Page 1

Global LCD Panel Exchange Center

Module

www.panelook.com

MODEL : LP141WP1 - TLA1

CAUTION

BEFORE SERVICING THE MODULE, READ THE SAFETY PRECAUTIONS

IN THIS MANUAL.

[ Lead Free ]

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

LCD Module is a display device to be divided into Board Ass’y and Backlight Ass’y. Board Ass’y consists of electric circuitry,

PCB and two sheets of glass. Polarizer films are attached on each surface. The space between two sheets of glass are filled

with Liquid Crystal. And the Backlight Ass’y includes Lamp Ass’y, optical sheets(Diffuser, Prism), LGP(Light Guide Panel),

supporter main.

When using / handing this LCD Module, pay attention to the below warning and cautions.

www.panelook.com

SAFETY PRECAUTIONS

Warning?

Warning statements identify conditions or

practices that could result in injury or loss of life

if the warning is ignored and the product is

handled incorrectly.

Caution?

Caution statements identify conditions or

practices that could result in damage to this

product or other property if the caution is

ignored and the product is handled

incorrectly.

WARNING

(1) Do not supply a voltage higher than that specified to this

product. This may damage the product and may cause a

fire.

(3) Do not install or use the product in a location that dose not

satisfy the specified environmental conditions. This may

damage the product and may cause a fire.

(4) If a foreign substance (such as water, metal, or liquid)gets

inside the product, immediately turn off the power.

Continuing to use the product and cause fire or electric

shock.

(5) If the product emits smoke or abnormal noise, immediately

turn off the power. Continuing to use the product cause fire

or electric shock.

(6) Do not disconnect or connect the connector while the

power is on.

(7) Do not pull out or insert the power cable from/to an outlet

with wet hands. It may cause electric shock.

(8) If the power cable is damaged or the connector is loose, do

not use the product : otherwise this can lead to fire or

electric shock.

(9) Backlight Inverter uses a high voltage for Lamp. Do not

touch circuit substrate and caution on electric shock when

handling the LCD Module Backlight Inverter unit.

(2) Do not use this product in locations where the humidity is

extremely high, where it may be splashed with water, or

where flammable materials surround it.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

English

Korean

CAUTION

(1) Do not place this product in a location that is subject to

heavy vibration, or an unstable surface such as an inclined

surface. The product may fall off or fall over, causing

injuries.

(2) Before disconnecting cable from the product, be sure to

turn off the power. Be sure to hold the connector when

disconnecting cables. Pulling a cable with excessive force

may cause the core of the cable to be exposed or break

the cable, and this can lead to fire or electric shock.

(3) This product contains glass. If shock, vibration, heat or

distortion is applied to the product, the glass may be broken.

(4) If glass surface of the display breaks or is scratched, do

not touched the broken pieces or the scratched with bare

hands. You may be injured.

(5) LCD Module requires to be handled with special care. LCD

Module is not to be touched with metal or hard materials.

Must not be stressed by heat or mechanical impact.

(6) There are some particular components on the rear panel of

this product. Skin contact with these components may

cause an electric shock. So, handle with care.

(7) While moving the product, be sure to turn off the power,

disconnect all cables and watch your step. Dropping the

product may cause injuries from electric shock. So, while

moving the product handle with care.

(8) When cleaning the panel is necessary, wipe it with a soft

and moistened cloth a neural detergent. Caution on

connector area. Do not use chemicals such as thinner or

benzene.

(9) LCD Module emits heat from the Lamp, Backlight lamp,

component parts. Therefore, the environmental

temperature must not exceed 50

Inverter system is driven by high voltage, so it must avoid

conductive materials.

(10) If repairing components with a lead line, high voltage or

high temperature components must be put out from a

lead line and fix.

(11) Do not place an object on the surface of the display. The

glass may break or be scratched.

(12) This product may be damaged if it is subject to excessive

stresses (such as excessive voltage, current, or

temperature). The absolute maximum ratings specify the

limits of these stresses.

(13) Do not cover or wrap with any covering materials while

power is applied to the product.

(14) This product is made from various material such as glass,

metal, and plastic. When discarding it, be sure to contact

a purchase place.

(15) If a discrepancy occurs due to any arbitrary modification

or disassembly, LG.Philips LCD is not responsible for

function, quality or other items.

(16) Within the warranty period, general faults may be charged

for depending on responsibility for the faults. You handle

with care.

. LCD Module Backlight

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

SERVICING PRECAUTIONS

Color TFT LCD Module is apt to be damaged by both electrical and mechanical stresses.

Users, therefore, are requested to follow the “Servicing precautions of color TFT LCD Module” on the followings.

www.panelook.com

System Assembler

(1) Follow power sequence.

Abnormal power sequence may cause critical malfunction

or electrical damage.

(2) Prevent physical stress.

(3) Prevent overheat.

High temperature on the surface of the screen may cause

poor quality. Please make LCD Module used on specified

temperature.

Low temperature under 10 makes LCD Module respond

slowly, make Backlight worse operated and shorten very

much the lifetime accordingly.

(4) Keep LCD Module dust-free.

LCD Module is sensitive against dust.

Dust can cause visual or functional problem.

(5) Do not touch TCP area.

Do not touch TCP area at any case. It causes Driver IC

crack, film crack etc. TCP is the weakest point of LCD

Module.

(6) Do not pull Backlight wire.

Please do not pull the Backlight wire it can cause the wire

disconnected or damaged.

(7)Check a connection of the Inverter & Backlight

connectors.

Incomplete connection with can cause burnt in Backlight

connector or damage the inverter.

(8) Handle with care.

Please do not drop, bend or hit the LCD Module. Physical

stress can cause the defect such as broken.

(9) Keep mounting screw length and motor driver’s torque.

Strong weaken motor driver’s torque can make a

mechanical defect on LCD Module. Please keep the

specification.

(10) Do not operate for a long time under the same pattern.

Operating LCD Module for a long time under the same

pattern can cause image persistence and can damage it.

(11) Defect panel also handled with care.

To prevent making another defect, please handle the

defective LCD Module as a good one.

Defective LCD Module should be repaired.

(12) Do not stack LCD Modules.

LCD Module consists of fragile components such as TCPs

or Glasses.

Stacking LCD Module can cause undesired defects.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

English

Korean

(13) Do not provide strong pressure at connecting.

Strong pressure can transfer the force to TCP which is the

weakest parts of LCD Module. Eventually can make TCP

crack or other unexpected defect.

(14) Let the Backlight Wire backside of LCD Module.

If let the Backlight wire front side of LCD Module, the

Backlight connector can hurt the surface of polarizer.

System Assembler/End User

(1) Keep clean the surface.

Please wear rubber glove when touch the surface of LCD

Module screen.

Please use soft and anti-static material with n-Hexane as

cleaner.

(2) Be careful not to make polarizer scratch.

Surface of polarizer is soft, so it’s easily scratched.

Please do not touch, press or rub on polarizer surface with

materials over HB hardness.

(3) Be careful swift Temperature & Humidity change.

Swift temperature and or humidity change can make dew

condensation or ice which cause nonconformance such as

malfunction.

(15) Never connect/disconnect at power on.

LCD Module consists of CMOS which is known as weak

component against EOS. It can hurt the product.

(16) Electro-static discharge can make damage.

Semi-assembled product should be handled with wrist strap.

Earth human body when handle the LCD Module.

Please do not touch the interface connector pin.

(4) Keep out of water.

Water on in the LCD Module can cause electrical short or

corrosion.

Please wipe out or dry water carefully.

(5) Keep LCD Module corrosive gases free.

Corrosive gas makes the polarizer and the circuitry parts

chemical damages and eventually cause defects.

(6) Keep the suitable temp. & suitable humidity.

High temp. & high humidity shorten the lifetime.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

CONTENTS

1. Product Overview

2. Module Formation

3. Exploded View

4. Exploded View Parts List

5. Block Diagram

6. Trouble shooting

7. Timing Check Sheet

8. Disassembly

9. Assembly

10. Parts List

11. Records of Revision

12. Derivative description

Annexing : Schematic Diagram / Printed Circuit Board

*

.......................................................

.......................................................

............................................

...........................................

..............................................

..............................

...............................................

............................................

.......................................

..................................................

.......................................

....................................

7

8

10

11

12

13

18

19

23

29

32

33

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

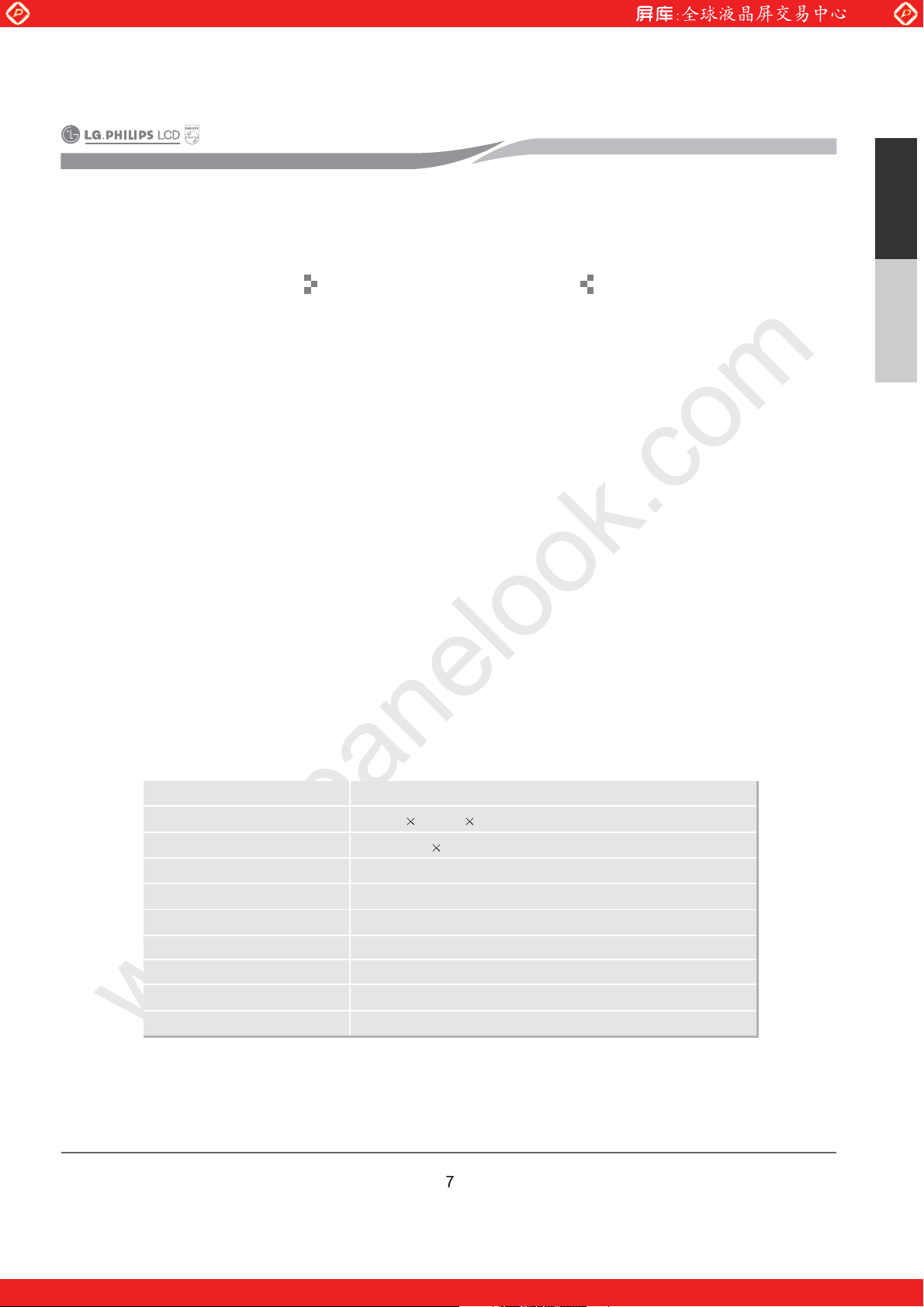

General Description

TFT-LCD is made up of the lower plate glass with TFT, the upper plate glass with color filter, the middle

Liquid Crystal. TFT convey and control the signal and the Liquid Crystal control transmitted ray as

molecular structure different by admitted volt. And as the ray pass color filter, show up the wanted color

and picture.

The LP141WP1-TLA1 is 14.1 inches diagonally measured active display area with WXGA+ resolution(900

vertical by 1440 horizontal pixel array). Each pixel is divided into Red, Green and Blue sub-pixels or dots

which are arranged in vertical stripes. Gray scale or the brightness of the sub-pixel color is determined with

a 6-bit gray scale signal for each dot, thus, presenting a palette of more than 262,144 colors.

The LP141WP1-TLA1 has been designed to apply the interface method that enables low power, high speed,

low EMI.

The LP141WP1-TLA1 is intended to support applications where thin thickness, low power are critical

factors and graphic display are important. In combination with the vertical arrangement of the sub-pixels,

the LP141WP1-TLA1 characteristics provide an excellent flat display for office automation products such

as Notebook PC.

www.panelook.com

English

1. Product Overview

Korean

Active Screen Size

Outline Dimension

Pixel Pitch

Pixel Format

Color Depth

Luminance, White

Power Consumption

Weight

Display Operating Mode

Surface Treatment

General Features

14.1 inches diagonal

320(H)

0.2109 mm

1440 horiz. By 900 vert. Pixels RGB strip arrangement

6-bit, 262,144 colors

220 cd/m

Total 6.0 Watt(Typ.)

435g (Max.), 425g(Typ.)

Transmissive mode, normally white

Anti-glare treatment of the front polarizer

206(V) 5.5(D, max)mm

0.2109 mm

2

(Typ. 5point)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

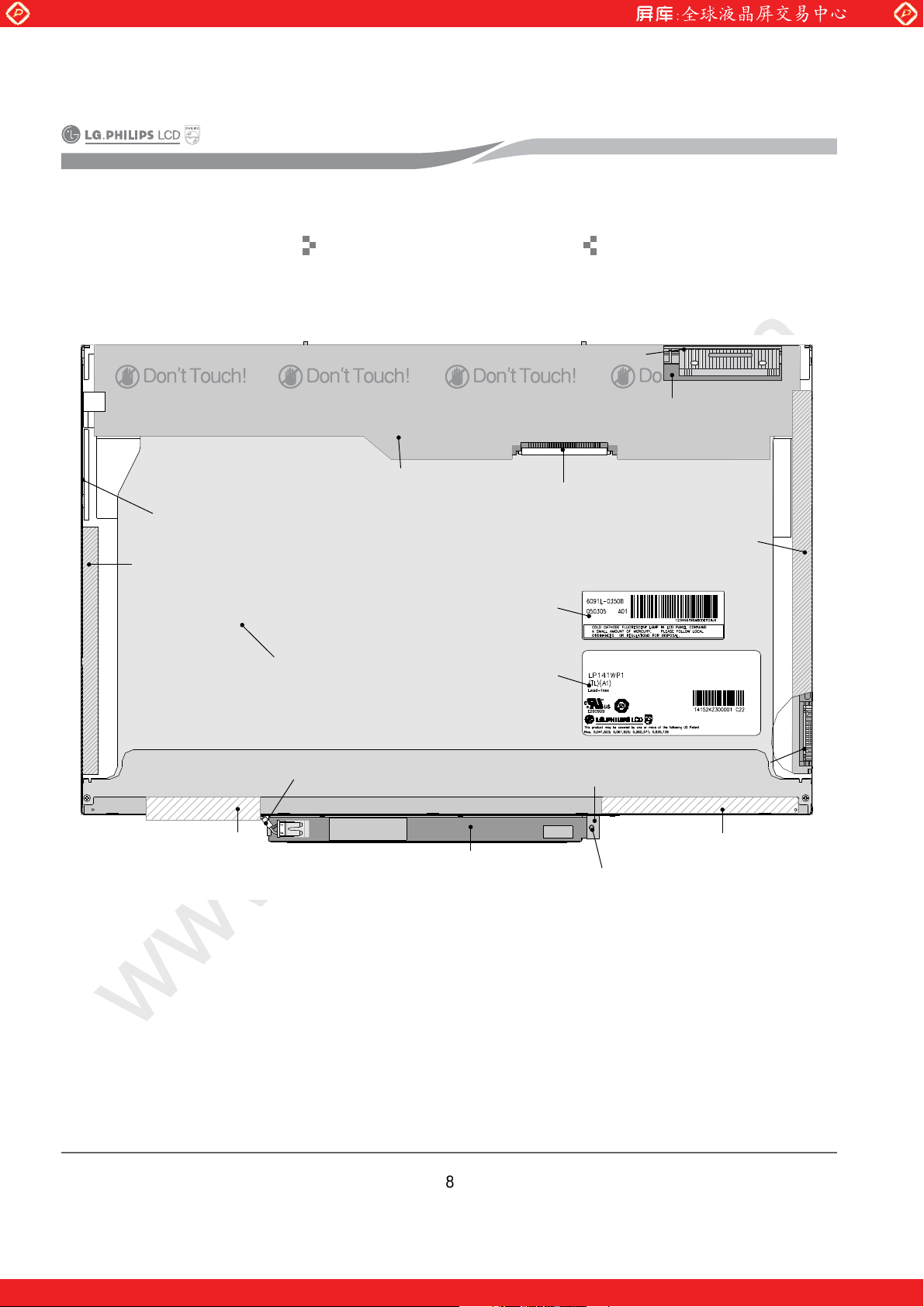

* Connector 1(CN1) : User Connector

www.panelook.com

2. Module Formation

Source COF(D-IC)

Source PCB

Case Ass’y

Adhesive Tape

Backlight Wire

Fixed Tape

Backlight Ass’y

Backlight Wire

Cover Shield(Source)

Backlight Label

Inverter

* Connector 1(CN1)

ID Label

Inverter Bracket

Inverter Fixed Screw

Cover Shield(Gate)

Gate COF(COF)

Adhesive Tape

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

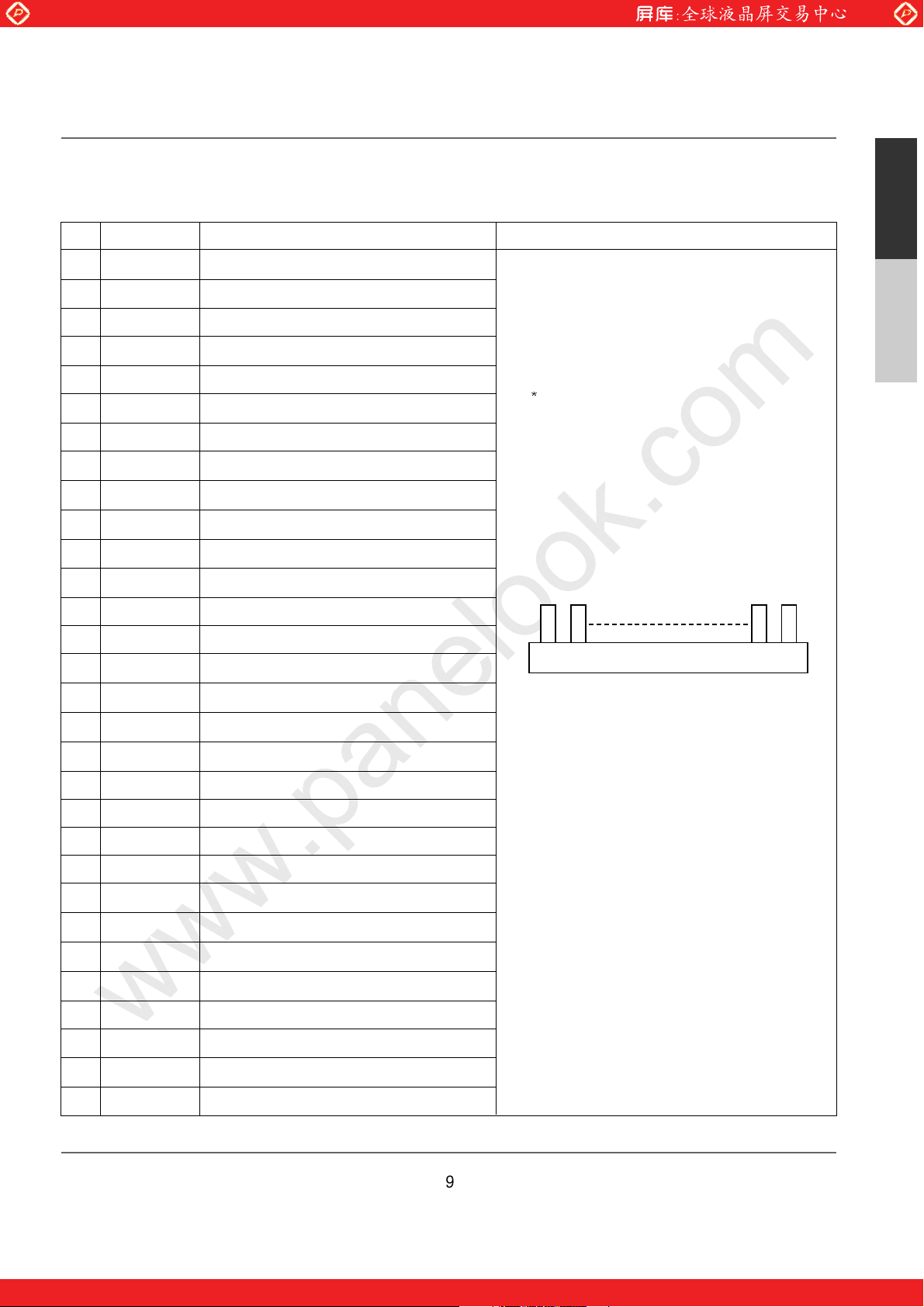

Module Connector Pin configuration(CN1)

www.panelook.com

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Symbol

GND

VCC

VCC

V EEDID

BIST

Clk EEDID

DATA EEDID

RA1-

RA1+

GND

RB1-

RB1+

GND

RC1-

RC1+

Description

Ground

Power Supply, 3.3V Typ.

Power Supply, 3.3V Typ.

DDC 3.3V power

Reserved for LCD supplier test point

DDC Clock

DDC Data

Negative LVDS differential data input,R0-G5,G0

Positive LVDS differential data input,R0-G5,G0

Ground

Negative LVDS differential data input,G1-G5,B0-B1

Positive LVDS differential data input,G1-G5,B0-B1

Ground

Negative LVDS differential data input,B2-B5,HS/VS/DE

Positive LVDS differential data input,B2-B5,HS/VS/DE

Notes

1. Interface chips

1.1 LCD : DAWIN,DTML012(LCD Controller)

including LVDS Receiver

(DAWIN co., LVD4107 x 2each)

1.2 System : It must include international standard

LVDS Trasmitter.

Pin to Pin compatible with LVDS

2. Connector

2.1 LCD : GT101-30S-HR11,LGC or its compatibles.

2.2 Mating : FI-X30M or equivalent.

2.3 Connector Pin arrangement

[LCD Module Rear View]

30 1

English

Korean

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

GND

RCLK1-

RCLK1+

GND

RA2-

RA2+

GND

RB2-

RB2+

GND

RC2-

RC2+

GND

RCLK2-

RCLK2+

Ground

Negative LVDS differential clock input

Positive LVDS differential clock input

Ground

Negative LVDS differential data input,R0-G5,G0

Positive LVDS differential data input,R0-G5,G0

Ground

Negative LVDS differential data input,G1-G5,B0-B1

Positive LVDS differential data input,G1-G5,B0-B1

Ground

Negative LVDS differential data input,B2-B5,HS/VS/DE

Positive LVDS differential data input,B2-B5,HS/VS/DE

Ground

Negative LVDS differential clock input

Positive LVDS differential clock input

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

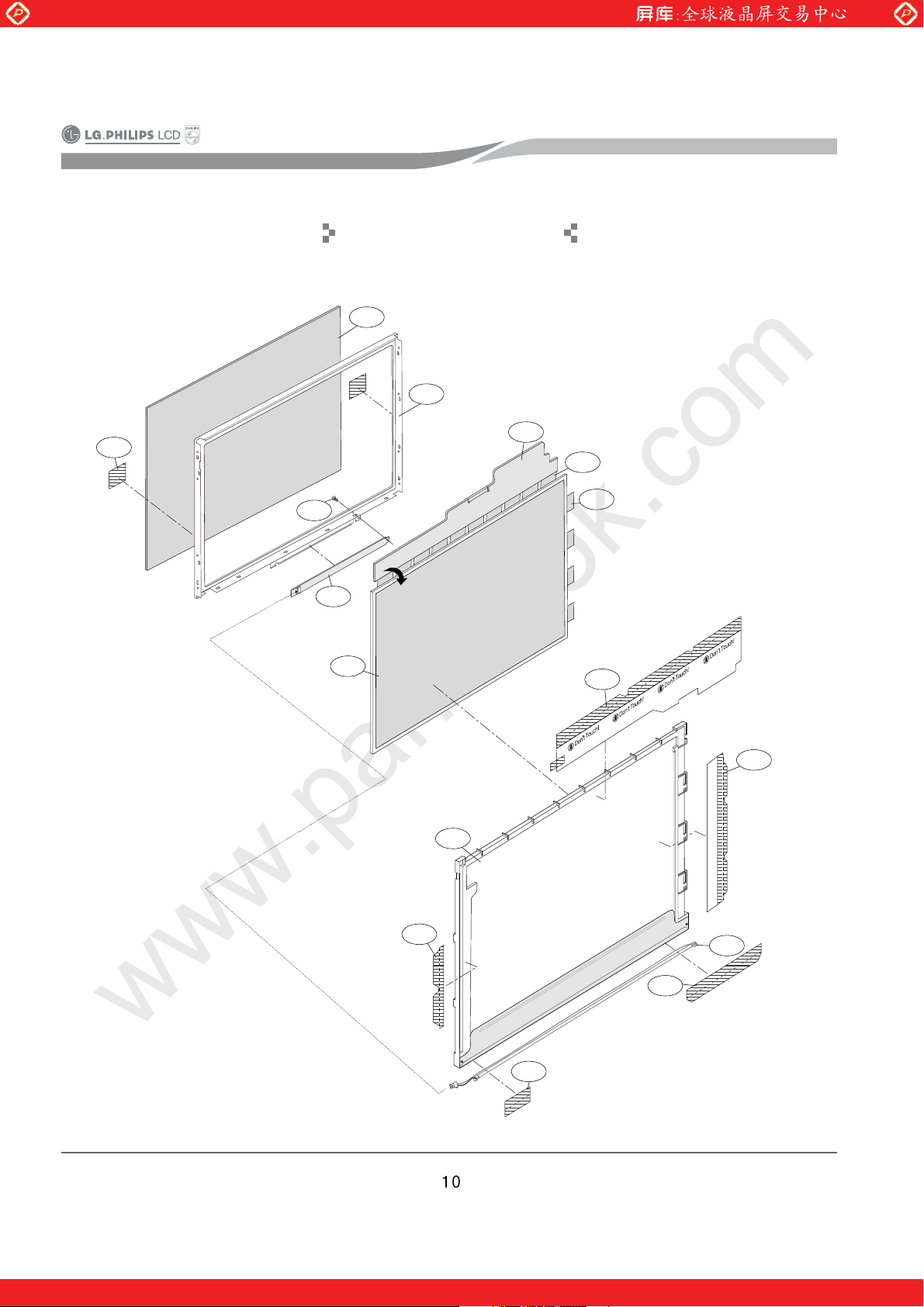

03

01

07

05

08

09

06

04

10

15

16

02

12

13

11

14

www.panelook.com

3. Exploded View

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

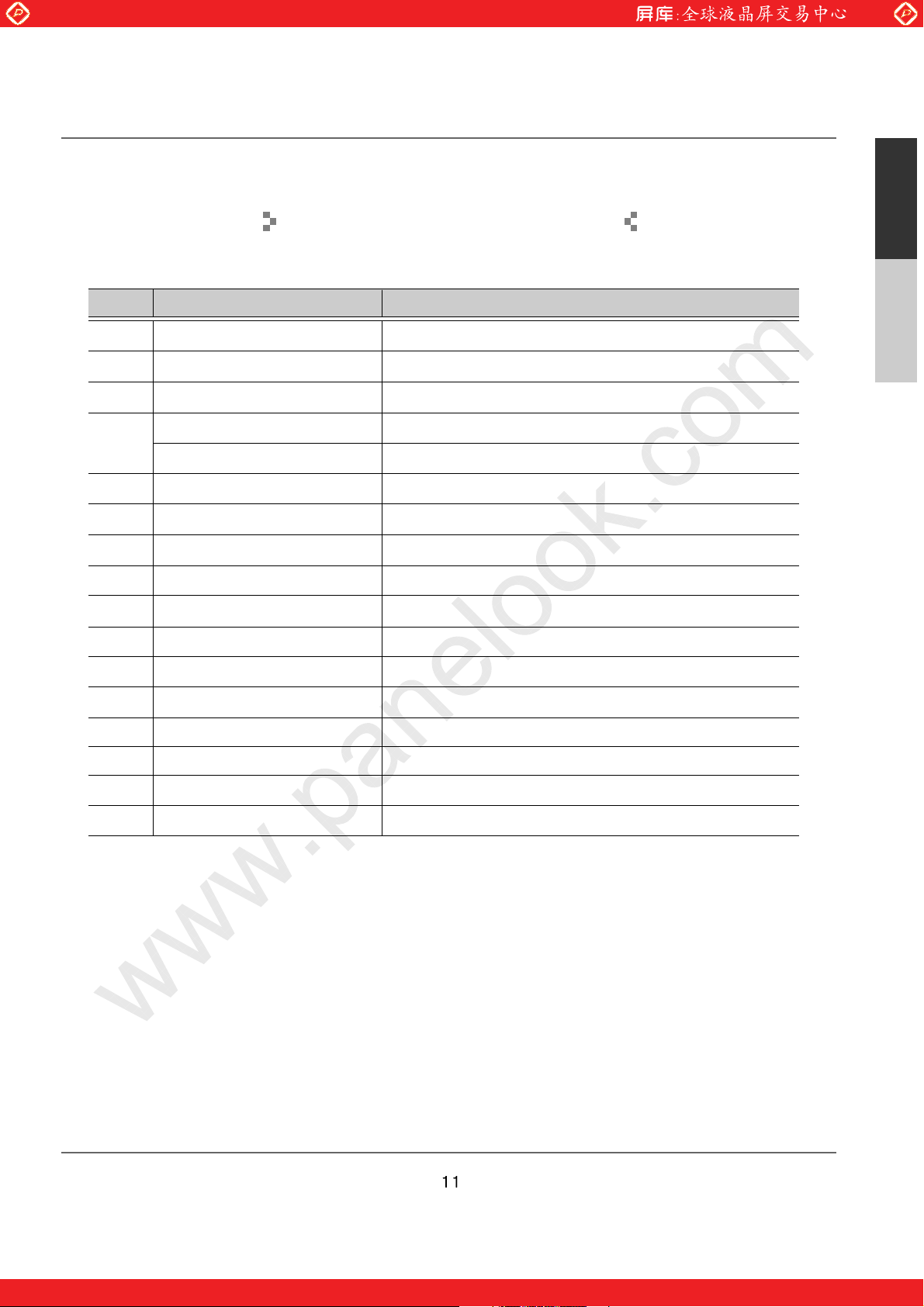

www.panelook.com

4. Exploded View Parts List

No.

1 5135L-0011V Protect Film

2 7250L-0023A Masking, Tape

3 3111L-0149A Case Ass’y

4

5 6091L-0350A BACKLIGHT Ass’y

6 6913L-0260C Lamp Ass’y

7 7250L-0080D Tape, Adhesive

8 7250L-0077A Tape, Teraoka

9 7250L-0074C Tape, Teraoka

10 3550S-0271A Cover shield , Gate

11 3550S-0263A Cover shield , Source

PART NO.

6308L-0039A POLARIZER(TOP)

6308L-00657A POLARIZER(BOTTOM)

English

DESCRIPTION

Korean

12 0IOKL-0039A TCP (D-IC, Gate)

13 0IHYL-0105A TCP (D-IC, Source)

14 6871L-0785A PWB(PCB) Ass’y , Source

15 6632L-0263A INVERTER

16 1STZL-0002B Screw

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

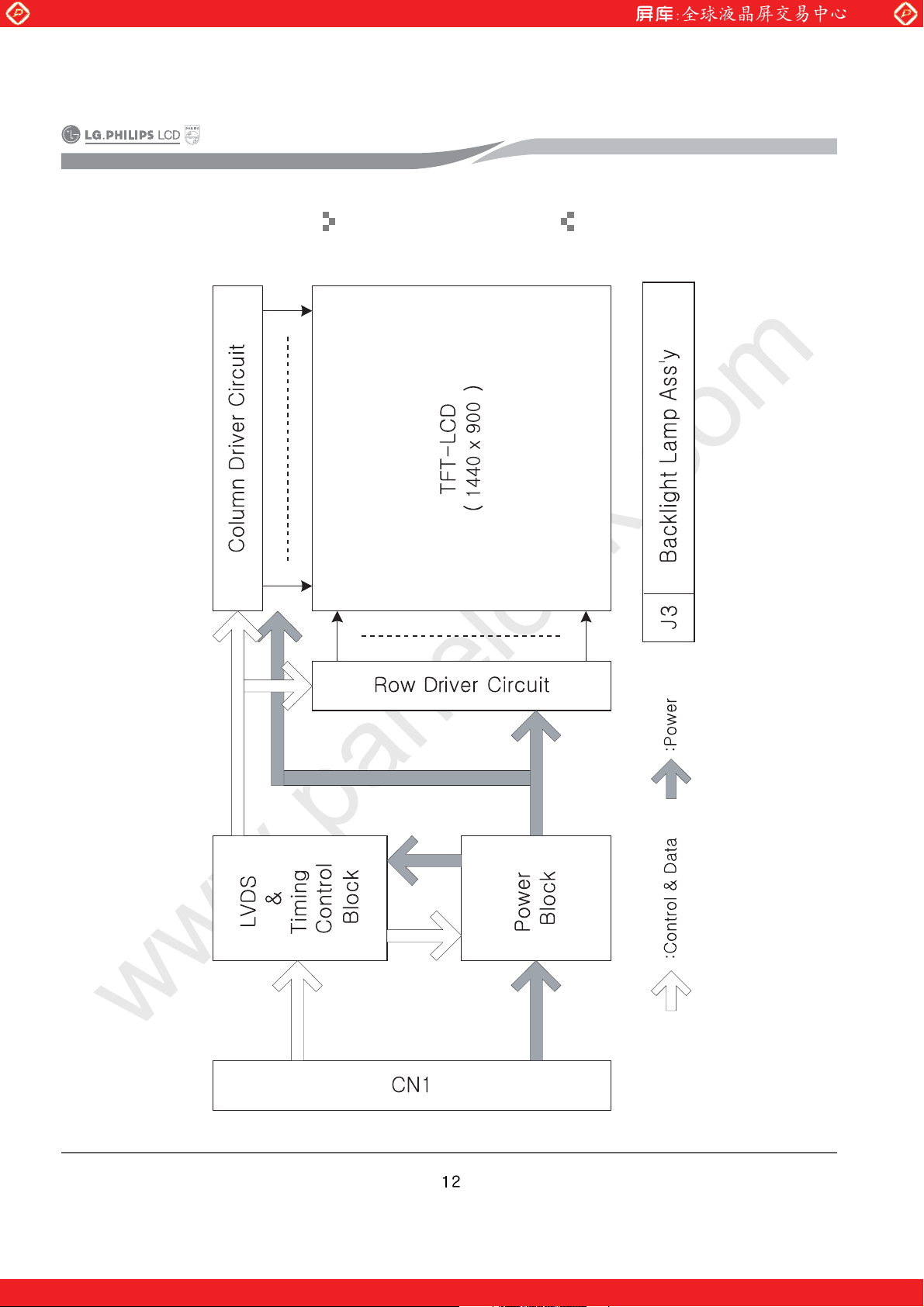

www.panelook.com

5. Block Diagram

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

www.panelook.com

No Display

F1 Pool soldering /

Damage check

NO

F1 Replace /

Resoldering

6. Trouble shooting

Means that the screen is not affected by the signal data when you connect the product to Backlight or

user connector and then 3.3V(Vcc) input power ON/OFF.

less than more than

Electricity Consumption

100mA

Damage

CN1 PIN Damage /

Pool soldering check

YES

L1 Pool soldering /

voltage check

YES

NO

NO

Replace /

Resoldering

Replace /

Resoldering

English

Korean

US1 Pool soldering/Short/

Oneself badness check/

RESET check

YES

Source, Gate input/output check

D/IC oneself badness /

Bonding badness

* Notes : It can use a Power IC(US1), One Chip.

NO

NO

Replace /

Resoldering

Replace

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

www.panelook.com

Abnormal Display

Means that the screen is affected

by the signal data when you

connect the product to Backlight or

user connector and then turn

3.3V(Vcc) input power ON/OFF.

CN1 PIN bend / Pool soldering check

YES

Panel Edge damage check Panel dump

YES

UC1 Input/Output, Voltage, Signal check

Short / Pool soldering /

RESET, RESET2 Voltage check

R17,R18,C11,C12

Around circuit check

VDD,VCC

Around circuit check

VGH Voltage check

D3

Around circuit check

Around circuit check

YES

YES

Voltage check

YES

US1

NO

NO

NO

NO

NO

NO

Replace/Resoldering

Replace/Resoldering

Replace/Resoldering

Replace/Resoldering

Replace/Resoldering

YES

VGL Voltage check

R62, R64

VR1,C41

GMA Voltage check SOURCE DRIVE IC GMA

Internal Short / Open check

Around circuit check

YES

VCOM Voltage check

Around circuit check

YES

Check of lower GMA TP

YES

S - #1, G - #1

Bonding check

YES

Source PCB

NO

NO

NO

NO

NO

Replace/Resoldering

Replace/Resoldering

Replace/Resoldering

Replace

Replace

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

English

Korean

signal and Clock are not divided.

Replace /

Resoldering

NO

Means that the abnormal screen displays at specified color when you connect the product to Backlight

or user connector and then turn 3.3V(Vcc) input power ON/OFF.

YES

CN1 #1~24, AR1,AR2

Pool soldering / Short check

Replace /

Resoldering

NO

#53~64

Short check

UC1 #36~48

Pool soldering /

YES

Replace /

Resoldering

NO

YES

check

R19~R30

Pool soldering / Short Damage

Replace /

Resoldering

NO

YES

Source D/IC

Check input / output

* Notes : Applied with mini LVDS T-con : RGB

Replace /

Resoldering

NO

Source PCB

Internal Short / Open check

Abnormal Color

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

EDID Operation Screen

www.panelook.com

How to use Button

(1) < Write Data > : Write EDID Data(Standard Data at the left> on EEPROM.

(2) < Write Data&Verify > : After confirming EDID Data, mark the OK, NG.

(3) < Read Data > : Read and mark EDID Data to the EEPROM.

(4) < Read Data&Verify > : Altering marking EDID Data by EEPROM, compare with standard data to mark

OK, NG.

(5) < Init > : Initializing board => OK : GREEN, NG : RED

When board displays RED, After click the inspection option <MENU>, check the address.

(6) < Start > : After connecting the Module, confirm connected state => OK : GREEN, NG : RED

When board displays RED contact connector or confirm power(3.3V).

(7) < Close > : End the program.

How to work

(1) Operate the program.

(2) Click the <lnit> button.

(3) Open the wanted model data, If not, program is edited.

(4) After connecting Module, confirm power(3.3V).

(5) Progress the wanted one(Write & Read).

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

EDID Badness

On the test - screen, when comparing,

standard data with Read data, If it is

failed, it is displayed NG on the testscreen.

CN1 PIN bend / Pool soldering

Damage check

YES

R12, 13, C13

Pool soldering / Damage check

YES

U1Pool soldering / Short /

Oneself badness check

YES

EDID Checksum check

(41)

NO

NO

NO

NO

Replace /

Resoldering

English

Replace /

Resoldering

Korean

Replace /

Resoldering

EDID Re-write

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

www.panelook.com

7. Timing Check Sheet

Condition : (VCC = 3.3V)

DATA

_ Setup

SSC

_ High

DATA_S = 2.9ns

DATA

_ Hold

DATA_H = 3.5ns

SSC

_ Low

SSC_H = 6.3ns

SSC_L = 5.9ns

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

www.panelook.com

English

8. Disassembly

Separate Cover

Shield(Gate)

Remove dust on the lower

Polarizer.

Attach dummy sheet on the

lower Polarizer.

Separate Cover

Shield(Source)

Separate Board Ass’y from

Adhesive Tape

Backlight Ass’y.

Take charge of Board

Ass’y in tray.

Separate

Separate

Adhesive/Fixed Tape.

Attach dummy sheet on the

upper Polarizer.

Attach the dummy sheet on

Backlight Ass’y.

Separate Inverter

Fixed Screw.

Remove dust on

the upper Polarizer.

Separate the Cover Shield(Gate).

Should be put on (electro static) wrist strap.

Should be cleared the bottom.

Light the Ion Blower.

Separate the Cover Shield(Source).

Separate

Inverter

Separate

Case Ass’y

Charge the Backlight Ass’y in Bag.

Korean

Separate the Adhesive Tape of the opposite Gate.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

Separate Cover

Shield(Gate)

Remove dust on the lower

Polarizer.

Attach dummy sheet on the

lower Polarizer.

Separate Cover

Shield(Source)

Separate Board Ass’y from

Backlight Ass’y.

Adhesive Tape

Take charge of Board

Ass’y in tray.

Separate

Separate

Adhesive/Fixed Tape.

Attach dummy sheet on the

upper Polarizer.

Attach the dummy sheet on

Backlight Ass’y.

Separate the

Adhesive Tape &

Backlight Wire

fixed Tape

of the opposite Source PCB.

Separate the fixed screw of Inverter.

Separate Inverter

Fixed Screw.

Remove dust on

the upper Polarizer.

Charge the Backlight Ass’y in Bag.

Separate

Inverter

Separate

Case Ass’y

Separate the Inverter.

If you need to replace the Inverter, separate the

Inverter.

It

s unnecessary to repair the normal TCP / Polarizer.

Separate the Case Ass’y.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

www.panelook.com

Separate Cover

Shield(Gate)

Remove dust on the lower

Polarizer.

Attach dummy sheet on the

lower Polarizer.

Separate Cover

Shield(Source)

Separate Board Ass’y from

Adhesive Tape

Backlight Ass’y.

Take charge of Board

Ass’y in tray.

Separate

Separate

Adhesive/Fixed Tape.

Attach dummy sheet on the

upper Polarizer.

Attach the dummy sheet on

Backlight Ass’y.

Separate Inverter

Fixed Screw.

Remove dust on

the upper Polarizer.

Charge the Backlight Ass’y in Bag.

Remove dust on the upper Polarizer.

Attach the dummy sheet on the upper Polarizer.

Separate

Inverter

Separate

Case Ass’y

English

Korean

Separate the Board Ass’y from Backlight Ass’y.

Remove dust on the lower Polarizer.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

Separate Cover

Shield(Gate)

Remove dust on the lower

Polarizer.

Attach dummy sheet on the

lower Polarizer.

Separate Cover

Shield(Source)

Separate Board Ass’y from

Adhesive Tape

Backlight Ass’y.

Take charge of Board

Ass’y in tray.

Separate

Separate

Adhesive/Fixed Tape.

Attach dummy sheet on the

upper Polarizer.

Attach the dummy sheet on

Backlight Ass’y.

Separate Inverter

Fixed Screw.

Remove dust on

the upper Polarizer.

Charge the Backlight Ass’y in Bag.

Attach the dummy sheet on the lower Polarizer.

Take charge of the Board Ass’y in tray.

Separate

Inverter

Separate

Case Ass’y

Attach the dummy sheet on Backlight Ass’y.

Take charge of the Backlight Ass’y in Bag.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

English

Detach the protection

film on the lower Polarizer.

Attach

Inverter

Assemble the fixed screw

of Inverter.

Wrap module

Attach dummy sheet on

the upper Polarizer.

Final

inspection

Clean the lower

Polarizer.

Attach a

Adhesive fixed Tape.

Attach the protection film on

9. Assembly

Remove dust the

lower Polarizer.

Assemble the

Case Ass’y.

the upper Polarizer.

Detach the dummy

sheet on Backlight Ass’y.

First screen

inspection

Attach a Cover

Shield(Source)

Detach the protection film

on the upper Polarizer.

Clean the upper

Polarizer.

Attach a Cover

Shield(Gate)

Separate dummy sheet on the

Detach the protection film on the lower Polarizer.

Assemble Board Ass’y

with Backlight Ass’y.

Attach Source PCB/

Gate COF

Attach

Adhesive Tape

upper Polarizer.

Korean

Detach it to opposite direction for preventing

static electricity.

Should be put on (electro static) wrist strap.

Should be cleared the bottom.

Light the Ion Blower.

Polish the lower Polarizer with soft wiper.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

www.panelook.com

Detach the protection

film on the lower Polarizer.

Attach

Inverter

Assemble the fixed screw

of Inverter.

Wrap module

Attach dummy sheet on

the upper Polarizer.

Final

inspection

Clean the lower

Polarizer.

Attach a

Adhesive fixed Tape.

Attach the protection film on

Assemble the

Case Ass’y.

the upper Polarizer.

Remove dust the

lower Polarizer.

First screen

inspection

Attach a Cover

Shield(Source)

Detach the dummy

sheet on Backlight Ass’y.

Detach the protection film

on the upper Polarizer.

Attach a Cover

Shield(Gate)

Clean the upper

Polarizer.

Remove dust of lower Polarizer with a Air Gun.

Assemble Board Ass’y

with Backlight Ass’y.

Attach Source PCB/

Gate COF

Attach

Adhesive Tape

Separate dummy sheet on the

upper Polarizer.

Detach the dummy sheet on Backlight Ass’y.

Assemble the Board Ass’y with Backlight Ass’y.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

www.panelook.com

Detach the protection

film on the lower Polarizer.

Attach

Inverter

Assemble the fixed screw

of Inverter.

Wrap module

Attach dummy sheet on

the upper Polarizer.

Final

inspection

Clean the lower

Polarizer.

Attach a

Adhesive fixed Tape.

Attach the protection film on

Assemble the

Case Ass’y.

the upper Polarizer.

Remove dust the

lower Polarizer.

First screen

inspection

Attach a Cover

Shield(Source)

Detach the dummy

sheet on Backlight Ass’y.

Detach the protection film

on the upper Polarizer.

Attach a Cover

Shield(Gate)

Clean the upper

Polarizer.

Attach and fold up Source PCB / Gate COF into

Backlight Ass’y bottom.

Be careful TCP(Tape Carrier Package),

COF(Chip On Film)crack.

Detach the protection film on the upper Polarizer.

Assemble Board Ass’y

with Backlight Ass’y.

Attach Source PCB/

Gate COF

Attach

Adhesive Tape

Separate dummy sheet on the

upper Polarizer.

English

Korean

Take a first screen inspection the Backlight.

Check the Backlight dust.

Assemble the Case Ass’y.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

Detach the protection

film on the lower Polarizer.

Attach

Inverter

Assemble the fixed screw

of Inverter.

Wrap module

Attach dummy sheet on

the upper Polarizer.

Final

inspection

Clean the lower

Polarizer.

Attach a

Adhesive fixed Tape.

Attach the protection film on

Assemble the

Case Ass’y.

the upper Polarizer.

Remove dust the

lower Polarizer.

First screen

inspection

Attach a Cover

Shield(Source)

Detach the dummy

sheet on Backlight Ass’y.

Detach the protection film

on the upper Polarizer.

Attach a Cover

Shield(Gate)

Clean the upper

Polarizer.

Attach the dummy sheet on the upper Polarizer.

Attach the Inverter.

Assemble Board Ass’y

with Backlight Ass’y.

Attach Source PCB/

Gate COF

Attach

Adhesive Tape

Separate dummy sheet on the

upper Polarizer.

If you need to replace the Inverter, separate the

Inverter. It’s unnecessary to repair the normal TCP /

Polarizer.

Assemble the fixed screw of Inverter.

Attach the

Adhesive Tape &

Backlight Wire

fixed Tape

of the opposite Source PCB.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

Detach the protection

film on the lower Polarizer.

Attach

Inverter

Assemble the fixed screw

of Inverter.

Wrap module

Attach dummy sheet on

the upper Polarizer.

Final

inspection

Clean the lower

Polarizer.

Attach a

Adhesive fixed Tape.

Attach the protection film on

Assemble the

Case Ass’y.

the upper Polarizer.

Remove dust the

lower Polarizer.

First screen

inspection

Attach a Cover

Shield(Source)

sheet on Backlight Ass’y.

Clean the upper

Polarizer.

Attach the Cover Shield(Source).

Attach the Cover Shield(Gate).

Detach the dummy

Detach the protection film

on the upper Polarizer.

Attach a Cover

Shield(Gate)

Assemble Board Ass’y

with Backlight Ass’y.

Attach Source PCB/

Gate COF

Attach

Adhesive Tape

Separate dummy sheet on the

upper Polarizer.

English

Korean

Attach the Adhesive Tape of the opposite Gate.

Separate the dummy sheet on the upper Polarizer.

Detach it to opposite direction for preventing

static electricity.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

Detach the protection

film on the lower Polarizer.

Attach

Inverter

Assemble the fixed screw

of Inverter.

Wrap module

Attach dummy sheet on

the upper Polarizer.

Final

inspection

Clean the lower

Polarizer.

Attach a

Adhesive fixed Tape.

Attach the protection film on

Assemble the

Case Ass’y.

the upper Polarizer.

Remove dust the

lower Polarizer.

First screen

inspection

Attach a Cover

Shield(Source)

Detach the dummy

sheet on Backlight Ass’y.

Detach the protection film

on the upper Polarizer.

Attach a Cover

Shield(Gate)

Clean the upper

Polarizer.

Polish the upper Polarizer with soft wiper.

Attach the protection film on the upper Polarizer.

Assemble Board Ass’y

with Backlight Ass’y.

Attach Source PCB/

Gate COF

Attach

Adhesive Tape

Separate dummy sheet on the

upper Polarizer.

Take a final inspection.

Wrap the module up in Shielding Bag.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

10. Parts List

* Specified parts list is subject to change.

PART No. DESCRIPTION SPECIFICATION LOCA. No.

6871L-0785A PWB(PCB) ASSY Source, LP141WP1-TLA1-C11, SURFACE MOUNTING

CIRCUIT_CAPACITOR

0CHZL-0018A CAPACITOR, 47N F, 25 Volt, M PER, X7R(JB), 3216 R/TP AC10

0CH2472K562 CAPACITOR,CHIP[CERAMIC 4.7NF 50V K X 1608 R/TP C1

0CH2104K562 CAPACITOR,CHIP[CERAMIC 0.1UF 50V K X7R 1608 R/TP C10,C104,C105,C106,C11,C114,C115,C116,

C12,C13,C14,C15,C16,C26,C35,C45,C5,C7

0CH2A-0023A CAPACITOR, 0.1U F, 25 Volt, K PER, X7R(JB), 1608 R/TP, T=0.9(MAX) C22

0CH2A-0006A CAPACITOR, 4.7U F, 16 Volt, K PER, X5R(JB), 3216 R/TP, T=1.0(MAX) C25,C3,C34,C36,C37,C38,C4,C41,C47,C50

0CH2A-0011A CAPACITOR, 10U F, 16 Volt, K PER, X5R(JB), 3216 R/TP, T=0.95(MAX) C27

0CH2A-0015A CAPACITOR, 1U F, 25 Volt, K PER, X5R(JB), 1608 R/TP, T=0.9(MAX) C28

0CH2104H942 CAPACITOR,CHIP[CERAMIC 0.1UF 25V Z F 1608 R/TP C30,C51,C54

0CH5681K412 CAPACITOR,CHIP[CERAMIC 680PF 50V J NP0 1608 R/TP C31

0CH2223H562 CAPACITOR,CHIP[CERAMIC 22NF 25V K X 1608 R/TP C52,C53

0CH2103K942 CAPACITOR,CHIP[CERAMIC 10NF 50V Z F 1608 R/TP C6,C8,C9

CIRCUIT_CONNECTOR

6630L-0167B CONNECTOR MDF76LBRW-30S-1H, HIROSE, 30 Pin, 1.0 mm CN1

CIRCUIT_DIODE

0DHZL-0004A DIODE Schottky, BAT750-7-F(0.75A), DIODES, R/TP, SOT-23 D1

0DHZL-0008A DIODE Switching, BAV99-7-F, DIODES, R/TP, SOT-23 D2,D3,D4

English

Korean

CIRCUIT_IC

0IDAL-0010A IC DTML012, 0IDAL-0010A, 100 Pin, TQFP, Tray, LVDS UC1

0ICS240200E IC,CATALYST

0IMXL-0004A IC,MAXIM MAX8758ETG+T, 24 Pin, QFN-24, R/TP, PWM,OP-AMP US1

CAT24WC02Y(CAT24FC02Y), 8 Pin, TSSOP, R/TP, EEPROM

U1

CIRCUIT_RESISTOR

0RHZL10005A RESISTOR,CHIP 100OHM 5% 1/16W 3216 R/TP AR1,AR2

0RH0000C622 RESISTOR,CHIP 0 OHM 1/16W 1608 5% D R/TP R11,R3,R8,R101,R103,R105,R31,

R4,R44,R46,R5,R50,R6,R62,R64

0RH4701C422 RESISTOR,CHIP 4.7K OHM 1/16W 1608 1% D R/TP R12,R13

0RH2202C422 RESISTOR,CHIP 22K OHM 1/16W 1608 1% D R/TP R14

0RH1002C422 RESISTOR,CHIP 10K OHM 1/16W 1608 1% D R/TP R15,R16,R52,R61

0RH3303C422 RESISTOR,CHIP 330K OHM 1/16W 1608 1% D R/TP R17

0RH3903C422 RESISTOR,CHIP 390K OHM 1/16W 1608 1% D R/TP R18

0RH1000C422 RESISTOR,CHIP 100 OHM 1/16W 1608 1% D R/TP R22,R23,R24,R25,R26,R27,R28,R29,R30,

R93,R19,R20,R21

0RH5603C422 RESISTOR,CHIP 560K OHM 1/16W 1608 1% D R/TP R40,R48

0RH2701C422 RESISTOR,CHIP 2.7K OHM 1/16W 1608 1% D R/TP R42

0RH1003C422 RESISTOR,CHIP 100K OHM 1/16W 1608 1% D R/TP R43,R60

0RH1803C422 RESISTOR,CHIP 180K OHM 1/16W 1608 1% D R/TP R49

0RH5602C422 RESISTOR,CHIP 56K OHM 1/16W 1608 1% D R/TP R51

0RH7501C422 RESISTOR,CHIP 7.5K OHM 1 / 16 W 1608 1% D R/TP R53

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

PART No. DESCRIPTION SPECIFICATION LOCA. No.

0RH3901C422 RESISTOR,CHIP 3.9K OHM 1/16W 1608 1% D R/TP R54

0RH1001C422 RESISTOR,CHIP 1K OHM 1/16W 1608 1% D R/TP R58

0RH0562C422 RESISTOR,CHIP 56 OHM 1/16W 1608 1% D R/TP R63

0RH2201C422 RESISTOR,CHIP 2.2K OHM 1/16W 1608 1% D R/TP R65

0RH3300C422 RESISTOR,CHIP 330 OHM 1/16W 1608 1% D R/TP R70

0RH3002C422 RESISTOR,CHIP 30K OHM 1/16W 1608 1% D R/TP R71

0RH2401C422 RESISTOR,CHIP 2.4K OHM 1/16W 1608 1% D R/TP R74

0RH8201C422 RESISTOR,CHIP 8.2K OHM 1/16W 1608 1% D R/TP R75

0RH1202C422 RESISTOR,CHIP 12K OHM 1/16W 1608 1% D R/TP R79

0RH1802C422 RESISTOR,CHIP 18K OHM 1/16W 1608 1% D R/TP R80

0RH1602C422 RESISTOR,CHIP 16K OHM 1/16W 1608 1% D R/TP R82,R83

0RH1302C422 RESISTOR,CHIP 13K OHM 1/16W 1608 1% D R/TP R87

0RH5601C422 RESISTOR,CHIP 5.6K OHM 1/16W 1608 1% D R/TP R88,R59

www.panelook.com

CIRCUIT_MISCELLANEOUS

6110L-P102A VOLUME PANASONIC, 1K ohm, EVM3WSX80B13 VR1

0LC6012101A INDUCTOR,CHIP PLN6012T-100MR80 TDK R/TP L1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

PART No. ITEM DESCRIPTION

6091L-0350A BACKLIGHT ASSY LP141WX1, TL01-C11, HEESUNG PRECISION, PRISM

6913L-0260C LAMP ASSY LP141WX1-TL01-C11

4930L-0397A HOLDER LAMP(H), SILICON

4930L-0398A HOLDER LAMP(G), SILICON

3022L-0307A DIFFUSER UP, 125TL2, LP141WX1-TL01

3034L-0208A REFLECTOR RP17N(0.22T)

3032L-0236A PRISM UP, M268YK(MRC)

3923L-0454A INNER PACKING LP141WP1-TLA1-C11

6632L-0263A INVERTER YPNL-N021A, LGIT, LP141WP1-TLA1/LP141WX1-TL04

6632L-0266B INVERTER K08I026.01, AMBIT, LP141WP1-TLA1/LP141WX1-TL04

0IOKL-0039A IC,OKI ML9132DVVCZ01L, 300 Pin, C-F, R/TP, GATE, 270/300CH, 2VGL

0IHYL-0105A IC,MAGNACHIP HM10SS639A-C3L, 705/720 Pin, C-B, R/TP, SOURCE

6308L-0658A POLARIZER LNC-TEGH2MP-E1032T, 310.14X195.24X0.13T, Nitto, TOP

6308L-0657A POLARIZER LNB-TEGAPMP-E1031B, 307.1X193.3X0.245T, Nitto, BOTTOM

6308L-0740A POLARIZER LGC-TSTH2LP-141E1034T, 310.14 X 195.24 X 0.135T

3850L-0034A LABEL PALLET YUPO 102X165

3850L-0077A LABEL BOX ART 100X100

3850L-0087A LABEL BOX YUPO 152X102

3850L-0088A LABEL ID YUPO 78X37 (TUV PS)

3850L-0085A LABEL B/L YUPO 62X21

3880L-0013D BAG LDPE 240X370

3920L-0389A PACKING TOP EPS LP141WX1

3920L-0390A PACKING BOTTOM EPS LP141WX1

3921L-0147B PACKING ASSY LP141WX1(DELL)

3930L-0007C PALLET WOOD 1040X900X150

3931L-0196B PALLET ASSY LP141WX1(DELL)

3000L-0016Q ANGLE COVER, DW3 1040X900X100

3000L-0013H ANGLE PACKING DW3 875X1022X831

6884L-0038A ACF CP5420ISL,L=1.5MMX200M, T=20UM,SONY

6884L-0027B ACF DP2252KSL, L=2MM*200M, SONY

6884L-0018B ACF CP9220IS L=1.5X200 T=15UM SONY

3890L-0035T BOX SWR4 420X324X269

3111L-0149A CASE ASSY LP141WX1-TL04/LP141WP1-TLA1

3110T-0138A CASE, TOP SUS304(0.3T), LP141WX1-TL01

3550B-0148A COVER, BOTTOM AL5050 H38(0.3T), LP141WX1

3550S-0263A COVER, SHIELD (S), SR93+TERAOKA 631S

3550S-0271A COVER, SHIELD (G),SR93+TERAOKA631S LP141WX1

6071L-0547A POL ASSY SE1W03-AAA

5135L-0011V PROTECT FILM SKYROL SH92,T=0.1,LP141WX1

1STZL-0002B SCREW T/TS PI2,L3(K0.2)

7250L-0041A TAPE(RAW) OPP 70MMX300M(LG,PHLIPS LCD)

7250L-0023A TAPE(RAW) MASKING 20MMX50M

7250L-0074C TAPE(RAW) TERAOKA(631S)+AL35FR

7250L-0080D TAPE(RAW) ADHESIVE, TERAOKA631S(0.05T)

7250L-0023A TAPE(RAW) MASKING 20MMX50M

7250L-0077A TAPE(RAW) TERAOKA 631S #25, 20MMX50M

7250L-0045L TAPE(RAW) (ADHESIVE) PVC T=0.15

7250L-0045Z TAPE(RAW) ADHESIVE PVC0.15T(LP150X08-A2)

www.panelook.com

BACKLIGHT & INVERTER

English

Korean

DRIVE IC

POLARIZER

LABEL

PACKING & BOX

MISCELLANEOUS

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 32

Global LCD Panel Exchange Center

www.panelook.com

11. Records of Revision

No.

A00

Date

2003.11.03

Contents Board

Part Number

Customer P/N

0F1124

Note

MSR

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 33

Global LCD Panel Exchange Center

www.panelook.com

Base Model : LP121X04-B2

Derivative description of Model

No.

1

Replace of PROTECT FILM 5135L-0009L 5135L-0012A

Contents

12. Derivative description

Part Number

Before After

English

Korean

Note

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 34

Global LCD Panel Exchange Center

MEMO

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 35

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 36

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 37

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 38

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

CE_TOP

CE_BOTTOM

www.panelook.com

Page 39

Global LCD Panel Exchange Center

www.panelook.com

MODEL : LP141WP1 - TLA1

March 2006

Printed in Korea

GPN06SM009M

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...