Page 1

Installation Manual

7171000D

Access Riser – Fits PRO370 and PRO380 Series

Contents

1.) General Information

2.) Installation

3.) Optional 2” Installation Kits

4.) Typical Installation Diagram

5.) Junction Box Template

Part Numbers and Descriptions

AR18 Riser only

AC18 Cover only

ARC18 Riser and cover kit

IKIT2-115 2” installation accessories, 115 volt hook-up

IKIT2-230 2” installation accessories, 230 volt hook-up

ARCKIT115 Complete kit …riser, cover and installation

accessories, 115 volt

ARCKIT230 Complete kit …riser, cover and installation

accessories, 230 volt

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

Website: www.libertypumps.com

©Copyright 2012 Liberty Pumps Inc. All rights reserved

Page 2

1. General Information

2. Installation

IMPORTANT: This unit is designed to allow a PRO370 or 380 simplex ejector system to be installed up to 18 inches

below grade in an outdoor installation. It is not a gas or water tight tank extension that increases the capacity of the basin.

The riser provides a convenient underground chamber for the electrical and pipe connections to exit underground and

out-of-sight. A green twist-lock cover can be removed to provide access to plumbing connections, valves and the

electrical junction box.

The riser is sold by itself or as a kit with all the necessary components for a professional installation including elbows,

electrical fittings and a junction box.

Check with your distributor if you purchased only the riser and would like the optional 2” installation kit.

NOTE: Due to size constraints, only 2” discharge installation kits are available. 3” discharge systems may require that

some components be mounted outside of the riser.

1. Install the PRO370 or PRO380 sewage system per the instructions included with it. Determine the overall

height of the system and riser when excavating and setting the basin. The cover of the access riser should be at

ground level when backfilling is complete. Burial depth of the system should not exceed 18” below finished grade.

Determine the discharge, electrical, and vent positions relative to the system. The access riser slides over the

PRO370/380 tank and can be rotated in any direction to simplify plumbing. The riser will rest on the concrete

splash lip of the basin.

2. Installation of sidewall pipe seal grommets. Once exit positions have been determined for both the vent and

discharge, a 2” pipe seal grommet can be installed by drilling a 3” hole in the sidewall of the riser. The riser has four

flat areas as well as a large ring that runs around the riser to which the discharge pipe or vent can exit. If both a

check and ball valve are required, the discharge needs to exit on the opposite side as illustrated on page 4. To

ease installation of the pipe through the pipe seal grommet, grease the pipe or use liquid soap as a lubricant.

3. Install the discharge. A short pipe can be threaded into the discharge port of the PRO-Series cover and a 90°

elbow attached. A check valve is recommended to prevent water from back flowing and filling the basin. NOTE: In

northern climates where frost may be a concern, pipes exiting from the side of the system may be exposed to

freezing conditions. If this unit is installed in a frost zone, do not use a check valve. Substitute a union to facilitate

cover removal and pump access. If a check valve is not used, the vertical lift should be minimized to reduce the

amount of back flow after each cycle. A maximum length of 30’ of 2” pipe can be pitched to drain back into the

system. Beyond 30’, discharge piping should be pitched down towards the final discharge destination. A ball valve

is recommended so that back flow can be prevented in the event that the pump or check valve must be removed for

service. When connecting the check valve, ball valve, etc. take care to position items as close to the sidewall of the

riser as possible to allow room for removal of the system cover. Use unions and couplings as necessary to allow for

this.

4. Connection of vent. To maintain hidden pipes, the vent pipe can be routed underground to an existing household

vent. For a 2” vent, a 3” hole should be drilled in the sidewall of the riser where the vent pipe is to exit. Install the

pipe seal grommet, which is included in the kit. The pipe should be lubricated with liquid soap or grease to ease

pipe installation. A 90° elbow with male threads should be threaded into the vent flange of the system. A rubber slip

coupler is provided and should be installed in the vent piping as illustrated on page 4 to allow easy removal of the

system cover and pump if service is required.

5. Connection of electrical. A NEMA 4X weatherproof pump station junction box (Liberty model JB120 or JB230) is

recommended. It can be mounted inside or outside of the access riser. If mounting inside, a template is included in

this manual to drill the four mounting holes. If nonmetallic conduit is used it must be mounted in such a fashion as to

be at least 18 inches below grade. Consult the National Electrical Code (NEC) and local codes for further

information. Additional instructions are included with the JB120 or JB230 box. A qualified electrician should perform

all electrical connections.

©Copyright 2012 Liberty Pumps Inc. All rights reserved - 2 -

Page 3

6. Backfilling. Use only fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone as backfill around the

access riser. Do not use sand or native soil as backfill. Tamp backfill lightly. Avoid running heavy equipment next to

the riser. A light layer of topsoil can be used at cover level.

7. Installation of cover. The cover features a twist-lock design and 4 stainless steel screws to secure it. When

installing the cover, line up the four tabs with the four receptacles and locking tongue which fits into a cut recess in

the under side of the cover. Push down and rotate the cover in a clockwise direction until the tongue bottoms in the

slot. Install the four stainless steel bolts to secure the cover. A padlock can be placed through a hole in the tongue

to deter unwanted entry. The cover is designed to handle light traffic loads such as walking or light lawn and garden

equipment. DO NOT RUN HEAVY TRACTORS OR OTHER EQUIPMENT OVER THE COVER. MAXIMUM LOAD

RATING IS 250 LBS.

Kit Number Description

IKIT2-115 Installation accessories Kit, 2” discharge, 115V wiring box

IKIT2-230 Installation accessories Kit, 2” discharge, 230V wiring box (1-phase)

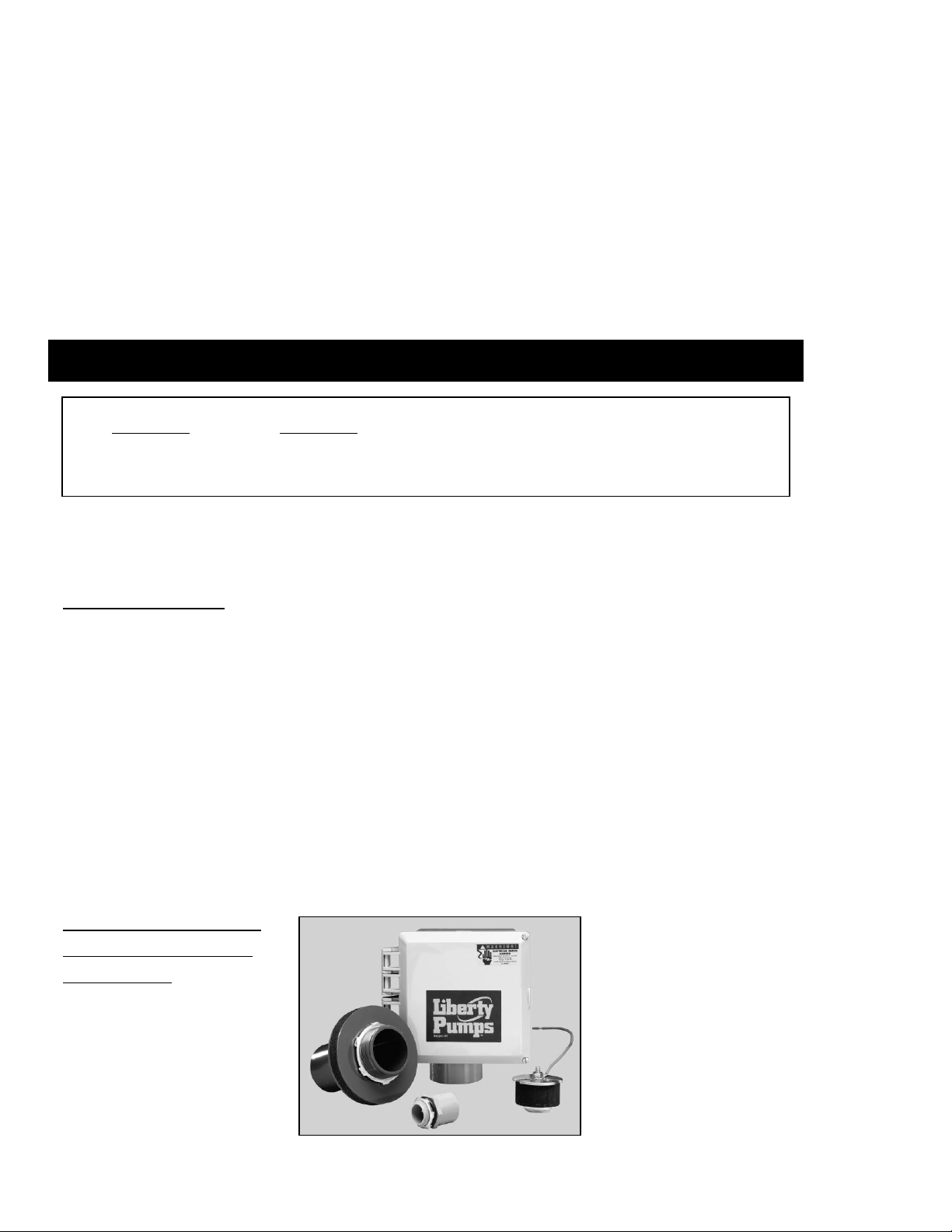

Liberty risers are sold independently or as a kit with all of the necessary installation accessories. If your riser did not

include the installation kit, contact your distributor for pricing and availability or call the factory at 1-800-543-2550. See

Liberty PRO-series literature for complete information on installation kits.

*Installation kits include:

Full flow 2” union-type check valve

PVC Ball Valve

(2) 90 degree PVC elbows

(2) 2” rubber pipe seal grommets

(2) SCH 80 PVC toe nipple ( Threaded pipe)

2” rubber coupler with clamps

Model JB120 or JB230 pump station wiring box with:

Terminal strip with separate alarm and pump control circuit

Receptacle for pump (115 volt or 230 volt depending on model)

Riser extension coupling and washers

Custom-engineered liquid tight cable seal for pump, switch and alarm cords

Electrical conduit hub

*Please note that installation kits do not include Schedule 40 PVC pipe.

JB120 or 230 Pump

Station Wiring Box

(NEMA 4X)

©Copyright 2012 Liberty Pumps Inc. All rights reserved - 3 -

Page 4

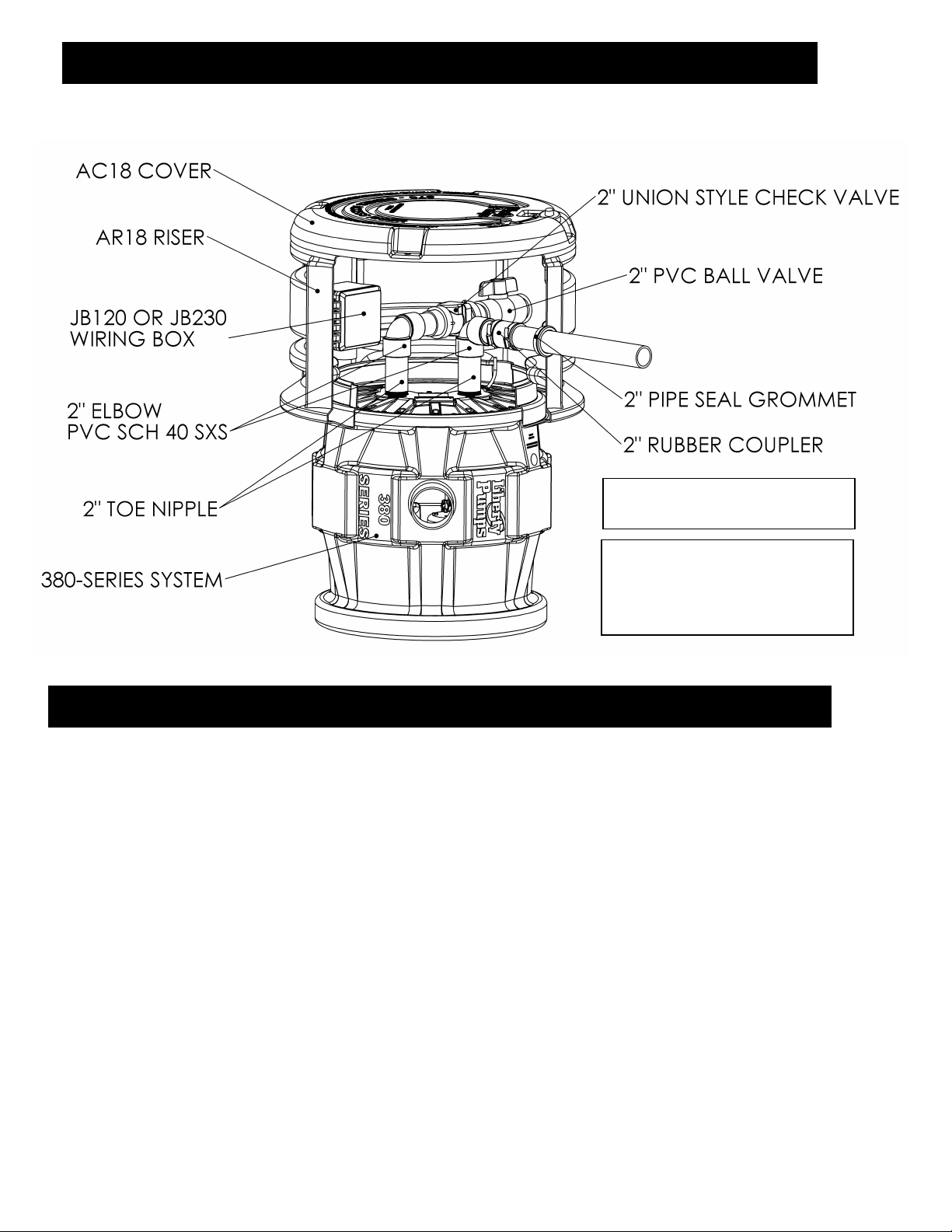

4. Typical Installation Diagram (PRO380 shown)

Liberty installation kits are available

in 2” only. Due to size constraints,

certain component of 3” discharge

systems may need to be mounted

outside of the riser.

Installation components from

IKIT2-115 or IKIT2-230 shown.

5. 3 Year Limited Warranty

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and workmanship

for a period of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt

noting the model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date

of return is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found by the

manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its

authorized service center, and provided that none of the following warranty-voiding characteristics are evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been

disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump

discharge has been reduced in size; if the pump has been used in water temperatures above the advertised rating, or

water containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or

hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label bearing the serial,

model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses

resulting from installation or use of its products, or for consequential damages, including costs of removal, reinstallation or

transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a particular

purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or

incidental damages under any and all warranties are excluded.

©Copyright 2012 Liberty Pumps Inc. All rights reserved - 4 -

Page 5

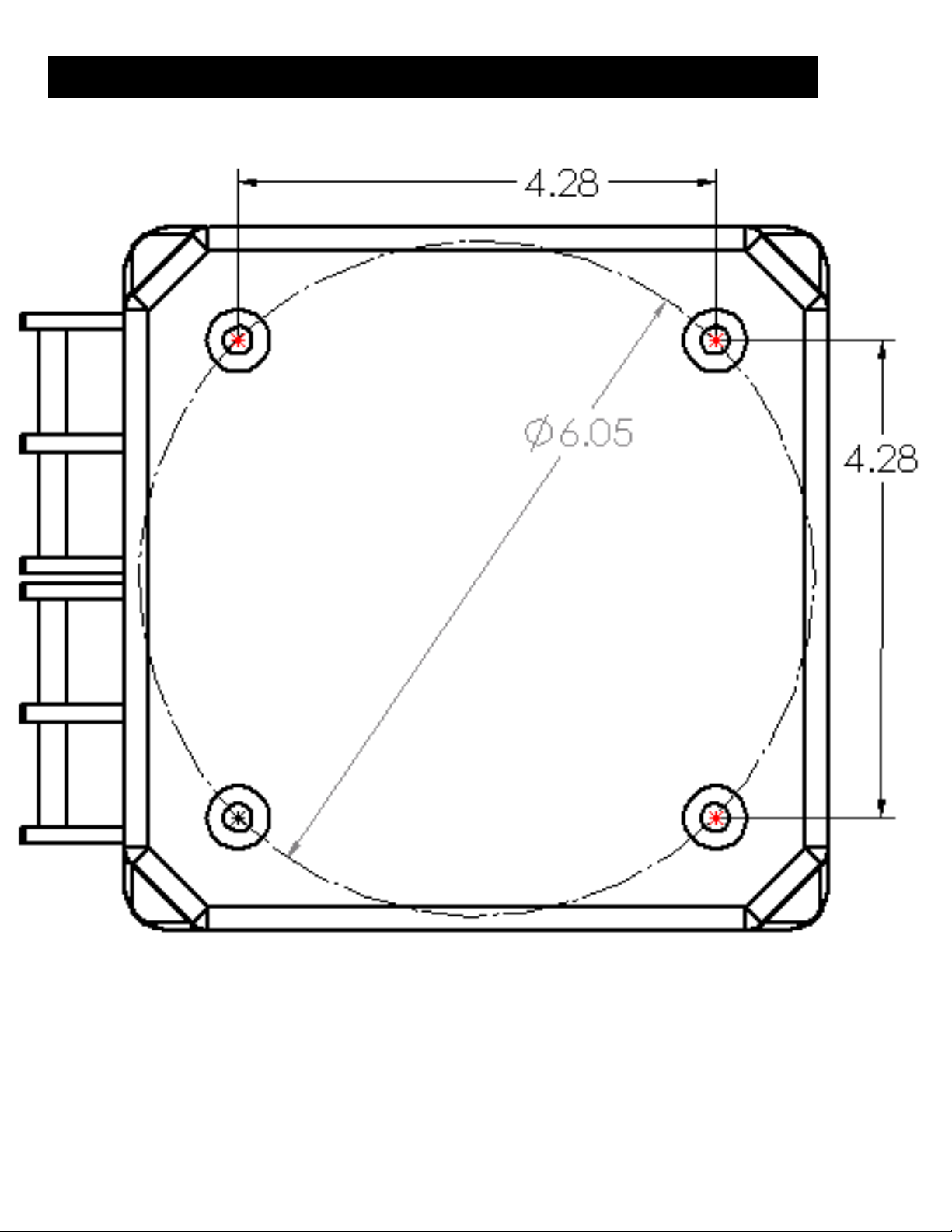

6. Junction Box Template

©Copyright 2012 Liberty Pumps Inc. All rights reserved - 5 -

Loading...

Loading...