Page 1

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

User Manual – Hipulse

Installation & Maintenance of Hipulse 130kVA Single phase 110V, Single & 1 + N System

Page 2

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 3

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Dear Customer,

Please accept our thanks for giving us the privilege to serve you by choosing a

Liebert make ‘UPS’.

If this is your first Liebert UPS, we hope it is the beginning of a long relationship

which delivers value to your organisation. If you already own and use a Liebert

product, we are doubly honoured by your decision of continuing this relationship.

It is our constant endeavor to partner you for the growth and success of your

business. This philosophy is reflected in our Mission statement “To deliver value

through Air & Power Quality solutions to achieve customer delight”. Please do give

us feedback to help us realize our Mission.

Emerson Network Power (India) Private Limited

Page 4

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 5

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Rev. No. Revision details Date

IMPORTANT

This manual contains information concerning the installation, operation and

maintenance of the Hipulse Uninterruptible Power System (UPS) for the single module

and one plus one Systems.

All relevant parts of the manual should be read prior to commencing installation.

The UPS must be commissioned by an engineer approved by the manufacturer (or his

agent) before being put into service. Failure to observe this condition will invalidate

any implied warranty.

The Hipulse UPS has been designed for Commercial / Industrial use only.

The Hipulse has not been designed for direct use in any life support application.

If you encounter any problem with the procedures contained in this manual you should

seek immediate assistance from Emerson Network Power (India) Pvt. Ltd. Sales Office

from whom the equipment was purchased. Alternatively contact the Emerson

Network Power (India) Pvt. Ltd Customer Service & Support department at the

address shown below:

EMERSON NETWORK POWER (INDIA) PRIVATE LIMITED

Plot No. C-20, Road No. 19

Wagle Industrial Estate

Thane – 400 604, INDIA

Phone : (00 91 22) 25807000

25828405

Fax : (00 91 22) 25800829

25828358

Emerson Network Power (India) Private Limited pursues a policy of continual product

development and reserves the right to change the equipment without notice.

@ Copyright 1999 by Emerson Network Power

Unauthorized reproduction prohibited

All rights reserved

Page 6

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 7

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

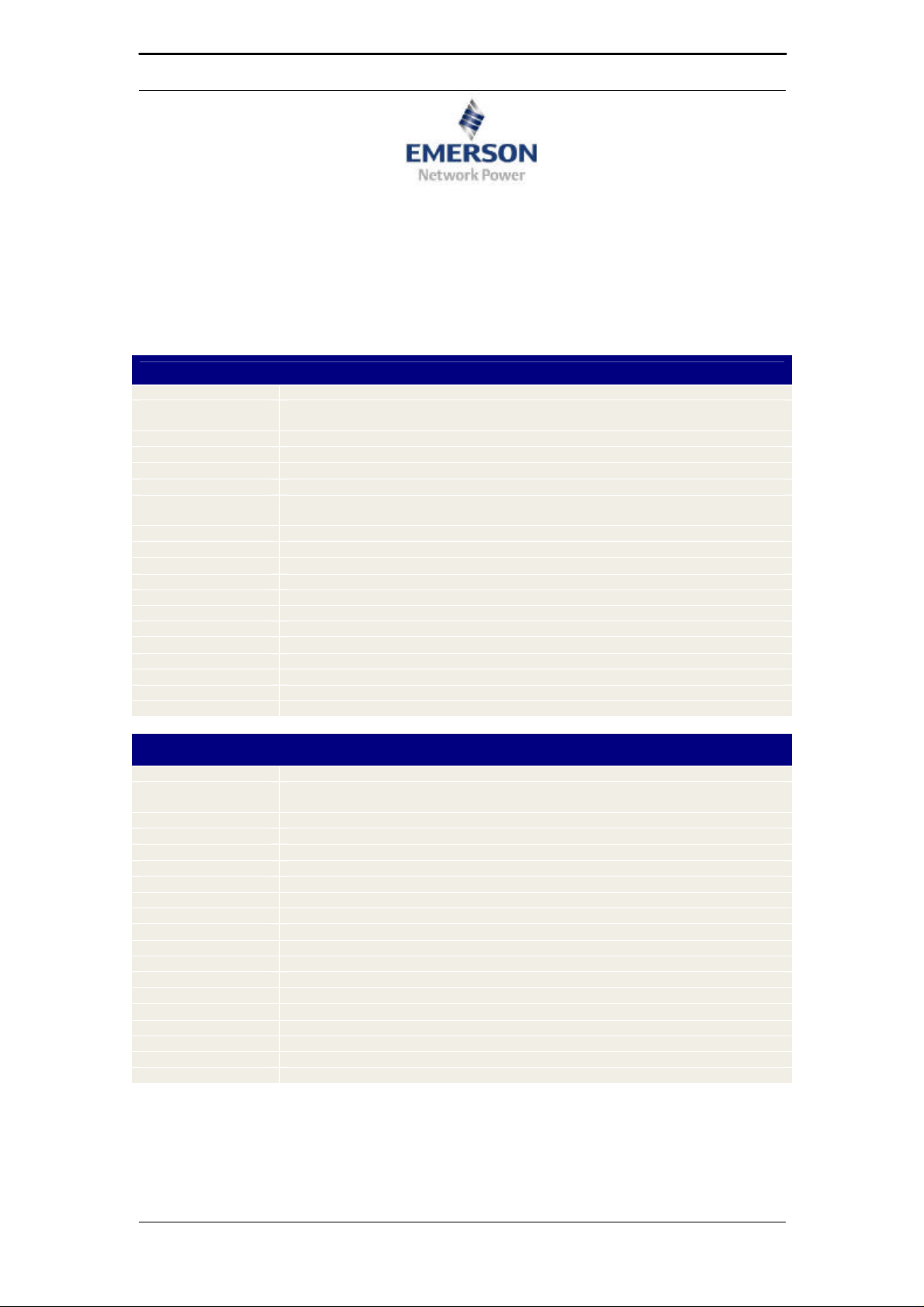

REGISTERED HEAD OFFICE

Emerson Network Power (India) Private Limited

PLOT NO. C-20, ROAD NO. 19

WAGLE INDUSTRIAL ESTATE

THANE – 400 604 MAHARASHTRA, INDIA

TELEPHONE: (00 91 22) 25807000/ 25828405 / 25802388

FAX: (00 91 22) 25800829 / 25828358

*** WEST ZONE ***

Mumbai

Address: B-414, 424, Bhaveshwar Arcade, (opp. Shreyas cinema), LBS Road, Ghatkopar, Mumbai

Tel: 91-22-2500 2318, 2500 2294, 2500 2437

Fax: 91-22-2500 2415

400 086

Pune

Address: B/6, Shree Dwarka Co-op. Soc., Hare Krishna Mandir Path, Model Colony, Off. University

Tel: 91-20-2567 0709, 2567 6975

Fax: 91-20-400 4020

Road, Pune 411 016

Baroda

Address: 39 / 2, Arunodaya Soc., Alkapuri, Baroda 390 005

Tel: 91-265-231 4296 / 2330 383

Fax: 91-265-2343937

Nagpur

Address: 203, Ganga Apts, 13, Giripeth, Nagpur 400 010

Tel: 91-712-540 423

Fax: 91-712-540 423

*** SOUTH ZONE ***

Bangalore

Address: No. 412, Jindal Center, 2nd Flr, 100 Fleet Road, Koramangalam, Opp. Sukhsagar Hotel,

Tel: 91-80-51135670 / 5770 / 5870

Fax: 91-80-2558 8546

Chennai

Address: OMS Court, No. 1, Nathamuni Street, T., Nagar, Chennai 600 017

Tel: 91-44-2815 1063, 2815 2596, 712 4863, 713 4884, 713 4883

Fax: 91-44-2815 1442

Kochin

Address: "Nedumparambil", No. 1419/36, Kattakara Road, Kaloor, Kochin 682 017

Tel: 91-484-2341 985/86

Fax: 91-484-2341 986

Secunderabad

Address: 1-1-40/1, 2nd floor, Vasavi Towers, S. D. Road, Secunderabad - 500 003

Tel: 91-40-27806774 / 5/ 6

Fax: 91-40-2780 6777

Bangalore - 95

Page 8

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 9

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

*** EAST ZONE ***

Kolkatta

Address: Jindal Towers, 21/1A/3, Darga Road, Kolkata - 700 017

Tel: 91-33-2289 0493 / 033 2289 0490

Fax: 91-33-2289 0492

Bhubaneshwar

Address: 69, Satya Nagar, Bhubaneshwar 751 007

Tel: 91-674-2520 778

Fax: 91-674-2520 778

Jamshedpur

Address: Kashi Kunji, Road No. 2, Ground Floor, Contractors Areas, Bistupur, Jamshedpur 831 001

Tel: 91-657-2227 678

Fax: 91-657-2227 678

*** NORTH ZONE ***

New Delhi

Address: 18/14, WEA, Pusa Lane, Karol Baug; New Delhi 110 005

Tel: 91-11-2582 4206 / 2582 4208 / 2582 4214 / 18

Fax: 91-11-2575 7601

Chandigarh

Address: SCO No. 272, Sector 32 -C & D, 1st Floor, Above Punjab and Sind Bank,Chandigarh.

Tel: 0172-5077531

Fax: 0172-5016531

Lucknow

Address: 213, 2nd Floor, Saran Chambers-II, 5, Park Road, Lucknow - 226 001 (U.P)

Tel: 91-522-2237174

Fax: 91-522-2239877

Guwahati

Address : C/o. Ashok Bhasin, South Sarania, Ashram Road, (Near GMC Tax Office), Ulubari,

781 007.

Tel: 91-361-2453270

Fax: 91-361-2453270

Guwahati -

(Updated: December 1, 2004)

Page 10

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 11

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Safety Procedure

WARNING

In a domestic environment, this product may cause radio interface in which case the

user may be required to take additional measures.

WARNING

HIGH EARTH LEAKAGE CURRENT: EARTH CONNECTIONS IS ESSENTIAL

BEFORE CONNECTING THE INPUT SUPPLY.

This equipment must be earthed in accordance with local electrical codes.

WARNING

THIS UPS DOES NOT INCORPORATE AUTOMATIC BACKFEED

PROTECTION. A WARNING LABEL MUST BE FITTED TO ALL EXTERNAL

PRIMARY POWER ISOLATIONS STATING.

INSULATE THE UNINTERRUPTIBLE POWER SYSTEM BEFORE WORKING

ON THIS CIRCUIT.

Page 12

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 13

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

GENERAL

As with other types of high power equipment, dangerous voltages are present within

the UPS and battery enclosure. The risk of contact with these is minimised as the live

component parts are housed behind a hinged, lockable door. Further internal safety

screens make the equipment protected to IP20 standards.

No risk exists to any personnel when operating the equipment in the normal manner,

following the recommended operating procedures.

All equipment maintenance and servicing procedures involve internal access and

should be carried out only by trained personnel.

BATTERIES

Battery manufacturers supply details of the necessary precautions to be observed

when working on, or in the vicinity of a large bank of battery cells. These

precautions should be followed implicitly at all times.

Particular attention should be paid to the recommendations concerning local

environmental conditions and the provision of protective clothing, first-aid and fire

fighting facilities

TEST EQUIPMENT

When the battery is under charge, it is earth-referenced about its mid-point –e.g. if

the battery s being charged at 460V the battery extremities will be at +230V and –

230V with respect to neutral (earth). When using mains-powered test equipment

such as oscilloscopes in the UPS voltage area, always use a differential mode of

operation to disconnect the oscilloscope frame earth.

PERSONNEL

When working inside the UPS (trained personnel only) it is recommended that

protection be worn to prevent eye damage, should an electric ware be struck by

mishandling or severe electrical fault.

Some of the power components are very heavy. If their removal is necessary, ensure

that sufficient manpower is available; otherwise use adequate mechanical handling

equipment.

When working in the general area of the UPS where high voltages are present, a

second person should be standing-by to assist and summon help in case of accident.

Page 14

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 15

User Manual

I N D E X

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

1 General Introduction 1

1.1 Introduction 1

1.2 Design Concept 1

1.2.1 Hipulse Module Design 1

1.2.2 Bypass Supplies 2

1.2.3 System control Philosophy 3

1.2.4 ECOMODE (for single UPS) 4

1.2.5 UPS Power Switch Configuration 5

1.2.6 Battery circuit breaker 5

1.2.7 Battery temperature compensation 5

1.2.8 System Expansion 5

2 Installation Procedure 7

2.1 Introduction 7

2.2 Environmental Considerations 8

2.2.1 UPS location 8

2.2.2 Battery Location 8

2.3 Mechanical Considerations 9

2.3.1 System composition 9

2.3.2 Moving the cabinets 9

2.3.3 Clearances 9

2.3.4 Fixing Magnetic Components 9

2.3.5 Cable entry 9

2.4 Preliminary Checks 10

2.5 Installation Drawings 10

3 Installation (Electrical) 13

3.1 Power Cabling 13

3.1.1 System Configuration 13

3.1.2 Cable rating 14

3.1.3 General Notes 14

3.1.4 Cable connections 14

3.1.5 Safety earth 14

3.1.6 Protective Devices 15

3.1.7 Cabling procedure 16

3.2 Control cables 19

3.2.1 Battery Control 19

3.2.2 Auxiliary Terminal Block X3 and X4 at UPS 20

3.2.3 Emergency Stop 21

3.2.4 Back feed Protection 21

4 Operator Control and Display 23

4.1 Introduction 23

4.1.1 Operator Control Panel 24

4.1.2 The Menu Options 27

Page 16

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 17

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

5 Operating Instructions 31

5.1 Introduction 31

5.1.1 General Notes 31

5.1.2 Power switches 31

5.2 Procedure for UPS Startup: without interrupting 32

power to the load

5.3 Procedure for UPS Startup: without power initially 34

supplied to the load

5.4 Procedure for Switching the UPS into Maintenance 36

Bypass condition from Normal Operation

5.5 Procedure for Switching the UPS ON from a 38

Maintenance Power condition

5.6 Procedure for completely Powering down the UPS 38

5.7 Procedure for carrying out at Reset after a recognized 39

controlled transfer to Bypass or EPO action

5.8 Adding a single module to an existing system 40

5.9 Procedure to completely switch ON/ OFF the UPS 41

at the UPS Display control panel

5.10 Procedure to switch ON/ OFF the Inverter at UPS 43

Display control panel

5.11 Setting the Battery test 44

5.12 Language selection 45

5.13 Changing the current Date and Time 45

6 Battery Installation 47

6.1 Introduction 47

6.2 Safety 47

6.3 UPS Batteries 48

6.4 Installation Design Considerations 49

6.5 Battery Installation and Maintenance 49

6.5.1 Temperature Considerations 49

6.5.2 Battery Population 49

6.6 Battery Protection 50

6.7 Battery Cabinet and Racks 50

6.7.1 Introduction 50

6.7.2 Specification 50

6.7.3 Battery racks 50

6.8 Battery Installation 52

6.9 Battery Circuit Breaker Boxes 52

6.10 Battery Temperature Board 54

Page 18

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 19

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

7 Display Panel Interpretation 55

7.1 LED Interpretation 55

7.2 Display Panel Messages 57

8 1 + N System 63

8.1 General 63

8.2 Installation Procedure 65

8.2.1 Preliminary Checks 65

8.2.2 Protective Devices 65

8.2.3 Power Cables 65

8.2.4 Control Cables 65

8.2.5 Battery Control 66

8.2.6 Emergency Stop 66

8.3 Operating Instructions 67

8.3.1 System Start-up and Shutdown procedures (separate batteries) 67

8.4 Display Panel Message Interpretation in ‘1+N’ System 70

9 Specification 71

9.1 Conformity and Standard 71

9.2 UPS Environmental 71

9.3 UPS Mechanical Characteristics 71

9.4 UPS Electrical Characteristics 72

9.5 UPS Electrical Characteristics (DC Intermediate circuit) 73

9.6 UPS Electrical Characteristics (Inverter Output) 74

9.7 UPS Electrical Characteristics (Bypass Input Mains) 75

10. ANNEXURE 77

10.1 Remote Alarm Monitor 79

10.1.1 Ram Connections 79

10.2 Input Transformer Cubicle 81

10.2.1 Introduction 81

10.2.2 Termination 81

10.2.3 Indication and Metering 81

10.2.4 Protection 81

10.3 Bypass Isolation Cubicle 82

10.3.1 Introduction 82

10.3.2 Termination 82

10.3.3 Indication and Metering 82

10.3.4 Protection 82

---- x ---- x ----- x ---- x ----

---- x ---- x ----- x ----

---- x ---- x -----

Page 20

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Page 21

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

CHAPTER 1

General Description

1.1 Introduction

The Hipulse Uninterruptible Power Supply (UPS) System is connected between a

critical load, such as a computer, and its three phase mains power supply. Being

designed to furnish a well regulated 1 phase output power supply under all rated load

and input supply conditions, the system offers the user the following advantages:

Increased power quality:

The UPS has its own internal voltage and frequency regulators which ensure that its

output is maintained within close tolerances independent of voltage and frequency

variations on the mains power lines.

Increased noise rejection:

By rectifying the input a.c. power to d.c. power, and then converting it back to a.c.,

any electrical noise present on the input mains supply line is effectively isolated from

the UPS output, therefore the critical load sees only clean power.

Power blackout protection:

If the mains power fails, the UPS continues to power the critical load from its battery

source, leaving the load immune from power disturbances.

1.2 Design Concept

1.2.1 Hipulse Module Design

This section describes an individual module's operating principles. The UPS basically

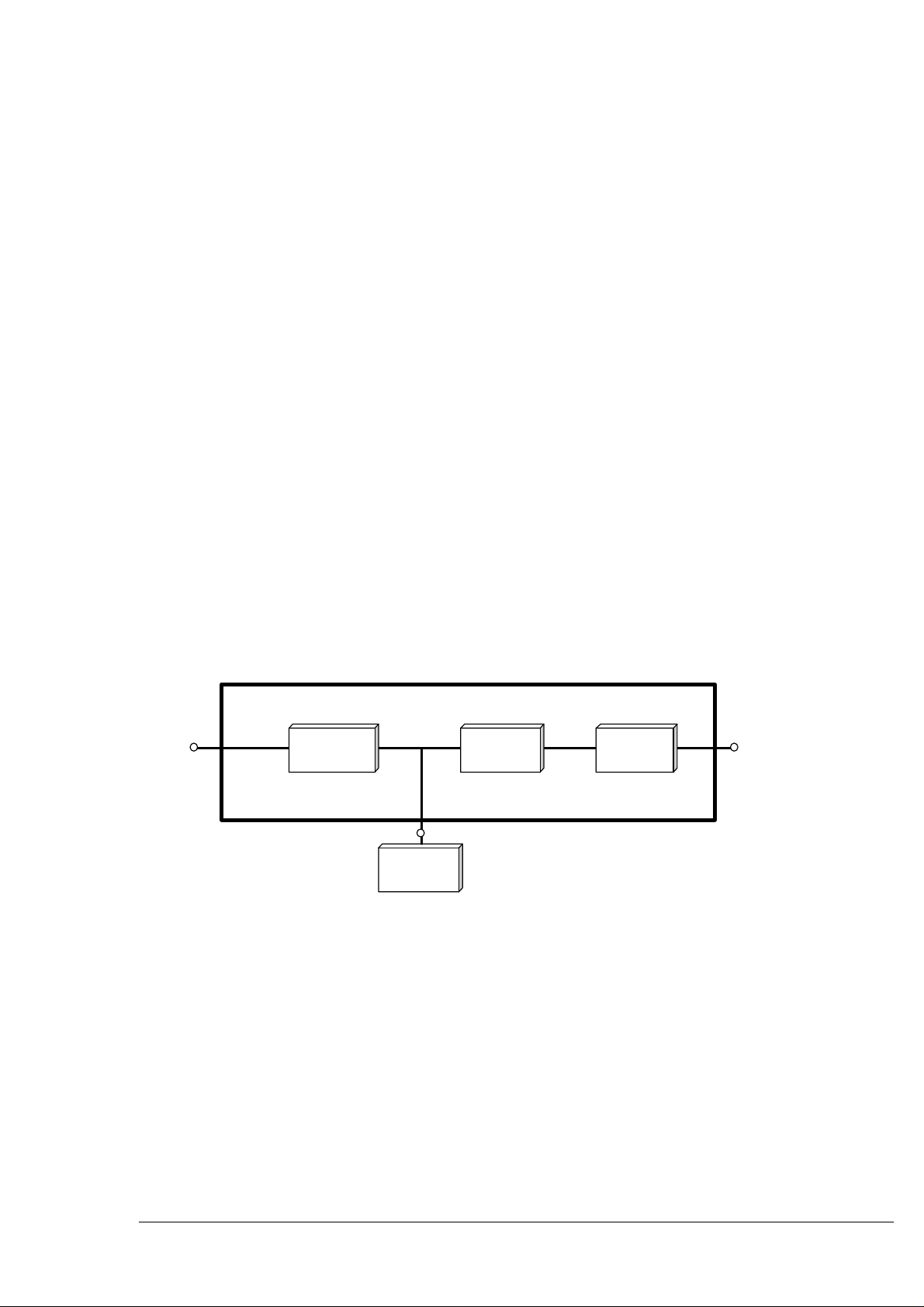

operates as an a.c. - d.c. - a.c. converter (see figure 1 -1 ). This first conversion stage

(from a.c. to d.c.) uses a 3 phase, fully-controlled SCR bridge rectifier to convert the

incoming mains supply into a regulated d.c. busbar.

Mains

Supply

(a.c.) (d.c.) (a.c.)

RECTIFIER

INVERTER

STATIC

SWITCH

(d.c.)

BATTERY

Fig 1-1 : Single Module block diagram

The d.c. busbar produced by the rectifier provides both battery charging power being equipped with a temperature compensated battery charging system, to prolong

battery life - and power to the inverter section - which utilizes the latest IGBT switching

pulse width modulation (PWM) design - and provides the second conversion phase,

i.e. reconverting the d.c. busbar voltage back into an a.c. voltage waveform.

UPS

Output

Supply

1

Page 22

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

During normal operation both the rectifier and inverter sections are active and provide

regulated load power whilst simultaneously float charging the battery. In the event of

a mains power failure, the rectifier becomes inoperative and the inverter is powered

solely from the battery. Critical load power is maintained under these conditions until

battery is fully discharged, where upon the UPS shuts down. The end of battery

discharge is assumed when the battery voltage falls below a preset value (i.e. 330 /

340V d.c. for a 400 V a.c. system).

The period for which the load can be maintained following a mains power failure is

known as the ‘System’s Autonomy Time’ and is dependent upon both the battery A/Hr

capacity and the applied percentage load.

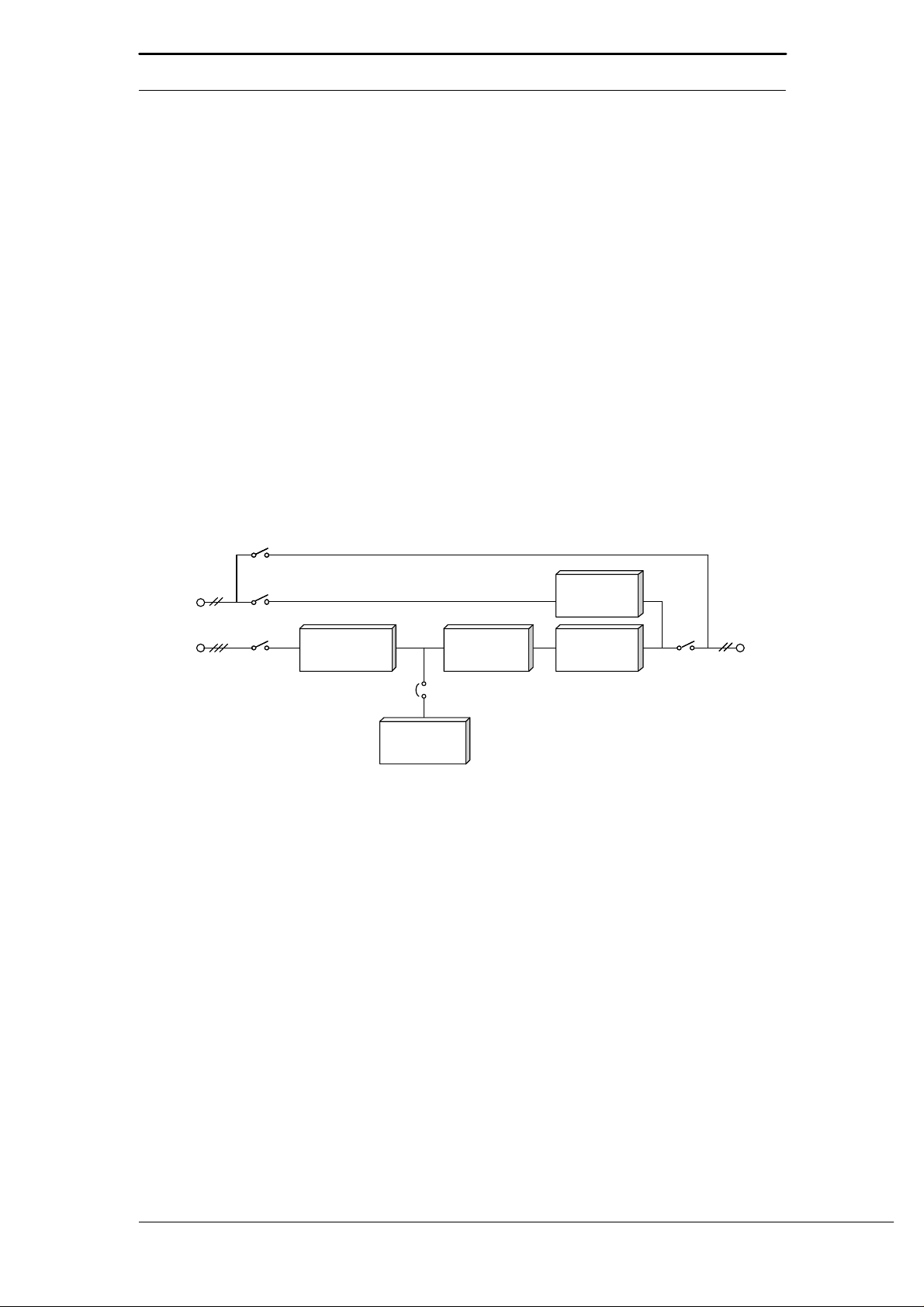

1.2.2 Bypass Supplies

The circuit block annotated ‘Static Switch’ in figure 1-2 contains an electronically

controlled switching circuit which enables the critical load to be connected either to

the inverter output or to a bypass power source via the ‘static bypass line’. During

normal system operation the load is connected to the inverter and the ‘inverter -side’

of the Static Switch is closed; but in the event of a UPS overload, or inverter failure, it

is automatically transferred to the static bypass supply line.

Maintenance Bypass

Isolator

Maintenance Bypass Line

Bypass

Supply

Bypass Isolator

Static Bypass Line

STATIC

SWITCH

Mains

Supply

Input

Isolator

RECTIFIER

INVERTER

Battery

Isolator

STATIC

SWITCH

Output

Isolator

UPS

Output

Supply

BATTERY

Fig 1-2 : UPS Power switches configuration

To provide a clean (no-break) load transfer between the inverter output and static

bypass line, the static switch activates connecting the load to the bypass supplies. To

achieve this, the inverter output and bypass supply must be fully synchronized during

normal operating conditions. This is achieved through the inverter control electronics

which make the inverter frequency track that of the static bypass supply provided that

the bypass remains within an acceptable frequency window. The synchronizing

window is pre-selected to 2% of nominal frequency, giving an acceptable frequency

window ±1 Hz.

A manually controlled, ‘Maintenance Bypass’ supply is also incorporated into the UPS

design. Its purpose is to enable the critical load to be powered from the mains

(bypass) supply while the UPS is shut down for routine maintenance.

Note: The load equipment is not protected from normal supply aberrations when operating on Bypass

side or in the maintenance bypass mode

2

Page 23

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

1.2.3 System Control Philosophy

Normal Operation

During normal operation, i.e. when the UPS input supply is present and within

specification, both the rectifier and inverter sections are active and the static switch is

turned on to connect the inverter output to the critical load busbars. The battery

circuit breaker is also closed and the battery is therefore permanently float charged at

the d.c. busbar voltage level.

(1+N Parallel UPS System)

Note: As the unit outputs are connected in parallel, the System checks that the inverter control circuits

are perfectly synchronised with one another and with the Bypass Mains in terms of both frequency and

phase and that they have the same output voltages. Current supplied to the load is automatically

divided among UPSs. A warning message appears while synchronisation is in progress.

A module's static switch cannot close until these conditions are satisfied.

Mains Failure

If the power mains has a failure or is out of tolerance the rectifier will go off

automatically, while the Inverter will continue to operate on power from the battery for

a period of time which depends on the load and the capacity of the battery. If the

mains supply has not retuned within this time, the Inverter will go off automatically and

an alarm message will appear on the UPS operator control panel display.

Critical load will not be interrupted in the event of a drop or return of the AC power

mains.

Return of power mains

When the mains return within the required tolerance, the Rectifier will start up again

automatically and gradually (power walk in), supplying power to the Inverter and

recharging the battery at the same time. There will be no interruption of the critical

load.

Off-Battery

If the battery system only is taken out of service for maintenance, it is disconnected

from the rectifier/ charger and inverters by means of (an) external disconnect

breaker(s). The UPS shall continue to function and meet all of the specified steadystate performance criteria, except for the power outage back-up time capability.

UPS Module fault

In the event of an Inverter fault, the Static Transfer Switch will automatically transfer

the load onto the Bypass Mains with no interruption. In such an event, request

qualified technical assistance.

(1+N Parallel UPS System)

In the event of a fault in a unit, the unit's Static Transfer Switch will automatically

exclude the unit from the system. If the system is still capable of providing the

required load, the remaining units will continue to supply the load with no interruption.

When the units still present in the system are no longer capable of fulfilling power

requirements, the load will automatically be transferred onto the MSS Bypass Mains.

The load will be transferred with no interruption if the Inverters are synchronised with

the network; if this is not the case, there will be an interruption lasting about 20

milliseconds.

3

Page 24

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Overload

In the event of an overload at the Inverter output which lasts longer than the typical

time/ current (refer to Chapter 9 - Specifications), the Inverter will shut down and the

Static Transfer Switch will automatically transfer the load onto the MSS Bypass Mains

with no interruption. If the overload falls within the typical time/ current that has been

specified, the load will be returned to the inverters when the power drops to a level

which can be supported by the number of active units in the system (parallel 1+N).

In the event of a short circuit in the output, the load will normally be transferred onto

the MSS Bypass Mains, which will cause the Inverter to shut down; this switch is

determined above all by the features of the protective devices in use in the system. In

either case, an alarm message will appear on the UPS operator control panel display.

(1+N Parallel UPS System)

The control logic system constantly monitors load requirements and controls the

power supplied by the UPS modules. In the event that an overload condition is

sustained for greater than a preset time, the load will transfer to the mains bypass

supply, when the number of active modules are unable to satisfy load requirements.

The load returns to the inverter supply if the power is reduced it a value that can be

sustained by the number of active modules in the system.

Maintenance Bypass

A second bypass circuit contained in the UPS cabinet, identified as the 'Maintenance

Bypass' line is included to enable a 'raw' mains supply to be made available to the

load while facilitating a safe working environment for carrying out scheduled UPS

system maintenance or troubleshooting. The circuit is manually selected by the

Maintenance Bypass Isolator which can be padlocked in the OFF position.

WARNING

The internal maintenance bypass must not be used when the UPS

system is comprised of more than two UPS modules in parallel.

CAUTION

If an automatic circuit breaker device is not present in the input

distribution panel, there remains a dangerously high voltage at the

output busbars of the UPS module that is switched off

1.2.4 ECOMODE

In this operating mode the System prefers to put the load on the Bypass Mains, with

the Inverter on stand-by. The load is switched over to the Inverter when the mains

goes outside of standard frequency and voltage values (or the values as modified

using the operator panel when starting up the system). The ECOMODE configuration

requires a different setup in the default menu configuration, which may be prepared in

the factory before shipment or during installation by personnel trained in the use of the

System.

Note: In order to operate in ECOMODE, UPSs must be provided with compatible software versions:

The 'UPS Logic' card must be release 9.0 or later (the S/W release of the cards may be

read on the front panel display, referring to Section 4.1.2 - Operating Instructions).

Operating Instructions in ECOMODE are the same as those described in Chapter 5,

except that the load is normally on the Bypass mains, the Load LED is normally on

Inverter (5), and corresponding alarm message will be replaced with Load on Mains

(6).

4

Page 25

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

WARNING

In ECOMODE the load is not protected against mains distortion.

1.2.5 UPS Power Switch Configuration

Figure 1-2 illustrates the Hipulse UPS module in what is known as the "Split Bypass"

configuration. In the Split Bypass configuration, the static bypass line is connected by

a separate power switch to a dedicated 'bypass' power source which also feeds the

maintenance bypass line. Where a separate power source is not available the Bypass

(Q2) and Rectifier input supply connections would be linked together.

With the exception of maintenance bypass isolator, all the isolators shown must be

closed during normal UPS operation.

1.2.6 Battery circuit breaker

The battery should be connected to the d.c. busbar through a circuit breaker fitted

inside the battery cabinet or located adjacent to batteries where a battery cabinet is

not used. This circuit breaker is closed manually, but it contains an undervoltage

release coil which enables it to be tripped from the UPS control electronics following

certain detected faults. It also has a magnetic trip facility for overload protection.

1.2.7 Battery temperature compensation

Hipulse UPS System offers a battery temperature compensation circuit. As the

temperature inside the battery cabinet area rises, the d.c. busbar voltage reduces in

order to sustain the battery at its optimum charge voltage. This must be used in

conjunction with the battery sensor board.

1.2.8 System Expansion

If necessary, a single -module system can be expanded to cater for an increased load

requirement by adding additional modules - upto a maximum of six UPS modules can

be connected in parallel. System expansion requires change in the SETUP of the

display panel.

Note: System expansion should be carried out only by trained service personal. The individual

modules connected to the system must be of the same power rating

5

Page 26

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

6

Page 27

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

CHAPTER 2

Installation Procedure

2.1 Introduction

WARNING

Do not apply electrical power to the UPS equipment before the

arrival of the commissioning engineer.

WARNING

The UPS equipment should be installed by a qualified engineer in

accordance with the information contained in this chapter and all

equipment not referred to this manual is shipped with the details its

own mechanical and electrical installation.

WARNING - Battery Hazards

• Special care should be taken when working with the batteries

associated with this equipment. When connected together, the

battery terminal voltage will exceed 400V DC, and is potential

lethal.

• Eye protection should be worn to prevent injury from accidental

electrical arcs.

• Remove rings, watches and all metal objects.

• Only use tools with insulated handles.

• Wear rubber gloves.

• If a battery leaks electrolyte, or is otherwise physically damaged, it

must be replaced, stored in container resistant to sulfuric acid and

disposed of in accordance with local regulations.

• If electrolyte comes into contact with the skin, the affected area

should be washed immediately with water.

NOTE

The UPS System can be connected to an IT (isolated neutral) power

system

This section describes the UPS system’s environmental requirements and mechanical

considerations that must be taken into account when planning the positioning and

cabling of the UPS equipment.

Because every site has its peculiarities, it is not the aim of this chapter to provide step-by-step

installation instructions, but to act as a guide as to the general procedures and practices that should be

observed by the installing engineer.

7

Page 28

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

2.2 Environmental considerations

2.2.1 UPS location

The UPS module should be located in a cool, dry, clean-air environment with

adequate ventilation to keep the ambient temperature within the specified operating

range (see Chapter 9 - Specifications).

All models in the ‘Hipulse’ UPS range are cooled with the aid of internal fans. Cooling

air enters the module through ventilation grills located at various parts of the cabinet

and exhausted through grills located on the back of UPS. When the cabinet is located

on a raised floor, and bottom cable entry is used, additional cooling air also enters the

UPS via the floor void. If necessary, a system of extractor fans should be installed to

aid cooling air-flow, and a suitable air filtration system used where the UPS is to

operate in a dirty environment.

Note 1: When batteries are cabinet-mounted adjacent to the UPS module, it is the battery which

dictates the designed maximum ambient temperature, not the UPS.

Note 2: Power losses from the System which may be used in an air conditioning system are intended

for operation using the Inverter, as in the ECOMODE configuration they would be undersized.

2.2.2 Battery location

Temperature is a major factor in determining the battery life and capacity. Battery

manufacturers quote figures for an operating temperature of 20oC. Operating above

this temperature will reduce the battery life, operation below this temperature will

reduce the battery capacity. On a normal installation the battery temperature is

maintained between 15oC and 25oC. Batteries should be mounted in an environment

where the temperature is consistent and even over the whole battery. Keep batteries

away from main heat sources or main air inlets etc.

The batteries can be mounted in purpose-built battery cabinet, which is positioned

adjacent to the UPS module. Pedestals are required for the battery cabinets when

they are located on raised floors, in the same way as for the UPS cabinets. If the

batteries are rack-mounted, or otherwise located remote to the main UPS cabinet, a

battery circuit breaker must be mounted as close as possible to the batteries

themselves, and connected using the most direct route possible. A customized

remote battery circuit breaker box, containing the circuit breaker and its necessary

control board, is also available as a standard option.

8

Page 29

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

2.3 Mechanical Considerations

2.3.1 System composition

A UPS system can comprise a number of equipment cabinets, depending on the

individual system design requirements - e.g. UPS cabinet, Battery cabinet. In general,

all the cabinets used in a particular installation are of the same height and designed to

be positioned side-by-side to form an aesthetically appealing equipment unit.

2.3.2 Moving the cabinets

WARNING

Ensure that any lifting equipment that used in moving the UPS

cabinet has sufficient lifting capacity.

Ensure that the UPS weight is within the designated surface weight loading

(Kg/sq.cm.) of any handling equipment. See the UPS specification for weight details.

The UPS cabinets can be moved by fork lift or crane. For operations with fork lift, it is

necessary to remove both the front, rear (or side) grille panels located on the base of

the cabinet. To enable the cabinet to be lifted by a crane, removable lifting bars, are

fitted to the top of the cabinet.

In the eventuality that the equipment cannot be moved by fork lift or crane, then rollers

should be used.

2.3.3 Clearances

As Hipulse has no ventilation grills at either the sides or the rear, no clearances are

required. Back -access is not an essential requirement for maintenance; however,

where space permits, a clearance of approximately 1000mm will ease access to

magnetic component parts. This will also ensure proper exhaust from rear.

Clearance around the front of the equipment should be sufficient to enable free

passage of personnel with the doors fully opened.

2.3.4 Fixing magnetic components

After the equipment is in place, remove the transportation restraints that hold the

output transformer in place.

2.3.5 Cable entry

Cables can enter for ‘Hipulse’ UPS and battery cabinet either from below or through

either side. Side entry is made possible by removing blanking pieces fitted in the side

panel to reveal the cable entry holes. This cable entry method allows the equipment

to be positioned on a solid floor without the need for cable trenching and allows

cables to pass from one module to the other when positioned side-by-side.

Note: When selecting the power cables for side entry to a module located on a solid floor,

consideration must be given to the minimum permissible bending radius of the proposed cables to

ensure that they can be fashioned to reach the UPS connection busbars.

9

Page 30

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

2.4 Preliminary Checks

Before you install the UPS hardware you should carry out the following preliminary

checks:

1. Verify that the UPS room satisfies the environmental conditions stipulated in the

equipment specification, paying particular attention to the ambient temperature and

air exchange system.

2. Remove any packaging debris, then visually examine the UPS and battery

equipment for transit damage, both internally and externally. Report any such

damage to the shipper immediately.

2.5 Installation Drawings

The following diagrams illustrate the key mechanical characteristics of the various

UPS system cabinets

Fig 2-1: Overall General Arrangement for 130 kVA Single Phase 110V UPS with 6 Pulse

rectifier Single Module and ‘1+N’

Fig 2-2: Cable entry and Foundation details for 130 kVA Single Phase 110V UPS with 6

Pulse rectifier Single Module and ‘1+N’.

10

Page 31

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

1000

875

AIR FLOW

F R O N T

3

19031903

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

842

1400

LEFT SIDE VIEW FRONT VIEW

4

1903

5

1750

1

1600

REAR VIEW TOP VIEW

Note - All dimensions are in mm

1. Removable grill for lifting with fork-lift truck

2. Air inlet grill

3. Removable grill – if using side cable entry

4. Cooling fan assembly for Rectifier & Inverter

5. Cooling fan assembly for Transformers

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

2

1

Fig 2-1: Overall General Arrangement for 130kVA Single Phase UPS

11

Page 32

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

1400

800

125

65

57090

40

570 90

A. CABLE ENTRY DETAILS

42.5

90

1315

1220

37.5

85

755

660

800

1400

Dia 14.0 Holes

FOUNDATION DETAILS

Note: All dimensions are in mm

Fig 2-2 : Cable entry and Foundation details for 130 kVA Single Phase UPS

12

Page 33

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

CHAPTER 3

Installation (Electrical)

The UPS requires both “Power” and “Control” cabling once it has been mechanically

installed. All Control cables, whether screened or not, should be run separate from

the Power cables in metal conduits or metal ducts which are electrically bonded to the

metalwork of the cabinets to which they are connected.

3.1 Power Cabling

WARNING

Before cabling-up the UPS, ensure that you are aware of the location

and operation of the external isolators that connect the UPS input/

bypass supply to the mains distribution panel.

Check that these supplies are electrically isolated, and post any

necessary warning signs to prevent their inadvertent operation.

For cable entry, refer to section 2.3.5

3.1.1 System Configuration

The power cables of the system must be size with respect to the following description:

Module input cables

The module input cables must be sized for the maximum input current, including the

maximum battery recharge current, given in the table 3-1, with respect to the module

rating and the input a.c. voltage.

Module Bypass and Output cables

The Bypass and Output cables must be sized for the nominal output current, given in

the table 3.1, with respect to the module rating and the output a.c. voltage.

Battery cables

Each UPS module has its own battery, which is connected using two cables, one

positive and one negative. The battery cables must be sized for the battery discharge

current at the end-of-discharge voltage, as given in the table 3-1, with respect to the

module rating.

13

Page 34

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

3.1.2 Cable rating

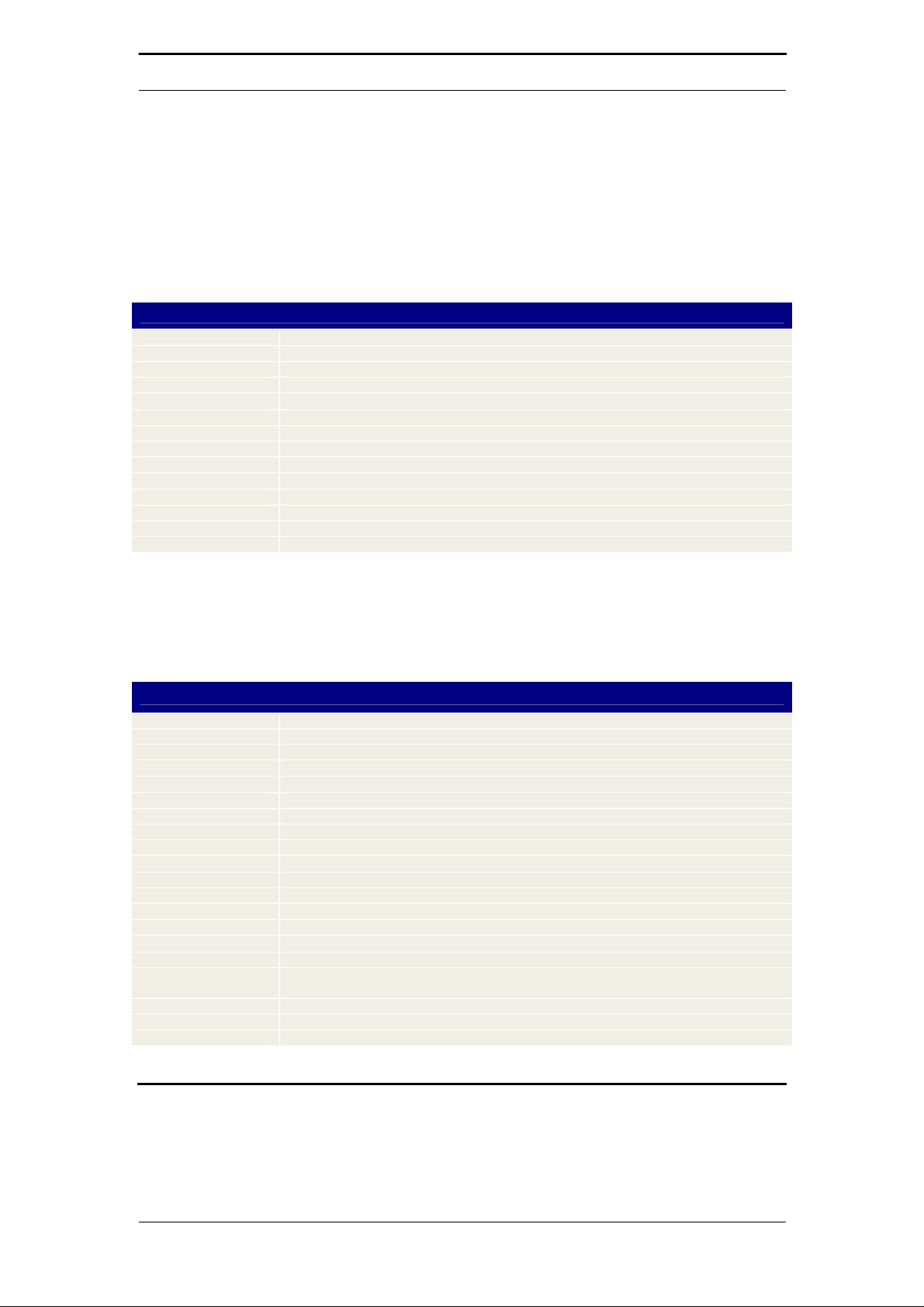

NOMINAL CURRENT (Amps)

UPS

Rating

(kVA)

120 245 233 223 1090 1043 1000 329 319 310

130 259 247 238 1181 1130 1083 357 346 336

150 300 285 275 1363 1304 1250 412 399 387

3 Phase Input Mains with full

battery re-charge

(less 5% for 12 pulse)

380V 400V 415V 110V 115V 120V 380V 400V 415V

30 63 60 58 272 260 250 83 80 77.5

40 84 80 77 364 349 334 110 106 103

50 105 100 96 454 434 416 137 133 129

60 126 119 115 545 521 500 164 159 155

80 165 157 151 727 695 666 219 213 206

1 Phase Output at full load

Battery at minimum

Battery Voltage

Table 3-1 UPS Module cabinet power cable rating

3.1.3 General Notes

The following are guidelines only and superseded by local regulations and codes of

practice where applicable:

1. The neutral conductor should be sized same as the output/ bypass current.

2. The earth conductor should be sized for carrying fault current for atleast 3 to 5

seconds or as guided by local electrical rules.

3. Consideration should be given to the use of paralleled smaller cables for heavy

currents, as this can ease installation considerably.

4. When sizing battery cables, a maximum volt drop of 3V d.c. is permissible at the

current ratings given in Table 3-1.

3.1.4 Cable Connections

The rectifier input, bypass, output and battery power cables (all require lug type

terminations) and are connected to busbars situated below the power isolator

switches - as shown in figure 3.1 for 80kVA and fig 3.2 for 120 /160/ 200kVA.

A terminal block X3 is used for connecting the control cables to the battery circuit

breaker and a second terminal block X4 is used for the external emergency stop

facility, external OFF inverter, ext. Bypass, etc. these are female spade type

connections (Fast-on 6.3 x 0.8) and are described later in Section 3.2

3.1.5 Safety earth

The safety earth busbar is located between the Bypass and Output power supply

connections as shown in the figure 3.1. The safety earth cable must be connected to

the earth busbar and bonded to each cabinet in the system.

All cabinets and cable trunking should be earthed in accordance with local

regulations.

14

Page 35

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

WARNING

Failure to follow adequate earthing procedures can result in electric

shock hazard to personnel, or the risk of fire, should an earth fault

occur.

3.1.6 Protective devices

For safety reasons, it is necessary to install, external to the UPS, circuit breaking

protective devices in the input a.c. supply and towards the battery. Given that every

installation has its own characteristics, this chapter provides general useful

information engineers, with knowledge of operating practices, of regulatory standards,

and of the equipment to be installed.

Rectifier and bypass inputs:

Protection against excessive over currents and short circuits

These inputs must be protected, installing suitable protective devices at the

distribution panel of the incoming main supply, considering that the protection should

discriminate with overload capacity of the system (see Chapter 9: Specification Electrical Characteristics).

Split Bypass :

In the case of a split bypass being used, separate protective devices should be

installed in the incoming mains distribution panel.

The protective devices must be selected for the nominal input current, with respect to

the UPS rating and the input a.c. supply voltage as given in table 3-1.

Protection against earth faults (RCD devices):

In the event of a differential (RCD) device being installed upstream of the input supply,

one must take into account transient and steady state earth leakage currents that are

produced during start-up of the UPS.

The presence of an RFI suppression filter inside the UPS, determines a residual earth

current greater than 3.5mA and less than 1000mA.

Residual current circuit breakers (RCCB) must be sensitive to d.c. unidirectional pulse

(class A) in the network and insensitive to transient current pulses.

They are identified by the symbols respectively.

These isolators must have an average sensitivity, possible adjustable between 0.3 and

1A.

It is recommended that the selectivity with every differential switch be verified both

upstream of the input distribution board and downstream (towards the load).

15

Page 36

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Parallel 1+N:

Use of differential circuit breakers on UPS unit inputs in a configuration with separate

inputs and one battery for each unit requires installation of a common device only on

the System Bypass Mains.

Use of differential circuit breakers on UPS unit inputs sharing a common battery

requires installation of device common to all the input lines. If inputs are configured

for separate mains, a common device will also be required for all System bypass

mains.

UPS Battery:

The UPS Battery is protected by means of a control circuit that operates the tripping

mechanism of an automatic circuit breaking device (having a variable trip setting).

The tripping mechanism using an undervoltage release coil that operates on a present

minimum voltage level.

The circuit breaker is essential for maintenance of the battery and is normally located

near to the battery installation. The characteristics and operation of the automatic

circuit breaker are given in Chapter 6.

Output of the System:

In the eventuality that an external distribution panel is used for load distribution, the

selection of protective device must proved discrimination with those that are use at

the input to the UPS module.

3.1.7 Cabling procedure

Once the equipment has been finally positioned and secured, connect the power

cables as described in the following procedure.

Study the connection diagram in the figures below.

1. Verify that the UPS equipment is totally isolated from its external power source and

all the UPS power isolators are open. Check that these supplies are electrically

isolated, and post any necessary warning signs to prevent their inadvertent operation.

2. Open the door(s) to the UPS cabinet and remove the lower protective cover to gain

access to the connections bars.

3. Connect the safety earth and any necessary bonding earth cables to the copper

earth bus busbar located on the floor of the equipment below the power connections.

Note: The earthing and neutral bonding arrangement must be in accordance with local and national

codes practice

Input Connections:

4. Connect the a.c. input supply cables to the input busbars (U1-V1-W1 terminals)

and the bypass a.c. supply cables to the bypass busbars (U3 - N3 terminals) and

tighten the connections.

ENSURE CORRECT PHASE ROTATION

Output System Connections:

5. Connect the system output cables between the output busbars (U2 - N2 terminals)

and the critical load and tighten the connections.

16

Page 37

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

WARNING

If the load equipment will not be ready to accept power on the arrival

of the commissioning engineer then ensure that the system output

cables are safely isolated at their ends.

6. Connect the Battery cables between the UPS terminals (+/ -) and its associated

battery circuit breaker. Connect screened auxiliary cables from each battery circuit

breaker control board to the auxiliary terminal block (X3) of UPS of their metal frame of

the Battery breaker mounted in input transformer cubicle or Battery circuit breaker

box (if used).

As a safety precaution remove the battery fuse in the module until the arrival of

commissioning engineer.

OBSERVE THE BATTERY CABLE POLARITY

WARNING

Do not close the battery circuit breaker before the equipment has

been commissioned.

Input-module Parallel Connections:

7. 1+N Parallel UPS System: Inside the module there is an Parallel Connectors Board

mounted on the left hand side. Connect one end of the interconnecting ribbon cables

to interface connector (X1) of the first UPS module and the other end to connector (X2)

of the second module, and so to the next module until a closed loop is formed. (see

fig 8-2).

Auxiliary Connections:

8. Connect the auxiliary cables of any external interface/ signals to the respective

connections of the output auxiliary terminal block (X4).

9. Refit the lower protective cover.

17

Page 38

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Q3

Q1 Q2 Q4

X4

X3

Q1 - INPUT

SUPPLY

Q2 - BYPASS

ISOLATOR

BATTERY INPUT BYPASS OUTPUT

Q3 - MAINTENANCE

BYPASS

Q4 - OUTPUT

ISOLATOR

Q3

Q1

Q2 Q4

U1 V1 W1+VE -VE U3 N3 U2 N2

Fig 3-1 : Cable connections for 130 kVA 1Ph UPS

18

Page 39

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

3.2 Control cables

3.2.1 Battery Control

The battery circuit breaker is controlled by the Battery Circuit Breaker Controller Board

which is located within the Input Transformer Cubicle - or adjacent to the Battery

Circuit Breaker when the batteries are rack-mounted. This board controls the circuit

breaker’s undervolts release coil and also provides a path for the circuit breaker

auxiliary contacts to signal the circuit breaker status back to the UPS control logic. All

the connections between the controller board and the UPS module are made via the

Auxiliary Terminal Block which is located in the base of the UPS cabinet.

B A T T E R Y C I R C U I T

B R E A K E R C O N T R O L L E R

B O A R D

1 2 3 4 5

X1

LINKS

Fig 3-2 : Auxiliary Terminal Block detail

Connect the battery circuit breaker control and temperature compensation cables

between the UPS auxiliary terminal block and battery circuit breaker controller board

as shown in figure 3-3. These cable must be shielded, shield should be connected at

protective earth of Input transformer cubicle or battery breaker, not of UPS.

CAUTION

If battery temperature compensation is not used the system must be

de-activated by commissioning engineer.

1

2

Common

I batt.

3

Common

4

Batt. Sw.

5

Batt. trip

6

7

8

9

10

11

12

X3

1

Ext OFF Inv.

2

3

Ext Sw. Out

4

5

Ext EPO

6

7

Ext BYP

8

9

10

11

12

X4

Back feed

Int EPO

AUXILIARY

TERMINAL

BLOCK

LOCATED IN

UPS

CABINET

19

Page 40

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

3.2.2 Auxiliary Terminal Block X3 and X4 at UPS

X3 terminal reference Reference label Description

2 Common Temperature sensor common (0V)

3 T Batt. Temperature sensor signal

4 Common Common (0V)

5 Batt. Sw. Battery circuit breaker trip control

6 Bat Trp Battery circuit breaker trip control

Note: The auxiliary cables of the battery must be screened and double insulated.

The screen is connected to the earth of the battery cabinet or supporting rack.

Use multiple-core shielded cables with a section of 0.5 to 1mm2

Connect the cables with the Fast-on 6.3 x 0.8 mm terminals (female)

X4 terminal reference Reference label Description

1-2 Ext. OFF Inv

3-4 Ext. Sw. Out

5-6 Ext. EPO

7-8 Ext. BYP

9-10 Back Feed

11-12 Int. EPO

Remotely provides control for switching off the inverter.

Normally open contact.

Indication to be provided at the UPS to note the opening of an external

module output isolator.

Normally closed contact.

If unused, leave the standard connectors in place.

Remotely provides control for switching off the UPS using a remote

emergency button.

Normally closed contact.

If unused, leave the standard connectors in place.

Indication to be provided at the UPS to note the opening of an external

maintenance bypass switch.

Normally closed contact.

If unused, leave the standard connectors in place.

Signal form the UPS to indicate a return flow of energy in the bypass mais.

Normally open contact.

Availability of a contact for switching off the UPS in the same way as the

internal emergency off button.

Normally closed contact.

Note: All auxiliary cables of terminal block X4 must be double insulated.

The cross-sectional area of the auxiliary cables is from 0.5 to 1 mm2

Connect the cables with the Fast-on 6.3 x 0.8 mm terminals (female)

Maximum contact rating on auxiliary terminals: 50 Vdc @ 1 Amp.

20

Page 41

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

To Battery

+

Sensor

3

Temperature

2

(Optional)

1

X3

X4

X5

X6

X7

V<

X8

X9

+

BATTERY

CIRCUIT

BREAKER

1 2 3 4 5

X2

X10

X1

UPS CABINET

X3

1

2

3

4

5

6

7

8

9

10

+

11

12

Battery C.B.

Controller

Fig 3-3: Battery Connection

3.2.3 Emergency Stop

If an external Emergency Stop facility is required it is connected to terminals 5 & 6 of

the Auxiliary Terminal Block (X4) and connect the ‘normally closed’ remote stop switch

between these two terminals using shielded cable. If this facility is not used then

terminals 5 & 6 must be linked-out as shown in Figure 3-3.

Note: The Emergency Stop action within the UPS shuts down the rectifier, inverter and static bypass

and trips the battery circuit breaker. It does not however internally disconnect the input mains supply.

If required, this additional action can be facilitated by feeding the UPS input via a circuit breaker

which can be tripped by a second contact of the Emergency Stop switch.

Note: Terminals 11 and 12 of the Auxiliary Terminal Block (X4) are connected to a normally closed

contact of the UPS Display Panel Emergency Stop button and go open circuit when the button is

pressed. This output can be used as part of a wider Emergency Stop system to initiate an external

action (such as tripping an external supply breaker)

3.2.4 Back Feed Protection

Using an auxiliary terminal (pins 9-10 of connector X4) the UPS provides a normally

open contact to be used for opening of an external circuit protection device, to protect

the operator against back feed of energy resulting from a short-circuit fault of the

Bypass line SCRs. This auxiliary contact can be used, for example, in series with an

external low voltage source, in order to supply the trip coil of an automatic circuit

breaking device, located upstream of the UPS Bypass mains input. In the vent of

energy being backfeed the auxiliary circuit will activate closing the normally open

contact and as a result opening of the external circuit-breaking device; the UPS is

disconnected from the Bypass mains supply. The electrical characteristics of the

auxiliary contact are 50V (a.c. or d.c.) @ 1 Amp.

21

Page 42

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

22

Page 43

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

CHAPTER 4

Operator Control and Display Panel

4.1 Introduction

On the front of the UPS there is a display and control panel, from which it is possible to

easily verify the status of the UPS included all the measured parameters and alarms of

the UPS and Battery. The operator control panel is divided into three functional areas:

‘Mimic LED display’ and Inverter Control switch,

‘Operator Panel’ and ‘LCD display’,

‘Bargraph section’.

As can be seen the left section consists of LEDs which indicate the operational and

alarm status of the system by turning ON or OFF or by flashing ON/ OFF.

The middle section of the operator control and display panel consists of a LCD (Liquid

Crystal Display) and its associated switches.

The following functional area (right section) shows the various UPS load and Battery

charging conditions.

HIPULSE

INV

ESC

MENU

ENTER

Fig 4-1: UPS Operator Control / Display Panel

%

23

Page 44

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

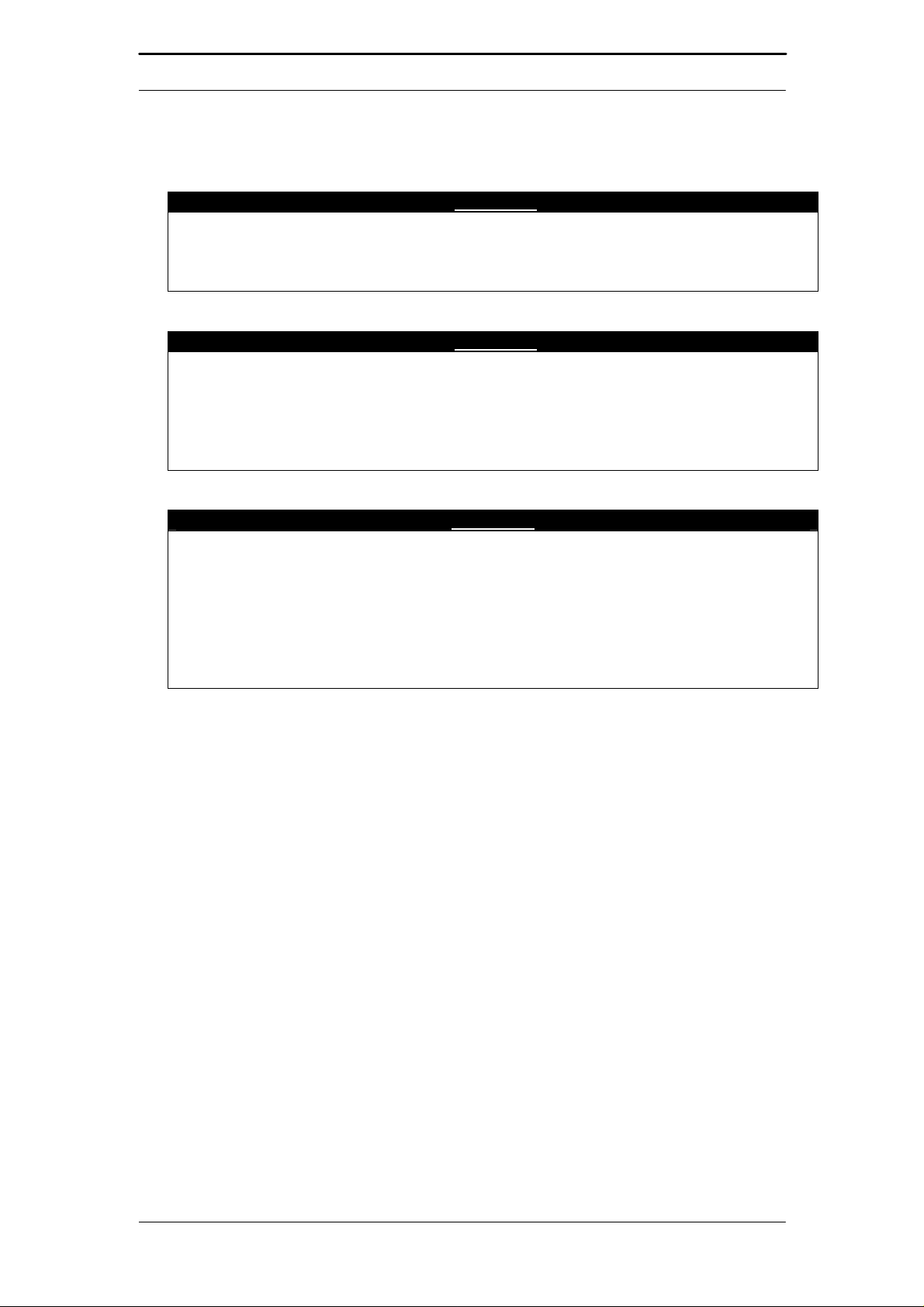

4.1.1 Operator control panel

The control and display panel LEd indications are illustrated in figure 4-2 and

described in the following text:

6

1

2

3

INV

ESC

MENU

DISPLAY

%

ENTER

7 8 9 10 11 12 13 14 15 16 17 18 194 5

Fig 4-2: Single module operator control panel

Mimic indications

Six LED’s mounted on a single line diagram represents the various UPS power paths

and show the current UPS operation status:

1. Bypass supply healthy

This led illuminates when the bypass a.c. input power switch is closed and the input

supply is within of set value nominal voltage (default ±10%)

2. Input supply healthy and Rectifier is operative.

3. Battery voltage healthy (i.e. between ‘under - voltage cut-off’ and ‘over - voltage

trip’ levels).

4. Inverter output healthy.

5. Load on Inverter status

This led illuminates when the output power switch is closed and the load is connected

to the inverter.

6. Load on Bypass status.

This led illuminates when the output power switch is closed and the load is connected

to the bypass a.c. supply via the static switch.

Inverter control switch

7. Inverter ON (Only for UPS above 80kVA rating) - Manual inverter selection switch.

8. Inverter LED - inverter status indicator contained within the switch icon.

The Inverter LED (yellow) indicates when the Inverter is switched OFF.

24

Page 45

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Menu Control switches

Four push button switches ESCape[9], DOWN [10], UP [11], ENTER [12], are located

below the LCD display and are used to navigate a menu-driven UPS operating and

control system.

Note: In addition to entering the day-to-day operating functions, the menu system is also used to set-up

various UPS operating parameters during commissioning. A system of password protection is therefor

used to limit the control functions accessible to the operator, whilst allowing full access to

maintenance personnel. A full description of the available menus is provided in the appropriate User

and Commissioning manuals.

Note: From the Display panel menu it is possible to select one of the following languages: English,

French, Italian, Spanish, German, Dutch. The sequence is Default window > FUNCTION > ENTER

PASSWORD > PANEL SETUP > LANGUAGE

9. ESC Pressing the ESCAPE cancels the most recent actions;

i.e. when selecting options it returns the prvious window to the LCD.

when setting parameters, it exits the window without saving the new settings.

10. MENU ∨ The DOWN push button moves a cursor down the LCD over the options

offered on certain windows, and changes the highlighted parameter values in others.

11. MENU ∧ The UP push button moves a cursor up the LCD over the options offered

on certain windows, and move a rectangular cursor to the next digit on the right when

changing parameter values in others;

12 ENTER Pressing ENTER, when selecting options, displays the next window;

The next window is determined by the option which has been selected in the present

window. When selecting new parameters its saves the new parameters.

13 Warning indicator - The red LED with the Alarm Silence switch illuminates when a

WARNING alarm is displayed on the LCD message screen, and is normally

accompanied by an audible alarm.

14. Alarm Silence Switch - Pressing the Alarm Silence switch cancels the audible

alarm but leaves the warning message display until the inappropriate condition is

rectified.

Operator Panel and LCD Display

15. LCD Display

The LCD display is capable of showing four rows of 20 characters: the top row

displays the UPS warning and alarm messages and the lower row indicate the

selected metered parameters.

During normal operation the top line of the LCD panel shows the general UPS Status

(e.g. NORMAL OPERATION) and the bottom line will indicate the current time and date

- this is known as the ‘Default Screen’. Pressing the ESCape button [9] changes the

displayed information to indicate the Communication Port status (if connected) and

the version of the software fitted to the UPS control boards.

25

Page 46

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Pressing the ENTER button [12] from the Default Screen gives the operator access to

the ‘Measurements’ menu which facilitates access to the following measurements:

Output Parameters

- Output Voltage (L-N)

- Output Current (L-N current displayed in Amperes or as a % Load)

- Output Power (displayed in kW or kVA)

- Output Frequency (of inverter and bypass mains)

Input Parameters

- Input Voltage (L-N for Bypass input)

Battery Parameters

- Battery Voltage

- Battery Current

- Battery Charge (in %)

Temperature

- Temperature (°C) at critical points

Bargraph Selection

This following functional area shows the various UPS load and battery charging

conditions.

16. Load Battery

The amber led situated at the beginning of the % Autonomy bargraph illuminates

when the battery voltage has discharged to 1.8V /cell and indicates that the battery is

approaching its low voltage cut-off point and the UPS will shortly shutdown.

17. % Battery state Autonomy time bargraph

When the battery is being charged (normal) the six leds illuminate progressively to

indicate the state of battery charge as a percentage of a charge. When the battery is

discharging (battery on-load) the bargraph function changes to provide an indication

of the remaining battery autonomy time, each step indicate approximately 2 minutes.

With a fully charged battery all five LEDs are illuminated indicating greater than 10

minutes remaining, as the autonomy falls below this time the LEDs will extinguish in

steps starting from the right-hand end.

18. % Load bargraph

The six leds illuminate progressively to indicate the applied load as a percentage of

the rated maximum current increasing in 20% steps to 100% of full load when all five

are illuminated.

19. Overload

The amber LED situated at the end of the % Load bargraph illuminates if the applied

load exceeds 100% of modules rated output current. This indication will be

accompanied by an audible alarm a alarm message.

26

Page 47

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

Emergency

Stop (EPO)

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

............................................

Fig 4 - 3: EPO on UPS module

20. Emergency Stop - housed beneath a safety cover to prevent inadvertent

operation.

When the emergency stop switch is pressed it disables the static switch block entirely

(so removing load power). It also disables the rectifier and inverter, and trips the

battery circuit breaker. Under normal circumstances it does not remove UPS input

power since this applied through a manually controlled external isolator; however, if

the UPS input supply is connected via a circuit breaker having an electrical trip facility,

another section of emergency power off can be used to drive the external circuit

breaker’s trip.

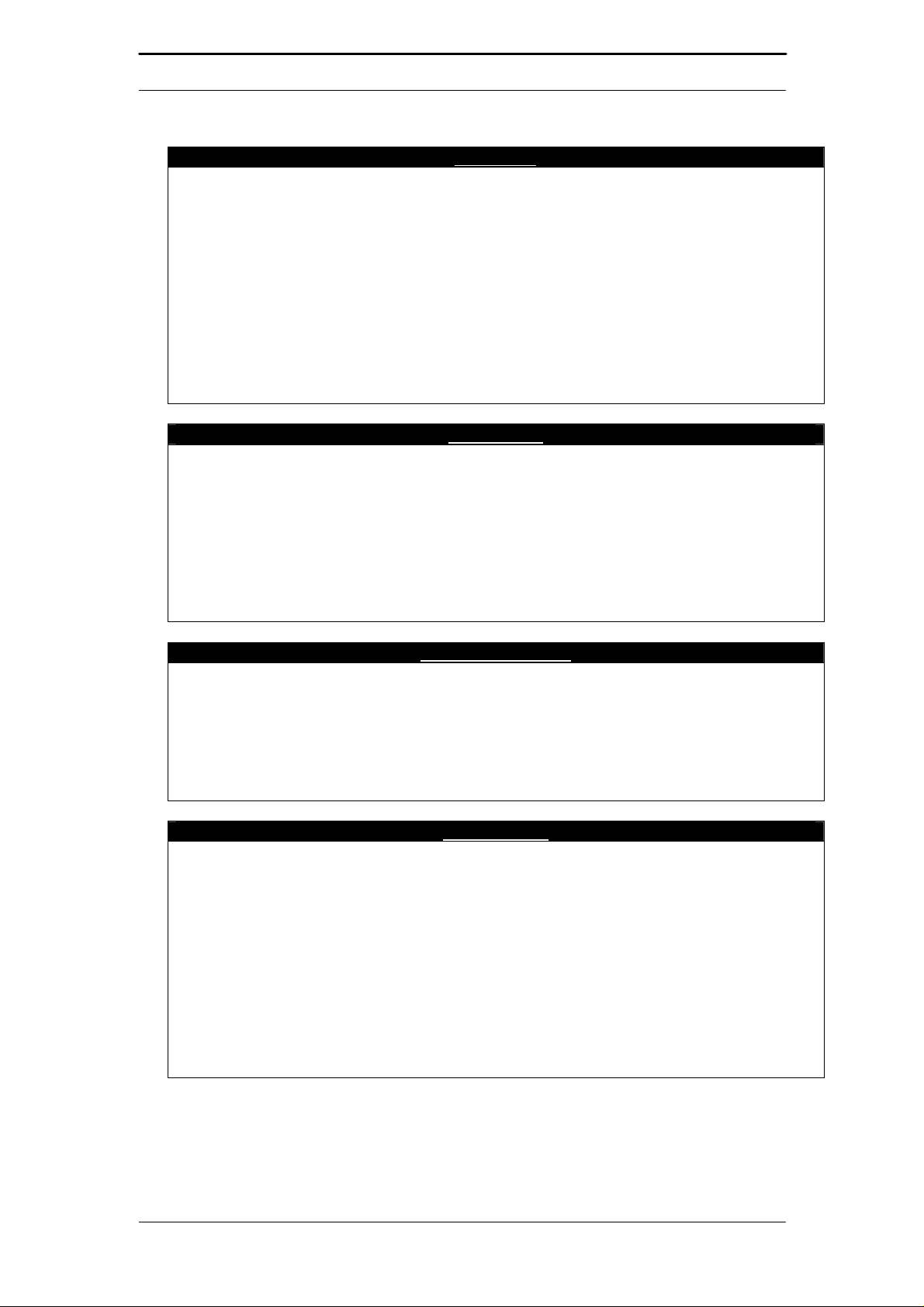

4.1.2 The Menu Options

A map of the routes to the options offered by the menu is provided in figure below.

Options include windows which show status information and windows which permit

data to be entered, or parameters for equipment control to be set. The menu map

shows that the route pass from the main menu through different intermediate

windows to reach the option targeted. The diagram shows each of the windows in the

format in which it appears on the LCD screen. The initializing, default & main menu

windows are described below.

27

Page 48

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

E

NORMAL OPERATION

NORMAL OPERATION

11:15.50 01.02.98

11:15.50 01.02.98

>MEASUREMENT <

>MEASUREMENT <

FUNCTION

FUNCTION

MAINTENANCE

MAINTENANCE

SETUP

SETUP

or. for

instanc

e

RECTIF. SWITCH OPEN

RECTIF. SWITCH OPEN

OUTPUT SWITCH OPEN

OUTPUT SWITCH OPEN

INV.: UNSYNCHRONIZED

INV.: UNSYNCHRONIZED

11:15.50 01.02.98

11:15.50 01.02.98

>OUTPUT <

>OUTPUT <

INPUT

INPUT

BATTERY

BATTERY

TEMPERATURE

TEMPERATURE

MODEM TYPE :

MODEM TYPE :

M-TECH.1932-ZDX

E E

>VOLTAGE <

>VOLTAGE <

CURRENT

CURRENT

POWER

POWER

FREQUENCY

FREQUENCY

M-TECH.1932-ZDX

MODEM STATUS :

MODEM STATUS :

NOT CONNECTED

NOT CONNECTED

OUTPUT : [Vrms]

OUTPUT : [Vrms]

VOLTAGE [Vrms]

VOLTAGE [Vrms]

L-N

L-N

XXX

XXX

CURRENT: [AMPS]

CURRENT: [AMPS]

L-N

L-N

XXXX

XXXX

LOAD : [%]

LOAD : [%]

L

L

XXX

XXX

REAL POWER : [KW]

REAL POWER : [KW]

B

B

XXX

XXX

SW VERSION

SW VERSION

PANEL V 02.0

PANEL V 02.0

UPS LOGIC V 01.0

UPS LOGIC V 01.0

FUNCTION

MAINTENANCE

SETUP

OUTPUT

OUTPUT

>INPUT <

>INPUT <

BATTERY

BATTERY

TEMPERATURE

TEMPERATURE

OUTPUT

OUTPUT

INPUT

INPUT

>BATTERY <

>BATTERY <

TEMPERATURE

TEMPERATURE

OUTPUT

OUTPUT

INPUT

INPUT

BATTERY

BATTERY

>TEMPERATURE <

>TEMPERATURE <

_ WRITE SAVE _

_ WRITE SAVE _

_ MOVE EXIT _

_ MOVE EXIT _

INPUT PASSWORD

INPUT PASSWORD

????????

????????

_ WRITE SAVE _

_ WRITE SAVE _

_ MOVE EXIT _

_ MOVE EXIT _

INPUT PASSWORD

INPUT PASSWORD

????????

????????

_ WRITE SAVE _

_ WRITE SAVE _

_ MOVE EXIT _

_ MOVE EXIT _

INPUT PASSWORD

INPUT PASSWORD

????????

????????

PRESS DOWN KEY

PRESS ENTER KEY

E

PRESS ESCAPE KEY

APP. POWER [KVA]

APP. POWER [KVA]

L

L

XXX

XXX

FREQUENCY : [Hz]

FREQUENCY : [Hz]

INVERTER XX.X

INVERTER XX.X

BYPASS XX.X

BYPASS XX.X

INPUT:

INPUT:

VOLTAGE [Vrms]

VOLTAGE [Vrms]

L-N

L-N

XXX

XXX

BATTERY:

BATTERY:

VOLTAGE XXX [V]

VOLTAGE XXX [V]

CURRENT XXXX [A]

CURRENT XXXX [A]

CHARGE XXX [%]

CHARGE XXX [%]

TEMPERATURE:

TEMPERATURE:

Tc xxx.x To xxx.x

Tc xxx.x To xxx.x

Ta xxx.x Tb xxx.x

Ta xxx.x Tb xxx.x

Fig 4 - 4: Map of screen display available to operator

28

Page 49

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

LCD Display Panel Messages

Initializing Window

After first connecting power to the UPS and closing

the bypass A.C. input power switch, the

EMERSON NETWORK POWER

EMERSON NETWORK POWER

3PH-1PH

3PH-1PH

UPS

UPS

INITIALIZATION message will appear on the LCD

screen. It persists for about five seconds while the

control firmware is loaded and the unit performs a

self-test. It is followed by a window showing

various messages with the time and date on the

bottom line.

RECTIF. SWITCH OPEN

RECTIF. SWITCH OPEN

BATTERY SWITCH OPEN

BATTERY SWITCH OPEN

OUTPUT SWITCH OPEN

OUTPUT SWITCH OPEN

hh.mm.ss dd.mm.yy

hh.mm.ss dd.mm.yy

When the power switches and battery circuit

breaker have been closed and the inverter has

stabilized the window will change to the default

window.

NORMAL OPERATION

NORMAL OPERATION

hh.mm.ss dd.mm.yy

hh.mm.ss dd.mm.yy

M0DEM TYPE

M0DEM TYPE

M-TECH.1932 -ZDX

M-TECH.1932 -ZDX

MODEM STATUS

MODEM STATUS

NOT CONNECTED

NOT CONNECTED

Default Window

The message shown below, will be seen on the

default window whenever the UPS is operating

normally.

The top lines display the UPS operational status

and indicates alarm conditions when they occur;

and line four normally shows the time and date.

Info Window

From Default Window, pressing the ESC key,

information about the modem programmed in

memory and its connection are shown on display.

Pressing again the ESC key, software release are

shown, both on UPS board and on Panel board;

this feature is useful upgrading SW for next

versions and to know exactly features of present

release.

Pressing again ESC key it goes back to Default

Window.

Main Menu Window

The main menu is selected from the Default

Window by pressing the ENTER key:

The four windows accessed from the Main Menu

offer further options, which are described in the

relevant chapters of this manual.

>MEASUREMENT <

>MEASUREMENT <

FUNCTION

FUNCTION

MAINTENANCE

MAINTENANCE

SETUP

SETUP

The MEASUREMENT option gives access to

windows which show the present values of

parameters such as input & output voltages and

current, load, etc. These parameters are useful

when determining the state of UPS or the cause of

alarms, and are described in more detail below.

29

Page 50

User Manual

Hipulse - Single Phase ‘1+N’ UPS System 130 kVA - 110V

The FUNCTION, MAINTENANCE and SETUP options all require a password which is

set by the commissioning engineer. This manual does not provide servicing

instructions and the options accessed from theses windows are therefore not shown

on the menu map in figure 4-4. Only trained service engineers should be authorized

with a password.

In any case FUNCTION, MAINTENANCE and SETUP options can be read but is not

possible to change them without password.

Option Selection Mode

If a window from which options can be selected is displayed, a pair of indicator arrows

appear at the extremities of the line.

The UP/ DOWN push buttons move these up and down the screen over the options.