Page 1

MICRO Hi-Fi SYSTEM

SERVICE MANUAL

MODEL : XC102 (XCS102F)

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL

.

MODEL : XC102 (XCS102F)

SERVICE MANUAL

P/NO : AFN32840891 APRIL, 2007

http://biz.lgservice.com

Page 2

1-1

CONTENTS

SECTION 1

GENERAL

SERVICING PRECAUTIONS......................................1-2

• NOTES REGARDING HANDLING OF THE PICK-UP

•

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

ESD PRECAUTIONS...................................................1-4

LOCATION OF USERS CONTROLS.........................1-5

SPECIFICATIONS ........................................................1-7

SECTION 2

EXPLODED VIEWS

CABINET EXPLODED VIEW......................................2-1

CD MECHANISM EXPLODED VIEW.........................2-3

SPEAKER EXPLODED VIEW ....................................2-5

MODEL : XCS102F................................................2-5

PACKING ACCESSORY VIEW...................................2-9

SECTION 3

AUDIO PART ELECTRICAL

AUDIO ELECTRICAL

TROUBLESHOOTING GUIDE....................................3-1

1. POWER (SMPS)................................................3-1

2. P-SENS...............................................................3-2

3. VKK CHECK.......................................................3-2

4. MICOM PART CHECK I....................................3-2

5. MICOM PART CHECK II ...................................3-3

6. IC103(KS4CD21CS) CHECK............................3-4

7. FLD DISPLAY CHECK ......................................3-5

8. PWM MODULATION PART CHECK................3-6

9. POWER AMP PART CHECK............................3-7

10. AUX FUNCTION CHECK..................................3-8

11. TUNER FUNCTION CHECK.............................3-9

12. PORTABLE IN FUNCTION CHECK...............3-10

INTERNAL BLOCK DIAGRAM OF ICs...................3-11

1. AK5358...............................................................3-11

2. BU4052...............................................................3-11

3. LC78692NW......................................................3-12

4. PS9829B............................................................3-13

5. PT6324...............................................................3-13

6. STR-W6753.......................................................3-14

7. TAS5142.............................................................3-15

8. U1739EJ2V1UD00/KF2_E...............................3-16

9. UTC MC4580.....................................................3-17

WIRING DIAGRAM ....................................................3-18

BLOCK DIAGRAM.....................................................3-20

1. SMPS BLOCK DIAGRAM...............................3-20

2. MAIN & FRONT BLOCK DIAGRAM ...............3-22

SCHEMATIC DIAGRAMS .........................................3-24

1. SMPS SCHEMATIC DIAGRAM.......................3-24

2. MAIN SCHEMATIC DIAGRAM........................3-26

3. AMP SCHEMATIC DIAGRAM..........................3-28

4. FRONT SCHEMATIC DIAGRAM.....................3-30

PRINTED CIRCUIT BOARD DIAGRAMS ...............3-32

1. MAIN P.C.BOARD............................................3-32

2. SMPS P.C.BOARD ..........................................3-36

3. FRONT P.C.BOARD ........................................3-38

SECTION 4

CD PART ELECTRICAL

CD ELECTRICAL TROUBLESHOOTING GUIDE....4-1

1. CD PART TROUBLESHOOTING.....................4-1

2. USB PART TROUBLESHOOTING...................4-9

WAVEFORMS OF MAJOR CHECK POINT............4-10

1. MICOM INTERFACE WAVEFORM.................4-10

2. SLED DRIVE AND MOTOR WAVEFORM......4-11

3. FOCUS DRIVE AND MOTOR

WAVEFORM ......................................................4-11

4. SPINDLE DRIVE AND MOTOR

WAVEFORM......................................................4-12

5. TRACK DRIVE AND MOTOR

WAVEFORM......................................................4-12

6. RF, FOCUS AND TRACKING

ERROR WAVEFORM.......................................4-12

SCHEMATIC DIAGRAMS .........................................4-13

1. CD SCHEMATIC DIAGRAM...........................4-13

2. USB SCHEMATIC DIAGRAM.........................4-15

PRINTED CIRCUIT BOARD DIAGRAM..................4-17

CD P.C.BOARD....................................................4-17

SECTION 5

REPLACEMENT PARTS LIST

........5-1

Page 3

1-2

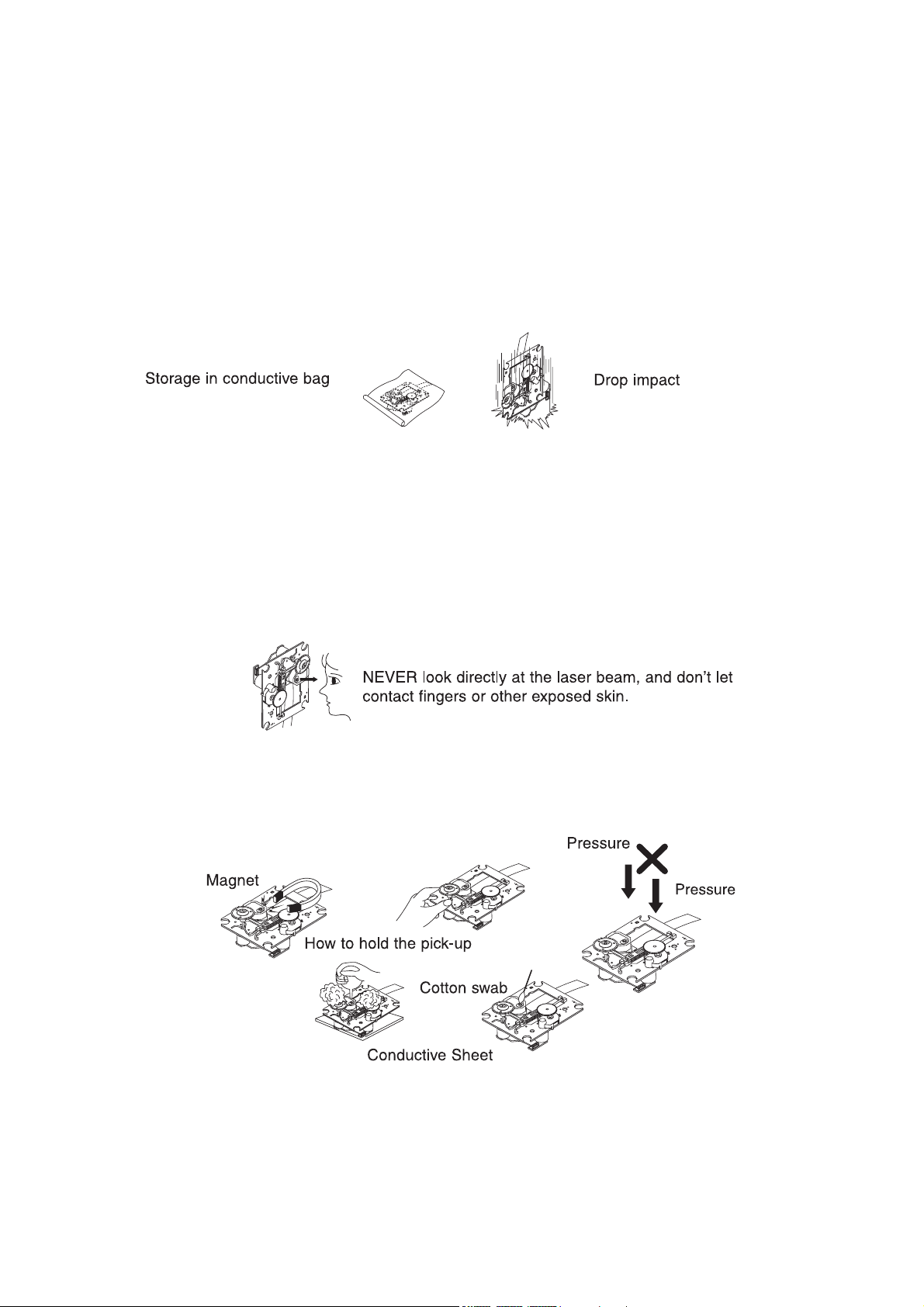

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton

swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do not

use any other liquid cleaners, because they will damage the lens.) Take care not to use too much of this

alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

SERVICING PRECAUTIONS

SECTION 1 GENERAL

Page 4

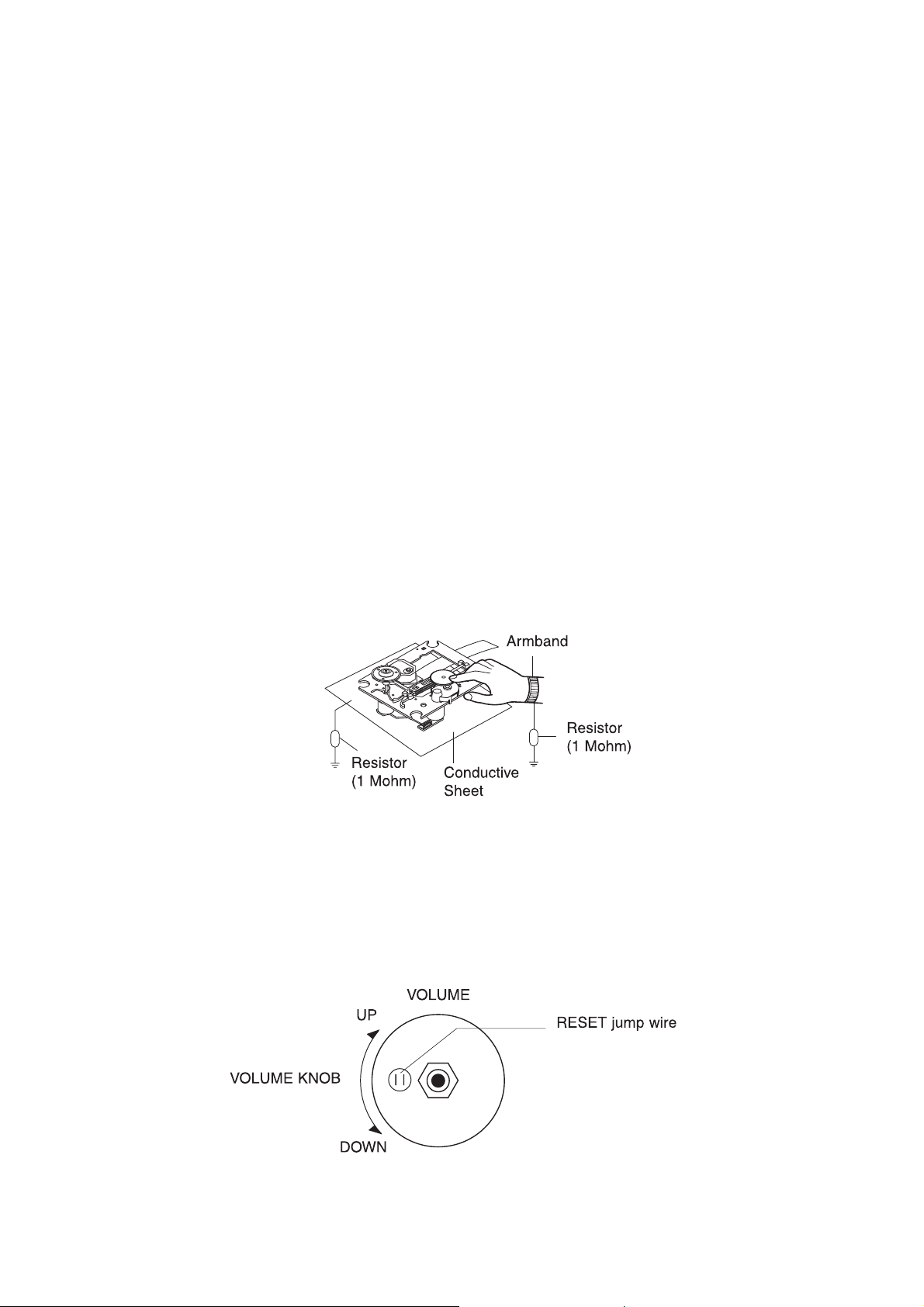

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

CLEARING MALFUNCTION

You can reset your unit to initial status if malfunction occur(button malfunction, display, etc.).

Using a pointed good conductor(such as driver), simply short the RESET jump wire on the inside of

the volume knob for more than 3 seconds.

If you reset your unit, you must reenter all its settings(stations, clock, timer)

NOTE: 1. To operate the RESET jump wire, pull the volume rotary knob and release it.

2. If you wish to operate the RESET jump wire, it is necessary to unplug the power cord.

1-3

Page 5

1-4

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called electrostatically sensitive devices (ESD). Examples of typical ESD devices are

integrated circuits and some field-effect transistors and semiconductor chip components. The following

techniques should be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a know earth ground. Alternatively, obtain and

wear a commercially available discharging wrist strap device, which should be removed for potential

shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static"

can generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together

by conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch

the protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL

OTHER SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor

can generate static electricity sufficient to damage an ESD device).

[CAUTION. GRAPHIC SYMBOLS]

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL. WITHIN AN EQUILATERAL

TRIANGLE, IS INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE

OF UNINSULATED "DANGEROUS VOLTAGE" THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENED TO

ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY

INFORMATION IN SERVICE LITERATURE.

Page 6

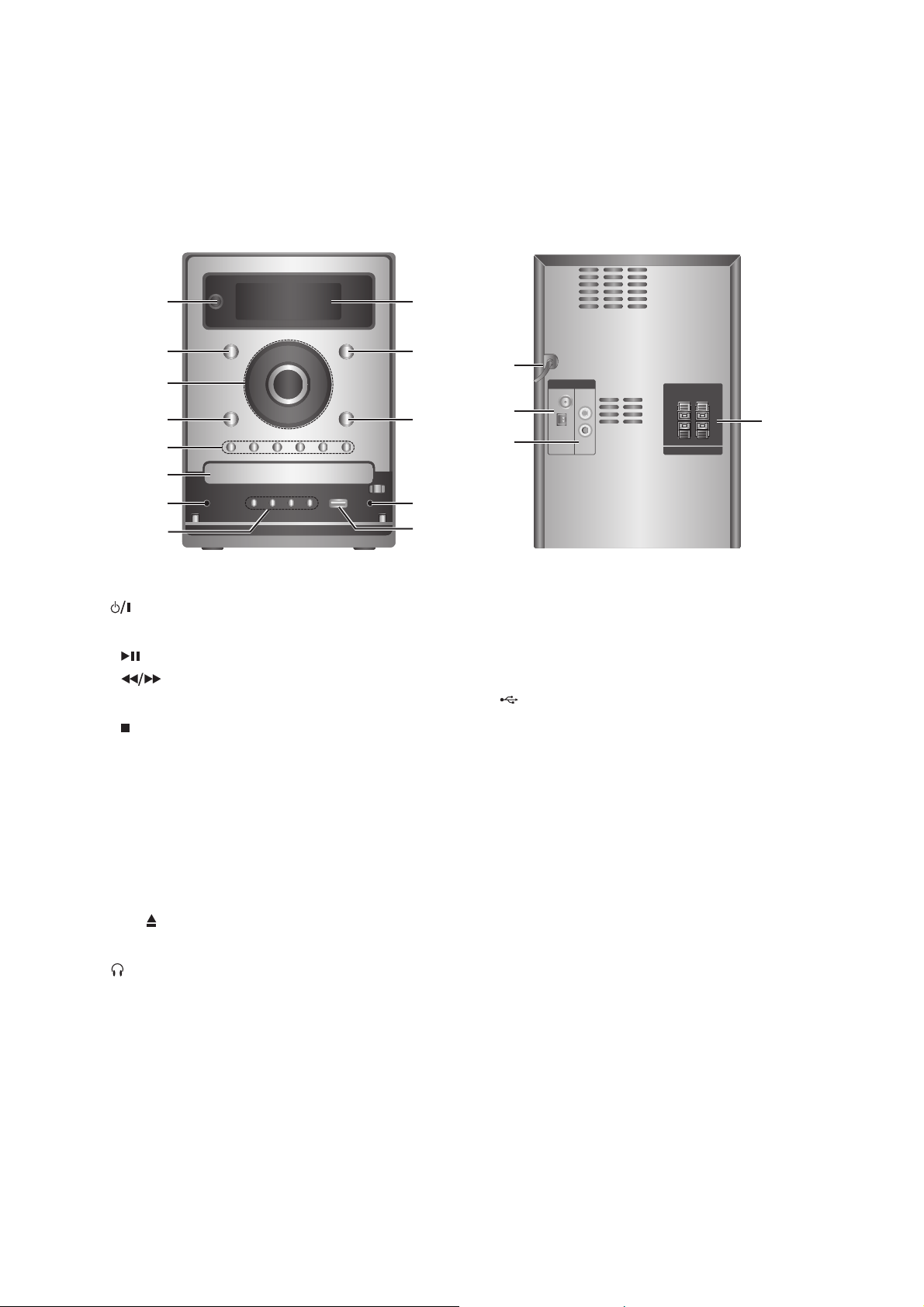

LOCATION OF USERS CONTROLS

17

15

16

14

1

2 12

11

10

13

4

5

6

7

8 9

3

1. (POWER)

2. CD

3. • (PLAY/PAUSE)

• (SKIP/SEARCH)

TUNE.-/+

• (STOP)

• VOLUME CONTROL KNOB

4. USB

5. • XDSS plus

• XTS pro

• EQ Master

• ST./MONO

• PROG.

• CD

6. DISC TRAY

7. (Headphone jack) : ø3.5mm

8. • DEMO

• TIMER

• CLOCK

• SET (RDS - OPTIONAL)

9. (USB connector)

10.PORT.IN jack

11.AUX (PORTABLE)

12.TUNER

13.DISPLAY WINDOW

14.POWER IN (POWER CORD)

15.AM/FM ANTENNA TERMINAL

16.AUX IN (AUXILIARY INPUT) connector

17.SPEAKER TERMINAL

FRONT / BACK PANEL

1-5

Page 7

1-6

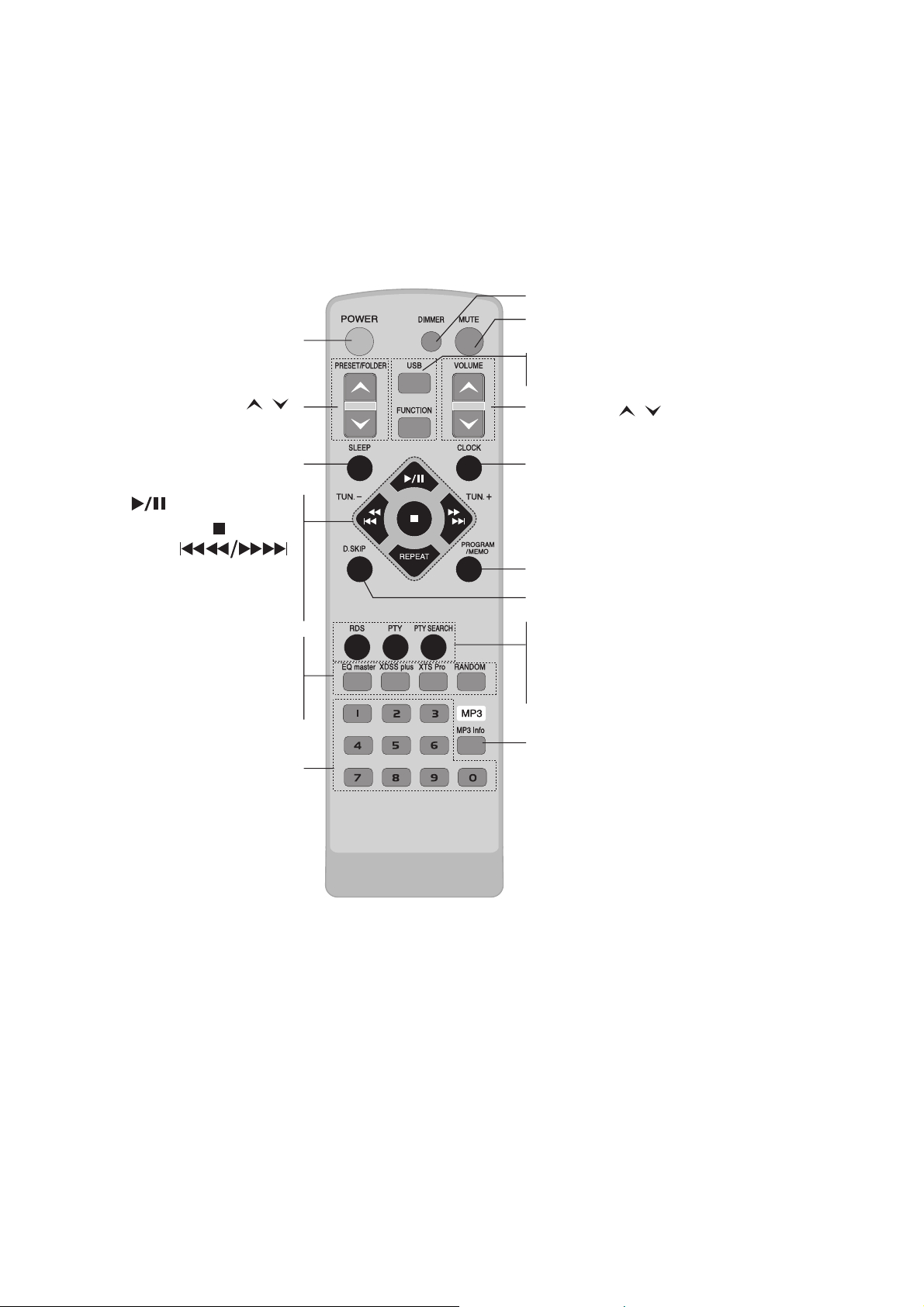

REMOTE CONTROL

POWER

PRESET/FOLDER(

)

SLEEP

•

(PLAY/PAUSE) •

(STOP) •

(SKIP/SEARCH)

TUN.-/+ •

REPEAT •

EQ master •

XDSS plus •

XTS Pro •

RANDOM •

NUMERIC

/

DIMMER

MUTE

• USB

• FUNCTION

VOLUME ( )

CLOCK

PROGRAM/MEMO

D.SKIP

RDS (Radio Data System) FUNCTION

• RDS : OPTIONAL

• PTY : OPTIONAL

• PTY SEARCH : OPTIONAL

MP3 Info

(MP3/WMA

file information display)

/

Page 8

SPECIFICATIONS

• GENERAL

Power supply Refer to the back panel of the unit.

Power consumption Refer to the back panel of the unit.

Net Weight 3.0kg

External dimensions (WxHxD) 174 x 245 x 278mm

• TUNER

FM Tuning Range 87.5 ~ 108.0MHz or 65 ~ 74MHz, 87.5 ~ 108.0MHz

Intermediate Frequency 10.7MHz

Signal to Noise Ratio 60/55dB

Frequency Response 50 ~ 10000Hz

AM Tuning Range 522 ~ 1620kHz or 520 ~ 1720kHz

Intermediate Frequency 450kHz

Signal to Noise Ratio 30dB

Frequency Response 140 ~ 1800Hz

• AMPLIFIER

Output Power 50W + 50W

T.H.D 0.5%

Frequency Response 40 ~ 20000Hz

Signal-to-noise ratio 75dB

• CD

Frequency response 40 ~ 20000Hz

Signal-to-noise ratio 75dB

Dynamic range 75dB

• SPEAKERS

Type 2 Way 2 Speaker

Impedance 4

Frequency Response 80 ~ 20000 Hz

Sound Pressure Level 82dB/W (1m)

Rated Input Power 50W

Max. Input Power 100W

Net Dimensions (WxHxD) 160 x 243 x 174mm

Net Weight (1EA) 2.02kg

1-7

Page 9

MEMO

1-8

Page 10

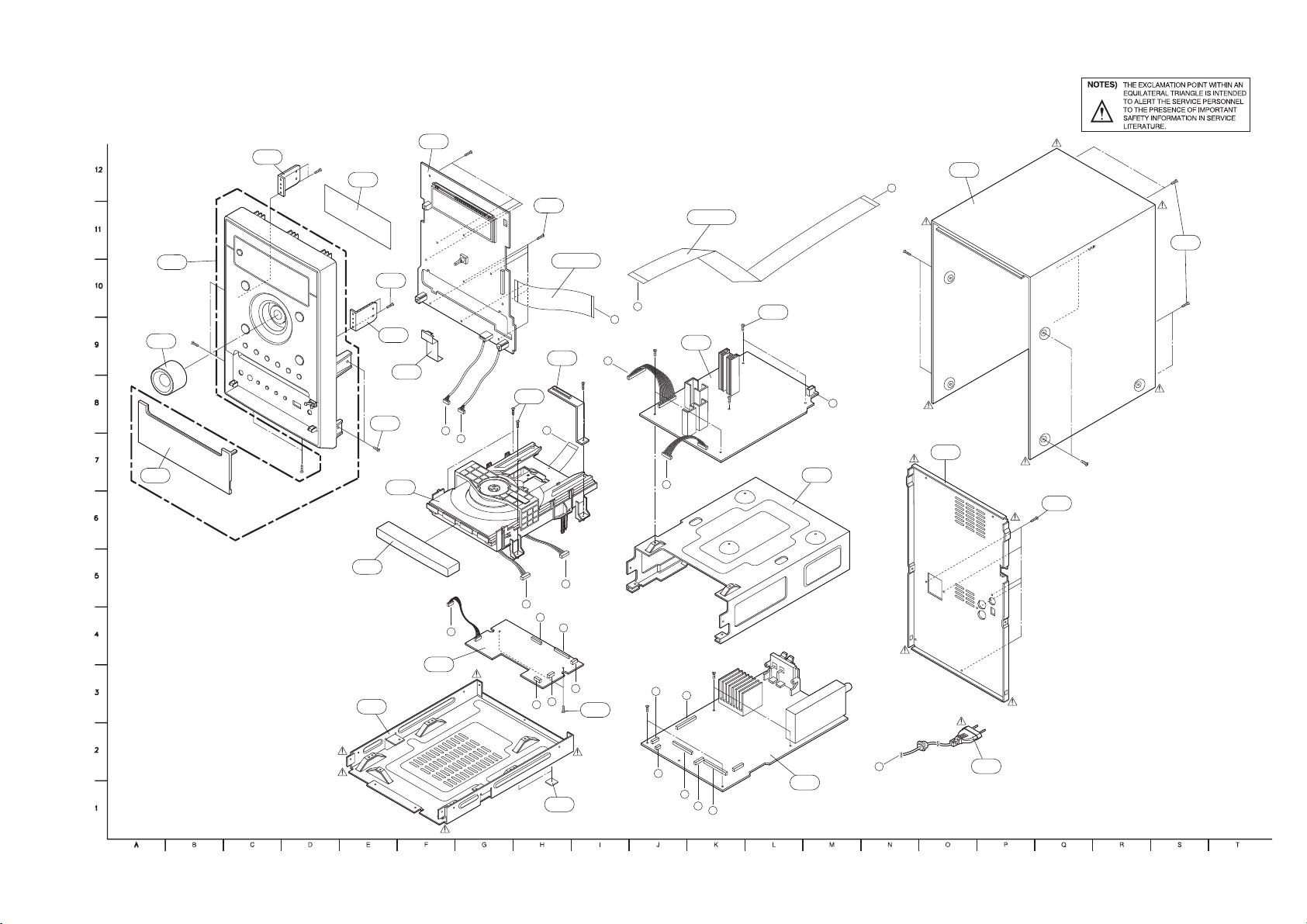

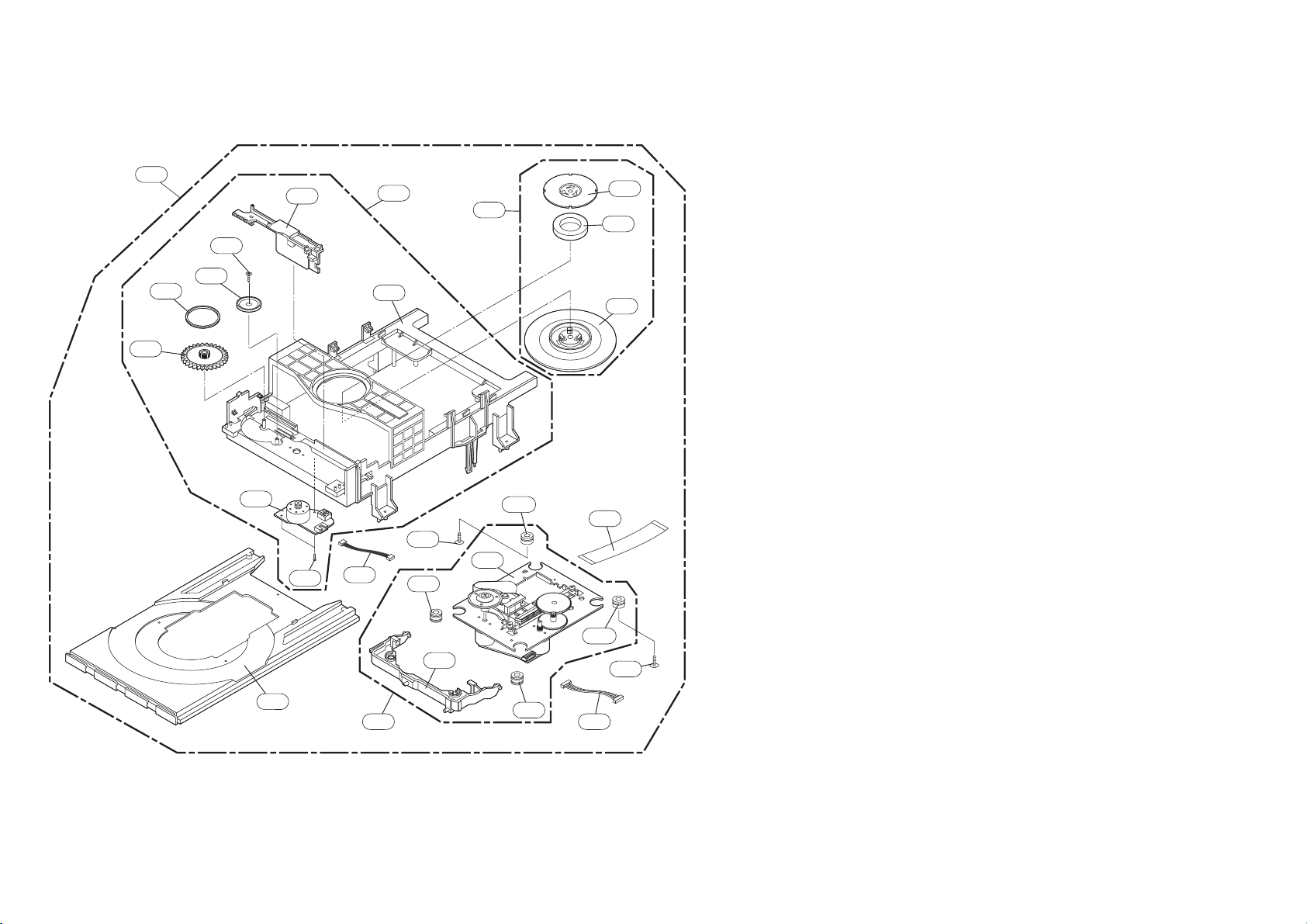

A

C

D

H

I

D

F

H

I

A

B

K

E

J

F

L

G

B

C

E

G

J

K

L

256

250

254

252

454

A26

A52

454

A46

305

454

454

454

A47

263

266

264

290

454

454

454

259

CAB LE 3

CAB LE 2

A43

255

257

267

256

258

SMPS

CD

MAIN

FRO NT

SECTION 2 EXPLODED VIEWS

CABINET EXPLODED VIEW

Page 11

A26

018

A02

020

A01

001

002

003

010

432

432

431

026

037

012

012

019

A03

016

015

036

012A

012A

439

014

013

017

CD MECHANISM (CDM-330) EXPLODED VIEW

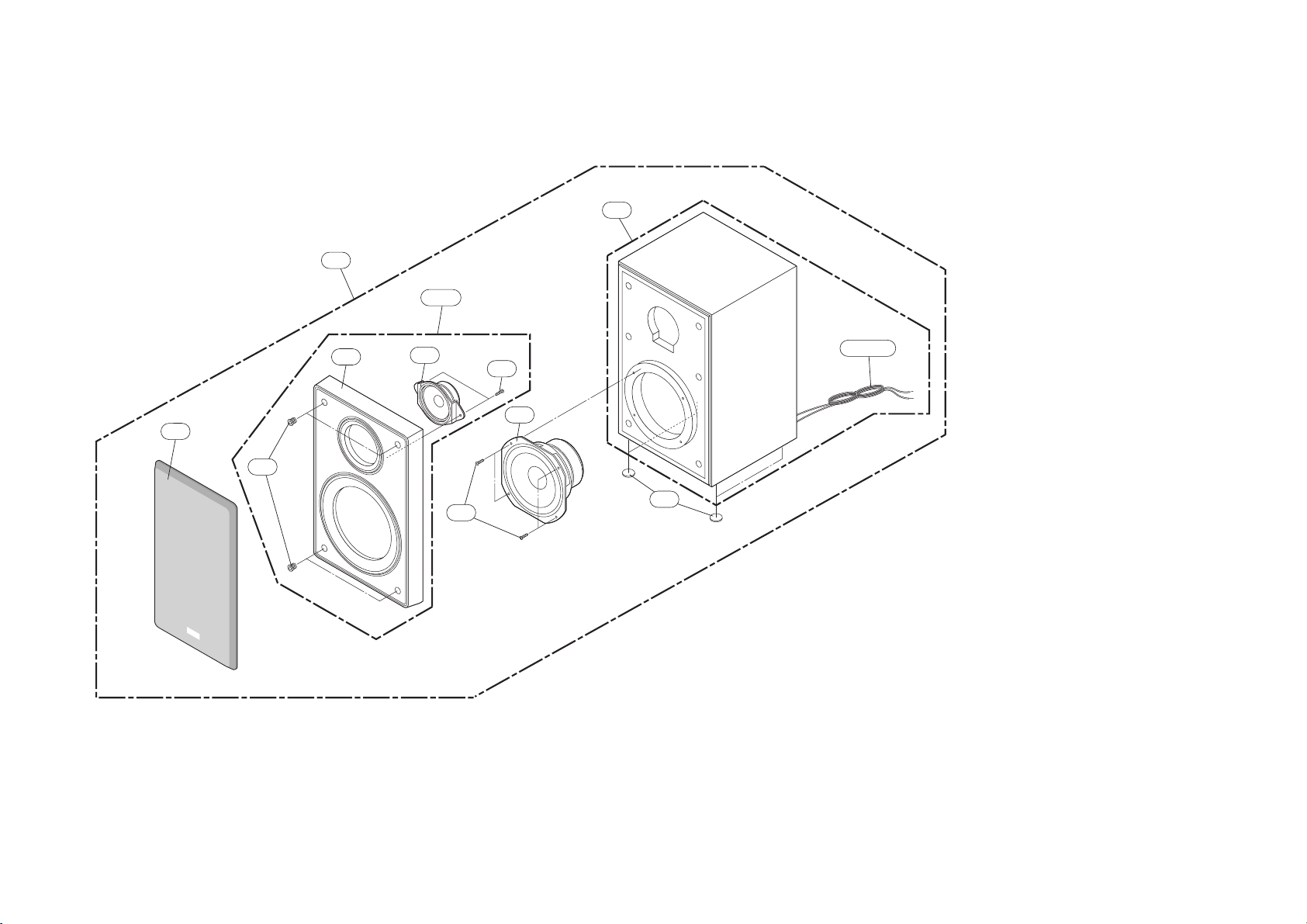

Page 12

850

851

852

853

854

855

856

857

858

WIRE80

A80

A80A

SPEAKER EXPLODED VIEW

MODEL : XCS102F

Page 13

MEMO MEMO

2-7 2-8

Page 14

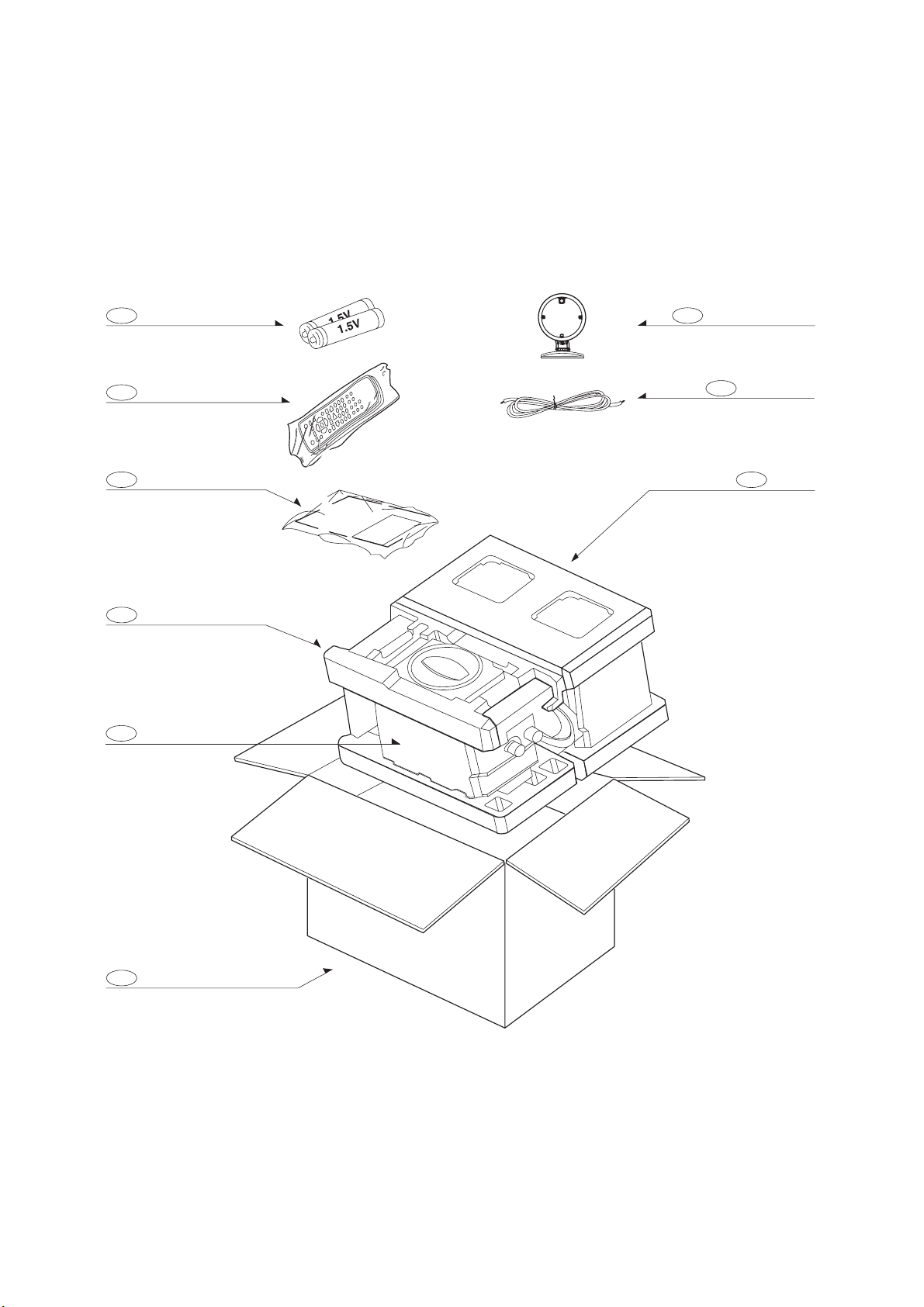

2-9

PACKING ACCESSORY VIEW

808 Battery

900 Remote Control

801 Instruction Ass'y

803 Packing

803 Packing

804 Bag

802 Box

825 Antenna (FM)

824 Antenna Loop (AM)

Page 15

3-1

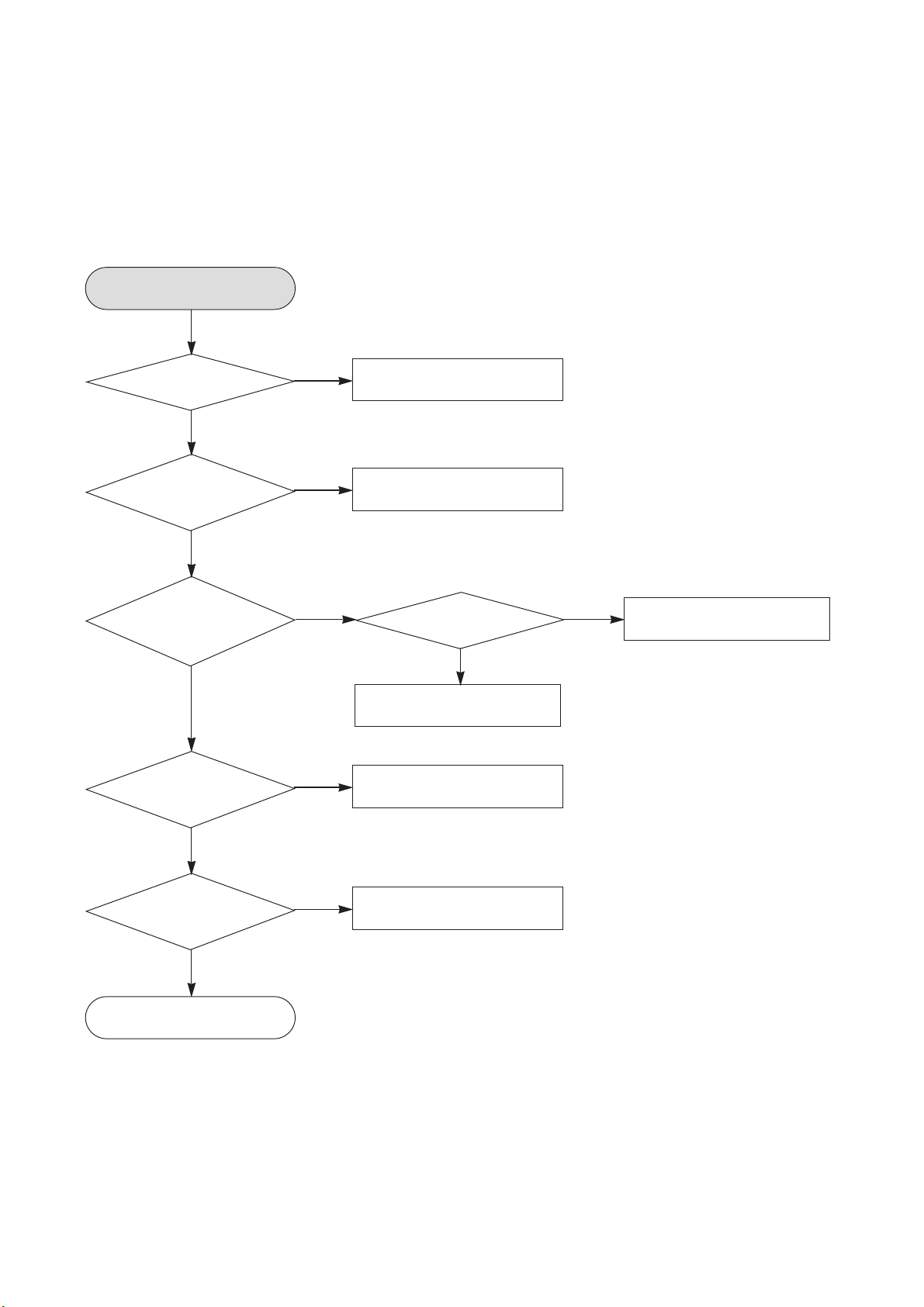

AUDIO ELECTRICAL TROUBLESHOOTING GUIDE

SECTION 3 AUDIO PART ELECTRICAL

1. POWER (SMPS)

POWER (SMPS)

OK

YES

YES

YES

Replace IC 901,902

Check IC901, 902

Check the fuse

F901

NONO

NO

YES

Check short of

P9701, P9702 line

Replace the fuse

Check

the DC V of C905.

If DC V is over

400V

NO

Check BD901, LF901, 902

Check the

DC V of C981, C945.

If DC V is 6.1V

NO

Check short of P9702 line

YES

YES

Chcek the

DC V of C950, C951

If DC V is in

31.5V

NO

Check short of P9701 line

Chcek the

DC V of C909, C903,

C921 If DC V is in 14~19V

and it is steady.

YES

Page 16

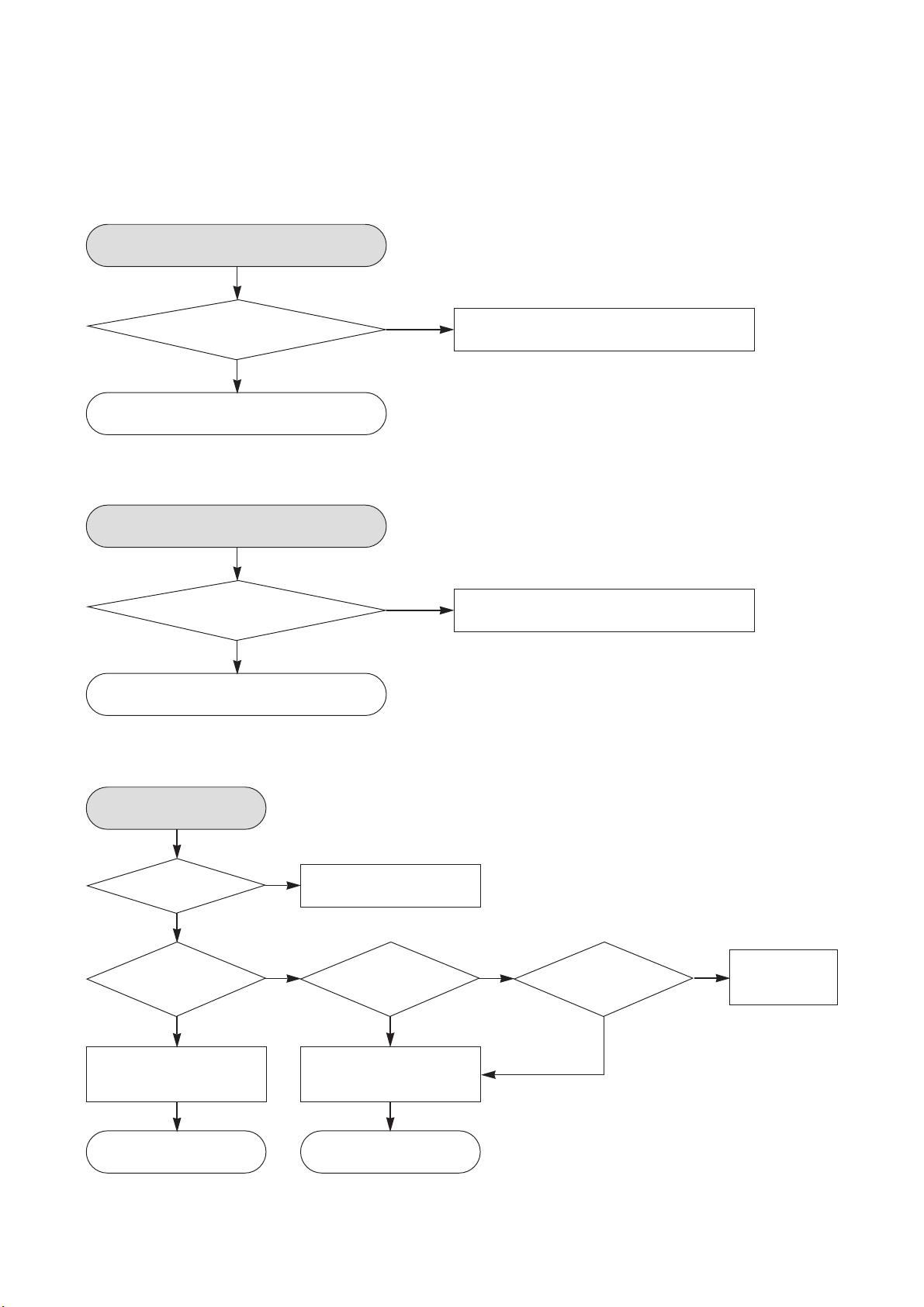

2. P-SENS

P-SENS

YES

Check

the PIN6 of P9702

If DC V is over 5.6V

3. VKK CHECK

VKK check

Check

the PIN3 of P9702

If DC V is over -28V ±2

OK

OK

YES

YES

YES

NO

NO

Check power circuit Trouble shooting

Check power circuit Trouble shooting

4. MICOM PART CHECK I

MICOM part check I

YES

Check P-SENS

(P7904)_PIN6.

YES

Check both

end voltage of IC101

(KIA7042).

YES

Check voltage of IC100

78KO/KF2_PIN1.

YES

OK OK

NO

SMPS troubleshooting.

NO

Check if IC101(KIA7042) of

output voltage is over 4.3V.

Refer to

Check

if input voltage of

IC101(KIA7042) is

over 5V.

YES

YES

3-2

NO

Check the

periphery of IC101

(KIA7042).

YES

NO

Replace IC101

(KIA7042).

Page 17

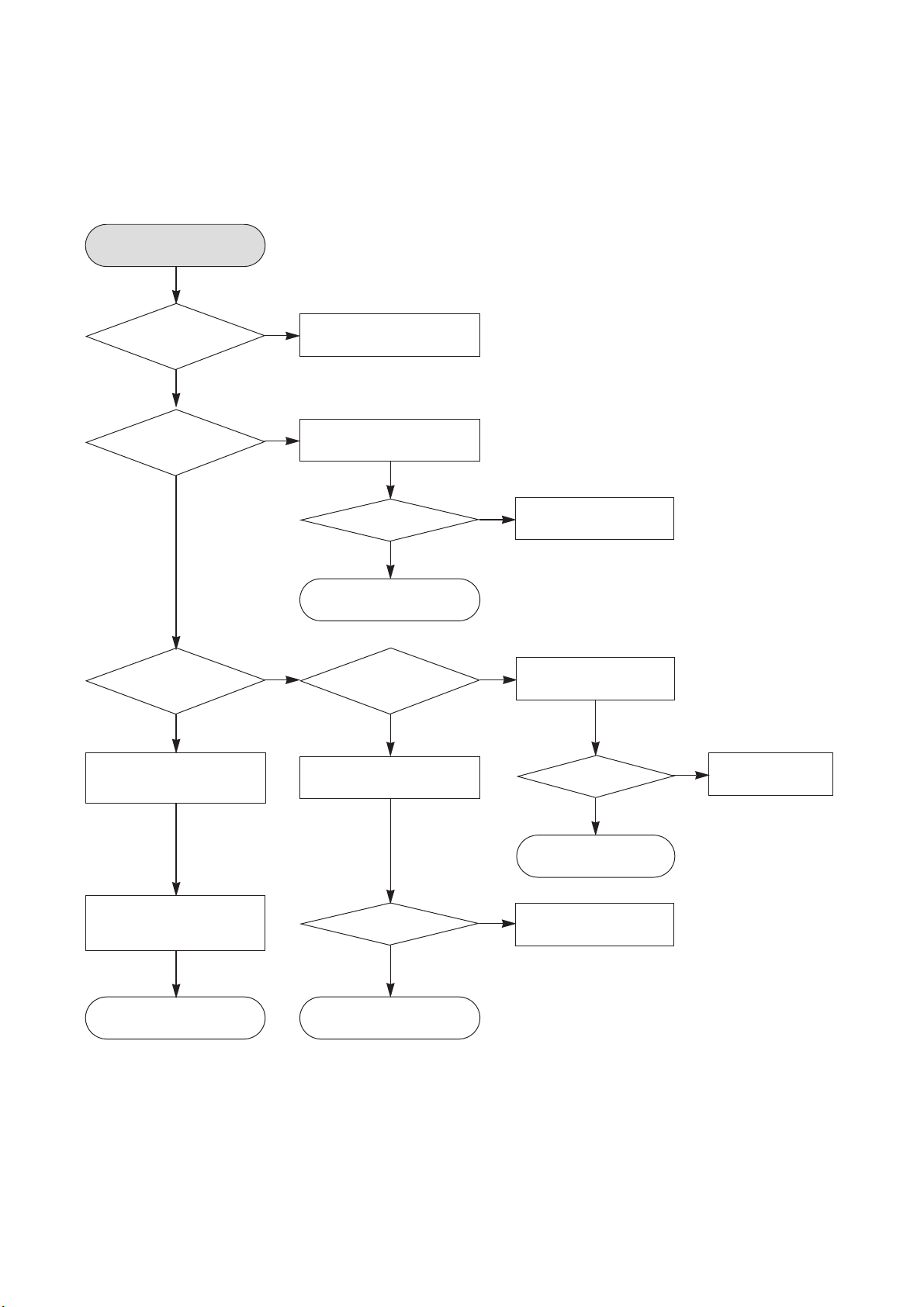

5. MICOM PART CHECK II

MICOM part check II

YES

Check if

voltage of P7904_PIN5

is 5.6V.

YES

Check

both end voltage of

D101

YES

Check

Q101_ emitter/collector

5V.

YES

Check if IC103_PIN8 and

IC100_PIN19, 20, 59 are 5V.

NO

NO

NO NO

Q102_collector 0.6V LOW.

Refer to

SMPS troubleshooting.

Check if output of

D101(RL104) is 5V.

YES

Check D101.

YES

OK

Check Q102_base

0.6V HIGH.

YES

NO

Replace D101.

Check if output of IC101

(KIA7042) is over 4.3V.

YES

Check IC101.

NO

Replace IC101.

YES

X101 : 32.768kHz

X100 : 9.8304MHz

Check the operation.

YES

OK

YES

Check Q102.

YES

OK

3-3

NO

YES

OK

Replace Q102.

Page 18

3-4

Check

IC100(78KOKF2)_

PIN 22, 24

OK

YES

YES

Refer to

micom troubleshooting

Check micom

voltage 5V.

PIN22

DATA PIN24 CLK

NONO

YES

Replace micom.

Check micom.

NO

YES

OK

6. IC103(KS4CD21CS) CHECK

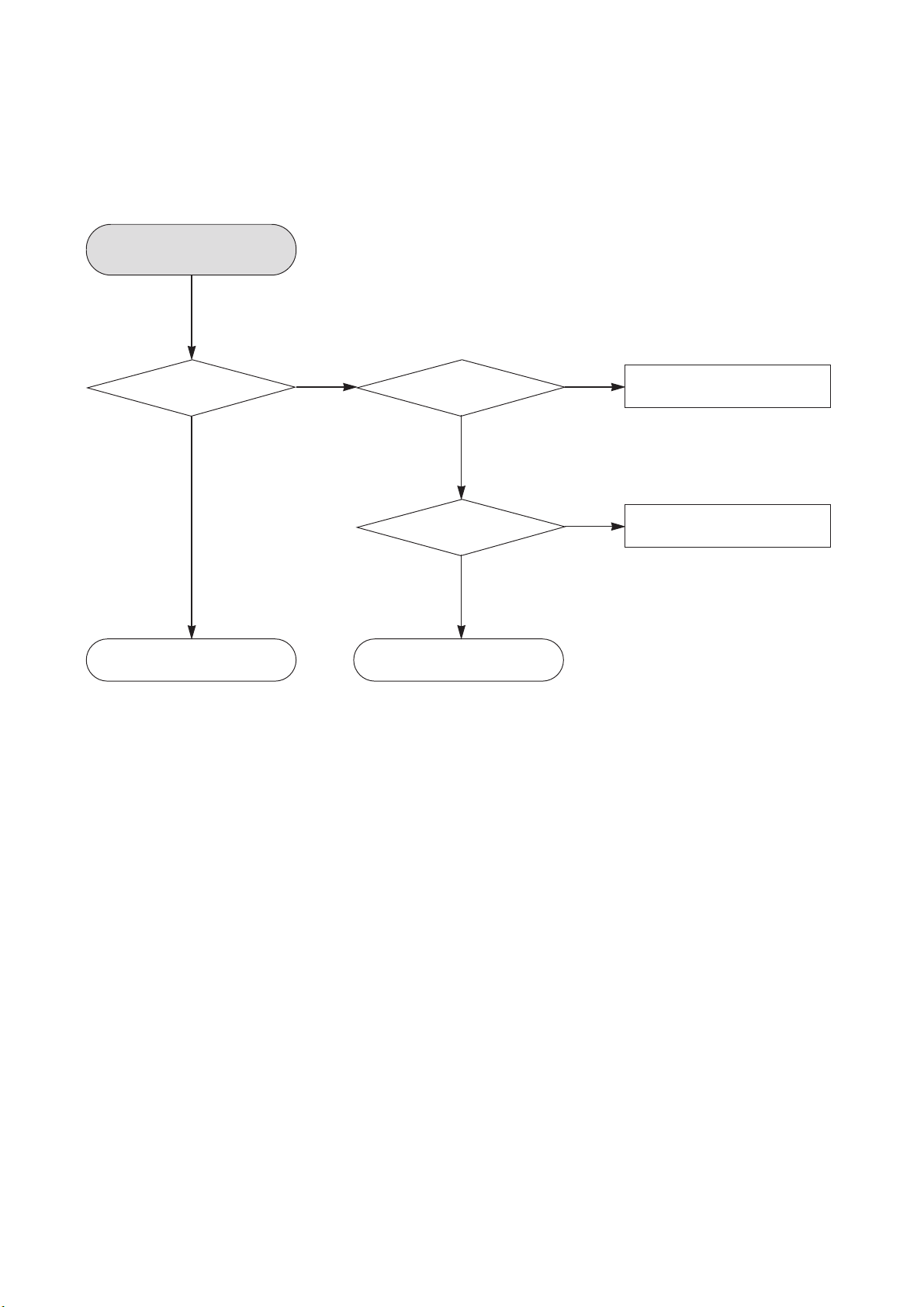

Page 19

3-5

FLD display check

YES

YES

Replace WF31.

Check each

PIN voltage.

NO

NO

YES

YES

OK

Replace IC301.

Check IC301.

NO

YES

Replace IC100FLD light on?

Check IC100.

NO

YES

YES

OK

Refer to SMPS

7. FLD DISPLAY CHECK

YES

YES

Check

P7904_PIN1, 2, 3 voltage

input.

NO

Check WF31 connection.

NO

If voltage is not 5V,

check input and output

of D301(1SR35).

YES

Check WF31

connection and power.

Pin1 : FL-22 Pin2 : FL+26

Pin3 : VKK- over

26V.

YES

YES

YES

YES

OKOK

76 PIN - > DO - - >

Check DATA in Check IC100.

NO

IC100

75 PIN - > STB

77 PIN - > 4PIN DI

78 PIN - > 1PIN CLK

Check data output.

IC100 - >

Check IC301

DATA communication.

PIN PIN

75PIN - > 3PIN STB

76PIN - > 2PIN D

78PIN - > 1PIN

CLK

Check

IC301(PT6324) voltage.

Pin50 VKK : -26V

PIN9.52 : +5V

Check if both end votage

of F1, F2 are over 3.7V.

VKK : over 26V.

Page 20

8. PWM MODULATION PART CHECK

PWM modulation

part check

YES

P7905_PIN9

3.3V checking

NO

Refer to

SMPS troubleshooting.

YES

Check IC604(PS9829)

VDD PIN voltage(3, 7, 8,

10, 22, 29, 39, 47, 56, 65,

72, 94).

Check X601_PIN2 3.3V.

YES

Check

X601 12.288MHz

operation.

YES

Check IC605_

PIN3 input and PIN2

output.

YES

IC604

(PS9829) PIN86 CLK

input check

YES

Check

IC100(78KOKF2)

21->PWM_CLK

22->PWM_DATA

43->PWM_REST

output.

YES

NO

NO

NO

NO

Check X601

12.288MHz.

Check IC605_

Check IC605_

Check IC605_

PIN2 output

Check R680

(470) output.

LINE registor output.

DATA:R671, CLK:R670

YES

OK

PIN8 3.3V.

YES

PIN3 input

YES

YES

OK

YES

OK

Check

RST:R665

YES

OK

NO

NO

NO

NO

NO

NO

Replace X601.

Check FB614

BEAD input, output and

voltage.

YES

OK

Check X601

2.288MHz

YES

Replace IC605.

Replace R680.

Replace R670, R671

and R665

NO

NO

Replace FB614

Replace X601.

OK

Check IC604

(PS9829) DATA input.

78 PIN->DATA

79 PIN->CLK

YES

Check PWM

modulator output.

FL:75(+)74(-)

FR:71(+)70(-)

YES

NO

NO

Check

DVD ASS`Y(PS9829)

communication

(P7403).

YES

Check

IC604(PS9829) DATA

input.

YES

OK

Check IC604(PS9829).OK

3-6

NO

NO

Refer to

CD troubleshooting.

Check each LINE

registor output.

Page 21

3-7

Power AMP part check

YES

Check each LINE registor output voltage.

IC700 : R701, 702, 726, 727

NO

Check

IC700 PIN1,17, 18, 19, 36

+12V input.

Refer to SMPS troubleshooting.

YES

YES

YES

NO

P7905_3PIN : +12V,

PIN13, 14, 15 : 35V.

YES

Replace the coils

YES

NO

Check output line coil.

Check PWM modulator input.

Each IC PIN4, 6, 14, 16

YES

Power IC700 PIN20, 27, 29, 34 output.

Check IC700 PIN21, 26, 29, 34 input voltage.

OK

9. POWER AMP PART CHECK

Page 22

10. AUX FUNCTION CHECK

AUX function check

YES

Check JK800 connection.

YES

Check

IC200(BU4052)_

PIN4, 11 input

waveform.

YES

Check IC200(BU4052)_

PIN3, 13 output waveform.

YES

Check

IC801(MC4580)_PIN 2, 6

input waveform.

YES

NO

NO

IC200(BU4052)_PIN16

Check

VDD, PIN8 VSS

power.

YES

Replace IC200

Check

IC801(MC4580)_PIN4

VSS, PIN8 VDD

power.

YES

Replace IC801OK

NO

NO

Check µ-COM(IC301)_

PIN83, 84 commucation.

Refer to

SMPS troubleshooting.

3-8

Page 23

11. TUNER FUNCTION CHECK

TUNER function check

YES

Check TUNER

module(TU601) operation.

YES

Check IC200(BU4052)_PIN1, 12 input

waveform.

YES

Check

IC200(BU4052)_PIN3, 13

output waveform and IC601

(BU4052)_PIN2,15 input

waveform.

YES

Check IC801(MC4580)_

PIN2, 6 input waveform.

NO

NO

NO

Check TUNER module voltage(PIN2 : 9V).

Check IC200(BU4052)_

PIN16 VDD, PIN8 VSS power.

YES

Replace IC200.

Replace IC200.

Check IC801(MC4580)_

PIN4 VSS, PIN8 VDD power.

YES

OK

YES

Replace IC801.

3-9

Page 24

12. PORTABLE IN FUNCTION CHECK

PORTABLE IN function check

YES

Check JK32 connection.

YES

Check

IC200(BU4052)_

PIN5, 14 input

waveform.

YES

Check IC200(BU4052)_

PIN3, 13 output waveform.

YES

Check

IC801(MC4580)_PIN 2, 6

input waveform.

YES

NO

NO

IC200(BU4052)_PIN16

Check

VDD, PIN8 VSS

power.

YES

Replace IC200

Check

IC801(MC4580)_PIN4

VSS, PIN8 VDD

power.

YES

Replace IC801OK

NO

NO

Check µ-COM(IC301)_

PIN83, 84 commucation.

Refer to

SMPS troubleshooting.

3-10

Page 25

INTERNAL BLOCK DIAGRAM OF ICs

1. AK5358

VA AGND VD DGND MCLK

Clock Divider

AINL

AINR

VCOM

2. BU4052

Modulator

Modulator

Voltage Reference

Decimation

Filter

Decimation

Filter

Serial I/O

Interface

DIFPDNCKS0CKS1CKS2

LRCK

SCLK

SDTO

3-11

Page 26

3. LC78692NW

SLCO

80

LRVSS

RCHO

LRREF

LCHO

LRVDD

XVDD

XIN

XOUT

XVSS

AMUTEB

DOUT

DVDD

DVSS

DVDD15

VVSS2

VPDOUT2

VCOC2

VPREF

VVDD2

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

EFMIN

RFOUT

LPF

PHLPF

AIN

CIN

BIN

DIN

SLCISET

RFMON

VREFO

JITTC

EIN

FIN

PCNCNT

TEOUT

TEIN

LDD

LDS

AVSS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

SLICE

LEVEL

CONTROL

RF

SIGNAL

PROCESSOR

MONITOR

VREF

TES, HFL,

DEFECT

JITIER

APC

D/A

A/D

LPF

1 Bit

DAC

GENERATOR

8FS DIGITAL

DEEMPHASIS

ATTENUATION CONTROL

Bass-Boost

INTERPOLATION MUTE

ERROR CORRECTION

Synchronization

Detection

Demodulation

CONTROL

CD PLL

CLOCK

FILTER

EFM

SERVO

DOUT

Control

DECODER

DECODER

SUBCODE

DECODER

MP3

&

WMA

ROM

TEXT

PORT

CONTROL

Audio Output

Memory I/F

PLL2

Control

Stream

Control

Memory

1M Bit

System

Control

MCU

PLL3

I/F

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

LRSY

DATACK

DATA

TEST1

STDATA

STCK

STREQ

TEST0

CONT0

CONT1

CONT2

INTB1

INTB0

RESB

DO

DI

CL

CE

DVSS

DVDD

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

FDO

AVDD

TDO

SPDO

SLDO

VVSS1

PDOUT1

PDOUT0

VVDD1

PCKIST

PUIN

DMUTEB

DEFECT

C2F

FSEQ

DVSS

DVDD

DVDD15

VVSS3

VVDD3

3-12

Page 27

4. PS9829B

MBCK

SBCK

SLRCK

MLRCK

MSDIN[0:3]

SSDIN[0:3]

MIC_MCLK

DMIX_MCLK

OLRCK

OBCK

DMIX_SDOUT

PWM1_P/M

PWM2_P/M

PWM3_P/M

PWM4_P/M

PWM5_P/M

PWM6_P/M

PWM7_P/M

PWM8_P/M

PWM_HP_L_P/M

PWM_HP_R_P/M

PWM_SWL_P/M

EPD_ENA

OVERLOAD

MIC_BCK

MIC_LRCK

MIC_SDIN

SPI/I2C

SO/SDA

SCK/SCL

SI/I2C_AD0

/

CS/I2C_AD2

EXT_MUTE

CLK_IN

/RESET

PLL_DVDD

PLL_DVSS

PLL_AVDD

PLL_AVSS

DVDD

DVSS

IO_VSS

IO_VDD

Internal Controls

Internal Clock Internal Reset

Host

Interface

(I

2

C, SPI)

Mic,

Input

Processor

Input

Mapper

Sample

Rate

Converter

Input

&

Output

MUX

Serial Audio

Output

Interface

Down

Mixer

Mixer

4 Band

EQ

Bass

Manager

Main

Volume

Trim

Volume

Serial

Audio

Output

Interface

PWM

Modulator

POP

NR

Power Supply

Output Mapper

PLL

Reset & Power Down

Automatic

Gain

Limiter

5. PT6324

SG1/KS1

SG2/KS2

SG3/KS3

SG4/KS4

SG5/KS5

SG6/KS6

SG7/KS7

SG7/KS7

SG8/KS8

SG9/KS9

SG10/KS10

SG11/KS11

SG12/KS12

SG13/KS13

SG14/KS14

SG15KS15

SG16/KS16

SG17

SG18

SG19

SG20

SG21

SG22

SG23

SG24

GR1

GR2

GR3

GR4

GR5

GR6

GR7

GR8

GR9

GR10

GR11

GR12

GR13

GR14

GR15

GR16

Segment Driver

Dimming Circuit

Grid

Driver

Control

DIN/DOUT

CLK

STB

OSC

LED1

K1 K2 VDD GND VEE

Timing Generator

Key Matrix Memory

LED

Driver

CSC

Serial

Data

Interface

Display Memory

3-13

Page 28

6. STR-W6753

4

Vcc

Start

Stop

Burst

OSC

Protection

latch

DRIVE

Reg

Delay

Burst

Control

BSD

OCP

GND

S

D

FB

FB

OCP/BD

SS/OLP

BD

Q

Q

S

S

R

R

MaxON

R Q

S

OLP

Reg&

Iconst

Soft Start

Counter

Bottom Selector

5

7

6

3

2

1

OVP

3-14

Page 29

7. TAS5142

2nd-Order L-C

Output Filter

for Each

Half-Bridge

Bootstrap

Capacitors

2-Channel

H-Bridge

BTL Mode

System

Microcontroller

OUT_A

OUT_B

OUT_C

OUT_D

BST_A

BST_B

BST_C

BST_D

RESET_AB

RESET_CD

System

Power

Supply

Hardwire

Mode

Control

PVDD

GVDD (12 V)/VDD (12 V)

GND

Hardwire

OC Limit

M1

M3

PVDD

Power

Supply

Decoupling

32 V

12 V

GND

VAC

PWM_A

PWM_C

PWM_D

PWM_B

V

ALID

M2

Left-

Channel

Output

Right-

Channel

Output

Input

HúBridge 1

Input

H-Bridge 2

GVDD

VDD

VREG

Power Supply

Decoupling

4

PVDD_A, B, C, D

GND_A, B, C, D

GVDD_A, B, C, D

4 4

VDD

GND

VREG

AGND

OC_ADJ

Bootstrap

Capacitors

2nd-Order L-C

Output Filter

for Each

Half-Bridge

SD

OTW

Output

H-Bridge 2

Output

H-Bridge 1

OTW

SD

T

AS5508

3-15

Page 30

8. U1739EJ2V1UD00/KF2_E

Port 0 P00 to P067

Port 1 P10 to P178

Port 2 P20 to P27

7

Port 3 P30 to P33

4

Port 4 P40 to P47

8

Port 5 P50 to P57

8

Port 6 P60 to P67

8

Port 7 P70 to P77

8

Port 12 P120 to P124

5

Port 13

P130

Port 14 P140 to P145

6

8

4

2

Key return

Reset control

On-chip debug

Note 2

Multiplier &

divider

System

control

Voltage

regulator

REGC

XT2/EXCLKS/P124

XT1/P123

XT1/P121

RESET

OCD0A

Note 2

/X1, OCD1A

Note 2

/P31

KR0/P70 to

KR7/P77

OCD0B

Note 2

/X2, OCD1B

Note 2

/P32

X2/EXCLK/P122

Internal high-speed

oscillator

8

Buzzer output

BUZ/P141

Clock output

control

Power on clear/

low voltage

indicator

POC/LVI

control

PCL/P140

EXLVI/P120

VDD,

EVDD

VSS,

EVSS

FLMD0

16-bit timer/

event counter 00

TO00/TI010/P01

TO01/TI011/P06

TI000/P00

TI001/P05

TOH0/P15

TOH1/P16

TI50/TO50/P17

TI51/TO51/P33

RxD0/P11

TxD0/P10

RxD6/P14

TxD6/P13

SI10/P11

SO10/P12

SI11/P03

SO11/P02

SCK11/P04

SCK11/P05

SIA0/P143

SOA0/P144

SCKA0/P142

STB0/P145

BUSY0/P141

EXSCL0/P62

SDA0/P61

SCL0/P60

AV

REF

RxD6/P14 (LINSEL)

INTP0/P120

INTP1/P30 to

INTP4/P33

INTP5/P16

INTP6/P140,

INTP7/P141

AV

SS

ANI0/P20 to

ANI7/P27

SCK10/P10

RxD6/P14 (LINSEL)

16-bit timer/

event counter 01

8-bit timer H0

8-bit timer H1

Watchdog timer

78K/0

CPU

core

Internal

high-speed

RAM

Internal

expansion

RAM

Flash

memory

BANK

Note 1

Watch timer

8-bit timer

event counter 50

8-bit timer

event counter 51

Serial

interface UART0

LINSEL

Serial

interface UART6

Serial

interface CSI10

Serial

interface CSI11

Serial

interface CSIA0

Serial

interface IIC0

A/D converter

Interrupt

control

Internal low-speed

oscillator

3-16

Page 31

9. UTC MC4580

9-2. TEST CIRCUIT

9-1. PIN CONFIGURATION

3-17

Page 32

3-18

6

P

5

P

16

P

8P

D PCB

2 CH SPK

AU

X

JACK

TUNER

MODUL

E

1

CD

INGLE M

D

P

CB

5

P

3

P

29

P

USB

PORT

IN

H/P

FRONT PCB

SMPS PCB

15

P

[Total CNT Q'ty : 10ea]

1. SMPS MAIN : 2ea

2. MAIN CD : 2ea

3. MAIN FRONT : 1ea

4. FRONT CD : 1ea

5. CD MD : 3ea

E

D

3-19

WIRING DIAGRAM

Page 33

AC INPUT

ZNR &

FILTER

T

R

A

N

S

#1

AMP

Switch

IC #

1

MAIN

Switch

IC #

2

T

R

A

N

S

#2

FL1-FL2 (4. 5V)

-12V

12V (78R12)

5V(P-SEN S)

6.1V (KIA278R05)

P9702

P9701

FEED BACK

AMP (+) 31.5V

3.5V (278R35)

-31. 5V(VKK)

RECTIFICATION

SMOOTHING

CIRCUIT

FEED BACK

3-20 3-21

BLOCK DIAGRAMS

1. SMPS BLOCK DIAGRAM

Page 34

PS9829B

PWM

MODULATOR

PS9829B

PWM

MODULATOR

TAS5142

Power Amp

TAS5142

Power Amp

FR

FL

FL+/ -, FR+/-

AMP BOARDMAIN BOARD

NEC

AUDIO

MICOM

NEC

AUDIO

MICOM

12.288 MHz

9.8304 MHz

9829_RESET

9829_CLK

9829_DAT

TAS5142_PDN

TAS5142_SD

HA1227

TAPE IC

REC MUTE

P/B MUTE

REC BIAS

DECK

MD

DECK/ HD

TUNER

MODULE

PLL DAT.CLK

RDS

DATA.CLK

BU4052

TAPE L/R

TUNER L/R

AUX L/R

OP AMP

AK5358

OP AMP

LEVEL METER

REC L/R

AK5358 REST

CD DATA.CLK

PORT INPUT

AUX INPUT

HEAD PHONES

BU4052 DATA

USB DA+.-. 5V

CD DATA.CLK

AK5358

CLK.DATA

H/P_SW

PW

M OUT

CD

SANYO

LC78692NW

FLD (DISPLAY)

VFD DRIVE IC

PT6324

XC102 : 2 CH (50W X 2Ch)

W/O DECK

XC62 : 2 CH (30W X 2Ch )

W /SINGLE DECK

LEVEL SHIFT IC

74VHCT244

R

L

PORT L/R

SOL "B"

MOTOR

MODE B

HALF B

P/B

L/R

REC L/R

XC62 ONLY

3-22 3-23

2. MAIN & FRONT BLOCK DIAGRAM

Page 35

SCHEMATIC DIAGRAMS

1. SMPS SCHEMATIC DIAGRAM

WHEN SERVICING TH IS CHASSI S, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN

BE MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WI TH TYPE S

IDENTICAL TO THOSE IN THE ORIGINAL CIRCUIT.

SPECIAL COMPONENTS AR E SHADE D ON THE

SCHEMATIC FOR EASY IDE NTIFICATION. THIS

CIRCUIT DIA GRAM MAY OCCASION ALLY DIFFER

FROM THE ACTUAL CIRCUIT US ED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMAN CE IMPROV EMENT CHANGE S INTO

THE SET IS NOT DELAYED UNTIL THE NEW SERVICE

LITERATURE IS PRINTED.

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

IMPORTANT SAFETY NOTE :

3-24 3-25

Page 36

3-26 3-27

2. MAIN SCHEMATIC DIAGRAM

Page 37

3. AMP SCHEMATIC DIAGRAM

3-28 3-29

Page 38

3-30 3-31

4. FRONT SCHEMATIC DIAGRAM

Page 39

1. MAIN P.C.BOARD

(TOP VIEW)

PRINTED CIRCUIT BOARD DIAGRAMS

3-32 3-33

Page 40

MAIN P.C.BOARD

(BOTTOM VIEW)

3-34 3-35

Page 41

2. SMPS P.C.BOARD

3-36 3-37

Page 42

3. FRONT P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3-38 3-39

Page 43

MEMO MEMO

3-40 3-41

Page 44

4-1

CD ELECTRICAL TROUBLESHOOTING GUIDE

1. CD PART TROUBLESHOOTING

Turn on CD

YES

YES

NO

OPEN CLOSE check

Connector check (PN804)

NO

Check voltage CN806

PIN1 : 12, PIN2 : 6.3V

NO

Check voltage PN805

PIN22 : CLOSE, PIN23 : OPEN

YES

NO

“Reading”

Display check

Connector check

(PN802, PN803, PN804, CN806)

NO

Check micom interface circuit (PN805)

(CE, BTL-MUTE, CD-IN, CD-OUT, CLK, WRQ, FSEQ)

YES

NO

Reading OK check

Connector check (PN801,PN802)

NO

YES

If PALY, AUDIO

OUTPUT check

Check PN805 audio data

PIN10 : DA_LRCK (IC801 PIN60 LRSY)

PIN11 : DA_BCK (IC801 PIN59 DATACLK)

PIN12 : DA_DATA0 (IC801 PIN58 DATA)

NO

Check pick up movement

NO

Check AM5810FP (IC802)

NO

Check LC78692 (IC801)

OK

SECTION 4 CD PART ELECTRICAL

Page 45

4-2

1-1. OPEN CLOSE NG

Connector locking check (PN804)

YES

YES

YES

YES

Check power

supply circuit (PN805, CN806)

CN806 PIN1 : 12V, PIN2 : 6.3V

PN805 PIN8 : +5V_AD

Defective main power supply

NO

Check voltage change LO+, LO- OF IC803

(PN805 PIN23 : OPEN, PIN22 : CLOSE)

Defective IC803

Defective mechanism

NO

Check voltage

change of OPEN CLOSE

IC803 INPUT voltage PIN6 : 12V,

PIN7:6.3V (PN805 PIN2 :

BTL_MUTE, 23 : OPEN,

22 : CLOSE)

Defective micom

NO

Page 46

1-2. “READING” DISPLAY CHECK (= ONLY “CD” DISPLAY)

Conector locking check

(PN802, PN804, PN805, CN806)

YES

Check power

supply port (PN805, CN806)

CN806 PIN1 : 12V, PIN2 : 6.3V,

PIN4 : 5V PN805

PIN8 = 5V_AD

YES

NO

Defective connector or main power supply

Check voltage

The PIN2 of IC804

IC804 PIN2 : 3.3V

YES

Check reset

signal of PN805

PN805 PIN19 : 5V

YES

Check micom interface circuit (PN805)

PN805 PIN1, 3, 4, 15, 19, 26 signal check

(1 : CE, 3 : DI, 4 : CLK, 15 : D0, 19 : RST,

18 : FSEQ, 26 : WRQ) PIN3 DI : From DSP

to micom PIN15 DO : From micom to DSP

Check the waveform #1

YES

NO

NO

NO

Defective IC804

Defective micom or connector

Defective micom or connector

Defective IC801

4-3

Page 47

4-4

Connector locking check

(PN801, PN802)

Is reading OK?

Defective pick up or

IC802 or IC801

Does sled move?

NO

NO

Check PN802

PIN3, 4 (SL+, SL-)

1-3. READING OK CHECK (= “NO DISC” DISPLAY)

Does lense move?

(= UP & DOWN)

YES

A

YES

Defective pick up or

IC802 or IC801

NO

NO

Check PN801

PIN13, 16 (FA+, FA-)

B

Defective pick up or IC801

Does laser light?

NO

NO

Check PN801 PIN10 (LD)

YES

C

Defective pick up or

IC802 or IC801

Does spindle rotate?

NO

NO

Check PN802

PIN5, 6 (SP+, SP-)

YES

D

Defective pick up or

IC802 or IC801

NO

NO

Check PN801

PIN14, 15 (TA+, TA-)

E

Page 48

1-4. READING OK CHECK #A (= “NO DISC” DISPLAY)

A

Does

SL+ waveform

appear at (IC802 PIN13

and PN802 PIN3)

waveform #2

sled motor

wave

YES

Check PN802 connector line

YES

NO

NO

Defective PN802 connector

Defective pick up sled motor

Does slin

waveform appear at

(IC802 PIN5)

waveform #2

sled drive

wave

YES

Defective IC802

1-5. READING OK CHECK #B (= “NO DISC” DISPLAY)

B

NO

Defective IC801

Does

FA+ waveform

appear at (IC802 PIN16

and PN801 PIN13)

waveform #3 focus

coil drive

wave

YES

Check PN801 connector line

YES

NO

NO

Does

fain-waveform

appear at (IC802 PIN25)

waveform #3

focus drive

wave

YES

Defective IC802

Defective PN801 connector

Defective pick up

focus actuator

4-5

NO

Defective IC801

Page 49

4-6

Defective IC804

Is ?V applied

to PIN10 of PN801

laser supply voltage

check

Is 3.3V

applied to

PIN30, 36, 39, 41, 61,

68, 75 of IC801 RF IC

supply voltage

check

NO

NO

1-6. READING OK CHECK #C (= “NO DISC” DISPLAY)

YES

YES

Defective IC801

Is 2.3V

PIN18 (LDO) of IC801

laser control voltage

check

NO

YES

C

Defective Q801 or D801

NO

Defective PN801 connector

Defective pick up laser part

Check PN801 connector line

YES

Page 50

1-7. READING OK CHECK #D (= “NO DISC” DISPLAY)

D

Does

SP+ waveform

appear at (IC802

PIN11 and PN802 PIN5)

waveform #4 spindle

motor drive

wave

YES

Check PN802 connector line

YES

NO

NO

Does

spin waveform

appear at (IC802 PIN6)

waveform #4

spindle drive

wave

YES

Defective IC802

Defective PN802 connector

Defective pick up

spindle motor

NO

Defective IC801

4-7

Page 51

1-8. READING OK CHECK #E (= “NO DISC” DISPLAY)

E

Does

TA+ waveform

appear at (IC802 PIN17

and PN801 PIN14)

waveform #5 tracking

coil drive

wave

YES

Check PN802

connector line

YES

Does

ARF signal appear?

(IC801 PIN 2)

waveform #6

YES

NO

NO

NO

Does

tain - waveform

appear at (IC802 PIN22)

waveform #5

tracking drive

wave

YES

Defective IC802

Defective PN802 connector

Defective pick up or IC801

NO

Defective IC801

Does FE, TE signal

appear? (IC801

PIN10 : RFMON, PIN16 : TE)

waveform #6

* REMON is FE

NO

Defective pick up or IC801

4-8

Page 52

2. USB PART TROUBLESHOOTING

Turn on USB

YES

“Checking” or

“USB” display check

YES

Reading OK check

YES

If PLAY, AUDIO

OUTPUT check

YES

NO

NO

NO

Connector check

(PN805, CN806, PN810 )

NO

Check power supply circuit (CN806)

NO

Check micom interface circuit (PN805)

PIN13 : RX (IC805 PIN49 : TXD)

PIN14 : TX (IC805 PIN33 : RXD)

Check PN810 1PIN : 5V

NO

Check PN810 PIN2(D-), 3(D+)

NO

Check OTI6888 (IC805)

Check signal STCK, STREQ, STDATA

STCK : IC805 PIN52, IC801 PIN55

STREQ : IC805 PIN53, IC801 PIN54

STDATA : IC805 PIN54, IC801 PIN56

NO

4-9

Connector check (CN806)OK

Page 53

WAVEFORMS OF MAJOR CHECK POINT

PIN26 : WRQ

PIN19 : RESET

PIN3 : DI (IC801 PIN46 DATA OUT)

PIN15 : DO (IC801 PIN45 DATA IN)

#1.MICOM INTERFACE WAVEFORM

(PN805 PIN26, 19, 3, 15) during normal play

PIN26 : WRQ

PIN19 : RESET

PIN3 : DI (IC801 PIN46 DATA OUT)

PIN15 : DO (IC801 PIN45 DATA IN)

#1.MICOM INTERFACE WAVEFORM

(PN805 PIN4, 1, 18) during power on

PIN4 : CL

PIN1 : CE

PIN18 : FSEQ

#1.MICOM INTERFACE WAVEFORM

(PN805 PIN4, 1, 18) during normal play

PIN4 : CL

PIN1 : CE

PIN18 : FSEQ

#1.MICOM INTERFACE WAVEFORM

(PN805 PIN26, 19, 3, 15) during power on

4-10

Page 54

4-11

#2.SLED DRIVE AND MOTOR WAVEFORM

(IC802 PIN5, 13) when focus search

PIN5 : SLIN

PIN13 : SL+

#2.SLED DRIVE AND MOTOR WAVEFORM

(IC802 PIN5, 13) during normal play

PIN5 : SLIN

PIN13 : SL+

#3.FOCUS DRIVE AND MOTOR WAVEFORM

(IC802 PIN25, IC802 PIN16)

• When focus search failed or there is no

disc on tray

PIN25 : FAO

PIN16 : FA+

#3.FOCUS DRIVE AND MOTOR WAVEFORM

(IC802 PIN25, IC802 PIN16)

• There is disc on tray and focus search success

PIN25 : FAO

PIN16 : FA+

Page 55

#4.SPINDLE DRIVE AND MOTOR WAVEFORM

PIN6 : SPIN

PIN11 : SP+

#5.TRACK DRIVE AND MOTOR WAVEFORM

(IC802 PIN22, IC802 PIN17) during normal play

#6.RF, FOCUS AND TRACKING ERROR WAVEFORM

(IC801 PIN2, 10, 16) during normal play

PIN2 : RFOUT

PIN 16 : TE

PIN10 : RFMON(FE)

PIN22 : TAO

PIN17 : TA+

(IC802 PIN6, 11) when TOC reading

4-12

Page 56

4-13 4-14

SCHEMATIC DIAGRAMS

1. CD SCHEMATIC DIAGRAM

Page 57

2. USB SCHEMATIC DIAGRAM

4-15 4-16

Page 58

CD P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

PRINTED CIRCUIT BOARD DIAGRAM

4-17 4-18

Page 59

4-19 4-20

MEMO MEMO

Loading...

Loading...