Page 1

DC P

OWER

Helios DC System 4000/48

1500, 3000, 4000 & 6000 A

DC Power System

User

Manual

Page 2

Page 3

TABLE OF CONTENTS

1.0 A

BOUT THIS DOCUMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Purpose of This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Applicability of This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 I

NTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Control and Distribution Cabinets - Typical Configurations. . . . . . . . . . . . . . . . . . . . . . . 4

3.0 S

PECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 Framework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.1 Mechanical Specifications of a Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.2 Electrical Specifications of the Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Conventional Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.1 Mechanical Specifications of the Conventional Controller . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.2 Electrical Specifications of the Conventional Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Distribution Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3.1 Fuse Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3.2 Circuit Breaker Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Externally Mounted Battery Return Busbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.1 Mechanical Specifications of the External Battery Return Busbar . . . . . . . . . . . . . . . . . 18

3.4.2 Electrical Specifications of the External Battery Return Busbar . . . . . . . . . . . . . . . . . . . 18

3.5 Terminating Assemblies (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6 MPS300 and MPA100 Power Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6.1 Mechanical Specifications of the MPS300 and MPA100 Power Shelves . . . . . . . . . . . . . 20

3.6.2 Electrical Specifications of the Power Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7 Rectifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.1 Helios Rectifier 100/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.2 Helios Rectifiers 200I/48 and 200E/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.7.3 Electrical Specifications of the Helios Rectifiers 200I/48 and 200E/48. . . . . . . . . . . . . . . 24

3.7.4 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.8 Helios Monitor 3000/48 (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.8.1 Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.8.2 Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.9 600 A and 1200 A Battery Disconnect Unit (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.10 AC Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.10.1 Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.10.2 Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

i

Page 4

3.11 Overall Power System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.11.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.11.2 Mechanical Specifications of Fully Equipped Power Cabinets . . . . . . . . . . . . . . . . . . . . . 26

3.11.3 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.11.4 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.11.5 Floor and Point Loading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.0 O

PERATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Conventional Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.2 Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3 MPS300 and MPA100 Power Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Rectifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5 AC Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6 Distribution Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.7 Terminating Assemblies (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.8 Helios Monitor 3000/48 (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.9 600 A and 1200 Battery Disconnect Units (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.0 M

AINTENANCE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.1 Helios Monitor 3000/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.2 Controller and Rectifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3 Addition / Replacement Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.1 Addition or Replacement of a Rectifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.2 Replacing a Rectifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3.3 Adding or Replacing a Battery String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3.4 Replacement of a Distribution Fuse Block or Circuit Breaker . . . . . . . . . . . . . . . . . . . . . 48

5.3.5 Replacing a Cabinet Alarm Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.0 R

7.0 L

EFERENCE DOCUMENTS

IST OF TERMS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

ii

Page 5

FIGURES

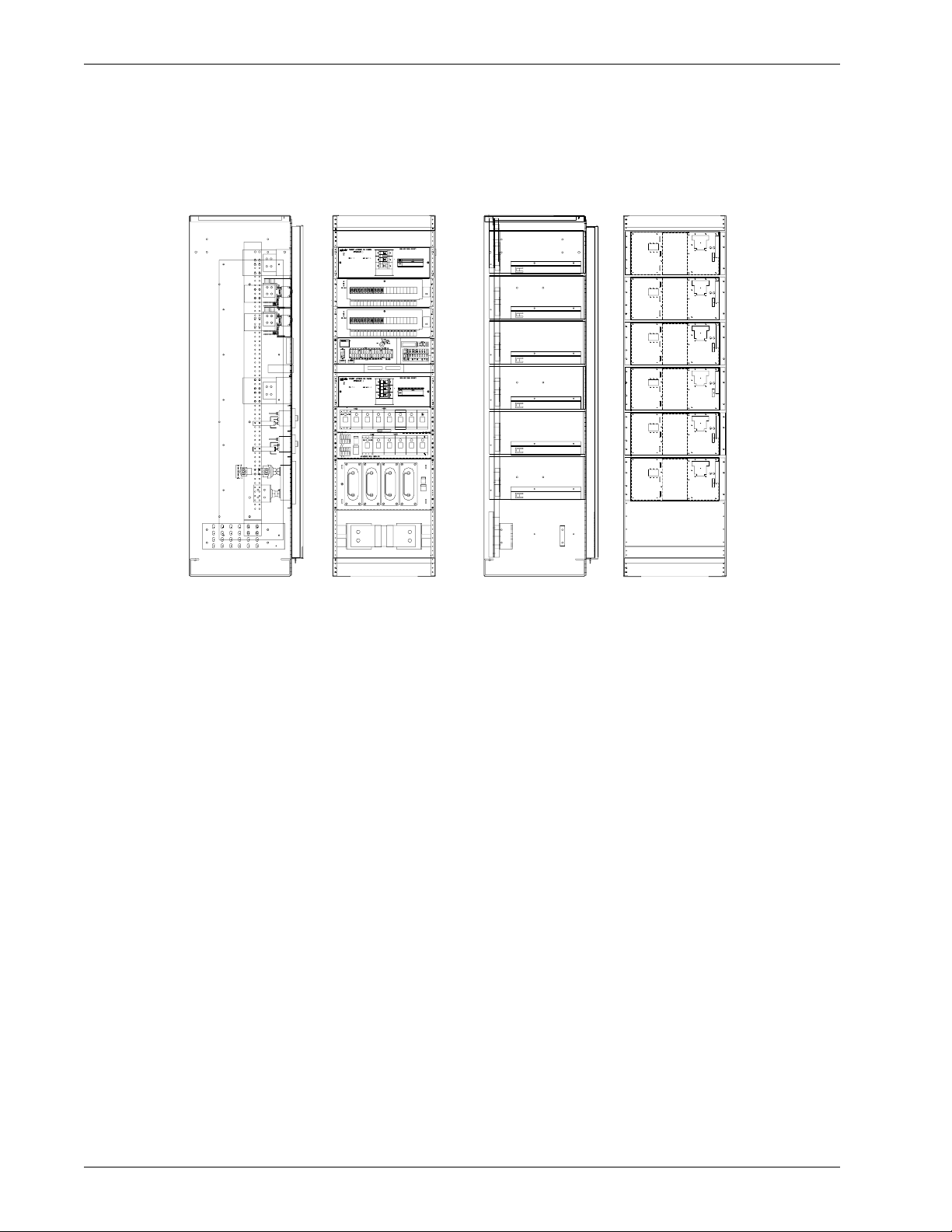

Figure 1 Front view of a typical bottom fed 4000 A Helios DC System 4000/48 power system . . . . . . . 2

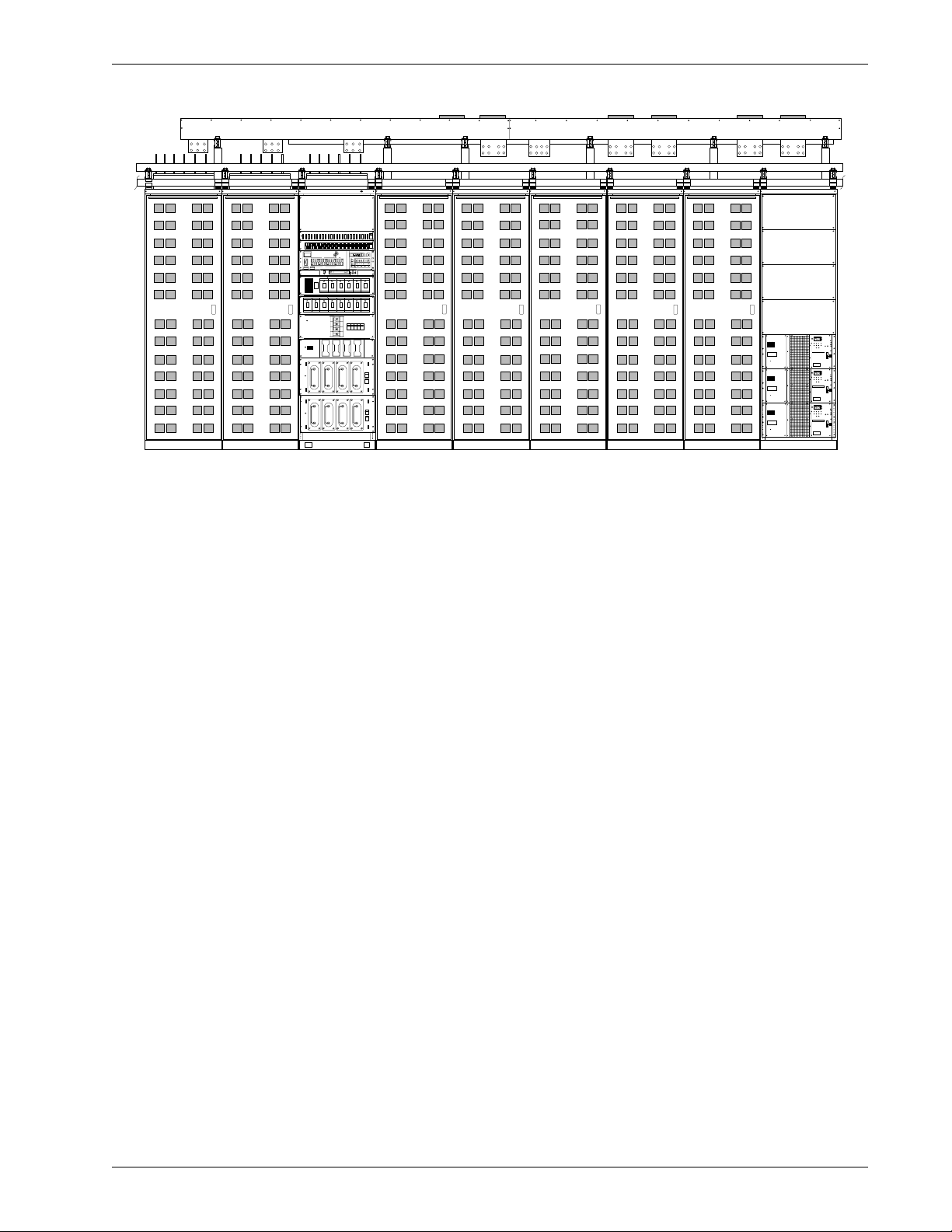

Figure 2 Front view of a typical 6000 A Helios DC System 4000/48 power system . . . . . . . . . . . . . . . . 3

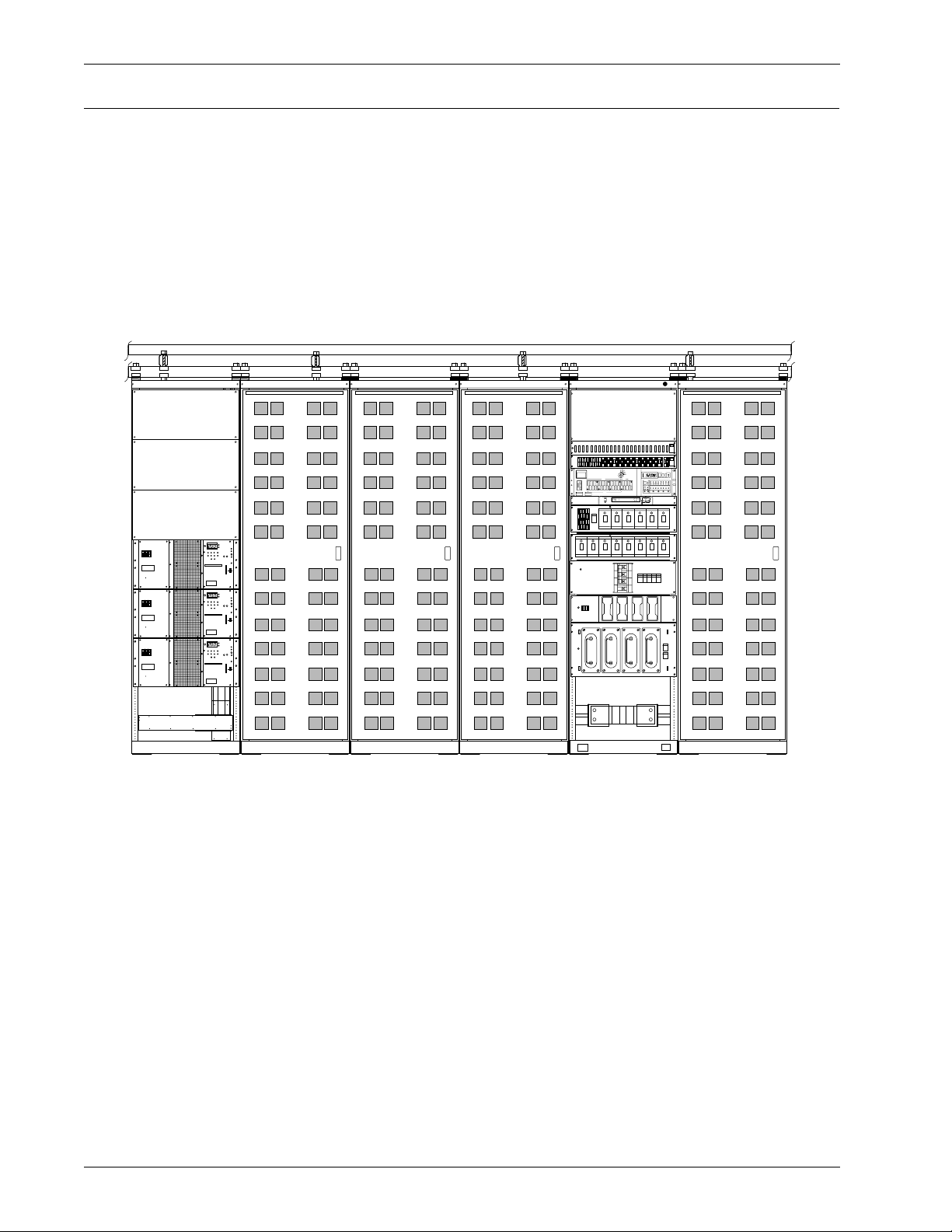

Figure 3 Typical configurations for Helios DC System 4000/48 control, distribution and

rectifier cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4 Front view of the Conventional Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

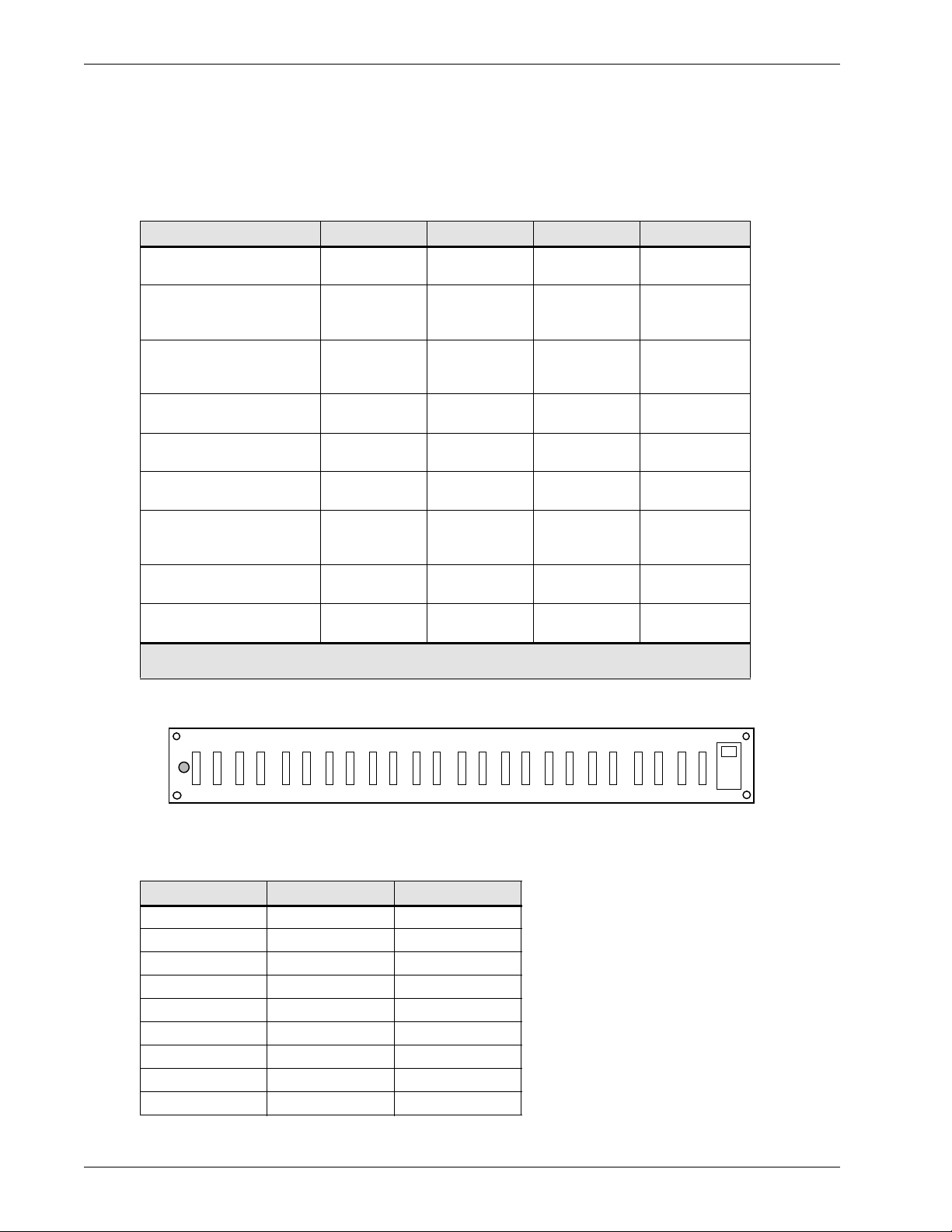

Figure 5 Front view of the 20 QFF 0-5 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6 Front view of the (16) QFF 0-5 A & (12) ABS 5-30 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7 Front view of the (16) QFF 0-5 A & (6) TPN 5-30 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 8 Front view of the (8) TPN 5-30 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 9 Front view of the (4) RS100P 70-100 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 10 Front view of the (4) CRS200P 150-200 A /

(4) CRS200P 150-200 A (w/load shunts) fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 11 Front view of the (4) TPL 225-600 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

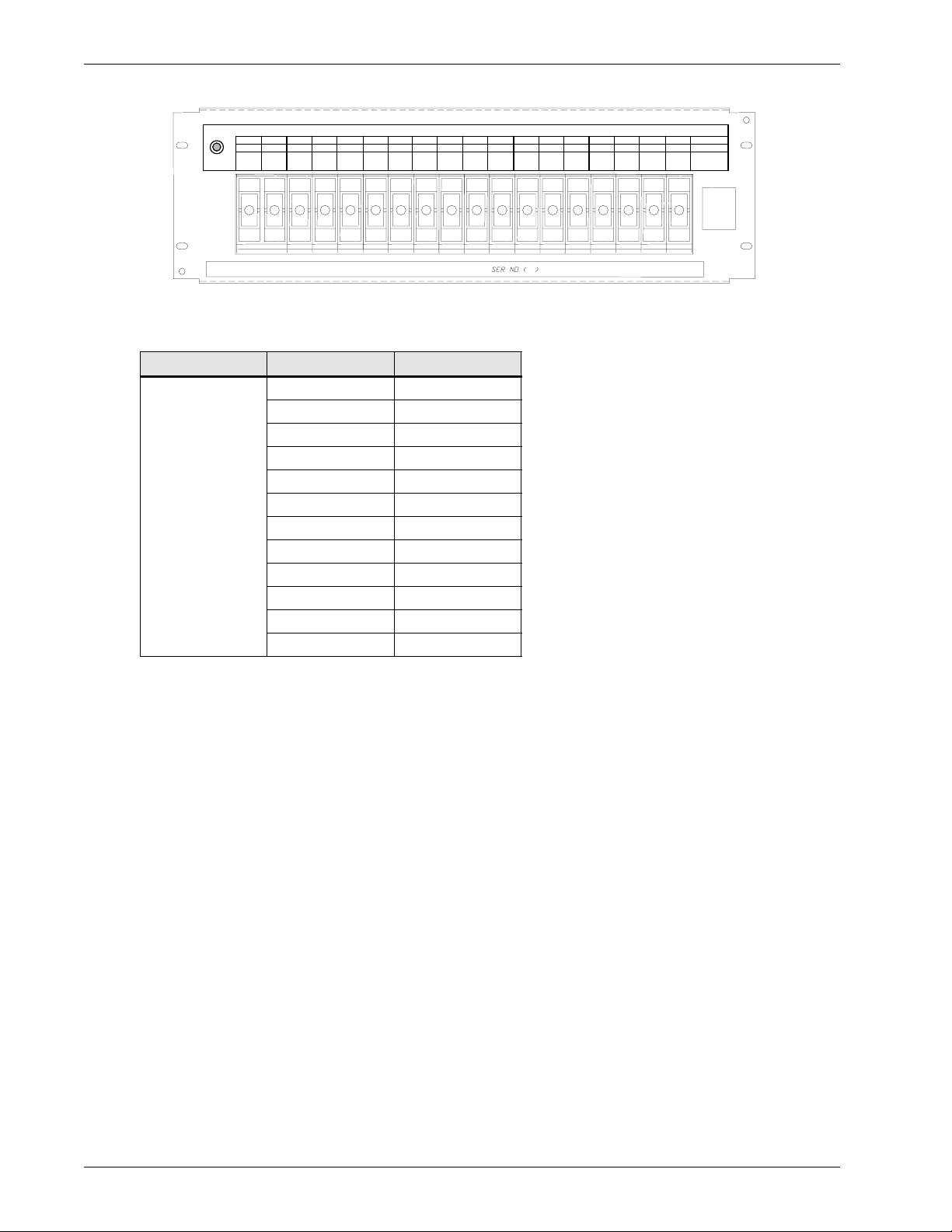

Figure 12 Front view of the (18) TPS 1-70 A fuse panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

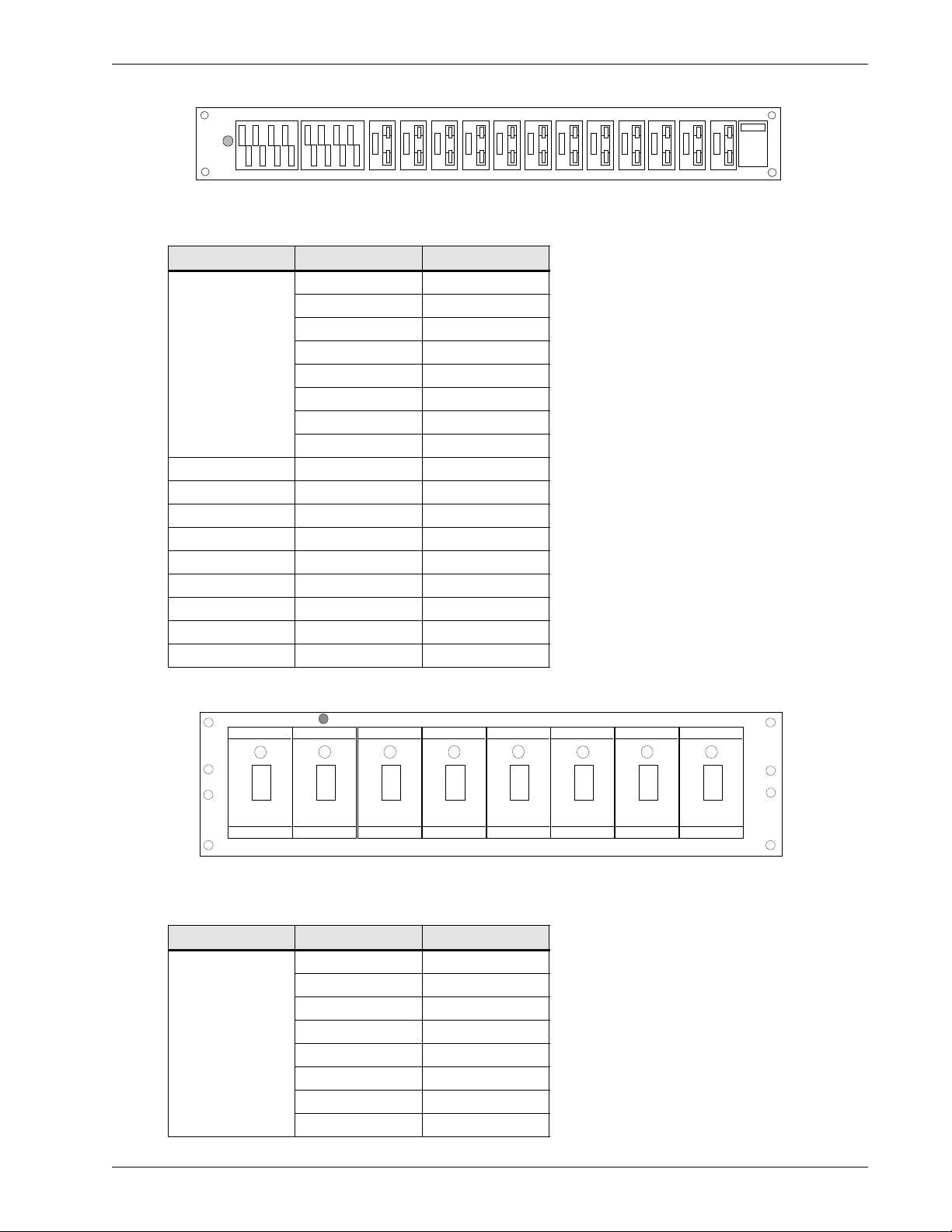

Figure 13 Front view of the (24) Plug-In 1-100 A circuit breaker panel . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 14 Front view of the (4) 70-250 A circuit breaker panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

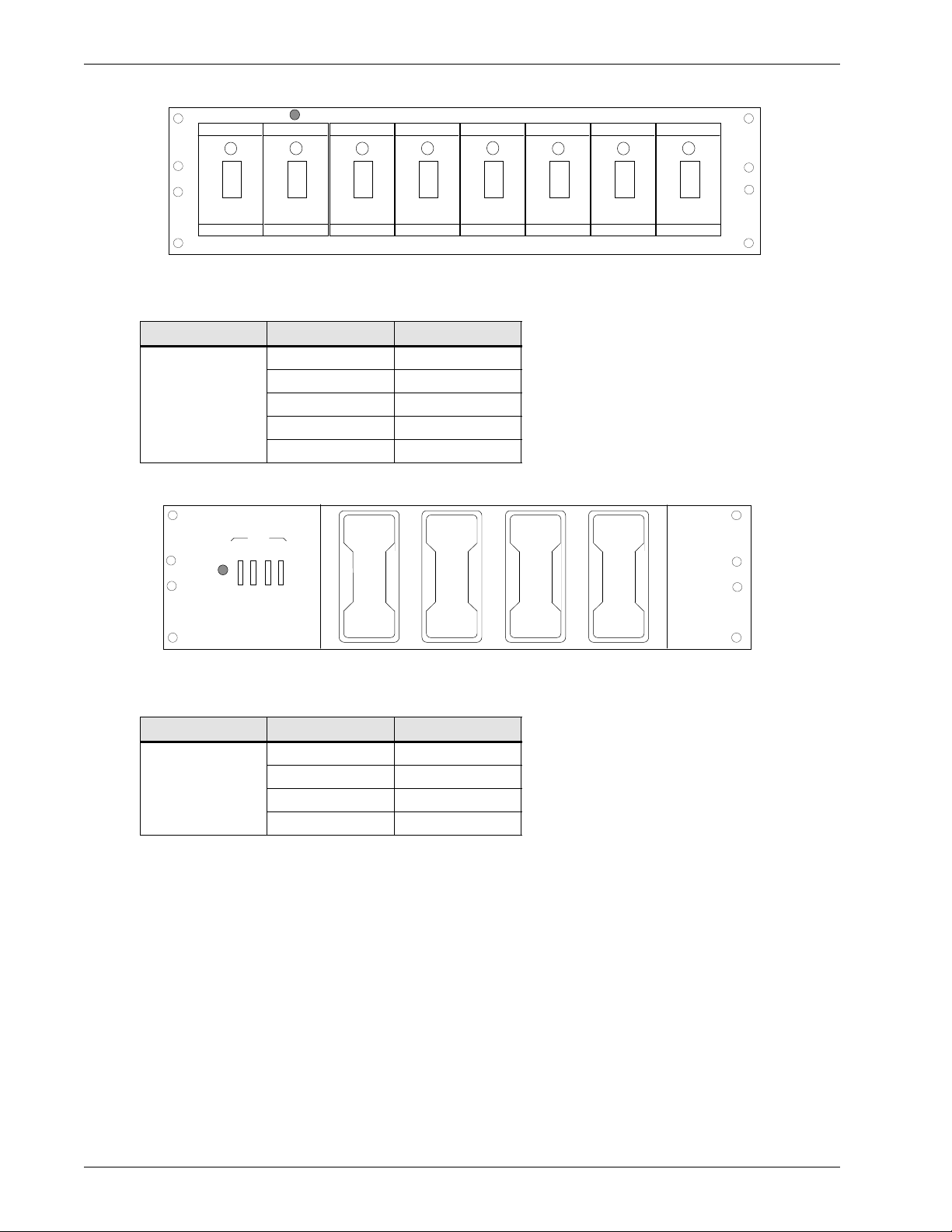

Figure 15 Front view of the (2) 400 A circuit breaker panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

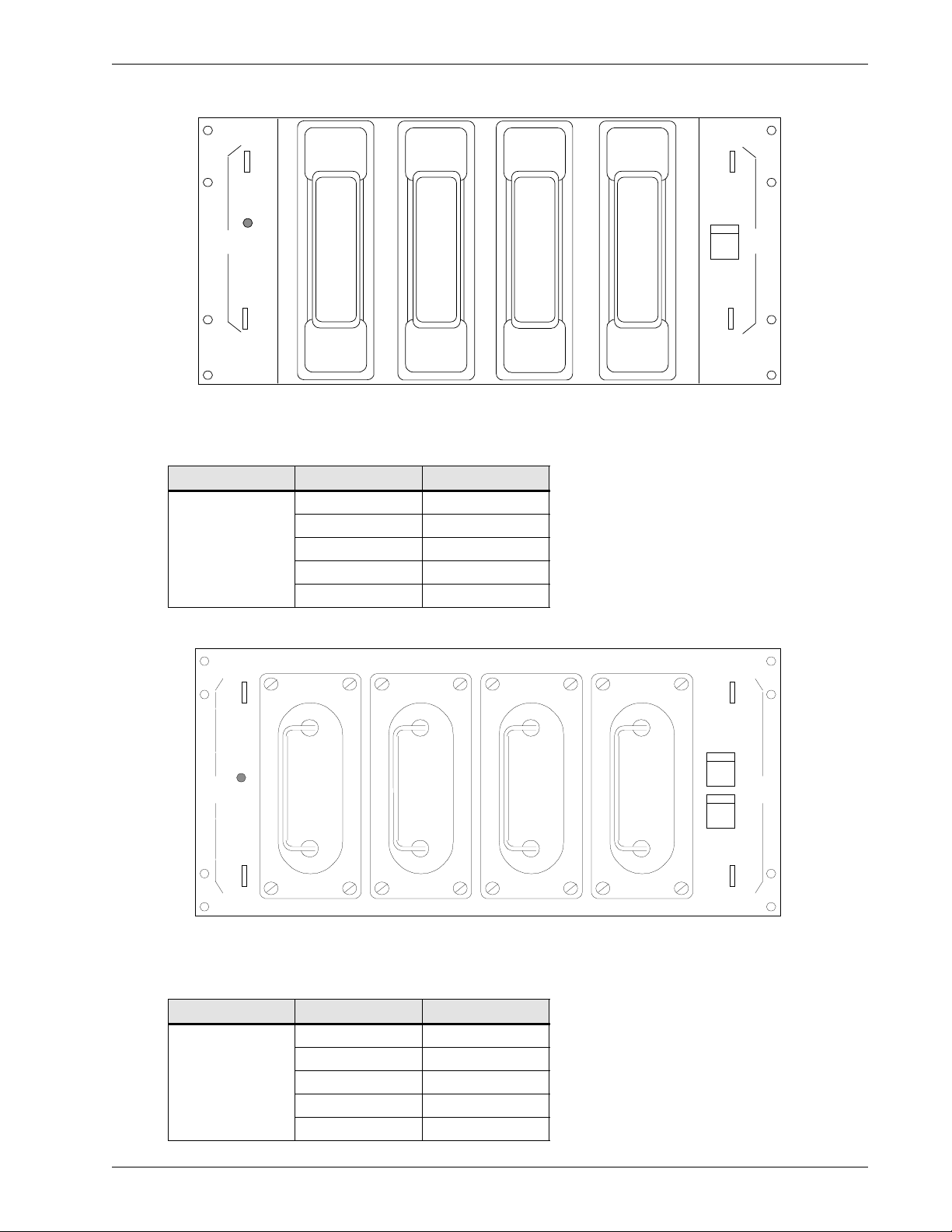

Figure 16 Front view of the (1) 600-700 A circuit breaker panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 17 Top and side views of the external battery return busbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 18 Perspective view of the a terminating assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 19 Front view of the MPS300 power shelf (shown empty) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 20 Front view of the MPA100 power shelf (shown empty) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 21 Front view of the Helios Rectifier 100/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 22 Front view of the Helios Rectifiers 200I/48 and 200E/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 23 Front view of the Helios Monitor 3000/48 (without the mounting brackets) . . . . . . . . . . . . . 25

Figure 24 600 A Battery Disconnect Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 25 Front view of the AC junction box (with the front panel open) . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 26 Front view of the Conventional Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 27 Shunt range selection settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 28 Equalize voltage and duration settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 29 Terminal blocks and connectors layout at the rear of the Conventional Controller. . . . . . . . 32

Figure 30 Wiring diagram and pin assignment of terminal blocks TB1 to TB4 . . . . . . . . . . . . . . . . . . . 33

Figure 31 Wiring diagram and pin assignment of terminal blocks TB5 and TB6, and

connectors P1 to P26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 32 AC connections in a Helios Rectifier 200E/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 33 AC connections in the female receptacle for a Helios Rectifier 200I/48 or

a Helios Rectifier 200E/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 34 AC connections inside the junction box (top fed shown) for a Helios Rectifier 200E/48. . . . . 43

Figure 35 AC cable routing for the Helios Rectifiers 200E/48 in a top fed system . . . . . . . . . . . . . . . . . 44

Figure 36 AC cable routing for the Helios Rectifiers 200E/48 in a bottom fed system . . . . . . . . . . . . . . 44

iii

Page 6

TABLES

Table 1 Rectifier cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2 Control and distribution cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3 Auxiliary distribution cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 4 Mechanical specifications of the cabinet (empty) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 5 Mechanical specifications of the Conventional Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 6 Mechanical specifications of the fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 7 Fuse sizes available for the (20) QFF 0-5 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 8 Fuse sizes available for the (16) QFF 0-5 A & (12) ABS 5-30 A fuse panels . . . . . . . . . . . . . . . 9

Table 9 Fuse sizes available for the (16) QFF 0-5 A & (6) TPN 5-30 A fuse panels . . . . . . . . . . . . . . . . 9

Table 10 Fuse sizes available for the (8) TPN 5-30 A fuse panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 11 Fuse sizes available for the (4) RS100P 70-100 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 12 Fuse sizes available for the (4) CRS200P 150-200 A/

(4) CRS200P 150-200 A (w/load shunts) fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 13 Fuse sizes available for the (4) TPL 225-600 A fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 14 Fuse sizes available for the (18) TPS 1-70 A fuse panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 15 Electrical specifications of the fuse panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 16 Mechanical specifications of the circuit breaker panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 17 Plug-in circuit breakers available for the (24) Plug-In 1-100 A circuit breaker panel . . . . . . 14

Table 18 Circuit breaker sizes available for the (4) 70-250 A circuit breaker panel . . . . . . . . . . . . . . . 15

Table 19 Circuit breaker kits available for the (2) 400 A circuit breaker panel . . . . . . . . . . . . . . . . . . . 16

Table 20 Circuit breaker kits available for the (1) 600-700 A circuit breaker panel . . . . . . . . . . . . . . . 16

Table 21 Electrical specifications of the circuit breaker panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 22 Mechanical specifications of a single lamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 23 Mechanical specifications of the MPS300 and MPA100 power shelves . . . . . . . . . . . . . . . . . . 20

Table 24 Mechanical specifications of the Helios Rectifier 100/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 25 Electrical specifications of the Helios Rectifier 100/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 26 Mechanical specifications of the Helios Rectifiers 200I/48 and 200E/48 . . . . . . . . . . . . . . . . . 22

Table 27 Electrical specifications of the Helios Rectifiers 200I/48 and 200E/48 . . . . . . . . . . . . . . . . . . 24

Table 28 Mechanical specifications of the Helios Monitor 3000/48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 29 Mechanical specifications of the AC junction box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 30 Mechanical specifications of fully equipped power cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 31 Floor and point loading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 32 Visual indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 33 Transmitted alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 34 Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 35 Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 36 DIP switch modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 37 Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 38 Test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 39 Fault diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

iv

Page 7

1.0 A

BOUT THIS DOCUMENT

1.1 Purpose of This Document

This document provides all the necessary information to operate and maintain a Helios DC Sys-

tem 4000/48 power system.

The installation procedures for the Helios DC System 4000/48 power system are covered in instal-

lation manual SL-60034.

1.2 Applicability of This Document

This document applies to Helios DC System 4000/48 power systems having any configuration of

equipment.

About This Document 1

Page 8

2.0 I

NTRODUCTION

2.1 Description

The Helios DC System 4000/48 is a positive ground, -48 V DC nominal power system consisting of

one control and distribution cabinet and one or more rectifier cabinets. It is available in capacities

of 1500, 3000, 4000 and 6000 A. Auxiliary distribution cabinets can be added as required for additional distribution. Remote monitoring, temperature compensation and battery disconnect

options are also available. The 1500, 3000 and 4000 A versions use internal -48 V bussing and

external BR+ bussing, while the 6000 A version uses overhead bussing.

bottom fed 4000 A system, while

Figure 1 Front view of a typical bottom fed 4000 A Helios DC System 4000/48 power system

Figure 2

shows a typical 6000 A system.

Figure 1

shows a typical

1200 A rectifier cabinets

Main cabinet

Aux dist. cabinet

2 Introduction

Page 9

Figure 2 Front view of a typical 6000 A Helios DC System 4000/48 power system

Aux dist. cabinets Main cabinet

Cables are used for inter-cabinet connections (1500, 3000 and 6000 A systems) or connections to

the overhead busbars (6000 A system) for ease of expansion on live systems. In a 1500, 3000 or

4000 A systems, the power system battery return (BR) busbar is mounted externally from the cab-

inet to facilitate the connections of the battery return cables. In a 6000 A system, a separate BR

busbar dedicated to the battery returns for the loads is mounted externally from the overhead

busbar duct to facilitate the connections of the load battery return cables.

The Helios DC System 4000/48 provides a variety of monitoring and alarm features, such as high/

low float and high/low voltage alarm, high voltage shutdown, fuse and breaker alarm and rectifier

failure alarms.

The Helios DC System 4000/48 uses Helios Rectifiers 200I/48, Helios Rectifiers 200E/48 or Helios

Rectifiers 100/48 connected in parallel as building blocks to reach the maximum capacities. The

Helios Rectifiers 200I/48 operate from a 380 V to 415 V three phase, 50 or 60 Hz AC source. The

Helios Rectifiers 200I/48 operate from a 480 V three phase, 50 or 60 Hz AC source. The Helios

Rectifiers 100/operate from a 208 V to 240 V single phase, 50 or 60 Hz AC source.

The 1200 A rectifier cabinet accepts up to six Helios Rectifiers 200I/48 or 200E/48, while the 1000

A rectifier cabinet accepts up to 10 Helios Rectifiers 100/48.

The control and distribution cabinet and the auxiliary distribution cabinets are available with

distribution busbar risers of 2000 A or 3000 A capacity.

The cabinets are seismic qualified to zone 4 (Bellcore) when anchored to a concrete floor whose

compressive strength is at least 2.11 kg/mm

The cabinets are seismic qualified to zone 2 without the seismic kit.

2

(3000 psi) and when equipped with a seismic kit.

1200 A rectifier cabinets

The cabinets are equipped with a ventilated, lockable door, a ventilated top cover and two rear

ventilated panels.

In many applications, such as with DMS, a consistent single-point ground (SPG) topology must be

maintained for all associated equipment. The Helios DC System 4000/48 complies with this

requirements for single-point grounding (the isolation kit is required).

2.2 Applications

The Helios DC System 4000/48 is designed to operate with DMS systems or any other telecommu-

nication systems whose input is nominal -48 V DC and whose current requirements do not exceed

6000 A capacity.

Introduction 3

Page 10

2.3 Control and Distribution Cabinets - Typical Configurations

Figure 3

DC System 4000/48 (bottom cabled cabinets are illustrated - top cabled versions are available).

Figure 3 Typical configurations for Helios DC System 4000/48 control, distribution and rectifier

shows the front and side views of typical rectifier and distribution cabinets for a Helios

cabinets

Control and Distribution cabinet 1200A Rectifier cabinet

4 Introduction

Page 11

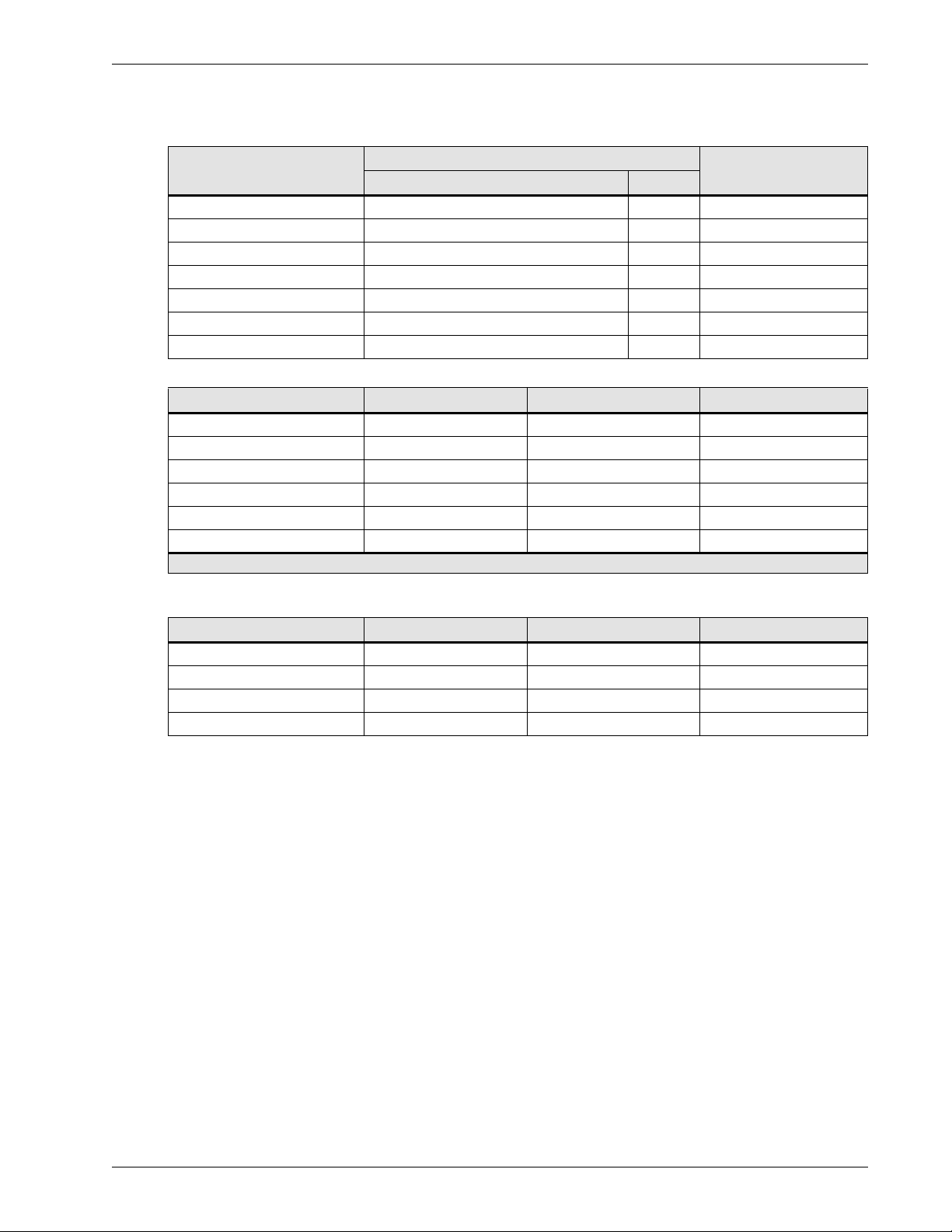

Cabinets are available in a variety of configurations as listed in the following tables. Note that for

a 6000 A system, the cabling is always at the top.

Table 1 Rectifier cabinets

Rectifier

Cabinet Capacity

1200 A Helios Rectifier 200I 6 Top

1200 A Helios Rectifier 200I 6 Bottom

1000 A Helios Rectifier 100/48 10 Top or bottom

1200 A Helios Rectifier 200E 6 Top

1200 A Helios Rectifier 200E 6 Bottom

1200 A Helios Rectifier 200E 6 Top

1200 A Helios Rectifier 200E 6 Bottom

Cabled top or bottomType Qty

Table 2 Control and distribution cabinets

Nominal cabinet capacity Shunt capacity Riser busbar capacity Cabled top or bottom

1500 A 2500 A 2000 A Top

3000 A 4000 A 3000 A Top

4000 A 5000 A 3000 A Top

1500 A 2500 A 2000 A Bottom

3000 A 4000 A 3000 A Bottom

4000 A 5000 A 3000 A Bottom

For a 6000 A system, the charge busbars and the shunt are mounted externally from the control and distribution cabinet.

Table 3 Auxiliary distribution cabinets

Nominal cabinet capacity Top busbar capacity Riser busbar capacity Cabled top or bottom

2000 A 3000 A 2000 A Top

2000 A 3000 A 2000 A Bottom

3000 A 4000 A 3000 A Top

3000 A 4000 A 3000 A Bottom

Introduction 5

Page 12

3.0 S

PECIFICATIONS

3.1 Framework

The Helios DC System 4000/48 uses cabinet type frameworks. The same cabinet design is used for

the main control and distribution cabinet, the auxiliary distribution cabinets and the rectifier cabinets. The cabinet is always equipped with a front door and door frame (lockable, equipped with

ground straps, and easily removable for installation or maintenance access), a ventilated top

cover made of non-flammable plastic, and two ventilated rear cover panels (equipped with ground

strap and easily removable for installation and maintenance access). Bussing and equipment

(controller, rectifiers, distribution panels, etc.) are added as required, depending on the use of the

cabinet. Seismic bracing is also available as options.

When using the Cable Trough, overhead cabling cannot enter from the front or rear of the system.

It must be confined to the system foot print and enter at the ends of the lineup.

The cabinets may be either top or bottom cabled as determined by the location of the bussing.

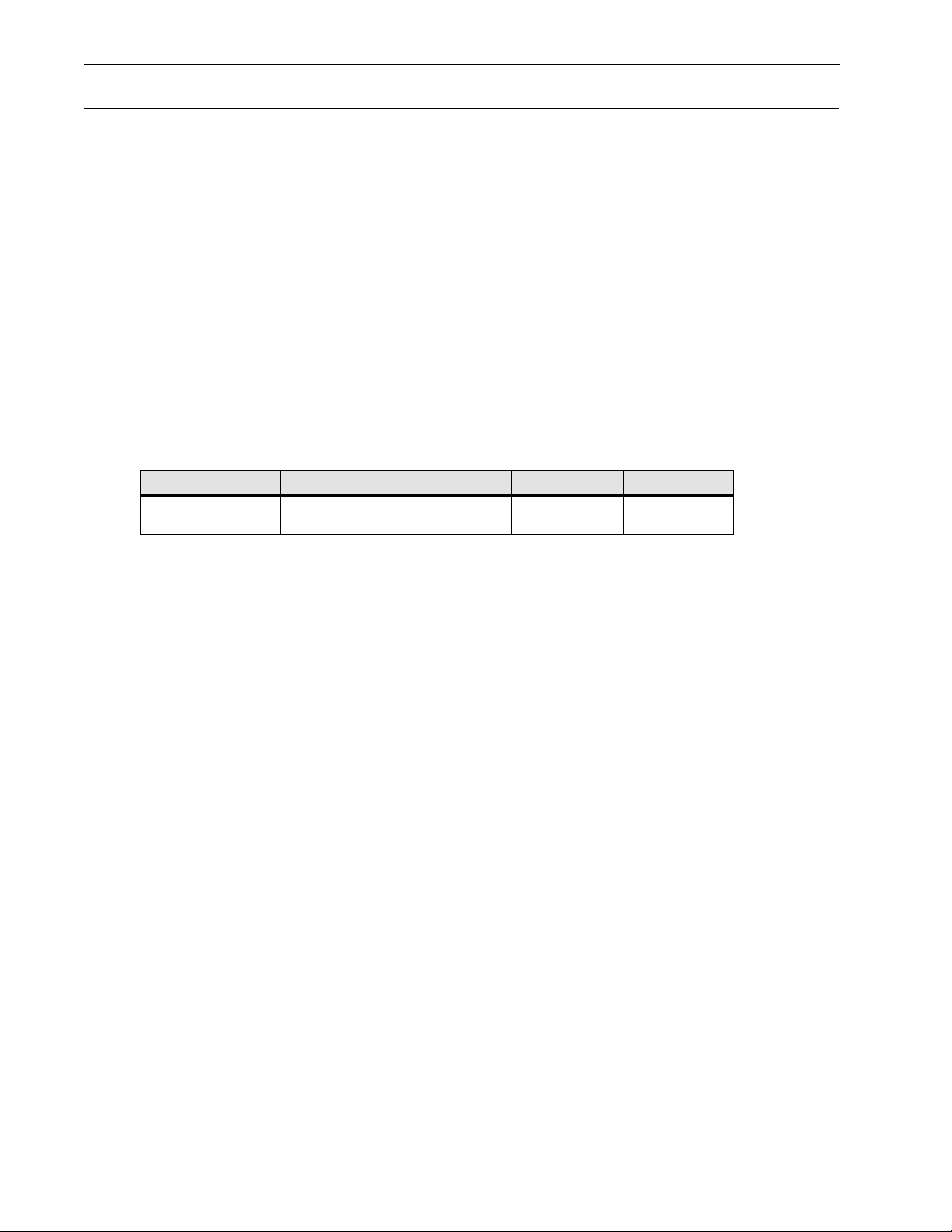

3.1.1 Mechanical Specifications of a Cabinet

The mechanical specifications of an empty cabinet are listed in

Table 4 Mechanical specifications of the cabinet (empty)

Framework type Height Depth Width Weight

Cabinet 2134 mm

Refer to

Figure 3

(84.0 in.)

for typical views of cabinets.

600 mm

(23.6 in.)

3.1.2 Electrical Specifications of the Cabinets

The electrical specifications of equipped cabinets are as follows:

• The main control and distribution cabinet for a 1500 A system has a 2000 A busbar riser and

a common equipment panel e/w one 1500 A CHG and DISCH busbar and a 2500 A system

shunt.

• The main control and distribution cabinet for a 3000A system has a 3000 A busbar riser and a

common equipment panel e/w two 1500 A CHG and DISCH busbars and a 4000 A system

shunt.

• The main control and distribution cabinet for a 4000A system has a 3000 A busbar riser and a

common equipment panel e/w three 1500 A CHG and DISCH busbars and a 5000 A system

shunt.

• A 6000 A system has a 3000 A busbar riser in the main control and distribution cabinet (the

CHG and DISCH busbar and the shunt are external).

• The auxiliary distribution cabinet is available with a 2000 or 3000 A busbar riser.

• A 1200 A rectifier cabinet has 1500 A busbar risers for the DC output of the rectifiers.

600 mm

(23.6 in.)

Table 4.

114 kg

(251 lb)

6 Specifications

Page 13

3.2 Conventional Controller

3.2.1 Mechanical Specifications of the Conventional Controller

The mechanical specifications of the Conventional Controller are listed in

Table 5 Mechanical specifications of the Conventional Controller

Figure Height Depth Width Weight

Figure 4

152 mm

(6.0 in.)

76 mm

(3.0 in.)

584 mm

(23 in.)

Figure 4 Front view of the Conventional Controller

3.2.2 Electrical Specifications of the Conventional Controller

The operating voltage is -48 V DC. Refer to the

listed in

6.0 - Reference Documents

for a detailed list of specifications, operating parameters

and features of the Conventional Controller.

4.0 - Operation

Table 5.

4.5 kg

(10 lb)

and the appropriate user manual

Specifications 7

Page 14

3.3 Distribution Panels

3.3.1 Fuse Panels

Mechanical specifications of the fuse panels

The mechanical specifications of the fuse panels are listed in

Table 6

below.

Table 6 Mechanical specifications of the fuse panels

Panel description Figure Height Width Weight

(20) QFF 0-5 A

60 A max

(16) QFF 0-5 A &

(12) ABS 5-30 A

300 A max

(16) QFF 0-5 A &

(6) TPN 5-30 A

250 A max

(8) TPN 5-30 A

250 A max

(4) RS100P 70-100 A

300 A max

(4) CRS200P 150-200 A

600 A max

(4) CRS200P 150-200 A

(w/load shunts)

600 A max

(4) TPL 225-600 A

1600 A max

(18) TPS 1-70 A

600 A max

An alarm circuit pack with an alarm indication LED is standard on all panels

Note 1:

(4) CRS200P 150-200 A (w/load shunts) is equipped with four shunts.

Note 2:

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 10

Figure 11

Figure 12

76.2 mm

(3.0 in.)

76.2 mm

(3.0 in.)

152.4 mm

(6.0 in.)

152.4 mm

(6.0 in.)

152.4 mm

(6.0 in.)

228.6 mm

(9.0 in.)

228.6 mm

(9.0 in.)

304.8 mm

(12.0 in.)

178 mm

(7.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

3 kg

(6.6 lb)

5 kg

(11.0 lb)

7 kg

(15.4 lb)

7 kg

(15.4 lb)

8 kg

(17.8 lb)

22 kg

(48.4 lb)

24 kg

(52.9 lb)

32 kg

(70.4 lb)

35 kg

(77.0 lb)

Figure 5 Front view of the 20 QFF 0-5 A fuse panels

FA

The DC output connections are wire wrap or solder.

Table 7 Fuse sizes available for the (20) QFF 0-5 A fuse panels

Fuse type Current (A) CPC

QFF1A 1.333 A0205202

QFF1B 2 A0205203

QFF1C 3 A0205204

QFF1D 5 A0205205

QFF1E 0.18 A0205206

QFF1F 0.25 A0205207

QFF1G 0.5 A0205208

QFF1H 0.75 A0205209

QFF3A DUMMY A0205210

8 Specifications

Page 15

Figure 6 Front view of the (16) QFF 0-5 A & (12) ABS 5-30 A fuse panels

FA

-48 V

The DC output connections are No. 8-32 studs equipped with two hex nuts.

Table 8 Fuse sizes available for the (16) QFF 0-5 A & (12) ABS 5-30 A fuse panels

Fuse type Current (A) CPC

5 A0327000

8 A0111415

10 A0315462

4AB (ABS)

QFF1A 1.333 A0205202

QFF1B 2 A0205203

QFF1C 3 A0205204

QFF1D 5 A0205205

QFF1E 0.18 A0205206

QFF1F 0.25 A0205207

QFF1G 0.5 A0205208

QFF1H 0.75 A0205209

QFF3A DUMMY A0205210

12 A0267003

15 A0344157

20 A0314873

25 A0243206

30 A0328460

Figure 7 Front view of the (16) QFF 0-5 A & (6) TPN 5-30 A fuse panels

FA

ALM 1/2 A

-48 V

The DC output connections are 0.250-20 studs equipped with two hex nuts.

Table 9 Fuse sizes available for the (16) QFF 0-5 A & (6) TPN 5-30 A fuse panels

Fuse type Current (A) CPC

1 A0380108

3 A0380109

6 A0380111

DC power (TPN)

10 A0380112

15 A0380113

20 A0380147

25 A0380148

30 A0380149

Specifications 9

Page 16

Figure 8 Front view of the (8) TPN 5-30 A fuse panels

FA

ALM 1/2 A

-48 V

The DC output connections are 0.250-20 studs equipped with two hex nuts.

Table 10 Fuse sizes available for the (8) TPN 5-30 A fuse panels

Fuse type Current (A) CPC

35 A0380150

40 A0380151

DC power (TPN)

45 A0380152

50 A0380114

60 A0380115

Figure 9 Front view of the (4) RS100P 70-100 A fuse panels

-48 V

FA

ALM

(1) (2) (3) (4)

(1)

(2) (3) (4)

The DC output connections are 0.375-16 studs equipped with two hex nuts.

Table 11 Fuse sizes available for the (4) RS100P 70-100 A fuse panels

Fuse type Current (A) CPC

70 A0722046

HRC1-K

80 A0722045

90 A0722044

100 A0722049

10 Specifications

Page 17

Figure 10 Front view of the (4) CRS200P 150-200 A / (4) CRS200P 150-200 A (w/load shunts) fuse panels

ALM

FA

(1)

(2)

(2)

(3)

(4)(1)

(3)

ALM

(4)

The DC output connections are 0.50-13 studs equipped with two hex nuts.

Table 12 Fuse sizes available for the (4) CRS200P 150-200 A/(4) CRS200P 150-200 A (w/load

shunts) fuse panels

Fuse type Current (A) CPC

110 A0329697

125 A0329696

HRC1-J

150 A0722041

175 A0722038

200 A0614832

Figure 11 Front view of the (4) TPL 225-600 A fuse panels

-48 V

(2)

ALM

(1)

(2)

(1)

FA

The DC output connections are busbar angles that can accept 535MCM or 750MCM cables, or the

metric equivalent. The lugs must be for two 1/2” dia. bolts at 1-3/4” c-c.

Table 13 Fuse sizes available for the (4) TPL 225-600 A fuse panels

Fuse type Current (A) CPC

225 A0380138

300 A0380140

DC power (TPL)

400 A0380141

500 A0380142

600 A0380143

(3)

(4)

(3)

ALM

(4)

Specifications 11

Page 18

Figure 12 Front view of the (18) TPS 1-70 A fuse panel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 UNIT

FA

FUSE PANEL NT6C 21XX

MAX FUSE 70A

AMPS

LOAD

600 A MAX PANEL CAPACITY

Can accept maximum 1/0 AWG cables and requires one-hole lugs for 1/4” diameter studs.

Table 14 Fuse sizes available for the (18) TPS 1-70 A fuse panel

Fuse type Current (A) CPC

1 A0601322

3 A0601323

5 A0601325

6 A0601326

10 A0601327

DC power (TPS)

15 A0601328

25 A0601330

30 A0601331

40 A0601332

50 A0601333

60 A0601334

70 A0601335

12 Specifications

Page 19

Electrical specifications of the fuse panels

The electrical specifications of the fuse panels are described in

Table 15 Electrical specifications of the fuse panels

Panel number Figure

(20) QFF 0-5 A

60 A max

(16) QFF 0-5 A &

(12) ABS 5-30 A

300 A max

(16) QFF 0-5 A &

(6) TPN 5-30 A

250 A max

(8) TPN 5-30 A

250 A max

(4) RS100P 70-100 A

300 A max

(4) CRS200P 150-200 A

600 A max

(4) CRS200P 150-200 A (w/load shunts)

600 A max

(4) TPL 225-600 A

1600 A max

(18) TPS 1-70 A

600 A max

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Quantity Capacity

20 0-5 A 60 A

16

12

8 0-30 A 250 A

8 31-60 A 300 A

4 70-100 A 300 A

4 101-200 A 600 A

4 225-600 A 1600 A

18 0-70 A 600 A

Table 15.

Fuses

0-30 A

0-5 A

Busbar

capacity

300 A

3.3.2 Circuit Breaker Panels

Mechanical specifications of the circuit breaker panels

The mechanical specifications of the circuit breaker panels are described in

Table 16 Mechanical specifications of the circuit breaker panels

Panel description Figure Height Width Weight

(24) Plug-In 1-100 A

900 A max

(4) 70-250 A

900 A max *

(2) 400 A

(1) 600-700 A

* The 250 A circuit breaker has two poles, thus the panel can accommodate a maximum of two 250 A breakers.

An alarm circuit pack with an alarm indication LED is standard on all panels.

Figure 13

Figure 14

Figure 15

Figure 16

165 mm

(6.5 in.)

178 mm

(7.0 in.)

178 mm

(7.0 in.)

178 mm

(7.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

584 mm

(23.0 in.)

Table 16.

9.1kg

(20 lb.)

10.5 kg

(25 lb)

10.5 kg

(25 lb)

10.5 kg

(25 lb)

Specifications 13

Page 20

Figure 13 Front view of the (24) Plug-In 1-100 A circuit breaker panel

The DC output connections vary according to the circuit breaker capacity: maximum cable size is

2/0AWG. The lugs must be for 3/8” dia. bolts at 1” c-c.

Refer to

Table 21

for the maximum panel capacity.

Table 17 Plug-in circuit breakers available for the (24) Plug-In 1-100 A circuit breaker panel

Nominal

current

1 A A0723076 A0722751

5 A A0723033 A0722752

10 A A0723035 A0722754

15 A A0723037 A0722755

20 A A0723007 A0722695

25 A A0723039 A0722707

30 A A0723040 A0722715

35 A A0723041 A0722717

40 A A0723042 A0722721

45 A A0723069 A0722722

50 A A0723008 A0722726

60 A A0723070 A0722727

65 A A0723071 A0722497

70 A A0723072 A0722732

80 A A0723074 A0722733

90 A A0723077 A0722750

100 A A0723009 A0722496

CPC Std Trip CPC Mid Trip

14 Specifications

Page 21

Figure 14 Front view of the (4) 70-250 A circuit breaker panel

CIRCUIT BREAKER PANEL

NT6C12EE

(4) 70-250 A

FA

REL ( )

SER NO ( )

900A MAX. PANEL CAPACITY

1

2

UNIT

AMPS

LOAD

3

4

1

225

2

225 225

3

4

225

The DC output connections can accommodate two 4/0 cables back to back for each circuit breaker.

The required lugs can be either for two 3/8” holes at 1” c-c or for two 1/2” holes at 1-3/4” c-c.

Refer to

Table 21

for the maximum panel capacity.

Table 18 Circuit breaker sizes available for the (4) 70-250 A circuit breaker panel

Nominal current CPC

70 A (no shunt) A0617079

70 A (with shunt) A0617080

70 A (with relay trip) A0617081

100 A (no shunt) A0616667

100 A (with shunt) A0616668

100 A (with relay trip) A0616669

150 A (no shunt) A0616670

150 A (with shunt) A0616671

150 A (with relay trip) A0616672

200 A (no shunt) A0616673

200 A (with shunt) A0616674

200 A (with relay trip) A0616675

225 A (no shunt) A0605489

225 A (with shunt) A0605490

225 A (with relay trip) A0605492

250 A (no shunt) A0616676

250 A (with shunt) A0616677

250 A (with relay trip) A0616678

The (4) 70-250 A circuit breaker panel can accept up to:

• four breakers (70 to 225 A) mid trip with or without the metering shunt option (1 pole breakers)

• two breakers (70 to 225 A) mid trip with the relay trip option (takes a 2 pole space)

• two breakers (250 A) mid trip with or without the metering shunt option (takes a two pole

breaker)

• one (250 A) breaker mid trip with the relay trip option (takes a 3 pole space)

Specifications 15

Page 22

Figure 15 Front view of the (2) 400 A circuit breaker panel

CIRCUIT BREAKER PANEL

NT6C12EF

FA

(2) 400 A

REL ( )

SER NO ( )

The DC output connections can accommodate two 750 MCM cables back to back for each circuit

breaker. The required lugs must be for two 1/2” holes at 1-3/4” c-c.

900A MAX. PANEL CAPACITY

1

UNIT

AMPS

LOAD

2

1

400

2

400

Refer to

Table 21

for the maximum panel capacity.

Table 19 Circuit breaker kits available for the (2) 400 A circuit breaker panel

Nominal current CPC

400 A (no shunt) P0748316

400 A (with shunt) P0748317

2 x 400 A (no shunt) P0748318

2 x 400 A (with shunt) P0748319

400 A (with relay trip) P0748320

The panel accepts up to:

• two breakers (400 A) mid trip with or without the metering shunt option

• one breaker (400 A) mid trip with the relay trip option (takes a 3 pole space)

Figure 16 Front view of the (1) 600-700 A circuit breaker panel

CIRCUIT BREAKER PANEL

NT6C12EG

(1) 600-700 A

FA

REL ( )

SER NO ( )

1

2

900A MAX. PANEL CAPACITY

UNIT

AMPS

LOAD

600

1

The DC output connections can accommodate four 750 MCM cables back to back. The lugs must

be for two 1/2” bolts at 1-3/4” c-c.

Refer to

Table 21

Table 20 Circuit breaker kits available for the (1) 600-700 A circuit breaker panel

Nominal current CPC

600 A (no shunt) P0875700

600 A (e/w shunt) P0875701

600 A (e/w relay trip) P0875702

16 Specifications

for the available circuit breakers and the maximum panel capacity.

Page 23

Electrical specifications of the circuit breaker panels

The electrical specifications of the circuit breaker panels are described in

Table 21 Electrical specifications of the circuit breaker panels

Panel description

(24) Plug-In 1-100 A

900 A max

(4) 70-250 A

900 A max

(2) 400 A

(1) 600-700 A

Figure

Figure 13

Figure 14

Figure 15

Figure 16

Circuit breakers

Max. Quantity Capacity

24 1-100 A 900A

4 70-250 A 900 A

2 400 A 900 A

1 600 A 900 A

Busbar

capacity

Table 21.

Specifications 17

Page 24

3.4 Externally Mounted Battery Return Busbar

&

A

A

The battery return busbar is designed to mount on the overhead racking for 6000 A systems and

top cabled 1500, 3000 or 4000 A power systems. It can also be mounted on a wall or on the floor

below the raised floor for bottom cabled 1500, 3000 or 4000 A power systems (which are assumed

to be installed on a raised, computer type floor).

3.4.1 Mechanical Specifications of the External Battery Return Busbar

The external battery return busbar kit consists of a group of single busbar laminations and

attachment hardware assembled as shown in

cally in such a way as to maintain the 3-ft maximum radius grounding requirement. Laminations

are added as required to increase the capacity. The mechanical specifications of a single lamination are listed in

Table 22.

Table 22 Mechanical specifications of a single lamination

Figure Length Width Thickness

Figure 17

863.6 mm

(34 inches)

Figure 17 Top and side views of the external battery return busbar

Figure 17

152.4 mm

(6 inches)

(6000 A shown). The kit can grow verti-

12.7 mm

(0.5 inches)

6” (152 mm)

Top view of the external ground bar

Future growth as required

34” (864 mm)

6”

Smaller busbar for

small wires and cables

Side view of the external ground bar installed on

auxiliary framing above the power system

NOTE

All bars and details are 0.5 in. thick.

* For a 1500 A system, only the bottom level is provided for the external

battery return ground bar.

Available

configurations:

= 1500*

3000 A

= 4000

= 6000

3.4.2 Electrical Specifications of the External Battery Return Busbar

A single busbar lamination has a current carrying capacity of 3000 A.

18 Specifications

Page 25

3.5 Terminating Assemblies (Optional)

The optional terminating assembly allows top access connections for up to six loads. Refer to

Figure 18.

c-c hole spacing, for cables up to 777 kcmil.

The terminating assembly is bolted to the top of the main or auxiliary distribution cabinets and,

therefore, increase the cabinet height by 12 inches. The weight of the terminating assembly is

12.5 kg (27.6 lb).

An optional Lexan

Figure 18 Perspective view of the a terminating assemblies

Glastic

insulating

material

Each load position is rated at 600 A and can accept up to three lugs having 1” or 1-3/4”

™

protective cover is available to protect the connections of the load cables.

Optional

protective

cover

NT6C2625

(for main distribution cabinet)

NT6C2624

(for auxiliary distribution cabinet)

Specifications 19

Page 26

3.6 MPS300 and MPA100 Power Shelves

The MPS300 and MPA100 power shelves are required for the Helios Rectifier 100/48, which is a

plug-in type rectifier. The MPA100 power shelf supports one Helios Rectifier 100/48, while the

MPS300 shelf can support up to three Helios Rectifiers 100/48.

3.6.1 Mechanical Specifications of the MPS300 and MPA100 Power Shelves

The mechanical specifications of the power shelves are listed in

Table 23 Mechanical specifications of the MPS300 and MPA100 power shelves

Shelf model Figure Height Depth Width Weight

MPS300

MPA100

Figure 19

Figure 20

533 mm

(21.00 in.)

178 mm

(7.00 in)

381 mm

(15.00 in.)

381 mm

(15.00 in.)

Figure 19 Front view of the MPS300 power shelf (shown empty)

Table 23.

584 mm

(23.00 in.)

584 mm

(23.00 in.)

16.6 kg

(36.5 lb)

5.4 kg

(12 lb)

20 Specifications

Page 27

Figure 20 Front view of the MPA100 power shelf (shown empty)

3.6.2 Electrical Specifications of the Power Shelves

Each rectifier position provides interconnection points for AC input (208 to 240 V nominal), DC

output (-48 V nominal) and control and alarm signals.

3.7 Rectifiers

The Helios system 4000/48 can be equipped with Helios Rectifiers 100/48 for single phase 208/240

V AC operation, with Helios Rectifiers 200I/48 for three phase 380/415 V AC operation, or with

Helios Rectifiers 200E/48 for three phase 480 V AC operation.

3.7.1 Helios Rectifier 100/48

Mechanical specifications of the Helios Rectifier 100/48

The mechanical specifications of the Helios Rectifier 100/48 are listed in

Table 24 Mechanical specifications of the Helios Rectifier 100/48

Figure Height Depth Width Weight

Figure 21

178 mm

(7.0 in.)

305 mm

(12.0 in.)

Figure 21 Front view of the Helios Rectifier 100/48

584 mm

(23.0 in.)

Table 24.

22.2 kg

(49 lb)

Specifications 21

Page 28

Electrical specifications of the Helios Rectifier 100/48

The electrical specifications of the Helios Rectifier 100/48 are listed in

Table 25 Electrical specifications of the Helios Rectifier 100/48

Parameter Specification

Input voltage:

Input current:

Recommended AC

service input:

Output voltage:

Output current:

Input protection:

Output protection:

Output regulation:

Efficiency:

Power factor:

Electromagnetic

interference (EMI):

Heat dissipation:

208/240 V AC, 1-phase, 47-63 Hz

Input voltage range: 176 to 264 V AC

31 A nominal at 208 V AC input and -56 V DC, 100 A output

50 A, two pole AC circuit breaker

Float: -48 to -58 V DC

Equalize: 0 to 4 V DC above Float

Maximum: -59.5 V DC

100 A per rectifier

100 A for a one position shelf

300 A for a three position shelf

A two pole / 45 A circuit breaker opens both lines.

The rectifier is protected by a 120 A circuit breaker at the output. The output current

is limited to a value adjustable from 50% to 105% of the rated capacity of the

rectifier. This circuit is factory set to 105 A.

The rectifier output voltage is automatically regulated to remain within ±0.5% of the

selected value under all load conditions and within the specified input voltage,

frequency, and ambient temperature ranges. And within + 1% for any combinations

of specified input, output and environmental conditions.

Efficiency is better than 88% at a nominal input voltage of 208/240 V AC and an

output load greater than 40 A.

Power factor is 0.99 at a nominal input voltage of 208 V AC and output loads greater

than 40 A.

The rectifier meets the FCC requirements for conducted and radiated EMI for Class

“A” equipment.

763 W (2606 Btu/hr)

Table 25.

3.7.2 Helios Rectifiers 200I/48 and 200E/48

Mechanical specifications of the Helios Rectifiers 200I/48 and 200E/48

The mechanical specifications of the Helios Rectifier 200I/48 and 200E/48 are listed in

Table 26 Mechanical specifications of the Helios Rectifiers 200I/48 and 200E/48

Figure Height Depth Width Weight

Figure 22

254 mm

(10 in.)

559 mm

(22 in.)

521 mm

(20.5 in.)

Table 26.

42.3 kg

(93 lb)

22 Specifications

Page 29

Figure 22 Front view of the Helios Rectifiers 200I/48 and 200E/48

VOLT

AMP

1

0

VOLT/AMP

THSD

RFA

FAN

HVSD

ALM

VOUT+

VOLT

CAL

CUR

CAL

SEN

FAIL

AC ON

CL

EQL

VOUTÐ

CL

ADJ

EQL

ADJ

EQL

FFI

FF2

FLT

1.0A

1.0A

FLT

ADJ

HVSD

ADJ

1

ST UP

DLY

FS

SLS

Specifications 23

Page 30

3.7.3 Electrical Specifications of the Helios Rectifiers 200I/48 and 200E/48

The electrical specifications of the Helios Rectifiers 200I/48 and 200E/48 are listed in

Table 27 Electrical specifications of the Helios Rectifiers 200I/48 and 200E/48

Parameter Specification

Input voltage

Input current

Input protection

Recommended AC

service input

Output voltage

Output current

Output protection

Output regulation

Efficiency

Power factor

Electromagnetic

interference (EMI)

Heat dissipation

Total harmonic

distortion (THD)

Helios Rectifier 200I/48:

380/415 V AC, three phase, 47-63 Hz

Input voltage range: 330 to 475 V AC

Helios Rectifier 200E/48:

480 V AC, three phase, 47-63 Hz

Input voltage range: 430 to 520 V AC

Helios Rectifier 200I/48: 18.3 A RMS nominal at 380 V AC input and -54 V DC, 200 A

output (24 A RMS worst case)

Helios Rectifier 200E/48: 15 A RMS nominal at 480 V AC input and -54 V DC, 200 A

output (17 A RMS worst case)

A 3 pole / 25 A circuit breaker opens all three lines.

30 A, 3 pole AC circuit breaker

Float: -46 to -58 V DC

Equalize: 0 to 4 V DC above Float

Maximum: -60 V DC

200 A nominal

Adjustable between 100 and 210 A

The rectifier is protected by a 250 A circuit breaker at the output.

The output current is limited to a value adjustable from 50% to 105% of the rated

capacity of the rectifier. This circuit is factory set to 205 A.

The rectifier output voltage is automatically regulated to remain within ±0.5% of the

selected value under all load conditions and within the specified input voltage,

frequency, and ambient temperature ranges. And within + 1% for any combinations of

specified input, output and environmental conditions.

Efficiency is better than 89% at nominal input voltage and an output load greater than

80 A.

Power factor is better than 0.99 at nominal input voltage and an output load greater

than 80 A.

The rectifier meets the FCC requirements for conducted and radiated EMI for Class

“B” equipment.

1,335 W (4,558 Btu/hr) at -54 V DC, 200 A output

THD is less than 5% between half load and full load at nominal input voltage

Table 27.

3.7.4 Standards

The following standards also apply to the rectifiers:

• ANSI Std. C62.41/IEEE Std. 587-1980, Class A and B lightning surge 6000 V, 3000 A, 1.2 x 50

ms impulse, 10 hits per second

• ANSI Std. C82.41 oscillatory surge 2500 V, 0.5 ms impulse, 100kHz positive/negative oscillating decay

• Bellcore TR-TSY-000947

• IEC-950, VDE EN 60950, EN 41003

• CISPR 22, Class A

• CE mark

24 Specifications

Page 31

3.8 Helios Monitor 3000/48 (Optional)

3.8.1 Mechanical Specifications

The mechanical specifications of the Helios Monitor 3000/48 are listed in

Table 28 Mechanical specifications of the Helios Monitor 3000/48

Figure Height Depth Width Weight

Figure 23

45 mm

(1.75 in.)

222 mm

(8.75 in.)

280 mm

(11.0 in.)

The above dimensions are without the mounting brackets. The weight may vary slightly depending on the number and type of analog interface modules installed in the unit.

Figure 23 Front view of the Helios Monitor 3000/48 (without the mounting brackets)

UNIT

ADRESS

Table 28.

2.8 kg

(6.2 lb)

POWER/FAIL

LED INDICATOR

ROTARY SWITCHES 12 DIGIT ALPHA-NUMERIC DISPLAY 4 PUSH-BUTTON KEYPAD

HELIOS Monitor 3000/48

3.8.2 Electrical Specifications

The input voltage of the Helios Monitor 3000/48 is -48 V DC nominal, with a range of -42 V DC to

-60 V DC.

The input current drain is 400 mA. This current drain may vary slightly depending upon the

number and type of analog interface modules installed in the unit.

For more detailed electrical specifications of the Helios Monitor 3000/48, refer to the appropriate

user manual listed in

6.0 - Reference Documents.

3.9 600 A and 1200 A Battery Disconnect Unit (Optional)

The Battery Disconnect Units are 11 inches high and provides for 500 mm (19 in.) or 600 mm

(23 in.) framework mounting or wall mounting. The units are equipped with a heavy duty circuit

breaker that can be used to manually or automatically disconnect a battery string. Reconnect is

manual only. The breaker is mid trip and equipped with a relay trip feature.

Figure 24 600 A Battery Disconnect Unit

600 A

NT6C18MA

BATTERY DISCONNECT UNIT

: MODE SELECTION

: PARAMETER SELECTION

DISABLE

BDA

AUTODISC

ONOFF ONOFF ONOFF

FA

DSBL SP CAL

TEST

DISC

CALIBRATE

VOLT

ADJ

GRD -48V

F1

3 A

For more detailed electrical specifications of the Battery Disconnect Unit, refer to the user manual, SL-60040.

Specifications 25

Page 32

3.10 AC Junction Box

The AC junction box is required as an AC connection interface in rectifier cabinets where the

Helios Rectifier 200E/48 is used.

Figure 25 Front view of the AC junction box (with the front panel open)

Six receptacles

to plug the

cables from the rectifiers

RECT 6

1 2 3 4 5 6 7 8 9 10 11 12

L1L2L3

RECT 5

L1L2L3

GRD

RECT 4

TB1

L1L2L3

GRD

3.10.1 Mechanical Specifications

The junction box is made of zinc plated steel and can accommodate up to six one-inch rigid or flexible conduits. The mechanical specifications are listed in

Table 29 Mechanical specifications of the AC junction box

Figure Height Depth Width

Figure 25

264 mm

(10.4 in.)

3.10.2 Electrical Specifications

The junction box is designed to accommodate six 3-phase circuits (3 wires plus ground) at a maximum voltage of 600 V AC and a capacity of 30 A per circuit.

3.11 Overall Power System Specifications

3.11.1 Standards

The Helios DC System 4000/48 meets the following North American and European standards:

RECT 3

1 2 3 4 5 6 7 8 9 10 11 12

L1L2L3

GRD

RECT 2

L1L2L3

GRD

TB2

GRD

Table 29.

284 mm

(11.2 in.)

RECT 1

L1L2L3

GRD

521 mm

(20.5 in.)

• UL-1801

• CSA 22.2 (#0.7, #225)

• TR-TSY-000406

•CE

•VDE

3.11.2 Mechanical Specifications of Fully Equipped Power Cabinets

Table 30 Mechanical specifications of fully equipped power cabinets

Height Depth Width

2134 mm

(84 in.)

26 Specifications

600 mm

(23.62 in.)

600 mm

(23.62 in.)

Total weight (4000 A control

and distribution cabinet)

363 kg

(800 lb) approx.

Total weight (1200 A rectifier

cabinet with six rectifiers)

440 kg

(970 lb) approx.

Page 33

3.11.3 Electrical Specifications

Refer to the individual component’s specifications.

Electromagnetic compliance (EMC)

The equipment contained in the power system complies with the specifications of FCC, Part 15,

Subpart B for class A equipment, CSA 108.8 for class A and CISPR 22 for class A.

Electrostatic discharge (ESD) immunity

No equipment damage or malfunctions shall occur when electrostatic discharge voltages of severity level 2 and 4, as specified by IEC-801-2, are applied to exposed parts of the power system.

3.11.4 Environmental Specifications

Operating

Temperature:

Humidity:

Altitude:

0° to +50°C (32° to 122°F)

0 to 95% non-condensing

Sea level to 2134 m (7000 ft)

Transportation

NOTE

Do NOT ship with the rectifiers installed in the rectifier cabinet(s).

During transportation the equipment may be subjected to the following conditions without damage:

Temperature:

Humidity:

Vibration:

Shock:

-50° to +75°C (-58° to +167°F)

0 to 95% (non condensing) 4kPa max. WVP for 10 days

TR-NWT-000063 section 5.4.4 Transportation Vibration (packaged equipment)

TR-NWT-000063, Section 5.4.1 Handling Drop Tests, and Section 5.4.3 Installation Shop Tests

Storage

Temperature:

Humidity:

-50° to +75°C (-58° to +167°F)

0 to 95% (non condensing) 4kPa max. WVP for 10 days

Heat dissipation

A Helios DC System 4000/48 rectifier cabinet equipped with six Helios Rectifier 200I/48 or 200E/

48 will dissipate a maximum of 8,010 watts or 27,350 Btu/hr.

3.11.5 Floor and Point Loading

The floor loading is based on a footprint of 600 mm x 600 mm (23.6 in. x 23.6 in.) plus a 30-inch

aisle width (15 inches front and rear).

The point loading is based on distributing the cabinet weight over four shims, each with an

assumed area of 25.8 cm

Figure 1

See

for a typical system configuration for floor and point loading calculations.

Table 31 Floor and point loading

Cabinet type Floor loading Point loading

Control and distribution cabinet 41.3 kN/sq m (90.9 lb/sq ft) 34.5 N/sq cm (50 lb/sq in.)

Auxiliary distribution cabinet 32.3 kN/sq m (71 lb/sq ft) 26.9 N/sq cm (39 lb/sq in.)

Rectifier cabinet 50.1 kN/sq m (110.2 lb/sq ft) 41.8 N/sq cm (60.6 lb/sq in.)

2

(4 in.2).

Specifications 27

Page 34

4.0 O

PERATION

4.1 General

This chapter describes the control, adjustment and operational features of the Helios DC System

4000/48.

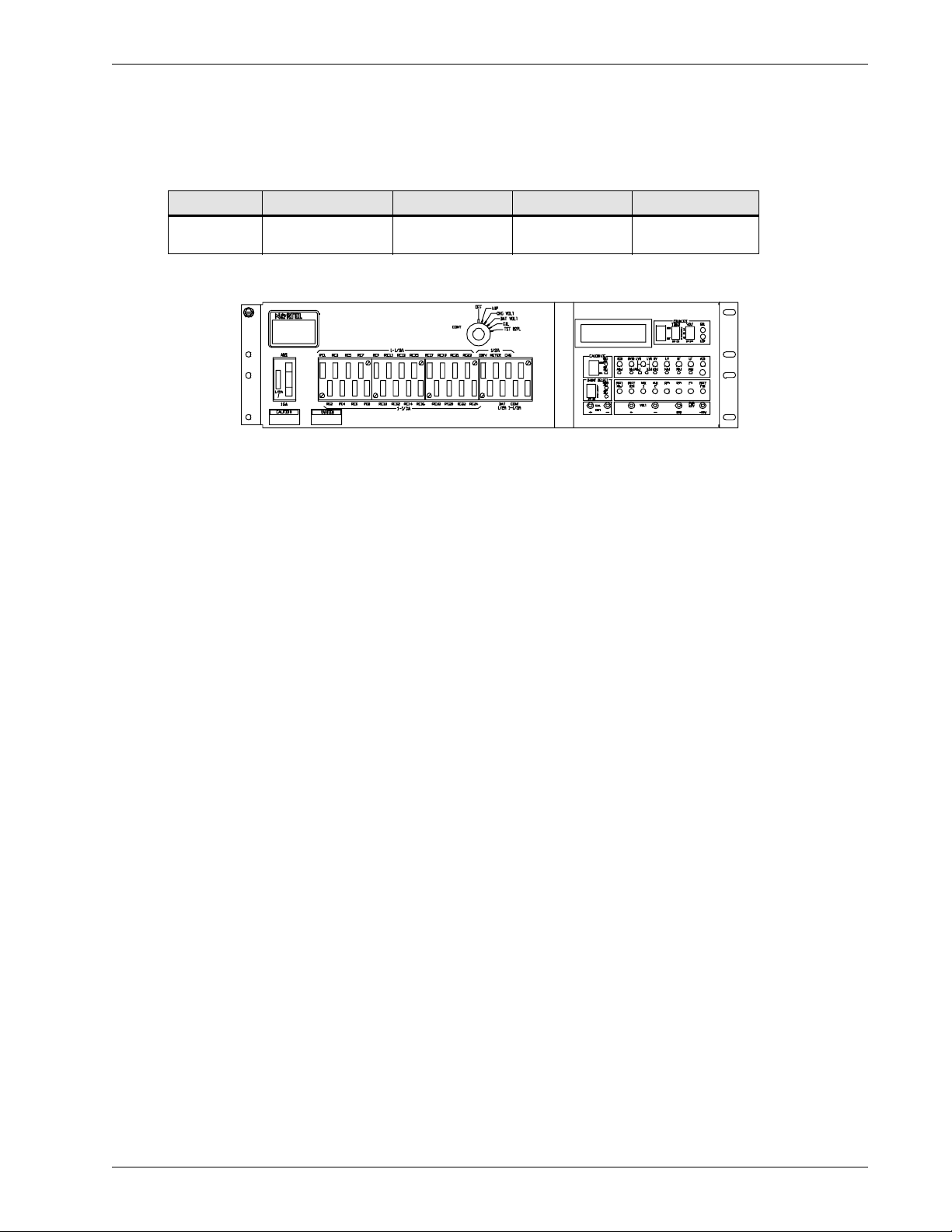

4.2 Conventional Controller

The Conventional Controller monitors the operation of the entire power plant. It monitors all the

alarms, and it controls and monitors the rectifiers.

Provision is made on the back of the Conventional Controller to extend any occurring alarm to the

alarm center through the facilities provided in the powered equipment.

All of the control switches, potentiometers, operational and alarm visual indications are located at

the front of the Conventional Controller.

4.2.1 Front Panel

The front panel of the Conventional Controller is provided with the control, alarm and operational

features shown in

Figure 26 Front view of the Conventional Controller

Figure 26

and described in the following subsections.

Visual indicators

A 4.5 digit red LED readout to display the system current and voltage, and 18 LEDs to display the

alarm conditions as described in

descent cabinet alarm lamp.

Table 32 Visual indicators

Designation Description Color

RECT FAN Rectifier Fan Failure yellow

EQL Equalize On yellow

FA Fuse Failure Alarm (Internal to the Controller) red

DFA Discharge Fuse Alarm red

CFA (not used) Charge Fuse Alarm red

RFA MIN Rectifier Failure Alarm Minor yellow

RFA MAJ Rectifier Failure Alarm Major red

ACO Alarm cut-off red

HVSD High Voltage Shutdown Alarm red

HV High Voltage Alarm red

LV Low Voltage Alarm red

HF High Float Alarm yellow

LF Low Float Alarm yellow

LVD Low Voltage Disconnect red

BOD Battery On Discharge red

LOP Loss of Phase red

AUX 1 (BDA) Auxiliary Major red

AUX 2 Auxiliary Minor yellow

Table 32.

All alarm conditions are also displayed by a red incan-

28 Operation

Page 35

Table 33 Transmitted alarms

Alarm Description

RECT FAN (1 - Form C contacts)

RFA MIN (1 - Form C contacts)

RFA MAJ (1 - Form C contacts)

H/L FLOAT (2 - Form C contacts)

EQL ALM (1 - Form C contacts)

H/L VOLT (2 - Form C contacts)

FA (1 - Form C contacts)

CHG FUSE (1 - Form C contacts)

DISCH FUSE (1 - Form C contacts)

LVD (1 - Form C contacts)

LOSS OF AC VOLT (1 - Form C contacts)

AUX 1 ALM (2 - Form C contacts)

AUX 2 ALM (2 - Form C contacts)

HVSD (1 - Form C contacts)

BOD (1 - Form C contacts)

MIN VIS (note 2) (2 - Form C contacts)

MAJ VIS (note 2) (2 - Form C contacts)

MIN AUD (2 - Form C contacts)

MAJ AUD (2 - Form C contacts)

NOTE

Form C contacts are rated at 0.5 A, 60 V AC.

MINOR VIS (2) and MAJ VIS (2) are used for the cabinet alarm lamp.

Potentiometers

Twelve potentiometers for the adjustment of alarm and control functions as described in

Table 34.

Table 34 Potentiometers

Designation Description

HVSD High Voltage Shutdown

HV High Voltage Alarm

LV Low Voltage Alarm

HF High Float Alarm

LF Low Float Alarm

LVD Low Voltage Disconnect

BOD Battery On Discharge

VOLT ADJ Plant Voltage Adjustment

REF CAL Reference Calibration

METER ADJ Meter Adjustment

AMP ADJ Ampere Adjustment

LVR Low Voltage Reconnect

Operation 29

Page 36

Switches

Four switches for the control of functions as described in

Table 35 Switches

Designation Description

EQUALIZE MAN/AUTO Used to activate or deactivate the equalize function.

ACO Used to cancel the audible alarm signal.

CALIBRATE NORM/CAL Used to activate or deactivate the calibration function.

CONT rotary switch Six position switch: OFF, AMP, CHG VOLT, BAT VOLT, CAL, TST DISPL

DIP switches

Three DIP switch modules for the setting of functions as described in

Figure 27

Table 36 DIP switch modules

Designation Description

SHUNT SELECT To select the shunt size

TIMER To select the duration of the equalize

VOLT To select the equalize voltage

Figure 27 Shunt range selection settings

and

Figure 28.

123456

S1

Table 35.

RANGE AMPS

MIN-MAX

Table 36

and as shown in

= SWITCH IS ON

55 to 100

100 to 170

170 to 340

340 to 500

500 to 1000

1000 to 1700

1700 to 3400

3400 to 7000

7000 to 14000

30 Operation

Page 37

Figure 28 Equalize voltage and duration settings

TIMER

VOLT

Switch # 1 2 3 4 5 6

OFF ON

1

2

3

4

5

6

10 sec.

20 sec.

38 sec.

1.25 h

3.0 h

5.0 h

LOP enabled

: switch in the ON position

Switch # 1 2 3

0.6V

1.3V

1.9V

2.6V

3.2V

3.9V

4.6V

1

2

3

ON OFF

Fuses

Thirty-four fuses for circuit protection as described in

small tube type (9/32” dia x 1-1/4” long), all fuses are of the QFF type.

Table 37 Fuse

Designation Capacity Description

ABS 15 A -48 V supply for the office alarm circuit(s)

ABS ALM 1/2 A Alarm fuse for the above ABS fuse

RC1 to RC24 1-1/3 A -48 V sense supply for the rectifiers of the system

CONV 1/2 A Protection for the internal converter in the controller

METER 1/2 A Protection for the meter and selector panel if so equipped

CHG 1/2 A Protection for internal circuitry of the controller when the CONT rotary switch

is in the CHG VOLT position

Spare 1 and 2 0 to 5 A For external loads as required (ex.: Helios Monitor)

BAT 1/2 A Protection for internal circuitry of the controller when the CONT rotary switch

is in the BAT VOLT position

CONT 1-1/3 A Protection for the internal circuitry of the controller

Plus one unused position

Table 37.

Except for the ABS fuse, which is

Test points

Three sets of test points for applications as described in

Table 38 Test points

Designation Description

CAL OUT + and - To connect an external meter when calibrating the LED readout for current readings

VOLT + and - To connect an external meter when adjusting the BOD, LF, LV, HF, HV, HVSD, LVD and

LVR thresholds

PWR EXT + and - The connect an external power supply when adjusting the LVR threshold

Table 38.

Operation 31

Page 38

4.2.2 Rear Panel

The rear panel of the Conventional Controller is provided with the connection interface features

shown in

Figure 29 Terminal blocks and connectors layout at the rear of the Conventional Controller

Figure 30

and described in the following subsections.

TB2

TB1

J7 J6

TB3

P25 P23 P21 P19 P17

J5

J4

TB4

TB5

J8

P3P15 P13 P11

J3

J2

J1

TB6

1

P2P10 P8 P6 P4P16 P14 P12P22 P20 P18P24P26

8

P1P9 P7 P5

Terminal blocks

Six terminal blocks to interface with external wiring as follows:

• TB1: various alarm outputs to the office alarm circuits and the cabinet alarm lamp

• TB2: various alarm outputs to the office alarm circuits, and remote equalize signal input

• TB3: various alarm outputs to the office alarm circuits, and charge and discharge fuse alarm

inputs

• TB4: various alarm outputs to the office alarm circuits, and LVD control and alarm

• TB5: various alarm outputs to the office alarm circuits, remote TR signal input, -48 V supply

to cabinet alarm lamp and various small loads, and AUX 1 and AUX 2 alarms inputs

• TB6: -48 V supply to office alarm circuits if required, VR+ and VR- inputs, and -48 V and

ground inputs

Refer to

Figure 30

and

Figure 31

for the pin assignment of terminal blocks TB1 to TB6.

32 Operation

Page 39

Figure 30 Wiring diagram and pin assignment of terminal blocks TB1 to TB4

)

(1)

(1)

v

To office

alarm

circuit

Input from DISCH fuse alarm circuits

Input from CHG fuse alarm circuits

NE-1451X cable

(or equivalent)

H/L FLOAT ALM (1

H/L FLOAT ALM (1)

H/L FLOAT ALM (2)

H/L FLOAT ALM (2)

MIN RECT ALM

MIN RECT ALM

MAJ RECT ALM

MAJ RECT ALM

LVD ALM

LVD ALM

LOSS OF AC VOLT ALM

LOSS OF AC VOLT ALM

DFA

CFA

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

C

C

C

C

C

C

TB3 TB1

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

C

NC

NO

BK ALARM VISUAL (C)

C

NC

NO

C

NC

NO

C

G ALARM VISUAL (NC)

NC

NO

C

NC

NO

C

NC

NO

C

NC

NE-1451X cable

(or equivalent)

MINOR VIS (1)

MINOR VIS (1)

MAJOR VIS (1)

MAJOR VIS

MINOR AUD (1)

MINOR AUD (1)

MINOR AUD (2)

MINOR AUD (2)

MAJOR AUD (1)

MAJOR AUD (1)

To small internal

battery return

busbar

To cabinet

alarm lamp

To office

alarm

circuit

NE-1451X cable

(or equivalent)

To office

alarm

circuit

Input alarm from LVD circuit

AUX ALM NO.1 (1)

AUX ALM NO.1 (1)

AUX ALM NO.1 (2)

AUX ALM NO.1 (2)

AUX ALM NO.2 (1)

AUX ALM NO.2 (1)

AUX ALM NO.2 (2)

AUX ALM NO.2 (2)

EQUALIZE ALM

EQUALIZE ALM

HVSD ALM

HVSD ALM

To LVD circuit

RLVD

LVDA

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

C

C

C

C

C

C

TB4 TB2

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

NO

C

NC

NO

C

NC

NO

C

NC

NO

C

NC

NO

C

NC

NO

C

NC

NO

REMOTE EQUALIZE START

NE-1451X cable

(or equivalent)

MAJOR AUD (2)

MAJOR AUD (2)

FUSE ALM

FUSE ALM

CHG FUSE ALM

CHG FUSE ALM

DISCH FUSE ALM

DISCH FUSE ALM

H/L VOLT ALM

H/L VOLT ALM (1)

H/L VOLT ALM (2)

H/L VOLT ALM (2)

To office

alarm

circuit

Input from office remote circuit

Operation 33

Page 40

Figure 31 Wiring diagram and pin assignment of terminal blocks TB5 and TB6, and connectors P1 to

P26

22GA 8-conductor

shielded cable

To alarm

To

NT6C43PA

interface

or

board or

NT6C43PB

rectifier

rectifier

interface

interface

card as

card as

required,

required,

or

or directly

directly

to rectifier

to

rectifier

22GA 2-conductor

shielded cable

Main

plant

SHUNT +

shunt

(the shunt

wires should

be fused near

the shunt to

prevent fire

hazard)

To AC

ALM

monitor

circuit

such as

NT6C18BA

EQL ( )

RG+ ( )

RC- ( )

TR ( )

FAN ( )

HVSD ( )

RFA ( )

NC

NC

SHUNT –

NC

NC

NC

NC

NC

NC

NC

NC

GRD

P1 TO P24

1

2

3

4

5

6

7

8

P25

1

2

3

4

5

6

7

8

P26

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

TB5

TB6

To office alarm circuit,

ABSF

If required

Input from office

TR

C

NC

NO

RECT FAN

RECT FAN

NE-1451X cable

(or equivalent)

LP (–48V)

–48V (SPARE 2)

-48V (METER)

remote circuit

To office alarm circuit

To cabinet alarm lamp

To load as required

To meter & selector

panel (NT6C10AA),

GRD

C

NC

NO

NE-1451X cable

(or equivalent)

AUX1 INPUT (MAJ)

AUX2 INPUT (MIN)

if so equipped

BOD

To office alarm circuit

BOD

–48 V CHG busbar

GRD alarm signals from

auxiliary equipment as

required

–48 (ABS)

To office alarm circuit

or alarm reporting

circuit, if required

10 AWG

VR–

Battery sense

VR+

leads

GRD

Power plant

–48V

10 AWG

busbars

Connectors

Twenty-six connectors to interface with external equipment as follows:

• P1 to P24: signaling between the controller and the rectifiers

• P25: interface with the main power system shunt

• P26: interface with an AC monitoring device

Refer to

Figure 31

for the pin assignment of connectors P1 to P26.

Eight connectors (J1 to J8) for the interface between the two circuit boards of the controller (for

factory use only).

4.3 MPS300 and MPA100 Power Shelves

The MPS300 power shelf provides the interconnecting points for all the AC, DC and control

cabling and wiring for three Helios Rectifier 100/48. The MPA100 power shelf does the same for

one Helios Rectifier 100/48.

Refer to the appropriate rectifier user manual listed in

operation information on the MPS300 and MPA100 power shelves.

34 Operation

6.0 - Reference Documents

for detailed

Page 41

4.4 Rectifiers

The rectifiers provide isolated, filtered and regulated DC power, from either a single-phase AC

source (Helios Rectifier 100/48) or a three-phase AC source (Helios Rectifier 200I/48 or 200E/48),

for charging a positive grounded battery.

The nominal output is adjustable over the range of -46 to -59.5 V to float a 23 or 24 cell battery

string.

The rectifiers are equipped with AC input and DC output circuit breakers, a digital ammeter,

potentiometers for the adjustment of thresholds, and LED indicators for alarm indications.

The rectifiers use high frequency switching technology and forced air-cooling.

Refer to the appropriate rectifier user manual listed in

operation information on the Helios Rectifier 100/48, the Helios Rectifier 200I/48, or the Helios

Rectifier 200E/48.

4.5 AC Junction Box

WARNING

!

PREVENTING ELECTRICAL SHOCKS

WHEN OPENING THE DOOR OR WIRING THE AC INPUT OF

THE RECTIFIERS INSIDE THE JUNCTION BOX, ENSURE THAT

THE ASSOCIATED AC BREAKERS, LOCATED IN THE AC

SERVICE PANEL, ARE IN THE OFF POSITION AND THAT A

WARNING TAG CLEARLY INDICATES THAT THESE BREAKERS

ARE TO REMAIN OFF UNTIL THE AC WIRING HAS BEEN

COMPLETED. DO NOT INSERT FUSES, OR OPERATE CIRCUIT

BREAKER OR SWITCHES TO ON UNTIL THE WIRING IS

COMPLETED AND YOU ARE INSTRUCTED TO DO SO.

The AC junction box is part of the rectifier cabinet used for the Helios Rectifier 200E/48. It is

located at the top of the cabinet for top fed systems, or at the bottom of the cabinet for bottom fed

systems.

The AC junction box provides AC connection interface for up to six rectifiers and facilitates the

addition and/or replacement of rectifiers in a working system. The AC supply from the AC service

panel is hard wired inside the box at the time of the initial installation. Detailed cabling and connecting guidelines for the AC junction box can be found in

6.0 - Reference Documents

5.0 - Maintenance.

for detailed

The rectifiers are provided with a factory-installed AC cord equipped with a male connector. This

male connector is plugged into a matching female receptacle at the rear of the AC junction box.

For the complete procedures for adding or replacing a rectifier, refer to

that caps are provided to protect the unused female receptacles.

4.6 Distribution Panels

All distribution panels provide local alarm indication on the panel itself, and alarm extension to

the controller for additional indication on the controller and the cabinet and further extension to

remote alarm facilities.

4.7 Terminating Assemblies (Optional)

Terminating assemblies are optional devices used to facilitate the connecting of loads to distribution fuses or circuit breakers larger than 199 A. These assemblies can be used in top fed systems

only (they cannot be used on bottom fed systems). Each terminating assembly provides connection

facilities for up to six loads without having to route the cables inside the cabinet during installation.