Page 1

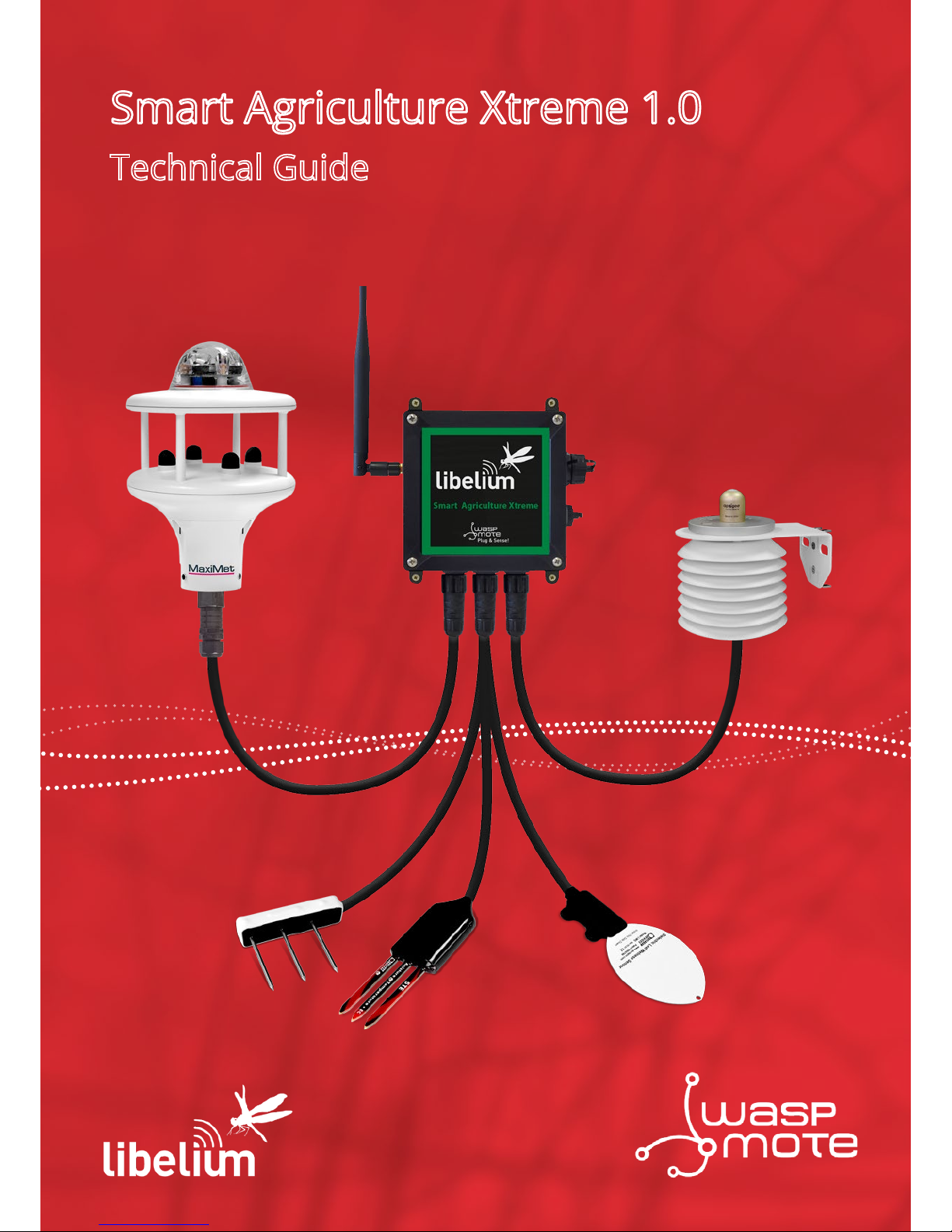

Smart Agriculture Xtreme 1.0

Technical Guide

Page 2

-2-

v7.2

Index

Document version: v.7.2 - 03/2019

© Libelium Comunicaciones Distribuidas S.L.

INDEX

1. General and safety information ......................................................................................................... 6

2. Important: Read before use ................................................................................................................ 7

3. Waspmote Plug & Sense! ..................................................................................................................... 8

3.4. Sensor probes .............................................................................................................................................................................14

3.5. Solar powered ............................................................................................................................................................................ 15

3.6. External Battery Module ......................................................................................................................................................... 16

3.7. Programming the Nodes ........................................................................................................................................................ 17

3.8. Program in minutes ..................................................................................................................................................................18

3.9. Radio interfaces ......................................................................................................................................................................... 19

3.10. Industrial Protocols ................................................................................................................................................................ 20

3.11. GPS ...............................................................................................................................................................................................22

3.12. Models ........................................................................................................................................................................................ 23

3.12.1. Smart Agriculture Xtreme .....................................................................................................................................24

4. Sensors probes .................................................................................................................................. 27

4.1. General comments ................................................................................................................................................................... 27

4.2. Non-contact surface temperature measurement sensor probe (Apogee SI-411) .............................................28

4.2.1. Specications ...............................................................................................................................................................28

4.2.2. Measurement process ..............................................................................................................................................29

4.2.3. Socket .............................................................................................................................................................................29

4.2.4. Installation ....................................................................................................................................................................30

4.2.5. Application examples ...............................................................................................................................................31

4.2.6. Certicate of calibration ..........................................................................................................................................31

4.3. Leaf and ower bud temperature sensor probe (Apogee SF-421) .........................................................................32

4.3.1. Specications ...............................................................................................................................................................32

4.3.2. Measurement process ..............................................................................................................................................33

4.3.3. Socket .............................................................................................................................................................................33

4.3.4. Installation ....................................................................................................................................................................34

4.3.5. Application examples ...............................................................................................................................................35

4.3.6. Quality Assurance Certicate .................................................................................................................................35

4.4. Soil oxygen level sensor probe (Apogee SO-411) ......................................................................................................... 36

4.4.1. Specications ...............................................................................................................................................................37

4.4.2. Measurement process ..............................................................................................................................................37

4.4.3. Socket .............................................................................................................................................................................38

4.4.4. Installation ....................................................................................................................................................................39

4.4.5. Application examples ...............................................................................................................................................40

4.4.6. Quality Assurance Certicate .................................................................................................................................40

4.5. Shortwave radiation sensor probe (Apogee SP-510) ..................................................................................................41

Page 3

-3-

v7.2

Index

4.5.1. Specications ...............................................................................................................................................................41

4.5.2. Measurement process ..............................................................................................................................................42

4.5.3. Socket .............................................................................................................................................................................42

4.5.4. Installation ....................................................................................................................................................................43

4.5.5. Application examples ...............................................................................................................................................45

4.5.6. Certicate of calibration ..........................................................................................................................................45

4.6. Solar radiation sensor probe for Smart Agriculture Xtreme (Apogee SQ-110) ..................................................46

4.6.1. Specications ...............................................................................................................................................................47

4.6.2. Measurement process ..............................................................................................................................................47

4.6.3. Socket .............................................................................................................................................................................48

4.6.4. Installation ....................................................................................................................................................................48

4.6.5. Application examples ...............................................................................................................................................50

4.6.6. Certicate of calibration ..........................................................................................................................................50

4.7. Ultraviolet radiation sensor probe for Smart Agriculture Xtreme (Apogee SU-100) ........................................ 51

4.7.1. Specications ...............................................................................................................................................................52

4.7.2. Measurement process ..............................................................................................................................................52

4.7.3. Socket .............................................................................................................................................................................53

4.7.4. Installation ....................................................................................................................................................................53

4.7.5. Application examples ...............................................................................................................................................55

4.7.6. Certicate of calibration ..........................................................................................................................................55

4.8. Temperature, humidity and pressure sensor probe (Bosch BME280) ................................................................... 56

4.8.1. Specications ...............................................................................................................................................................56

4.8.2. Measurement process ..............................................................................................................................................57

4.8.3. Socket .............................................................................................................................................................................57

4.8.4. Application examples ...............................................................................................................................................58

4.9. Conductivity, water content and soil temperature GS3 sensor probe (Decagon GS3) ................................... 59

4.9.1. Specications ...............................................................................................................................................................60

4.9.2. Measurement process ..............................................................................................................................................60

4.9.3. Socket .............................................................................................................................................................................61

4.9.4. Installation ....................................................................................................................................................................61

4.9.5. Application examples ...............................................................................................................................................62

4.9.6. Quality Assurance Certicate .................................................................................................................................62

4.10. Conductivity, water content and soil temperature 5TE sensor probe (Decagon 5TE) ................................. 63

4.10.1. Specications ............................................................................................................................................................64

4.10.2. Measurement process ............................................................................................................................................64

4.10.3. Socket ..........................................................................................................................................................................65

4.10.4. Installation ..................................................................................................................................................................66

4.10.5. Application examples.............................................................................................................................................66

4.10.6. Quality Assurance Certicate ..............................................................................................................................66

4.11. Soil temperature and volumetric water content sensor probe (Decagon 5TM) ............................................. 67

4.11.1. Specications ............................................................................................................................................................68

4.11.2. Measurement process ............................................................................................................................................68

4.11.3. Socket ..........................................................................................................................................................................69

4.11.4. Installation ..................................................................................................................................................................69

4.11.5. Application examples.............................................................................................................................................70

Page 4

-4-

v7.2

4.11.6. Quality Assurance Certicate ..............................................................................................................................70

4.12. Soil water potential sensor probe (Decagon MPS-6) .................................................................................................71

4.12.1. Specications ............................................................................................................................................................72

4.12.2. Measurement process ............................................................................................................................................72

4.12.3. Socket ..........................................................................................................................................................................73

4.12.4. Installation ..................................................................................................................................................................73

4.12.5. Application examples.............................................................................................................................................74

4.12.6. Quality Assurance Certicate ..............................................................................................................................74

4.13. Vapor pressure, temperature, barometric pressure and relative humidity sensor (Decagon VP-4) .........75

4.13.1. Specications ............................................................................................................................................................76

4.13.2. Measurement process ............................................................................................................................................78

4.13.3. Socket ..........................................................................................................................................................................79

4.13.4. Installation ..................................................................................................................................................................79

4.13.5. Application examples.............................................................................................................................................80

4.13.6. Quality Assurance Certicate ..............................................................................................................................80

4.14. Leaf wetness Phytos 31 sensor probe (Decagon Phytos 31) .................................................................................81

4.14.1. Specications ............................................................................................................................................................82

4.14.2. Measurement process ............................................................................................................................................82

4.14.3. Socket ..........................................................................................................................................................................82

4.14.4. Installation .................................................................................................................................................................83

4.14.5. Application examples.............................................................................................................................................83

4.14.6. Quality Assurance Certicate ..............................................................................................................................83

4.15. Dendrometer sensor probes for Smart Agriculture Xtreme (Ecomatik DC2, DD-S and DF) ........................84

4.15.1. Ecomatik DC2 specications (Trunk diameter) ............................................................................................84

4.15.2. Ecomatik DD-S specications (Stem diameter) ............................................................................................85

4.15.3. Ecomatik DF specications (Fruit diameter) ..................................................................................................85

4.15.4. Measurement process ............................................................................................................................................85

4.15.5. Socket ..........................................................................................................................................................................86

4.15.6. Installation .................................................................................................................................................................87

4.15.7. Application examples.............................................................................................................................................87

4.16. Weather station sensor probes (Gill Instruments MaxiMet series) ...................................................................... 88

4.16.1. MaxiMet GMX-100 (PO) sensor probe ..............................................................................................................89

4.16.2. MaxiMet GMX-101 (R) sensor probe .................................................................................................................89

4.16.3. MaxiMet GMX-200 (W) sensor probe ...............................................................................................................90

4.16.4. MaxiMet GMX-240 (W-PO) sensor probe ........................................................................................................91

4.16.5. MaxiMet GMX-300 (T-H-AP) sensor probe ......................................................................................................92

4.16.6. MaxiMet GMX-301 (T-H-AP-R) sensor probe ..................................................................................................92

4.16.7. MaxiMet GMX-400 (PO-T-H-AP) sensor probe ...............................................................................................93

4.16.8. MaxiMet GMX-500 (W-T-H-AP) sensor probe.................................................................................................94

4.16.9. MaxiMet GMX-501 (W-T-H-AP-R) sensor probe.............................................................................................95

4.16.10. MaxiMet GMX-531 (W-PT-T-H-AP-R) sensor probe ....................................................................................96

4.16.11. MaxiMet GMX-541 (W-PO-T-H-AP-R) sensor probe ...................................................................................97

4.16.12. MaxiMet GMX-550 (W-x-T-H-AP) sensor probe ..........................................................................................98

4.16.13. MaxiMet GMX-551 (W-x-T-H-AP-R) sensor probe ......................................................................................99

4.16.14. MaxiMet GMX-600 (W-PO-T-H-AP) sensor probe ...................................................................................100

Index

Page 5

-5-

v7.2

4.16.15. Specications for each weather station sensor ....................................................................................... 101

4.16.16. Measurement process ......................................................................................................................................102

4.16.17. Socket ..................................................................................................................................................................... 103

4.16.18. Installation ............................................................................................................................................................ 103

4.16.20. Product test report ............................................................................................................................................106

4.17. Solar radiation and temperature Datasol MET probe (Atersa Datasol MET) ...................................................107

4.17.1. Specications ......................................................................................................................................................... 107

4.17.2. Measurement process ......................................................................................................................................... 108

4.17.3. Socket .......................................................................................................................................................................108

4.17.4. Installation ...............................................................................................................................................................109

4.17.5. Application examples..........................................................................................................................................112

4.17.6. Certicate of calibration ..................................................................................................................................... 112

4.18. Luminosity sensor (AMS TSL2561) ..................................................................................................................................113

4.18.1. Specications ......................................................................................................................................................... 113

4.18.2. Measurement process ......................................................................................................................................... 114

4.18.3. Socket .......................................................................................................................................................................114

4.18.4. Application examples..........................................................................................................................................114

4.19. Ultrasound sensor probe (Maxbotix MB7040) ..........................................................................................................115

4.19.1. Specications ......................................................................................................................................................... 115

4.19.2. Measurement process ......................................................................................................................................... 116

4.19.3. Socket .......................................................................................................................................................................116

4.19.4. Installation ...............................................................................................................................................................117

4.19.5. Application examples..........................................................................................................................................117

5. Board conguration and programming ........................................................................................118

5.1. Hardware conguration .......................................................................................................................................................118

5.2. API .................................................................................................................................................................................................118

5.2.1. Before starting to program .................................................................................................................................. 118

5.2.2. Sending sensor values with the Frame class ................................................................................................. 119

6. Consumption ................................................................................................................................... 120

6.1. Consumption table.................................................................................................................................................................120

7. API changelog .................................................................................................................................. 121

8. Documentation changelog ............................................................................................................. 122

9. Certications .................................................................................................................................... 123

10. Maintenance ................................................................................................................................. 124

11. Disposal and recycling ................................................................................................................. 125

Page 6

-6-

v7.2

General and safety information

1. General and safety information

Important:

• All documents and any examples they contain are provided as-is and are subject to change without notice.

Except to the extent prohibited by law, Libelium makes no express or implied representation or warranty of

any kind with regard to the documents, and specically disclaims the implied warranties and conditions of

merchantability and tness for a particular purpose.

• The information on Libelium’s websites has been included in good faith for general informational purposes

only. It should not be relied upon for any specic purpose and no representation or warranty is given as to its

accuracy or completeness.

• Read carefully Limited Warranty and Terms and Conditions of Use before using “Waspmote Plug & Sense!”.

• Do not open casing and do not damage black warranty stickers. If you do so, you will lose warranty.

• Do not remove any of the connectors.

• Do not allow contact between metallic objects and electronic parts to avoid injury and burns.

• Never immerse equipment in any liquid.

• Keep equipment within temperature range indicated in recommendation section.

• Do not connect or power equipment using cables that have been damaged.

• Place equipment in an area to which only maintenance personnel can have access (in a restricted access zone).

• In any case keep children away from the equipment.

• If there is a power failure, immediately disconnect from the mains.

• If using a battery whether or not in combination with a solar panel as a power source follow the voltage and

current specications indicated in the section “External solar panel connector”.

• If a software failure occurs, contact Libelium technical support before doing any action by yourself.

• Do not place equipment on trees or plants as they could be damaged by its weight.

• Be particularly careful if you are connected through a software interface for handling the machine; if settings

of that interface are incorrectly altered, it could become inaccessible.

• If you need to clean the node, wipe it with a dry towel.

• If Waspmote Plug & Sense! needs to be returned please send it completely dry and free from contaminants.

• Waspmote Plug & Sense! is not designed to be placed in hard environmental conditions, under dangerous

chemical elements, explosive atmospheres with ammable gases, high voltage installations or special

installations. Please contact Libelium technical support to ensure your application is compatible with

Waspmote Plug & Sense!

Page 7

-7-

v7.2

Important: Read before use

2. Important: Read before use

The following list shows just some of the actions that produce the most common failures and warranty-voiding.

Complete documentation about usage can be found at http://www.libelium.com/development. Failure to comply

with the recommendations of use will entail the warranty cancellation.

Software:

• Upload code only using Waspmote IDE. If a dierent IDE is used, Waspmote can be damaged and can become

unresponsive. This use is not covered under warranty.

• Do not unplug any connector while uploading code. Waspmote can become unresponsive. This use is not

covered under warranty.

• Do not connect or disconnect any connector while Waspmote is on. Waspmote can become unstable or

unresponsive, and internal parts can be damaged. This fact is not covered under warranty.

Hardware:

• Do not handle black stickers seals on both sides of the enclosure ( Warranty stickers). Their integrity is the

proof that Waspmote Plug & Sense! has not been opened. If they have been handled, damaged or broken, the

warranty is void.

• Do not open Waspmote Plug & Sense! in any case. This will automatically make the warranty void.

• Do not handle the four metallic screws of Waspmote Plug & Sense!. They ensure waterproof seal.

• Do not submerge Waspmote Plug & Sense! in liquids.

• Do not place nodes on places or equipment where it could be exposed to shocks and/or big vibrations.

• Do not expose Waspmote Plug & Sense! to temperatures below -20 ºC or above 60 ºC.

• Do not power Waspmote with other power sources than the original provided by Libelium. Voltage and current

maximum ratings can be exceeded, stopping Waspmote working and voiding warranty.

• Do not try to extract, screw, break or move Waspmote Plug & Sense! connectors far from necessary usage,

waterproof sealing can be damaged and warranty will be voided.

• For more information: http://www.libelium.com

• Do not connect any sensor on the solar panel connector and also do not connect the solar panel to any of

sensor connectors. Waspmote can be damaged and warranty void.

• Do not connect any sensor not provided by Libelium.

• Do not place Waspmote Plug & Sense! where water can reach internal parts of sensors.

• Do not get the magnet close to a metal object. The magnet is really powerful and will get stuck.

• Do not place the magnet close to electronic devices, like PCs, batteries, etc, they could be damaged, or

information could be deleted.

Page 8

-8-

v7.2

Waspmote Plug & Sense!

3. Waspmote Plug & Sense!

This section shows main parts of Waspmote Plug & Sense! and a brief description of each one. In later sections

all parts will be described deeply.

3.1. Specications

• Material: polycarbonate

• Sealing: polyurethane

• Cover screws: stainless steel

• Ingress protection: IP65

• Impact resistance: IK08

• Rated insulation voltage AC: 690 V

• Rated insulation voltage DC: 1000 V

• Heavy metals-free: Yes

• Weatherproof: true - nach UL 746 C

• Ambient temperature (min.): -30 °C*

• Ambient temperature (max.): 70 °C*

• Approximated weight: 800 g

* Temporary extreme temperatures are supported. Regular recommended usage: -20, +60 ºC.

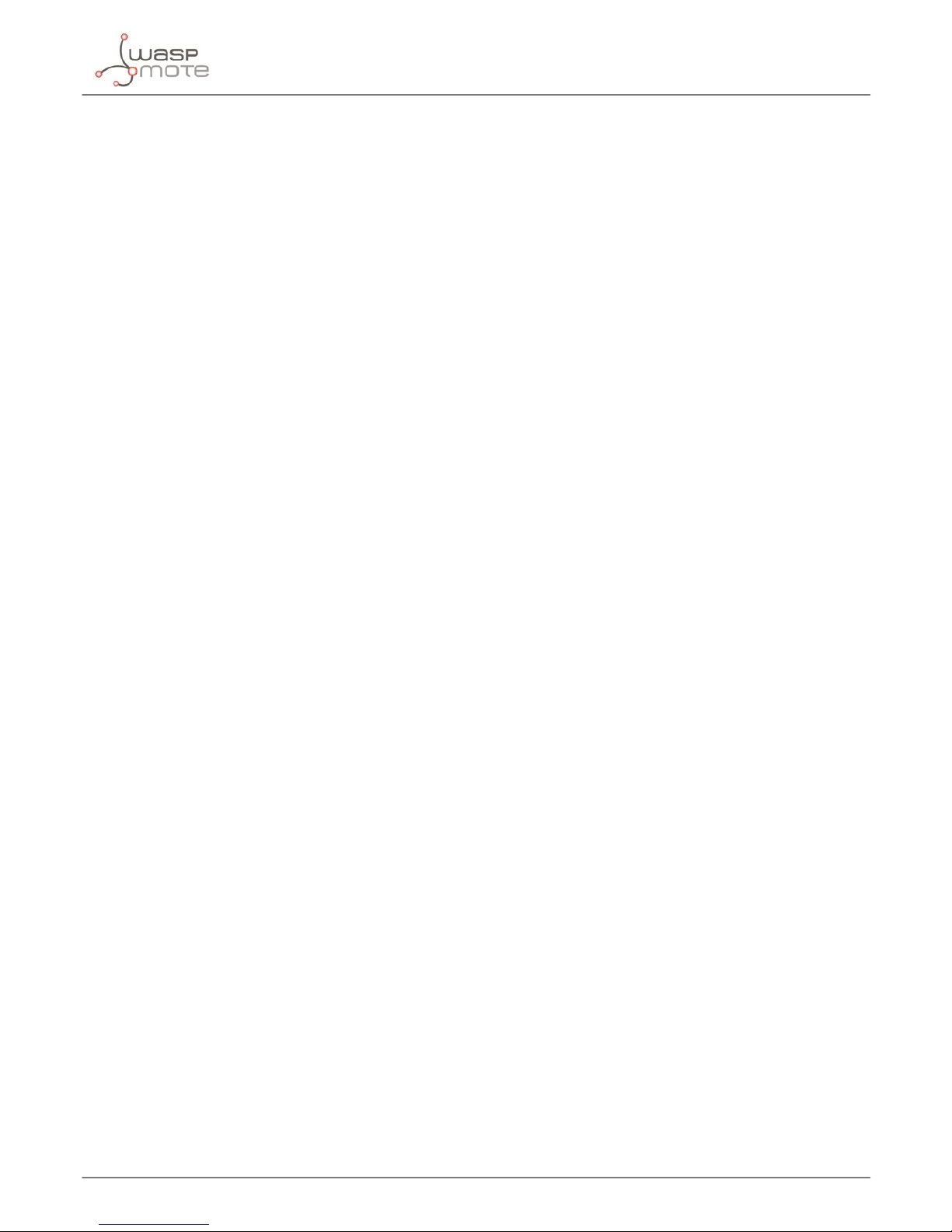

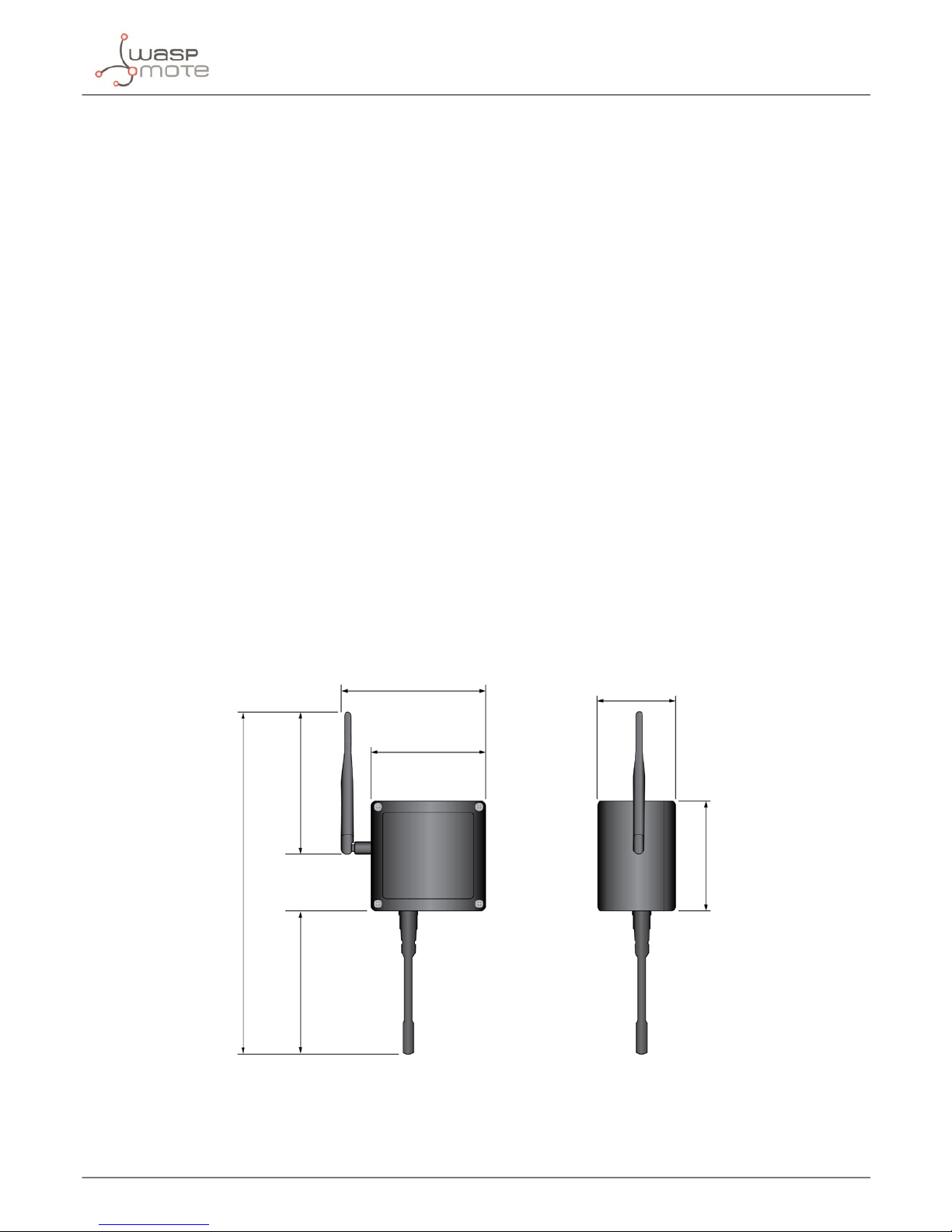

In the pictures included below it is shown a general view of Waspmote Plug & Sense! main parts. Some elements

are dedicated to node control, others are designated to sensor connection and other parts are just identication

elements. All of them will be described along this guide.

164 mm

124 mm

175 mm

410 mm

160 mm

122 mm

85 mm

Figure: Main view of Waspmote Plug & Sense!

Page 9

-9-

v7.2

Waspmote Plug & Sense!

Figure: Control side of the enclosure

Control side of the enclosure for 4G model

Figure: Sensor side of the enclosure

Page 10

-10-

v7.2

Waspmote Plug & Sense!

Figure: Antenna side of the enclosure

Figure: Front view of the enclosure

Figure: Back view of the enclosure

Page 11

-11-

v7.2

Waspmote Plug & Sense!

Figure: Warranty stickers of the enclosure

Important note: Do not handle black stickers seals of the enclosure (Warranty stickers). Their integrity is the proof

that Waspmote Plug & Sense! has not been opened. If they have been handled, damaged or broken, the warranty is

automatically void.

3.2. Parts included

Next picture shows Waspmote Plug & Sense! and all of its elements. Some of them are optional accessories that

may not be included.

1

2

3

4

5

7

6

8

9

10

Figure: Waspmote Plug & Sense! accessories: 1 enclosure, 2 sensor probes, 3 external solar panel, 4 USB cable, 5 antenna, 6 cable ties,

7 mounting feet (screwed to the enclosure), 8 extension cord, 9 solar panel cable, 10 wall plugs & screws

Page 12

-12-

v7.2

Waspmote Plug & Sense!

3.3. Identication

Each Waspmote model is identied by stickers. Next gure shows front sticker.

Model identication colour

Enclosure model

Figure: Front sticker of the enclosure

There are many congurations of Waspmote Plug & Sense! line, all of them identied by one unique sticker. Next

image shows all possibilities.

Figure: Dierent front stickers

Page 13

-13-

v7.2

Waspmote Plug & Sense!

Moreover, Waspmote Plug & Sense! includes a back sticker where it is shown identication numbers, radio MAC

addresses, etc. It is highly recommended to annotate this information and save it for future maintenance. Next

gure shows it in detail.

Figure: Back sticker

Sensor probes are identied too by a sticker showing the measured parameter and the sensor manufacturer

reference.

CO - TGS2442

Measure

parameter

Sensor

reference

Figure: Sensor probe identication sticker

Page 14

-14-

v7.2

Waspmote Plug & Sense!

3.4. Sensor probes

Sensor probes can be easily attached by just screwing them into the bottom sockets. This allows you to add new

sensing capabilities to existing networks just in minutes. In the same way, sensor probes may be easily replaced

in order to ensure the lowest maintenance cost of the sensor network.

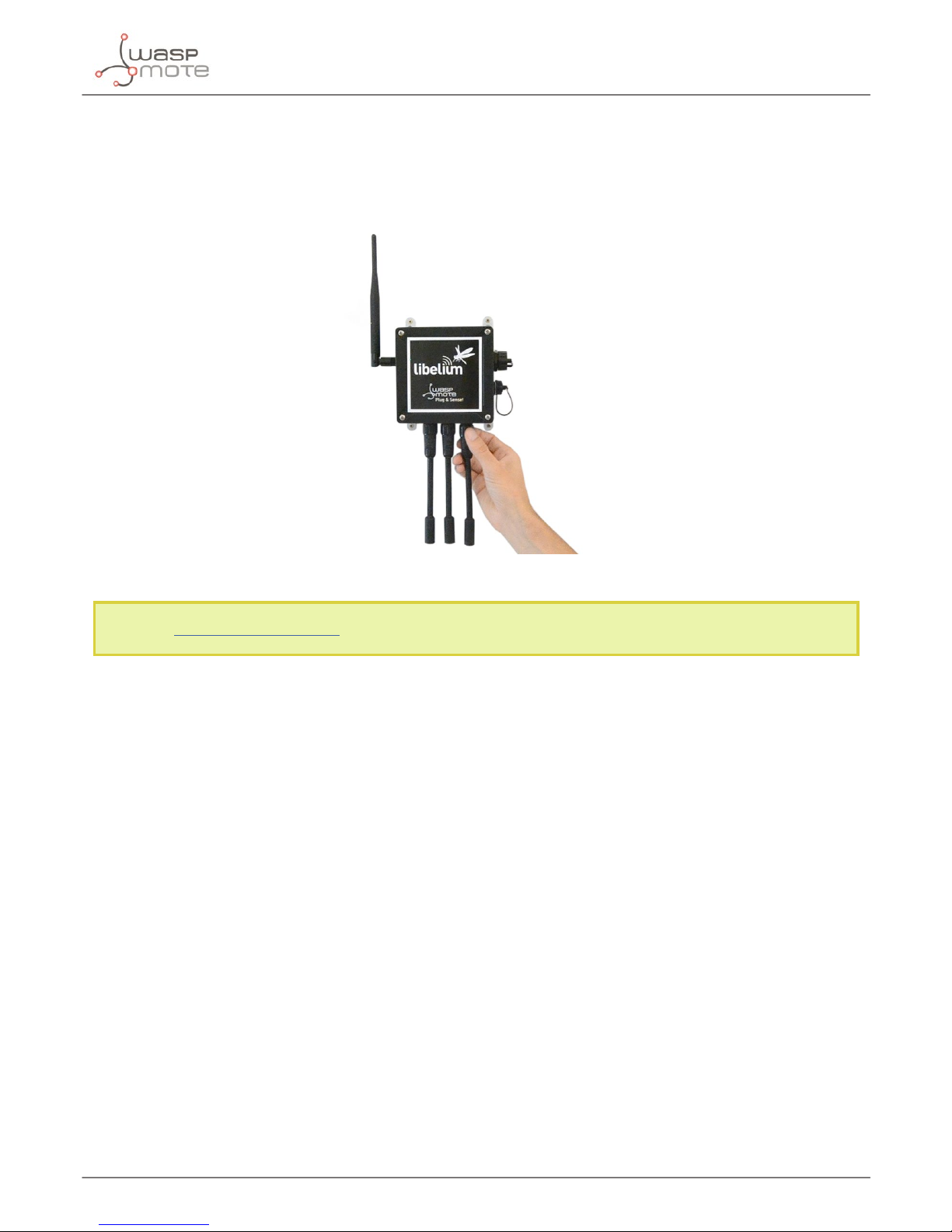

Figure: Connecting a sensor probe to Waspmote Plug & Sense!

Go to the Plug & Sense! Sensor Guide to know more about our sensor probes.

Page 15

-15-

v7.2

Waspmote Plug & Sense!

3.5. Solar powered

The battery can be recharged using the waterproof USB cable but also the external solar panel option.

The external solar panel is mounted on a 45º holder which ensures the maximum performance of each outdoor

installation.

Figure: Waspmote Plug & Sense! powered by an external solar panel

Page 16

-16-

v7.2

Waspmote Plug & Sense!

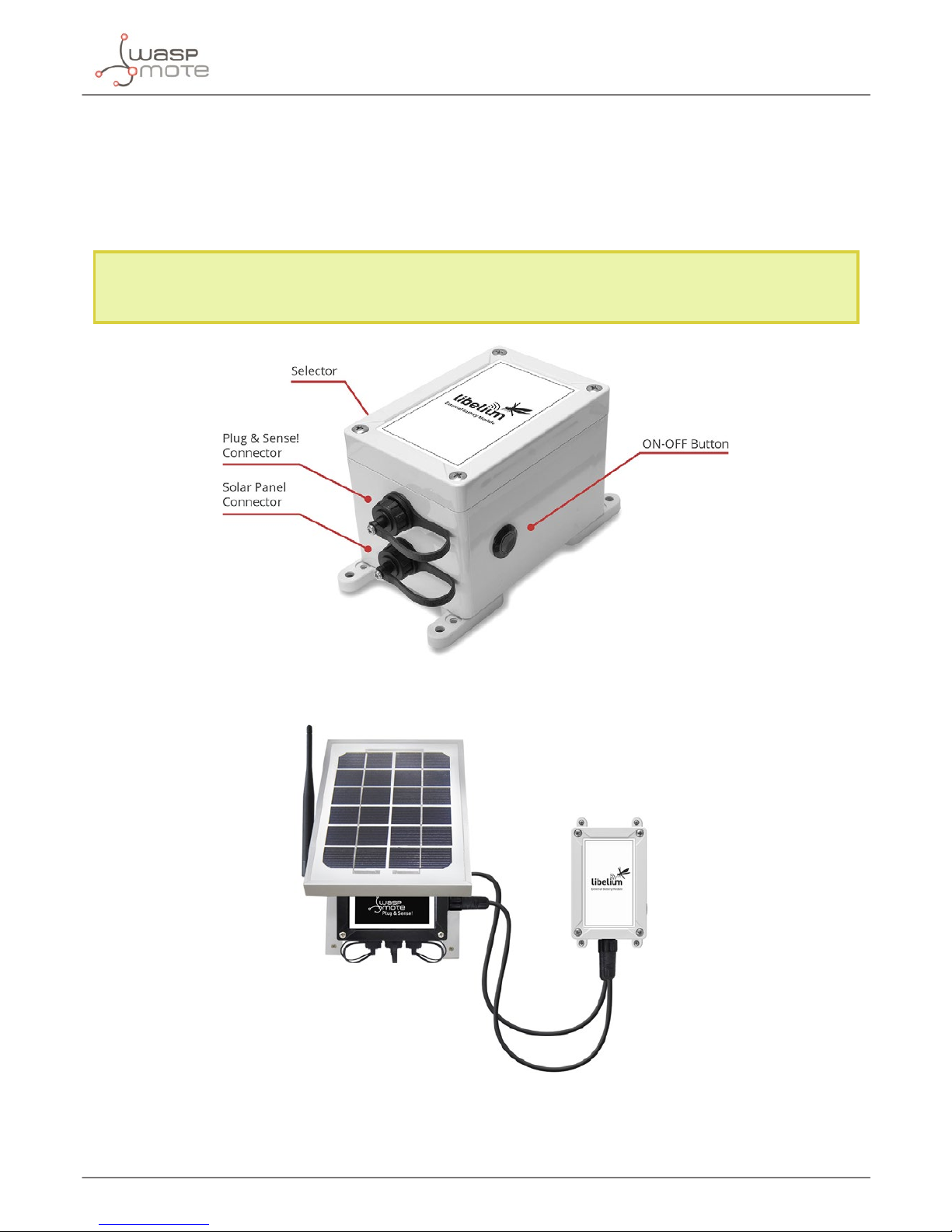

3.6. External Battery Module

The External Battery Module (EBM) is an accessory to extend the battery life of Plug & Sense!. The extension

period may be from months to years depending on the sleep cycle and radio activity. The daily charging period is

selectable among 5, 15 and 30 minutes with a selector switch and it can be combined with a solar panel to extend

even more the node’s battery lifetime.

Note: Nodes using solar panel can keep using it through the External Battery Module. The EBM is connected to

the solar panel connector of Plug & Sense! and the solar panel unit is connected to the solar panel connector

of the EBM.

Figure: Plug & Sense! with External Battery Module

Figure: Plug & Sense! with External Battery Module and solar panel

Page 17

-17-

v7.2

Waspmote Plug & Sense!

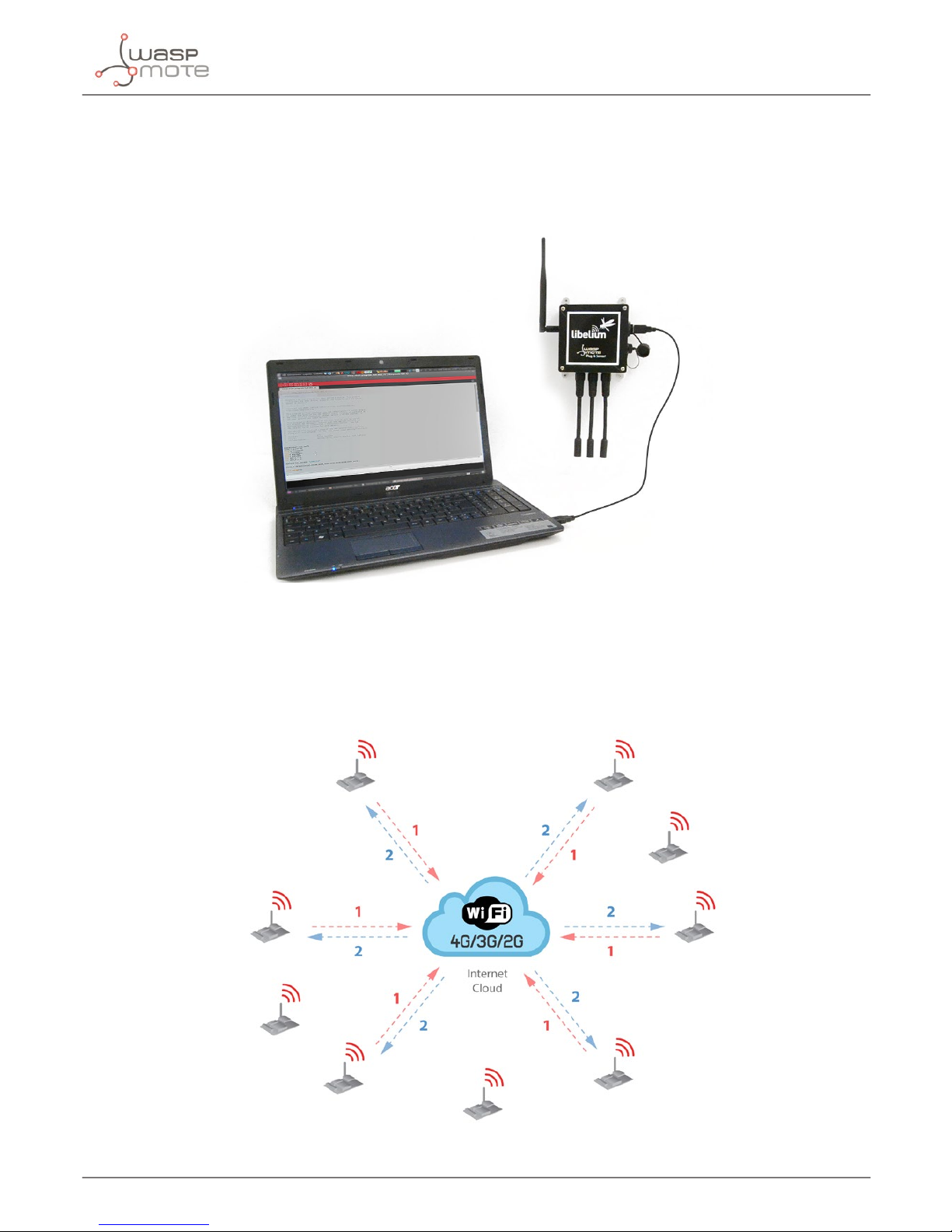

3.7. Programming the Nodes

Waspmote Plug & Sense! can be reprogrammed in two ways:

The basic programming is done from the USB port. Just connect the USB to the specic external socket and then

to the computer to upload the new rmware.

Figure: Programming a node

Over the Air Programming (OTAP) is also possible once the node has been installed (via WiFi or 4G radios). With

this technique you can reprogram, wireless, one or more Waspmote sensor nodes at the same time by using a

laptop and Meshlium.

Figure: Typical OTAP process

Page 18

-18-

v7.2

Waspmote Plug & Sense!

3.8. Program in minutes

The Programming Cloud Service is an intuitive graphic interface which creates code automatically. The user just

needs to to ll a web form to obtain binaries for Plug & Sense!. Advanced programming options are available,

depending on the license selected.

Check how easy it is to handle the Programming Cloud Service at:

https://cloud.libelium.com/

Figure: Programming Cloud Service

Page 19

-19-

v7.2

Waspmote Plug & Sense!

3.9. Radio interfaces

Radio Protocol

Frequency

bands

Transmission

power

Sensitivity Range*

Certication

XBee-PRO 802.15.4

EU

802.15.4 2.4 GHz 10 dBm -100 dBm 750 m CE

XBee-PRO 802.15.4 802.15.4 2.4 GHz 18 dBm -100 dBm 1600 m

FCC, IC, ANATEL,

RCM

XBee 868LP RF 868 MHz 14 dBm -106 dBm 8.4 km CE

XBee 900HP US RF 900 MHz 24 dBm -110 dBm 15.5 km FCC, IC

XBee 900HP BR RF 900 MHz 24 dBm -110 dBm 15.5 km ANATEL

XBee 900HP AU RF 900 MHz 24 dBm -110 dBm 15.5 km RCM

WiFi

WiFi

(HTTP(S),

FTP, TCP,

UDP)

2.4 GHz 17 dBm -94 dBm 500 m

CE, FCC, IC,

ANATEL, RCM

4G EU/BR

4G/3G/2G

(HTTP, FTP,

TCP, UDP)

GPS

800, 850, 900,

1800, 2100, 2600

MHz

4G: class 3

(0.2 W, 23 dBm)

4G: -102

dBm

- km - Typical

base station

range

CE, ANATEL

4G US

4G/3G/2G

(HTTP, FTP,

TCP, UDP)

GPS

700, 850, 1700,

1900 MHz

4G: class 3

(0.2 W, 23 dBm)

4G: -103

dBm

- km - Typical

base station

range

FCC, IC, PTCRB,

AT&T

4G AU

4G

(HTTP, FTP,

TCP, UDP)

700, 1800, 2600

MHz

4G: class 3

(0.2 W, 23 dBm)

4G: -102

dBm

- km - Typical

base station

range

RCM

Sigfox EU Sigfox 868 MHz 16 dBm -126 dBm

- km - Typical

base station

range

CE

Sigfox US Sigfox 900 MHz 24 dBm -127 dBm

- km - Typical

base station

range

FCC, IC

Sigfox AU / APAC /

LATAM

Sigfox 900 MHz 24 dBm -127 dBm

- km - Typical

base station

range

-

LoRaWAN EU LoRaWAN 868 MHz 14 dBm -136 dBm > 15 km CE

LoRaWAN US LoRaWAN 902-928 MHz 18.5 dBm -136 dBm > 15 km FCC, IC

LoRaWAN AU LoRaWAN 915-928 MHz 18.5 dBm -136 dBm > 15 km -

LoRaWAN IN LoRaWAN 865-867 MHz 18.5 dBm -136 dBm > 15 km

-

LoRaWAN ASIA-PAC

/ LATAM

LoRaWAN 923 MHz 18.5 dBm -136 dBm > 15 km

-

* Line of sight and Fresnel zone clearance with 5dBi dipole antenna.

Page 20

-20-

v7.2

Waspmote Plug & Sense!

3.10. Industrial Protocols

Besides the main radio of Waspmote Plug & Sense!, it is possible to have an Industrial Protocol module as a

secondary communication option. This is oered as an accessory feature.

The available Industrial Protocols are RS-485, Modbus (software layer over RS-485) and CAN Bus. This optional

feature is accessible through an additional, dedicated socket on the antenna side of the enclosure.

Figure: Industrial Protocols available on Plug & Sense!

Page 21

-21-

v7.2

Waspmote Plug & Sense!

Finally, the user can choose between 2 probes to connect the desired Industrial Protocol: A standard DB9 connector

and a waterproof terminal block junction box. These options make the connections on industrial environments or

outdoor applications easier.

Figure: DB9 probe

Figure: Terminal box probe

Page 22

-22-

v7.2

Waspmote Plug & Sense!

3.11. GPS

Any Plug & Sense! node can incorporate a GPS receiver in order to implement real-time asset tracking applications.

The user can also take advantage of this accessory to geolocate data on a map. An external, waterproof antenna

is provided; its long cable enables better installation for maximum satellite visibility.

Figure: Plug & Sense! node with GPS receiver

Chipset: JN3 (Telit)

Sensitivity:

• Acquisition: -147 dBm

• Navigation: -160 dBm

• Tracking: -163 dBm

Hot start time: <1 s

Cold start time: <35 s

Positional accuracy error < 2.5 m

Speed accuracy < 0.01 m/s

EGNOS, WAAS, GAGAN and MSAS capability

Antenna:

• Cable length: 2 m

• Connector: SMA

• Gain: 26 dBi (active)

Available information: latitude, longitude, altitude, speed, direction, date&time and ephemeris management

Page 23

-23-

v7.2

Waspmote Plug & Sense!

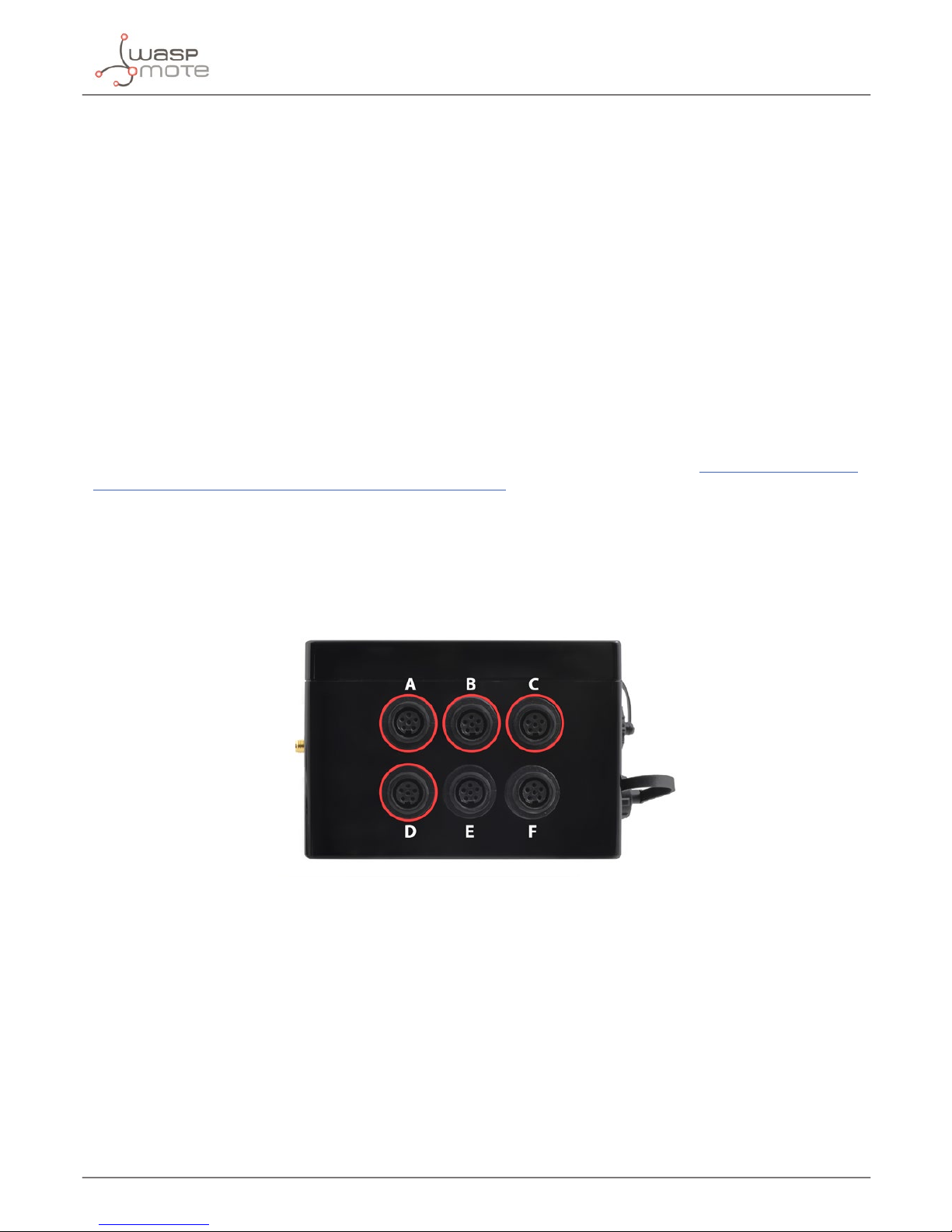

3.12. Models

There are some dened congurations of Waspmote Plug & Sense! depending on which sensors are going to be

used. Waspmote Plug & Sense! congurations allow to connect up to six sensor probes at the same time.

Each model takes a dierent conditioning circuit to enable the sensor integration. For this reason each model

allows to connect just its specic sensors.

This section describes each model conguration in detail, showing the sensors which can be used in each case

and how to connect them to Waspmote. In many cases, the sensor sockets accept the connection of more than

one sensor probe. See the compatibility table for each model conguration to choose the best probe combination

for the application.

It is very important to remark that each socket is designed only for one specic sensor, so they are not

interchangeable. Always be sure you connected probes in the right socket, otherwise they can be damaged.

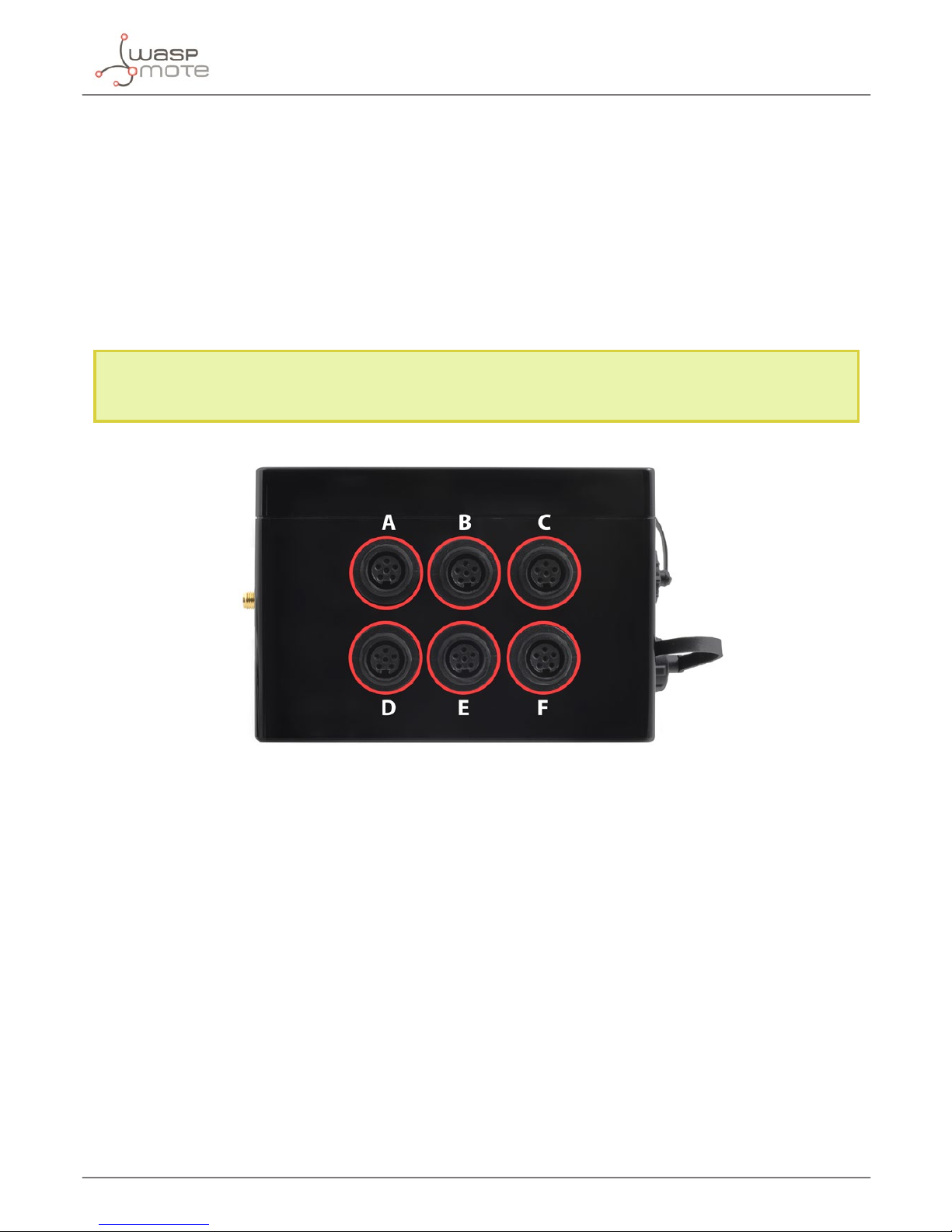

Figure: Identication of sensor sockets

Page 24

-24-

v7.2

Waspmote Plug & Sense!

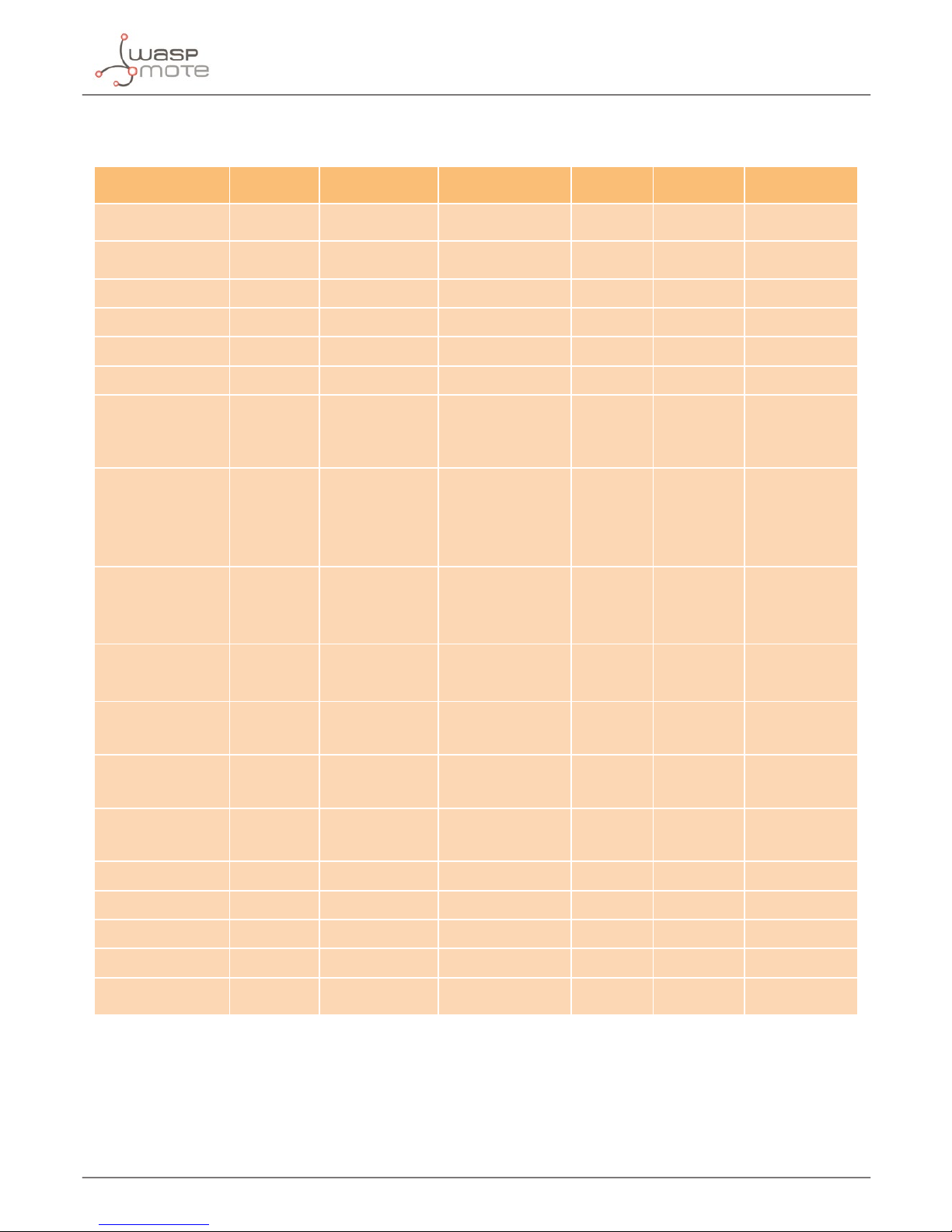

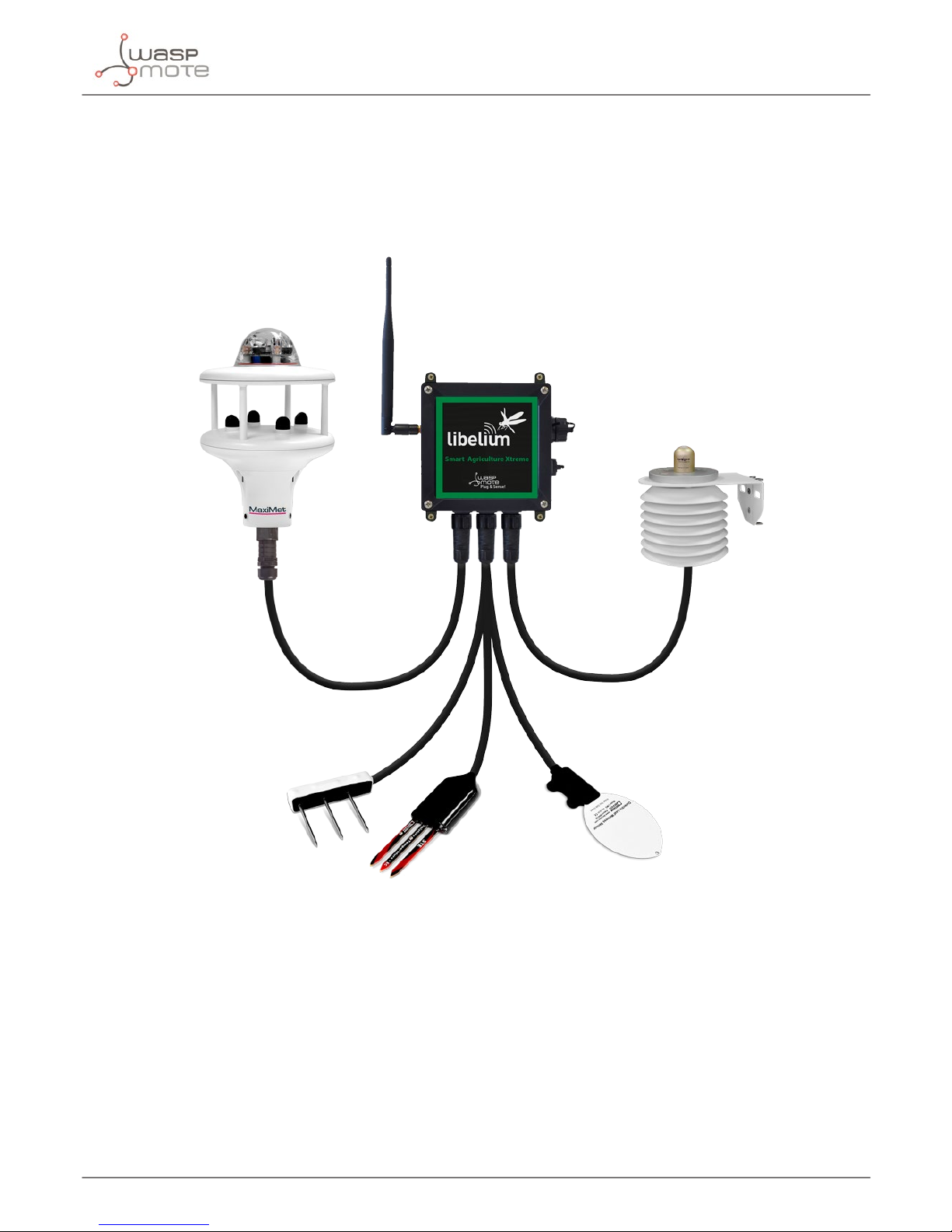

3.12.1. Smart Agriculture Xtreme

The Plug & Sense! Smart Agriculture Xtreme is an evolution of our Agriculture line with a new selection of highend professional sensors. It allows to monitor multiple environmental parameters involving a wide range of

applications, from plant growing analysis to weather observation. There are sensors for atmospheric and soil

monitoring and plants health. Up to 33 sensors can be connected.

Figure: Smart Agriculture Xtreme Waspmote Plug & Sense! model

Page 25

-25-

v7.2

Waspmote Plug & Sense!

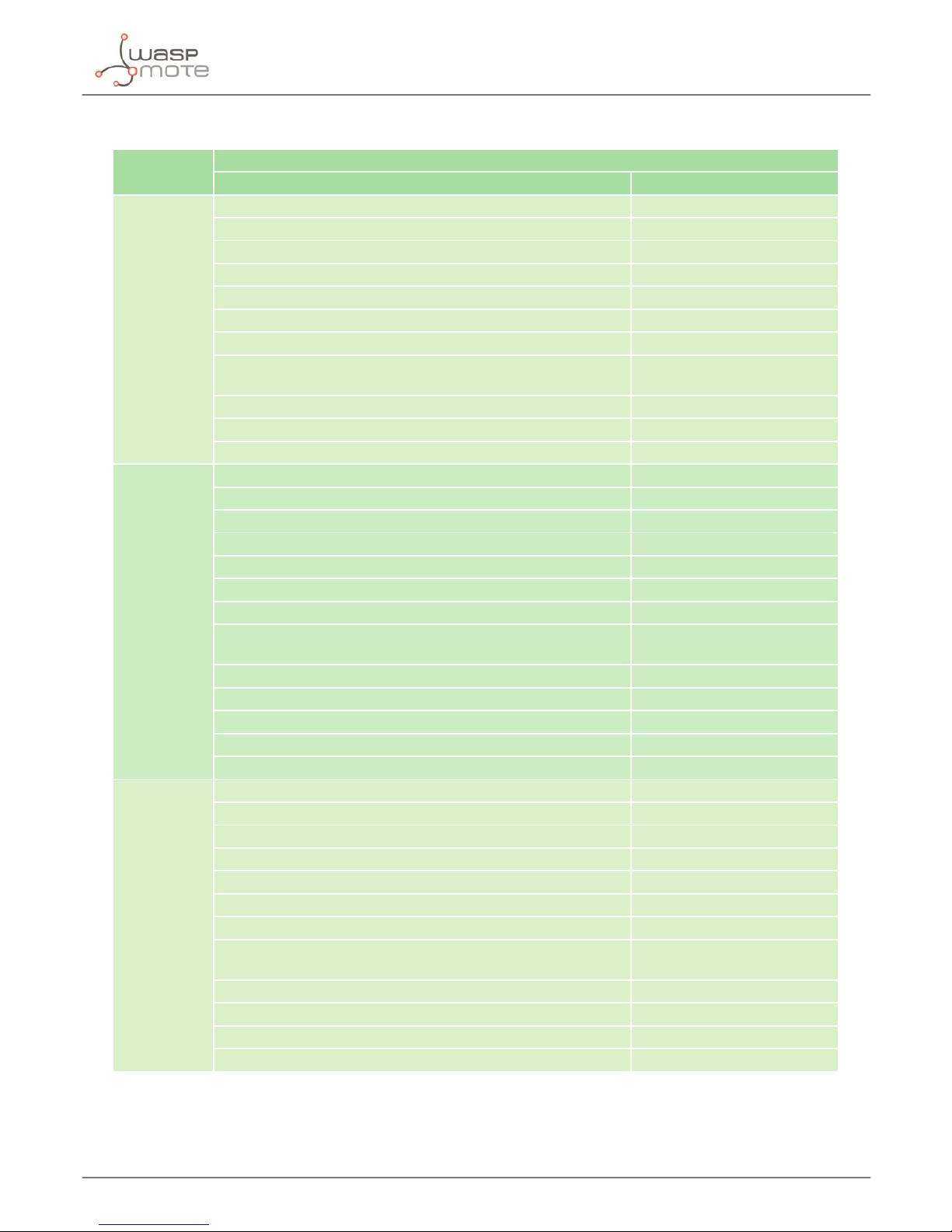

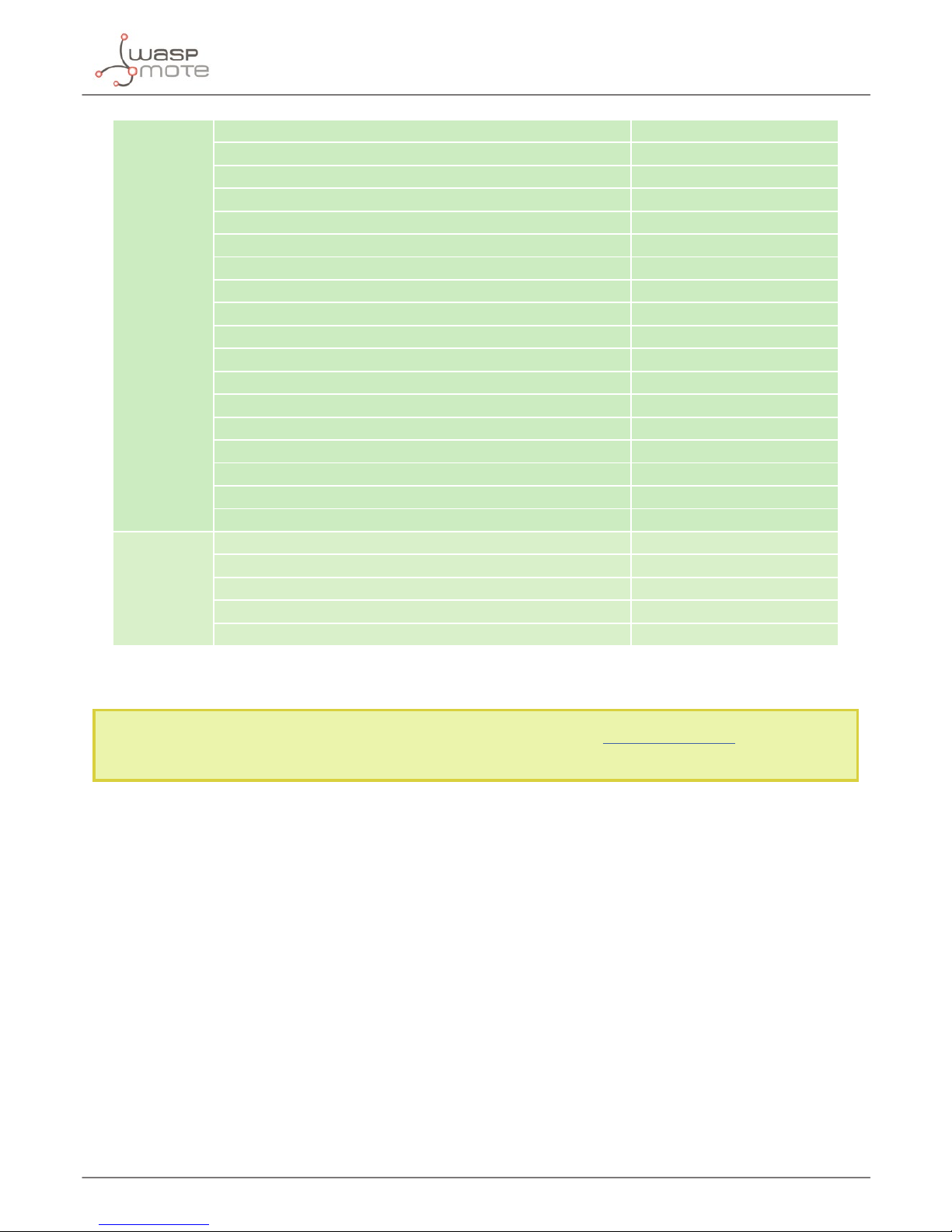

Sensor sockets are congured as shown in the gure below.

Sensor

Socket

Sensor probes allowed for each sensor socket

Parameter Reference

A and D

Non-contact surface temperature measurement SI-411 9468-P

Leaf and ower bud temperature SF-421 9467-P

Soil oxygen level SO-411 9469-P

Conductivity, water content and soil temperature 5TE 9402-P

Conductivity, water content and soil temperature GS3 9464-P

Soil temperature and volumetric water content 5TM 9460-P

Soil water potential MPS-6 9465-P

Vapor pressure, humidity, temperature, and atmospheric

pressure in soil and air VP-4

9471-P

Temperature, air humidity and pressure 9370-P

Luxes 9325-P

Ultrasound 9246-P

B

Non-contact surface temperature measurement SI-411 9468-P

Leaf and ower bud temperature SF-421 9467-P

Soil oxygen level SO-411 9469-P

Conductivity, water content and soil temperature 5TE 9402-P

Conductivity, water content and soil temperature GS3 9464-P

Soil temperature and volumetric water content 5TM 9460-P

Soil water potential MPS-6 9465-P

Vapor pressure, humidity, temperature, and atmospheric

pressure in soil and air VP-4

9471-P

Leaf wetness Phytos 31 9466-P

Shortwave radiation SP-510 9470-P

Solar radiation (PAR) SQ-110 for Smart Agriculture Xtreme 9251-PX

Ultraviolet radiation SU-100 for Smart Agriculture Xtreme 9257-PX

4-20 mA type (generic) -

C

Non-contact surface temperature measurement SI-411 9468-P

Leaf and ower bud temperature SF-421 9467-P

Soil oxygen level SO-411 9469-P

Conductivity, water content and soil temperature 5TE 9402-P

Conductivity, water content and soil temperature GS3 9464-P

Soil temperature and volumetric water content 5TM 9460-P

Soil water potential MPS-6 9465-P

Vapor pressure, humidity, temperature, and atmospheric

pressure in soil and air VP-4

9471-P

Dendrometers (DC2, DD-S, DF) for Smart Agriculture Xtreme 9252-PX, 9253-PX, 9254-PX

Shortwave radiation SP-510 9470-P

Solar radiation (PAR) SQ-110 for Smart Agriculture Xtreme 9251-PX

Ultraviolet radiation SU-100 for Smart Agriculture Xtreme 9257-PX

Page 26

-26-

v7.2

Waspmote Plug & Sense!

E

Shortwave radiation SP-510 9470-P

Solar radiation (PAR) SQ-110 for Smart Agriculture Xtreme 9251-PX

Ultraviolet radiation SU-100 for Smart Agriculture Xtreme 9257-PX

Weather station GMX-100 (PO) Probe 9472-P

Weather station GMX-101 (R) 9473-P

Weather station GMX-200 (W) 9474-P

Weather station GMX-240 (W-PO) 9463-P

Weather station GMX-300 (T-H-AP) 9475-P

Weather station GMX-301 (T-H-AP-R) 9476-P

Weather station GMX-400 (PO-T-H-AP) 9477-P

Weather station GMX-500 (W-T-H-AP) 9478-P

Weather station GMX-501 (W-T-H-AP-R) 9479-P

Weather station GMX-531 (W-PT-T-H-AP-R) 9480-P

Weather station GMX-541 (W-PO-T-H-AP-R) 9481-P

Weather station GMX-550 (W-x-T-H-AP) 9482-P

Weather station GMX-551 (W-x-T-H-AP-R) 9483-P

Weather station GMX-600 (W-PO-T-H-AP) 9484-P

Solar radiation and temperature Datasol MET probe 9496-P

F

Shortwave radiation SP-510 9470-P

Solar radiation (PAR) SQ-110 for Smart Agriculture Xtreme 9251-PX

Ultraviolet radiation SU-100 for Smart Agriculture Xtreme 9257-PX

RS-232 type (generic) -

4-20 mA type (generic) -

Figure: Sensor sockets configuration for Smart Agriculture model

Note: For more technical information about each sensor probe go to the Development section on the Libelium

website.

Page 27

-27-

v7.2

Sensors probes

4. Sensors probes

4.1. General comments

The following sections describe the main features and the general usage for all the sensors probes included in the

Plug & Sense! Smart Agriculture Xtreme model.

It is important to remark that Smart Agriculture Xtreme is only available in the Waspmote Plug & Sense! line. It is

not available for the Waspmote OEM line. Besides, keep in mind that Smart Agriculture Xtreme is not compatible

with the former Smart Agriculture or Smart Agriculture PRO models. In other words, the sensor probes described

in this Guide are only compatible with Smart Agriculture Xtreme, because its advanced electronics allow these

specic sensor integrations (some exceptions are the BME, Ultrasound or Luminosity sensors).

In order to keep this guide as short as possible, some manufacturer information has been omitted. Libelium

encourages the reader to visit the manufacturer websites and to spend some time studying all the technical papers

and application notes provided for each sensor. Measured parameters on the great majority of Smart Agriculture

applications require a deep knowledge of the environmental parameters and, what is a more, sophisticated

measure techniques to obtain the best accuracy.

Additionally, Libelium highly recommends to carry out comprehensive laboratory tests before installing the system

on the eld, as well as proof of concepts on the eld during a reasonable period, before going to a real deploy.

Thanks to these good practices, the user will have an idea of the platform behavior, which will be very close to the

reality. Parameters like accuracy over time or battery drain can be only measured with real tests.

Finally, always take into account a maintenance factor for each sensor probe. The environmental conditions could

aect the sensor behaviour and accuracy therefore it will become mandatory a periodic maintenance for each

sensor probe, to watch out things like dirty on sensor probes, measure position or wire connections. The period

between these maintenance actions will be dierent on each application. Contact our Sales department through

the next link if you require more information: http://www.libelium.com/contact.

Page 28

-28-

v7.2

Sensors probes

4.2. Non-contact surface temperature measurement sensor probe (Apogee SI-411)

The Non-contact surface temperature measurement sensor probe is able to measure the electromagnetic radiation

that every object with a temperature above absolute zero emits, which is used to calculate surface temperature

from a distance. Thanks to this, the temperature of the object surface is not altered in any way when measuring it.

Figure: The non-contact surface temperature measurement sensor probe (Apogee SI-411)

4.2.1. Specications

• Operating environment: -45 to 80 ºC

• Operation humidity: 0 ~ 100% RH (non-condesing)

• Calibration uncertainty (-20 to 65 ºC), when target and detector temperature are within 20 ºC: 0.2 ºC

• Calibration uncertainty (-40 to 80 ºC), when target and detector temperature are dierent by more than

20 ºC: 0.5 ºC

• Measurement repeatability: less than 0.05 ºC

• Stability (Long-term drift): less than 2 % change in slope per year when germanium lter is maintained in a

clean condition

• Field of view: 22º half angle

• Spectral range: 8 to 14 µm; atmospheric window

• Dimensions: 23 mm diameter; 60 mm length

• Mass: 190 g (with 5m of lead wire)

• Cable: 5 m

Page 29

-29-

v7.2

Sensors probes

4.2.2. Measurement process

The SI-411 sensor provides a digital signal using the SDI-12 protocol.

Reading code:

{

// 1. Declare an object for the sensor

Apogee_SI411 mySensor(XTR_SOCKET_A);

// 2. Turn ON the sensor

mySensor.ON();

// 3. Read the sensor. Values stored in class variables

// Check complete code example for details

mySensor.read();

// 4. Turn off the sensor

mySensor.OFF();

}

You can nd a complete example code for reading this sensor probe in the following link: http://www.libelium.com/

development/waspmote/examples/ag-xtr-01-SI-411-sensor-reading

4.2.3. Socket

Connect the infrared radiometer sensor to the Plug & Sense! Smart Agriculture Xtreme in any of the sockets

shown in the image below.

Figure: Available sockets for the SI-411 sensor probe

Page 30

-30-

v7.2

Sensors probes

4.2.4. Installation

When choosing the distance of the sensor to the object to be measured at the installation of the sensor, it must be

taken into account that it has a eld of view (FOV) of 22º (half angle), as you can see in the image below.

It is necessary to remove the green protective cover to measure, it is only used to protect the sensor when it is

not being used.

Figure: Sensor eld of view

An Angle mounting bracket (Apogee AM-220) can also be used for the installation. This accessory is recommended

to mount the sensor on a pole with an outer diameter from 3.3 to 5.3 cm in dierent angles.

Figure: Angle mounting bracket (Apogee AM-220)

Page 31

-31-

v7.2

Sensors probes

Looking into above picture, the black plastic part on the right must be facing the pole, while the metal angled part

on the left must x the sensor.

First, attach the accessory to the pole screwing the 2 nuts just enough to hold the accessory to the pole. Keep the

2 washers to avoid the installation loosening.

Then, place the sensor into the accessory, taking into account that the sensor must point towards the desired

target.

Finally, adjust the angles by rotating the sensor and hold it into the desired position while the nuts are tightened.

Figure: Angle mounting bracket installation with the SI-411 sensor

You can nd the complete sensor manual on the manufacturer’s website.

4.2.5. Application examples

• Plant canopy temperature measurement for plant water status estimation

• Road surface temperature measurement for determination of icing conditions

• Terrestrial surface (soil, vegetation, water, snow) temperature measurement in energy balance studies

4.2.6. Certicate of calibration

Together with this sensor we provide a calibration certicate in which the manufacturer ensures that the sensor

has passed a calibration procedure with traceability to an accredited laboratory.

Page 32

-32-

v7.2

Sensors probes

4.3. Leaf and ower bud temperature sensor probe (Apogee SF-421)

Frost events may happen in plants even though the ambient temperature is not 0 ºC or lower because the canopy

temperature can be dierent than air temperature, this is called radiation frost. The Leaf and bud temperature

sensor probe is designed to predict frost events.

Radiation frost occurs when there is a lack of air mixing by the wind near the surface and a negative net long wave

radiation balance at the surface.

Figure: Leaf and bud temperature sensor probe (Apogee SF-421)

4.3.1. Specications

• Operating temperature: -50 to 70 ºC

• Operation humidity: 0 ~ 100% RH

• Measurement range: -50 to 70 ºC

• Measurement Uncertainty:

- 0.1 ºC (from 0 to 70 ºC)

- 0.2 ºC (from -25 to 0 ºC)

- 0.4 ºC (from -50 to -25 ºC)

• Measurement repeatability: less than 0.05 ºC

• Stability (Long-term drift): Less than 0.02 ºC per year

• Equilibration time: 10 s

• Self-heating: Less than 0.01 ºC

• Dimensions: 57 cm length, 2.1 cm pipe diameter, 7.0 cm disk diameter (see image below)

• Mass: 400 g

• Cable: 5 m

Figure: Radiation frost detector dimensions

Page 33

-33-

v7.2

Sensors probes

4.3.2. Measurement process

The SF-421 sensor provides a digital signal using the SDI-12 protocol.

Reading code:

{

// 1. Declare an object for the sensor

Apogee_SI421 mySensor(XTR_SOCKET_A);

// 2. Turn ON the sensor

mySensor.ON();

// 3. Read the sensor. Values stored in class variables

// Check complete code example for details

mySensor.read();

// 4. Turn off the sensor

mySensor.OFF();

}

You can nd a complete example code for reading this sensor probe in the following link: http://www.libelium.com/

development/waspmote/examples/ag-xtr-02-SF-421-sensor-reading

4.3.3. Socket

Connect the SF-421 sensor probe to Plug & Sense! Smart Agriculture Xtreme in any of the sockets shown in the

image below.

Figure: Available sockets for the SF-421 sensor probe

Page 34

-34-

v7.2

Sensors probes

4.3.4. Installation

The shape of the SF-421 sensor is designed to resemble a plant leaf and ower bud and be able to measure

radiation frost events. The sensor should be installed near the plant canopy where the radiation frost detection

is required.

Figure: SF-421 sensor installation

An Angle mounting bracket (Apogee AM-220) can also be used for the installation. This accessory is recommended

to mount the sensor on a pole with an outer diameter from 3.3 to 5.3 cm in dierent angles.

Figure: Angle mounting bracket (Apogee AM-220)

Looking into above picture, the black plastic part on the right must be facing the pole, while the metal angled

part on the left must x the sensor.

First, attach the accessory to the pole screwing the 2 nuts just enough to hold the accessory to the pole. Keep the

2 washers to avoid the installation loosening.

Then, place the sensor into the accessory, taking into account that the sensor must point towards the desired

target.

Page 35

-35-

v7.2

Sensors probes

Finally, adjust the angles by rotating the sensor and hold it into the desired position while the nuts are tightened.

Figure: Angle mounting bracket installation with the SF-421 sensor

You can nd the complete sensor manual on the manufacturer’s website.

4.3.5. Application examples

• Leaf and bud temperature estimates in cropped elds, orchards, and vineyards.

• Detection of potential frost damage to crops.

4.3.6. Quality Assurance Certicate

Together with this sensor we provide a quality assurance certicate in which the manufacturer ensures that the

sensor has passed the internal quality procedures.

Page 36

-36-

v7.2

Sensors probes

4.4. Soil oxygen level sensor probe (Apogee SO-411)

Oxygen is the second major constituent of Earth’s atmosphere and it is crucial for the development of life. There

are sensors which measures oxygen in 2 states: dissolved in a solution and in a gaseous state. The Soil oxygen

level sensor probe measures gaseous oxygen.

The Soil oxygen level sensor probe consists of a galvanic cell type sensor and oers a measure of the percentage

of the total number of molecules of oxygen in the air. This sensor is specially designed for use in soil or porous

media.

Figure: Soil oxygen level sensor probe (Apogee SO-411)

Figure: SO-411 sensor with diusion head AO-001

Page 37

-37-

v7.2

Sensors probes

4.4.1. Specications

• Operating environment: -20 to 60 ºC; 60 to 114 kPa

• Operation humidity: 0 ~ 100% RH (non-condensing)

• Measurement range: 0 to 100 % O

2

• Measurement repeatability: Less than 0.1 % of mV output at 20.95 % O

2

• Non-linearity: Less than 1 %

• Long-term drift (Non-stability): 1.0 mV per year

• Oxygen consumption rate: 2.2 µmol O2 per day at 20.95 % O2 and 23 ºC

• Response time: 60 s

• Dimensions: 32 mm diameter, 68 mm length

• Mass: 175 g

• Cable: 5 m

4.4.2. Measurement process

The SO-411 sensor provides a digital signal using the SDI-12 protocol.

Reading code:

{

// 1. Declare an object for the sensor

Apogee_SO411 mySensor(XTR_SOCKET_A);

// 2. Turn ON the sensor

mySensor.ON();

// 3. Initialization delay, necessary for this sensor

delay(60000);

// 4. Read the sensor. Values stored in class variables

// Check complete code example for details

mySensor.read();

// 5. Turn off the sensor

mySensor.OFF();

}

You can nd a complete example code for reading this sensor probe in the following link: http://www.libelium.com/

development/waspmote/examples/ag-xtr-03-SO-411-sensor-reading

Page 38

-38-

v7.2

Sensors probes

4.4.3. Socket

Connect the SO-411 sensor probe to Plug & Sense! Smart Agriculture Xtreme in any of the sockets shown in the

image below.

Figure: Available sockets for the SO-411 sensor probe

Page 39

-39-

v7.2

Sensors probes

4.4.4. Installation

The SO-411 sensor is designed to be installed in soil or porous media in vertical position, with the opening pointing

down and the cable pointing up.

This sensor can be used with the accessory model A0-001, designed to facilitate measurements in soil or porous

media. It consists of a diusion head that maintains an air pocket and provides protection to the teon membrane

where gas diusion occurs.

Figure: Diusion head accessory A0-001

Figure: SO-411 sensor installation with diusion head accessory

You can nd the complete sensor manual on the manufacturer’s website.

Page 40

-40-

v7.2

Sensors probes

4.4.5. Application examples

• Measurement of O2 in laboratory experiments.

• Monitoring gaseous O2 in indoor environments for climate control.

• Monitoring of O2 levels in compost piles and mine tailings.

• Monitoring redox potential in soils.

• Determination of respiration rates through measurement of O2 consumption in sealed chambers.

• Measurement of O2 gradients in soil/porous media.

4.4.6. Quality Assurance Certicate

Together with this sensor we provide a quality assurance certicate in which the manufacturer ensures that the

sensor has passed the internal quality procedures.

Page 41

-41-

v7.2

Sensors probes

4.5. Shortwave radiation sensor probe (Apogee SP-510)

The Shortwave radiation sensor probe (Apogee SP-510) measures incoming global shortwave radiation from the

Sun. Shortwave radiation is radiant energy with wavelengths in the visible (VIS), near-ultraviolet (UV), and nearinfrared (NIR) spectra.

This sensor consists of a thermopile detector, acrylic diuser, heater, and signal processing circuitry mounted in

an anodized aluminum housing.

Figure: Shortwave radiation sensor probe (Apogee SP-510)

4.5.1. Specications

General specications

• Operating temperature: -50 to 80 ºC

• Operation humidity: 0 ~ 100% RH

• Sensitivity (variable from sensor to sensor, typical values listed): 0.057 mV per W m

-2

• Calibration factor (reciprocal of sensitivity): 17.5 W m-2 per mV

• Calibration uncertainty: ± 5%

• Calibrated output range: 0 to 114 mV

• Measurement range: 0 to 2000 W m-2 (net shortwave radiation)

• Measurement repeatability: less than 1%

• Long-term drift (non-stability): less than 2% per year

• Non-linearity: less than 1%

• Detector response time: 0.5 s

• Field of view: 180º

• Spectral range (wavelengths where response is 50% of maximum): 385 to 2105 nm

• Directional (cosine) response: less than 30 W m-2 up to solar zenith angles of 80º

• Temperature response: less than 5% from -15 to 45 ºC

• Cable length: 5 m

Page 42

-42-

v7.2

Sensors probes

4.5.2. Measurement process

The SP-510 sensor provides an analog signal.

Reading code:

{

// 1. Declare an object for the sensor

Apogee_SP510 mySensor(XTR_SOCKET_B);

// 2. Turn ON the sensor

mySensor.ON();

// 3. Read the sensor. Values stored in class variables

// Check complete code example for details

mySensor.read();

// 4. Turn off the sensor

mySensor.OFF();

}

You can nd a complete example code for reading this sensor probe in the following link: http://www.libelium.com/

development/waspmote/examples/ag-xtr-06-SP-510-sensor-reading

4.5.3. Socket

Connect the SP-510 sensor probe to Plug & Sense! Smart Agriculture Xtreme in any of the sockets shown in the

image below.

Figure: Available sockets for the SP-510 sensor probe

Page 43

-43-

v7.2

Sensors probes

4.5.4. Installation

The SP-510 sensor includes a nylon mounting screw on the base in order to mount the sensor on a solid surface.

Figure: Pyranometer installation

The Solar sensors mounting accessory can also be used for the installation. This accessory is optional but highly

recommended for the solar sensors. With this accessory you will get a secure fastening while keeping the sensor

as level as possible, always pointing up.

The accessory is composed of 2 main parts:

A - Mounting bracket: it will be fastened to a pipe or mast with its u-bolt

B - Leveling plate: it holds the sensor and includes a bubble level

Page 44

-44-

v7.2

Sensors probes

Figure: Solar sensors mounting accessory

Mounting the system is very easy, just follow these steps:

1 - Attach the solar sensor to the leveling plate, in its central hole. Use the black nylon screw (every sensor comes

with one, nd it on its bottom) and a screwdriver.

2 - Fasten the leveling plate to the mounting bracket with the 3 long gray screws. Do not insert them too rmly,

the nal adjustment is done later.

3 - Decide if you want to mount the whole structure to a vertical or horizontal pipe or mast (its outer diameter can

go from 3.3 to 5.3 cm). Depending on horizontal or vertical conguration, you will use the bottom or the side of

the mounting bracket.

4 - Place the black plastic piece in contact with the pipe. Then use the u-bolt to grab the mounting bracket to the

pipe. On both ends of the u-bolt, insert rst the washers, then the lock washers and nally the nuts.

5 - Place the structure in the desired position and tighten the nuts rmly with a wrench.

Figure: Final look of the whole structure

Page 45

-45-

v7.2

Sensors probes

6 - You may take advantage of the holes on the mounting bracket and the pipe to secure the cable of the sensor,

avoiding its rotation. You can do that with some cable ties. To minimize azimuth error, the sensor should be

mounted with the cable pointing toward true north in the northern hemisphere or true south in the southern

hemisphere. Azimuth error is typically less than 1%, but it is easy to minimize by proper cable orientation.

7 - Once installed, use the long gray screws of the plate for ne adjustment of the level, making sure the bubble is

inside the black circle. The wave spring will keep the leveling plate in place.

Note: the sensor should be mounted so that obstructions (pipe/mast, sensors, enclosures, leaves, walls, etc) do

not shade the sensor.

You can nd the complete sensor manual on the manufacturer’s website.

4.5.5. Application examples

• Incoming shortwave radiation measurement in agricultural, ecological, and hydrological weather networks

• Optimization of photo-voltaic systems

4.5.6. Certicate of calibration

Together with this sensor we provide a calibration certicate in which the manufacturer ensures that the sensor

has passed a calibration procedure with traceability to an accredited laboratory.

Page 46

-46-

v7.2

Sensors probes

4.6. Solar radiation sensor probe for Smart Agriculture

Xtreme (Apogee SQ-110)

Photosynthetically active radiation (PAR) is the radiation that drives photosynthesis and is typically dened as

total radiation across a range from 400 to 700 nm. PAR is often expressed as photosynthetic photon ux density

(PPFD): photon ux in units of micromoles per square meter per second (μmol·m-2s-1).

Figure: Solar radiation sensor probe for Smart Agriculture Xtreme (Apogee SQ-110)

Figure: Graph of the spectral response of the PAR sensor (Apogee SQ-110) compared to the photosynthetic response of a plant

Page 47

-47-

v7.2

Sensors probes

4.6.1. Specications

• Operation temperature: -40 ~ 70 ºC

• Operation humidity: 0 ~ 100% RH

• Sensitivity: 0.2 mV / μmol·m-2s

-1

• Calibration factor (Reciprocal of sensitivity): 5 μmol·m-2s-1 / mV

• Non-linearity: < 1% (up to 4000 μmol·m-2s-1 / mV)

• Non-stability (long-term drift): <2% per year

• Spectral range: 410 ~ 655 nm

• Repeatability: <0.5%

• Diameter: 2.4 cm

• Height: 2.8 cm

• Cable length: 5 m

4.6.2. Measurement process

The SQ-110 sensor provides an analog signal.

Reading code:

{

// 1. Declare an object for the sensor

Apogee_SQ110 mySensor(XTR_SOCKET_B);

// 2. Turn ON the sensor

mySensor.ON();

// 3. Read the sensor. Values stored in class variables

// Check complete code example for details

mySensor.read();

// 4. Turn off the sensor

mySensor.OFF();

}

You can nd a complete example code for reading this sensor probe in the following link: http://www.libelium.com/

development/waspmote/examples/ag-xtr-05-SQ-110-sensor-reading

Page 48

-48-

v7.2

Sensors probes

4.6.3. Socket

Connect the SQ-110 sensor probe to Plug & Sense! Smart Agriculture Xtreme in any of the sockets shown in the

image below.

Note: This sensor has a specic wiring for the Plug & Sense! Smart Agriculture Xtreme model, so it is not compatible

with other Plug & Sense! models and vice versa. Refer to our Sales department for more information.

Figure: Available sockets for the SQ-110 sensor probe

4.6.4. Installation

The SQ-110 sensor includes a nylon mounting screw on the base in order to mount the sensor on a solid surface.

Figure: SQ-110 sensor installation

The Solar sensors mounting accessory can also be used for the installation. This accessory is optional but highly

recommended for the solar sensors. With this accessory you will get a secure fastening while keeping the sensor

as level as possible, always pointing up.

Page 49

-49-

v7.2

Sensors probes

The accessory is composed of 2 main parts:

A - Mounting bracket: it will be fastened to a pipe or mast with its u-bolt

B - Leveling plate: it holds the sensor and includes a bubble level

Figure: Solar sensors mounting accessory

Mounting the system is very easy, just follow these steps:

1 - Attach the solar sensor to the leveling plate, in its central hole. Use the black nylon screw (every sensor comes

with one, nd it on its bottom) and a screwdriver.

2 - Fasten the leveling plate to the mounting bracket with the 3 long gray screws. Do not insert them too rmly,

the nal adjustment is done later.

3 - Decide if you want to mount the whole structure to a vertical or horizontal pipe or mast (its outer diameter can

go from 3.3 to 5.3 cm). Depending on horizontal or vertical conguration, you will use the bottom or the side of

the mounting bracket.

4 - Place the black plastic piece in contact with the pipe. Then use the u-bolt to grab the mounting bracket to the

pipe. On both ends of the u-bolt, insert rst the washers, then the lock washers and nally the nuts.

5 - Place the structure in the desired position and tighten the nuts rmly with a wrench.

Figure: Final look of the whole structure

Page 50

-50-

v7.2

Sensors probes

6 - You may take advantage of the holes on the mounting bracket and the pipe to secure the cable of the sensor,

avoiding its rotation. You can do that with some cable ties. To minimize azimuth error, the sensor should be

mounted with the cable pointing toward true north in the northern hemisphere or true south in the southern

hemisphere. Azimuth error is typically less than 1%, but it is easy to minimize by proper cable orientation.

7 - Once installed, use the long gray screws of the plate for ne adjustment of the level, making sure the bubble is

inside the black circle. The wave spring will keep the leveling plate in place.

Note: the sensor should be mounted so that obstructions (pipe/mast, sensors, enclosures, leaves, walls, etc) do

not shade the sensor.

You can nd the complete sensor manual on the manufacturer’s website.

4.6.5. Application examples

Photosynthetic photon ux density (PPFD) measures in:

• Plant canopies in outdoor environments

• Greenhouses and growth chambers

• Evapotranspiration analysis

• Aquatic environments, including salt water aquariums where corals are grown

4.6.6. Certicate of calibration

Together with this sensor we provide a calibration certicate in which the manufacturer ensures that the sensor

has passed a calibration procedure with traceability to an accredited laboratory.

Page 51

-51-

v7.2

Sensors probes

4.7. Ultraviolet radiation sensor probe for Smart Agriculture Xtreme (Apogee SU-100)

Ultraviolet (UV) radiation is typically dened as total radiation across a range from 100 to 400 nm and is subdivided

into 3 wavelength ranges: UV-A (315 to 400 nm), UV-B (280 to 315 nm) and UV-C (100 to 280 nm). Much of the UV-B

and all of the UV-C wavelengths from the sun are absorbed by the Earth’s atmosphere.

The Ultraviolet radiation sensor probe for Smart Agriculture Xtreme (Apogee SU-100) detects UV radiation from

250 to 400 nm and is calibrated in photon ux units of micromoles per square meter per second (μmol·m-2s-1). .

Figure: Ultraviolet radiation sensor probe for Smart Agriculture Xtreme (Apogee SU-100)

Figure: Graph of the spectral response of the SU-100 sensor probe compared to the photosynthetic response of a plant

Page 52

-52-

v7.2

Sensors probes

4.7.1. Specications

• Operation temperature: -40 to 70 ºC

• Operation humidity: 0 to 100 %

• Sensitivity: 0.2 mV / μmol·m-2s

-1

• Calibration factor (reciprocal of sensitivity): 5.0 μmol·m-m-2s-1 / mV

• Non-stability (long-term drift): <3% per year

• Non-linearity: <1% (up to 300 μmol·m-2s-1)

• Spectral range: 250 ~ 400 nm

• Repeatability: <1%

• Diameter: 2.4 cm

• Height: 2.8 cm

• Cable length: 5 m

4.7.2. Measurement process

The SU-100 sensor provides an analog signal.

Reading code:

{

// 1. Declare an object for the sensor

Apogee_SU100 mySensor(XTR_SOCKET_B);

// 2. Turn ON the sensor

mySensor.ON();

// 3. Read the sensor. Values stored in class variables

// Check complete code example for details

mySensor.read();

// 4. Turn off the sensor

mySensor.OFF();

}

You can nd a complete example code for reading this sensor probe in the following link: http://www.libelium.com/

development/waspmote/examples/ag-xtr-04-SU100-sensor-reading

Page 53

-53-

v7.2

Sensors probes

4.7.3. Socket

Connect the SU-100 sensor probe to Plug & Sense! Smart Agriculture Xtreme in any of the sockets shown in the

image below.

Note: This sensor has a specic wiring for the Plug & Sense! Smart Agriculture Xtreme model, so it is not compatible

with other Plug & Sense! models and vice versa. Refer to our Sales department for more information.

Figure: Available sockets for the SU-100 sensor probe

4.7.4. Installation

The SU-100 sensor includes a nylon mounting screw on the base in order to mount the sensor on a solid surface.

Figure: SU-100 sensor probe installation

The Solar sensors mounting accessory can also be used for the installation. This accessory is optional but highly

recommended for the solar sensors. With this accessory you will get a secure fastening while keeping the sensor

as level as possible, always pointing up.

The accessory is composed of 2 main parts:

A - Mounting bracket: it will be fastened to a pipe or mast with its u-bolt.

B - Leveling plate: it holds the sensor and includes a bubble level.

Page 54

-54-

v7.2

Sensors probes

Figure: Solar sensors mounting accessory