LG WM2501H Series, WM2501HA Service Manual

Website: http://www.LGEservice.com

E-mail: http://www. LGEservice.com/techsup. html

WASHING

RVlC

MACHINE

A AL

,&,CAUTION

READ THiS MANUAL CAREFULLY TO DIAGNOSE

PROBLEMS CORRECTLY BEFORE SERViCiNG THE UNIT,

MODEL: WM2501H*A

CONTENTS

1. SPECIFICATIONS ............................................................................................................... 3

2. FEATURES AND TECHNICAL EXPLANATION ................................................................. 4

3. PARTS IDENTIFICATION ................................................................................................... 7

4. INSTALLATION AND TEST ................................................................................................ 8

5. OPERATION ...................................................................................................................... 11

5-1. CONTROL PANEL FEATURES ................................................................................. 11

5-2. CYCLE GUIDE ........................................................................................................... 13

5-3. SPECIAL FUNCTIONS .............................................................................................. 14

5-4. EXPLANATION OF EACH PROCESS ....................................................................... 15

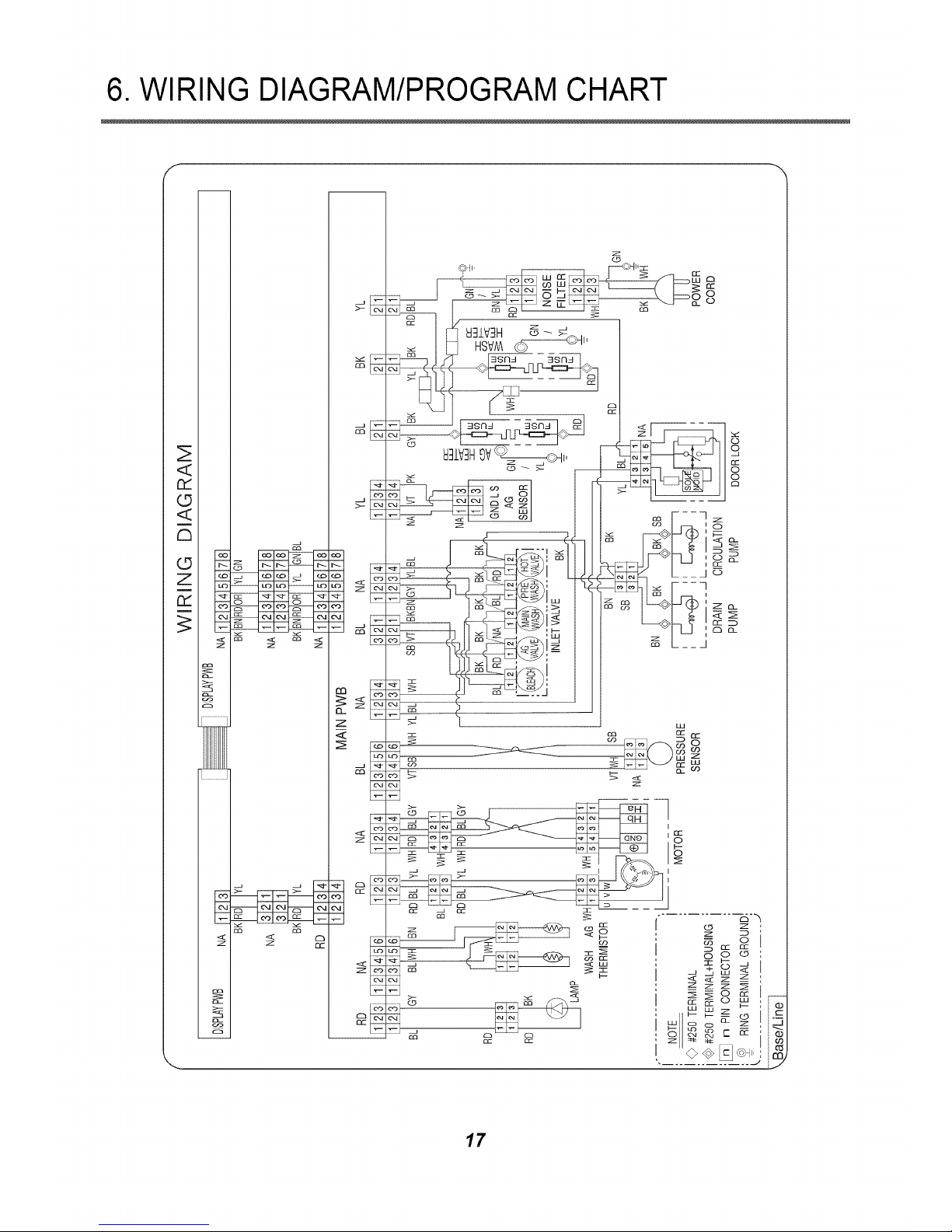

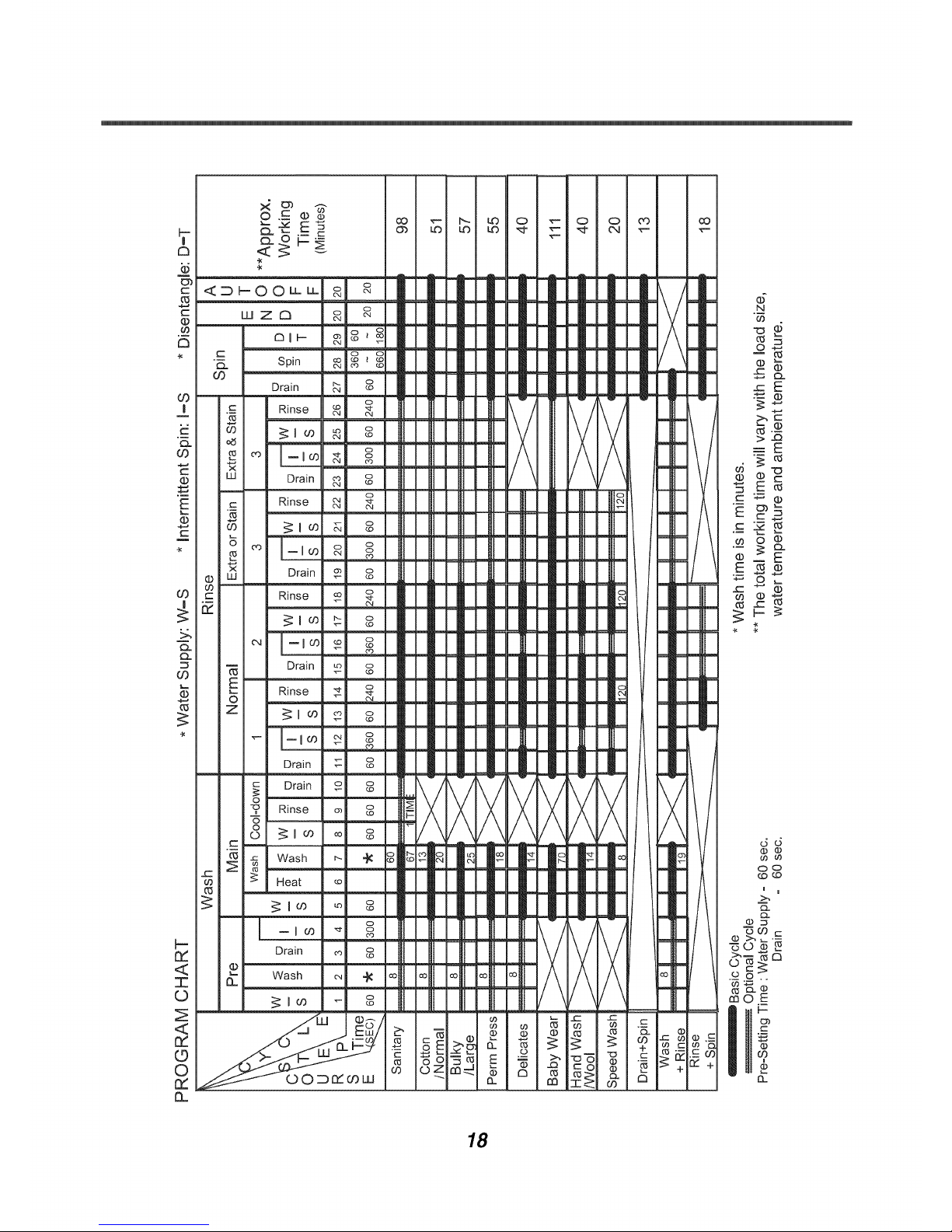

6. WIRING DIAGRAM/PROGRAM CHART .......................................................................... 17

7. TEST MODE ..................................................................................................................... I9

7-1. SAFETY CAUTION .................................................................................................... 19

7-2. LOAD TEST MODE ................................................................................................... 19

7-3. HOW TO CHECK THE WATER LEVEL FREQUENCY ............................................. 19

8. TROUBLESHOOTING ...................................................................................................... 20

8-1. SAFETY CAUTION .................................................................................................... 20

8-2. ERROR MODE SUMMARY ...................................................................................... 20

8-3. TROUBLESHOOTING SUMMARY ......................................................................... 22

8-4. TROUBLESHOOTING WITH ERROR ....................................................................... 23

8-5. TROUBLESHOOTING ELSE ..................................................................................... 30

9. COMPONENT TESTING INFORMATION ........................................................................ 35

9-1. FILTER ASSEMBLY (LINE FILTER) .......................................................................... 35

9-2. DOOR LOOK SWITCH ASSEMBLY .......................................................................... 36

9-3. STATOR ASSEMBLY ................................................................................................. 38

9-4. PUMP MOTOR ASSEMBLY ....................................................................................... 41

9-5. INLET VALVE ASSEMBLY ......................................................................................... 42

9-6. HEATER ASSEMBLY ................................................................................................. 43

9-7. THERMISTOR ASSEMBLY ....................................................................................... 44

9-8. STEAM GENERATOR ASSEMBLY ........................................................................... 46

9-9. LA

10. DISASSEMBLY INSTRUCTIONS .................................................................................... 49

11.EXPLODED VIEW ............................................................................................................ 60

11-1. CABINET AND CONTROL PANEL ASSEMBLY ...................................................... 60

11-2. DRUM AND TUB ASSEMBLY .................................................................................. 61

11-3. DISPENSER ASSEMBLY ........................................................................................ 62

2

1. SPECIFICATIONS

ITEM WM2501H*A

COLOR W:BLUE WHITE, V:STAINLESS SILVER, R:CANDY APPLE RED

POWER SUPPLY AC 120 V, 60 Hz

PRODUCT WEIGHT 192 Ibs (87kg)

WASHING 280 W

ELECTRIC POWER

DRAIN MOTOR 80 W

CONSUMTION

WASH HEATER 1000 W

WASH 46 rpm

REVOLUTION SPEED

SPIN 0-1200 rpm

CYCLES 9

WASH/RINSE TEMPERATURES 5

SPIN SPEEDS 5

OPTIONS Prewash, Rinse+Spin, Extra Rinse, Water Plus, Stain Cycle

WATER CIRCULATION Incorporated

OPERATIONAL WATER PRESSURE 14.5-116 psi (100-800 kPa)

CONTROL TYPE Electronic

WASH CAPACITY [cu.ft] 3.63 (4.2 IEC)

DIMENSIONS 27" (W) X 293/4 ,,(D) X 3811/16" (H), 5013/16" (D, door open)

DELAY WASH up to 19 hours

DOOR SWITCH TYPE PTC + Solenoid

WATER LEVEL 10 steps (by sensor)

LAUNDRY LOAD SENSING Incorporated

ERROR DIAGNOSIS Incorporated

AUTO POWER OFF Incorporated

CHILD LOCK Incorporated

RLM ENABLE

ST EAM Inco rporated

3

2. FEATURES& TECHNICAL EXPLANATION

2-1. FEATURES

\\1

m

Ultra Capacity

The Larger drum enables not just higher head drop and stronger

centrifugal force, but also less tangling and wrinkling of the

laundry. Heavier loads, such as king size comforters, blankets,

and curtains, can be washed.

@

m

Direct Drive System

The advanced Brushless DC motor directly drives the drum

without belt and pulley.

m

Tilted Drum and Extra Large Door Opening

Tilted drum and extra large opening make it possible fo load

and unload clothing more easily.

m

Roller Jets

Washing ball enhances the wash performance and reduces

damage fo the clothing. The jets spray and help tumble clothes

fo enhance washing performance while maintaining fabric care.

m Aufomafio Wash Load Defection

Automatically detects the load and optimizes the washing time.

m

Built-in Heater

Internal heater helps to maintain water temperature af its

optimum level for selected cycles.

m

Child Lock

The Child lock prevents children from pressing any button fo

change the settings during operation.

m

Steam Washing and SfeamFresh TM

Steam Washing features upgraded washing performance with low

energy and water consumption. SfeamFresh TMcycle removes

wrinkles from dry clothes.

4

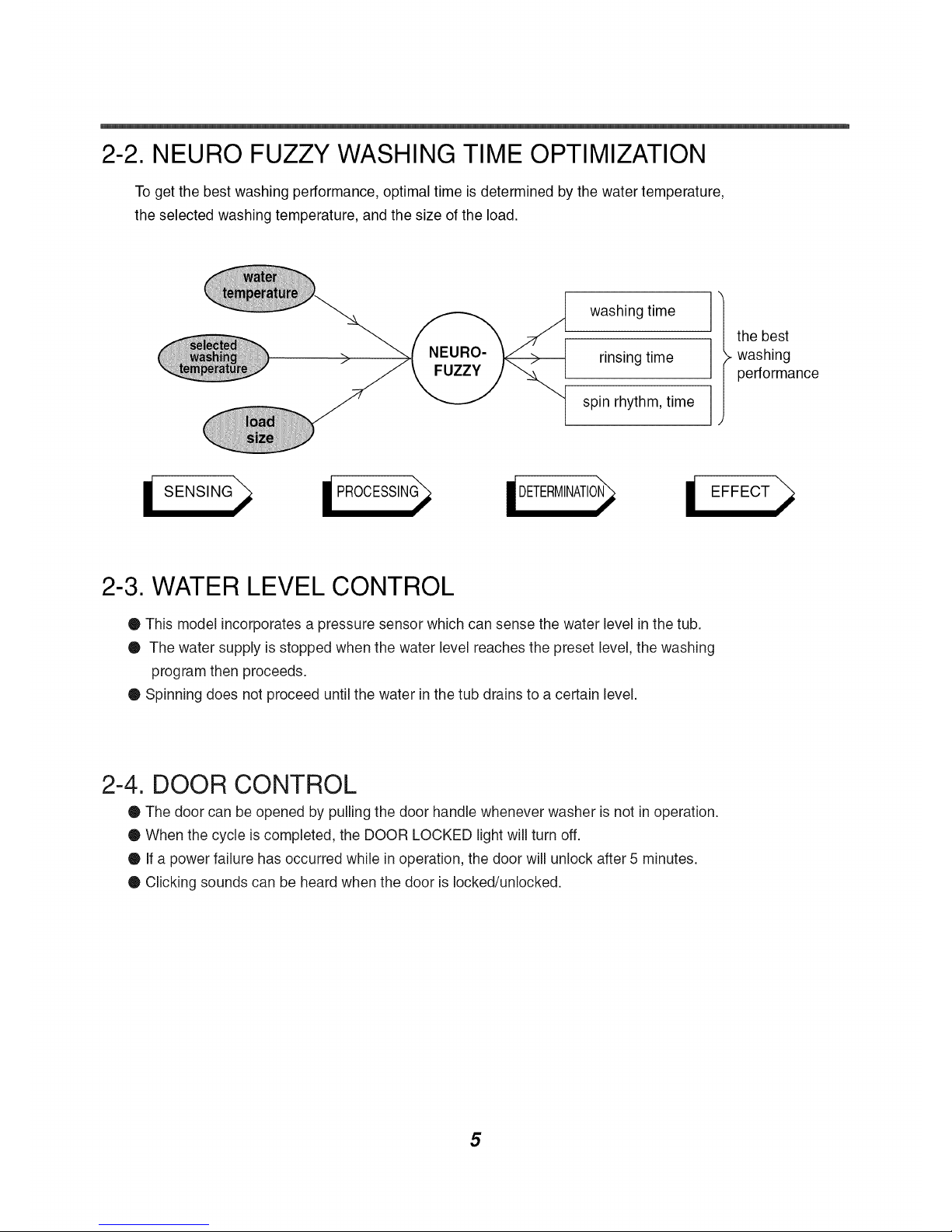

2-2. NEURO FUZZY WASHING TIME OPTIMIZATION

To get the best washing performance, optimal time is determined by the water temperature,

the selected washing temperature, and the size of the load.

NEURO-

FUZZY

washing time

rinsing time

spin rhythm, time

the best

washing

performance

EFFECT

2-3. WATER LEVEL CONTROL

Q This modeEincorporates a pressure sensor which can sense the water EeveEin the tub.

Q The water supply is stopped when the water EeveEreaches the preset EeveE,the washing

program then proceeds.

Q Spinning does not proceed until the water in the tub drains to a certain level.

2-4. DOOR CONTROL

Q The door can be opened by pulling the door handle whenever washer is not in operation.

Q When the cycle is completed, the DOOR LOCKED light will turn off.

Q If a power failure has occurred while in operation, the door will unlock after 5 minutes.

Q Clicking sounds can be heard when the door is locked/unlocked.

5

2-5. THE DOOR CAN NOT BE OPENED

® While program is operating.

®

O

®

2-6

When a power failed and power plug is taken out in operation.

While Door Lock lights turn on.

While the motor is in the process of intertial rotating, through the operation is paused.

• DOOR LOCKED LAMP LIGHTS

® When the frequency of water level is lower than 22.9 kHz

(It can be canceled when the frequency is more than 23.8 kHz)

® When the temperature inside the tub is higher than 45% and water level is not 25.5 kHz

(It can be canceled when the water level is 25.5 kHz or the temperature inside the tub is lower

than 40% )

2-7. CHILD LOCK

® Use this option to prevent unwanted use of the washer. Press and hold PRE WASH button

for 3 seconds to lock/unlock control.

® When child lock is set, CHILD LOCK lights and all buttons are disabled except the Power

button. You can lock the controls of the wash while washing.

2-8. WATER CIRCULATION

® When washing and rinsing function of shower at the upper part of Gasket.

® When washing, it continuously operates for 3 minutes and intermittently.

® When rinsing, it continuously operates after completion of water supply.

2-9

®

®

®

®

• STEAM

For tough stained clothes, sick room linens or baby clothes.

Steam Wash is available with Sanitary, Bulk/Large, Perm. Press, CoHon/Normal cycles.

This option features upgraded washing performance with low energy and water consumption

Do not load delicates such as wool, silk, and easily discolored clothes.

0. DRUM LIGHT

The Drum Light comes on when the Power button is pressed. It goes off when the door

is closed and the washer starts operation.

® The Drum Light remains off when the door is locked.

® The Drum Light can be turned on while the washer is in operation by pressing the Rinse+Spin

button for 3 seconds. The light will turn off automatically 4 minutes later.

® The Drum Light comes on when the washing cycle is finished and goes off 4 minutes later.

6

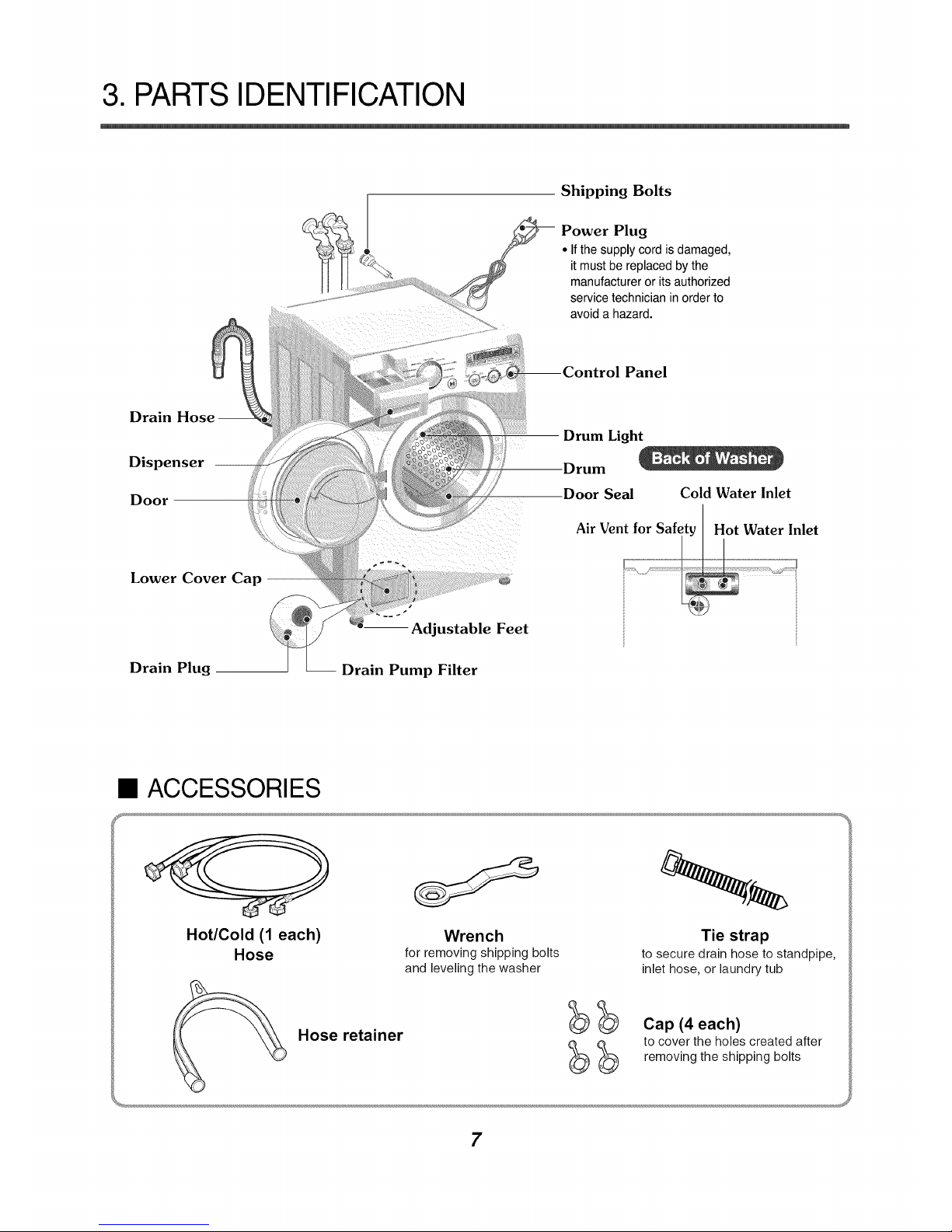

3. PARTS IDENTIFICATION

Shipping Bolts

Power Plug

• Ifthe supply cord is damaged,

it must be replaced bythe

manufacturer or its authorized

service technician in order to

avoid a hazard.

Panel

Drain Hose-

Dispenser

Door

Lower Cover Cap

-- Adjustable Feet

Drum Light

---Drum

.Door Seal

Cold Water Inlet

Air Vent for Safety Hot Water Inlet

Drain Plug

-- Drain Pump Filter

I ACCESSORIES

Hot/Cold (1 each)

Hose

Hose retainer

Wrench

for removing shipping bolts

and leveling the washer

Tie strap

to secure drain hose to standpipe,

inlet hose, or laundry tub

Cap (4 each)

to cover the holes created after

removing the shipping bolts

7

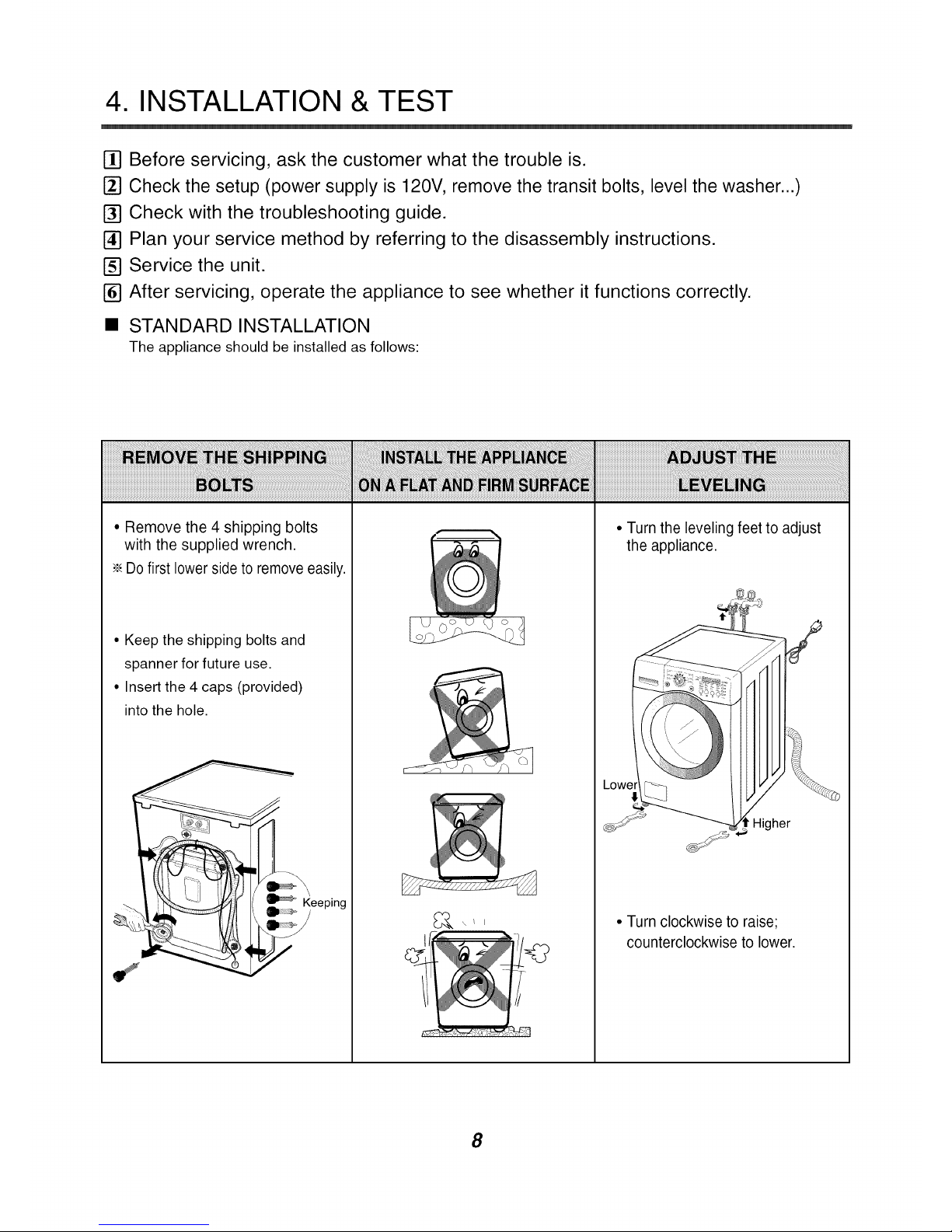

4. INSTALLATION & TEST

Ii1 Before servicing, ask the customer what the trouble is.

[] Check the setup (power supply is 120V, remove the transit bolts, level the washer...)

I-J] Check with the troubleshooting guide.

[] Plan your service method by referring to the disassembly instructions.

[] Service the unit.

[] After servicing, operate the appliance to see whether it functions correctly.

• STANDARD INSTALLATION

The appliance should be installed as follows:

8

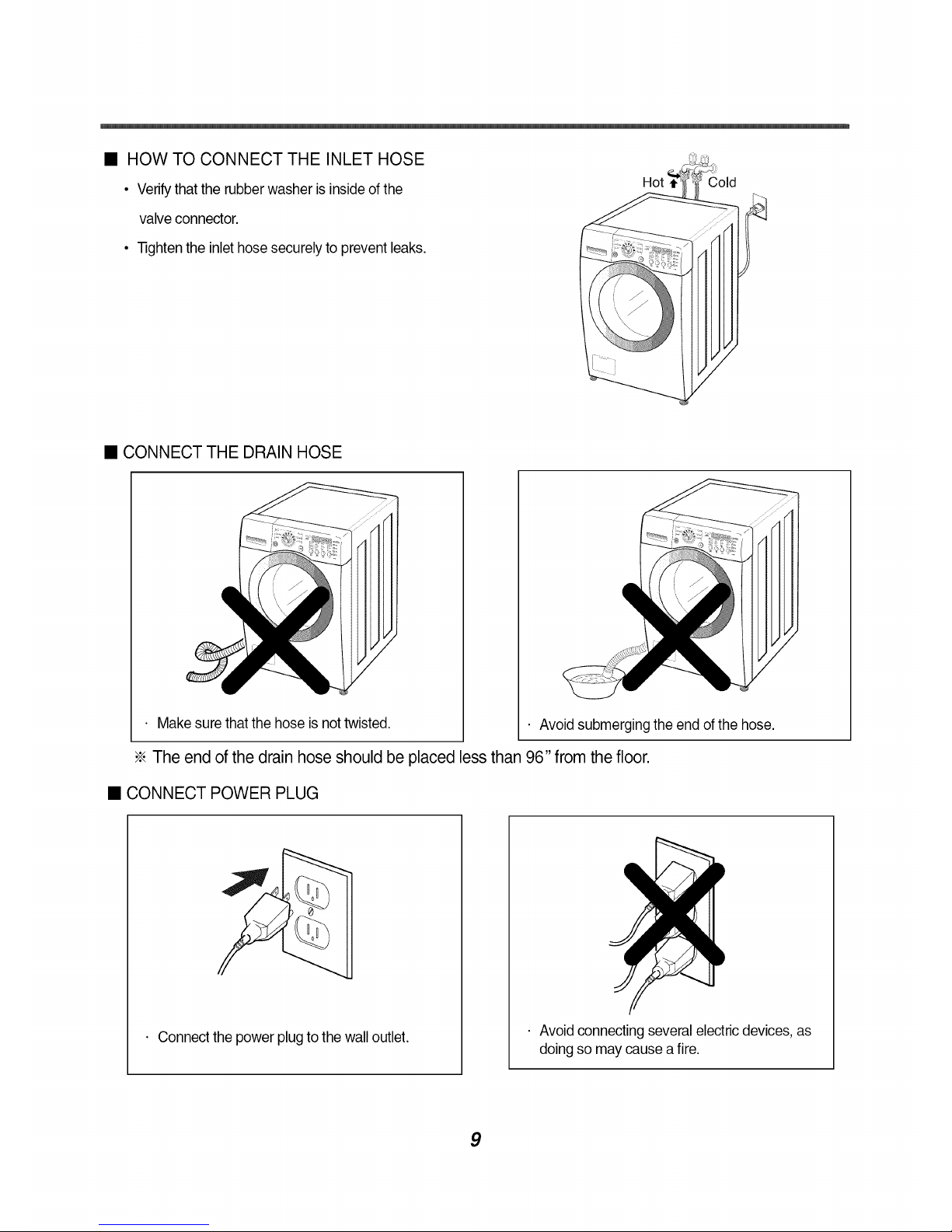

HOW TO CONNECT THE INLET HOSE

• Verify that the rubber washer is inside of the

valve connector.

• Tighten the inlet hose securely to prevent leaks.

• CONNECT THE DRAIN HOSE

Make sure that the hose is not twisted. Avoid submerging the end of the hose.

•_ The end of the drain hose should be placed less than 96" from the floor.

• CONNECT POWER PLUG

Connect the power plug to the wall outlet.

Avoid connecting several electric devices, as

doing so may cause a fire.

9

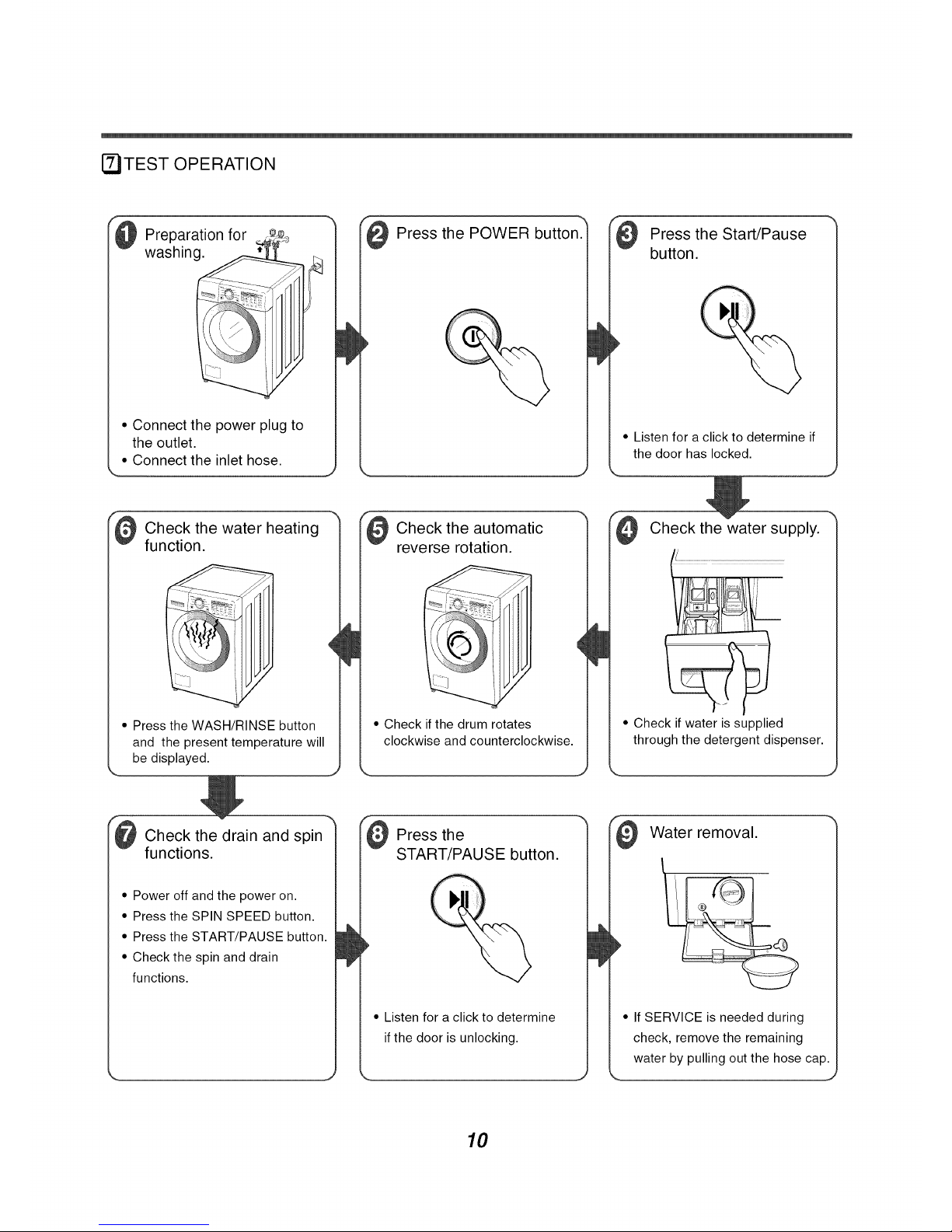

_TEST OPERATION

• Connect the power plug to

the outlet.

• Connect the inlet hose.

Press the POWER button.

Press the Start/Pause

button.

• Listen for a click to determine if

the door has locked.

e heck the water heating

function.

• Press the WASH/RINSE button

and the present temperature will

be displayed.

_ Check the automatic

reverse rotation.

• Check if the drum rotates

clockwise and counterclockwise.

0

Check the water supply.

• Check if water is supplied

through the detergent dispenser.

_ heck the drain and spin

functions.

• Power off and the power on.

• Press the SPIN SPEED button.

• Press the START/PAUSE button.

• Check the spin and drain

functions.

Press the

START/PAUSE button.

• Listen for a click to determine

if the door is unlocking.

Water removal.

• If SERVICE is needed during

check, remove the remaining

water by pulling out the hose cap.

10

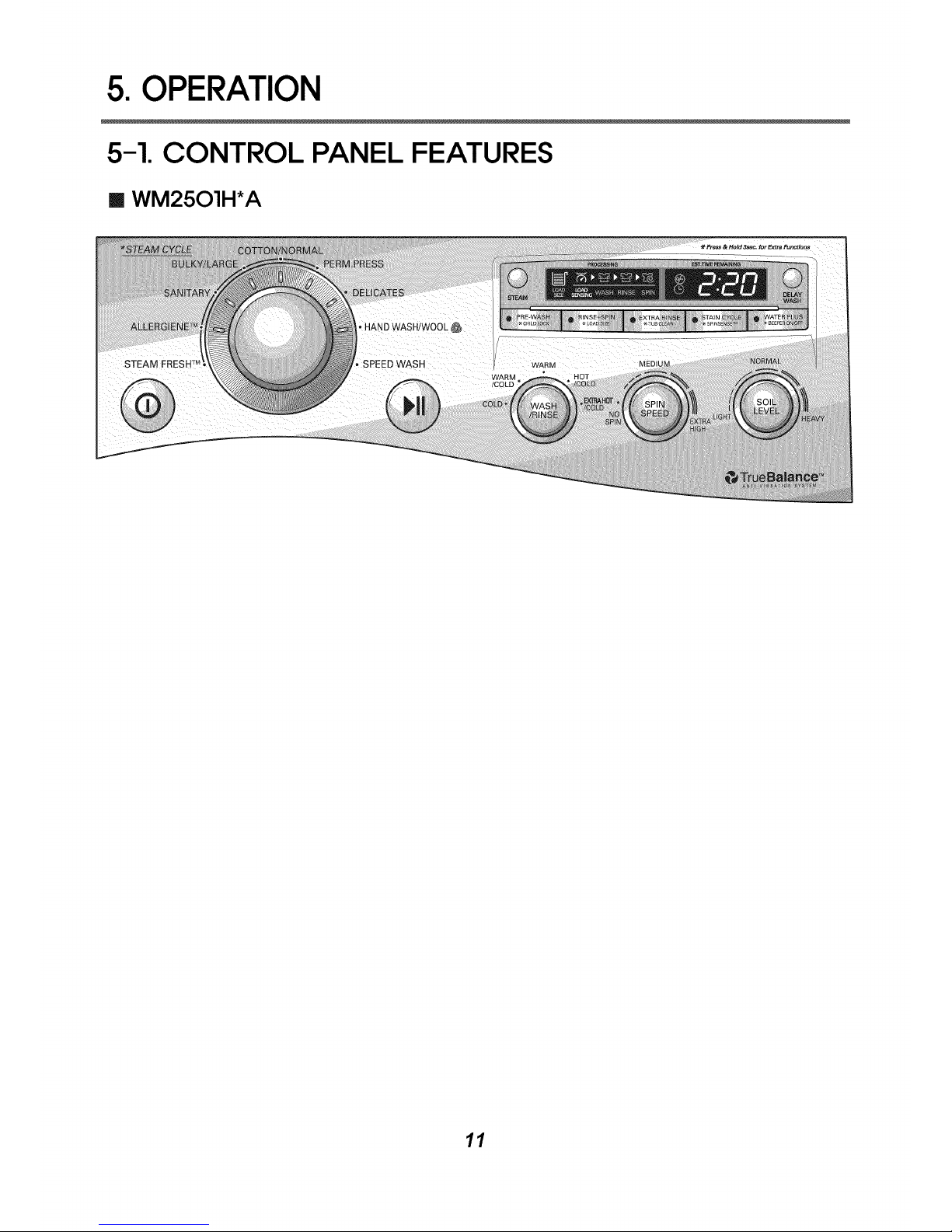

5. OPERATION

5-1. CONTROL PANEL FEATURES

II WM2501H*A

11

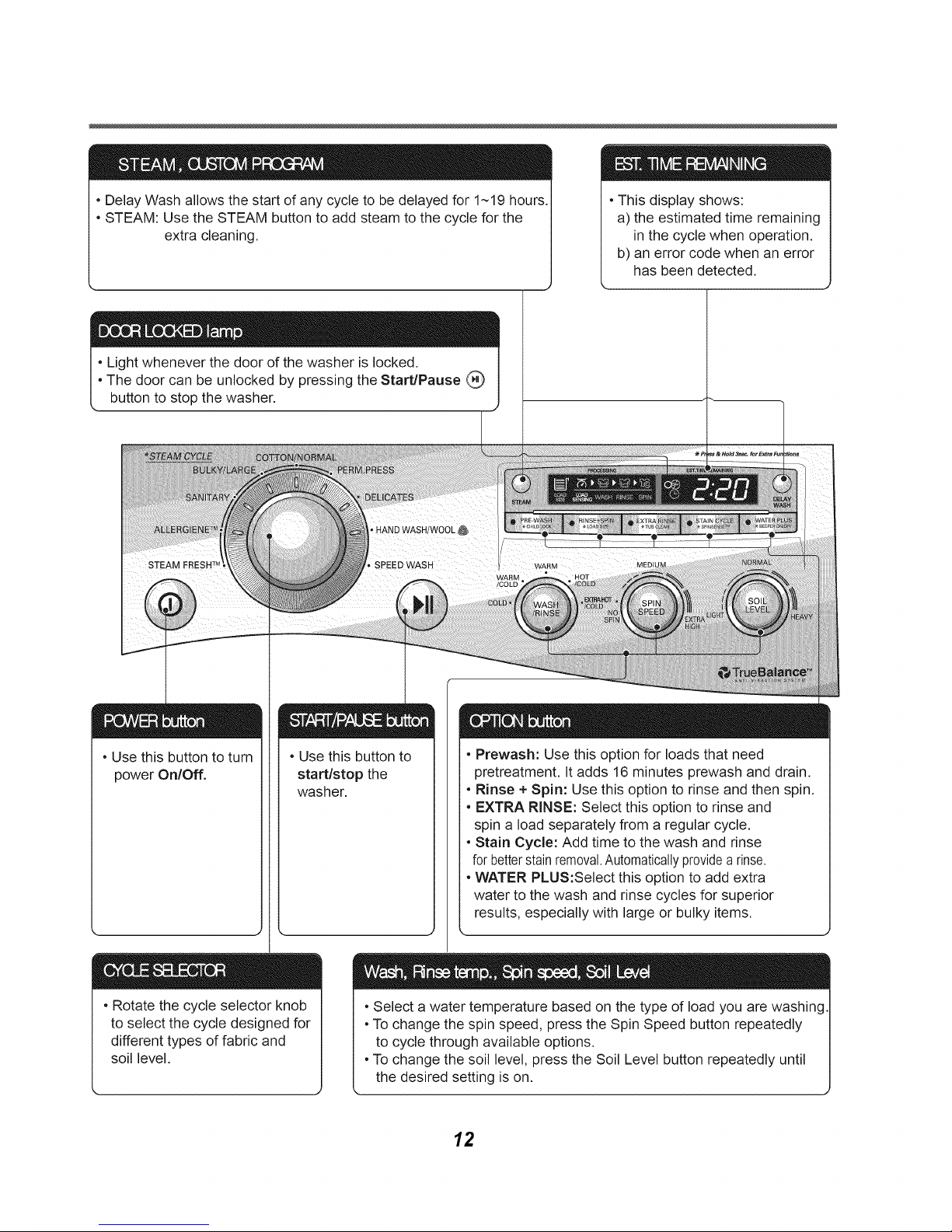

• Delay Wash allows the start of any cycle to be delayed for 1_-19hours.

• STEAM: Use the STEAM button to add steam to the cycle for the

extra cleaning.

, This display shows:

a) the estimated time remaining

in the cycle when operation.

b) an error code when an error

has been detected.

• Light whenever the door of the washer is locked.

• The door can be unlocked by pressing the Start/Pause

button to stop the washer.

STEAM FRESW_

• Use this button to turn

power On/Off.

• HAND WASH/WOOL

• SPEED WASH

• Use this button to

start/stop the

washer.

WAR_

WARM

COLD"

• Prewash: Use this option for loads that need

pretreatment. It adds 16 minutes prewash and drain.

• Rinse + Spin: Use this option to rinse and then spin.

• EXTRA RINSE: Select this option to rinse and

spin a load separately from a regular cycle.

• Stain Cycle: Add time to the wash and rinse

forbetterstainremoval.Automaticallyprovidea rinse.

. WATER PLUS:Select this option to add extra

water to the wash and rinse cycles for superior

results, especially with large or bulky items.

k.

• Rotate the cycle selector knob

to select the cycle designed for

different types of fabric and

soil level.

• Select a water temperature based on the type of load you are washing.

• To change the spin speed, press the Spin Speed button repeatedly I

to cycle through available options. I

• To change the soil level, press the Soil Level button repeatedly until I

the desired setting is on. J

12

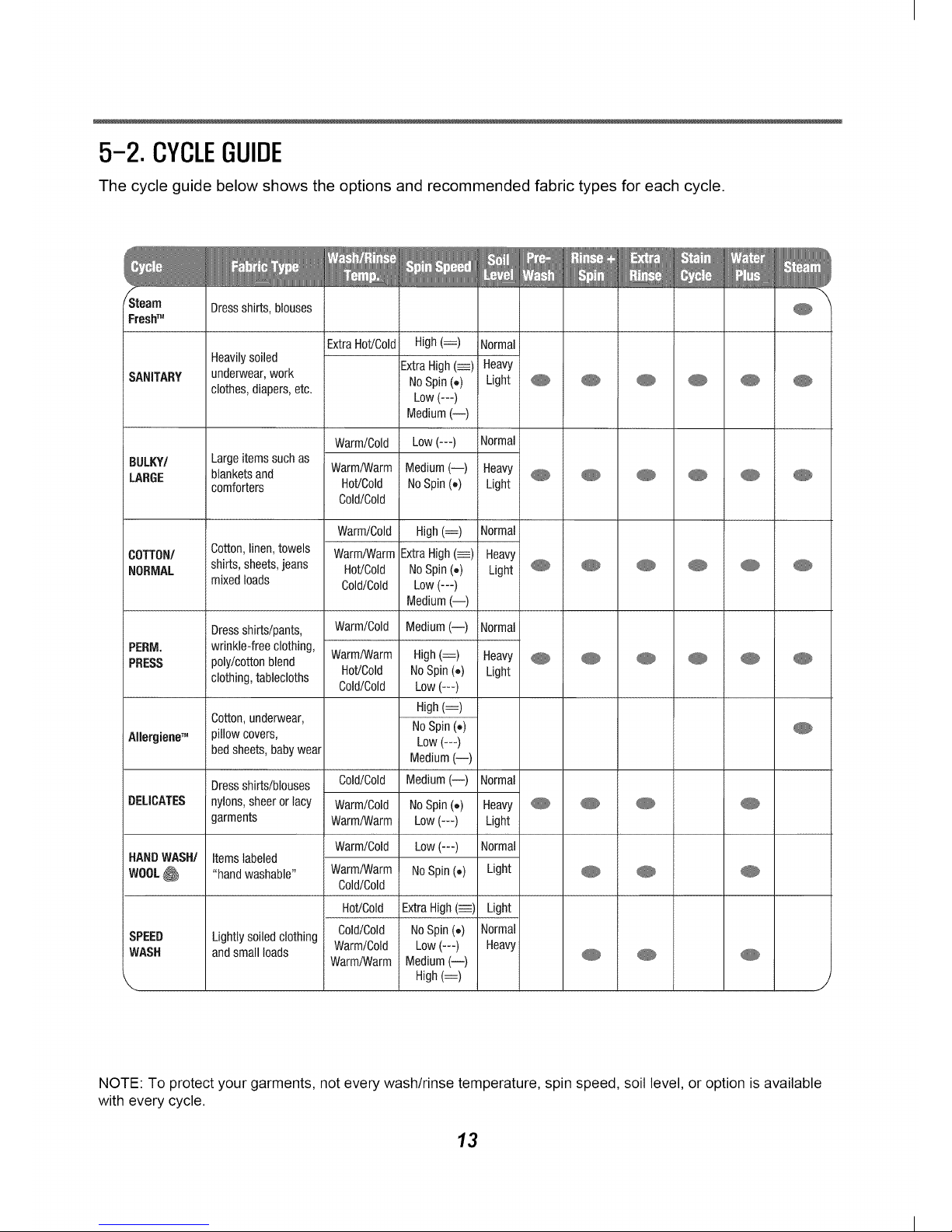

5-2. CYCLEGUIDE

The cycle guide below shows the options and recommended fabric types for each cycle.

SANITARY

BULKY/

LARGE

COTTON/

NORMAL

PERM,

PRESS

AllergieneTM

DEUCATES

HANDWASH/

WOOL

SPEED

WASH

Dressshirts, blouses

Heavilysoiled

underwear,work

clothes,diapers,etc.

ExtraHot/Cold

Warm/Cold

Largeitemssuch as

blanketsand Warm/Warm

comforters Hot/Cold

Cold/Cold

Warm/Cold

Cotton,linen,towels Warm/Warm

shirts,sheets,jeans Hot/Cold

mixedloads Cold/Cold

Dressshirts/pants, Warm/Cold

wrinkle-freeclothing, Warm/Warm

poly/cottonblend

Hot/Cold

clothing,tablecloths Cold/Cold

Cotton,underwear,

pillow covers,

bedsheets,babywear

Dressshirts/blouses Cold/Cold

nylons,sheeror lacy Warm/Cold

garments Warm/Warm

Warm/Cold

items labeled

"handwashable" Warm/Warm

Cold/Cold

Hot/Cold

Cold/Cold

Lightlysoiledclothing Warm/Cold

andsmall loads

Warm/Warm

High(=) Normal

ExtraHigh(_) Heavy

NoSpin(o) Light

Low(---)

Medium(--)

Low(---) Normal

Medium(--) Heavy

NoSpin(o) Light

High(=) Normal

ExtraHigh(_) Heavy

NoSpin(o) Light

Low(--4

Medium(--)

Medium(--) Normal

High(=) Heavy

No Spin(_) Light

Low(---)

High(=)

NoSpin(o)

Low(---)

Medium(--)

Medium(--) Normal

NoSpin(o) Heavy

Low(---) Light

Low(---) Normal

NoSpin(o) Light

ExtraHigh(_-) Light

NoSpin(.) Normal

Low(---) Heavy

Medium(--)

High(=)

/

NOTE: To protect your garments, not every wash/rinse temperature, spin speed, soil level, or option is available

with every cycle.

13

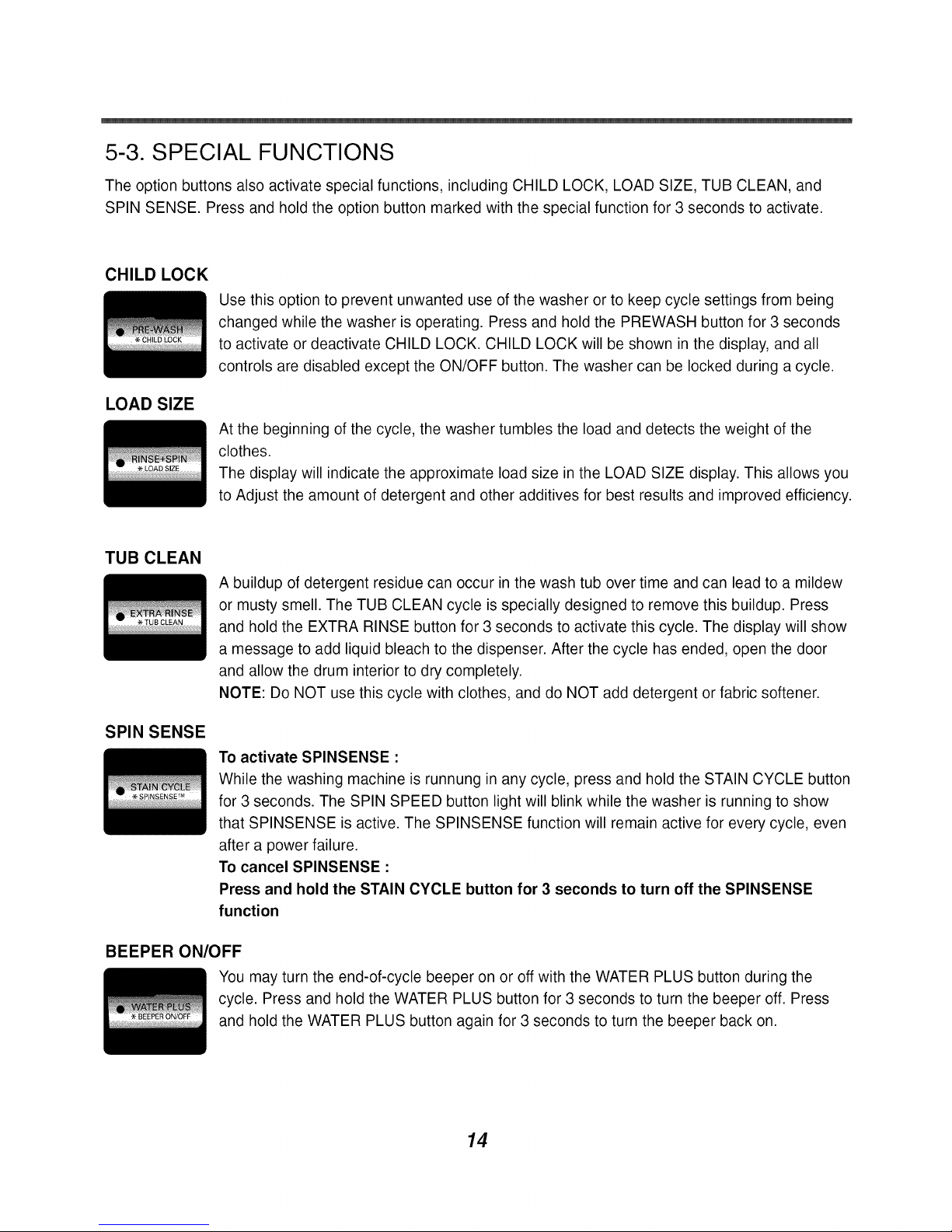

5-3. SPECIAL FUNCTIONS

The option buttons also activate special functions, including CHILD LOCK, LOAD SIZE, TUB CLEAN, and

SPIN SENSE. Press and hold the option button marked with the special function for 3 seconds to activate.

CHILD LOCK

LOAD SIZE

Use this option to prevent unwanted use of the washer or to keep cycle settings from being

changed while the washer is operating. Press and hold the PREWASH button for 3 seconds

to activate or deactivate CHILD LOCK. CHILD LOCK will be shown in the display, and all

controls are disabled except the ON/OFF button. The washer can be locked during a cycle.

At the beginning of the cycle, the washer tumbles the load and detects the weight of the

clothes.

The display will indicate the approximate load size in the LOAD SIZE display. This allows you

to Adjust the amount of detergent and other additives for best results and improved efficiency.

TUB CLEAN

SPIN SENSE

A buildup of detergent residue can occur in the wash tub over time and can lead to a mildew

or musty smell. The TUB CLEAN cycle is specially designed to remove this buildup. Press

and hold the EXTRA RINSE button for 3 seconds to activate this cycle. The display will show

a message to add liquid bleach to the dispenser. After the cycle has ended, open the door

and allow the drum interior to dry completely.

NOTE: Do NOT use this cycle with clothes, and do NOT add detergent or fabric softener.

To activate SPINSENSE :

While the washing machine is runnung in any cycle, press and hold the STAIN CYCLE button

for 3 seconds. The SPIN SPEED button light will blink while the washer is running to show

that SPINSENSE is active. The SPINSENSE function will remain active for every cycle, even

after a power failure.

To cancel SPINSENSE :

Press and hold the STAIN CYCLE button for 3 seconds to turn off the SPINSENSE

function

BEEPER ON/OFF

You may turn the end-of-cycle beeper on or off with the WATER PLUS button during the

cycle. Press and hold the WATER PLUS button for 3 seconds to turn the beeper off. Press

and hold the WATER PLUS button again for 3 seconds to turn the beeper back on.

14

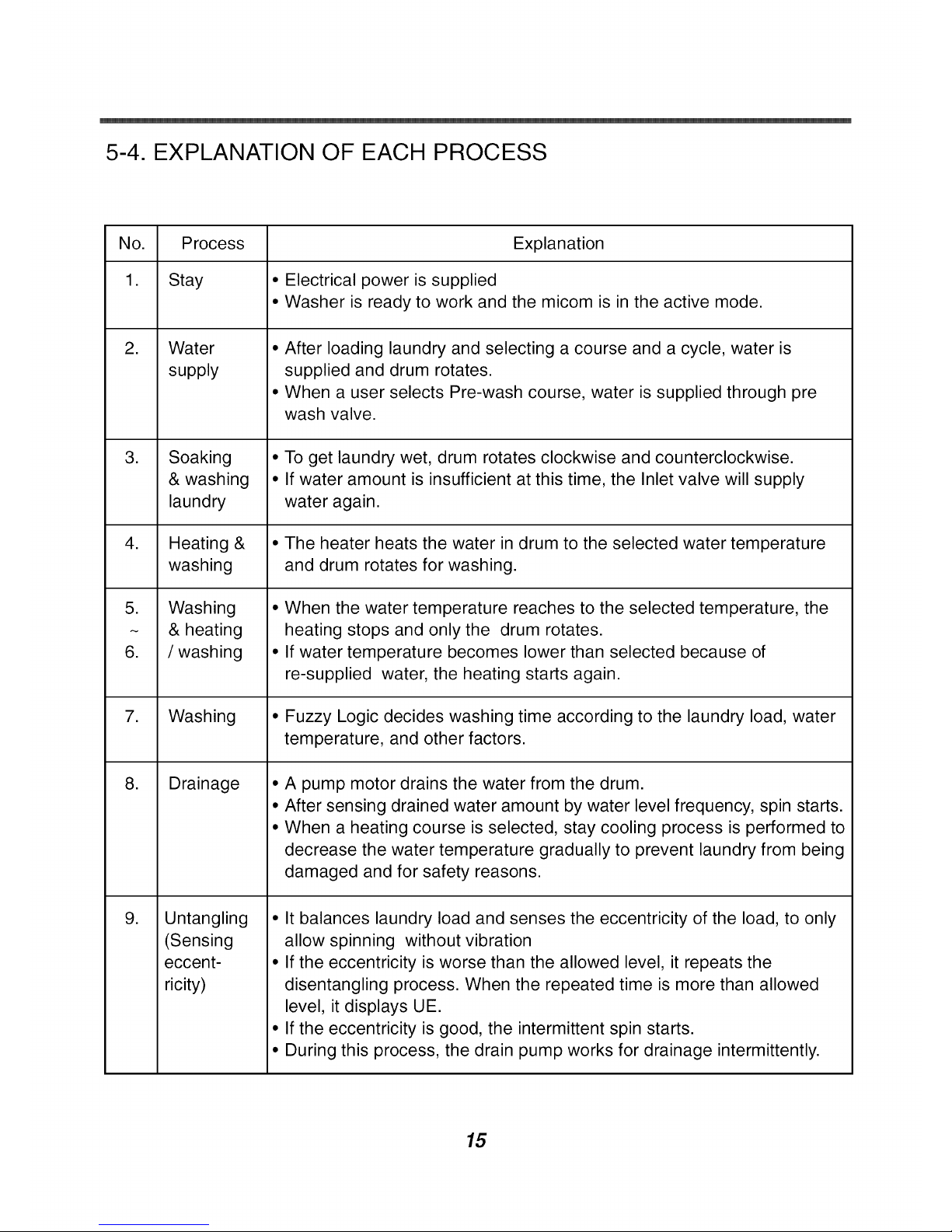

5-4. EXPLANATION OF EACH PROCESS

No. Process Explanation

1. Stay • Electrical power is supplied

• Washer is ready to work and the micom is in the active mode.

2. •

.

.

.

6.

.

.

.

Water

supply

Soaking

& washing

laundry

Heating &

washing

Washing

& heating

/ washing

Washing

Drainage

Untangling

(Sensing

eccent-

ricity)

After loading laundry and selecting a course and a cycle, water is

supplied and drum rotates.

When a user selects Pre-wash course, water is supplied through pre

wash valve.

To get laundry wet, drum rotates clockwise and counterclockwise.

If water amount is insufficient at this time, the Inlet valve will supply

water again.

• The heater heats the water in drum to the selected water temperature

and drum rotates for washing.

• When the water temperature reaches to the selected temperature, the

heating stops and only the drum rotates.

• If water temperature becomes lower than selected because of

re-supplied water, the heating starts again.

• Fuzzy Logic decides washing time according to the laundry load, water

temperature, and other factors.

A pump motor drains the water from the drum.

After sensing drained water amount by water level frequency, spin starts.

When a heating course is selected, stay cooling process is performed to

decrease the water temperature gradually to prevent laundry from being

damaged and for safety reasons.

• It balances laundry load and senses the eccentricity of the load, to only

allow spinning without vibration

• If the eccentricity is worse than the allowed level, it repeats the

disentangling process. When the repeated time is more than allowed

level, it displays UE.

• If the eccentricity is good, the intermittent spin starts.

• During this process, the drain pump works for drainage intermittently.

15

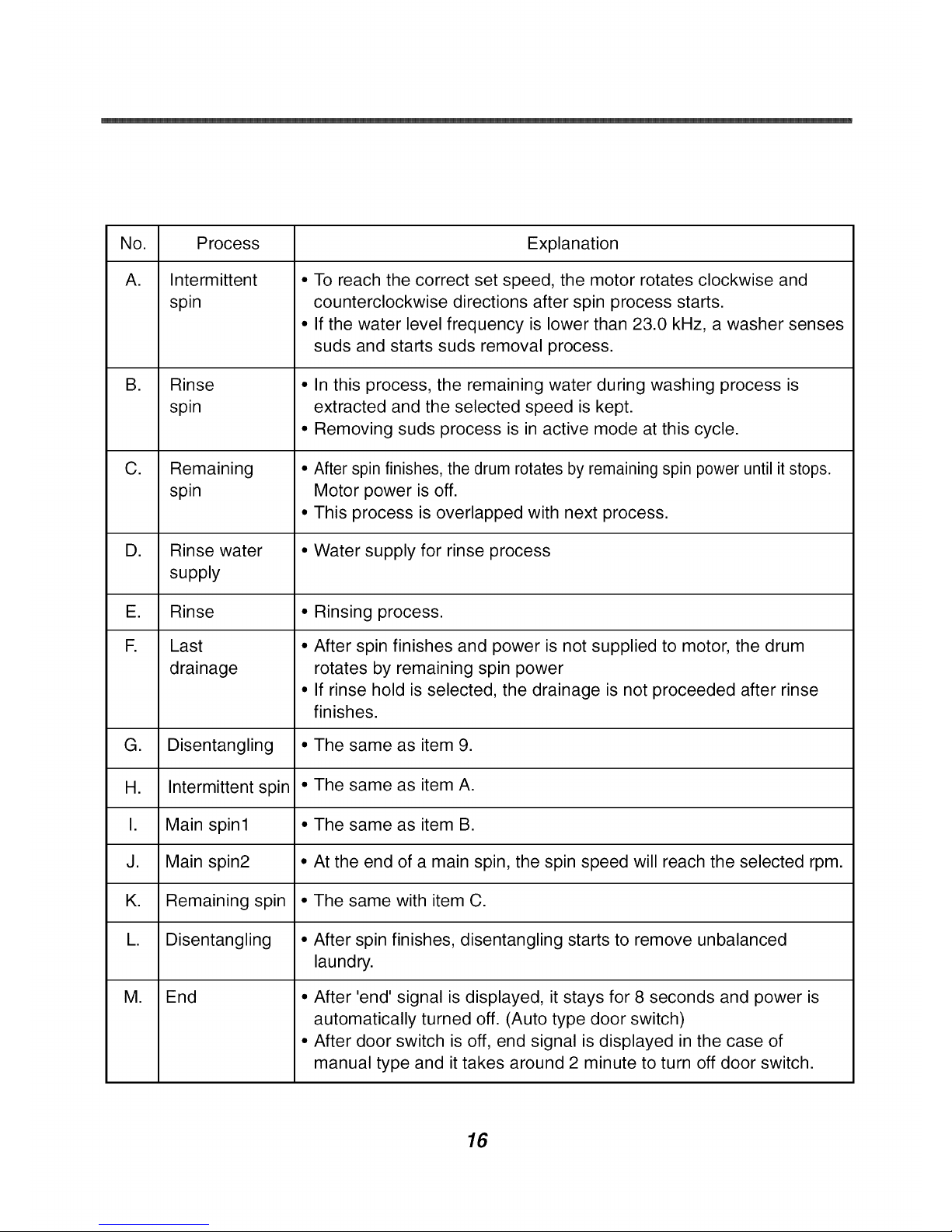

No. Explanation

A. •

Process

Inte rm ittent

spin

B. Rinse

spin

C. Remaining

spin

To reach the correct set speed, the motor rotates clockwise and

counterclockwise directions after spin process starts.

If the water level frequency is lower than 23.0 kHz, a washer senses

suds and starts suds removal process.

• In this process, the remaining water during washing process is

extracted and the selected speed is kept.

• Removing suds process is in active mode at this cycle.

D. Rinse water • Water supply for rinse process

supply

E. Rinse • Rinsing process.

R •

Last

drainage

After spin finishes, the drum rotates by remaining spin power until it stops.

Motor power is off.

This process is overlapped with next process.

After spin finishes and power is not supplied to motor, the drum

rotates by remaining spin power

If rinse hold is selected, the drainage is not proceeded after rinse

finishes.

G. Disentangling • The same as item 9.

H. Intermittent spin • The same as item A.

I. Main spin1 • The same as item B.

J. Main spin2 • At the end of a main spin, the spin speed will reach the selected rpm.

K. Remaining spin • The same with item C.

L. Disentangling • After spin finishes, disentangling starts to remove unbalanced

laundry.

M. End •

After 'end' signal is displayed, it stays for 8 seconds and power is

automatically turned off. (Auto type door switch)

After door switch is off, end signal is displayed in the case of

manual type and it takes around 2 minute to turn off door switch.

16

6. WIRING DIAGRAM/PROGRAM CHART

<

C9

_<

C3

C9

z

_J

co

z z

_J J

>_ >_ _

crl col

z

2_

cfl

i EF]ZVqH _'_ I,

HSVM O_ _'

NgZV3H__,

_ z

i

Lx_ ca _

>__ >__ _

cxl ,_

cc o2

a

o

o

Z o._ 0

q

rr"

0

0

CQ I

Z _ i Z Q,.,.

C3 n

-- LLI

S

I

1

z

z

0 0 Cg

Z Z

klA klA

m c,o E _

5

17

C_

D)

C

C

09

C_

CO

|

co

c

,m

E

C

m

co

co

Od

<:

I

0

<

©

0

CL

Spin

Drain

i

m

m

B

m

m

m

m

m

m

m

E

m

/

m

m

m

m

E

E

o8

E

£

C

C

c

m

m

m

E

m

t

R

m

m

m

R

m

?

\

m

m

m

E

m

m

m m

m

m m

m m

m

-\

t m

E

m !

m m

m m

m m

m m

! m

7_

\ \

m m

m m

m !

! m

m

m

m

m

z

B

m

m

E

m

m

E

/

m

m

\

/

E m

m m

/ /

\ \

E

m

m

o

m

m

m m

m

8

m

m m

?7

¢o

m

/ /

\ \

o

18

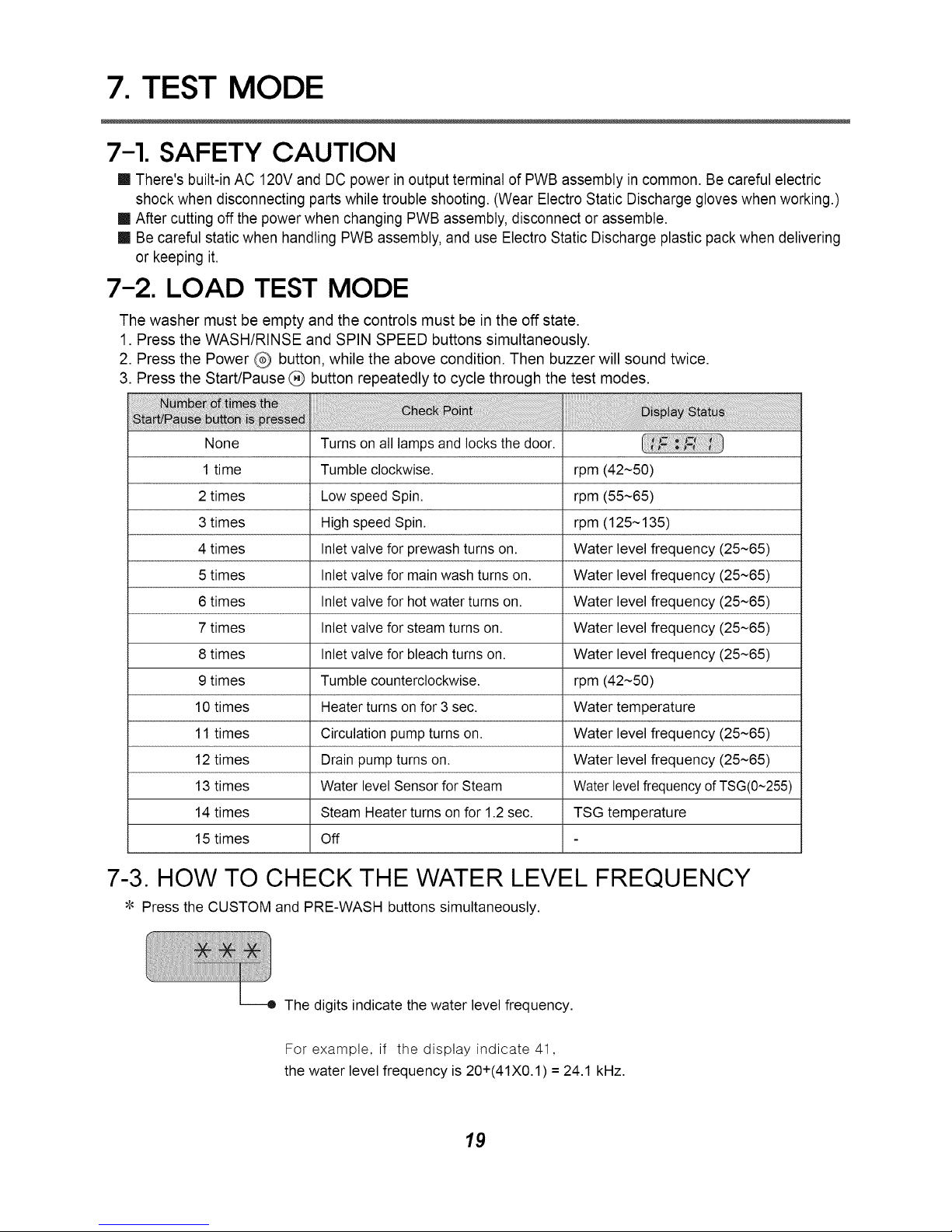

7. TEST MODE

7-'1. SAFETY CAUTION

II There's built-in AC 120V and DC power in output terminal of PWB assembly in common. Be careful electric

shock when disconnecting parts while trouble shooting. (Wear Electro Static Discharge gloves when working.)

II After cutting off the power when changing PWB assembly, disconnect or assemble.

II Be careful static when handling PWB assembly, and use Electro Static Discharge plastic pack when delivering

or keeping it.

7-2. LOAD TEST MODE

The washer must be empty and the controls must be in the off state.

1. Press the WASH/RINSE and SPIN SPEED buttons simultaneously.

2. Press the Power _ button, while the above condition. Then buzzer will sound twice.

3. Press the Start/Pause _ button repeatedly to cycle through the test modes.

None

1 time

2 times

3 times

4 times

5 times

6 times

7 times

8 times

9 times

10 times

11 times

12 times

13 times

14 times

15 times

Turns on all lamps and locks the door.

Tumble clockwise.

Low speed Spin.

High speed Spin.

Inlet valve for prewash turns on.

Inlet valve for main wash turns on.

Inlet valve for hot water turns on.

Inlet valve for steam turns on.

Inlet valve for bleach turns on.

Tumble counterclockwise.

Heater turns on for 3 sec.

Circulation pump turns on.

Drain pump turns on.

Water level Sensor for Steam

Steam Heater turns on for 1.2 sec.

Off

rpm (42~50)

rpm (55~65)

rpm (125~135)

Water level frequency (25~65)

Water level frequency (25~65)

Water level frequency (25~65)

Water level frequency (25~65)

Water level frequency (25~65)

rpm (42~50)

Water temperature

Water level frequency (25~65)

Water level frequency (25~65)

Water level frequency of TSG(0~255)

TSG temperature

7-3. HOW TO CHECK THE WATER LEVEL FREQUENCY

Press the CUSTOM and PRE-WASH buttons simultaneously.

--o The digits indicate the water level frequency.

For example, if the display indicate 41,

the water level frequency is 20+(41X0.1) = 24.1 kHz.

1£

Loading...

Loading...