Page 1

Operation and Maintenance Manual

Operation and Maintenance Manual

Introduction

Read all instructions thoroughly. Installation of the OilTector must comply with all Federal, State and Local Codes, Regulations

and Practices. The OilTector must be installed by qualified personnel familiar with all applicable local electrical and mechanical codes. Refer to the National Electrical Code (NFPA 70). Failure to properly install and test this product can result in

personal injury or equipment malfunction.

The OilTector control system is designed and approved for the safe operation of pumping, alarming and monitoring of elevator

sump pits, transformer vaults and leachate well applications. The OilTector will activate a pump to remove water from elevator

pits in accordance with ASME A17.1. The OilTector stops the pump before oil or other harmful substances enter our water

supply. Indicator lights will illuminate on the control panel for the following: power, pump running, high alarm, high oil. The panel

has a set of auxiliary contacts that activate on power loss or high Oil/Water conditions. These contacts can be connected to the

OilTector remote panel which contains audio/visual alarming along with auxiliary contacts for connection to building automation

system or SCADA system. The recommended minimum sump size is Ø18” x 30” high.

Safety Guidelines

1. DO NOT USE WITH FLAMMABLE OR EXPLOSIVE FLUIDS SUCH AS GASOLINE, FUEL OIL, KEROSENE, ETC. DO NOT USE IN EXPLOSIVE ATMOSPHERES. PROBE/FLOAT SWITCH SHOULD

ONLY BE USED WITH WATER.

2. DO NOT HANDLE THE OILTECTOR SYSTEM WITH WET HANDS OR WHEN STANDING ON A WET

OR DAMP SURFACE OR IN WATER.

3. DISCONNECT ALL ELECTRICAL SERVICE BEFORE WORKING OR HANDLING THE OIL ALERT

SYSTEM.

4. INCOMING VOLTAGE MUST MATCH OILTECTOR SYSTEM VOLTAGE.

5. TO PREVENT ELECTRICAL SHOCK AND EQUIPMENT MALFUNCTION, USE ONLY WITH A PUMP

SUPPLIED WITH A GROUNDING CONDUCTOR AND GROUNDING-TYPE ATTACHMENT PLUG. BE

CERTAIN TO PLUG THE OILTECTOR PANEL INTO A PROPERLY GROUNDED, GROUNDING-TYPE

RECEPTACLE.

6. CONTROL PANEL AND ALARM MUST BE MOUNTED INDOORS. FOR OUTDOOR APPLICATIONS

CONSULT FACTORY.

7. SECURE LEVEL SENSOR ON DISCHARGE PIPE AT A LEVEL THAT GUARANTEES PARTIAL PUMP

SUBMERGANCE WHEN WATER LEVEL IS JUST BELOW THE “OFF” PROBE (THE LONGEST

PROBE). (See Figure 5 on page 3 of this manual). FAILURE TO PROPERLY MOUNT THE LEVEL

SENSOR MAY CAUSE THE PUMP TO ACTIVATE EVEN WHEN OIL IS PRESENT IN THE SUMP.

8. CAUTION! REMOVE ANY FLOAT SWITCH THAT IS CURRENTLY USED OR SUPPLIED WITH THE

PUMP. IF THE FLOAT CANNOT BE REMOVED, SECURE SWITCH SO THAT IT IS ALWAYS ON.

Part Numbers

OTC-115 - OilTector 115 volt Oil Sensor Control System (Control Panel, Alarm Panel, Level

Sensor). NEMA 4X enclosure.

OTC-230 - OilTector 230 volt Oil Sensor Control System (Control Panel, Alarm Panel, Level

Sensor). NEMA 4X enclosure.

Page 1 of 6

Manual 7235000H

DWG#7235000H

7000 Apple Tree Avenue, Bergen, NY 14416 Phone: (800) 543-2550-Fax: (585) 494-1839-www.libertypumps.com

Page 2

Operation and Maintenance Manual

Operation and Maintenance Manual

Description of Operation

On water rise, level reaches pump “start” probe to start the pump. Pump will remain on until level is below

“off” probe. The “off” probe senses air or oil and turns the pump off so the oil layer will not be pumped out of

the sump. If the liquid level reaches alarm probe and mechanical float, the system will differentiate between

water and oil and activate the remote alarm.

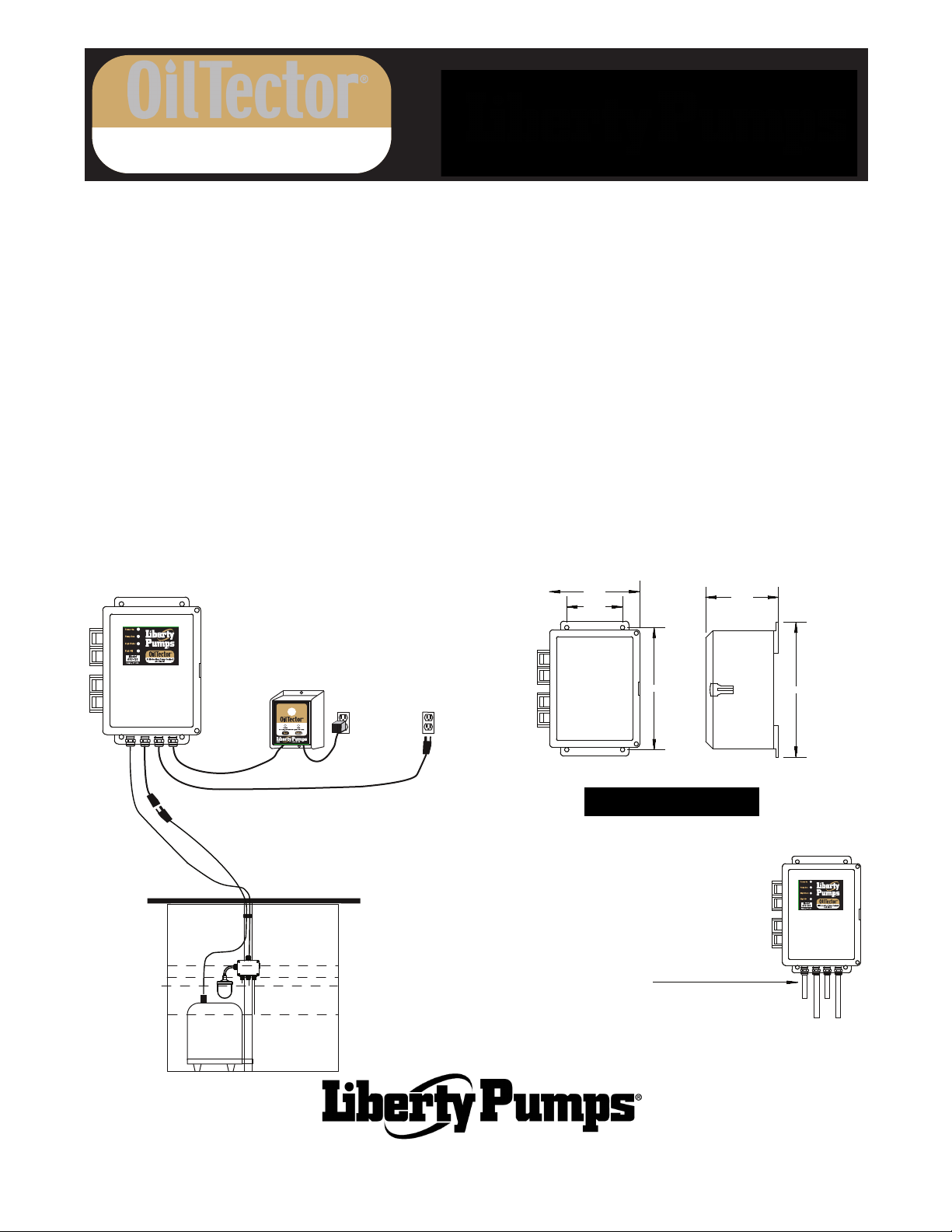

Installation of the Control Panel

1. It is highly recommended to mount the control panel in the same area as the sump pump to eliminate any

splicing of sensor and pump wires. See “Installation of Preset Level Sensor Holder” for more information on

splicing.

2. Determine mounting location for the control panel. Mount panel at the desired location making sure the

mounting location of the control panel is within 6 feet of electrical receptacle.

3. Plug pump cable into control panel receptacle cable. Plug power cable into receptacle only when ready for

testing. See Testing System installation.

4. If the panel is to be installed with conduit, the cables and cord seals must first be removed. Please make

note of wire locations. The incoming power 115V is connected to L1 and L2 of the contactor, pump receptacle

is T1 and T2 on the contactor. Low voltage cable from the level sensing module: green - TB1 off probe,

yellow - TB2 start probe, red - TB3 alarm probe, white - TB4 float, black - TB5 float. Low voltage auxiliary

contacts are TB6 and TB7. Do not mix low voltage probe wires or auxiliary contacts in high voltage conduits.

See figure 3 and figure 6.

Control Panel

60500A0

Elevator Sump

Pump “On”

Level

Pump “Off”

Level

Figure 1

Remote alarm can be mounted

2500 ft. from control panel!

Remote Alarm has

additional auxiliary

contacts for building

alarm system.

120 V

Receptacle

Oil “Film”

Detection Level

Figure 2

.50"

4.02"

8.82"

120V/240V

Power

Depending

On Model

Warning – Do not mix high and low voltage circuits in the

same conduit, failure to do so will cause system malfunction. The Preset Level Sensor and Auxiliary

Contact wires are low voltage class 2 circuits

- Do not install sensor cables in conduits

with main power or pump cables.

Figure 3

Conduit

A Conduit – Low Voltage Preset Level Sensor

B Conduit – High Voltage Pump Cable

C Conduit – High Voltage Incoming Power Cable

D Conduit – Low Voltage Auxiliary Contact for Remote Alarm

5.25"

9.75"

ABC

A B C

60500A0

D

D

Page 2 of 6

Manual 7235000H

DWG#7235000H

7000 Apple Tree Avenue, Bergen, NY 14416 Phone: (800) 543-2550-Fax: (585) 494-1839-www.libertypumps.com

Page 3

Operation and Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Installation of Preset Level Sensor Holder

1. Review figures 4, 5 and 6.

2. Attach sensor holder to discharge pipe or separate pipe (mounted to side wall) using the stainless

steel pipe clamp. Make sure sensor is clear of inlet water and at least 1” to 2” away from any conductive

material. Make sure the bottom probe (off level) is at the same height as the top of the pump or just slightly

below ensuring submergence of the pump. See figure 5.

3. Route the five conductor cable to the control panel through the liquid tight cord connector and tighten

compression nut.

4. Connect the wires from the level sensor to the terminal strip inside the control panel. See figure 6.

5. If splicing on sensor cable is required:

Figure 4

A. For any splicing longer than 100 feet, consult factory.

B. Use liquid tight junction boxes and appropriate liquid tight

connectors and/or conduit.

C. Do not mix high and low voltage circuits in same junction box.

D. For level sensor splice, it is recommended to use 5 conductor,

18 AWG shielded cable. Only ground the shield on one end of

the cable – easiest to ground shield wire in panel to the ground

High Level

Float

lug.

Preset Level

Sensor Holder

High Level

Probe

Pump

Start

Off

Probe

Side Wall

Mount

Circuit Board

1 2

Figure 6

4 6 7

3

5

Figure 5

Discharge Pipe

Mount

Green

Off

Probe

Yellow

Start

Probe

Red

Alarm

Probe

White

Float

Black

Auxiliary Contacts

Float

24VDC, 1A

Conect to Remote Alarm

Or BAS/SCADA System

5 Conductor Cable from

Preset Level Sensor

Page 3 of 6

Manual 7235000H

DWG#7235000H

7000 Apple Tree Avenue, Bergen, NY 14416 Phone: (800) 543-2550-Fax: (585) 494-1839-www.libertypumps.com

Page 4

Operation and Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Installation of the Alarm Panel

The OilTector Remote Alarm Panel is powered by 120 VAC coming from standard wall outlets and is transformed to 9VDC.

Installing a 9 Volt battery provides battery back-up.

When the OilTector Control Panel’s Auxiliary Contacts “close” the buzzer and light will turn “on” and the alarm panel’s auxiliary

contacts will be activated. Pressing the “silence switch deactivates the buzzer and auxiliary contacts. When the OilTector Control

res

Panel’s Auxiliary Contacts reset, the remote alarm panel will automatically

et itself.

Test product weekly. Make sure the green ”power on” light is “on”. Press the “Test” switch; the red alarm light and buzzer should

turn “on”. If the battery back up system is utilized, unplug the wall mount power supply (the green light will be off). Now press the

“Test” switch; the red alarm light and buzzer will turn “on”. If the buzzer sounds less loudly than when tested with the normal power

supply, then replace the battery.

stall 9 VDC battery (Duracell

1. To install/replace the battery for the backup power feature, remove the two side screws and

in

model MX 1604B2). After installing battery, press the test button to activate the alarm to make sure the battery works properly.

Reinstall side screws. See Figures 7.

2. Determine mounting location for the Alarm Panel. Make sure power outlet is within 6 feet of the alarm. Make sure the outlet

is on a separate circuit breaker from any other device and not on a switched receptacle to maintain power integrity. Mount the

alarm using two #8 x 1 1/4" self tapping screws (not included). Use #8 plastic anchor if mounting to sheet rock. See Figure 8.

The alarm can be mounted up to 2500 feet from the panel using 18 ga wire.

3. If Auxiliary Contacts are used, continue; otherwise go to step 4. Remove cover from base and remove 1/2" electrical knockout

from base. Use 16 - 2 AWG stranded wire - make sure there is at least 6" of wire inside of enclosure. Install a 1/2" strain relief

with jam nut. Connect wires for required application using wire nuts. Caution

! - Whe

n installing wires, route all wires away from

sharp objects & internal components. See figures 9 & 10.

4. There are two terminals on the bottom of the alarm panel. Connect a wire from the first terminal to the CONTROL PANEL

terminal #6 and connect another wire from the second terminal of the alarm panel to CONTROL PANEL terminal #7. See Figure

8

5. Plug the power supply into a 120VAC, 50/60 HZ standard wall outlet. For UL applications, remove center screw on receptacle

and place cord from wallmount transformer inside the plastic cord holder. Secure plastic cord holder to

the rece

ptacle by reinstall

ing screw to the center hole of receptacle. See Figure 8. For Canadian applications DO NOT INSTALL Plastic Cord Holder! The

green "Normal" light should come on.

6. Test the system by pressing the "Test" switch. The buzzer and the red warning light will be "on". The green "Normal" light will

be "off". While holding the “Test” switch, press the “Silence” switch. The buzzer will silence, but the alarm light will remain “on”.

” ind

Let go of the “Test” switch and the alarm light will turn “off” and the green “Normal” light will turn “On

icating the system is now

in a normal condition.

Figure 7 - Installing/Replacing Battery

Battery Strap

Connector

Battery

Holder

Figure 9 - Installing Field Wiring for

2 wire cable

To BAS/SCADA

1/2" Strain

Relief

Auxiliary Contacts

1/2" Electrical

Knockout

Jam

Nut

Base

Duracell Model

MX1604B2

9 VDC Battery

Wire Nuts

Use #8 X 1 1/4"

Self Tapping Screws

Terminal Block

connects to terminal

blocks 6 & 7 of the

CONTROL PANEL

Auxiliary Contacts

Connects to BAS/SCADA system

White - Common

Red - Normally Closed

Black - Normally Open

Class 2, 24 VDC/VAC(50/60HZ)

500 milliamps MAXIMUM!

Figure 8 - Mounting

Cover

Base

Figure 10

OilTector

Center

Screw

Mounting Hole (2)

Side Screw

120VAC Wallmount

Receptacle

Plastic

Cord

Holder

Page 4 of 6

Manual 7235000H

DWG#7235000H

7000 Apple Tree Avenue, Bergen, NY 14416 Phone: (800) 543-2550-Fax: (585) 494-1839-www.libertypumps.com

Page 5

Operation and Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Testing the complete system

Upon complete installation of controls, pump and piping, the complete system should be tested for quality assurance.

1. Test high oil circuit by lifting the float switch with the sump empty of water. Oil is non conductive like “air”, and

when the float is lifted only the HIGH OIL indicator will be illuminated. The auxiliary contacts in the control panel

and the remote alarm will activate.

2. Test a pump cycle by slowly filling tank with water. Stop filling tank with water when the level touches middle

probe. When the water touches the middle probe, pump should start and pump down to the bottom probe at

which time the pump will stop. Check discharge plumbing for leads and make sure discharge is going to the

correct area.

3. Test high water circuit. Unplug the pump from the control panel and slowly fill the tank until the water level just

touches the upper probe. When the water touches the upper probe, the HIGH WATER indicator will be illuminated. The auxiliary contacts in the control panel and the remote alarm will activate.

4. Test the remote alarm for power loss. Unplug the power cord on the control panel. The auxiliary contacts will

close and the remote alarm will activate.

Testing panel - Using 5 gallon pail.

If it is not possible to test the complete system outlined above, then test the panel operation using a 5 gallon pail

filled with water. The system requires a temporary ground wire run from the control panel into the liquid in the pail

for correct operation.

1. Run Temporary Ground wire (14 AWG Copper Wire) from the ground lug inside panel and into the pail of

water. Make sure at least ½” of copper wire is exposed and immersed in the water.

2. Before lowering the sensor probe into the pail, lift the float switch, the HIGH OIL indicator will be illuminated.

The auxiliary contacts in the control panel and the remote alarm will activate.

3. Lower the sensor probe into the bucket of water slowly so that the longest probe is immersed in the water.

Slowly continue to lower so the middle probe touches the water, the pump should activate. While the pump is

activated, slowly remove the sensor probe out of the water until the longest probe is no longer in the water, the

pump should turn off. Repeat a couple of times for quality assurance.

4. Lower the sensor probe into the bucket of water slowly so that the longest probe and the middle probe are

immersed in water, the pump will activate. Continue to lower sensor probe so that water touches the shortest

probe, the HIGH WATER indicator will be illuminated. The auxiliary contacts in the control panel and the remote

alarm will activate.

5. This completes testing. Remove temporary ground from panel and retighten ground lug with all the green

wires. Return to manual for “Installation of Preset Level Sensor Holder”.

Ground Lug

60500A0

Temporary 14 AWG Ground Wire

120 V

Receptacle

P

age 5 of 6

Manual 7235000H

DWG#7235000H

7000 Apple Tree Avenue Bergen, NY 14416 Phone: (800) 543-2550-Fax: (585) 494-1839-www.libertypumps.com

:

Page 6

Operation and Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Maintenance

1. The preset level control must be kept clean and free of rust, mud, soap or any conductive material.

2. Every year clean probes keeping them free of debris, calcium or iron deposits.

3. Fuses in control panel are 5mm X 20mm 1/2amp for F1 and 5mm X 20mm 1amp for F2.

(Spare fuses are included for your convenience)

4. Every year replace 9 Volt Battery in Remote Alarm.

Trouble Shooting

Symptom Possible Cause Action

Pump does not run Panel Power Cord Unplugged Plug in Outlet, Check Power

Pump not plugged into panel Plug pump to panel plug

Defective Contactor Replace Contactor

Loose level sensor wires Tighten connections

Pump failure Replace pump

Pump turns off before Poor pump ground or system ground Check grounding system

bottom probe

P

age 6 of 6

Manual 7235000H

DWG#7235000H

7000 Apple Tree Avenue Bergen, NY 14416 Phone: (800) 543-2550-Fax: (585) 494-1839-www.libertypumps.com

:

Loading...

Loading...