Page 1

HEAT REMOVAL/ENVIRONMENTAL CONTROL

Drycoolers - 60 Hz

GENERAL DATA

Page 2

Page 3

TABLE OF CONTENTS

LIEBERT DRYCOOLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

FEATURES AND BENEFITS OF LIEBERT DRYCOOLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ELECTION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

S

P

ERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DIMENSIONAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Standard Features for Direct Drive Propeller Fan Drycoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Casing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fan Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COMPONENT ASSEMBLY/INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

APPLICATION/INSTALLATION GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Location Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drycooler Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical Requirements of the Drycooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Glycol/Inhibitor Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Piping Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PUMP PACKAGES & EXPANSION TANK - OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

UPPLEMENTARY APPLICATION DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

S

MAINTENANCE GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

i

Page 4

Figures

Figure 1 Drycooler model numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2 Capacity correction factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3 Pressure drop correction factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4 Dimensional data—1-4 fan models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5 Dimensional data—6 & 8 fan models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 6 Typical footprint and unit anchor plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 7 General arrangement diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8 Pump package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9 Pump mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 10 Expansion tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 11 Pump curve, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table s

Table 1 Drycooler performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2 Determining actual BTUH and MBH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 3 Altitude correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 4 Drycooler performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 5 Drycooler physical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 6 Drycooler electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 7 Drycooler electrical data—Quietline models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 8 Pump data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 9 Room dew point temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 10 Glycol concentration at various ambients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 11 Volume in standard tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ii

Page 5

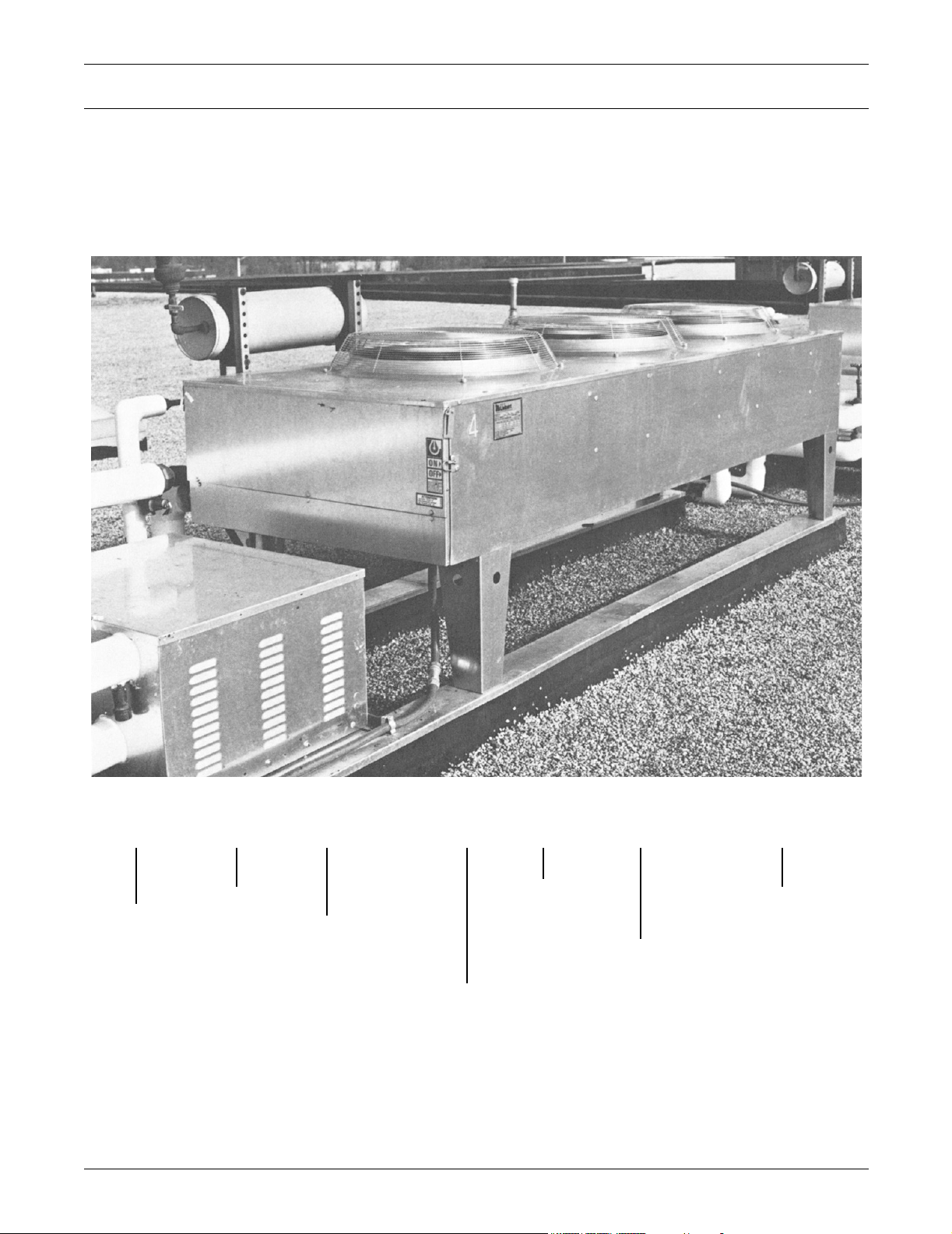

LIEBERT DRYCOOLERS

Liebert drycoolers are designed to be used in conjunction with water cooled refrigeration and air conditioning

machines as well as a variety of commercial and industrial applications requiring the rejection of heat from

machinery or processes via a cooling fluid. During periods of low ambient temperatures, drycoolers may assist

or replace the capacity requirements of mechanical chillers for a “free cooling” effect.

Liebert offers a full range of control options as well as expansion tank and pump packages. For cooling fluids

other than water or water/glycol mixtures, contact Liebert, Heat Transfer.

Figure 1 Drycooler model numbers

DDN C1 0 9Y

Drycooler

Optional

Disconnect

(DNC, DNL,

& DNT only)

N = Single Circuit

(No Pump)

S = Single Circuit

(With Pump)

D = Single Circuit

(Dual Pumps)

Model Size

Control Code:

C = No Control

L = Main Control

T = Fan Cycling

O = Fan Cycling &

Pump Control

S = Special

1

D

Optional

Circuiting

(see Table 4)

Letter Code for Voltage,

Phase and Frequency:

Y = 208/230-3-60

A = 460-3-60

B = 575-3-60

P = 208/230-1-60

Z = 460-1-60

V = 575-1-60

N = 200/230-3-50

M = 380/415-3-50

W = 200/230-1-50

Page 6

FEATURES AND BENEFITS OF LIEBERT DRYCOOLERS

Heat Rejection Module

The low-profile direct-drive propeller-fan type drycoolers utilize optimum circuitry to balance the heat rejection of the corresponding load. Constructed of aluminum with a copper-tube aluminum coil, the unit is quiet

and corrosion resistant.

Low Noise Level

All Liebert drycoolers are designed to operate at a minimal noise level. This is accomplished as the result of

the Liebert fan blade design combined with a cabinet structure that minimizes air resistance. Quiet-Line

models use low speed motors to achieve the quietest unit available.

Easy Installation and Service

The heat rejection module is quickly and easily installed, because all internal wiring is completed at the factory with only electrical connections to be made at the job site.

Maximum Reliability

Because these units are factory wired and tested, start-up problems are eliminated, and reliability of the

overall system is greatly increased.

Table 1 Drycooler performance data

Standard Unit Data

Model

Number

*D**

Standard Models

033 37950 10 9.1 4 3/4 1 7200 72.5 1.2 390

069 67040 20 8.9 8 1-1/4 1 6870 72.5 2.4 410

092 92380 30 8.6 12 1-1/2 1 6600 72.5 3.7 430

109 108760 40 8.1 16 2 1 6300 72.5 4.9 450

112 118200 40 10.1 16 2 1 6090 72.5 5.8 470

139 134100 40 7.1 16 2 2 13700 75.5 4.8 565

174 173400 40 10.5 16 2 2 13300 75.5 6.9 605

197 197000 40 13.9 16 2 2 12645 75.5 9.0 645

225 231000 65 10.9 26 2 2 12200 75.5 11.1 685

260 260200 60 10.1 24 2 3 19900 77.3 10.0 826

310 310500 80 9.8 32 2 3 19000 77.3 13.1 886

350 353000 80 14.6 32 2 3 17400 77.3 19.4 946

352 328400 60 12.9 24 2 4 24800 78.5 13.1 1070

419 393600 80 12.7 32 2 4 23650 78.5 17.4 1160

466 441200 100 12.7 40 2-1/2 4 22800 78.5 22.0 1250

491 469100 120 12.8 48 2-1/2 4 21700 78.5 26.3 1340

620 621000 160 9.8 64 2) 2-1/8 6 37900 80.3 27.0 1770

650 652100 130 15.2 52 2) 2-1/8 6 36500 80.3 33.1 1830

700 706100 160 14.6 64 2) 2-1/8 6 34800 80.3 39.3 1890

790 787200 160 12.7 64 2) 2-1/8 8 47300 81.5 35.0 2320

880 882000 200 12.7 80 4) 2-1/8 8 45500 81.5 44.4 2500

940 938200 240 12.5 96 4) 2-1/8 8 43400 81.5 52.6 2680

Quiet-Line Models

040 44435 20 8.8 8 1-1/4 1 3110 56.5 2.4 410

057 57000 30 8.6 12 1-1/2 1 2990 56.5 3.7 430

060 62790 40 8.1 16 2 1 2840 56.5 4.9 450

080 88865 40 7.0 16 2 2 6220 59.5 4.8 565

111 110765 40 10.4 16 2 2 5980 59.5 6.9 605

121 120800 40 13.7 16 2 2 5680 59.5 9.0 645

158 166150 60 10.0 24 2 3 8970 61.3 10.0 825

173 184850 80 9.7 32 2 3 8520 61.3 13.1 885

178 186040 80 14.5 32 2 3 7440 61.3 19.4 950

205 218980 60 12.9 24 2 4 11680 62.5 13.1 1070

248 248420 80 12.5 32 2 4 11360 62.5 17.4 1160

347 369100 160 9.8 64 2) 2-1/8 6 17040 64.3 27.0 1940

356 371800 160 14.6 64 2) 2-1/8 6 14880 64.3 39.3 2060

453 496000 60 12.6 64 2) 2-1/8 8 22720 65.5 35.0 2550

498 505230 240 12.4 96 4) 2-1/8 8 19840 65.5 52.6 2910

Standard data based on 95°F EAT, 120°F EFT, 40% EG.

** Sound Level - dBA @ 5 feet.

+ Connections 2" and smaller are FPT; 2-1/8" are ID. SWEAT

Total

Heat Rej.

@ 25 ITD

Flow

Rate

(gpm)

Press.

Drop

(Ft. Water)

#

Internal

Circuits

Conn. +

Size

In/Out

#

26"

Fans

Air

Flow

(CFM) dBA**

Internal

Volume

(gal.)

Shipping

Weight

(lbs.)

2

Page 7

SELECTION PROCEDURE

Table 4 shows the performance specifications for

Liebert drycoolers using a 40% by volume ethylene

glycol solution at an average fluid temperature of

115°F with flow rates from 1.5 to 3 GPM/circuit and

at standard air (.075 lbs/ft

3

). Figure 2 and Figure 3

offer correction factors to Table 4 for average fluid

temperatures and glycol percentages other than

115°F and 40%. Table 3 correction factors may be

used for performance at altitudes above sea level.

For cooling applications other than shown, contact

the Liebert Heat Transfer Division.

To select a drycooler from the tables in this

bulletin, the following information must be known:

1. Fluid Flow Rate (GPM).

2. % Ethylene Glycol (% EG).

3. Design Air Temperature at the Drycooler (EAT).

4. Entering and Leaving Fluid Temperatures (EFT,

LFT) or Total Heat Rejection (BTU/HR) and one

of the Fluid Temperatures.

5. ITD (Initial Temperature Difference) = EFT -

EAT

From the known data, calculate the following:

• Average Fluid Temperature (AFT) = (EFT +

LFT)/2.

• Heat Rejection (BTUH) = Fluid Temp. Diff. x

GPM x BTU/GPM Factor (Table 2).

• Leaving Fluid Temperature =

EFT - BTUH

(GPM) (BTU/GPM)

• Other useful information:

Leaving Air Temp. = EAT +

Drycooler BTUH

(1.08) (Drycooler CFM)

(Leaving Air Temperature should be lower than

145°F for proper motor operation.)

Using Table 4 to select a drycooler

Calculate required MBH/ITD with corrections for

glycol % and average fluid temperature.

1. Required MBH/ITD =

BTUH

(EFT - EAT) (1000) (Fig. 1 Factor)

2. Locate Model No. in Table 4 having a GPM

range within the required flow rate and an MBH

equal to or greater than required. This gives an

approximate size.

3. Divide the given GPM by the “No. of circuits” of

the drycooler selected. The result is “GPM/CIR”

and should be in the range of 1-1/2 to 3.

4. In Table 4, look up the model selected above and

under “GPM/CIR” find the actual MBH. You may

interpolate between columns.

The MBH found should be equal to or greater than

the “required MBH /ITD.”

If the MBH is less than required, repeat from Step 2

with a larger model. You may wish to repeat from

Step 2 with a smaller model for the most economical

selection meeting the required MBH/ITD.

Pressure Drop - After selecting a model, look up

the unit pressure drop following Step 3 and 4 above.

Multiply the pressure drop found by the Figure 3

correction factor. If the product is higher than your

system design, go back to Step 2 and select a model

with more circuits. This may be the same, or larger,

unit.

Example

Cool 40 GPM 20% ethylene glycol and water solution

from 125(F) to 115(F). Design EAT = 95(F).

Calculate:

BTUH = (125 - 115) x (40 GPM) x (480 BTU/

GPM)

BTUH = 192,000

AFT = (125 + 115)/2 = 120(F)

From Figure 2, corr. factor for 120 AFT and

20% EG = 1.04

1. Required MBH/ITD =

192,000 BTUH

(125-95) (1000) (1.04)

2. Locate model in Table 4. Models 092 through

139 fall into the GPM range but do not have the

MBH capacity. Model 174 with 16 circuits is the

smallest model meeting both the GPM range and

MBH requirements.

3. GPM/CIR = 40 GPM/16 CIR = 2.5 GPM/CIR.

4. In Table 4, Model 174 with 16 circuits at the 2.5

GPM/CIR column provides 6.9 MBH/ITD, which

exceeds the required MBH/ ITD of 6.15.

Pressure Drop = 10.5 ft. (from Table 4) x 0.93 (from

Figure 3) = 9.8 ft. H

Table 2 Determining actual BTUH and MBH

% Glycol

Solution

BTUH/GPM 500 490 480 470 450 433

0% 10% 20% 30% 40% 50%

Table 3 Altitude correction

Alt. (Ft.) 0 1000 2000 5000 8000 12000 15000

Corr. Fact. 1 .979 .96 .9 .841 .762 .703

O.

2

3

Page 8

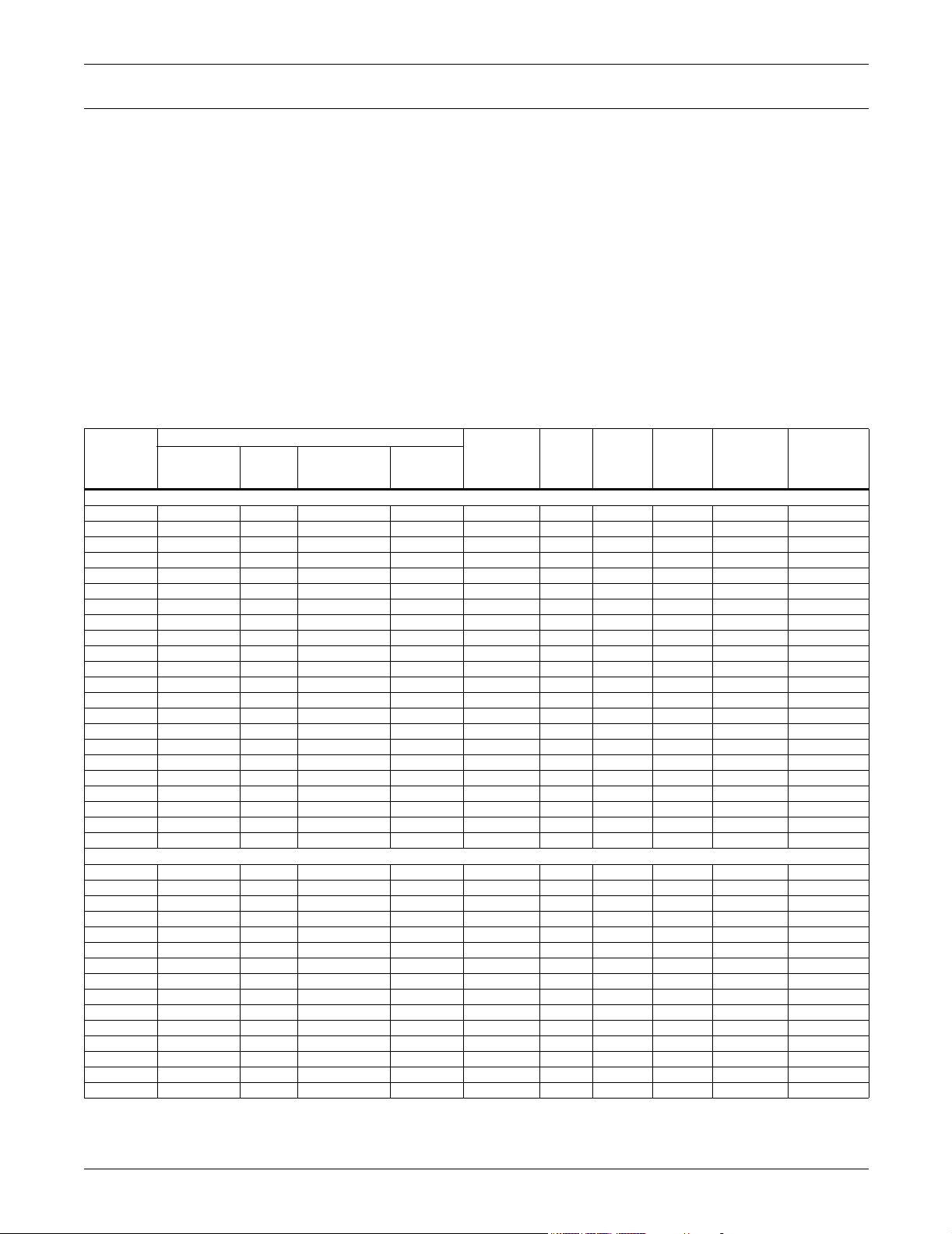

PERFORMANCE DATA

Table 4 Drycooler performance data

MBH/°F Initial Temperature Difference

Model

Number

Standard Models

033 6-12 4* 1.3 4.2 1.5 6.2 1.6 9.2 1.7 12.8

069 6-12 4 1.8 7.3 2.1 11.4 2.3 17.0 2.4 23.6

092 9-18 6 2.7 7.0 3.0 11.7 3.3 16.7 3.5 23.0

109 12-24 8 3.3 7.1 3.7 11.3 3.9 16.8 4.1 23.3

112 24-48 16* 4.2 4.6 4.5 7.3 4.7 10.2 4.8 14.1

139 12-24 8 3.6 6.2 4.1 9.8 4.6 14.6 4.9 20.2

174 24-48 16* 5.8 4.7 6.5 7.5 6.9 10.5 7.3 14.5

197 24-48 16* 6.5 6.2 7.3 9.9 7.9 14.1 8.2 19.4

225 24-48 16 7.1 7.4 8.0 12.0 8.6 17.2 9.0 23.9

260 24-48 16 7.5 6.4 8.7 10.2 9.5 14.7 10.1 20.3

310 24-48 16 8.3 8.4 9.7 13.5 10.7 19.5 11.4 26.9

350 24-48 16 9.2 12.2 10.9 20.9 12.1 29.1 12.9 40.2

352 24-48 16 8.8 8.1 10.4 13.1 11.6 18.9 12.5 26.2

419 24-48 16 9.5 10.6 11.4 17.3 12.9 25.1 14.0 36.7

466 39-78 26 13.1 7.9 15.0 13.2 16.2 19.6 17.1 27.1

491 24-48 16 10.1 15.6 12.5 25.6

620 48-96 32 16.7 8.0 19.4 13.3 21.4 19.4 22.8 26.9

650 60-120 40 19.9 8.0 22.7 13.1 24.6 19.5 26.0 27.0

700 48-96 32 18.5 11.8 21.8 19.8 24.1 29.0

790 48-96 32 18.9 10.2 22.8 17.1 25.7 25.0

880 78-156 52 26.2 8.1 29.9 13.1 32.4 19.5 34.2 26.6

940 48-96 32 20.2 15.3 25.0 25.4

GPM

Range

12-24 8* 2.3 3.9 2.5 6.0 2.7 8.9 2.8 12.4

18-36 12' 3.2 3.7 3.5 6.2 3.7 8.7 3.8 12.1

24-48 16 3.4 3.0 3.6 4.6 3.8 6.3 3.9 8.7

24-48 16* 3.9 3.8 4.1 6.0 4.3 8.2 4.5 11.4

39-78 26 4.5 2.6 4.7 4.4 4.9 6.6 5.0 9.2

24-48 16* 4.5 3.3 5.0 5.2 5.4 7.1 5.6 9.8

36-72 24 6.4 3.2 7.0 4.9 7.4 7.3 7.6 10.1

48-96 32 7.7 3.0 8.3 5.0 8.7 7.0 8.9 9.8

39-78 26* 8.1 4.4 8.8 7.4 9.2 11.0 9.5 15.2

36-72 24* 9.7 4.4 9.7 6.8 10.4 10.4 10.9 14.0

48-96 32* 10.7 4.1 11.7 6.9 12.4 9.8 12.9 13.6

48-96 32* 12.3 6.0 13.4 10.1 14.1 14.6 14.6 20.2

72-144 48 13.4 4.2 14.2 6.7 14.8 10.0 15.1 13.5

36-72 24* 10.6 5.5 12.1 8.7 13.1 12.9 13.9 17.9

48-96 32* 13.2 5.2 14.7 8.8 15.7 12.7 16.5 17.5

60-120 40* 15.2 5.3 16.7 8.6 17.6 12.7 18.3 17.6

48-96 32 14.9 7.7 16.6 12.9 17.7 18.9 18.4 26.1

72-144 48* 16.7 5.3 18.0 8.6 18.8 12.8 19.3 17.4

96-192 64* 21.4 4.1 23.5 6.8 24.8 9.8 25.8 13.6

78-156 52* 22.0 6.3 24.4 10.2 26.1 15.2 27.2 20.6

120-240 80 24.6 4.1 26.5 6.7 27.8 9.9 28.7 13.4

96-192 64* 24.6 6.0 26.8 10.0 28.2 14.6 29.2 20.2

144-288 96 26.7 4.0 28.5 6.7 29.5 9.8 30.2 13.5

96-192 64* 26.4 5.2 29.4 8.7 31.5 12.6 33.0 17.5

120-240 80* 30.4 5.2 33.4 8.5 35.3 12.7 36.6 17.3

96-192 64 29.8 7.7 33.2 12.9 35.4 18.8 36.8 26.0

144-288 96* 33.4 5.1 35.9 8.6 37.5 12.6 38.6 17.4

No. of

Circuits

1.5 GPM/CIR 2.0 GPM/CIR 2.5 GPM/CIR 3.0 GPM/CIR

MBH/ITD PD ft. water MBH/ITD PD ft. water MBH/ITD PD ft. water MBH/ITD PD ft. water

4

Page 9

Table 4 Drycooler performance data (continued)

MBH/°F Initial Temperature Difference

Model

Number

GPM

Range

No. of

Circuits

1.5 GPM/CIR 2.0 GPM/CIR 2.5 GPM/CIR 3.0 GPM/CIR

MBH/ITD PD ft. water MBH/ITD PD ft. water MBH/ITD PD ft. water MBH/ITD PD ft. water

Quiet-Line Models

040 6-12 4 1.4 7.4 1.5 11.4 1.6 17.0 1.7 23.5

12-24 8* 1.6 3.9 1.7 5.9 1.8 8.9 1.8 12.3

057 18-36 12* 2.1 3.6 2.2 6.1 2.3 8.6 2.3 11.9

24-48 16 2.2 3.0 2.3 4.6 2.3 6.2 2.4 8.6

060 12-24 8 2.2 7.1 2.3 11.3 2.4 16.6 2.5 23.0

24-48 16* 2.4 3.8 2.5 5.9 2.5 8.1 2.5 11.3

080 12-24 8 2.7 6.2 3.0 9.8 3.2 14.5 3.3 20.1

24-48 16* 3.2 3.3 3.4 5.1 3.6 7.0 3.7 9.7

111 24-48 16* 4.4 4.7 4.3 7.4 4.4 10.4 4.5 14.3

36-72 24 4.2 3.2 4.4 4.8 4.6 7.2 4.6 10.0

121 24-48 16* 4.4 6.1 4.7 9.7 4.8 13.7 4.9 18.9

48-96 32 4.8 2.9 4.9 4.9 5.0 7.0 5.1 9.6

158 24-48 16 5.6 6.4 6.0 10.3 6.3 14.7 6.6 20.3

36-72 24* 6.0 4.3 6.4 6.7 6.6 10.0 6.8 13.8

173 24-48 16 6.1 8.4 6.6 13.5 6.9 19.5 7.1 26.9

48-96 32* 6.9 4.1 7.2 6.8 7.4 9.7 7.5 13.5

178 24-48 16 6.5 12.3 6.9 20.0 7.1 29.1 7.3 40.1

48-96 32* 7.1 6.0 7.3 10.0 7.4 14.5 7.5 20.0

72-144 48 7.3 4.1 7.4 6.6 7.5 9.9 7.6 13.3

205 24-48 16 6.9 8.2 7.7 13.2 8.2 18.9 8.6 26.2

36-72 24* 7.8 5.5 8.4 8.7 8.8 12.9 9.0 17.6

248 24-48 16 7.6 10.7 8.5 17.4 9.1 25.2 9.4 34.8

48-96 32* 9.1 5.2 9.6 8.7 9.9 12.5 10.1 17.3

347 48-96 32 12.2 8.0 13.2 13.3 13.9 19.4 14.3 26.8

96-192 64* 13.8 4.1 14.4 6.7 14.8 9.7 15.0 13.4

356 48-96 32 12.9 11.9 13.8 19.8 14.3 29.0 14.5 40.0

96-192 64* 14.2 6.0 14.7 9.9 14.9 14.4 15.0 20.0

144-288 96 14.6 4.0 14.9 6.6 15.0 9.6 15.2 13.3

453 48-96 32 15.2 10.3 17.0 17.2 18.1 25.1 18.9 34.7

96-192 64* 18.2 5.2 19.2 8.7 19.9 12.5 20.3 17.3

498 48-96 32 16.1 15.4 17.8 25.6 18.8 37.6 19.2 51.8

96-192 64 18.8 7.7 19.5 12.8 19.9 18.6 20.1 25.7

144-288 96* 19.5 5.1 20.0 8.5 20.2 12.4 20.4 17.2

* Standard Circuiting

Based on 40% Ethylene Glycol Solution at 115°F average solution temperature expressed in MBH.

Specifications subject to change without notice.

Figure 2 Capacity correction factor Figure 3 Pressure drop correction factor

Glycol % and average temperature °F

Correction Factor

Average Fluid Temperature

Correction Factor

5

Glycol % and fluid temperature °F

Average Fluid Temperature

Page 10

DIMENSIONAL DATA

Figure 4 Dimensional data—1-4 fan models

Eyebolts for lifting

condenser provided on

4, 6 & 8 fan models only

43-3/16"

(1097mm)

Figure 5 Dimensional data—6 & 8 fan models

36" (914.4mm)

clearance

recommended on

all sides for

proper operation

and component

access

(1778mm)

(1778mm)

L

70"

70"

L

18" (457mm)

43-9/16"

(962mm)

Height to top

37-7/8"

(962mm)

of fan guard

43-1/8"

(1095mm)

C

Center leg provided on 4 & 8 fan models only

87-1/8"

(2213mm)

Height to top

of fan guard

43-1/8"

37-7/8"

(1095mm)

(962mm)

86-3/4"

(2203mm)

Outlet/inlet connections

Figure 6 Typical footprint and unit anchor plan

1"

(25.4mm)

1-3/4"

(44.5mm)

4-1/4"

(108mm)

1-3/4"

(44.5mm)

4-1/4"

(108mm)

1"

(25.4mm)

18" (457mm)

C

Center leg provided on 4 & 8 fan models only

C

A B

6

Page 11

Table 5 Drycooler physical data

Drycooler

Model Circuits A B C L

Standard Models

-033 any 42 - 44 51.5 1 3/4

-069 any 42 - 44 51.5 1 1-1/4

-092 any 42 - 44 51.5 1 1-1/2

-109 any 42 - 44 51.5 1 2

-112 any 42 - 44 51.5 1 2

-139 any 82 - 84 91.5 2 2

-174 any 82 - 84 91.5 2 2

-197 any 82 - 84 91.5 2 2

-225 any 82 - 84 91.5 2 2

-260 any 122 - 124 131.5 3 2

-310 any 122 - 124 131.5 3 2

-350 any 122 - 124 131.5 3 2

-352 any 82 80 164 171.5 4 2

-419 any 82 80 164 171.5 4 2

-466 any 82 80 164 171.5 4 2-1/2

-491 any 82 80 164 171.5 4 2-1/2

-620 64

-620 32 122 124 131.5 6 2) 2-1/8*

-650 80 122 124 131.5 6 4) 2-1/8*

-650 52

-650 40 122 124 131.5 6 2) 2-1/8*

-700 96 122 124 131.5 6 4) 2-1/8*

-700 64

-700 32 122 124 131.5 6 2) 2-1/8*

-790 64

-790 32 82 80 164 171.5 8 2) 2-1/8*

-880 80

-880 52 82 80 164 171.5 8 2) 2-1/8*

-940 96

-940 64 82 80 164 171.5 8 2) 2-1/8*

-940 32 82 80 164 171.5 8 2) 2-1/8*

Quiet-Line Models

-040 any 42 - 44 51.5 1 1-1/4

-057 any 42 - 44 51.5 1 1-1/2

-060 any 42 - 44 51.5 1

-080 any 82 - 84 91.5 2 2

-111 any 82 - 84 91.5 2 2

-121 any 82 - 84 91.5 2 2

-158 any 122 - 124 131.5 3 2

-173 any 122 - 124 131.5 3 2

-178 any 122 - 124 131.5 3 2

-205 any 82 80 164 171.5 4 2

-248 any 82 80 164 171.5 4 2

-347 any 122 - 124 131.5 6 2) 2-1/8*

-356 64

-356 32 122 - 124 131.5 6 2) 2-1/8*

-453 64

-453 32 82 80 164 171.5 8 2) 2-1/8*

-498 96

-498 64 82 80 164 171.5 8 2) 2-1/8*

-498 32 82 80 164 171.5 8 2) 2-1/8*

* Connections are ODS

** Motors are 3/4 HP - standard models; 1/4 HP - Quiet-Line models

1. Standard circuiting

1

1

1

1

1

1

1

1

1

122 124 131.5 6 2) 2-1/8*

122 124 131.5 6 2) 2-1/8*

122 124 131.5 6 2) 2-1/8*

82 80 164 171.5 8 2) 2-1/8*

82 80 164 171.5 8 4) 2-1/8*

82 80 164 171.5 8 4) 2-1/8*

122 - 124 131.5 6 2) 2-1/8*

82 80 164 171.5 8 2) 2-1/8*

82 80 164 171.5 8 4) 2-1/8*

#Fans

& Motors**

Conn FNPT

In/Out

7

Page 12

ELECTRICAL DATA

Table 6 Drycooler electrical data

# of

Fans123468

Model

# 33,69,92,109,112 139,174,197,225 260,310,350 352,419,466,491 620,650,700 790,880,940

Pump

Hp ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD

208/230/60

0.75 1 11.6 13.5 20.0 - - - - - - - - - - - - - - - - - - - -

0.75 3 7.0 7.9 15.0 3 10.5 11.4 15.0 3 14.0 14.9 15.0 3 17.5 18.4 20.0 3 24.5 25.4 25.0 3 31.5 32.4 35.0

1.5 3 10.1 11.8 15.0 3 13.6 15.3 20.0 3 17.1 18.8 25.0 3 20.6 22.3 25.0 3 27.6 29.3 35.0 3 34.6 36.3 40.0

2.0 3 11.0 12.9 20.0 3 14.5 16.4 20.0 3 18.0 19.9 25.0 3 21.5 23.4 30.0 3 28.5 30.4 35.0 3 35.5 37.4 40.0

3.0 3 14.1 16.8 25.0 3 17.6 20.3 30.0 3 21.1 23.8 30.0 3 24.6 27.3 35.0 3 31.6 34.3 40.0 3 38.6 41.3 50.0

5.0 3 20.2 24.4 40.0 3 23.7 27.9 40.0 3 27.2 31.4 45.0 3 30.7 34.9 50.0 3 37.7 41.9 50.0 3 44.7 48.9 60.0

7.5 3 27.7 33.8 50.0 3 31.2 37.3 60.0 3 34.7 40.8 60.0 3 38.2 44.3 60.0 3 45.2 51.3 70.0 3 52.2 58.3 80.0

10.0 3 34.3 42.0 70.0 3 37.8 45.5 70.0 3 41.3 49.0 70.0 3 44.8 52.5 80.0 3 51.8 59.5 90.0 3 58.8 66.5 90.0

15 3 49.7 61.3 100.0 3 53.2 64.8 110.0 3 56.7 68.3 110.0 3 60.2 71.8 110.0 3 67.2 78.8 110.0 3 74.2 85.8 125.0

460/3/60

0.75 3 3.3 3.7 15.0 3 5.0 5.4 15.0 3 6.7 7.1 15.0 3 8.4 8.8 15.0 3 11.8 12.2 15.0 3 15.2 15.6 15.0

1.5 3 4.7 5.5 15.0 3 6.4 7.2 15.0 3 8.1 8.9 15.0 3 9.8 10.6 15.0 3 13.2 14.0 15.0 3 16.6 17.4 20.0

2.0 3 5.1 6.0 15.0 3 6.8 7.7 15.0 3 8.5 9.4 15.0 3 10.2 11.1 15.0 3 13.6 14.5 15.0 3 17.0 17.9 20.0

3.0 3 6.5 7.7 15.0 3 8.2 9.4 15.0 3 9.9 11.1 15.0 3 11.6 12.8 15.0 3 15.0 16.2 20.0 3 18.4 19.6 20.0

5.0 3 9.3 11.2 15.0 3 11.0 12.9 20.0 3 12.7 14.6 20.0 3 14.4 16.3 20.0 3 17.8 19.7 25.0 3 21.2 23.1 30.0

7.5 3 12.7 15.5 25.0 3 14.4 17.2 25.0 3 16.1 18.9 25.0 3 17.8 20.6 30.0 3 21.2 24.0 30.0 3 24.6 27.4 35.0

10.0 3 15.7 19.2 30.0 3 17.4 20.9 30.0 3 19.1 22.6 35.0 3 20.8 24.3 35.0 3 24.2 27.7 40.0 3 27.6 31.1 45.0

15 3 22.7 28.0 45.0 3 24.4 29.7 50.0 3 26.1 31.4 50.0 3 27.8 33.1 50.0 3 31.2 36.5 50.0 3 34.6 39.9 60.0

575/3/60

0.75 3 2.7 3.1 15.0 3 4.1 4.5 15.0 3 5.5 5.9 15.0 3 6.9 7.3 15.0 3 9.7 10.1 15.0 3 12.5 12.9 15.0

1.5 3 3.8 4.4 15.0 3 5.2 5.8 15.0 3 6.6 7.2 15.0 3 8.0 8.6 15.0 3 10.8 11.4 15.0 3 13.6 14.2 15.0

2.0 3 4.1 4.8 15.0 3 5.5 6.2 15.0 3 6.9 7.6 15.0 3 8.3 9.0 15.0 3 11.1 11.8 15.0 3 13.9 14.6 15.0

3.0 3 5.3 6.3 15.0 3 6.7 7.7 15.0 3 8.1 9.1 15.0 3 9.5 10.5 15.0 3 12.3 13.3 15.0 3 15.1 16.1 15.0

5.0 3 7.5 9.0 15.0 3 8.9 10.4 15.0 3 10.3 11.8 15.0 3 11.7 13.2 15.0 3 14.5 16.0 20.0 3 17.3 18.8 20.0

7.5 3 10.4 12.7 20.0 3 11.8 14.1 20.0 3 13.2 15.5 20.0 3 14.6 16.9 25.0 3 17.4 19.7 25.0 3 20.2 22.5 30.0

10.0 3 12.4 15.2 25.0 3 13.8 16.6 25.0 3 15.2 18.0 25.0 3 16.6 19.4 30.0 3 19.4 22.2 30.0 3 22.2 25.0 35.0

15 3 18.4 22.7 35.0 3 19.8 24.1 40.0 3 21.2 25.5 40.0 3 22.6 26.9 40.0 3 25.4 29.7 45.0 3 28.2 32.5 45.0

8

Page 13

Table 7 Drycooler electrical data—Quietline models

# of

Fans123468

Model

# 40,57,60 80,111,121 158,173,178 205,248 347,356 453,498

Pump

Hp ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD ph FLA WSA OPD

208/230/60

0.75 3 5.3 6.2 15.0 3 7.1 8.0 15.0 3 8.9 9.8 15.0 3 10.7 11.6 15.0 3 14.3 15.2 15.0 3 17.9 18.8 20.0

1.5 3 8.4 10.1 15.0 3 10.2 11.9 15.0 3 12.0 13.7 20.0 3 13.8 15.5 20.0 3 17.4 19.1 25.0 3 21.0 22.7 25.0

2.0 3 9.3 11.2 15.0 3 11.1 13.0 20.0 3 12.9 14.8 20.0 3 14.7 16.6 20.0 3 18.3 20.2 25.0 3 21.9 23.8 30.0

3.0 3 12.4 15.1 25.0 3 14.2 16.9 25.0 3 16.0 18.7 25.0 3 17.8 20.5 30.0 3 21.4 24.1 30.0 3 25.0 27.7 35.0

5.0 3 18.5 22.7 35.0 3 20.3 24.5 40.0 3 22.1 26.3 40.0 3 23.9 28.1 40.0 3 27.5 31.7 45.0 3 31.1 35.3 50.0

7.5 3 26.0 32.1 50.0 3 27.8 33.9 50.0 3 29.6 35.7 50.0 3 31.4 37.5 60.0 3 35.0 41.1 60.0 3 38.6 44.7 60.0

10.0 3 32.6 40.3 70.0 3 34.4 42.1 70.0 3 36.2 43.9 70.0 3 38.0 45.7 70.0 3 41.6 49.3 80.0 3 45.2 52.9 80.0

15 3 48.0 59.6 100.0 3 49.8 61.4 100.0 3 51.6 63.2 100.0 3 53.4 65.0 110.0 3 57.0 68.6 110.0 3 60.6 72.2 110.0

460/3/60

0.75 3 2.5 2.9 15.0 3 3.4 3.8 15.0 3 4.3 4.7 15.0 3 5.2 5.6 15.0 3 7.0 7.4 15.0 3 8.8 9.2 15.0

1.5 3 3.9 4.7 15.0 3 4.8 5.6 15.0 3 5.7 6.5 15.0 3 6.6 7.4 15.0 3 8.4 9.2 15.0 3 10.2 11.0 15.0

2.0 3 4.3 5.2 15.0 3 5.2 6.1 15.0 3 6.1 7.0 15.0 3 7.0 7.9 15.0 3 8.8 9.7 15.0 3 10.6 11.5 15.0

3.0 3 5.7 6.9 15.0 3 6.6 7.8 15.0 3 7.5 8.7 15.0 3 8.4 9.6 15.0 3 10.2 11.4 15.0 3 12.0 13.2 15.0

5.0 3 8.5 10.4 15.0 3 9.4 11.3 15.0 3 10.3 12.2 15.0 3 11.2 13.1 20.0 3 13.0 14.9 20.0 3 14.8 16.7 20.0

7.5 3 11.9 14.7 25.0 3 12.8 15.6 25.0 3 13.7 16.5 25.0 3 14.6 17.4 25.0 3 16.4 19.2 30.0 3 18.2 21.0 30.0

10.0 3 14.9 18.4 30.0 3 15.8 19.3 30.0 3 16.7 20.2 30.0 3 17.6 21.1 35.0 3 19.4 22.9 35.0 3 21.2 24.7 35.0

15 3 21.9 27.2 45.0 3 22.8 28.1 45.0 3 23.7 29.0 45.0 3 24.6 29.9 50.0 3 26.4 31.7 50.0 3 28.2 33.5 50.0

575/3/60

0.75 3 2.0 2.3 15.0 3 2.7 3.0 15.0 3 3.4 3.7 15.0 3 4.1 4.4 15.0 3 5.5 5.8 15.0 3 6.9 7.2 15.0

1.5 3 3.1 3.7 15.0 3 3.8 4.4 15.0 3 4.5 5.1 15.0 3 5.2 5.8 15.0 3 6.6 7.2 15.0 3 8.0 8.6 15.0

2.0 3 3.4 4.1 15.0 3 4.1 4.8 15.0 3 4.8 5.5 15.0 3 5.5 6.2 15.0 3 6.9 7.6 15.0 3 8.3 9.0 15.0

3.0 3 4.6 5.6 15.0 3 5.3 6.3 15.0 3 6.0 7.0 15.0 3 6.7 7.7 15.0 3 8.1 9.1 15.0 3 9.5 10.5 15.0

5.0 3 6.8 8.3 15.0 3 7.5 9.0 15.0 3 8.2 9.7 15.0 3 8.9 10.4 15.0 3 10.3 11.8 15.0 3 11.7 13.2 15.0

7.5 3 9.7 12.0 20.0 3 10.4 12.7 20.0 3 11.1 13.4 20.0 3 11.8 14.1 20.0 3 13.2 15.5 20.0 3 14.6 16.9 25.0

10.0 3 11.7 14.5 25.0 3 12.4 15.2 25.0 3 13.1 15.9 25.0 3 13.8 16.6 25.0 3 15.2 18.0 25.0 3 16.6 19.4 30.0

15 3 17.7 22.0 35.0 3 18.4 22.7 35.0 3 19.1 23.4 40.0 3 19.8 24.1 40.0 3 21.2 25.5 40.0 3 22.6 26.9 40.0

9

Page 14

GUIDE SPECIFICATIONS

Standard Features for Direct Drive Propeller Fan Drycoolers

Furnish and install Liebert Model

________ Air-Cooled Drycoolers,

arranged for vertical air flow. Drycoolers shall be draw-through

design and shall perform in accordance with the schedule.

General

Each drycooler shall consist of casing, drycooler coil, propeller fans

direct-driven by individual fan

motors, fan guards, and mounting

legs.

Fan motors shall be furnished for

operation on a _______ V, ____PH,

______ Hz power supply.

Coil

The drycooler coil shall be constructed on copper tubes on a staggered tube pattern. Tubes shall be

expanded into continuous, rippled

aluminum fins. The fins shall have

full-depth fin collars completely

covering the copper tube. Copper

tubes shall be connected to heavy

wall type “L” headers, inlet coil

connector tubes shall pass through

relieved holes in the tube sheet, for

maximum resistance to piping

strain and vibration.

Coils shall be factory leak-tested at

300 PSIG (minimum) dehydrated,

evacuated and sealed.

Casing

The drycooler casing shall be constructed of bright aluminum

sheet. Casing shall be divided into

individual fan sections by full

width baffles. Structural support

members, including coil support

frame, motor and drive support

shall be galvanized steel for

strength and corrosion resistance. Aluminum legs with rigging holes shall be provided for

hoisting the unit into position.

Fans

Fans shall have zinc plated steel

or aluminum blades. Fan shall be

secured to fan shaft by means of a

heavy-duty keyed hub and dual

set screws. Fan diameter shall be

30" or less. Fans shall be factorybalanced and run before shipment.

Fan guards shall be heavy gauge,

close-meshed, steel wire, with corrosion resistant finish.

Fan Motors

Fan motors shall be equipped

with rain slingers and permanently sealed ball bearings.

Motors shall include built-in overload protection. Motors shall be

rigidly mounted on die-formed

galvanized steel supports.

Quiet-Line Motors

Fan motors shall be 12-pole,

570 rpm, equipped with rain

shields and permanently sealed

ball bearings. Motors shall

include built-in overload protection. Motors shall be rigidly

mounted on die-formed galvanized steel supports.

Electrical Control

All electrical connections (and

electrical low ambient control

options) shall be provided in

weatherproof enclosure. The

enclose shall be integral with the

drycooler for pleasing appearance

as well as functional protection.

The base model (DNC) shall have

the motor(s) factory wired to a

three phase power block in the

electrical enclosure. Main electrical control model (DNL) provides

magnetic contactor and control

voltage for remote starting of the

drycooler.

The drycooler shall be provided

with optional disconnect switch

mounted and wired.

Fan cycling model (DNT) shall be

used to control leaving fluid temperature by cycling fans in one or

two steps. The 24 volt control circuit furnished, consists of control

transformer, fan contactor(s) and

temperature controls) as specified.

Fan cycling with pump control

model (DSO)-single pump, (DDO)dual pump shall have the features

as the fan cycling model plus

starter(s) for the pump(s) and a

built-in disconnect switch.

10

Page 15

COMPONENT ASSEMBLY/INSTALLATION

Leg Assembly

The legs are shipped loose and are

to be field mounted as shown with

the hardware provided.

Secure each leg to drycooler

frame at all four points shown

using hardware provided

Figure 7 General arrangement diagram

Typical rigging

Rigging

Holes in the drycooler legs permit

lifting the unit. Spreader bars are

required. Four, 6 and 8 fan models

have additional lifting eyes.

High Voltage Electrical Connections

Line Voltage is

connected to the

terminal strip

or directly to

the factory supplied locking

disconnect

(optional).

Check voltage

and compare to nameplate.

Low Voltage Electrical Connections

A control interlock between the

indoor and outdoor equipment

must be minimum 16 ga. for

up to 75 ft. or not

to exceed 1 volt

drop in control

line.

Expansion

tank field

installed at

highest point

in system

Pressure

port*

Hose

bib*

Flow direction

Outlet

Inlet

Models 069-491

Models 620 through 940 have 2 sets

of connections on end of unit

Fill*

Drycooler coil

Drycooler

electric box

*

s

n

o

i

n

U

*

e

v

l

a

v

g

n

i

x

i

M

Gate or ball*

valve for bypass

Flow switch supplied

with dual pump systems*

Flow regulating valve*

Pressure port*

Air vents at top of risers*

* Components are not supplied by Liebert,

and all components shown may not be

necessary for system operation.

Electrical service

supply by others

Unions*

Gate or ball*

valve for

isolation (typ)

Optional dual pump

system shown

Glycol

pumps

Pump

housing

Check valves*

on dual pump

systems only

Field piping

11

Page 16

APPLICATION/INSTALLATION GUIDELINES

Location Guidelines

To ensure an adequate air supply,

locate drycoolers in a clean air

area, away from loose dirt and foreign matter that may clog the coil.

In addition, drycoolers must not

be placed near steam, hot air, or

fume exhausts. Also, drycoolers

should be no closer than 3 feet

from a wall, obstruction or adjacent unit with no obstructions over

the unit. Install drycoolers in a

level position to assure proper vent

and drain.

All drycooler legs have mounting

holes for securing the unit to steel

supports or concrete pads.

For roof installation, mount drycoolers on steel supports in accordance with local codes. To

minimize sound and vibration

transmission, mount steel supports across load-bearing walls.

For ground installations, a concrete pad will support the load.

Drycooler Installation

The drycooler should be located

for maximum security and maintenance accessibility. Avoid

ground level sites with public

access or areas which contribute

to heavy snow or ice accumulations. Utilize centrifugal fan drycoolers when placing a drycooler

in a building.

Electrical Requirements of the Drycooler

Electrical service is required for

all drycoolers at the location of the

outdoor system. The power supply

does not necessarily have to be the

same voltage supply as required

by the indoor unit. This separate

power supply may be 208, 230,

460 or 575 volt, 60 Hz. For electrical characteristics of the standard

voltage drycoolers, see Full Load

Amps (FLA) of the drycooler in

Tables 6 and 7 and FLA of the

pump, if used, in Table 8. Dual

element, time delay type fuses or

“HACR” circuit breakers at the

main power source. The only electrical connection between the

indoor unit and the drycooler is a

two wire control interlock which is

field-connected when provided.

Glycol/Inhibitor Solution

The percentage of glycol to water

will be determined by the outdoor

ambient in which the system is

operating. Just as critical is the

inhibitor used with the glycol.

Commercial ethylene glycol

(Union Carbide Ucartherm, Dow

Chemical Dowtherm SR-1, and

Texaco E.G. Heat Transfer Fluid

100), when pure, is generally less

corrosive to the metals than water.

It will, however, assume the corrosivity of the water from which it is

prepared and may become increasingly corrosive with use if not

properly inhibited. Proper inhibitor maintenance must be performed to prevent corrosion of the

glycol system. Consult glycol manufacturer for testing and maintenance of inhibitors.

Automotive antifreeze is unacceptable and must not be used

in any glycol fluid system.

There are two basic concepts of

corrosion inhibition: They are classified as corrosion inhibitors or

environmental stabilizers. The corrosion inhibitors function by forming a surface barrier that protects

the metals. Environmental stabilizers decrease corrosion by stabilizing or favorably altering the

overall environment. An alkaline

buffer, such as borax, is a simple

example, since its prime purpose is

to maintain an alkaline condition

(ph above 7).

The quality of the water of dilution must be considered because

water may contain corrosive elements which reduce the effectiveness of the inhibited formulation.

Surface waters that are classified

as soft and are low in chloride and

sulfate ion content (less than

100 ppm each) should be

employed.

Piping Considerations

CAUTION: When using water

under pressure to test the system

for leaks, immediately charge the

tested system with glycol. Complete system drain-down cannot be

assured. Replacing broken, frozen

piping is a needless exercise. A

preferred test method utilizes common refrigerant gas pressurized

with nitrogen. A refrigerant type

leak detector will find even the

smallest leak when properly used.

Galvanized pipe or other components should not be used

with an inhibited glycol system.

All fluid piping must comply

with local codes. Care in sizing

pipes will help reduce pumping

power and operating costs.

Manual shut-off valves and unions

should be installed at the supply

and return line of each major system component. This permits routine service or emergency isolation

of the component.

Where connecting to a city water

supply, provide a disconnection

means. A city water source is desirable for initially charging the system and as an emergency standby

cooling source.

The minimum glycol temperature

to be supplied from the drycooler

determines whether the supply

and return lines should be insulated to prevent condensation (see

Table 9).

Vents are required at system high

points to vent trapped air when

filling the system.

Since the system is not open to the

atmosphere, an expansion tank

must be provided for expansion

and contraction of the fluid with

temperature change. A relief

valve is also necessary.

A fill port is necessary for charging the system with glycol.

Depending on the complexity of the

system, various other devices may

be specified, such as pressure

gauges, valves, pumps and sensors.

12

Page 17

PUMP PACKAGES & EXPANSION TANK - OPTIONS

Figure 8 Pump package

See

Note 1

19"

(483mm)

Pump suction

connections

Provided on dual

pump package only

Pump

discharge

connections

30-1/4"

(768.4mm)

Figure 9 Pump mounting

1/2" (12.7mm)

diameter holes

See

Note

2

3/4"

(19.1mm)

Pump Package

Mounting

23"

(584.2mm)

3-1/2"

(88.9mm)

Notes

1. Single pump packages are

17-1/4" (438.2mm) wide. Dual

pump packages are 32-1/4"

(819.2mm) wide.

2. Mounting holes are 15-11/32"

(389.7mm) apart on single

pump packages and

30-11/32" (770.7mm) apart on

dual pump packages.

3. 7-1/2hp dimensions not

shown—consult factory.

Figure 10 Expansion tank

Expansion Tank- (P/N 1C16717P1)

This tank, included in a standard pump package, has an internal volume of 8.8 gal. (33 l)

and a maximum pressure of 100 psi (690 kPa).

This tank is sized for a typical “open” system with a fluid volume of less than 75 gal.

(280l). When used in a “closed” system, volumes of up to 140 gal. (910l) can be accommodated. The use of a safety relief valve, field supplied, is recommended for systems

“closed” to atmospheric venting. Other piping accessories for filling, venting, or adjusting

the fluid in the system, are recommended, but not included.

Table 8 Pump data

Connections

Pump

Model

3/4 1-1/4" 3/4" 3/4 1 7.6 6.9 N/A N/A

3/4 1-1/4" 3/4" 3/4 3 3.5 3.2 1.6 1.3

1-1/2 1-1/4" 3/4" 1-1/2 3 6.6 6.0 3.0 2.4

2 1-1/4" 3/4" 2 3 7.5 6.8 3.4 2.7

3 1-1/2" 1" 3 3 10.6 9.6 4.8 3.9

5 1-1/2" 1-1/4" 5 3 16.7 15.2 7.6 6.1

7-1/2 3" 3" 7-1/2 3 24.2 22.0 11.0 9.0

To Calculate Total Pump and Drycooler Full Load Amps (FLA):

Total FLA = Pump FLA + Drycooler FLA

To Calculate Total Pump and Drycooler Wire Size Amps (WSA)

Total WSA = Largest Motor FLA x 1.25 + Sum of other Motor FLA values

To Calculate Total Pump and Drycooler Maximum Overcurrent Protective Device (OPD)

Total OPD = Largest Motor FLA x 4.0 + Sum of other Motor FLA values

Select standard fuse size (15A, 20A, 25A, 30A, etc.)

NPT

Suction

Female

Discharge PH

HP

Figure 11 Pump curve, 60 Hz

180

160

140

Electric @ 60Hz

208

FLA

230

FLA

460

FLA

575

FLA

Total Head - ft. water

120

100

80

60

40

20

0 10 20 30 40 50 60 70 80 120 160 200 250 300 400

Flow Rate - GPM

13

Page 18

SUPPLEMENTARY APPLICATION DATA

Table 9 Room dew point temperatures

Dry bulb

°F (°C)

70 57.2 45 41.1

70 58.5 50 50.5

72 58.9 45 50.0

72 60.0 50 52.4

75 61.2 45 52.4

75 62.5 50 55.0

* Minimum glycol temperature before condensation will occur

Wet bulb

°F (°C)

Rel. hum.%Dew point*

°F (°C)

Table 10 Glycol concentration at various

ambients

% Glycol

by volume

Freezing

point °F

Apparent

specific

gravity

@50°F

0 1020304050

32 25 16 5 -10 -32

1.000 1.014 1.028 1.042 1.057 1.071

Table 11 Volume in standard tube

Type “L” copper tube

Diameter (in.) Volume

Outside Inside Gal/ft (L/m)

.50 0.430 0.0075 (0.09)

.625 0.545 0.0121 (0.15)

.75 0.666 0.0181 (0.22)

.875 0.785 0.0251 (0.31)

1.125 1.025 0.0429 (0.53)

1.375 1.265 0.0653 (0.81)

1.625 1.505 0.0924 (1.15)

2.125 1.985 0.161 (2.00)

2.625 2.465 0.248 (3.08)

3.125 2.945 0.354 (4.40)

3.625 3.425 0.479 (5.95)

4.125 3.905 0.622 (7.73)

MAINTENANCE GUIDELINES

Restricted airflow through the

drycooler coil will reduce the operating efficiency of the unit and

can result in high fluid temperatures and loss of cooling.

Clean the drycooler coil of all

debris that will inhibit air flow.

This can be done with compressed

air or commercial coil cleaner.

Check for bent or damaged coil

fins and repair as necessary. In

winter, do not permit snow to

accumulate around the sides or

underneath the drycooler.

Check all fluid lines and capillaries for vibration isolation. Support

as necessary.

Visually inspect all fluid lines for

signs of fluid leaks.

Inspect the motor/fan assembly to

insure bearings are (free) and

motor is secure within the mount.

The glycol in drycooler systems

level must be periodically

checked. At the high point of the

system check:

• For positive pressure.

• For air to be vented.

• For an unlogged expansion

tank. A fluid sample for

proper concentrations of antifreeze and inhibitors.

The first three checks may give

indication of leaks in the system.

Important

When ordering replacement parts

for heat rejection equipment, it is

necessary to specify unit model

number - serial number - voltage.

Enter this information below for

future use.

Model No.

Serial No.

Voltage

14

Page 19

Page 20

Drycoolers - 60 Hz

HEAT REMOVAL/ENVIRONMENTAL CONTROL

GENERAL DATA

The Company Behind the Products

With over a million installations around the globe,

Liebert is the world leader in computer protection

systems. Since its founding in 1965, Liebert has

developed a complete range of support and

protection systems for sensitive electronics:

• Environmental systems—close-control air

conditioning from 1 to 60 tons

• Power conditioning and UPS with power

ranges from 300 VA to more than 1000 kVA

• Integrated systems that provide both

environmental and power protection in a

single, flexible package

• Monitoring and control—from systems of any

size or location, on-site or remote

• Service and support through more than 100

service centers around the world and a 24/7

Customer Response Center

While every precaution has been taken to ensure

the accuracy and completeness of this literature,

Liebert Corporation assumes no responsibility and

disclaims all liability for damages resulting from

use of this information or for any errors or

omissions.

© 1994 Liebert Corporation

All rights reserved throughout the world.

Specifications subject to change without notice.

® Liebert and the Liebert logo are registered

trademarks of Liebert Corporation. All names

referred to are trademarks or registered

trademarks of their respective owners.

Technical Support

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Single-Phase UPS

800-543-2378

Outside the United States

614-841-6598

3-Phase UPS

800-543-2378

Environmental Control

800-543-2778

Italy

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD)

+39 049 9719 111

FAX: +39 049 5841 257

Asia

23F, Allied Kajima Bldg.

138 Gloucester Road

Wanchai

Hong Kong

+852 2 572 2201

FAX: +852 2 831 0114

Web Site

www.liebert.com

E-mail

UPStech@liebert.com

SL-10058 (10/02)

Loading...

Loading...