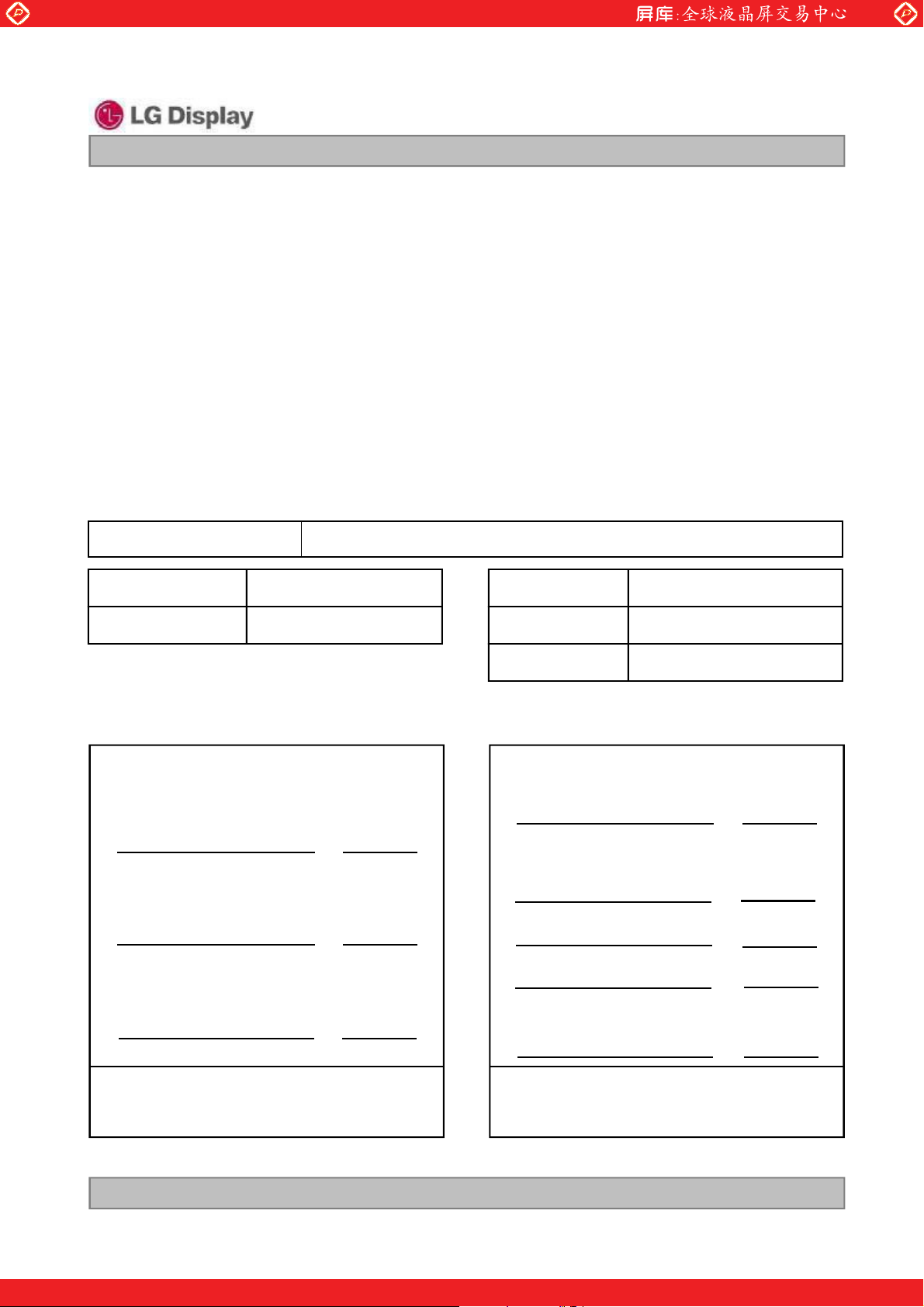

LG Display LM190E08-TLK1 Specification

Global LCD Panel Exchange Center

( ) Preliminary Specification

(

) Final Specification

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

SPECIFICATION

FOR

APPROVAL

Title 19.0” SXGA TFT LCD

BUYER

MODEL

SIGNATURE DATE

/

/

HP

SUPPLIER LG Display Co., Ltd.

*MODEL LM190E08

SUFFIX TLK1

*When you obtain standard approval,

please use the above model name without suffix

APPROVED BY

K.G. Park / G.Manager

REVIEWED BY

J.H. Shin / Manager [C]

H.D. Joo / Manager [M]

J.C. Lim / Manager [P]

DATE

/

Please return 1 copy for your confirmation

With your signature and comments.

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PREPARED BY

D.Y. Shin / Engineer

Product Engineering Dept.

LG Display Co., Ltd

1/31

www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

Contents

No ITEM

COVER 1

CONTENTS 2

RECORD OF REVISIONS 3

1 GENERAL DESCRIPTION 4

2 ABSOLUTE MAXIMUM RATINGS 5

3 ELECTRICAL SPECIFICATIONS 6

1) ELECTRICAL CHARACTERISTICS 6

2) INTERFACE CONNECTIONS 9

3) LVDS characteristics 12

4) SIGNAL TIMING SPECIFICATIONS 15

5) SIGNAL TIMING WAVEFORMS 16

6) COLOR INPUT DATA REFERNECE 17

7) POWER SEQUENCE 18

8) POWER DIP CONDITION 19

4 OPTICAL SFECIFICATIONS 20

Page

5 MECHANICAL CHARACTERISTICS 24

6 RELIABILITY 27

7 INTERNATIONAL STANDARDS 28

1) SAFETY 28

2) EMC 28

3) ENVIRONMENT 28

8PACKING 29

1) DESIGNATION OF LOT MARK 29

2) PACKING FORM 29

9 PRECAUTIONS 30

1) MOUNTING PRECAUTIONS 30

2) OPERATING PRECAUTIONS 30

3) ELECTROSTATIC DISCHARGE CONTROL 31

4) PRECAUTIONS FOR STRONG LIGHT EXPOSURE 31

5) STROAGE 31

6) HANDLING PRECAUTIONS FOR PROTECTION FILM 31

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

2/31

www.panelook.com

Global LCD Panel Exchange Center

Revision No DescriptionDate Page

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

Record of revisions

Ver. 0.1

Ver. 0.2

Ver. 1.0

SEP.30. 2011

DEC.07. 2011

JAN.10.2012

15, 20

First Draft, Preliminary Specifications.

Changed viewing angle Spec, Timing Spec

Final specifications

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

3/31

www.panelook.com

Global LCD Panel Exchange Center

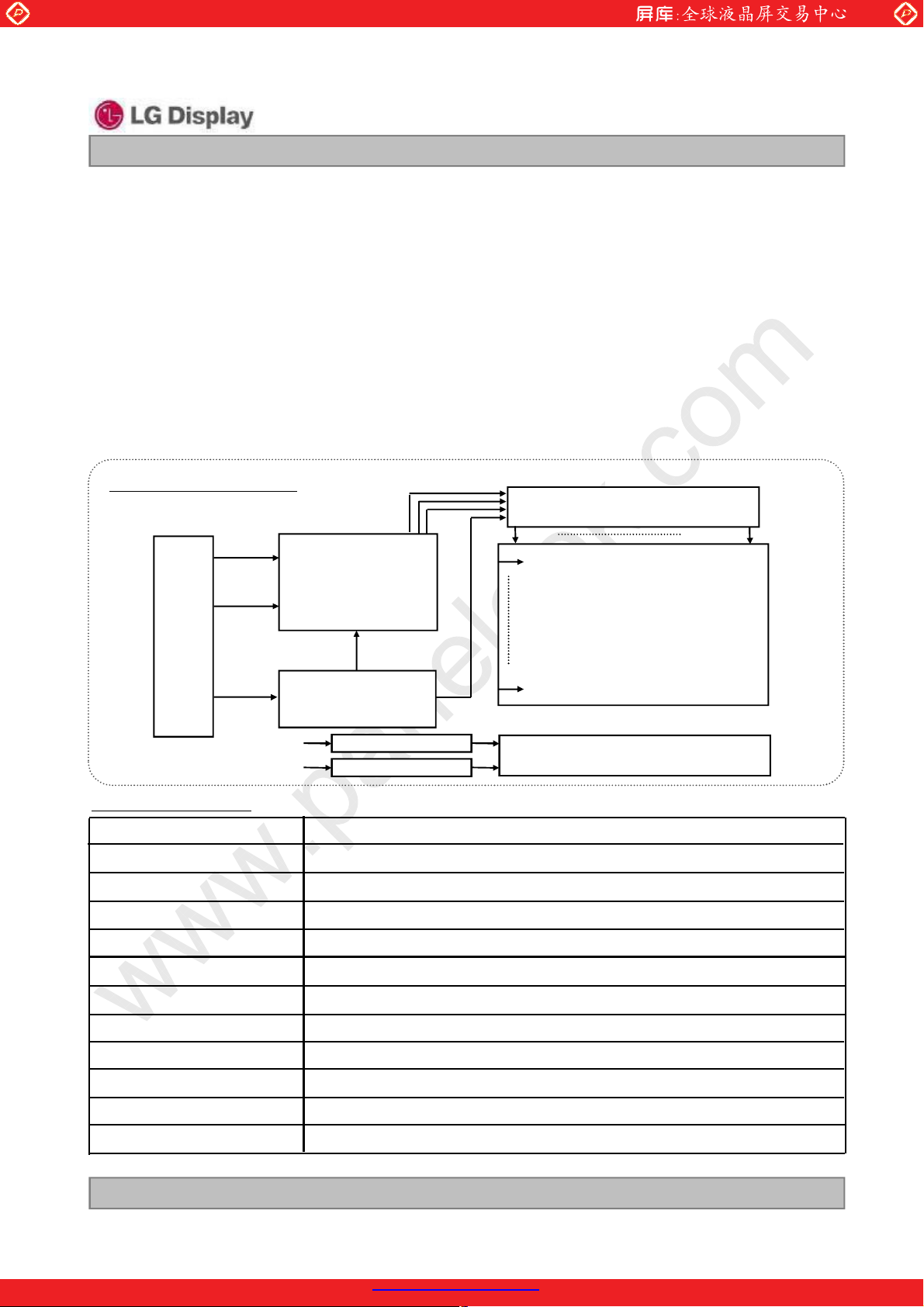

1. General description

LM190E08-TLK1 is a Color Activ e Matrix Liquid Crystal Display with an integral Cold Cathode Fluorescent

Lamp(CCFL) backlight system. The matrix employs a-Si Thin Film Transistor as the active element. It is a

transmissive type display operating in the normally white mode. It has a 19.0 inch diagonally measured active

display area with SXGA resolution (1024 vertical by 1280 horizontal pixel array) Each pixel is divided into Red,

Green and Blue sub-pixels or dots which are arranged in vertical stripes. Gray scale or the brightness of the

sub-pixel color is determined with a 8-bit gray scale signal for each dot, thus, presenting a palette of more than

16,7M colors with Advanced-FRC(Frame Rate Control). It has been designed to apply the interface method

that enables low power, high speed, low EMI. FPD Link or compatible must be used as a LVDS(Low Voltage

Differential Signaling) chip. It is intended to support applications where thin thickness, wide viewing angle, low

power are critical factors and graphic displays are important. In combination with the vertical arrangement of

the sub-pixels, the LM190E08-TLK1 characteristics provide an excellent flat panel display for office automation

products such as monitors.

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

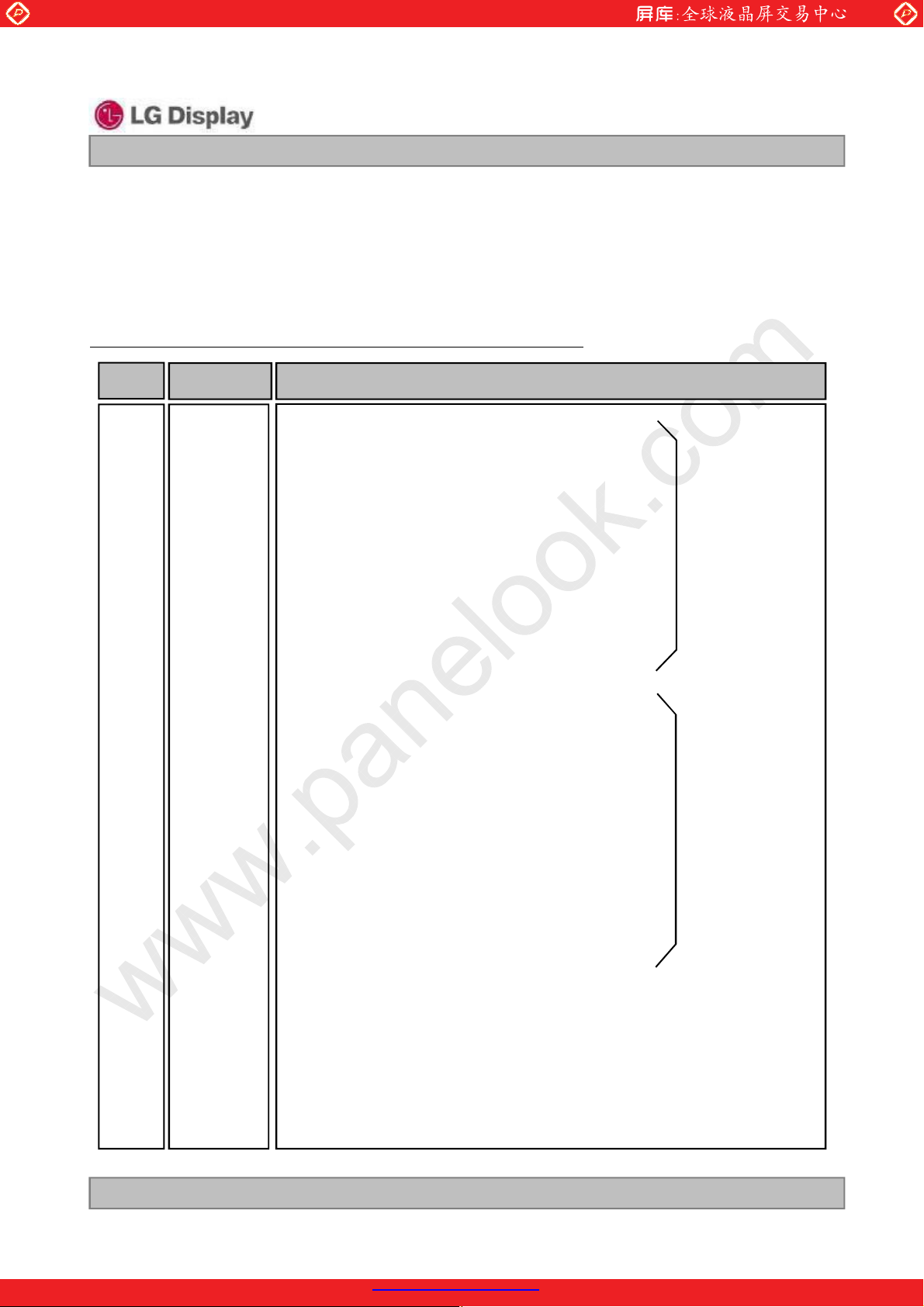

FIG. 1 Block diagram

LVDS

pair #1

LVDS

CN1

(30Pin)

pair #2

+5V

V

LCD

Timing

controller

Power circuit

block

CN2 (2pin)

CN3 (2pin)

RGB

Source driver circuit

S1

G1

TFT-LCD Panel

(1280RGB1024 pixels)

G1024

Backlight assembly (2 CCFLs)

S1280

General features

Active screen size 19.0 inches (481.9mm) diagonal

Outline Dimension 396.0(H) x 324.0(V) x 15.5(D) mm(Typ.)

Pixel Pitch 0.098*RGB(H)mm x 0.294(V)mm

Pixel Format 1280 horizontal By 1024 vertical Pixels. RGB stripe arrangement

Interface LVDS 2Port

Color depth 16.7M colors

Luminance, white 250 cd/m

2

(Center 1Point, typ)

Viewing Angle (CR>10) R/L 170(Typ.), U/D 160(Typ.)

Power Consumption

Total 14.65W (Typ.), (4.9W@V

, 9.75W@IBL=7.5mA)

LCD

Weight 2,450g (Typ.)

Display operating mode Transmissive mode, normally White

Surface treatments Hard coating (3H), Anti-glare treatment of the front polarizer

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

4/31

www.panelook.com

Global LCD Panel Exchange Center

2. Absolute maximum ratings

The following are maximum values which, if exceeded, may cause faulty operation or

damage to the unit.

Table 1. Absolute maximum ratings

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

Parameter Symbol

Units Notes

Min Max

Values

Power Supply Input Voltage V

Operating Temperature T

Storage Temperature T

Operating Ambient Humidity H

Storage Humidity H

LCD

OP

ST

OP

ST

-0.3 +6.0 Vdc

050

-20 60

C

C

10 90 %RH

10 90 %RH

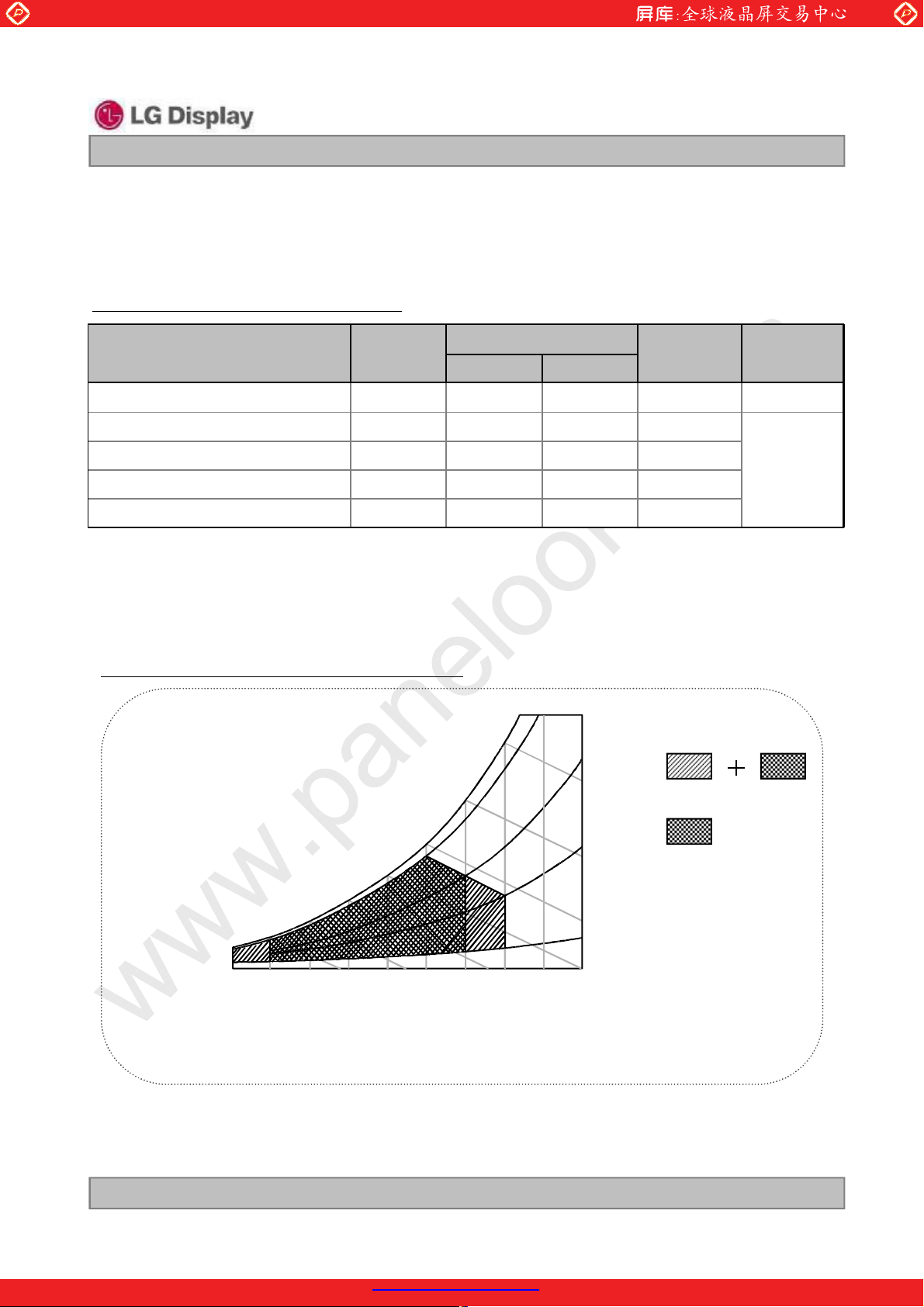

Note : 1. Temperature and relative humidity range are shown in the figure below.

Wet bulb temperature should be 39 C Max, and no condensation of water.

2. Maximum Storage Humidity is up to 40, 90% RH only for 4 corner light leakage Mura.

3. Storage condition is guaranteed under packing condition

FIG. 2 Temperature and relative humidity

90%

60

60%

At 25

1,2,3

Wet Bulb

50

Temperature []

40

30

20

10

0

10 20 30 40 50 60 70 800-20

Dry Bulb Temperature []

Ver. 1.0 JAN, 10, 2012

40%

10%

Humidity

Storage

Operation

[(%)RH]

5/31

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

3. Electrical specifications

3-1. Electrical characteristics

It requires two power inputs. One is employed to power the LCD electronics and to drive the

TFT array and liquid crystal. The second input power for the CCFL/Backlight, is typically

generated by an inverter. The inverter is an external unit to the LCDs.

Table 2. Electrical characteristics

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

Parameter Symbol

Values

Unit Notes

Min Typ Max

MODULE :

Power Supply Input Voltage V

Permissive Input Voltage Ripple V

I

Power Supply Input Current

LCD-MOSAIC

I

LCD-BLACK

Power Consumption P

Inrush current I

LCD

RF

LCD

RUSH

4.5 5.0 5.5 Vdc

- - 200 mV 3

- 980 1130 mA 1

- 1140 1305 mA 2

- 4.90 5.65 Watt 1

--3.0 A 4

Note :

1. The specified current and power consumption are under the V

condition whereas mosaic pattern(8 x 6) is displayed and f

LCD=5.0V, 25 ± 2C,f

is the frame frequency.

V

2. The current is specified at the maximum current pattern.

3. Permissive power ripple should be measured under V

LCD=5.0V, maximum frame rate (fV) at 25C.

Additionally, we recommend the bandwidth configuration of oscilloscope is to be under 20MHz.

4. The duration of rush current is about 5ms and rising time of power Input is 500us ± 20%.

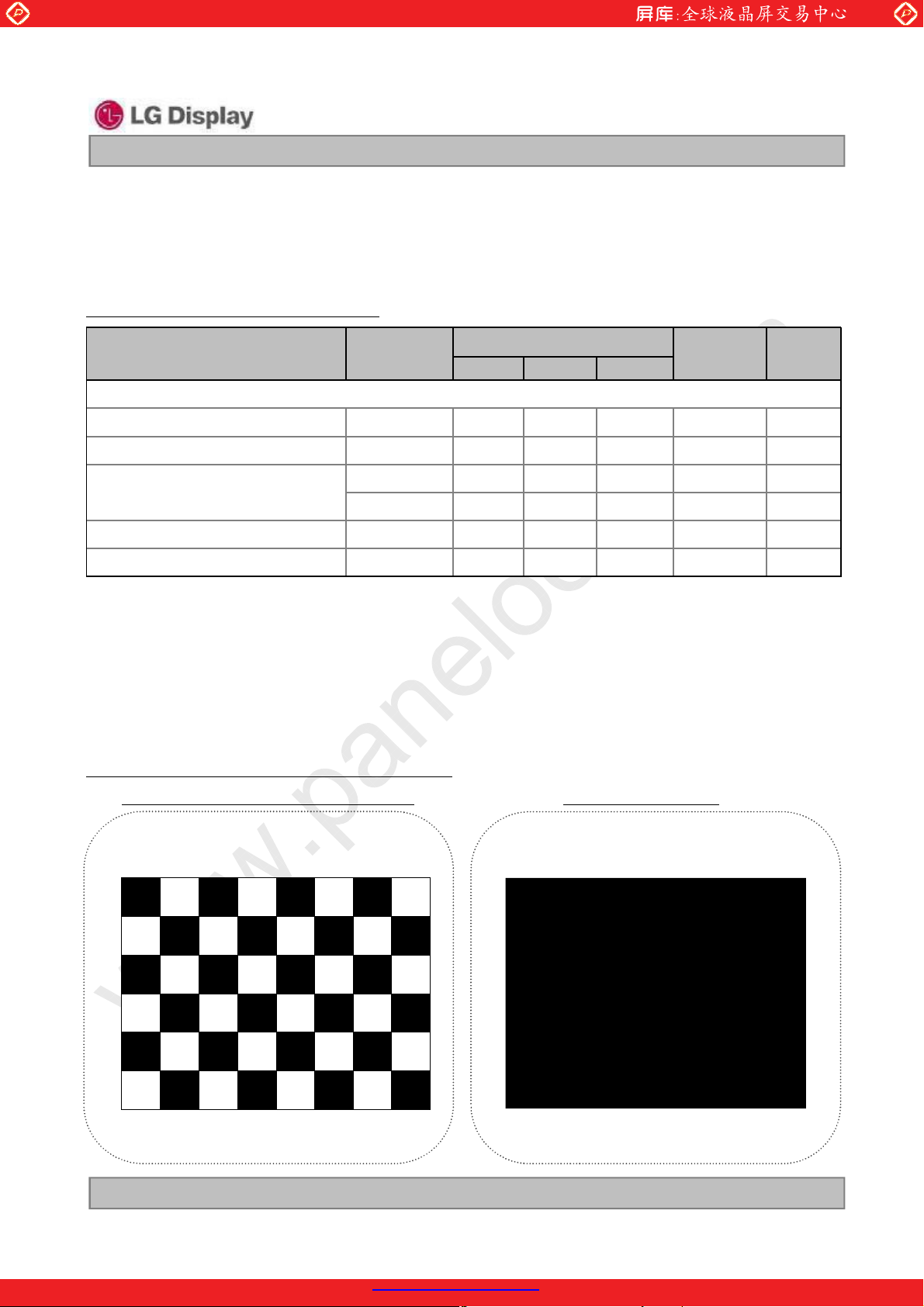

FIG.3 pattern for Electrical characteristics

=60Hz

V

power consumption measurement

White : 255Gray

Black : 0Gray

Mosaic Pattern(8 x 6)

Ver. 1.0 JAN, 10, 2012

power input ripple

Full Black Pattern

6/31

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

Table 3. Electrical characteristics

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

Parameter

Sym

bol

Min Typ Max

Values

Unit Notes

LAMP :

Operating Voltage V

Operating Current I

BL

BL

640

(8.0mA)

2.5 7.5 8.0 mA

650

(7.5mA)

790

(2.5mA)

V

RMS

RMS

1, 2

1

Established Starting Voltage Vs 1, 3

at 25 C

at 0 C

Operating Frequency f

Discharge Stabilization Time T

Power Consumption P

BL

BL

40 - 70 kHz 4

S

-- 3Min1, 5

9.75 10.73 Watt 6

1,100 V

1,400 V

RMS

RMS

Life Time 50,000 - Hrs 1, 7

Note :

The design of the inverter must have specifications for the lamp in LCD Assembly.

The performance of the Lamp in LCM, for example life time or brightness, is extremely influenced

by the characteristics of the DC-AC inverter. So all the parameters of an inverter should be carefully

designed so as not to produce too much leakage current from high-voltage output of the inverter.

When you design or order the inverter, please make sure unwanted lighting caused by the mismatch of

the lamp and the inverter (no lighting, flicker, etc) never occurs. When you confirm it, the LCD–Assembly

should be operated in the same condition as installed in you instrument.

Do not attach a conducting tape to lamp connecting wire. If the lamp wire attach to a conducting tape,

TFT-LCD Module has a low luminance and the inverter has abnormal action.

Because leakage current is occurred between lamp wire and conducting tape.

1. Specified values are for a single lamp.

2. Operating voltage is measured at 25 ± 2C. The variance of the voltage is ± 10%.

3. The voltage above V

(Inverter open voltage must be more than lamp starting voltage.)

Otherwise, the lamps may not be turned on. The used lamp current is the lamp typical current.

4. Lamp frequency may produce interface with horizontal synchronous frequency and as a result

this may cause beat on the display. Therefore lamp frequency shall be as away possible from

the horizontal synchronous frequency and from its harmonics in order to prevent interference.

5. Let’s define the brightness of the lamp after being lighted for 5 minutes as 100%.

is the time required for the brightness of the center of the lamp to be not less than 95%.

T

S

6. The lamp power consumption shown above does not include loss of external inverter.

The used lamp current is the lamp typical current. (P

7. The life is determined as the time at which brightness of the lamp is 50% compared to that

of initial value at the typical lamp current on condition of continuous operating at 25 ± 2C.

should be applied to the lamps for more than 1 second for start-up.

S

= VBLx IBLx N

BL

Lamp

)

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

7/31

www.panelook.com

Global LCD Panel Exchange Center

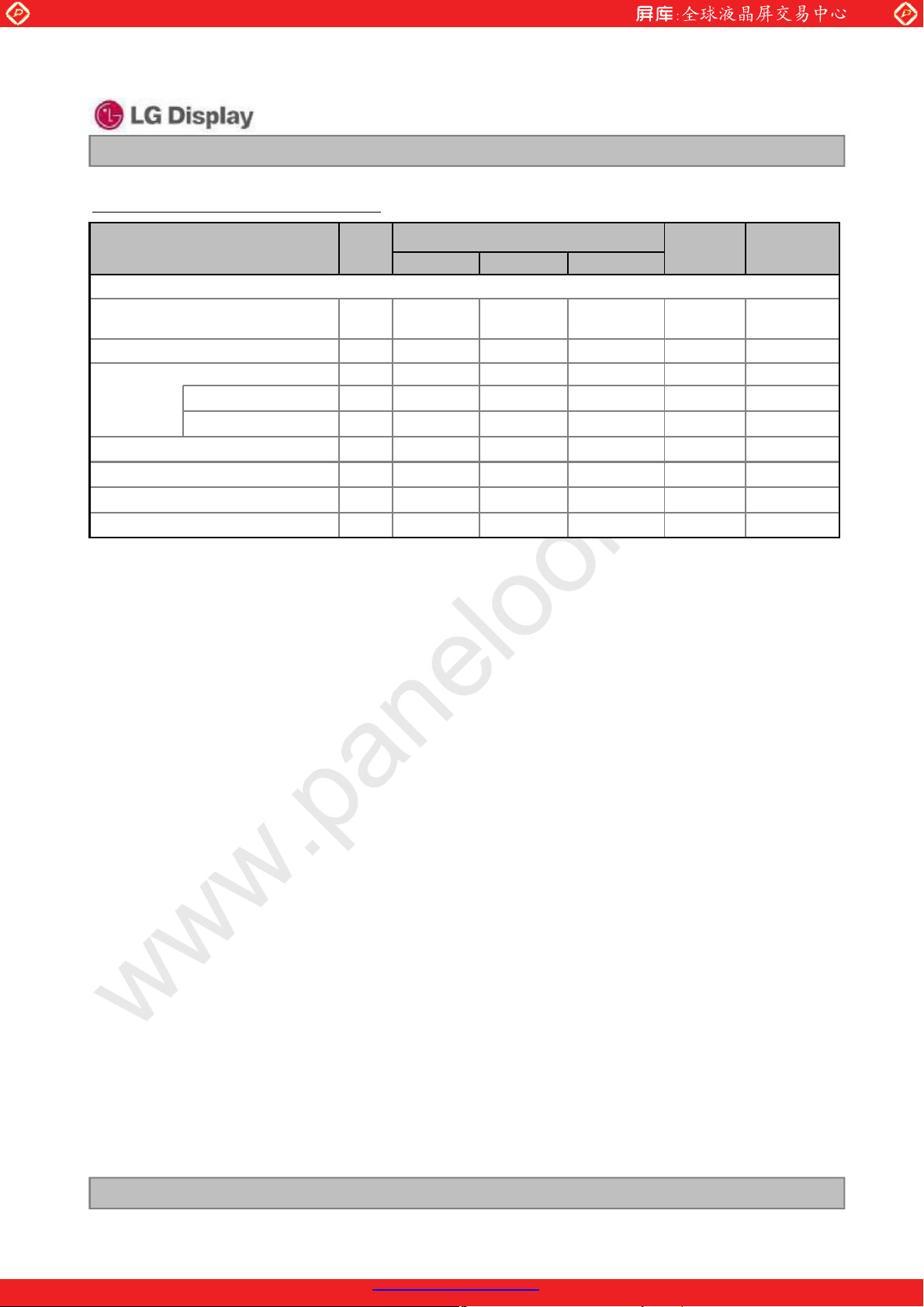

Note :

8. The output of the inverter must have symmetrical(negative and positive) voltage

waveform and symmetrical current waveform (Unsymmetrical ratio is less than 10%).

Please do not use the inverter which has unsymmetrical voltage and unsymmetrical

current and spike wave. Requirements for a system inverter design, which is intended to

have a better display performance, a better power efficiency and a more reliable lamp,

are following.It shall help increase the lamp lifetime and reduce leakage current.

a. The asymmetry rate of the inverter waveform should be less than 10%.

b. The distortion rate of the waveform should be within √2 10%.

* Inverter output waveform had better be more similar to ideal sine wave.

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

* Asymmetry rate:

I p

|I

p

–I–p|/I

rms

x 100%

* Distortion rate

I -p

(or I–p)/I

I

p

9. The inverter which is combined with this LCM, is highly recommended to connect

coupling(ballast) condenser at the high voltage output side. When you use the inverter

which has not coupling(ballast) condenser, it may cause abnormal lamp lighting because

of biased mercury as time goes.

10.In case of edgy type back light with over 4 parallel lamps, input current and voltage

wave form should be synchronized

rms

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

8/32

www.panelook.com

Global LCD Panel Exchange Center

3-2. Interface connections

LCD connector(CN1) : GT103-30S-H15 (LSM), IS100-L30O-C23(UJU)

Mating connector : FI-X30H and FI-X30HL (JAE) or Equivalent

Table 4. Module connector(CN1) pin configuration

www.panelook.com

LM190E08

Liquid Crystal Display

Product Specification

Pin No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Symbol Description

RXO0RXO0+

RXO1RXO1+

RXO2RXO2+

GND

RXOCRXOC+

RXO3RXO3+

RXE0RXE0+

GND

RXE1RXE1+

GND

RXE2RXE2+

RXECRXEC+

RXE3RXE3+

GND

NC

NC

PWM_OUT

LCD

V

VLCD

VLCD

Minus signal of 1st channel 0 (LVDS)

Plus signal of 1st channel 0 (LVDS)

Minus signal of 1st channel 1 (LVDS)

Plus signal of 1st channel 1 (LVDS)

Minus signal of 1st channel 2 (LVDS)

Plus signal of 1st channel 2 (LVDS)

Ground

Minus signal of 1st clock channel (LVDS)

Plus signal of 1st clock channel (LVDS)

Minus signal of 1st channel 3 (LVDS)

Plus signal of 1st channel 3 (LVDS)

Minus signal of 2nd channel 0 (LVDS)

Plus signal of 2nd channel 0 (LVDS)

Ground

Minus signal of 2nd channel 1 (LVDS)

Plus signal of 2nd channel 1 (LVDS)

Ground

Minus signal of 2nd channel 2 (LVDS)

Plus signal of 2nd channel 2 (LVDS)

Minus signal of 2nd clock channel (LVDS)

Plus signal of 2nd clock channel (LVDS)

Minus signal of 2nd channel 3 (LVDS)

Plus signal of 2nd channel 3 (LVDS)

Ground

No Connection (I2C Serial interface for LCM)

No Connection (I2C Serial interface for LCM)

For Control Burst frequency of Inverter

Power Supply (5.0V)

Power Supply (5.0V)

Power Supply (5.0V)

First Pixel data

Second Pixel data

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

9/31

www.panelook.com

Global LCD Panel Exchange Center

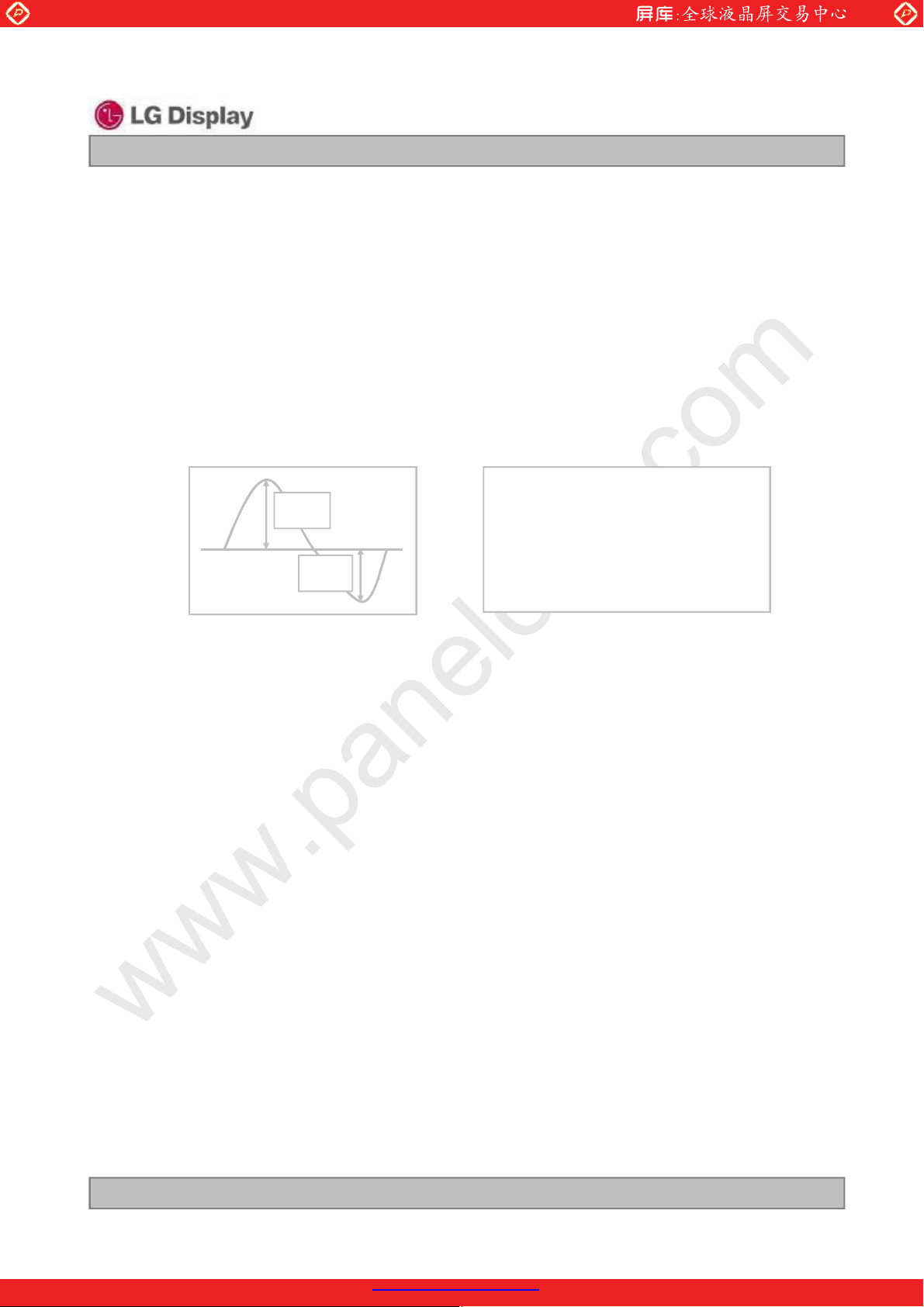

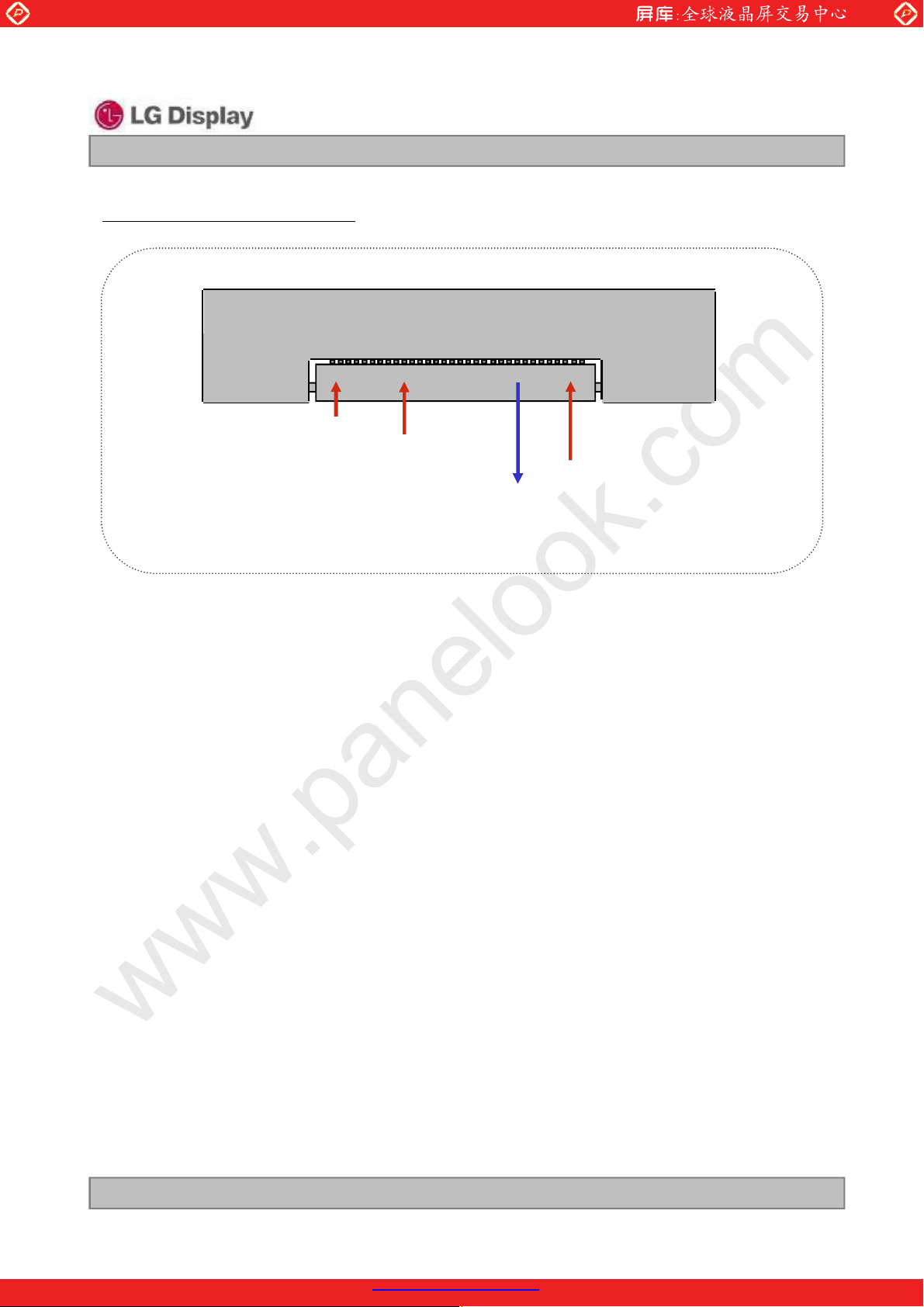

FIG. 4 Connector diagram

1’st signal pairs

www.panelook.com

Product Specification

GT103-30S-H15 (LSM)

#

1

#1 #30

2’nd signal pairs

CN1

#30

LM190E08

Liquid Crystal Display

Note:

Power(+5V)

PWM_OUT

Rear view of LCM

1. All GND(ground) pins should be connected together and to Vss which should also

be connected to the LCD’s metal frame.

2. All V

3. Input Level of LVDS signal is based on the IEA 664 Standard.

4. PWM_OUT is a reference signal for inverter control.

This PWM signal is synchronized with vertical frequency.

Its frequency is 3 times of vertical frequency, and its duty ratio is 50%.

If you don’t use this pin, it should be no connection.

(power input) pins should be connected together.

LCD

Ver. 1.0 JAN, 10, 2012

PDF created with pdfFactory trial version www.pdffactory.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

10 / 31

www.panelook.com

Loading...

Loading...