Page 1

Precision Cooling

For Business-Critical Continuity

™

User Manual

Liebert® DM 16kW Air Conditioner

Page 2

Liebert_DM 16kW Air Conditioner User Manual

Liebert_DM 16kW Air Conditioner

User Manual

Version

V1.0

Revision date

March 5, 2013

BOM

31012820

Emerson Network Power provides customers with technical support. Users may contact the nearest

Emerson local sales office or service center.

Copyright © 2013 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Page 3

Page 4

Liebert_DM 16kW Air Conditioner User Manual

Contents

Chapter 1 Overview ............................................................................................................................................................ 1

1.1 Model Description ................................................................................................................................................. 1

1.2 Product Introduction .............................................................................................................................................. 1

1.3 Main Components ................................................................................................................................................. 1

1.3.1 Indoor Unit ................................................................................................................................................. 1

1.3.2 Outdoor Unit .............................................................................................................................................. 2

1.3.3 Controlling System .................................................................................................................................... 2

1.3.4 Controller ................................................................................................................................................... 2

1.4 Environment Requirements .................................................................................................................................. 3

1.4.1 Operation Environment .............................................................................................................................. 3

1.4.2 Storage Environment ................................................................................................................................. 3

Chapter 2 Mechanical Installation ....................................................................................................................................... 4

2.1 Transportation, Unpacking And Inspection ........................................................................................................... 4

2.1.1 Transportation And Movement .................................................................................................................. 4

2.1.2 Unpacking .................................................................................................................................................. 4

2.1.3 Inspection .................................................................................................................................................. 5

2.2 Installation Notes .................................................................................................................................................. 5

2.3 System Installation Arrangement .......................................................................................................................... 6

2.3.1 General Arrangement ................................................................................................................................ 6

2.3.2 System Installation Sketch Map ................................................................................................................. 6

2.3.3 Mechanical Paremeters ............................................................................................................................. 7

2.4 Installing Indoor Unit ............................................................................................................................................. 9

2.4.1 Preparing Equipment room ........................................................................................................................ 9

2.4.2 Installation Space ...................................................................................................................................... 9

2.4.3 Requirement Of Maintenance Space ....................................................................................................... 10

2.4.4 Installation Procedures ............................................................................................................................ 11

2.5 Installing Outdoor Unit ........................................................................................................................................ 11

2.5.1 Installation Notes ................................................................................................................................ ..... 11

2.5.2 Space Requirements ............................................................................................................................... 12

2.5.3 Mounting base dimension ........................................................................................................................ 12

2.6 Piping .................................................................................................................................................................. 14

2.6.1 General .................................................................................................................................................... 14

2.6.2 Charging refrigerant and adding refrigerant oil ........................................................................................ 17

2.7 Base/Side Panel Cutout Locations ...................................................................................................................... 17

2.8 Removing Transport Fastener And Vibration Absorber ...................................................................................... 19

2.9 Component Adjustment ...................................................................................................................................... 22

2.10 Installation Inspection ....................................................................................................................................... 22

Chapter 3 Electrical Installation ......................................................................................................................................... 23

3.1 Work Introduction And Notes .............................................................................................................................. 23

3.2 Wiring Of Indoor Unit .......................................................................................................................................... 23

3.2.1 Locating Electrical Interface Of Indoor Unit ............................................................................................. 23

Page 5

3.2.2 Connecting Power Cable Of Indoor Unit .................................................................................................. 23

3.2.3 Connecting Control Cables ...................................................................................................................... 24

3.2.4 Connecting Extension Component Solenoid Valve (For Site Installation)................................................ 25

3.3 Wiring Of Outdoor Unit ........................................................................................................................................ 26

3.3.1 Connecting Power Cables For Outdoor Unit ............................................................................................ 26

3.3.2 Connecting Control Signal Cables Of Outdoor Unit ................................................................................. 26

3.3.3 Installation Inspection .............................................................................................................................. 27

3.3.4 HMI .......................................................................................................................................................... 28

3.3.5 Operation Description Of HMI .................................................................................................................. 29

Chapter 4 System Start-Up And Commissioning .............................................................................................................. 32

4.1 Location Of MCBs ............................................................................................................................................... 32

4.2 Power-on Commissioning ................................................................................................................................... 32

4.2.1 Preparation Before Commissioning ......................................................................................................... 32

4.2.2 Commissioning Procedures ..................................................................................................................... 33

4.2.3 Commissioning Complete Inspection....................................................................................................... 34

Chapter 5 Precision Air Conditioner Controller .................................................................................................................. 35

5.1 Appearance ........................................................................................................................................................ 35

5.2 Control Button ..................................................................................................................................................... 35

5.2.1 Function Description ................................................................................................................................ 35

5.2.2 Operation Example .................................................................................................................................. 35

5.3 Indicator ................................................................................................ .............................................................. 36

5.4 Control Interface ................................................................................................................................................. 36

5.4.1 OFF Interface .......................................................................................................................................... 36

5.4.2 MAIN Interface ......................................................................................................................................... 37

5.4.3 Password Interface .................................................................................................................................. 38

5.5 Menu Structure ................................................................................................................................................... 38

5.5.1 Guide On Finding Menus ......................................................................................................................... 38

5.5.2 Main Menu ............................................................................................................................................... 38

5.5.3 Alarm Menu ............................................................................................................................................. 39

5.5.4 Set Point Control ..................................................................................................................................... 41

5.5.5 System Status ......................................................................................................................................... 42

5.5.6 System Menu ........................................................................................................................................... 43

5.5.7 Set Time/Date .......................................................................................................................................... 46

5.5.8 Graph Menu ............................................................................................................................................. 47

5.5.9 Run Hours ............................................................................................................................................... 47

5.5.10 On/Off Record ....................................................................................................................................... 48

5.5.11 Team Work ............................................................................................................................................ 48

5.6 Help Menu .......................................................................................................................................................... 49

Chapter 6 System O&M .................................................................................................................................................... 50

6.1 Operation and maintenance of indoor unit ................................................................................................ .......... 50

6.1.1 Self-diagnosing Functions ....................................................................................................................... 50

6.1.2 Electric Control Part ................................................................................................................................. 50

6.1.3 Dust Filter ................................................................................................................................................ 51

6.1.4 Fan Kit ..................................................................................................................................................... 52

Page 6

Liebert_DM 16kW Air Conditioner User Manual

6.1.5 Infrared Humidifier ................................................................................................................................... 52

6.1.6 Electric Reheat ........................................................................................................................................ 54

6.1.7 Cooling System ....................................................................................................................................... 54

6.1.8 Replacing The Compressor ..................................................................................................................... 56

6.2 Operation and maintenance of outdoor unit ........................................................................................................ 57

6.2.1 Maintenance ............................................................................................................................................ 57

6.2.2 Troubleshooting ....................................................................................................................................... 58

Chapter 7 Troubleshooting ................................................................................................................................................ 59

Appendix 1 SiteMonitor Software Introduction .................................................................................................................. 63

Appendix 2 Circuit Diagram of DME16 .............................................................................................................................. 64

Appendix 3 Circuit diagram of DMC16M2 ......................................................................................................................... 65

Appendix 4 Menu Structure ............................................................................................................................................... 66

Appendix 5 Alarm Control Menu Table.............................................................................................................................. 67

Appendix 6 Parameter Setting Table ................................................................................................................................ 68

Page 7

Page 8

Chapter 1 Overview 1

Liebert_DM 16kW Air Conditioner User Manual

Chapter 1 Overview

This chapter introduces the features, main parts, requirements on transportation and storage environment of the

Liebert_DM 16kW (DME16) air conditioner.

1.1 Model Description

The model description of Liebert_DM 16kW air conditioner is shown in Figure 1-1.

Figure 1-1 Model description

1.2 Product Introduction

Liebert_DM 16kW air conditioner is a medium-large sized precision environment control system, suitable to the

environment control of the equipment room or computer room. It aims to provide a sound operation environment for

precision equipment, such as sensitive equipment, industry processing equipment, communication equipment and

computers.

Liebert_DM 16kW air conditioner features high reliability, high sensible heat ratio and large airflow. It is configured with

an infrared humidifier adjustable to different water qualities, and is compatible with R407C refrigerant to meet the

requirement.

Liebert_DM 16kW air conditioner comprises indoor unit and outdoor unit. With the standard condenser unit, the

Liebert_DM 16kW air conditioner can reduce noise pollution to the minimum while meeting system cooling

requirement.

1.3 Main Components

1.3.1 Indoor Unit

The indoor unit of the Liebert_DM 16kW air conditioner includes compressor, evaporator, electric reheat, fan, controller,

infrared humidifier, thermal expansion valve, sight glass and drier-filter.

Compressor

The Copeland scroll compressor features low vibration, low noise and high reliability. The connection mode of

Rotalock makes the maintenance easier.

Evaporator

Finned tube evaporator with high heat dissipation efficiency is used. The distributor, with its model-specific design,

ensures that the refrigerant is distributed evenly in each loop, improving the evaporator efficiency to a great extent.

Thermal expansion valve

The external equalizer type thermal expansion valve collects temperature and pressure signals at the same time, so

that it can regulate the refrigerant flow more accurately.

DM E

16

U M H

2

Version

Power supply

: M -

three phase

/

50

Hz / 400 V E - indoor unit

; C -

outdoor unit

Liebert_DM

Cooling capacity class

:

16 - 16

kW

Air path

: U -

upflow

; F -

downflow

; D -

duct

C - cooling only

; O -

with heater

; H -

with heater and humidifier

Page 9

2 Chapter 1 Overview

DM Series 16kW Air Conditioner User Manual

Infrared humidifier

The infrared humidifier is designed with a simple structure, which is easy for teardown, cleaning and maintenance. It is

adjustable to a wide range of water qualities, with fast startup and high humidifying efficiency.

Fan

The system uses centrifugal fan with high efficiency and reliability, large airflow and long blowing distance. With the

belt transmission mechanism, it is easy for maintenance.

Electric reheat

The indoor unit adopts the PTC electric heater with a quick heating rate and even heat quantity.

Sight glass

The sight glass is the window for observing the system refrigerant recycle, mainly the moisture content of system.

When the moisture content is too high, the color will change from green to yellow.

Filter drier

The filter drier can effectively eliminate the moisture in system within a period of time, filtrate the impurities generated

during long-term system operation and ensure normal system operation.

1.3.2 Outdoor Unit

The outdoor unit DMC16M2 condenser is applicable to Liebert_DM 16kW air-cooled series.

The DMC16M2 condenser is the newly standard configuration outdoor unit of the Liebert_DM 16kW AC. It adopts

corrugated finned tube heat exchanger which features high heat dissipation efficiency, convenient cleaning and

maintenance. External rotor axial fan with unique ‘sickle’ shape metal fan leaf has the superior aerodynamic property.

The six and eight pole fan, with specially designed draught ring, makes the air flow noise through the fan leaf

significant reduction. The high performance three-phase motor that is customized for the base station power grid

environment can be applicable to the wide voltage range and has the higher reliability. The advanced fan speed

control system regulates the voltage output by detecting the condensing pressure of the system to control the outdoor

fan speed and make the system pressure and heat load adaptable. It makes sure that the AC unit can operate stably,

reliably and efficiently.

1.3.3 Controlling System

1.3.4 Controller

The micro-processing controller of Liebert_DM 16kW air conditioner uses the LCD screen with blue backlight and 240

× 128 pixels. The user interface operation is simple. The multi-level password protection can effectively prevent illegal

operation. The controller also features power failure auto-restoration and high / low voltage protection function. The

operation time of components is available through the menus. The expert-level fault diagnosis system can display the

current fault information automatically, facilitating the maintenance. The controller can store 200 records of historical

events. The panel of micro-processing controller is shown in Figure 1-2.

LCD screen

UP button

ENTER button

DOWN button

ON/OFF button

ESC button

Running indicator

Alarm indicator

Figure 1-2 The panel of micro-processing controller

Page 10

Chapter 1 Overview 3

Liebert_DM 16kW Air Conditioner User Manual

1.4 Environment Requirements

1.4.1 Operation Environment

See Table 1-1 for the details.

Table 1-1 Operation enviroment requirement

Item

Requirement

Environment temperature

Indoor: 0℃~40℃

Outdoor:

-15℃~+45℃

Protection level (outdoor unit)

IP55

Altitude

<1000m. Above that, derating is required

Operation voltage range

380V (-10% ~ +15%), 3N ~ 50Hz

1.4.2 Storage Environment

Table 1-2 Storage enviroment requirement

Item

Requirement

Storage environment

Indoor, no dust

Environment humidity

5%RH ~ 85%RH (non-condensing)

Environment

temperature

-40℃~+70℃

Storage time

Total transportation and storage time should not exceed 6 months. Otherwise, the performance needs

to be re-evaluated

Page 11

4 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

Chapter 2 Mechanical Installation

This chapter introduces the mechanical installation of the Liebert_DM 16kW air conditioner, which includes

transportation, installation arrangement and installation procedures.

2.1 Transportation, Unpacking And Inspection

2.1.1 Transportation And Movement

Railroad transportation and shipping are the recommended means of transportation. If truck transportation is

unavoidable, choose roads that are less bumpy in order to protect the equipment.

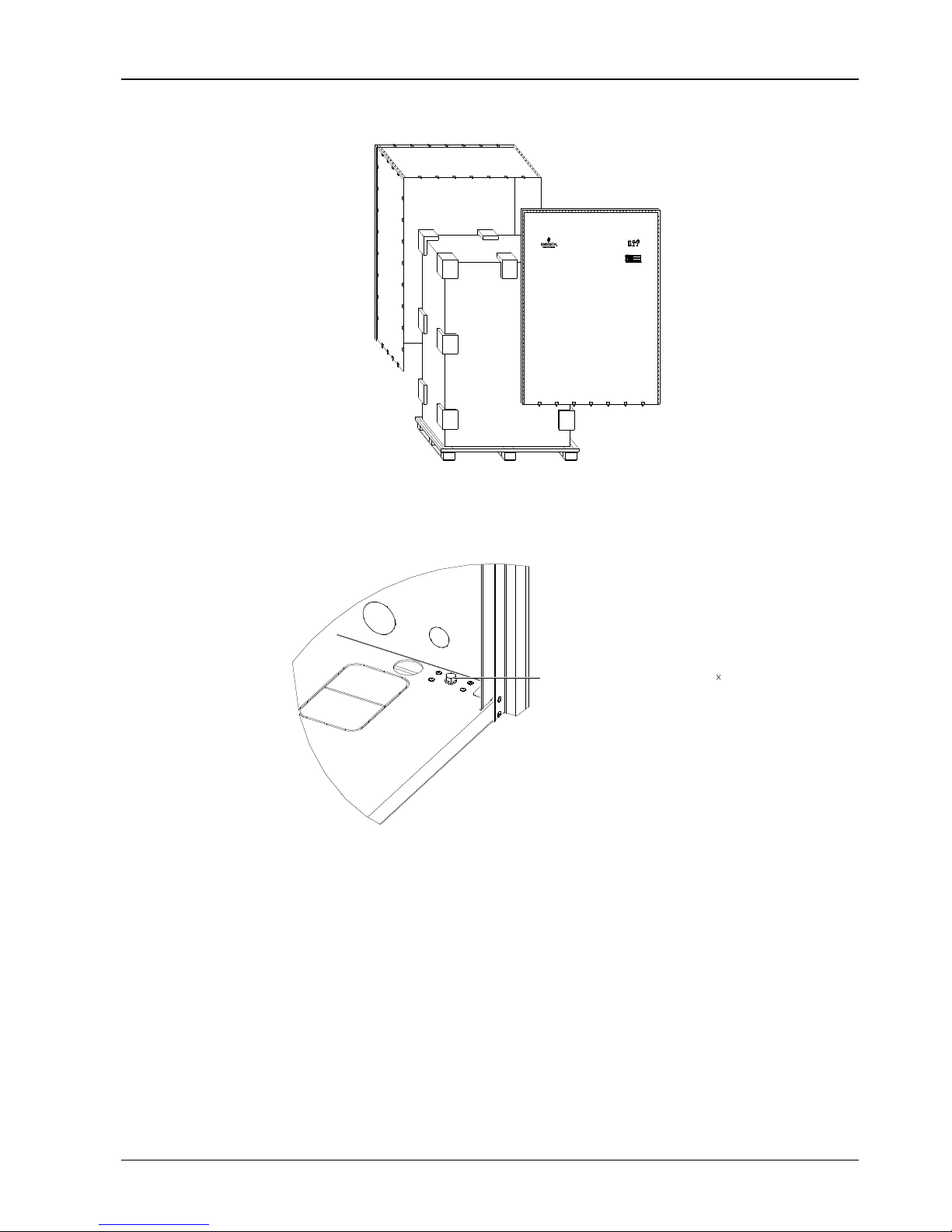

The Liebert_DM 16kW air conditioner is heavy (see Table 2-1 for the weight parameters). It is recommended to use

mechanical handbarrow such as electric forklift when unpacking and moving the equipment to the place most close to

the installation site. Insert the tines of the forklift below the pallet, as shown in Figure 2-1. Align the tines to the center

of gravity to prevent the unit from falling over.

Figure 2-1 Forklift removal

When moving the indoor unit, keep the obliquity within 75° ~ 105°, as shown in Figure 2-2.

105

75

Figure 2-2 The obliquity of indoor unit

2.1.2 Unpacking

Move the product to the place most close to the final installation site before unpacking the unit.

Follow the procedures below to unpack the unit:

1. Removing the side boards and top cover

Liebert_DM 16kW air conditioner uses the international packaging. You can use a hammer or straight screwdriver to

straighten the hook, as shown in Figure 2-3.

Figure 2-3 Straighten the hook

Page 12

Chapter 2 Mechanical Installation 5

Liebert_DM 16kW Air Conditioner User Manual

At first, straighten all the hooks that fix side board I, and remove side board 1. Then straighten all the hooks that fix

side board 2, and remove side board 2. At last remove top cover 3, as shown in Figure 2-4.

Kg

1790 x 950 x 2020mm

1816 x 976 x 2175mm

1

2

1

2

3

Figure 2-4 Remove side boards and top cover

2. Removing the pallet

Liebert_DM 16kW air conditioner is fixed onto the pallet with M10 × 70 screws, as shown in Figure 2-5. You can use

M10 open-end spanner, ratchet spanner or sleeve to remove the screws.

Fixed screw on base pallet (M10 70)

Figure 2-5 Screws on pallet

2.1.3 Inspection

After receiving the product, you should check against the packing list. If any parts are found missing, distorted or

damaged, please report to the carrier immediately. If any covert defects are found, please report to the carrier and the

distributor.

2.2 Installation Notes

To realize the designed performance and maximum product life, the installation must be correct. This section should

be used in conjunction with local industry standards for mechanical and electrical installations.

Liebert_DM 16kW air conditioner is designed for split floor installation. The indoor unit must be installed on the floor of

the equipment room or computer room, and the outdoor unit can be installed outdoors or on the floor of other rooms.

Before installation, make sure that the installation environment meets the requirements (see 1.4 Environment

Requirements) and the building should be transformed to accommodate the construction work of piping, wiring and

ventilation ducts.

Page 13

6 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

Follow the design drawings strictly when installing the equipment, and reserve the space for maintenance. The

manufacturer’s engineering dimensions drawings can serve as a reference.

2.3 System Installation Arrangement

2.3.1 General Arrangement

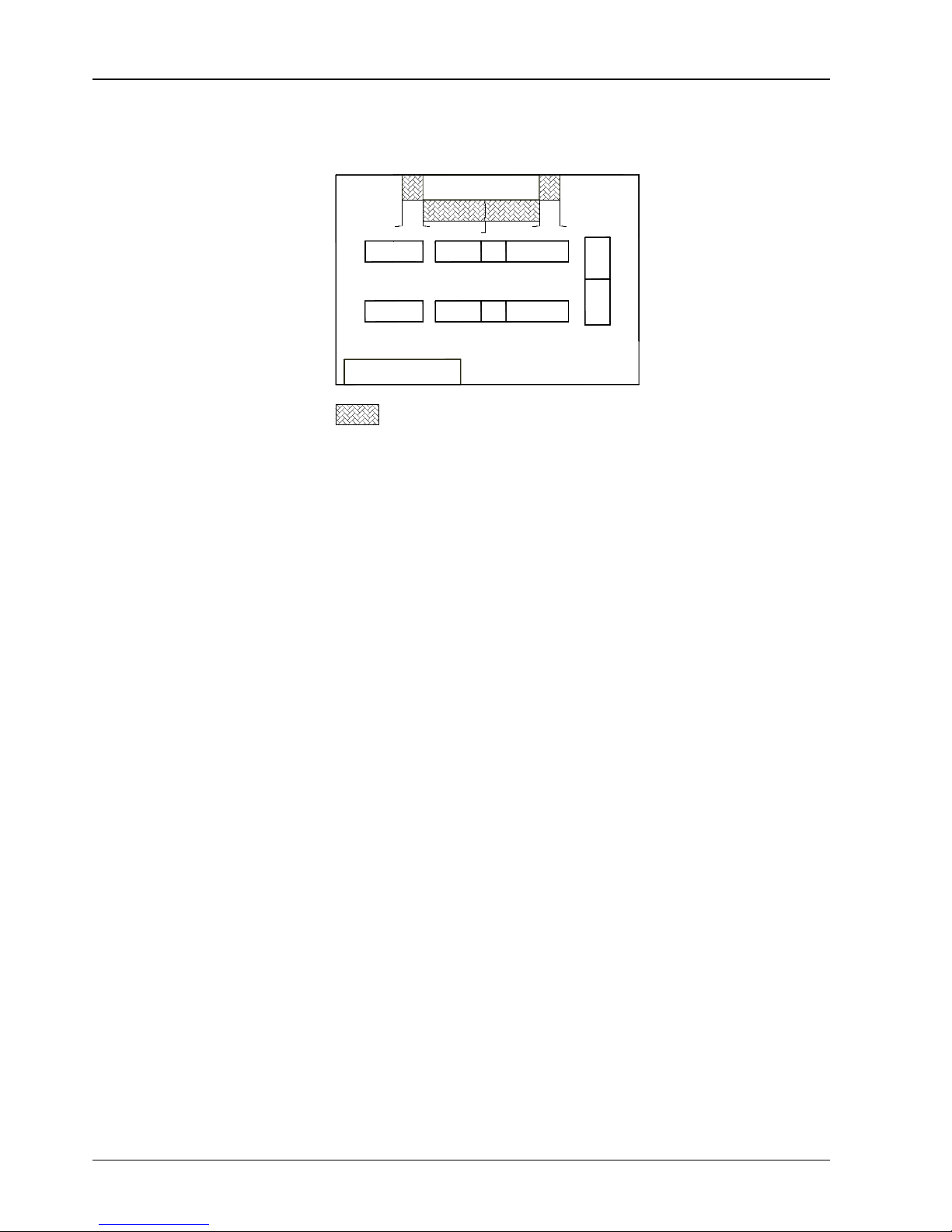

The general arrangement of Liebert_DM 16kW air conditioner is shown in Figure 2-6.

Scroll compressor

Service valve

Suction line

Discharge line

Ball

valves

Sensing bulb

Evaporator coil

Dehum solenoid valve

Thermal expansion valve

Sight glass

Filter drier

Solenoid valve

High pressure switch

Charging port

Low pressure switch

Condenser coil

Check valve

Distributor

Traps(every 7.5m

of vertical lift)

#1 circuit only

Figure 2-6 General arrangement diagram of air-cooled series

Note

1. : Factory piping.

2. : Field piping (by others).

3. *: Components are not supplied by Emerson but are recommended for proper circuit operation and maintenance.

4. +: Components are required when the equivalent length exceeds 30m.

2.3.2 System Installation Sketch Map

The installation mode of air-cooled series unit is shown in Figure 2-7 and Figure 2-8.

Note

1. If the condenser is installed higher than the compressor, an external back bend should be fitted to the suction line and liquid

return line of the condenser, so as to prevent the liquid refrigerant from flowing back when the condenser stops.

2. The top end of the back bend must be installed higher than the highest copper pipe of the condenser.

Page 14

Chapter 2 Mechanical Installation 7

Liebert_DM 16kW Air Conditioner User Manual

Slope dicharge

Back bend (higher than the highest copper pipe of condenser

)

Liquid line

( do not expose liquid line to sun )

Trap

Heat insulation floor

Seal

Outdoor unit

Indoor unit

Floor

Condenser

Humidifier

The earth surface

Max.7

.

5

m

Max

.20m

water in

water out

Supporting bar

Figure 2-7 Condenser installed higher than compressor

Supporting bar

Slope dicharge

Heat insulation floor

Seal

Outdoor unit

Floor

Condenser water out

Humidifier water in

The earth surface

Max.5m

Slope liquid

Indoor unit

Figure 2-8 Compressor installed higher than condenser

2.3.3 Mechanical Paremeters

Indoor unit

The mechanical parameters of the indoor unit are shown in Figure 2-9.

Page 15

8 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

874

256

54

1970

853

50

400

874

1970

853

50

Figure 2-9 Mechanical parameters of the indoor unit

Plenum

You can select the air supply plenum with grids for the upflow system. The appearance of the plenum is shown in

Figure 2-10. The dimensions are listed in Table 2-1.

C

B

A

Figure 2-10 Appearance of the plenum

Table 2-1 Dimensions of plenum

A B C

867 853

400 (600,optional)

Note

If the height of the plenum selected for air conditioner unit exceeds 600mm, consult the factory for non-standard production..

Outdoor unit

The appearance of outdoor unit is shown in Figure 2-11.

The dimensions and mechanical parameters of outdoor unit are shown in Figure 2-12.

Page 16

Chapter 2 Mechanical Installation 9

Liebert_DM 16kW Air Conditioner User Manual

风机

电控盒(内有风

机转速控制器)

压力传感器

Fan

Electrical control box(there is a fan speed

controller inside)

Pressure sensor

Figure 2-11 Appearance of outdoor unit

1385

992

664

Figure 2-12 Dimensions and mechanical parameters of outdoor unit

2.4 Installing Indoor Unit

2.4.1 Preparing Equipment room

The requirements of equipment room are as follows:

1. Damp proof and heat preservation must be done to make sure that the system can operate normally.

2. The equipment room should have good heat insulation and sealed damp proof layer. The damp proof layer of the

ceiling and walls must use polyethylene film, and the coating of the concrete wall and the floor must be damp proof.

3. Prevent the outdoor air from entering the equipment room, because the outdoor air that enters the equipment room

may increase the load of heating, cooling, humidifying and dehumidification of the system. It is recommended that the

inhalation of outdoor air be kept below 5% of the total indoor airflow.

4. All the doors and windows should be closed and the seams should be as narrow as possible.

2.4.2 Installation Space

Note

Liebert_DM 16kW air conditioner system will generate condensed water, and water leakage may damage the precision

equipment nearby. So do not install the system in the vicinity of any precision equipment, and the installation site must provide

draining pipes.

1. To ensure normal operation, the installation space for the indoor unit shall be capacious enough.

2. Too small space for the indoor unit will baffle the airflow, shorten the cooling cycle; the air supply and air exhaust

may mix, and the decibel may rise.

3. Do not place the indoor unit in a concave or at the end of a strip area.

4. Do not huddle multiple indoor units, lest there should be mixed airflow, unbalanced load and competitive operation.

Page 17

10 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

5. For the convenience of daily maintenance, do not install other equipment (such as smoke detector) above the

cabinet.

Figure 2-13 shows the installation place of the indoor unit.

Good place

Unit

Unit

Note:

The reserved maintenance space while installing

600600 600

Bad place

Figure 2-13 Installation place of indoor unit (unit: mm)

2.4.3 Requirement Of Maintenance Space

Leave more than 600mm of maintenance space in the front and two sides of the indoor unit, as shown in Figure 2-13.

Page 18

Chapter 2 Mechanical Installation 11

Liebert_DM 16kW Air Conditioner User Manual

2.4.4 Installation Procedures

The installation procedures of indoor unit are as follows:

1. Make the mounting base according to the dimensions in Figure 2-14 and the requirements in Table 2-2. You can

make it by yourself or contact Emerson Network Power Co., Ltd. for non-standard production.

161.5

530

161.5

67

680.5

820

760

853

H

46.5

Steel plate

Angle steel

Installation hole

for expansion bolt

4-Ф 14

cabinet installation hole

Rubber cushion(top)

Front side of cabinet

Rubber cushion (bottom)

Rear side of

cabinet

Rubber cushion (lateral)

46.5

Figure 2-14 Mounting base of one bay series

Table 2-2 Specifications of indoor unit mounting base

Item

Specification

Remark

Steel plate

100mm × 100mm × (5 ~ 6.5)mm

-

Angle steel

40mm × 40mm × 3mm

-

Rubber

cushion

Top

Thickness: 3mm ~ 5mm

-

Lateral

Thickness: 2mm ~ 3mm

-

Botton

Thickness: 10mm ~ 12mm

-

Installation hole for

expansion hole

-

Install the holes according to your requirements

H

One bay

H = 200mm (upflow unit)

H = 300mm (downflow unit, according to the floor

height)

1. The upflow unit do not need the flow deflector

2. The H dimension is only a reference. It should

be determined accroding to your actual

requirements during making the mounting base

Two bay

Three bay

Note:

The external side boards of the unit cannot bear weight. Take this into consideration while selecting angle steel and fixing holes

As the value of H exceeds 450mm, please strengthen the mounting base or contact Emerson Network Power Co., Ltd.

2. Lay a layer of rubber cushion on the top, lateral of mounting base and on the bottom of the steel plate respectively.

See Figure 2-18, Figure 2-19 and Figure 2-20 for their positions and see Table 2-3 for the thickness.

3. Identify the installation position. Fix the mounting base onto the mounting base according to the site conditions and

your requirement.

4. Fix the AC unit onto the mounting base with nuts, spring washers, flat washers and bolts.

2.5 Installing Outdoor Unit

2.5.1 Installation Notes

The installation notes of the condenser are as follows:

1. To ensure the heat dissipation capacity, install the condenser in the place with smooth air flow. Do not install it where

the coil of the condenser may be obstructed by dust and snow. Ensure that there is no steam or waste heat around.

2. If possible, the horizontal installation is recommended to reduce the noise.

3. The condenser should be installed as far away as possible from residential areas (≥15m).

Page 19

12 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

4. Be careful not to damage the waterproof layer and observe the local rules and regulations when the condenser is

installed on the roof of building.

5. Position the condenser higher than the indoor unit to ensure normal oil return.

6. Follow the installation arrows on the condenser for the installation direction.

2.5.2 Space Requirements

Note

1. A 4000mm clearance is required around the condenser air outlet.

2. The 600mm service spaces are required on the four sides of the condenser.

The condenser needs sufficient installation and service space around the installation place. The detailed space

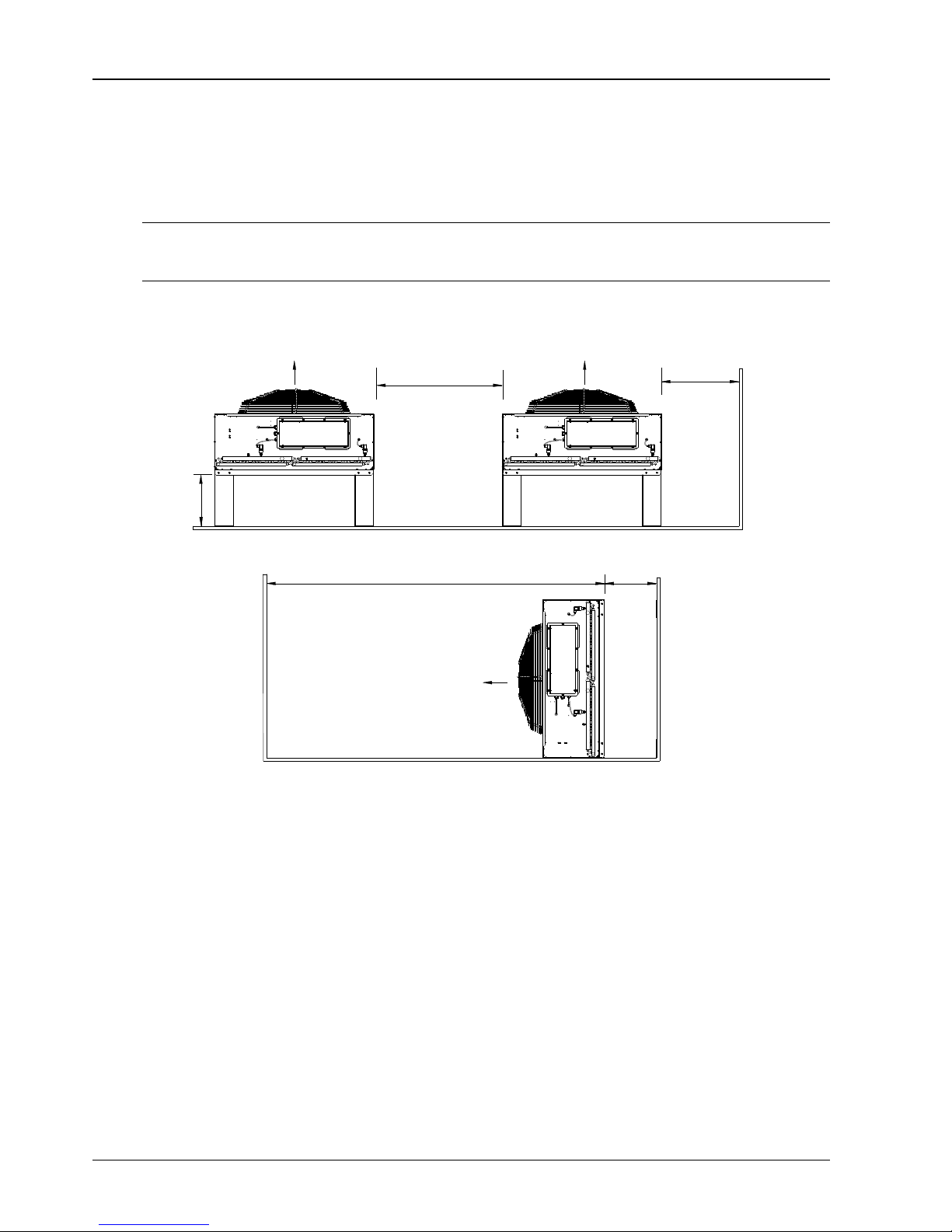

requirements are shown in Figure 2-15 and Figure 2-16.

600

1200

450

Air flowAir flow

Figure 2-15 Horizontal installation space requirement (unit: mm)

600

4000

Air flow

Figure 2-16 Vertical installation space requirement (unit: mm)

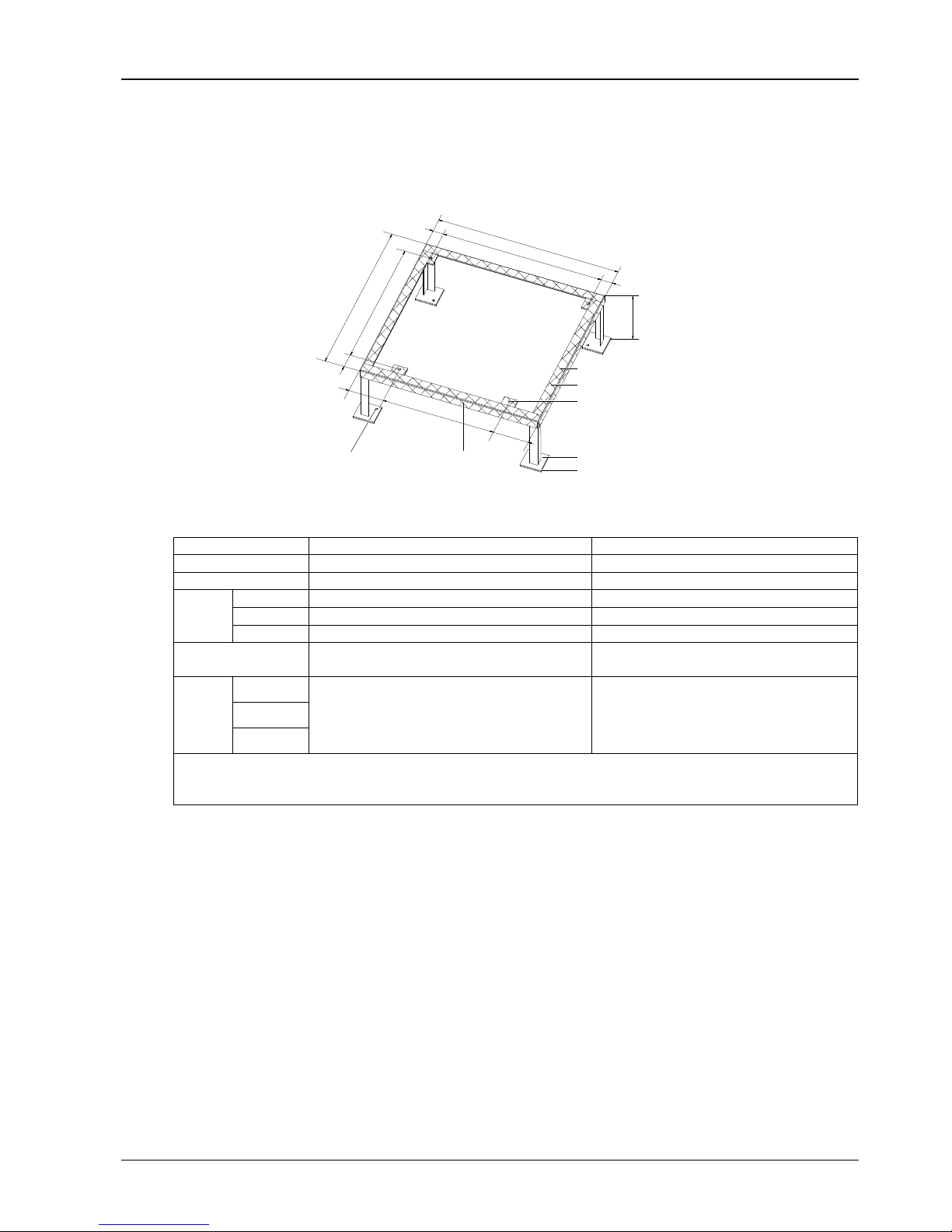

2.5.3 Mounting base dimension

Mounting base for horizontal installation

The mounting base for horizontal installation is shown in Figure 2-17 and the mounting base dimensions of each

model are listed in Table 2-3.

Page 20

Chapter 2 Mechanical Installation 13

Liebert_DM 16kW Air Conditioner User Manual

D

D

L'

D

H'

D

Amplified part figure

D

D

Installation holes

(8 holes in total )

Bottom view

455

455

148 B

148

C

Front view Side view

Figure 2-17 Mounting base dimensions for horizontal installation (unit: mm)

Table 2-3 Mounting base dimensions for horizontal installation (unit: mm)

Model

Dimension

(L' × H' × D)

B

C

DMC16M2

1126 × 837 × 53

980

691

Note

The installation holes are long and flat holes. It is recommended to use M10 × 20 bolts to fix the mounting base.

Mounting base for vertical installation

The mounting base for vertical installation is shown in Figure 2-18, and the dimensions of each model are listed in

Table 2-4.

250

102

452

490

a

2020

Installation

hole (4 pcs)

Amplified

part figure

Figure 2-18 Mounting base dimensions for vertical installation (top view) (unit: mm)

Table 2-4 Mounting base dimensions for vertical installation (unit: mm)

Model

Dimension ‘a’

DMC16M2

1280

Note

1. The installation holes are long and flat holes. It is recommended to use M10 × 20 bolts to fix the mounting base.

2. When one condenser needs to be installed on another one, the upper condenser must be installed on a rack and cushion pads

should be used between the condenser and the rack for damping. It is prohibited to stack two condensers and bolt them together

directly.

Page 21

14 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

2.6 Piping

All joints of the cooling pipes must be silver brazed. Standard industry procedures must be followed in selecting, laying,

and fixing the pipes, and in vacuuming the system and charging refrigerant. Take pipeline pressure drop, oil return to

the compressor and minimization of noise and vibration into consideration during the design and construction.

2.6.1 General

The recommended pipe sizes are ‘equivalent lengths’ (see Table 2-5 for equivalent lengths of partial components),

which has included the resistance brought about by bends. You should confirm that the sizes are appropriate for the

site conditions.

1. If the one-way equivalent length exceeds 30m, or if the vertical difference between indoor unit and outdoor unit

exceeds the values in Table 2-5, consult the factory before installation for confirmation whether extended components

are needed.

Table 2-5 Vertical difference between indoor unit and outdoor unit

Relative position

Value

Indoor unti lower than outdoor unit

Max.: +20m

Outdoor unit lower than indoor unit

Max.: -5m

2. The pipe sizes recommended in Table 2-6 are ‘equivalent lengths’, which has included the resistance brought about

by bends and valves. You should confirm that the sizes are appropriate for the site conditions.

Table 2-6 Equivalent lengths of partial components

Outer Diameter (OD) of

liquid pipe (inch)

Equivalent length (m)

90°bend

45°bend

T type three way

3/8

0.21

0.10

0.76

1/2

0.24

0.12

0.76

5/8

0.27

0.15

0.76

3/4

0.3

0.18

0.76

7/8

0.44

0.24

1.1

1-1/8

0.56

0.3

1.4

Note

A trap is required for every 7.5m of vertical lift. Please consult the factory for detailed information.

Connecting pipes

The pipes to connect include:

1. Cooling water drain-pipe of indoor unit

2. Water supply pipe of infrared humidifier

3. Connecting copper pipe (exhaust pipe and liquid return pipe) between indoor unit and outdoor unit

4. Installing extension subassembly (optional)

Connecting cooling water drain-pipe of indoor unit

The cooling water of infrared humidifier and evaporator is converged by the cross connector and drains through the

draining pipe, as shown in Figure 2-19. The OD of the pipe is 25mm. If the draining pipe is used by three or more units,

the minimal OD of the pipe should be 40mm.

Note

Because the humidifier contains boiling water, the plastic pipe must be rated higher than 90℃.

Page 22

Chapter 2 Mechanical Installation 15

Liebert_DM 16kW Air Conditioner User Manual

Water supply pipe of

infrared humidifier

Connector of condensation

water drain pipe

To condensation water

pan of evaporator

To infrared humidifier

water pan

Cross connector

Hose clamp

To condensation water

pan of evaporator

To the condensation

water drain pipe

Figure 2-19 Connection of drain pipe

Note

1. A Φ25 hose clamp is delivered as an accessory to connect the draining pipe.

2. When connecting the draining pipe, make sure that the U bend is installed vertically and the ‘U’ shape is not distorted, so as to

ensure that the cooling water can be drained immediately and effectively.

Connecting water supply pipe of infrared humidifier

The water pipes should be connected for the infrared humidifier. To facilitate maintenance, a strainer / non-return

isolation valve is fitted to the supply water pipe. The infrared humidifier water supply pipe reserves a copper pipe (OD:

6.35mm, see Figure 2-20) with a 1/4” copper nut at the end of the pipe. Take out of the 1/4” × 1/2” screw-thread copper

connector from the accessory bag and screw the connector onto the copper pipe. You can also select other connection

modes according to the site condition. Make sure the connection is well sealed to prevent leakage. The pipe pressure

is 100kPa ~ 700kPa.

Where the main pressure may rise above 700kPa, a pressure reducer should be fitted. Where the pressure falls below

100kPa, a water tank and pump system should be used.

Note

Main water supply connections must be made in accordance with local laws and regulations.

Water supply solenoid valve

Water level sensor

Water supply pipe

Ceramic terminal socket

Over-temperature

protection relay

Water pan (removable)

OD6.35mm

Over-temperature protection

switch (under the pan)

Water pan fixing screw

Water level regulator

Stainless steel bolt

Over-temperature

protection switch

Water outlet

A direction

Wiring cover plate

A direction

Water supply pipe

Figure 2-20 Infrared humidifier

Page 23

16 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

Connecting copper pipe (exhaust pipe and liquid return pipe) between indoor unit and outdoor unit

The indoor unit and outdoor unit are connected through welded copper pipes. The connection of discharge pipe / liquid

pipe of indoor unit is shown in Figure 2-21. Note that the ball valve must be wrapped with a wet cloth before welding. In

addition, many notes and instruction labels are pasted onto the base board and side board close to the ball valve. Do

not have them burned during the welding operation.

Note

The exposure time of system pipes do not exceed 15min. Otherwise, it will lead to the POE refrigeration oil moisture effect the

life of the key components and the system operation stability.

Horizontal sections of discharge pipes should be sloped downward from the compressor, with a slope of at least 1:200

(5mm down for each 1m run). Discharge pipes should be heat insulated where they are routed in the conditioned

space (including under a raised floor).

The liquid pressure drop should not exceed 40kPa (5psi ~6psi), provided that there is no loss of refrigeration. The

liquid line pressure drop is the sum of liquid flow resistance from the tubing and fitting (including the drier), plus the

loss of head pressure due to elevation above the condenser. If the liquid temperature is 38℃, the static pressure loss

is 11kPa (1.6 psi) per meter of lift.

Ball valve(liquid line)

Ball valve(discherge line)

Figure 2-21 Connection of discharge pipe / liquid return pipe

Considering the effect of the pipe OD to the system pressure drop, the pipe OD of indoor unit and outdoor unit should

be determined according to the specifications listed Table 2-7.

Table 2-7 Recommended pipe sizes

Eq.Lgth D L

10m

22

13

20m

22

13

30m

22

13

40m*

22

13

50m*

22

13

60m*

22

16

Note

1. Extension subassembly should be added to the “Eq.Lgth” marked with *.

2. D: discharge line, L: liquid line.

3. Consult factory if the line length exceeds 60m.

Installing the extension subassembly (be applicable to site installation)

When the equivalent length of pipe exceeds 30m, the extension subassembly should be installed. It is recommended

to install the solenoid valve of the extension subassembly to the outside project pipe of the ball valve on the liquid pipe,

or the outer side (or on the bottom) of the unit.

So, during installing the solenoid valve, you need not to cut the indoor unit pipes. After the whole system is installed,

you can open the ball valve to keep pressure and carry out vacuum operation, avoiding the moisture absorption of the

compressor refrigeration oil and ensuring the operation safety and life of the compressor. For installation valve of the

check valve, refer to Figure 2-6.

Page 24

Chapter 2 Mechanical Installation 17

Liebert_DM 16kW Air Conditioner User Manual

2.6.2 Charging refrigerant and adding refrigerant oil

1. Charging with refrigerant

The Liebert_DM 16kW air conditioner had been charged with 2bar nitrogen to keep pressure at the factory. In project

installation, see the unit nameplate for the initial charging capacity of Liebert_DM 16kW air conditioner.

If the connecting pipe between the indoor unit and the outdoor unit is longer than 10m, add refrigerant to the system in

order to ensure normal system operation.

The amount of the refrigerant is calculated through the following formula:

Refrigerant amount (kg) = unit length liquid pipe refrigerant amount (kg/m) × length of extended pipe (m)

See Table 2-8 for the unit length liquid pipe refrigerant amount.

Length of extended pipe (m) = Total length of liquid pipe (m) - 10m

Table 2-8 Unit length liquid pipe refrigerant amount of pipes with different ODs

Pipe OD (mm)

Unit length liquid pipe refrigerant

amount (kg/m)

Pipe OD (mm)

Unit length liquid pipe refrigerant

amount (kg/m)

9.52

0.060

19

0.261

12.7

0.112

22

0.362

16

0.181

28.6

0.618

2. Adding POE refrigerant oil

The added refrigerant will dilute the POE refrigerant oil in the system, undermining the lubricating and cooling effects

of the POE refrigerant oil. Therefore more POE refrigerant oil should be added. See the formula below:

Amount of refrigerant oil to be added (ml) = amount of added refrigerant (kg) × 22.6

2.7 Base/Side Panel Cutout Locations

Base cutout locations

Figure 2-22 and Figure 2-23 show the base figures with the side panel removed, and the distance between the dashed

lines and the rear panels is 25 mm, where is the mounting place of inner side panel.

530

160

72.5

80

200

45

760

7245109

798

680.5

161

140

D

IRWI

F

F

F

F

P

WO

/LL

WI

/DL

K K

4-Φ 13

25

25

50

Knock-out

Knock-out

2-Φ 35

Knock-out

2-Φ 64

Knock-out

2-Φ 40

IRWI: Infrared humidifier water in

D: Drain

P: Power cable entry (Φ30)

F: Unit set screw

K: Knock-out

LL/DL: Liquid line / discharge line (air-cooled models)

WI/WO: Condenser water inlet and outlet (water-cooled

models)

Figure 2-22 Base cutout location of upflow models

Page 25

18 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

160

530

680.5

72.5

45

143

80

45

140

103.5

75

45

81

72.5

70

kk

D

IRWI

WO/LL

WI

/DL

P

F

F

50

4-Φ 13

Knock-out

Fan aperture

2-Φ 35

Knock-out

2-Φ 64

Knock-out

2-Φ 40

P: Power cable entry

D: Drain

IRWI: Infrared humidifier water in

K: Knock-out (250×120)

F: Unit set screw

LL/DL: Liquid line / discharge line (air-cooled models)

WI/WO: Condenser water inlet and outlet (water-cooled models)

Figure 2-23 Base cutout location of downflow models

Side panel cotout locations

The knock-out dimensions of side panels are shown in Figure 2-24 and Figure 2-25.

95

20

59

50.8

53

45

49.2

4-Ф 64敲落孔

2-Ф 25敲落孔

4-Φ64 knock-out

2-Φ25 knock-out

Figure 2-24 Left side panel

79

.

8

160

.

2

50

145

4-Ф35

knock-out

Figure 2-25 Right side panel

Page 26

Chapter 2 Mechanical Installation 19

Liebert_DM 16kW Air Conditioner User Manual

2.8 Removing Transport Fastener And Vibration Absorber

In order to protect partial components from damaging and distorting due to bumping, impact and resonation, fasteners

and vibration absorbers are mounted at certain locations before delivery. Remove the fasteners and vibration

absorbers before installation and commissioning.

Removing transport fixing plate from the compressor

To reduce the compressor operation vibration and noise, the vibration absorbing cushions are added to the

compressor base. However, such device cannot best restrain the equipment vibration during the transportation,

resulting in loosened connections and wearing of certain parts. To counteract such effect, three L shaped plates are

added to the compressor base during the transportation, as shown in Figure 2-26.

Fixing plates

Figure 2-26 Compressor fixing plates

After the installation and before the commissioning, remove the three fixing plates, then restore the washers and bolts.

The fastening torque of the bolts is (12 ± 1)N.m.

Removing transport fastener of fan compoents

1. Upflow unit

The motor base of the fan is designed with a semi-free self-tension structure to minimize the fan operation noise and

prolong the belt life. During the transportation, to protect the semi-free structure from failing or collapsing due to

resonation, the upflow unit is especially fastened with bolts (left and right symmetrical, two at either side), as shown in

Figure 2-27. You should cut the binding string on the belt and remove the four fixing bolts before the power-on

operation, otherwise the fan could be damaged and even cause personal injury. Removing the bolts requires the

collaboration of two persons, with one holding the motor and the other removing the bolts.

Note

After you open the front door of unit, you will see a warning label concerning bolt removal on the sealing panel of the fan. Do

remove the bolts by following the preceding instructions.

Transportation bolts

(two on either side)

Binding string

Figure 2-27 Fixed bolts and trap wrench of transport fan components

Page 27

20 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

2. Downflow unit

During the transportation, some cushion foam is inserted into the triangle formed by the motor base and the fan.

Remove the foam before the power-on operation.

Warning

Never put hands into the triangle gap between the motor base and fan.

Removing the transport components of infrared humidifier

Warning

Removal of the transport protection foam may cause fire.

In order to protect the infrared humidifier pump from rupturing during transportation, the protection foam is fitted to the

infrared humidifier components before delivery. Before the unit operation, remove the protection foam and connect the

cable of the high water-level test switch. If you do not operate following the instruct bellow, the infrared humidifier will

not work normally and even the fire may be caused.

The detailed operation procedures are as follows:

1. Cut the cable tie and remove the protection foam fixed under the pump, as shown in Figure 2-28 and Figure 2-29.

High water-level

test switch cable

Cable tie

Protection foam is at the

bottom of metal sheet

Cable hole of high water-level

test switch cable

Figure 2-28 Removing protection foam

Protection foam

Pump

Protection foam

Figure 2-29 Protection foam

2. Remove four self-tapping screws and remove the front cover plate of the infrared humidifier connection box, as

show in Figure 2-30.

Page 28

Chapter 2 Mechanical Installation 21

Liebert_DM 16kW Air Conditioner User Manual

Remove secf-tapping

screw (4 pcs)

Remove front cover plate

of infrared humidifier

connection box

Figure 2-30 Removing front cover plate of infrared humidifier connection box

3. Lead the cable of high water-level test switch through the cable hole (see Figure 2-28) and insert the cable terminal

into the HWA cable terminal in the connection box, as shown in Figure 2-31.

HWA cable

Terminal inserting

High water-level test switch cable

Figure 2-31 Inserting cable terminal of high water-level test cable into HWA cable terminal

4. Restore the front cover plate of the infrared humidifier connection box and fasten the self-tapping screws.

5. Remove the rubber string bound on the floating pole and the high water-level test switch.

The floating pole and the infrared humidifier high water-level test switch are tightly bound together with a rubber string

before delivery, as shown in Figure 2-32. Remove the rubber string before the unit operation. Otherwise, the unit

cannot test the high water-level alarm.

Rubber string

Floating pole

Figure 2-32 Floating pole of high water-level test switch and rubber string positions

Removing fastener of pipes

During the transportation, to prevent the long copper pipes from scratching the metal plate and get damaged, the pipes

are cushioned with foam or bound up before delivery. Remove those materials before the power-on commissioning.

Page 29

22 Chapter 2 Mechanical Installation

DM Series 16kW Air Conditioner User Manual

2.9 Component Adjustment

Water level regulator

The water level regulator of the infrared humidifier is screwed down completely. Before the commissioning, unscrew

the water level regulator till its head is 45mm above the water pan bottom, as shown in Figure 2-33.

45mm

Figure 2-33 Water level regulator adjustment

2.10 Installation Inspection

After the mechanical installation is completed, you should check:

1. A certain space is left around the unit for maintenance.

2. The equipment is installed vertically and the installation fasteners have been fixed.

3. The pipes connecting the indoor unit and outdoor unit have been connected, and the ball valves of indoor unit and

outdoor unit have been opened completely.

4. The condensate pump (if needed) has been installed.

5. The draining pipe has been connected.

6. The water supply pipe for infrared humidifier has been connected.

7. All pipe joints have been fixed.

8. The transport fasteners have been removed.

9. The water level regulator of the infrared humidifier has been unscrewed to the required height.

10. The debris (such as transportation material, structure material and tools) inside or around the equipment has been

cleaned.

After confirming the preceding points, you can then start the electrical installation.

Page 30

Chapter 3 Electrical Installation 23

Liebert_DM 16kW Air Conditioner User Manual

Chapter 3 Electrical Installation

This chapter introduces the electrical installation of the Liebert_DM 16kW air conditioner, which includes work

introduction, installation notes, wiring of indoor unit, connecting power cables for outdoor unit and installation

inspection.

3.1 Work Introduction And Notes

Wires to connect on-site

1. The power cable of indoor unit.

2. Outdoor unit (air-cooled): standard signal cable.

3. Input and output control cables.

Notes

1. The connection of all power cables, control cables and ground cables should comply with local electrician

regulations.

2. See the equipment nameplate for the full load current. The cable sizes should meet the local wiring rules.

3. Mains supply requirement: 380Vac, 50Hz.

4. The electrical installation must be completed by trained personnel.

5. Before the wiring, use a multimeter to measure the power supply voltage and make sure that the power supply has

been switched off.

3.2 Wiring Of Indoor Unit

3.2.1 Locating Electrical Interface Of Indoor Unit

Open the front door of the indoor unit, and you will see the interfaces of the electrical control box, as shown in Figure

3-1.

电源接口

N/PE端子排

控制接口

Power interface

Control interface N/PE terminal block

Figure 3-1 Interfaces of electrical control box of one-bay system

3.2.2 Connecting Power Cable Of Indoor Unit

The power interfaces are located as shown in Figure 3-1, Figure 3-2 and Figure 3-3. The power interface is amplified

as shown in Figure 3-4. Connect terminals L1 ~ L3, N, and PE to their counterparts of external power supply.

Fix the input cables to the cable clamp, as shown in Figure 3-5. As for the cable specification, see the unit maximum

operation current in Table 3-1.

Page 31

24 Chapter 3 Electrical Installation

DM Series 16kW Air Conditioner User Manual

L

1

L2

L3

NNPE

PE

Cable clamp

Figure 3-2 Amplified figure of power supply interface

Figure 3-3 Cable clamp

Note

The cable sizes should meet the local wiring rules.

Table 3-1 System maximum operation current (unit: A)

Model

Maximum operationi current

upflow unit 23.1

downflow unit

23.1

3.2.3 Connecting Control Cables

The control interfaces are located as shown in Figure 3-1, Figure 3-2 and Figure 3-3. The control interface is amplified

in Figure 3-6. The upper part of the terminal block is connected to the system, while the lower part is used as user

control signal interfaces.

94

37C

75

89

76

8459

85 51

37

96959197

37B

38C

38B

9392 8180

2438 50

72

71

77

1211

78

5655 70

73

71A

70A

5882

83

88

42 44

43

41

4143838889

75

76 949596 97 91 92 93 80 81 11 12

77

78 72 73

42 38C44 8482 58 59

37C

85

51

38

38B

37B 37 24 50 5655

70

70A

71 71A

Short connecting line, no short line if

the remote shut down is connected

50,51,55 is defined alarm terminals,

Connecting with common alarm

Connecting with smoke sensor,

Alarm output of smoke sensor

24# is its common terminal

91# is its common terminal

Figure 3-4 Control interfaces

Note

The wiring personnel must take antistatic measures before wiring the control cables.

Water-under-floor sensor

Every unit is supplied with one water sensor. You should connect one end of the sensor to terminal 51, and the other

end to the common terminal 24. The number of sensors in parallel connection is not limited, but there is only one water

alarm for each unit.

Page 32

Chapter 3 Electrical Installation 25

Liebert_DM 16kW Air Conditioner User Manual

Remote shutdown

Terminals 37 and 38 can be connected to the remote shutdown switch. By default, terminals 37 and 38 are shorted.

Remove the shorting wire if a remote shutdown signal is needed.

Note

When terminals 37 and 38 are open, the unit is shut down.

When two remote shutdown signals are to be connected, connect the connection cable 39-3# of the control board to

terminal 37B#, instead of 37#, and series connect the terminals 38B# and 37# (the cable is not provided). Then the

second remote shutdown signal is connected through the terminals 37B# and 38B# on lower side of the terminal block.

When three remote shutdown signals are to be connected, connect the connection cable 39-3# of the control board to

terminal 37C#, instead of 37#, and series connect the terminals 38B# & 37# and 38C# & 37B# (the cables are not

provided). Then the second and third remote shutdown signals are respectively connected through terminals 37B# &

38B# and 37C# & 38C# on lower side of the terminal block.

Smoke sensor

The smoke sensor can be connected to terminals 91, 92 and 93, with 91 being the common terminal, 92 being the NO

contact, and 93 the NC contact. You can select NO or NC contact according to the smoke sensor logic.

Terminals 80 and 81 are used to output external alarms for the smoke sensor.

Control signals of outdoor unit

Terminals 70, 71, and terminals 70A, 71A are two pairs of control signal input terminals of outdoor unit. Their on/off

state is the same as that of the compressor.

Customized alarm terminals

Terminals 50, 51, 55 can be connected to three kinds of sensors, including fire sensor and water sensor. Terminal 24 is

the common terminal. After connecting sensors to the terminals, you should set the corresponding customized alarm

through the microprocessor. See

错误!未找到引用源。错误!未找到引用源。

for details. When the contactor is open

and there is no external alarm, the input state of the customized terminal is open. But when the contactor is closed and

the external alarm is raised, the input state of the customized terminal will be shorted. At this time, the system will raise

sirens, and the LCD of the controller will display the alarm information. If a PC installed with Emerson monitoring

software is connected to the system, the alarm will also be displayed on the PC.

The terminals can be defined as follows:

Terminals 50 and 24: remote alarm.

Terminals 51 and 24: water sensor (by default).

Terminals 55 and 24: safe switch for condensation water pump (optional).

External alarm terminals

Terminals 75 and 76 can be used as external alarm terminals. They are controlled by the external alarm relay K3 on

the circuit board. They output signals to external alarm devices, such as the alarm indicator. When critical alarm occurs,

the contactor will close to trigger remote alarms, send signals to the building management system or dial the paging

system automatically. The power supply of the external alarm system is user self-prepared.

Refer to Appendix 2 Circuit Diagram of DME16 for the detailed definition of other terminals.

3.2.4 Connecting Extension Component Solenoid Valve (For Site Installation)

The extension subassembly solenoid valve has three connection cables, two of which are control cables (brown) used

to connect with the corresponding terminals of control board and one of which is ground cable used to connect the

ground terminal block. Note that the solenoid valve cables of 1# system and 2# system in double system unit should

be remarked for voiding wrong connection. For detailed terminal positions, refer to the LLSV1 and LLSV2 connection

terminal No. in Appendix 2 Circuit Diagram of DME16.

Page 33

26 Chapter 3 Electrical Installation

DM Series 16kW Air Conditioner User Manual

3.3 Wiring Of Outdoor Unit

3.3.1 Connecting Power Cables For Outdoor Unit

1. Identifying the cable specifications

Select the power supply cables and the start/stop signal cables of the condenser according to the fan rated operation

current (see Table 3-2) and the site conditions, such as the distance between indoor unit and condenser.

Table 3-2 Operation current of fan under 380V voltage

Condenser Model

Rated current (A)

DMC16M2

1.65

Note

1. The 20AWG (0.52mm2) start / stop signal cable of the condenser is recommended.

2. The protected tube or shielded line is required for the outdoor part of the connection cable between the indoor unit and the

condenser. The ground cable should be connected to the ground nearby, and the length cannot exceed 3m.

3. The cables cannot contact with hot objects, such as the copper tube and water pipe without insulation, to avoid damaging the

insulation layers.

4. The cables should be connected in accordance with the local regulations.

2. Connecting cables

See Figure3-5 and Appendix 3 Circuit Diagram of DMC16M2 for the connections of external power cables.

Accessing terminal of external Fan speed controller board

power supply (single fan)

Water joint of external

power cables

Figure 3-5 Connection figure of single fan external power cables (taking LDF42 for example)

Note

1. The external power lines and compressor signal lines enter the electrical controlling box through the water joint of external

power cables whose inside diameter is Φ10mm.

2. After connecting the external power lines, the waterproof sealant treatment is required to ensure the good waterproof

performance of electrical controlling box.

3. The phase order of three-phase AC input (L1, L2, L3) must be correct. Otherwise, the fan speed controller will generate the

phase loss alarm, and there will be no AC output.

3.3.2 Connecting Control Signal Cables Of Outdoor Unit

The wiring terminals are located on the fan speed controller board (see Figure3-5). Their distribution is shown in

Figure3-6 and the definitions are listed in Table3-3. Refer to Appendix 3 Circuit Diagram of DMC16M2 for detailed

connections.

Page 34

Chapter 3 Electrical Installation 27

Liebert_DM 16kW Air Conditioner User Manual

J9

J3(HP1)

J4(HP2)

J14(HP2)

J15(HP1)

J5(Out Temp)

J11(RS232)

J7(Fan1Sta)

J10(Fan2Sta)

J6(CompSta)

W

V

U

L3

L1

L2

PE

J8(SCRTemp)

J17

J18

J1

D16 D22

D15

LCD and keys

Figure 3-6 Layout of wiring terminals

Table 3-3 Definitions of wiring terminals

Silk print

Definition

Definition of pins

J1

AC I/O terminal

PE: protection earth

L1, L2, L3: three-phase AC input

U, V, W: three-phase AC output, which connects with the

power supply terminals

The middle terminal pin without logo is reserved

J9

Passive dry contactor relay output (for the

power switch of fan power supply contactor)

Pin 1: normally closed terminal of relay, which is reserved

Pin 2: common terminal of relay, which is used for AC input

Pin 3: normally open terminal of relay, which is used for AC

output

J3 (HP1)

Input terminal of voltage pressure sensor 1

(spare)

Pin 1: positive terminal of 5V power

Pin 2: input terminal of 0.5V ~ 4.5V pressure voltage signal

Pin 3: negative terminal of 5V power

J4 (HP2)

Input terminal of voltage pressure sensor 2

(spare)

J15 (HP1)

Input terminal of current pressure sensor 1

Pin 1: positive terminal of 12V power

Pin 2: input terminal of 4mA ~ 20mA pressure current signal

J14 (HP2)

Input terminal of current pressure sensor 2

J17, J18

Shorting jumpers of current pressure sensor

Current pressure sensor: the short circuit ring must be installed

on the shorting jumpers

Voltage pressure sensor: the open state of short jumpers must

be kept

J5 (Out Temp)

Input terminal of environment temperature

sensor (spare)

Pin 1: input terminal of temperature signal

Pin 2: signal ground

J11 (RS232)

Serial communication interface (used for

maintenance)

Pin 1: communication ground

Pin 2: reception terminal of communication

Pin 3: transmission terminal of communication

J7 (Fan1Sta)

Detecting terminal of fan 1 over temperature

state

Pin 1: output terminal of 19V AC signal

Pin 2: return terminal of 19V AC signal

J10 (Fan2Sta)

Detecting terminal of fan 2 over temperature

state

J6 (CompSta)

Detecting terminal of compressor state

Note :

J8 (SCRTemp) in Figure3-6 is the interface of fan speed controller board, and not to be used by users

3.3.3 Installation Inspection

After the electrical installation is completed, you should check and confirm that:

1. The power resource voltage meets the rating on the nameplate.

2. The system electric loop has no open circuit or short circuit.

3. Power cables and grounding cables are connected to the circuit breakers, indoor unit and outdoor unit.

Page 35

28 Chapter 3 Electrical Installation

DM Series 16kW Air Conditioner User Manual

4. The ratings of the circuit breakers and fuses are correct.

5. The control cables are properly connected.

6. All the cables connections are fastened, with no loose screws.

You can start commissioning after confirming the preceding points.

3.3.4 HMI

The fan speed controller can realize the HMI function through indicators, RS232 serial communication port, keys and

LCD.

Indicators

There are three indicators (see Figure 3-6) on the fan speed controller board. See Table 3-4 for the functions of

indicators.

Table 3-4 Functions of indicators

Silk print

Definition

Color

State

Function

D16

Power indicator

Green

On

The CPU circuit of fan speed controller board is

supplied with 5V power

Off

There is a faulty on fan speed controller board

D22

Run indicator

Green

On or off

There is a faulty on fan speed controller board

Blinking at 1Hz (slowly)

The system is running normally without alarm

Blinking at 5Hz (quickly)

There is an alarm or the compressor is shut down

D15

Power switch controlling

indicator of AC contactor

Red

On

The control switch which supplies the AC contactor

with the driving power is open

Off

The control switch which supplies the AC contactor

with the driving power is closed

RS232 serial communication port

RS232 serial communication port provides a port to interface the computer using factory-defined protocol. It is used in

factory commissioning and maintenance.

Keys and LCD

The keys and LCD, which can realize the functions in Table 3-5, provide the HMIs for maintenance personnel. Refer to

错误!未找到引用源。错误!未找到引用源。

for the detailed operations of keys and LCD HMI.

Table 3-5 Function descriptions of keys and LCD

NO.

Function

Description

1

Inquire the acquisition

data in real time

The inquiried acquisition data includes condensing pressure, environment temperature, SCR

temperature, output percentage

2

Inquire the current

alarm data in real time

The inquiried current alarm data includes phase loss alarm, SCR over temperature, fan 1 over

temperature, fan 2 over temperature, pressure sensor failure, EEPROM read fault alarm, SCR

temperature sensor failure and abnormal frequency

3

Inquire the historical

alarm data in real time

The present 100 historical alarms saved can be inquiried

4

Change the configured

parameters in real time

The changeable configured parameters include running pressure, pressure controlling range,

minimum voltage, maximum voltage, fan number, pressure sensor type; or resume the default

values

The keys and LCD are on the upper right corner of the fan speed controller, as shown in Figure 3-6. Their appearance

is shown in Figure 3-7.

LCD

ENT key

DOWN key

ESC key

UP key

Figure 3-7 Keys and LCD

Page 36

Chapter 3 Electrical Installation 29

Liebert_DM 16kW Air Conditioner User Manual

3.3.5 Operation Description Of HMI

Initial Interface

The LCD will display alternately ‘F01’ and the bigger one of condensing pressure 1 and condensing pressure 2 when

the fan speed controller is powered on initially. The ‘F01’ is the maximum pressure logo. However, the pressure value

will be displayed as ‘88.8’ on the LCD upon the following occasions:

1. The pressure sensor is not installed,

2. The short jumper cap of current pressure sensor is not installed.

3. The pressure sensor is disabled.

The show order is shown in the following figure (the ‘16.1’ is only an example, and the actual value is determined by

the sampling result).

F01 16.1 F01 16.1

Main Menu Interface

Press the ESC key on the initial interface, the main menu interface will appear on the LCD. The main menu interface

includes the analog main menu interface, current alarm main interface, historical alarm main menu interface and

configuration main menu interface. Press the UP key and DOWN key to select the different main menu interface, and

press the ENT key to enter the submenu of the current main menu on the main interface. The switching operation

processes and orders of the main menus are shown in the following figure.

F A H C

DOWN keyDOWN key

DOWN key

UP

key

UP

key

UP

key

DOWN key

UP key

Configuration main

Analog main Current alarm

main interface

Historical alarm main

menu interface

menu interface menu interface

- -

- - - - - -

Page 37

30 Chapter 3 Electrical Installation

DM Series 16kW Air Conditioner User Manual

Analog main menu interface

Press the ENT key to enter the analog submenu interface when the current main interface shows ‘F--’ (the symbol of

analog main menu). The switching operation processes and orders of the analog submenu are shown in the following

figure.

ENT key

DOWN key

ESC key

UP key

F

F01

F02

F03

F04

F05

F06

16.1

16.1

.0

-15

60

88

Analog main menu

Analog submenu shows

Initial interface

Analog ID definitions

F01: The maximum pressure between the

F02: Pressure 1

F03: Pressure 2

F04: Ambient temperature

F05: SCR temperature

F06: Output voltage percentage

pressure 1 and pressure 2; 88.8 will be

shown when the pressure sensor is disabled

the ID and values circulary

- -