Page 1

Precision Cooling

For Business-Critical Continuity

™

Liebert Mini-Mate2™1 To 8 Tons

Overhead Precision Cooling And Humidity Control

Page 2

The Solution For Your Cooling Needs May Be Right Above You

When the need calls for precision cooling and humidity

control, but your floor space says otherwise, the Liebert

Mini-Mate2

™

can provide the overhead answer. This

flexible, space-saving system is the ideal solution for

all areas where space is at a premium:

sm

Network Closets

VoIP

IDF

Telecommunications Equipment

Data Processing

Control Rooms

Desktop Publishing

Network Facilities

Laboratories

Other Critical Electronic Systems

Liebert Mini-Mate2 Offers:

Reliability:

High Sensible Cooling Capacity. Unlike “comfort” air

conditioners, Liebert systems are designed for the

cooling requirements of electronic equipment – 80% of

the capacity dedicated to the removal of dry “sensible”

heat, and 20% for the control of humidity.

Reliable. Based on a field-proven system, the Liebert

Mini-Mate2 is manufactured with rugged, efficient

components. To ensure 365 days x 24 hours operation

at your site, each system is factory tested.

Warranty Protection. In addition to the standard

one-year warranty, your Liebert Representative can

offer extended warranties on the unit, compressor,

parts and labor.

Preventive Maintenance Programs. Liebert

factory-certified personnel provide regular inspections

and service to extend the life of the system.

Liebert Spare Parts. Highest-quality parts, designed for

our system, are easily available through your Liebert

y

service representative.

:

y

ilit

exib

l

F

The components in units are located for easy service

(1 ton self-contained unit shown)

s Z

e

s

U

o

g units ar

nsin

de

on

c

uiring minimal site disturbance.

eq

, r

g

lin

i

e

c

Simple Control. Split systems require simple

thermostat-type wiring to controls and

condensing units.

Designed For Easy Component Access. Most units can

be serviced from the front.

tion Kits.

p

O

densate pumps, duct adapters and other options are

on

c

red as kits, ensuring availability of required parts

de

or

omplete compatibility with your system.

d c

an

cy Listed.

n

e

g

A

rtified to meet U.S. and Canadian safety

e

ed/c

t

lis

ards, and MEA listed for New York City

d

an

t

s

cations. These agency listings ensure fast,

li

p

p

a

-free inspection and building code approvals.

sle

s

a

h

e m

-point power kits, sweat adapters,

gle

Sin

ard 60Hz units are CSA Agency

d

an

t

S

por

a

v

The e

unted above the dropped

loor Space.

o F

r

e

a

or an

t

d indoor

2

Page 3

Low Total Cost Of Ownership:

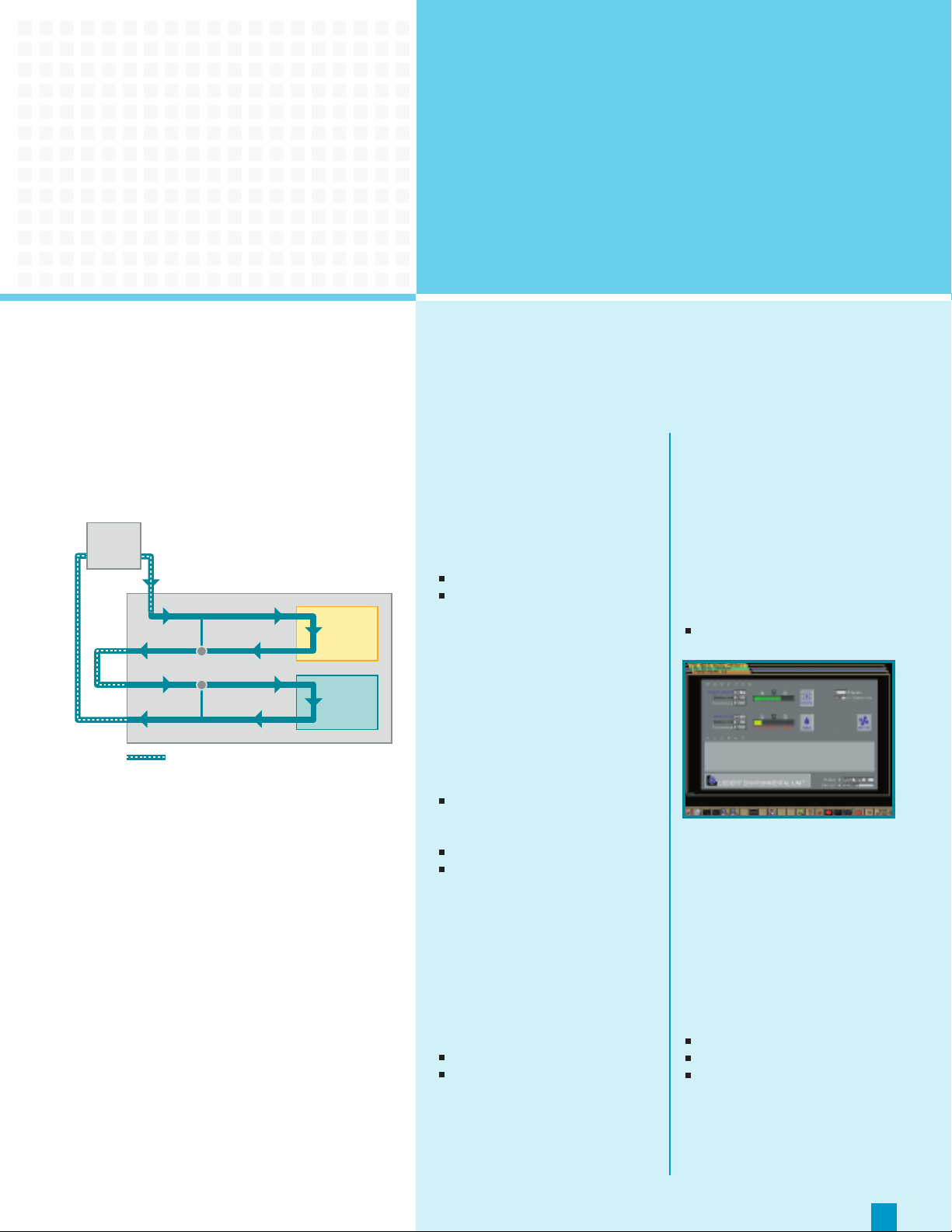

Water Temperature Sensor

Free

Cooling

Coil

Building

Cooling

Tow er

Water/

Glycol

Condenser

High-Efficiency Compressor. The rotary or scroll

compressors are both energy-efficient and rugged,

to ensure continuous operation.

Free-Cooling Option. A second cooling coil allows

the system to take advantage of colder outdoor

temperatures and bypass compressor operation.

Free-Cooling Option

Field-supplied piping

Liebert Monitoring Solutions:

When You Need To Know

You will find a full-range of monitoring and control systems,

communications modules designed to interface Liebert equipment with

a variety of building management systems, plus stand-alone monitoring,

control and leak detection devices.

Local And Remote

onitoring Panels

M

These units provide basic monitoring

and control for a single unit or small

groups of equipment either at the

equipment location or to a remote site.

Products include:

Liebert Universal Monitor

Liebert Controllers

Leak Detection

Liebert Liqui-tect®leak detection

systems alert facility personnel to

the presence of leaking fluids before

serious damage results. They provide

quick sensing and accurate reporting

of leaks below the floor, above the

ceiling or at the perimeter of a room.

Advanced Monitoring

Liebert SiteScan®Web offers

comprehensive, centralized

monitoring, control, data analysis

and reporting for a full-range

of computer support systems. It

provides web-based site monitoring,

alarm management and

trending/analysis for critical sites.

Products include:

Liebert SiteScan Web Software

When water temperature goes below 45˚F, cooling switches over to

Free-Cooling operation. A separate chilled water source can also be

used with Air-Cooled system. Note: Special cupro-nickel free-cooling

ust be specified when applied to open cooling tower.

l m

i

o

c

cts include:

Produ

Li

ebert Liqui-tect Panel

Two Channel Direct Read

Leak Detection

Liebert Zone Leak Detection Kits

ebert Point Leak Detection Sensor

Li

Fundamental Monitoring

Liebert Nform™is

tralized monitoring and

n

e

a c

communications software package

that combines full-scale monitoring

with cost-effective deployment

through the use of the existing

network infrastructure.

Products include:

Liebert Nform Software

Liebert IntelliSlot Web/485

d ADPT

ar

C

r information,

the

ur

or f

F

please refer to www.liebert.com

arty Monitoring

d P

Thir

System Connectivity

f open protocols allows

e o

s

The u

you to interface Liebert units and

monitoring systems with other types

and brands of control equipment

MS, NMS, SCADA and fire

g B

in

d

lu

inc

al

arm systems.

Protocols supported:

odbus

M

BACnet

NMP

S

3

Page 4

The Right Size To Fit Your Space And Application

With more than 10,000 possible configurations, there is a LiebertMini-Mate2 system

available to fit the needs of many room cooling or spot cooling requirements.

iebert Mini-Mate2™ Product

L

Features Include:

vailable in 1,1.5, 2, 3, 5 & 8 ton capacities

A

tage cooling on 8-ton)

(3-s

Self-contained or split systems allow for fitting

systems with a variety of architectures

Reliable refrigeration components featuring rotary

or scroll compressors with copper tube aluminum

fin coils provide high-efficiency

Units are fully charged with refrigerant and come

standard with quick-connect fittings to reduce

installation time.

Available in air-cooled, water-cooled, glycol-cooled

or chilled-water configurations

Easy-to-use menu-driven microprocessor control

Optional room sensors available

Hot gas bypass for low load applications

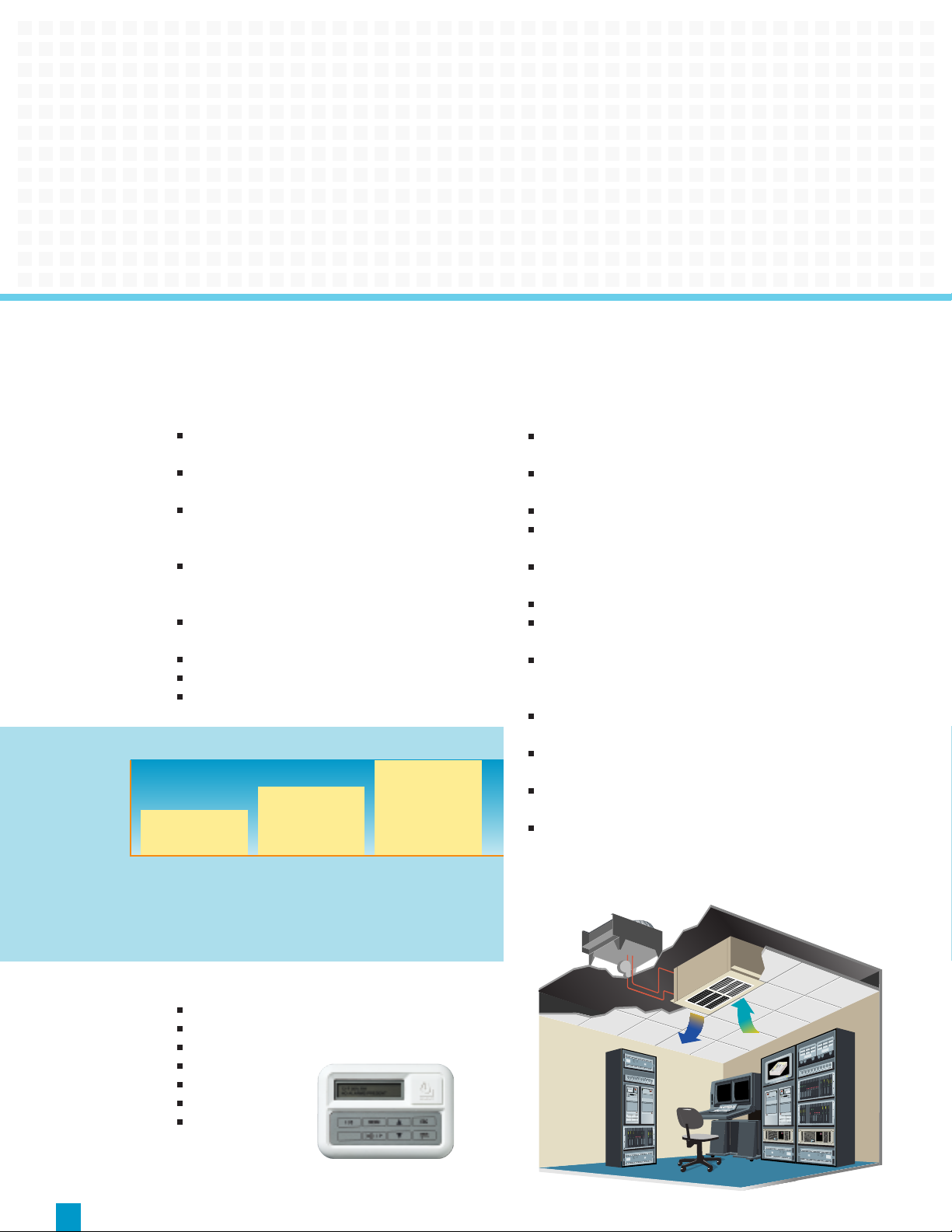

3-Stage Cooling (8 ton system only)

Improved Load Tracking

Capacity

48%

72%

100%

A Variety Of Options Help You Meet

Numerous Applications:

Grille (1-1.5 tons) or Plenum (2-3 tons) that fits 2’x4’

ceiling grid for direct supply & return air distribution

Fan speed and/or blower options to handle supply air

ductwork with higher external static pressures

Filter box or duct kits to connect to ducted sites

Hot water reheat to utilize building hot water

for energy savings

Stainless steel electric reheat and/or canister

humidifier for humidity control

High-pressure chilled water systems

Single-point power connection kit to facilitate close

coupled evaporator & condensing unit wiring

Multiple air-cooled heat rejection solutions: indoor

ducted, outdoor, (standard ambient, high ambient

and Quiet-Line)

2-way or 3-way water regulating valves rated for

standard or high-pressure applications

Unit disconnect, smoke sensor, and/or high-temp

ensor options

s

Site monitoring and communication devices

to meet monitoring needs

R407C refrigerant

age 1

t

S

A unique compressor staging system utilizes independent 3-ton and

n circuits to provide better control of room conditions. The unit

o

5-t

microprocessor continuously monitors recent cooling operation,

and selects the most economical cooling stage to satisfy demand.

t

S

age 2

t

S

age 3

1-1.5 Ton with grille

Microprocessor Control Features:

U

ser-friendly wall-mount display

Provides precise control of all unit functions

Temperature Control

Humi

dity Control

Alarm Indication

g

ammin

ogr

Pr

Auto Restart

4

Page 5

Evaporator

Condensing Unit

Evaporator

(or chilled water)

Blower

HEPA Filter Box

Motor

High Static

Blower Box

5-Ton Ducted

Liebert Mini-Mate2

apacity (Tons)

Product Option Availability

Chilled Water (rated @ 300 psi static pressure) • • •

Chilled Water (rated @ 400 psi static pressure) ••

Self-Contained Air-Cooled • •

lf-Contained Water/Glycol-Cooled • •

Se

plit System Air-Cooled w/Centrifugal Indoor Condensing Unit • • • •

S

plit System Air-Cooled w/Outdoor High Ambient Prop Fan Condensing Unit • • •

S

plit System Air-Cooled w/Outdoor Prop Fan Condensing Unit • • • • • •

S

System Types

Split System Air-Cooled w/Outdoor Quiet-Line Prop Fan Condensing Unit • • •

Split System Water/Glycol-Cooled (2- or 3-way Valve, 150 or 350 psi) • • • • • •

50 & 60 Hz voltages • • • • • •

Canister Humidifier • • • • • •

1

Chilled Water w/High Close-Off Pressure Valve • • • •

Direct-Drive Motor/Two-Speed • • • •

Filter Clog Alarm • • • • • •

High Temp Sensor (Firestat) • • • • • •

Free-Cooling Coil (Cu or CuNi Versions) • • • • • •

Hot Gas Reheat (self-contained systems only) • •

Hot Water Reheat • • • • •

Internal Disconnect Switch • • • • • •

SCR Reheat • • • • • •

Factory Installed Options

Smoke Sensor • • • • • •

Stainless Steel Electric Reheat • • • • • •

R407C ••••••

High External Static Option ••••

15’ or 30’ Refrigerant Line Sets (R22 only) • • • •

1

Condensate Pump Kit • • • • • •

Duct Kit • • • • • •

Filter Box • • • • • •

Remote Sensors • • • • • •

Ship Loose

Accessories

Single Point Power Kit ••••

Supply & Return Grille/Plenum • • • •

Liebert Controller • • • • • •

Liebert Liqui-tect 410 Point Detection Leak Detection Sensor • • • • • •

Liebert LT460-K Zone Leak Detection Kits • • • • • •

2

Liebert IntelliSlot Web/485 Card ADPT • • • • • •

ring

Liebert ENV-DO Environmental Interface Card • • • • • •

o

ebert AC8 Controller • • • • • •

Li

nit

o

ebert RCM4 Four-Point Dry Contact Monitor • • • • • •

Li

M

ebert Universal Monitor Remote Dry Contact Monitor • • • • • •

Li

ebert Site Scan Monitoring • • • • • •

Li

Single-Point Power Kit

8-ton Configuration Shown

1

i

H

2-3 T

1.5 2 3 5 8

a

t

gh S

wn

on Sho

C

tic Pressure Option

1

on/acc

ti

Some op

combinations are not available.

2

For further information,

er to www.liebert.com

f

e

e r

s

a

e

pl

y

or

s

s

e

Field installed single-point power kit

simplifies connection and installation.

vaporator Supply

E

á

á

á

á

a

por

a

v

E

ns

onde

C

Condenser Supply

or Return

t

t

e

r R

e

5

n

ur

Page 6

1 And 1-1/2 Ton Systems

Cooling Tower

Cooling Tower

P

ump

Dr

ycooler

Expansion Tank

Pump

Drycooler

Expansion Tank

Evaporator

Prop Fan

Condensing

Unit

Evaporator

E

Prop Fan

Condensing

Unit

Air-Cooled Water/Glycol Chilled-Water

Self-Contained Air-Cooled with Grille

Self-Contained Air-Cooled Ducted

Optional Filter Box, Duct Connection Available

Split System with Grille

Self-Contained Glycol System with Grille Chilled-Water with Grille

Self-Contained Glycol System Ducted

Optional Filter Box, Duct Connection Available

Self-Contained Water-Cooled with Grille

Optional Filter Box, Duct Connection Available

Chilled-Water Ducted

Evaporator Supply

á

Evaporator Return

á

Condenser Return

á

Condenser Supply

á

6

em Ducted

t

s

plit Sy

ptional Filter Box, Duct Connection Available

O

S

tained Water-Cooled Ducted

on

-C

lf

Se

ptional Filter Box, Duct Connection Available

O

Page 7

Specifications

1 And 1-1/2 Ton Systems

60 HZ 50 HZ

with Outdoor Condensing Unit with Centrifugal Condensing Unit with Outdoor Condensing Unit with Centrifugal Condensing Unit

Split System Self-Contained Split System Self-Contained

on 1.5 Tons 1 Ton 1.5 Tons 1 Ton 1.5 Tons 1 Ton 1.5 Tons

vaporator MMD12E MMD18E MMD12A MMD18A MMD11E MMD17E MMD11A MMD17A

E

Condensing Unit PFH014A PFH020A MM2CF MM2CF PFH013A PFH019A MM2CF MM2CF

Net Capacity Data*BTUH (kW) High Fan Speed

80 F (27.7) DB Total 14,100 (4.1) 19,800 (5.8) 13,300 (3.9) 19,300 (5.7) 14,400 (4.2) 21,200 (4.2) 13,400 (3.9) 20,800 (6.1)

50% RH Sensible 11,600 (3.4) 15,500 (4.5) 11,300 (3.3)

75 F (23.9 C) DB Total 13,000 (3.8) 18,400 (5.4) 12,300 (3.6) 18,000 (5.3) 13,300 (3.9) 19,800 (5.8) 12,400 (3.6) 19,500 (5.7)

50% RH Sensible 11,200 (3.3) 15,000 (4.4) 10,900 (3.2) 14,900 (4.4) 11,300 (3.3) 15,600 (4.6) 10,900 (3.2) 15,500 (4.5)

72 F (22.2 C) DB Total 12,400 (3.6)

50% RH Sensible 10,900 (3.2) 14,800 (4.3)

Net Capacity Data*BTUH (kW) Low Fan Speed

80 F (26.7) DB Total 14,000 (4.1) 19,300 (5.7) 13,300 (3.9) 18,800 (5.5) 14,300 (4.2) 20,600 (6.0) 13,400 (3.9) 20,300 (5.9)

50% RH Sensible 10,500 (3.1) 13,800 (4.0) 10,200 (3.0) 13,700 (4.0) 10,600 (3.1) 14,400 (4.2) 10,200 (3.0) 14,200 (4.2)

75 F (23.9 C) DB Total 12,900 (3.8) 18,000 (5.3) 12,300 (3.6) 17,700 (5.2) 13,200 (3.9) 19,200 (5.6) 12,400 (3.6) 18,900 (5.5)

50% RH Sensible 10,100 (3.0) 13,500 (4.0) 9,900 (2.9) 13,400 (3.9) 10,200 (3.0) 14,000 (4.1) 9,900 (2.9) 13,900 (4.1)

72 F (22.2) DB Total 12,300 (3.6) 17,200 (5.0) 11,800 (3.5) 16,900 (5.0) 12,600 (3.7) 18,400 (5.4) 11,900 (3.5) 18,200 (5.3)

50% RH Sensible 9,900 (2.9) 13,300 (3.9) 9,700 (2.8) 13,100 (3.8) 10,000 (2.9) 13,800 (4.0) 9,700 (2.8) 14,200 (4.2)

Evaporator MMD14W MMD20W MMD14W MMD20W MMD13W MMD19W MMD13W MMD19W

Net Capacity Data*BTUH (kW) High Fan Speed

80F (26.7) DB Total 15,000 (4.4) 22,000 (6.4) 13,700 (4.0) 19,900 (5.8) 15,000 (4.4) 23,000 (6.7) 13,900 (4.1) 21,300 (6.2)

50% RH Sensible 12,500 (3.7) 16,600 (4.9) 12,000 (3.5) 15,800 (4.6) 12,400 (3.6) 15,500 (4.5) 12,000 (3.5) 16,400 (4.8)

75 F (23.9 C) DB Total 13,900 (4.1) 20,500 (6.0) 12,800 (3.8) 18,600 (5.4) 13,900 (4.1) 21,300 (6.2) 12,900 (3.8) 20,000 (5.9)

50% RH Sensible 12,000 (3.5) 16,100 (4.7) 11,600 (3.4) 15,400 (4.5) 12,000 (3.5) 15,100 (4.4) 11,600 (3.4) 15,900 (4.7)

72 F (22.2 C) DB Total 13,300 (3.9) 19,600 (5.7) 12,300 (3.6) 17,900 (5.2) 13,300 (3.9) 20,400 (5.6) 12,400 (3.6) 19,200 (5.6)

50% RH Sensible 11,800 (3.5) 15,800 (4.6) 11,400 (3.3) 15,100 (4.4) 11,800 (3.5) 14,900 (4.4) 11,400 (3.3) 15,700 (4.6)

Net Capacity Data*BTUH (kW) Low Fan Speed

80 F (26.7) DB Total 14,600 (4.3) 21,100 (6.2) 13,400 (3.9) 18,900 (5.5) 14,500 (4.2) 23,900 (7.0) 13,500 (4.0) 20,700 (6.1)

50% RH Sensible 11,000 (3.2) 14,800 (4.3) 10,500 (3.1) 13,900 (4.1) 11,000 (3.2) 17,300 (5.1) 10,600 (3.1) 14,600 (4.3)

75 F (23.9 C) DB Total 13,500 (4.0) 19,700 (5.8) 12,500 (3.7) 17,800 (5.2) 13,500 (4.0) 22,200 (6.5) 12,600 (3.7) 19,300 (5.7)

50% RH Sensible 10,700 (3.1) 14,400 (4.2) 10,200 (3.0) 13,600 (4.0) 10,600 (3.1) 16,900 (5.0) 10,300 (3.0) 14,300 (4.2)

72 F (22.2 C) DB Total 12,900 (3.8) 18,900 (5.5) 12,000 (3.5) 17,100 (5.0) 12,900 (3.8) 21,200 (6.2) 12,100 (3.5) 18,600 (5.4)

50% RH

Evaporator MMD23C MMD22C

Capacity Data BTUH (kW) High Fan Speed

80 F (26.7) DB Total 21,800 (6.4) 21,800 (6.4)

50% RH Sensible 16,000 (4.7) 16,000 (4.7)

75 F (23.9 C) DB Total 14,300 (4.2) 14,300 (4.2)

50% RH

72 F (22.2 C) DB

50% RH

apacity Data BTUH (kW) Low Fan Speed

C

80 F (26.7) DB

50% RH

75 F (23.9 C) DB

50% RH

72 F (22.2 C) DB

50% RH

ac

p

a

t c

*The ne

nsibl

Se

nsible 13,100 (3.8) 13,100 (3.8)

Se

otal 11,000 (3.2) 11,000 (3.2)

T

nsible 11,000 (3.2) 11,000 (3.2)

Se

Total 17,100 (5.2) 17,100 (5.2)

Sensible 12,800 (3.7) 12,800 (3.7)

Total 11,300 (3.1) 11,300 (3.1)

Sensible 10,300 (3.0) 10,300 (3.0)

Total 8,500 (2.5) 8,500 (2.5)

Sensible 8,500 (2.5) 8,500 (2.5)

ity data has fan motor heat factored in for all ratings and the entering air condition of 72˚F (22.2˚C), 50% RH is the standard rating condition of ASHRAE 127-2001

1 T

17,700 (5.2) 11,800 (3.5) 17,300 (5.1) 12,700 (3.7) 19,000 (5.6) 11,900 (3.5) 18,700 (5.5)

10,600 (3.1) 14,600 (4.3) 11,000 (3.2) 15,300 (4.5) 10,700 (3.1) 15,200 (4.5)

60 HZ 50 HZ

WATER COOLED GLYCOL COOLED WATER COOLED GLYCOL COOLED

Self-Contained Self-Contained Self-Contained Self-Contained

1 Ton 1.5 Tons 1 Ton 1.5 Tons 1 Ton 1.5 Tons 1 Ton 1.5 Tons

e 10,400 (3.0) 14,200 (4.2) 10,000 (2.9) 13,400 (3.9) 10,400 (3.0) 16,500 (4.8) 10,100 (3.0) 14,000 (4.1)

60 HZ 50 HZ

Self-Contained Self-Contained

1.5 Tons 1.5 Tons

AIR COOLED SYSTEM

15,300 (4.5) 11,700 (3.4) 16,000 (4.7) 11,300 (3.3) 15,900 (4.7)

CHILLED WATER

7

Page 8

2 And 3 Ton Systems

Centrifugal Fan

Condensing Unit

Evaporator

Centrifugal Fan

Condensing Unit

Evaporator

E

Pump

Cooling Tower

Water/Glycol

Condensing Unit

Evaporator

Pump

Cooling Tower

Water/Glycol

Condensing Unit

Evaporator

E

Water/Glycol

Condensing Unit

Evaporator

E

Drycooler

Expansion Tank

Pump

Water/Glycol

C

ondensing Unit

Drycooler

Expansion Tank

Pump

Evaporator

Prop Fan

Condensing Unit

Evaporator

Prop Fan

Condensing Unit

Evaporator

E

Air-Cooled

tilizes Split System Evaporator

U

Remote Air-Cooled Condensing Unit

Supply & Return Air Plenum

Remote Air-Cooled Condensing Unit

Supply & Return Air Ducted

Optional Filter Box, Duct Connection Available

Water/Glycol

tilizes Split System Evaporator

U

Remote Water/Glycol-Condensing Unit

Supply & Return Air Plenum

Remote Water/Glycol-Condensing Unit

Supply & Return Air Ducted

Optional Filter Box, Duct Connection Available

Chilled-Water

Chilled-Water

Supply & Return Plenum

Chilled-Water

Supply & Return Air Ducted

Optional Filter Box, Duct Connection Available

Note: All split systems may be

se-coupled or configured with

lo

c

nsing unit located remotely

onde

c

f

rom the evaporator.

8

Outdoor Prop Fan Condensing Unit

Supply & Return Air Plenum

Outdoor Prop Fan Condensing Unit

Supply & Return Air Ducted

er Box, Duct Connection Available

lt

i

al F

on

ti

p

O

Remote Water/Glycol-Condensing Unit

Supply & Return Air Plenum

Remote Water/Glycol-Condensing Unit

Supply & Return Air Ducted

er Box, Duct Connection Available

lt

i

al F

on

ti

p

O

Evaporator Supply

á

Evaporator Return

á

Condenser Return

á

Condenser Supply

á

Page 9

Specifications

2 And 3 Ton Split Systems

60 HZ

with Outdoor Condensing Unit with Centrifugal Condensing Unit with Outdoor Condensing Unit with Centrifugal Condensing Unit

vaporator MMD24E MMD36E MMD24E MMD36E MMD23E MMD35E MMD23E MMD35E

E

ondensing Unit

C

Net Capacity Data*BTUH (kW) High Fan Speed

80 F (26.7 C) DB Total 25,600 (7.5) 36,900 (10.8) 24,200 (7.1) 34,100 (10.0) 23,800 (7.0) 34,500 (10.1) 22,700 (6.7) 31,800 (9.3)

50% RH Sensible 20,900 (6.1) 26,600 (7.8) 20,300 (5.9) 28,300 (8.3) 20,200 (5.9) 28,400 (8.3) 19,800 (5.8) 27,400 (8.0)

75 F (23.9 C) DB Total 23,800 (7.0) 34,200 (10.0) 22,400 (6.6) 31,700 (9.3) 22,100 (6.5) 32,100 (9.4) 21,000 (6.2) 29,600 (8.7)

50% RH Sensible 20,100 (5.9) 25,700 (7.5) 19,500 (5.7) 27,200 (8.0) 19,400 (5.7) 27,400 (8.0) 19,000 (5.6) 26,400 (7.7)

72 F (22.2 C) DB Total 22,900 (6.7) 32,900 (9.6) 21,400 (6.3) 30,400 (8.9) 21,200 (6.2) 30,800 (9.0) 20,100 (5.9) 28,300 (8.3)

50% RH Sensible 19,700 (5.8) 25,200 (7.4) 19,100 (5.6) 26,500 (7.8) 19,000 (5.6) 26,700 (7.8) 18,500 (5.4) 25,700 (7.5)

Net Capacity Data*BTUH (kW) Low Fan Speed

80 F (26.7 C) DB

50% RH Sensible 19,800 (5.8) 26,600 (7.8) 19,300 (5.7) 25,300 (7.4) 19,100 (5.6) 25,400 (7.4) 18,700 (5.5) 24,400 (7.1)

75 F (23.9 C) DB Total 23,800 (7.0) 34,200 (10.0) 22,300 (6.5) 31,300 (9.2) 22,000 (6.4) 31,700 (9.3) 20,900 (6.1) 29,300 (8.6)

50% RH Sensible 19,200 (5.6) 25,700 (7.5) 18,500 (5.4) 24,300 (7.1) 18,400 (5.4) 24,600 (7.2) 18,000 (5.3) 23,600 (6.9)

72 F (22.2 C) DB Total 22,700 (6.7) 32,900 (9.6) 21,300 (6.2) 29,900 (8.8) 21,100 (6.2) 30,400 (8.9) 20,000 (5.9) 28,000 (8.2)

50% RH Sensible 18,700 (5.5) 25,200 (7.4) 18,100 (5.3) 23,900 (7.0) 18,000 (5.3) 24,100 (7.1) 17,500 (5.1) 23,100 (6.8)

Evaporator MMD24E MMD36E MMD24E MMD36E MMD23E MMD35E MMD23E MMD35E

Condensing Unit MCD26W MCD38W MCD26W MCD38W MCD25W MCD37W MCD25W MCD37W

Net Capacity Data*BTUH (kW) High Fan Speed

80 F (26.7 C) DB Total 26,600 (7.8) 38,400 (11.3) 23,000 (6.7) 35,200 (10.3) 24,900 (7.3) 35,700 (10.5) 21,300 (6.2) 32,600 (9.6)

50% RH Sensible 21,300 (6.2) 29,900 (8.8) 19,900 (5.8) 28,700 (8.4) 20,600 (6.0) 28,900 (8.5) 19,300 (5.7) 27,700 (8.1)

75 F (23.9 C) DB Total 24,600 (7.2) 35,600 (10.4) 21,400 (6.3) 32,700 (9.6) 22,800 (6.7) 33,000 (9.7) 19,800 (5.8) 30,400 (8.9)

50% RH Sensible 20,400 (6.0) 28,800 (8.4) 19,100 (5.6) 27,600 (8.1) 19,700 (5.8) 27,700 (8.1) 18,500 (5.4) 26,700 (7.8)

72 F (22.2 C) DB Total 23,400 (6.9) 33,900 (9.9) 20,500 (6.0) 31,300 (9.2) 21,800 (6.4) 31,500 (9.2) 18,700 (5.5) 29,100 (8.5)

50% RH Sensible 19,900 (5.8) 28,100 (8.2) 18,700 (5.5) 27,000 (7.9) 19,200 (5.6) 27,100 (7.9) 18,700 (5.5) 26,000 (7.6)

Net Capacity Data*BTUH (kW) Low Fan Speed

80 F (26.7 C) DB Total 26,200 (7.7) 37,400 (11.0) 22,700 (6.7) 34,200 (10.0) 24,500 (7.2) 34,600 (10.1) 21,100 (6.2) 31,800 (9.3)

50% RH Sensible 20,100 (5.9) 26,700 (7.8) 18,800 (5.5) 25,500 (7.5) 19,500 (5.7) 25,700 (7.5) 18,200 (5.3) 24,600 (7.2)

75 F (23.9 C) DB Total 24,200 (7.1) 34,400 (10.1) 21,100 (6.2) 31,800 (9.3) 22,600 (6.6) 32,000 (9.4) 19,600 (5.7) 29,600 (8.7)

50% RH Sensible 19,400 (5.7) 25,800 (7.6) 18,100 (5.3) 24,700 (7.2) 18,700 (5.5) 24,800 (7.3) 17,500 (5.1) 23,700 (6.9)

72 F (22.2 C) DB Total 23,000 (6.7) 32,900 (9.6) 20,300 (5.9) 30,500 (8.9) 21,500 (6.3) 30,600 (9.0) 18,800 (5.5) 28,300 (8.3)

50% RH Sensible 18,900 (5.5) 25,200 (7.4) 17,700 (5.2) 24,100 (7.1) 18,200 (5.3) 24,200 (7.1) 17,000 (5.0) 23,200 (6.8)

Total 25,500 (7.5) 36,900 (10.8) 24,000 (7.0) 33,600 (9.8) 23,700 (6.9) 34,000 (10.0) 22,600 (6.6) 31,500 (9.2)

2 Tons 3 Tons 2 Tons 3 Tons 2 Tons 3 Tons 2 Tons 3 Tons

PFH027A PFH037A MCD24A MCD36A PFH026A PFH036A MCD23A MCD35A

60 HZ 50 HZ

WATER COOLED GLYCOL COOLED WATER COOLED GLYCOL COOLED

2 Tons 3 Tons 2 Tons 3 Tons 2 Tons 3 Tons 2 Tons 3 Tons

AIR COOLED SYSTEM

50 HZ

60 HZ

ons

aporator MMD40C MMD39C

v

E

pacity Data

a

C

80 F (26.7 C) DB

50% RH

75 F (23.9 C) DB

50% RH

72 F (22.2 C) DB

50% RH

apacity Data BTUH (kW) Low Fan Speed

C

80 F (26.7 C) DB

50% RH

75 F (23.9 C) DB

50% RH

72 F (22.2 C) DB

50% RH

*The net capacity data has fan motor heat factored in for all ratings and the entering air condition of 72˚F (22.2˚C), 50% RH is the standard rating condition of ASHRAE 127-2001

TUH (kW) Hi

B

Se

Se

Sensible 24,900 (7.3) 24,900 (7.3)

Sensible 26,900 (7.9) 26,900 (7.9)

Sensible 22,300 (6.5) 22,300 (6.5)

Sensible 19,800 (5.8) 19,800 (5.8)

gh Fan Speed

otal 49,200 (14.4) 49,200 (14.4)

T

nsible 33,100 (9.7) 33,100 (9.7)

otal 33,900 (9.9) 33,900 (9.9)

T

nsible 27,800 (8.1) 27,800 (8.1)

otal 27,100 (7.9) 27,100 (7.9)

T

Total 40,700 (11.9) 40,700 (11.9)

Total 27,700 (8.1) 27,700 (8.1)

Total 21,700 (6.4) 21,700 (6.4)

3 T

LLED WATER

I

CH

50 HZ

3 Tons

9

Page 10

5 And 8 Ton Systems

E

vaporator

Centrifugal Fan

Condensing Unit

Evaporator

P

rop Fan

Condensing Unit

Evaporator

Cooling Tower

Water/Glycol-

Condensing Unit

Evaporator

Water/Glycol-

Condensing Unit

Drycooler

Pump

Expansion Tank

Evaporator

Evaporator

Evaporator

Water/Glycol-

Condensing Unit

Drycooler

Expansion

Tank

Pump

Evaporator

Cooling Tower

Water/Glycol-

Condensing Unit

Evaporator

Centrifugal Fan

Condensing Unit

Evaporator

Prop Fan

Condensing Unit

Air-Cooled

Utilizes Split System Evaporator

Indoor Air-Cooled Condensing Unit

Supply & Return Air Ducted

Optional Filter Box/Duct Connection Available

5 Ton System

Outdoor Prop Fan Condensing Unit

Supply & Return Air Ducted

Optional Filter Box/Duct Connection Available

Water/Glycol

Utilizes Split System Evaporator

Remote Water/Glycol-Condensing Unit

Supply & Return Air Ducted

Optional Filter Box/Duct Connection Available

Remote Water/Glycol Condensing Unit

Supply & Return Air Ducted

Optional Filter Box/Duct Connection Available

Chilled-Water

Chilled-Water Coil

Supply & Return Air Ducted

Optional Filter Box/Duct Connection Available

1010

Indoor Air-Cooled Condensing Unit

Supply & Return Air Ducted

Optional Filter Box/Duct Connection Available

8 Ton System

O

Optional Filter Box/Duct Connection Available

op Fan Condensing Unit

door Pr

t

u

y & R

pl

p

Su

n Air Ducted

ur

t

e

Remote Water/Glycol-Condensing Unit

Supply & Return Air Ducted

Optional Filter Box/Duct Connection Available

e Water/Glycol-Condensing Unit

t

mo

e

R

pl

p

Su

Optional Filter Box/Duct Connection Available

y & R

n Air Ducted

ur

t

e

oil

-C

r

e

t

a

ed W

ll

hi

C

Supply & Return Air Ducted

tional Filter Box/Duct Connection Available

p

O

Evaporator Supply

á

Evaporator Return

á

Condenser Return

á

Condenser Supply

á

Page 11

Specifications

5 And 8 Ton Split Systems

60 Hz 50 Hz

w/Outdoor Condensing Unit w/Centrifugal Condensing Unit w/Outdoor Condensing Unit w/Centrifugal Condensing Unit

5 T

Evaporator MMD60E MMD60E MMD59E MMD59E

Condensing Unit PFH067A MCD65A PFH066A MCD64A

N

et Capacity Data*-BTUH (kW)

80 F (26.7 C) DB

50% RH

75 F (23.9 C) DB Total 60,500 (17.7) 61,800 (18.1) 60,000 (17.6) 61,000 (17.9)

50% RH

72 F (22.2 C) DB Total 58,100 (17.0) 59,400 (17.4) 57,200 (16.8) 58,600 (17.2)

50% RH

Evaporator MMD60E MMD60E MMD92C MMD59E MMD59E MMD91C

Condensing Unit MCD69W MCD69W MCD68W

Net Capacity Data*-BTUH (kW)

80 F (26.7 C) DB Total 70,800 (20.7) 63,400 (18.6) 94,000 (27.5) 70,000 (20.5) 62,000 (18.2) 94,000 (27.5)

50% RH Sensible 56,900 (16.7) 54,200 (15.9) 64,000 (18.8) 56,600 (16.6) 53,700 (15.7) 64,000 (18.8)

75 F (23.9 C) DB Total 66,100 (19.4) 59,300 (17.4) 62,900 (18.4) 65,100 (19.1) 57,900 (17.0) 62,900 (18.4)

50% RH Sensible 55,200 (16.2) 52,500 (15.4) 53,300 (15.6) 54,800 (16.1) 51,900 (15.2) 53,300 (15.6)

72 F (22.2 C) DB Total 63,300 (18.5) 57,000 (16.7) 51,300 (15.0) 62,200 (18.2) 55,700 (16.3) 51,300 (15.0)

50% RH Sensible 54,100 (15.9) 51,400 (15.1) 48,300 (14.2) 53,600 (15.7) 50,900 (14.9) 48,300 (14.2)

Evaporator MMD96E MMD96E MMD95E MMD95E

Condensing Unit PFH096A MCD96A PFH095A MCD95A

Net Capacity Data*-BTUH (kW)

80 F (26.7 C) DB Total 100,200 (29.4) 95,900 (28.1) 96,700 (28.3) 93,800 (27.5)

50% RH Sensible 80,500 (23.6) 79,400 (23.3) 79,300 (23.2) 78,300 (22.9)

75 F (23.9 C) DB

50% RH Sensible 78,600 (23.0) 77,000 (22.6) 77,400 (22.7) 76,200 (22.3)

72 F (22.2 C) DB Total 89,200 (26.1) 86,800 (25.4) 86,200 (25.3) 83,600 (24.5)

50% RH Sensible 77,200 (22.6) 76,500 (22.4) 75,900 (22.2) 74,900 (21.9)

Evaporator MMD96E MMD96E MMD8TC MMD95E MMD95E MMD8TC

Condensing Unit MCD98W MCD98W MCD97W MCD97W

t Capacity Data*-BTUH (kW)

e

N

80 F (26.7 C) DB Total 105,000 (30.8) 93,000 (27.2) 145,600 (42.7) 101,100 (29.6) 89,600 (26.3) 145,600 (42.7)

50% RH Sensible 83,300 (24.4) 77,500 (22.7) 98,300 (28.8) 81,000 (23.7) 76,500 (22.4) 98,300 (28.8)

75 F (23.9 C) DB

50% RH Sensible 81,300 (23.8) 75,000 (22.0) 81,400 (23.8) 78,700 (23.1) 75,600 (22.2) 81,400 (23.8)

72 F (22.2 C) DB Total 93,200 (27.3) 84,100 (24.6) 80,200 (23.5) 89,400 (26.2) 81,100 (23.8) 80,200 (23.5)

50% RH Sensible 79,000 (23.1) 75,300 (22.1) 74,300 (21.8) 77,100 (22.6) 73,900 (21.7) 74,300 (21.8)

Total 65,000 (19.0) 66,200 (19.4) 65,400 (19.2) 65,500 (19.2)

Sensible 54,400 (15.9) 54,800 (16.1) 54,800 (16.1) 54,800 (16.1)

Sensible 52,600 (15.4) 53,100 (15.6) 52,600 (15.4) 53,000 (15.5)

Sensible 51,500 (15.1) 52,100 (15.3) 51,300 (15.0) 51,900 (15.2)

otal 93,100 (27.3) 89,500 (26.2) 90,200 (26.4) 87,400 (25.6)

T

t

o

T

WATER COOLED GLYCOL COOLED CHILLED WATER WATER COOLED GLYCOL COOLED CHILLED WATER

w/Outdoor Condensing Unit w/Centrifugal Condensing Unit w/Outdoor Condensing Unit w/Centrifugal Condensing Unit

WATER COOLED GLYCOL COOLED CHILLED WATER WATER COOLED GLYCOL COOLED CHILLED WATER

al

97,400 (28.5) 86,400 (25.3) 96,900 (28.4) 93,600 (27.4) 84,500 (24.8) 96,900 (28.4)

ons 5 Tons 5 Tons 5 Tons

5 Tons 5 Tons 5 Tons 5 Tons 5 Tons 5 Tons

60 Hz 50 Hz

8 Tons 8 Tons 8 Tons 8 Tons

8 Tons 8 Tons 8 Tons 8 Tons 8 Tons 8 Tons

AI

R COOLED SYSTEM

AIR COOLED SYSTEM

MCD68W

*The net capacity data has fan motor heat factored in for all ratings and the entering air condition of 72˚F (22.2˚C), 50% RH is the standard rating condition of ASHRAE 127-2001

1111

Page 12

Emerson Network Power.

The global leader in enabling Business-Critical Continuity

™

.

EmersonNetworkPower.com

AC Power

Connectivity

DC Power

Embedded Computing

Embedded Power

Monitoring

Outside Plant

Power Switching & Controls

Racks & Integrated Cabinets

Services

Precision Cooling

Surge Protection

Liebert Corporation

1050 Dearborn Drive

P.O. Box 29186

Columbus, Ohio 43229

800 877 9222 Phone (U.S. &

Canada Onl

y)

614 888 0246 Phone (Outside U.S.)

614 841 6022

FAX

Via

Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD)

Italy

39 049 9719 111 Phone

39 049 5841 257 FAX

Emerson Network Power Asia Pacific

7/F., Dah Sing Financial Centre

108 Gloucester Rd, Wanchai

Hong Kong

852 25722201 Phone

852 28029250 FAX

liebert.com

24 x 7 Tech Support

800 222 5877 Phone

614 841 6755 (outside U.S.)

Ensuring The High Availability Of

Mission-Critical Data And Applications.

Emerson Network Power, the global leader in enabling business-critical continuity,

nsures network resiliency and adaptability through a family of technologies —

e

including Liebert power and cooling technologies — that protect and support

business-critical systems. Liebert solutions employ an adaptive architecture that

responds to changes in criticality, density and capacity. Enterprises benefit

from greater IT system availability, operational flexibility, and reduced capital

equipment and operating costs.

le every precaution has been taken to ensure accuracy and

Whi

completeness in this literature, Liebert Corporation assumes no

responsibility, and disclaims all liability for damages resulting

rom use of this information or for any errors or omissions.

f

ation. All rights reserved throughout

por

or

t C

r

be

e

© 2007 Li

pecifications subject to change without notice.

. S

ld

or

the w

All names referred to are trademarks or registered trademarks

of their respective owners.

ebert and the Liebert logo are registered trademarks

® Li

of the Liebert Corporation.

SL-10500 (R12/07) Printed in USA

Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co.

©2007 Emerson Electric Co.

Loading...

Loading...