Liberty Systems CCR Liberty User Manual

Liberty

MANUAL

Content

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Use of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Responsibility of the CCR Liberty user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System of documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

User support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Depth limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Water temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CO2 scrubber duration limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Technical design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1 Basic schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Dive/surface valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.1 Inhalation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.2 Exhalation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.3 Mouthpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.4 Usage with a full face mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3 Corrugated hoses and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3.1 Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3.2 Attachment to the head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3.3 Connection to the breathing bags . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3.4 Attachment of the DSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4 Inhalation bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.1 Automatic diluent valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.2 Manual diluent bypass valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5 Exhalation bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5.1 Manual oxygen bypass valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5.2 Overpressure valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.6 Oxygen tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.6.1 Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.6.2 Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.6.3 Reduction valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.6.4 Pressure reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.7 Diluent tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1

1.7.1 Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.7.2 Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.7.3 Reduction valve and pressure reading . . . . . . . . . . . . . . . . . . . . . . . 20

1.7.4 Backup regulator (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.8 CO2 scrubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.9 Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.9.1 Control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.9.2 Direct measurement of ppO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.9.3 Measurement of He content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.9.4 Pressure and depth measurement . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.9.5 Temperature measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.9.6 Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.9.7 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.10 Visual display units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.10.1 Handsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.10.2 Head-up display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.10.3 Buddy display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

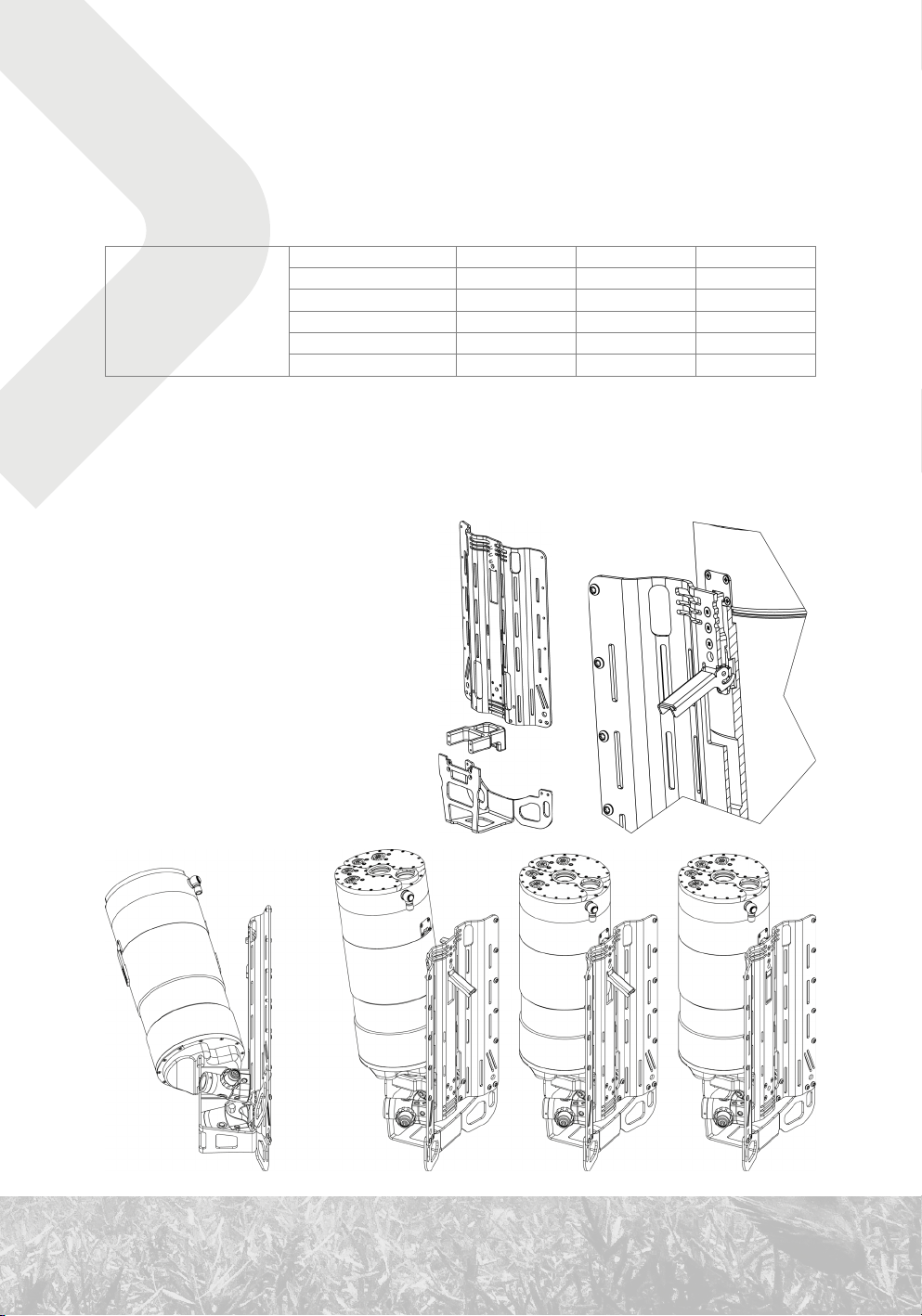

1.11 Backplate and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.12 Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.13 Buoyancy compensator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.14 Ballast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.15 Weights of individual parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2. Control-unit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1 Control elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.1 Meanings of inputs in surface modes . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.2 Meanings of inputs in dive modes . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.1.3 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.2 Switching on the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.2.1 Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3 Surface mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.1 Entering surface mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.2 Surface mode primary screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.3 Surface mode O2 sensors screen . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3.4 Switching to other modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3.5 ppO2 control in surface mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4.1 Editor use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.2 Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.3 Mixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

2.4.4 Decompression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.4.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.4.6 Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.4.7 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.4.8 Faulty sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.4.9 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.5 Dive mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.5.1 Detailed screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.5.2 Synoptic screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.5.3 Big Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.5.4 Dive profile screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.5.5 Sensors screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.5.6 TTS Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.6 CCR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.6.1 Entering CCR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.6.2 Switching to other modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2.6.3 ppO2 regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.6.4 Decompression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.6.5 Specific handset control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.7 Manual CCR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.7.1 Entering manual CCR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.7.2 Switching to other modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.7.3 ppO2 regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.7.4 Decompression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.8 Bailout OC mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.8.1 Entering bailout OC mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.8.2 Switching to other modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.8.3 Mixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.8.4 Decompression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.8.5 Specific handset control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.9 Ascent plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.10 Setup in Dive mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.11 Games . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2.11.1 Sokoban . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.11.2 Snake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3. Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.1 Dive plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.1.1 Planner settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.1.2 Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3

3.2 Dive preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.2.1 Replacement of CO2 sorbent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.2.2 Assembling the rebreather body . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.2.3 Mounting the rebreather body . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.2.4 Attaching the counterlungs and hoses . . . . . . . . . . . . . . . . . . . . . . 71

3.2.5 Tank filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.2.6 Battery charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.2.7 Helium sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.2.8 Calibration of the oxygen sensors . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.9 Preparing the bailout apparatus . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.2.10 Setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.2.11 Directional valve check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.2.12 Physical inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.3 Pre-dive inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.3.1 Internal testing of the control units . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3.2 Pressure sensor test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3.3 Comparison of oxygen sensors and their calibration . . . . . . . . . . . . . . 79

3.3.4 Helium-sensor test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.3.5 Battery testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.3.6 Solenoid testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.3.7 HUD inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.3.8 BD inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.3.9 Negative pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.3.10 Positive pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.3.11 Predive checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.3.12 Prebreathe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.4 Diving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.4.1 Breathing high oxygen content gases . . . . . . . . . . . . . . . . . . . . . . . 85

3.4.2 Putting on the apparatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.4.3 Using the DSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.4.4 Monitoring of devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.4.5 Switching to CCR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.4.6 Water entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.4.7 Submersion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.4.8 In-water check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.4.9 Descent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.4.10 Controlling buoyancy and trim . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3.4.11 Mask clearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.4.12 Increased physical exertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.4.13 Ascent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4

3.5 Post-dive procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.5.1 Immediately after surfacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.5.2 CO2 scrubber maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.5.3 Cleaning and disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.5.4 Battery care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.5.5 Dive log download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.5.6 Long-term storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.6 Emergency procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.6.1 Emergency ascent (bailout) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.6.2 Oxygen-source malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.6.3 Diluent-source malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3.6.4 Scrubber malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

3.6.5 Inadvertent release of the mouthpiece . . . . . . . . . . . . . . . . . . . . . 100

3.6.6 Flooding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

3.6.7 Loss of buoyancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.6.8 Rescue on the surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.6.9 Malfunction of oxygen-concentration measuring . . . . . . . . . . . . . . . 102

3.7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.7.1 Tools and replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.7.2 Detection of leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.7.3 Regular service inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.7.4 Long-term maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.7.5 Firmware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3.8 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3.8.1 By car . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3.8.2 By boat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3.8.3 By plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5

Introduction

Use of this manual

This user manual is part of the CCR Liberty documentation.

The CCR Liberty is intended to be used exclusively by a trained person who is capable of fully

understanding the instructions contained in this manual or is in the process of training with

the CCR Liberty in a course accredited by the manufacturer. The initial requirements of such

a training course include qualification for diving with trimix recognized by a training agency

and sufficient experience with technical diving.

Responsibility of the CCR Liberty user

Strong emphasis was placed on reliability during the development of the CCR Liberty. Individual

internal parts are separated in order to minimize the impact that failure of any given part

may have on the rebreather’s basic functionality. A number of systems have multiple backups.

The logic of the CCR Liberty’s control never prohibits the start of a dive even in the event that

malfunctions are detected; it only indicates the status if able to do so in light of the damage.

When cave diving, the inability to submerge can mean not being able to return from a dive;

therefore, the CCR Liberty does not impede submersion.

The user must always decide responsibly whether he/she switches to a backup apparatus or

even starts a dive with a partially malfunctioning rebreather.

A CCR Liberty user must accept the fact that diving involves risk. Following everything that

the user has learned in the CCR Liberty’s technical documentation and in training on diving

with this rebreather can reduce the risk but cannot eliminate it. Safety when diving is further

improved by regular training, methodical education and following good diving practices. Diving

with a rebreather requires a far higher degree of carefulness and discipline than diving with an

open-circuit apparatus.

If you do not accept the risk and you are not a trained, careful and disciplined diver, do not dive

with the CCR Liberty.

The manufacturer does not bear any responsibility for use of the CCR Liberty if the apparatus

has been modified in any way that is not stated in this manual or in the technical guidelines

issued by the manufacturer.

6

System of documentation

Version

The technical documentation is subjected to a process of continual development and

improvement. Therefore, please regularly check the website at www.CCRLiberty.com for

updates.

This manual provides operating instructions for the hardware and software (firmware) version

of the CCR Liberty written on the tittle page.

Technical guidelines

The manufacturer can issue technical guidelines. It is strongly recommended that the user

regularly checks www.CCRLiberty.com for new guidelines. Registered users will receive

notifications by e-mail.

Update of printed documentation

The electronic form of the manual is always available in its complete, updated form.

The electronic and printed forms of the manual may not be completely identical. In case of

insignificant changes (correction of minor typing errors, for example), only the electronic

version is updated.

User support

Registered users are entitled to technical support. The extent of free support can be limited.

The technical support department at Liberty systems s.r.o. will provide limited support for

potential and unregistered users. Prior to submitting a question, please familiarize yourself

with the general principles of rebreather diving with trimix and the freely available CCR Liberty

technical documentation.

7

Technical data

Depth limits

The maximum depth for which The CCR Liberty meets the requirements of the Harmonized

Standard EN 14143:2013 is 100 m.

Diluent Max. depth

Air 40 m

tmx 21/35 66 m

tmx 18/45 78 m

tmx (heliox) 10/90 > 78 m

Additional limitation of depth depends on the used diluent, see 72 Tank filling – Diluent.

The CCR Liberty currently is configured with Apeks Environmentally sealed DST4 1st stages,

the Maximum Operational Depth of the unit with this 1st stage configuration is 170 m. Beyond

170 meters the gas reduction valves ie. 1st stage regulators MUST be replaced with the Apeks

UST4 Environmentally unsealed 1st stage kit.

All components are tested in overpressure 6 MPa (depth 600 m). The depth gauge is checked

and calibrated in overpressure 3.5 MPa (depth 350 m). EC Type-examination was performed to

a 100 m simulated depth.

Water temperature limits

The CCR Liberty is intended for use in water temperatures above 4 °C and below 34 °C

according to the requirements of EN 14143:2013 (Article 5.1).

The minimal temperature is determined through CO2 scrubber duration tests, which are done

at 4 °C.

CO2 scrubber duration limit

The maximum safe operating period of the sorbent is 168 min, determined by a test in

accordance to EN 14143:2013 (Article 6.6.2). During the test 1.6 l/min of CO2 were added to the

8

breathing loop with ventilation of 40 l/min in water with temperature 4 °C, exhaled gas with

temperature 32±4 °C, 40 m depth and limit at ppCO2 5 mBar.

The sorbent’s actual maximum operating period can differ depending on the sorbent,

temperature, depth and the diver’s physical effort.

In normal conditions scrubber duration is considered to range from 4 h in deep cold water with

moderate work to 6 hours for an easy dive. For details see 66 Sorbent service life.

Weight

The total weight of The CCR Liberty, readied for a dive, including fillings, is approx. 37 kg.

For details see 30 Weights of individual parts.

The recommended service intervals are at 1 year, 3 years and 5 years.

The servicing of the unit can only be performed by authorised service technician or technical

centre.

Not performing services at regular intervals may result in voiding your warranty.

Date of issue: 29. June 2018

CU HW rev. 1.4, HS HW rev. 3.0, FW 2.11

Authors: Adam Procháska, Jakub Šimánek, Aleš Procháska

Published by Liberty systems s.r.o., CCRLiberty.com

9

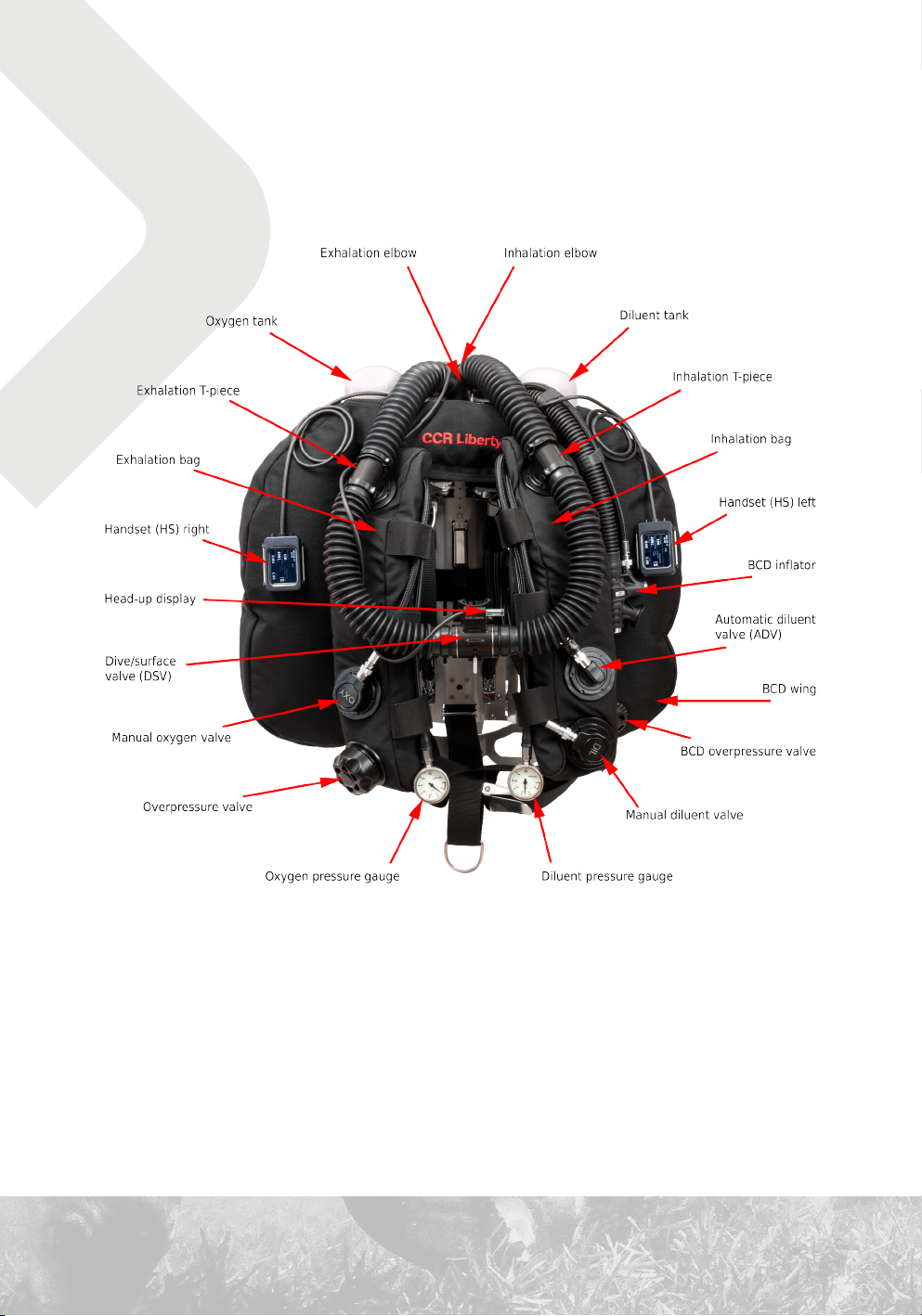

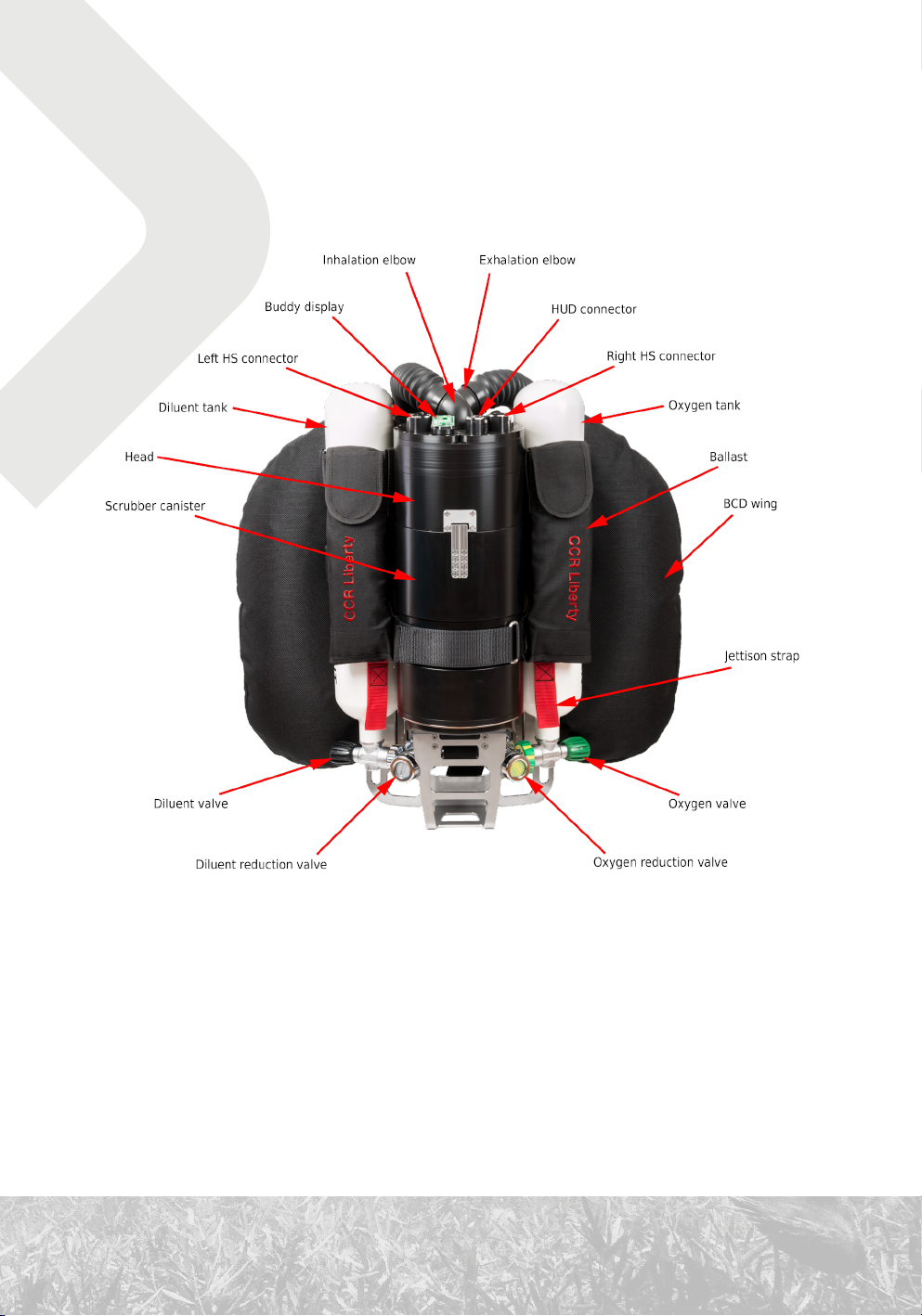

1. Technical design

10

11

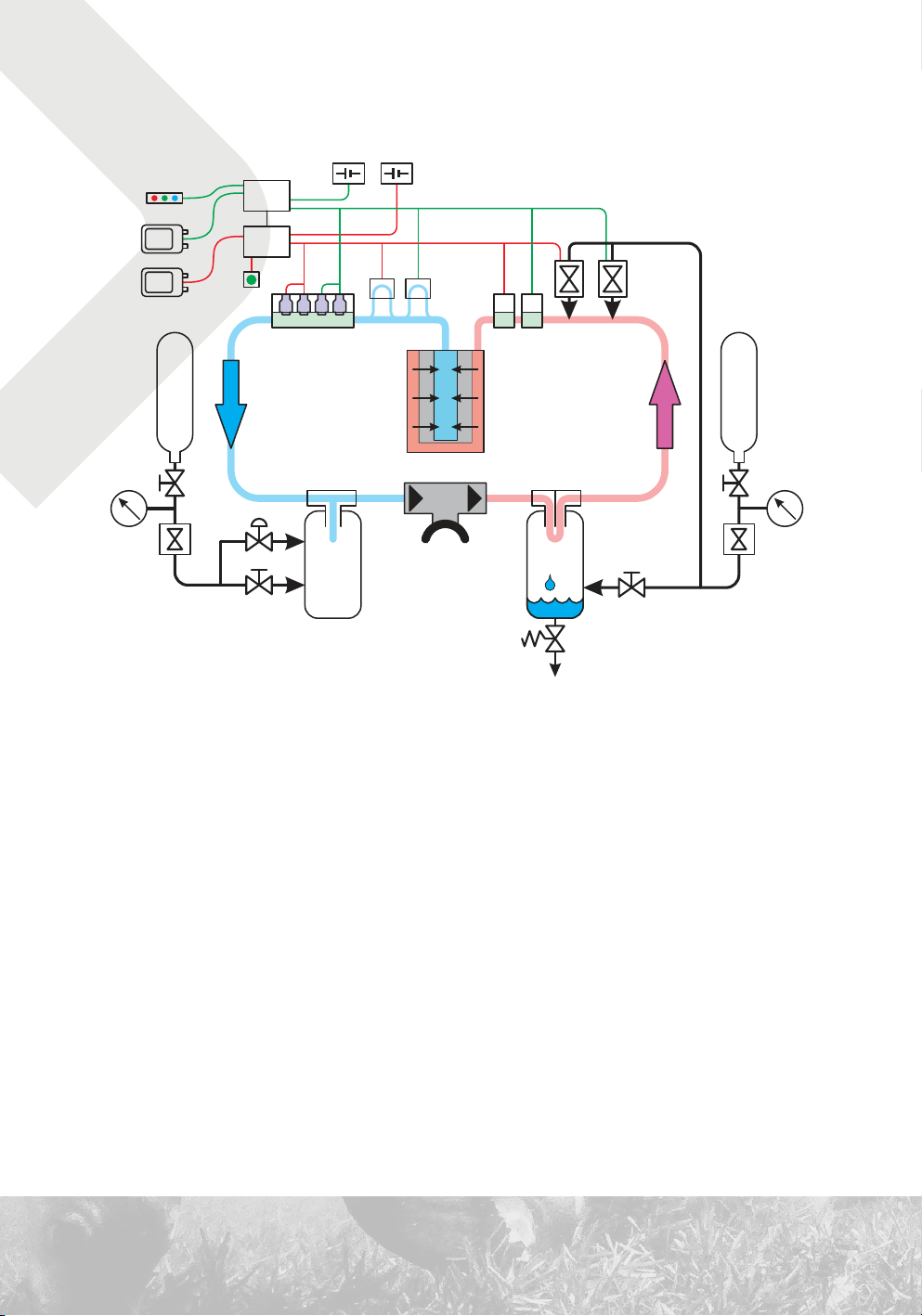

1.1 Basic schematic

Displayunits

Diluent

reduction

valve

HUD

HS

HS

Buddy

display

DILUENT

Manualdiluentvalve

Controlunits

ADV

CU

CU

ppO sensors

2

Inhalation

bag

Rechargeablebatteries

He%

sensors

Pressure

&temperature

sensors

CO absorbent

Dive/surface

valve

Watertrap

Overpressure

valve

2

Exhalation

bag

Solenoid

valves

Manualoxygenvalve

OXYGEN

Oxygen

reduction

valve

The principle of the rebreather consists in recycling the breathing mixture. Carbon dioxide

is removed from the exhaled mixture and is again prepared for the next inhalation after

replenishment with oxygen. The composition of the breathing mixture changes continuously.

12

1.2 Dive/surface valve

The breathing mixture is delivered to the

dive/surface valve (DSV) through the

corrugated hose from the left. When inhaling,

the mixture passes through the inhalation

valve to the mouthpiece and then into the

diver’s respiratory tract. When exhaling, it

passes through the exhalation valve into the

corrugated hose on the right.

The direction of the mixture’s flow is indicated

on the DSV.

1.2.1 Inhalation valve

The inhalation valve ensures that the

exhaled mixture cannot directly return to the

inhalation bag and is not repeatedly inhaled

by the diver without the removal of carbon

dioxide and the addition of oxygen.

The inhalation valve is situated within the

connection of the left corrugated hose.

A similar mushroom valve can be found in, for example, the exhalation valve of the second

stage of the regulator of an open-circuit apparatus.

This is one of the most critical parts of the rebreather. It is difficult to detect a malfunction in

this part during a dive, and such a malfunction can lead to loss of consciousness.

1.2.2 Exhalation valve

The exhalation valve directs the exhaled mixture via the corrugated hose to the exhalation bag.

It ensures that the diver does not directly re-inhale the exhaled mixture.

The exhalation valve is situated within the connection of the right corrugated hose.

13

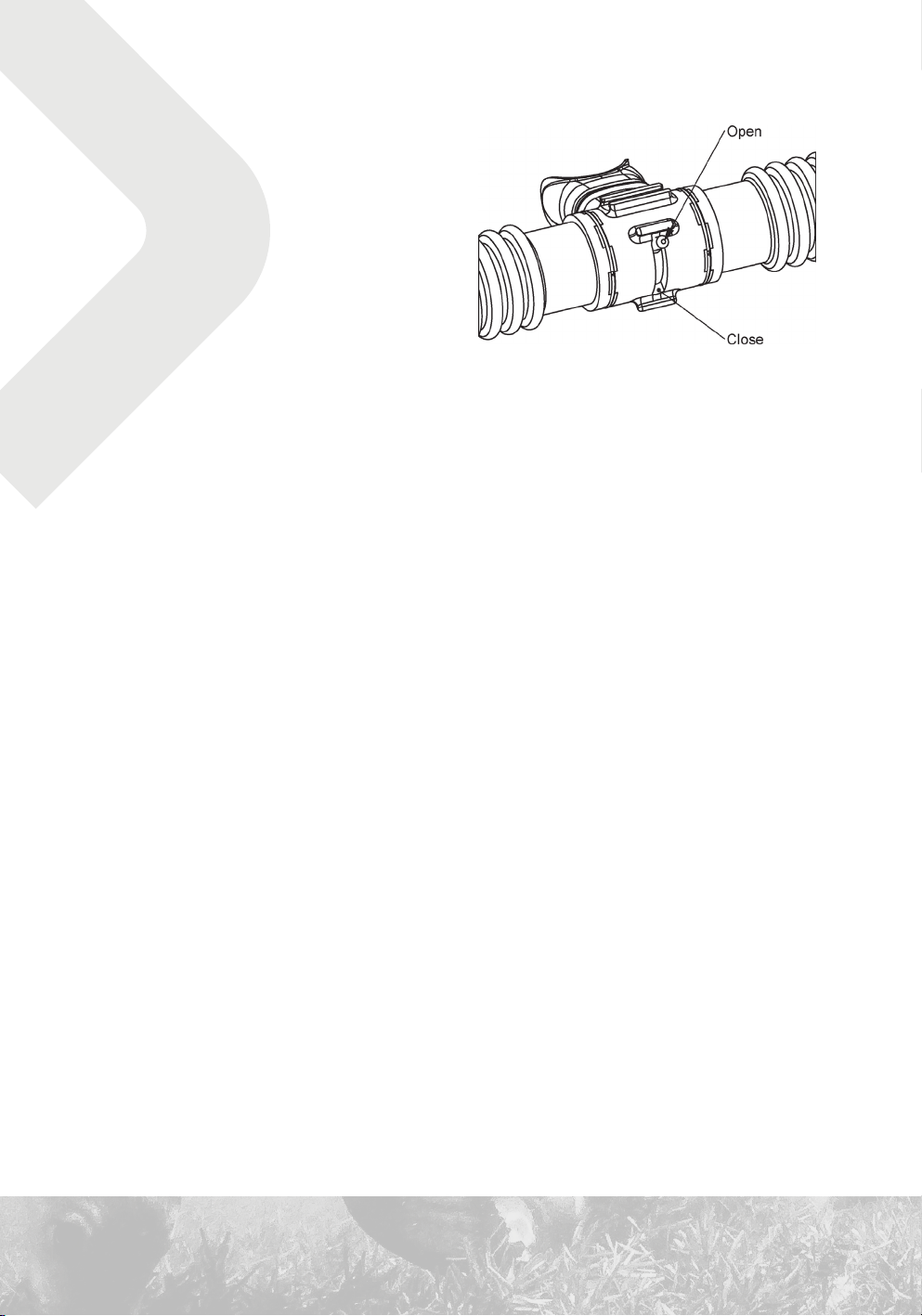

Closing the dive/surface valve

If the diver is in the water and not using the

DSV, the DSV must be closed. Otherwise, the

circuit will be flooded with water.

Closing the DSV is done by using the gate

handle in the front part of the DSV. In the open

position, the handle is put up; in the closed

position, it is down.

1.2.3 Mouthpiece

Tightly sealed mouthpiece in the diver’s mouth prevents water from entering into the circuit.

The DSV and corrugated hoses function with greater force than the regulator of an open-circuit

apparatus. Therefore, an anatomically suitable shape of the rebreather’s mouthpiece and

proper clenching in the mouth are very important.

We do not recommend using a mouthpiece that can be shaped to the diver’s bite after heating.

This kind of mouthpiece restricts the movement of the lower jaw, which leads to unilateral

stress and will rapidly exhaust the mastication muscles.

1.2.4 Usage with a full face mask

Even though the mechanical dimensions would allow the connection of the DSV to a full face

mask, in a full face mask it is not possible to switch the mixture inlet from an open circuit with

an inlet from a rebreather. One of the reasons for this is the necessity of defogging the visor.

Consult with the manufacturer regarding possibilities of connecting the rebreather to a full

face mask. Use of such an apparatus will require procedures that deviate from this manual and

from standard procedures taught in a course accredited by the rebreather’s manufacturer.

14

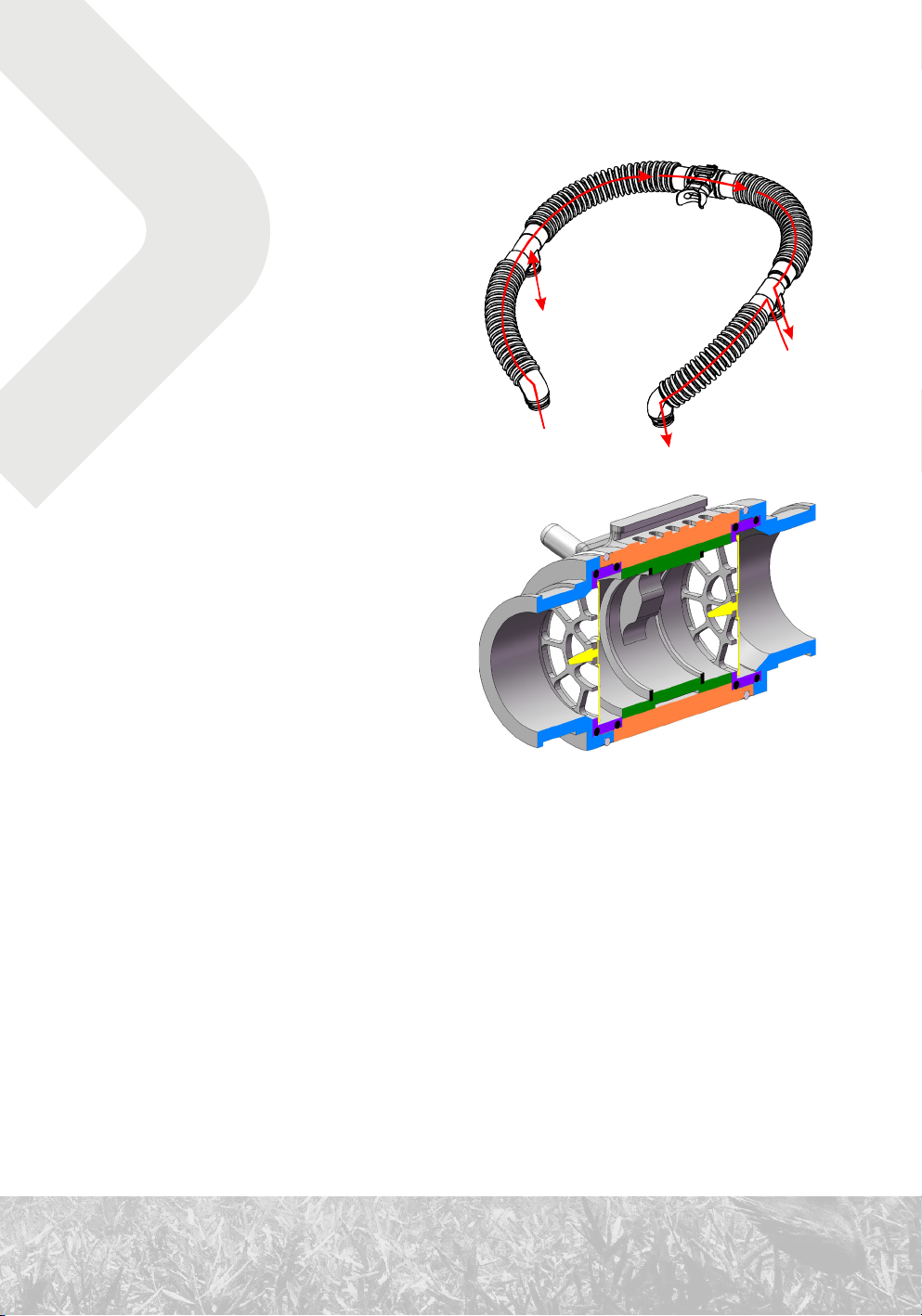

1.3 Corrugated hoses and accessories

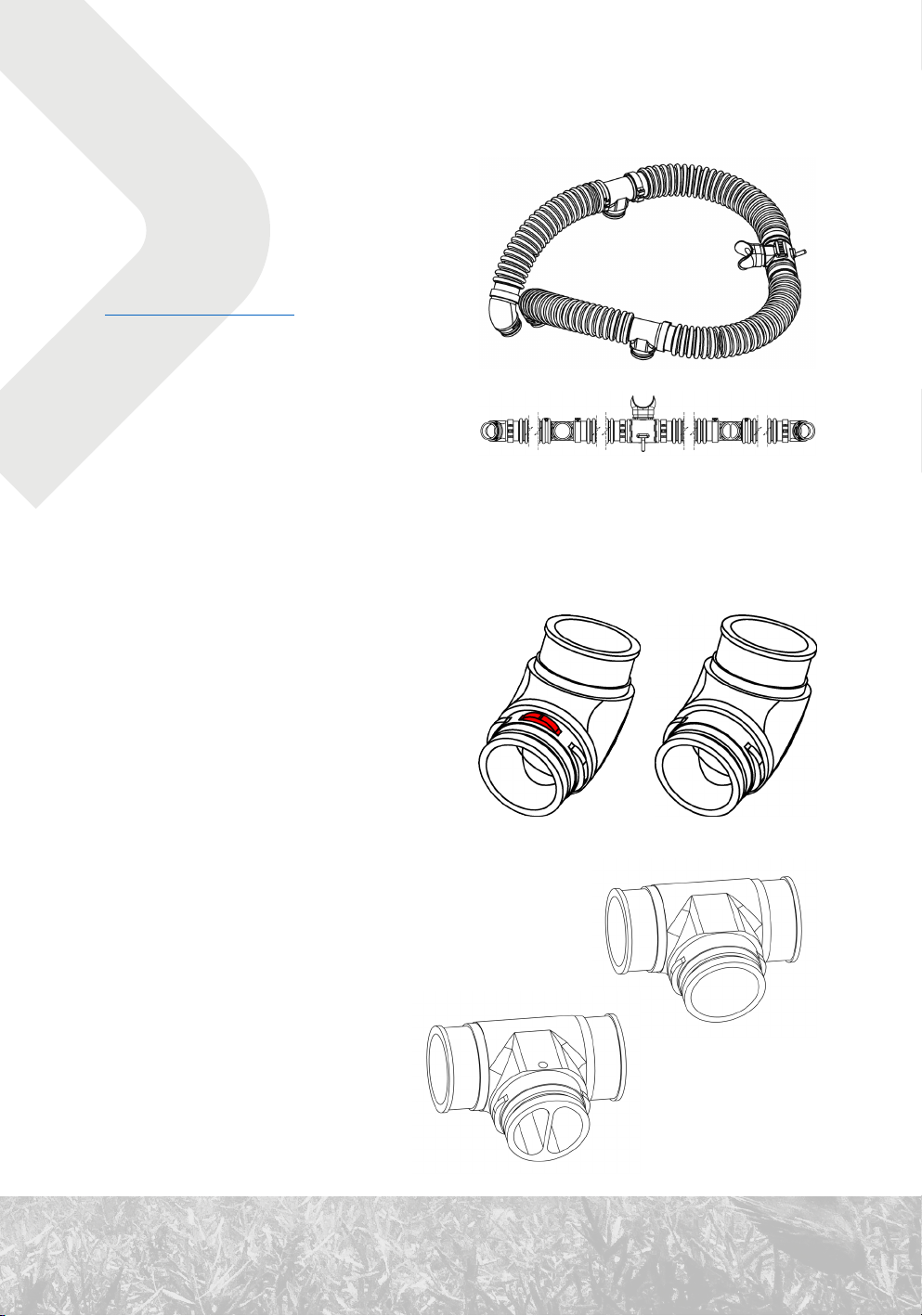

1.3.1 Hoses

The corrugated hoses are made of EPDM

rubber. Compatible chemical agents must

be used for cleaning and disinfection (see 92

Cleaning and disinfection).

The corrugated hoses can be damaged if

subjected to excessive stress. In particular, it

is necessary to avoid perforation, cutting and

excessive wear. Avoid long-term deformation

of the hose, for example when storing the unit.

Do not use the hoses as a handle.

The corrugated hoses are one of the least durable mechanical parts of the CCR Liberty. Pay

appropriate attention to protecting them.

1.3.2 Attachment to the head

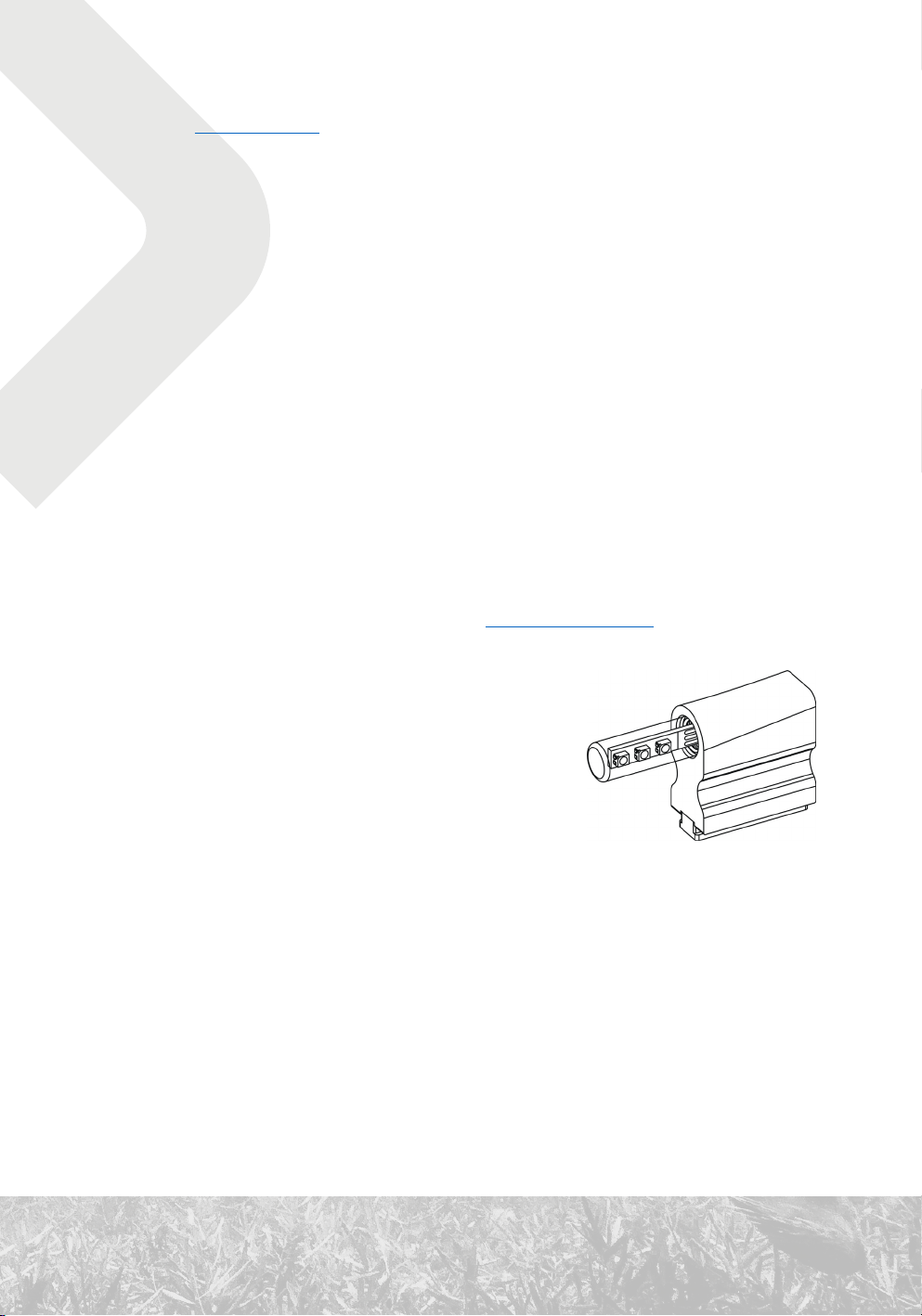

Unlike almost all other bayonet connectors

on the CCR Liberty, the bayonet connector on

the exhalation side has three protrusions. This

prevents incorrect attachment of the hoses.

Elbow on the exhalation side (left) and

inhalation side (right).

1.3.3 Connection to the breathing bags

The T-pieces have standard bayonet connections. On the

exhalation side, the T-piece has a partition that directs any

water that has entered the DSV to the exhalation bag and

improves the blending of the

mixture with oxygen added using

the manual bypass valve.

15

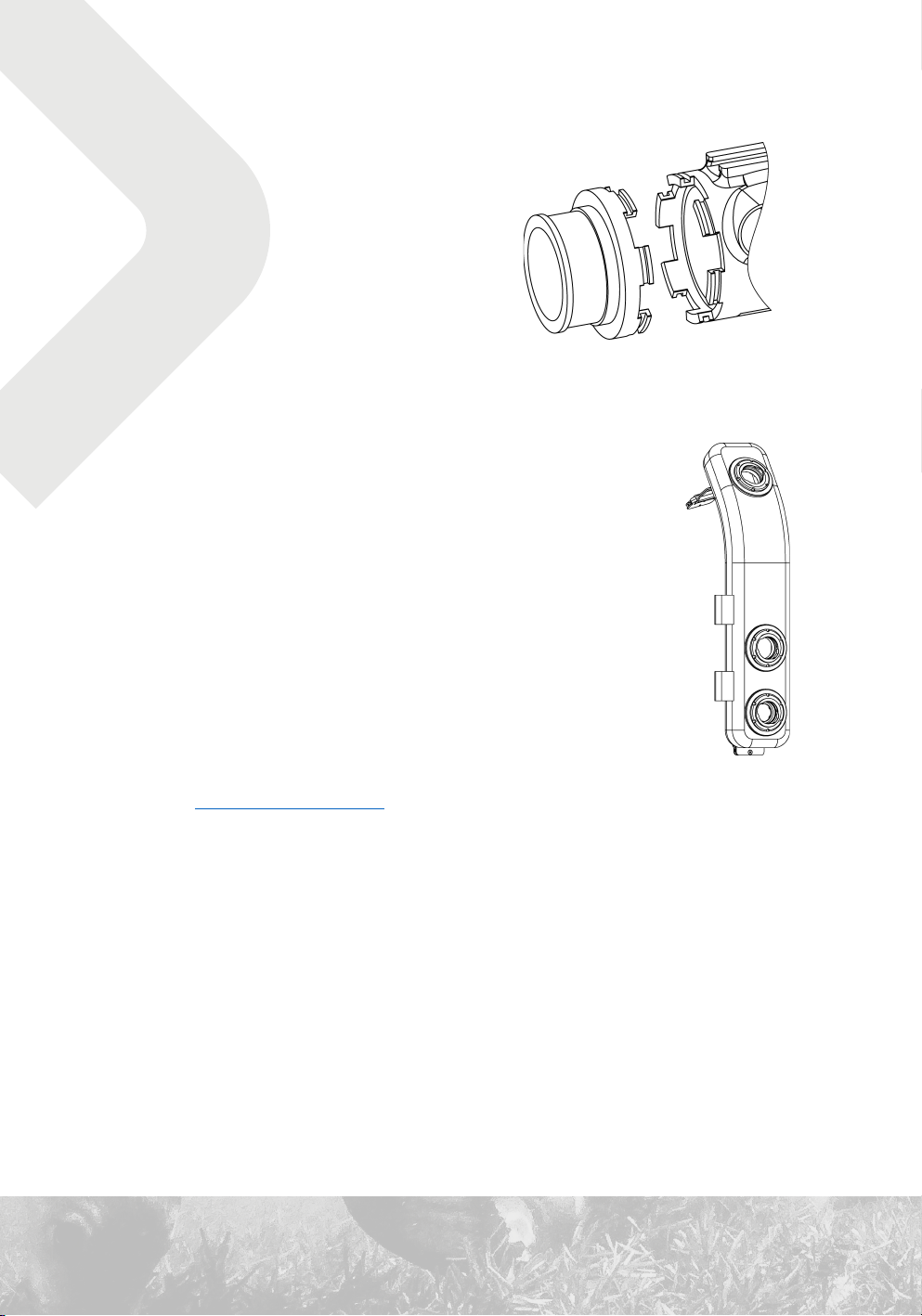

1.3.4 Attachment of the DSV

Attachment to the corrugated hoses is done

with axial teeth that fit together and are

secured with a wire retaining ring.

The baskets of the mushroom valves are

inserted into the connector. When handling

the baskets, pay attention to their correct

orientation.

1.4 Inhalation bag

The inhalation bag is mounted on the left part of the harness (from the

diver’s perspective when wearing the CCR Liberty).

The external cover is made from a resilient textile, ensuring mechanical

protection. The internal bag is made from polyurethane. It is connected to

the breathing circuit with a T-piece via the upper bulkhead with a bayonet

connector.

The inhalation bag is affixed to the harness with two stainless-steel

buckles and with Velcro flaps. It can be easily removed for cleaning,

disinfection and other handling.

See also 92 Cleaning and disinfection.

1.4.1 Automatic diluent valve

The automatic diluent valve (ADV) is mounted in the middle bulkhead with a bayonet connector.

When the volume of the inhalation bag decreases, the ADV is pressed. The ADV then

automatically adds diluent to the breathing circuit.

The ADV can be closed by sliding the collar.

The sensitivity of the ADV can be decreased with an additional spring, which is included as

a spare part.

16

1.4.2 Manual diluent bypass valve

The manual diluent bypass valve is situated in the lower bulkhead of the inhalation bag and is

equipped with a bayonet connector.

It is attached to the low pressure (LP) hose with a seatec-style quick-release connector.

It is operated by pressing the center button.

The safety lock prevents diluent valve from accidentally falling out. Follow

these steps to remove.

1.5 Exhalation bag

The exhalation bag is situated on the right side of the harness It’s design and

the way it is connected to the harness and the breathing loop are similar to

those of the inhalation bag.

1.5.1 Manual oxygen bypass valve

The manual oxygen bypass valve is situated in the middle

bulkhead of the exhalation bag and is equipped with a bayonet

connector.

It is attached to the intermediate pressure hose with an oxygen

quick-release connector. This connector is like a standard

seatec-style quick-release connector with a collar. A standard

connector cannot be connected to the oxygen quick-release

connector. Though it is possible to connect the oxygen hose to the normal connector. Do not

remove the collar from the oxygen connector as connecting the wrong gas to the wrong valve

could potentially be dangerous. This is a requirement of the EN 14141 norm.

The bayonet connector on the oxygen bypass valve has three protrusions.

Use oxygen-compatible lubricant for maintenance of the oxygen bypass valve (We recommend

DuPont Krytox GPL-226).

17

1.5.2 Overpressure valve

The overpressure valve (OPV) is mounted in the lower bulkhead of

the exhalation bag and is equipped with a bayonet connector.

The required overpressure is regulated via rotation. When set to

minimal overpressure (by turning counterclockwise), the valve is

opened; only a mushroom valve ensures minimal overpressure.

A safety lock prevents the OPV from accidentally falling out. To remove the valve push it in to

unlock it and rotate in the direction of the arrows.

1.6 Oxygen tank

1.6.1 Tank

The CCR Liberty uses a three-liter steel tank with 100 mm diameter and 200 bar filling

pressure. The original 300 bar filling pressure of the bare tank was changed according to valid

technical standards.

The tank is labeled OXYGEN.

The tank is situated on the right from the diver’s perspective when wearing the CCR Liberty.

18

When connecting the oxygen tank to the unit screw in the hand wheel only when the tank is

upright. If you straighten the bottle when it is screwed in you will tighten the threads to the

point when it will be hard to remove without the usage of tools

For more information on filling, see 73 Oxygen.

1.6.2 Valve

The valve has a M26×2 200 bar outlet connection. The valve is not compatible with standard

DIN valves to eliminate possible mix-up between oxygen and diluent bottles, this is

a requirement of the EN 14141 norm.

1.6.3 Reduction valve

The CCR Liberty uses an Apeks DST4 first-stage regulator with a specially made low-pressure

turret, which is mounted on the backplate. This serves as the lower tank-mounting point; in the

middle part, the tank is attached with a Velcro strap.

The Apeks DST4 first-stage regulator comes with an environmentally sealed first-stage kit.

This seal causes an operational limitation at a depth of 170 meters. It is recommended that in

order to conduct dives beyond 170 meters the diver must replace the first-stage regulator with

the Apeks UST4 environmentally unsealed kit.

The reduction valve is equipped with an intermediate-pressure safety overpressure valve.

1.6.4 Pressure reading

The oxygen pressure gauge is situated on the right side; the HP hose runs through an opening in

the backplate.

1.7 Diluent tank

1.7. 1 Tank

The CCR Liberty uses a three-liter steel tank with 100 mm diameter and 230 bar filling

pressure. The original 300 bar filling pressure of the bare tank was changed because a 230 bar

valve is used.

The tank is labeled DILUENT.

19

The tank is situated on the left from the diver’s perspective when wearing the CCR Liberty.

For more information on filling, see 72 Diluent.

1.7. 2 Valve

The valve has a DIN G 5/8” 230 bar outlet connection.

1.7.3 Reduction valve and pressure reading

The design is similar to that of the oxygen tank, only reversed.

1.7. 4 Backup regulator (optional)

The second stage of a regulator may be connected to the output of the first stage of the

diluent through LP hose of appropriate length. This regulator can be used as a backup if the

diluent at a given depth is breathable (oxygen partial pressure between 0.16 and 1.6 bars).

Having the backup regulator connected to the diluent may be useful for sanity breaths and for

prolonged switching to a backup apparatus.

However, it is advised to use the bailout only in special circumstances, for example during

extreme shallow dives.

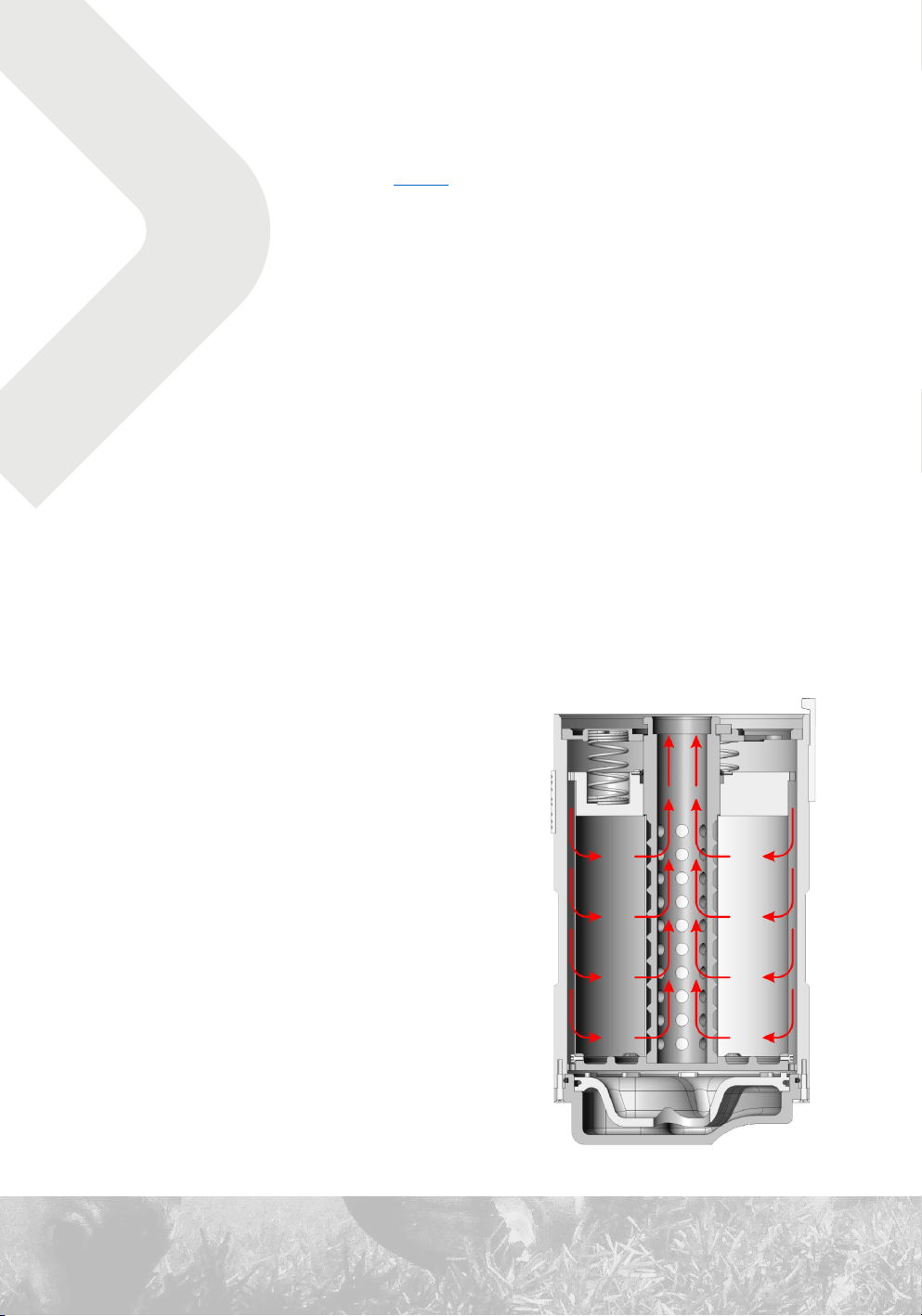

1.8 CO2 scrubber

The CCR Liberty uses a radial scrubber. The breathing

mixture flows from the outside to the center of the

scrubber cartridge.

The scrubber consists of a scrubber cartridge inserted

into a scrubber canister. A water trap is situated in the

lower part of the canister.

The walls of the cartridges consist of external and

internal metal mesh. A lid presses down on the scrubber

cartridge by means of springs attached to the pressure

plate. The pressure plate is fastened to the central tube

with a retaining ring.

20

The scrubber cartridge capacity is

approximately 2.5 kg of sorbent. The

sorbent volume is approximately

2.82-2.99 l.

The service life and replacement of

the sorbent are described in chapter

66 Replacement of CO2 sorbent.

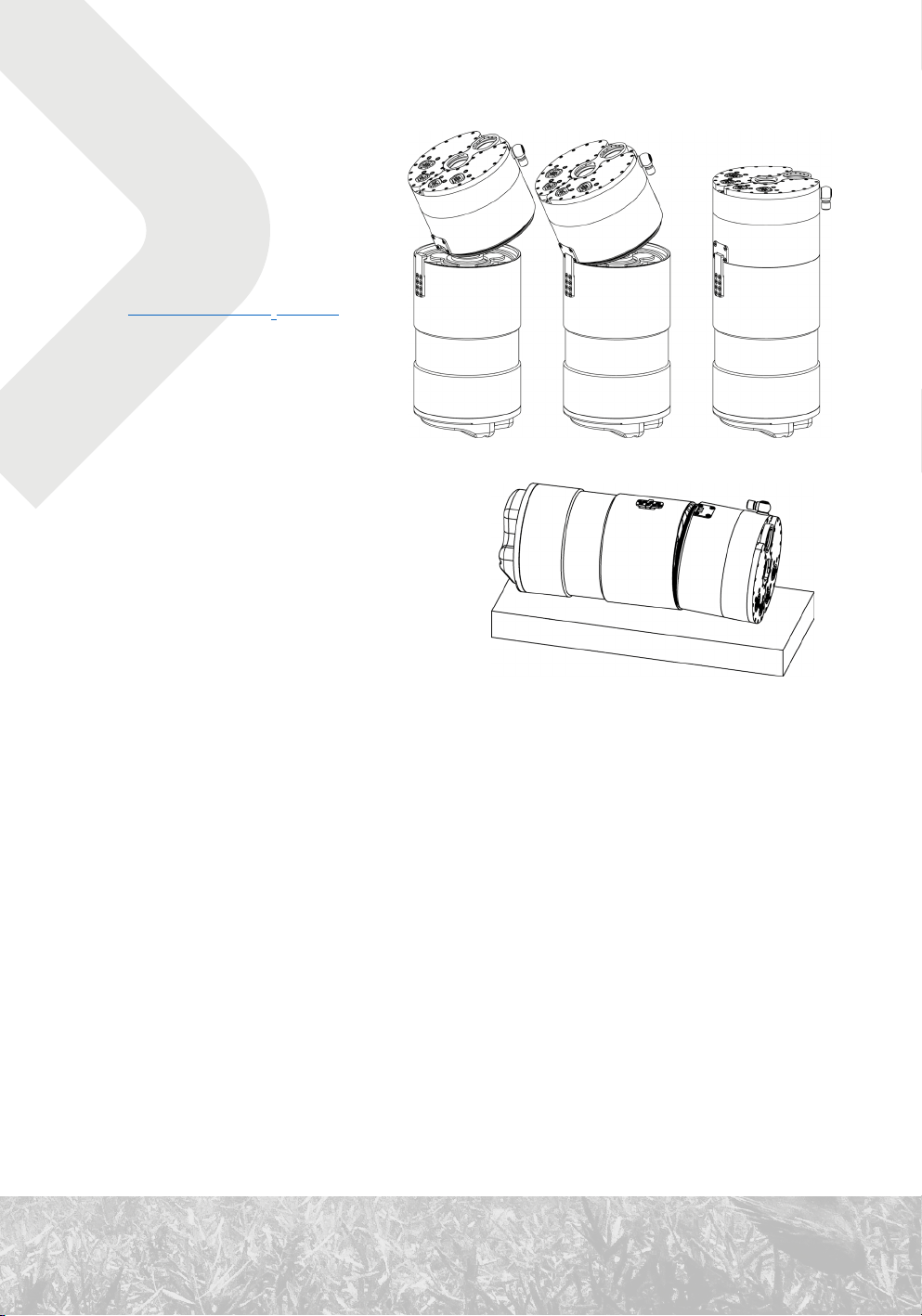

1.9 Head

The head is mounted on the CO2

scrubber canister.

When mounting the head, push the

scrubber-canister pin into the opening on

the head and close it.

If it is difficult to remove the head, place

the rebreather on a hard surface with the

pin facing downwards, as shown in the

illustration. Press down on the head and the scrubber canister with your hands.

1.9.1 Control units

The control units (hereinafter referred to as the CUs) are independent. A display unit (hereinafter referred to as the HS) is connected to each CU, which each has its own power source, solenoid, temperature gauge and pressure, O2 partial pressure and He concentration sensors.

If one control unit fails, the other control unit takes over automatically.

CUs and HSs are independent computers communicating via a bus. Each handset displays the results of both CU’s activities and is used to control both CUs. Each HS is powered through the corresponding CU. In the event of a malfunction of both handsets, either CUs (or the remaining functional CU) will continue to regulate ppO2 without change according to the last adjusted setpoint.

If communication between CUs breaks down, each unit controls one solenoid. The control

algorithm is sufficiently robust to ensure that any deviations of ppO2 from the allowed limits

will not occur during dual, parallel regulation.

21

Connection to a personal computer

The memory of operating protocols and content of the memory card can be read using a USB

adapter connected to the handset connector as a mass storage device (like a flash drive). The

connection to Windows, Mac, Linux, Android and iOS was tested, but there is no guarantee of

compatibility with all operating systems and all computers.

During the time of USB connection, the control unit is powered from the USB port and, at the

same time, the battery is charged.

Each control unit contains the same dive logs, to download them you only need to connect one

control unit to the computer.

1.9.2 Direct measurement of ppO

To measure ppO2 use only DIVESOFT R22D-type sensors. The usage of other sensors from other

manufacturers is prohibited.

Two sensors are connected to each CU. All sensors are located on the inhalation side. Both CU

have access to all four oxygen sensors as the control units continually exchange the measured

data.

The diver can manually exclude a sensor from operation and manually return an excluded

sensor to averaging. The manual option has a higher priority than automatic detection of faulty

sensors. If all sensors are excluded, the CCR Liberty can be switched to a backup algorithm for

calculation of the partial pressure of oxygen indirectly using measurement of the He content

(assuming the used diluent contains >20% He).

Circulation of the mixture in the breathing loop is necessary for the measurement accuracy. If

the user does not breathe from the rebreather, the mixture in the vicinity of the oxygen sensors

can have a different proportion of oxygen than the mixture in different parts of the breathing

loop and the displayed data can thus be inaccurate.

A discrepancy can similarly occur in the event of rapid descent, when a larger amount of

diluent is added, or when the setpoint is changed to high and ppO2 in the loop is changing to the

new level

2

The sensors are constantly automatically evaluated. The ppO2 measured by one sensor is

always compared to average of the other sensor. This way each individual sensor is constantly

being cross-checked and monitored for possible deviations. If the average deviation of the

22

sensors from the diameter exceeds 0.1 bar, the sensor that deviates most from the average is

automatically excluded.

Only one sensor can be automatically excluded at the same time, and the maximum number

of automatically excluded sensors is 2. There will always be at least two sensors that the

diver has to evaluate by themselves. This procedure is described in Chapter 3.4.4 Monitoring of

devices.

WARNING: Sensor exclusion works on the principle of a mathematical algorithm. Despite the

efforts of developers to find the ideal risk-control solution, there is still a chance that the

excluded sensor will only be the only right one. Always verify your oxygen sensors.

Refer to the chapter “Oxygen sensors” on how to handle and maintain your sensors.

1.9.3 Measurement of He content

The helium concentration is determined by the velocity of sound in the mixture. The He

concentration sensors are connected to the inhalation side.

A pressure drop caused by circulation of the mixture in the breathing

loop allows the mixture to pass through the sensor. If the user does

not breathe from the rebreather, this will not occur and sensor

reading may be inaccurate.

If the utilized diluent contains >20% He and its composition is known,

the He-concentration measuring function can be used for reverse

determination of the concentration of oxygen in the mixture based

on the fact that the ratio of inert gases remains constant (process

according to patent no. 303577). This principle of measuring the

oxygen concentration (and its subsequent automatic conversion on

the basis of the known ambient pressure to partial pressure) is used as the backup method of

measuring ppO2 in case all electrochemical ppO2 sensors malfunction.

Oxygen measuring using helium sensors must be manually turned on in Setup / Faulty sensors

/ pO2 source. This method is intended for use only in emergency situations. If possible, use

bailout apparatus.

The use of helium sensors also depends on Liberty’s settings. For the helium sensor function,

the “TMX only” must be set in Menu / Setup / Preferences / He Measurement.

23

For proper functioning of helium sensors, the sensors must be calibrated from time to time.

Refer to Calibrating Helium Sensors for the calibration procedure

Always keep your helium sensors dry to ensure their long lifetime and functionality (see

also 92 – 3.5.1 Immediately after surfacing).

Do not disassemble the sensors; disassembly can result in irreparable damage.

WARNING: Do not remove the helium sensors from the unit, even when faulty. Their removal

will “short -circuit” the scrubber, which won’t be able to filter CO2 from the breathing mixture.

1.9.4 Pressure and depth measurement

Each of the CCR Liberty’s control units uses dual pressure sensors. The first sensor, intended

for measuring low pressure, is used for determining sea level, for calibration of the ppO2

sensors, and for improving the accuracy of depth data in shallow depth.

The second sensor is intended mainly for measuring hydrostatic pressure. The maximum scope

of the sensor corresponds to the depth of 300 m.

1.9.5 Temperature measurement

The temperature in the breathing circuit is measured by temperature sensors within the

pressure sensors. The water temperature sensors are situated in the handsets.

Temperature data serve primarily for correction of the measuring of other quantities. The water

temperature shown on the HS display is only approximate.

1.9.6 Solenoids

The control units communicate with each other and, in normal circumstances, open the

solenoid valves, which supply oxygen to the breathing circuit.

The solenoids are opened alternately left – right in the interval of 6 s. The solenoid opening is

indicated in the dive mode by the equator in the left or right bottom corner of the handset screen.

1.9.7 Power supply

CCR Liberty uses two Li-Ion batteries, one to power each control unit. The minimum service life

of Li-Ion batteries is six months. The typical service life of the batteries is two years.

24

See also 74 Battery charging.

Battery compartments are pressure resistant. If overpressure is formed inside a battery

compartment because of battery malfunction or helium diffusion, then an overpressure valve

will release excess gases out of the rebreather and into the surrounding water.

1.10 Visual display units

1.10.1 Handsets

The handsets provide the CCR Liberty’s user with comprehensive information on the

rebreather’s status and the course of the dive. All functions of the control units are controlled

using the handsets.

The functionality of both handsets is identical. Each handset controls both CUs simultaneously.

In the event of a malfunction of one handset, the diver simply uses the other handset. During

a dive, it is possible to set a different display mode on each handset.

For more information on handset operation, see 31 Control-unit operation.

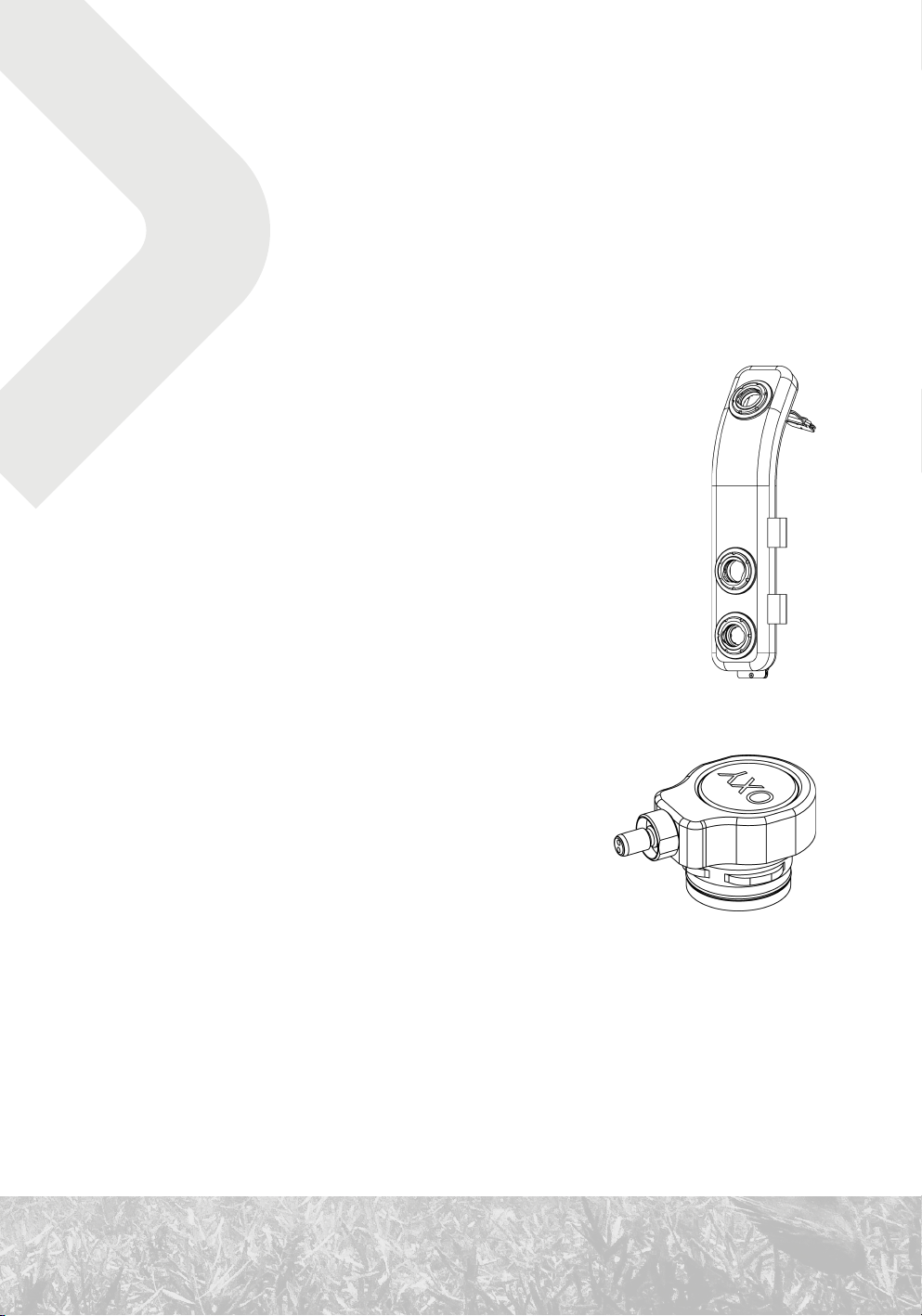

1.10.2 Head-up display

The head-up display (HUD) shows the current partial

pressure or CCR error status during the dive.

Other statuses are displayed in standby mode, during

charging and when the unit is connected to a computer.

If you are not entirely sure what the HUD is displaying, check the parameters on the handset

display. Always check it if the HUD displays a warning (outer LED blinks red) or an alarm (all

three LEDs flashes red four times).

See the following table for the various HUD signals.

1.10.3 Buddy display

The buddy display shows whether the values of the partial pressure of oxygen are within

the range that is suitable for breathing or if an error situation has occurred. The displayed

information is intended for the diving partner of the CCR Liberty’s user.

25

Prior to diving, the user of the CCR Liberty must familiarize his/her diving partner with the

buddy display’s functionality and agree on the emergency procedure to be carried out in the

event that the buddy display indicates an error situation.

See the following table for the various buddy-display signals.

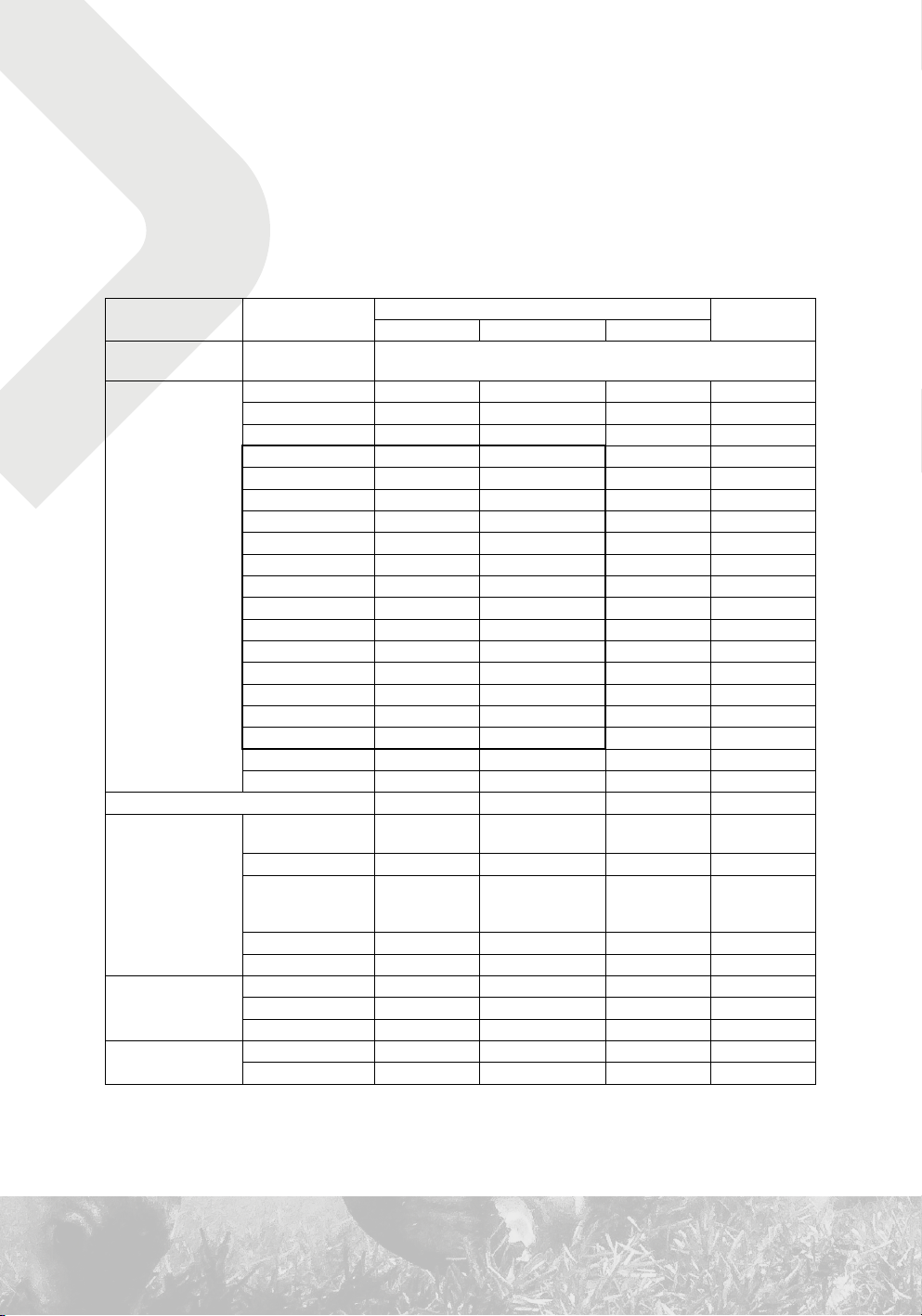

HUD and buddy-display signals

Mode Event / state

Startup

Initializing

components

ppO2 < 0.16 • red blinking • red blinking • red blinking

0.16 ≤ ppO2 < 0.20 • red blinking • red blinking • red

0.20 ≤ ppO2 < 0.25 • red blinking • red blinking • green

0.3 • 7× blue flash • green

0.4 • 6× blue flash • green

0.5 • 5× blue flash • green

0.6 • 4× blue flash • green

0.7 • 3× blue flash • green

ppO

2

in dive mode

1

(bar; standard)

0.8 • 2× blue flash • green

0.9 • 1× blue flash • green

1.0 • green • green

1.1 • 1× green flash • green

1.2 • 2× green flash • green

1.3 • 3× green flash • green

1.4 • 4× green flash • green

1.5 • 5× green flash • green

1.6 • 6× green flash • green

1.65 < ppO2 ≤ 2.0 • red blinking • red blinking • red

ppO2 > 2.0 • red blinking • red blinking • red blinking

Dive mode alarm • 4× red flash • 4× red flash • 4× red flash no change

Standby • slowly flashing

Charging • 1. red • 2. red • 3. red • red

Standby (switched

off from menu)

Charger connected

but no power

supply

Fully charged • green • green • green • green

Charging failed • red blinking • red blinking • red blinking • red blinking

Mass storage

mode (USB adaptor

connected)

Download firmware

Reading • green • orange • green

Writing • red • orange • red intensive

No action • orange

Connected • purple • purple blinking • purple

Downloading • purple • purple

HUD signals

LED 1 LED 2 LED 3

BD signals

Binary coded service numbers

• slowly

flashing

• red blinking • red blinking

1

Indicated ppO2 value in the range ±0.05 bar

26

Color blind mode

If you cannot distinguish blue and green LED lights, check “Color blind mode” in Setup

→ Preferences → Indication. Signals for 1.05 ≤ ppO2 ≤ 1.65 will be changed according the

following table:

1.1 • 1× green flash • 1× green flash

1.2 • 2× green flash • 2× green flash

ppO2 in dive mode

(bar; color blind)

1

Indicated ppO2 value in the range ±0.05 bar

1

1.3 • 3× green flash • 3× green flash

1.4 • 4× green flash • 4× green flash

1.5 • 5× green flash • 5× green flash

1.6 • 6× green flash • 6× green flash

1.11 Backplate and mounting

The method of mounting the CCR Liberty

on the diver’s body is based on the

backplate and harness common among

wing-type buoyancy compensators used

in technical diving.

The body of the rebreather, comprised of

the scrubber canister and attached head,

is attached to the backplate with a cam.

The cam lever cannot be released when

the diver is wearing the rebreather.

27

The CCR Liberty’s integrated stand, which serves as a lumbar support, is intended for setting

the rebreather on a hard, level surface with sufficient rigidity. Always secure the standing

rebreather to prevent falling.

If needed, it is possible to remove the CCR Liberty’s backplate, together with the buoyancy

compensator from the components specific for the rebreather and use it with the harness

for open-circuit diving. It enables attachment of a twin-set (two tanks firmly connected with

stainless steel bands) using bolts and wing nuts as is common in technical diving, as well as

attachment of a single tank with a strap with fastener (not included with the CCR Liberty).

When mounting the CCR Liberty onto the backplate, set the bottom of the scrubber cannister

into the protrusion in the rebreather stand.

1.12 Harness

The backplate is equipped with harness that is threaded through in a way that ensures proper

system functioning. Do not change the way it is made. If you do try to take the harness out,

record or remember exactly how it is threaded through to prevent interference with the

functioning of the whole system.

It is necessary to adjust the harness so that it fits properly. Adjust the harness without the

mounted scrubber canister, head, corrugated hoses and breathing bags.

Adjust the length of the shoulder straps so that it is possible to insert three fingers under the

straps at the collar-bone level without great resistance but not entirely freely.

The chest D-rings should be as low as possible, while still allowing you to cross your arms over

your chest comfortably. The D-rings should be high enough for you to reach the left ring with

your left thumb, and the right ring with your right thumb. The D-ring on the left side of the

waist strap should be roughly on your hip.

Adjust the length of the left part of the belt strap so that it passes through the eye of the

crotch strap and there is approximately 5 cm (strap width) between the ring and the eye. Adjust

the right part so that the strap is slightly tight. If you shorten a strap, leave sufficient reserve

for different suits and possible change of body dimensions. After shortening, it is necessary to

deburr the ends of the straps by heat sealing them with a cigarette lighter or candle. Do this

carefully so as not to form a hard surface on the strap ends.

28

Adjust the length of the crotch strap so that it passes closely to the body but does not

bind. Set the position of the rear D-ring as low as possible but sufficiently high so that it

does not place pressure on the buttocks when swimming. The rear D-ring should be within

the diver’s reach. Test the exact position of the rear D-ring in the water with the complete

apparatus.

1.13 Buoyancy compensator

The CCR Liberty uses a wing-type buoyancy compensator (BCD) with displacement of 200 N.

The compensator’s design and materials are very durable and even suitable for cave and wreck

diving.

The wing has a two-ply design. The internal bladder is made of high-frequency-welded Cordura

560 fabric with PU coating. The wing’s external cover is made of Cordura 2000 fabric.

The wing is attached with screws along the edge of the backplate.

To achieve the correct position of the inflator, pass the low-pressure hose through the rubber

ring on the corrugated hose, then through the rubber ring on the shoulder strap and finally

through the second rubber ring on the corrugated hose. Do not skip either of the rings on the

corrugated hose; upon disconnecting the quick-release connector from the inflator, it could

recede so far that it would be difficult to find it.

The buoyancy compensator is not a life preserver. It does not maintain the diver in a face-up

position. It is not designed to hold the diver’s face above the surface should he/she become

unconscious or immobile.

1.14 Ballast

The ballast system is composed of two pouches placed on the sides of the scrubber canister

and is attached to the tanks. In the lower part of the pouches, there is a loop through which

the attachment strap of the rebreather body is passed. The internal pouches, which contain

the individual weights, are inserted into the external pouches. The upper flap of the external

pouch is intended for inserting weights before a dive and removing them after. For emergency

jettisoning of ballast, pull the red strap on the lower part of the pouch. This will open the

external pouch and will release the internal pouch containing the ballast.

29

Loading...

Loading...