Page 1

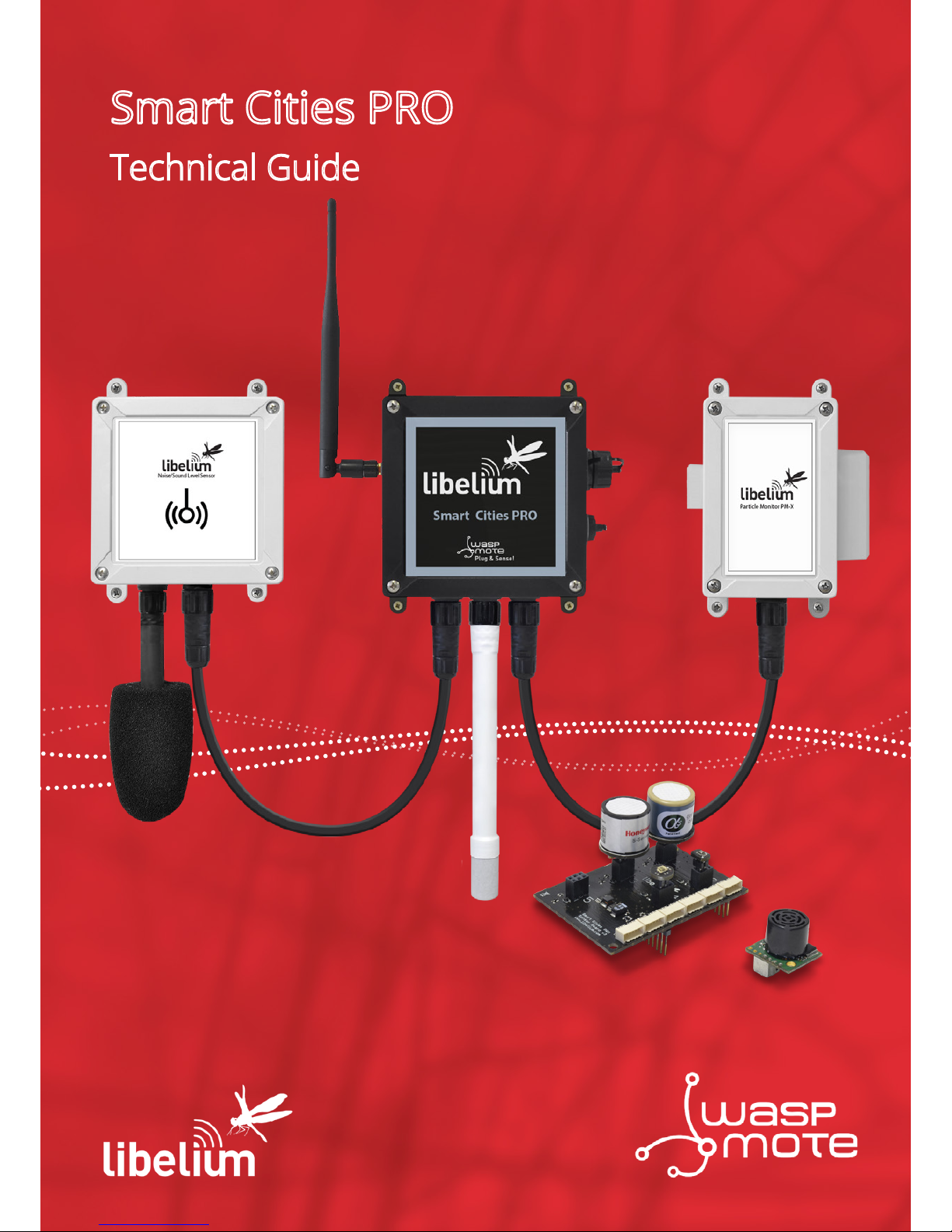

Smart Cities PRO

Technical Guide

Page 2

-2-

v7.3

Index

Document version: v7.3 - 11/2017

© Libelium Comunicaciones Distribuidas S.L.

INDEX

1. General ................................................................................................................................... 5

1.1. General and safety information ...................................................................................................... 5

1.2. Conditions of use .............................................................................................................................. 6

2. New version: Smart Cities PRO v3.0 ....................................................................................7

3. Waspmote Plug & Sense! ...................................................................................................... 8

3.1. Features ............................................................................................................................................. 8

3.2. General view ...................................................................................................................................... 9

3.3. Specications ..................................................................................................................................... 9

3.4. Parts included .................................................................................................................................. 12

3.5. Identication .................................................................................................................................... 13

3.6. Sensor probes ................................................................................................................................. 15

3.7. Solar powered ................................................................................................................................. 16

3.8. External Battery Module ................................................................................................................ 18

3.9. Programming the Nodes ................................................................................................................ 19

3.10. Program in minutes ...................................................................................................................... 20

3.11. Radio interfaces ............................................................................................................................ 21

3.12. Industrial Protocols ...................................................................................................................... 22

3.13. GPS ................................................................................................................................................. 24

3.14. Models ............................................................................................................................................ 25

3.14.1. Smart Cities PRO ...............................................................................................................26

4. Hardware .............................................................................................................................28

4.1. General description ........................................................................................................................ 28

4.2. Specications ................................................................................................................................... 28

4.3. Electrical characteristics ................................................................................................................. 28

5. Sensors ................................................................................................................................. 29

5.1. Temperature, Humidity and Pressure Sensor ............................................................................. 29

5.1.1. Specications .......................................................................................................................29

5.1.2. Measurement process ........................................................................................................30

5.1.3. Socket ...................................................................................................................................31

5.2. Ultrasound sensor probe (MaxSonar® from MaxBotix™) ......................................................... 32

5.2.1. Specications .......................................................................................................................32

5.2.2. Measurement Process ........................................................................................................34

5.2.3. Socket ...................................................................................................................................34

5.3. Luminosity (Luxes accuracy) Sensor ............................................................................................. 35

5.3.1. Specications .......................................................................................................................35

5.3.2. Measurement process ........................................................................................................35

5.3.3. Socket ...................................................................................................................................35

5.4. Particle Matter (PM1 / PM2.5 / PM10) - Dust Sensor .................................................................. 36

Page 3

-3-

v7.3

Index

5.4.1. Specications .......................................................................................................................36

5.4.2. Particle matter: the parameter ..........................................................................................37

5.4.3. Measurement process ........................................................................................................37

5.5. Noise / Sound Level Sensor ........................................................................................................... 38

5.5.1. Specications of the Sound Level Sensor probe .............................................................38

5.5.2. Specications of the enclosure ..........................................................................................38

5.5.3. Sound pressure level measurement .................................................................................38

5.5.4. Equivalent continuous sound level ...................................................................................39

5.5.5. The A-weighting ...................................................................................................................39

5.5.6. International standard IEC 61672-1:2013 ........................................................................40

5.5.7. Measurement process ........................................................................................................40

5.5.8. Calibration Tests ..................................................................................................................40

5.5.9. Mounting the Noise / Sound Level Sensor and supplying power .................................43

5.6. Carbon Monoxide (CO) Gas Sensor for high concentrations [Calibrated] ............................... 48

5.6.1. Specications .......................................................................................................................48

5.6.2. Cross-sensitivity data ..........................................................................................................49

5.7. Carbon Monoxide (CO) Gas Sensor for low concentrations [Calibrated] ................................ 50

5.7.1. Specications .......................................................................................................................50

5.7.2. Cross-sensitivity data ..........................................................................................................51

5.8. Carbon Dioxide (CO2) Gas Sensor [Calibrated] ............................................................................ 52

5.8.1. Specications .......................................................................................................................52

5.9. Molecular Oxygen (O2) Gas Sensor [Calibrated] .......................................................................... 53

5.9.1. Specications .......................................................................................................................53

5.10. Ozone (O3) Gas Sensor [Calibrated] ............................................................................................ 54

5.10.1. Specications .....................................................................................................................54

5.10.2. Cross-sensitivity data ........................................................................................................55

5.11. Nitric Oxide (NO) Gas Sensor for low concentrations

[Calibrated] ............................................................................................................................................. 56

5.11.1. Specications .....................................................................................................................56

5.11.2. Cross-sensitivity data ........................................................................................................57

5.12. Nitric Dioxide (NO2) high accuracy Gas Sensor

[Calibrated] ............................................................................................................................................. 58

5.12.1. Specications .....................................................................................................................58

5.12.2. Cross-sensitivity data ........................................................................................................59

5.13. Sulfur Dioxide (SO2) high accuracy Gas Sensor [Calibrated] ................................................... 60

5.13.1. Specications .....................................................................................................................60

5.13.2. Cross-sensitivity data ........................................................................................................61

5.14. Ammonia (NH3) Gas Sensor for low concentrations [Calibrated] ........................................... 62

5.14.1. Specications .....................................................................................................................62

5.14.2. Cross-sensitivity data ........................................................................................................63

5.15. Ammonia (NH3) Gas Sensor for high concentrations [Calibrated] .......................................... 64

5.15.1. Specications .....................................................................................................................64

5.15.2. Cross-sensitivity data ........................................................................................................65

5.16. Methane (CH4) and Combustible Gas Sensor

Page 4

-4-

v7.3

[Calibrated] ............................................................................................................................................. 66

5.16.1. Specications .....................................................................................................................66

5.16.2. Sensitivity data ..................................................................................................................67

5.17. Molecular Hydrogen (H2) Gas Sensor [Calibrated] .................................................................... 68

5.17.1. Specications .....................................................................................................................68

5.17.2. Cross-sensitivity data ........................................................................................................69

5.18. Hydrogen Sulde (H2S) Gas Sensor [Calibrated] ....................................................................... 70

5.18.1. Specications .....................................................................................................................70

5.18.2. Cross-sensitivity data ........................................................................................................71

5.19. Hydrogen Chloride (HCl) Gas Sensor [Calibrated] .................................................................... 72

5.19.1. Specications .....................................................................................................................72

5.19.2. Cross-sensitivity data ........................................................................................................73

5.20. Hydrogen Cyanide (HCN) Gas Sensor [Calibrated] ................................................................... 74

5.20.1. Specications .....................................................................................................................74

5.20.2. Cross-sensitivity data ........................................................................................................75

5.21. Phosphine (PH3) Gas Sensor [Calibrated] .................................................................................. 76

5.21.1. Specications .....................................................................................................................76

5.21.2. Cross-sensitivity data ........................................................................................................77

5.22. Ethylene Oxide (ETO) Gas Sensor [Calibrated] .......................................................................... 78

5.22.1. Specications .....................................................................................................................78

5.22.2. Cross-sensitivity data ........................................................................................................79

5.23. Chlorine (Cl2) Gas Sensor [Calibrated] ........................................................................................ 80

5.23.1. Specications .....................................................................................................................80

5.23.2. Cross-sensitivity data ........................................................................................................81

5.24. Important notes for Calibrated Sensors .................................................................................... 82

6. Board conguration and programming ........................................................................... 83

6.1. Hardware conguration ................................................................................................................ 83

6.2. API ..................................................................................................................................................... 83

6.2.1. Before starting to program ................................................................................................83

6.2.2. Gases sensors ......................................................................................................................83

6.2.3. Temperature, humidity and pressure sensor (BME280) ................................................84

6.2.4. Luxes sensor ........................................................................................................................84

6.2.5. Ultrasound sensor ...............................................................................................................85

7. Consumption ....................................................................................................................... 86

7.1. Consumption table ......................................................................................................................... 86

8. API changelog ...................................................................................................................... 87

9. Documentation changelog ................................................................................................88

10. Certications ..................................................................................................................... 89

11. Maintenance ......................................................................................................................90

12. Disposal and recycling ...................................................................................................... 91

Index

Page 5

-5-

v7.3

General

1. General

Important:

• All documents and any examples they contain are provided as-is and are subject to change without notice.

Except to the extent prohibited by law, Libelium makes no express or implied representation or warranty of

any kind with regard to the documents, and specically disclaims the implied warranties and conditions of

merchantability and tness for a particular purpose.

• The information on Libelium’s websites has been included in good faith for general informational purposes

only. It should not be relied upon for any specic purpose and no representation or warranty is given as to its

accuracy or completeness.

1.1. General and safety information

• In this section, the term “Waspmote” encompasses both the Waspmote device itself and its modules and

sensor boards.

• Read through the document “General Conditions of Libelium Sale and Use”.

• Do not allow contact of metallic objects with the electronic part to avoid injuries and burns.

• NEVER submerge the device in any liquid.

• Keep the device in a dry place and away from any liquid which may spill.

• Waspmote consists of highly sensitive electronics which is accessible to the exterior, handle with great care

and avoid bangs or hard brushing against surfaces.

• Check the product specications section for the maximum allowed power voltage and amperage range and

consequently always use a current transformer and a battery which works within that range. Libelium is only

responsible for the correct operation of the device with the batteries, power supplies and chargers which it

supplies.

• Keep the device within the specied range of temperatures in the specications section.

• Do not connect or power the device with damaged cables or batteries.

• Place the device in a place only accessible to maintenance personnel (a restricted area).

• Keep children away from the device in all circumstances.

• If there is an electrical failure, disconnect the main switch immediately and disconnect that battery or any

other power supply that is being used.

• If using a car lighter as a power supply, be sure to respect the voltage and current data specied in the “Power

Supplies” section.

• If using a battery in combination or not with a solar panel as a power supply, be sure to use the voltage and

current data specied in the “Power supplies” section.

• If a software or hardware failure occurs, consult the Libelium Web Development section.

• Check that the frequency and power of the communication radio modules together with the integrated

antennas are allowed in the area where you want to use the device.

• Waspmote is a device to be integrated in a casing so that it is protected from environmental conditions such

as light, dust, humidity or sudden changes in temperature. The board supplied “as is” is not recommended for

a nal installation as the electronic components are open to the air and may be damaged.

Page 6

-6-

v7.3

General

1.2. Conditions of use

• Read the “General and Safety Information” section carefully and keep the manual for future consultation.

• Use Waspmote in accordance with the electrical specications and the environment described in the “Electrical

Data” section of this manual.

• Waspmote and its components and modules are supplied as electronic boards to be integrated within a nal

product. This product must contain an enclosure to protect it from dust, humidity and other environmental

interactions. In the event of outside use, this enclosure must be rated at least IP-65.

• Do not place Waspmote in contact with metallic surfaces; they could cause short-circuits which will permanently

damage it.

Further information you may need can be found at http://www.libelium.com/development/waspmote

The “General Conditions of Libelium Sale and Use” document can be found at:

http://www.libelium.com/development/waspmote/technical_service

Page 7

-7-

v7.3

New version: Smart Cities PRO v3.0

2. New version: Smart Cities PRO v3.0

This guide explains the new Smart Cities Sensor Board v3.0. This board was designed for our new product lines

Waspmote v15 and Plug & Sense! v15, released on October 2016.

The previous version of this board (Smart Cities v2.0) was designed for Waspmote v12 and Plug & Sense! v12, and

it is NOT recommended to mix product generations. If you are using previous versions of our products, please use

the corresponding guides, available on our Development website.

You can get more information about the generation change on the document “New generation of Libelium product

lines”.

Dierences of Smart Cities PRO v3.0 with the previous version:

• Added the new Noise Level Sensor, able to read LeqA (integrated equivalent continuous sound level,

A-weighted) in dBA. The sensor achieves high accuracy in a wide range of frequencies.

• I2C sockets allow the connection of digital sensors, even gas sensors from Gases PRO, Temperature, Humidity

and Pressure sensor or Luxes and Ultrasound sensors.

• The Particle Matter – Dust Sensor (PM1 / PM2.5 / PM10) is now available on this board.

• New connectors to improve the Plug & Sense! wiring, making it more robust.

• Added an I2C isolator chip to avoid aecting to the Waspmote I2C bus.

Page 8

-8-

v7.3

Waspmote Plug & Sense!

3. Waspmote Plug & Sense!

The Waspmote Plug & Sense! line allows you to easily deploy Internet of Things networks in an easy and scalable

way, ensuring minimum maintenance costs. The platform consists of a robust waterproof enclosure with specic

external sockets to connect the sensors, the solar panel, the antenna and even the USB cable in order to reprogram

the node. It has been specially designed to be scalable, easy to deploy and maintain.

Note: For a complete reference guide download the “Waspmote Plug & Sense! Technical Guide” in the Development

section of the Libelium website.

3.1. Features

• Robust waterproof IP65 enclosure

• Add or change a sensor probe in seconds

• Solar powered with internal and external panel options

• Radios available: 802.15.4, 868 MHz, 900 MHz, WiFi, 4G, Sigfox and LoRaWAN

• Over the air programming (OTAP) of multiple nodes at once (via WiFi or 4G radios)

• Special holders and brackets ready for installation in street lights and building fronts

• Graphical and intuitive interface Programming Cloud Service

• Built-in, 3-axes accelerometer

• External, contactless reset with magnet

• Optional industrial protocols: RS-232, RS-485, Modbus, CAN Bus

• Optional GPS receiver

• Optional External Battery Module

• External SIM connector for the 4G models

• Fully certied: CE (Europe), FCC (USA), IC (Canada), ANATEL (Brazil), RCM (Australia), PTCRB (USA, cellular

connectivity), AT&T (USA, cellular connectivity)

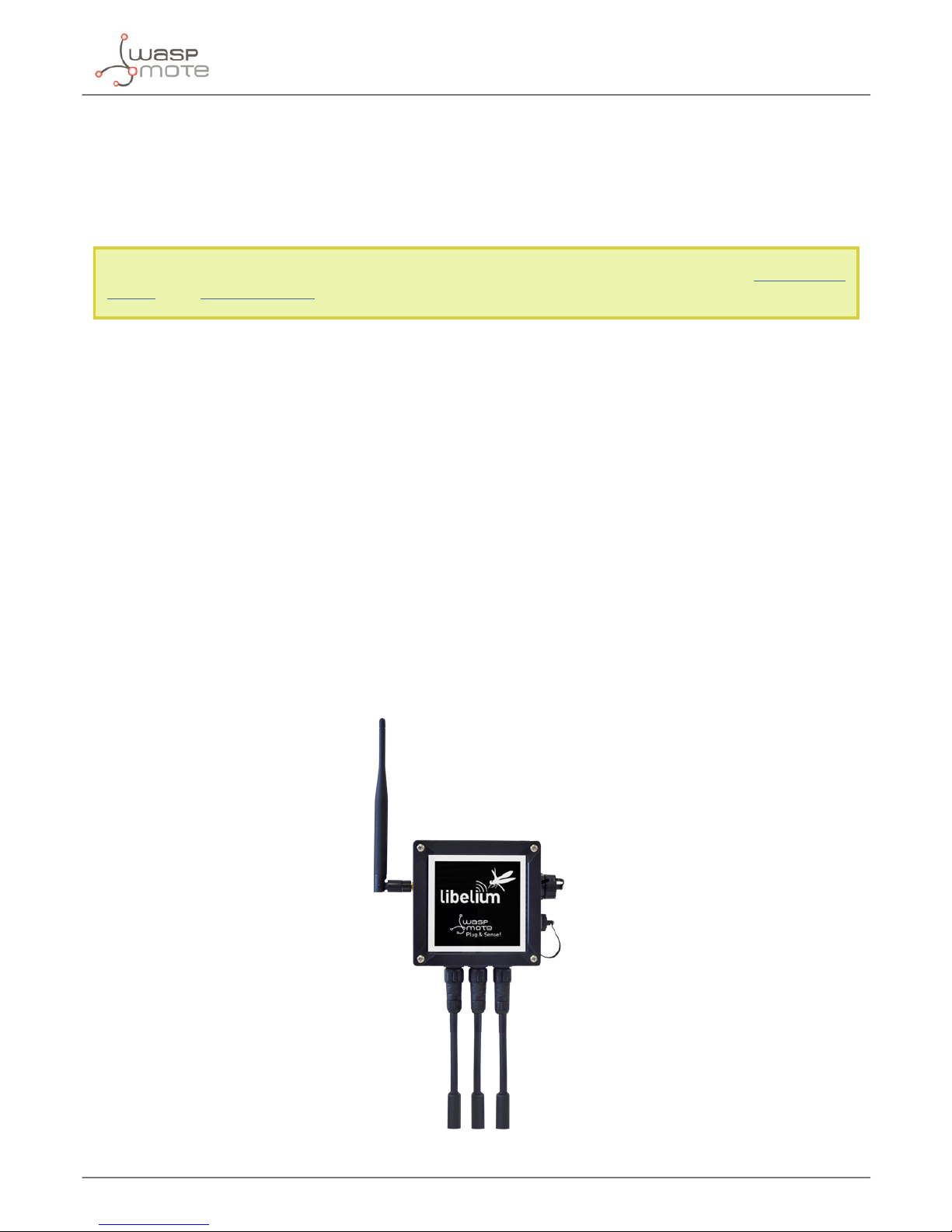

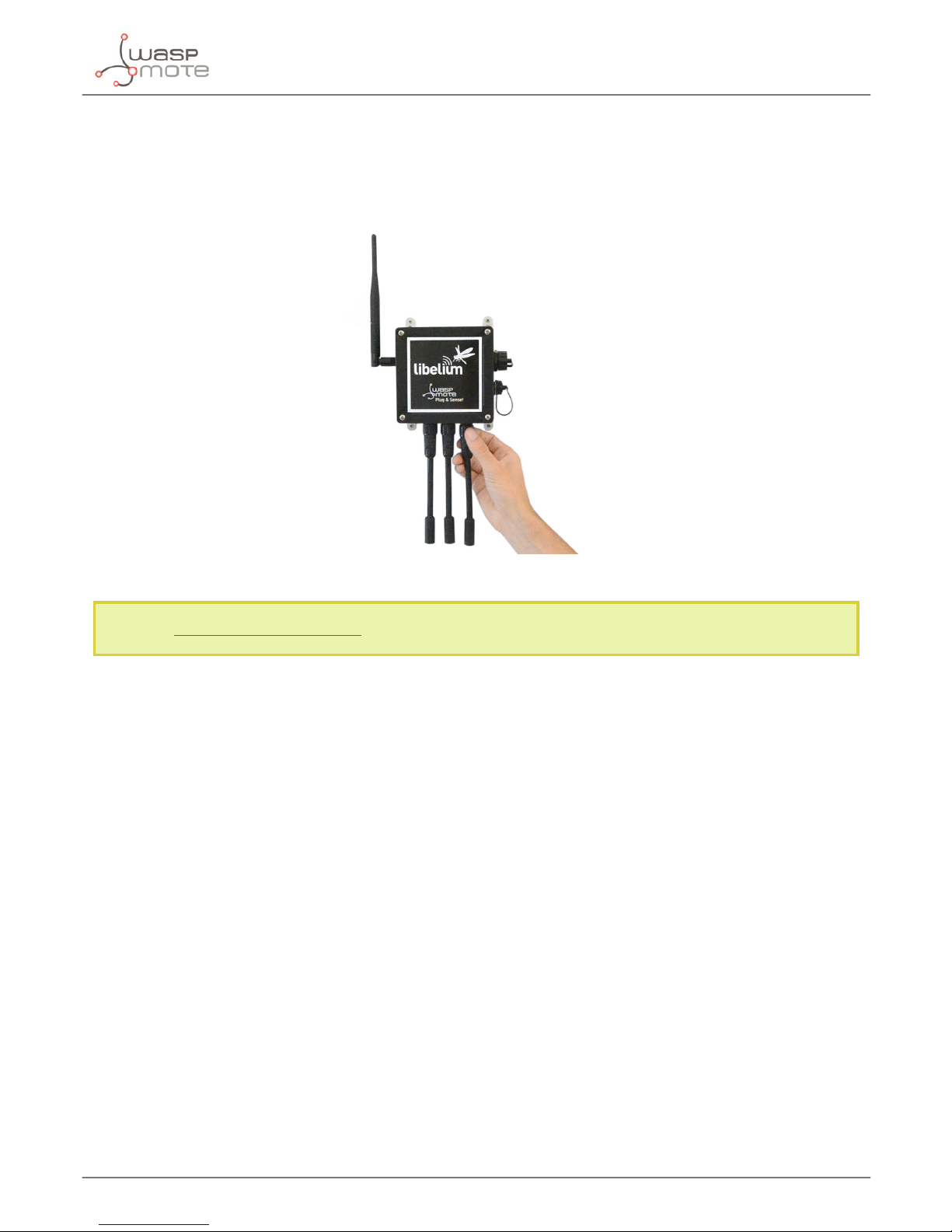

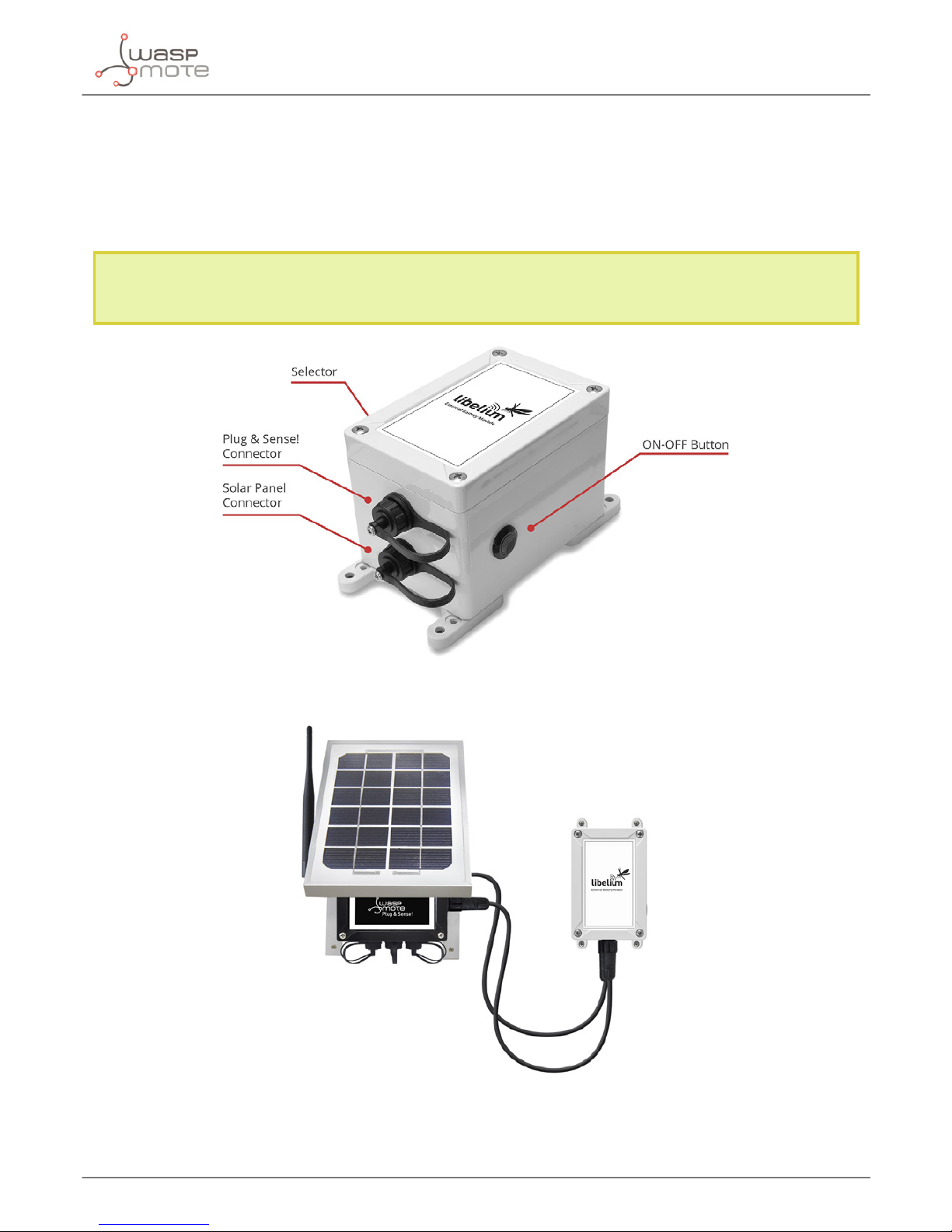

Figure: Waspmote Plug & Sense!

Page 9

-9-

v7.3

Waspmote Plug & Sense!

3.2. General view

This section shows main parts of Waspmote Plug & Sense! and a brief description of each one. In later sections

all parts will be described deeply.

3.3. Specications

• Material: polycarbonate

• Sealing: polyurethane

• Cover screws: stainless steel

• Ingress protection: IP65

• Impact resistance: IK08

• Rated insulation voltage AC: 690 V

• Rated insulation voltage DC: 1000 V

• Heavy metals-free: Yes

• Weatherproof: true - nach UL 746 C

• Ambient temperature (min.): -30 °C*

• Ambient temperature (max.): 70 °C*

• Approximated weight: 800 g

* Temporary extreme temperatures are supported. Regular recommended usage: -20, +60 ºC.

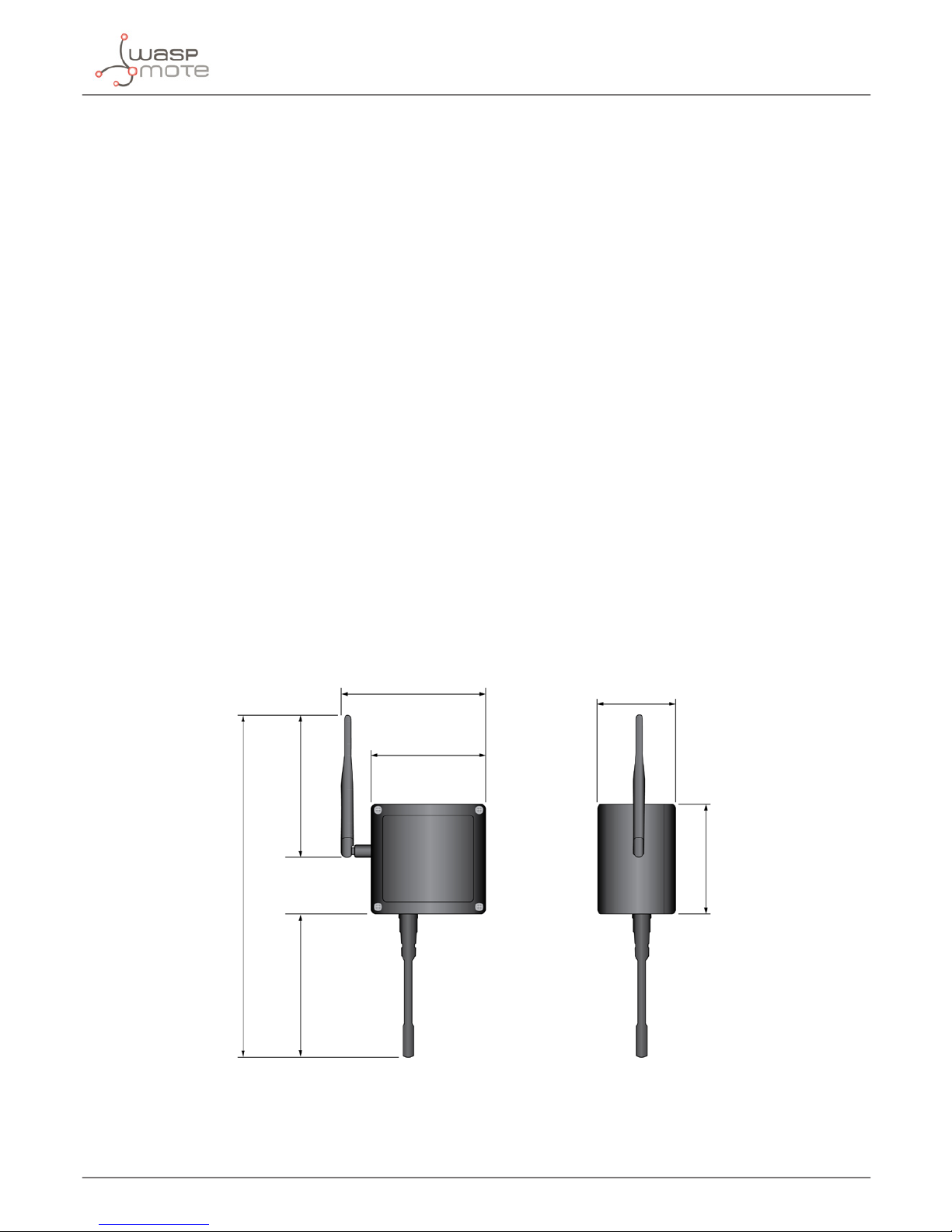

In the pictures included below it is shown a general view of Waspmote Plug & Sense! main parts. Some elements

are dedicated to node control, others are designated to sensor connection and other parts are just identication

elements. All of them will be described along this guide.

164 mm

124 mm

175 mm

410 mm

160 mm

122 mm

85 mm

Figure: Main view of Waspmote Plug & Sense!

Page 10

-10-

v7.3

Waspmote Plug & Sense!

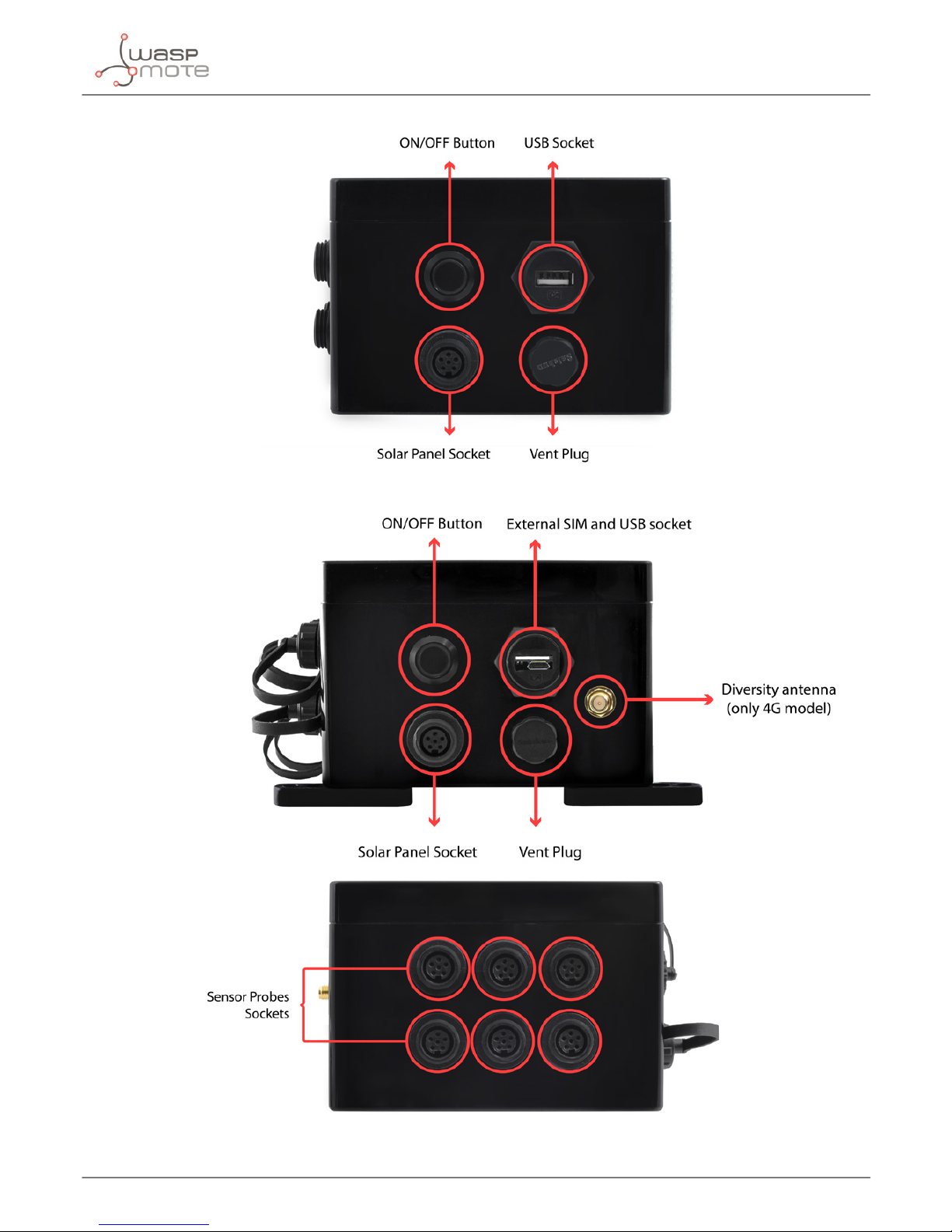

Figure: Control side of the enclosure

Figure: Control side of the enclosure for 4G model

Figure: Sensor side of the enclosure

Page 11

-11-

v7.3

Waspmote Plug & Sense!

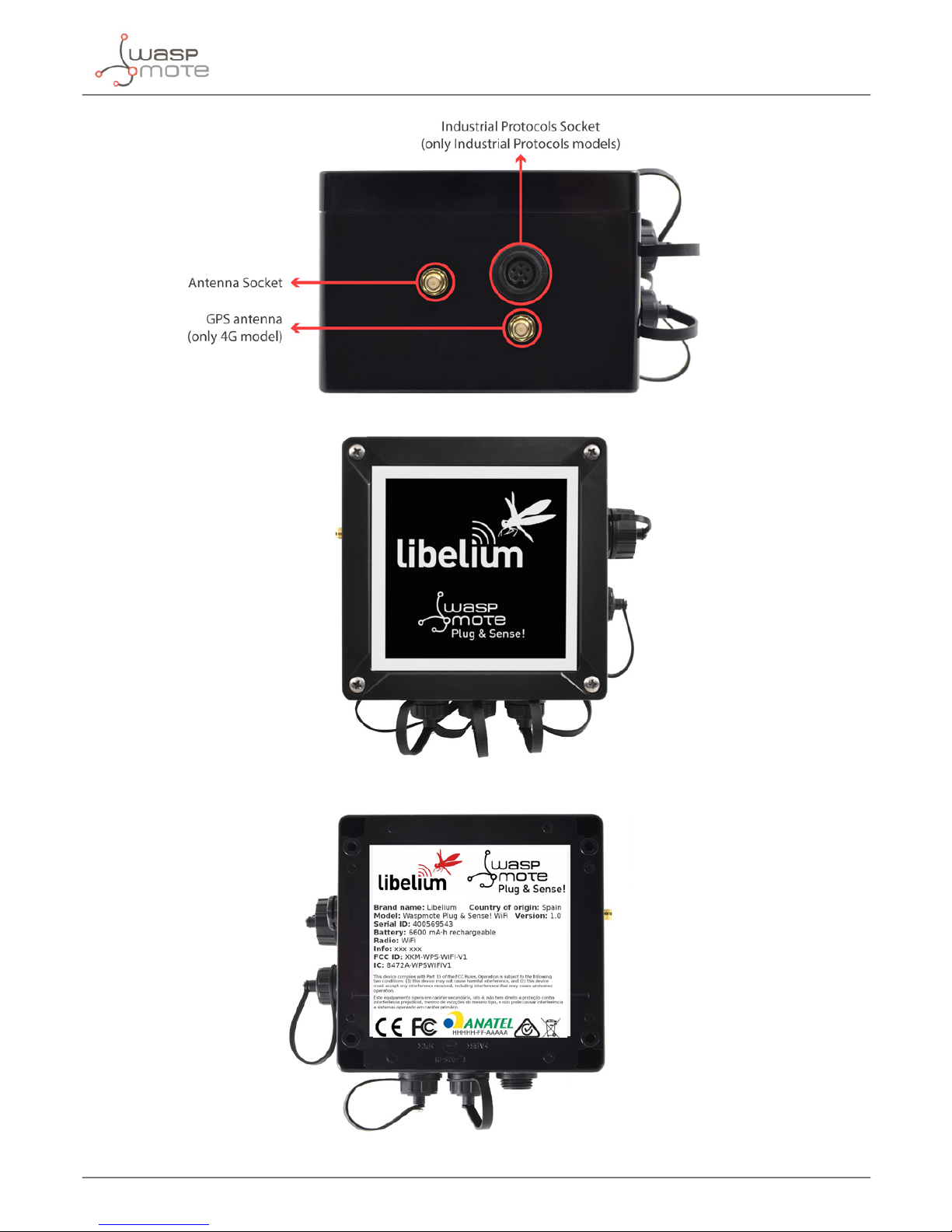

Figure: Antenna side of the enclosure

Figure: Front view of the enclosure

Figure: Back view of the enclosure

Page 12

-12-

v7.3

Waspmote Plug & Sense!

Figure: Warranty stickers of the enclosure

Important note: Do not handle black stickers seals of the enclosure (Warranty stickers). Their integrity is the proof

that Waspmote Plug & Sense! has not been opened. If they have been handled, damaged or broken, the warranty is

automatically void.

3.4. Parts included

Next picture shows Waspmote Plug & Sense! and all of its elements. Some of them are optional accessories that

may not be included.

1

2

3

4

5

7

6

8

9

10

Figure: Waspmote Plug & Sense! accessories: 1 enclosure, 2 sensor probes, 3 external solar panel, 4 USB cable, 5 antenna, 6 cable ties,

7 mounting feet (screwed to the enclosure), 8 extension cord, 9 solar panel cable, 10 wall plugs & screws

Page 13

-13-

v7.3

Waspmote Plug & Sense!

3.5. Identication

Each Waspmote model is identied by stickers. Next gure shows front sticker.

Model identication colour

Enclosure model

Figure: Front sticker of the enclosure

There are many congurations of Waspmote Plug & Sense! line, all of them identied by one unique sticker. Next

image shows all possibilities.

Figure: Dierent front stickers

Page 14

-14-

v7.3

Waspmote Plug & Sense!

Moreover, Waspmote Plug & Sense! includes a back sticker where it is shown identication numbers, radio MAC

addresses, etc. It is highly recommended to annotate this information and save it for future maintenance. Next

gure shows it in detail.

Figure: Back sticker

Sensor probes are identied too by a sticker showing the measured parameter and the sensor manufacturer

reference.

CO - TGS2442

Measure

parameter

Sensor

reference

Figure: Sensor probe identication sticker

Page 15

-15-

v7.3

Waspmote Plug & Sense!

3.6. Sensor probes

Sensor probes can be easily attached by just screwing them into the bottom sockets. This allows you to add new

sensing capabilities to existing networks just in minutes. In the same way, sensor probes may be easily replaced

in order to ensure the lowest maintenance cost of the sensor network.

Figure: Connecting a sensor probe to Waspmote Plug & Sense!

Go to the Plug & Sense! Sensor Guide to know more about our sensor probes.

Page 16

-16-

v7.3

Waspmote Plug & Sense!

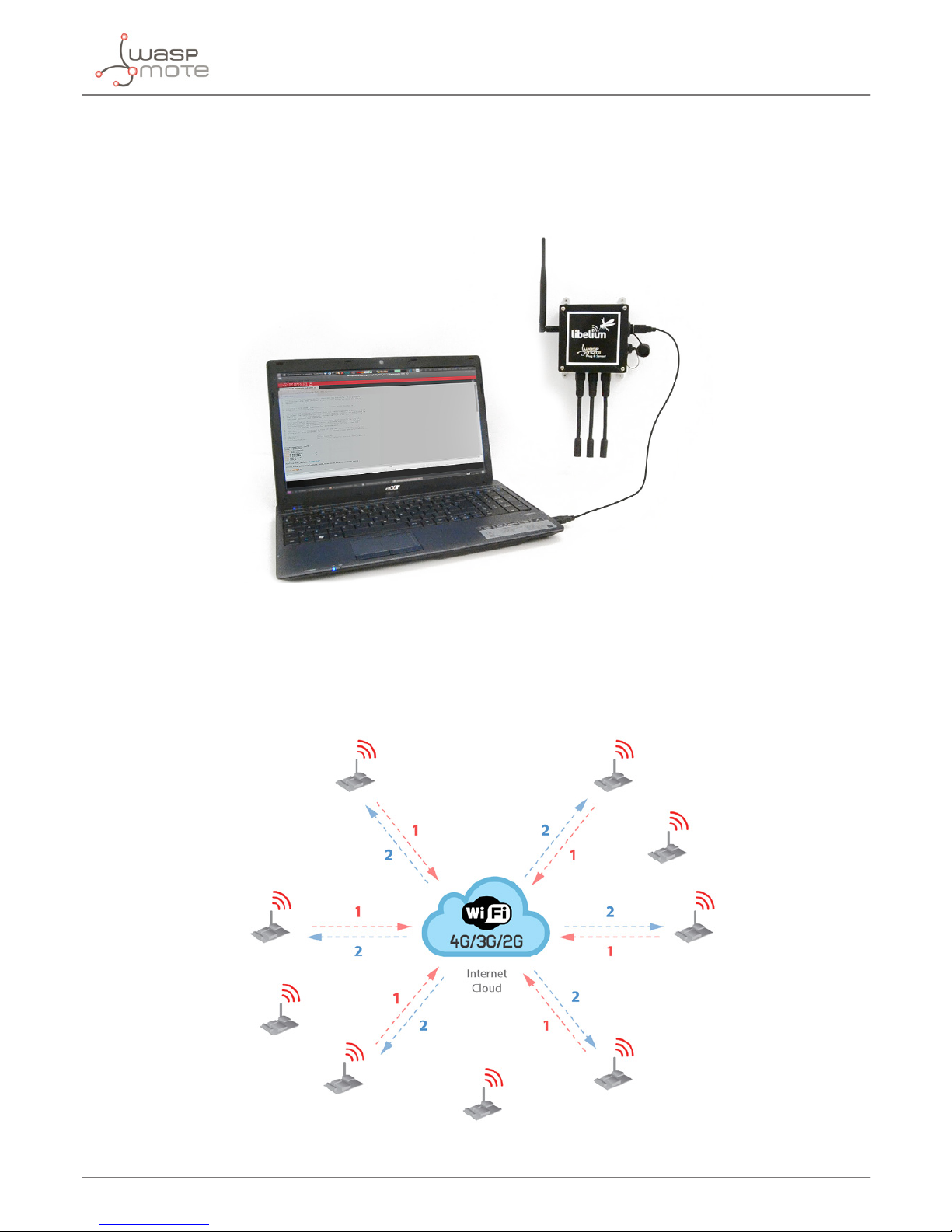

3.7. Solar powered

The battery can be recharged using the waterproof USB cable but also the internal or external solar panel options.

The external solar panel is mounted on a 45º holder which ensures the maximum performance of each outdoor

installation.

Figure: Waspmote Plug & Sense! powered by an external solar panel

For the internal option, the solar panel is embedded on the front of the enclosure, perfect for use where space is

a major challenge.

Figure: Internal solar panel

Page 17

-17-

v7.3

Waspmote Plug & Sense!

Figure: Waspmote Plug & Sense! powered by an internal solar panel

Page 18

-18-

v7.3

Waspmote Plug & Sense!

3.8. External Battery Module

The External Battery Module (EBM) is an accessory to extend the battery life of Plug & Sense!. The extension

period may be from months to years depending on the sleep cycle and radio activity. The daily charging period is

selectable among 5, 15 and 30 minutes with a selector switch and it can be combined with a solar panel to extend

even more the node’s battery lifetime.

Note: Nodes using solar panel can keep using it through the External Battery Module (EBM). The EBM is

connected to the solar panel connector of Plug & Sense! and the solar panel unit is connected to the solar

panel connector of the EBM.

Figure: Plug & Sense! with External Battery Module

Figure: Plug & Sense! with External Battery Module and solar panel

Page 19

-19-

v7.3

Waspmote Plug & Sense!

3.9. Programming the Nodes

Waspmote Plug & Sense! can be reprogrammed in two ways:

The basic programming is done from the USB port. Just connect the USB to the specic external socket and then

to the computer to upload the new rmware.

Figure: Programming a node

Over the Air Programming (OTAP) is also possible once the node has been installed (via WiFi or 4G radios). With

this technique you can reprogram, wireless, one or more Waspmote sensor nodes at the same time by using a

laptop and Meshlium.

Figure: Typical OTAP process

Page 20

-20-

v7.3

Waspmote Plug & Sense!

3.10. Program in minutes

The Programming Cloud Service is an intuitive graphic interface which creates code automatically. The user just

needs to to ll a web form to obtain binaries for Plug & Sense!. Advanced programming options are available,

depending on the license selected.

Check how easy it is to handle the Programming Cloud Service at:

https://cloud.libelium.com/

Figure: Programming Cloud Service

Page 21

-21-

v7.3

Waspmote Plug & Sense!

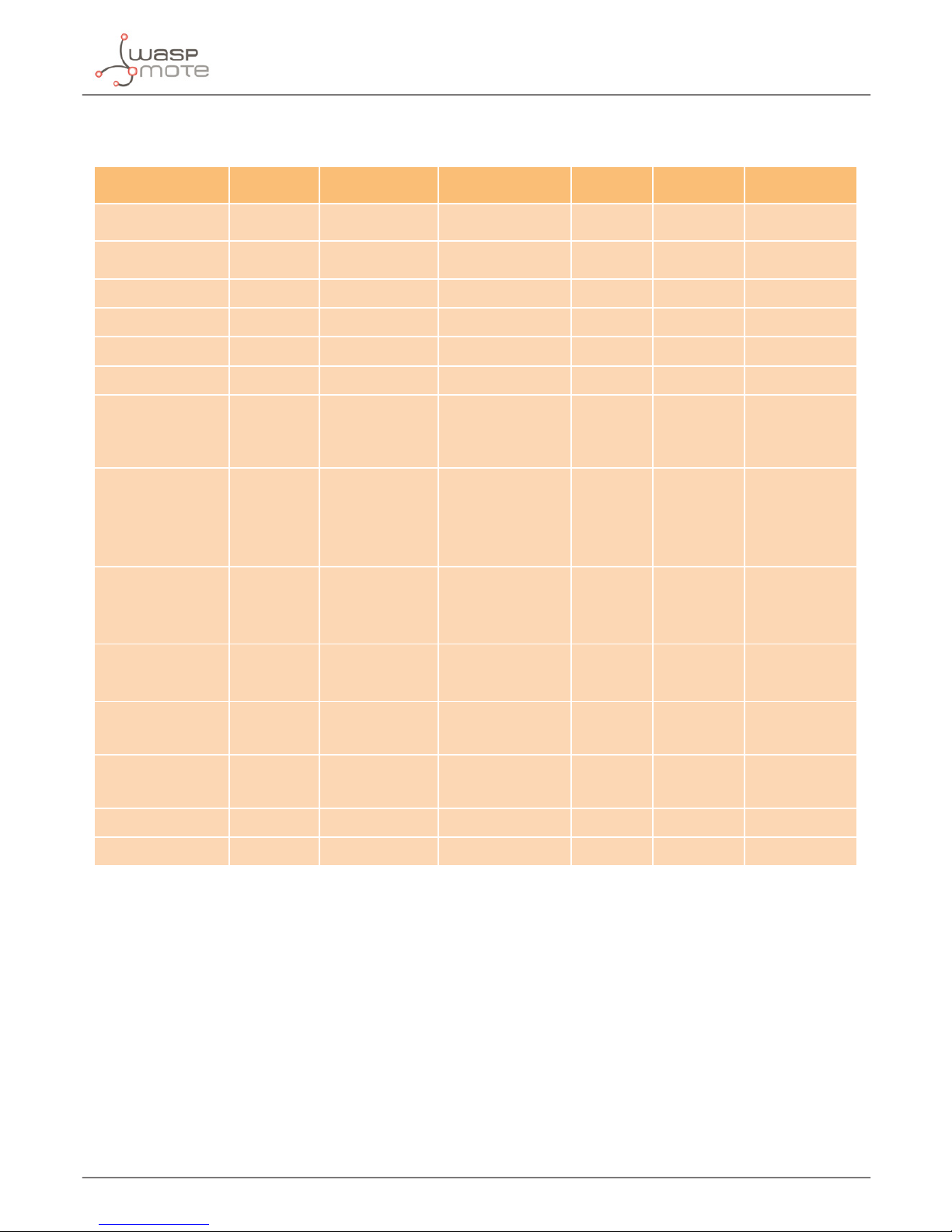

3.11. Radio interfaces

Radio Protocol

Frequency

bands

Transmission

power

Sensitivity Range*

Certication

XBee-PRO 802.15.4

EU

802.15.4 2.4 GHz 10 dBm -100 dBm 750 m CE

XBee-PRO 802.15.4 802.15.4 2.4 GHz 18 dBm -100 dBm 1600 m

FCC, IC, ANATEL,

RCM

XBee 868LP RF 868 MHz 14 dBm -106 dBm 8.4 km CE

XBee 900HP US RF 900 MHz 24 dBm -110 dBm 15.5 km FCC, IC

XBee 900HP BR RF 900 MHz 24 dBm -110 dBm 15.5 km ANATEL

XBee 900HP AU RF 900 MHz 24 dBm -110 dBm 15.5 km RCM

WiFi

WiFi

(HTTP(S),

FTP, TCP,

UDP)

2.4 GHz 17 dBm -94 dBm 500 m

CE, FCC, IC,

ANATEL, RCM

4G EU/BR

4G/3G/2G

(HTTP, FTP,

TCP, UDP)

GPS

800, 850, 900,

1800, 2100, 2600

MHz

4G: class 3

(0.2 W, 23 dBm)

4G: -102

dBm

- km - Typical

base station

range

CE, ANATEL

4G US

4G/3G/2G

(HTTP, FTP,

TCP, UDP)

GPS

700, 850, 1700,

1900 MHz

4G: class 3

(0.2 W, 23 dBm)

4G: -103

dBm

- km - Typical

base station

range

FCC, IC, PTCRB,

AT&T

4G AU

4G

(HTTP, FTP,

TCP, UDP)

700, 1800, 2600

MHz

4G: class 3

(0.2 W, 23 dBm)

4G: -102

dBm

- km - Typical

base station

range

RCM

Sigfox EU Sigfox 868 MHz 16 dBm -126 dBm

- km - Typical

base station

range

CE

Sigfox US Sigfox 900 MHz 24 dBm -127 dBm

- km - Typical

base station

range

FCC, IC

LoRaWAN EU LoRaWAN 868 MHz 14 dBm -136 dBm > 15 km CE

LoRaWAN US LoRaWAN 900 MHz 18.5 dBm -136 dBm > 15 km FCC, IC

* Line of sight and Fresnel zone clearance with 5dBi dipole antenna.

Page 22

-22-

v7.3

Waspmote Plug & Sense!

3.12. Industrial Protocols

Besides the main radio of Waspmote Plug & Sense!, it is possible to have an Industrial Protocol module as a

secondary communication option. This is oered as an accessory feature.

The available Industrial Protocols are RS-232, RS-485, Modbus (software layer over RS-232 or RS-485) and CAN Bus.

This optional feature is accessible through an additional, dedicated socket on the antenna side of the enclosure.

Figure: Industrial Protocols available on Plug & Sense!

Page 23

-23-

v7.3

Waspmote Plug & Sense!

Finally, the user can choose between 2 probes to connect the desired Industrial Protocol: A standard DB9 connector

and a waterproof terminal block junction box. These options make the connections on industrial environments or

outdoor applications easier.

Figure: DB9 probe

Figure: Terminal box probe

Page 24

-24-

v7.3

Waspmote Plug & Sense!

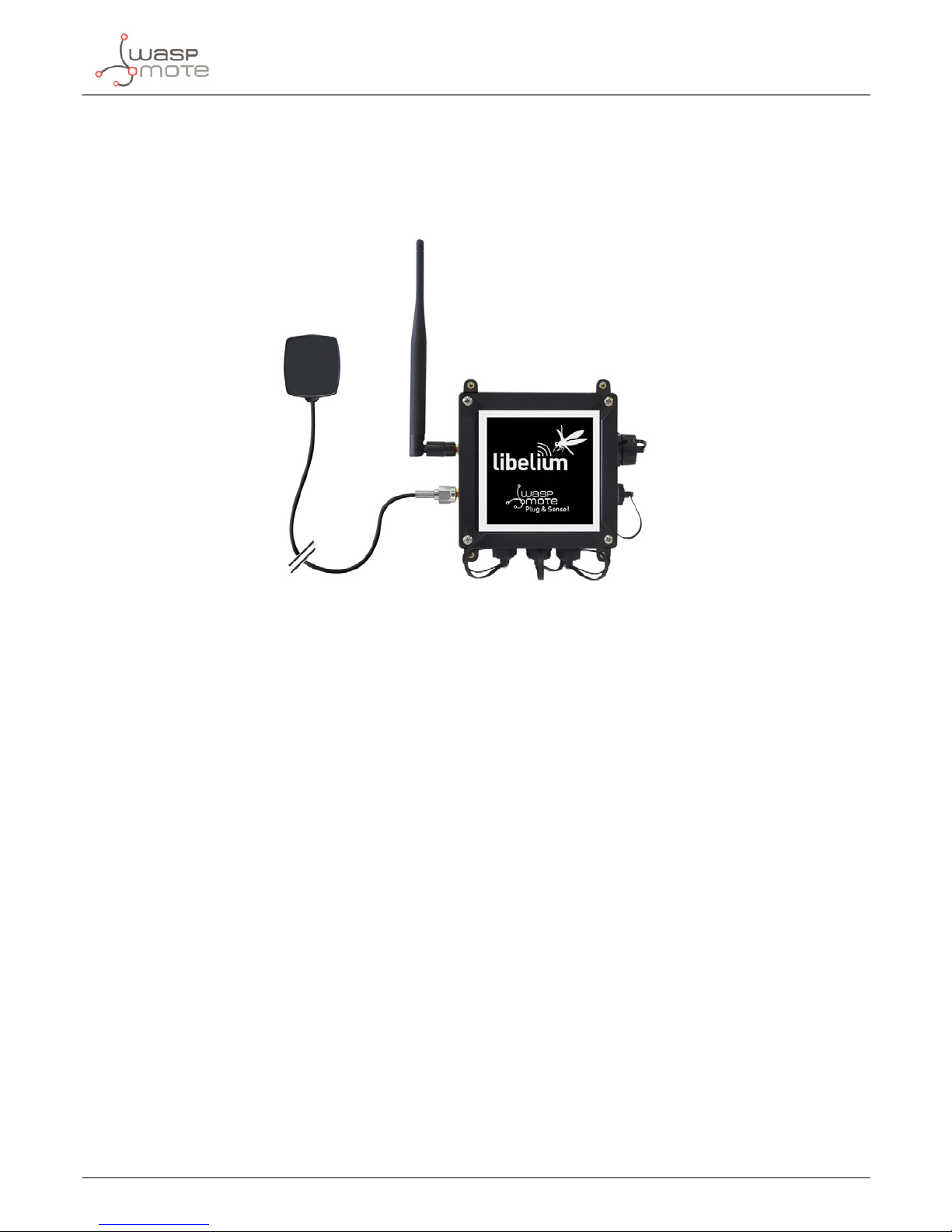

3.13. GPS

Any Plug & Sense! node can incorporate a GPS receiver in order to implement real-time asset tracking applications.

The user can also take advantage of this accessory to geolocate data on a map. An external, waterproof antenna

is provided; its long cable enables better installation for maximum satellite visibility.

Figure: Plug & Sense! node with GPS receiver

Chipset: JN3 (Telit)

Sensitivity:

• Acquisition: -147 dBm

• Navigation: -160 dBm

• Tracking: -163 dBm

Hot start time: <1 s

Cold start time: <35 s

Positional accuracy error < 2.5 m

Speed accuracy < 0.01 m/s

EGNOS, WAAS, GAGAN and MSAS capability

Antenna:

• Cable length: 2 m

• Connector: SMA

• Gain: 26 dBi (active)

Available information: latitude, longitude, altitude, speed, direction, date&time and ephemeris management

Page 25

-25-

v7.3

Waspmote Plug & Sense!

3.14. Models

There are some dened congurations of Waspmote Plug & Sense! depending on which sensors are going to be

used. Waspmote Plug & Sense! congurations allow to connect up to six sensor probes at the same time.

Each model takes a dierent conditioning circuit to enable the sensor integration. For this reason each model

allows to connect just its specic sensors.

This section describes each model conguration in detail, showing the sensors which can be used in each case

and how to connect them to Waspmote. In many cases, the sensor sockets accept the connection of more than

one sensor probe. See the compatibility table for each model conguration to choose the best probe combination

for the application.

It is very important to remark that each socket is designed only for one specic sensor, so they are not

interchangeable. Always be sure you connected probes in the right socket, otherwise they can be damaged.

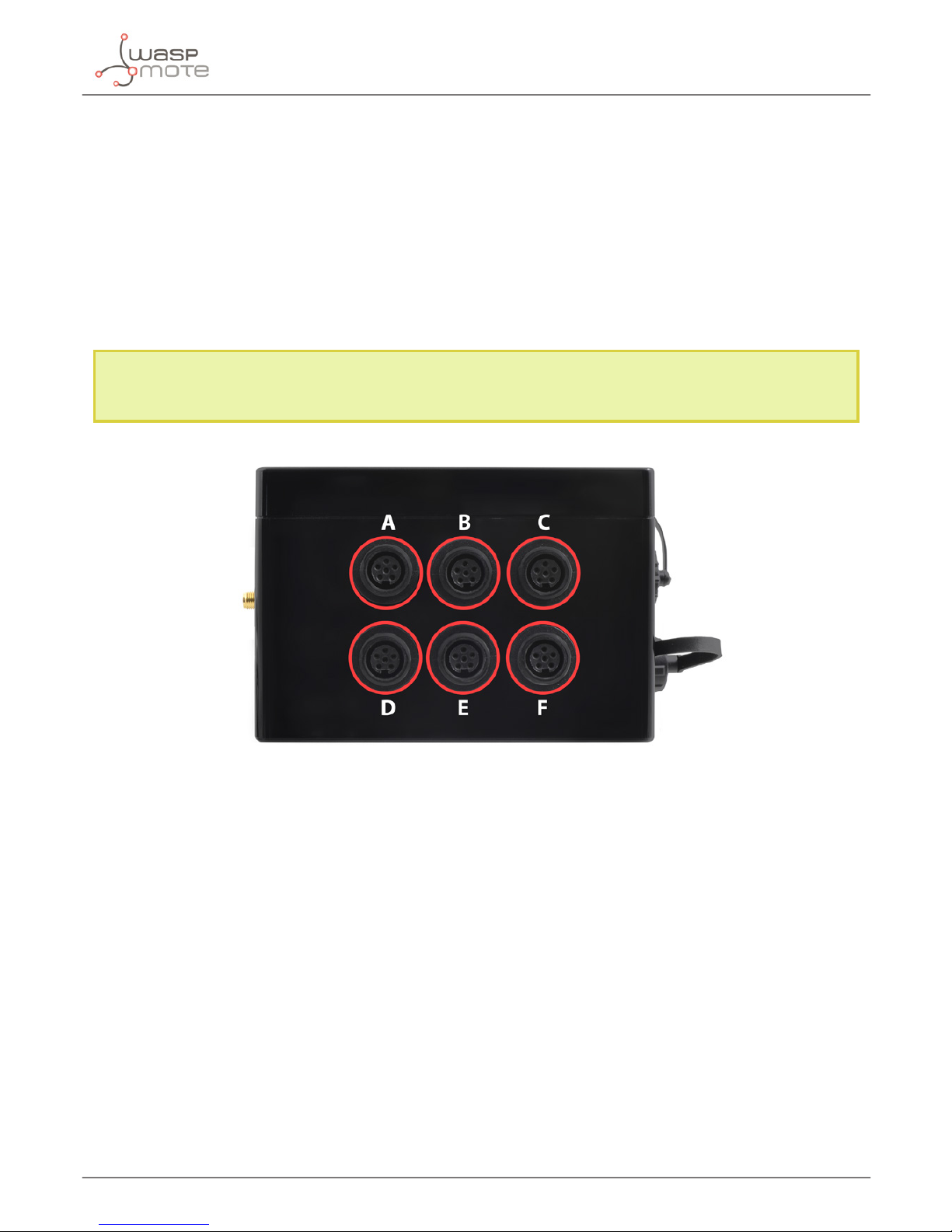

Figure: Identication of sensor sockets

Page 26

-26-

v7.3

Waspmote Plug & Sense!

3.14.1. Smart Cities PRO

The main applications for this Waspmote Plug & Sense! model are noise maps (monitor in real time the acoustic

levels in the streets of a city), air quality, waste management, smart lighting, etc. Refer to Libelium website for

more information.

Figure: Smart Cities PRO Waspmote Plug & Sense! model

Page 27

-27-

v7.3

Waspmote Plug & Sense!

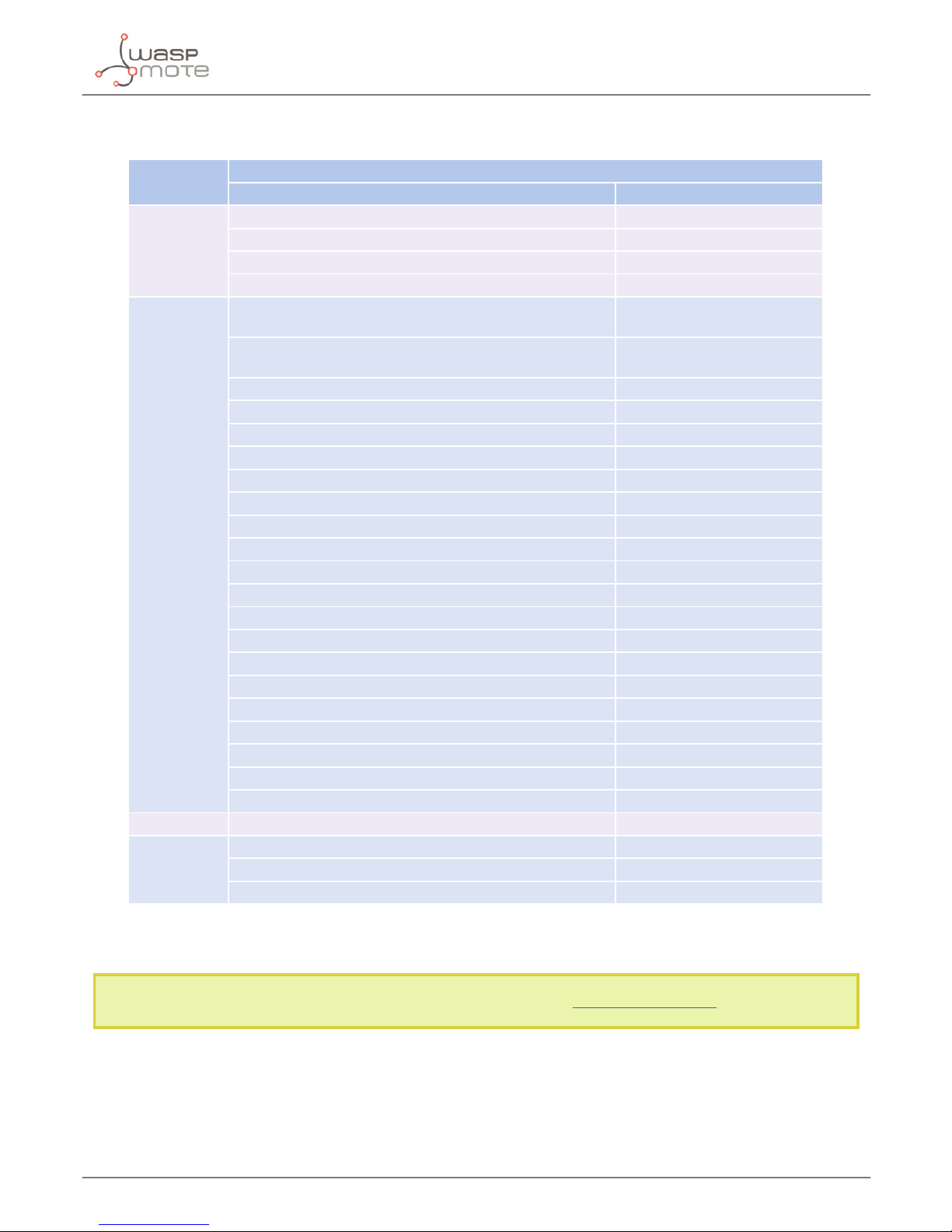

Sensor sockets are congured as shown in the gure below.

Sensor

Socket

Sensor probes allowed for each sensor socket

Parameter Reference

A

Noise level sensor NLS

Temperature + Humidity + Pressure 9370-P

Luminosity (Luxes accuracy) 9325-P

Ultrasound (distance measurement) 9246-P

B, C and F

Carbon Monoxide (CO) for high concentrations

[Calibrated]

9371-P

Carbon Monoxide (CO) for low concentrations

[Calibrated]

9371-LC-P

Carbon Dioxide (CO2) [Calibrated] 9372-P

Oxygen (O2) [Calibrated] 9373-P

Ozone (O3) [Calibrated] 9374-P

Nitric Oxide (NO) for low concentrations [Calibrated] 9375-LC-P

Nitric Dioxide (NO2) high accuracy [Calibrated] 9376-HA-P

Sulfur Dioxide (SO2) high accuracy [Calibrated] 9377-HA-P

Ammonia (NH3) for low concentrations [Calibrated] 9378-LC-P

Ammonia (NH3) for high concentrations [Calibrated] 9378-HC-P

Methane (CH4) and Combustible Gas [Calibrated] 9379-P

Hydrogen (H2) [Calibrated] 9380-P

Hydrogen Sulde (H2S) [Calibrated] 9381-P

Hydrogen Chloride (HCl) [Calibrated] 9382-P

Hydrogen Cyanide (HCN) [Calibrated] 9383-P

Phosphine (PH3) [Calibrated] 9384-P

Ethylene (ETO) [Calibrated] 9385-P

Chlorine (Cl2) [Calibrated] 9386-P

Temperature + Humidity + Pressure 9370-P

Luminosity (Luxes accuracy) 9325-P

Ultrasound (distance measurement) 9246-P

D Particle Matter (PM1 / PM2.5 / PM10) - Dust 9387-P

E

Temperature + Humidity + Pressure 9370-P

Luminosity (Luxes accuracy) 9325-P

Ultrasound (distance measurement) 9246-P

Figure: Sensor sockets configuration for Smart Cities PRO model

Note: For more technical information about each sensor probe go to the Development section in Libelium website.

Calibrated gas sensors are manufactured once the order has been placed to ensure maximum durability of the

calibration feature. The manufacturing process and delivery may take from 4 to 6 weeks. The lifetime of calibrated

gas sensors is 6 months working at maximum accuracy. We strongly encourage our customers to buy extra gas

sensors to replace the original ones after that time to ensure maximum accuracy and performance.

Page 28

-28-

v7.3

Hardware

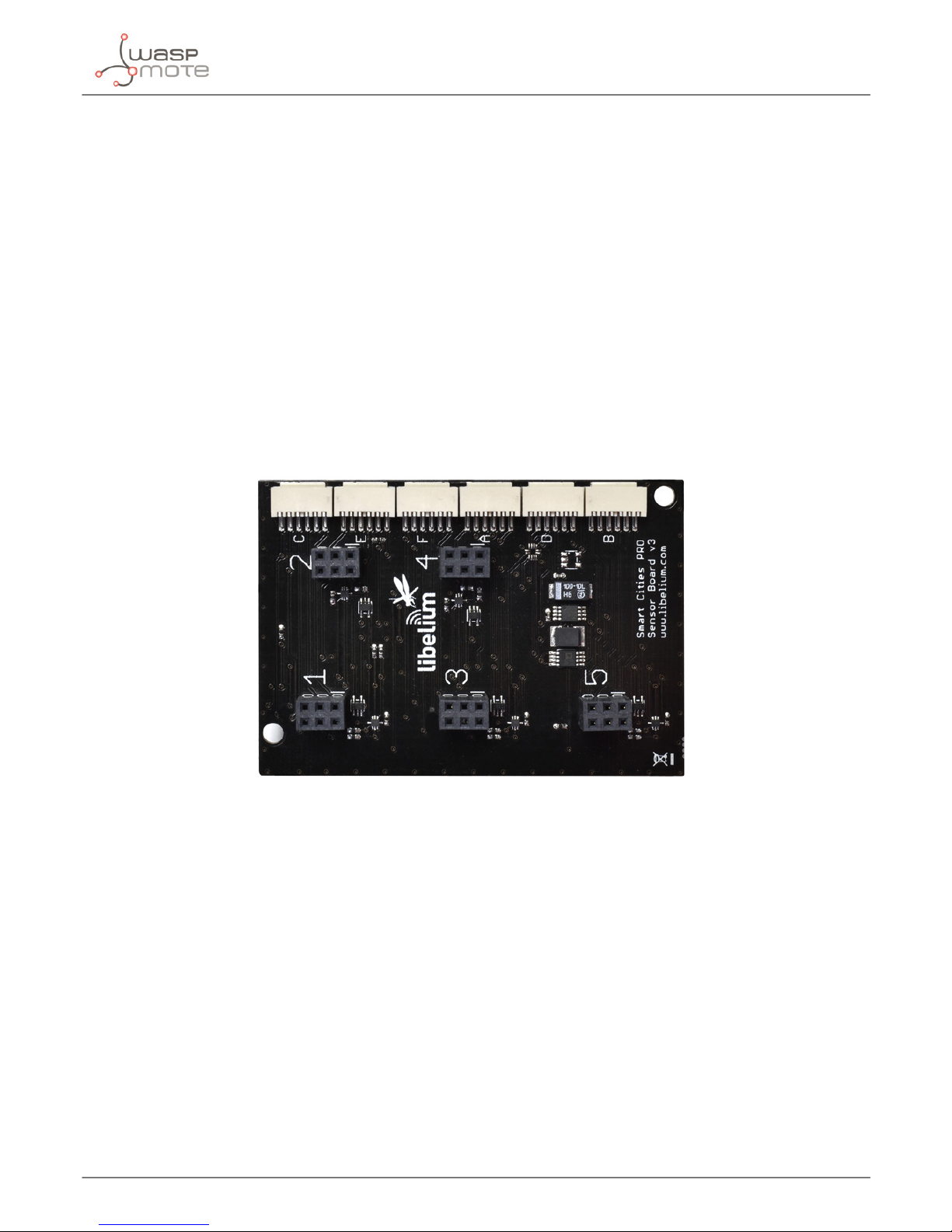

4. Hardware

4.1. General description

The purpose of the Waspmote Smart Cities PRO board is to extend the monitoring functionalities from indoor

environments to outdoor locations, in order to perform IoT projects in Smart Cities and urban environments.

Most of the sensors available for Smart Cities PRO are available for the Gases PRO Sensor Board. Also, the Smart

Cities PRO board adds support for the Noise Level Sensor.

4.2. Specications

• Weight: 20 g

• Dimensions: 73.5 x 51 x 22 mm (without sensors)

• Temperature range: [-20 ºC, 65 ºC]

Figure: Top side of the Smart Cities PRO Sensor Board

4.3. Electrical characteristics

• Board power voltages: 3.3 V and 5 V

• Sensor power voltages: 3.3 V and 5 V

• Maximum admitted current (continuous): 200 mA

• Maximum admitted current (peak): 400 mA

Page 29

-29-

v7.3

Sensors

5. Sensors

Many of the sensors available for Smart Cities PRO are actually migrated from the Gases PRO sensor board,

where they were integrated initially. For a better understanding of the characteristics of sensors, its calibration

and performance, it is highly advised to read the Gases PRO Technical Guide, specially the chapters “Gases

PRO sensor board”, “Hardware” and “Sensors”.

5.1. Temperature, Humidity and Pressure Sensor

The BME280 is a digital temperature, humidity and atmospheric pressure sensor developed by Bosch Sensortec.

5.1.1. Specications

Electrical characteristics

Supply voltage: 3.3 V

Sleep current typical: 0.1 μA

Sleep current maximum: 0.3 μA

Temperature sensor

Operational range: -40 ~ +85 ºC

Full accuracy range: 0 ~ +65 ºC

Accuracy: ±1 ºC (range 0 ºC ~ +65 ºC)

Response time: 1.65 seconds (63% response from +30 to +125 °C).

Typical consumption: 1 μA measuring

Humidity sensor

Measurement range: 0 ~ 100% of relative humidity (for temperatures < 0 °C and > 60 °C see gure below)

Accuracy: < ±3% RH (at 25 ºC, range 20 ~ 80%)

Hysteresis: ±1% RH

Operating temperature: -40 ~ +85 ºC

Response time (63% of step 90% to 0% or 0% to 90%): 1 second

Typical consumption: 1.8 μA measuring

Maximum consumption: 2.8 μA measuring

Figure: Temperature, Humidity and Pressure Sensor

Page 30

-30-

v7.3

Sensors

Figure: Humidity sensor operating range

Pressure sensor

Measurement range: 30 ~ 110 kPa

Operational temperature range: -40 ~ +85 ºC

Full accuracy temperature range: 0 ~ +65 ºC

Absolute accuracy: ±0.1 kPa (0 ~ 65 ºC)

Typical consumption: 2.8 μA measuring

Maximum consumption: 4.2 μA measuring

5.1.2. Measurement process

The BME280 is as combined digital humidity, pressure and temperature sensor based on proven sensing principles.

The humidity sensor provides an extremely fast response time for fast context awareness applications and high

overall accuracy over a wide temperature range.

The pressure sensor is an absolute barometric pressure sensor with extremely high accuracy and resolution and

drastically lower noise.

The integrated temperature sensor has been optimized for lowest noise and highest resolution.

Its output is used for temperature compensation of the pressure and humidity sensors and can also be used for

estimation of the ambient temperature.

When the sensor is disabled, current consumption drops to 0.1 μA.

You can nd a complete example code for reading the BME280 sensor in the following link:

http://www.libelium.com/development/waspmote/examples/scp-v30-05-temperature-humidity-and-pressuresensor

Page 31

-31-

v7.3

Sensors

5.1.3. Socket

This sensor can be connected in sockets 1, 2, 3, 4 and 5 in Waspmote OEM and sockets A, B, C, E and F in Plug &

Sense!.

Figure: Temperature, Humidity and Pressure Sensors in sockets 1, 2, 3, 4 and 5

In the image above we can see highlighted the four pins of the terminal block where the sensor must be connected

to the board. The white dot on the luxes board, must match the mark of the Smart Cities PRO Sensor Board.

Please mind that each socket has 3 rows, but only 2 are used for that sensor, because it only has 2x2 pins. A bad

connection can cause malfunction or even hardware damage.

Page 32

-32-

v7.3

Sensors

5.2. Ultrasound sensor probe (MaxSonar® from MaxBotix™)

5.2.1. Specications

I2CXL-MaxSonar®-MB7040™

Operation frequency: 42 kHz

Maximum detection distance: 765 cm

Interface: Digital bus

Power supply: 3.3 V

Consumption (average): 2.1 mA

Consumption (peak): 50 mA

Usage: Indoors and outdoors (IP-67)

A 1.72” dia. 43.8 mm dia.

B 2.00” 50.7 mm

C 0.58” 14.4 mm

D 0.31” 7.9 mm

E 0.18” 4.6 mm

F 0.1” 2.54 mm

G 3/4” National Pipe Thread Straight

H 1.032” dia. 26.2 dia.

I 1.37” 34.8 mm

weight: 1.76 oz. ; 50 grams

Figure: Ultrasonic I2CXL-MaxSonar®-MB7040 sensor dimensions

In the gure below we can see a diagram of the detection range of the sensor developed using dierent detection

patterns (a 0.63 cm diameter dowel for diagram A, a 2.54 cm diameter dowel for diagram B, an 8.25cm diameter

rod for diagram C and a 28 cm wide board for diagram D):

Figure: Diagram of the sensor beam extracted from the data sheet of the XL-MaxSonar®-WRA1™ sensor from MaxBotix

Figure: Ultrasonic I2CXL-MaxSonar®-MB7040 from MaxBotix™

sensor

Page 33

-33-

v7.3

Sensors

I2CXL-MaxSonar®-MB1202™:

Figure: Ultrasonic I2CXL-MaxSonar®- MB1202 from MaxBotix™

Sensor

• Operation frequency: 42 kHz

• Maximum detection distance: 765 cm

• Consumption (average): 2 mA

• Consumption (peak): 50 mA

• Usage: Indoors only

A 0.785” 19.9 mm H 0.100” 2.54 mm

B 0.870” 22.1 mm J 0.645” 16.4 mm

C 0.100” 2.54 mm K 0.610” 15.5 mm

D 0.100” 2.54 mm L 0.735” 18.7 mm

E 0.670” 17.0 mm M 0.065” 1.7 mm

F 0.510” 12.6 mm N 0.038” dia. 1.0 mm

dia.

G 0.124” dia. 3.1 mm

dia.

weight: 4.3 grams

Figure: Ultrasonic I2CXL-MaxSonar®-MB1202 Sensor dimensions

In the gure below we can see a diagram of the detection range of the sensor developed using dierent detection

patterns (a 0.63 cm diameter dowel for diagram A, a 2.54 cm diameter dowel for diagram B, an 8.25 cm diameter

rod for diagram C and a 28 cm wide board for diagram D):

Figure: Diagram of the sensor beam extracted from the data sheet of the Ultrasonic I2CXL-MaxSonar®-MB1202 sensor from MaxBotix

Page 34

-34-

v7.3

Sensors

5.2.2. Measurement Process

The MaxSonar® sensors from MaxBotix can be connected through the digital bus interface.

In the next gure, we can see a drawing of two example applications for the ultrasonic sensors, such as liquid level

monitoring or presence detection.

Figure: Examples of application for the MaxSonar® sensors

The MB7040 sensor is endowed with an IP-67 casing, so it can be used in outdoors applications, such as liquid

level monitoring in storage tanks.

You can nd a complete example code for reading the distance in the following link:

www.libelium.com/development/waspmote/examples/scp-v30-06-ultrasound-sensor

5.2.3. Socket

These sensors can be connected in socket 1, 2, 3, 4 and 5 in Waspmote OEM and sockets A, B, C, E and F in Plug

& Sense!.

Figure: Images of the sockets for connecting the MaxSonar® Sensors

Page 35

-35-

v7.3

Sensors

5.3. Luminosity (Luxes accuracy) Sensor

5.3.1. Specications

Electrical characteristics

Dynamic range: 0.1 to 40000 lux

Spectral range: 300 ~ 1100 nm

Voltage range: 2.7 ~ 3.6 V

Supply current typical: 0.24 mA

Sleep current maximum: 0.3 μA

Operating temperature: -30 ~ 70 ºC

5.3.2. Measurement process

This is a light-to-digital converter that transforms light intensity into a digital signal output. This device combines

one broadband photo-diode (visible plus infrared) and one infrared-responding photo-diode on a single CMOS

integrated circuit capable of providing a near-photopic response over an eective 20-bit dynamic range (16-bit

resolution). Two integrating ADCs convert the photo-diode currents to a digital output that represents the irradiance

measured on each channel. This digital output in lux is derived using an empirical formula to approximate the

human eye response.

You can nd a complete example code for reading the luminosity in the following link:

www.libelium.com/development/waspmote/examples/scp-v30-07-luxes-sensor

5.3.3. Socket

This sensor can be connected in socket 1, 2, 3, 4 and 5 in Waspmote OEM and sockets A, B, C, E and F in Plug &

Sense!

Figure: Luxes sensors connected in sockets 1, 2, 3, 4 and 5

In the image above we can see highlighted the four pins of the terminal block where the sensor must be connected

to the board. The white dot on the luxes board, must match the mark of the Smart Cities PRO Sensor Board.

Please mind that each socket has 3 rows, but only 2 are used for that sensor, because it only has 2x2 pins. A bad

connection can cause malfunction or even hardware damage.

Figure: Image of the Luminosity Sensor

Page 36

-36-

v7.3

Sensors

5.4. Particle Matter (PM1 / PM2.5 / PM10) - Dust Sensor

5.4.1. Specications

Sensor: OPC-N2

Performance Characteristics

Laser classication: Class 1 as enclosed housing

Particle range (um): 0.38 to 17 spherical equivalent size (based on RI of 1.5)

Size categorization (standard): 16 software bins

Sampling interval (seconds): 1 to 10 histogram period

Total ow rate: 1.2 L/min

Sample ow rate: 220 mL/min

Max particle count rate: 10000 particles/second

Max Coincidence probability: 0.91% at 10 particles/L

0.24% at 500 particles/mL

Power Characteristics

Measurement mode (laser and fan on): 250 mA @ 5 Volts (typical)

Voltage Range: 4.8 to 5.2 V DC

Operation Conditions

Temperature Range: -10 ºC to 50 ºC

Operating Humidity: 0 to 99% RH non-condensing

This sensor has a high current consumption. It is very important to turn on the sensor to perform a measure and

then, turn it o to save battery. Also, it is advised to operate with a minimum battery level of 40%, just to avoid

voltage drops (due to high current peaks) which could lead to resets in the system.

Dust, dirt or pollen may be accumulated inside the dust sensor structure, especially when the sensor is close

to possible solid particle sources: parks, construction works, deserts. That is why it is highly recommended to

perform maintenance/cleaning tasks in order to have accurate measures. This maintenance/cleaning frequency

may vary depending on the environment conditions or amount of obstructing dust. In clean atmospheres or

with low particle concentrations, the maintenance/cleaning period will be longer than a place with a high particle

concentrations.

Important note: Do not handle the stickers seals of the enclosure (Warranty stickers). Their integrity is the proof that the

sensor enclosure has not been opened. If they have been handled, damaged or broken, the warranty is automatically

void.

DO NOT remove the external housing: this not only ensures the required airow, also protects the user from the

laser light. Removal of the casing may expose the user to Class 3B laser radiation. You must avoid exposure to

the laser beam. Do not use if the outer casing is damaged. Return to Libelium. Removal of the external housing

exposes the OPC circuitry which contains components that are sensitive to static discharge damage.

Note: The Particle Matter (PM1 / PM2.5 / PM10) – Dust Sensor is available only for the Plug & Sense! line (socket D).

Figure: Image of the Particle Matter sen-

sor, encapsulated

Page 37

-37-

v7.3

Sensors

5.4.2. Particle matter: the parameter

Particle matter is composed of small solid or liquid particles oating in the air. The origin of these particles can be

the industrial activity, exhaust fumes from diesel motors, building heating, pollen, etc. This tiny particles enter our

bodies when we breath. High concentrations of particle matter can be harmful for humans or animals, leading to

respiratory and coronary diseases, and even lung cancer. That is why this is a key parameter for the Air Quality

Index.

Some examples:

• Cat allergens: 0.1-5 μm

• Pollen: 10-100 μm

• Germs: 0.5-10 μm

• Oil smoke: 1-10 μm

• Cement dust: 5-100 μm

• Tobacco smoke: 0.01-1 μm

The smaller the particles are, the more dangerous, because they can penetrate more in our lungs. Many times,

particles are classied:

• PM1: Mass (in μg) of all particles smaller than 1 μm, in 1 m

3

• PM2.5: Mass (in μg) of all particles smaller than 2.5 μm, in 1 m

3

• PM10: Mass (in μg) of all particles smaller than 10 μm, in 1 m

3

Many countries and health organizations have studied the eect of the particle matter in humans, and they have

set maximum thresholds. As a reference, the maximum allowed concentrations are about 20 μm/m3 for PM2.5

and about 50 μm/m3 for PM10.

5.4.3. Measurement process

Like conventional optical particle counters, the OPC-N2 measures the light scattered by individual particles

carried in a sample air stream through a laser beam. These measurements are used to determine the particle size

(related to the intensity of light scattered via a calibration based on Mie scattering theory) and particle number

concentration. Particle mass loading- PM2.5 or PM10, are then calculated from the particle size spectra and

concentration data, assuming density and refractive index. To generate the air stream, the OPC-N2 uses only a

miniature low-power fan.

The OPC-N2 classies each particle size, at rates up to ~10,000 particle per second, adding the particle diameter

to one of 16 “bins” covering the size range from ~0.38 to 17 μm. The resulting particle size histograms can be

evaluated over user-dened sampling times from 1 to 10 seconds duration, the histogram data being transmitted

along with other diagnostic and environmental data (air temperature and air pressure). When the histogram is

read, the variables in the library are updated automatically. See the API section to know how to manage and read

this sensor.

You can nd a complete example code for reading the Particle Matter Sensor in the following link:

http://www.libelium.com/development/waspmote/examples/scp-v30-04-particle-matter-sensor

Page 38

-38-

v7.3

Sensors

5.5. Noise / Sound Level Sensor

5.5.1. Specications of the Sound Level Sensor probe

• Target parameter: LeqA

• Microphone sensitivity: 12.7 mV / Pa

• Range of the sensor: 50 dBA to 100 dBA

• Accuracy: +/-0.5dBA (1KHz)

• Frequency range: 20 Hz – 20 kHz

• Omni-directional microphone

• A-weighting measure

• Sound pressure level measurement (no weighting lter)

• FAST mode (125 ms) and SLOW mode (1 second), software congurable

5.5.2. Specications of the enclosure

• Material: polycarbonate

• Sealing: polyurethane

• Cover screws: stainless steel

• Ingress protection: IP65

• Impact resistance: IK08

• Rated insulation voltage AC: 690 V

• Rated insulation voltage DC: 1000 V

• Heavy metals-free

• Weatherproof: true - nach UL 746 C

• Ambient temperature (min.): -10 °C

• Ambient temperature (max.): 50 °C

• Approximated weight: 800 g

5.5.3. Sound pressure level measurement

The sound pressure level or acoustic pressure level is a measure of the eective pressure of a sound relative to

a reference value, normally referenced to pressure in air (20 µPa), which is considered as the threshold of the

human hearing. The expression of the sound pressure level is dened by:

Figure: Sound pressure level expression

Figure: Noise / Sound Level Sensor

Page 39

-39-

v7.3

Sensors

Where p is the root mean square sound pressure and p0 is the reference sound pressure (20 µPa). The next table

shows some examples of dierent sound pressure measurements:

Sound sources examples

Sound pressure level

(dB)

Sound pressure (Pa = N/

m2)

Sound intensity (W/m2)

Threshold of pain 130 63.2 10

Threshold of discomfort 120 20 1

Airport 110 6.3 0.01

Factory 100 2 0.001

Heavy trac 90 0.63 0.0001

Hair dryer 80 0.2 0.00001

Restaurant 70 0.063 0.000001

Conversation 60 0.02 0.0000001

Background noise 50 0.0063 0.00000001

Refrigerator 40 0.002 0.000000001

Library 30 0.00063 0.0000000001

Recording studio 20 0.0002 0.00000000001

Anechoic chamber 10 0.000063 0.000000000001

Threshold of hearing 0 0.00002 0.0000000000001

5.5.4. Equivalent continuous sound level

The sound pressure level parameter, explained in the previous section, is not much used in noise measurements.

Instead, an average value called Leq, is used. Equivalent Continuous Sound Level (Leq) is the average of the sound

pressure level during a period of time. This value is very used when the noise level is varying quickly. Below the

equation to calculate the Leq value in decibels.

The Leq is the most used parameter by most countries for measuring the exposure to noise levels and earing

damage risk. A better approximation to the human ear response is the LAeq (equivalent continuous A-weighted

sound pressure level). The A-weighting lter is described in the next section of this guide.

5.5.5. The A-weighting

The A-weighting is the most used curve of the family of curves dened by the IEC 61672 standard. It is very used

for measuring environmental and industrial noise, due to the fact that the curve follows the frequency sensitivity

of the human ear. Noise measurements made with the A-weighting scale are designated dBA. The A-weighting

also predicts quite well the damage risk of the ear. The next graph shows the response of the A-weighting across

the frequency range 10 Hz – 20 kHz.

Page 40

-40-

v7.3

Sensors

Figure: Graph of the A-weighting curve

5.5.6. International standard IEC 61672-1:2013

The new Noise / Sound Level Sensor has been designed following the specications of the IEC 61672 standard for

sound meters. Specically with an accuracy of ±2 dBA similar to the Class 2 type devices. The value given is the

LeqA (Equivalent continuous sound level, with A weighting) that allows to calculate the average sound pressure

level during a period of time. Leq is often described as the average noise level during a noise measurement and it

is the magnitude used for many regulations of noise control at work places and the street.

5.5.7. Measurement process

As mentioned previously, the Sound Level Sensor can only be used in combination with a Plug & Sense! Smart

Cities PRO device. Once the sensor is connected following the previous steps, the Waspmote Plug & Sense! unit

must be programmed for reading the sound pressure values.

You can nd a complete example code for reading the temperature sensor in the following link:

http://www.libelium.com/development/waspmote/examples/scp-v30-08-noise-level-sensorg

5.5.8. Calibration Tests

In order to ensure the high quality of the Noise / Sound Level Sensor, each device is veried in an independent

test laboratory.

Tests are performed inside an isolated anechoic chamber. The sound sensor probes are exposed to 5 dierent

levels of white noise, created by a specialized sound generator and a cutting-edge, omni-directional speaker: 55,

65, 75, 85 and 95 dBA. The exact level is conrmed by the technician with a certied IEC 61672 soundmeter, placed

at the same distance from the sound source than the 16 sensors. For each noise level, the output of each one of

the 16 sensors is captured by a software system.

Tested equipment

Noise source

Page 41

-41-

v7.3

Sensors

After those tests, an ocial test report is issued by the laboratory for every Noise / Sound Level Sensor, so the

customer can verify the accuracy in dBA at dierent frequencies for each sound level probe. See below an example

of this document.

Figure: Example of test report obtained in the laboratory

Page 42

-42-

v7.3

Sensors

Page 43

-43-

v7.3

Sensors

5.5.9. Mounting the Noise / Sound Level Sensor and supplying power

Important: The Noise Level Sensor has been designed to be used with the Waspmote Plug & Sense! Smart Cities

PRO and it cannot be used independently. This sensor cannot be used on a Waspmote OEM with a Smart Cities PRO

board, for example.

The Sound Level Sensor consists of the next items shown in the gure below:

1

2

5

3

4

Figure: Noise Level Sensor items: 1 Noise Level Sensor. 2 Noise Level Sensor enclosure. 3 Data cable. 4 Power supply cable. 5 Protection

cover

Page 44

-44-

v7.3

Sensors

The images below show the dierent sockets of the Noise Level Sensor.

Microphone Data Cable

Figure: Identication of the connectors

Power Supply

Figure: Power supply connector

Figure: Noise Level Sensor probe

Page 45

-45-

v7.3

Sensors

To connect the Sound Level Sensor probe to the enclosure, It should be taken into account that the sensor probe

connector has only one matching position. The user should align the sensor probe connector looking at the little

notch of the connector (see image below). Notice that the sensor connector is male-type and the enclosure sensor

connector is female-type.

Figure: Detail of the sensor probe connector

Besides, there is a locking nut which should be screwed till the connector is completely xed to the enclosure.

Figure: Connecting the sensor probe to the enclosure

Page 46

-46-

v7.3

Sensors

After connecting the sensor, connect the the power supply cable to the USB connector, as shown in the picture

below and the Noise Level Sensor will power up. Then, connect one end of data cable to the Sound Level Sensor

and the other one to the associated Plug & Sense! Smart Cities PRO device.

Data cable

Power supply

cable

Figure: Connecting the data cable and the power supply cable to the Noise Level Sensor

Figure: Connecting the data cable to the associated Plug & Sense! Smart Cities device

Page 47

-47-

v7.3

Sensors

Finally, the Noise Level Sensor can be installed outdoors in a streetlight or directly on a wall. The protection cover

should be placed like the pictures below, to protect the Sound Level Sensor probe from the rain.

Figure: Installing the Noise Level Sensor on a wall

Notice that the power supply cable has a waterproof end, suitable for outdoor applications. But, on the other side,

it has a non-waterproof end thought to be connected to a USB charger (AC/DC, 5 V output). Bear in mind that this

end is not waterproof so it cannot be used outdoors. Please protect it accordingly.

A typical application is to power a node placed on the facade of a building; the power supply cables go indoors

through a nearby window and the USB ends remain indoors, connected to a wall adapter. Many lampposts also

have a 220 V output inside.

Figure: Typical installation of the Noise Level Sensor

Page 48

-48-

v7.3

Sensors

5.6. Carbon Monoxide (CO) Gas Sensor for high concentrations [Calibrated]

5.6.1. Specications

Gas: CO

Sensor: 4-CO-500

Performance Characteristics

Nominal Range: 0 to 500 ppm

Maximum Overload: 2000 ppm

Long Term Output Drift: < 2% signal/month

Response Time (T90): ≤ 30 seconds

Sensitivity: 70 ± 15 nA/ppm

Accuracy: as good as ±1 ppm* (ideal conditions)

Operation Conditions

Temperature Range: -20 ºC to 50 ºC

Operating Humidity: 15 to 90% RH non-condensing

Pressure Range: 90 to 110 kPa

Storage Temperature: 0 ºC to 20 ºC

Expected Operating Life: 5 years in air

Sockets for Waspmote OEM:

• SOCKET_1

• SOCKET_3

• SOCKET_5

Sockets for Plug & Sense!:

• SOCKET_B

• SOCKET_C

• SOCKET_F

Average consumption: less than 1 mA

* Accuracy values are only given for the optimum case. See the “Calibration” chapter in the Gases PRO Technical Guide

for more detail.

The electrochemical sensors must be always powered on in order to get optimum measurements. This implies

a power consumption, however it improves the performance of the sensor. This should also be applied when

entering sleep modes so the sensor is not powered o selecting the proper sleep option.

Calibrated gas sensors are manufactured once the order has been placed to ensure maximum durability of the

calibration feature. The manufacturing process and delivery may take from 4 to 6 weeks. The lifetime of calibrated

gas sensors is 6 months working at maximum accuracy. We strongly encourage our customers to buy extra gas

sensors to replace the original ones after that time to ensure maximum accuracy and performance.

Figure: Image of the Carbon Monoxide

Sensor for high concentrations mounted on its AFE module

Page 49

-49-

v7.3

Sensors

5.6.2. Cross-sensitivity data

Gas Formula

Concentration

(ppm)

Output Signal

(ppm CO

equivalent)

Hydrogen Sulde H2S 24 0

Sulfur Dioxide SO

2

5 0

Cholrine Cl

2

10 0-1

Nitric Oxide O

2

25 0

Nitric Dioxide NO

2

5 0

Hydrogen H

2

100 40

Ethylene C2H

4

100 16

Figure: Cross-sensitivity data for the CO Sensor for high concentrations

You can nd a complete example code for reading the CO Sensor for high concentrations in the following link:

www.libelium.com/development/waspmote/examples/scp-v30-01-electrochemical-gas-sensors

Page 50

-50-

v7.3

Sensors

5.7. Carbon Monoxide (CO) Gas Sensor for low concentrations [Calibrated]

5.7.1. Specications

Gas: CO

Sensor: CO-A4

Performance Characteristics

Nominal Range: 0 to 25 ppm

Maximum Overload: 2000 ppm

Long Term Sensitivity Drift: < 10% change/year in lab air, monthly test

Long Term zero Drift: < ±100 ppb equivalent change/year in lab air

Response Time (T90): ≤ 20 seconds

Sensitivity: 220 to 375 nA/ppm

Accuracy: as good as ±0.1 ppm* (ideal conditions)

H2S lter capacity: 250000 ppm·hrs

Operation Conditions

Temperature Range: -30 ºC to 50 ºC

Operating Humidity: 15 to 90% RH non-condensing

Pressure Range: 80 to 120 kPa

Storage Temperature: 0 ºC to 20 ºC

Expected Operating Life: 3 years in air

Sockets for Waspmote OEM:

• SOCKET_1

• SOCKET_3

• SOCKET_5

Sockets for Plug & Sense!:

• SOCKET_B

• SOCKET_C

• SOCKET_F

Average consumption: less than 1 mA

* Accuracy values are only given for the optimum case. See the “Calibration” chapter in the Gases PRO Technical Guide

for more detail.

The electrochemical sensors must be always powered on in order to get optimum measurements. This implies

a power consumption, however it improves the performance of the sensor. This should also be applied when

entering sleep modes so the sensor is not powered o selecting the proper sleep option.

Calibrated gas sensors are manufactured once the order has been placed to ensure maximum durability of the

calibration feature. The manufacturing process and delivery may take from 4 to 6 weeks. The lifetime of calibrated

gas sensors is 6 months working at maximum accuracy. We strongly encourage our customers to buy extra gas

sensors to replace the original ones after that time to ensure maximum accuracy and performance.

Figure: Image of the Carbon Monoxide

Sensor for low concentrations mounted

on its AFE module

Page 51

-51-

v7.3

Sensors

5.7.2. Cross-sensitivity data

Gas Formula

Concentration

(ppm)

Output signal

(ppm CO

equivalent)

Hydrogen Sulde H2S 5 < 0.1

Nitric Dioxide NO

2

5 < -2

Chlorine Cl

2

5 < 0.1

Nitric Oxide NO 5 < -2

Sulfur Dioxide SO

2

5 < 0.1

Hydrogen H

2

100 < 10

Ethylene C2H

4

100 < 0.5

Ammonia NH

3

20 < 0.1

Figure: Cross-sensitivity data for the CO Sensor for low concentrations

You can nd a complete example code for reading the CO Sensor for low concentrations in the following link:

www.libelium.com/development/waspmote/examples/scp-v30-01-electrochemical-gas-sensors

Page 52

-52-

v7.3

Sensors

5.8. Carbon Dioxide (CO2) Gas Sensor [Calibrated]

5.8.1. Specications

Gas: CO

2

Sensor: NE20-CO2P-NCVSP

Performance Characteristics

Nominal Range: 0 to 5000 ppm

Long Term Output Drift: < ± 250 ppm/year

Warm up time: 60 seconds @ 25 ºC

At least 30 min for full specication @ 25 °C

Response Time (T90): ≤ 60 seconds

Resolution: 25 ppm

Accuracy: as good as ±50 ppm*, from 0 to 2500 ppm range (ideal conditions)

as good as ±200 ppm*, from 2500 to 5000 ppm range (ideal conditions)

Operation Conditions

Temperature Range: -40 ºC to 60 ºC

Operating Humidity: 0 to 95%RH non-condensing

Storage Temperature: -40 ºC to 85 ºC

MTBF: ≥ 5 years

Sockets for Waspmote OEM:

• SOCKET_1

Sockets for Plug & Sense!:

• SOCKET_B

• SOCKET_C

• SOCKET_F

Average consumption: 80 mA

Note: The CO2 Sensor and the Methane (CH4) and Combustible Gas Sensor have high power requirements and

cannot work together in the same Smart Cities PRO Sensor Board. The user must choose one or the other, but not

both.

* Accuracy values are only given for the optimum case. See the “Calibration” chapter in the Gases PRO Technical Guide

for more detail.

Calibrated gas sensors are manufactured once the order has been placed to ensure maximum durability of the

calibration feature. The manufacturing process and delivery may take from 4 to 6 weeks. The lifetime of calibrated

gas sensors is 6 months working at maximum accuracy. We strongly encourage our customers to buy extra gas

sensors to replace the original ones after that time to ensure maximum accuracy and performance.

You can nd a complete example code for reading the CO2 Sensor in the following link:

http://www.libelium.com/development/waspmote/examples/scp-v30-02-ndir-gas-sensors

Figure: Image of the Carbon Dioxide Sensor mounted on its AFE module

Page 53

-53-

v7.3

Sensors

5.9. Molecular Oxygen (O2) Gas Sensor [Calibrated]

5.9.1. Specications

Gas: O

2

Sensor: 4-OL

Performance Characteristics

Nominal Range: 0 to 30 Vol.%

Maximum Overload: 90 Vol.%

Long Term Output Drift: < 2% signal/3 months

Response Time (T90): ≤ 30 seconds

Sensitivity: 1.66 ± 0.238 nA/ppm

Accuracy: as good as ± 0.1 % (ideal conditions)

Operation Conditions

Temperature Range: -20 ºC to 50 ºC

Operating Humidity: 5 to 90%RH non-condensing

Pressure Range: 90 to 110 kPa

Storage Temperature: 0 ºC to 20 ºC

Expected Operating Life: 2 years in air

Sockets for Waspmote OEM:

• SOCKET_1

• SOCKET_3

• SOCKET_5

Sockets for Plug & Sense!:

• SOCKET_B

• SOCKET_C

• SOCKET_F

Average consumption: less than 1 mA

* Accuracy values are only given for the optimum case. See the “Calibration” chapter in the Gases PRO Technical Guide

for more detail.

The electrochemical sensors must be always powered on in order to get optimum measurements. This implies

a power consumption, however it improves the performance of the sensor. This should also be applied when

entering sleep modes so the sensor is not powered o selecting the proper sleep option.

Calibrated gas sensors are manufactured once the order has been placed to ensure maximum durability of the

calibration feature. The manufacturing process and delivery may take from 4 to 6 weeks. The lifetime of calibrated

gas sensors is 6 months working at maximum accuracy. We strongly encourage our customers to buy extra gas

sensors to replace the original ones after that time to ensure maximum accuracy and performance.

You can nd a complete example code for reading the O2 Sensor in the following link:

www.libelium.com/development/waspmote/examples/scp-v30-01-electrochemical-gas-sensors

Figure: Image of the Molecular Oxygen

Sensor mounted on its AFE module

Page 54

-54-

v7.3

Sensors

5.10. Ozone (O3) Gas Sensor [Calibrated]

5.10.1. Specications

Gas: O

3

Sensor: OX-A431

Performance Characteristics

Nominal Range: 0 to 18 ppm

Maximum Overload: 50 ppm

Long Term sensitivity Drift: -20 to -40% change/year

Response Time (T90): ≤ 45 seconds

Sensitivity: -200 to -550 nA/ppm

Accuracy: as good as ±0.2 ppm* (ideal conditions)

High cross-sensitivity with NO2 gas. Correction could be necessary in ambients with NO2.

Operation Conditions

Temperature Range: -30 ºC to 40 ºC

Operating Humidity: 15 to 85 %RH non-condensing

Pressure Range: 80 to 120 kPa

Storage Temperature: 3 ºC to 20 ºC

Expected Operating Life: > 24 months in air

Sockets for Waspmote OEM:

• SOCKET_1

• SOCKET_3

• SOCKET_5

Sockets for Plug & Sense!:

• SOCKET_B

• SOCKET_C

• SOCKET_F

Average consumption: less than 1 mA

* Accuracy values are only given for the optimum case. See the “Calibration” chapter in the Gases PRO Technical Guide

for more detail.

The electrochemical sensors must be always powered on in order to get optimum measurements. This implies

a power consumption, however it improves the performance of the sensor. This should also be applied when

entering sleep modes so the sensor is not powered o selecting the proper sleep option.

Calibrated gas sensors are manufactured once the order has been placed to ensure maximum durability of the

calibration feature. The manufacturing process and delivery may take from 4 to 6 weeks. The lifetime of calibrated

gas sensors is 6 months working at maximum accuracy. We strongly encourage our customers to buy extra gas

sensors to replace the original ones after that time to ensure maximum accuracy and performance.

Figure: Image of the Ozone Sensor mounted

on its AFE module

Page 55

-55-

v7.3

Sensors

5.10.2. Cross-sensitivity data

Gas Formula

Concentration

(ppm)

Output Signal

(ppm CO

equivalent)

Hydrogen Sulde H2S 5 < 100

Nitric Dioxide NO

2

5 70 to 120

Chlorine Cl

2

5 < 30

Nitric Oxide NO 5 < 3

Sulfur Dioxide SO

2

5 < -6

Carbon Monoxide CO 5 < 0.1

Hydrogen H

2

100 <0.1

Ethylene C2H

4

100 < 0.1

Ammonia NH

3

20 <0.1

Carbon Dioxide CO

2

50000 0.1

Halothane Halothane 100 < 0.1

Figure: Cross-sensitivity data for the O3 Sensor

This sensor has a very high cross-sensitivity with NO2 gas. So, the output in ambients with NO2 will be a mix of

O3 and NO2. A simple way to correct this eect is to subtract NO2 concentration from O3 concentration with an NO2

gas sensor. The measure from the NO2 sensor must be accurate in order to subtract the right value. See the related

section in the “Board conguration and programming” chapter to use the right function.

You can nd a complete example code for reading the O3 Sensor in the following link:

www.libelium.com/development/waspmote/examples/scp-v30-01-electrochemical-gas-sensors

Page 56

-56-

v7.3

Sensors

5.11. Nitric Oxide (NO) Gas Sensor for low concentrations

[Calibrated]

5.11.1. Specications

Gas: NO

Sensor: NO-A4

Performance Characteristics

Nominal Range: 0 to 18 ppm

Maximum Overload: 50 ppm

Long Term Sensitivity Drift: < 20% change/year in lab air, monthly test

Long Term zero Drift: 0 to 50 ppb equivalent change/year in lab air

Response Time (T90): ≤ 25 seconds

Sensitivity: 350 to 550 nA/ppm

Accuracy: as good as ±0.2 ppm* (ideal conditions)

Operation Conditions

Temperature Range: -30 ºC to 50 ºC

Operating Humidity: 15 to 85% RH non-condensing

Pressure Range: 80 to 120 kPa

Storage Temperature: 0 ºC to 20 ºC

Expected Operating Life: 2 years in air

Sockets for Waspmote OEM:

• SOCKET_1

• SOCKET_3

• SOCKET_5

Sockets for Plug & Sense!:

• SOCKET_B

• SOCKET_C

• SOCKET_F

Average consumption: less than 1 mA

* Accuracy values are only given for the optimum case. See the “Calibration” chapter in the Gases PRO Technical Guide

for more detail.

The electrochemical sensors must be always powered on in order to get optimum measurements. This implies

a power consumption, however it improves the performance of the sensor. This should also be applied when

entering sleep modes so the sensor is not powered o selecting the proper sleep option.

Calibrated gas sensors are manufactured once the order has been placed to ensure maximum durability of the

calibration feature. The manufacturing process and delivery may take from 4 to 6 weeks. The lifetime of calibrated

gas sensors is 6 months working at maximum accuracy. We strongly encourage our customers to buy extra gas

sensors to replace the original ones after that time to ensure maximum accuracy and performance.

Figure: Image of the Nitric Oxide Sensor

for low concentrations mounted on its

AFE module

Page 57

-57-

v7.3

Sensors

5.11.2. Cross-sensitivity data

Gas Formula

Concentration

(ppm)

Output Signal

(ppm NO

equivalent)

Carbon Monoxide CO 300 0