Page 1

LIEBERT XD CHILLER (XDC) WITH iCOM CONTROLS

STANDARD FEATURES

TANDEM COMPRESSORS - Scroll with a suction gas cooled motor, vibration isolators, thermal overloads, manual reset high-pressure switch and pump

down low-pressure switch.

REFRIGERATION SYSTEM - Dual R-407C refrigeration circuits each including liquid line filter dryers, refrigerant sight glass with moisture indicator,

electronic control valve, adjustable externally equalized expansion valves and liquid line solenoid valves.

HEAT EXCHANGER - Brazed plate design with interwoven circuiting constructed of stainless steel plates, copper brazed.

PUMPS - Centrifugal type. Uses R-134a.

STANDARD CONTROL PROCESSOR - The standard control system is microprocessor-based with an external LCD numerical display to allow

observation of specified settable functions. Normal operating conditions are indicated on the LCD display panel, which is mounted to the unit. The control

system also monitors unit operation and activates an alarm when any of the specified factory preset conditions are exceeded.

CABINET AND FRAME - Custom powder painted steel panels. A hinged control access panel opens to a second front panel, which is a protected

enclosure for all high voltage components. Frame is constructed of 14 gauge heli-arc welded tubular steel and painted using an auto-deposition coating

system.

CANBUS ISOLATOR - Electrically isolates external CANBUS from internal CANBUS. Allows for greater total length of external CANBUS cables.

REFER TO SL-16655, LIEBERT XTREME DENSITY SYSTEM DESIGN MANUAL, AND SL-16674, LIEBERT XDC USER MANUAL FOR ADDITIONAL DETAIL.

DPN001599

PAGE 1/6

REV 12/11

REV 4

Page 2

LIEBERT XD CHILLER (XDC) WITH iCOM CONTROLS

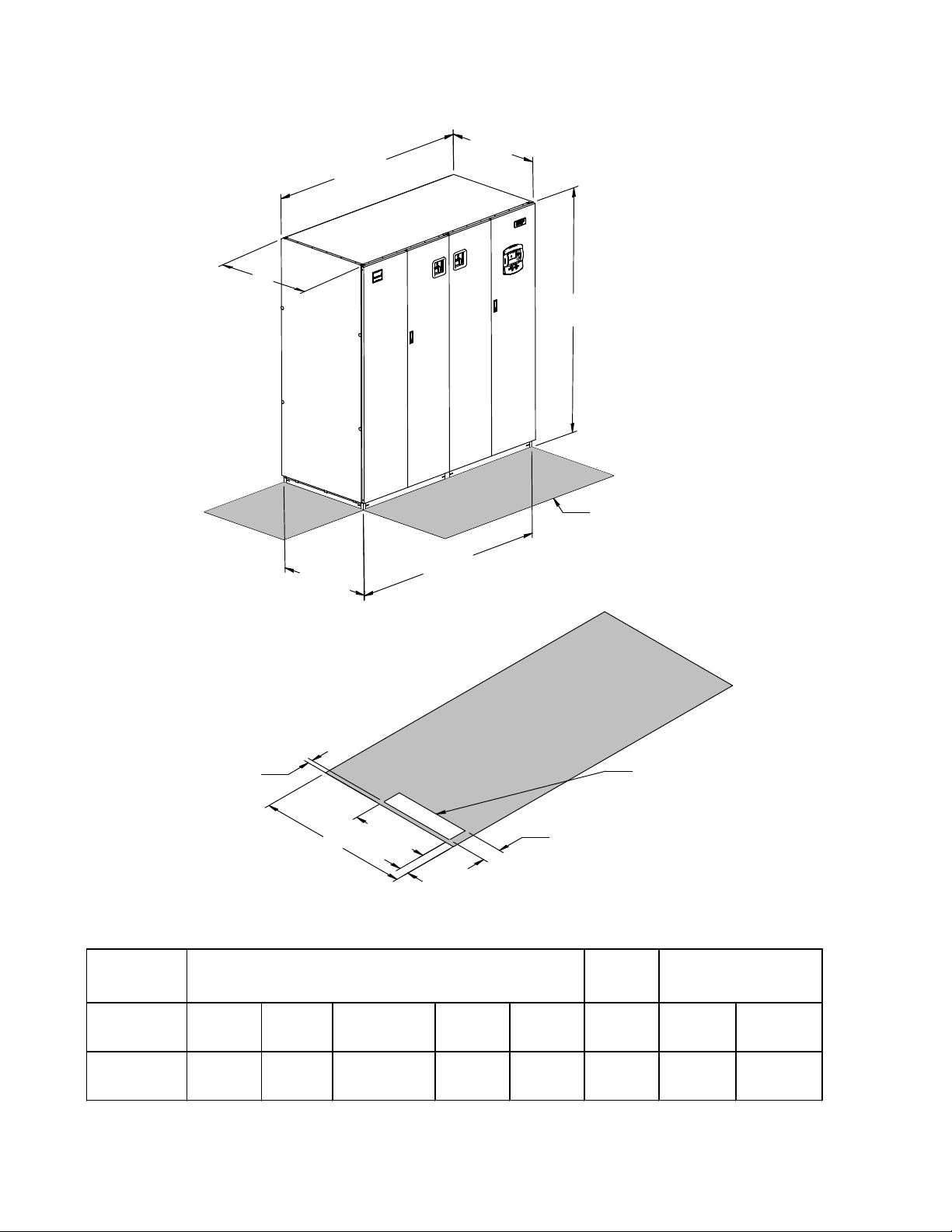

SHIPPED WEIGHT

B

A

Overall

C

Overall

F

Height of Unit

1in

25.4mm

E

D

Unit Base

Unit Base

UNIT DIMENSIONAL DATA

17in

431.8mm

D

2in

50.8mm

FLOOR CUTOUT DIMENSIONS

SHADED AREAS INDICATE A RECOMMENDED

CLEARANCE OF 36in (914mm) BE PROVIDED FOR

5in

127 mm

COMPONENT ACCESS.

RECOMMENDED MINIMUM

HOT GAS SUPPLY &

LIQUID RETURN

PIPING OPENING

MODEL

50/60 HZ

XDC160 74 (1880) 34 (864) 33-1/8 (841) 33 (838) 72 (1829) 78 (1981) 1975 (896) 2109 (957)

* Dimension Does Not Include the Bezel of the Disconnect Switch or iCOM Display.

REFER TO SL-16655, LIEBERT XTREME DENSITY SYSTEM DESIGN MANUAL, AND SL-16674, LIEBERT XDC USER MANUAL FOR ADDITIONAL DETAIL.

DPN001599

DIMENSIONAL DATA inches (mm)

lbs (kg)

A B * C D E F DOM. EXPORT

PAGE 2/6

REV 12/11

REV 4

Page 3

LIEBERT XD CHILLER (XDC) WITH iCOM CONTROLS

MODEL

To First Cooling Module or

Bypass Flow Controller **

Install Replaceable Filter Drier Assembly

in Liquid Supply Line

22in

559mm

Orientation

21in

533mm

Defined by

Installer.*

DIMENSIONS ARE SUBJECT

TO CHANGE WITHOUT NOTICE.

6in

152 mm

23in

584 mm

47in

1194 mm

Return Line From

A

Cooling Units

(line is spin closed)

(elbow customer provided)

44in

~

1118 mm

3 1/4in

83mm

8in

*

203mm

Liquid Supply Line

B

To Cooling Units

* Allow 8in (204mm) Of Clearance For Filter Replacement.

Filter assembly may be positioned horizontally.

** To Ensure All Refrigerant Flow is Filtered, Install the Filter

Drier Assembly Between the Discharge Line of the Liebert

XDC and the first Bypass Flow Controller or the first

Liebert XD Cooling Module.

Hot Gas Refrigerant Lines

C

Liquid Refrigerant Lines

D

UNIT PIPING OUTLET CONNECTION SIZES, inches

A

50/60 HZ

OD CUBOD CUCOD CUDOD CU

XDC160 2-1/8 1-1/8 1-3/8 7/8

REFER TO SL-16655, LIEBERT XTREME DENSITY SYSTEM DESIGN MANUAL, AND SL-16674, LIEBERT XDC USER MANUAL FOR ADDITIONAL DETAIL.

DPN001599

PAGE 3/6

REV 12/11

REV 4

Page 4

LIEBERT XD CHILLER (XDC) WITH iCOM CONTROLS

Bypass Flow Control Assembly

Bypass Flow Controller

Factory Supplied and

Field Installed

Return Main

Ball Valve

Supply Main

Field Supplied and

Field Installed

LIEBERT

XD

Field Supplied and

Field Installed

COOLING

MODULE

RETURN

RETURN

Flow Direction

Must be toward

Return Main.

Install Bypass Flow Control Assembly

between the Liebert XDC and first

Liebert XD Cooling module. See System

Design Manual SL-16655 for quantity

required.

SUPPLY

Replaceable

Filter Drier

Assembly

Install Replaceable

Filter Drier Assembly

in liquid supply line

SUPPLY

LIEBERT XDC

Factory Piping

Field Piping

REFER TO SL-16655, LIEBERT XTREME DENSITY SYSTEM DESIGN MANUAL, AND SL-16674, LIEBERT XDC USER MANUAL FOR ADDITIONAL DETAIL.

DPN001599

PAGE 4/6

REV 12/11

REV 4

Page 5

LIEBERT XD CHILLER (XDC) WITH iCOM CONTROLS

Three phase electric

service not provided

by Liebert.

Field supplied disconnect

switch may not be required,

check local codes.

HEAT REJECTION CONNECTION (R-407C Side)

Field supplied 24V. Class 1 wiring to

interlock heat rejection from pigtails:

70A & 71A - Compressor 1 circuit

70B & 71B - Compressor 2 circuit

70C & 71C - Dual Cool relay (optional)

Three phase electric service

not by Liebert.

ELECTRIC CONDUIT KNOCKOUTS

On top of electric box. Knockout size

2 in (51 mm)

Factory installed unit

disconnect switches

iCOM display

EARTH GROUND CONNECTION

Connection terminal for field supplied

earth grounding wire.

Electrical handy box factory

installed with cover.

THREE PHASE CONNECTION

Electric service connection terminals

Factory wired to components

on electric panel

Factory installed disconnect switch

EARTH GROUND BAR (50Hz only)

Connection terminal with factory

ground from each high voltage

component

60HZ COMPONENTS SHOWN

NOTE: Refer to specification sheet for full load amp. and wire size amp. ratings.

CANBUS ISOLATOR

ALARM AND WARNING OUTPUT RELAYS

Field supplied 24V Class 2 wire for

special alarms.

(Not to exceed 1.0A @ 24v each.)

REMOTE UNIT SHUTDOWN

Replace existing jumper between terminals

37 & 38 with normally closed switch having

a minimum 50VA rating. Use field supplied

24V Class 2 wire.

INTELLISLOTS

Two Liebert Intellislots for optional

OCWEB-LBDS or OC485-LBDS card.

®

®

REFER TO SL-16655, LIEBERT XTREME DENSITY SYSTEM DESIGN MANUAL, AND SL-16674, LIEBERT XDC USER MANUAL FOR ADDITIONAL DETAIL.

DPN001599

PAGE 5/6

REV 12/11

REV 4

Page 6

LIEBERT XD CHILLER (XDC) WITH iCOM CONTROLS

Liebert XDC Extra Low Voltage field connection points

TO REMOTE T/H SENSOR A

P67

DO NOT

USE

TO P64 ON ICOM CONTROL BOARD

RED ETHER NET CABLE

TO LIEBERT XD COOLING

MODULE AND REMOTE

T/H SENSOR B

TO OPTIONAL

EXTERNAL

CONNECTIONS

P64

P67P66

UNIT DISPLAY (REAR VIEW)

FACTORY WIRED

TEMPERATURE SENSOR.

TO P66 ON ICOM CONTROL BOARD

TERMINATION PLUG

COMMON WARNING OUTPUT

FOR CONTACTS INDICATING AN

ALARM CONDITION.

(MAX) 1.0AMP @ 24V

K11NO

TO REMOTE ALARM

CIRCUIT BY OTHERS

INPUT: REMOTE ALARM DEVICE

FOR INDICATION OF ALARM, WIRE

N.O. CONTACTS FROM REMOTE

ALARM DEVICE AS SHOWN.

N.O. CONTACT BY OTHERS

INPUT: CONDENSATION

ALARM WHEN CLOSED.

N.O. CONTACTS REQUIRED

INPUT: FAN BREAKER STATUS

1

K11

K11

K11COM

24 50

DETECTION

K11NC

5124

NOTES:

1. CONTROL WIRING MUST BE CLASS 2 AND INSTALLED IN

ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE (NEC).

2. REQUIRES SHIELDED CABLE.

ALARM WHEN CLOSED.

5424

N.O. CONTACTS REQUIRED

COMMON ALARM OUTPUT

FOR CONTACTS INDICATING AN

ALARM CONDITION.

(MAX) 1.0AMP @ 24V

K3

K3

K3COM

K3NO

TO REMOTE ALARM

1

CIRCUIT BY OTHERS

INPUT: REMOTE SHUTDOWN

FOR SHUTDOWN OF CONTROL

CIRCUIT, REMOVE JUMPER

BETWEEN TERMINALS 37 & 38

AND REPLACE WITH N.C. CONTACT

N.C. CONTACTS BY OTHERS

K3NC

3837

21

REFER TO SL-16655, LIEBERT XTREME DENSITY SYSTEM DESIGN MANUAL, AND SL-16674, LIEBERT XDC USER MANUAL FOR ADDITIONAL DETAIL.

DPN001599

PAGE 6/6

REV 12/11

REV 4

Loading...

Loading...