Liberty XL2 Maintenance Manual

Maintenance Manual

1383 General Aviation Drive

Melbourne, FL 32935

800-759-5953

Table of Contents

XL2 Airplane

Table of Contents

Record of Revision iii

Check List iv

List of Temporary Revisions v

List of Service Bulletins vi

Table of Chapters

General

Introduction 01

General Description 03

Airworthiness Limitations 04

Time Limits/Maintenance Checks/Inspection

Intervals 05

Dimensions and Areas 06

Lifting and Jacking 07

Leveling and Weighing 08

Towing and Taxiing 09

Parking and Mooring 10

Required Placards 11

Servicing 12

Equipment

Standard Practices-Airframe 20

Environmental Systems 21

Communications 23

Electrical Power 24

Equipment and Furnishings 25

Flight Controls 27

Fuel System 28

Indication and Recording Systems 31

Landing Gear 32

Lights 33

Navigation and Pitot/Static 34

Chapters

Chapters

Table of Contents

XL2 Airplane

Airframe

Chapters

Structures 51

Doors 52

Fuselage 53

Stabilizers 55

Windows 56

Wings 57

Propeller

Chapter

Propeller 61

Power Plant

Chapters

Standard Practices-Engine 70

Power Plant 71

Engine 72

Engine Fuel System 73

Ignition 74

Engine Air 75

Engine Controls 76

Engine Indicating 77

Exhaust 78

Oil 79

Starting 80

Wiring Diagrams 91

Revision

Number

Original Issue April 2005 All

1 April 2005 4-2, 4-4

2 May 2005

Record of Revisions

Date Affected Pages

Replace: 5- Inspection Check list pg.,

5,6,7. 31-Table of Contents. Add: 31-10

iii

Check List

This Check List should be used for control of all revisions issued and installed in

this manual. The affected pages of any revision, as well as the Record of

Revisions must be inserted into the manual upon receipt. The pages superseded

by the revision must be removed and destroyed. The Check List should be

updated by hand. Changes are identified on those pages affected by a revision

bar.

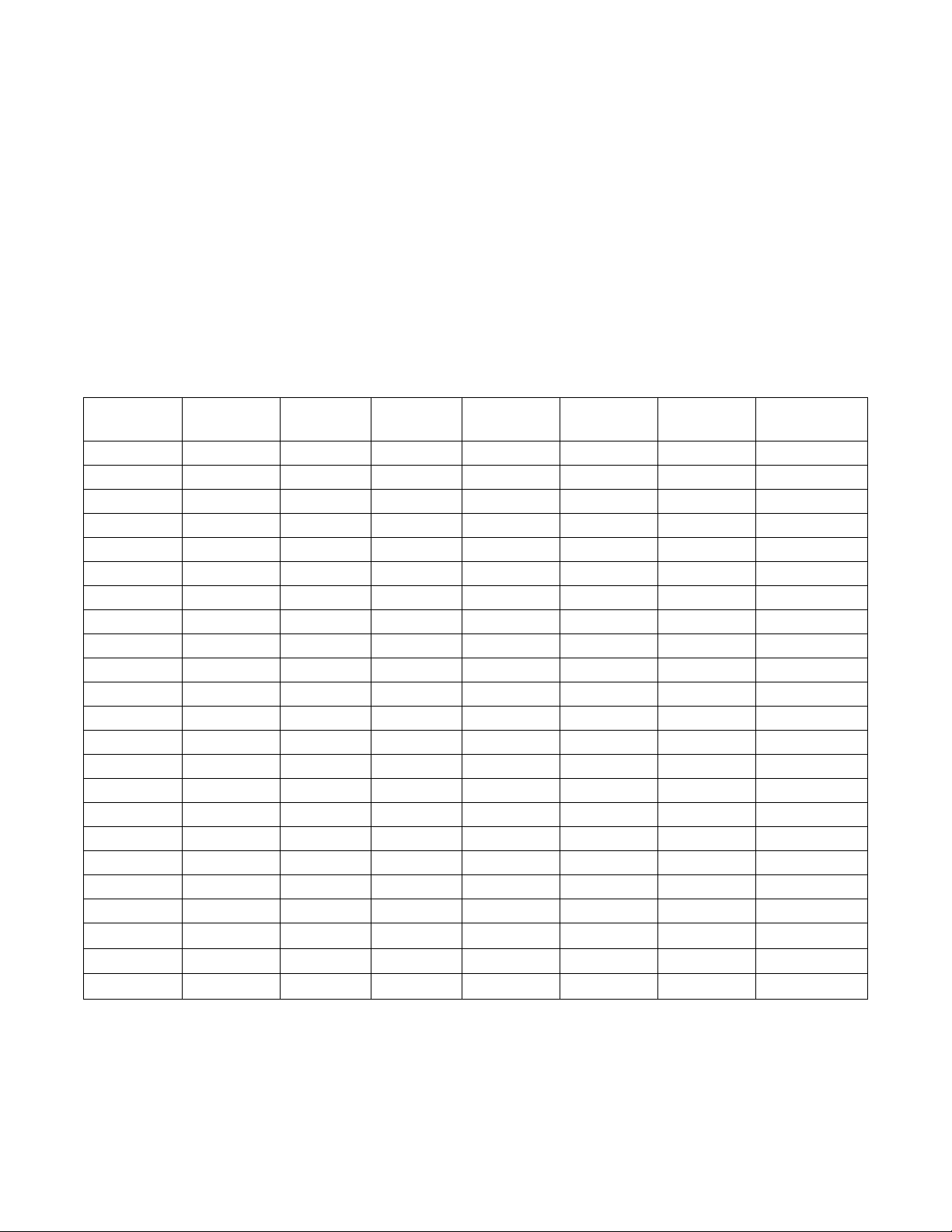

Revision

Number:

Date

Issued:

Inserted

On:

Inserted

By:

Revision

Number:

iv

Date

Issued:

Inserted

On:

Inserted

By:

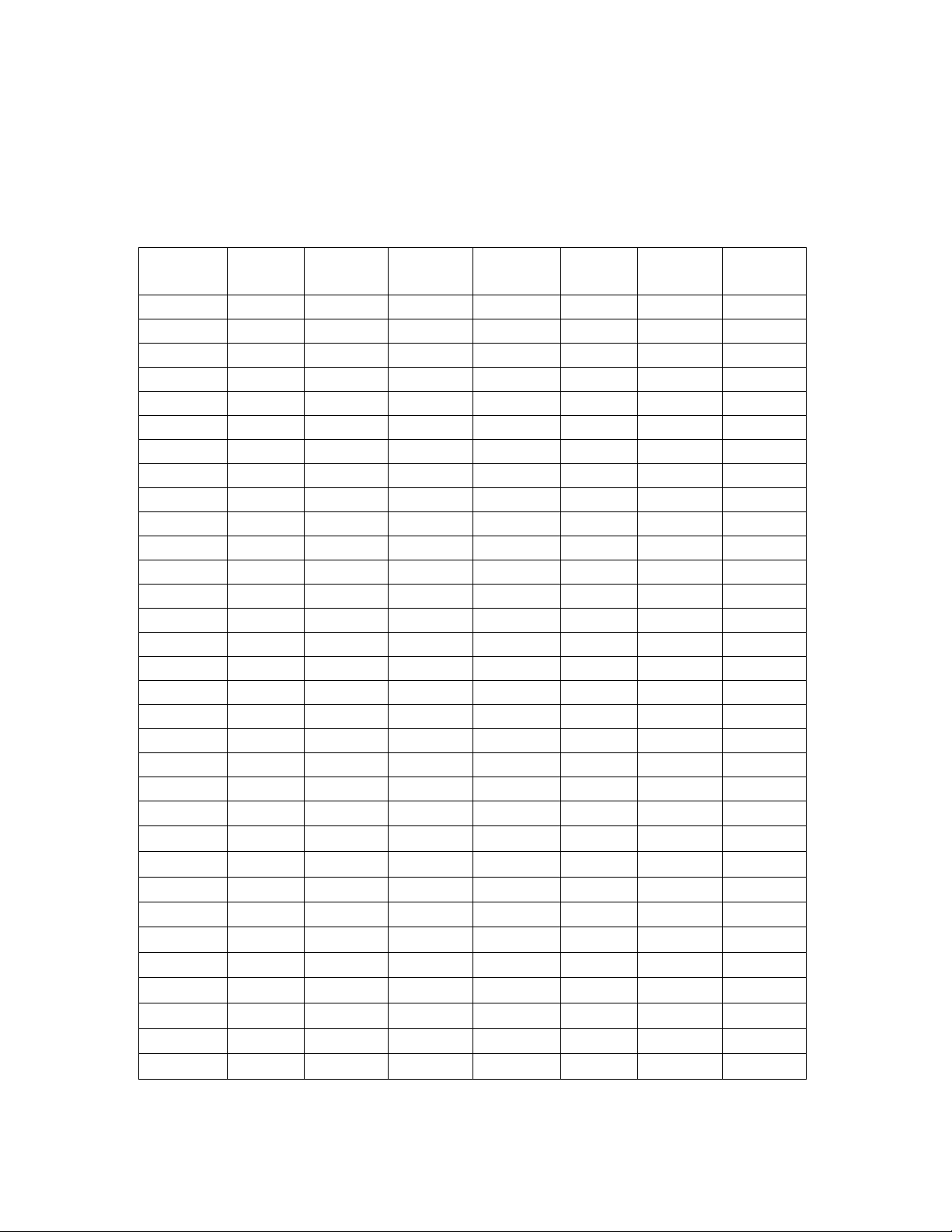

List of Temporary Revisions

Revision

Number:

Date

Issued:

Inserted

on:

Inserted

By:

Revision

Number:

v

Date

Issued:

Inserted

on:

Inserted

By:

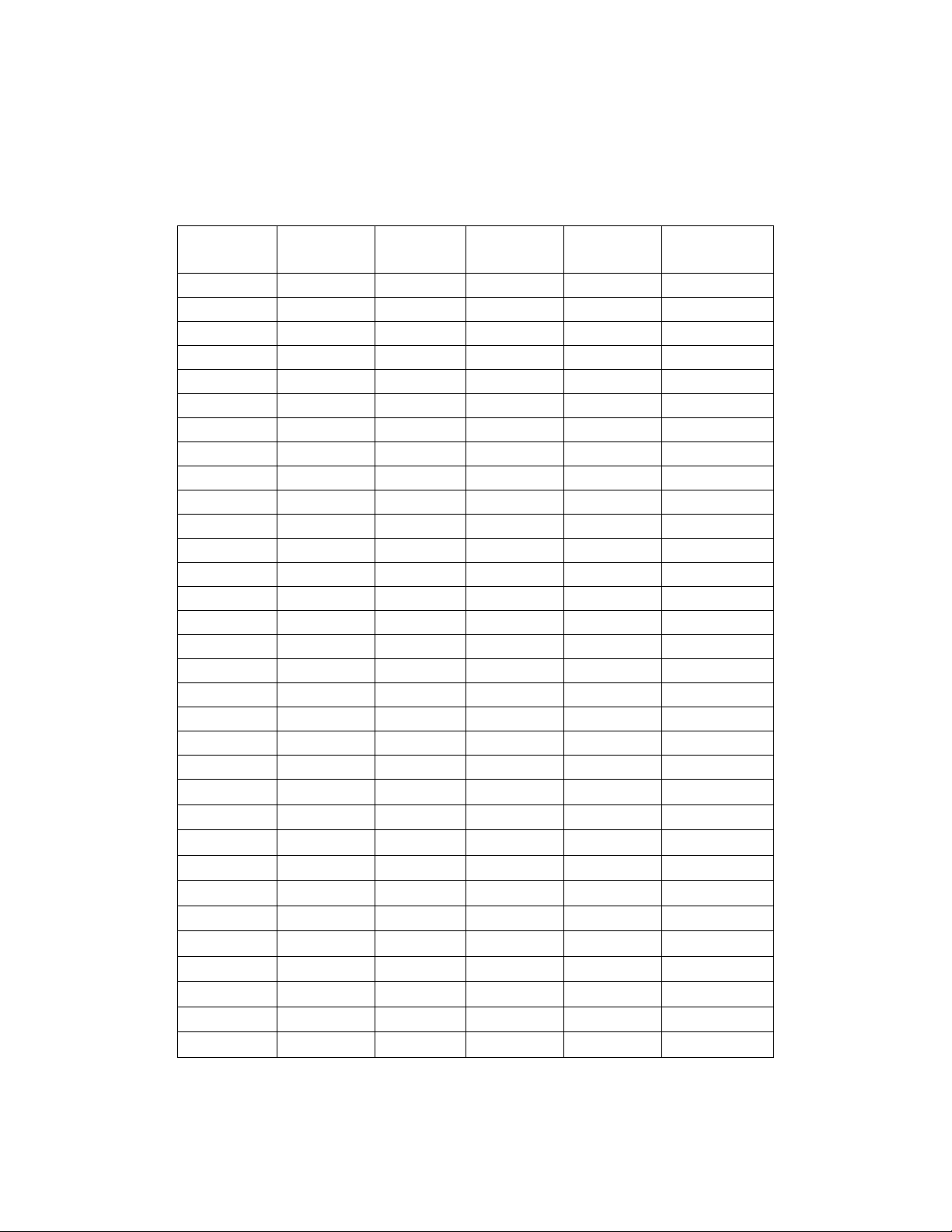

List of Service Bulletins

Service

Bulletin:

Revision

Number:

Inserted

On:

Service

Bulletin:

vi

Revision

Number:

Inserted

On:

Introduction

XL2 Airplane

Chapter 01

INTRODUCTION

INITIAL RELEASE

P/N 135A-970-006 - 1 -

Introduction

XL2 Airplane

Introduction

Table of Contents

GENERAL

REVISIONS

WARNINGS, CAUTIONS, NOTES

MANUAL ARRANGEMENT

MAIN CHAPTER GROUPS

3

3

4

4

5

INITIAL RELEASE

P/N 135A-970-006 - 2 -

Introduction

XL2 Airplane

General:

This Maintenance Manual is intended to furnish maintenance personnel with all data

required for normal maintenance of the Liberty XL2 airplane. It comprises detailed

system and subsystem descriptions, troubleshooting tables, component removal,

reinstallation procedures, and detailed maintenance procedures.

Unless otherwise specified, this Maintenance Manual contains only removal and

reinstallation instructions for specific components i.e.: generator, fuel system

components, instruments, etc. Detailed maintenance and service instructions for

individual components are to be obtained from the applicable component

manufacturer’s maintenance manual.

All maintenance work including inspections, routine maintenance, and repairs are to

be performed in accordance with the procedures set forth in this Maintenance

Manual.

Other documentation to be used with this manual includes, but is not limited to:

Liberty XL2 Approved Flight Manual/Pilot Operating Handbook (AFM/POH).

Operator’s Manual for TCM IOF-240 Engine p/n: OI-22.

Maintenance Manual for TCM IOF-240 Engine, TCM p/n: M-22.

Maintenance Manual for Sensenich W69EK7-63G Propeller.

Operator’s manuals for avionics components installed on the airplane.

Revisions:

The revision number and date of original issue or revision of each page of this

Maintenance Manual is printed at the foot of each page. A Record of Revisions is

provided at the front of the manual. A Page Control sheet is provided to verify the

status of each page of this manual. A new Page Control sheet is provided with each

revision.

Liberty Aerospace, through document 135A-995-221, Product Support and Service

Difficulties, provides a method for communication with customers using service

letters and service bulletins.

A Record of Revisions is provided to allow verification that all revisions have been

entered in a timely manner.

The Maintenance Manual will be reissued in its entirety from time to time as number

and volume of revisions warrant.

INITIAL RELEASE

P/N 135A-970-006 - 3 -

Introduction

XL2 Airplane

Changed Text:

Changes to text as a result of revisions are indicated by a vertical line in the margin

adjacent to the text that has been changed.

Blank Pages:

Blank pages may appear in either originally issued or revised sections of the

Maintenance Manual. They are identified by the legend:

PAGE LEFT INTENTIONALLY BLANK

in the center of each page.

Warnings, Cautions, Notes:

The following definitions apply to Warnings, Cautions, and Notes found throughout

this Maintenance Manual:

WARNING:

AN OPERATING PROCEDURE, INSPECTION, REPAIR OR MAINTENANCE PR ACTICE, WHICH

IF NOT CORRECTLY FOLLOWED, COULD RESULT IN PERSONAL INJURY OR LOSS OF LIFE.

CAUTION:

AN OPERATING PROCEDURE, INSPECTION, REPAIR OR MAINTENANCE PRACTICE, WHICH IF

NOT STRICTLY OBSERVED COULD RESULT IN DAMAGE OR DESTRUCTION OF EQUIPMENT.

NOTE:

An operating procedure, inspection, repair or maintenance condition, etc, which is

deemed essential to highlight.

Manual Arrangement:

The overall arrangement of this Maintenance Manual is in accordance with the Air

Transport Association of America (ATA) Specification number: 100 and the General

Aviation Manufacturers Association (GAMA) Specification number: 2. The title of

each chapter can be found in the general Table of Contents located at the front of

the manual, and on the divider tabs separating the chapters.

Each main system is covered by a specific chapter which is subdivided into sections

describing relevant subsystems.

INITIAL RELEASE

P/N 135A-970-006 - 4 -

Introduction

XL2 Airplane

The chapters are combined in main groups as follows:

GENERAL Chapters 01 - 12

EQUIPMENT Chapters 20 - 34

AIRFRAME Chapters 51 - 57

PROPELLER Chapter 61

ENGINE Chapters 71 - 92

Each of the main groups as well as each chapter is divided by a cover page showing

chapter number and the title.

INITIAL RELEASE

P/N 135A-970-006 - 5 -

General Description

XL2 Airplane

CHAPTER 03

GENERAL DESCRIPTION

P/N 135A-970-006 Chap 03

INITIAL RELEASE - 1 -

General Description

XL2 Airplane

Chapter 03

Table of Contents

Chapter 03

Table of Contents 2

Chapter 03-00

General 3

Description 3

Vendor

Documentation 4

P/N 135A-970-006 Chap 03

INITIAL RELEASE - 2 -

General Description

XL2 Airplane

General Description

General:

The Liberty XL2 airplane is manufactured by

Liberty Aerospace, Inc.

1383 General Aviation Drive

Melbourne, Florida, USA, 32935

1-800-759-5953

and is approved in the normal airworthiness category.

The XL2 may be operated under DAY or NIGHT VFR conditions depending on

installed standard and optional equipment. IFR certification is pending.

Description:

The Liberty XL2 airplane is a low-wing two-place aircraft with tricycle landing gear.

Its central structural element is a welded steel tubing frame or “chassis” which has

the following components attached:

• Engine and Propeller

• Wings (conventional aluminum construction)

• Main landing gear (aluminum construction)

• Nose landing gear (steel construction)

• Fuselage (composite construction), including;

• Aft fuselage with vertical fin (composite construction)

• Rudder and stabilators (aluminum construction)

• Center fuselage including crew/passenger cabin, fuel tank, and baggage

compartment

• Engine cowlings.

The wings are bonded aluminum semimonocoque structures, and are secured to the

chassis by means of heavy steel pins in attach fittings. With the wing or wings

removed the fuselage remains supported by the landing gear. The removable

aluminum horizontal tail is a stabilator type in which the entire unit moves to change

pitch on the aircraft. The only movable surfaces on the horizontal tail are the antiservo tabs which are used for both pitch trim and anti-servo functions.

The composite vertical fin is integrated into the fuselage structure; the rudder is an

aluminum structure.

Ailerons and stabilators are operated by pushrods from cockpit control sticks.

P/N 135A-970-006 Chap 03-00

INITIAL RELEASE - 3 -

General Description

XL2 Airplane

The rudder is operated by pushrods attached to adjustable cockpit rudder pedal

assemblies. Aluminum trailing edge flaps are electrically operated.

The XL2 is powered by an air-cooled Teledyne Cont inental Motors IOF-240-B four

cylinder, horizontally opposed, fuel injected engine. The engine is rated at 125

continuous SAE horsepower at 2800 RPM. The engine is equipped with a Full

Authority Digital Engine Control (FADEC) system to control ignition timing and fuel

mixture without pilot intervention. Fuel is supplied from a single 28 gallon capacity

aluminum tank. It is installed in the fuselage between the pilot/passenger seatbacks

and the baggage compartment. The propeller is fixed pitch, constructed of wood

and fiberglass made by Sensenich p/n: W69EK7 63G.

Vendor Documentation:

Engine:

Teledyne Continental Motors, IOF-240-B

2039 Broad Street

Mobile, AL. 36615

Tel: 251-438-3411

Fax: 251-432-7352

www.tcmlink.com

Propeller:

Sensenich, W69EK7-63G

14 Citation Lane

Lititz, PA. 17543

Tel: 717-569-0435

Fax: 717-560-3725

www.sensenich.com

Main Wheel Brakes:

Parker-Hannifin, Aircraft Wheel & Brakes

1160 Center Road

Avon, OH. 44011-0158

Tel: 440-937-6211

Fax: 440-937-6416

Navigation and Communication Equipment:

Garmin International Inc.

1200 East 151

Olathe, KS. 66062

Tel: 913-397-8200

Fax: 913-397-8282

Apollo Aircraft products Tel: 503-391-3411 ext. 3991

st

Street

P/N 135A-970-006 Chap 03-00

INITIAL RELEASE - 4 -

General Description

XL2 Airplane

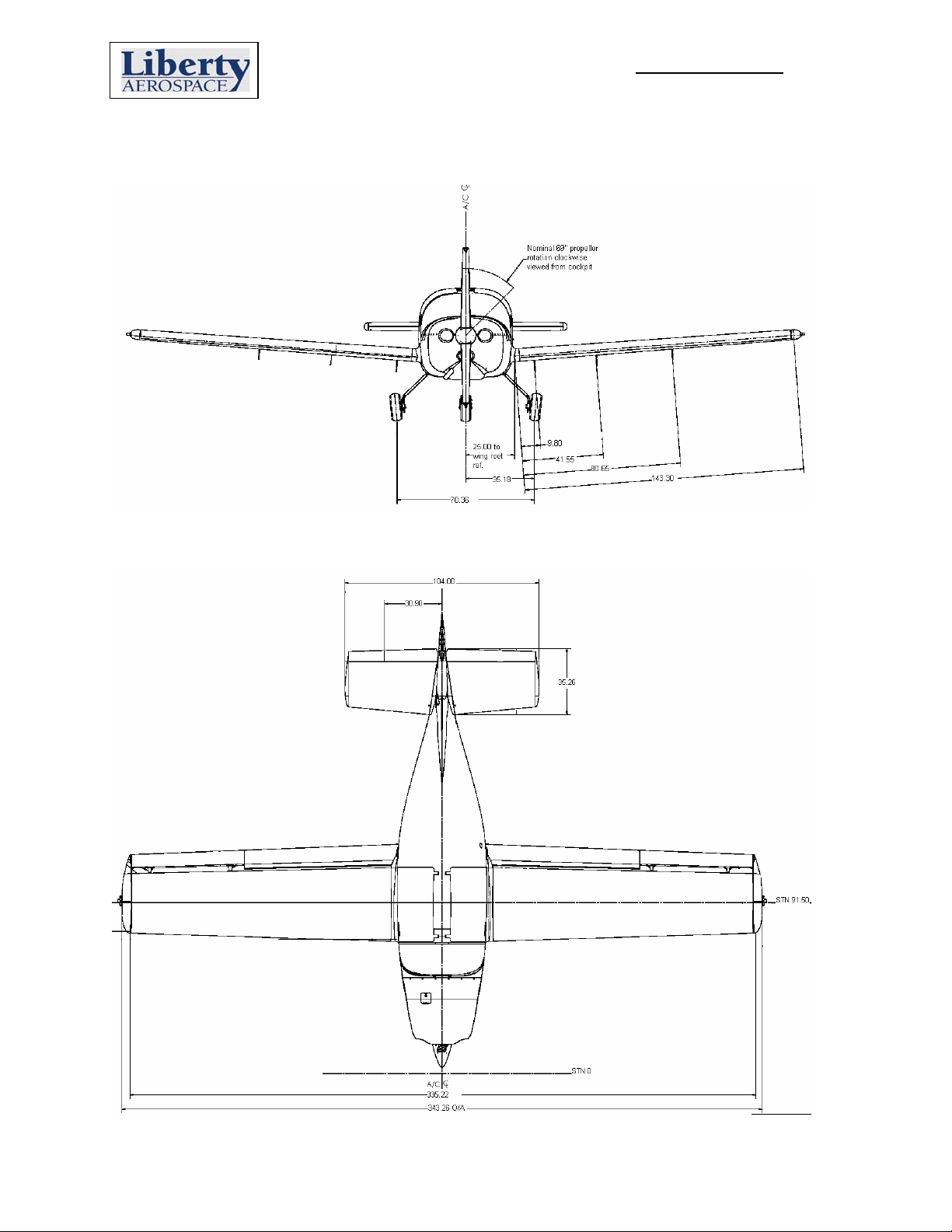

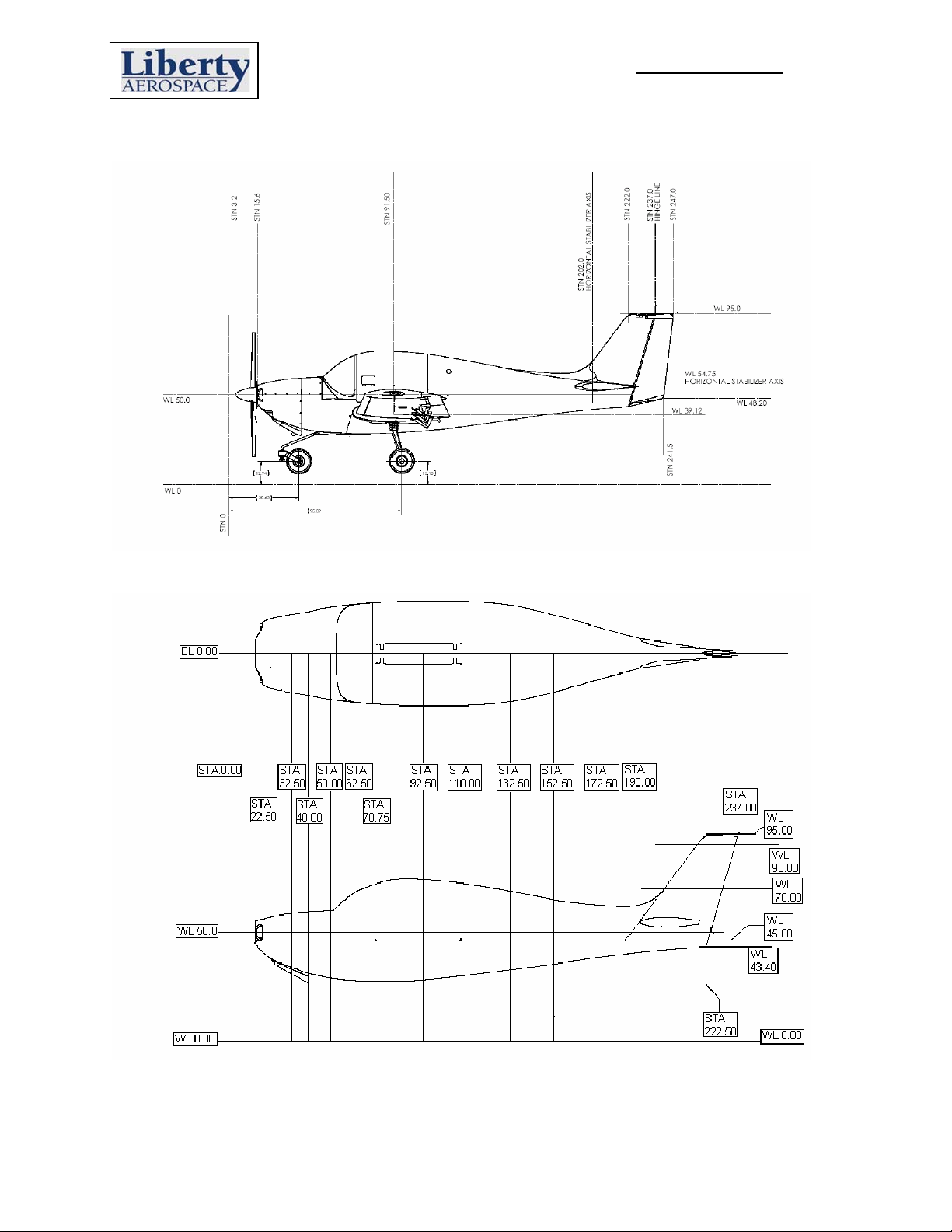

Aircraft measurements:

P/N 135A-970-006 Chap 03-00

INITIAL RELEASE - 5 -

General Description

XL2 Airplane

P/N 135A-970-006 Chap 03-00

INITIAL RELEASE - 6 -

General Description

XL2 Airplane

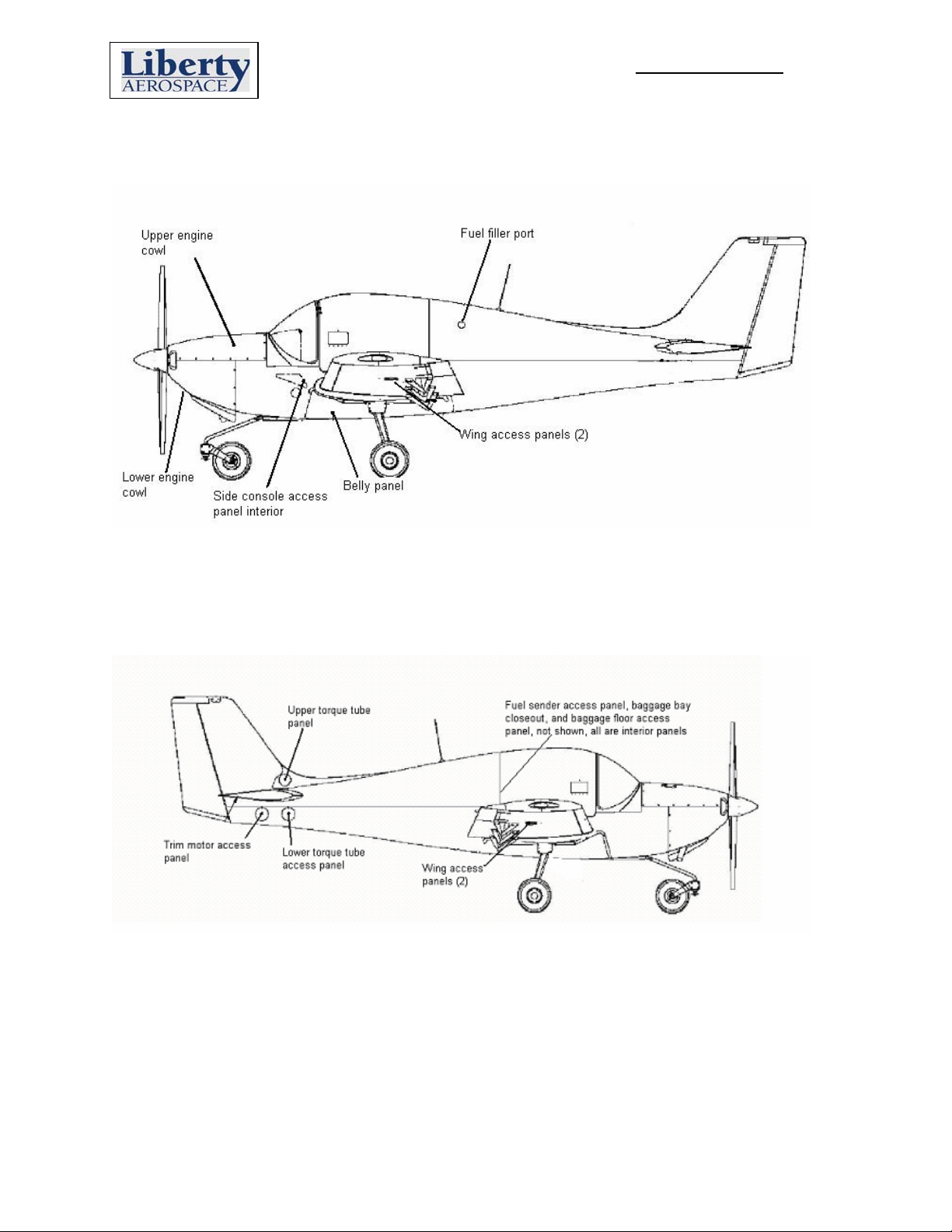

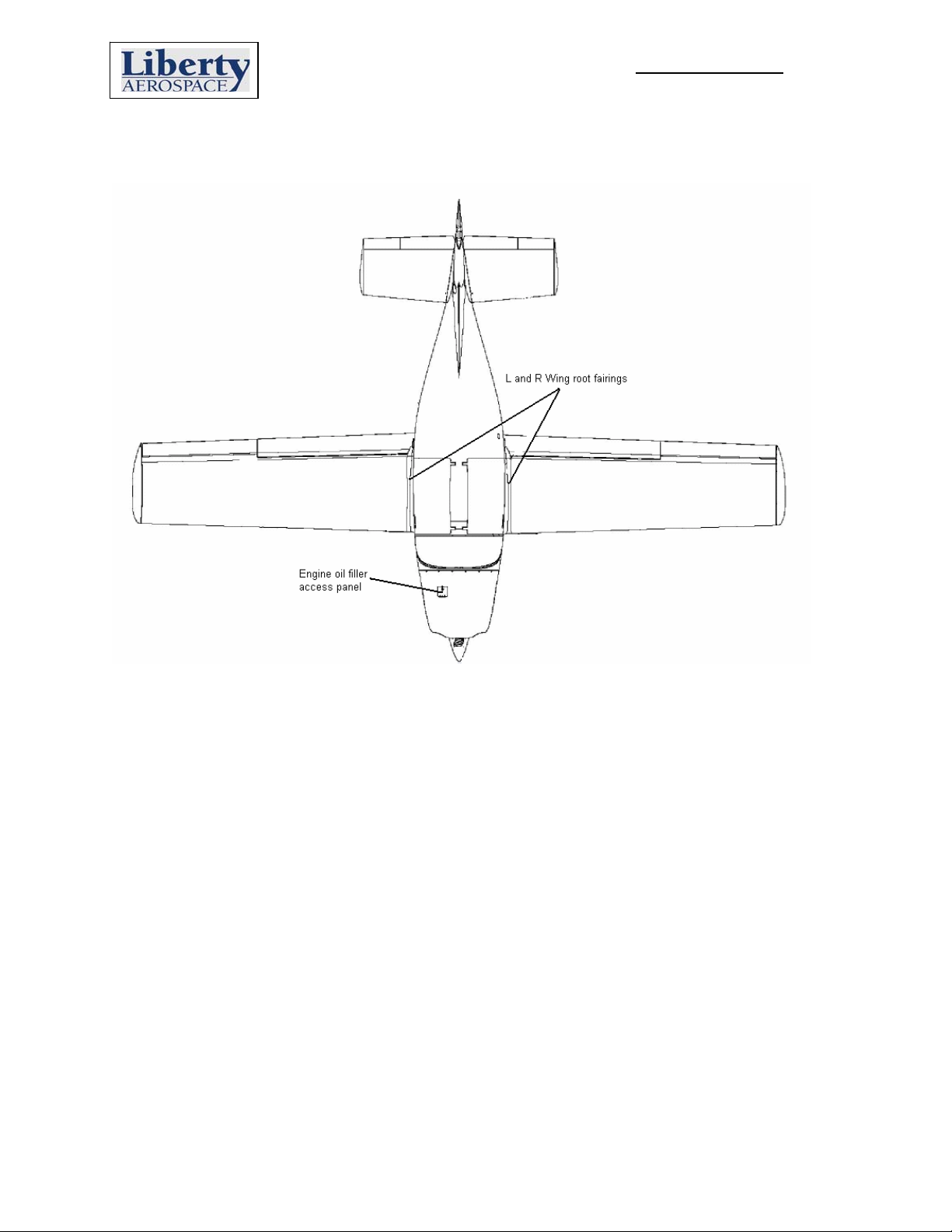

Aircraft access panels.

P/N 135A-970-006 Chap 03-00

INITIAL RELEASE - 7 -

General Description

XL2 Airplane

P/N 135A-970-006 Chap 03-00

INITIAL RELEASE - 8 -

Airworthiness Limitations

XL2 Airplane

CHAPTER 04

AIRWORTHINESS LIMITATIONS

P/N 135A-970-006 Page 4 - 1

April 2005

04-TITLE

Airworthiness Limitations

XL2 Airplane

The Airworthiness Limitations Section is FAA approved and specifies inspections

and other maintenance required under paragraphs 43.16 and 91.403 of the

Federal Aviation Regulations unless an alternative program has been FAA

approved.

REV

IR

DATE

FEB. 19, 2004

A

AIRWORTHINESS LIMITATIONS

APPROVED

/s/ Ronald F. May

Ronald F. May, Manager

Denver Aircraft Certification Office

Federal Aviation Administration

Northwest Mountain Region

.

Melvin D. Taylor, Manager

Atlanta Aircraft Certification Office

Federal Aviation Administration

Southeast Region

P/N 135A-970-006 04-00-00 Page 4 - 2

April 2005

Airworthiness Limitations

XL2 Airplane

SECTION 04-10:

AIRFRAME

The structural inspection procedures and inspection intervals for both life limited

components and components subject to a more detailed level of inspection are

listed below in Section 4-20.

P/N 135A-970-006 04-00-00 Page 4 - 3

April 2005

Airworthiness Limitations

XL2 Airplane

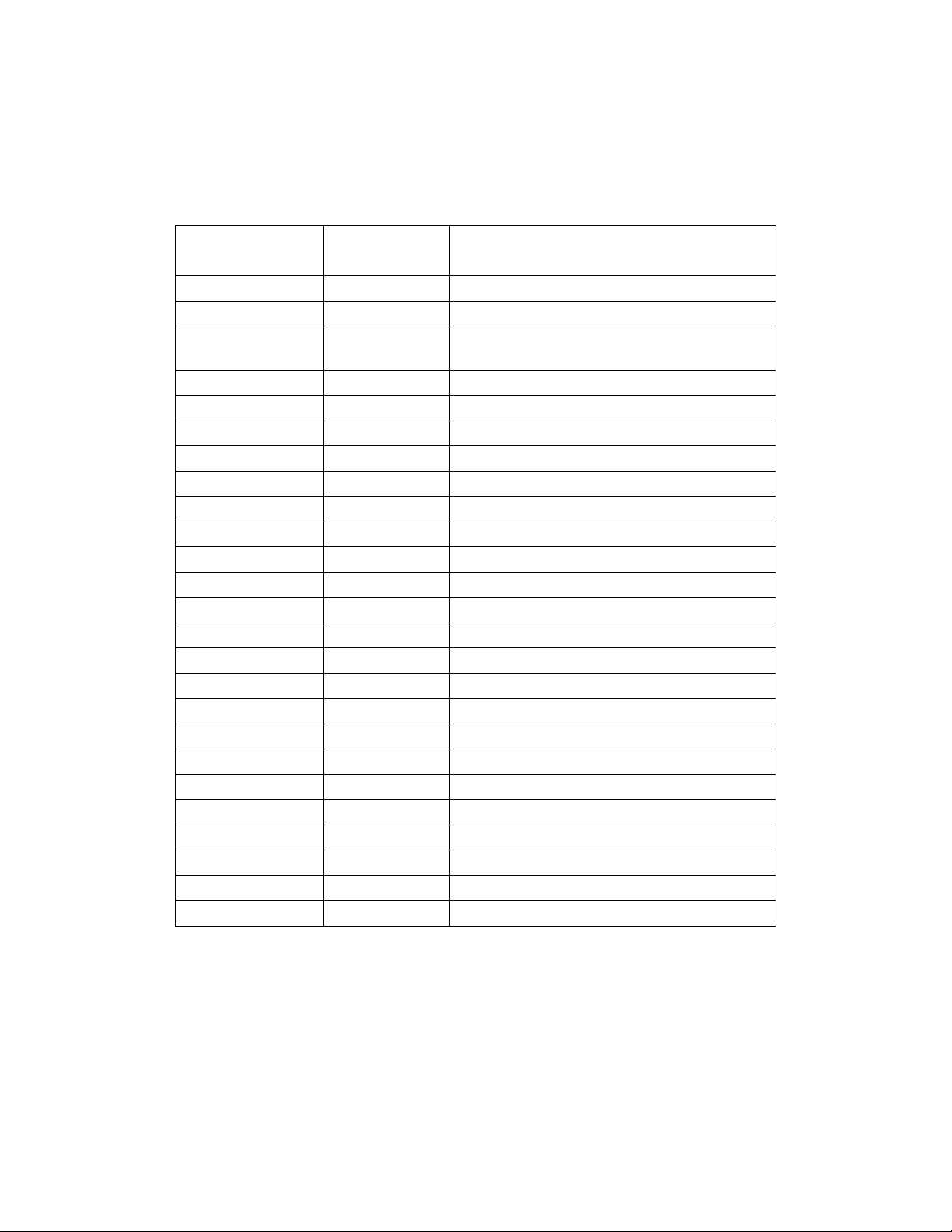

SECTION 04-20:

COMPONENTS SUBJECT TO LIFE LIMITS OR REQUIRING MORE

DETAILED LEVELS OF INSPECTION

Items listed below are considered components that are either life-limited with

distinct times between replacement, or components subject to a higher level of

inspection. The life-limited components must be removed from service at the

replacement times indicated and rendered unserviceable and discarded to

prevent re-use.

Note

: Record new aircraft serial number, hours and at installation and removal.

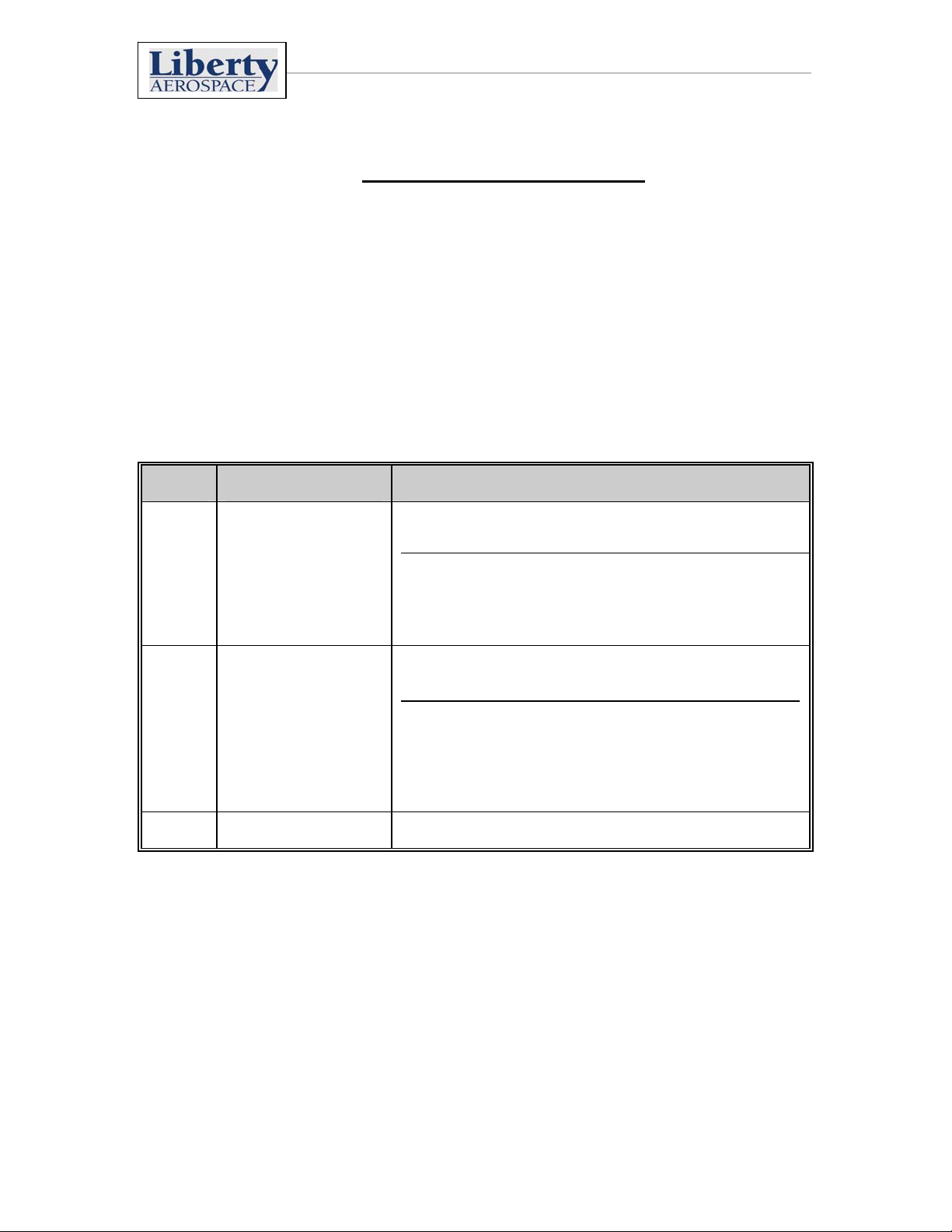

COMPONENTS SUBJECT TO LIFE-LIMITS

Component P/N Inspection Interval

Fuselage and Chassis

Wing Skin and Spar

Wing Root Fittings

Wing Carry Through Structure 135A-10-075

Nose Lock Pin 135A-40-565

Tail Plane Mass Balance Drive Arm 135A-45-615

Tail Plane Attachment Lug 135A-30-591

Firewall 33M1154-301

135A-00-025

135A-10-035

135A-20-005

135A-20-006

135A-10-085

135A-10-086

135A-20-501

135A-20-502

Annual for all aircraft and

100 hr as applicable per

Part 91

Annual for all aircraft and

100 hr as applicable per

Part 91

Annual for all aircraft and

100 hr as applicable per

Part 91

Annual for all aircraft and

100 hr as applicable per

Part 91

Annual for all aircraft and

100 hr as applicable per

Part 91

Annual for all aircraft and

100 hr as applicable per

Part 91

Annual for all aircraft and

100 hr as applicable per

Part 91

Annual for all aircraft and

100 hr as applicable per

Part 91

Mandatory

Replacement Time

225 hrs

9800 hrs

5250 hrs

1500 hrs

500 hrs

500 hrs

500 hrs

Annual

FADEC Backup Battery RG-1207 Annual for all aircraft Annual

FADEC Backup Battery 656070 Annual for all aircraft Annual

P/N 135A-970-006 04-20-00 Page 4 - 4

April 2005

Airworthiness Limitations

XL2 Airplane

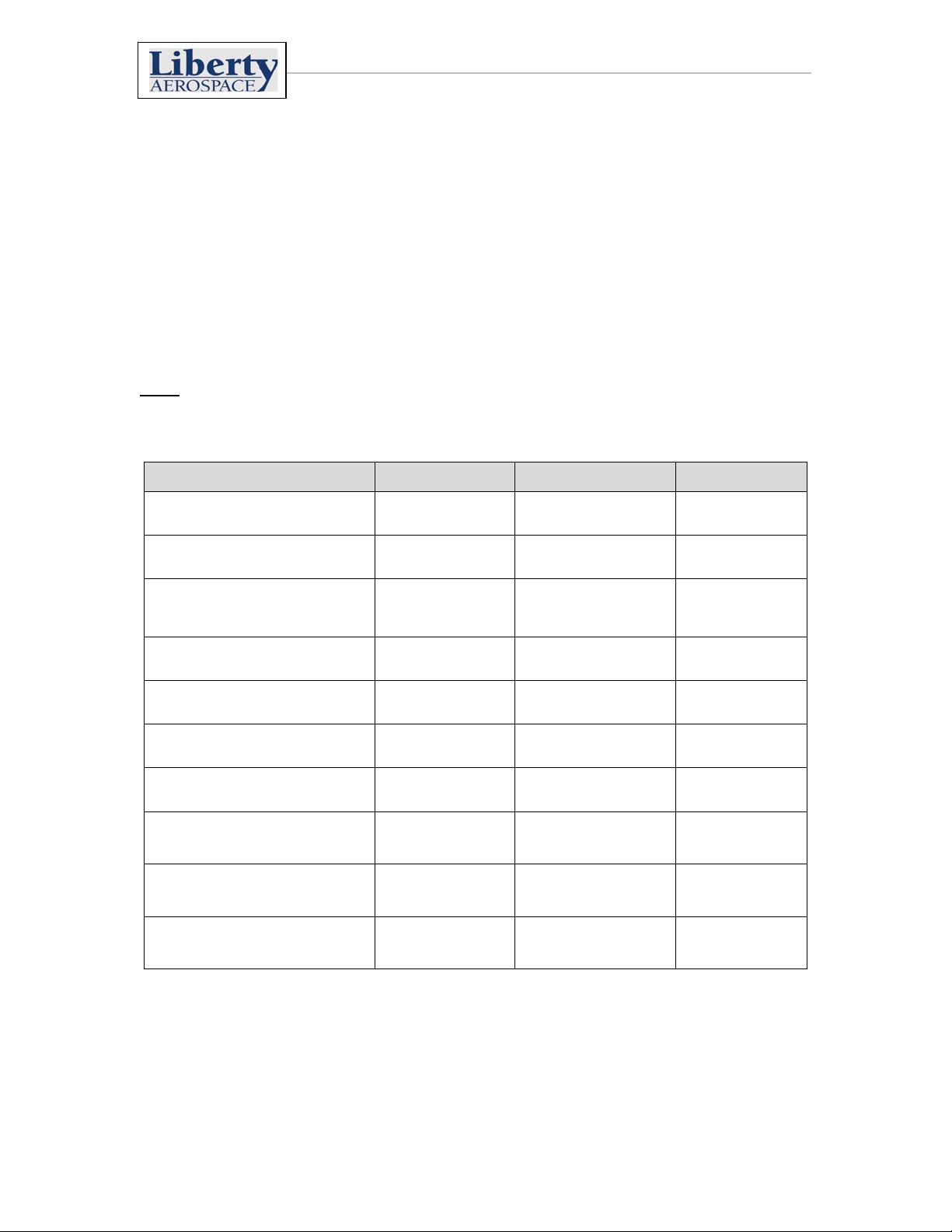

COMPONENTS REQUIRING A MORE DETAILED LEVEL OF INSPECTION

Mandatory

Component P/N Inspection Interval

Throttle Control System

Composite Fuselage

2

1

135A-50-015

135A-10-105

Annual for all aircraft and 100 hr

as applicable per Part 91

Inspection Type: Visual

Inspection of all fuselage bondlines and the fuselage structure

Inspection interval: Prior to each

flight

Inspection Type: Tap test

inspection of all fuselage bondlines and fuselage-laminate for

damage. Associated inspection

interval: Annual for all aircraft

and 100 hr as applicable per part

91

Date of removal and replacement of life-limited components, including flight

hours, must be recorded in aircraft maintenance records to ensure correct

observation of the stated interval(s).

Replacement

Time

None

225 hrs

1

The inspection procedure for the XL2 throttle cable installation will be conducted as directed in

Chapter 5 of these Instructions for Continued Airworthiness.

2

The inspection procedure for the XL2 fuselage will be conducted as directed in Chapter 5 of

these Instructions for Continued Airworthiness.

P/N 135A-970-006 04-20-00 Page 4 - 5

April 2005

Airworthiness Limitations

XL2 Airplane

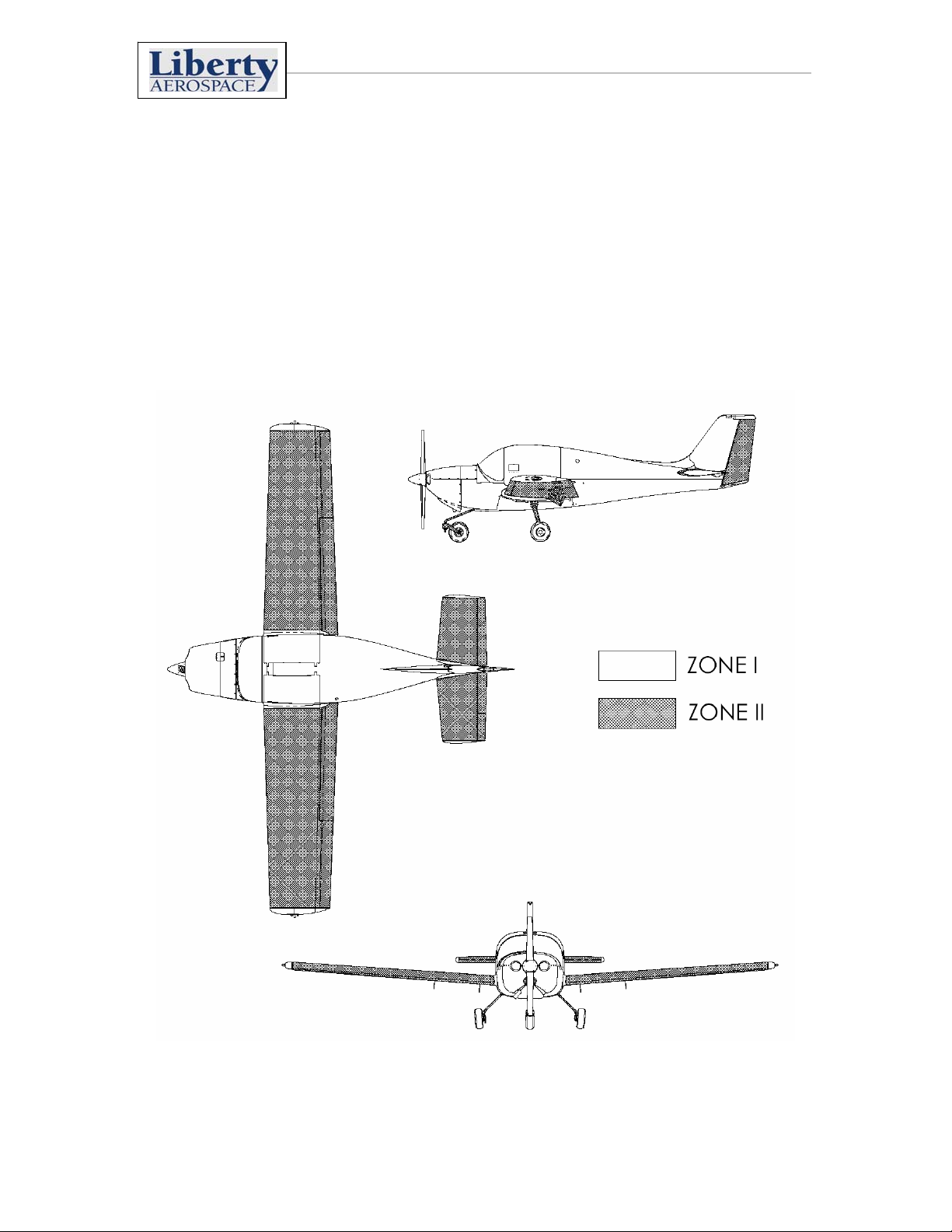

SECTION 04-30

PAINT FINISH

To ensure that the temperature of the load-bearing composite structure is kept

below the structural temperature limit, the outer surface of the composite

components must be painted white except for areas of registration marks,

placards, and minor trim. Figure 4.1 defines the zones and limitations for exterior

paint color.

1. Zone I: These areas are composite and therefore must be painted white.

2. Zone II: These areas are metallic and therefore may be painted any color.

Figure 4.1 Paint Zones

P/N 135A-970-006 04-30-00 Page 4 - 6

April 2005

Time Limits/Maintenance Checks/Inspection Intervals

CHAPTER 05

TIME LIMITS/MAINTENANCE CHECKS/INSPECTION

INTERVALS

XL2 Airplane

INITIAL RELEASE - 1 -

P/N 135A-970-006 Chap 05

Time Limits/Maintenance Checks/Inspection Intervals

XL2 Airplane

Chapter 05

Table of Contents

Chapter 05

Table of Contents

Chapter 05-00

General

Chapter 05-10

Time Limits

Chapter 05-20

General

50, 100, and 500 hour inspections, checklist

Check Flight checklist

Chapter 05-30

General Inspections

General

Preflight Inspections

Post-Flight Inspections

Chapter 05-40

Unscheduled Inspections

General

Special Inspections

2

1

1

1

1

1

1

1

1

1

1

P/N 135A-970-006 Chap 05-

INITIAL RELEASE - 2 -

Time Limits/Maintenance Checks/Inspection Intervals

XL2 Airplane

Time Limits/Maintenance Checks/Inspection Intervals

Section 05-00

General:

Maintenance personnel should refer to chapters 04 and 05 as guidelines for proper

scheduling and execution of inspections and maintenance.

The inspections and intervals described in these two chapters are considered the

minimum required to maintain the airplane in airworthy condition.

WARNING:

TO PREVENT INJURY TO PERSONNEL, ENSURE THAT THE PROPELLER AREA IS CLEAR OF

ANY PERSON IN THE EVENT THAT ANY INSPECTION OR MAINTENANCE MUST BE

PERFORMED WITH THE MASTER AND EITHER FADEC “A” OR FADEC “B” SWITCH “ON”,

BATTERY CONNECTED AND THE PROPELLER BEING MOVED. IF IGNITION SWITCH OR

GROUND WIRE IS DEFECTIVE, UNINTENTIONAL ENGINE FIRING OR RUNNING IS POSSIBLE

EVEN WITH THE IGNITION SWITCH “OFF”.

P/N 135A-970-006 Chap 05-00

INITIAL RELEASE - 1 -

Time Limits/Maintenance Checks/Inspection Intervals

Section 05-10

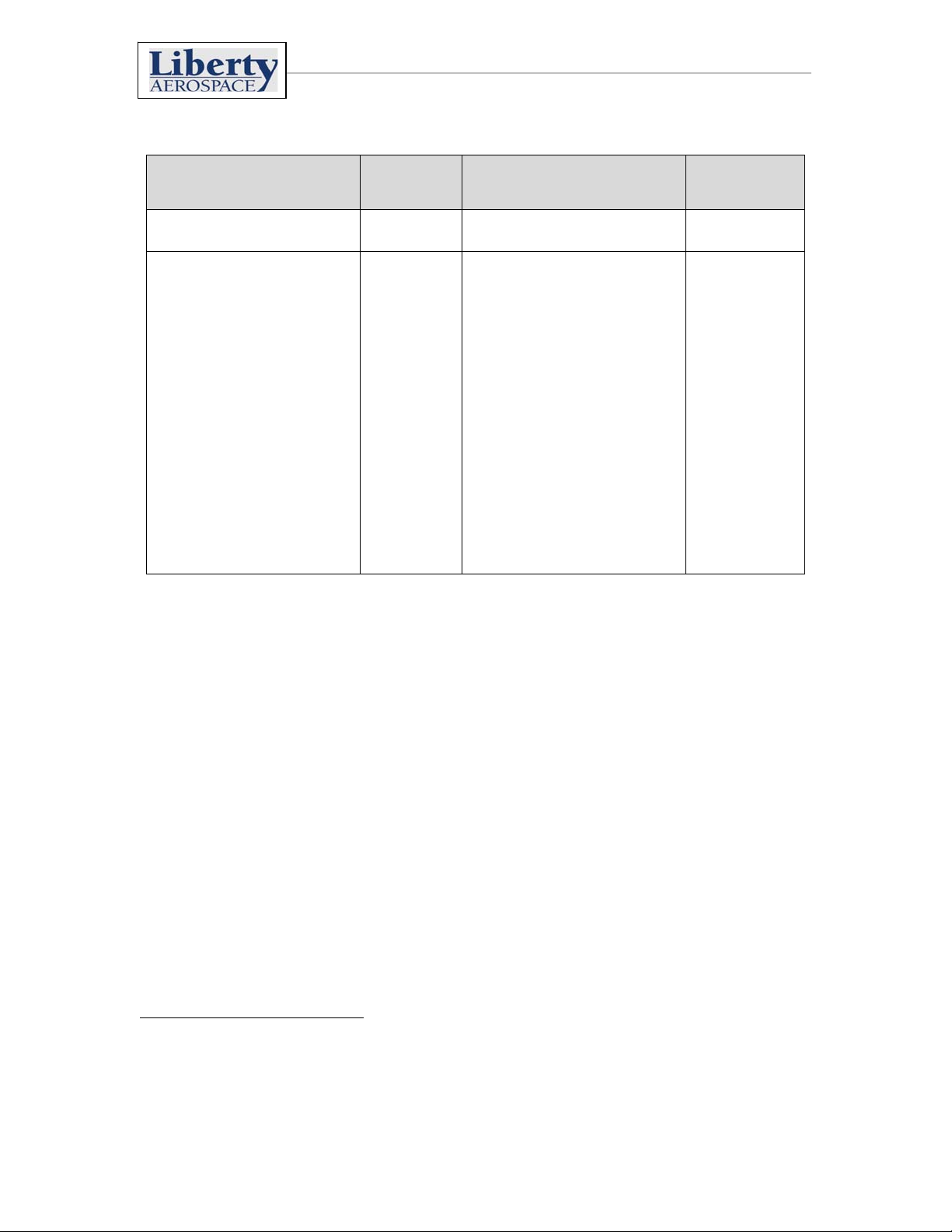

Time Limits:

Component time limits:

Component Specified Time Between Overhaul

Engine, Teledyne Continental

Motors, model IOF-240-B.

Including accessories 2000 operating hours or 12 years

Propeller, Sensenich model

W69EK7-63G To be inserted

XL2 Airplane

P/N 135A-970-006 Chap 05-20

INITIAL RELEASE - 1 -

Loading...

Loading...