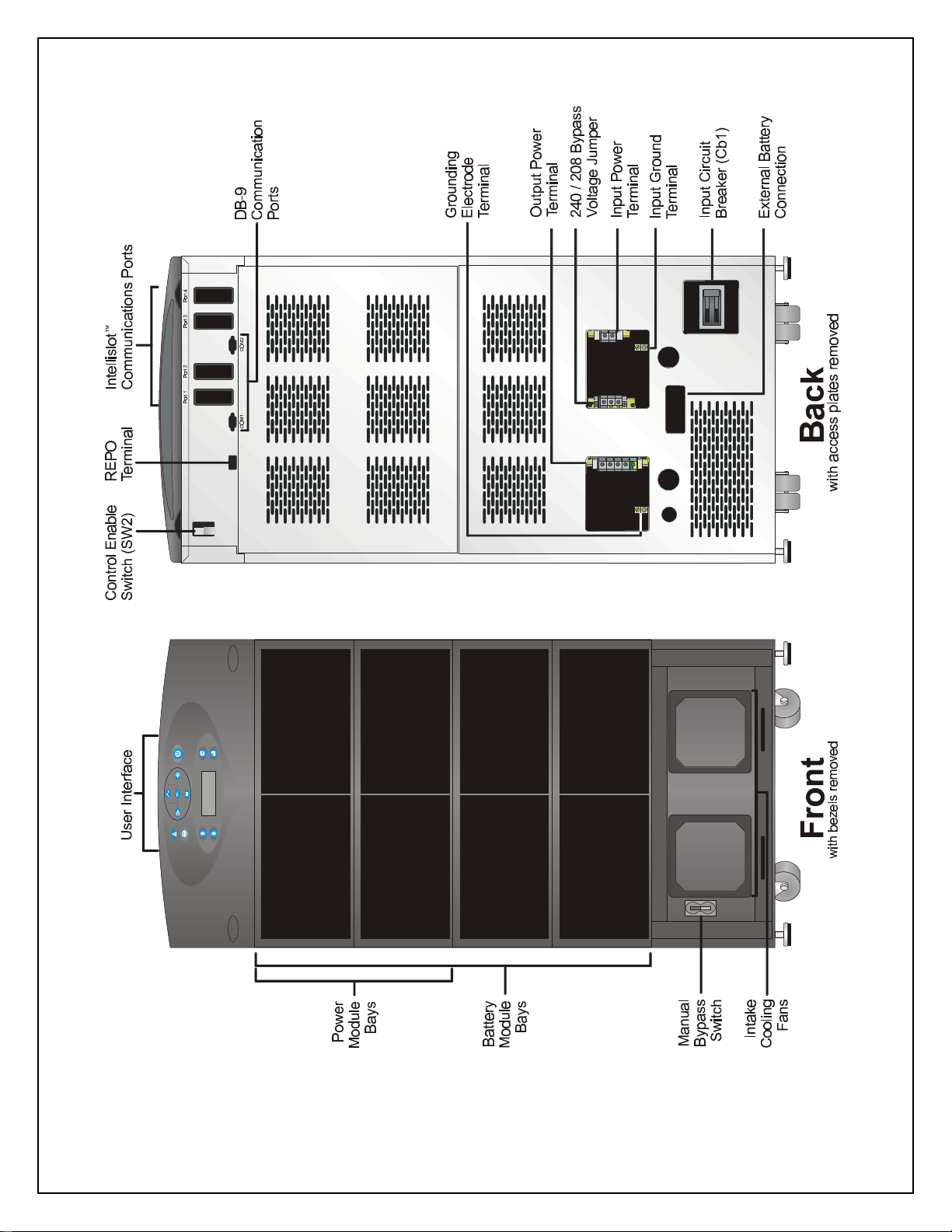

Major Components

The following is a general description

of each component and its functions.

Please review this section carefully, as

it will give you a better understanding

as to how Nfinity operates.

Unit Frame

Nfinity’s frame houses all of the other

system components. Looking at the

front of Nfinity™, one will see a series

of plastic bezels. By grabbing these

bezels from the side and pulling out,

you will remove the bezel to reveal the

Battery / Power Module bays. The

bottom bezel covers the cooling fans

and the Manual Bypass Switch.

The User Interface Module is located

above the Power / Battery Module bays

for easy access. From here the user

may find out various information about

Nfinity’s condition. By moving the User

Interface and setting it on top of the

frame, you will see the System Control

Module bays.

Nfinity’s frame with bezels removed

7

Page 10

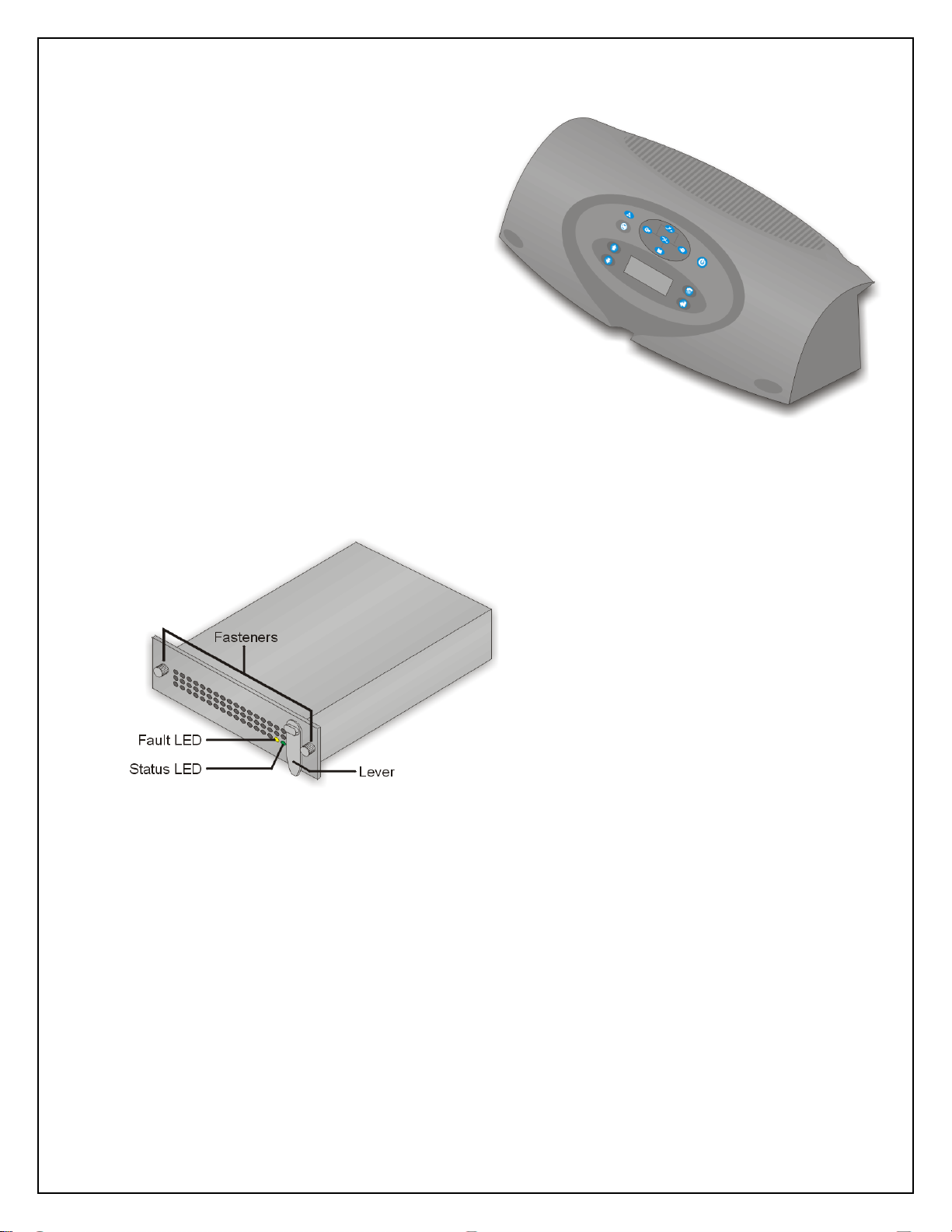

User Interface Module

The User Interface Module is the primary source of

communication between the UPS and the user.

From the interface, the user can:

§ View the status of the UPS

§ Custom configure the system

§ Review the event log to assist with

troubleshooting

§ Enable / disable the output power

§ Silence the audible alarm

For a more detailed explanation on how to operate

the User Interface module, see the Controls and

Indicators section of this manual.

System Control Module

User Interface Module

System Control Module

The System Control Module is the

communicative backbone of the UPS. It

gathers input from all modules and processes

the data to control the operation of the

system – including monitoring the condition of

each module. An optional second System

Control Module can be installed to provide full

system functionality (operation and

communication), in the unlikely event a

Control Module should fail.

Under normal operation, the Status LED

(green) will blink and the Fault LED (amber)

will be off. For any condition other than this,

check the Troubleshooting section of this

manual.

8

Page 11

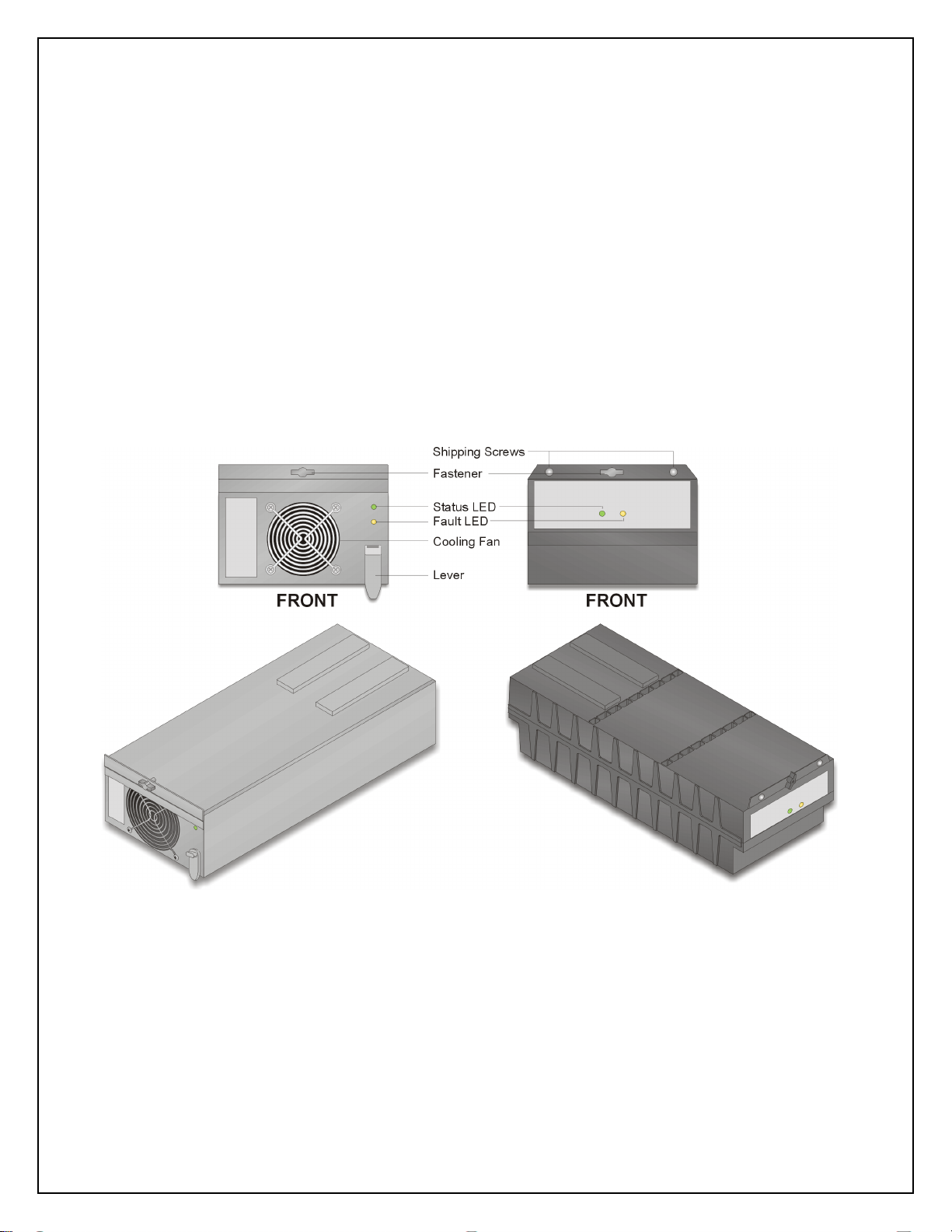

Power Module

Under Normal Operation, the Status LED (green) will blink and the Fault LED (amber) will be off. For any

The Power Module maintains the condition of

power in the Nfinity UPS. Each module is an

independent 4-kVA unit, consisting of a power

factor corrected rectifier, battery charger, and

inverter, with associated monitoring and controlcircuitry. The modules are paralleled to provide

greater capacity and/or redundancy. Modules

may be added or replaced on-line with no

interruption or danger to the connected

equipment.

Battery Module

The Battery Modules provide back-up power in

the event of input utility failure. Each module

contains a quantity of ten individual 12-volt valve

regulated (VRLA) battery blocks with associated

monitoring and controls to isolate the battery

module in the event of a battery failure. The

modules are paralleled to provide greater backup time and/or redundancy. Modules may be

added or replaced on-line with no interruption or

danger to the connected equipment.

Power Module Battery Module

condition other than this, check the Troubleshooting section of this manual.

9

Page 12

10

Installation

Preparation

Unloading

Cable Installation

Communications

Page 13

Preparation

These installation instructions provide all the

information needed for positioning the UPS

(including environmental requirements) and for

connecting the input and output power cables.

Inspection

Upon receiving the UPS, examine the packaging

for any signs of mishandling or damage. If any

damage is noted, call your local Liebert

representative and/or notify your carrier.

Environment

Note: Operating in temperatures above 77° F

(25° C) will reduce battery life. The UPS

environment must be free of conductive

contaminants and excessive moisture (water

condensation, flammable vapors, chemical

fumes, or corrosive gasses and liquids).

Required Setup Equipment

The tools below are required in order to properly

setup your UPS:

§ Pallet jack

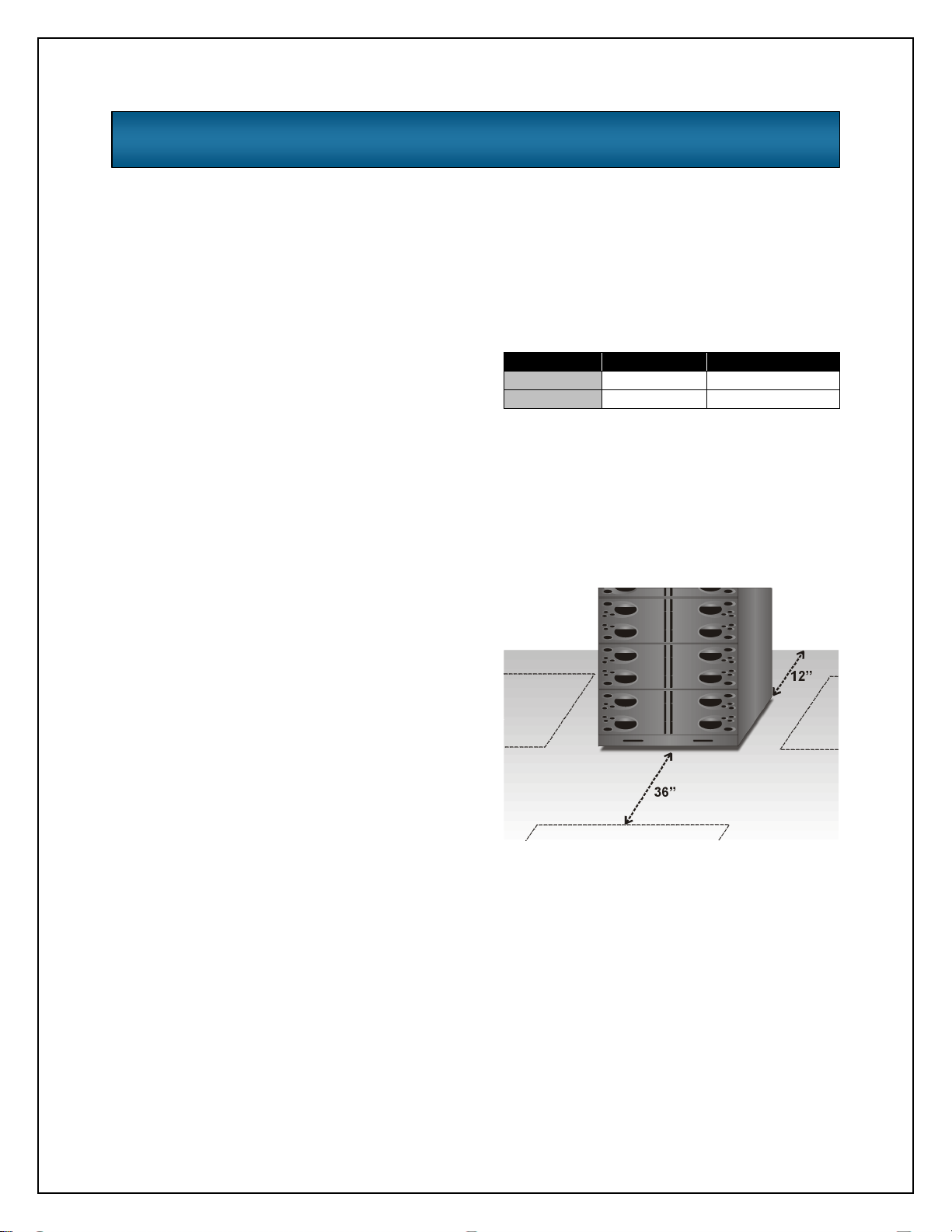

Site Preparation

When deciding where to locate your UPS,

consider the weight and size of the unit. Make

sure that the structural integrity of the floor can

withstand the weight of a fully loaded unit. Refer

to the table below for size and fully populated

weight considerations:

Model Max Weight H x W x D

8 bay 871 40” x 20” x 28”

12 bay 1186 53” x 20” x 28”

Check to make sure that your UPS will be

located in a well-ventilated area with at least 12

inches behind it. The UPS is force cooled with

the aid of internal cooling fans. Cooling air

enters from the front of the UPS and is

exhausted through ventilation grills in the back.

It should also have at least 36 inches in front, in

order to change modules when necessary.

§ 1/2” (13mm) ratchet or wrench

§ Torque Wrench (in / lb)

§ Flathead Screwdriver

§ #2 Phillips Screwdriver

The unit frame is bolted to the shipping pallet to

ensure safety. It is recommended that a pallet

jack be used to transport the unit to its operating

location (prior to unbolting the unit).

11

Page 14

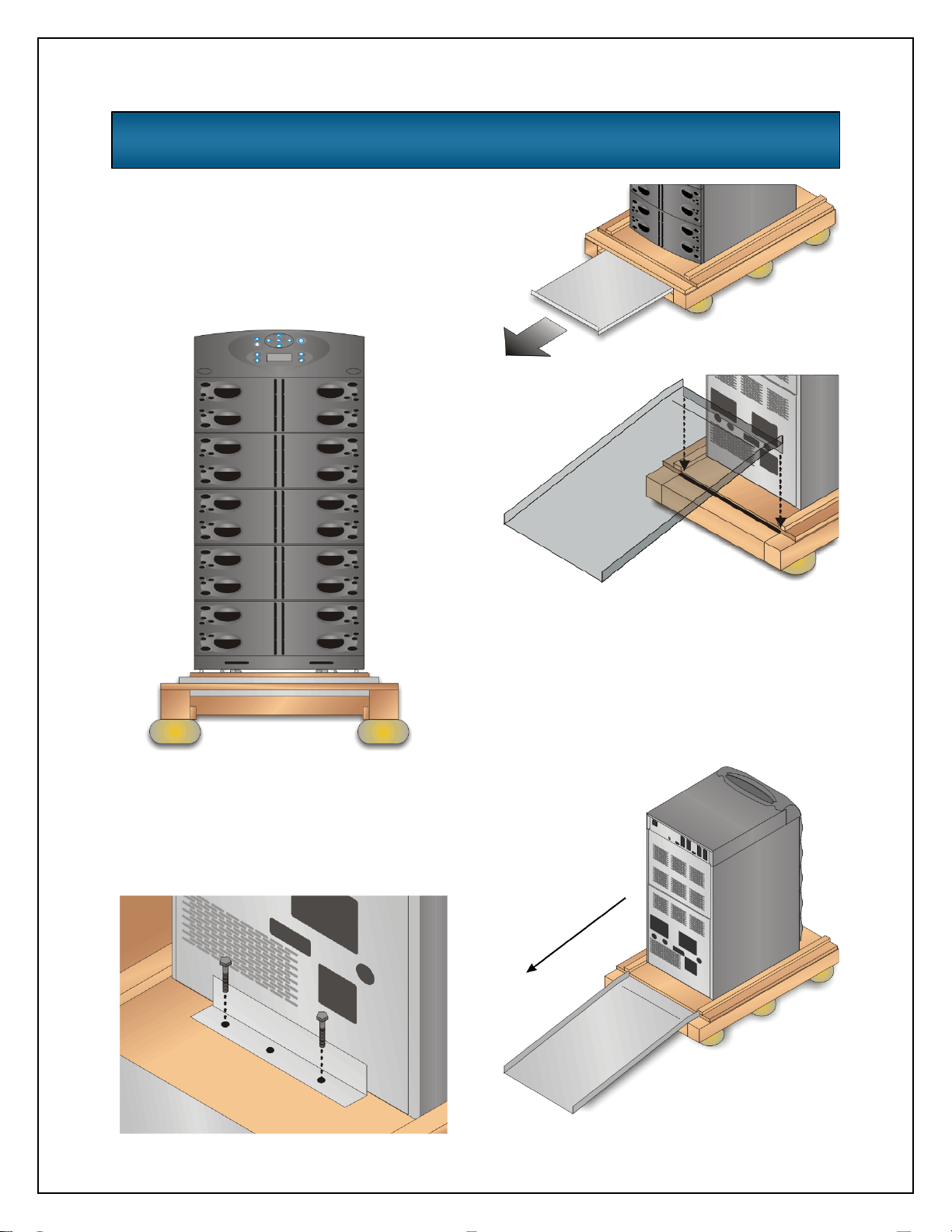

Unloading

Unloading the UPS

CAUTION: This UPS is very heavy (see weight

on previous page). At least two people should

be present to unload it off of the pallet.

1. Once the UPS is near the desired operating

location, remove the cardboard cover.

2. Use a ratchet (1/2” or 13mm) or open-ended

wrench to remove the four mounting bolts

from the pallet brackets. Remove mounting

brackets from the pallet and UPS. Keep

brackets for future transportation of UPS, or

for additional stability once in place.

3. Remove the metal ramp from the bottom of

the UPS, rotating it. Fit ramp in pallet slot as

shown above.

4. Using two people, slowly move the UPS

down the ramp until the UPS is on level

ground.

12

Page 15

5. Once the UPS in its desired location, adjust

the leveling feet to secure its position.

Stationary Mounting

Additional stability can be added by bolting the

mounting brackets (used in shipping) to the

floor.

For greater stability, use a higher-grade bolt.

Refer to the dimensions below when drilling

holes for stationary mounting.

13

Page 16

Cable Installation

Wiring Preparation

WARNING: Please read this section thoroughly

before attempting to install wiring to this unit.

Be sure that the unit is not connected to any AC

utility power source before installing any wiring

to this unit. This UPS should be installed by a

qualified / certified electrician.

Removing the Cover Plates

On the back of the

UPS, cover plates

are over the input

and output

terminals, as

shown on right.

Remove these

using a Phillips

screwdriver. Keep

screws and plates

to one side.

Configuring the Bypass Voltage (TB2)

The UPS voltage is factory set to 208V. Should

the user have a utility supply of 240V, the

bypass voltage jumper will have to be changed

to ensure correct output voltage.

Power Cable Installation

Refer to the charts below when selecting cables:

Power Cable and Protection Ratings

120V 208V 240V

Max Input

Current

Input

Protection

Max Output

Current

Input / Output

Terminal

Details

90°C rated copper wire is recommended

Notes:

If the start-up is on bypass the UPS has a 3cycle inrush current that is 6 times the rated

output current. This must be taken into account

when selecting the overload protection device at

the AC input supply distribution point. To avoid

random tripping on start up, it is recommended

that the AC input supply be protected with a

circuit breaker capable of withstanding this initial

inrush.

This UPS is fitted with EMI suppression filters.

Earth leakage current is less than 40mA.

Transient and steady state earth leakage

currents may occur when starting the

equipment. This should be taken into account

when selecting ground current detection

devices, as the earth leakage currents of both

the UPS and load will be carried.

Input and output cables must be run in separate

conduits.

A branch rated overcurrent protection device

(circuit breaker or fused disconnect switch) must

be installed for the AC output.

67A /

phase

79 A

69 A

100 A 90 A

77 A

67 A

2 AWG max (35 mm²)

6 AWG min (16 mm²)

Torque Rating: 22-26 in/lb

(2.5-3 nm)

14

Page 17

Input Wiring (TB1)

UPS contains an isolation

transformer that generates a neutral

conductor for the connected equipment.

The UPS is a separately derived source

o ground bonding

jumper. A grounding electrode conductor

(GEC) must be installed in accordance

with national and local wiring code /

To connect the input wiring, follow these steps:

1. Locate the

input wiring

access,

remove the

knockout

and pull the

three input

wires

through it,

allowing

some slack

for

installation.

2. Secure the conduit to the rear panel of the

UPS.

3. Input Power cables connect to screw

terminals on the Input Terminal Block

located to the right of the Bypass Voltage

Terminal. Connect the wires to the block

connections as shown below. Using a

torque wrench, turn the screws clockwise

until tightened to the proper torque value.

Insert the ground wire through the grounding

lug and tighten it to the proper torque value.

Output Wiring (TB3)

Output wiring may be configured one of two

different ways (240 / 120 or 208 / 120). Refer to

the chart and diagram below when configuring

the output wiring.

Note the Neutral / Ground jumper

on the terminal above.

Voltage 120 208 240

Terminals

Only use the connections listed above. Other connections

will produce non-standard voltages.

The Nfinity

1, 4

3, 4

2, 3

1, 3

Grounding Conductor Installation

An insulated grounding conductor must be

identical in size, insulation material, and

thickness as the grounded and ungrounded

branch-circuit supply conductors. This cable

must be green with or without one or more

yellow stripes, and is to be installed as part of

the branch circuit that supplies the unit or

system.

The grounding conductor is to be grounded to

earth at the service equipment or, if supplied by

a separately derived system, at the supply

transformer or motor-generator set.

and contains a neutral t

regulations.

15

Page 18

Connecting to External Panel Boards

UPS Output Panel Board

UPS Output Panel Board

If connected equipment will operate at 240 / 120

VAC, use a standard single-phase panel board.

If connected equipment will ONLY operate at

208 / 120 VAC, use a three-phase panel board.

Ensure that all 120V equipment is connected

L1 – N, L3 – N. Ensure that all 208V equipment is

connected L1 – L2.

Input

Input

REPO Switch

Nfinity is equipped with a Remote Emergency

Power Off (REPO) Switch.

The user must supply a means of interfacing

with the REPO circuit to allow disconnecting

the UPS input feeder breaker to remove all

sources of power to the UPS and connected

equipment to comply with national and local

wiring codes / regulations.

Remove

jumper

before

wiring.

1 = 24V DC, 35 mA

2 = sense

3 = sense

4 = ground

If the installation does not require connection

to a REPO system, the jumper must be

removed.

Caution: To maintain safety (SELV) barriers

and electromagnetic compatibility signal

cables should be segregated and run

separately from power cables.

16

Page 19

Communication

COM Ports

Nfinity is able to communicate through multiple

communication ports simultaneously.

Pin Assignment

COM 1 – Relay Contacts

Relay contacts are available through a DB-9F

communications connector. Contact closure

provides the following:

Pin Assignment

1 Low Battery (normally open)

UPS shutdown in battery mode

4

(5-12 V DC for 1.5 sec)

5 Common

7 Low Battery (common)

8 On Battery (common)

9 On Battery (normally open)

The contacts are rated 48V DC, 1 Amp

maximum and are compatible with the SiteNet

MultiLink software.

COM 2 – Serial

Nfinity is able to communicate via Liebert

proprietary protocol. The pin-out configuration

of the DB-9 connector is:

Pin Assignment

2 Transmit Data

3 Receive Data

5 Common

Intellislot™ Ports

The following communication cards may be

used with Nfinity:

Intellislot™ SNMP cards – allows the Nfinity

communicate intelligently with your Ethernet

network. The SNMP card must be installed in

port 1; any additional cards can be added in

consecutive ports.

Intellislot™ MultiPort4 cards– allows up to

four client computer systems to simultaneously

monitor the status of Nfinity.

Intellislot™ Relay Contacts cards – provides

contact closures for remote monitoring of alarm

conditions; On Battery, On Bypass, Low Battery,

Summary Alarm, UPS Fault and On UPS

signals. It will integrate with AS400 computers

(additional cable required) and other monitoring

systems.

17

Page 20

Operating Instructions

Controls and Indicators

Operating Procedures

Main Menu

18

Page 21

Controls and Indicators

A Warning has occured. Consult event log.

Display Controls

The Front Display Panel informs the user of the status of the UPS, and lets him configure the UPS to his

own needs or preferences through the user interface.

It consists of a series of Status LED’s, a 4 line by 20 character LCD display window, and buttons for

navigation (as displayed above).

Buttons

Refer to the legend below in order to properly

navigate the Nfinity User Interface.

LEDs

Refer to the legend below to indicate occurrence

when an LED is lit.

!

Fault / Warning

Solid Flashing-

AC Input

On Bypass

Inverter On

On Battery

AC Output

A UPS fault condition has occured.

- AC utility is available

- The Bypass is supplying the power

- The Inverter is supplying the power

- Battery is supplying power to the inverter

- Power is available to supply the load

19

Page 22

Status LED Modes

LED Off

LED Flashing

LED On

UPS is Off or Initializing

UPS On, Utility Good and Output Off

UPS On, Utility Good and Output On

(Normal Operation)

UPS On, Utility Bad and Output On

(On Battery Operation)

UPS On, Utility Bad, and Output Off

Unit in Bypass Operation

(Manual or Automatic)

Unit in Manual Bypass Operation with

Utility out of Bypass Operation Range

Shutdown Due to end of Discharge

20

Page 23

Navigating the Menu

In order to review or change any settings on the

UPS, it must be navigated using the buttons

seen on the previous page. Because some

menus contain more than four rows of

information, you may see an arrow on the

display pointing up or down (as shown below) –

indicating to scroll using the $ or # buttons.

If you are scrolling through any of the main

menus, items will scroll one line at a time with

the menu heading on the top line:

Pressing # reveals:

Note the arrows on the screen indicating that the

user scroll up or down to reveal more

information.

21

Page 24

Operating Procedures

Start-up and Initialization

Follow these steps in order to start up the UPS.

1. Close Input Circuit Breaker (CB1) and close

the Enable Switch (SW2). Ensure the

manual bypass switch is in UPS position.

You should see the following on the LCD

display window:

2. Press & button.

Manual Transfer to Bypass

In the event of a UPS overload or failure, the

UPS will transfer to bypass via its automatic

bypass switch. It is possible for the user to

manually transfer the UPS to bypass by

operating the manual bypass switch located

behind the lowest front cover to the bypass

position. To transfer the UPS from bypass to

normal mode, simply operate the manual bypass

switch back to the UPS position.

It should be noted that the load is not protected

from utility interruptions when in bypass mode.

3. Press % to access the main menu.

Shutting down the UPS

Use the following procedure to power down the

UPS.

1. Press & to disable power from the

connected equipment.

2. Verify request to disable the output by

pressing %.

3. Turn off the Enable Switch (SW2). Open the

Input Circuit Breaker (CB1).

22

Page 25

Main Menu

After initialization, the % button will take you to the main menu. From here you may check on the status

of the UPS, review the event and alarm log, configure your UPS, and even receive instructions on

replacing modules. The main menu is divided into five sub-menus as shown below:

Use the $ # buttons to select the desired menu item and press % to access the appropriate sub-menu.

23

Page 26

UPS Status Screen

From the main menu the user may select UPS Status and press %. Once at the UPS Status Screen, the

user may access any information on the present condition of the UPS. Note the chart below when

reviewing the UPS. Any underlined text indicates measured parameters.

24

Page 27

UPS Configuration Screen

Main Menu

Review Settings

Follow this procedure to review your UPS

configuration settings. Any underlined text

indicates factory default values.

Follow the menus below by pressing # or $ to

review the settings:

>

UPS Configuration

>

Review Settings

Voltage Settings

Voltage Settings

Input 208/120 LLG

Battery Settings

Battery Settings

Test intervl weeks

on at :

Wed0600

Low Batt Warn : min

Alarm Settings

Alarm Settings

Power:

Max Load: kVA

N+1

2

2

xx.x

Service Contact

Service Contact

Liebert Corp.

1-800-543-2378

25

Page 28

Change Configuration Settings

Main Menu

Change Settings Menu

Starting from the Main Menu, locate and press

UPS Configuration. From the UPS Configuration

screen, select the Change Settings option. Here

one may configure Nfinity from a large variety of

selections. Items indicated by an asterisk (*) or

underlined are the selected settings.

>

UPS Configuration

>

Set Password: Set a Password to prevent

unauthorized users from changing the

configuration of the Nfinity. It can be up to 7

characters in length. Once set, the password

will be required to change the configuration.

Auto Battery Test: Configure when and how

often the Nfinity’s automatic battery test will run.

This test is designed to ensure Battery system

integrity and warn of early problems.

Change Settings

Input Voltage: Select the required input voltage

setting. This voltage must match the bypass

voltage jumper setting.

Input Voltage

208/120 LLNG

*

208/120 LLNG

Low Battery Warning: Notifies user as to how

much runtime is available. Can be set from 1 to

30 minutes.

26

Page 29

Auto Restart: Automatically restarts once both

delay parameters (battery capacity percentage

and countdown timer) are met.

Set Date/Time: Allows user to enable DST

(Daylight Savings Time), change the Day, Date

and Time setting on Nfinity. When enabled, the

time will automatically adjust to Daylight

Savings.

User Settings: From here one can enter the

UPS ID or adjust the contrast of the user

interface LCD.

Max Load Alarm Set: Allows an alarm to set

when Nfinity’s load reaches a specific level.

UPS Shutdown Delay: Delays UPS shutdown

for specified amount of time after receiving

shutdown command via communications (serial

or SNMP).

27

Page 30

Redundant Alarm Set: Sets Alarm to notify

user when redundancy is no longer available.

UPS Test: Allows user to test the Batteries,

LED’s, LCD, or Alarm.

Service Contact: Set a contact for the user to

reach if problems occur.

Remote Shutdown: Enables / Disables the

Remote Communications Shutdown.

If you are using SiteNet™ software, this

parameter should be enabled in order for the

UPS output to be turned off once the operating

system has been shutdown.

External Battery: Sets total amp-hour for

external batteries to provide a more accurate

runtime remaining value on the LCD display and

through communications.

Enter in the following when using the External

Battery Cabinets with Chargers.

(P/N: PB10SLF105WC120)

# Cabinets AH Value

1 0105

2 0210

3 0315

4 0420

5 0525

6 0630

28

Page 31

Event Log

One may open the Event Log from the main

menu. By accessing the Event Log, the user

may scroll through the Nfinity’s past 255

occurrences in chronological order by pressing

the $ # buttons.

The typical event log screen will display the

event number and reference code on the first

line. The purpose of this code is to assist

factory trained service personnel in

troubleshooting. Please make a note of the

code number when contacting technical support.

The second line contains the event description.

The third line will have either more detail about

the event, a serial number indicating as to which

module the event occurred, or be left blank. The

last line will show the date and time the event

occurred.

Press " to go back to the main menu.

In the event of an event / alarm, the User

Interface LCD will display the last message

regardless of the default screen. A list of

possible event / alarm messages is displayed at

right. If you encounter one of these or other

messages and are unsure of the corrective

action to take, please contact a qualified Liebert

representative at the number listed in the back

of this manual.

For more information regarding events, consult

the troubleshooting section.

Alarm Log

When an alarm sounds, the User Interface LCD

will display a general explanation as to what the

alarm is indicating. These alarms will also be

displayed in the Alarm Log, which will display

the last 32 alarm messages. To view these

messages in chronological order, press the $ #

buttons.

The first line of a typical alarm log screen will

display the reason for the alarm occurrence.

The second line will give a more specific detail

of the occurrence (i.e.; module serial number).

Press " to go back to the main menu.

Below is a list of possible events / alarms.

Occurrence Event Alarm

Battery EOD

Battery Mod Removed

Battery Module Added

Battery Module Fail

Battery Test Fail

Battery Test Pass

Display Panel Added

Display Panel Removed

Firmware Error

General UPS Fail

Main Control Fail with

redundant control

Max Load Alarm

Power Mod Added

Power Mod Failure

Power Mod Removed

Red. Power Alarm

Transformer Fan Fail

UPS Auto Restart

UPS CANBus Fail

UPS Low Battery

UPS on Battery

UPS on Bypass (auto)

UPS on Bypass (manual)

UPS Shutdown

UPS Shutdown Imminent

Wrong Voltage

4

4

4

4 4

4 4

4

4

4

4 4

4 4

4 4

4 4

4

4 4

4

4 4

4 4

4

4 4

4 4

4 4

4 4

4 4

4

4 4

4

29

Page 32

Module Replacement

For more details on module replacement, consult the troubleshooting section of this user manual.

The user interface also supplies instructions for

removing and replacing modules. From the

main menu, access the module replacement

screen and select the type of module. Refer to

the screens below for reference:

30

Page 33

Troubleshooting

Module LED Indication

Alarm Messages

Module Replacement

31

Page 34

Alarm Messages

In the event of an alarm, the User Interface LCD will display the last message regardless of the default

screen. A list of possible alarm messages is displayed below. If you encounter one of these or other

alarm messages and are unsure of the corrective action to take, please contact a qualified Liebert

representative at the number listed in the back of this manual.

Alarm Message

Battery Module Failure Battery Module is no longer working

Power Module Failure A Power Module is no longer working

General UPS Failure The UPS is operating on bypass. Contact a Liebert Global Services at

Battery Test Failed Unit has detected a battery module problem. Verify the battery status via the display

Redundant Power Alarm The UPS is no longer redundant. Replace faulty module to regain

Maximum Load Alarm Maximum load has been exceeded. Insert additional modules to increase

System Control

Module Failure

Firmware version error Firmware is incompatible. Download latest firmware version from

On Battery Load is currently being supplied from UPS. Wait for input AC to return.

Low Battery Battery power is low. Allow batteries time to recharge.

UPS on Bypass (auto) UPS switched to auto bypass. Alarm screen should indicate reason

UPS on Bypass (manual) User switched UPS to manual bypass. When ready, switch back to UPS.

Transformer fan failure The transformer cooling fans are no longer

UPS CanBus Failure The internal communications are not

UPS Shutdown Imminent The UPS is about ready to shut down Check for faulty modules, output

Wrong Voltage The input voltage configuration and bypass

Cause Action

Refer to Module LED indication section

properly.

properly.

System Control Module no longer working

properly.

working properly.

working properly.

jumper settings DO NOT MATCH.

for corrective action.

Replace the faulty Power Module by

following the procedure in this manual.

1-800- 543-2378.

and perform self-battery test.

redundancy.

load capacity or reduce current load.

Replace faulty module.

www.liebert.com.

for auto bypass.

Contact a Liebert Global Services at

1-800- 543-2378.

Contact a Liebert Global Services at

1-800- 543-2378.

overloads, or Contact a Liebert Global

Services at 1-800- 543-2378.

Check to make sure the bypass

voltage matches the input voltage and

ensure the input voltage configuration

matches the bypass jumper setting.

32

Page 35

Module LED Indication

On every Battery, Power or Control Module are two LEDs to help inform the user of the module status.

Refer to the chart below for Power and Battery Modules:

Status LED

(Green)

OFF

OFF ON Module is initializing (max 10 seconds*).

FLASHING OFF Normal Operation

FLASHING FLASHING Module is in start-up qualification mode, or module warning. **

FLASHING ON Module failed, is off-line and module control is functioning.

OFF FLASHING

ON OFF

ON ON

ON FLASHING

* If this persists for more than 10 seconds, check to verify the lever is in the down position or the module is faulty.

** If both Green and Amber LEDs are flashing for more than 30 seconds, then re-insert module.

Fault LED

( Amber)

OFF

Module Status

Module not inserted into frame.

System is OFF.

Abnormal operation, re-insert module. If this persists, call Liebert Global

Services at 1-800- 543-2378.

33

Page 36

Module Replacement

Occasionally a control, battery or power module

will need to be removed or replaced. Follow the

instructions below when such an event occurs.

To order additional modules, contact your

Liebert representative or call 1-800-LIEBERT.

Removing Modules

1. Remove bezel cover of appropriate module.

When replacing a Power or Battery Module,

verify the faulty module by confirming the

amber LED is lit.

2. If removing a Control or Power Module with

no redundant modules, switch UPS to

manual bypass.

3. Pull out and lift the lever if replacing a

Control or Power Module, then turn fastener

counter-clockwise until it is loosened.

4. Start to pull out module. About 2/3 out it will

stop. Slide module away from the center of

the UPS. Continue to pull until module is

removed. (Seen at right)

Caution: Battery Modules are heavy (66

lbs, 30 kg). Make sure to use two people

when removing a Battery Module.

5. Dispose of module in an environmentally

responsible way that complies with local

codes / regulations or return to Liebert for

proper disposal.

Note: Battery Modules may contain shipping

screws. These screws may be removed and

discarded.

34

WARNING

POTENTIAL TIP HAZARD

Install all modules starting from

bottom to top bays. For module

removal, start from top to bottom

bays. Do Not remove more than one

module at a time. Failure to do so

may cause unit to tip over and cause

serious injury.

Page 37

Replacing Modules

1. Lift module to appropriate bay, resting end

of module on bay shelf. Use caution not to

rest the module on the lower bezel cover.

2. Push module into bay. Once half way in,

slide module sideways toward the center of

the UPS. Continue pushing module fully

inserted.

Replacing the User Interface

1. Lift off user interface and set it on top of the

UPS frame.

2. The attached cable will be connected to an

Intellislot card, found in a port between the

control modules.

3. Press and turn fastener clockwise until

locked. If replacing a Control or Power

Module, press lever down.

4. Wait about 15 seconds as the module

performs a start-up test and synchronizes

with the other modules. Both the amber and

green LEDs should be flashing. A green

flashing LED will then confirm the module is

properly connected.

5. If UPS was placed in bypass manually,

transfer back to UPS operation.

6. Replace bezels.

3. Disconnect the cable from the Intellislot

card.

4. Plug the new user interface cable into the

Intellislot card.

5. Set replacement User Interface into proper

position.

35

Page 38

Scheduled Maintenance

Maintenance

Proper Care

Replacing Fan Filters

36

Page 39

Maintenance

Proper Care

Keeping your Liebert Nfinity UPS operating

properly is imperative to optimal performance

and life of the unit. It is recommended that a

certified technician perform preventive and

corrective maintenance. Liebert Global Services

(LGS) is dedicated to ensuring the highest level

of performance and unmatched support for your

Nfinity UPS. Contact an LGS representative at

1-800-LIEBERT for services to guarantee

maximum reliability and system availability.

Scheduled Maintenance

It is recommended the following maintenance is

performed at least monthly:

§ Clean unit

§ Clean / replace filters

§ Verify proper airflow

It is recommended the following maintenance is

performed annually:

§ Verify all power modules are operating

properly.

§ Verify all battery modules are operating

properly.

§ Verify redundancy (if applicable).

Replacing Fan Filters

Nfinity’s intake fans contain filters that will need

to be replaced / cleaned periodically, depending

on the surrounding environment. Check by

removing the bottom bezel and noting the

condition of the two filters. If filters are dirty,

replace them by removing the plastic cover over

the filter frame and inserting a new filter in its

place. Use caution when replacing filters when

fans are running.

The fan filters are washable and can be reused.

To wash filters, place them under a running

faucet (with the dirt side down) to remove dirt

and dust. Blot dry with a towel and allow airdrying before reusing.

37

Page 40

Warranty

Reference

Specifications

Battery Run Times

Technical Support

38

Page 41

Specifications

General & Environmental Units 4 8 12 16

kVA 4 8 12 16 Unit Rating

kW 2.8 5.6 8.4 11.2

Conducted and Radiated EMC Levels FCC Part 15, Class A

Compliant Safety Standards UL 1778; c-UL

Compliant Immunity Standards IEEE C62.41, Category B

Mechanical Units 8 Bay 12 Bay

Dimensions:

Environmental Units

Operating Temperature (max) F (C) 32° - 104° (0° - 40°)

Relative Humidity 0-95% non-condensing

Maximum operating altitude Ft. (M) 10,000 (3000)

Nominal heat dissipation BTU/Hr 1062 2124 3186 4248

Acoustic noise level dBA <62 @ 1 meter

Input Data Units

Nominal input voltage VAC 170 to 276

Power factor Cos Ø >.98

Input frequency (nominal) Hz 60

Input frequency range Hz 40-70

Battery Module Units

Number of lead acid batteries 10

Number of battery cells 60

Battery capacity A/hr 9

Autonomy time (full load)

Maximum charge current (full load) A 3

Nominal Voltage VDC 120

Recharge Time Hrs 3-5 (to 90% capacity)

Output Data Units

Output voltage VAC 208/120 or 240/120

Voltage regulation % ±3

Voltage stability (100% step load) % ±7

Recovery time msec 96

Voltage distortion:

Output frequency Hz 60

Efficiency at 100% load % 89

Output overload capability %

Width 20 (508.0) 20 (508.0)

Depth 28 (711.2) 28 (711.2)

Height

In (mm)

mins

40 (1016.0) 53 (1346.2)

6

(With an equal number of Battery & Power Modules,

in a non-redundant configuration)

%

<3 THD, linear load

<7 THD, non-linear load

110-125% for 10 min

126-150% for 10 sec

>151 – 200% for 2 cycles

39

Page 42

Battery Run Times

8 Bay Frame

Internal and External (minutes)

Load Load

VA Watts 1 2 3 4 5 6 7 1 2 3 4 5 6

16,000 11,200 - - - 6 - - - 24 60 100 120 180 240

15,500 10,850 - - - 6 - - - 26 63 107 140 195 255

15,000 10,500 - - - 6 - - - 27 67 114 160 210 270

14,500 10,150 - - - 6 - - - 28 70 120 180 225 285

14,000 9,800 - - - 7 - - - 30 73 127 190 240 300

13,500 9,450 - - - 7 - - - 31 77 135 200 252 320

13,000 9,100 - - - 8 - - - 32 80 142 210 264 340

12,500 8,750 - - - 8 - - - 34 85 150 220 276 360

12,000 8,400 - - 6 9 12 - - 36 90 157 230 288 375

11,500 8,050 - - 6 9 13 - - 38 95 165 240 300 390

11,000 7,700 - - 6 10 14 - - 40 100 173 255 320 405

10,500 7,350 - - 7 10 15 - - 42 110 180 270 340 420

10,000 7,000 - - 7 11 18 - - 45 120 195 285 360 450

9,500 6,650 - - 8 13 18 - - 50 130 210 300 390 480

9,000 6,300 - - 9 14 19 - - 53 140 225 320 420 510

8,500 5,950 - - 9 15 20 - - 57 150 240 340 450 540

8,000 5,600 - 6 10 18 21 26 - 60 160 260 360 480 570

7,500 5,250 - 6 11 18 23 28 - 65 170 280 390 510 600

7,000 4,900 - 7 13 19 25 29 - 70 180 300 420 540 660

6,500 4,550 - 8 14 21 27 30 - 80 200 330 480 600 720

6,000 4,200 - 9 18 24 29 36 - 90 220 360 510 660 810

5,500 3,850 - 10 19 26 30 39 - 100 240 420 540 720 900

5,000 3,500 - 12 20 29 36 43 - 120 270 450 600 810 1,000

4,500 3,150 - 14 24 30 40 46 - 140 300 480 720 900 1,100

4,000 2,800 6 18 26 36 43 49 52 160 360 540 810 1,080 1,200

3,500 2,450 7 19 29 41 48 52 56 180 420 600 900 1,260 1,440

3,000 2,100 9 24 36 46 51 56 62 210 480 720 1,050 1,440 1,620

2,500 1,750 12 29 43 51 56 63 68 240 600 900 1,200 1,620 1,800

2,000 1,400 18 36 50 57 64 68 72 360 720 1,200 1,440 1,800 2,880

1,500 1,050 24 46 56 65 69 73 74 480 900 1,440 2,400 3,000 3,600

1,000 700 36 56 68 73 74 75 78 720 1,440 2,400 3,600 4,320 4,320

900 630 39 59 69 73 75 78 78 900 1,800 3,000 4,320 4,320 4,320

800 560 43 63 72 74 76 78 79 1,080 2,100 3,600 4,320 4,320 4,320

700 490 48 68 73 75 78 79 79 1,260 2,400 4,320 4,320 4,320 4,320

600 420 51 69 74 77 79 79 80 1,440 3,000 4,320 4,320 4,320 4,320

500 350 56 72 75 78 79 80 80 1,440 3,600 4,320 4,320 4,320 4,320

Note: Back-up times are in minutes and are based upon resistive loading at an ambient of 25°C, for non-redundant (standard)

configurations. Back-up times for external battery cabinets with chargers include internal battery modules that are equal to the

number of power modules in the UPS frame.

Quantity of

Battery Modules

External Battery Cabinets with charger

Quantity of

40

Page 43

Battery Run Times

12 Bay Frame

Internal and External (minutes)

Load Load

VA Watts 1 2 3 4 5 6 7 8 9 10 11 1 2 3 4 5 6

16,000 11,200 - - - 6 8 10 13 18 - - - 24 60 100 120 180 240

15,500 10,850 - - - 6 8 11 14 18 - - - 26 63 107 140 195 255

15,000 10,500 - - - 6 9 11 15 18 - - - 27 67 114 160 210 270

14,500 10,150 - - - 6 9 12 15 19 - - - 28 70 120 180 225 285

14,000 9,800 - - - 7 9 13 18 19 - - - 30 73 127 190 240 300

13,500 9,450 - - - 7 10 14 18 20 - - - 31 77 135 200 252 320

13,000 9,100 - - - 8 11 14 18 21 - - - 32 80 142 210 264 340

12,500 8,750 - - - 8 11 15 19 22 - - - 34 85 150 220 276 360

12,000 8,400 - - 6 9 12 18 20 23 26 - - 36 90 157 230 288 375

11,500 8,050 - - 6 9 13 18 20 24 27 - - 38 95 165 240 300 390

11,000 7,700 - - 6 10 14 19 21 25 29 - - 40 100 173 255 320 405

10,500 7,350 - - 7 10 15 19 23 27 29 - - 42 110 180 270 340 420

10,000 7,000 - - 7 11 18 20 25 28 30 - - 45 120 195 285 360 450

9,500 6,650 - - 8 13 18 21 26 29 31 - - 50 130 210 300 390 480

9,000 6,300 - - 9 14 19 24 27 30 36 - - 53 140 225 320 420 510

8,500 5,950 - - 9 15 20 25 29 31 38 - - 57 150 240 340 450 540

8,000 5,600 - 6 10 18 21 26 30 36 39 43 - 60 160 260 360 480 570

7,500 5,250 - 6 11 18 23 28 30 38 42 45 - 65 170 280 390 510 600

7,000 4,900 - 7 13 19 25 29 36 41 44 48 - 70 180 300 420 540 660

6,500 4,550 - 8 14 21 27 30 38 43 47 50 - 80 200 330 480 600 720

6,000 4,200 - 9 18 24 29 36 42 46 49 51 - 90 220 360 510 660 810

5,500 3,850 - 10 19 26 30 39 44 49 51 54 - 100 240 420 540 720 900

5,000 3,500 - 12 20 29 36 43 48 51 54 56 - 120 270 450 600 810 1,000

4,500 3,150 - 14 24 30 40 46 50 54 57 59 - 140 300 480 720 900 1,100

4,000 2,800 6 18 26 36 43 49 52 56 59 63 66 160 360 540 810 1,080 1,200

3,500 2,450 7 19 29 41 48 52 56 60 64 68 69 180 420 600 900 1,260 1,440

3,000 2,100 9 24 36 46 51 56 62 65 68 69 72 210 480 720 1,050 1,440 1,620

2,500 1,750 12 29 43 51 56 63 68 69 72 73 73 240 600 900 1,200 1,620 1,800

2,000 1,400 18 36 50 57 64 68 72 73 74 74 75 360 720 1,200 1,440 1,800 2,880

1,500 1,050 24 46 56 65 69 73 74 75 76 78 78 480 900 1,440 2,400 3,000 3,600

1,000 700 36 56 68 73 74 75 78 78 79 79 80 720 1,440 2,400 3,600 4,320 4,320

900 630 39 59 69 73 75 78 78 79 79 80 80 900 1,800 3,000 4,320 4,320 4,320

800 560 43 63 72 74 76 78 79 79 80 80 80 1,080 2,100 3,600 4,320 4,320 4,320

700 490 48 68 73 75 78 79 79 80 80 81 81 1,260 2,400 4,320 4,320 4,320 4,320

600 420 51 69 74 77 79 79 80 80 81 81 82 1,440 3,000 4,320 4,320 4,320 4,320

500 350 56 72 75 78 79 80 80 81 82 82 82 1,440 3,600 4,320 4,320 4,320 4,320

Note: Back-up times are in minutes and are based upon resistive loading at an ambient of 25°C, for non-redundant (standard)

configurations. Back-up times for external battery cabinets with chargers include internal battery modules that are equal to the

number of power modules in the UPS frame.

Quantity of

Battery Modules

External Battery Cabinets with charger

Quantity of

41

Page 44

Warranty

Liebert Corporation extends the following LIMITED WARRANTY to the

purchaser and to its customer (collectively referred to as the "Purchaser"):

the enclosed Uninterruptible Power System (UPS) and components are

free from defects in materials and workmanship under normal use,

service, and maintenance FOR A PERIOD OF TWO YEARS FROM THE

DATE OF ORIGINAL PURCHASE from Liebert or the Liebert dealer or

retailer. THE FOREGOING WARRANTY IS THE ONLY WARRANTY

GIVEN AND NO OTHER WARRANTY IS PROVIDED, EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION, MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. Certain aspects of

disclaimers are not applicable to consumer products acquired by

individuals and used for personal, family, or household purposes (as

distinguished from industrial or other purposes). Local laws may not allow

limitations on how long an implied warranty lasts, so the above limitation

may not apply to you. This warranty gives you specific legal rights, and

you may have other rights, which vary according to local law.

Certain repairs or services are the responsibility of the Purchaser and the

Purchaser is expected to pay for them. This warranty does not extend

either to products with removed or altered serial numbers or to any losses

or damages due to act of God or source external to the product, misuse,

accident, abuse, neglect, negligence, unauthorised modification,

alteration, or repair, use beyond rated capacity, or improper installation,

maintenance, application or use, including, without limitation, use in a

manner contrary to the accompanying instructions or applicable codes.

WARNING: Warranty is void if the battery is allowed to discharge below

the minimum battery cut-off point. The battery must be recharged every

four (4) to six (6) months when not in use.

If the UPS fails to conform to the above warranty within the two-year

warranty period, Liebert will repair or replace the UPS, at Liebert's option.

Repairs or replacements are warranted for the remainder of the original

warranty period. Purchaser, to make a warranty claim, should call to

obtain a Returned Goods Authorisation number and shipping instructions.

Return transportation costs to Liebert are the responsibility of the

Purchaser.

Due to the diversity of applications and considerations to be applied in

each case, Liebert does not recommend or knowingly sells its products for

such use.

The responsibility for risk assessment and management in applications

where the malfunction or failure of the UPS could be reasonably expected

to give rise to a risk of human life shall be the sole responsibility of the

purchaser. Liebert accepts no liability for consequential harm in such

applications.

LIMITED WARRANTY

"LIFE SUPPORT" APPLICATIONS

42

Page 45

While every precaution has been taken to

ensure accuracy and completeness of this

literature, Liebert Corporation assumes no

for

damages resulting from use of this information

© 2000 Liebert Corporation. All rights reserved

throughout the world. Specifications subject to

® Liebert and the Liebert logo are registered

demarks of Liebert Corporation. All names

referred to are trademarks or registered

(7/00) Rev. 2

Nfinity™ Power System

208 V / 240 V 60 Hz

4 to 16 kVA

Technical Service and Support

Worldwide FAX tech support +614-222-5877 option #4

Worldwide Support. +614-841-6755 or 1-800-222-5877

The Company Behind The Products

With over a million installations around the

globe, Liebert is the world leader in

computer protection systems. Since it’s

founding in 1965, Liebert has developed a

complete range of support and protection

systems for sensitive electronics:

• Environmental systems: close-control air

conditioning from 1.5 to 60 tons.

• Power conditioning and UPS with power

ranges from 250 VA to more than 1000 kVA.

• Integrated systems that provide both

environmental and power protection in a

single, flexible package.

• Monitoring and control — on-site or remote

— from systems of any size or location

• Service and support, through more than 100

service centers around the world, and a 24hour Customer Response Center.

U.S.A.

U.K. +44 (0) 1628 403200

France +33 (0) 1 43 60 01 77

Germany +49 89 99 19 220

Netherlands +31 (0) 475 503333

E-mail upstech@liebert.com

Web site http://www.liebert.com

Italy +39 02 98250 324

1-800-LIEBERT

responsibility, and disclaims all liability

or for any errors or omissions.

change without notice.

tra

trademarks of their respective owners.

SL-23950

43

Loading...

Loading...