Liberty Pumps ALM-P1, ALM-2, ALM-2-1, ALM-PK, SJ10A Installation Manual

...

Installation and User Manual 2138000D

ALM-Series Indoor Alarms

Product Features:

NEMA 1 enclosure - Rated for indoor use only

Automatic alarm and alarm silence reset

360° red alarm indicator beacon

4 ft. (1.2m) power cord

9V Battery back-up with low battery indicator

Pre-installed connector on level sensor for

plug-and-play installation

Auxiliary dry contacts for triggering external

alarm

Multiple level sensing options available

Internet connectivity available with NightEye

Table of Contents

Safety Informaon ..................................... 1

General Informaon .................................. 2

Installaon ................................................. 3

Operaon ................................................... 4

Warranty .................................................... 5

®

enabled devices

DO NOT THROW

AWAY OR LOSE THIS

MANUAL

Models Covered

Standard Models

ALM-P1

ALM-2

ALM-2-1

ALM-PK

SJ10A

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

NightEye® Wireless Enabled Models

ALM-P1-EYE

ALM-2-EYE

ALM-2-1-EYE

ALM-PK-EYE

SJ10A-EYE

© Copyright 2017 Liberty Pumps Inc. All rights reserved

Safety Information

RISK OF ELECTRIC SHOCK

NEVER enter a flooded space without

proper Personal Protective Equipment.

Always wear dielectric rubber boots and

other applicable protective equipment

when water is on the floor and you must

service an energized pump or alarm

system.

NEVER install this alarm system outdoors.

The system is rated for indoor use only.

DO NOT enter the water if the water level

is higher than that of the protection your

PPE offers or if your PPE is not

watertight.

DISCONNECT POWER before installing

or servicing this product. A qualified

service person must install and service

this product according to applicable

electrical and plumbing codes.

RISK OF FIRE

NEVER use this product with or near

flammable liquids.

DO NOT install this product in locations

classified as hazardous or in explosive

atmospheres as defined by any

applicable electrical safety code.

Failure to follow the above precautions could result in serious injury or death. Replace product

immediately if sensor or power cable becomes damaged or severed. Keep these instructions in a safe

place for future reference. This product must be installed in accordance with National Electric Code,

ANSI/NFPA 70 so as to prevent moisture from entering or accumulating within junction boxes, conduit

bodies, fittings, float housing, alarm enclosure, or cable.

General Information

Before use, please read the following instructions carefully. Each Liberty Pumps alarm system is tested individually in

the factory to ensure proper performance and operation. Closely following these instructions will eliminate potential

operating problems, providing years of trouble-free service.

This high water level alarm system is designed for applications such as monitoring sump pump basins, sewage pump

basins, and water powered back-up pumps. The alarm system comes standard with a 9V battery back-up to enable

continuous water level monitoring, even when the power is out. A built-in battery monitor alerts the user when the 9V

battery needs to be replaced.

NightEye

wireless network, by means of an Android® or iOS® device, and send notifications about your system in real time. This

system can provide peace of mind about the status of your sump pump system even when you are not home.

All of the alarms come standard with Liberty Pumps’, patent pending, 360° red alarm beacon powered by super-bright

LEDs. In combination with the 86dB (at 10’ (3m)) alarm siren, the alarm is sure to alert occupants of the high-water

condition.

Each device is specifically designed for use in an indoor residential wastewater application. The systems come with

liquid level sensors that conform to the needs of the intended application. The sensor types are as follows:

®

enabled devices come equipped with wireless internet connectivity. These devices can connect to your

Snap-on enclosed float - (ALM-P1, ALM-P1-EYE, SJ10A, SJ10A-EYE) - Sump Pump Applications

Tethered float - ( ALM-2, ALM-2-1, ALM-2-EYE, ALM-2-1-EYE) - Sewage Pump Applications

Water puck - (ALM-PK, ALM-PK-EYE) - Puddle Sensing.

If you need one alarm to monitor multiple locations, Liberty offers a splitter to connect up to 3 sensors (Kit: K001633).

© Copyright 2017 Liberty Pumps Inc. All rights reserved 3

© Copyright 2017 Liberty Pumps Inc. All rights reserved 1

Installation

RISK OF ELECTRIC SHOCK

NEVER install this alarm system outdoors. The system

is rated for indoor use only.

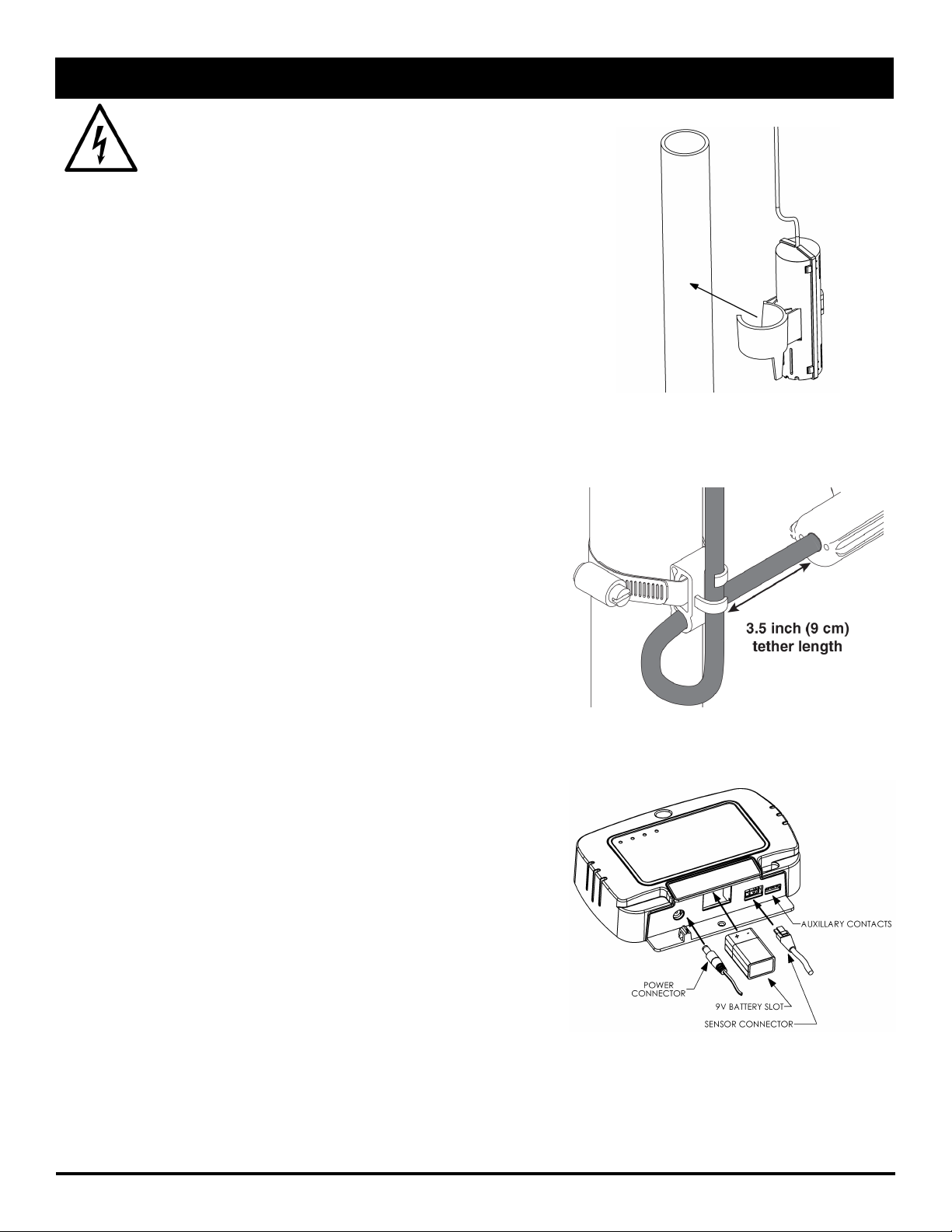

Enclosure Installation

1) Select an indoor mounting location for the alarm unit. Liberty

Pumps recommends a location between 48in (1.2m) and 66in

(1.7m) above floor level.

2) Using the supplied template on the rear cover of this manual, mark

screw locations on the mounting surface.

3) If the screw locations are NOT directly over a wall stud, or the

alarm will be mounted to a masonry wall, the use of the supplied

anchors is recommended. A 3/16” (5mm) hole must be drilled

before inserting the anchor into the wall.

4) Mount the alarm enclosure to the wall using the supplied anchors

and screws (where applicable).

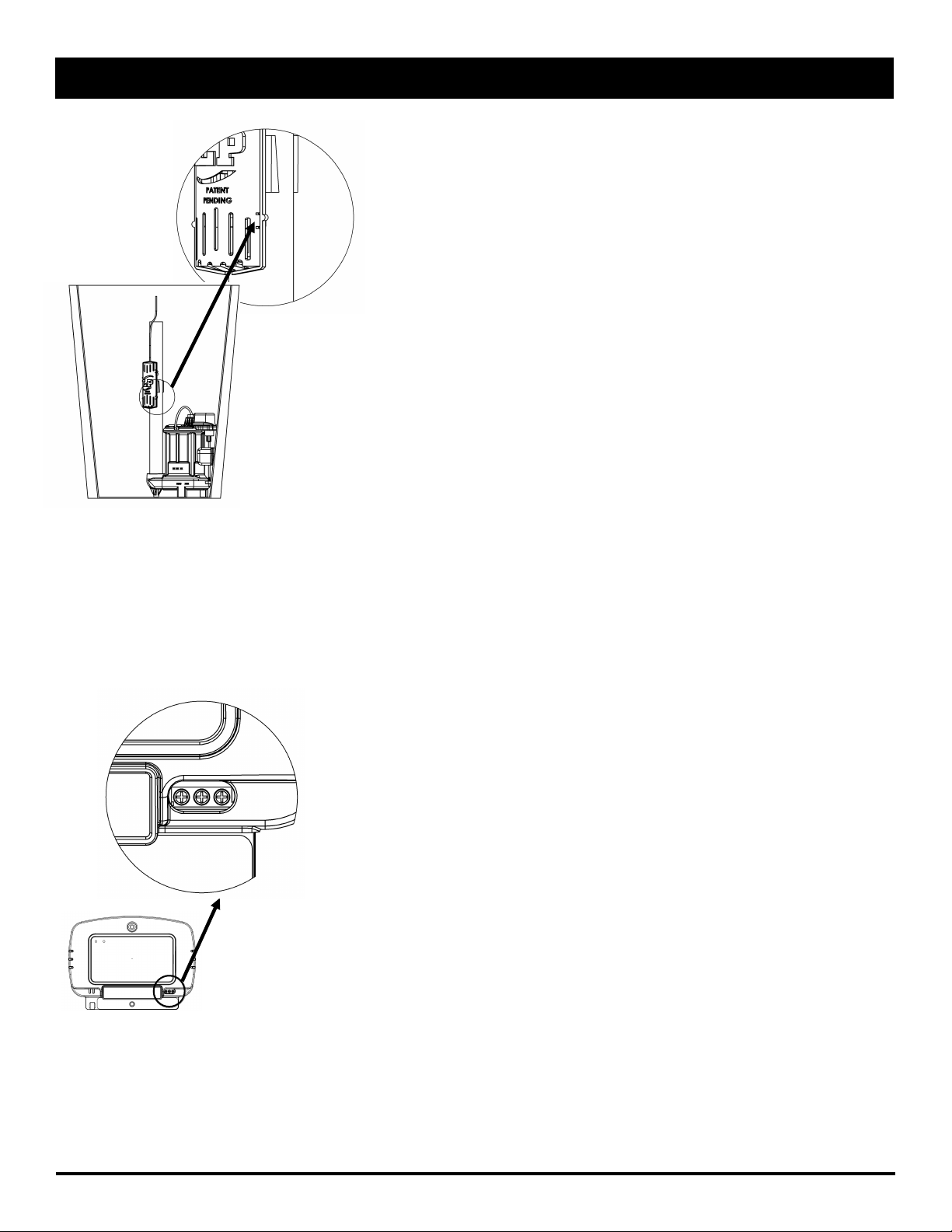

Sensor Installation

Sump Pump Sensor

1) Remove sump pump sensor from packaging.

2) Apply a small amount of glue to the inside of the snap feature of the

sensor. NOTE: Over-gluing the sensor will make future removal

very difficult.

3) Snap sensor over the discharge pipe of your sump pump as shown

in Figure 1.

4) Route the sensor cable out of the sump pit and connect it to the

bottom of the alarm enclosure. See Figure 3.

Sewage Pump Sensor

1) Place the float switch cord into the clamp as shown in Figure 2.

2) Locate the clamp at the desired activation level and secure the

clamp to the pump discharge pipe as shown in Figure 2.

Note: Do not install cord under hose clamp.

3) Tighten the hose clamp using a screwdriver. Over tightening may

result in damage to the plastic clamp. Make sure the float cable is

not allowed to touch the excess hose clamp band during operation.

Note: All hose clamp components are made of 18-8 stainless

steel. See your Liberty Pumps® supplier for replacements.

4) Route the sensor cable out of the sewage pit and connect it to the

bottom of the alarm enclosure ensuring it does not interfere with the

operation of the primary pump’s float. See Figure 3.

Water Puck Sensor

1) Remove the puck sensor from its packaging.

2) Place sensor in the location susceptible to water intrusion or buildup

(example: under hot water heater, near laundry sink, near

problematic foundation wall, etc.).

3) Route water puck cable such that it will not pose a tripping hazard.

4) Plug water puck cable into the ALM sensor connector.

5) Test water puck for operation by setting it in a small puddle or by

holding a damp towel on its bottom surface.

To install up to 3 sensors, use a Liberty alarm connector splitter

(sold separately, Kit: K001633).

Sump Pump Sensor Installaon

Sewage Pump Sensor Installaon

Connecon locaons on boom of alarm unit.

Note the 9V baery installaon—paying

aenon to polarity, the baery should gently

push into place and latch on the ledge at the

boom of the baery chamber.

Figure 1

Figure 2

Figure 3

© Copyright 2017 Liberty Pumps Inc. All rights reserved 4

© Copyright 2017 Liberty Pumps Inc. All rights reserved 2

Installation (con’t)

Connect Power

1) Connect the supplied power adapter to the alarm unit as shown in

Figure 3. Plug the power adapter into the wall receptacle and verify

that the green “power” indicator illuminates.

Note: It is recommended that the alarm is connected to a circuit

that is separate from the pump circuit. This allows the alarm to

continue to operate if the pump circuit fails.

2) Install the 9V battery as shown in Figure 3 (previous page). Paying

attention to polarity, the battery should gently push into place and

latch on the ledge at the bottom of the battery chamber.

Note: A 9V battery must be installed in the device at all times to

ensure proper operation.

NightEye® Configuration

If your device is NightEye® enabled, it is now time to configure the device

to connect to your wireless network.

For configuration instructions, please consult the NightEye® quick-start

guide that is included with your device. If the quick-start guide has been

lost or damaged, electronic copies are available at LibertyPumps.com.

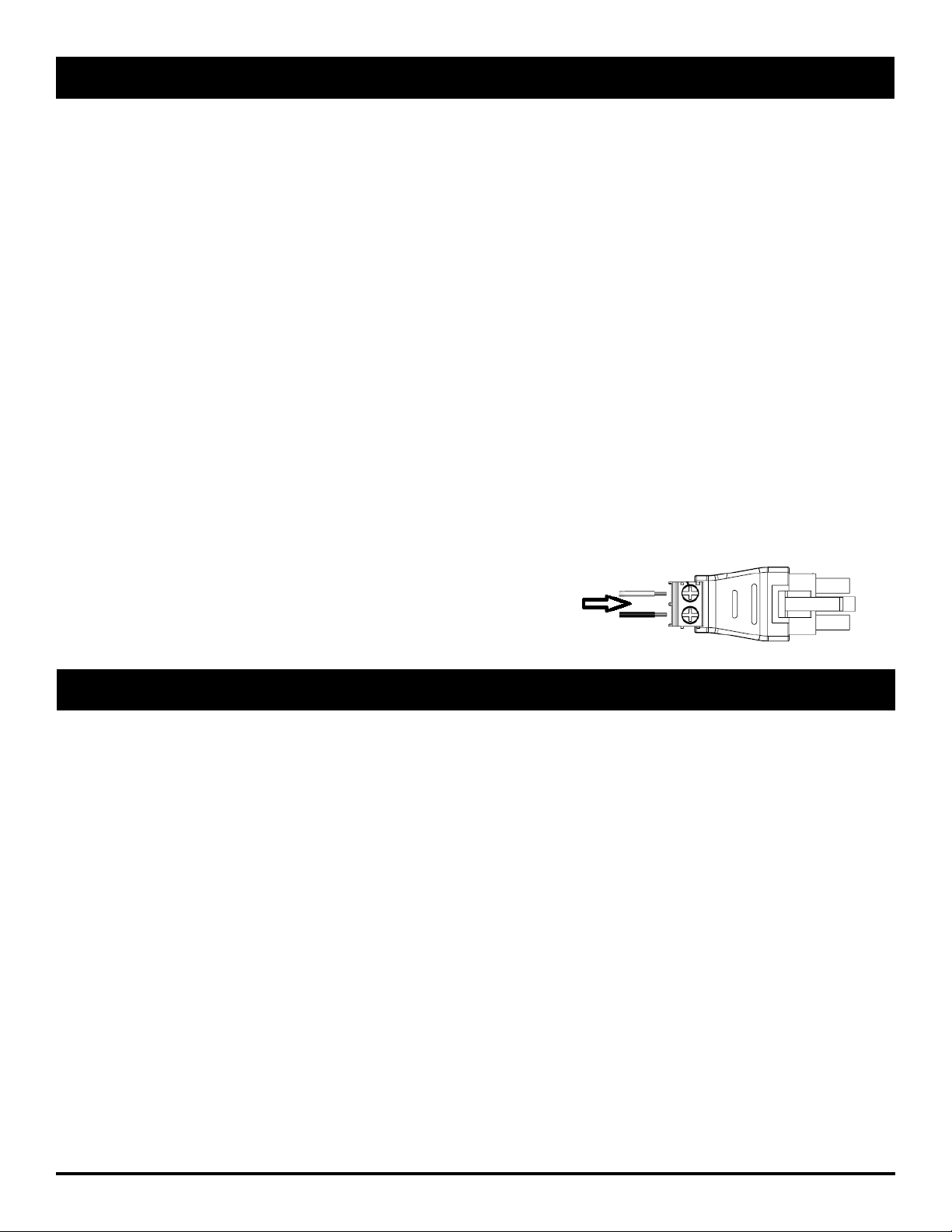

Figure 5

Tesng sump pump liquid sensor

1—2—3

Terminal Connecons:

1: Normally Open

2: Common

3: No Connecon

Figure 6

Auxiliary Contact Connecons

NOTE: 24 VDC/VAC, 500 mA MAX

Alarm Testing

Sump Pump Sensor

This switch is a self contained unit. The internal float may not be visible

from the outside of the switch housing. The switch should be placed

such that the activation point (Figure 5) is slightly higher than the pump

activation point.

1) In order to test the proper operation of the float switch, we

recommend raising the water level in your sump pit above it’s normal

operating level. If raising the water level is not feasible, a cup of

water can be used to confirm float operation.

2) When the water level reaches the lowest mark on the side of the

float housing, the alarm will activate. (Figure 5)

3) Once alarm begins to sound, it will continue to sound until the water

level is lowered. The audible alarm can be silenced using the

Silence button on the front of the device. (The alarm will stay

silenced for 6 hours after the silence button is pressed)

4) Once testing is complete, lower the water level in the pit back to its

normal range.

Sewage Pump Sensor

1) Manually tip the float up.

2) Once alarm begins to sound, it will continue to sound until the float is

tipped down. The audible alarm can be silenced using the Silence

button on the front of the device. (The alarm will stay silenced for 6

hours after the silence button is pressed.)

3) Lower the float back to its resting position to reset the alarm.

© Copyright 2017 Liberty Pumps Inc. All rights reserved 5

© Copyright 2017 Liberty Pumps Inc. All rights reserved 3

Installation (con’t)

Auxiliary Contacts

This device comes equipped with auxiliary contacts. These contacts can be used to integrate the output of this alarm

with an existing home monitoring system. See Figure 6 for contact connections diagram.

Contact Rating: Class 2, 24 VDC/VAC (50/60 HZ) 500 mA MAXIMUM

Regular Operation

Now that your alarm unit has been configured and tested, it is ready for operation. The following is a list of regular

maintenance tasks:

It is highly recommended that the alarm system be tested every 6 months. Follow the procedure outlined in the

Alarm Testing section above.

In the event the 9V battery is low, the alarm will emit a short chirp about twice per minute. The 9V battery should be

replaced any time the yellow “low battery” indicator on the alarm unit is lit or every 12 months.

In the event that an alarm condition is detected by the system, the audible and visual alarms will activate. The automatic

reset feature of the alarm will turn the audible and visual alarms off once the condition has been corrected.

Float Adapter

If your system already has an alarm float installed, and you do not want to replace it with the float included with your

Liberty ALM series product, you can use the included terminal block adapter.

1) Turn both screws in the float adapter counter-clockwise, until the conductor receptacles are fully open.

2) Insert the float conductors into the float adapter, one conductor per

receptacle. Polarity does not matter.

3) Tighten the screws in the float adapter until they bottom out.

4) Insert the float adapter into the connector on your Liberty ALM series

alarm.

3 Year Limited Warranty

Liberty Pumps, Inc. warrants that its products are free from all factory defects in material and workmanship for a period

of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt noting the

model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date of return

is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's sole obligation under this Warranty shall be limited to the repair or replacement of any parts found

by the manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its

authorized service center, and provided that none of the following warranty-voiding events have taken place.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump

discharge has been reduced in size; if the pump has been used in water temperatures above the advertised rating, or in

water containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label bearing the serial,

model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses

resulting from installation or use of its products, or for indirect, incidental, and consequential damages, including costs of

removal, reinstallation or transportation.

THE WARRANTIES SET FORTH ABOVE ARE IN LIEU OF ALL OTHER WARANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, AND ALL SUCH OTHER WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED BY LIBERTY

© Copyright 2017 Liberty Pumps Inc. All rights reserved 6

© Copyright 2017 Liberty Pumps Inc. All rights reserved 4

Loading...

Loading...