Page 1

IMPORTANT:

Prior to installation, record Model, Serial Number, and

Code Number from pump nameplate for future reference.

MODEL ________________________

SERIAL ______________________

CODE ______________________

INSTALLATION

DATE _______________________

Installation Manual

7298000B

Manual Contents:

1. General Information

2. Precautions / Pre-Installation

3. Installation Instructions

4. Maintenance & Troubleshooting

5. Guide rail Assembly

Engineered Pump Systems (EPS)

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

By definition, an EPS system is a custom product and some differences in materials, pumps, and

design are unavoidable. This manual is intended as a generic guideline only. Any specific questions

should be directed to Technical Customer Service Department at the Liberty Pumps Factory

(PH: 1-800-543-2550, E: support@libertypumps.com)

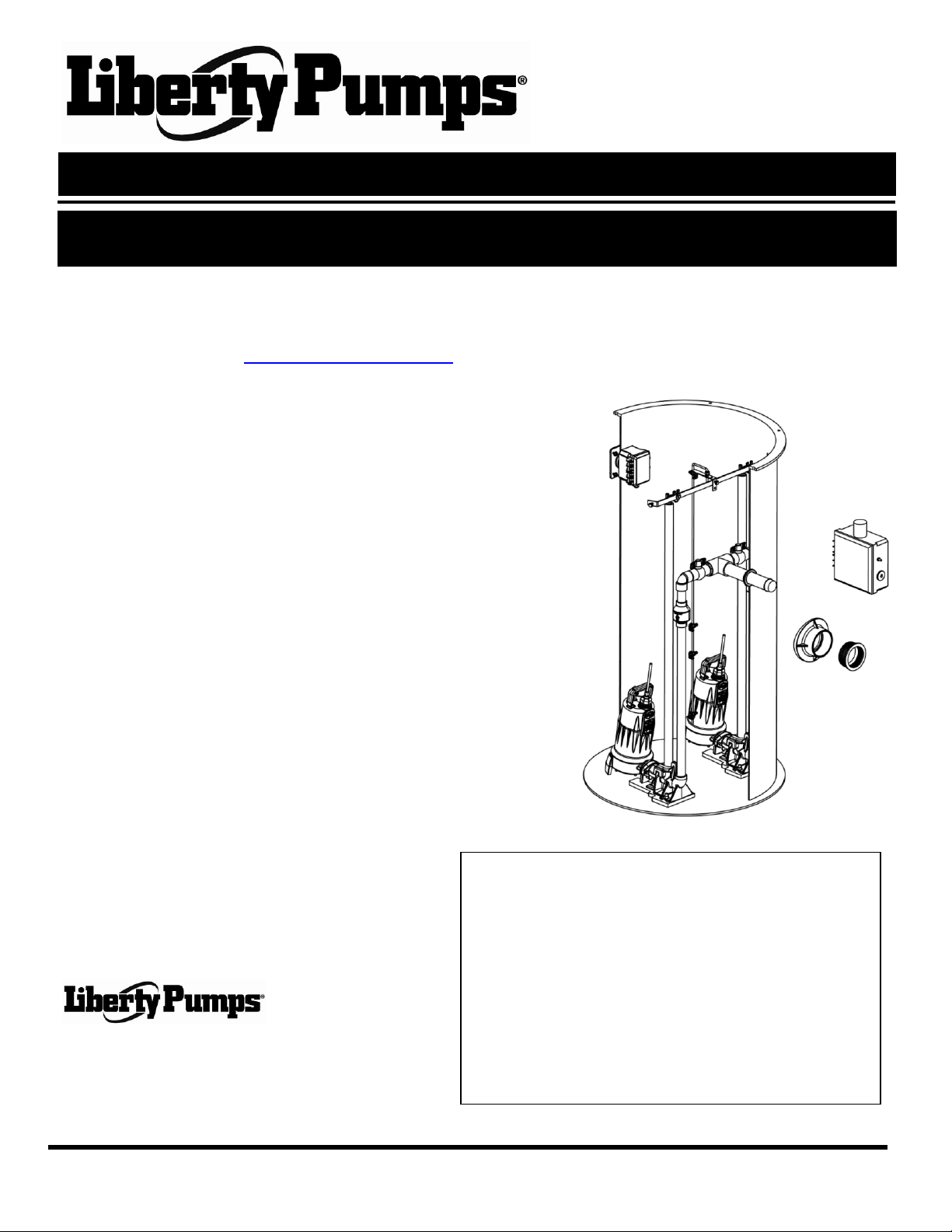

Common Components:

Fiberglass Tank

Sump, Effluent, Sewage or Grinder Pump(s)

Factory Installed Guide Rail System

Pre-mounted float system

NEMA 4X Junction Box

Inlet hub

Control Panel or Alarm System

©Copyright 2014 Liberty Pumps Inc. All rights reserved 1

Page 2

1 General Information

®

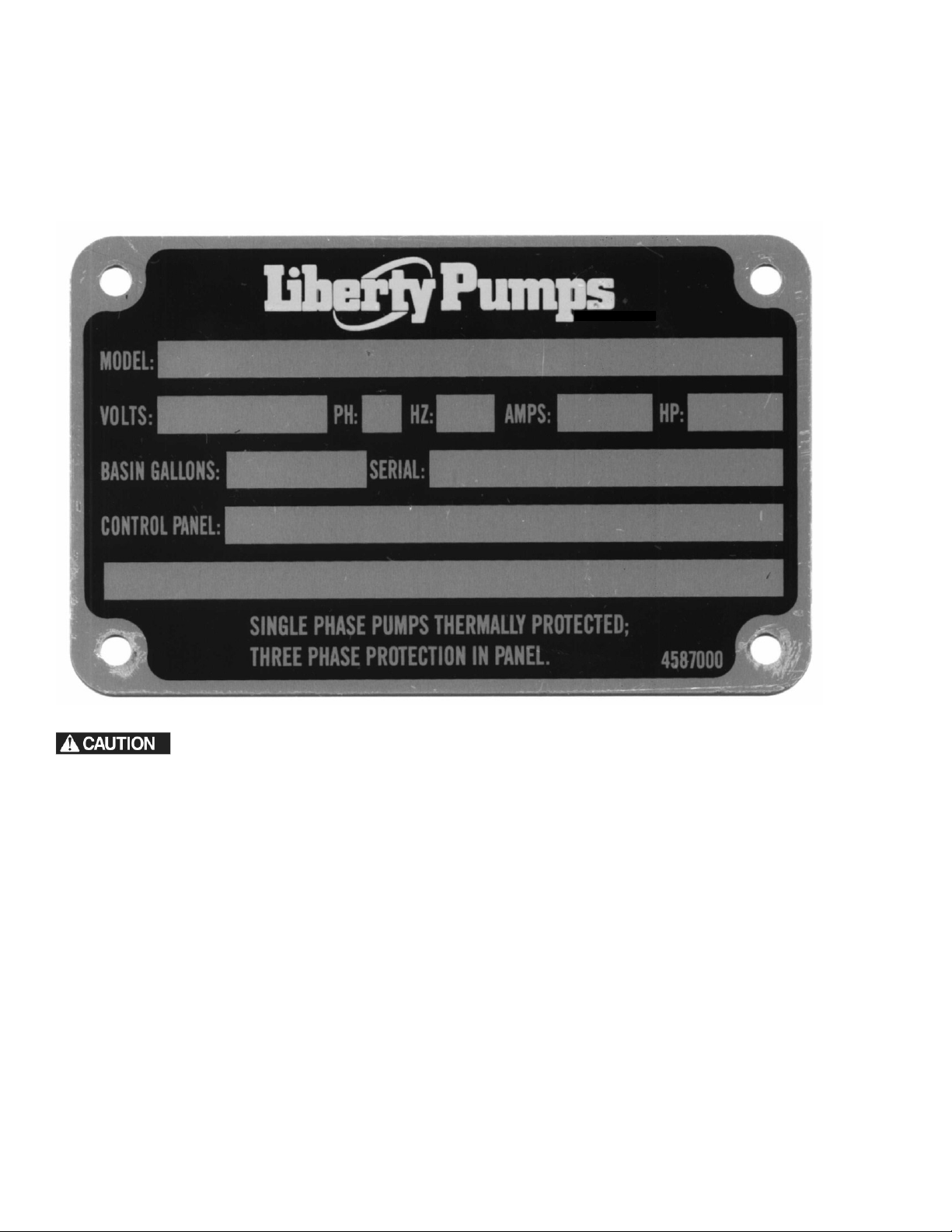

General information about a particular EPS can be found on a stamped metal tag that is located on the basin

cover. This will identify the EPS model number as well as the horsepower, voltage, and amp draw for the

pumps. Separate tags are located on the pump(s). Duplicate pump tags are packaged with the system. These

should be mounted on the tank cover or at the control panel for accessibility and immediate knowledge of the

pump(s) installed.

The pump and the control panel are supplied with their own separate Installation/Operation/Maintenance manuals.

Ensure that you have received these manuals, and that you read and understand them prior to installing this unit. Your familiarity with

the pump manual and the control panel manual is critical. This installation manual gives a brief overview of the system, and deals mainly

with inspection and installation of the basin, but it does not cover the specifics of the pump operation or the control panel operation. If

you have any questions, call customer service at (800) 543-2550.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 2

Page 3

2 Precautions / Pre-Installation

Risk of electric shock. Always disconnect the pump from the power source before handling or making adjustments.

These pumps are not to be installed in locations classified as hazardous in accordance with the National Electric Code, ANSI/NFPA

70.

The electrical connections and wiring for a pump installation should only be made by qualified personnel.

This pump is supplied with a grounding conductor or a grounding-type attachment plug. To reduce the risk of electric shock, be

certain that the grounding conductor is connected only to a properly grounded control panel or, if equipped with a grounding-type

plug, that it is connected to a properly grounded, grounding-type receptacle.

Do not bypass grounding wires or remove ground prong from attachment plugs.

Do not remove cord and strain relief, and do not connect conduit to pump.

Do not use an extension cord.

This system requires separate, properly fused and grounded branch circuit. Make sure the power source is properly sized for the

voltage and amperage requirements of the system, as noted on the nameplate.

The installation must be in accordance with the National Electric Code and all applicable local codes and ordinances.

Sump and sewage pumps often handle materials which could cause illness or disease. Wear adequate protective

clothing when working on a used pump or piping.

Never enter a pump basin after it has been used. Sewage and effluent can emit several gases which are poisonous.

Pre-installation checklist:

1. Inspect the unit upon arrival to ensure that there is

no shipping damage. Pay careful attention to the

condition of the fiberglass basin, control floats,

pump guide rail brackets, and control panel. Notify

the carrier immediately if there is any damage.

2. Read all instructions and familiarize yourself with

the unit’s operation prior to proceeding with the

installation.

3. A qualified licensed electrician should install and

test all electrical circuits.

4. Check to ensure that your power source is adequate

to handle the pump amperage as noted above and on

the pump nameplate. Ensure that the electrical supply

circuit is equipped with fuses or breakers of the proper

capacity.

5. A separate 115V branch circuit should be installed for

the control circuit. We do not recommend splitting

the incoming pump power circuit to power the control

circuit.

6. All electrical connections should be tested to ensure

that a proper ground has been established

3 Installation Instructions

1. Excavation: Excavate the hole for the basin as small as possible, with a minimum base diameter at least 2”

wider than the diameter of the anti-floatation flange. Never place the basin in direct contact with rocks or other

sharp objects. Place enough fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone at the bottom of

the excavation to create a minimum of 12 inches stone or gravel after compaction. Do not use sand or native soil

as backfill*. Properly compact underneath the basin to provide a solid, level base that can support the weight of

the filled basin. If a concrete pad will be used under the basin, the compacted stone sub-base can be reduced to

6 inches.

2. Connections & Backfill: Pour enough concrete over and around the anti-floatation flange to anchor the basin

and prevent upward movement. Connect schedule 80 PVC pipe to the pump discharge. Do not increase the

discharge piping to a larger size than the pump can handle. The remainder of the discharge line should be as

short as possible with a minimum number of turns. Connect the inlet line to the inlet hub that was included with

the system. Connect the electrical coupling to 2” electrical conduit and run the power and float cords through the

conduit to the control panel. The remaining backfill should be only fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2"

washed, crushed stone. Do not use sand or native soil as backfill*. Do Not exert heavy pressure or run heavy

equipment over the backfill material, as it may cause tank collapse.

*Other backfill options may be available – consult the factory for special instructions relative to your situation.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 3

Page 4

EPS

System

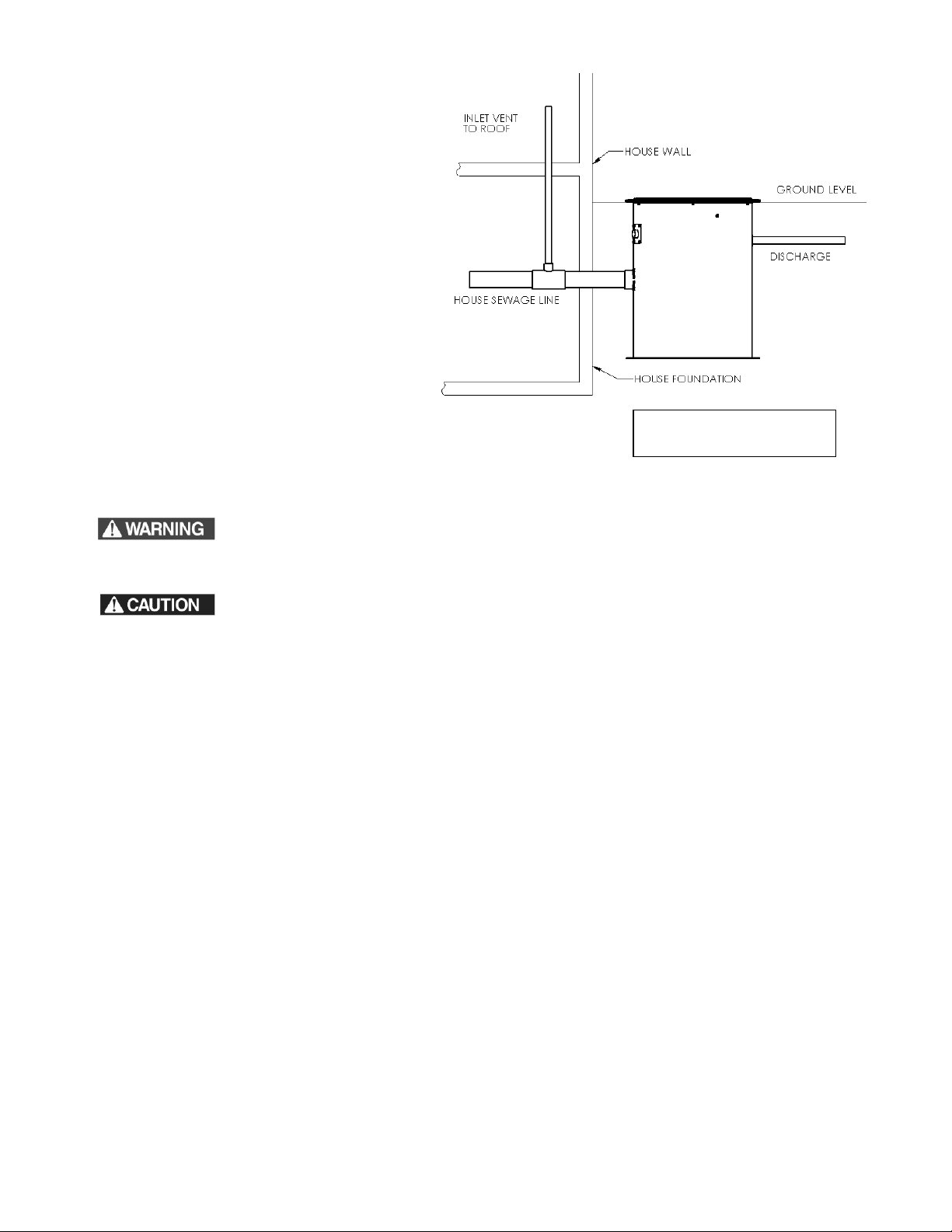

Figure A – Inlet Venting

3. Venting: The fiberglass basin provided

with the system must be completely sealed

and properly vented in order to meet health

and plumbing code requirements. The

system is designed to be vented through

the inlet to an existing building vent stack.

In order to accomplish this, there must be

no traps between the system inlet and the

nearest building vent stack connection.

See Figure A for an example. If this is not

possible or desirable in your application, a

vent flange or grommet can be installed in

a hole cut into the solid fiberglass cover.

4. Control Panel:

Risk of Electric shock: This pump is supplied with a grounding conductor. To reduce the risk of

electric shock, be certain that it is connected only to a properly grounded earth wire. All electrical circuitry should be

installed in accordance with the National Electric Code (NEC) and all applicable local codes or ordinances.

The control panel or alarm that is an integral part of this complete unit is supplied with its own

separate Installation/Operation/Maintenance manual. Ensure that you have received this manual, and that you read

and understand it prior to installing this unit. Your familiarity with the control panel manual is critical.

A separate 115V branch circuit should be installed for the control circuit. We do not recommend splitting the

incoming pump power circuit to power the control circuit. Connect the grinder pump leads and the float switch leads

to the control panel in accordance with the instructions included with those units.

5. Float Switches: The EPS is commonly supplied with a control panel that will either use float switches or a

pressure transducer to detect the water level in the basin. The float switches are pre-mounted on a quick tree.

For quick tree removal, loosen the cord nut and pull the tree straight out of the tank. The pump cycle is pre-set at

the factory, but may need to be modified depending on the depth in which the inlet hub is installed. Please call

the factory if you need to adjust the pump cycle beyond this recommended level.

6. Testing and Startup: Follow the testing and startup procedures found in the pump and control panel manual.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 4

Page 5

4 Maintenance and Troubleshooting

The pump(s) and control panel are supplied with their own separate Installation/Operation/Maintenance

manuals. Ensure that you have received these manuals, and that you read and understand them prior to installing this

unit. Your familiarity with the pump manual and the control panel manual is critical. Please follow the Maintenance and

Troubleshooting procedures provided in those manuals.

Because an EPS system can contain a large array of components, it would be ineffective to

include a complete troubleshooting list for each an every combination of components. Below

we have listed the most common problems and explanations. For further questions, please

contact our Technical Customer Service Department at 1-800-543-2550 or

support@libertypumps.com.

Pump running, but not pumping

1) Open ball valves at the street

Many times ball valves are left closed after installation and before the system is in use. Because there could be

multiple contractors or installers involved on a project, this could be missed when the system is finally in use.

With the ball valves closed, the pumps cannot remove water and will run continuously. This could cause flooding,

overheating the pumps, and damage to the system. To prevent this from happening, observe a complete cycle to

confirm pump(s) can remove water.

2) Open ball valves inside the tank

All EPS systems come equipped with ball valves for servicing. Ball valves should come from the factory in the

“open” position, but an installer may close them initially while the system is not in service. A closed ball valve

would not allow the pumps to remove any water and they would run continuously. This may cause overheating

and possibly damage to the system. A closed ball valve will have the handle perpendicular to the valve, while an

open ball valve will have the handle parallel to the valve. To prevent this occurrence, check all the ball valves

before powering-up the system and do a test run to make sure that any pumps in the system are able to evacuate

water.

3) Ensure that the pump is positioned correctly on the guide rail base

Liberty guide rail systems (GR20, GR22, and GR30) feature a self-aligning mounting bracket. When properly

installed, the pump should sit at an angle with the guide rail claw seated firmly on the guide rail base and the

guide rail gasket will be compressed by the weight of the pump. If the pump does not seat properly, the gasket

will not seal which will result in blow-by when the pump turns on. The same could happen if the guide rail gasket

is out of place. This could result in the water not evacuating the tank, longer cycle times, pump overheating, and

possibly even damage to the system. To fix this problem, pull on the lifting chain to move the pump into correct

position in respect to the guide rail (see Section 5).

4) Check Voltage at the panel

When pumps need to be installed long distances from a power source, special care must be taken to properly

size the wire being used. Considerations must be made for the pump’s required voltage, phase, Full-load amps,

and the length of wire. Proper sizing should be done by a professional electrician, but using a sizing tool as a

guide should get you an approximation. This would be a better alternative than guessing or even worse, using

the same gauge wire as the pump was supplied with. When insufficient wire size is used, there will be a Voltage

drop across the wire (anything higher than a 3% drop would be insufficiently sized). To detect a Voltage drop, the

©Copyright 2014 Liberty Pumps Inc. All rights reserved 5

Page 6

Figure B – Pump Rotation

voltage should be measured at the implementation point, usually the control panel, with the pump running.

Measuring the voltage at the implementation point will show you what Voltage the pump is seeing. Measuring the

voltage while the pump is running will give you a good idea of the voltage drop while the pump is under load. A

pump should not be used in voltage extremes greater than it is designed to handle.

5) Check pump rotation (3 phase only)

Three phase power uses three separate alternating currents that peak at different integrals. With pumps that are

powered by three phase electric, the phase sequence of the motor must match the phase sequence of the power

source. When the sequences match, the pump will operate properly. However, when the phases are out of

order the pump will run backwards (i.e. the impeller will rotate in the wrong direction). This will cause an extreme

loss of performance and could raise the amps drawn, which could result in tripping an overload or circuit breaker.

To ensure that the power to the pump is installed correctly, always check the rotation of the pump before lowering

it into the pit. The correct rotation is shown below for a grinder and sewage pump (Figure B). If the pumps are

rotating in the wrong direction, turn off the power and reverse any two leads. This will reverse the phase

sequence and will correct the pump rotation.

6) Check to see if pump is jammed

The nature of sewage pumps is to pass solids. Each sewage pump has a solids-handling specification that it is

designed to pass. On the other hand a grinder pump will grind any solids into a slurry, and then pump them.

Occasionally, a pump being used to pump sewage will become jammed on a large solid, especially when it is not

the intended usage. When a pump is jammed, some foreign material is keeping the impeller or cutter (grinder

pumps only) from rotating, which effectively stops the motor. If a pump remains on in this condition, you should

be able to detect a humming noise coming from the pump and the pump will usually overheat itself and turn off

due to thermal overload. To check for a jam, the pump must be removed from the basin. Always disconnect the

pump from electrical power before checking for a jam. The pump inlet is located on the bottom of the pump, so

we recommend putting the pump on its side or fixturing it upside down to look at the inlet. Inspect the impeller or

cutter for any foreign material, and try to spin the motor shaft. If it is unable to rotate, the pump is jammed.

Locate the jam, and attempt to remove whatever is restricting the impeller or cutter. A grinder pump has such a

small gap, that it may require the cutter to be hit with a screwdriver and hammer in the reverse direction to

remove any foreign material.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 6

Page 7

Pump not turning on

1) Check that control floats are unobstructed and operate properly

Most EPS systems come with control panels to operate the pumps. These panels commonly make use of float

switches to send a signal back to the panel. The floats will be positioned at various levels to accomplish the

intended pump cycle. As the water level raises, the floats will rise as well on their tether and activate a switch

located inside the float. If something inside the tank obstructs the float from rising, it would not be able to activate

and the control panel would not operate the pumps. This would usually result in the high level alarm triggering or

flooding. Likewise, if a float switch is trying to drop and it cannot because it is resting on another object, it would

not signal the control panel to disengage the pumps and they would run continuously. This would result in

overheating or damage to the system. Always check for proper float operation throughout the cycle. Take care

to notice if the float has the ability to hang up on anything inside the tank including the pumps themselves or the

power cords.

2) Check that panel has control power

Control panels utilize a complex series of circuits to properly control the duty cycles of the pumps. These circuits

must be powered, commonly with 120 V, single phase electric. The circuit powering the controls should be

separate from the circuit powering the pumps. There will be a dedicated set of terminals to connect power to the

control circuitry. Failing to power the controls will result in the pumps not operating automatically. Most panels

have an LED light that will turn on when control power is properly installed.

3) Attempt to run pump(s) manually with control panel

All control panels should come equipped with HAND-OFF-AUTO switches (H-O-A) that can be used to change

the operation of the control panel. The HAND mode is another name for manual. If the control panel is set to

HAND mode it will automatically run the pump no matter what the current liquid level is. The OFF mode does the

opposite. When the control panel is set to OFF mode it will not run the pumps no matter what the current liquid

level is. The AUTO mode is the normal operation mode. In AUTO mode the floats (or in some cases transducer)

will trigger the control panel to operate the pump, turning “On” when the liquid level reaches a certain height, and

turning “Off” when the liquid level falls to a certain height. If the pump(s) is not turning on in the AUTO mode, you

may troubleshoot the system by temporarily changing the control panel to HAND mode. If the pumps operate

and pump down the liquid level, this would signify that the problem is with sensing the water level, most likely one

of the floats is not working correctly. It could be out of position, obstructed, or defective.

4) Attempt to run pump(s) automatically by hand or by adding water to the tank

All of our systems are meant to run automatically. The pump(s) would be controlled by an automatic float switch

or through a control panel which would utilize either float switches or a pressure transducer. After installing a

pump system, it would be a good idea to run the pump(s) through a cycle by adding water into the pit in order to

operate the pump. If adding water is not an option, raising the float switches by hand in the order that they would

normally raise would simulate water entering the pit. If the pumps turn on, evacuate the water, and turn off, then

you would know that they system is working properly. This same method can be used to troubleshoot a pump

that is not turning on some time after installation. An advantage of using a control panel is that commonly each

float would have its own LED light inside the panel. By raising the floats by hand or with water, you could easily

tell if a float was not functioning by whether or not it turns on its corresponding LED light.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 7

Page 8

5) Check that control fuse is not blown

Control panels will usually have circuit breakers or other overload protection to protect a pump from burning itself

out from overdrawing current. Similar to this, the control circuit has its own built in protection in the form of a fuse.

Usually there will be two circuits, one for control power and one for alarm power. Each will have its own fuse that

would blow under a high amperage condition. If power is not reaching the control circuitry, it is possible that the

control power fuse has blown and would need to be changed. To check the fuse, there is plastic fuse holder that

needs to be loosened and then pulled out. Turn this knob counterclockwise to loosen and pull the fuse holder out.

If the fuse has blown, it will appear blackened and burnt. For the user’s convenience, the control panels are

equipped with replacement fuses of the correct size on the inside of the front door.

Problems Exclusive to 3 Phase Systems:

1) Check for rotation on 3-phase pumps

Three phase power uses three separate alternating currents that peak at different integrals. With pumps that are

powered by three phase electric, the phase sequence of the motor must match the phase sequence of the power

source. When the sequences match, the pump will operate properly. However, when the phases are out of

order the pump will run backwards (i.e. the impeller will rotate in the wrong direction). This will cause an extreme

loss of performance and could raise the amps drawn by the pumps. To ensure that the power to the pump is

installed correctly, always check the rotation of the pump before lowering it into the pit. The correct rotation is

shown below for a grinder and sewage pump (Figure B). If the pumps are rotating in the wrong direction, turn off

the power and reverse any two leads. This will reverse the phase sequence and will correct the pump rotation.

2) Check overloads for tripping in 3-phase panel

All the three phase panels have overload protection included inside the control panel enclosure, usually located

directly adjacent to the motor contactors. These switches are set for a certain amp rating based on the pump

being used. The switches are in the horizontal position when tripped (off). To reset the switch, turn the knob

clockwise into a vertical position. Please note that the switches come in “off” position. They must be reset during

installation to be able to supply power to the pumps.

3) Check overload amp level in 3-phase panel

All the three phase panels have overload protection included inside the control panel enclosure, usually located

directly adjacent to the motor contactors. These switches are set for a certain amp rating based on the pump

being used. Underneath a clear screen on the overload, there is a dial which represents the amp level that

overloads are set to. This amp level should represent the Full-load amps (FLA) of the pump being connected to

the control panel. To check that the amp level is correct look at the tags located on your pumps. There will be a

FLA listed on the tag. The setting on the overload should be set at least this high, and could be set as much as

10% or 1 amp higher, whichever is greater. Not having this set correctly could result in nuisance tripping of the

overload which would not allow the pump to operate.

4) Confirm that transformer connections were made

Our three phase panels power the controls through a transformer that will accept three phase power, and convert

it to 120 V, single phase for control power. All of our three phase panels are designed to be able to run on 208 V,

240 V, and 480 V three phase electric, and thus an adjustable transformer is required. To accommodate each

different voltage, there is a lead to the primary voltage tap to the transformer that needs to be connected. The

lead will come with a label to instruct which terminal to connect to, based on which voltage is being used. If this

lead is not connected, the transformer will not deliver power to the controls of the panel and the panel will not be

able to operate the pumps. If this lead is incorrectly connected, the control panel circuits could be damaged.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 8

Page 9

ENSURE THAT

GROMMET IS

PROPERLY

INSTALLED

GR20

GR30

GR22

ENSURE THAT

RUBBER

GROMMET IS

PROPERLY

INSTALLED HERE

5 GR-Series Quick Disconnect Assembly

GR20, GR22, and GR30 Assembly

The GR20, GR22 and GR30 quick disconnect assembly provided with your EPS system is designed to allow easy

installation and removal of the pump. When installed correctly it will seal and provide a means to lift the pump without

disconnecting any of the discharge piping. Please ensure that installation is done as per the diagrams below.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 9

Page 10

10-25 DEGREES

GR20 OPERATING POSITION

GR22 OPERATING POSITION

GR30 OPERATING POSITION

GR20 DISCONNECTED POSITION

GR22 DISCONNECTED POSITION

GR30 DISCONNECTED POSITION

1-1/4”

GUIDE RAIL

PIPE

1-1/4”

GUIDE RAIL

PIPE

1-1/4”

GUIDE RAIL

PIPE

1-1/4”

DISCHARGE

PIPE

2”

DISCHARGE

PIPE

3”

DISCHARGE

PIPE

©Copyright 2014 Liberty Pumps Inc. All rights reserved 10

Page 11

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

3 Year Limited Warranty

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and workmanship

for a period of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt

noting the model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date

of return is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found by the

manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its

authorized service center, and provided that none of the following warranty-voiding characteristics are evident:

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been

disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump

discharge has been reduced in size; if the pump has been used in water containing sand, lime, cement, gravel or other

abrasives; if the pump has been used in water above the advertised temperature rating; if the product has been used to

pump chemicals or hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label

bearing the serial, model and code number has been removed.

Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses resulting from installation or use of its products,

or for consequential damages, including costs of removal, reinstallation or transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a

particular purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential

or incidental damages under any and all warranties are excluded.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 11

Loading...

Loading...