Liebersew 737 Operations Manual And Parts Book

SUPER

HIGH

SPEED

OVERLOCK

SEWING

MAGHINE

Operation

Manual

Parts

Book

Contents

TO

THE OPERATERS

......

HOW

TO INSTALL

THE

MACHINE

...

HOW

TO OPERATE

THE

NEW

MACHINE

LUBRICATION

AND

DRAINAGE

""''""

I

l.Lubrication

"""""'

"""""""

I

2.Drainage

3. Needle

Cooling

Lubrication-silicon

oil

""""":"""""""

"

j""""""""""'

I

THREADING

THE MACHINE

""'"''

2

THREAD

TENSION

.",...",

2

l.TensionNutsAdjustment

"""

""""""2

2. Needle Thread

Control

3.

LooperThreadControl

"""""""'3

..',....3

4. Chain Looper

Thread

Cam

Contol

""""""

ST]TCH LENGTH

ADJUSTMENT

...

"""

3

NEEDLE

REPLACEMENT

:...".".''

DIFFERENTIAL

FEED

RATIO

ADJUSTMENT

."

"""

4

PARTS

RELATION

AND

TIMING

...."

'""""'"

4

l. Needle

and

Needle Plate

"'

"""

4

2. Upper

Looper

andNeedle

3. LowerlooperandNeedle

"""""""""'5

4. Upper

Looper

aird

Lower

LoPPer

5.

Needle

and

Needle

Guard

"""""""""

5

6. Chain

Looper and

Needle

" "

"

5

Clear

a

stoppage

""""""'

6

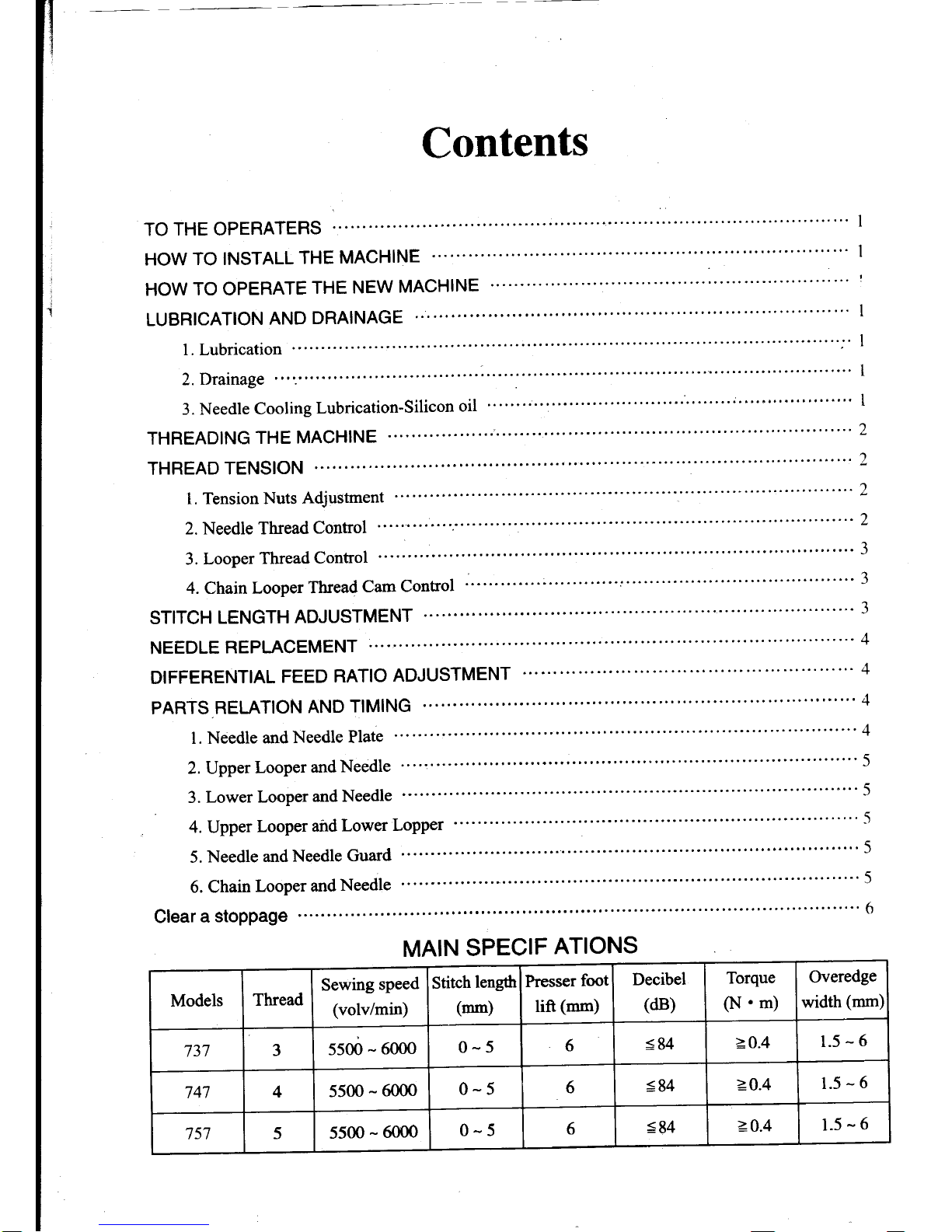

MAIN

SPECIF

ATIONS

Models

Thread

Sewing

speed

(volv/min)

Stitch

length

(mm)

Presser

foot

lift

(mm)

Decibel

(dB)

Torque

(N'm)

Overedge

width

(mm)

3

5500

-

6000

0-5

6

=84

=0.4

1.5-6

747

4

5500

-

6000

0-5

6

=84

=0.4

1.5-6

7s7

5

5500

-

6000

0-5

6

s84

>_o.4

1.5-6

Machine.

Before operating

this machine,

please

study this book

thoroughly,

understand

the functions

and

features of the

machine. Then

it

will help

you to

increase

your

sewing efficiency

and

quality.

ATTENTION:

Because

this

is an ultra

high

speed machine.

Do

not run it before filling oil

and

i::king

sure the correct turection

of

motor.

ffi

1. Install

the machine according

to the table

cut-out

diagram, Cushion

Rubber

and Rest Board

as enc-

losed. In case of semi-submerged,

the

distance

between Needle

plate

top surface and Table

Top is

about

100mm,

and

for fully-submerged

is about

5mm.

2. Setting

the

pedal

of

clutch motor

to the left

side

and the

pedal

of

presser foot lift at right ride.

3.

Install the

cloth

waste

chute,

thread stand

as

parts

list.

4. Be sure the motor

turning direction

is clockwise.

And the belt can

be

pressed

inward about 10mm.

NOTE:

The dimensions

of motor

pulley

and sewing

speed are

shown

in Table 1.

Please run the new machine in the

first

four at20Vo less

speed than maximum. Then replace the

new oil and threafter the machine

may be operated

up

to

maxim um

speed.

Lubricatdn.And'

age

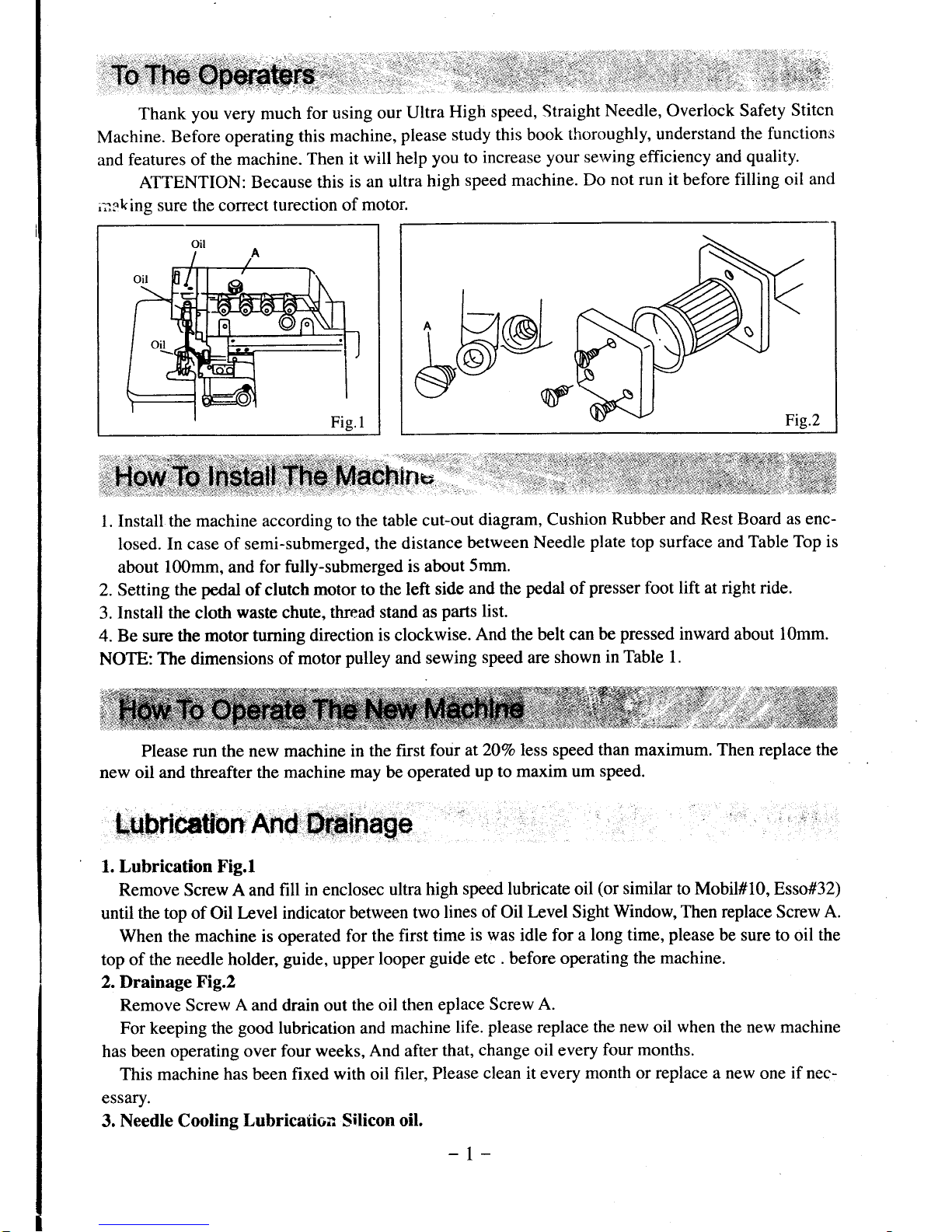

1. Lubrication Fig.l

Remove Screw A and fill

in enclosec

ultra high

speed lubricate oil

(or

similar

to Mobil#lO, Esso#32)

until

the top of

Oil

level indicator between

two

lines

of

Oil

Level Sight

Window,

Then replace Screw A.

When the

machine

is operated

for the

first time

is was

idle for

a long time,

please

be

sure to oil

the

top of

the needle holder,

guide,

upper

looper

guide etc . before operating

the machine.

2. Drainage

Fig.2

Remove Screrv

A

and drain out

the oil then

eplace Screw

A.

For keeping the

good

lubrication and

machine

life.

please

replace the

new

oil

when

the new machine

has been operating

over four

weeks, And after

that,

change

oil every

four months.

This machine

has been fixed with oil

filer, Please

clean it every

month or replace a new

one

if nec-

essary.

3. Needle Cooling

Lubrication

Silicon

oil.

_,:-

.:

:

:

. i

.

'.:

"

'

.:

S,

l,

:,.,.

1'11'11:::11r:r,,:L:;1

-1-

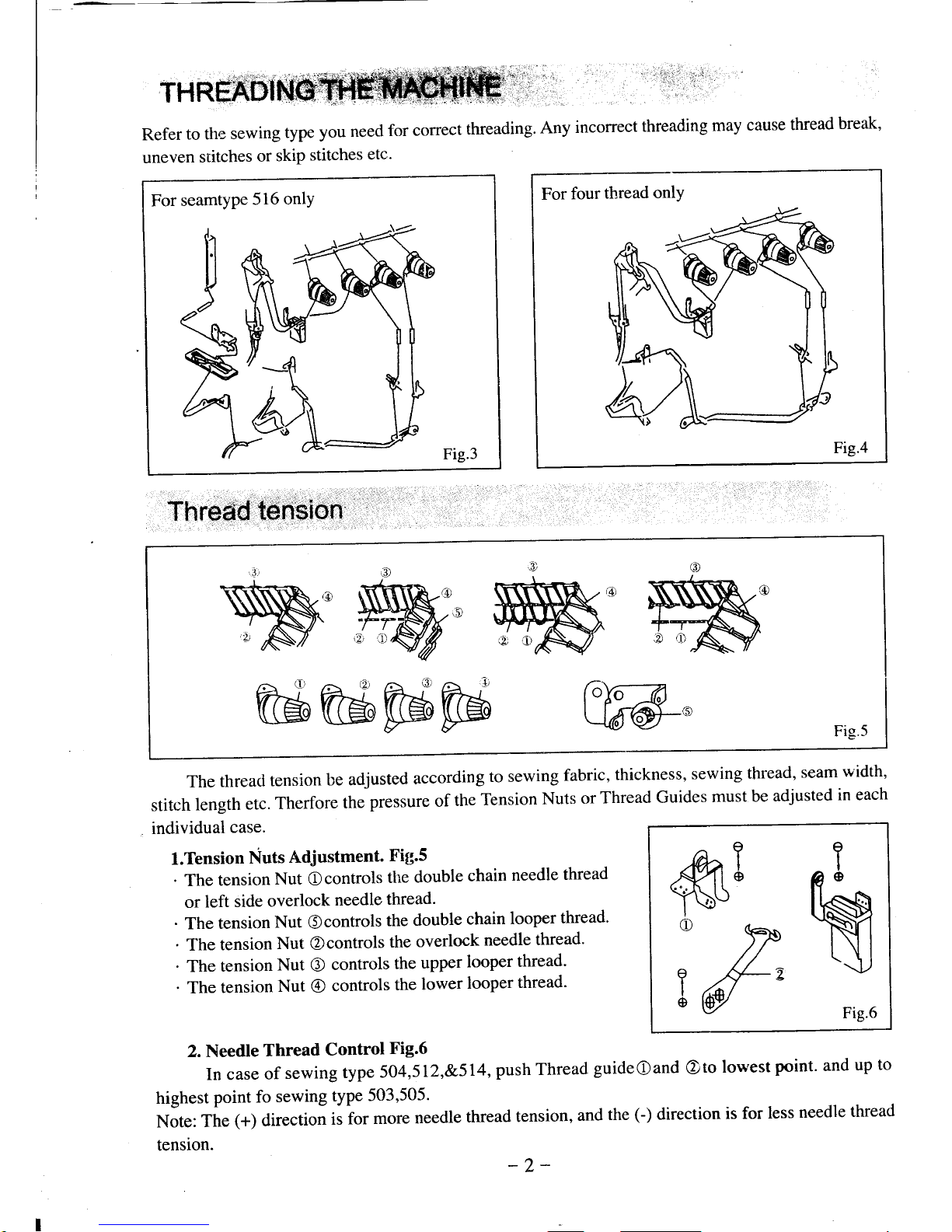

Refer

to the

sewing

type

you

neecl

for correct

threading.

Any

incorrect

threading

may

cause

thread

break'

uneven

stitches

or

skip

stitches

etc.

For

seamtypc

516

onlY

Fig.3

Thre€ftI&n's'ion

tubG@@

Fig.5

The

threaci

tension

be adjusted

according

to sewing

fabric,

thickness,

sewing

thread,

seam

width,

stitch

length

etc.

Therfore

the

pressure

of

the

Tension

Nuts

or

Thread

Guides

must

be

adjusted

in each

individual

case.

l.Tension

Nuts

Adjustment.

Fig.S

.

The

tension

Nut

Ocontrols

the

double

chain

needle

thread

or

left

side

overlock

needle

thread.

'

The

tension

Nut

Ocontrols

the

double

chain

looper

thread'

'

The

tension

Nut

@controls

the

overlock

needle

thread'

'

The

tension

Nut

O

controls

the

upper

looper

thread'

'

The

tension

Nut

@

controls

the

lower

looper

thread'

2. Needle

Thread

Control

Fig.6

In case

of

sewing

type

504,512,&5l4,push

Thread

guideOand

Oto

lor*'est

point.

and

up

to

highest

point fo

sewing

type

503,505.

Note:

The

(+)

direction

is

for

more

needle

thread

tension,

antl

the

(-)

direction

is for

less

needle

thread

tension.

-2-

i

ffi3

[i

:PN

Ttr'

.,,U

For

four

thread

onlY

3.

Looper

thread Control

l'ig.7

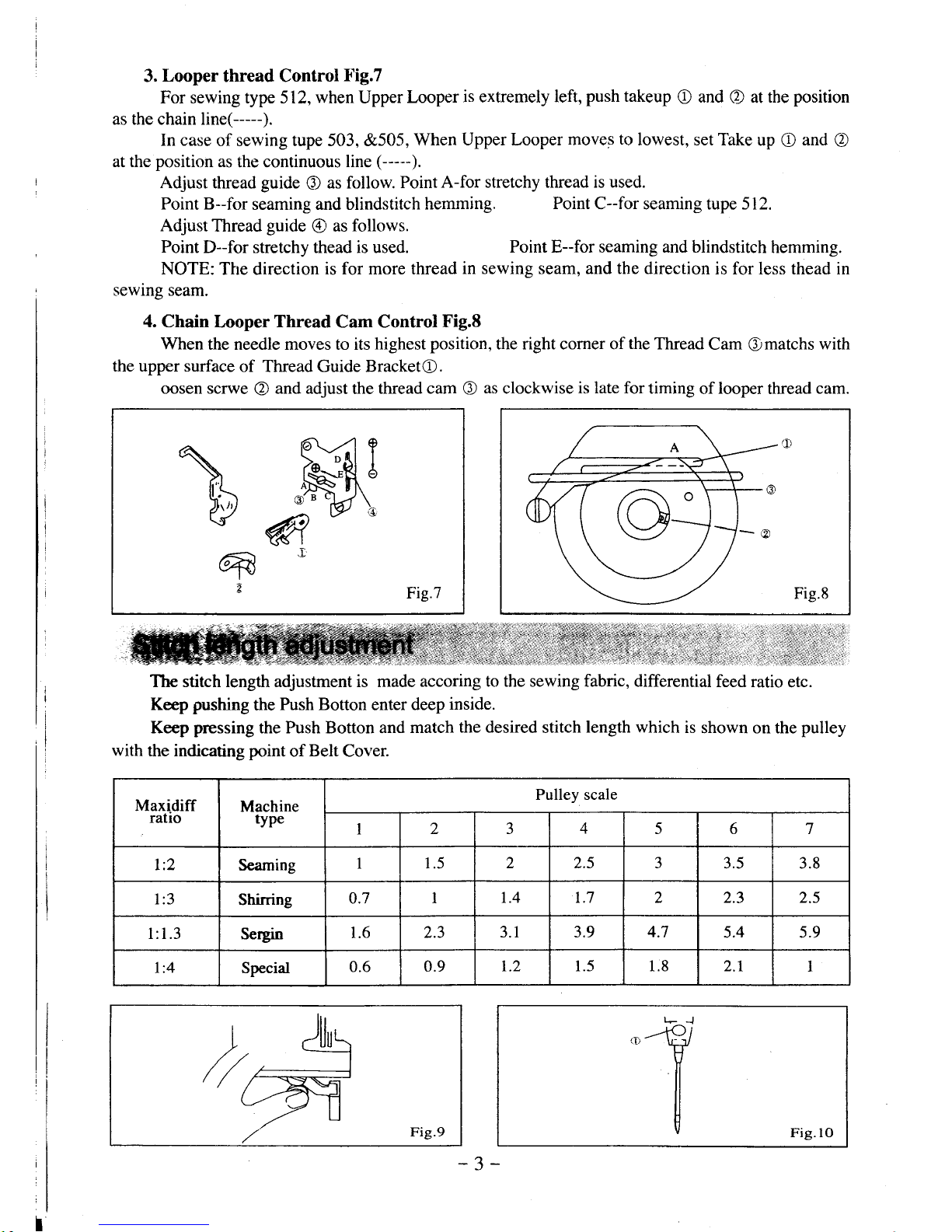

For sewing type 512,

when

Upper

Looper

is extremely left,

push

takeup

O

and

(D

at

the

position

as the chain line(-----).

In case

of sewing tupe 503, &505,

When

Upper Looper moves

to

lowest, set Take

up

O

and

O

at the

position

as

the continuous

line

(-----).

Adjust thread

guide

G)

as follow.

Point

A-for stretchy thread is used.

Point B--for

seaming and blindstitch

hemming.

Point

C--for seaming tupe 512.

Adjust

Thread

guide

@

as

follows.

Point

D--for stretchy thead is used.

NOTE:

The direction

is for more thread

in

sewing seam.

4. Chain

Looper

Thread

Cam Control

Fig.8

When

the needle moves to its

highest

position,

the right corner of

the

Thread

Cam

Omatchs

with

the upper surface

of Thread Guide BracketO.

oosen scrwe @ and adjust

the

thread cam

O

as

clockwise

is late for

timing

of

looper

thread

cam.

Point E--for seaming and blindstitch

hemming.

sewing seam, and the direction

is for less thead in

\

b

@

2

Fig.7

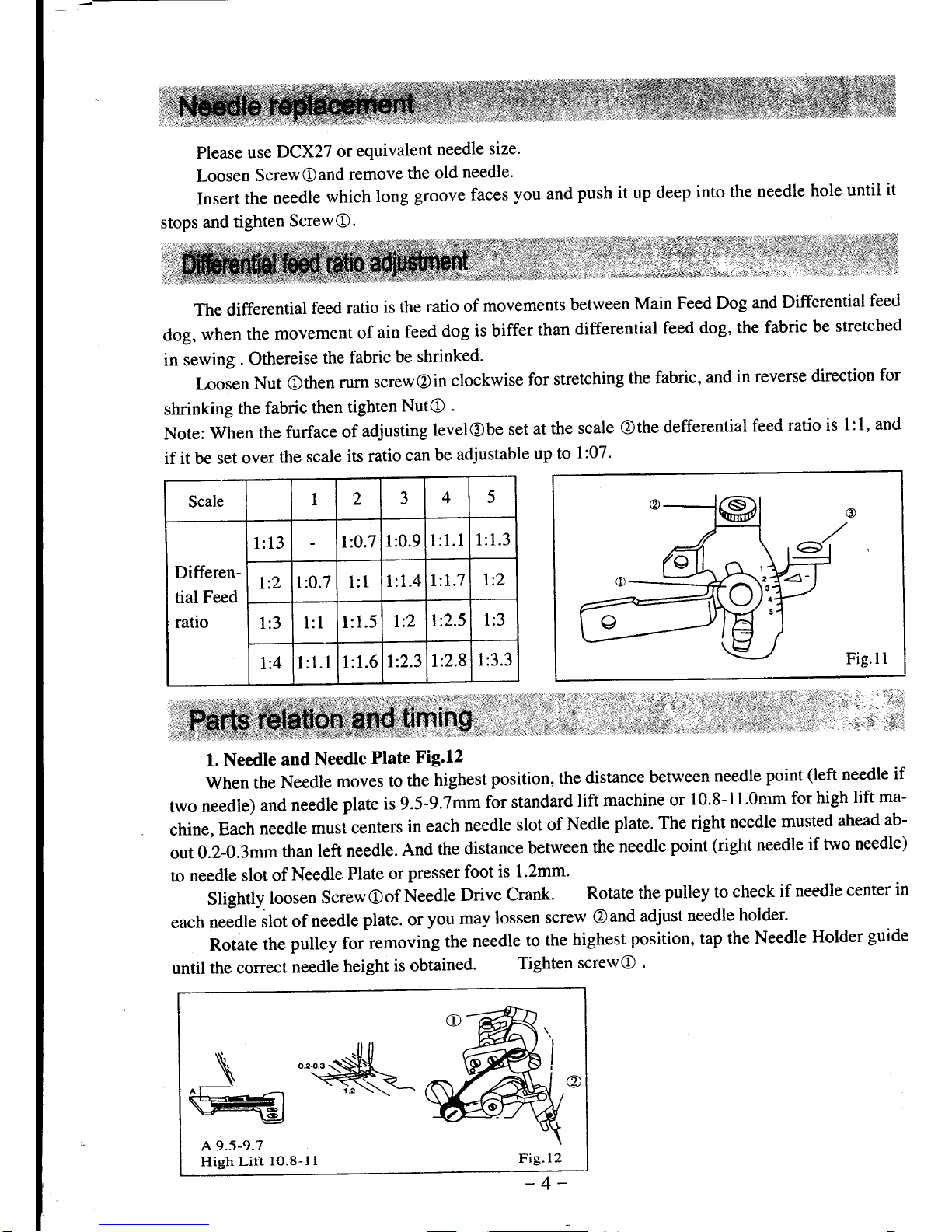

The stitch length adjustment is made

accoring to the sewing fabric, differential

feed ratio

etc.

Keep

pushing

the

Push Botton

enter

deep

inside.

Keep

pressing

the Push Botton and

match

the desired

stitch

length which

is

shown on the

pulley

with

the indicating

point

of

Belt

Cover.

Maxidiff

ratio

Machine

type

Pulley scale

I

2

J 4

5 6 7

l:2

Seaming

I 1.5

2 2.5

J

3.5 3.8

l:3

Shirring

0.7

I

1.4 1.7 2 2.3 2.5

1:1.3

Sergin

1.6

2.3 3.1 3.9 4.7

5.4 5.9

l:4 Special

0.6

0.9

r.2 1.5 1.8 2.1

I

Fig.9

Fig. lO

-3-

Please

use

DCX27

or

equivalent

needle

size'

Loosen

ScrewOand

remove

the

old

needle'

Insert

the

needle

which

long

groove

faces

you

and

pusl

it up deep

into

the

needle

hole

until

it

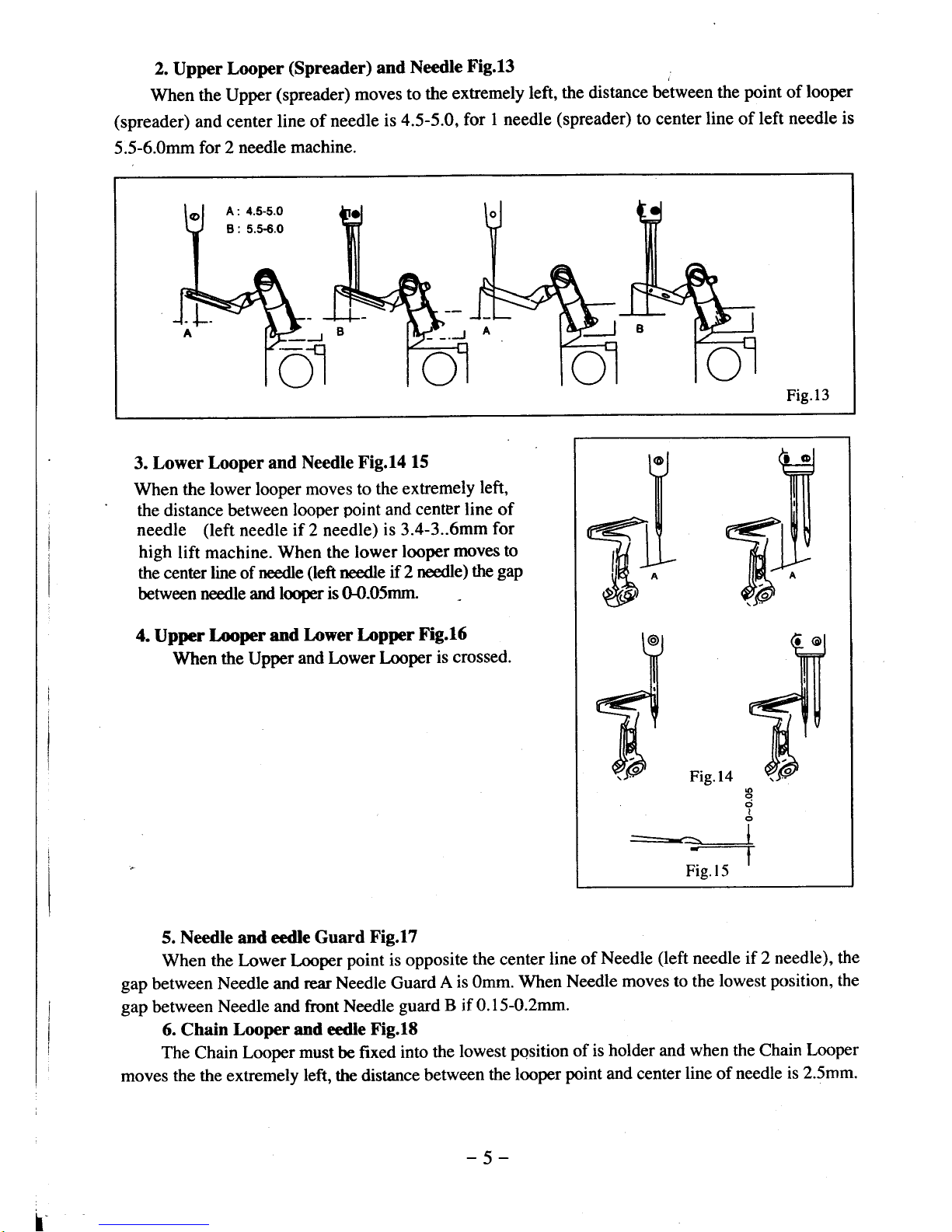

The

differential

feed

ratio

is the

ratio

of

movements

between

Main

Feed

Dog

and

Differential

feed

dog,

when

the

movement

of

ain

feed

dog

is biffer

than

differential

feed

dog,

the

fabric

be stretched

in sewing

. Othereise

the

fabric

be shrinked.

Loosen

Nut

Othen

rum

screwq)in

clockwise

for stretching

the fabric,

and

in reverse

direction

for

shrinking

the

fabric

then

tighten

NutO

'

Note:

When

the

furface

of

adjusting

level@be

set

at

the

scale

@the

defferential

feed

ratio

is

1:1,

and

if it be set over

the

scale

its

ratio

can

be

adjustable

up to

1:07'

Scale

I 2

3

4

5

Differen-

tial Feed

ratio

1:13

l:0.7

l:0.9

1:1.1

l:1.3

I:2

1:0.7

1:1

l:I.4

l:1.7

l:2

l:3 l:l

1:1.5

I:2

l:2.5

1:3

1:4

l:1.1

l:1.6

l:2.3

l:2.8

1:3.3

Fig.l

I

stops

and

tighten

ScrewO.

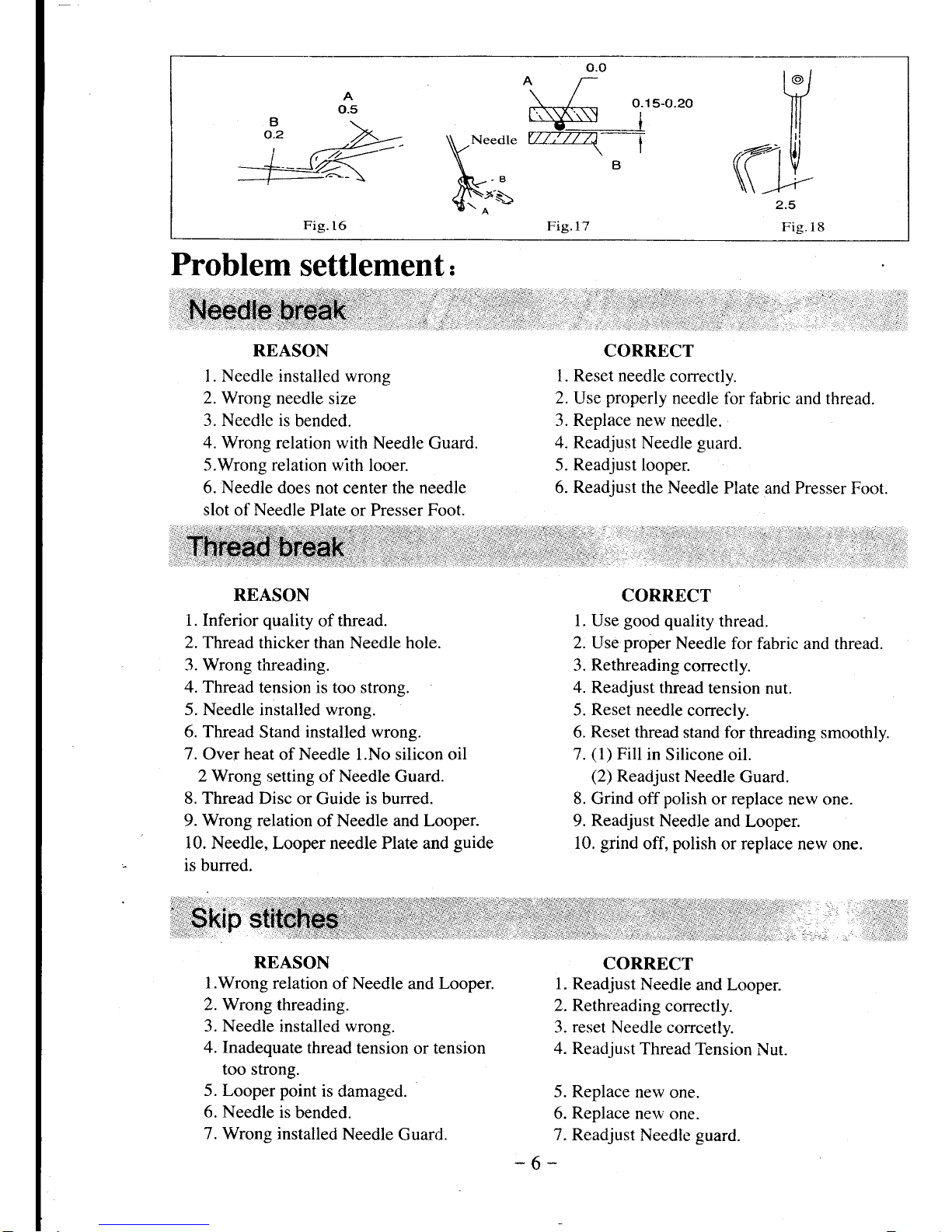

1. Needle

and

Needle

Plate

Fig.12

When

the

Needle

moves

to

the

highest

position,

the

distance

between

needle

point

(left

needle

if

two

needle)

and

needle

plate

is

9.5-9.7mm

for standard

lift

machine

or

10'8-ll.Omm

for

high

lift

ma-

chine,

Each

needle

must

centers

in each

needle

slot of

Nedle

plate.

The

right

needle

musted

ahead

ab-

out 0.2-0.3mm

rhan

left

needle.

And

the

distance

between

the

needle

point

(right

needle

if nvo

needle)

to

needle

slot of

Needle

Plate

or

presser

foot

is 1'2mm'

Slightly

loosen

ScrewOof

Needle

Drive

Crank.

Rotate

the

pulley to

check

if

needle

center

in

each

needle

slot

of

needle

plate. or

you may

lossen

screw

@and

adjust

needle

holder.

Rotate

the

pulley foiremoving

the

needle

to the

highest

position, tap

the Needle

Holder

guide

until

the correct

needle

height

is obtained.

Tighten

screwO

'

\

+E--<-r

.reJ

A9.5-9.7

High

Lift

rO.8-11

Fig.

l2

-4-

2.

Upper

Looper

(Spreader)

and

Needle

Fig.13

When the Upper

(spreader)

moves

to the

extremely

left,

the distance

between the

point

of

looper

(spreader)

and center

line of

needle

is

4.5-5.0,

for

I needle

(spreader)

to center

line

of

left needle is

5.5-6.0mm for 2

needle machine.

A: 4.5-5.0

B: 5.S.0

Fig.l3

3.

Lower

Looper and Needle

Fig.14

15

When the lower looper

moves to the

extremely

left,

the distance between

looper

point

and

center line

of

needle

(left

needle if 2 needle)

is

3.4-3..6mm

for

high

lift machine.

When the

lower

looper

moves to

the center line of

needle

(eft

needle

if 2

needle)

the

gap

beween needle and

looper is 04.05mm.

4.

Upper

Looper

and

Lower Lopper

Fig.16

When

the

Upper

and l,ower l-ooper

is crossed.

5. Needle and eedle

Guard

Fig.17

When

the Lower

Looper

point is opposite

the center

line

of

Needle

(left

needle if 2 needle), the

gap

between

Needle and rcar

Needle Guard

A

is Omm. When

Needle

moves to the lowest

position, the

gap

between

Needle and front Needle

guard

B if 0.15-0.2mm.

6. Chain

Looper and eedle

Fig.18

The

Chain

Looper

must

be fixed

into

the

lowest

pgsition

of

is

holder and when the Chain

Looper

moves

the the

extremely

left,

the distance

between

the looper

point

and center

line

of needle

is

2.5mm.

d

d

o

g

o

I

o

I

-----

|

F;;-T

-5-

\i7

K-y

2.5

Fig. 18

Fig.l6

Fig. 17

Problem

settlement,

REASON

l. Needle installed wrong

2.

Wrong needle

size

3. Needle

is bended.

4.

Wrong relation with

Needle Guard.

5.Wrong relation

with looer.

6. Needle does

not center the

needle

slot

of

Needle

Plate

or

Presser Foot.

REASON

1. Inferior

quality

ofthread.

2.

Thread thicker than

Needle

hole.

3. Wrong threading.

4. Thread

tension is too strong.

5. Needle

installed

wrong.

6. Thread

Stand

installed wrong.

7.

Over

heat

of Needle 1.No silicon oil

2 Wrong

setting of Needle Guard.

8. Thread Disc

or Guide is burred.

9.

Wrong relation

of Needle and Looper.

10. Needle, Looper needle Plate and

guide

is burred.

REASON

l.Wrong

relation

of Needle and Looper.

2. Wrong

threading.

3. Needle

installed wrong.

4. Inadequate

thread tension

or

tension

too

strong.

5. Looper point

is damaged.

6. Needle is

bended.

7. Wrong installed

Needle

Guard"

CORRECT

1. Readjust

Needle

and Looper.

2. Rethreading

correctly.

3. reset Needle

corrcetly.

4. Readjust

Thread

Tension

Nut.

5. Replace

new

one.

6.

Replace

new

one.

7. Readjust

Needle

guard.

-6-

i+

:,',,'n,:,::i1:r:,:i.i;iit'';+.ir+lit:ti::liiti::.i:':l ,::.,.r,-:!"1;::,r;.

,::,..

':.i:.,:'

i I

ir:.i,;i:i

CORRECT

l. Reset needle

correctly.

2.

Use

properly

needle

for fabric and thread.

3. Replace new

needle.

4. Readjust

Needle

gr.rard.

5.

Readjust

looper.

6.

Readjust

the Needle

Plate

and

Presser

Foot.

CORRECT

l. Use

good

quality

thread.

2.

Use

proper

Needle

for fabric

and thread.

3. Rethreading

correctly.

4. Readjust

thread tension

nut.

5.

Reset

needle

correcly.

6.

Reset

thread

stand for threading smoothly.

7.

(1)

Fill

in

Silicone oil.

(2)

Readjust

Needle

Guard.

8. Grind off

polish

or

replace

new one.

9.

Readjust

Needle

and Looper.

10.

grind

off,

polish

or

replace

new one.

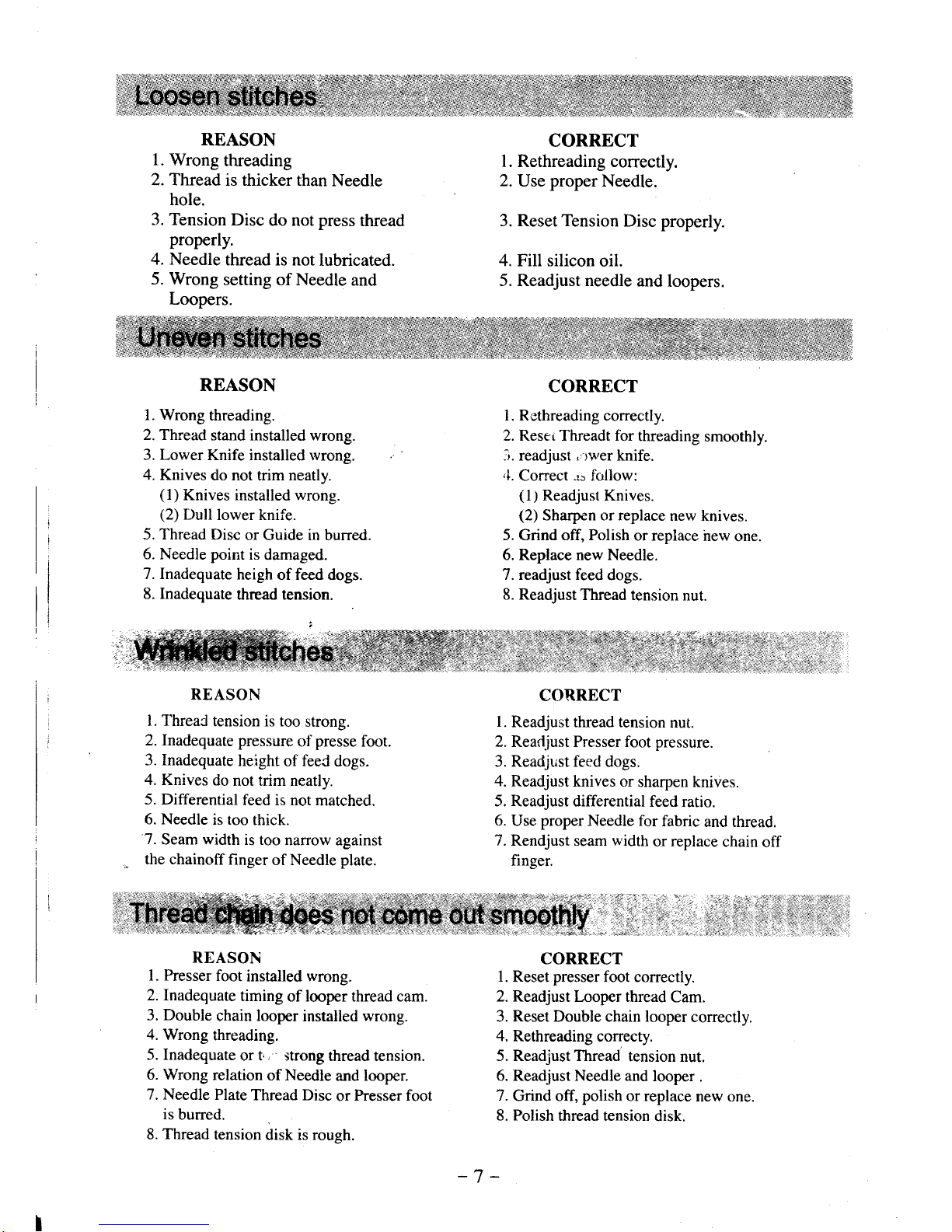

REASON

1.

Wrong

threading

2. Thread

is thicker than

Needle

hole.

3. Tension

Disc

do not

press

thread

properly.

4. Needle

thread is not

lubricated.

5. Wrong

setting of Needle

and

Loopers.

CORRECT

1. Rethreading correctly.

2.

Use

proper

Needle.

3. Reset Tension

Disc properly.

4. Fill silicon

oil.

5. Readjust needle

and

loopers.

REASON

l. Wrong

threading.

2. Thread

stand

installed wrong.

3. Lower Knife

installed rvrong.

4. Knives

do not trim neatly.

(1)

Knives installed wrong.

(2)

Dull

lower knife.

5. Thread

Disc

or Guide in burred.

6. Needle point

is

damaged.

7. Inadequate

heigh

of feed dogs.

8. Inadequate

thread tension.

REASON

l. ThreaC

tension is too

strong.

2. Inadequate

pressure

ofpresse foot.

3. Inadequate

height

of

feeC

dogs.

4. Knives

do

not trim neatly.

5. Differential

feed is not

matched.

6. Needle

is too

thick.

7.

Seam

width

is too

narrow against

the chainoff

finger

of Needle

plate.

REASON

l. Presser

foot

installed wrong.

2. Inadequate

timing

of looper thread cam.

3.

Double

chain looper

installed wrong.

4.

Wrong

threading.

5. Inadequate

or t,,

'

strong

thread tension.

6. Wrong

relation

of Needle

and looper.

7. Needle

Plate

Thread Disc

or

Presser foot

is

burred.

8.

Thread

tension

disk is rough.

CORRECT

l. Rethreading

correctly.

2. Resei Threadt for

threading

smoothly.

ii. readjust ,.rwer knife.

,1.

Correct

-r"

follow:

(l)

Readjust Knives.

(2)

Sharpen or replace

new

knives.

5. Grind off, Polish

or replace

irew

one.

6. Replace new Needle.

7. readjust feed

dogs.

8. Readjust

Thread tension

nut.

CORRECT

R.eadjust thread tension

nut.

Readjust Presser foot pressure

Readjrist feed dogs.

Readjust knives or

sharpen knives.

Readjust differential

feed ratio.

Use

proper

Needle for

fabric

and thread.

Rendjust

seam

width

or replace

chain

off

finger.

l.

2.

4.

5.

6.

"7.

+irffi$iffi

CORRECT

l. Reset presser foot

correctly.

2.

Readjust Looper thread

Cam.

3. Reset Double chain looper

correctly.

4.

Rethreading correcty.

5. Readjust Thread tension

nut.

6. Readjust Needle and

looper

.

7.

Grind off,

polish

or replace

new

one.

8.

Polish

thread tension

disk.

-7

-

Loading...

Loading...