Liebert 1000kVA User Manual

SERIES 610™ UPS

AC POWER SYSTEMS

OPERATION & MAINTENANCE MANUAL

100-1000kVA, 60Hz

Three Phase

Multi-Module

BATTERY CABINET PRECAUTIONS

The following warning applies to all battery cabinets supplied with UPS systems. Additional warnings and cautions applicable to battery cabinets may be found in Important Safety Instructions

and 4.4 - Battery Maintenance.

WARNING

!

Internal battery strapping must be verified by manufacturer prior to moving a battery cabinet

(after initial installation).

• Battery cabinets contain non-spillable batteries.

• Keep units upright.

• Do not stack.

• Do not tilt.

Failure to heed this warning could result in smoke, fire or electric hazard.

Call 1-800-LIEBERT prior to moving battery cabinets (after initial installation).

CONTACTING LIEBERT FOR SUPPORT

To contact Liebert Global Services for information or repair service in the United States, call

1-800-LIEBERT (1-800-543-2378). Liebert Global Services offers a complete range of start-up

services, repair services, preventive maintenance plans and service contracts.

For repair or maintenance service outside the 48 contiguous United States, contact Liebert Global

Services, if available in your area. For areas not covered by Liebert Global Services, the authorized

distributor is responsible for providing qualified, factory-authorized service.

For LGS to assist you promptly, please have the following information available:

Part numbers: _________________________________________________________________

Serial numbers:________________________________________________________________

kVA Rating: ___________________________________________________________________

Date purchased: _______________________________________________________________

Date installed:_________________________________________________________________

Location:______________________________________________________________________

Input voltage/frequency:________________________________________________________

Output voltage/frequency: ______________________________________________________

Battery reserve time:___________________________________________________________

TABLE OF CONTENTS

BATTERY CABINET PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

CONTACTING LIEBERT FOR SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.0 I

NTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.1 Normal—Load on UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.2 Input Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.3 Recharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.4 Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.5 Redundant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.6 Bypass—Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.7 Maintenance Bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.8 Off-Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Operator Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.0 THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.1 General Component Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.1 System Control Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.2 UPS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.3 Battery Plant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Detailed Component Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.2 Rectifier/Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.3 Battery Charging Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.4 Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.5 Static Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.6 Redundant Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.1 Display Screen and Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Menu Tree Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Master Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.2 SCC Monitor/Mimic Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.3 Module Monitor/Mimic Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.4 Walk-In Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2.5 Status Reports Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2.6 System Configuration Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.7 Alarm Limit Settings Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.2.8 Load Transfer Procedures Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.2.9 Start-Up Procedures Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.2.10 Shutdown Procedures Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.2.11 Battery Time Screen (Module Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.2.12 Meter Calibration Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.2.13 Battery Equalize Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3.2.14 Alarm and Status Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.2.15 Communication Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

i

3.3 Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.3.1 Load on Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.3.2 OK to Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.3.3 Momentary Overloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.3.4 Input Power Failure—Load on Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.3.5 One Module Off-Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3.6 Off Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.3.7 Emergency Modules Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.3.8 Remote Emergency Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.3.9 System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.3.10 Maintenance Bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.4 Manual Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.4.1 SCC Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.4.2 UPS Module Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.4.3 Load Transfer Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.4.4 Maintenance Bypass Load Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.4.5 Shutdown Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.5 Automatic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.5.1 Overloads (Without Transfer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.5.2 Automatic Transfers to Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.5.3 Automatic Retransfers to UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.5.4 Automatic Module Off-Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.5.5 Automatic Emergency Modules Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

4.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.2 Liebert Global Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.3 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4.3.1 Record Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4.3.2 Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4.3.3 Limited Life Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4.4 Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4.4.1 Battery Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4.4.2 Torque Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4.5 Detection of Trouble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4.6 Reporting a Problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4.7 Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4.8 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4.9 Upstream Feeder Circuit Breaker Setting Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.0 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

5.1 Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.3 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.4 Battery Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.5 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

ii

FIGURES

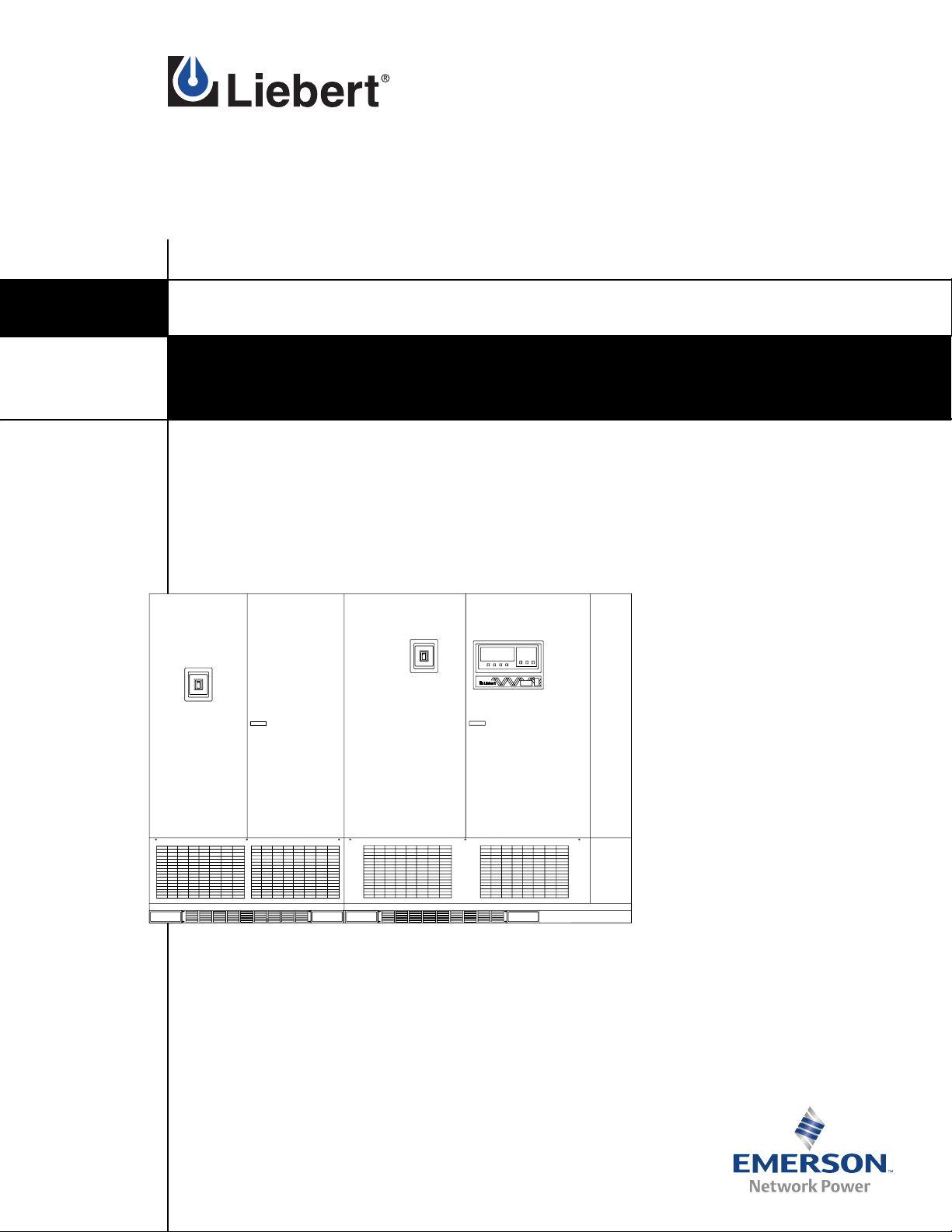

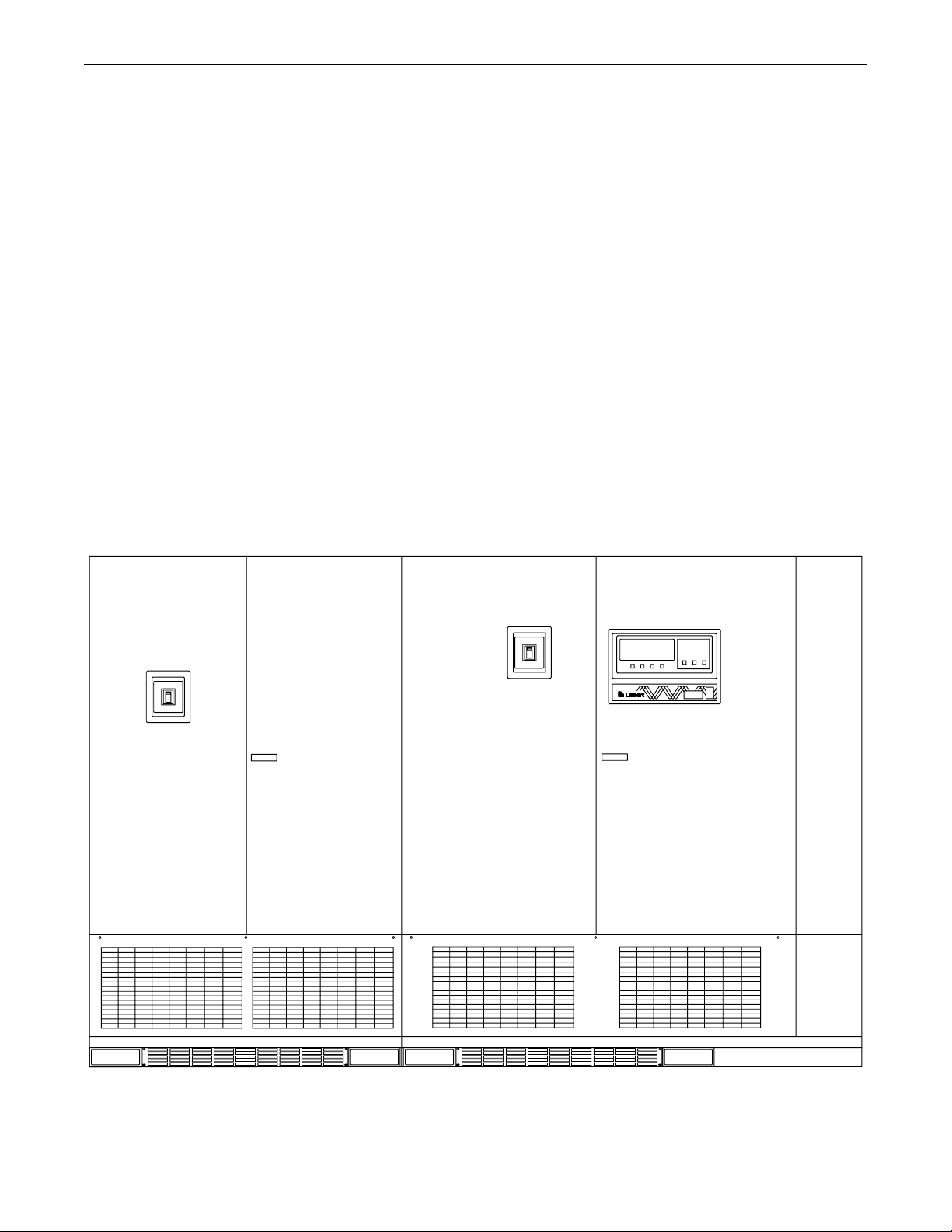

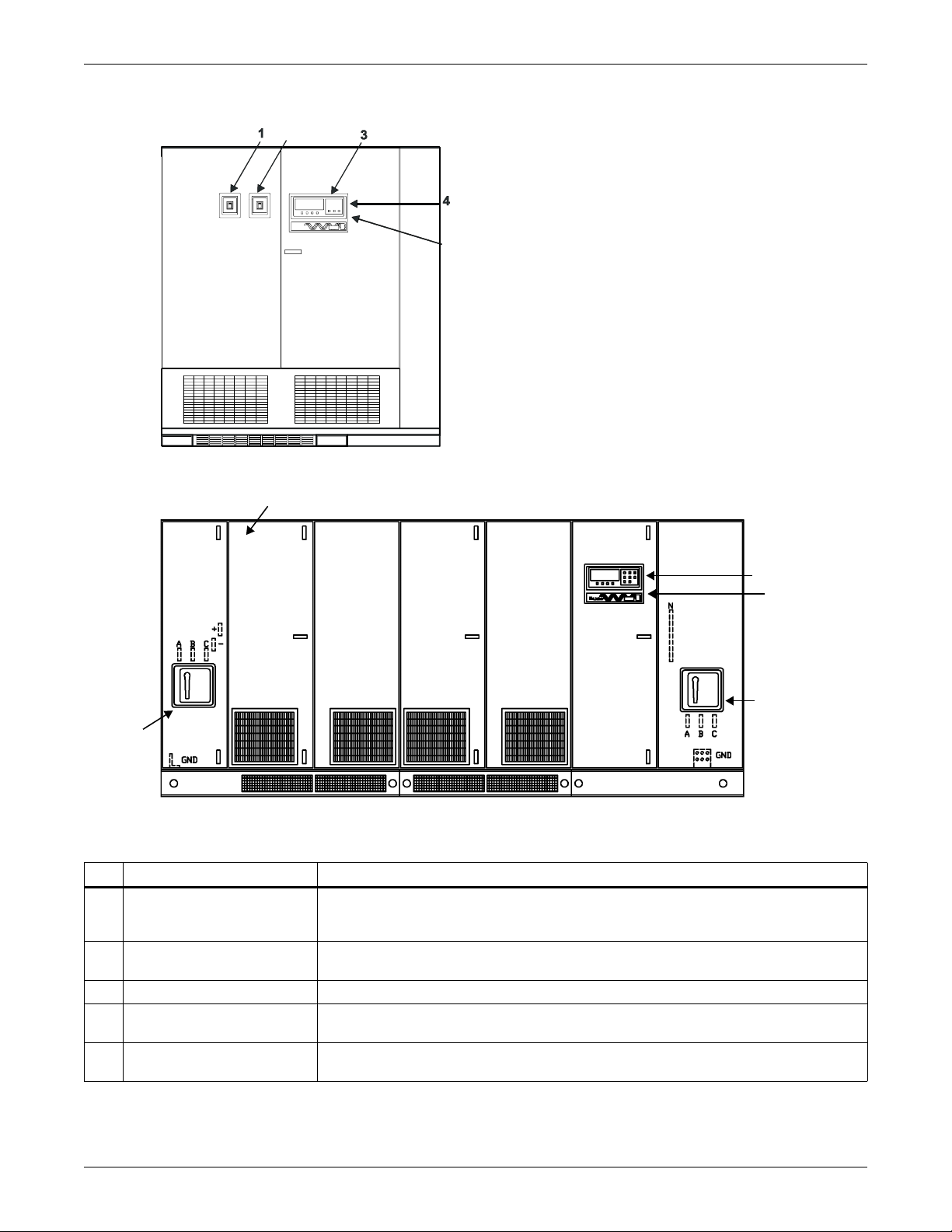

Figure 1 Multi-Module UPS, 100-500kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

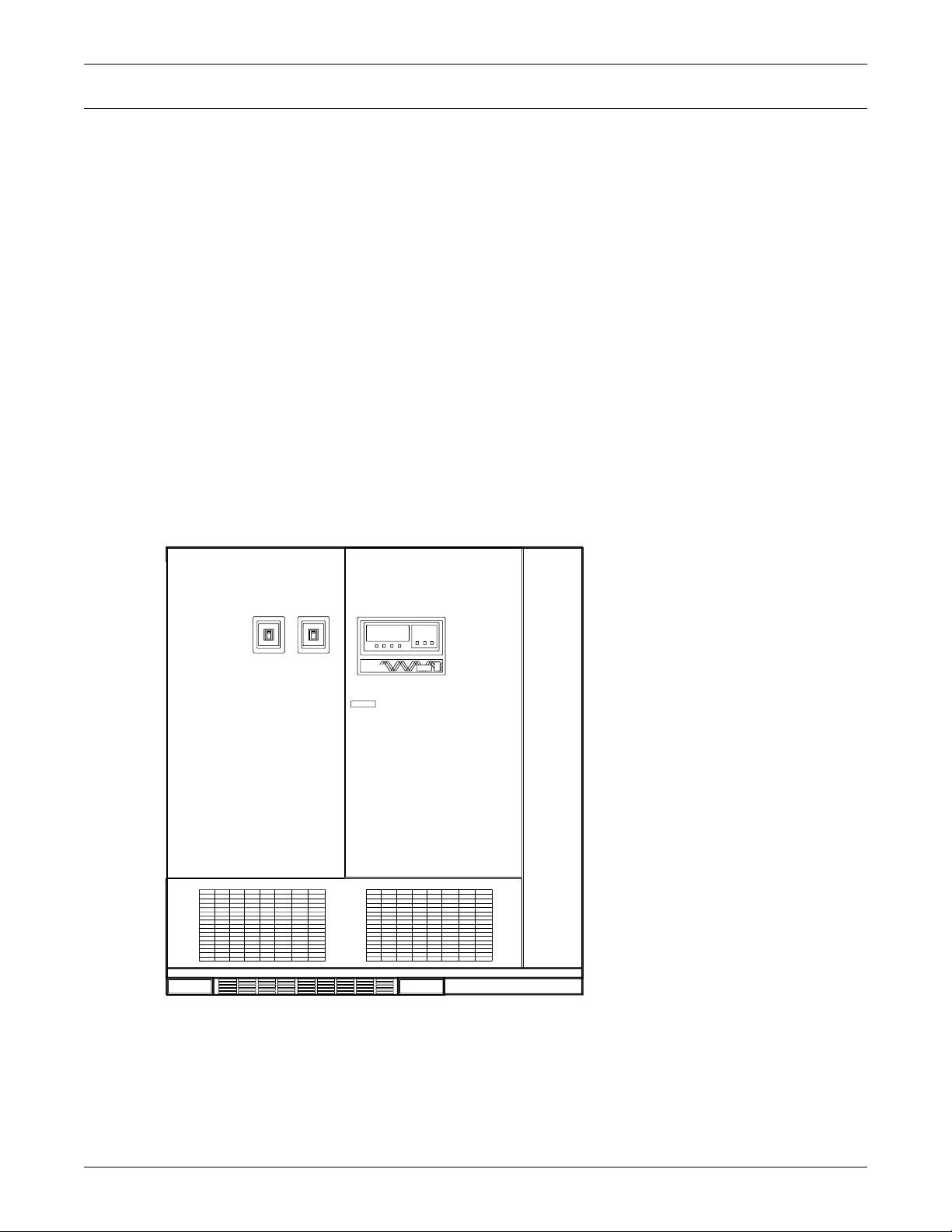

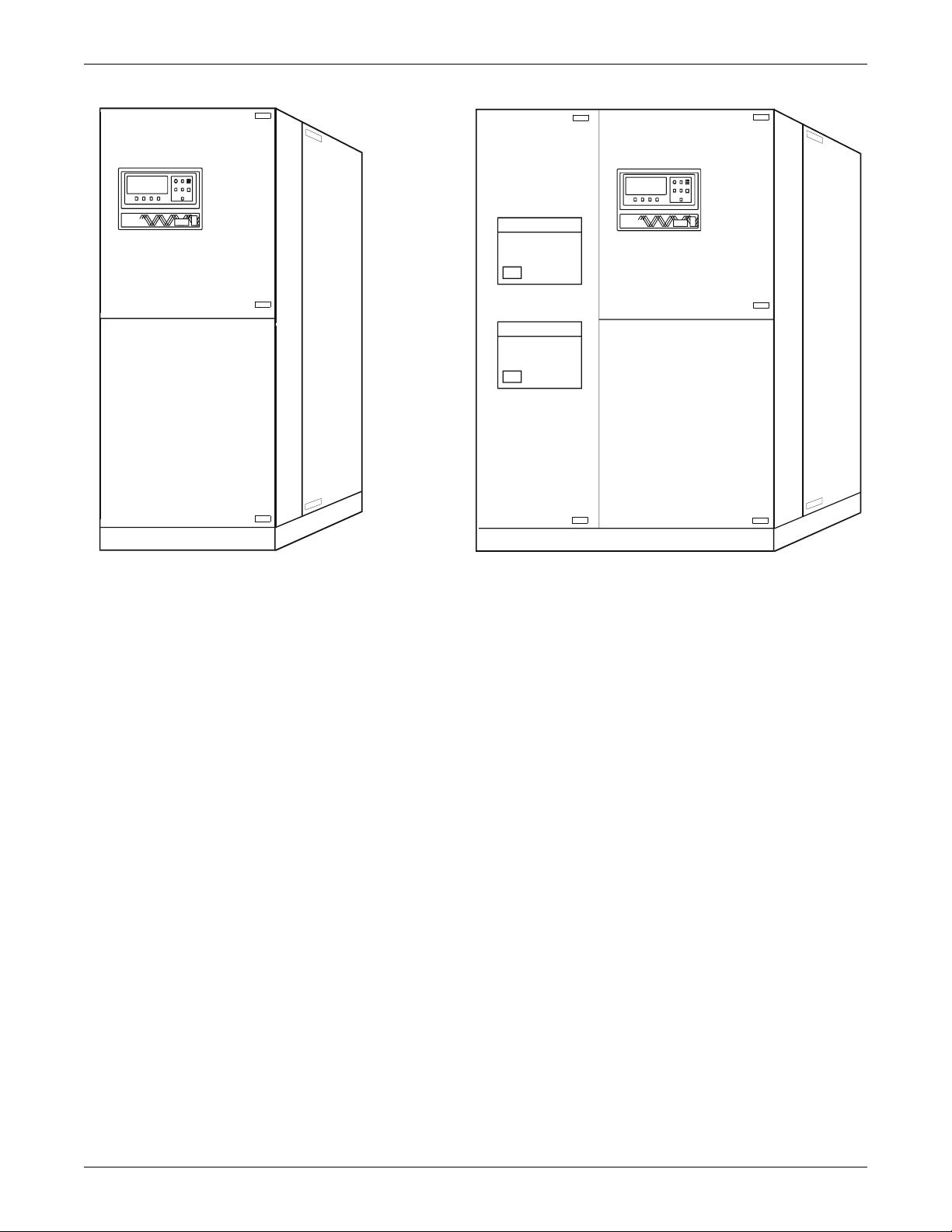

Figure 2 Multi-Module UPS, 500-750kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

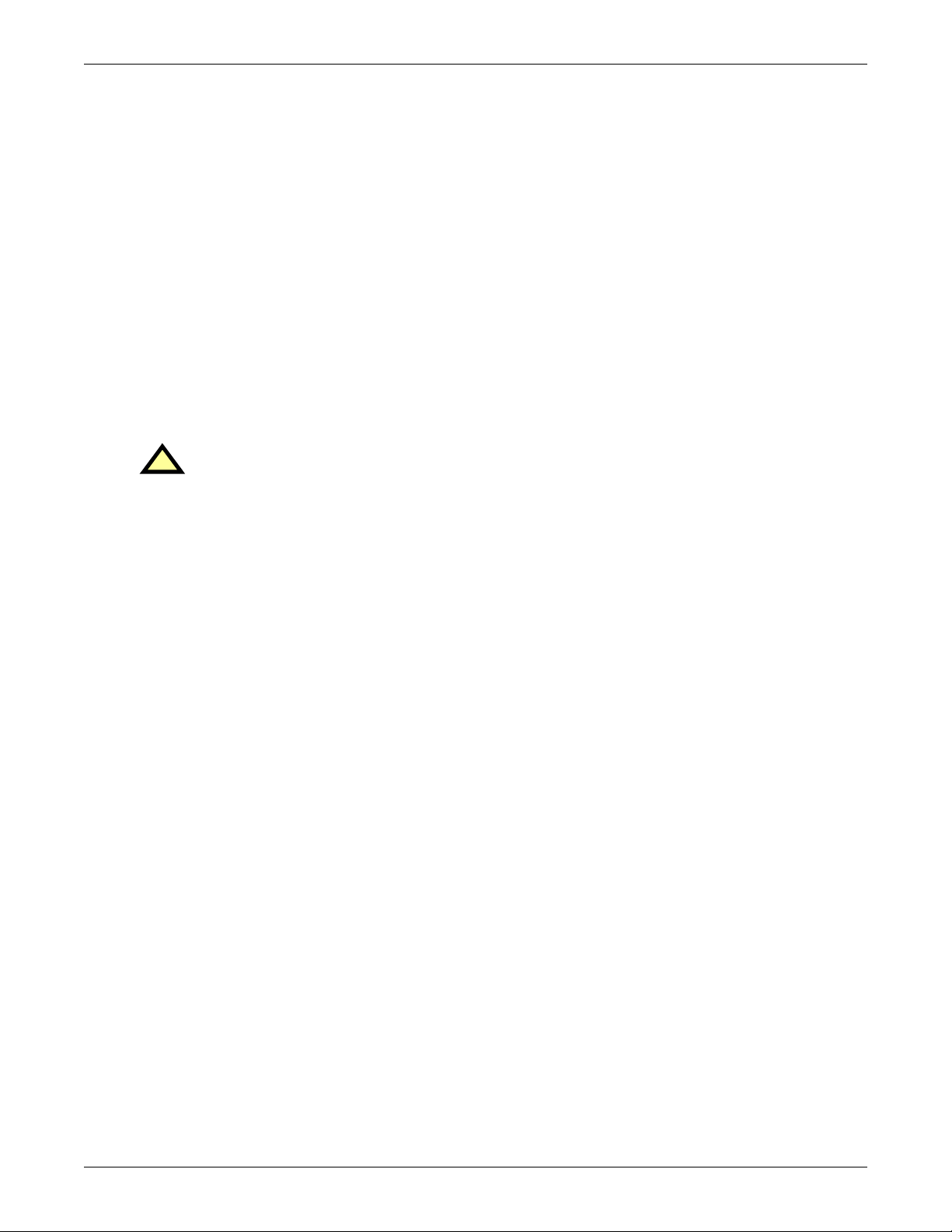

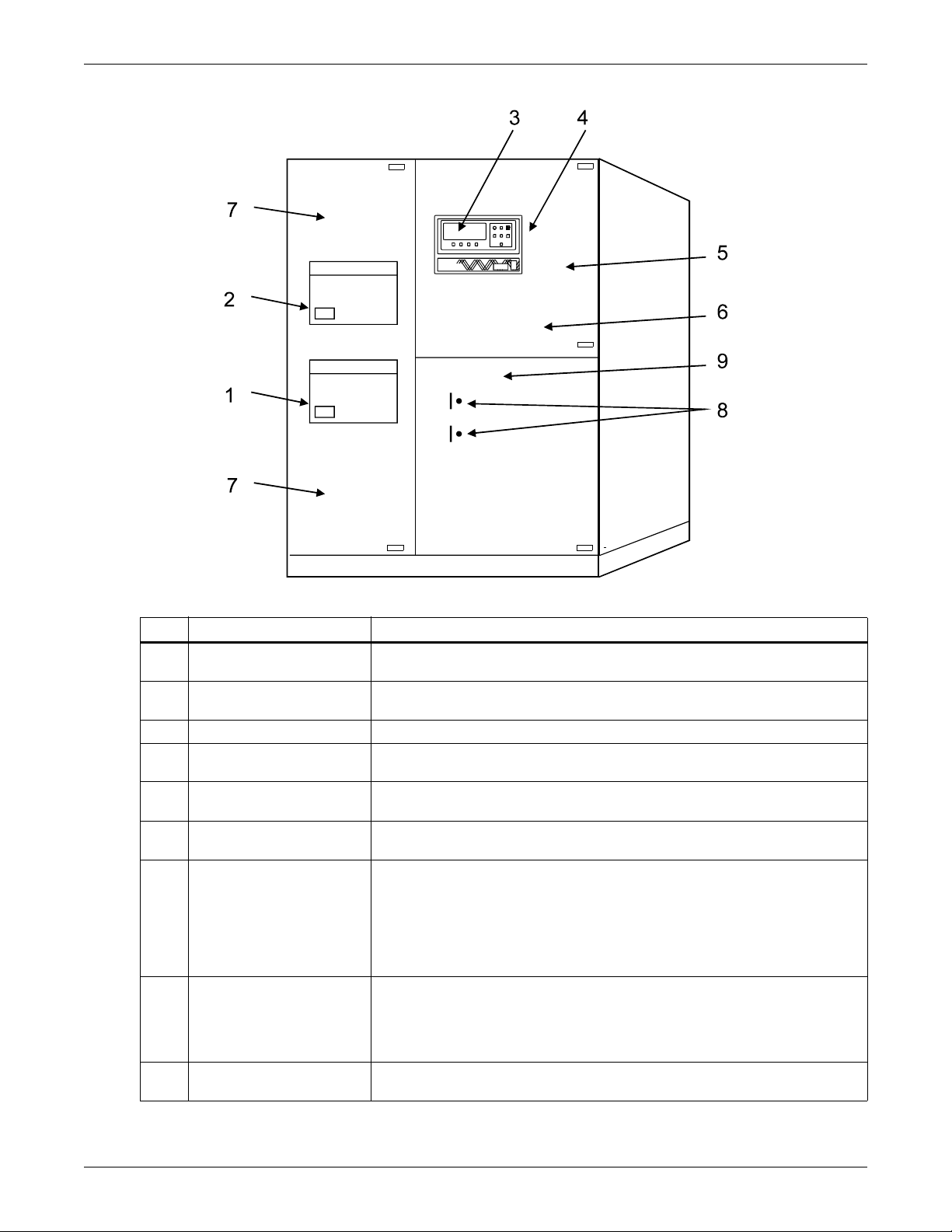

Figure 3 System Control Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

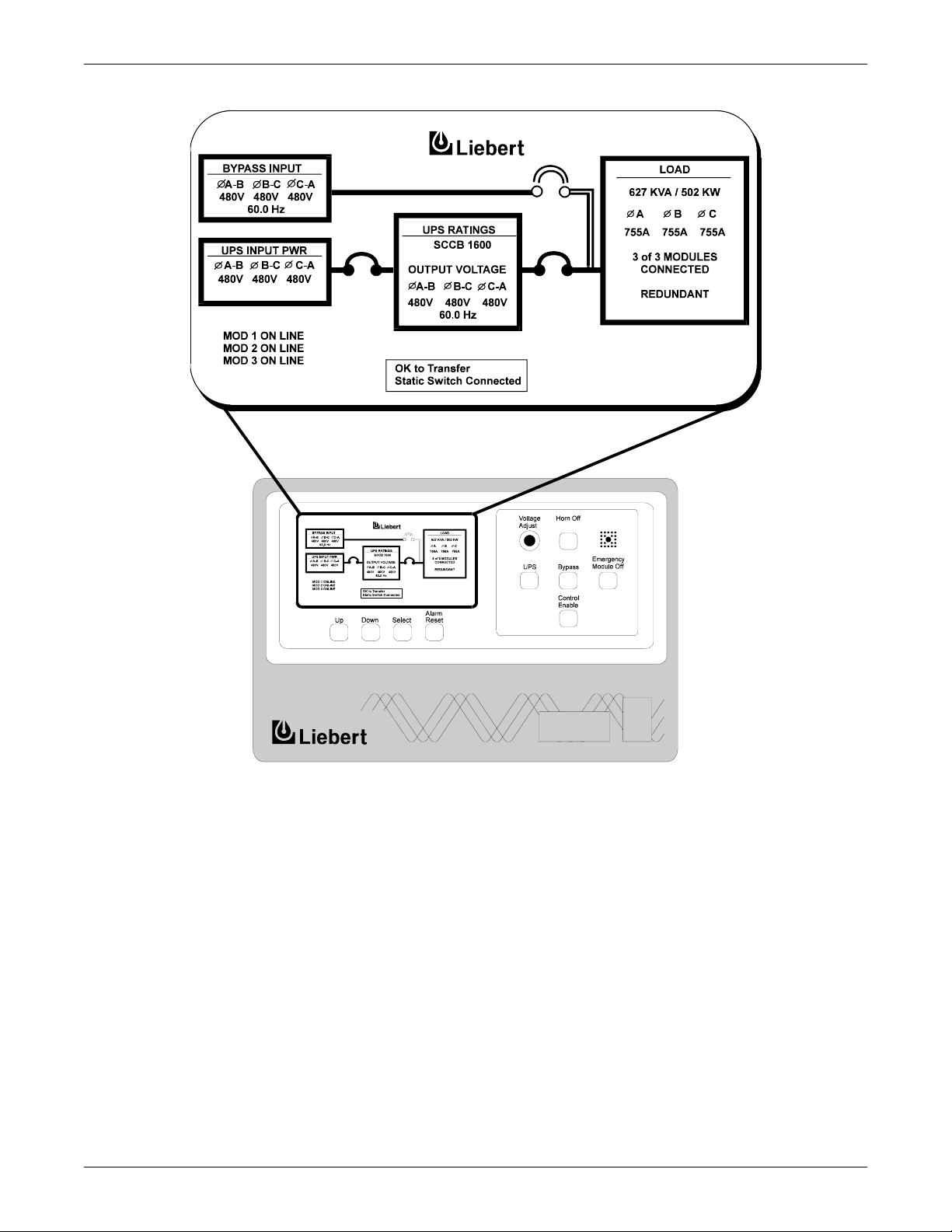

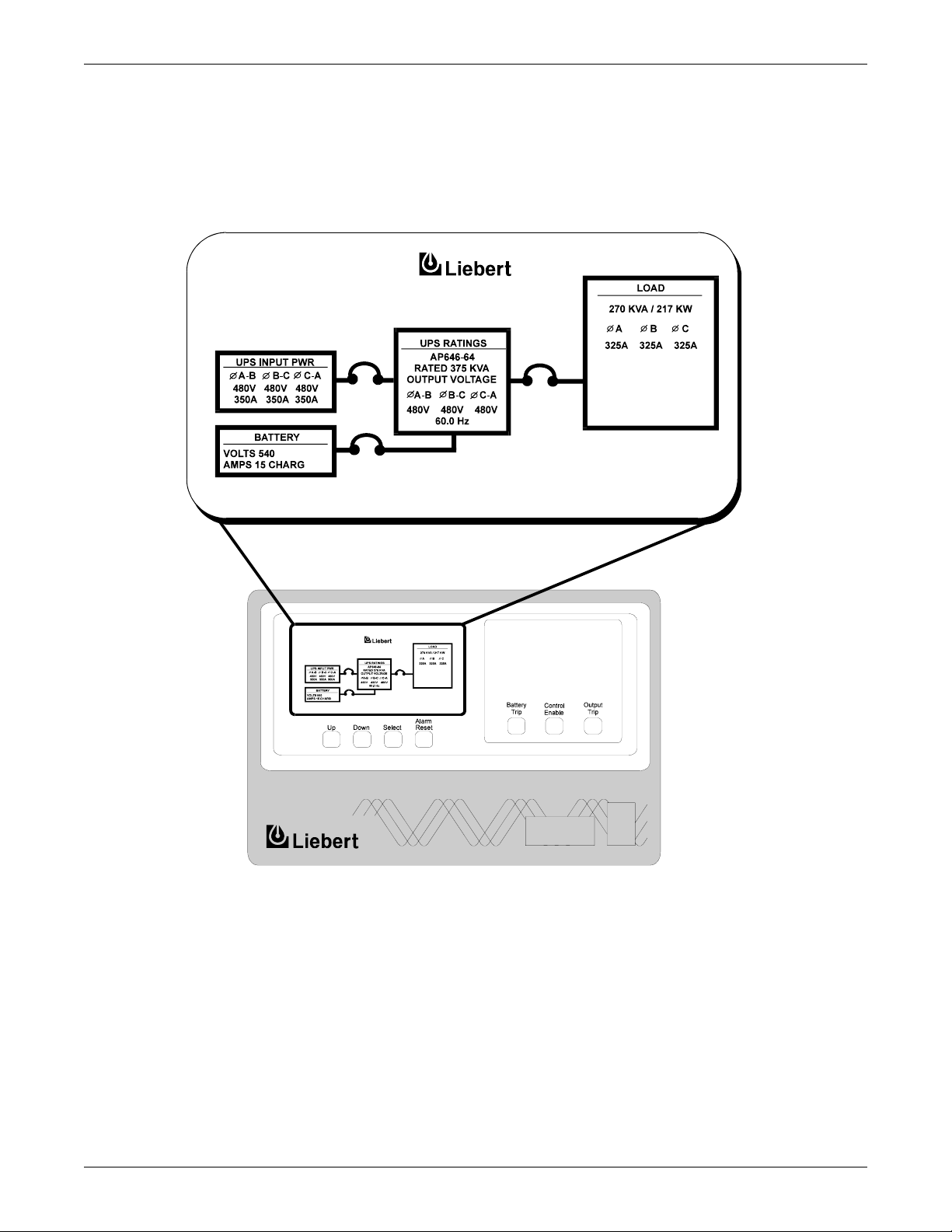

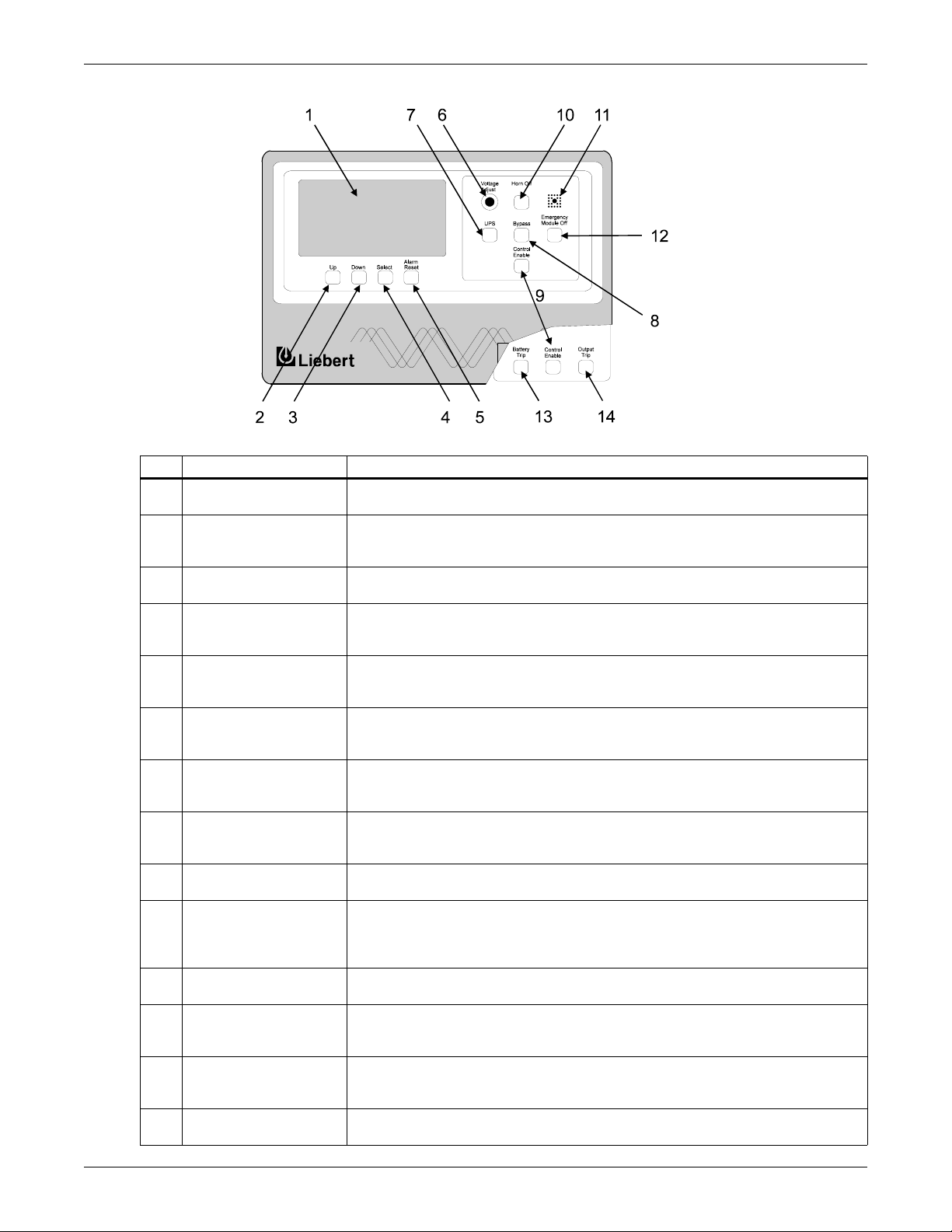

Figure 4 SCC controls and display screen with example of the Monitor/Mimic screen . . . . . . . . . . . . . . . . 7

Figure 5 Module controls and display screen with example of the Monitor/Mimic screen . . . . . . . . . . . . . . 8

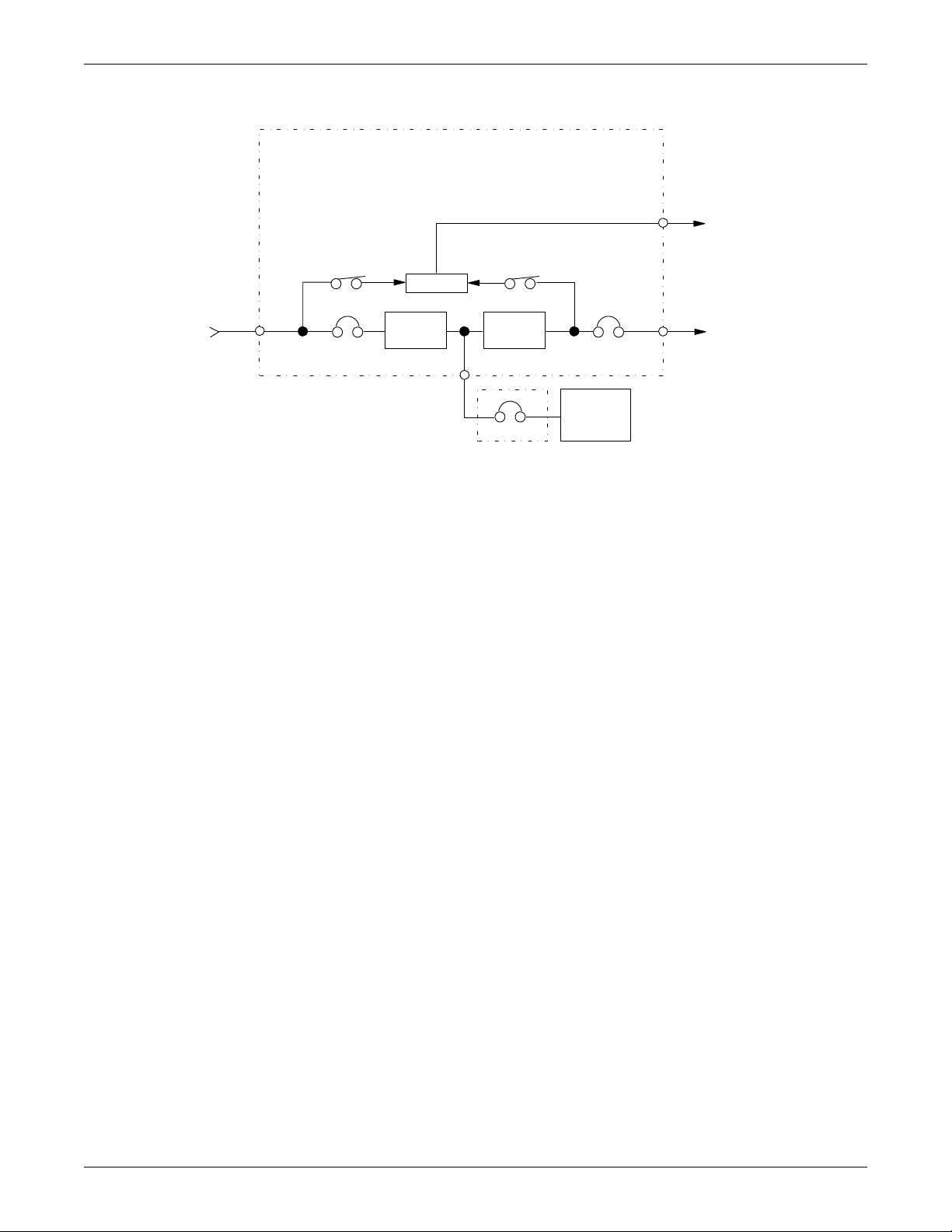

Figure 6 UPS module block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

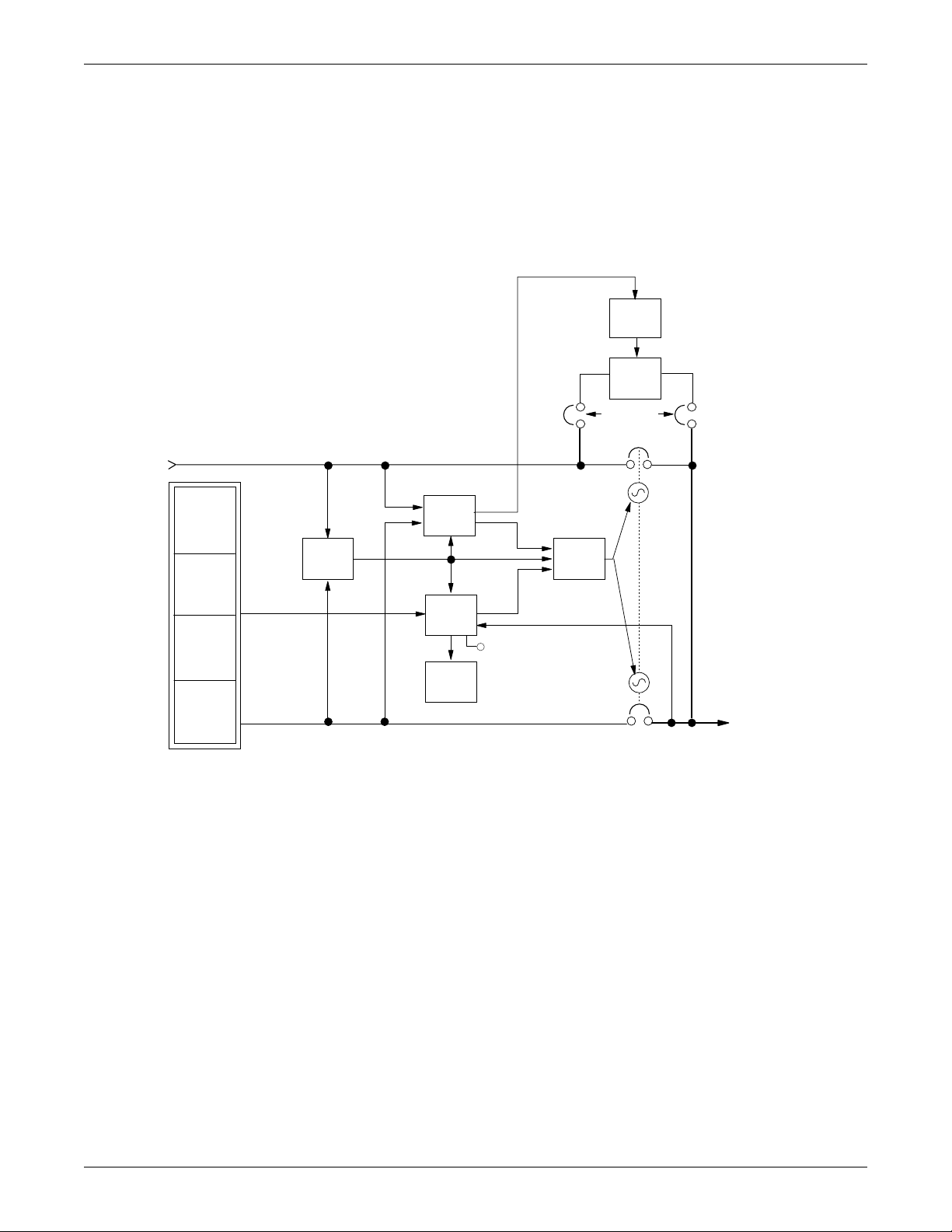

Figure 7 System Control Cabinet block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8 Typical operator controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 9 Operator controls, typical SCCT System Control Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 10 Series 610 UPS and SCC operator control panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 11 Switches behind SCC control panel door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 12 Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 13 SCC and module master menu screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 14 SCC Monitor/Mimic display screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 15 Module Monitor/Mimic display screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 16 Monitor/Mimic display example: Normal power flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 17 Monitor/Mimic display example: Utility fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 18 Monitor/Mimic display example: Load on bypass, UPS modules on and charging battery . . . . . 34

Figure 19 Monitor/Mimic display example: Load on UPS, one UPS module off line . . . . . . . . . . . . . . . . . . . 35

Figure 20 Monitor/Mimic Display example: Load on bypass, all UPS modules off line . . . . . . . . . . . . . . . . 36

Figure 21 Walk-in display screen during start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 22 Status reports screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 23 Present status report screens, SCC (above) and module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 24 Event history report screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 25 History status report screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 26 Battery cycle monitor screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 27 Battery cycle monitoring summary screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 28 Typical data on discharge cycles of 91 to 240 seconds duration during the recording period . . . 43

Figure 29 SCC system configuration screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 30 Date screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 31 Time screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 32 Auto dial setting screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 33 Modem baud rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 34 Maximum auto-retransfer attempts screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 35 SCC system options screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 36 MMU system options screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 37 Battery test screen—MMU only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 38 Battery test results screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 39 Monitor/Mimic display example: Continuous Duty Static Switch . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 40 Module alarm limit settings screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 41 Load transfer procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 42 SCC start- up procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 43 Module start- up procedures screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 44 SCC shutdown procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 45 Module shutdown procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 46 Battery time screen (15 minute discharge) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 47 Battery time screen (45-minute discharge) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 48 Accuracy range of values for calculated battery times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 49 Meter calibration screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

iii

Figure 50 Battery equalize screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 51 SCC status and alarm message areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 52 Load on bypass, UPS not available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 53 Load on bypass, UPS available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 54 Load on UPS, bypass available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 55 Momentary overload, pulsed static bypass switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 56 Input power fail—load on battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 57 One module off-line, load on UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 58 Load on UPS—battery not available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 59 Emergency modules off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 60 Emergency power off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 61 System shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 62 Load on maintenance bypass, two breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 63 Load on maintenance bypass, three breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 64 SCC start-up procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 65 Module start-up procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 66 Load transfer procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 67 SCC shutdown procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 68 Module shutdown procedures screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 69 Current-versus-time curves of module overload capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 70 Output power envelope for 0.8 and 0.9 pf rated units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

TABLES

Table 1 Typical operator controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 2 Typical SCCT System Control Cabinet operator controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 3 Series 610 UPS and SCC operator control panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 4 Series 610 UPS and SCC operator control panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 5 Alarm conditions that freeze history data gathering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 6 SCC and module remote monitor indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 7 Other alarms that activate summary alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 8 Abbreviations used in alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 9 Alarm messages - meaning and corrective action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 10 Alarm messages - summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 11 Series 610 terminal commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 12 Circuit breaker abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 13 Battery retorque values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 14 Battery voltage record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 15 Torque specifications (unless otherwise labeled) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 16 Recommended test equipment and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 17 Specifications applicable to environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

iv

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during installation and maintenance of your Series 610 UPS and batteries.

WARNING

!

Exercise extreme care when handling UPS cabinets to avoid equipment damage or injury to

personnel. Refer to separate installation manual for equipment handling information and

installation procedures.

Follow all battery safety precautions in 4.0 - Maintenance when installing, charging or

servicing batteries. In addition to the hazard of electric shock, gas produced by batteries can

be explosive and sulfuric acid can cause severe burns.

In case of fire involving electrical equipment, use only carbon dioxide fire extinguishers or

others approved for use in electrical fire fighting.

Extreme caution is required when performing maintenance.

Be constantly aware that the UPS system contains high DC as well as AC voltages. With

input power off and the battery disconnected, high voltage at filter capacitors and power

circuits should be discharged within 30 seconds. However, if a power circuit failure has

occurred, you should assume that high voltage may still exist after shutdown. Check with a

voltmeter before making contact.

AC voltage will remain on the system bypass, the UPS output terminals and the static bypass

switch, unless associated external circuit breakers are opened.

Check for voltage with both AC and DC voltmeters prior to making contact.

When the UPS system is under power, both the operator and any test equipment must be

isolated from direct contact with earth ground and the UPS chassis frame by using rubber

mats.

Some components within the cabinets are not connected to chassis ground. Any contact

between floating circuits and the chassis is a lethal shock hazard. Exercise caution that the

test instrument exterior does not make contact either physically or electrically with earth

ground.

1

1.0 INTRODUCTION

1.1 System Description

The role of the parallel-redundant multi-module UPS system is to supply uninterruptible, clean

power to the critical load. The UPS maintains a full-voltage, low-distortion output, even if the utility

source power sags, becomes distorted or fails.

If there is an outage of the source power, the UPS maintains power to the load until an alternate

source of power is activated or until the original power source is restored. If input AC power is not

restored, the UPS maintains the load (with a storage battery plant) long enough that the critical

equipment can be shut down in an orderly manner or an alternate power source (e.g., Genset) can be

brought on line. The Series 610 UPS module displays the rate of battery discharge and calculates the

amount of battery time remaining based on the actual connected load. The time that the battery will

maintain the load depends on the capacity of the battery backup plant and the size of the load.

The system control logic automatically manages critical bus operation. System logic is resident in digital control logic for precise control and improved reliability.

If the critical load current exceeds the rated load of the Series 610 UPS system, the control logic determines the magnitude of the overload and reacts appropriately. Overloads are usually the result of

inrush current requirements. The UPS system supports loads that are 150% of the rated load for up

to 30 seconds and 125% of the rated load for up to 10 minutes. If the system is operating in the nonredundant mode (e.g., a UPS module is off line), the overload limits are automatically adjusted.

Introduction

Figure 1 Multi-Module UPS, 100-500kVA

100-500kVA

If the load surpasses the overload capacity of the UPS, the load is automatically transferred to bypass

without interruption. When the load returns to within the UPS rating, it is either automatically or

manually returned (retransferred) to the UPS. How and when the load is returned to the UPS

depends on several factors: how long the overload lasted, how many overload conditions occurred

before transfer, whether there is an imminent failure of any part of the UPS, etc. Refer to 3.5 - Auto-

matic Operations.

2

Introduction

In the unlikely event of a fault within the UPS, the SCC control logic, which continuously monitors all

critical circuits within the UPS system, transfers the load to bypass without interruption and simultaneously activates local and remote alarms. If a fault is detected in an individual UPS module, that

module is automatically disconnected from the critical bus and shut down. A Module Off Line status

message will appear at the SCC display. The module can be manually returned to service when the

fault has been corrected.

If the multi-module UPS system is operating in the redundant mode (at least one extra module is

available for the connected critical load), the load will remain on the UPS system if one individual

module is disconnected from the critical bus (off line). If the UPS system is operating in the nonredundant mode, the load will be automatically transferred to bypass if a module goes off line.

The Series 610 UPS display system provides precise monitoring of the UPS, fast alarm response and

quick troubleshooting. For easy manual operations, menu-driven software provides access to several

step-by-step help screens. All operator functions are performed using menu-prompted displays and a

minimum number of operator controls. The System Control Cabinet includes external communication

capability with both automatic transmit and receive features for early warning and diagnosis of

abnormal conditions.

System software allows the operator or Liebert Global Services to enter application specific information. Overload, overvoltage, battery discharge and shutdown limits can be set by the operator. In

effect, UPS operations are tailored for each site.

The UPS system protects critical equipment from source power disturbances and outages, load faults

and UPS malfunctions. This triple protection virtually eliminates computer and computing equipment downtime as a result of utility source power problems.

Figure 2 Multi-Module UPS, 500-750kVA

3

Figure 3 System Control Cabinets

Introduction

Types of System Control Cabinets (SCCs)

• SCCT—A stand-alone cabinet containing system control logic for up to six UPS modules, a static

bypass switch, manually operated disconnects for the static bypass switch and two motor-operated system circuit breakers.

• SCCI—System control logic and static bypass switch are integrated into a switchboard cabinet

manufactured by others, which also includes the system circuit breakers.

• SCCC—An integrated configuration like the SCCI, but with a static switch rated for continuous

duty.

1.2 Reliability

Reliability is the most important design goal for Uninterruptible Power Systems. Liebert Series 610

UPS systems have demonstrated reliability by achieving a field-proven critical bus MTBF in excess of

2 million hours. In addition, our Quality Assurance program is certified to the requirements of

ISO 9001 standards.

Liebert Large UPS systems are ETL listed to the requirements of UL 1778. All equipment and components are manufactured to applicable UL, NEC, NEMA, ANSI, IEEE and CSA standards and guidelines.

Designed for Success

The keys to reliability in the design of the UPS system are using conservatively rated components,

minimizing transfers to bypass, making operator controls understandable and providing easy access

for maintenance and repair. Liebert UPS systems lead the industry in all these areas.

For example, the Series 610 can handle substantial overloads through the solid state static bypass

switch without transferring to the bypass source. By minimizing transfers to bypass, the Series 610

minimizes operation of motor-operated circuit breakers and enhances system reliability.

As another example, the system control logic has been packaged into digital control logic to eliminate

the failure-prone discrete logic boards used in other brands of UPS products. Furthermore, the logic is

isolated from heat-generating components to ensure optimal operating temperatures.

4

Other Factors to Consider

Reliability depends on more than just UPS module design. Improper installation can cause any system to fail. To prevent this, customer engineers from Liebert Global Services thoroughly inspect the

installation of all our systems to ensure they are installed properly and operating within performance

specifications.

Once a UPS is properly installed, you—the on-site equipment operator—are the most important factor in preventing critical bus failures or unplanned transfers to bypass. To make your task easier, the

Series 610 UPS provides easy-to-follow, prompted instructions on the industry’s largest operator display screen.

If you ever need help, call Liebert Global Services (24 hours a day at 1-800-LIEBERT). Your attention

to proper installation, operation and periodic maintenance will ensure that your mission-critical operations receive the best possible protection from electrical disturbances and outages.

1.3 Safety Precautions

Read this manual thoroughly, paying special attention to the sections that apply to you, before working with the UPS. Also refer to the battery manufacturer’s manual, available on the manufacturer’s

Web site, before working on or near the battery.

Under typical operation and with all UPS doors closed, only normal safety precautions are necessary.

The area around the UPS system and battery should be kept free from puddles of water, excess moisture or debris.

Introduction

Special safety precautions are required for procedures involving handling, installation and maintenance of the UPS system or the battery. Observe precautions in the separate Installation Manual

before handling or installing the UPS system. Observe precautions in 4.0 - Maintenance before as

well as during performance of all maintenance procedures on the UPS system or battery. Observe all

battery safety precautions in 4.0 - Maintenance before working on or near the battery.

This equipment contains circuitry that is energized with high voltage. Only test equipment

designated for troubleshooting should be used. This is particularly true for oscilloscopes. Always

check with an AC and DC voltmeter to ensure safety before making contact or using tools. Even when

the power is turned Off, dangerously high voltage may exist at the capacitor banks. Observe all battery precautions when near the battery for any reason.

ONLY qualified service personnel should perform maintenance on the UPS system. When

performing maintenance with any part of the equipment under power, service personnel and test

equipment should be standing on rubber mats. The service personnel should wear insulating shoes for

isolation from direct contact with the floor (earth ground).

Unless all power is removed from the equipment, one person should never work alone. A second person should be standing by to assist and summon help in case an accident should occur. This is particularly true when work is performed on the battery.

1.4 Modes of Operation

Refer to 2.0 - Theory of Operation and 3.0 - Operation for more details.

1.4.1 Normal—Load on UPS

The utility AC source provides power to the rectifier/charger in each UPS module. Each rectifier/

charger converts the utility AC power to DC and supplies DC power to the UPS module inverter while

simultaneously float charging the battery plant. Each UPS module inverter converts DC to AC and

furnishes AC power to the critical bus. The System Control Cabinet (SCC) is the tie point for the paralleled modules and monitors and controls the critical bus performance.

1.4.2 Input Power Failure

If the utility source power fails or is outside the acceptable range, the battery plant becomes the primary supplier of DC power to the inverter.

5

1.4.3 Recharge

After the utility source power is restored or an alternate power source becomes available, each rectifier/charger slowly walks-in to once again power the inverters and recharge the battery plant.

1.4.4 Overload

Overloads in critical systems may be caused by inrush currents during connected equipment start-up

or by faults in the critical load or distribution network. The Liebert Series 610 UPS system can maintain full output voltage regulation while sustaining the following overloads:

• Up to 150% for 30 seconds

• Up to 125% for 10 minutes

• Up to 104% for an indefinite period of time

For momentary faults above 155% of rated SCC current, the static switch turns on for 40 milliseconds

to supply power from the bypass source. Up to 1000% of the rated current can be supplied for less

than one cycle, while up to 500% of rated load can be sustained for the full 40 milliseconds of pulsedparallel operation.

The critical load remains on the UPS modules for the above conditions. If the UPS system overload

capacity is exceeded, an automatic transfer to bypass is initiated, which closes the system bypass circuit breaker (SBB) and opens the UPS output circuit breaker.

CAUTION

!

Whenever an overload occurs, it is imperative to determine the cause of the overload.

1.4.5 Redundant

If the multi-module UPS system includes one more module than the number required to supply the

critical load, the UPS system can operate in the redundant mode. This means that the load will

remain on the UPS system if one of the modules is disconnected because of an overload, an internal

fault or for maintenance. If the additional module is not included in the system design or if the additional module is disconnected from the critical bus, the UPS system operates in the non-redundant

mode.

1.4.6 Bypass—Internal

The SCC control logic initiates an automatic transfer to the bypass source if the overload-current-versus-time curve is exceeded or if specified UPS system faults occur. You can also manually transfer the

load to the bypass (without interruption) if you must take the UPS module out of service for maintenance.

The SCC internal bypass will allow most key components and operating modes to be checked without

disturbing the critical bus. However, certain key power-carrying components, such as the output and

bypass circuit breakers, will require isolation through an external maintenance bypass cabinet or

complete system shutdown to maintain 100% critical load operation.

1.4.7 Maintenance Bypass

The installation of a Maintenance Bypass Cabinet, Panelboard or Switchboard is recommended to

allow you to totally isolate the UPS from all power sources. Use of the Maintenance Bypass is

described in 3.0 - Operation.

1.4.8 Off-Battery

The battery plant can be disconnected from the rectifier/charger by using an external Module Battery

Disconnect (MBD) circuit breaker. The UPS module continues to function normally, though it does

not have power outage back-up capability until the battery plant is reconnected.

Introduction

1.5 Operator Controls

The Liebert Series 610 UPS System Control Cabinet (SCC) and each individual module are equipped

with a microprocessor-based Operator Display Screen and Control Panel designed for convenient and

reliable operation.

The front panel location of the monitoring and control system enables the user to quickly identify the

current status of the UPS and to perform most of the manual operations. The operator display screen

(a backlit liquid crystal display or LCD) is driven by an easy-to-follow menu-prompted software program that controls and monitors the UPS system.

6

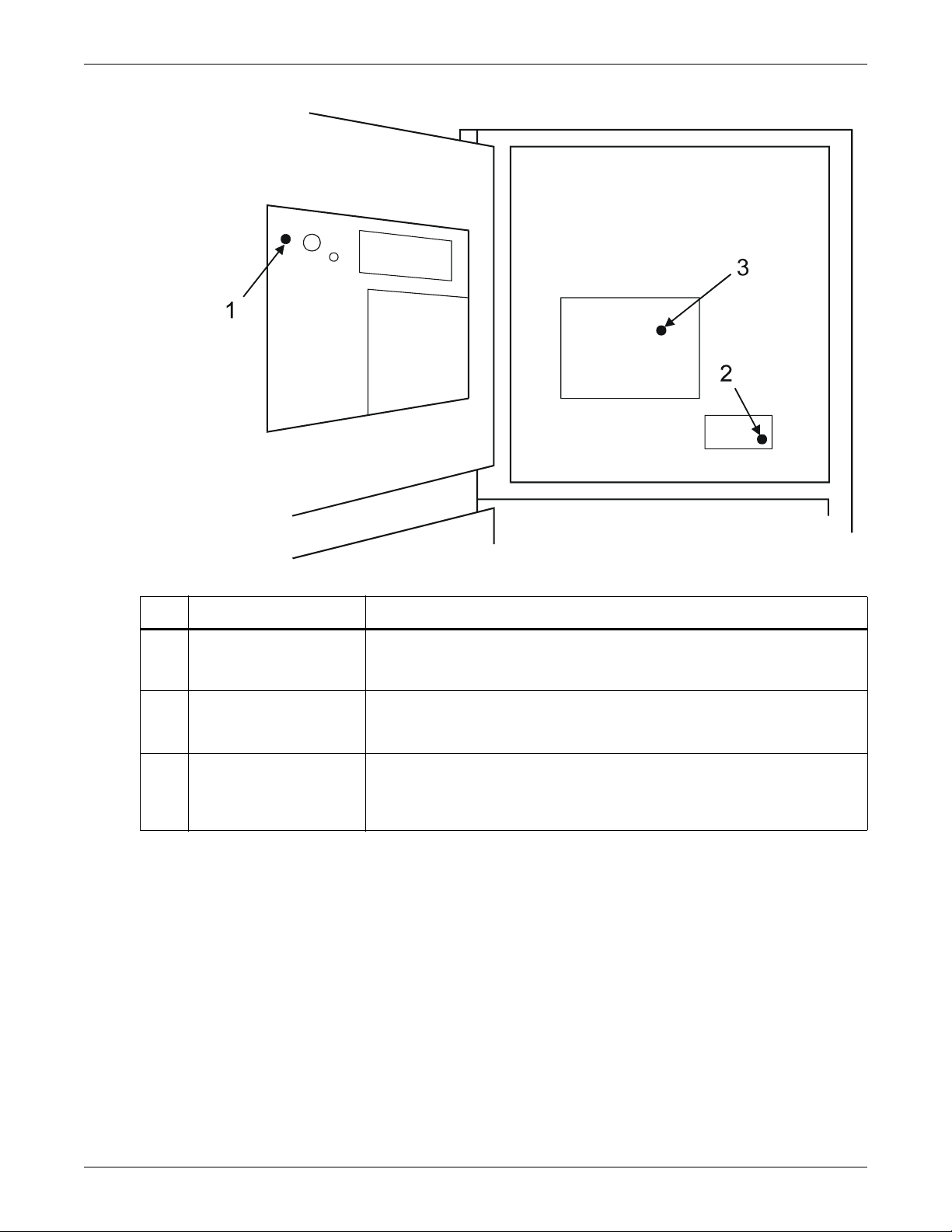

Figure 4 SCC controls and display screen with example of the Monitor/Mimic screen

© 1989-2003

Introduction

7

The operator controls and Monitor/Mimic screen for the System Control Cabinet (SCC) are shown in

Figure 4. The controls and display screen for each UPS module are shown in Figure 5. Each cabinet

(SCC or module) has the displays and controls required to monitor and perform its functions.

Figure 4 shows a three-module system designed for redundant operation. A multi-module UPS system may include up to six (6) modules for each SCC.

Detailed instructions on how to interpret the displays and use the controls are in 3.0 - Operation.

Figure 5 Module controls and display screen with example of the Monitor/Mimic screen

© 1989-2003

Introduction

1.6 Options

A number of options are available from Liebert for your UPS system. (Some options are not available

for all ratings.) Described below are the most frequently provided options. Note that the battery items

( 1- 3) are required to complete the UPS system. The remaining options provide improved system performance or convenience. Other options are available. Contact your Liebert sales representative for

more information.

1. Battery

The batteries provide power in the event of a power outage. The Liebert UPS can use a variety of

battery types, provided the battery plant is designed for the UPS DC voltage range and the load

requirements of your application.

8

Introduction

2. Battery Racks or Cabinets

The battery racks are specifically designed for stationary service batteries. They are painted with

electrolyte-resistant paint for corrosion resistance. Battery cabinets are available for 150 through

600kVA modules.

3. Module Battery Disconnect

The UPS system utilizes a separate Module Battery Disconnect for remotely located batteries. A

sensing circuit in the UPS module, set at the battery low voltage limit, trips the Module Battery

Disconnect to safeguard the battery from excessive discharge. The Module Battery Disconnect has

an undervoltage release mechanism designed to ensure that during any shutdown or failure mode

all battery potential is removed from the UPS system.

4. Input Current Distortion Filter

This filter reduces rectifier input current reflected harmonic distortion to less than 7% reflected

THD and less than 4% reflected THD for modules with the optional 12-pulse rectifier. The filter is

factory installed within the UPS. This filter also improves the input power factor to better than

0.92 lagging.

5. 12-Pulse Rectifier

All 500-750kVA models may be ordered with the optional 12-pulse rectifier section; this feature is

standard in 1000kVA models. This provides input isolation and reduces input current reflected

THD to less than 9% or less than 4% with optional input filter.

6. Isolation Transformers

An optional rectifier input isolation transformer is available in a matching transformer cabinet;

this feature is standard in 1000kVA models. A bypass isolation transformer is also available.

7. Three Breaker Maintenance Bypass

This switchboard provides make-before-break maintenance bypass. It includes: UPS Bypass

Input Breaker (BIB), Maintenance Bypass Breaker (MBB) and Maintenance Isolation Breaker

(MIB).

8. Two Breaker Maintenance Bypass

This switchboard provides make-before-break maintenance bypass. It includes: Maintenance

Bypass Breaker (MBB) and Maintenance Isolation Breaker (MIB).

9. Load Bus Synchronization (LBS)

The Load Bus Sync (LBS) option keeps two independent UPS systems (and therefore their critical

load buses) in sync, even when the modules are operating on batteries or asynchronous AC

sources. This means that critical loads connected to both load buses through a Static Bus Transfer

Switch can be switched seamlessly between the two.

10. SiteScan Central Monitoring System

Liebert manufactures a central monitoring system that automatically displays key UPS measure-

ments and alarms, as well as data from a variety of sensors. This monitoring system activates

alarms so corrective action can be taken. Events and data can be printed in hard copy. Data can

be logged for analysis.

11. Remote Monitor Panel

The UPS system may also be provided with an optional Remote Monitor Panel. This Panel pro-

vides eight LED indicators and may be placed at a convenient location near the critical load. A

functional description of the Remote Monitor Panel is provided in 3.0 - Operation of this manual.

12. Customer Alarm Interface

This optional interface board allows the input and display of 8 alarms from customer-supplied

contacts, each with a customer-selected name of up to 16 characters. The following attributes can

be user programmed for each alarm: latching, summary, freeze history, sound horn, auto-dial and

time delay (0 to 999.9 seconds).

13. Temperature-Compensated Charging

When battery temperature climbs above a preset limit (typically 77 degrees F), this optional cir-

cuit proportionally reduces float charging voltage to prevent overcharging the battery.

14. Battery Load Testing

When activated, this option forces the battery string to assume the load for a short period of time.

The UPS then compares the test results to data collected during the UPS commissioning to see if

the battery system appears to meet specifications.

9

2.0 THEORY OF OPERATION

2.1 General Component Descriptions

The UPS system includes all of the equipment necessary to continuously provide computer-grade AC

power to a critical load, even when there is an interruption of the utility power. It consists of a System

Control Cabinet (SCC), UPS modules and a back-up battery plant. Refer to Figure 6 and Figure 7.

Except where otherwise noted, the configuration is presumed to be parallel-redundant (with at least

one more UPS module than required to support the rated load).

2.1.1 System Control Cabinet

The System Control Cabinet (SCC) includes system controls, static bypass switch, load transfer control, protective devices and other accessories. The system controls simultaneously monitor two or

more parallel UPS modules sharing a critical load for increased capacity and/or redundancy. The two

(2) motor-operated system circuit breakers (system bypass breaker—SBB and UPS output breaker)

may be contained within the SCC, depending on the configuration designed for your installation.

System Controls: The system control logic automatically manages critical bus operation and monitors performance of the UPS modules. Microprocessor technology and dedicated firmware provide

advanced logic control and a comprehensive display of information. The system control logic synchronizes the output of the UPS system to the bypass source. The SCC includes ports for communicating

with external devices. Liebert Multi-Module Units do not require an SCC for load sharing. Automatic,

parallel module load sharing is a function built into the modules themselves; however interconnection

through the SCC enables the modules to share data for more precise control. Modules do not require

master clocks or controls in order to load share or free-run at 60.0 Hz.

Theory of Operation

Static Bypass Switch: The static (solid-state) bypass switch immediately transfers the load from

the inverter to the bypass AC power source in the event of a severe overload on the system or a failure

within the UPS. This transfer takes place without any interruption of the power supplied to the load.

In all SCCT control cabinets 1600A or larger and in all SCCI and SCCC control cabinets, the system

includes redundant circuits to detect and isolate shorted SCRs in the static switch.

Fuses are installed in series with the static bypass circuit (with the exception of the continuous duty

static switch installed in the SCCC control cabinet) to ensure reliable overload protection in the

unlikely event of a catastrophic output condition (e.g., a dropped wrench) electrically close to the output of your UPS system. The static switch SCRs themselves are rated to easily handle the fuse-blowing current.

Bypass Circuit: The bypass circuit consists of electrically operated circuit breakers and associated

synchronizing and control circuitry to transfer the load to/from the bypass source.

10

Figure 6 UPS module block diagram

MULTI-MODULE UPS SYSTEM

CONTROL POWER

Theory of Operation

Control

Wiring

To SCC

Controls

Utility

Input

Power

2.1.2 UPS Module

The UPS module consists of module controls, a rectifier/charger, an inverter, protective devices and

other accessories.

Module Controls: The module control logic monitors performance of the UPS module. The UPS

module status is displayed locally and is also sent to the System Control Cabinet.

Rectifier/Charger: The rectifier/charger converts utility power from AC to DC to charge the battery

and provide the DC input to the inverter. Its design limits reflected harmonic current distortion to

source power and provides low-ripple DC power for charging batteries. Multiple rectifier/chargers can

share a common battery plant, if that configuration is preferred for your application.

Inverter: The inverter converts DC power into the precise AC power required to supply a sensitive

critical load. The inverter converts DC power into a pulse-width-modulated (PWM)/six-step waveform

that is easily filtered into a clean sine wave output. The PWM/stepwave also minimizes the harmonic

voltage distortion caused by typical switching power supplies and other non-linear load components

used in computers and related electronics.

Input

CB

Rectifier/

Charger

Inverter

MBD

Output

Output

CB

Battery

CB - Circuit Breaker

MBD - Module Battery Disconnect

SCC - System Control Cabinet

Power

To SCC

2.1.3 Battery Plant

The battery is used as the alternate source of power to supply DC power to the inverter if the AC supply voltage is outside the acceptable range. The battery supplies power to the inverter until the utility

power is restored or until an alternate power source is available. If AC source power is not restored or

an alternate power source is not available, the battery can be sized to provide power long enough for

an orderly shutdown of the load.

11

2.2 Detailed Component Descriptions

2.2.1 Controls

Hardware

The Series 610 UPS Operator Interface Display System is designed to provide all of the information

that is required for the operation of each UPS cabinet (the System Control Cabinet and each module).

The following is a list of the hardware features:

1. The control logic performs automatic operations with minimal operator interface. The limited

number of manual controls are easy-to-use.

2. Each Series 610 UPS cabinet is equipped with an easy-to-read 640 x 200 pixel backlit liquid

crystal display (LCD) screen. It presents information in a way that is easy to understand at an

eye-level front panel location.

3. The display is controlled by a dedicated microprocessor with a flash-updatable program, nonvolatile static RAM and a battery-backed system clock.

4. The Series 610 System Control Cabinet (SCC) has communication ports (terminal board

connections) for:

a. Transmission of present status information to remote terminals via a resident auto-dial

communications program and an optional internal or external modem. This port also

responds to inquiries of the UPS system status and history from the remote terminal.

b. Reporting UPS system status and history information in response to inquiries from a local

terminal (no modem required).

c. Reporting to a local monitor the information requested from the local terminal.

d. Reporting information to a Liebert SiteScan central monitoring system.

e. Relaying selected alarm messages to a Liebert Remote Monitor Panel and to a separate

terminal board for customer use.

f. Relaying performance and status information to your network monitoring system via SNMP

interface (optional).

Theory of Operation

Software

The operator interface display system software enables the operator to monitor the UPS system status, to control the power flow through the UPS, to monitor all of the meter readings, to execute the

start-up, shutdown and load transfer procedures, to access the event history files and to make adjustments to the programmable parameters. The following is a list of the software features:

1. The menu-driven software prompts the operator for input.

2. Step-by-step instructions assist the operator during the start-up, shutdown and load transfer

procedures. This helps to eliminate operator errors.

3. Graphics-based mimic diagrams illustrate circuit breaker status and the power flow through the

UPS system.

4. The Present Status screen reports information about the system’s present status. The History

Status screen chronicles the events leading up to and immediately after a fault. The Event

History screen lists all of the alarm messages that have been logged over a period of time.

5. The Battery Cycle Monitor records information on up to 132 battery discharge events.

Information includes date, time, length of discharge, highest current demand, lowest battery

voltage and cumulative battery amp hours discharged.

Refer to 3.0 - Operation for a description of the controls and indicators located on the Operator Control Panel.

12

2.2.2 Rectifier/Charger

The UPS module rectifier/charger consists of an input circuit breaker, AC current limiting circuit,

battery equalize charge circuit, DC filter, battery charge current limiting circuit and bridge rectifiers.

Optional items are an isolation transformer and a 12-pulse rectifier (these are standard on 1000kVA

units).

Operation

The rectifier/charger converts the AC input power to DC power. This conversion is accomplished by

3-phase bridge rectifiers using SCRs. All phases are individually fused. Input current reflected THD is

less than 7% at full load with optional input filter or 30% without. For modules 500kVA and larger, the

optional 12-pulse rectifier reduces reflected THD to less than 4% with optional filter or 9% without.

The filtered output of the rectifier/charger provides regulated DC power to drive the inverter and

charge the battery.

Input Circuit Breaker

The input circuit breaker (CB1) is sized to allow enough current to recharge the battery and supply a

full rated load at the same time. The circuit breaker contains a thermal magnetic trip mechanism and

an undervoltage release that interrupts power, preventing damage to the system, if there is an internal AC overcurrent condition or a short circuit. The circuit breaker also opens during certain alarmed

faults. This circuit breaker must be closed manually.

Isolation Transformer

The optional input isolation transformer—standard with 1000kVA models and with the 12-pulse rectifier option—has a dry type core and copper windings with Class H insulation. The transformer on

modules with standard 6-pulse rectifier has wye primary and delta secondary windings. For models

with the optional 12-pulse rectifier, the transformer has a delta primary, with delta and wye secondary windings. The isolation transformer provides the initial step of critical bus isolation. This reduces

the AC shock hazard at the battery and at other DC components and prevents a DC fault from disrupting upstream AC circuitry.

The transformer has a nominal tap and one tap 6% below the rated nominal input voltage (normally

used for 460 VAC input).

Theory of Operation

Input Current Limit

AC input current-sensing transformers (CTs) are used to measure current levels. Control circuitry

connected to the CTs restricts the AC current to less than 125% of the full input current rating by

reducing the battery charging voltage. This current limit is adjustable from 100 to 125% and is factory-set at 115%.

An optional second level of input current limit is initiated by an external contact closure (field supplied for use with back-up generator) and is adjustable from 85 to 100% (factory-set at 100%). This

second level of input current limit may be used to set the maximum amount of input current permitted under all operating conditions of connected load and battery recharge.

During a start-up procedure, the current slowly ramps up (walks-in) from 20% of the rated input current to 100% over 15 to 20 seconds. The maximum rate of change of the AC input current is 15% per

second. The input current walk-in reduces the start-up surge effects on all other equipment connected

to the same source and prolongs the service life of internal components.

Input Current Inrush

The maximum sub-cycle of inrush current due to the optional input isolation transformer is typically

less than five times the rated input current for the first 1/2 cycle with the optional input filter. Without this transformer, inrush current is typically less than three times nominal.

Input Power Factor

The rated input power factor is not less than 0.85 lagging at the nominal input voltage and the full

rated UPS load. The optional input filter will improve the power factor to better than 0.92 lagging at

full load. Refer to your submittal package or installation drawings in the installation manual for your

specific model.

13

2.2.3 Battery Charging Circuit

The UPS module charging circuit is capable of recharging the battery plant to 95% of full capacity

within 10 times the discharge time. Recharging the last 5% takes longer because of characteristics

inherent in the battery. DC ripple voltage is limited to less than 0.5% RMS to preserve battery life

during long-term float charging while the UPS system is operating on utility source power.

Multiple UPS module rectifier/chargers can share a common battery plant, if that configuration is

preferred for your application.

Operation After Discharge

When commercial power is interrupted, the battery continues to supply DC power to the inverter

without interruption to the critical load. If the AC source power is restored before the battery has

fully discharged, the rectifier automatically restarts and resumes carrying the inverter and battery

recharge load requirements.

Operation After End-of-Discharge

The battery time screen displayed on the control panel enables you to estimate when battery shutdown will occur. If the battery plant discharges to the shutdown point during an outage, the UPS

automatically disconnects the load, the AC input and the battery. After AC input power is restored,

the rectifier can be manually restarted by the user.

Battery Disconnect

The external module battery disconnect (MBD) circuit breaker is used to isolate the UPS module from

the battery during maintenance and to automatically disconnect the battery from the inverter at the

end of battery discharge. The MBD circuit breaker can be opened or tripped automatically, from the

control panel or manually. It must be closed manually.

Theory of Operation

Battery Charge Current Limiting

The battery recharge current, after a battery discharge, is limited to between 1 and 25% (adjustable)

of the full load discharge current. An additional (optional) charge-limiting circuit can be activated by

external dry contact closure (field supplied) for use when operating on a back-up generator. These two

levels of control regulate the amount of current that flows from the power source to the battery while

the battery is recharging.

The battery charge current limit is factory-set at 10% for normal operation and at 1% for alternate

power source recharge operation.

Battery Equalize Charge Circuit

The battery equalize charge feature can be manually initiated or it can be programmed to operate

automatically. Either can be selected from the battery equalize screen displayed on the control panel.

The battery equalizing charge circuit increases the rectifier/charger output voltage to charge the battery any time there is a power outage of 30 seconds or longer. The equalizing voltage is slightly higher

than the float voltage. Equalize charging is primarily used in flooded battery systems to boost individual cells that are at a low state of charge, per the battery manufacturer's specification and recommendations.

NOTE

Do not use equalize charging with valve-regulated lead-acid batteries.

Consult the battery manufacturer’s manual, available on the manufacturer’s Web site, for

specific information about equalize charging.

14

2.2.4 Inverter

The inverter is a solid state device that converts the DC output of the rectifier/charger or the battery

to AC power.

Operation

The inverter converts DC power—from either the battery or the rectifier/charger—into three pulsewidth-modulated/six-step waveforms. These waveforms are filtered into low-distortion sine wave

power. The inverter is controlled by digitally controlled logic. This logic controls the precise synchronization, amplitude and frequency of the output voltage.

In addition to the inverter efficiently supplying a regulated AC output from a DC source, the output

isolation transformer acts as a second stage of isolation between the critical load bus and the commercial source power. The inverter is configured to handle most critical load inrush surges. It maintains

output voltage Total Harmonic Distortion (THD) within specifications even when handling non-linear

computer loads. Refer to Non-Linear Load Characteristics.

Output Regulation and Overload Performance

The inverter is capable of sustaining full output voltage (±2% of the nominal voltage) for up to 150%

overload at the output for as long as 30 seconds without reducing the output voltage. It can also handle at least 125% of the rated current for up to 10 minutes and 104% of the rated current continuously. The System Control Cabinet (SCC) will transfer the critical load to the bypass source if the

overload exceeds the system capacity or the capacity of the modules on-line. The multi-module overload capacity (in terms of percent of rated full load current of modules on-line) is 140% for 20 seconds,

108% for 10 minutes and 104% continuously.

Theory of Operation

Note that in normal operation the SCC will transfer the load to bypass before a UPS module exceeds

its overload capacity. If an individual module overload condition is sustained (beyond inverter capacity) the UPS module is automatically taken off-line (disconnected from the critical bus) and is shut

down. If the UPS system is operating in the redundant mode, the load may remain on the UPS system. Refer to 3.5 - Automatic Operations.

Non-Linear Load Characteristics

Computers and computer equipment with switching power supplies generate non-linear currents rich

in fifth and seventh harmonics.

The inverter pulse-width-modulated/six-step waveform, coupled with the output filter, provides a natural path for reducing the fifth and seventh harmonic currents produced by the load. The inverter/filter limits the output voltage THD to less than 5% with up to 100% typical electronic data processing

(EDP) loads. EDP equipment characteristically includes both non-linear and linear load components.

Unbalanced Load Characteristics

Unbalanced loads are actively regulated. The phase-to-phase voltage balance is maintained to within

2%, even with a 50% load imbalance.

The three-phase, root mean square (RMS—approximately 70% of the peak) average voltage is also

regulated through a separate control circuit (phase-to-phase sensing).

15

2.2.5 Static Bypass

A static bypass is an integral part of the UPS System Control Cabinet (SCC). Refer to Figure 7. The

static bypass consists of two reverse-paralleled SCRs (silicon-controlled rectifiers) per phase and

solid-state switching devices working in conjunction with the motor-operated System Bypass Breaker

(SBB). An automatic transfer control circuit senses the status of the operator controls, UPS logic signals and alarm messages and critical bus operating conditions. If the UPS modules can no longer supply the critical load, the static bypass switch (in conjunction with the SBB and UPS Output Breaker)

automatically transfers the critical load to the bypass source without interruption.

Figure 7 System Control Cabinet block diagram

Bypass Line

Gate

Driver

Static

Bypass

Switch

Static Switch

Disconnects

Static Bypass Breaker

Theory of Operation

Sync &

Transfer

UPS

System

Modules

Control

Power

Supply

System

Monitor

Alarms

Voltage

Adjust

Transfer

Control

UPS Output

To Critical

Load

Fuse Protection

The static bypass switch path uses two back-to-back SCRs per phase. Each phase is individually protected by a fuse sized to clear only in the event of a catastrophic fault (with the exception of the continuous duty static switch used in the SCCC control cabinet). This is a more reliable method than

depending on external protection devices. The fuses are in the circuit to protect the critical bus distribution equipment against catastrophic faults. The static switch SCRs are oversized to easily handle

any current surges that may blow the fuses.

Shorted SCR Monitoring

In all SCCI and SCCC control cabinets, and all SCCT control cabinets 1600A and larger, the static

bypass system has redundant shorted SCR sensing circuits and disconnects. This will prevent UPS

output power backfeed to the distribution system even if two component failures exist simultaneously. If a shorted SCR is detected, the static bypass switch is isolated and annunciated at the SCC

control panel, and the critical load remains on UPS output power.

In all SCCT control cabinets smaller than 1600A, the static bypass system is equipped with redundant disconnect circuits that prevent backfeed of lethal voltage to a de-energized bypass input in the

event of a shorted static switch SCR. If the bypass input power is interrupted, the static switch disconnect devices will open, preventing backfeed of inverter voltage to the bypass input terminals.

16

Theory of Operation

Static Switch Isolation

The motor-operated system bypass circuit breaker (SBB), wired in parallel with the static switch,

automatically closes in approximately 200 milliseconds after the load is transferred to the bypass

power source, removing the static switch from the power flow.

Also, if required for maintenance, the static switch can be isolated from the bypass line by opening (to

the OFF position) the Static Switch Disconnects. For maintenance, this should only be done with the

UPS system critical load on bypass power.

Pulsed Parallel Operation

When an overload condition such as magnetic inrush current or a branch load circuit fault exceeds the

overload capacity of the connected modules, the static bypass switch pulses on for 40 milliseconds.

This allows up to 1000% of the rated full load current from the bypass line to clear the overload without closing the bypass circuit breaker. The bypass source is briefly in parallel with the UPS system,

permitting the bypass source to carry the initial overload current. If the overload clears before 40 milliseconds, a load transfer to bypass is not made. If the overload condition continues, the automatic

transfer is made (maintaining the load voltage within the specified limits).

This pulsed static switch operation reduces nuisance operation of motor-operated circuit breakers for

such short-term conditions and serves, under some circumstances, as a backup in the event that an

external bypass feeder breaker trips open during this pulse-paralleling period.

Load Transfers

Transfers to (transfer) or from (retransfer) the bypass may be performed automatically or manually in

a make-before-break sequence. This is accomplished through the overlapping operation of the UPS

output and the system bypass power switching devices.

Manual load transfers and retransfers are initiated by the operator from the System Control Cabinet

(SCC).

In a manual operation or an automatic retransfer, the two motorized circuit breakers—UPS output

and system bypass—are both closed simultaneously for a short period of time (overlap).

Automatic transfers are initiated by the SCC system control logic when an overload is beyond the

specified capabilities of the UPS system or when a fault occurs within a non-redundant UPS module.

An automatic retransfer is initiated if this function is enabled and if system conditions for a retransfer are present.

In an automatic transfer, the circuit breakers do not overlap, but, during the short time gap, bypass

power is supplied to the critical load through the solid state static switch. In an SCCC control cabinet

with a continuous duty static switch, if for some reason the Static Bypass Breaker (SBB) fails to close,

the static switch will carry the load continuously.

17

Theory of Operation

Transfer and Retransfer Conditions

1. Automatic Transfers to Bypass

Critical bus conditions that will initiate an automatic transfer of the critical load from the UPS

system to the bypass source are:

a. System Overload: overcurrent condition in excess of the overload rating of the System Control

Cabinet (SCC).

b. Output Overload: overcurrent condition in excess of the current-versus-time overload capacity

of UPS modules ON LINE.

c. Overvoltage/Undervoltage (OV/UV): critical bus voltage is outside the allowable tolerance.

d. Non-redundant UPS Module Inoperative: an essential UPS module is taken OFF LINE for

one of the reasons below.

1. Battery discharged to the shutdown voltage.

2. Inverter overload capacity exceeded.

3. Inverter or rectifier fault condition (power, logic or overtemperature) present or

imminent.

4. Failure of UPS module logic or logic power.

e. SCC Logic:

1. Emergency Module Off (EMO) circuit activated.

2. Failure of UPS system logic or logic power.

2. Manual Transfers

Manual transfers may be initiated at any time provided no transfer inhibition conditions are

present.

3. Transfer Inhibited

A manual transfer to the bypass source will be inhibited if any of the following conditions exist:

a. UPS system to bypass voltage difference (∆V) exceeds a predetermined percentage (normally

5%).

b. Static switch disconnects open.

c. OK to Transfer signal from the control logic is not present.

NOTE

A load transfer to the bypass line will be completed whenever an automatic transfer to bypass

is initiated. If the Static Switch Unable alarm message is present for any reason (including a

±20° phase lock synchronization error), the automatic transfer will be interrupted for

40-120 milliseconds. Because of the reliability of the UPS components, an interrupted load

transfer is a very unlikely occurrence.

4. Automatic Retransfers to UPS

Critical bus conditions that must be present to initiate an automatic retransfer (Auto-Rexfer) of

the critical load from the bypass source to the UPS system are:

a. The number of Auto-Rexfer Attempts selected must be greater than zero (0). If zero (0) is

selected, no automatic retransfer will occur.

b. Critical load was initially transferred to the bypass source due to a system overload only.

c. Overload has since dropped below 100% of the rated SCC current.

d. Enough UPS modules are ON LINE to supply the critical load.

e. OK to Transfer signal received from the control logic for at least 10 seconds, within 5 minutes

of the overload transfer. (A manually initiated retransfer from bypass is required for

overloads lasting 5 minutes or more.)

f. Cyclic-type system overloads, which occur up to five (select range is 0 to 5) times in

60 minutes, are automatically returned to the UPS system for each event including the Nth

overload. A manually initiated retransfer from bypass is required for the N+1 overload.

5. Manual Retransfers

Manual retransfers may be initiated at any time provided no retransfer inhibition conditions are

present.

18

6. Retransfer Inhibited

A retransfer from the bypass source to the UPS system shall be inhibited if any of the following

conditions exist:

a. Manual (and Automatic) Retransfer Inhibitions:

1. UPS system-to-bypass voltage difference (∆V) exceeds a predetermined percentage

(normally 5%).

2. System circuit breaker (UPS output or SBB) is inoperative.

3. OK to Transfer signal from the control logic is not present.

4. Not enough UPS modules are ON LINE to supply the connected critical load.

b. Automatic Retransfer Inhibitions (in addition to those above):

1. The load transfer to bypass was not caused by a system overload.