Page 1

Liebert® Challenger™ ITR

Installation Manual - Nominal Capacities 23 or 33 kW, 50 & 60Hz

Precision Cooling

For Business-Critical Continuity™

Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 System Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Self Contained Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Chilled Water Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.3 Split Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1 Room Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Equipment Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Location Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3.1 Remote Sensor Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 Equipment Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4.1 Handling With Skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4.2 Removal of Skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.5 Piping Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.1 Drain Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Balancing the Air Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7.1 Ducted Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7.2 Plenum Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Checklist for Completed Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.0 AIR-COOLED MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.1 Condenser Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.3 Lee-Temp/Flood Back Head Pressure Control Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Fan Speed Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.1 Materials Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.2 Dehydration/Leak Test and Charging Procedures for R22 (standard) or R407C (Optional) . 18

3.4.3 Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 Lee-Temp/Flood Back Head Pressure Control Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.1 Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.2 Materials Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5.3 Dehydration/Leak Test and Charging Procedures for R22 (Standard) or R407C (Optional). 21

3.5.4 Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.0 WATER-COOLED MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.1 Piping Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Water Regulating Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.1 Water Regulating Valve Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.2 Water Regulating Valve Manual Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.3 Testing Valve Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.0 GLYCOL/GLYCOOL-COOLED MODELS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.1 Drycooler Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

i

Page 4

5.2 Drycooler Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.2 Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.3 Pump and Drycooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4 Glycol Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4.1 Expansion Tanks, Fluid Relief Valves and Other Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 Filling Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5.1 Preparing the System for Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5.2 Glycol Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5.3 Filling the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6 Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.7 Glycol Regulating Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.7.1 Glycol Regulating Valve Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.7.2 Testing Valve Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.0 CHILLED WATER MODELS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.1 Piping Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.0 SPLIT SYSTEM MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1 Location Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.1 Air-Cooled Condensing Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.2 Water/Glycol-Cooled Condensing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2.2 Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3 Piping Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3.1 Refrigerant Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3.2 Quick Connect Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.4 Outdoor Air-Cooled Condensing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

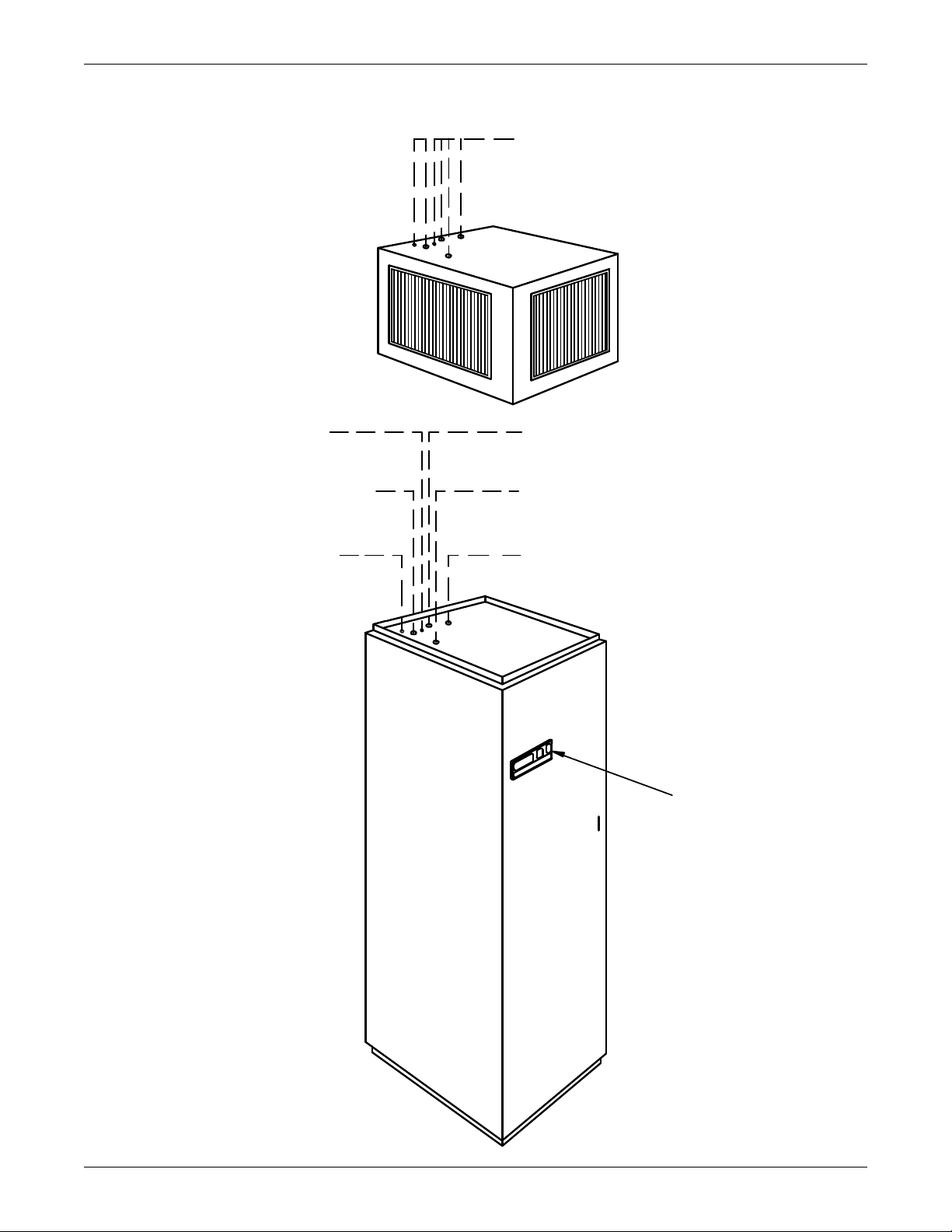

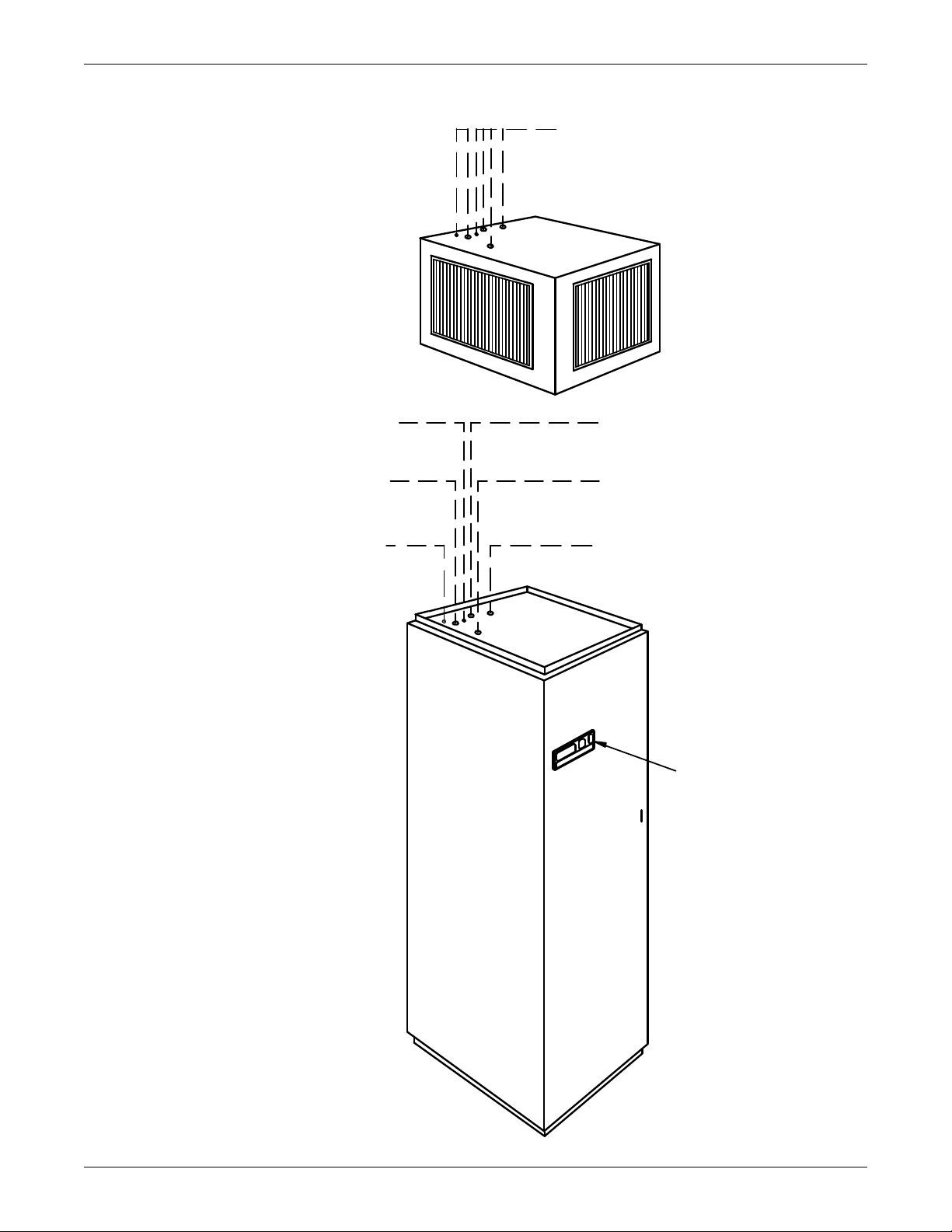

7.5 Centrifugal Air-Cooled Condensing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

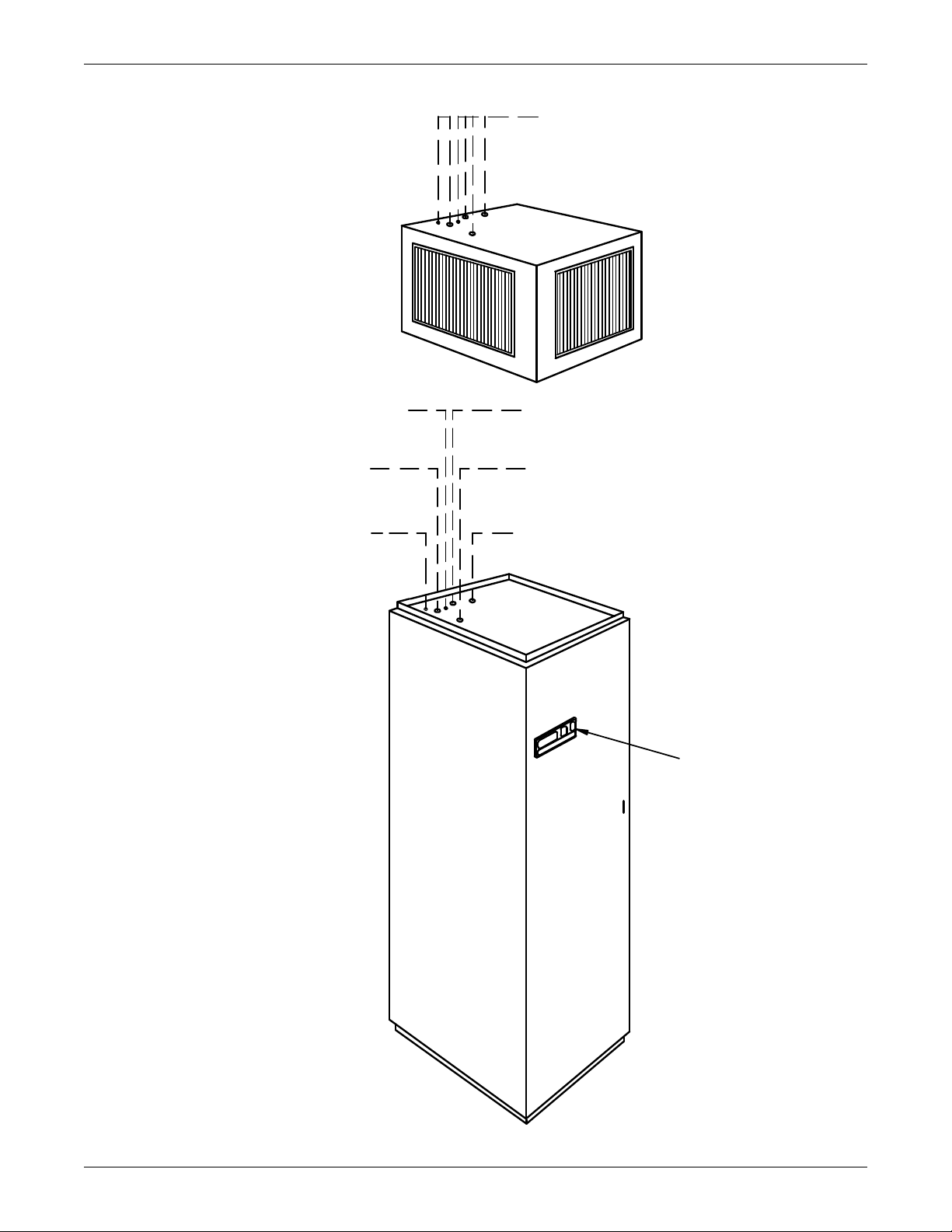

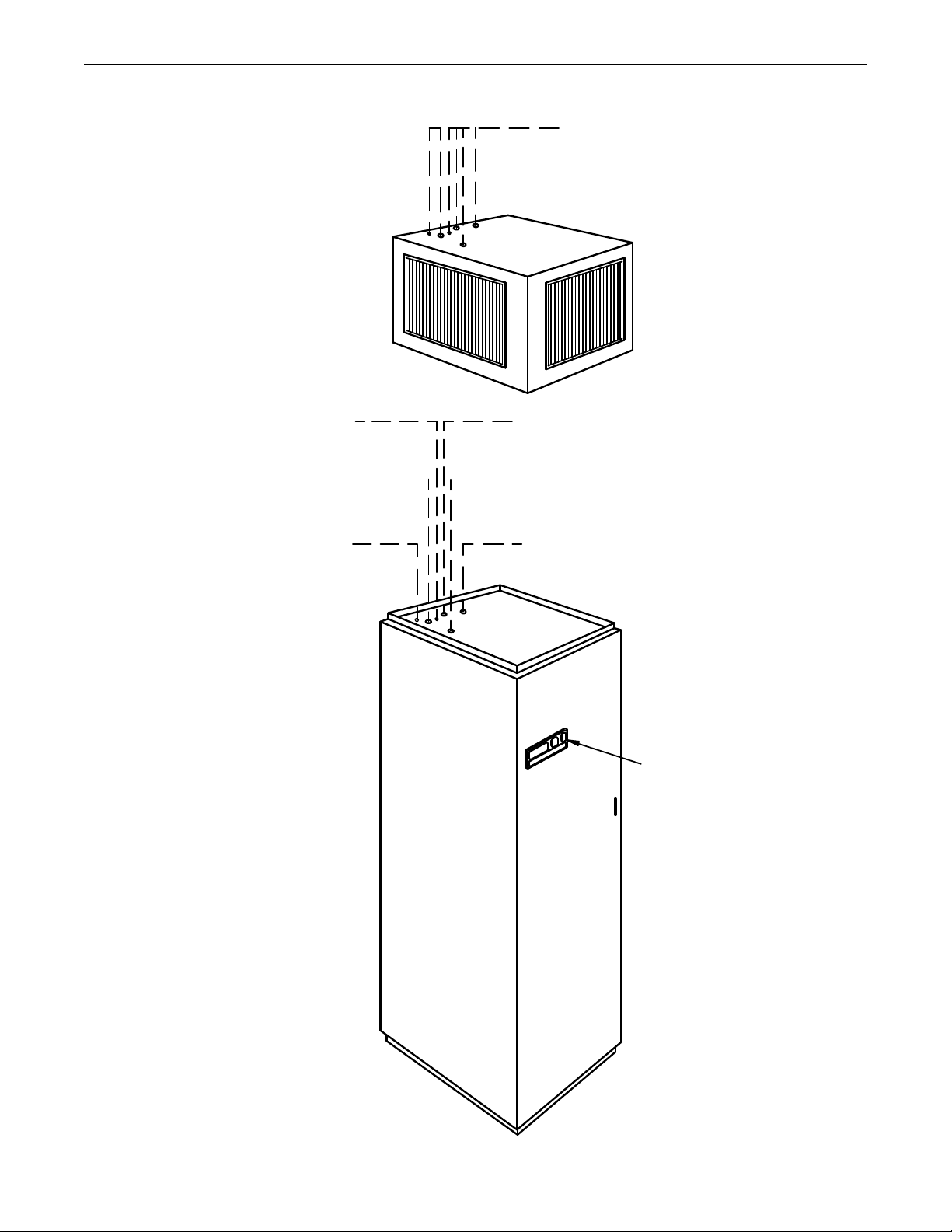

7.5.1 Installing the Indoor Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.5.2 Ducting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.6 Water and Glycol-Cooled Condensing Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6.1 Piping Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6.2 Condenser Water Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6.3 Regulating Valve Adjustment and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6.4 Glycol Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.0 R407C REFRIGERANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.1 Calculating Subcooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ii

Page 5

FIGURES

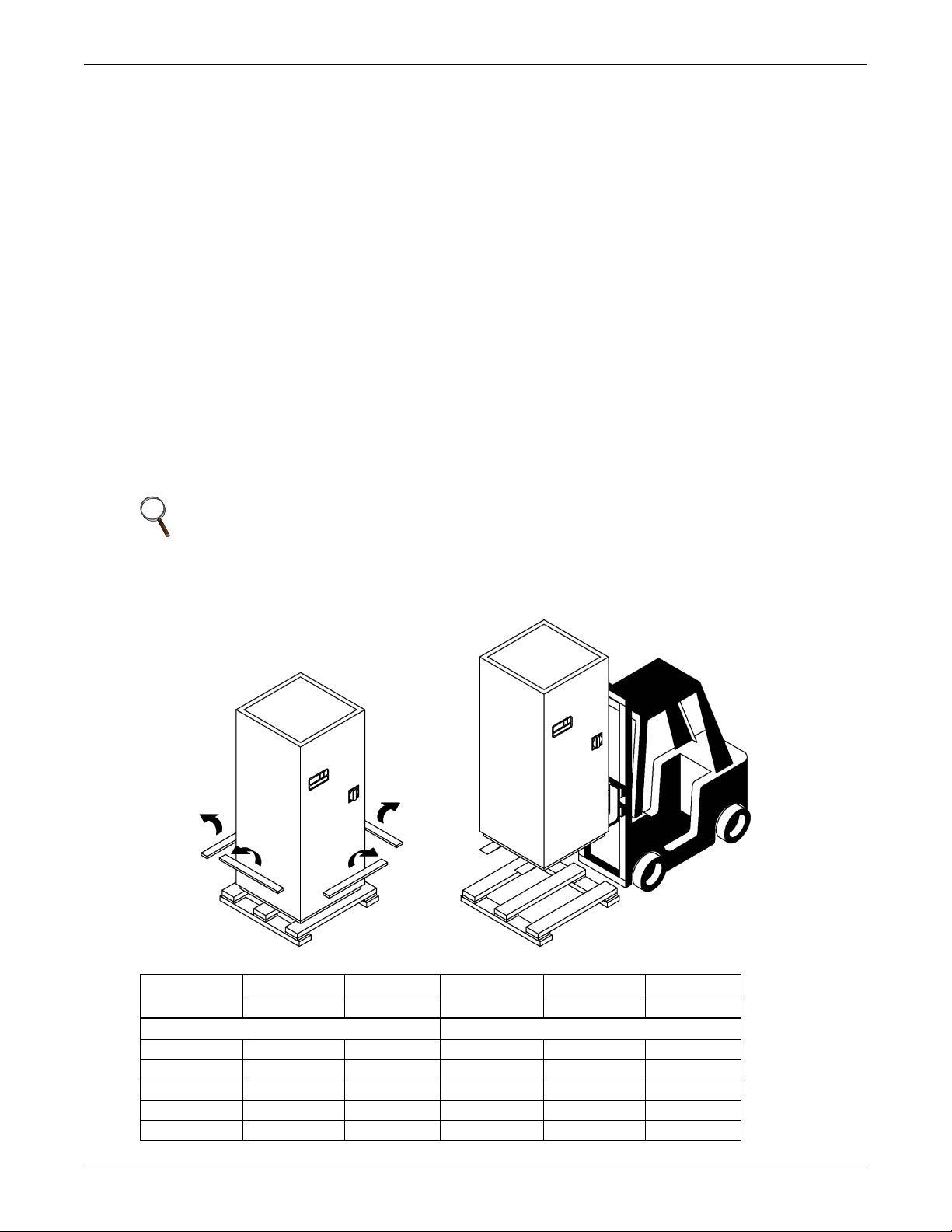

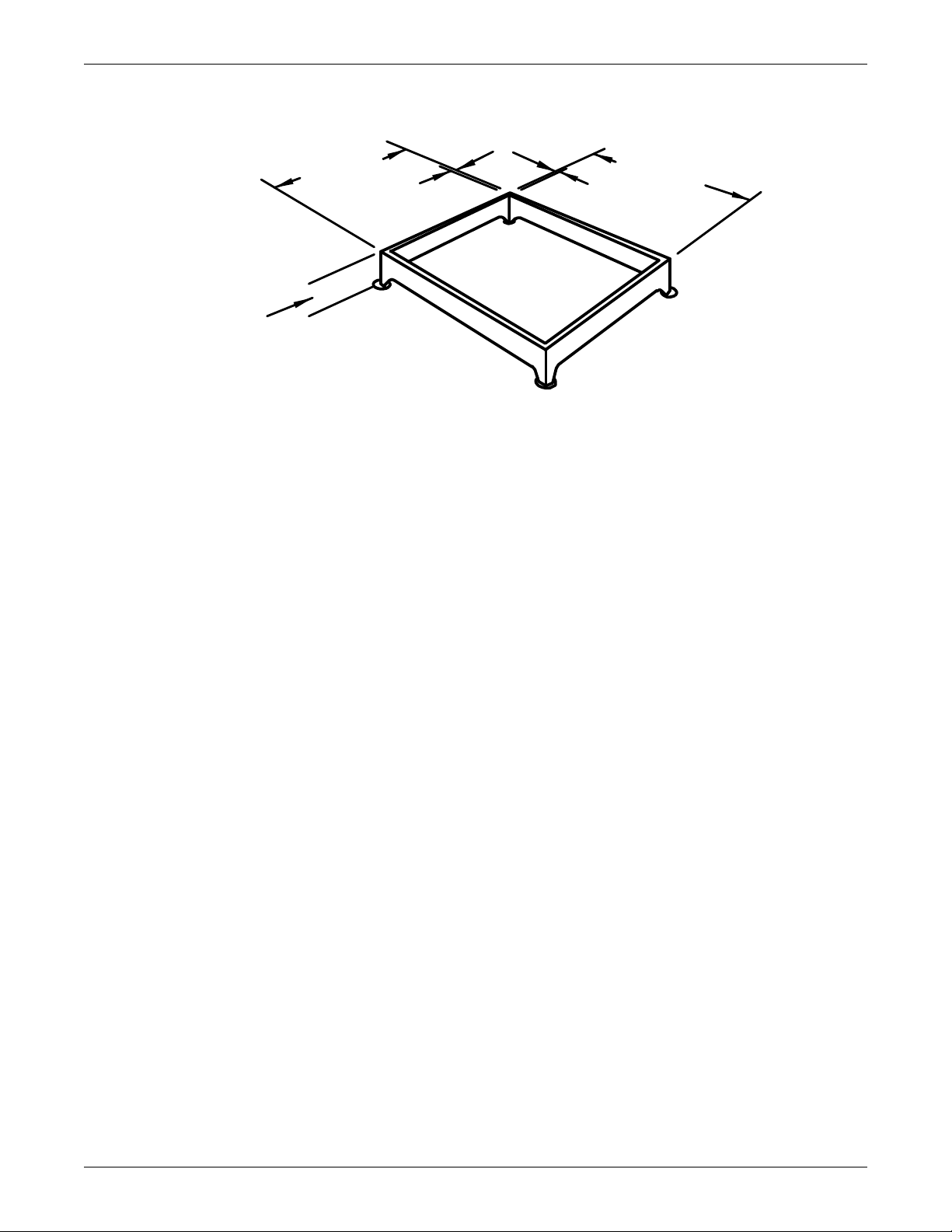

Figure 1 Removing Liebert Challenger ITR from skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

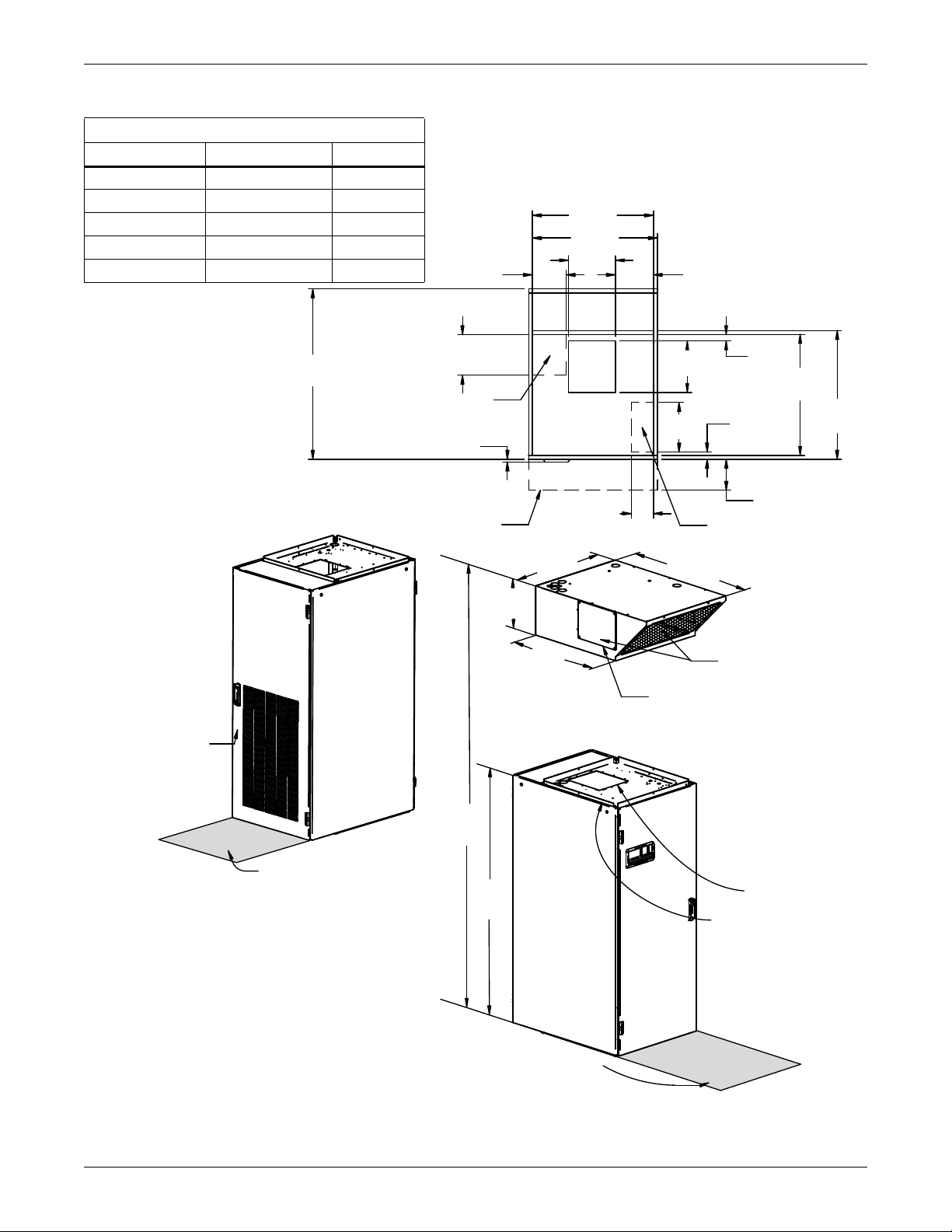

Figure 2 Cabinet dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3 Optional floor stand dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4 Piping connections for air-cooled units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5 Piping connections for split system fan coil units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6 Piping connections for water/glycol and GLYCOOL units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7 Piping connections for chilled water self-contained units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9 Air-cooled condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10 Air-cooled fan speed control general arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11 Air-cooled, Lee-Temp general arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 12 Water-cooled general arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 13 Johnson Controls valve adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 14 Drycoolers and pump packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 15 Pump packages—expansion tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 16 Glycol general arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 17 GLYCOOL general arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 18 Chilled water general arrangement - horizontal flow (BR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 19 Refrigerant piping diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 20 Outdoor air-cooled condensing unit—horizontal air discharge models . . . . . . . . . . . . . . . . . . . . . 43

Figure 21 Outdoor air-cooled condensing unit—top air discharge models . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 22 Electrical field connections, prop fan condensing module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 23 Detail of ceiling hanging bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 24 Centrifugal air-cooled condensing unit dimensional data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 25 Centrifugal air-cooled condensing unit dimensional data (con't.) . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 26 Split systems general arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 27 Water/glycol-cooled condensing unit dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 28 Water/glycol-cooled condensing unit (con't.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

iii

Page 6

TABLES

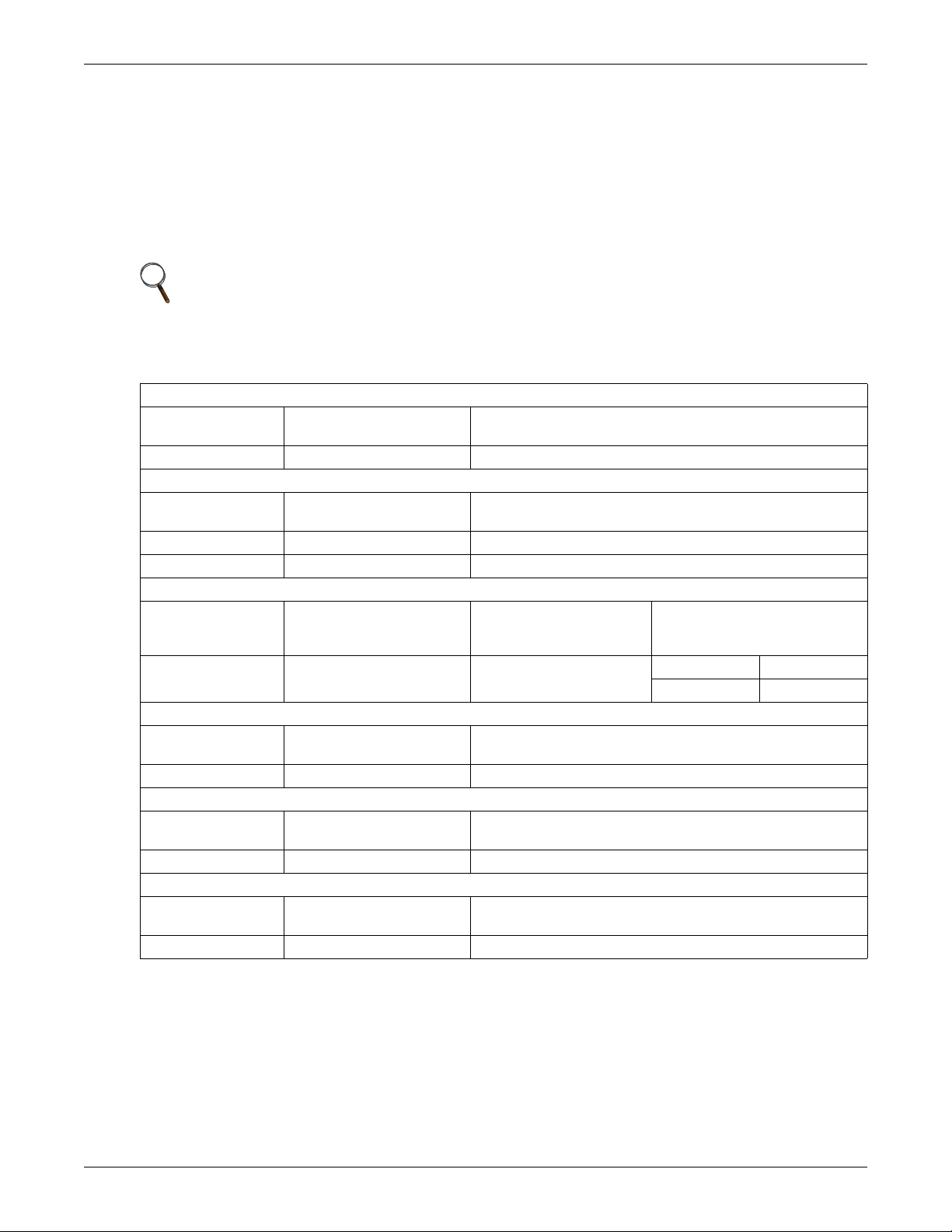

Table 1 Unit shipping weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2 Piping connection size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3 Air-cooled condenser statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 4 Recommended line sizes — OD copper (inches)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5 Equivalent lengths (feet) for various pipe fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 6 Indoor unit refrigerant charge lb (kg) R22 or R407C (per unit serial tag) . . . . . . . . . . . . . . . . . . 17

Table 7 Line charges - refrigerant per 100 ft (30 m) of Type “L” copper tube. . . . . . . . . . . . . . . . . . . . . . . 17

Table 8 Condenser refrigerant (per serial tag) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 9 Refrigerant control settings psi (kPa) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 10 Refrigerant control settings psi (kPa) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 11 Room dew point temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 12 Indoor unit glycol volume approximate gallons (liters) max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 13 Volume in standard Type “L” copper piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 14 Ethylene glycol concentrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 15 Mounting hole dimensional data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 16 Drycooler data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 17 Glycol pump data* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 18 Refrigerant control settings psi (kPa) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 19 Unit refrigerant charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 20 Line charges - refrigerant per 100 ft (30 m) of Type “L” copper tube. . . . . . . . . . . . . . . . . . . . . . . 40

Table 21 Recommended refrigerant lines (R22 or R407C) sizes OD copper . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 22 Line coupling sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 23 Equivalent lengths (feet) for various pipe fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 24 Horizontal air discharge cabinet and floor planning dimensional data. . . . . . . . . . . . . . . . . . . . . 44

Table 25 Horizontal air discharge piping and electrical connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 26 Cabinet and floor planning dimensional data - prop fan condensing modules, top

air discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 27 Piping and electrical connections - top air discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 28 Indoor centrifugal condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 29 Airflow CFM (CMH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 30 Water and glycol-cooled unit connection sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 31 Water and glycol-cooled condensing unit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 32 R407C pressure/temperature chart for operation and superheat (discharge/hot gas

and suction gas). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 33 R407C pressure/temperature chart for subcooling only (liquid measurements). . . . . . . . . . . . . . 57

iv

Page 7

1.0 INTRODUCTION

1.1 System Descriptions

Liebert Challenger ITR™ environmental control systems are available in three main system configurations:

• self contained system with a scroll compressor in the room unit

• self contained chilled water system

• split system with an evaporator section and a remote condensing unit

All three types are available in horizontal flow configurations. Each model requires three-phase

power. Units are available in 208, 230, 460, or 575 V, 60 Hz; and 200, 230 or 380/415 V, 50 Hz.

The following features are included as standard in all room units regardless of the type of system:

V-frame coil, infrared humidifier, finned tubular stainless steel electric reheat, 2" filter, individual

high voltage fused protection, and fan assembly.

Each configuration can operate with either Advanced Microprocessor Controls (A), or Advanced

Microprocessor Controls with Graphics (G). A brief description of each, including operational differences, is listed below. Check model numbers to see what is supplied with your unit.

1.1.1 Self Contained Systems

Air-Cooled Models

Complete refrigeration system including hot gas bypass and crankcase heater with standard condenser and fan speed control for 95°F (35°C) ambient at sea level.

Introduction

Water-Cooled Models

Compete refrigeration system including hot gas bypass with water/glycol-cooled condenser and twoway water regulating valve with bypass.

Glycol-Cooled Models

The water-cooled model as described above plus pump package and 95°F (35°C) design ambient drycooler.

GLYCOOL Models

Complete refrigeration system including hot gas bypass with glycol condenser and three-way water regulating valve plus an integrally piped Econ-O-Coil with three-way modulating control valve.

1.1.2 Chilled Water Models

Chilled Water models include chilled water piping, three-way modulating valve and actuator assembly.

1.1.3 Split Systems

Each Air-Cooled split system consists of an evaporator section and one of the following condensing units.

Prop Fan

Includes scroll compressor, condenser coil, prop fan, high pressure switch, and Lee-Temp head pressure control. Unit is designed for outdoor location.

Centrifugal Fan

Includes scroll compressor, condenser coil, centrifugal blower assembly, high pressure switch, head

pressure control valve, Lee-Temp receiver and liquid line solenoid valve. Unit must be mounted

indoors. Duct flanges are optional.

Water/Glycol Condensing Units

Each water-cooled split system consists of an evaporator section and a water/glycol condensing unit,

which includes scroll compressor, coaxial condenser, water regulating valve, and high pressure switch.

Design pressure is 150 psi (1034 kPa) as standard and 350 psi (2413 kPa) as optional.

Each glycol-cooled split system consists of an evaporator section, a water/glycol condensing unit (as

described above), a pump package and a 95°F (35°C) design ambient drycooler.

1

Page 8

2.0 INSTALLATION

!

2.1 Room Preparation

The room should be well insulated and must have a sealed vapor barrier. The vapor barrier in the

ceiling can be a polyethylene film type. Use a rubber or plastic base paint on concrete walls and floors.

Doors should not be undercut or have grilles in them.

Outside (or fresh) air should be kept to an absolute minimum. Outside air adds to the heating, cooling, humidifying and dehumidifying loads of the site. It is recommended that outside air be kept

below 5% of the total air circulated in the room and be preconditioned.

2.2 Equipment Inspection

Upon arrival of the unit, inspect all items for visible and concealed damage. Damage should be immediately reported to the carrier and a damage claim filed with a copy sent to Liebert or to your sales

representative.

2.3 Location Considerations

The Liebert Challenger ITR can sit on top of an accessible elevated flooring system. It may be necessary to furnish additional pedestal support below the unit to ensure maximum structural support (see

Table 1). A separate floor stand for the unit may be used as support, independent of the elevated floor

and installed prior to the flooring system.

Provide approximately 34" (864 mm) service clearance in the front and rear of the unit.

The unit can be installed between equipment racks or at the end of a row of racks. Consideration

should be given before installing refrigerant and liquid lines next to, under or above electronic equipment. Avoid placing the Liebert Challenger ITR in an alcove. Placing units too close together will

reduce the effectiveness of the air distribution.

Installation

NOTE

Locate and remove shipping screw on fan motor base.

2.3.1 Remote Sensor Installation Location

The remote temperature and humidity sensor should be installed in the cold aisle in front of the

equipment to be cooled. It should be mounted at the farthest point from the cooling unit that supply

air needs to reach but still within the unit's area of influence. The sensor should be installed at the

highest point that equipment will draw in cooled air.

2.4 Equipment Handling

WARNING

Risk of equipment tipping over. Can cause damage, injury or death.

The instructions listed below must be adhered to when handling this unit with or without the

skid. There is the potential for this unit to tip over if handled improperly.

2

Page 9

2.4.1 Handling With Skid

Remove plywood skirting holding

unit and skid in place.

Raise unit with fork lift

or similar machine.

• Always keep the Liebert Challenger ITR upright, indoors and protected from damage.

• Do not use the extended rear door frame to lift the unit.

• If possible, transport the unit using a fork lift; otherwise, use a crane with belts or cables, avoiding pressing on the top edges of the packaging.

• If using a fork lift, make sure that the forks, if adjustable, are spread to the widest allowable distance to still fit under the skid.

NOTICE

Do not attempt to lift the Liebert Challenger ITR with the extended rear door frame.

Attempting to do so will damage the unit. Lift the unit only from its main base.

NOTICE

While on the skid, the Liebert Challenger ITR is too tall to fit through a standard height

doorway (83 inches or 2108 mm tall). Any attempt to move the unit, while on the skid,

through a standard doorway will damage the unit.

2.4.2 Removal of Skid

1. Remove the plywood skirting that keeps the skid and unit in place.

2. Raise the Liebert Challenger ITR off the skid. Liebert recommends using a fork lift (see Figure 1)

or similar machine to ensure that the unit is lifted properly.

Installation

NOTE

Lift the Liebert Challenger ITR only from its main base. Do not use the extended rear door

frame to lift the unit.

3. Once the unit is raised, the skid can be removed.

Figure 1 Removing Liebert Challenger ITR from skid

Table 1 Unit shipping weights

Domestic Export

Model

BR059E 650 (295) 750 (340) BR060E 650 (295) 750 (340)

BR065A 745 (340) 845 (385) BR067A 745 (340) 845 (385)

BR070WG 815 (370) 915 (415) BR071WG 815 (370) 915 (415)

BM058G 855 (390) 955 (435) BM061G 855 (390) 955 (435)

BR101C 660 (300) 760 (345) BR102C 660 (300) 760 (345)

lb (kg) lb (kg) lb (kg) lb (kg)

50Hz Models 60Hz Models

Model

3

Domestic Export

Page 10

Figure 2 Cabinet dimensions

DPN001523

Pg. 2, Rev. 1

Filter Access

by Opening Door

UNIT

TOP VIEW

32-1/2"

(826mm)

5/8"

(16mm)

9-5/8"

(244mm)

8-1/2"

(216mm)

31-1/2"

(800mm)

1-7/8"

(48mm)

12-1/2"

(318mm)

30-1/2"

(775mm)

30-1/2"

(775mm)

32-1/2"

(826mm)

32-1/2"

(826mm)

1-5/8"

(41mm)

13"

(330mm)

Projection of

Display Bezel

Standard Piping Location

45-1/8"

(1147mm)

5-1/2"

(140mm)

15-1/16"

(382mm)

76"

(1930mm)

91-1/16"

(2313mm)

Blower Outlet with

1" (25.4mm) Flange

Shaded area indicates

a recommended

clearance of 34" (864mm)

for component access

Shaded area indicates a recommended

clearance of 34" (864mm) for component access

UNIT DIMENSIONAL DATA

FRONT VIEW

UNIT DIMENSIONAL DATA

REAR VIEW

10-1/4"

(260mm)

7/8" (22.2mm) Flange for

Duct or Plenum Connection

43-5/16"

(1100mm)

11- 3/ 4"

(298mm)

Remove Blocker Panel

for Air Discharge Left

and/or Right Side Panels

Standard Electrical Outlet

Location Through Unit

12-5/8"

(321mm)

Discharge Air Opening

Plenum Overhang

Unit Weight

50 Hz Models 60 Hz Models lb. (kg)

BR059E BR060E 649 (294)

BR065A BR067A 744 (337)

BR070WG BR071WG 814 (369)

BR101C BR102C 659 (299)

BM058G BM061G 854 (387)

Installation

4

Page 11

Figure 3 Optional floor stand dimensions

30-1/2"

(775mm)

30-1/2"

(775mm)

1"

(25.4mm)

See Specification Sheet

for height of floor stand ordered.

SL-11897

Pg. 7

Installation

5

Page 12

2.5 Piping Considerations

Consideration should be given before installing refrigerant and liquid lines next to, under or above

electronic equipment.

2.5.1 Drain Line

A 3/4" (19.1 mm) female pipe thread (FPT) connection is provided for the evaporator coil condensate

drain. This drain line also drains the humidifier, if applicable. The drain line must be located so it will

not be exposed to freezing temperatures. The drain should be at least the full size of the drain connection and pitched a minimum of 1/8" per ft. (11 mm per meter).

NOTE

This line may contain boiling water. Select appropriate drain system materials.

The Challenger ITR comes standard with a condensate pump will require a field-supplied trap

downstream from the pump. The drain line must comply with all applicable codes.

Table 2 Piping connection size

Air-Cooled Unit Connection Sizes—in.

Model No. BR/BM

60Hz (50Hz)

067A (065A) 1/2 7/8

Split System Fan Coil Unit Connection Sizes—in.

Model No. BR/BM

60Hz (50 Hz)

Liquid Line O.D. Copper

L

Liquid Line

L

Installation

Hot Gas Line O.D. Copper

HG

Suction Line

SC

060E (059E) 1/2 O.D. Cu 1-1/8 O.D. Cu

All Units: Connection Sizes—in.

Humidifier Line

O.D. Copper

H

1/4 1/2 OD Cu 1/2

Water/Glycol-Cooled Unit Connection Sizes—in.

Model No. BR/BM

60Hz (50 Hz)

071WG (070WG) 1-1/8 1-1/8

GLYCOOL Unit Connection Sizes —in.

Model No. BR/BM

60Hz (50 Hz)

061G (058G) 1-1/8 1-1/8

Chilled Water Unit Connection Sizes—in.

Model No. BR/BM

60Hz (50 Hz)

102C (101C) 1-1/8 1-1/8

Condensate

Drain Line

C

Supply Line

S

Supply Line

S

Supply Line

CWS

Condensate Pump Line

O.D. Copper

P

Return Line

Return Line

Return Line

CWR

Hot Water Reheat

O.D. Copper

Supply HWS Return HWR

5/8 5/8

R

R

6

Page 13

Figure 4 Piping connections for air-cooled units

Piping outlet locations through the

plenum are the same as the unit.

See below for descriptions and

connection sizes.

Hot Water Return

5/8" OD CU (optional)

Hot Water Supply

5/8" OD CU (optional)

Liquid Refrigerant Line

1/2" OD CU on Models BR067A/BR065A

Humidifier Water

Supply Line 1/4" OD CU

Hot Gas Refrigerant Line

7/8" OD CU on Models

BR067A/BR065A

Condensate Pump

Line 1/2" OD CU

Monitoring Panel

PIPING OUTLET LOCATIONS

(See Cabinet and Floor Planning

Dimensional Data for Piping

Opening Sizes.)

DPN001525

REV 0

Installation

7

Page 14

Figure 5 Piping connections for split system fan coil units

Piping outlet locations through the

plenum are the same as the unit.

See below for descriptions and

connection sizes.

Hot Water Supply

5/8" OD CU (optional)

Condensate Pump Line

1/2" OD CU

PIPING OUTLET LOCATIONS

(See Cabinet and Floor Planning

Dimensional Data for Piping

Opening Sizes.)

Hot Water Return

5/8" OD CU (optional)

Liquid Refrigerant Line

1/2" OD CU on Models

BR060E/BR059E

Humidifier Water Supply Line

1/4" OD CU

Suction Refrigerant Line

1 1/8" OD CU on

Models BR060E/BR059E

Monitoring Panel

DPN001534

REV 0

Installation

8

Page 15

Figure 6 Piping connections for water/glycol and GLYCOOL units

Piping outlet locations through the

plenum are the same as the unit.

See below for descriptions and

connection sizes.

Hot Water Supply

5/8" OD CU (optional)

Condensate Pump Line

1/2" OD CU

PIPING OUTLET LOCATIONS

(See Cabinet and Floor Planning

Dimensional Data for Piping

Opening Sizes.)

Hot Water Return

5/8" OD CU (optional)

Condenser Supply Line

1-1/8" OD CU on

Models BR071WG/BR070WG

Humidifier Water Supply Line

1/4" OD CU

Condenser Return Line

1 1/8" OD CU on

Models BR071WG/BR070WG

DPN001528

REV 0

Monitoring Panel

Installation

9

Page 16

Figure 7 Piping connections for chilled water self-contained units

Piping outlet locations through

the plenum are the same as the

unit. See below for descriptions

and connection sizes.

Hot Water Return

5/8" OD CU (optional)

Chilled Water Return Line

1-1/8" OD CU

Hot Water Supply

5/8" OD CU (optional)

Humidifier Water Supply

Line 1/4" OD CU

Chilled Water Supply Line

1-1/8" OD CU

Condensate Pump Line

1/2" OD CU

Monitoring Panel

PIPING OUTLET LOCATIONS

(See Cabinet and Floor Planning

Dimensional Data for Piping

Opening Sizes.)

DPN001531

REV 0

Installation

10

Page 17

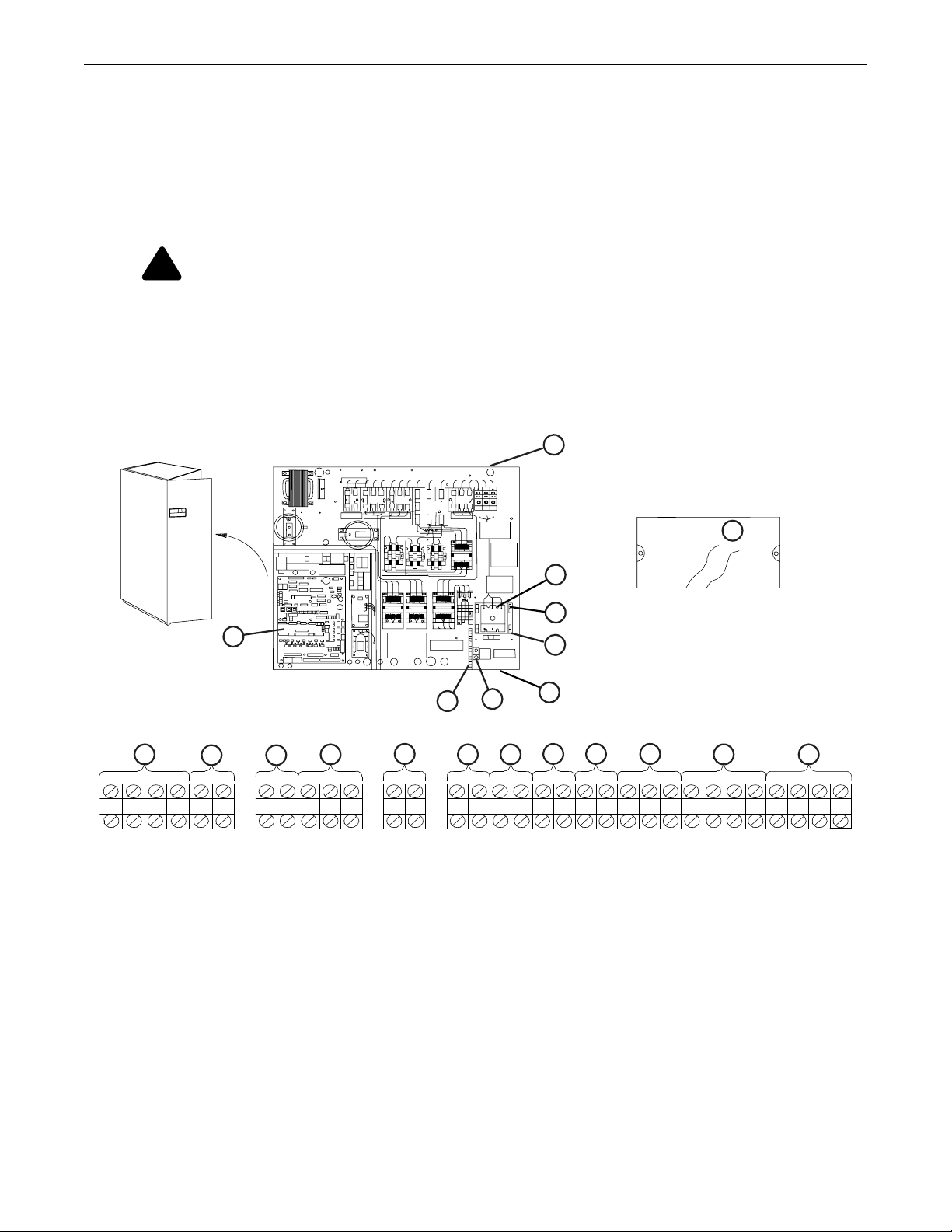

2.6 Electrical Connections

!

757682

83 84 85 88 899192 93 94 95 96

97 1

37C 38C 37B 37 38 24 50 51 55 56

77 78

4

7

2

3

4

5

71

70

15

6

11

13

12

17

16

14

1310

9

8

8

9

1

1

2338B

Terminal Block*

(for customer connections)

Electrical Handy Box*

(factory-installed with cover)

DPN001524

REV 0

Three-phase electrical service is required for all models in either 208, 230, 460, or 575 V, 60 Hz; or

200, 230, or 380/415 V, 50 Hz. Electrical service shall conform to national and local electrical codes.

Refer to equipment nameplate regarding wire size and circuit protection requirements. Refer to electrical schematic when making connections.

A manual electrical disconnect switch should be installed within 5 feet (1.6 m) of the Liebert Challenger ITR in accordance with codes. A factory-supplied, locking disconnect switch is factory-mounted

within the unit behind the front door.

WARNING

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power before working within the unit. Use a voltmeter

to make sure power is turned off before making any electrical connections.

NOTICE

Three-phase power must be connected to the Liebert Challenger ITR line voltage terminals in

the proper sequence so that scroll the compressor rotates in the proper direction.

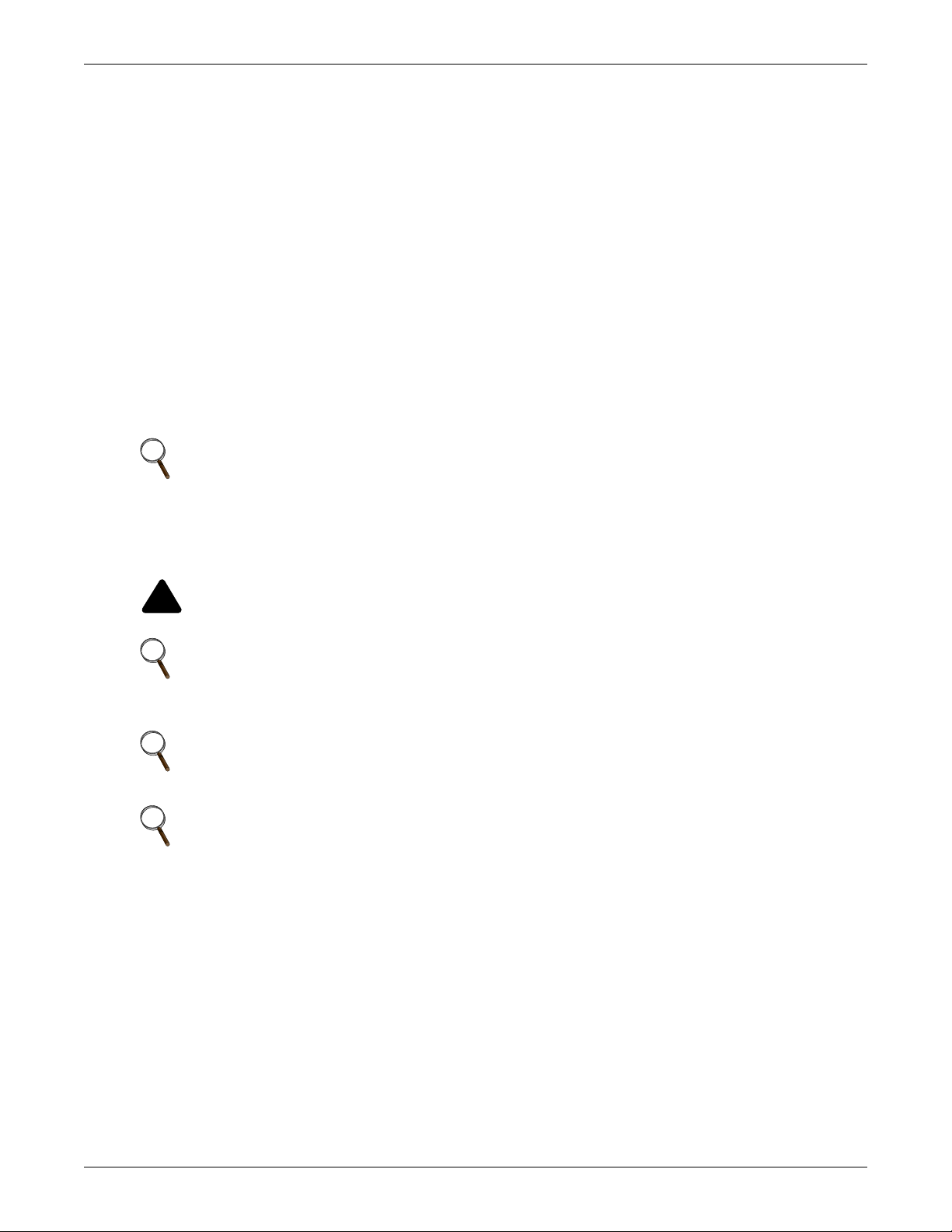

Figure 8 Electrical connections

Installation

1. Electric conduit knockouts on top and bottom of electric box. Knockout size 1-3/4" (44.5mm).

2. Three phase connection. Electric service connection terminals when factory disconnect switch

is supplied.

3. Factory-installed locking disconnect switch.

4. Three-phase electric service not by Liebert.

5. Earth ground connection (50/60Hz). Connection terminal for field-supplied earth grounding wire.

6. Earth ground bar (50Hz only). Connection terminals with factory ground from each high

voltage component for field supplied earth grounding wire.

7. Control and monitoring section of electric box.

8. Remote unit shutdown. Replace existing jumper between Terminals 37 + 38 with normally

closed switch having a minimum 75VA, 24VAC rating. Use field-supplied Class 1 wiring. Two

additional contact pairs available as an option (labeled as 37B & 38B, 37C & 38C). Replace

existing jumper for appropriate pair as done for 37 & 38.

11

Page 18

Installation

9. Special alarm connections. Field-supplied 24V Class 1 wiring for special alarm. Connection

made by adding normally open contacts between terminals 24 + 50. Optional additional

connections available with Advanced or Advanced with Graphics controls and appropriate

optional accessories (connections 51, 55, and 56).

10. Liebert SiteScan

pair, communication cable (available from Liebert or others) to optional Liebert SiteScan.

11. Remote condensing unit connection. Field-supplied 24V Class 1 wiring to remote condensing

unit terminals 1, 2, 3, & 4 from (R2) relay (split system only).

12. Smoke detector alarm connections. Field-supplied 24V Class 1 wiring to remote alarm circuits.

Factory-wired contacts from optional smoke detector are #91-comm., #92-NO, and #93-NC.

13. Common alarm connection. Field-supplied 24V Class 1 wiring to common alarm terminals 75 + 76

(and optional 94 + 95, and 96 + 97), which are factory-connected to common alarm relay (R3).

14. Reheat and Humidifier Lockout. Optional emergency power lockout of reheat and/or humidifier:

connections provided for remote 24V AC source.

15. Heat rejection connection. Field-supplied 24V Class 1 wiring to interlock heat rejection from

pigtails 70 + 71 which are factory-connected to compressor side switch (self-contained units only

and to Glycool relay (R5), Glycool units only).

16. Main Fan Auxiliary Switch. Optional main fan auxiliary side switch. Terminals located in field

wiring compartment for remote indication that the evaporator fan motor/unit is on. Field to

connect 24V maximum.

17. Optional Condensate Alarm (Dual Float Condensate Pump only). Relay terminals located in field

wiring compartment for remote indication.

®

connection. Terminals 77 (-) and 78 (+) are for connection of a 2-wire, twisted

*Located inside Liebert Challenger ITR on top.

NOTE: Refer to specification sheet for full load amp. and wire size amp. ratings.

2.7 Balancing the Air Distribution

2.7.1 Ducted Applications

For ducted applications, the duct work may be attached to the top perimeter of the Liebert Challenger

ITR (see Figure 2).

The duct work must allow access to the motors/blowers for maintenance. The duct work must be

designed within the capacity of the Liebert Challenger ITR, otherwise air flow and performance will

be compromised.

2.7.2 Plenum Installation

A solid plenum or plenum with discharge grille(s) may be installed. The plenum and instructions for

its installation ship separately from the Liebert Challenger ITR.

12

Page 19

2.8 Checklist for Completed Installation

___ 1. Unpack and check received material.

___ 2. Proper clearance for service access has been maintained around the equipment.

___ 3. Equipment is level and mounting fasteners are tight.

___ 4. Piping completed to refrigerant or coolant loop (if required). Piping has been leak checked,

evacuated and charged (if required).

___ 5. Check piping within the Liebert Challenger ITR and outside of the unit. Remove potential of

rub-through or chaffing.

___ 6. Condensate pump installed.

___ 7. Drain line connected.

___ 8. Water supply line connected to humidifier (if required).

___ 9. Field provided pan with drain installed under all ceiling mounted fluid condensing units (if

installed).

___ 10. Ducting completed (if applicable).

___ 11. Filter(s) installed.

___ 12. Line voltage to power wiring matches equipment serial tag.

___ 13. Power wiring connections completed between disconnect switch, evaporator and condensing

unit, including earth ground.

___ 14. Power line circuit breakers or fuses have proper ratings for equipment installed.

___ 15. Control wiring connections completed to evaporator and condensing unit.

___ 16. Verify water detection is properly installed around all units (if installed).

___ 17. All wiring connections are tight.

___ 18. Control panel DIP switches set based on customer requirements.

___ 19. Foreign materials have been removed from, in and around all equipment installed (literature,

shipping materials, construction materials, tools, etc.).

___ 20. Fans and blowers rotate freely.

___ 21. Inspect all piping connections for leaks during initial operations. Correct as needed.

___ 22. Verify that a blank start-up sheet has been sent with the unit(s) and is ready to be completed

by the installer.

Installation

13

Page 20

3.0 AIR-COOLED MODELS

!

3.1 Condenser Location

The air-cooled condenser should be located for maximum security and maintenance accessibility.

Avoid ground level sites with public access or areas that contribute to heavy snow or ice accumulations. Utilize centrifugal condensers whenever interior building locations must by used. To assure

adequate air supply, it is recommended that condensers be located in a clean air area, away from

loose dirt and foreign matter that may clog the coil. In addition, condensers should not be located in

the vicinity of steam, hot air, or fume exhausts. Also, condensers should be located no closer than

three feet (1 meter) from a wall, obstruction, or adjacent unit.

Install condensers in a level position to assure proper refrigerant flow and oil return. For roof installation, mount condensers on steel supports in accordance with local codes. To minimize sound and

vibration transmission, mount steel supports across load bearing walls. For ground installation, a

concrete pad will provide adequate support. Condenser legs have mounting holes for securing the condenser to the steel supports or concrete pad.

3.2 Electrical Connections

Refer to equipment nameplate regarding wire size and circuit protection requirements. Refer to electrical schematic when making connections. Make all wiring and electrical connection in accordance

with local and national codes.

WARNING

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power before working within the unit. Use a voltmeter

to make sure power is turned off before making any electrical connections.

Air-Cooled Models

3.2.1 Line Voltage

Line voltage electrical service is required for all air-cooled condensers at the location of the condenser.

This power supply does not have to be the same voltage as the indoor unit. This separate power source

may be 208, 230, 460, or 575 V, 60 Hz; or 200, 230, or 380/415 V, 50 Hz. The disconnect switch may be

factory-supplied and mounted in the electrical panel or field-supplied and mounted per local and

national codes.

3.2.2 Low Voltage

A control interlock between the condenser and the indoor unit is required and is connected between

70 and 71 in the handy box of the indoor unit and the electric panel of the air-cooled condenser. NEC

Class 1 wiring is required.

3.2.3 Lee-Temp/Flood Back Head Pressure Control Condensers

Lee-Temp condensers require a separate power supply for the heated receivers. This power supply is

connected to the electrical connection box on the end of the receiver.

14

Page 21

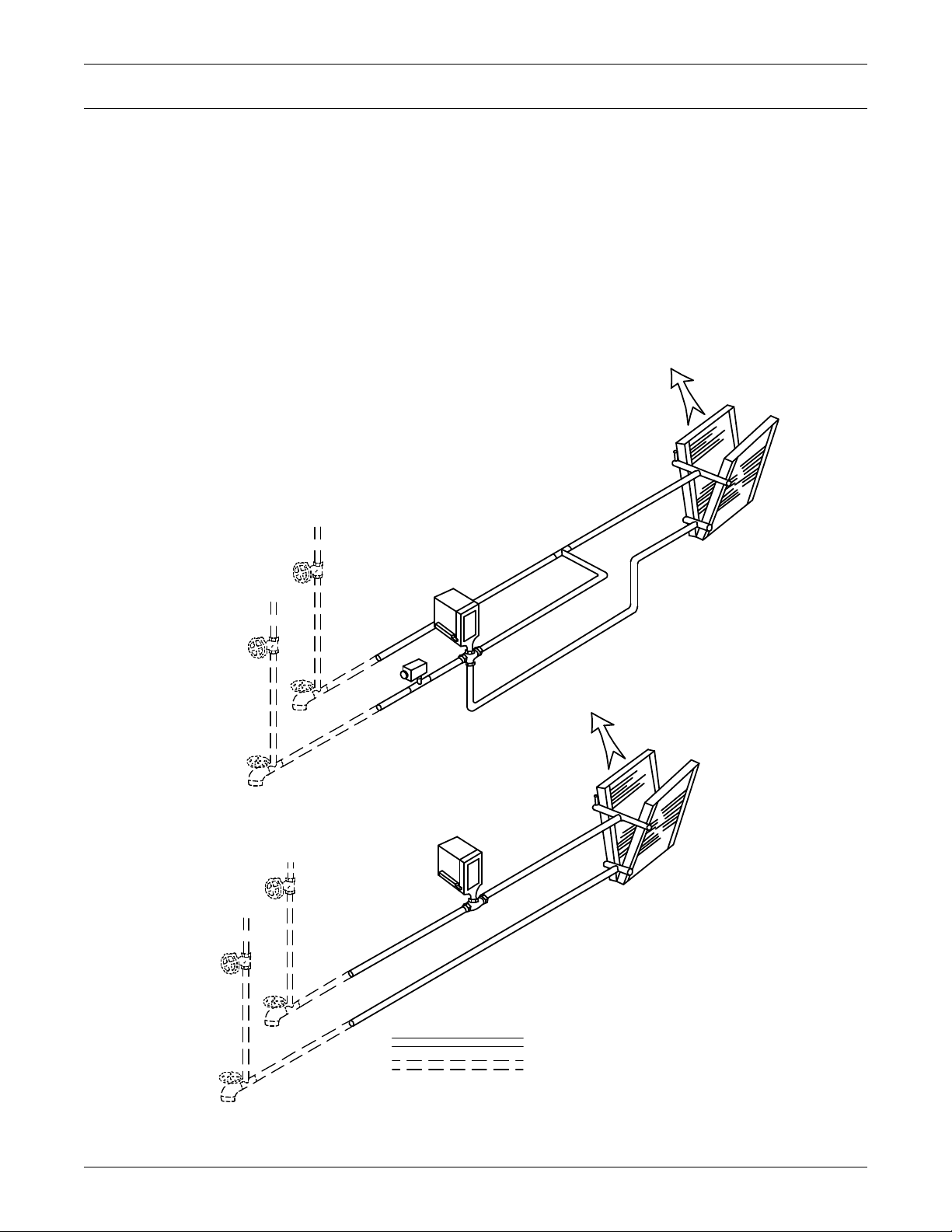

Figure 9 Air-cooled condensers

Secure each leg to condenser frame at all

points shown using hardware provided.

Liquid line

* B

TYPICAL FOOTPRINT

Lee-Temp heater pad

connection box

*B - Inverted traps are to be field-supplied and installed

(typ). When installing traps, provide clearance for swing

end of access door. Traps are to extend above base of

coil by a minimum of 7-1/2" (190 mm)

Liquid line

Hot gas line

Electric service

supplied by

others

Electric

service

supplied by

others

Hot gas

line

* B

LEE-TEMP CONDENSER

FAN SPEED CONDENSER

44"

(1118mm )

18" (457.2mm)

43-9/16"

(1106mm)

51-7/16"

(1306.5mm)

37-7/8"

(962mm)

Common to all models. See Table 3

below for key to “A” dimension.

CONDENSER MOUNTING

1"

(25.4mm)

1-3/4"

(44.5mm)

4-1/4"

(108mm)

4-1/4"

(108mm)

1-3/4"

(44.5mm)

1"

(25.4mm)

1-3/4"

(44.5mm)

1" typ.

(25.4mm)

1-3/4"

(44.5mm)

37-11/16"

(957.3mm)

1-3/4"

(44.5mm)

A

9/16" (14.3mm)

diameter holes

8 places for

1/2" (12.7mm)

diameter bolts

43-3/16"

(1097mm)

SINGLE FAN

AIR-COOLED CONDENSERS

1" typ.

(25.4mm)

Air-Cooled Models

Table 3 Air-cooled condenser statistics

Model

083 1 7/8 5/8 295 (133.8) 42 (1067)

104 1 1-1/8 5/8 315 (142.8) 42 (1067)

Number

of Fans

Connection Sizes

(OD Copper)

Net Weight

“A” Dimension

lb (kg)

15

in (mm)Hot Gas (in.) Liquid (in.)

Page 22

3.3 Refrigerant Piping

All refrigeration piping should be installed with high temperature brazed joints. Prevailing good

refrigeration practices should be employed for piping supports, leak testing, dehydration and charging of the refrigeration circuits.

Unit refrigeration components and piping are shipped from the factory with a nitrogen holding

charge.

NOTE

The refrigeration piping should be isolated from the building by the use of vibration isolating

supports.

NOTE

Piping, including inverted trap(s), must be routed to allow unobstructed access to the panel

per the NEC.

NOTE

When installing field piping, care must be taken to protect all refrigerant lines from the

atmosphere, especially when using refrigerants with POE oils. Do not allow the piping to stand

open to air for more than 15 minutes. Units designed for R407C have a compressor that

contains POE oil that is very hygroscopic; that is, it quickly absorbs water from the air. The

longer the compressor piping is left open to air, the harder it will be to fully evacuate. If left

open too long, the POE oil may need to be replaced before achieving the required vacuum level.

Air-Cooled Models

NOTE

Keep the evaporator unit and condenser closed with their factory charge of dry nitrogen while

all field piping is installed. Keep the field piping clean and dry during installation, and do not

allow it to stand open to the atmosphere. When all the field interconnecting piping is in place,

vent the condenser dry nitrogen charge and connect to the field piping. Finally, vent the

evaporator unit dry nitrogen charge and make its piping connections last.

Follow all proper brazing practices including a dry nitrogen purge to maintain system

cleanliness.

Traps should be installed in the hot gas line on vertical risers at the base and every 25 feet (7.6

meters) in elevation. These traps will collect condensed refrigerant and refrigerant oil during the off

cycle of the unit and ensure flow of refrigerant oil during operation.

A check valve is factory-supplied with the unit to be field-installed on the discharge side of the scroll

compressor. Be sure to install the check valve with the refrigerant flow in the proper direction. When

soldering or brazing the valve, it is very important to protect the internal parts by wrapping the valve

with a damp cloth to keep the valve temperature below 250°F (121°C).

Approval is required whenever:

• a refrigerant piping run exceeds 150 ft. (46 m) equivalent length

• an R22 system condenser must be located more than 15 ft. (4.6 m) below the level of the cooling

coil

• an R407C system condenser must be located below the level of the cooling coil.

Total discharge line pressure drop must not exceed 10 PSIG (69 kPa).

Consult your local Liebert representative when considering installations outside these guidelines.

Table 4 Recommended line sizes — OD copper (inches)*

23 & 33 kW 067A (065A)

Equivalent Length

50 ft. (15 m) 7/8 1/2

100 ft. (30 m) 7/8 5/8

150 ft. (45 m) 7/8 5/8

*Recommended vertical line sizes must be used for proper oil return at all cooling and dehumidification steps.

Hot Gas Line Liquid Line

16

Page 23

Table 5 Equivalent lengths (feet) for various pipe fittings

Copper Pipe

O.D. in.

1/2 0.8 1.3 0.4 2.5 0.26 7.0 4.0

5/8 0.9 1.4 0.5 2.5 0.28 9.5 5.0

3/4 1.0 1.5 0.6 2.5 0.3 12.0 6.5

7/8 1.45 1.8 0.8 3.6 0.36 17.2 9.5

1-1/8 1.85 2.2 1.0 4.6 0.48 22.5 12.0

1-3/8 2.4 2.9 1.3 6.4 0.65 32.0 16.0

1-5/8 2.9 3.5 1.6 7.2 0.72 36.0 19.5

Refrigerant trap = 4 times equivalent length of pipe per this table.

90 Degree

Elbow Copper

90 Degree

Elbow Cast

45 Degree

Elbow Tee

Gate

Valve

Globe

Valve

Angle

Valve

Table 6 Indoor unit refrigerant charge lb (kg) R22 or R407C (per unit serial tag)

R22 R407C

Model

67A/65A 1.5 (0.68) 1.4 (0.6)

Approximate Charge

lb (kg)

Approximate Charge

lb (kg)

Table 7 Line charges - refrigerant per 100 ft (30 m) of Type “L” copper tube

R22 R407C

O.D.

Liquid Line

lb (kg)

Hot Gas Line

lbs (kg)

Liquid Line

lb (kg)

Hot Gas Line

lb (kg)

Air-Cooled Models

1/2" 7.3 (3.3) 1.3 (0.6) 6.9 (2.9) -

5/8" 11.7 (5.3) 2.1 (1.0) 11.0 (4.6) 2.2 (0.9)

3/4" 16.6 (7.5) 3.0 (1.4) 15.7 (6.5) 3.1 (1.3)

7/8" 24.4 (11.1) 4.4 (2.0) 23.0 (9.6) 4.5 (1.9)

Table 8 Condenser refrigerant (per serial tag)

R22 R407C

Approximate Charge

lb (kg)

Model

Fan Speed Lee-Temp* Fan Speed Lee-Temp*

083 5 (2.27) 27 (12.3) 8 (3) 25 (12)

104 8 (3.63) 39 (17.7) 9 (4) 37 (17)

* Charge includes the receiver charge.

3.4 Fan Speed Control Systems

Fan Speed Control provides an infinite number of speed variations on specially designed, permanent

split-capacitor motors. The control module varies the air quantity passing over the condenser coil by

monitoring refrigerant pressure.

3.4.1 Materials Supplied

1. Built-in pre-wired condenser control box

2. Air-cooled condenser

3. Piping access cover to be reinstalled when piping is complete

4. Bolts (four per leg) 3/8" x 5/8"

5. Terminal block for two-wire, 24-volt interlock connection between unit and condenser

6. Condenser legs, four on one-fan models

Approximate Charge

lb (kg)

17

Page 24

Air-Cooled Models

!

3.4.2 Dehydration/Leak Test and Charging Procedures for R22 (standard) or R407C (Optional)

Fan Speed Control Type Condenser

CAUTION

All local codes for handling refrigerant must be followed.

NOTE

As R22 and R407C are similar in properties, proper safety equipment and proper

refrigeration tools are required on both types. Check unit nameplate for correct refrigerant

type before topping off or recharging a system.

NOTE

Refrigerant R407C uses a POE (polyol ester) lubricant. The R407C refrigerant must be

introduced and charged from the cylinder only as a liquid.

NOTE

When installing field piping, care must be taken to protect all refrigerant lines from the

atmosphere, especially when using refrigerants with POE oils. Do not allow the piping to stand

open to air for more than 15 minutes. Units designed for R407C have a compressor which

contains POE oil that is very hygroscopic; that is, it quickly absorbs water from the air. The

longer the compressor piping is left open to air, the harder it will be to fully evacuate. If left

open too long, the POE oil may need to be replaced before achieving the required vacuum level.

Dehydration/Leak Test

1. Make sure unit is OFF. Open all disconnects and remove all fuses except control fuses. On units

supplied with circuit breakers, open all breakers except for the transformer.

2. Add a jumper to the Fan Safety Switch between Common and Normal Open and disconnect the

wire connected to the Normally Closed. Turn unit disconnect ON. (Fan operation not required.)

NOTE

The above allows the technician to use unit 24 VAC power and controls to open liquid line

solenoid valve(s) and hot gas bypass solenoid valve(s) for the dehydration process. If no

power is at the unit disconnect, the technician is to use a separate 24 VAC source rated at

75 VA and connect to the system liquid line solenoid valve(s) and hot gas bypass solenoid

valve(s) directly.

3. Connect refrigeration gauges to the suction and discharge service valves of the compressor. Open

all compressor service valves.

4. To energize the liquid line solenoid valves through the control system power, set the control

temperature setpoint (see operation manual) to 60°F (15°C) and set the % relative humidity

setpoint higher than the conditioned room ambient to ensure that solenoid valves and hot gas

bypass valves are open during the dehydration process.

5. Pressurize the system circuit(s) to 150 PSIG (1034 kPa) by using dry nitrogen with a trace of

refrigerant. Check system for leaks with suitable leak finder.

6. After completion of leak testing, release the test pressure (per local code) and pull a deep vacuum

on the system with a suitable pump.

7. After four hours, check the pressure readings, and if they have not changed, break vacuum with

refrigerant. Pull another vacuum to 250 microns or less. Recheck the pressure after two hours.

After completing this step, pressurize the circuits with refrigerant (R407C liquid or R22 vapor per

unit nameplate) until suction and discharge pressures have equalized.

18

Page 25

Figure 10 Air-cooled fan speed control general arrangement

SL -11 89 7 PG 5

Con de nser

Co il

Sc hra de r

Va lv e

Fu si bl e

Pl ug

In ve rted Trap s* on disch ar ge

an d retu rn li ne s to ex te nd

ab ov e ba se of co il by a

mi ni mu m of 7 1 /2" (1 90 mm )

Tr ap s* ev er y

25 ft. (7.6 m)

of ris e

Ev ap or at or

Co il

Ex pa nsio n

Va lv e

Hot Ga s

Bypass

Va lv e

So le no id

Va lves

Si ght

Gl as s

Fi lt er

Dryer

Li qu id Ret ur n

Sh ut o ff *

Va lv e

Se ns in g

Bu lb

Ex ter na l

Eq ua li zers

Scr ol l

Co mp re ss or

Se rv ic e

Va lves

Hot Ga s

Bypass

Hot Ga s

Di sch ar ge

Che ck Va

lv e

(S hi pp ed Lo os e fo r

Fi el d I n st al la ti on )

SI NG LE CIRC UI T SH OW N

FA CT OR Y

PI PI NG

FI EL D

PI PI NG

*Comp on ent s ar e no t su pp li ed by Li eb ert bu t

ar e re co mm en d ed fo r pr op er ci rcui t op er at io n

an d ma in te na nc e.

Air-Cooled Models

19

Page 26

3.4.3 Charging

1. Make sure unit is OFF. Open all disconnect switches and, on units supplied with circuit breakers,

open all breakers. Replace all fuses for the Fan and Compressors or close breakers.

2. Remove jumper on the Fan Safety Switch and reconnect the system wire connections. Ensure that

all operational components are clear of debris. Turn unit ON. (Fan operation is required.) Check

the evaporator fan for proper rotation and correct if necessary.

3. Connect the refrigerant gauge charging hose to the drum of refrigerant and to the suction and

discharge service valves of the compressor.

4. Calculate the amount of charge for the system. Weigh in as much of the system charge as

possible. Refer to the unit, condenser and refrigerant line charge tables.

5. Set the control temperature setpoint (see operation manual) to 60°F (15°C) and set the % relative

humidity setpoint higher than the conditioned room ambient to ensure that solenoid valves and

hot gas bypass valves are open during the charging procedure. You may have to bypass the

LP Switch (low pressure switch) to start the compressors and stop short cycling. Reset the Head

Pressure switch(es) if open.

6. Add refrigerant (R407C liquid, or R22 vapor per unit nameplate) to the suction side of the

compressor until there is sufficient pressure to energize the low-pressure switch.

NOTE

When adding refrigerant to an operating system, it may be necessary to add the refrigerant

through the compressor suction service valve. Because the refrigerant leaving the

refrigerant cylinder must be in a liquid state, care must be exercised to avoid damage to the

compressor. It is suggested that a sight glass be connected between the charging hose and

the compressor suction service valve. This will permit adjustment of the cylinder hand

valve so that liquid can leave the cylinder while allowing vapor to enter the compressor.

Air-Cooled Models

Then you may remove the manual bypass you applied earlier.

7. Charge the unit until the liquid line sight glass becomes clear. Then add one additional pound of

refrigerant.

8. As head pressure builds, the condenser fan starts rotating. The fan becomes fully energized when

sufficient head pressure is developed. (Fan starts to rotate at 190 psi and is full speed at 250 psi.)

Table 9 Refrigerant control settings psi (kPa)

Low Pressure

Cut Out

20 (137.9) 65 (448.2) 360 (2482)

Low Pressure

Cut In

High Pressure

Cut Out

3.5 Lee-Temp/Flood Back Head Pressure Control Systems

The Lee-Temp system consists of a modulating type head pressure control valve and insulated

receiver with heater pad to ensure operation at ambient temperatures as low as -30°F (-34.4°C).

3.5.1 Piping

Lee-Temp systems have two factory-supplied, field-installed check valves: one on the discharge side of

the scroll compressor and one on the inlet side of the receiver. Be sure to install the check valves with

the refrigerant flow in the proper direction. When soldering or brazing the valves, it is very important

that the internal parts be protected by wrapping the valve with a damp cloth to keep the valve temperature below 250°F (121°C).

20

Page 27

3.5.2 Materials Supplied

!

1. Built-in pre-wired condenser control box

2. Air-cooled condenser

3. Piping access cover to be reinstalled when piping is complete

4. Bolts (four per leg) 3/8" x 5/8"

5. Terminal block for two-wire 24V interlock connection between the unit and the condenser

6. Condenser legs: four on one-fan models

7. Lee-Temp system:

a. Insulated storage receiver

b. Head pressure control valve with integral check valve

c. Adapter assembly

d. Rotalock valve

e. Pressure relief valve

f. Liquid level sight glass

g. Check valve

8. Bolts - (six per receiver) 3/8" x 1"

NOTE

Lee-Temp heater pad requires a separate, continuous electrical source of either 115 VAC or

200/208/230 VAC.

Air-Cooled Models

3.5.3 Dehydration/Leak Test and Charging Procedures for R22 (Standard) or R407C (Optional)

Lee-Temp Control Type Condenser

CAUTION

All local codes for handling refrigerant must be followed.

NOTE

As R22 and R407C are similar in properties, proper safety equipment and proper refrigeration

tools are required on both types. Check unit nameplate for correct refrigerant type and oil type

before topping off or recharging a system.

NOTE

Refrigerant R407C uses a POE (polyol ester) lubricant. The R407C refrigerant must be

introduced and charged from the cylinder only as a liquid.

NOTE

When installing field piping, care must be taken to protect all refrigerant lines from the

atmosphere, especially when using refrigerants with POE oils. Do not allow the piping to stand

open to air for more than 15 minutes. Units designed for R407C have a compressor which

contains POE oil that is very hygroscopic; that is, it quickly absorbs water from the air. The

longer the compressor piping is left open to air, the harder it will be to fully evacuate. If left

open too long, the POE oil may need to be replaced before achieving the required vacuum level.

21

Page 28

Air-Cooled Models

Dehydration/Leak Test

1. Make sure unit is OFF. Open all disconnect switches and pull all fuses except control fuses. On

units supplied with circuit breakers, open all breakers except for the transformer.

2. Add a jumper to the Fan Safety Switch between Common and Normal Open and disconnect the

wire connected to the Normally Closed. Turn unit disconnect ON. (Fan operation not required.)

NOTE

The above allows the technician to use unit 24 VAC power and controls to open liquid line

solenoid valve(s) and hot gas bypass solenoid valve(s) for the dehydration process. If no power

is at the unit disconnect, the technician is to use a separate 24 VAC source rated at 75 VA and

connect to the system liquid line solenoid valve(s) and hot gas bypass solenoid valve(s) directly.

3. Connect refrigeration gauges to the suction and discharge service valves of the compressor and open.

4. Attach a “jumper” hose from the Rotalock fitting on the outlet of the receiver and the Schrader fitting

on the liquid header of the condenser. Front seat the Rotalock valve approximately two turns.

5. To energize the liquid line solenoid valve(s) through the control system, set the temperature

setpoint (see operation manual) to 60°F (15°C) and set the % relative humidity setpoint higher

than the conditioned room ambient to ensure that solenoid valves and hot gas bypass valves are

open during the dehydration process.

6. Pressurize system circuit(s) to 150 PSIG (1034 kPa) by using dry nitrogen with a trace of

refrigerant. Check system for leaks with suitable leak finder.

7. After completion of leak testing, release test pressure (per local code) and pull a vacuum on the

system.

8. After 4 hours, check pressure readings and, if they have not changed, break vacuum with

refrigerant. Pull a second and third vacuum of 250 microns or less. Recheck pressure after

2 hours.

3.5.4 Charging

1. Make sure unit is OFF. Open all disconnect switches and, on units supplied with circuit breakers,

open all breakers. Replace all fuses for the Fan and Compressors or close breakers.

2. Remove jumper on the Fan Safety Switch and reconnect the system wire connections. Ensure that

all operational components are clear of debris. Turn unit ON. (Fan operation is required.) Check

the evaporator fan for proper rotation and correct if necessary.

3. Connect the refrigerant gauge charging hose to the drum of refrigerant and to the suction and

discharge service valves of the compressor(s).

4. Calculate the amount of charge for the system. Weigh in as much of the system charge as

possible. Refer to the unit, condenser and refrigerant line charge tables.

5. Set the control temperature setpoint (see operation manual) to 60°F (15°C) and set the % relative

humidity setpoint higher than the conditioned room ambient to ensure that solenoid valves and

hot gas bypass valves are open during the charging procedure. You may have to bypass the

LP Switch (low pressure switch) to start the compressors and stop short cycling. Reset the Head

Pressure switch(es) if open.

6. Add refrigerant (R407C liquid or R22 vapor per unit nameplate) to the suction side of the

compressor until there is sufficient pressure to energize the low pressure switch.

NOTE

When adding refrigerant to an operating system, it may be necessary to add the refrigerant

through the compressor suction service valve. Because the refrigerant leaving the

refrigerant cylinder must be in a liquid state, care must be exercised to avoid damage to the

compressor. It is suggested that a sight glass be connected between the charging hose and

the compressor suction service valve. This will permit adjustment of the cylinder hand

valve so that liquid can leave the cylinder while allowing vapor to enter the compressor.

Then you may remove the manual bypass you applied earlier.

7. Charge the unit until the proper charge is weighed in.

Table 10 Refrigerant control settings psi (kPa)

Low Pressure Cut Out Low Pressure Cut In High Pressure Cut Out

20 (137.9) 65 (448.2) 360 (2482)

22

Page 29

Figure 11 Air-cooled, Lee-Temp general arrangement

FACTOR

Y PIPING

FIELD PIPING

SINGLE CIRCUIT SHOWN

SL-10061 PG 4 SL-10071 PG 4

Piping Assembly * *

Condenser Coil

Rotalock Valve **

1/4" ( 6.4mm)

Pressure Relief

Valve * *

Sight Glass

Lee-Temp

Receiver

Head Pressure

Control with

Integral Check

Valve

Check Valve

Liquid Return

from Condenser

Inverted Trap * on

discharge line to

extend above base

of coil by a

minimum of 7 1/2"

(190mm)

Traps * Every

25 Ft. (7.6m)

of rise on Hot

Gas Line only

Evaporator Coil

Sensing Bulb

Expansion Valve

Hot Gas

Bypass

Valve

Solenoid Valves

Sight Glass

Filter Drier

Liquid Return

Shutoff

Valve *

External Equalizers

Service

Valves

Scroll Compressor

Hot Gas

Bypass

Hot Gas Discharge

Check Valve * *

* Components are not supplied by Liebert

but are recommended for proper

circuit operation and maintenance.

* * Components supplied by Liebert

and must be field installed.

OPTIONAL PIPING

Air-Cooled Models

23

Page 30

4.0 WATER-COOLED MODELS

4.1 Piping Considerations

Manual shut-off valves should be installed at the supply and return lines of each unit. This will provide for routine maintenance or emergency isolation of the unit.

When the water source for the condenser is of poor quality, it is good practice to provide cleanable filters in the supply line. These filters will trap the particles in the water supply and extend the service

life of the water-cooled condenser.

To provide for the emergency of water leaks and the consequences of sub-floor flooding, floor drains

should be provided with wet traps or a water detection system such as a Liqui-tect sensor that is

installed near the base of the unit or below the elevated floor.

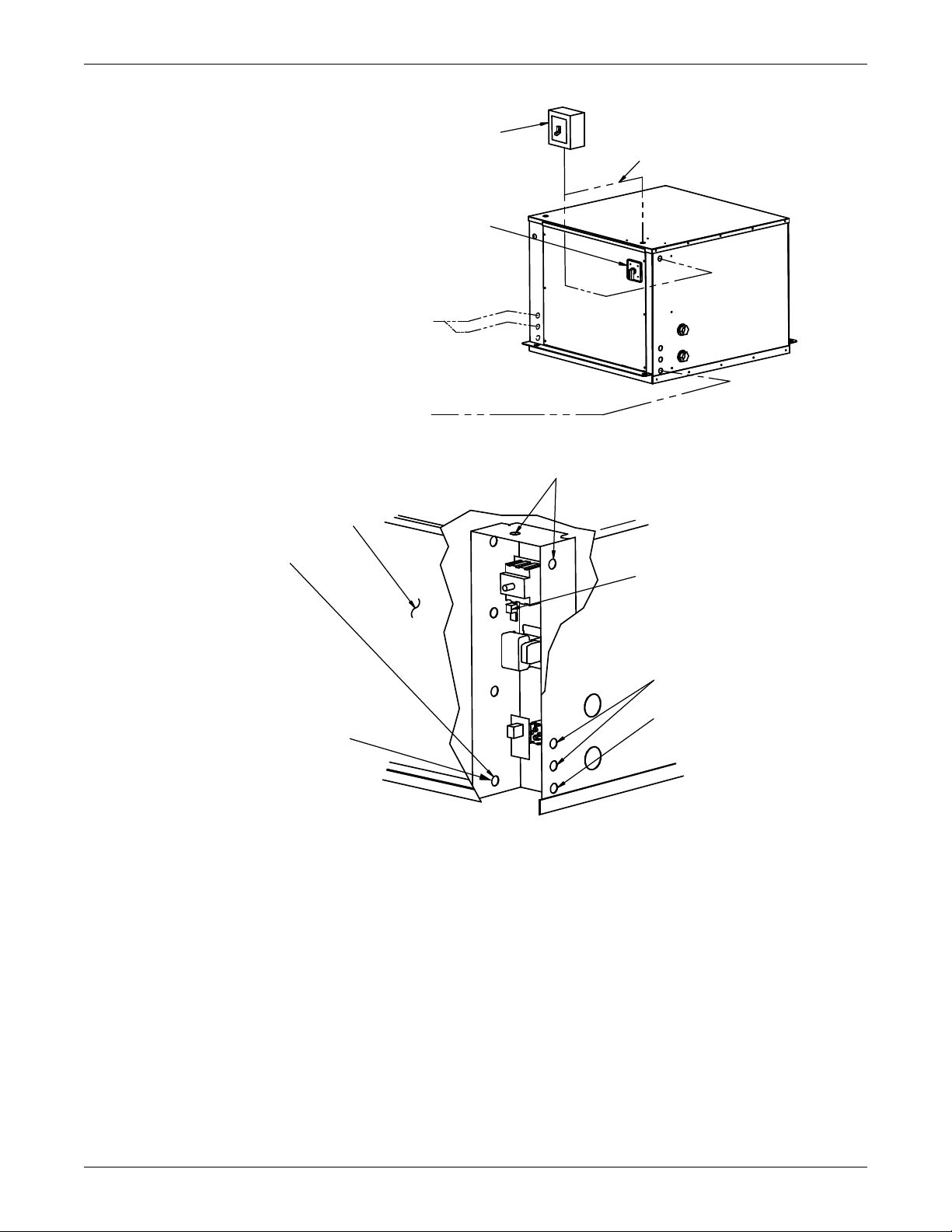

4.2 Condenser

The condenser is designed to operate in conjunction with either a cooling tower or city water. The

maximum water pressure is 150 psig (1034 kPa). A high pressure system rated at 350 psig (2413 kPa)

is available as an option.

Water-Cooled Models

24

Page 31

Figure 12 Water-cooled general arrangement

SL-11898 PG 5

Evaporator

Coil

Expansion

Valve

Sensing

Bulb

External

Equalizers

Hot Gas

Bypass

Valve

Scroll

Compressor

Service

Valves

Hot Gas

Bypass

Solenoid

Valve

Sight

Glass

Filter

Drier

Hot Gas

Bypass

Tube

in Tube

Condenser

Bypass

Valve

2-Way Water

Regulating

Valve

3-Wa

y Water

Regulating Valve

(optional)

Fluid

Return

From

Unit

Fluid

Supply

To

Un

it

Fluid

Return

From

Unit

Fluid

Su

pply

To

Unit

Shutoff*

Valves

Hose Bibs*

FACTORY

PIPING

FIELD

PIPING

*Components are not supplied by Liebert but

are recommended for proper circuit operation

and maintenance.

Tube

in Tube

Condenser

Water-Cooled Models

25

Page 32

4.3 Water Regulating Valve

Range

spring

Valve spring

guide

Top

retainer

Range adjustment screw

Insert screwdrivers underneath

the valve spring guide

The water regulating valve automatically regulates the amount of fluid necessary to remove the heat

from the refrigeration system, permitting more fluid to flow when load conditions are high and less

fluid to flow when load conditions are low. The valve consists of a brass body, balance spring, valve

seat, valve disc holders, capillary tube to discharge pressure, and adjusting screw.

4.3.1 Water Regulating Valve Adjustment

The Liebert Challenger ITR may be equipped with either a standard Johnson Controls valve, 150 psig

(1034 kPa) or with a high-pressure Johnson Controls valve, 350 psig (2413 kPa).

The valve may be adjusted with a standard refrigeration service valve wrench or screw driver.

To lower the head pressure setting, turn the square adjusting screw clockwise until the high pressure

gauge indicates the desired setting.

To raise the head pressure setting, turn the adjusting screw counterclockwise until the desired setting is obtained.

Figure 13 Johnson Controls valve adjustment

Water-Cooled Models

4.3.2 Water Regulating Valve Manual Flushing

The valve may be flushed by inserting screwdrivers or similar tools under the opposing sides of the

main spring and lifting. This action will open the valve seat and flush any dirt particles from the seat.

If this fails, the valve must be disassembled for cleaning the seat.

4.3.3 Testing Valve Function

When the refrigeration system has been off for 10-15 minutes, the water flow should stop.

Should the water continue to flow, the valve is either improperly adjusted or the pressure sensing

capillary is not properly connected to the condenser.

26

Page 33

5.0 GLYCOL/GLYCOOL-COOLED MODELS

!

5.1 Drycooler Location

The drycooler should be located for maximum security and maintenance accessibility. Avoid groundlevel sites with public access or areas which contribute to heavy snow or ice accumulations. To assure

adequate air supply, it is recommended that drycoolers be located in a clean air area, away from loose

dirt and foreign matter that may clog the coil. In addition, drycoolers should not be located in the

vicinity of steam, hot air or fume exhausts. Also, drycoolers should not be located closer than 3 feet

(1 meter) from a wall, obstruction or adjacent unit.

5.2 Drycooler Installation

For roof installation, mount drycoolers on steel supports in accordance with local codes. To minimize

sound and vibration transmission, mount steel supports across load bearing walls. For ground installation, a concrete pad will provide adequate support. Drycooler legs have mounting holes for securing

the drycooler to steel supports or concrete pad.

5.3 Electrical Connections

Refer to equipment nameplate regarding wire size and circuit protection requirements. Refer to electrical schematic when making connections. Make all wiring and electrical connections in accordance

with local and national codes.

Glycol/GLYCOOL-Cooled Models

WARNING

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power before working within the unit. Use a voltmeter

to make sure power is turned off before making any electrical connections.

5.3.1 Line Voltage

Line voltage electrical service is required for all drycoolers at the location of the drycooler. This power

supply does not have to be the same voltage as the indoor unit. This separate power source may be

208, 230, 460, or 575 V, 60 Hz; or 200, 230, or 380/415 V, 50 Hz. The disconnect switch is factory-supplied and mounted in the electric panel.

5.3.2 Low Voltage

A control interlock between the drycooler and the indoor unit is required and is connected between 70

and 71 in the handy box of the indoor unit and the pump and drycooler control box of the drycooler.

NEC Class 1 wiring is required.

5.3.3 Pump and Drycooler

All wiring to the pump and drycooler from the control box should be done in accordance with the electrical schematic on the inside lid of the drycooler control box and with local and national codes.

27

Page 34

5.4 Glycol Piping

NOTICE

Galvanized pipe must not be used in or with systems or units that contain glycol. The

phosphates in the inhibitor can react with the zinc in the galvanized pipe, precipitating an

insoluble material that can eventually foul the system.

To help prevent piping failures, supply and return lines must be supported in a way that

keeps their weight from bearing on the piping of the unit, drycooler or pumps.

To avoid the possibility of burst pipes, it is necessary to install a relief valve in the system.

This valve may be obtained from the supplier as an option or obtained from another vendor.

Fluid-cooled condensers have small internal flow passages. To avoid clogging and other

resulting system operation problems, install a 16-20 mesh filter in the fluid supply line to the

indoor unit. The filter should be located where it can be easily serviced or replaced.

Do not install unit on open-loop systems. Debris carried by the fluid will clog the brazed plate

condenser.

It is recommended that manual service shut-off valves be installed at the supply and return connections to each unit. This enables routine service and/or emergency isolation of the unit. In addition,

multiple pump packages require a check valve at the discharge of each pump to prevent back flow

through the standby pump(s).

To facilitate filling, installation of hose bibs at the lowest point of the system is recommended.

Glycol/GLYCOOL-Cooled Models

Consideration of the minimum glycol temperature to be supplied from the drycooler will determine if

the need exists to insulate the glycol supply and return lines. Insulation will prevent condensation on

the glycol lines in low ambient conditions.

All fluid piping must comply with local codes. Care in sizing pipes will help reduce pumping power

and operating costs.

Table 11 Room dew point temperatures

Dry Bulb

°F (°C)

70 (21.1)

70 (21.1)

72 (22.2)

72 (22.2)

75 (23.8)

75 (23.8)

* Minimum glycol temperature before condensation will occur.

Wet Bulb

°F (°C)

57.2 (14.0)

58.5 (14.7)

58.9 (24.9)

60.0 (15.5)

61.2 (16.2)

62.5 (16.9)

Relative

Humidity

45

50

45

50

45

50

Dew Point*

°F (°C)

48.0 (8.9)

50.5 (10.3)

50.0 (10.0)

52.4 (11.3)

52.4 (11.3)

55.0 (12.7)

5.4.1 Expansion Tanks, Fluid Relief Valves and Other Devices

An expansion tank must be provided for expansion and contraction of the fluid due to temperature

change in this closed system. Vents are required at system high points to vent trapped air when filling the system. A relief valve is a also a necessary piping component.