Page 1

IMPORTANT:

Prior to installation, record Model, Serial Number, and

Code Number from pump nameplate for future reference.

MODEL ________________________

SERIAL ______________________

CODE ______________________

INSTALLATION

DATE _______________________

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contents

1.) General Information

2.) Precautions/Pre-installation

3.) Installation

4.) Pump Specifications and Parts List

5.) Maintenance and Troubleshooting

Installation Manual 4617000K

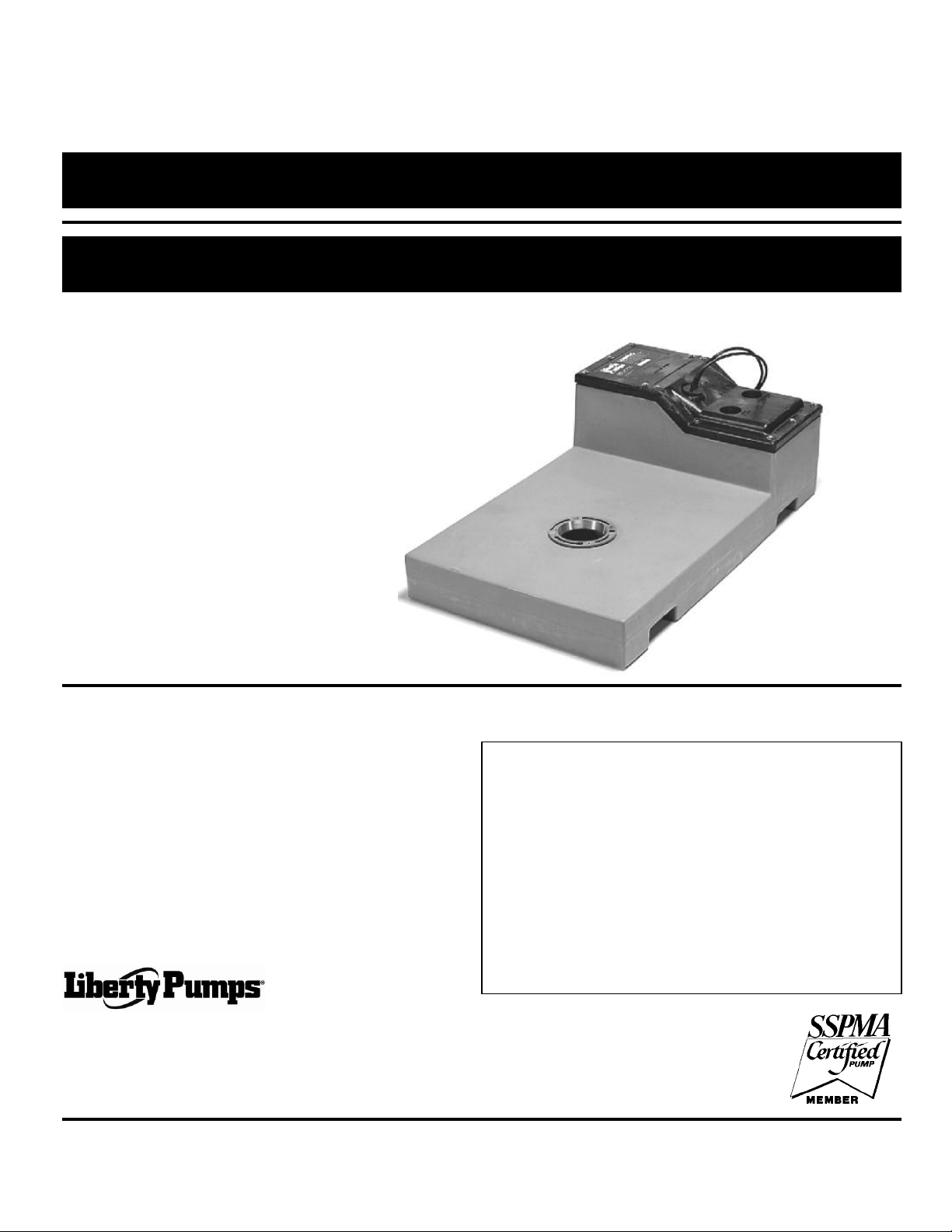

LowPro41LP Low Profile Sewage System

Models

LowPro41LP 4/10 HP 115V

©Copyright 2012 Liberty Pumps Inc. All rights reserved

Page 2

1. General Information

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to insure proper

performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

Risk of electric shock – The pump power cord is equipped with a grounding conductor and grounding-type 3-prong plug. To

reduce the risk of electric shock, be certain that it is connected only to a 115V properly grounded grounding-type receptacle. All

electrical circuitry should be installed in accordance with the National Electric Code (NEC) and all applicable local codes or

ordinances. These pumps are not to be installed in locations classified as hazardous in accordance with the National

Electric Code, ANSI/NFPA 70.

Installation must be in accordance with the National Electric Code and all applicable local codes.

Installation and servicing is to be conducted by qualified personnel.

Do not use these pumps in water over 140 F.

The Uniform Plumbing Code (UPC) states that sewage systems shall have an audio and visual alarm that signals a malfunction of

the system, to reduce the potential for property damage.

Dimensional Data

©Copyright 2012 Liberty Pumps Inc. All rights reserved 2

Page 3

TEMPORARY

MANUAL

OPERATION

DO!

DON’T!

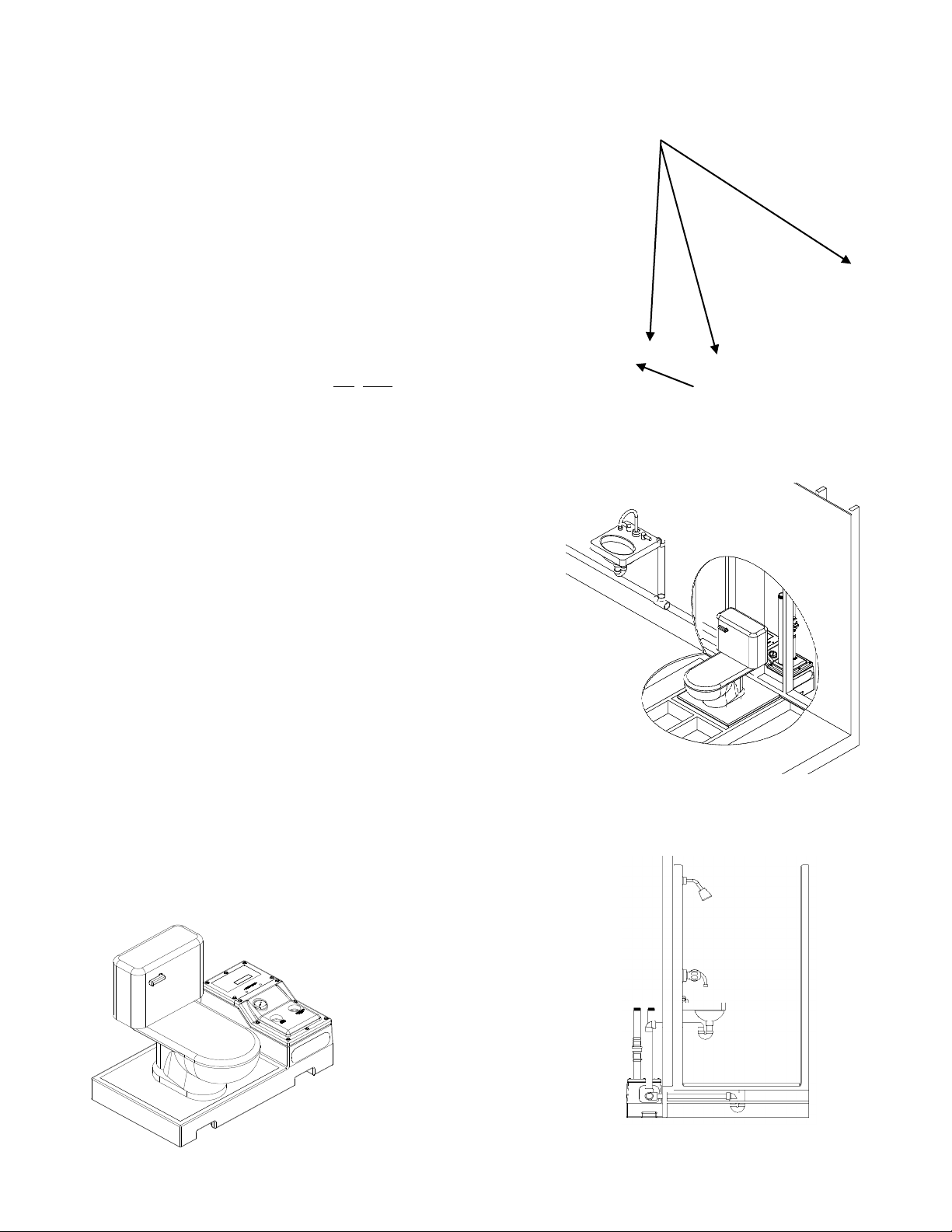

Fig. 1 Piggyback plug installation.

2. Precautions/Pre-Installation

3. Installation

1. Inspect all materials for shipping damage and to ensure that all parts have been received. Contact your dealer with any problems

prior to installation.

2. Read all instructions and familiarize yourself with the unit's operation prior to proceeding with the installation. Read pump

specifications to assure pump has adequate head performance prior to installation - See "Note" under pump specifications.

3. Risk of electric shock. Always disconnect the pump from the power source before handling or making

adjustments. The pump power cord is equipped with a grounding conductor and grounding-type 3-prong plug.

To reduce the risk of electric shock, be certain that the Sumpbox™ unit is connected only to a properly

grounded grounding-type receptacle. This receptacle should be protected by a ground fault circuit interrupter

(GFCI). All electrical circuitry should be installed in accordance with the National Electric Code (NEC) and all

applicable local codes or ordinances. Never remove the ground pin from the plug.

Never remove the ground pin from the plug.

4. Make certain that the outlet is within reach of the power supply cord. Never use an extension cord.

5. The power cords from the LowPro system are equipped

with piggyback plugs and must be connected in series to

operate automatically (see fig. 1).

6. Check to ensure that your power source is adequate to

handle the pump amperage. Pump amperage can be

found on the nameplate and/or the product literature.

Ensure that the electrical supply circuit is equipped with

fuses or breakers of the proper capacity.

7. It is recommended that a separate branch circuit be

installed for the pump. Such a branch circuit should be

sized in accordance with the NEC.

8. Each electrical outlet should be tested to ensure that a

proper ground has been established. A UL listed circuit

analyzer will indicate if the power, neutral, and ground wire

are properly connected.

9. A qualified licensed electrician should install and test all electrical circuits.

10. All plumbing (waste and vent) must be installed to meet local plumbing codes. This unit must be properly vented. Automatic

or mechanical plumbing vent devices must not be used. This pump is not to be installed in a location classified as hazardous

in accordance with the NEC, ANSI/NFPA 70.

11. Liquid temperature must not exceed 140F (60C).

12. Always disconnect the pump from the power source prior to removing or servicing.

1. The LowPro is shipped factory assembled; inspect tank, pump and accessories for shipping damage. Contact your dealer with any

problems prior to installation

2. The tank installation location must be level. Position the tank in its final location and ensure that it is level. Use hydraulic cement

or similar material for leveling the floor if necessary.

3. If installing walls or floor joists, use caution to ensure that nails, screws, or other sharp objects do not puncture the tank

when framing.

4. Determine the closest and most readily accessible locations to tie in the discharge and vent lines to existing lines. Take the

necessary measurements and determine what plumbing fittings and pipes are needed.

5. An inlet for a 2" PVC drain line from additional fixtures (i.e. sink or shower) may be installed using the rubber pipe grommet

(supplied). Determine the best location for the drain line to enter the tank making sure it is within the marked textured a reas of the

pump chamber. See fig. 2. Do not drill below or outside of the textured areas. Make sure drain lines have adequate gravity

flow to the system. If a shower is being used, elevate the shower to allow for proper trapping and drainage. Drill a 3" diameter

©Copyright 2012 Liberty Pumps Inc. All rights reserved 3

Page 4

Fig. 2 Tank contains three textured areas acceptable

for installing rubber pipe grommet.

Installation outside of these areas may result

In damage to internal components.

Fig. 5 Optional orientation of toilet

Do not drill below this line

Fig.3 Typical finished installation

Fig. 4 Side view with elevated shower

hole and insert the grommet. Slide the 2" PVC drain line into the pipe

grommet, lubricating the pipe if necessary to ease installation.

Note: If installing a washing machine, the preferred method would be to

drain washer into a tub sink with a lint sock prior to the LowPro. Also,

periodically remove access cover and clean lint and debris off of switch

6. NOTE: Threaded connections at tank - HAND TIGHTEN ONLY. Use

Teflon tape as a thread sealant. Install a 2" PVC pipe to the connection

labeled "Discharge". Attach the 2” check valve (Fig. 8, item 14) to the

discharge pipe as close to the top of the tank as possible. Make sure

that the arrows on the check valve are pointing up, away from the pump.

Do not reduce the discharge pipe size below 2".

7. Complete the discharge piping to the house waste line using a minimum

number of turns. See "Note" under Pump Specifications for maximum

head performance of the LowPro system.

8. Install a 2" vent pipe into the vent opening on the cover. Connect

the vent pipe to the house vent line or directly to the atmosphere.

Unit must be vented directly to the atmosphere in accordance with

national and local plumbing codes. DO NOT use an automatic or

mechanical vent device.

9. If you are not installing a finished floor above the LowPro tank system,

skip steps 10 through 12, and resume installation at step 13.

10. The rough opening size required for installation using standard 2”X6” floor

joists will vary depending on your actual installation and the orientation of

the tank. The overall rough opening size needed to enclose the entire

LowPro tank is 42” X 24½”.

11. Measure the finished flooring thickness and determine the number of closet

flange spacers (Figure 8, item 17) needed to bring the closet flange up to

the finish floor. See Figure 6.

12. Set the proper number of plastic closet flange spacers (as determined in

step 11) onto the brass closet flange. The foam gasket material on the

spacer(s) must be facing down. The spacer(s) will not be secured to the

closet flange, so use care not to move them during the installation of the

toilet.

13. Install the wax toilet bowl seal ring provided onto the toilet following the

directions included with the toilet. Install the toilet onto the closet flange

following the directions included with the toilet. Hook up the water line to

the toilet. Turn the water on and fill the toilet tank. Test for leaks. Flush

the toilet several times and allow the pump to cycle to ensure proper

operation.

NOTE: The LowPro features an internal jet spray to help break down solids

and reduce jamming. Due to limited water volumes per pump cycle on

systems of this type, care must be taken to avoid flushing extreme amounts

of toilet paper or any reinforced papers, paper towels, sanitary products and

other foreign objects into the LowPro.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 4

Page 5

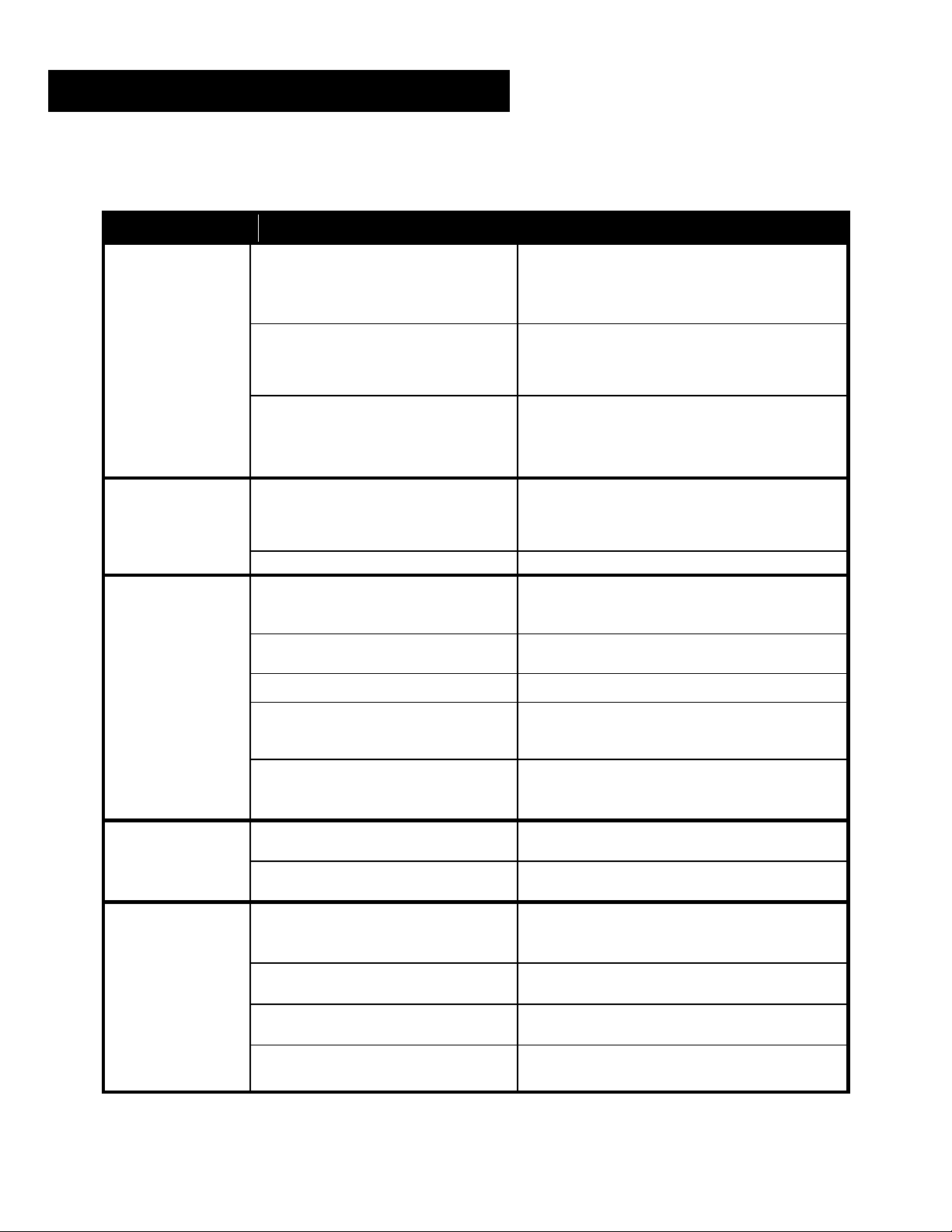

Pump Specifications LOWPRO41LP

Hp 4/10

Volts 115

Phase 1

Full Load Amps 12

Hz 60

Solids-handling 2"

Discharge size 2"

NOTE: The LowPro has a shut-off head

(maximum lift) of 19 feet. Actual maximum

useable head to provide adequate flow is

approximately 17.5 feet and may be less

depending on amount of run and friction loss

factors. Please consult factory for proper

pump sizing.

4. Pump Specifications and Parts List

Refer to the diagram

to adjust the float

switch (5). The

pump should engage

at a waste depth of

approximately 4.0”

and pump down to

around 3.0”. To

adjust the float

switch, remove the

switch access cover

(6) and lift the float

switch (5) out of the

tank. After adjusting

to the lengths

pictured above,

replace the switch by

placing the cord

between the two

bosses. Reattach

the access cover to

the tank.

Fig. 6

Spacer (one each of 1/4" and 1/2" provided.

May be stacked for total of 3/4")

Finish Flooring (Tile, Linoleum etc.)

Sub-flooring (Plywood etc.)

Item Part No. Description Qty.

1 4622000 Tank, low profile 1

2 LE41LP Pump, 4/10Hp sewage, 115V 1

3 4623000 Nipple, 2” PVC Sched. 80 1

4 462100B Cover, pump access 1

5 4616000 Switch, vertical master 1

6 462000B Cover, switch access 1

7 8131000 Washer, flat 1/4” X 3/4” S.S. 14

8 8129000 Bolt, 1/4”-20 X 5/8”, Hex head S.S. 14

9 4022000 Stopper, double cord hole 1

10 4624000 Closet Flange, brass 1

11 8018000 Screw, 1/4”-20 X 5/8” slotted Flt. Hd. 4

12 4039000 Gasket, cover 1” X 1/8” tape 1

13 4039RA0 Gasket Tape, for closet flange 1

14 CV200C Check Valve, 2” PVC compression fit 1

15 4762000 Grommet, Pipe seal, 2” 1

16 4627000 Wax Ring 1

17 4626000 Closet flange extension kit 1

18 4625000 Closet bolt kit

1

©Copyright 2012 Liberty Pumps Inc. All rights reserved 5

Page 6

Problem

Cause

Correction

Pump will not run.

Blown fuse or other interruption of

power; improper voltage.

Check that the unit is securely plugged in.

Have an electrician check all wiring for proper

connections and adequate voltage and

capacity.

Switch is unable to move to the

“turn on” position due to

interference with the side of basin

or other obstruction

Position the pump or switch so that it has

adequate clearance for free operation.

Insufficient liquid level.

Make sure the liquid level is allowed to rise

enough to activate switch(s).

Defective switch.

Remove and replace switch.

Pump will not turn

off.

Switch(s) unable to move to the

“turn off” position due to

interference with the side of basin

or other obstacle.

Position the pump or switch so that it has

adequate clearance for free operation.

Defective switch.

Remove and replace switch.

Pump runs or hums,

but does not pump.

Discharge is blocked or restricted.

Check the discharge line for foreign material,

including ice if the discharge line passes

through or into cold areas.

Check valve is stuck closed or

installed backwards.

Remove check valve(s) and examine for

freedom of operation and proper installation.

Gate or ball valve is closed.

Open gate or ball valve.

Total lift is beyond pump's

capability.

Try to route piping to a lower level. If not

possible, a larger pump may be required.

Consult the factory.

Pump impeller is jammed or volute

casing is plugged.

Remove the pump from the basin. Detach the

pump base and clean the area around the

impeller. Reassemble and reinstall.

Pump runs

periodically when

fixtures are not in

use.

Check valve was not installed, is

stuck open or is leaking.

Remove check valve(s) and examine for

freedom of operation and proper installation.

Fixtures are leaking.

Repair fixtures as required to eliminate leakage.

Pump operates

noisily.

Foreign objects in the impeller

cavity.

Remove the pump from the basin. Detach the

pump base and clean the area around the

impeller. Reassemble and reinstall.

Broken impeller.

Consult the factory for information regarding

replacement of impeller.

Worn bearings.

Return pump to the factory or authorized repair

station for repair.

Piping attachments to building are

too rigid.

Replace a portion of the discharge line with

rubber hose or connector.

5. Maintenance and Troubleshooting

Risk of electric shock. Always disconnect the pump from the power source before handling or making

adjustments.

NOTE: Liberty Pumps, Inc. assumes no responsibility for damage or injury due to disassembly in the field. Disassembly, other than at

Liberty Pumps or its authorized service centers, automatically voids warranty.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 6

Page 7

3 Year Limited Warranty

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

NOTE: Liberty Pumps, Inc. assumes no responsibility for damage or injury due to disassembly in the field. Disassembly,

other than at Liberty Pumps or its authorized service centers, automatically voids warranty.

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and workmanship

for a period of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt

noting the model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date

of return is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found by the

manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its

authorized service center, and provided that none of the following warranty-voiding characteristics are evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been

disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump

discharge has been reduced in size; if the pump has been used in water temperatures above the advertised rating, or

water containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or

hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label bearing the serial,

model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses

resulting from installation or use of its products, or for consequential damages, including costs of removal, reinstallation or

transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a partic ular

purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or

incidental damages under any and all warranties are excluded.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 7

Page 8

©Copyright 2012 Liberty Pumps Inc. All rights reserved 8

Page 9

IMPORTANTE:

Apunte el modelo, el número de serie y el código que

aparecen en la placa de la bomba antes de instalarla para

que le sirvan de referencia en el futuro.

MODELO _______________________

SERIE ______________________

CÓDIGO _____________________

FECHA DE

INSTALACIÓN____________________

7000 Apple Tree Avenue

Bergen, NY 14416, EUA

Teléfono: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contenido

1.) Información general

2.) Precauciones/Preinstalación

3.) Instalación

4.) Especificaciones y lista de piezas de la bomba

5.) Mantenimiento y diagnóstico de problemas

Sistema de Saneamiento de Perfil Rebajado LowPro41LP

Modelos

LowPro41LP 4/10 HP 115V

Manual de instalación 4617000K

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados

Page 10

1. Información general

Lea con atención estas instrucciones antes de instalar la bomba. Todas las bombas de Liberty se someten a prueba en fábrica como

garantía de su funcionamiento. Siga estas instrucciones al pie de la letra para prevenir problemas de funcionamiento y conseguir

muchos años de servicio satisfactorio.

Riesgo de electrocución – el cable de potencia de la bomba lleva un conector a tierra y un enchufe de 3 espigas con conexión a

tierra. Enchufe la bomba a un tomacorrientes a tierra debidamente conectado a masa para evitar electrocuciones. Todos los

circuitos eléctricos deberán cumplir con el código eléctrico nacional (NEC) de Estados Unidos y los códigos locales que

correspondan. La bomba no se deberá instalar en un lugar clasificado como peligroso por el NEC, ANSI/NFPA 70.

Se deberá instalar la unidad según las disposiciones del NEC y todos los códigos y regulaciones locales que

correspondan.

La instalación y el mantenimiento deberán estar a cargo de personal calificado.

La bomba no se debe utilizar con agua por encima de los 60 C (140 ° F).

El código uniformado de fontanería (UPC) de Estados Unidos exige que todos los sistemas de saneamiento dispongan de una

alarma visual y sonora que indique averías del sistema con el fin de evitar daños a la propiedad.

Dimensiones

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 2

Page 11

OPERACIÓN

MANUAL

TEMPORAL

¡SÍ!

¡NO!

Figura 1 Enchufe en cascada

2. Precauciones/Preinstalación

3. Instalación

1. Inspeccione toda la unidad para asegurarse de que no haya sufrido daños durante el transporte y que estén presentes todas las

piezas. Comuníquese con el distribuidor si se presenta algún problema antes de la instalación.

2. Lea las instrucciones en su integridad y familiarícese con el funcionamiento del sistema antes de instalarlo. Lea las

especificaciones para asegurarse de que la altura práctica sea la correcta antes de su instalación. Lea la nota en la sección de

especificaciones.

3. Riesgo de electrocución. Desenchufe la bomba siempre que vaya a moverla o a realizar algún ajuste. El

cable de potencia de la bomba lleva un conector a tierra y un enchufe de 3 espigas con conexión a tierra.

Enchufe la unidad Sumpbox™ a un tomacorrientes a tierra debidamente conectado a masa para evitar

electrocuciones. Dicho tomacorrientes deberá estar protegido por un interruptor de circuito de tierra

accidental. Todos los circuitos eléctricos deberán cumplir con el código eléctrico nacional (NEC) de Estados

Unidos y los códigos locales que correspondan. No quite la espiga a tierra del enchufe.

No quite la espiga a tierra del enchufe.

4. El tomacorrientes deberá estar al alcance del cable de potencia. Nunca utilice un cable prolongador.

5. Los cables de potencia del sistema LowPro llevan enchufes en cascada y se tendrán que enchufar en serie para que funcionen

automáticamente (ver fig. 1).

6. Verifique que la fuente de energía sea adecuada para el

amperaje de la bomba. La información del amperaje está

en la placa y en el material informativo del producto. El

circuito de suministro eléctrico tendrá que tener fusibles o

interruptores automáticos de capacidad suficiente.

7. Es recomendable instalar un circuito de derivación

exclusivamente para la bomba. Este circuito deberá

cumplir las recomendaciones del NEC.

8. Compruebe que todos los tomacorientes estén conectados a tierra. Se

puede usar un analizador de circuitos con aprobación UL

para verificar que la energía, el neutro y el hilo de masa estén bien conectados.

9. La instalación y prueba de los circuitos eléctricos deberá estar a cargo de un electricista licenciado.

10. Todas la tuberías tanto de residuos como de ventilación se tendrán que instalar respetando los códigos de fontanería locales. La

unidad necesita ventilación adecuada. No se deben utilizar artefactos de ventilación de tuberías automáticos ni

mecánicos. La bomba no se deberá instalar en un lugar clasificado como peligroso por el NEC, ANSI/NFPA 70.

11. La temperatura del líquido no podrá superar los 60ºC (140°F) .

12. Desconecte la bomba antes de moverla o mantenerla.

1. El sistema LowPro viene montado de fábrica; verifique que el tanque, la bomba y los accesorios no hayan sufrido daños durante el

transporte. Comuníquese con el distribuidor si se presenta algún problema antes de la instalación.

2. El emplazamiento del tanque tendrá que estar nivelado. Coloque el tanque en su ubicación final y compruebe que esté nivelado.

Si no lo está, puede usar cemento hidráulico o un material similar para rectificar el problema.

3. Si va a instalar viguetas en el piso o en la pared, tenga cuidado de no agujerear el tanque con clavos, tornillos y otros

objetos puntiagudos.

4. Determine cuál es el punto más cercano y accesible para conectar las líneas de desagüe y ventilación a las tuberías existentes.

Haga las mediciones necesarias para decidir las conexiones y tuberías que se van a necesitar.

5. Con la arandela de caucho que se incluye se puede instalar una entrada para una tubería de drenaje de PVC de 5.08 cm (2 plg)

para instalar otros accesorios, como por ejemplo un fregadero o una ducha. Determine el mejor punto para la entrada de la tubería

de drenaje en el tanque, siempre dentro de las áreas texturadas de la cámara de la bomba. Vea la fig. 2. No taladre por debajo o

por fuera de estas áreas texturadas. Las tuberías de drenaje deberán tener un flujo por gravedad adecuado hacia el sistema. Si

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 3

Page 12

Fig. 2 El tanque tiene tres áreas texturadas donde se

puede instalar la arandela de caucho.

Si se instala fuera de estas áreas existe el peligro

de dañar los componentes internos.

Fig.3 Instalación típica terminada

Fig. 4 Vista lateral con ducha elevada

Fig. 5 Orientación opcional del inodoro

No taladre por debajo de esa línea.

se va a utilizar una ducha, se deberá elevar para que desagüe

correctamente. Taladre un orificio de 7.62 cm (3 plg.) de diámetro e

inserte la arandela. Introduzca la tubería de drenaje de PVC de 5.08 cm

(2 plg.); lubríquela si es necesario.

Nota: si se va a instalar una lavadora, lo más conveniente es vaciarla en

una pileta con una bolsa filtrante antes del sistema LowPro. Además

habrá que quitar la tapa periódicamente para limpiar la pelusa y demás

suciedad del interruptor.

6. NOTA: las conexiones del tanque se deberán APRETAR CON LA

MANO SOLAMENTE. Use cinta de teflón para sellar las roscas. Instale

una tubería de PVC de 5.08 cm (2 plg) en la conexión con la etiqueta

«Discharge». Conecte la válvula de retención de 5.08 cm (2 plg) (Fig. 8,

pieza 14) a la tubería de desagüe tan cerca de la parte superior del

tanque como sea posible. Las flechas en la válvula deben apuntar hacia

arriba en dirección contraria a la bomba. El tamaño de la tubería de

desagüe nunca debe bajar de 5.08 cm (2 plg).

7. Lleve las tuberías de desagüe hasta la línea de aguas residuales del

edificio; mantenga los giros al mínimo. En la nota de la sección de

especificaciones encontrará la altura máxima para el sistema LowPro.

8. Instale una tubería de ventilación de 5.08 cm (2 plg) en el

respiradero de la tapa. Conecte la tubería a la línea de ventilación

del edificio o directamente al exterior. La unidad deberá ventilarse

directamente al aire libre según los códigos nacionales y locales. NO

utilice un artefacto de ventilación automático ni mecánico.

9. Si no se va a instalar un piso acabado encima del tanque LowPro,

sáltese los pasos del 10 al 12, y continúe con el paso 13.

10. La abertura en estado tosco necesaria para la instalación con viguetas

para piso de 5.08 x 15.24 cm (2 x 6 plg.) variará dependiendo del

emplazamiento y la orientación del tanque. La abertura necesaria para

abarcar todo el tanque LowPro es de 106.68 x 62.23 cm (42 x 24½ plg.).

11. Mida el grosor del piso acabado y determine el número de espaciadores

para collarines (Figura 8, pieza 17) que se necesitan para levantar los

collarines al nivel del suelo acabado. Vea la Figura 6.

12. Coloque los espaciadores de plástico necesarios (según el paso 11) en el

collarín de latón. La espuma obturadora de los espaciadores debe estar

orientada hacia abajo. El espaciador no se adherirá al collarín, por lo que

es importante que no lo mueva cuando instale el inodoro.

13. Instale el sello de cera incluido en el inodoro según las instrucciones del

mismo. Instale el collarín en el inodoro según las instrucciones del mismo.

Conecte la línea de agua al inodoro. Abra la llave del agua y llene el

tanque del inodoro. Compruebe que no haya fugas. Tire de la cadena

varias veces y deje que la bomba pase por su ciclo para asegurarse de

que funciona correctamente.

NOTA: el sistema LowPro lleva un chorro interno a presión que ayuda a deshacer los

elementos sólidos y por consiguiente a reducir los atascos. Debido a que el volumen

de agua por ciclo de bombeo no es muy elevado en este tipo de sistemas, es

importante que no eche en el LowPro una cantidad excesiva de papel higiénico, ni

papel reforzado, toallitas de papel, compresas y tampones y otros objetos foráneos.

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 4

Page 13

Especificaciones LOWPRO41LP

Hp 4/10

Volts 115

Fase 1

Amps carga total 12

Hz 60

Sólidos 5.08 cm (2 plg.)

Tamaño salida 5.08 cm (2 plg.)

NOTA: el sistema LowPro tiene una altura

de desconexión (elevación máxima) de

6.33m (19 pies). La altura práctica para

obtener un flujo adecuado es de 5.83m (17.5

pies) y puede ser inferior dependiendo de la

carrera y la fricción. En la fábrica le

informarán del tamaño de bomba adecuado

para su caso.

Consulte el diagrama para ajustar el

interruptor de flotador (5). La bomba

arranca cuando hay 10.16 cm (4

plg.) de desechos y los reduce a

7.60 cm (3 plg.) aproximadamente.

Para ajustar el interruptor, quite su

tapa (6) y saque el interruptor (5) del

tanque. Una vez ajustado a los

largos indicados anteriormente,

coloque el cordón entre los dos

bujes para instalar el interruptor.

Vuelva a colocar la tapa en el

tanque.

Espaciador (se incluyen uno de 0.63 cm y

otro de 1.27 cm) (1/4 y 1/2 pulgada)

Piso acabado (losa, linóleo, etc.)

Subpiso (madera

contrachapada, etc.)

4. Especificaciones y lista de piezas de la bomba

VIGUETA PARA PISO DE

5.08 x 15.24 (2 x 6 plg.)

TANQUE LowPro

Fig. 6

Pieza Núm. pieza Descripción Cantidad

1 4622000 Tanque, perfil rebajado 1

2 LE41LP Bomba, saneamiento 4/10Hp, 115V 1

3 4623000 Empalme, 5.08 cm (2 plg.) PVC 80 1

4 462100B Tapa, acceso bomba 1

5 4616000 Interruptor, vertical 1

6 462000B Tapa, acceso interruptor 1

7 8131000 Arandela, plana 0.63 cm x 1.90 cm

(1/4 X 3/4 plg.) 14

8 8129000 Perno, de 20 giros, 0.63 cm x 1.60 cm

(1/4-20 X 5/8 plg.), cabeza hexagonal 14

9 4022000 Tope, orificio doble cordón 1

10 4624000 Collarín, latón 1

11 8018000 Tornillo, de 20 giros, 0.63 cm x 1.60 cm

(1/4-20 X 5/8 plg.) ranurado 4

12 4039000 Junta, cinta 2.54 cm x 0.33 cm

(1 X 1/8 plg.) tapa 1

13 4039RA0 Cinta obturadora, para collarín 1

14 CV200C Válvula de retención, ajuste de

compresión PVC 5.08 cm (2 plg.) 1

15 4762000 Arandela, sello tubería, 5.08 cm (2 plg.) 1

16 4627000 Anillo de cera 1

17 4626000 Extensión collarín 1

18 4625000 Pernos collarín 1

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 5

Page 14

Problema

Causa

Solución

La bomba no

funciona.

Se ha fundido un fusible o el flujo

eléctrico se ha visto interrumpido

de algún otro modo; tensión

incorrecta.

Compruebe que la bomba esté enchufada.

Haga que un electricista compruebe que todos

los cables estén correctamente conectados y

la capacidad sea la necesaria.

El interruptor no puede cambiar a la

posición de encendido por culpa de

una interferencia con el lateral del

tanque u otra obstrucción.

Coloque la bomba o el interruptor de forma que

pueda funcionar libremente.

Líquido insuficiente.

El líquido debe subir lo suficiente como para

activar el interruptor.

Interruptor defectuoso.

Reemplace el interruptor.

La bomba no

se apaga.

El interruptor no puede cambiar a la

posición de apagado por culpa de

una interferencia con el lateral del

tanque u otra obstrucción.

Coloque la bomba o el interruptor de forma que

pueda funcionar libremente.

Interruptor defectuoso.

Reemplace el interruptor.

La bomba funciona

o zumba pero

no bombea.

El desagüe está atascado.

Compruebe que no haya atascos en la línea de

desagüe, como puede ser hielo si la línea pasa

por áreas frías.

Compruebe que la válvula no se

haya quedado cerrada o esté

instalada al revés.

Saque la válvula de retención y asegúrese de

que funciona sin impedimentos y fue instalada

correctamente.

La válvula de compuerta/bola

está cerrada .

Abra la válvula de compuerta o de bola .

La elevación total es superior a la

capacidad de la bomba.

Dirija las tuberías a una altura inferior. Si esto

no es posible, necesitará adquirir otra bomba

de mayor capacidad. Consulte con la fábrica.

El rotor de la bomba está atascado

o la cubierta de voluta está

taponada.

Saque la bomba de la cubeta. Separe la base

de la bomba y limpie la zona que rodea al

rotor. Monte la bomba y vuélvala a instalar.

La bomba se pone a

funcionar cuando la

maquinaria no

está en uso.

No hay instalada una válvula de

retención, se queda abierta o tiene

una fuga.

Saque la válvula de retención y asegúrese de

que funciona sin impedimentos y fue instalada

correctamente.

Las piezas gotean.

Repare las piezas para eliminar las fugas.

La bomba hace

demasiado ruido.

Material foráneo en la cavidad del

rotor.

Saque la bomba de la cubeta. Separe la base

de la bomba y limpie la zona que rodea al

rotor. Monte la bomba y vuélvala a instalar.

Rotor roto.

La fábrica le puede informar sobre cómo

reemplazar el rotor.

Cojinetes desgastados.

Envíe la bomba a reparar a la fábrica o a un

centro de reparación autorizado.

Las conexiones de las tuberías al

edificio son demasiado rígidas.

Cambie una parte de la línea de desagüe con

una manguera o conector de caucho.

5. Mantenimiento y diagnóstico de problemas

Riesgo de electrocución. Desenchufe la bomba siempre que vaya a moverla o a realizar algún ajuste.

NOTA: Liberty Pumps, Inc. no asume ninguna responsabilidad por desperfectos o lesiones resultantes del desmontaje de la bomba

sobre el terreno. Si el desmontaje de la bomba no lo lleva a cabo Liberty Pumps o uno de sus centros de servicio autorizados, la

garantía quedará anulada.

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 6

Page 15

Garantía limitada de 3 años

7000 Apple Tree Avenue

Bergen, NY 14416

Teléfono: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

NOTA: Liberty Pumps, Inc. no asume ninguna responsabilidad por desperfectos o lesiones resultantes del desmontaje

de la bomba en el campo. Si el desmontaje de la bomba no lo lleva a cabo Liberty Pumps o uno de sus centros de

servicio autorizados, la garantía quedará anulada.

Liberty Pumps, Inc. garantiza que las bombas que fabrica están libres de defectos en los materiales y la mano de obra

por un período de 3 años a partir de la fecha de compra. La fecha de compra se determinará con el recibo de compra

fechado, que incluya el modelo y el número de serie de la bomba. Este recibo deberá acompañar a la bomba si la fec ha

de devolución ocurre más de 3 años después de la fecha de fabricación (código-CODE) indicada en la placa de la

unidad.

Las obligaciones del fabricante bajo esta garantía se limitarán a la reparación o el reemplazo de las piezas que el

fabricante determine que son defectuosas, siempre que la pieza o el ensamblaje se devuelva con el porte pagado al

fabricante o a uno de sus centros de servicio autorizados y que no se evidencie ninguna de las siguientes características,

lo que supondría la anulación de la garantía.

El fabricante no tendrá obligación alguna bajo esta garantía si el producto no ha sido instalado correctamente; si ha sido

desmontado, modificado, abusado o forzado; si el cordón eléctrico se ha cortado, dañado o empalmado; si se redujo el

tamaño de la descarga de la bomba; si la bomba se usó con agua más caliente de la temperatura nominal, o agua con

arena, cal, cemento, grava u otros elementos abrasivos; si se utilizó para bombear productos químicos o hidrocarburos;

si un motor no sumergible fue sometido a exceso de humedad; o si se retiró la etiqueta con el número de serie, modelo y

código. Liberty Pumps, Inc. no se hace responsable de pérdidas, daños o gastos que resulten por la instalación o uso de

sus productos, o por daños emergentes, incluidos los costos de desmontar, reinstalar o transportar la unidad.

No se ofrece ninguna otra garantía expresa. Todas las garantías implícitas, incluidas las de comerciabilidad y adecuación

para un propósito determinado, están limitadas a un plazo de tres años a partir la fecha de compra.

Esta garantía representa el único remedio del comprador y, siempre que se permita, se excluye toda responsabilidad por

daños emergentes y fortuitos bajo toda otra garantía.

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 7

Page 16

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 8

Page 17

IMPORTANT :

Avant l’installation, noter les numéros de modèle, de série

et de code qui figurent sur la plaque signalétique pour

éventuellement s’y référer.

MODÈLE _____________________

SÉRIE _______________________

CODE ______________________

DATE

D'INSTALLATION _____________

7000, avenue Apple Tree

Bergen (NY) 14416

Téléphone : (800) 543-2550

Télécopieur : (585) 494-1839

www.libertypumps.com

Table des matières

1.) Renseignements généraux

2.) Précautions/préinstallation

3.) Installation

4.) Caractéristiques de la pompe et liste

de pièces

5.) Entretien et dépannage

Manuel d’installation 4617000K

Système d'égout pour espace restreint LowPro41LP

Modèle

LowPro41LP 4/10 HP 115 V

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés

Page 18

1. Renseignements généraux

Lire attentivement les directives avant d’effectuer l’installation. Chaque pompe de marque Liberty est testée individuellement en usine

pour assurer un bon fonctionnement. Le fait de suivre ces directives à la lettre éliminera les risques de problèmes de fonctionnement et

assurera des années de service sans soucis.

Danger d'électrocution : Le cordon d’alimentation électrique de la pompe est muni d’un conducteur de mise à la terre et d’une

fiche de branchement de type mise à la terre à trois broches. Afin de réduire les dangers d'électrocution, s’assurer que celle-ci est

raccordée seulement à une prise de 115 V correctement mise à la terre. L’installation de tout circuit électrique doit être faite en

respectant le code national de l’électricité et tous les codes locaux et règlements en vigueur. Cette pompe ne doit pas être

installée dans un endroit classé dangereux selon la norme ANSI/NFPA 70 du NEC.

L’installation doit être faite en respectant le code national de l’électricité et tous les codes locaux en vigueur.

Confier l’installation et la réparation à des personnes qualifiées.

Ne pas utiliser ces pompes dans de l'eau dont la température est supérieure à 60 °C (140 F)

Le Uniform Plumbing Code (UPC, Code de plomberie universel) indique que les systèmes d’égout doivent être munis d’une

d’alarme sonore et visuelle qui signale tout mauvais fonctionnement du système, afin de réduire les risques de dommages à la

propriété.

Données sur les dimensions

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 2

Page 19

MANUEL

OUI !

NON !

Fig. 1 Installation de prises siamoises.

FONCTIONNEMENT

TEMPORAIRE

2. Précautions/préinstallation

3. Installation

1. Inspecter tous les matériaux pour s’assurer qu’aucune pièce n’a subi de dommages lors du transport et que tous les composants

ont été reçus. Communiquer avec votre revendeur en cas de problème avant l’installation.

2. Lire toutes les directives et se familiariser avec le fonctionnement de l’appareil avant de procéder à l’installation. Prendre

connaissance des caractéristiques assignées de la pompe afin de vérifier que son rendement est adéquat avant l’installation Ŕ

consulter la « remarque » au chapitre des caractéristiques de la pompe.

3. Danger d’électrocution. Toujours débrancher la pompe de l'alimentation électrique avant de la manipuler ou

d'y effectuer des réglages. Le cordon d’alimentation électrique de la pompe est muni d’un conducteur de mise

à la terre et d’une fiche de branchement de type mise à la terre à trois broches. Afin de réduire les dangers

d'électrocution, s’assurer que le SumpBoxMC est raccordé seulement à une prise correctement mise à la

terre. Cette prise devrait être protégée par un disjoncteur de fuite de terre (différentiel). L’installation de tout

circuit électrique doit être faite en respectant le code national de l’électricité et tous les codes locaux et

règlements en vigueur. Ne jamais retirer la broche de mise à la terre de la fiche.

Ne jamais retirer la broche de mise à la terre de la fiche.

4. S’assurer que la prise murale est à la portée du cordon d’alimentation. Ne jamais utiliser de rallonge.

5. Les cordons d’alimentation du système LowPro sont munis

de connecteurs siamois qui doivent être raccordés en série

pour fonctionner automatiquement (voir fig. 1).

6. S’assurer que la source d’alimentation électrique convient

à l’intensité du courant électrique de la pompe. On peut

trouver l’intensité du courant électrique de la pompe sur la

plaque signalétique et/ou la documentation du produit.

S’assurer que le circuit d’alimentation électrique est muni

de fusibles ou de coupe-circuit de la bonne puissance.

7. Il est recommandé d’installer la pompe sur un circuit de

dérivation. Un tel circuit de dérivation doit être conçu en

respectant le code de l’électricité.

8. On doit vérifier toutes les prises électriques pour s’assurer que la mise à la terre fonctionne bien. Un multimètre approuvé par UL

indiquera si les fils sous tension, neutres et de mise à la terre sont raccordés correctement.

9. Un électricien autorisé qualifié doit installer et vérifier tous les circuits électriques.

10. Toute la plomberie (évacuation et ventilation) doit être installée conformément aux codes de plomberie en vigueur. Cet appareil

doit être adéquatement ventilé. On ne doit pas utiliser de systèmes d’évent automatique ou mécanique. Cette pompe ne

doit pas être installée dans un endroit classé dangereux selon la norme ANSI/NFPA 70 du NEC.

11. La température du liquide ne doit pas dépasser 60 ºC (140 ºF).

12. Toujours débrancher la pompe de l'alimentation électrique avant de la retirer ou d’effectuer l’entretien.

1. L’appareil LowPro est expédié déjà monté; inspecter le réservoir, la pompe et les accessoires pour repérer tout dommage subi lors

du transport. Communiquer avec le revendeur en cas de problème avant l’installation.

2. L’emplacement où le réservoir sera installé doit être au niveau. Placer le réservoir à l’endroit où il sera installé et s’assurer qu’il est

bien au niveau. Utiliser du ciment hydraulique ou un matériau semblable pour mettre le plancher au niveau, si nécessaire.

3. Faire preuve de prudence lors de l’installation de murs ou de solives de planchers, afin d’éviter que des clous, vis ou

autres objets pointus ne percent le réservoir en construisant le cadre.

4. Déterminer quels sont les endroits les plus rapprochés et facilement accessibles pour raccorder les conduits d’évacuation et d’évent

aux canalisations existantes. Prendre les mesures et déterminer quels raccordements de plomberie et tuyaux sont nécessaires.

5. On peut installer un tuyau de vidange de 2 po en PVC provenant d’autres installations (par ex. : un évier ou une douche) en utilisant

un œillet à tuyaux en caoutchouc (fourni). Déterminer le meilleur endroit où le tuyau de vidange doit pénétrer dans le réservoir en

s’assurant qu’il se trouve dans la zone texturée identifiée de la chambre de la pompe. Voir l’exemple à la fig. 2. Ne pas percer en-

dessous ou à l’extérieur des zones texturées. S’assurer que les tuyaux de vidange sont installés de manière à permettre

l’écoulement par gravité vers le système. Lors du raccordement d’une douche, s’assurer qu’elle est assez élevée pour permettre une

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 3

Page 20

Fig. 2 Le réservoir contient trois zones texturées qui conviennent

à l’installation d’un œillet à tuyaux en caoutchouc.

L’installation à l’extérieur de ces zones peut

endommager les composants internes

Fig. 5 Orientation

facultative de la cuvette

Fig. 3 Installation type avec finition

Ne pas percer sous cette ligne.

Fig. 4 Vue latérale d’une douche surélevée

interception et un écoulement adéquats. Percer un trou de 7,6 cm (3 po)

et insérer l’œillet. Faire glisser le tuyau d’évacuation de 2 po dans l’œillet

à tuyau, en lubrifiant le tuyau de manière à faciliter l’installation.

Remarque : Pour l’installation d’une laveuse, il est recommandé de

prévoir son écoulement dans un bassin muni d’un filtre à charpie avant

l’écoulement dans le LowPro. De plus, on doit retirer régulièrement le

couvercle protecteur et déloger les charpies et résidus de l’interrupteur.

6. REMARQUE : Raccordements filetés au réservoir Ŕ RESSERRER À LA

MAIN SEULEMENT. Utiliser du ruban Teflon® pour sceller les filets.

Installer un tuyau de PVC de 2 po aux raccordements d’évacuation

identifiés. Fixer le clapet antiretour de 2 po (fig. 8, article 14) au tuyau

d’évacuation le plus près possible du réservoir. S’assurer que les flèches

qui se trouvent sur le clapet antiretour pointent vers le haut, dans la

direction opposée de la pompe. Ne pas installer de tuyau

d’évacuation d’une dimension inférieure à 5 cm (2 po).

7. Compléter le raccordement du tuyau d’évacuation au tuyau d’égout de la

maison le plus directement possible. Voir la « remarque » au chapitre

des caractéristiques de la pompe pour connaître le rendement maximum

du système LowPro.

8. Installer un tuyau d’évent de 2 po dans l’orifice de ventilation sur le

couvercle. Raccorder le tuyau d’évent à la canalisation de

ventilation de la maison ou directement à l’air libre. Le dispositif de

ventilation de l’appareil doit déboucher à l’air libre, selon les

recommandations des codes de plomberie nationaux ou locaux NE

JAMAIS utiliser avec un système d’évent automatique ou mécanique.

9. S’il n’est pas prévu d’installer un plancher fini par-dessus le système de réservoir

LowPro, sauter les étapes 10 à 12 et reprendre l’installation à l’étape 13.

10. La dimension intérieure de l’ouverture brute nécessaire à cette installation,

à l’aide de solives de plancher 2 po X 6 po standard, variera en fonction de

l’installation comme telle et de l’orientation du réservoir. La dimension

intérieure de l’ouverture brute nécessaire pour contenir entièrement le

réservoir LowPro est de 107 cm X 62 cm (42 po X 24½ po).

11. Mesurer l’épaisseur du plancher fini et déterminer le nombre de coussinets

de bride de plancher (figure 8, article 17) nécessaires pour amener la bride

de plancher au niveau du plancher fini. Voir figure 6.

12. Installer la quantité nécessaire de coussinets de plastique pour bride de

plancher (telle qu’établie à l’étape 11) sur la bride de plancher en laiton. Le

joint d’étanchéité en mousse sur le(s) coussinet(s) doit être orienté vers le

bas. Le(s) coussinet(s) ne sont pas fixés à la bride de plancher, alors il faut

faire attention de ne pas le(s) déplacer lors de l’installation de la cuvette.

13. Installer l’anneau d’étanchéité ciré fourni sur la cuvette en suivant les

directives incluses avec la cuvette. Installer la cuvette sur la bride de

plancher en suivant les directives incluses avec la toilette. Raccorder la

canalisation d’alimentation en eau à la toilette. Ouvrir l’arrivée d’eau et

remplir le réservoir de la toilette. Vérifier la présence de fuites. Actionner la

chasse d’eau à plusieurs reprises afin de permettre à la pompe de compléter

son cycle et ainsi s’assurer de son bon fonctionnement.

REMARQUE : La système LowPro est muni d’un jet de pulvérisation interne afin d’aider à

défaire les amas solides et réduire les risques de blocage. En raison du volume limité d’eau

utilisé lors de chaque cycle dans les systèmes de ce type, il faut éviter de jeter de grandes

quantités de papier de toilette dans la cuvette à la fois, ni aucun papier renforcé, des

serviettes hygiéniques ou d’autres corps étrangers dans le système LowPro.

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 4

Page 21

Caractéristiques de la pompe LOWPRO41LP

Hp 4/10

Volts 115

Phase 1

Intensité maximale 12

Hz 60

Tolérance des solides 51 mm (2 po)

Évacuation 51 mm (2 po)

REMARQUE : Le modèle The LowPro

comporte une hauteur de chute maximum

(hauteur géométrique d’aspiration maximum)

de 6,33 m (19 po). La hauteur d’élévation

maximum acceptable pour fournir un débit

adéquat est d’environ 5,83 m (17,5 po) et

peut varier en raison de facteur relatif à la

friction et à la longueur du parcours.

Consulter le fabricant pour déterminer la

taille de la pompe qui convient.

Consulter le schéma pour

régler l’interrupteur à flotteur

(5). La pompe doit se mettre

en marche lorsque la

profondeur des matières à

pomper est d’environ 10 mm

(4 po) et continuer à

fonctionner jusqu’à ce qu’elle

atteigne 7 mm (3 po). Pour

régler l’interrupteur à flotteur,

retirer le couvercle

d’accès (6) et soulever

l’interrupteur à flotteur (5)

pour le retirer du réservoir.

Après l’avoir réglé selon les

longueurs illustrées cidessus, remettre l’interrupteur

à flotteur en plaçant le cordon

entre les deux protubérances.

Remettre le couvercle

d’accès en place sur le

réservoir.

Fig. 6

Coussinets d’espacement (un de 6 mm

[¼ po] et un de 13 mm [½ po] fournis.

Revêtement de plancher

(céramique, linoléum, etc.)

Sous-plancher

(contreplaqué, etc.)

SOLIVES DE

PLANCHER 2 X 6

RÉSERVOIR LowPro

4. Caractéristique de la pompe et liste des pièces

Article Nº de pièce Description Qté.

1 4622000 Réservoir, profil bas 1

2 LE41LP Pompe d’égout, 4/10 Hp, 115 V 1

3 4623000 Mamelon, 2 po PVC, nomenclature 80 1

4 462100B Couvercle protecteur de la pompe 1

5 4616000 Interrupteur vertical principal 1

6 462000B Couvercle protecteur de l’interrupteur 1

7 8131000 Rondelle plate ¼ po x ¾ po A. I. 14

8 8129000 Boulon à tête hex. Nº 20, ¼ po X 5/8 po, A. I. 14

9 4022000 Bouchon, orifice double 1

10 4624000 Bride de plancher en laiton 1

11 8018000 Vis à tête bombée nº 20, ¼ po X 5/8 po 4

12 4039000 Joint d’étanchéité de couvercle,

ruban de 1 po X 1/8 po 1

13 4039RA0 Ruban d’étanchéité pour bride de plancher 1

14 CV200C Clapet antiretour, 2 po PVC, raccordements

à compression 1

15 4762000 Œillet d’étanchéité de tuyau, 2 po 1

16 4627000 Bague cirée 1

17 4626000 Trousse d’extension de bride de plancher 1

18 4625000 Ensemble de boulons de cabinet 1

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 5

Page 22

Problème

Cause

Mesure correctrice

La pompe ne

fonctionne pas.

Fusible brûlé ou autre interruption

d'alimentation; tension inadéquate.

S’assurer que le branchement de l’appareil est

sécuritaire. Demander à un électricien de vérifier le

branchement de tous les câbles et de s’assurer que

la capacité et l’intensité sont adéquates.

* L’interrupteur ne peut se mettre en

position de marche en raison de

l’interférence du côté du bassin ou d’un

autre type d’obstacle.

Placer la pompe ou l’interrupteur de manière à ce

que le dégagement soit suffisant pour bien

fonctionner.

Niveau de liquide insuffisant.

S’assurer que le niveau de liquide peut s’élever

suffisamment pour activer le(s) interrupteur(s).

Interrupteur défectueux.

Remplacer l'interrupteur s'il est défectueux.

La pompe refuse

de s’éteindre.

* Le(s) interrupteur(s) ne peu(ven)t se

mettre en position d’arrêt en raison de

l’interférence du côté du bassin ou d’un

autre type d’obstacle.

Placer la pompe ou l’interrupteur de manière à ce que

le dégagement soit suffisant pour bien fonctionner.

Interrupteur défectueux .

Remplacer l'interrupteur s'il est défectueux.

La pompe tourne

ou gronde, mais

ne pompe pas.

Conduits d’évacuation bloqués ou

restreints.

Vérifier dans la canalisation d’évacuation qu’il n’y ait

pas de corps étrangers, y compris de formation de

glace si la canalisation d’évacuation se trouve dans

des zones froides ou les traverse.

Clapet antiretour bloqué en position

fermée ou incorrectement installé.

Retirer tout clapet antiretour et vérifier qu’il

fonctionne librement et est bien installé.

Robinet vanne ou clapet à bille fermé.

Ouvrir le robinet-vanne ou le clapet à bille.

La charge ascensionnelle totale dépasse

la capacité de la pompe.

Essayer de rediriger le tuyau à un niveau inférieur.

Si c’est impossible, il faut probablement se procurer

une pompe plus puissante. Consulter le fabricant.

Le rotor de la pompe est bloqué ou le

corps de pompe en spirale est bouché.

Retirer la pompe du bassin. Détacher la base de la

pompe et nettoyer la zone entourant le rotor.

Remonter et réinstaller.

La pompe tourne

périodiquement

lorsque les

accessoires ne

sont pas utilisés.

Clapet antiretour non installé, bloqué en

position ouverte ou qui fuit.

Retirer tout clapet antiretour et vérifier qu’il

fonctionne librement et est bien installé.

Les accessoires coulent.

Réparer les accessoires au besoin pour éliminer

les fuites.

La pompe fait

du bruit.

Corps étrangers dans les cavités du

rotor.

Retirer la pompe du bassin. Détacher la base de la

pompe et nettoyer la zone entourant le rotor.

Remonter et réinstaller.

Rotor brisé.

Consulter le fabricant pour obtenir de l’information

au sujet du remplacement du rotor.

Coussinets usés.

Retourner la pompe au fabricant ou la faire réparer

par un réparateur autorisé.

Raccordements des tuyaux trop rigides à

la structure de la maison.

Remplacer une partie du tuyau d’évacuation par un

boyau ou un raccord en caoutchouc.

5. Entretien et dépannage

Danger d’électrocution. Toujours débrancher la pompe de l'alimentation électrique avant de la manipuler ou d'y

effectuer des réglages.

REMARQUE : Liberty Pumps, Inc. n’est pas responsable des dommages ou blessures résultant d’un démontage sur le terrain. Le

démontage effectué ailleurs que chez Liberty Pumps ou à l’un de ces centres de services autorisés annule automatiquement la garantie.

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 6

Page 23

Garantie limitée de 3 ans

7000, avenue Apple Tree

Bergen (NY) 14416

Téléphone : (800) 543-2550

Télécopieur : (585) 494-1839

www.libertypumps.com

REMARQUE : Liberty Pumps, Inc. n’est pas responsable des dommages ou blessures résultant d’un démontage sur le

terrain. Le démontage effectué ailleurs que chez Liberty Pumps à l’un de ces centres de services autorisés annule

automatiquement la garantie.

Liberty Pumps, Inc. garantit que les pompes sortant de son usine sont exemptes de tout défaut de matériau et de

fabrication pour une période de 3 ans à partir de la date d’achat. La date d'achat sera établie par une facture d’achat

datée indiquant les numéros de modèle et de série de la pompe. La pompe retournée doit être accompagnée de la

facture d’achat datée si la date de retour se situe à plus de 3 ans du numéro de « CODE » (date de fabrication) indiqué

sur la plaque signalétique de la pompe.

L’obligation de garantie du fabricant se limite à la réparation ou au remplacement de toute pièce jugée défectueuse par le

fabricant, à condition que la pièce ou l’appareil soient retournés franco de port au fabricant ou à son centre d'entretien

autorisé et à condition qu’il n’y ait aucune preuve que les critères suivants annulant la garantie sont en cause.

Le fabricant ne peut en aucun cas être tenu responsable, selon les dispositions de cette garantie, si le produit n’a pas été

correctement installé; s’il a été démonté, modifié, soumis à un usage abusif ou endommagé; si le cordon électrique a été

coupé, endommagé ou ligaturé; si la taille du tuyau d’évacuation de la pompe a été réduite; si la pompe a été utilisée pour

pomper de l’eau d'une température supérieure aux recommandations ci-dessus ou de l’eau contenant du sable, de la

chaux, du ciment, du gravier ou autres matières abrasives; si le produit a été utilisé pour pomper des produits chimiques

ou des hydrocarbures; si un moteur non submersible a été exposé à de l’humidité excessive; ou si l’étiquette portant le

numéro de série, de modèle et de code a été retirée. Liberty Pumps, Inc. ne pourra être tenue responsable des pertes,

dommages, frais attribuables à l’installation ou l’utilisation de ses produits ni pour les dommages accessoires ou

consécutifs, y compris les coûts de retrait, de réinstallation ou de transport.

Il n’y a aucune autre garantie expresse. Toute garantie implicite, y compris celles de qualité marchande et d'aptitude

à une fin particulière est limitée à trois ans à partir de la date d’achat.

Cette garantie contient le recours exclusif de l’acheteur et exclut, lorsque permis par la loi, toute responsabilité pour

dommages consécutifs ou accessoires en vertu de toutes autres garanties.

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 7

Page 24

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 8

Loading...

Loading...