Page 1

Technical Data

Manual

Keeping Business in Business

Liebert

LPN: SLE CP TDM E.1

HPN: 272030 (17/6/99)

Challenger

Plus

Page 2

Page 3

Ta ble of Con tents

No men cla ture 1

In tro duc tion 2

Stan dard fea tures - all models 6

Stan dard fea tures - DX mod els 9

Stan dard fea tures - chilled wa ter mod els 12

Op tional fea tures - all mod els 13

Air cooled data 18

Water cooled data 20

Air cooled dual source data 22

Water cooled dual source data 24

Free cool ing data 26

Chilled wa ter cooled data 28

Con denser match ing ta bles 30

Chilled wa ter data - all mod els 31

Elec tri cal data - all mod els 32

Sound data - all mod els 37

Tech ni cal data - op tional com po nents 39

Di men sional data - all mod els 47

Page 4

Page 5

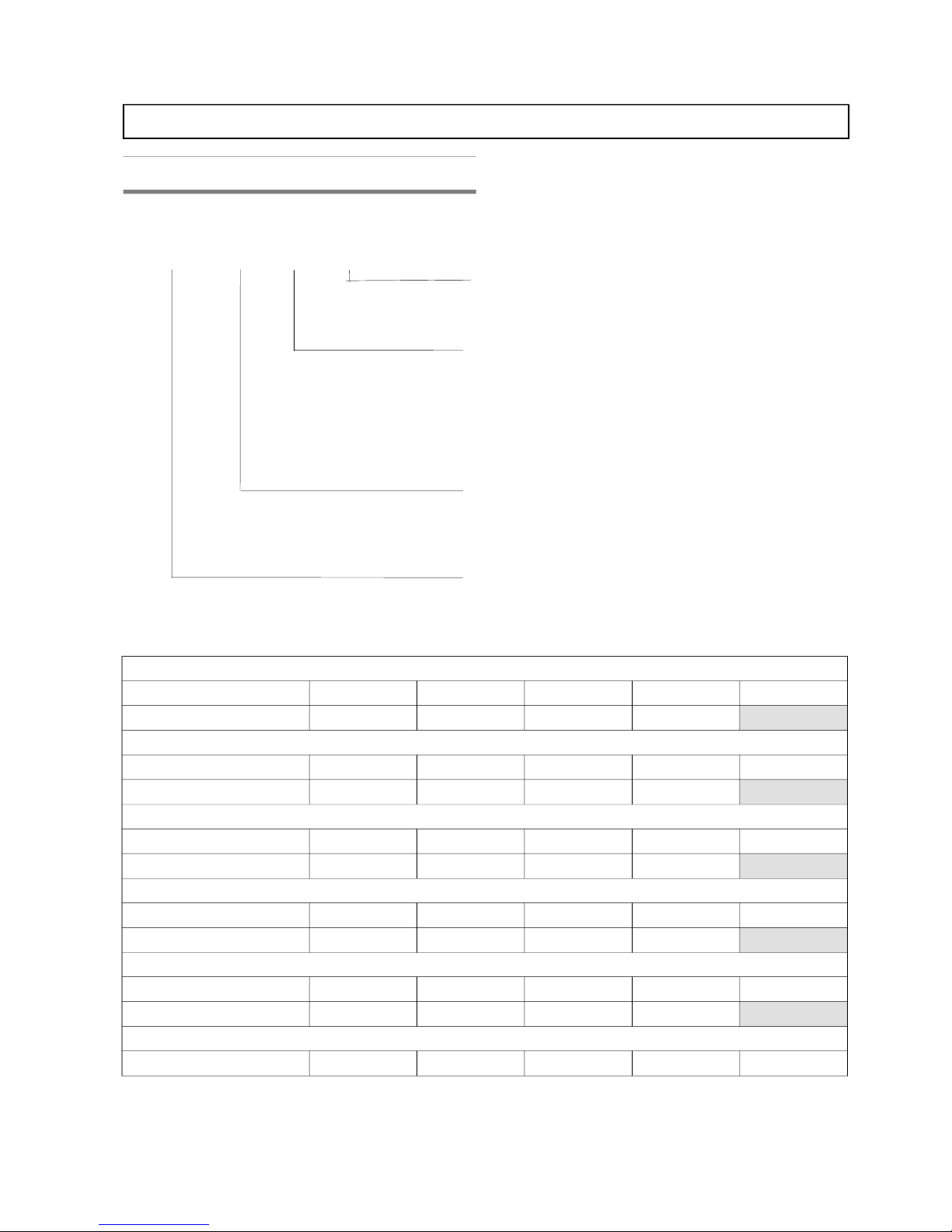

No men cla ture

System nomenclature

SLE CP TDM E.1 (06/99) 1

Challenger Plus - Technical Data Manual

20 DA

Air Distribution:

D = Downflow

U = Upflow

System type:

A = Air Cooled

W = Water/ Glycol Cooled

F = Freecooling

D = Dual Source Air Cooled

H = Dual Source Water Cooled

C = Chilled Water Cooled

Model Number:

Nominal capacity in kW at 240C, 50% RH

Liebert Challenger Plus Unit

The range of mod els is as fol lows:

Air Cooled

Sin gle Cir cuit CP20A U/D CP24A U/D CP28A U/D CP34A U/D CP40A U/D

Dual Cir cuit CP26A U/D CP32A U/D CP42A U/D CP46A U/D

Wa ter /Gly col Cooled

Sin gle Cir cuit CP20W U/D CP24W U/D CP28W U/D CP34W U/D CP40W U/D

Dual Cir cuit CP26W U/D CP32W U/D CP42W U/D CP46W U/D

Free cool ing

Sin gle Cir cuit CP20F U/D CP24F U/D CP28F U/D CP34F U/D CP40F U/D

Dual Cir cuit CP26F U/D CP32F U/D CP42F U/D CP46F U/D

Dual Source Air Cooled

Sin gle Cir cuit CP20D U/D CP24D U/D CP28D U/D CP34D U/D CP40D U/D

Dual Cir cuit CP26D U/D CP32D U/D CP42D U/D CP46D U/D

Dual Source Wa ter Cooled

Sin gle Cir cuit CP20H U/D CP24H U/D CP28H U/D CP34H U/D CP40H U/D

Dual Cir cuit CP26H U/D CP32H U/D CP42H U/D CP46H U/D

Chilled Wa ter Cooled

Sin gle Cir cuit CP25C U/D CP35C U/D CP50C U/D CP60C U/D CP70C U/D

CP

Page 6

In tro duc tion

Pre ci sion en vi ron mental con trol may be de fined as the

si mul ta ne ous con trol of air tem pera ture, hu mid ity,

dis tri bu tion and clean li ness on a con tin ual, around- the- clock

ba sis.

Con ven tional build ing or ‘co mfort’ sys tems, as they are

called, are not de signed for this 24- hour, year- round us age;

they lack the abil ity to pro vide the pre ci sion and re li abil ity or

‘close con trol ‘ that is so criti cal to many ap pli ca tions.

The Lie bert Chal lenger Plus is a new se ries of air

con di tion ers de signed by Lie bert to meet the re quire ments of

data proc ess ing cen ters and other small and me dium sized

criti cal ar eas.

The Challenger Plus se ries com prises both di rect ex pan sion

units and chilled wa ter units. Cool ing ca paci ties range from

20 to 70 kW, for a to tal of 54 mod els. Di rect ex pan sion units

are equipped with com pli ant scroll com pres sors. The de sign

of the scroll com pres sor, en sures a con stant re frig er ant

pres sure, thus im prov ing re li abil ity, en ergy con sump tion and

sound emis sion.

Liebert technology and energy

efficiency

Lie bert has be come a world leader in pre ci sion

en vi ron mental con trol sys tems by pro vid ing maxi mum

en ergy ef fi ciency with out com pro mis ing pre ci sion and

re li abil ity.

Lie bert takes a no- compromise ap proach to en vi ron mental

con trol sys tem de sign. All en hance ments to en ergy

ef fi ciency are de signed to re duce op er at ing time of key

com po nents. This is ac com plished by tak ing ad van tage of

al ter nate sources of cool ing when avail able or, by re duc ing

com pres sor work load when the heat load in the criti cal space

is lower.

Applications

The Chal lenger Plus unit is ide ally suited for pre ci sion close

con trol of the fol low ing types of en vi ron ment:

• Data processing centers

• Telecommunications

• Industrial applications

The de sign of the Chal lenger Plus unit can vary de pend ing on

the ap pli ca tion, con sult the Lie bert Ap pli ca tions En gi neer ing

De part ment for spe cific de tails.

Manufacture

All units are built in ac cor dance Euro pean di rec tives

98/37/CE (89/392/CEE; 91/368/CEE; 93/68/CEE),

89/336/CEE; 73/23/CEE. The Lie bert Air Con di tion ing

Qual ity Sys tem is ap proved by LRQA in ac cor dance with the

stan dards UNI EN ISO 9001: 1994.

Each unit is sup plied com plete with a Test Cer tifi cate and

Dec la ra tion of Con formity.

All Chal lenger Plus units carry the “CE ” mark and fully

com ply with Euro pean Di rec tives con cern ing me chani cal,

elec tri cal and elec tro mag netic safety.

Features

• New fan sec tion - sin gle inlet, radial cen trifu gal fans (plug

fans) with back ward curved blades. Variable speed motor

with external rotor. Avail able static pres sure up to 350 Pa,

stan dard con figu ra tion

• High COP (Co-efficient Of Performance)

• High SHR (Sensible Heat Ratio)

• Low energy consumption; High EER (Energy Efficiency

Ratio)

• Low operating cost

• All materials used in the unit are fully recyclable

• Low internal air-side pressure drop

• High efficiency filtration, up to EU8 available

• Modular construction

• Sandwich construction of panels with non-flammable -

Class 0 (ISO 1182.2) insulation

2 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Page 7

In tro duc tion (con tin ued)

System types

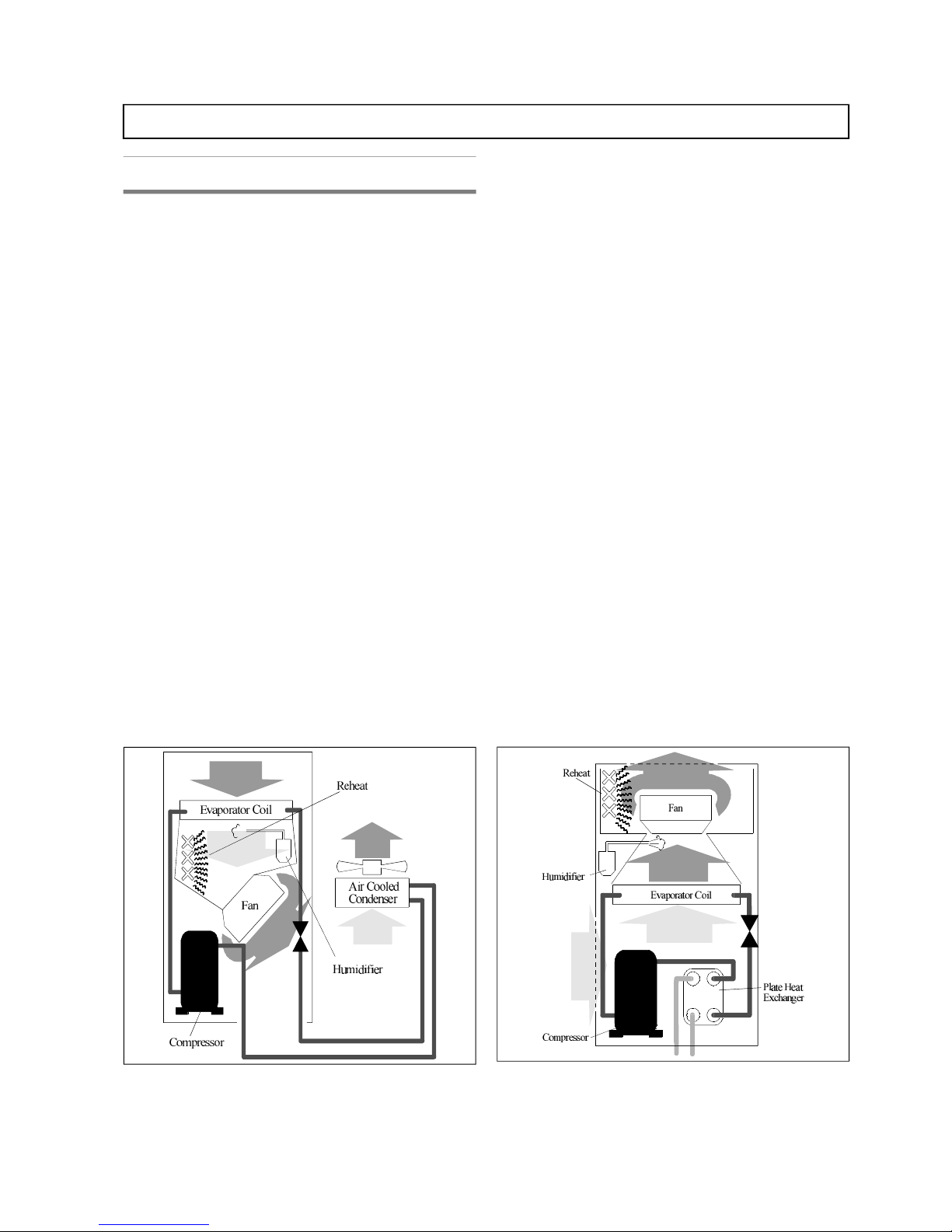

Air cooled units

Air cooled mod els con sist of an evapo ra tor coil, a com pli ant

scroll com pres sor, high and low pres sure switches, an

ex ter nally equal ised, ad just able, ther mo static ex pan sion

valve, serv ice ports, re frig er ant line sight glass, liq uid

re ceiver with pressure- relief valve and fil ter drier. The units

are shipped with a hold ing charge of dry Ni tro gen.

Mod els CP20A, CP24A, CP28A, CP34A and CP40A are

sin gle cir cuit. Mod els CP26A, CP32A, CP42A and CP46A

are dual cir cuit.

Air cooled units re quire matched air cooled con dens ers. Fan

speed con trolled con dens ers are avail able from Lie bert for a

full range of out side am bi ent tem pera tures. Refer to the

Condensers Technical Data Manual (P/N SLE CD TDM) for

full details.

Wa ter/Gly col cooled units

Wa ter/Gly col cooled mod els con sist of an evapo ra tor coil, a

com pli ant scroll com pres sor, high and low pres sure

switches, an ex ter nally equal ised, ad just able, ther mo static

ex pan sion valve, serv ice ports, re frig er ant line sight glass,

fil ter drier, stainless- steel plate heat ex changer and a

head- pressure con trol valve (wa ter regu lat ing valve).

Pres sure re lief valves are fit ted down stream of the plate heat

ex changer. The re frig er ant cir cuits are pre charged with

re frig er ant in the factory.

Mod els CP20W, CP24W, CP28W, CP34W, CP40W are

sin gle cir cuit. Mod els CP26W, CP32W, CP42W and CP46W

are dual cir cuit.

The units op er ate with mains wa ter, cool ing tower wa ter or

wa ter in a closed cir cuit with an ex ter nal drycooler.

When op er at ing in a closed cir cuit, it may be nec es sary

(de pend ing on out side tem pera tures) to add mono eth yl ene

gly col to pre vent the wa ter freez ing in win ter, re fer to the unit

In stal la tion Man ual for ap pli ca ble per cent ages.

A pump is used to cir cu late wa ter (wa ter/gly col) through the

unit (not sup plied as standard).

If mains wa ter or tower wa ter is used, it is rec om mended to fit

a me chani cal fil ter on the wa ter line to pro tect the plate heat

ex changer against pos si ble im pu ri ties con tained in the wa ter

(for plate heat ex changer clean ing, re fer to the In stal la tion

Man ual).

SLE CP TDM E.1 (06/99) 3

Challenger Plus - Technical Data Manual

Fig ure 1 - Air Cooled Down flow Unit

Fig ure 2 - Wa ter/Gly col Cooled Up flow Unit

Page 8

In tro duc tion (con tin ued)

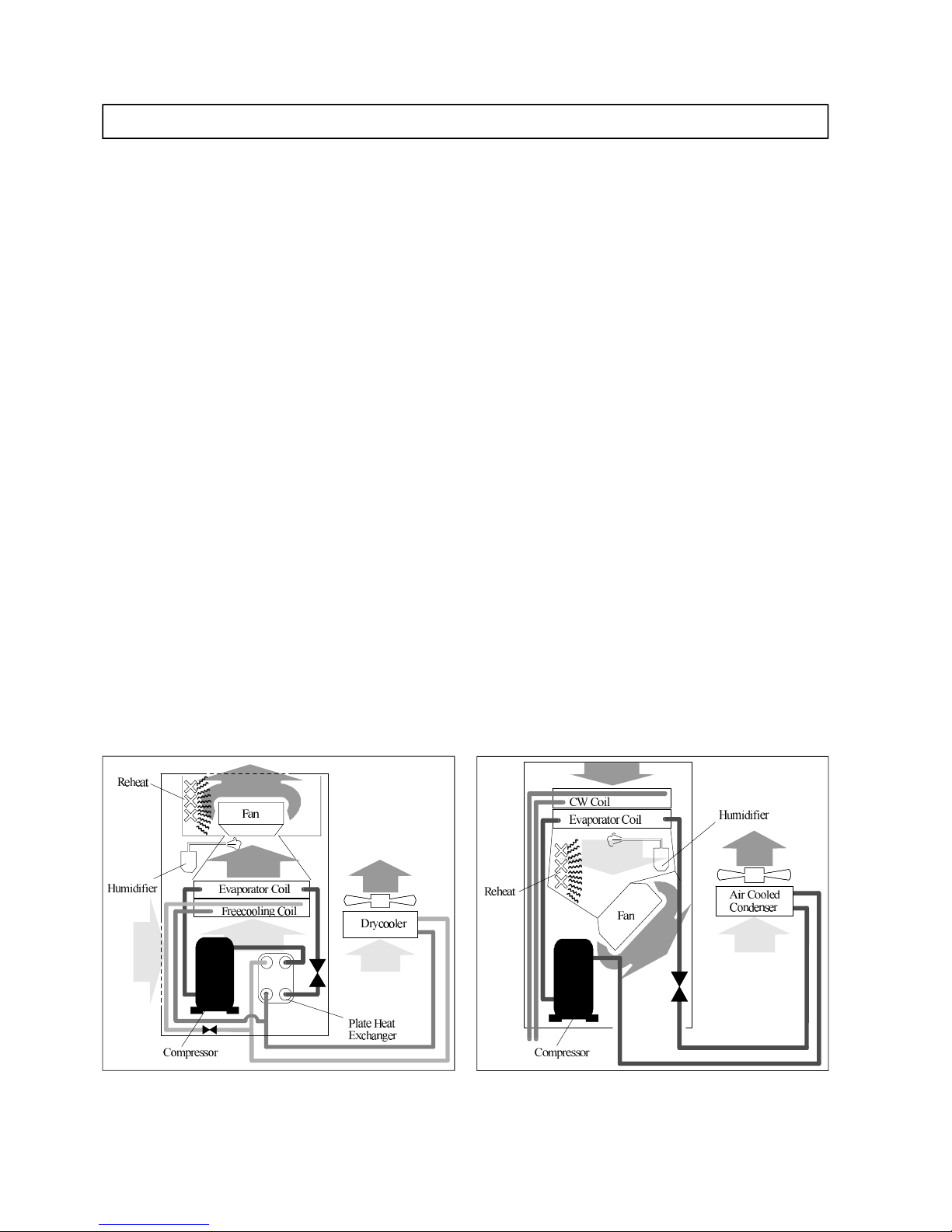

Freecooling units

Freecooling mod els con sist of an evapo ra tor coil, a

com pli ant scroll com pres sor, high and low pres sure

switches, an ex ter nally equal ised, ad just able, ther mo static

ex pan sion valve, serv ice ports, re frig er ant line sight glass,

fil ter drier, stainless- steel plate heat ex changer, a

head- pressure con trol valve (wa ter regu lat ing valve), a

2- way modu lat ing valve and a free cooling coil. Pres sure

re lief valves are fit ted down stream of the plate heat

ex changer. The re frig er ant cir cuits are pre charged with

re frig er ant in the factory.

Mod els CP20F, CP24F, CP28F, CP34F, CP40F are sin gle

cir cuit. Mod els CP26F, CP32F, CP42F and CP46F are dual

cir cuit.

The units op er ate with wa ter in a closed cir cuit from an

ex ter nal drycooler.

When op er at ing in a closed cir cuit, it may be nec es sary

(de pend ing on out side tem pera tures) to add mono eth yl ene

gly col to pre vent the wa ter freez ing in win ter, re fer to the unit

In stal la tion Man ual for ap pli ca ble per cent ages.

A pump is used to cir cu late wa ter (wa ter/gly col) through the

unit (not sup plied as standard).

Operation

Free cool ing units have two modes of op era tion, de pend ing

on the out side tem pera ture.

In nor mal op era tion, the unit cools the air in the con di tioned

space us ing the com pres sor and refrig er ant coil (di rect

ex pan sion).

When out side tem pera tures are low enough, wa ter from the

ex ter nal dry cooler is used to cool the air in the con di tioned

space di rectly us ing the Free cool ing coil. This tem pera ture is

the ZET or Zero En ergy Tem pera ture.

Dual source air cooled

Dual Source Air Cooled mod els con sist of an evapo ra tor

coil, a com pli ant scroll com pres sor, high and low pres sure

switches, an ex ter nally equal ised, ad just able, ther mo static

ex pan sion valve, serv ice ports, re frig er ant line sight glass,

liq uid re ceiver with pressure- relief valve, fil ter drier, 3- way

mo tor ised modu lat ing valve and a chilled wa ter coil. The

units are shipped with a hold ing charge of dry Ni tro gen.

Mod els CP20D, CP24D, CP28D, CP34D and CP40D are

sin gle cir cuit. Mod els CP26D, CP32D, CP42D and CP46D

are dual cir cuit.

Air cooled units re quire matched air cooled con dens ers. Fan

speed con trolled con dens ers are avail able from Lie bert for a

full range of out side am bi ent tem pera tures. Refer to the

Condensers Technical Data Manual (P/N SLE CD TDM) for

full details.

Op era tion

In nor mal op era tion, when the tem pera ture of the sec ond

source is low enough, the chilled wa ter coil is used to cool the

air in the con di tioned space. If the tem pera ture of the chilled

wa ter rises above the tem pera ture re quired to main tain the

load, chilled wa ter cool ing is stopped and the com pres sor is

started. The load is then main tained us ing dx cool ing.

4 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Fig ure 3 - Free cool ing Up flow Unit

Fig ure 4 - Dual Source Air Cooled Down flow Unit

Page 9

In tro duc tion (con tin ued)

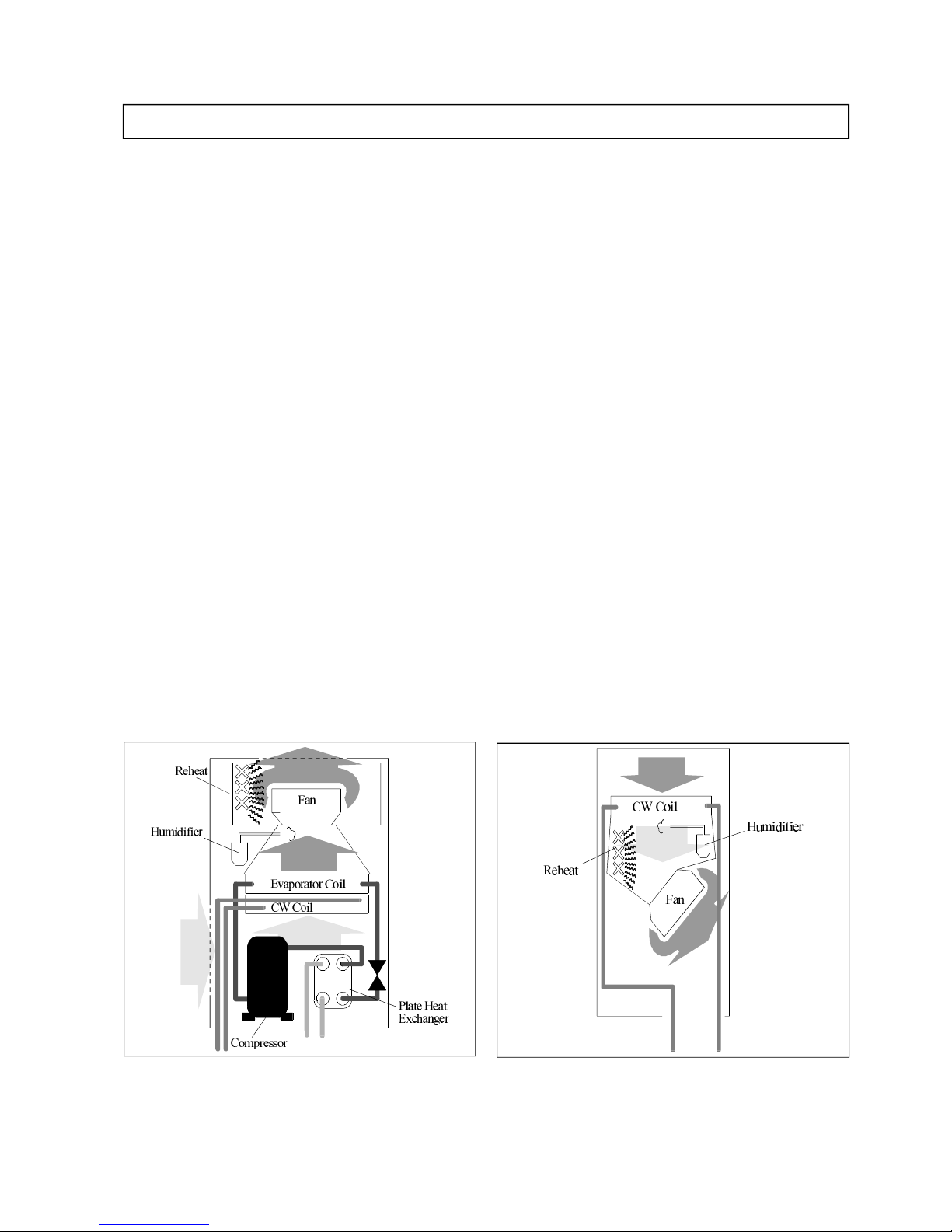

Dual source water/glycol cooled

Dual Source Wa ter/Gly col cooled mod els con sist of an

evapo ra tor coil, a com pli ant scroll com pres sor, high and low

pres sure switches, an ex ter nally equal ised, ad just able,

ther mo static ex pan sion valve, serv ice ports, re frig er ant line

sight glass, fil ter drier, stainless- steel plate heat ex changer, a

head- pressure con trol valve (wa ter regu lat ing valve), a

3- way mo tor ised modu lat ing valve and a chilled wa ter coil.

Pres sure re lief valves are fit ted down stream of the plate heat

ex changer. The re frig er ant cir cuits are pre charged with

re frig er ant in the factory.

Mod els CP20H, CP24H, CP28H, CP34H, CP40H are sin gle

cir cuit. Mod els CP26H, CP32H, CP42H and CP46H are dual

cir cuit.

Nor mal Op era tion

In nor mal op era tion, when the tem pera ture of the sec ond

source is low enough, the chilled wa ter coil is used to cool the

air in the con di tioned space. If the tem pera ture of the chilled

wa ter rises above the tem pera ture re quired to main tain the

load, chilled wa ter cool ing is stopped and the com pres sor is

started. The load is then main tained us ing dx cool ing.

DX Op era tion

The units op er ate with mains wa ter, cool ing tower wa ter or

wa ter in a closed cir cuit with an ex ter nal drycooler.

When op er at ing in a closed cir cuit, it may be nec es sary

(de pend ing on out side tem pera tures) to add mono eth yl ene

gly col to pre vent the wa ter freez ing in win ter, re fer to the unit

In stal la tion Man ual for ap pli ca ble per cent ages.

A pump is used to cir cu late wa ter (wa ter/gly col) through the

unit (not sup plied as standard).

If mains wa ter or tower wa ter is used, it is rec om mended to fit

a me chani cal fil ter on the wa ter line to pro tect the plate heat

ex changer against pos si ble im pu ri ties con tained in the wa ter

(for plate heat ex changer clean ing, re fer to the In stal la tion

Man ual).

Chilled water cooled

Chilled wa ter mod els in cor po rate a chilled wa ter coil with a

three- way modu lat ing mo tor ised chilled wa ter valve and

in su lated pip ing.

SLE CP TDM E.1 (06/99) 5

Challenger Plus - Technical Data Manual

Fig ure 5 - Dual Source Wa ter Cooled Up flow Unit

Fig ure 6 - Chilled Wa ter Cooled Down flow Unit

Page 10

Stan dard fea tures - all sys tems

Access/Maintenance

Rou tine main te nance ac cess to re frig er ant cir cuit

com po nents, com pres sor, liq uid re ceiver, ther mal ex pan sion

valve, sight glass, fil ter dryer etc. is avail able through the

front panel of the unit. Serv ice ac cess to the air fil ter, the fan,

hu midi fier, elec tric panel, elec tronic con trol ler PCB, elec tric

re heats etc. is also through the unit front panel.

Cus tomer con nec tions to the re frig er ant cir cuit (hot gas and

liq uid line), cool ing wa ter cir cuits, mains power in put

sup ply, hu midi fier wa ter sup ply and con den sate drain lines

are lo cated in the base of the unit.

The com pres sor is housed in a sepa rate air tight com part ment

within the unit, al low ing ac cess to the com pres sor while the

unit is in op era tion.

Cabinet and panels

The cabi net is manu fac tured from zin tec, painted with

epoxy- polyester pow der paint and as sem bled us ing stain less

steel screws.

The front and rear pan els are double- skinned, with 22mm

fi ber glass in su la tion sand wiched be tween the pan els to

re duce noise emis sion and heat loss. The side pan els, which

are iso lated from the in side of the unit, are lined with 22mm

fi ber glass in su la tion sealed in an alu mi num foil.

The edges of the pan els are fit ted with seals to pre vent air loss

and to keep noise lev els to an ab so lute mini mum.

The struc ture is fully in com pli ance with Class 0 (ISO

1182.2). All sur faces in con tact with the air flow are

wash able in or der to re duce the for ma tion of bac te ria. All

ma te ri als used are CFC- free and may be re cy cled.

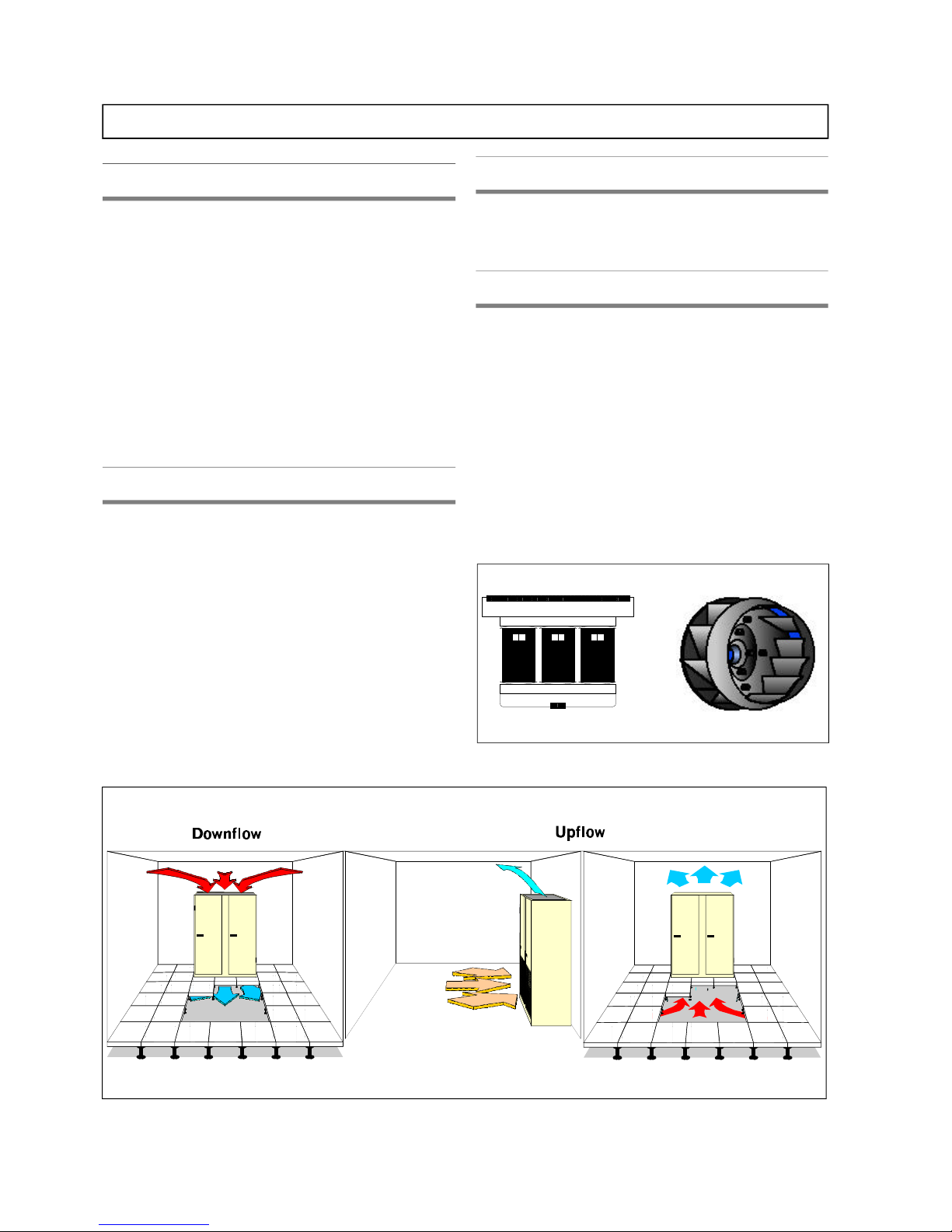

Air distribution

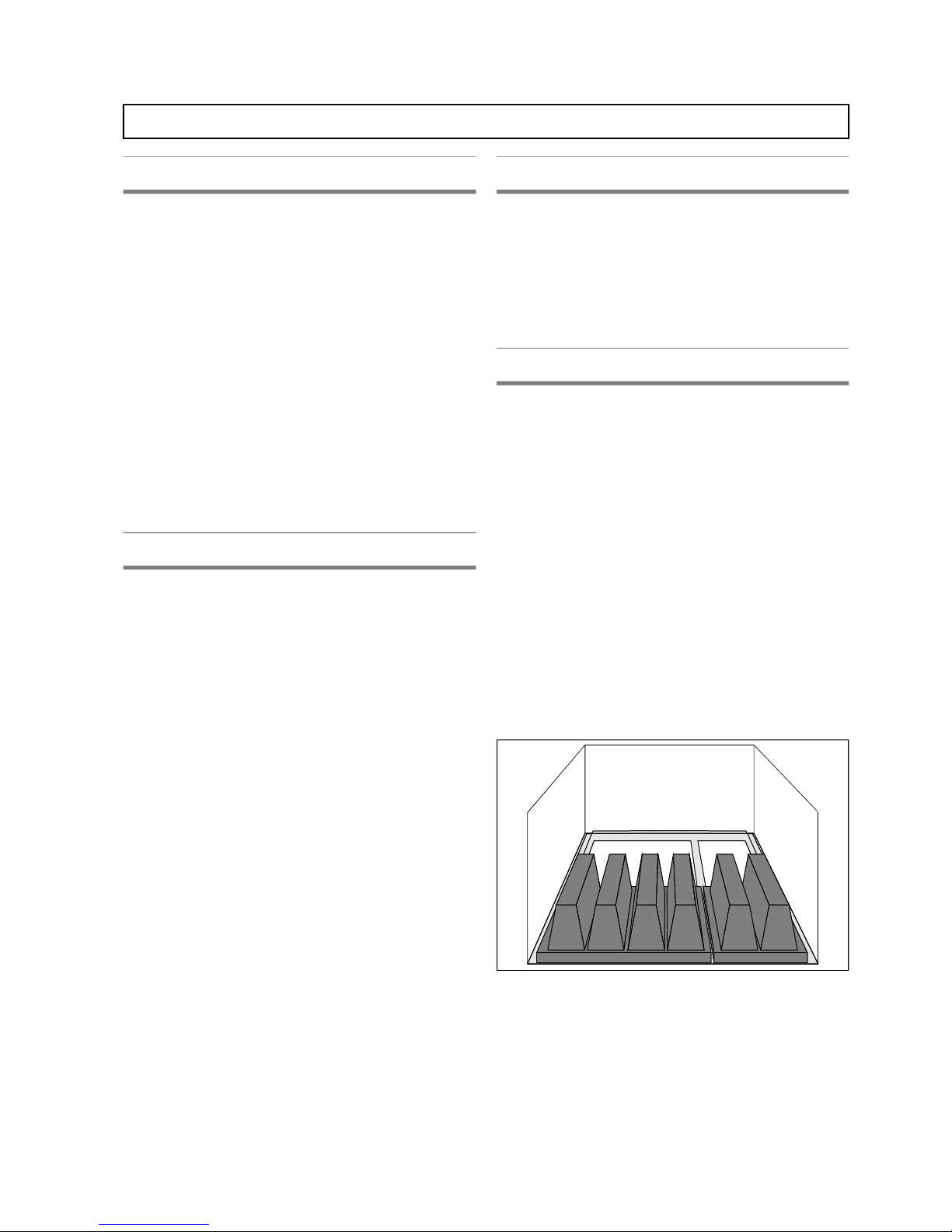

All units in the range are avail able in three con figu ra tions,

Down flow, Up flow Front Re turn and Up flow Bot tom

Re turn, re fer to Fig ure 7.

Fan section

The unit is fit ted with a direct- drive, sin gle in let back ward

curved, gal va nized painted steel ra dial cen trifu gal fan (plug

fan). The fan mo tor is a three- phase, 25- speed mo tor (speed

is ad just able via an au to trans former). The mo tor is rated to

IP44 and com plete with in ter nal ther mal pro tec tion.

The fan im pel ler is stati cally and dy nami cally bal anced and

equipped with self- lubricating bear ings. The fan is mounted

on vibration- absorbing rub ber sup ports to re duce vi bra tion

trans mis sion be tween the fan and the unit frame. This

vi bra tion at tenua tion helps to keep noise emis sion to a

mini mum. The mo tor is ca pa ble of pro vid ing the rated

air flow at ex ter nal static pres sures of up to 350 Pa.

6 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Fig ure 7 - Air Dis tri bu tion

Fig ure 8 - Autotransformer and Fan

Page 11

Stan dard fea tures - all sys tems (con tin ued)

Fil tra tion

The air fil ter is made of syn thetic fi ber cells in a card board

frame and is de signed to mini mise the air pres sure drop while

main tain ing maxi mum fil ter ef fi ciency. It is eas ily

ac cessed/re placed by open ing the front doors of the unit.

The guar an teed ef fi ciency is EU4 (Eu rov ent EU4/5, 30%

ef fi ciency), (G4, CEN stan dard). Optional fil tra tion lev els to

EU8 (G8) are avail able on re quest.

Pre fil ters are avail able on up flow mod els.

Electrical panel

The elec tric panel, lo cated at the front of the unit in an air tight

compartment, con tains the MCB’s, con tac tors, trans former,

con trol ler PCB and over load re lays etc. Each high volt age

sys tem com po nent is pro vided with a sepa rate over cur rent

pro tec tive de vice. All high- voltage com po nents are touch

pro tected by means of a plas tic cover. The elec tric panel

com plies with the EN 60204-1.

All units are de signed for op era tion at 400V/3ph/50 Hz ( +

10%) and are fit ted with a mains dis con nect switch.

Microprocessor controller Microface

The Mi cro face en vi ron mental con trol sys tem is

mi cro proc es sor based and can be pro grammed to match the

unique needs of any ap pli ca tion. The proc es sor in te grates the

sepa rate me chani cal and elec tri cal com po nents into a

‘state -of -the -art’ con di tioned space sup port sys tem that

con trols and moni tors tem pera ture, hu mid ity, air flow and air

clean li ness.

The con trol sys tem of fers a tai lored and well proven ad vance

in re li abil ity and con trol flexi bil ity al low ing the unit to

mod ify its per form ance in re sponse to chang ing criti cal space

con di tions.

The con trol ler al lows lo cal moni tor ing and pro gram ming of

the fol low ing room con di tions:

Tem pera ture (oC)

Tem pera ture set point (5.0oC – 40.0oC in steps of 0.1 oC)

Tem pera ture sen si tiv ity (1.0oC - 10oC in steps of 0.1 oC)

Hu mid ity (%RH)

Hu mid ity set point (20%RH - 80%RH in steps of 1%)

Hu mid ity sen si tiv ity (5%RH - 20%RH in steps of 1%)

The pa rame ters are enun ci ated us ing sym bols and text on an

LCD dis play. Nor mal op er at ing modes are in di cated by

sym bols on the dis play. Alarm con di tions ac ti vate a vis ual

in di ca tor.

The fol low ing alarms are stan dard:

• High temperature

• Low temperature

• Fan failure

• High pressure alarm – (compressorised systems only)

• Low pressure alarm - (compressorised systems only)

• Electrical reheat high temperature

• Memory failure

• Common alarm

Other alarms are also avail able when the rele vant op tion is

or dered with the unit (e.g. if a hu midi fier is or dered with the

unit, the High Hu mid ity, Low Hu mid ity etc. alarms are

en abled). For a full list of all the op tions and alarms avail able

with the Mi cro face con trol ler, re fer to the Mi cro face

Con trol ler Op era tion Man ual (P/N SLE MF OM).

The con trol ler also in cor po rates a se quen tial auto- restart

timer, al low ing field ad just able time de lays to be ap plied to

unit re start af ter a power loss (or other shut down). The tim ers

al low mul ti ple units to be re started while lim it ing

in stan ta ne ous in rush cur rent.

SLE CP TDM E.1 (06/99) 7

Challenger Plus - Technical Data Manual

Page 12

Stan dard fea tures - all sys tems (con tin ued)

Electric reheat

The three-stage re heat is of rigid de sign for ex tended

op era tional life. The re heat has am ple ca pac ity to main tain

room dry- bulb con di tions dur ing a sys tem call for

de hu midi fi ca tion. The low- watt den sity, elec tri cally

en closed ele ments are made of alu mi num sur rounded by high

ef fi ciency fins, re duc ing sheath tem pera tures and

elimi nat ing ioni sa tion. The re heat is phase- balanced.

Re heat con trol is of the ON-OFF type. The re heat is pro vided

with a man ual re set, re heat safety ther mo stat, to dis able the

re heat in the event of high tem pera ture.

The re heat safety stat. also in cor po rates a magneto- thermal

switch which pro tects the re heat from short cir cuits, should

the har ness be dam aged ac ci den tally.

Elec tric re heat can be com bined with hot gas or hot wa ter

re heat ac ti vated in dif fer ent stages.

Re fer to the Tech ni cal Data Ta bles for re heat ca paci ties,

FLA’s etc.

Humidifier

The unit is fit ted with an elec tronic steam bot tle hu midi fier

suit able for use with wa ter of vary ing degrees of hard ness,

pro vided that the wa ter is not treated or demineralized. The

hu midi fier is com plete with a wa ter inlet valve, a wa ter outlet

valve and a maximum wa ter level sensor.

The steam cyl in der is in stalled in the unit’s air tight

com part ment to avoid heat losses. Steam from the cyl in der is

mixed with the dis charge air from the evapo rat ing coil by

means of a cop per steam dis tribu tor.

The unit con trol ler moni tors the con di tion of the steam

cyl in der, and gen er ates an alarm when the cyl in der needs to

be changed. Cyl in der re place ment is easy and quick.

The hu midi fier is com plete with a self- adapting flow con trol

sys tem which moni tors wa ter con duc tiv ity and con trols the

elec tri cal cur rent pass ing through the cyl in der. Out put

ad just ment is from 30 - 100% via the unit con trol ler.

Hu midi fi ca tion con trol may be of the pro por tional or of the

on- off type, ac cord ing to the re quire ments of the in stal la tion:

On- off con trol is set as stan dard.

Re fer to the Op tional sec tion of the Tech ni cal Data Ta bles for

hu midi fier ca paci ties, FLA’s, etc.

Dehumidification

On air- cooled mod els, the unit de hu midi fies the air by

re duc ing the air flow across the coil (the fan is switched to a

lower speed) and switch ing on the com pres sor.

In chilled wa ter mod els, the unit de hu midi fies by fully

open ing the chilled wa ter valve.

In Dual Source units, the unit de hu midi fies us ing the

"Cur rent" cool ing source. If the cur rent source is DX, the unit

de hu midi fies the air by re duc ing the air flow across the coil

(the fan is switched to a lower speed) and switch ing on the

com pres sor. If the cur rent source is chilled wa ter, the unit

de hu midi fies by fully open ing the chilled wa ter valve.

In Free cool ing units, the unit dis ables free cool ing on a call

for de hu midi fi ca tion and de hu midi fies the air by re duc ing

the air flow across the coil (the fan is switched to a lower

speed) and switch ing on the com pres sor.

Packaging

As stan dard, the units are wrapped in bubble- wrap to pro tect

painted sur faces, en closed in a card board box and mounted

on a wooden pal let.

On re quest, for sea trans port etc., the units can be packed in

wooden crates or cases com plete with sili con des ic cant.

Warranty clauses

The war ranty does not cover any dam age or mal func tion of

the unit which may oc cur dur ing or as a re sult of op er at ing

the unit out side of the speci fied ap pli ca tion lim its.

Liebert does not accept responsibility for any damage caused

by improper use of the product.

8 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Page 13

Stan dard fea tures - DX sys tems (con tin ued)

Refrigerant circuit

Units are avail able as sin gle and dual cir cuit. The cir cuit(s)

con sist of a com pres sor, a ther mal ex pan sion valve, a liq uid

line sight glass, a fil ter dryer, an evapo ra tor coil, a liq uid

re ceiver (air cooled only) and high and low pres sure

switches.

For safety rea sons, (es pe cially dur ing ma chine start- up), it is

rec om mended to in stall a non- return valve(s) (sup plied as an

op tion, on re quest) on the liq uid line from the con denser, to

pro tect the com pres sor from un ex pected re frig er ant

mi gra tions. All low tem pera ture parts of the re frig er ant

cir cuit are in su lated as stan dard.

Evaporator

The evapo ra tor coils are de signed to pro vide maxi mum coil

area for more pre cise con trol of tem pera ture and hu mid ity.

With this com puter de signed coil ar range ment, low ve loc ity

air passes through the coil pro vid ing the most ef fec tive

sur face ex po sure with less tur bu lence and greater ef fi ciency

in the cool ing and de hu midi fi ca tion pro cesses. The coil is

de signed for the high sen si ble heat ra tio re quired by criti cal

spaces. The coil is tested to 30 Bar.

The evapo ra tor coil is made of cop per tubes with treated

alu mi num fins (to with stand cor ro sive at mos pheres). A

cor ro sion re sis tant drain pan is pro vided with the coil on all

mod els.

Compressors

The fully her metic com pli ant scroll com pres sor in cor po rates

sev eral safety fea tures for pro tec tion dur ing nor mal and the

oc ca sional ab nor mal op er at ing con di tions. They are:

• Self resetting overloads to sense excessive currents and

temperatures.

• An internal pressure relief valve which limits discharge

pressure to protect mechanical parts.

• Motor insulation that is resistant to chemical attack.

• Rubber mounting to ensure reduced compressor noise and

vibration.

• IP54 pro tec tion

Schrae der con nec tions are fit ted to the unit for serv ice

ac cess.

Refrigerant

R22 HCFC is the stan dard re frig er ant used in the Chal lenger

Plus range. An op tional “Green” re frig er ant, R407C is also

avail able. In this case the com pres sor is sup plied with es ter

oil. Air cooled units are shipped with a ni tro gen hold ing

charge, wa ter, dual source wa ter and free cool ing units are

charged with re frig er ant in the factory.

Sight glass

Re frig er ant line sight glasses serve as a means of quick vis ual

in spec tion to de ter mine if there is mois ture in the sys tem and

if the sys tem is prop erly charged.

Filter-dryer

Liq uid line filter- dryers en sure a clean, moisture- free

re frig er ant sys tem for ex tended com po nent life. The fil ter

drier is suit able for use with stan dard R22 and op tional “Zero

ODP” re frig er ant R407C.

Expansion valve

The ex ter nally equal ised, ad just able, ther mo static ex pan sion

valve smoothly con trols re frig er ant flow dur ing vary ing

in door heat loads and out door am bi ent tem pera tures by

con trol ling evapo ra tor su per heat.

Safety controls

Each com pres sor has a manual- reset high pres sure switch for

high pres sure pro tec tion and a high pres sure alarm cir cuit to

warn of high sys tem pres sures, al low ing cor rec tive ac tion to

be taken be fore a sig nifi cant loss of tem pera ture con trol

oc curs.

The low pres sure switch is auto- resetting and de tects low

pres sure con di tions such as loss of re frig er ant charge. The

pres sure switch cali bra tion val ues are shown in the

In stal la tion, Op era tion & Main te nance Man ual sup plied

with the ma chine.

Crankcase heaters

Crank case heat ers are sup plied with all com pres so rised

mod els. They main tain mini mum re frig er ant tem pera ture

and are en er gised while the unit is pow ered and the

com pres sor is off.

SLE CP TDM E.1 (06/99) 9

Challenger Plus - Technical Data Manual

Fig ure 9 - Scroll Compressor

Page 14

Stan dard fea tures - DX mod els (con tin ued)

Air cooled only

Liquid receiver

A welded steel liq uid re ceiver is pro vided to main tain

con stant and even re frig er ant flow to the ex pan sion valve, in

all cir cum stances. Shut- off valves are in stalled as stan dard on

the in let and out let of the re ceiver to as sist main te nance of the

cir cuit, if re quired.

A suita bly rated pres sure re lief valve is in stalled on the liq uid

re ceiver. The valve is equipped with a threaded con nec tion to

al low the re frig er ant to be dis charged out side of the

con di tioned space.

Air cooled condenser

A match ing Lie bert air cooled con denser with fan speed

con trol should be or dered with the unit. De tails of the

con dens ers are pro vided in this man ual, full de tails of all

con dens ers for all out door am bi ents are avail able in the

Con denser Tech ni cal Data Man ual, (P/N SLE CD TDM).

Note: The suggested condenser selections/performances for

each outdoor ambient are based on calculated data. The

actual selection of a condenser should always be verified on

the basis of the specific working conditions on each site.

Water cooled/freecooling units only

Plate heat exchanger

All wa ter cooled units (mod els W, H, F) are fit ted with a

brazed plate heat ex chang ers made of stain less steel. This

type of con denser is de signed for high ef fi ciency heat

ex change. The con denser is in ten tion ally over sized for the

ap pli ca tion to re duce pres sure drops (and the en ergy

con sump tion of the cir culation pump) in the wa ter sup ply and

thus al low the unit to op er ate with an ex ter nal wa ter cooler in

a closed cir cuit at high out door tem pera tures. Pres sure re lief

valves are fit ted down stream of the con denser. The valve is

equipped with a threaded con nec tion to al low the re frig er ant

to be dis charged out side of the con di tioned space.

Wa ter cooled units can op er ate with mains wa ter, cool ing

tower wa ter or wa ter in a closed cir cuit with an ex ter nal

dry cooler. Free cool ing units op er ate with wa ter in a closed

cir cuit from an ex ter nal dry cooler only.

When op er at ing in a closed cir cuit, it may be nec es sary

(de pend ing on out side tem pera tures) to add mono eth yl ene

gly col to pre vent the wa ter freez ing in win ter , re fer to the unit

In stal la tion Man ual for ap pli ca ble per cent ages.

A pump is used to cir cu late wa ter (wa ter/gly col) through the

unit (it is not sup plied).

If mains wa ter or tower wa ter is used, it is rec om mended to fit

a me chani cal fil ter on the wa ter line to pro tect the con denser

against pos si ble im pu ri ties con tained in the wa ter (for

con denser clean ing, re fer to the In stal la tion Man ual).

Drycooler

A dry cooler can be sup plied, if re quired. Full de tails of all

dry cool ers are avail able in the Dry cooler Tech ni cal Data

Man ual, P/N SLE DC TDM.

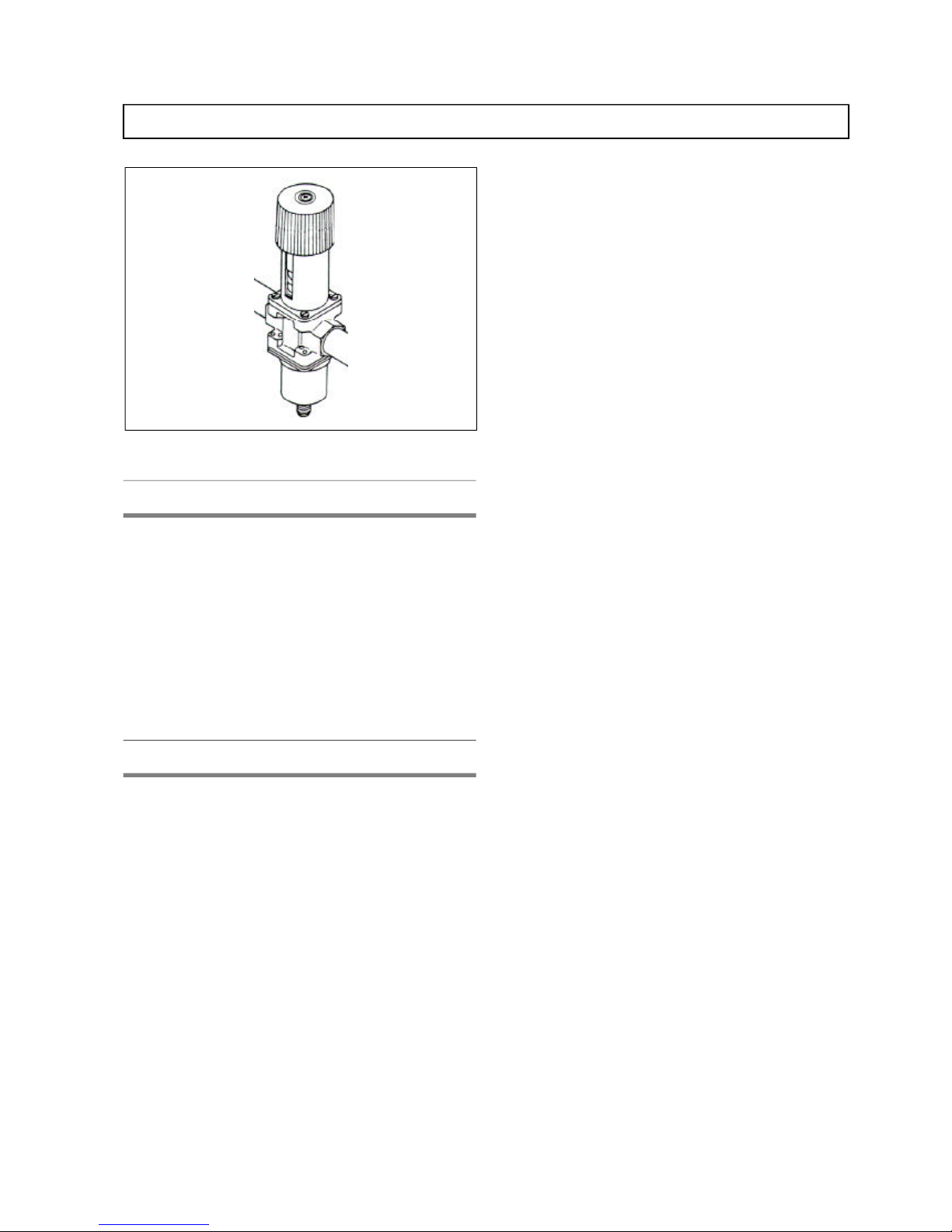

Head pressure control valve

Head pres sure op er ated regu lat ing valves ac cu rately con trol

the con dens ing tem pera ture and sys tem ca pac ity for vari ous

en ter ing fluid tem pera tures. A 2- way head pres sure con trol

valve is fit ted as stan dard on wa ter/gly col cooled, dual source

wa ter cooled and free cool ing units.

The valve con trols the con dens ing pres sure by regu lat ing the

wa ter flow to the plate con denser. It is in stalled at the

con denser out let with the pres sure probe po si tioned on the

re frig er ant dis charge line. It is auto mati cally closed when the

com pres sor is not op er at ing. It is sized for in let wa ter flow

tem pera tures lower than 17 0C re sult ing in low water- side

pres sure drops.

For higher wa ter in let tem pera tures, higher wa ter flowrates

are re quired and pos si bly spe cial wa ter regu lat ing valves,

con sult Lie bert Ap pli ca tions En gi neers for de tails.

Freecooling only

Freecooling coil

The Freecooling coil is lo cated on the re turn air side of the

evapo ra tor coil. Wa ter/gly col flow to the coil is con trolled by

a pre-piped 2- way modu lat ing motorised valve. When

sup plied with a coolant so lu tion of suf fi ciently low

tem pera ture, the coil is suf fi ciently sized to of fer an equal

cool ing ca pac ity to that ob tained us ing the re frig era tion

cir cuit. The coil is tested to 30 Bar.

2-way control valve

As the out door am bi ent drops to a suf fi ciently low

tem pera ture, the 2- way mo tor ised valve modu lates the flow

to the coil, as in a chilled wa ter sys tem. The valve in cludes an

op er at ing link age and elec tric mo tor.

10 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Page 15

Stan dard fea tures - DX mod els (con tin ued)

Dual source only

Dual source units con sist of the stan dard di rect ex pan sion

re frig era tion cir cuit and an ad di tional cool ing coil with a

three- way mo tor ised modu lat ing valve.

The ad di tional coil is lo cated on the re turn air side of the

evapo ra tor coil. Flow to the coil is con trolled by a pre- piped

3- way equal per cent age mo tor ised valve.

The nor mal con trol strat egy of the unit is to use the sec on dary

source (chil ler sup ply, pro cess wa ter sup ply etc.) to main tain

the room load un til a sen sor de tects that the sec on dary source

is no longer at the re quired tem pera ture. Di rect ex pan sion

cool ing is then switched on and main tains the load.

Operating limits (DX models)

Chal lenger Plus di rect ex pan sion units are de signed for

op era tion within the fol low ing work ing lim its (the lim its are

ap pli ca ble to newly com mis sioned ma chines which have

been cor rectly in stalled and main tained).

Indoor operating range

All models from 18.0°C, 45% R.H. to 27.0°C, 55% R.H.

To mini mise the pos si bil ity of wa ter carry over, (i.e. too

much con den sate on the evapo ra tor coil lead ing to the

for ma tion of wa ter drop lets), it is criti cal to en sure that the

la tent load (dif fer ence be tween to tal and sen si ble load) does

not ex ceed 5.5 kW.

Outdoor operating range (Air cooled - A, D)

Lower limit

-20°C with fan speed con trol in stalled in the con denser.

Upper limit

This is de ter mined by the ca pac ity of the con denser cou pled

to the unit (at the rele vant out door am bi ent). If the limit is

ex ceeded, the High Pres sure Switch will shut the com pres sor

down. The switch must then be manu ally re set af ter the

prob lem has been rec ti fied.

Condenser installation

Condenser above indoor unit

Maxi mum dis tance be tween in door unit and ex ter nal air

con denser: 30 me ters equiva lent length.

Con denser be low in door unit

Maxi mum geo detic height dif fer ence be tween con denser

and unit: 3 me ters.

Air flow

The mini mum and maxi mum air flows and avail able

Ex ter nal Static Pres sure are given in the Tech ni cal Data

sec tion of this man ual. The fan mo tor ther mal over load

pro tects the unit from any dam age which could re sult from

op er at ing out side the speci fied val ues.

Voltage tolerance

All mod els 400 V ± 10%

Fre quency tol er ance

50 Hz ± 2 Hz.

SLE CP TDM E.1 (06/99) 11

Challenger Plus - Technical Data Manual

Fig ure 10 - Head Pressure Control Valve

Page 16

Stan dard fea tures - chilled water mod els

Cooling coil

The large face area/low face ve loc ity, deep wave fin coil

al lows pre cise con trol of tem pera ture and hu mid ity dur ing

cool ing and de hu midi fi ca tion, and is de signed to op ti mize

fluid ve loc ity and mini mize pres sure drop. The full face area

is ac tive dur ing cool ing and de hu midi fi ca tion, re sult ing in

op era tional en ergy sav ing in the ap pli ca tion area. A

cor ro sion re sis tant drain pan is pro vided on all mod els. The

coil is tested to 30 Bar.

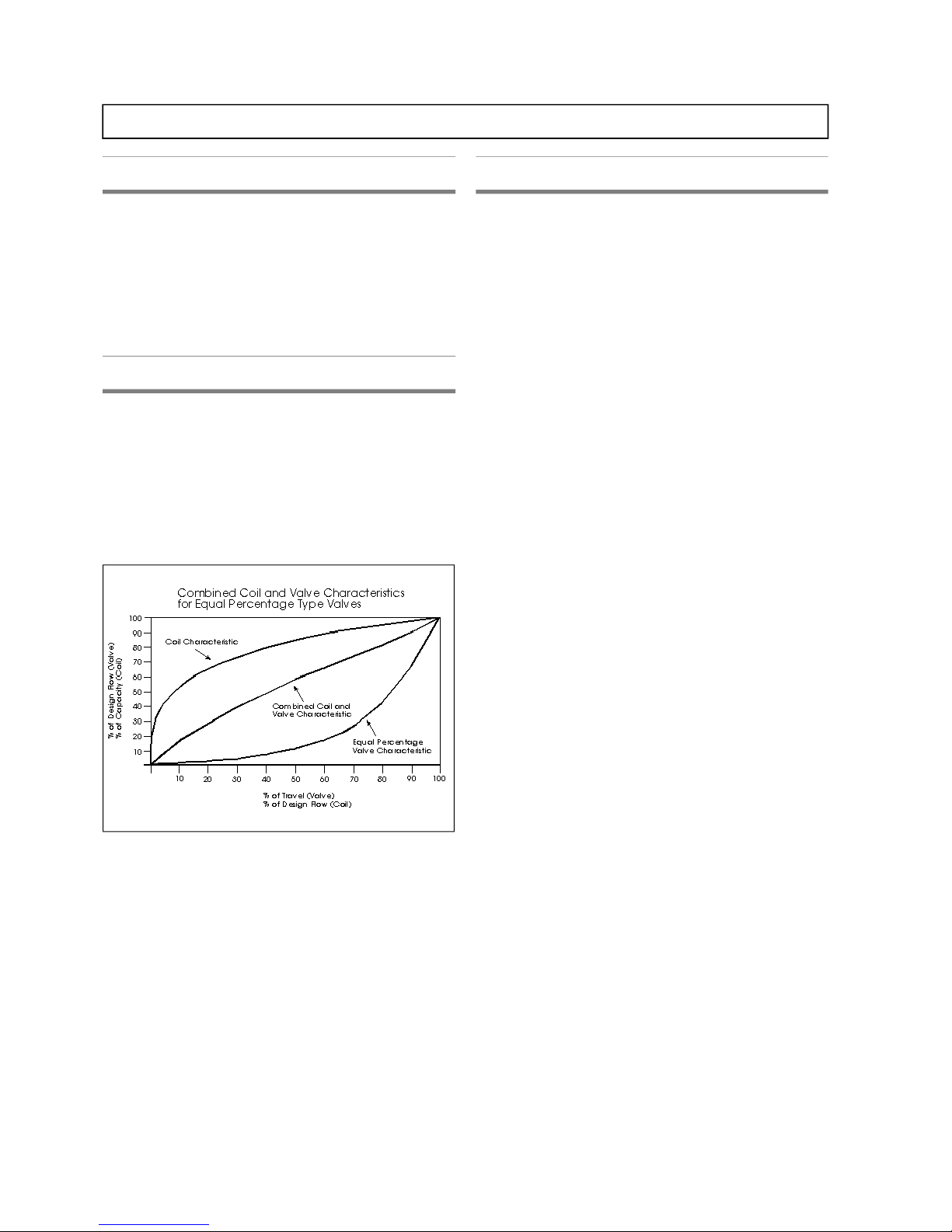

3-way control valve

The mo tor ised chilled wa ter valve pro vides equal per cent age

con trol ac tion in re sponse to room tem pera ture and hu mid ity

as sensed by the mi cro proc es sor. This re sults in a

pro por tional ra tio of ca pac ity to stem travel. The valve

in cludes an op er at ing link age and elec tric mo tor. The valve

can be manu ally ad justed to the closed po si tion (on the

coil- side of the valve) us ing the tool pro vided.

Operating limits

Chal lenger Plus chilled wa ter units are de signed for

op era tion within the fol low ing work ing lim its (the lim its are

ap pli ca ble to newly com mis sioned ma chines which have

been cor rectly in stalled and main tained).

Indoor operating range

All models from 18.0°C, 45% R.H. to 27.0°C, 55% R.H.

To mini mise the pos si bil ity of wa ter carry over, (i.e. too

much con den sate on the evapo ra tor coil lead ing to the

for ma tion of wa ter drop lets), it is criti cal to en sure that the

la tent load (dif fer ence be tween to tal and sen si ble load) does

not ex ceed 5.5 kW

Air flow

The mini mum and maxi mum air flows and avail able

Ex ter nal Static Pres sure are given in the Tech ni cal Data

sec tion of this man ual. The fan mo tor ther mal over load

pro tects the unit from any dam age which could re sult from

op er at ing out side the speci fied val ues.

Voltage tolerance

All mod els 400 V ± 10%

Fre quency tol er ance

50 Hz ± 2 Hz.

12 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Fig ure 11 - Equal Per cent age Valve Characteristic

Page 17

Op tional fea tures - all mod els

Hot gas reheat

Chal lenger Plus can be sup plied with a hot gas re heat coil if

re quired. This type of re heat uses the heat which is nor mally

re jected in the con denser to heat the air in the con di tioned

space, thus sav ing en ergy. A con trol valve pre vents the

re frig er ant from flow ing to the re heat ing coil when re heat is

not re quired. The re heat coil is sin gle or dou ble row

de pend ing on the model, and con structed of cop per tubes

with alu mi num fins.

When hot gas re heat is re quested, it is sup plied in con junc tion

with elec tri cal re heat in two stages as fol lows:

Stage 1: Hot gas re heat

Stage 2: Hot gas re heat + elec tri cal re heat

Note: The ca pac ity of the elec tri cal re heat in stage 2 is equal

to two thirds of the to tal ca pac ity of the stan dard elec tri cal

re heat for a given model.

Re fer to the Op tional sec tion of the Tech ni cal Data Ta bles for

re heat ca paci ties etc.

Hot water reheat

The eco nomi cal hot wa ter re heats are con trolled by a 3- way

(on/off) valve from the mi cro proc es sor con trol panel. The

sys tem is com pletely pre- piped and in cludes an air bleed

valve. The re heat coil is sin gle or dou ble row de pend ing on

the model, and con structed of cop per tubes with alu mi num

fins. The coil is tested to a pres sure of 30 bar.

A hot wa ter ther mo stat (pro vided by the cus tomer) is used in

the valve con trol se quence to de ter mine the avail abil ity of

re heat ca pac ity.

When hot water re heat is re quested, it is sup plied in

con junc tion with elec tri cal re heat in two stages as fol lows:

Stage 1: Hot water re heat

Stage 2: Hot water re heat + elec tri cal re heat

Note: The ca pac ity of the elec tri cal re heat in stage 2 is equal

to two thirds of the to tal ca pac ity of the stan dard elec tri cal

re heat for a given model.

Re fer to the Op tional sec tion of the Tech ni cal Data Ta bles for

re heat ca paci ties etc.

Non-return valves (models A and D)

Re frig er ant non- return valves for air- cooled units are

avail able as an op tion.

The valve is in stalled on the liq uid line, close to the

con denser and mounted ver ti cally.

Lie bert rec om mend that the valve be in stalled when the to tal

sys tem charge ex ceeds the speci fied val ues given in the

Op tional sec tion of the Tech ni cal Data Ta bles.

High efficiency filters

EU5 filters

Op tional 100mm EU5 high ef fi ciency fil ters are avail able for

all mod els. The high ef fi ciency fil ters are in ter change able

with the stan dard fil ters. The fil ters are EU5 (Eu rov ent 4/5),

fil tra tion class G4 (CEN stan dards).

EU6, EU7 and EU8 fil ters

Op tional 290mm high ef fi ciency fil ters, class EU6, EU7 and

EU8 (Eu rov ent 4/5), are avail able on re quest. The fil ters are

made of fi ber glass fil ter me dia. The fil ter me dia is

con structed in ”V” sec tions with a rigid ex ter nal frame to

with stand high pres sure drops and flow varia tions.

If these fil ters are or dered, a 600mm fil ter ple num is re quired

to house them. The ple num is of the same col our as the unit

and in stalled on the top of the unit. (Re fer to Op tions sec tion

of the Tech ni cal Data Ta bles for de tails).

SLE CP TDM E.1 (06/99) 13

Challenger Plus - Technical Data Manual

Fig ure 12 - EU6, EU7, EU8 Filters

Page 18

Op tional fea tures - all mod els (con tin ued)

Filter clog switch

An ad just able dif fer en tial pres sure switch can be fit ted to

ini ti ate a change fil ter alarm when a pre- selected pres sure

drop across the fil ter bank is ex ceeded.

Water detection sensors

A wa ter de tec tion sensor, con tain ing an iso lated switch that

closes when wa ter (or other con duc tive liq uid) is de tected by

the sen sor probes may be or dered as an op tion. The sen sor is

her meti cally sealed, ro bust and should be fit ted in the

lo ca tion where wa ter prob lems might oc cur.

Smoke alarm

A smoke de tec tor/alarm is avail able as an op tion. The smoke

de tec tor will ac ti vate the alarm and stop the unit if smoke is

de tected in the re turn air. The sen sor is an op tic smoke

de tec tor (Tyn dall ef fect) which is in sen si tive to light or air

move ment.

Firestat

A firestat/alarm is avail able as an op tion. The firestat

de ac ti vates the unit when the re turn air tem pera ture is too

high. The firestat can be mounted in the unit or re motely,

con sult Ap pli ca tions En gi neers for de tails. The de tec tor is

com plete with an NTC ther mis tor.

Environmental Alarm Package

The Elec tronic En vi ron men tal Alarm Pack age (EEAP) is a

re mote tem pera ture and rela tive hu mid ity sen sor (ad di tional

to the in ter nal sen sor) con nected to the unit con trol ler.

The sen sor can be in stalled up to 20m from the unit and

gen er ates an alarm if the tem pera ture or the rela tive hu mid ity

ex ceeds one of the 4 user- set lim its:

• HighTemperature Limit

(Adjustable from 10°C to 50 °C)

• Low Temperature Limit

(Adjustable from 0 °C to 30 °C)

• High Humidity Limit

(Adjustable from 30% to 99%)

• Low Humidity Limit

(Adjustable from 10% to 70%).

Fresh air kit

The fresh air in take kit is rec om mended for use where the

con di tioned space is con tinu ously occupied. The kit con sists

of a cy lin dri cal EU3 fil ter mounted in the unit which

con nects to a 100mm di ame ter duct (the flexi ble duct can

also be sup plied if the length is speci fied).

The fresh air is then mixed with the dis charge air from the

unit through a slot on the in take side of the fan.

Floorstand

Floor stands are avail able in a range of heights, 300mm,

500mm and 800mm. Each height of floorstand is fit ted with

ad just able legs (± 25mm). The floor stands per mit in stal la tion

and con nec tion of the sys tem prior to in stal la tion of the raised

floor.

Turning vane

A fac tory in stalled turn ing vane may be speci fied to di rect the

air as re quired within the floor stand.

14 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Fig ure 13 - Floorstand

Page 19

Op tional fea tures - all mod els (con tin ued)

Base module - upflow units only

A 200mm base mod ule can be sup plied on re quest to sup port

up flow Chal lenger Plus units. The mod ule is used when

cus tomer con nec tions must be made through the base of the

unit, but no false floor is avail able.

Al ter na tively the base mod ule can be used for bot tom air

re turn where there is no raised floor.

Sound attenuation package

In ap pli ca tions where sound emis sion from the unit is of

criti cal im por tance, a spe cial sound at tenu at ing cartridge,

at tached to the top of the unit, is avail able to re duce sound

lev els to an ab so lute mini mum.

The car tridges, made of a self- extinguishing ma te rial with a

high at tenua tion ca pac ity are guar an teed against

dis in te gra tion and re lease of par ti cles due to fric tion within

the duct.

It is pos si ble to in stall one or two rows of car tridges in the

plenum de pend ing on the sound at tenua tion re quired. A

sin gle row re quires a 600 mm high ple num, two rows re quire

a 1200 mm high plenum.

A single car tridge in a 600mm high ple num pro vides a noise

re duc tion of -8.5 dB(A) at 2 m in front of the unit and 1.5 m

from the ground. A sin gle car tridge in a 1200mm high

ple num pro vides a noise re duc tion of -13 dB(A) at 1 m in

front of the unit and at an an gle of 45o to the unit top.

A dou ble car tridge in a 1200mm ple num will pro vides a noise

re duc tion of -9.5 dB(A) at 2 m in front of the unit and 1.5 m

from the ground. It will provide a noise reduction of -14

dB(A) at 1 m in front of the unit and at an an gle of 45o to the

unit top.

Re fer to the Op tions sec tion of the Tech ni cal Data Ta bles for

fur ther de tails.

Special packaging

Where the unit is to be trans ported by sea or in other cases

where heavy duty pack ag ing is re quired, spe cial crat ing is

avail able.

This can con sist of ei ther a wooden crate over the stan dard

car board/bub ble wrap pack ag ing or the en tire unit can be

en cased in a wooden box.

Spe cial pack ing for sea trans port, con sist ing of a wooden box

or crate in ad di tion to nor mal card board, can be sup plied on

re quest.

SLE CP TDM E.1 (06/99) 15

Challenger Plus - Technical Data Manual

Figure 14 - Base Module

Fig ure 15 - Sound Attenuation Cartridge

Fig ure 16 - Special Packaging

Page 20

Op tional fea tures - all mod els (con tin ued)

Plenum

An in take/sup ply ple num is avail able for con nec tion be tween

the unit and a false ceil ing. The ple num is manu fac tured from

the same ma te rial and in the same col our as the unit.

The ple num con sists of sand wich pan els lined with class 0

(ISO 1182.2), 30 kg/m3 den sity, non- flammable in su la tion.

Avail able heights range from 600 mm to 1200 mm.

Plenum with fixed grille (upflow)

A sup ply air ple num with fixed hori zon tal air flow can be

in stalled on top of the unit. The 900 mm high ple num is

manu fac tured from the same ma te rial and in the same col our

as the unit.

The ple num con sists of sand wich pan els lined with class 0

(ISO 1182.2), 30 kg/m3 den sity, non- flammable in su la tion.

Plenum with adjustable louvered grille

(upflow)

A sup ply air ple num with ad just able (up and down) air flow

can be in stalled on top of the unit. The 900 mm high ple num is

manu fac tured from the same ma te rial and in the same col our

as the unit.

The ple num con sists of sand wich pan els lined with class 0

(ISO 1182.2), 30 kg/m3 den sity, non- flammable in su la tion.

Cau tion is ad vised against ex treme de flec tion of the lou vers

as this can ob struct the air flow and re duce the unit’s cool ing

ca pac ity.

Condensate pump

A con den sate drain pump can be sup plied if re quired. The

pump is com plete with a flow cut out switch al low ing the

pump to stop and re set auto mati cally. De pend ing on the unit

type, it can be sup plied fit ted or loose for field fit ting, con sult

Lie bert Ap pli ca tions En gi neers for de tails. The fol low ing

ta ble lists pump ca pac ity vs. avail able head.

Flow (l/s)

0.083 0.167 0.250 0.333

Avail able Head (kPa)

20 19 18 14

Air intake from the bottom (upflow

models)

Up flow mod els are nor mally front re turn. If re quired, they

can be sup plied as bot tom re turn. Bot tom re turn mod els are

fit ted with a blank front panel (this re duces the sound level of

the unit).

Dampers

Chal lenger Plus units can be pro vided with mo tor ised

shut- off damp ers for down flow mod els and grav ity-fed

damp ers for up flow models.

Al ter na tive re frig er ant R407C

An op tional “green” re frig er ant, R407C can be sup plied with

all com pres so rised mod els.

The com pres sor is filled with a spe cial es ter oil re quired for

R407C. Air cooled units are filled ex-factory with a holding

charge of dry nitrogen. Wa ter, Dual Source Wa ter and

Free cooling units are charged with R407C.

16 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

Fig ure 17 - Ple num with grille

Page 21

Op tional fea tures - all mod els (con tin ued)

Hiromatic graphic

The Hi ro matic Graph ic is a purpose- designed con trol sys tem

for pre ci sion air- conditioning. It si mul ta ne ously moni tors

the criti cal space and sig nals alarms ei ther lo cally or

re motely. The graph ics screen dis plays all the ma jor

pa rame ters, in clud ing sym bolic rep re sen ta tion of unit

func tions, such as heat ing, cool ing etc.; in ad di tion

tem pera ture and hu mid ity varia tions with time can be

pre sented graphi cally on the screen. All di ag nos tic

pro ce dures, in clud ing the check ing and cali bra tion of in put

and out put sig nals, and of the mi cro proc es sor it self, can be

run from the front panel. The con trol ler al lows lo cal

moni tor ing and pro gram ming of the fol low ing room

con di tions:

Tem pera ture (oC)

Tem pera ture set point (5.0– 40.0oC in steps of 0.1oC)

Tem pera ture sen si tiv ity (1.0 - 10oC in steps of 0.1 oC)

Hu mid ity (%RH)

Hu mid ity set point (20%RH - 80%RH in steps of 1%)

Hu mid ity sen si tiv ity (5%RH - 20%RH in steps of 1%)

A full range of alarms, High and Low Tem pera ture, High and

Low Hu mid ity, Fan Fail ure, High and Low Pres sure etc. are

stan dard with the con trol ler.

Features

• Backlit LCD graphics display

• User interface via pushkeys

• Battery-backed clock for date/time and real time functions

• Password control for setpoints, unit/control setup and

service functions

• Graphics display of temperature and humidity over a 24

hour period

The Hi ro matic Graphic is menu- driven and user menu’s are

avail able in 10 lan guages. The Hi ro matic Graphic rec ords the

last 120 “events” (Alarms, Warn ings etc.) oc cur ring in the

sys tem along with a “Graphic Data Re cord” for the unit. The

Graphic Data Re cord dis plays the tem pera ture and hu mid ity

read ings for the last 24 hours (stored since the last start- up of

the unit).

The Hi ro matic Graphic con trols date and time func tions

us ing them as op er at ing in for ma tion for the cus tomer and as a

ref er ence when ever a status change oc curs, log ging the status

change in the “Status Re port”. De tails of the event which

oc curred, the date and time at which the event oc curred are

also stored. Us ing buff ered RAM, the Hi ro matic also stores

the op er at ing hours of each com po nent (com pres sor, fan,

elec tric heat ers, hu midi fier etc.) for each con nected unit.

A fur ther fea ture of the Hi ro matic Graphic is “Sleep Mode”.

Sleep Mode al lows units to be pro grammed to switch on and

off at dif fer ent times of the day, and on dif fer ent days of the

week.

The Hi ro matic Graphic can be sup plied in stalled in a unit, or

in kit form for in stal la tion in a re mote con trol panel.

BEMS Interface

The Hi ro matic Graphic al lows units on a net work to be

in te grated with the Hi ro link Com mu ni ca tions Bus when an

RS422 card is in stalled at the back of Hi ro matic. Hi ro matic

can con trol up to 8 Mi cro face units in this con figu ra tion and

com mu ni cate the rele vant data to Hi ro link.

Hi ro link works as a com mu ni ca tions man ager be tween the

Hi ro matic Graphic and Mi cro face units and in dus try

stan dard field bus ses and pro to cols used in Build ing

Man age ment Sys tems such as Mod- Bus, J- Bus, Satch well,

etc.

Note: For full de tails of the Hi ro matic Graphic, re fer to the

Hi ro matic Graphic Operations Man ual, (P/N SLE HG OM).

SLE CP TDM E.1 (06/99) 17

Challenger Plus - Technical Data Manual

Page 22

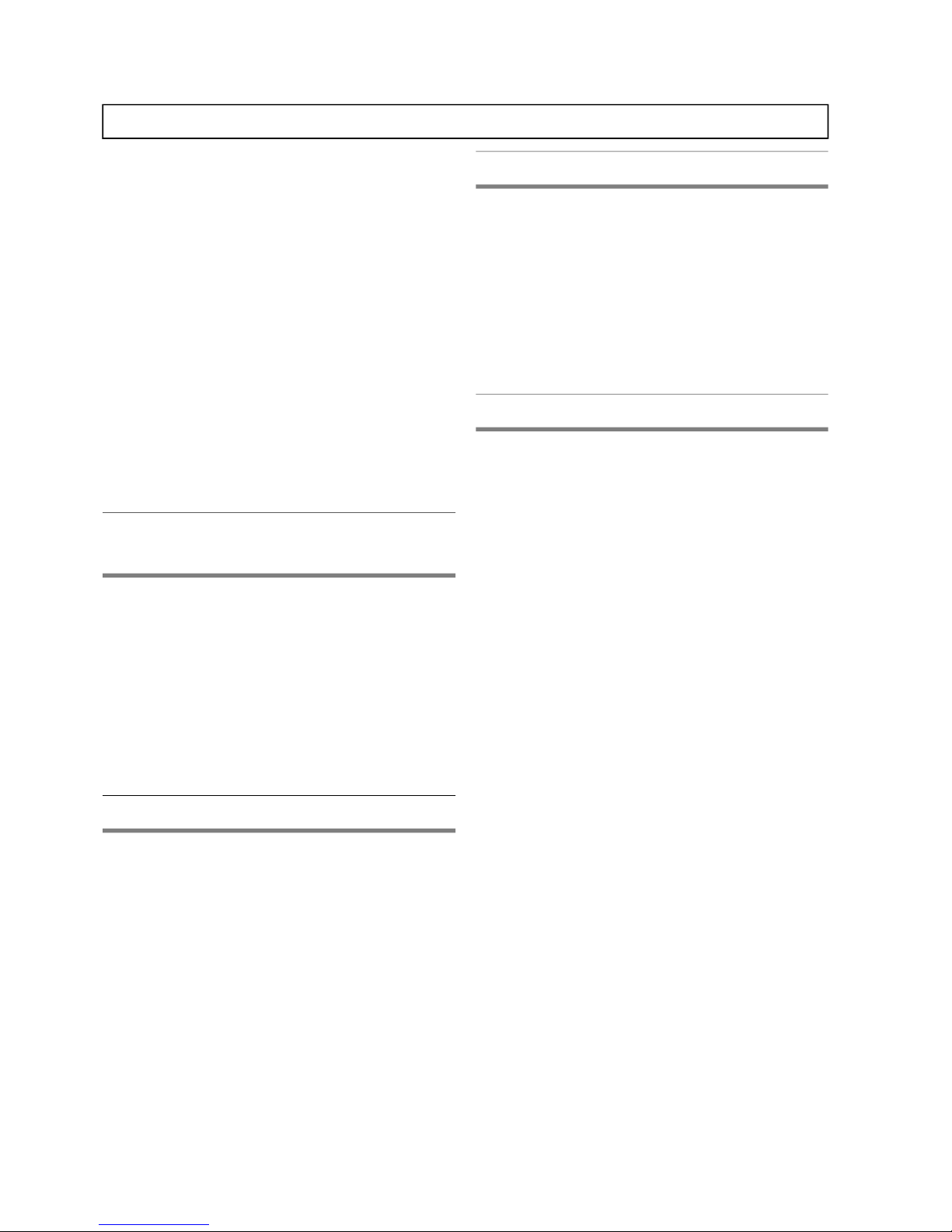

Air cooled data - down flow units (R407C)

+

18 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

MODEL CP20AD CP24AD CP28AD CP34AD CP40AD CP26AD CP 32AD CP 42AD CP 46AD

Re frig er ant Cir cuit - Sin gle Dou ble

PER FORM ANCE DATA

(1)

Air Flow m3/h 5800 6600 9980 11040 12510 9980 11040 12510 13500

Avail able ESP

(2)

Pa 450 380 430 400 370 430 400 370 320

To tal Capacity kW 19.6 24.9 32.7 36.1 47.3 29.2 34.7 41.9 54.0

Sen si ble Capacity kW 18.8 23.2 29.5 33.5 42.6 28.0 33.3 41.1 47.0

Sen si ble Heat Ratio - 0.96 0.93 0.90 0.93 0.90 0.96 0.96 0.98 0.87

En ergy Out put/Input - 3.39 3.25 3.37 3.20 3.49 3.24 3.25 3.42 3.44

Sound Pres sure Level

(3)

dB(A) 51.1 54.4 56.4 57.5 59.0 56.4 57.5 59.0 60.8

Comp.Power Absorbed kW 4.80 6.37 7.53 8.91 10.93 6.84 8.32 9.60 12.76

Comp.Cur rent Absorbed A 11.1 11.8 14.7 16.2 18.9 2 x 6.5 2 x 8.0 2 x 11.1 2 x 11.8

Fan Power Absorbed kW 0.98 1.31 2.17 2.34 2.65 2.17 2.34 2.65 2.96

Fan Cur rent Absorbed A 3.9 4.2 2 x 4.1 2 x 4.1 2 x 4.2 2 x 4.1 2 x 4.1 2 x 4.2 2 x 4.3

To tal Power Absorbed kW 5.8 7.7 9.7 11.3 13.6 9.0 10.7 12.3 15.7

FAN SEC TION

Quan tity 1 2

Type - Sin gle in let, back ward curved, ra dial cen trifu gal fan (plug fan)

COM PRES SOR SEC TION

Quan tity 1 2

Type Scroll compressor

Rated power HP 6 7.8 9 10 13 2 x 4 2 x 5 2 x 6 2 x 7.8

EVAPO RA TOR COIL

Quan tity n. 1

Tubes/Fins Cop per tubes / Treated alu min ium fins

Coil Sur face Area m

2

0.74 1.49

Configuration - In clined

RE FRIG ER ANT CON NEC TIONS (Brazed, O.D.)

Hot Gas Line mm 18 22 28 16 18 22

Liq uid Line mm 16 18 22 14 16 18

DI MEN SIONS

Width mm 1000 1750

Depth mm 890

Height mm 1950

Foot print m

2

0.89 1.56

WEIGHTS

Net kg 380 385 580 585 590 590 595 600 605

Gross kg 385 390 585 590 595 595 600 605 610

+

R22 Capacities are approximately the same as R407C capacities + 5%. Consult Liebert Applications Engineers for specific details.

1

At the following standard conditions: 24°C db; 50% R.H. (17°C wb) - condensing temperature: 49° C.

Power Supply Voltage 400/3/50, 20Pa ESP (External Static Pressure)

2

Max available ESP at quoted airflow

3

Measured in front of the unit at 1m height, 2 m distance, in the free field, fan and compressor run ning, 20Pa ESP.

Note: Quoted capacities are gross capacities, for nett capacities, deduct fan motor kW. EER is based on i ndoor unit only. Unit air flow is quoted for standard

configuration, with a clean EU4 filter.

Page 23

Air cooled data - up flow units (R407C)+

SLE CP TDM E.1 (06/99) 19

Challenger Plus - Technical Data Manual

MODEL CP20AU CP 24AU CP 28AU CP34AU CP40AU CP26AU CP32AU CP42AU CP46AU

Re frig er ant Cir cuit Sin gle Dou ble

PER FORM ANCE DATA (1)

Air Flow m3/h 5785 6690 9820 10790 12465 9820 10790 12465 13201

Avail able ESP

(2)

Pa 450 380 430 370 330 430 370 330 280

To tal Capacity kW 19.4 24.7 32.5 36.3 47.0 29.3 34.4 40.8 53.0

Sen si ble Capacity kW 18.6 22.7 28.9 33.4 42.8 27.8 33.0 40.8 46.2

Sen si ble Heat Ratio - 0.96 0.92 0.89 0.92 0.91 0.95 0.96 1.0 0.87

En ergy Out put/Input - 3.28 3.17 3.28 3.09 3.35 3.18 3.08 3.21 3.28

Sound Pres sure Level

(3)

dB(A) 52.7 55.8 57.8 60.0 61.6 57.8 60.0 61.6 62.9

Comp. Power Absorbed kW 4.80 6.37 7.53 8.91 10.92 6.84 8.32 9.60 12.74

Comp. Cur rent Absorbed kW 11.1 11.8 14.7 16.2 18.9 2 x 6.5 2 x 8.0 2 x 11.1 2 x 11.8

Fan Power Absorbed kW 1.12 1.42 2.37 2.85 3.11 2.37 2.85 3.11 3.41

Fan Cur rent Absorbed A 4.1 4.3 2 x 4.1 2 x 4.3 2 x 4.4 2 x 4.1 2 x 4.3 2 x 4.4 2 x 4.4

To tal Power Absorbed kW 5.9 7.8 9.9 11.8 14.0 9.2 11.2 12.7 16.2

FAN SEC TION

Quan tity 1 2

Type Sin gle in let, back ward curved, ra dial cen trifu gal fan (plug fan)

COM PRES SOR SEC TION

Quan tity 1 2

Type Scroll compressor

Rated power HP 6 7.8 9 10 13 2 x 4 2 x 5 2 x 6 2 x 7.8

EVAPO RA TOR COIL

Quan tity 1

Tubes/Fins Cop per tubes / Treated alu min ium fins

Coil Sur face Area m

2

0.74 1.49

Configuration - In clined

RE FRIG ER ANT CON NEC TIONS (Brazed, O.D.)

Hot Gas Line mm 22 28 18 22

Liq uid Line mm 18 22 16 18

DI MEN SIONS

Width mm 1000 1750

Depth mm 890

Height mm 1950

Foot print m

2

0.89 1.56

WEIGHTS

Net kg 390 395 590 595 600 600 605 610 615

Gross kg 395 400 595 600 605 605 610 615 620

+

R22 Capacities are approximately the same as R407C capacities + 5%. Consult Liebert Applications Engineers for specific details.

1

At the following standard conditions: 24°C db; 50% R.H. (17°C wb) - condensing temperature: 49°C .

Power Supply Voltage 400/3/50, 50Pa ESP (External Static Pressure)

2

Max available ESP at quoted airflow

3

Measured in front of the unit at 1m height, 2 m distance, in the free field, fan and compressor run ning, 50Pa ESP.

Note: Quoted capacities are gross capacities, for nett capacities, deduct fan motor kW. EER is based on i ndoor unit only. Unit air flow is quoted for standard

configuration, with a clean EU4 filter.

Page 24

Wa ter cooled data - down flow units (R407C)+

20 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

MODEL CP20WD CP24WD CP28WD CP 34WD CP 40WD CP 26WD CP32WD CP 42WD CP 46WD

Re frig er ant Cir cuit - Sin gle Dou ble

PER FORM ANCE DATA

(1)

Air Flow m3/h 5800 6600 9980 11040 12510 9980 11040 12510 13500

Avail able ESP

(2)

Pa 450 380 430 400 370 430 400 370 320

Fan Power Absorbed kW 0.98 1.31 2.17 2.34 2.65 2.17 2.34 2.65 2.96

Fan Cur rent Absorbed A 3.9 4.2 2 x 4.5 2 x 4.1 2 x 4.2 2 x 4.1 2 x 4.1 2 x 4.2 2 x 4.3

Sound Pres sure Level

(3)

dB(A) 51.1 54.4 56.4 57.5 59.0 56.4 57.5 59.0 60.8

Wa ter in let tem pera ture: 24°C - Con densing Tem pera ture: 40.5°C (0% gly col)

To tal Cool ing Ca pac ity kW 21.5 28.2 35.6 40.5 51.0 32.3 38.0 45.3 58.1

Sen si ble Cool ing Ca pac ity kW 19.6 24.3 30.2 35.2 43.9 29.1 34.5 42.2 48.2

SHR Sen si ble Heat Ratio 0.91 0.86 0.85 0.87 0.86 0.90 0.91 0.93 0.83

EER (En ergy Out/In put) 4.35 4.28 4.23 4.19 4.31 4.15 4.09 4.28 4.28

Wa ter Flow Rate l/s 0.40 0.66 0.79 0.87 1.16 0.62 0.79 0.87 1.39

To tal Water Pres sure Drop

(4)

kPa 7 + 5 18 + 13 7 + 11 8 + 8 14 + 11 3 + 8 4 + 14 2 + 6 5 + 15

Comp. Power Absorbed kW 3.97 5.30 6.22 7.31 9.18 5.60 6.92 7.94 10.60

Comp. Cur rent Absorbed A 10.3 10.4 12.81 14.3 16.4 2 x 5.8 2 x 7.2 2 x 10.3 2 x 10.4

To tal Power Absorbed kW 4.95 6.60 8.40 9.66 11.82 7.78 9.27 10.59 13.57

Wa ter in let tem pera ture: 30°C - Con densing Tem pera ture: 45°C (0% gly col)

To tal Cool ing Ca pac ity kW 20.7 27.1 34.0 38.3 49.5 31.0 36.6 43.5 56.7

Sen si ble Cool ing Ca pac ity kW 19.5 24.1 29.9 34.5 43.5 28.8 34.0 41.8 48.2

SHR (Sen si ble Heat Ra tio) 0.94 0.89 0.88 0.90 0.88 0.93 0.93 0.96 0.85

EER (En ergy Out/In put) 3.85 3.79 3.74 3.66 3.87 3.70 3.67 3.78 3.86

Wa ter Flow Rate l/s 0.49 0.82 0.98 1.03 1.41 0.73 0.95 1.05 1.74

To tal Wa ter Pres sure Drop

(4)

kPa 7+26 20+73 16+40 12+45 16+83 12+15 19+25 8+16 23+31

Comp. Power Absorbed kW 4.4 5.8 6.9 8.1 10.1 6.2 7.6 8.8 11.7

Comp. Cur rent Absorbed A 10.7 11.1 13.7 15.3 17.6 2 x 6.1 2 x 7.6 2 x 10.7 2 x 11.1

To tal Power Absorbed kW 5.4 7.1 9.1 10.5 12.8 8.4 10.0 11.5 14.7

FAN SECTION

Quan tity n. 1 2

Type - Sin gle in let, back ward curved, ra dial cen trifu gal fan (plug fan)

COM PRES SOR SECTION

Quan tity n. 1 2

Type Scroll compressor

Rated power HP 6 7.8 9 10 13 2 x 4 2 x 5 2 x 6 2 x 7.8

EVAPO RA TOR COIL

Quan tity 1

Tubes/Fins Cop per tubes / Treated alu min ium fins

Coil Sur face Area m

2

0.74 1.49

Orientation - In clined

CON DENSER

Type - Plate- heat ex changer in stain less steel (AISI 316)

Quan tity 1 2

Wa ter Con nec tions inch 1” 1¼“ 1/2" 1”

DI MEN SIONS

Length mm 1000 1750

Depth mm 890

Height mm 1950

Footprint m

2

0.89 1.56

WEIGHTS

Net kg 390 395 590 595 600 600 605 610 615

Gross kg 395 400 595 600 605 605 610 615 620

+

R22 Capacities are approximately the same as R407C capacities + 5%. Consult Liebert Applications Engineers for specific details.

1

At the following standard conditions: 24°C db; 50% R.H. (17°C wb), Power Supply Voltage 400/3/50, 20Pa ESP (External Static Pressure).

2

Max available ESP at quoted airflow

3

Measured in front of the unit at 1m height, 2 m distance, in the free field, fan and compressor run ning, 20Pa ESP.

4

Valve pressure drop + condenser pressure drop.

5

Valve pressure drop + coil pressure drop.

Note: Quoted capacities are gross capacities, for nett capacities, deduct fan motor kW. EER is based on i ndoor unit only. Unit air flow is quoted for standard

configuration, with a clean EU4 filter.

Page 25

Wa ter cooled data - up flow units (R407C)

+

SLE CP TDM E.1 (06/99) 21

Challenger Plus - Technical Data Manual

MODEL CP20WU CP 24WU CP 28WU CP 34WU CP 40WU CP 26WU CP 32WU CP 42WU CP 46WU

Re frig er ant Cir cuit Sin gle Dou ble

PER FORM ANCE DATA

(1)

Air Flow m3/h 5785 6690 9820 10790 12465 9820 10790 12465 13200

Avail able ESP

(2)

Pa 450 380 430 370 330 430 370 330 280

Fan Power Absorbed kW 1.12 1.42 2.37 2.85 3.11 2.37 2.85 3.11 3.41

Fan Cur rent Absorbed A 4.1 4.3 2 x 4.1 2 x 4.3 2 x 4.4 2 x 4.1 2 x 4.3 2 x 4.4 2 x 4.4

Sound Pres sure Level

(3)

dB(A) 52.7 55.8 57.8 60.0 61.6 57.8 60.0 61.6 62.9

Wa ter in let tem pera ture: 24°C - Con densing Tem pera ture: 40.5°C (0% gly col)

To tal Cool ing Ca pac ity kW 21.1 27.3 35.3 40.0 50.7 31.5 36.9 44.8 57.9

Sen si ble Cool ing Ca pac ity kW 19.2 24.0 30.0 34.8 44.1 28.6 34.0 42.1 48.0

SHR Sen si ble Heat Ratio 0.91 0.88 0.85 0.87 0.87 0.91 0.92 0.94 0.83

EER (En ergy Out/In put) 4.14 4.06 4.11 3.93 4.13 3.95 3.78 4.05 4.13

Wa ter Flow Rate l/s 0.39 0.62 0.78 0.85 1.15 0.62 0.78 0.85 1.36

To tal Wa ter Pres sure Drop

(4)

kPa 6 + 5 16 + 11 6 + 10 8 + 8 14 + 11 3 + 8 4 + 13 2 + 5 5 + 14

Comp. Power Absorbed kW 3.97 5.29 6.22 7.31 9.17 5.60 6.92 7.94 10.60

Comp. Cur rent Absorbed A 10.3 10.4 12.8 14.3 16.4 2 x 5.8 2 x 7.2 2 x 10.3 2 x 10.4

To tal Power Absorbed kW 5.09 6.71 8.60 10.16 12.28 7.98 9.77 11.05 14.01

Wa ter in let tem pera ture: 30°C - Con densing Tem pera ture: 45°C (0% gly col)

To tal Cool ing Ca pac ity kW 20.3 26.2 33.6 38.0 49.0 30.5 36.1 43.1 55.4

Sen si ble Cool ing Ca pac ity kW 19.1 23.9 29.6 34.2 43.7 28.4 33.6 41.4 47.1

SHR (Sen si ble Heat Ra tio) 0.94 0.91 0.88 0.90 0.89 0.93 0.93 0.96 0.85

EER (En ergy Out/In put) 3.08 3.03 3.63 3.46 3.68 3.56 3.45 3.59 3.65

Wa ter Flow Rate l/s 0.48 0.78 1.00 1.02 1.40 0.72 0.94 1.03 1.70

To tal Wa ter Pres sure Drop

(4)

kPa 7+25 18+65 16+39 12+43 16+81 11+14 19+24 9+11 21+30

Comp. Power Absorbed kW 4.4 5.8 6.9 8.1 10.1 6.2 7.6 8.8 11.7

Comp. Cur rent Absorbed A 10.7 11.1 13.7 15.3 17.6 2 x 6.1 2 x 7.6 2 x 10.7 2 x 11.1

To tal Power Absorbed kW 6.6 8.6 9.3 11.0 13.3 8.6 10.5 12.0 15.2

FAN SECTION

Quan tity 1 2

Type Sin gle in let, back ward curved, ra dial cen trifu gal fan (plug fan)

COM PRES SOR

Quan tity 1 2

Type Scroll compressor

Rated power HP 6 7.8 9 10 13 2 x 4 2 x 5 2 x 6 2 x 7.8

EVAPO RA TOR COIL

Quan tity 1

Tubes/Fins Cop per tubes / Treated alu min ium fins

Coil Sur face Area m

2

0.74 1.49

Orientation In clined

CON DENSER

Type Plate- heat ex changer in stain less steel (AISI 316)

Quan tity 1 2

Wa ter Con nec tions inch 1” 1¼“ 1/2" 1”

DI MEN SIONS

Length mm 1000 1750

Depth mm 890

Height mm 1950

Footprint m

2

0.89 1.56

WEIGHTS

Net kg 400 405 600 605 610 610 615 620 625

Gross kg 405 410 605 610 615 615 620 625 630

+

R22 Capacities are approximately the same as R407C capacities + 5%. Consult Liebert Applications Engineers for specific details.

1

At the following standard conditions: 24°C db; 50% R.H. (17°C wb), Power Supply Voltage 400/3/50, 50Pa ESP (External Static Pressure)

2

Max available ESP at quoted airflow

3

Measured in front of the unit at 1m height, 2 m distance, in the free field, fan and compressor run ning, 50Pa ESP.

4

Valve pressure drop + condenser pressure drop.

5

Valve pressure drop + coil pressure drop.

Note: Quoted capacities are gross capacities, for nett capacities, deduct fan motor kW. EER is based on i ndoor unit only. Unit air flow is quoted for standard

configuration, with a clean EU4 filter.

Page 26

Air cooled dual source data - down flow units (R407C)

+

22 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

MODEL CP20DD CP 24DD CP 28DD CP34DD CP 40DD CP26DD CP 32DD CP42DD CP 46DD

Re frig er ant cir cuit Sin gle Dou ble

PER FORM ANCE

(1)

Air Flow m3/h 5570 6280 9980 10960 11910 9980 10960 11910 13100

Avail able ESP

(2)

Pa 435 325 410 390 340 410 390 340 280

Fan Power Absorbed kW 1.15 1.57 2.46 2.78 3.00 2.45 2.67 2.99 3.47

Fan Cur rent Absorbed A 4.11 4.41 2 x 4.16 2 x 4.25 2 x 4.35 2 x 4.16 2 x 4.25 2 x 4.35 2 x 4.423

PER FORM ANCE WITH ME CHANI CAL COOL ING

To tal Cool ing Ca pac ity kW 19.5 25.7 32.7 36.4 47.5 29.2 34.4 41.1 54.4

Sen si ble Cool ing Ca pac ity kW 18.9 23.2 29.5 33.5 42.7 28.0 33.1 41.1 47.9

SHR (Sen si ble Heat Ratio) 0.97 0.90 0.90 0.92 0.90 0.96 0.96 1.0 0.88

EER(En ergy Out/Input) 3.28 3.24 3.28 3.15 3.41 3.15 3.13 3.26 3.35

Sound Pres sure Level

(3)

dB(A) 51.3 55.4 55.8 57.6 59.1 55.8 57.6 59.1 61.2

Comp. Power Absorbed kW 4.8 6.37 7.53 8.91 10.93 6.84 8.32 9.6 12.8

Comp.Cur rent Ab sorbed A 11.1 11.8 14.7 16.19 18.9 2 x 6.5 2 x 7.98 2 x 11.11 2 x 11.83

To tal Power Absorbed kW 5.95 7.94 9.98 11.6 13.92 9.3 11.0 12.6 16.22

PER FORM ANCE WITH CHILLED WA TER COOLING

To tal Cool ing Ca pac ity kW 24.5 29.6 51.7 63.5 67.3 51.7 63.5 67.3 71.9

Sen si ble Cool ing Ca pac ity kW 21.8 25.5 42.4 48.9 52.5 42.4 48.9 52.5 56.8

Sound Pres sure Level

(3)

dB(A) 50.8 54.9 55.3 57.1 58.6 55.3 57.1 58.6 60.7

In let/Out let Water Temp. °C 7/12 7/12 7/12 7/12 7/12 7/12 7/12 7/12 7/12

Wa ter Flow Rate l/s 1.17 1.41 2.5 3.03 3.21 2.5 3.03 3.21 3.43

To tal Wa ter Pres sure Drop

(4)

kPa 18 + 15 10 + 16 31 + 48 46 + 52 21 + 58 31 + 48 46 + 52 21 + 58 24 + 64

FAN SECTION

Quan tity 1 2

Type Sin gle in let, back ward curved, ra dial cen trifu gal fan (plug fan)

COM PRES SOR

Quan tity 1 2

Type Scroll

Rated Power HP 6 7.8 9 10 13 2 x 4 2 x 5 2 x 6 2 x 7.8

EVAPO RAT ING COIL

Quan tity 1

Tubes/fins Cop per tubes / Treated alu min ium fins

Coil Sur face Area m

2

0.74 1.49

Orientation In clined

CHILLED WA TER CON NEC TIONS (MALE THREADED)

Wa ter Con nec tions inch 1” 1¼“ 1½“ 1¼“ 1½“

RE FRIG ER ANT CON NEC TIONS (Brazed, O.D.)

Hot Gas Line mm 18 22 28 16 18 22

Liq uid Line mm 16 18 22 14 16 18

DI MEN SIONS

Length mm 1000 1750

Depth mm 890

Height mm 1950

Footprint m

2

0.89 1.56

WEIGHTS

Net kg 500 510 790 795 800 805 810 815 820

Gross kg 505 515 795 800 805 810 815 820 825

+

R22 Capacities are approximately the same as R407C capacities + 5%. Consult Liebert Applications Engineers for specific details.

1

At the following standard conditions: 24°C db; 50% R.H. (17°C wb) - condensing temperature: 49° C, Power Supply Voltage 400/3/50, 20Pa ESP (External

Static Pressure)

2

Max available ESP at quoted airflow

3

Measured in front of the unit at 1m height, 2 m distance, in the free field, fan and compressor run ning, 20Pa ESP.

4

Valve pressure drop + coil pressure drop.

5

Valve pressure drop + condenser pressure drop.

Note: Quoted capacities are gross capacities, for nett capacities, deduct fan motor kW. EER is based on i ndoor unit only. Unit air flow is quoted for standard

configuration, with a clean EU4 filter.

Page 27

Air cooled dual source data - up flow units (R407C)+

SLE CP TDM E.1 (06/99) 23

Challenger Plus - Technical Data Manual

MODEL CP20DU CP 24DU CP 28DU CP 34DU CP 40DU CP 26DU CP32DU CP 42DU CP46DU

Re frig er ant cir cuit Sin gle Dou ble

PER FORM ANCE

(1)

Air Flow m3/h 5640 6350 9880 10480 11860 9880 10480 11860 12850

Avail able ESP

(2)

Pa 435 325 410 350 305 410 350 305 240

Fan Power Absorbed kW 1.24 1.66 2.62 2.94 3.46 2.62 2.94 3.46 3.87

Fan Cur rent Absorbed A 4.173 4.41 2 x 4.21 2 x 4.307 2 x 4.4 2 x 4.21 2 x 4.31 2 x 4.4 2 x 4.44

PER FORM ANCE WITH ME CHANI CAL COOL ING

To tal Cool ing Ca pac ity kW 18.8 24.3 32.7 35.9 46.7 29.4 33.5 40.3 53.0

Sen si ble Cool ing Ca pac ity kW 18.1 22.6 29.5 32.7 42.1 28.3 32.2 40.3 46.1

SHR (Sen si ble Heat Ratio) 0.96 0.93 0.90 0.91 0.90 0.96 0.96 1.00 0.87

EER(En ergy In/Output) 3.12 3.02 3.22 3.03 3.25 3.11 2.97 3.09 3.19

Sound Pres sure Level

(3)

dB(A) 52.9 57.1 57.8 58.10 61.6 57.8 58.1 61.6 63.4

Comp. Power Absorbed kW 4.80 6.4 7.53 8.90 10.92 6.84 8.32 9.60 12.74

Comp. Cur rent Absorbed A 11.09 11.83 14.7 16.17 18.88 2 x 6.48 2 x 7.99 2 x 11.1 2 x 11.83

To tal Power Absorbed kW 6.04 8.03 10.15 11.84 14.38 9.45 11.26 13.06 16.62

PER FORM ANCE WITH CHILLED WA TER COOL ING

To tal Cool ing Ca pac ity kW 24.6 29.8 50.8 58.6 63.9 50.8 58.6 63.9 67.4

Sen si ble Cool ing Ca pac ity kW 21.9 25.6 41.7 46.3 51.1 41.7 46.3 51.1 54.6

Sound Pres sure Level

(3)

dB(A) 52.4 56.6 57.3 57.6 61.1 57.3 57.6 61.1 62.9

In let/Out let Wa ter

Tem pera ture

°C 7/12 7/12 7/12 7/12 7/12 7/12 7/12 7/12 7/12

Wa ter Flow Rate l/s 1.2 1.42 2.42 2.8 3.04 2.42 2.8 3.04 3.21

To tal Wa ter Pres sure Drop

(4)

kPa 18 + 15 10 + 16 30 + 47 40 + 46 19 + 53 30 + 47 40 + 46 19 + 53 21 + 58

FAN SECTION

Quan tity 1 2

Type Sin gle in let, back ward curved, ra dial cen trifu gal fan (plug fan)

COM PRES SOR

Quan tity 1 2

Type Scroll compressor

Rated Power HP 6 7.8 9 10 13 2 x 4 2 x 5 2 x 6 2 x 7.8

EVAPO RA TOR COIL

Quan tity 1

Tubes/Fins Cop per tubes / Treated alu min ium fins

Coil Sur face Area m

2

0.74 1.49

Orientation In clined

CHILLED WA TER CON NEC TIONS (MALE THREADED)

Wa ter Con nec tions inch 1” 1¼“ 1½“ 1¼“ 1½“

RE FRIG ER ANT CON NEC TIONS (Brazed, O.D.)

Hot Gas Line mm 18 22 28 16 18 22

Liq uid line mm 16 18 22 14 16 18

DI MEN SIONS

Length mm 1000 1750

Depth mm 890

Height mm 1950

Footprint m

2

0.89 1.56

WEIGHTS

Net kg 500 510 790 795 800 815 820 825 830

Gross kg 505 515 795 800 805 820 825 830 835

+

R22 Capacities are approximately the same as R407C capacities + 5%. Consult Liebert Applications Engineers for specific details.

1

At the following standard conditions: 24°C db; 50% R.H. (17°C wb) - condensing temperature: 49° C.

Power Supply Voltage 400/3/50, 50Pa ESP (External Static Pressure)

2

Max available ESP at quoted airflow

3

Measured in front of the unit at 1m height, 2 m distance, in the free field, fan and compressor run ning, 50Pa ESP.

4

Valve pressure drop + coil pressure drop.

5

Valve pressure drop + condenser pressure drop.

Note: Quoted capacities are gross capacities, for nett capacities, deduct fan motor kW. EER is based on i ndoor unit only. Unit air flow is quoted for standard

configuration, with a clean EU4 filter.

Page 28

Wa ter cooled dual source data - down flow units (R407C)

+

24 SLE CP TDM E.1 (06/99)

Challenger Plus - Technical Data Manual

MODEL CP20HD CP 24HD CP 28HD CP 34HD CP 40HD CP 26HD CP 32HD CP 42HD CP46HD

Re frig er ant Cir cuit Sin gle Dou ble

PER FORM ANCE WITH ME CHANI CAL COOL ING

(1)

Air Flow m3/h 5570 6280 9980 10960 11910 9980 10960 11910 13100

Avail able ESP

(2)

Pa 435 325 410 390 340 410 390 340 280

Fan Power Ab sorbed kW 1.15 1.57 2.46 2.68 3.00 2.45 2.67 2.99 3.47

Fan Cur rent Ab sorbed A 4.11 4.41 2 x 4.16 2 x 4.25 2 x 4.35 2 x 4.16 2 x 4.23 2 x 4.35 2 x 4.423

Sound Pres sure Level

(3)

dB(A) 51.3 55.4 55.8 57.6 59.1 55.8 57.6 59.1 61.2

Wa ter in let tem pera ture: 24°C - Con densing Tem pera ture: 40.5°C (0% gly col)

To tal Cool ing Ca pac ity kW 21.0 27.9 35.6 40.0 51.1 32.3 37.6 45.2 58.6

Sen si ble Cool ing Ca pac ity kW 19.3 24.0 30.2 34.8 44.0 29.1 34.3 42.0 49.2

SHR (Sen si ble Heat Ra tio) 0.92 0.86 0.85 0.87 0.86 0.90 0.91 0.93 0.84

EER(En ergy Out/In put) 4.11 4.06 4.10 4.01 4.20 4.00 3.92 4.13 4.16

Wa ter Flow Rate l/s 0.392 0.653 0.791 0.853 1.158 0.621 0.792 0.875 1.404

To tal Wa ter Pres sure Drop

(5)

kPa 6 + 5 18 + 13 7 + 11 8 + 8 14 + 11 3 + 8 4 + 14 2 + 6 5 + 15

Comp. Power Ab sorbed kW 3.97 5.29 6.22 7.31 9.18 5.60 6.92 7.94 10.60

Comp. Cur rent Ab sorbed A 10.33 10.40 12.81 14.34 16.38 2 x 5.78 2 x 7.24 2 x 10.32 2 x 10.4

To tal Power Ab sorbed kW 5.12 6.86 8.67 9.99 12.17 8.06 9.60 10.94 14.07

Wa ter in let tem pera ture: 30°C - Con densing Tem pera ture: 45°C (0% gly col)

To tal Cool ing Ca pac ity kW 20.3 27.0 34.0 38.2 49.6 31.0 36.3 43.3 56.7