LG WM2496M Training Manual

TRAINING MANUAL

WM2496 Washer Training

Spring 2007

Service

Digital Appliance

WM2496H*M

Contact Information cover

Safety Notices and Warnings 1

Contents 2

Introduction 4

Specifications 5

Features 6

Display and Controls 7

Warranty 8

Serial Number Identification 9

Fuzzy Logic 10

Door Lock 10

Door Locked Lamp 10

Water Circulation 11

Parts Identification (Callout) 12

Accessories 13

Remote Monitor and Modem 14

Installation 15

Pedestal 16

Connections 18

Water 18

Drain 18

Electrical 18

Program Chart 19

Before Performing Service 19

Dispenser 20

Test Mode 22

Check Water Level Frequency 22

Error Display (Error Codes) 23

Diagnosis and Check Lists 25

Door Error 25

Drain Error 25

Oversudsing 26

Laundry products Do Not Dispense 26

Other Errors 26

WM2496H*M Page 2 of 58 TRAINING MANUAL

Diagnosis and Troubleshooting 27

No Power 27

Noise and Vibration During Spin 28

SpinSense (to resolve vibration issues) 29

No Water Supply 30

Detergent Does Not Flow In 30

Bleach and Softener Do Not Flow In 31

Heater Operation Without Water 32

Abnormal Sound 32

Drain Malfunction 32

Wash Heater Malfunction (No Heating) 33

Heater Malfunction (Continuous Overheating) 33

No Water Circulation 34

Spin Malfunction 35

dE Error Code 35

Disassembly and Repair 36

Block Wiring Diagram 36

Top Plate 36

Control Panel 37

Main Board 38

Dispenser 39

Noise Filter 39

Front Cabinet Cover 40

Door 42

Door Switch Removal 42

Pumps (Drain and Circulation) 43

Heater 44

Thermistor 44

Removal of Objects Between Tub and Drum 45

Motor 46

Tub and Drum 48

Damper 49

Tips and Tricks 50

Hoses 50

Baffles (Roller Jets) 50

Mushroom Valve 50

Ball Sensor (Off Balance Sensor) 50

Wiring Diagram 51

Exploded Views 52

Parts List 55

070125

WM2496H*M Page 3 of 58 TRAINING MANUAL

INTRODUCTION

The WM2496 washer and dryer are very similar to the previous series, with the

exception of the re-shaped front panel and the convertible dryer control. The

WM2496 machines are specifically designed to be sold as a stacked product,

and the dryer is delivered with the control panel mounted at the bottom of the

dryer. This causes the washer and dryer control panels to be adjacent when the

products are installed and stacked. Of course, they can be installed in a standard,

side-by-side configuration with the dryer controls mounted at the top of the dryer.

WM2496H*M Page 4 of 58 TRAINING MANUAL

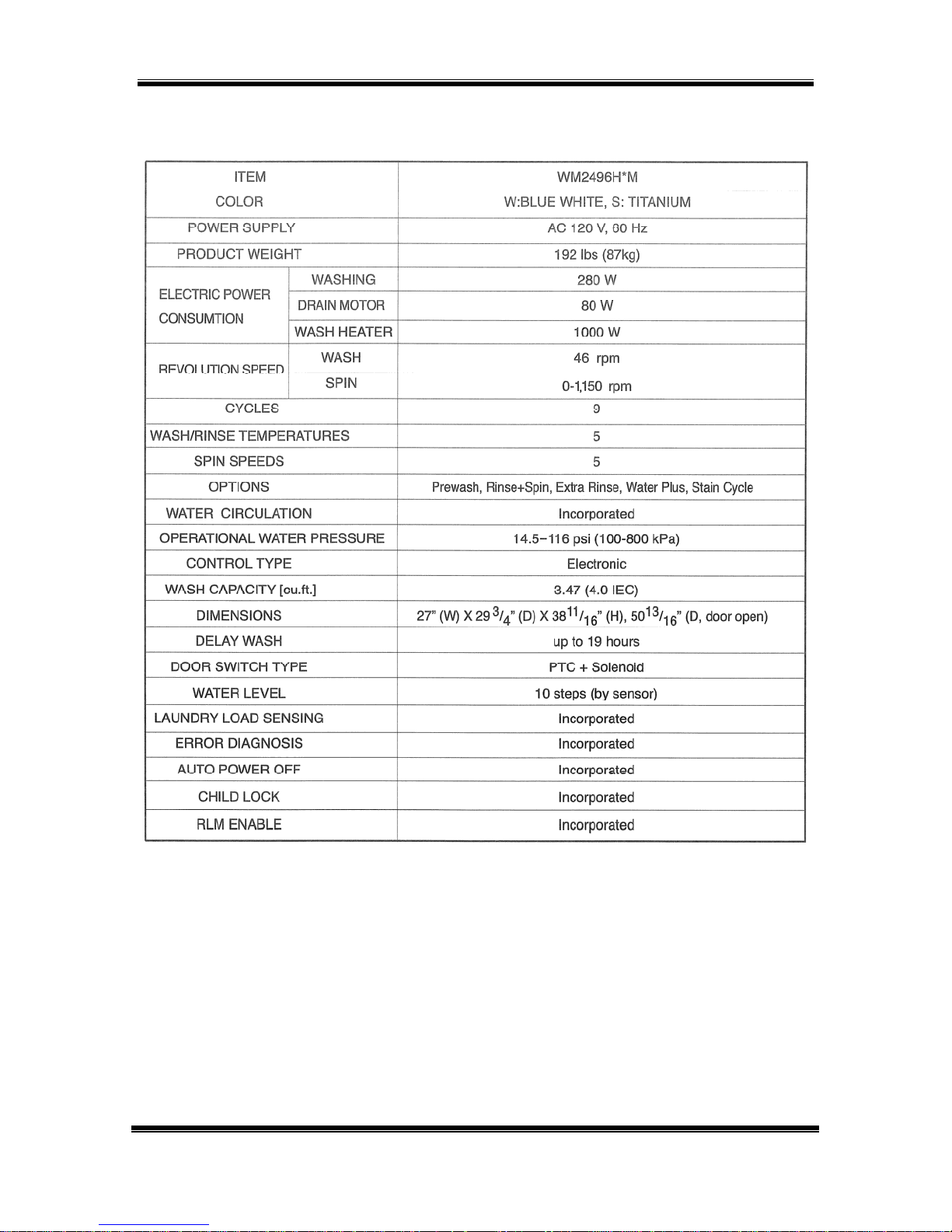

SPECIFICATIONS

WM2496H*M Page 5 of 58 TRAINING MANUAL

FEATURES

LARGE CAPACITY

The larger drum (4.0 cu. ft.) allows washing of

larger (heavier) loads and oversized items

(comforters, curtains, blankets, etc.) There is less

wrinkling and tangling of the laundry.

DIRECT DRIVE

The brushless DC motor drives the drum directly

without belts, pulleys, or transmissions. The

maximum spin speed of 1,150 RPM extracts more

water from the laundry, reducing drying times.

TILTED DRUM/LARGE DOOR

The tilted drum (10°) and large door opening allow

easier loading and unloading.

ROLLER JETS and BALLS

The baffles pick up water as the drum turns and

allow it to pour through the clothing as it tumbles.

The balls enhance the washing performance while

maintaining fabric care.

AUTOMATIC LOAD DETECTION

The microprocessor reads the current required to

turn the drum and determines the weight of the

load. This input is used to make numerous

decisions during the wash cycle.

WM2496H*M Page 6 of 58 TRAINING MANUAL

FEATURES, continued

DISPLAY and CONTROLS

BUILT-IN HEATER

The internal heater helps maintain the water

temperature at its optimal temperature for

selected cycles. The SANITARY cycle kills most

common germs and bacteria.

CHILD LOCK

This allows the user to lock the controls. Children

then cannot play with the buttons and disturb the

wash cycle.

REMOTE LAUNDRY MONITOR

Available separately, the remote monitor displays

the cycle and remaining time on the washer and

dryer. It can be plugged in to any outlet in the

house.

The control panel is located on the front of the WM2496 Washer. All options are

available from the control panel.

Extra Hot 167° F

Hot 122° F

Warm 104° F

Cold 77° F

Press EXTRA HOT/COLD and EXTRA HIGH to read the drum RPM.

Press WARM/WARM and NORMAL to read the water temperature in ° Celsius.

Press WARM/COLD and LOW to read the water level frequency.

WM2496H*M Page 7 of 58 TRAINING MANUAL

Extra High 1,150

High 980

Normal 960

Low 600

SOIL LEVEL

adds time to

wash and

spin cycles

STAIN CYCLE

adds time and

changes

temperature

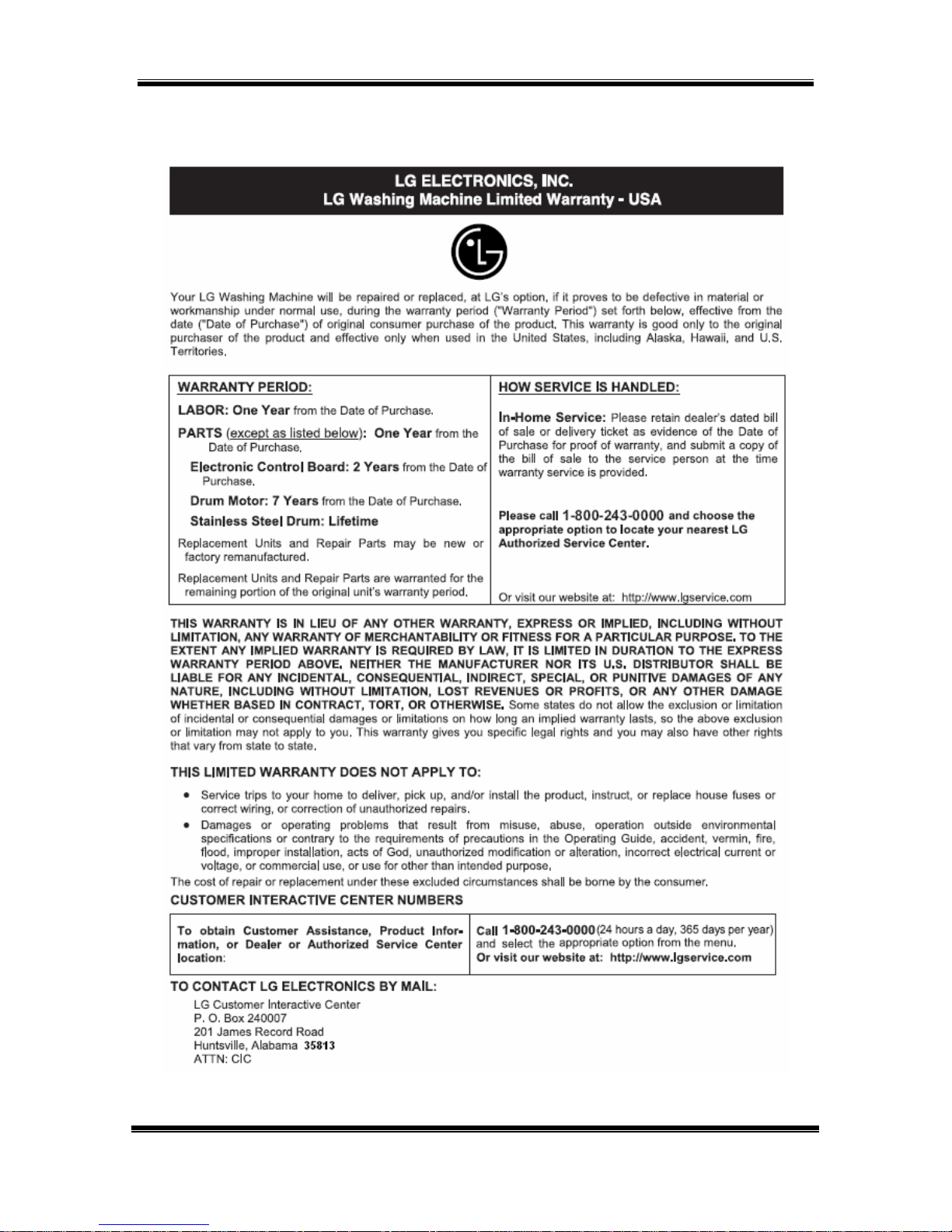

WARRANTY

WM2496H*M Page 8 of 58 TRAINING MANUAL

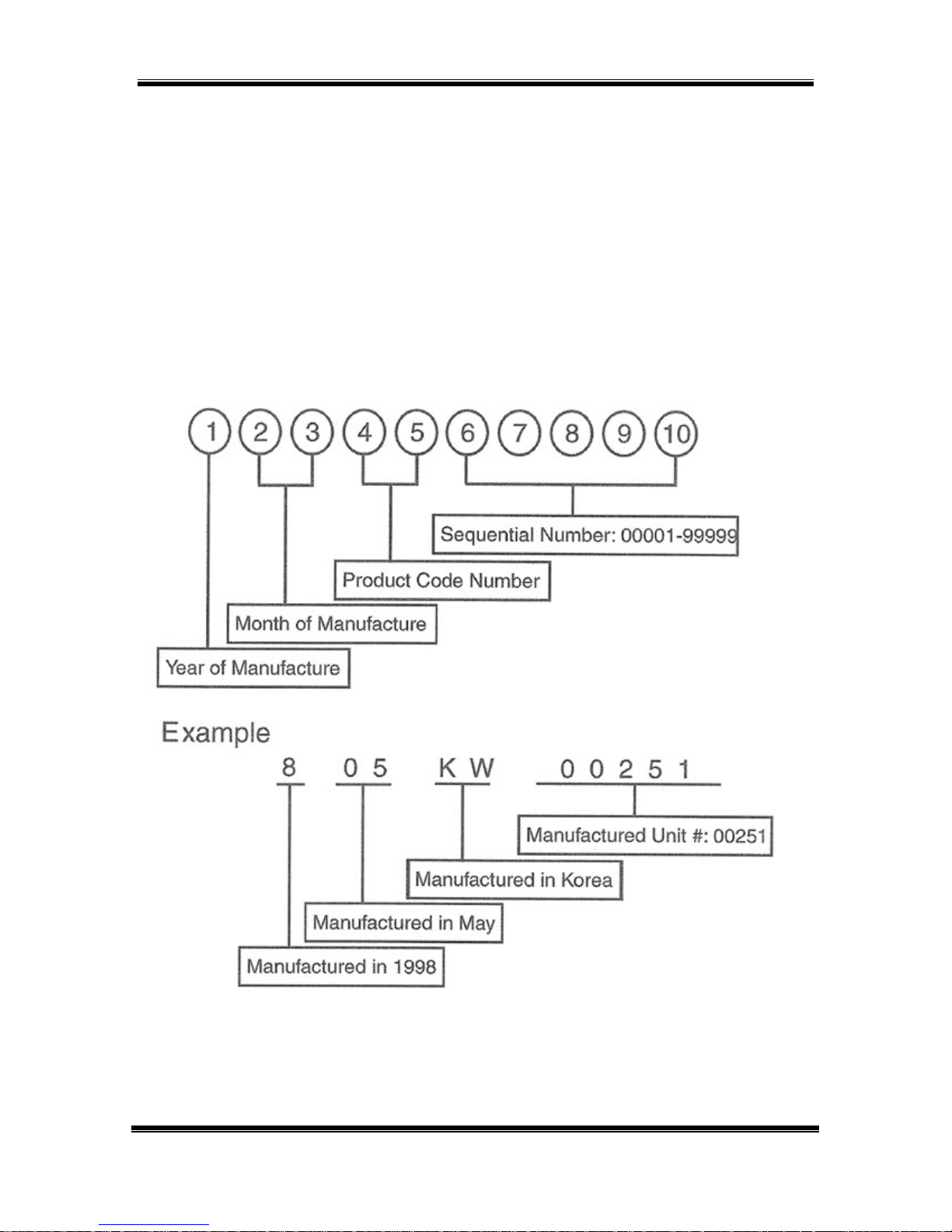

SERIAL NUMBER IDENTIFICATION

The serial number is unique to each product. It gives information concerning the

time and place of manufacture. The serial number is required to be paid for

warranty service and to get the correct part in the event a running production

change was made. Some models may have four (4) letters instead of two (2) for

the product code number. The third and fourth letters are significant only to the

manufacturing facility.

This chart will help you decode the serial number.

WM2496H*M Page 9 of 58 TRAINING MANUAL

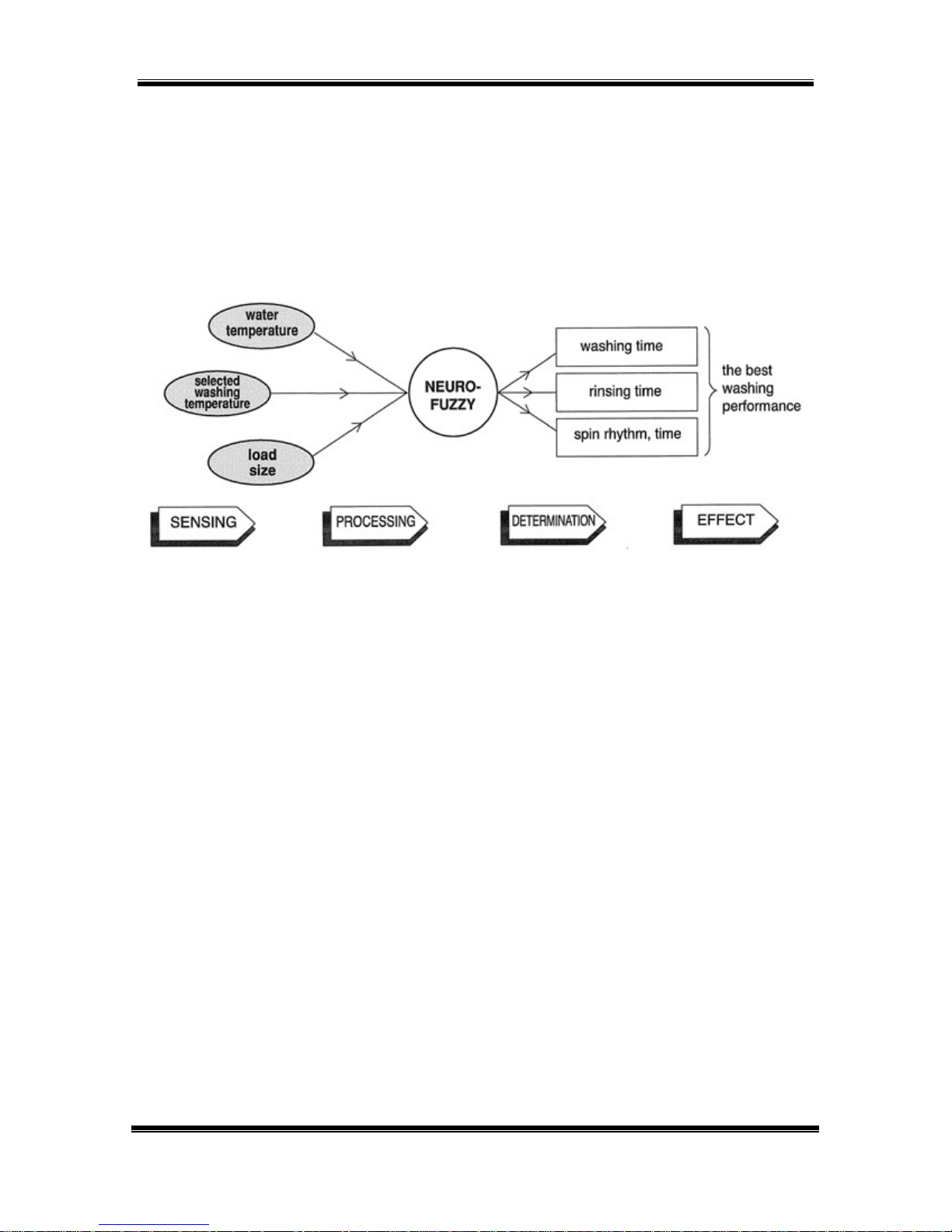

FUZZY LOGIC

To get the best washing performance, the user selects one of the standard

cycles and sensors in the WM2496 make an infinitely variable number of

adjustments as the cycle progresses. Adjustments are automatically made for

load size, incoming water temperature, soil level, rinses required, and other

variables.

DOOR LOCK

The door has an automatic, electrically operated lock system. When the machine

is off or paused, the door can be opened by pulling it. When the machine is

operating, the electric latch keeps the door closed.

The door cannot be opened:

• When the WM2496 is operating

• When the power failed or the washer is unplugged

(until the capacitor discharges and releases the lock)

• When the DOOR LOCK light is on

• When the drum is still turning

DOOR LOCKED LAMP

The DOOR LOCK lamp lights:

• When the WM2496 is operating

• When the water level sensor frequency is lower than 22.9 kHz

• When the temperature inside the tub is over 45° C (113°F)

WM2496H*M Page 10 of 58 TRAINING MANUAL

WATER CIRCULATION

The recirculation pump circulates the water during most of the cycle. During the

WASH cycle, it runs continuously for the first 3 minutes and then intermittently

throughout the cycle. During the RINSE cycle, it runs continuously as soon as the

appropriate amount of rinse water has been added. This recirculated water

enters the drum at the top of the door at a small shower head. This spray not

only keeps the window and gasket clean, it allows the clothes to be soaked with

detergent or rinse water more quickly and can be used to control an oversudsing

event.

The recirculation pump is separate

from the drain pump, but they are

attached to opposite sides of the filter

housing.

When the sanitary cycle is used, the

door will remain locked until the

laundry has cooled to a safe

temperature (below 45° C / 113°F).

The pumps and filter are located at

the bottom left front corner. The filter

can be unscrewed, cleaned, and

replaced by opening the small cover.

Use the small drain hose to evacuate

the water remaining in the bottom of

the tub before removing the filter. Do

not pull it out so far the hose is kinked

or water will not flow.

The drain pump is on the left and

exhausts the water via the gray

corrugated hose.

The recirculating pump is on the right

and recirculates water from the tub to

the shower spray at the top of the

door gasket via the smaller black

hose.

WM2496H*M Page 11 of 58 TRAINING MANUAL

PARTS IDENTIFICATION

The air vent on the back of the machine must be left open and clear at all times.

If the washer is installed in a closet or closed laundry alcove, there must be

sufficient clearance and ventilation. The closet should have a full louvered door

2

with at least 350 square inches (0.5 m

) of open area for ventilation.

The washer requires a space of at least 1 inch (2.5 cm) between the wall and the

machine on each side and at least 4 inches (10 cm) between the back of the

washer and the wall. Additional space may be needed for servicing.

WM2496H*M Page 12 of 58 TRAINING MANUAL

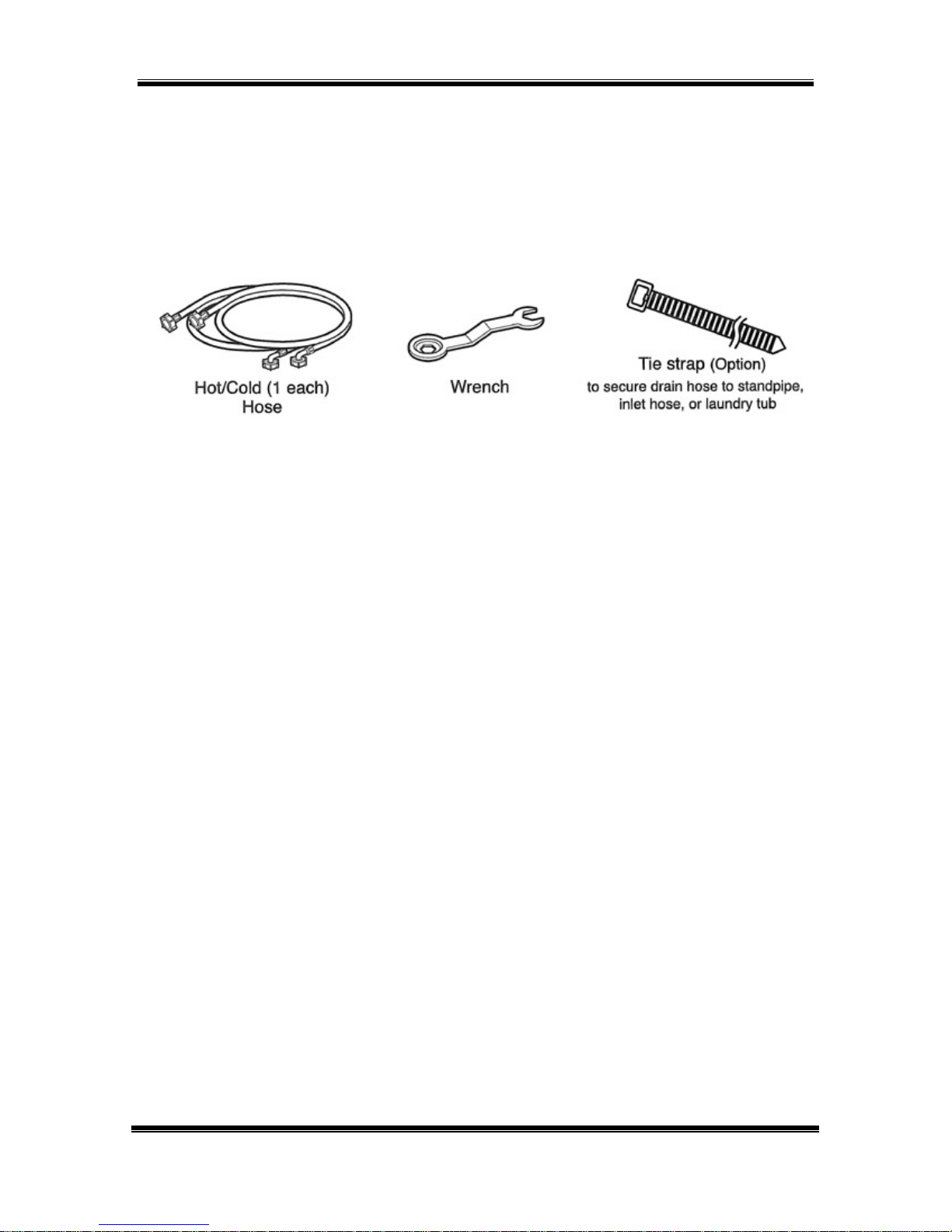

ACCESSORIES

The washer comes with the two input hoses. The blue stripe is for cold water and

the red stripe is for hot water. While the hoses appear to be mechanically

identical, the temperature and pressure ratings are different. It is critical to the

performance of the washer to have the hot and cold hoses connected correctly.

The wrench is used to remove (and replace) the shipping bolts and to adjust the

leveling feet. Be sure to leave it and encourage the customer to retain the wrench,

the four shipping bolts, and the manual in a safe place in the event the washer

requires service or the customer moves.

The shipping bolts MUST BE REMOVED before operating the washer. (See

page 15.) Also check for the packing block, which sometimes remains in the

base when the washer is unpacked.

WM2496H*M Page 13 of 58 TRAINING MANUAL

REMOTE MONITOR and MODEM

The remote laundry monitor (RLM)

allows the user to monitor the

progress of both washer and dryer,

provided they are both equipped with

a modem.

Remove the cover and install the

modem on the back of the washer.

Save the small socket cover and

screws in the event you need to

remove the modem for some reason.

The socket should be covered at all

times.

While you’re at it, go ahead and install

the modem on the dryer now.

Remove the cover and install the

modem on the back of the dryer.

Save the small socket cover and

screws in the event you need to

remove the modem for some reason.

The socket should be covered at all

times.

After installation is complete, plug in

the washer, dryer, and monitor, in that

order. Turn on the washer and dryer.

Press and hold the SET button on the

monitor.

WM2496H*M Page 14 of 58 TRAINING MANUAL

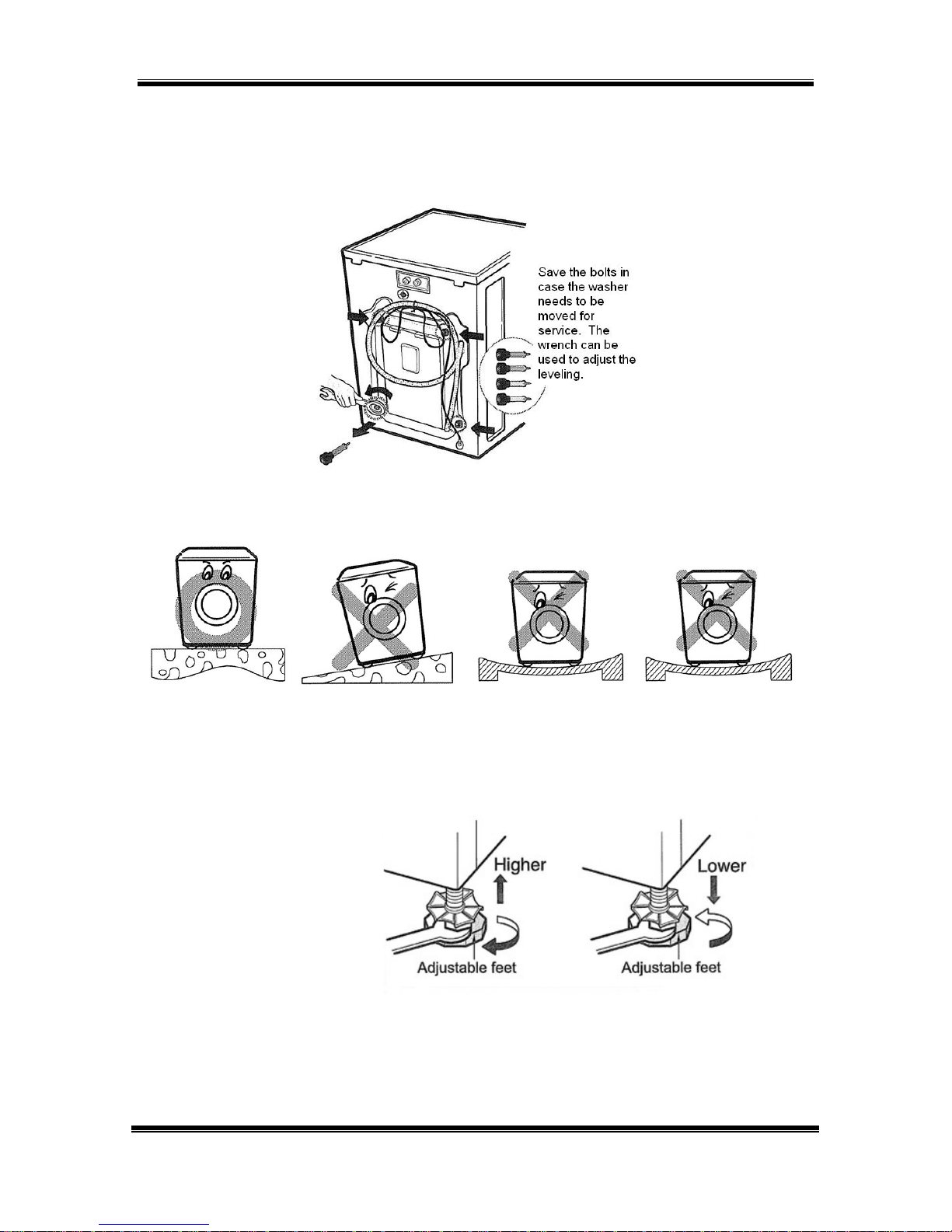

INSTALLATION

REMOVE THE SHIPPING BOLTS.

INSTALL THE WASHER ON A FIRM, FLAT SURFACE.

ADJUST THE FEET TO BE LEVEL.

If you’re installing the washer on a pedestal, install the pedestal now.

(See next page.)

WM2496H*M Page 15 of 58 TRAINING MANUAL

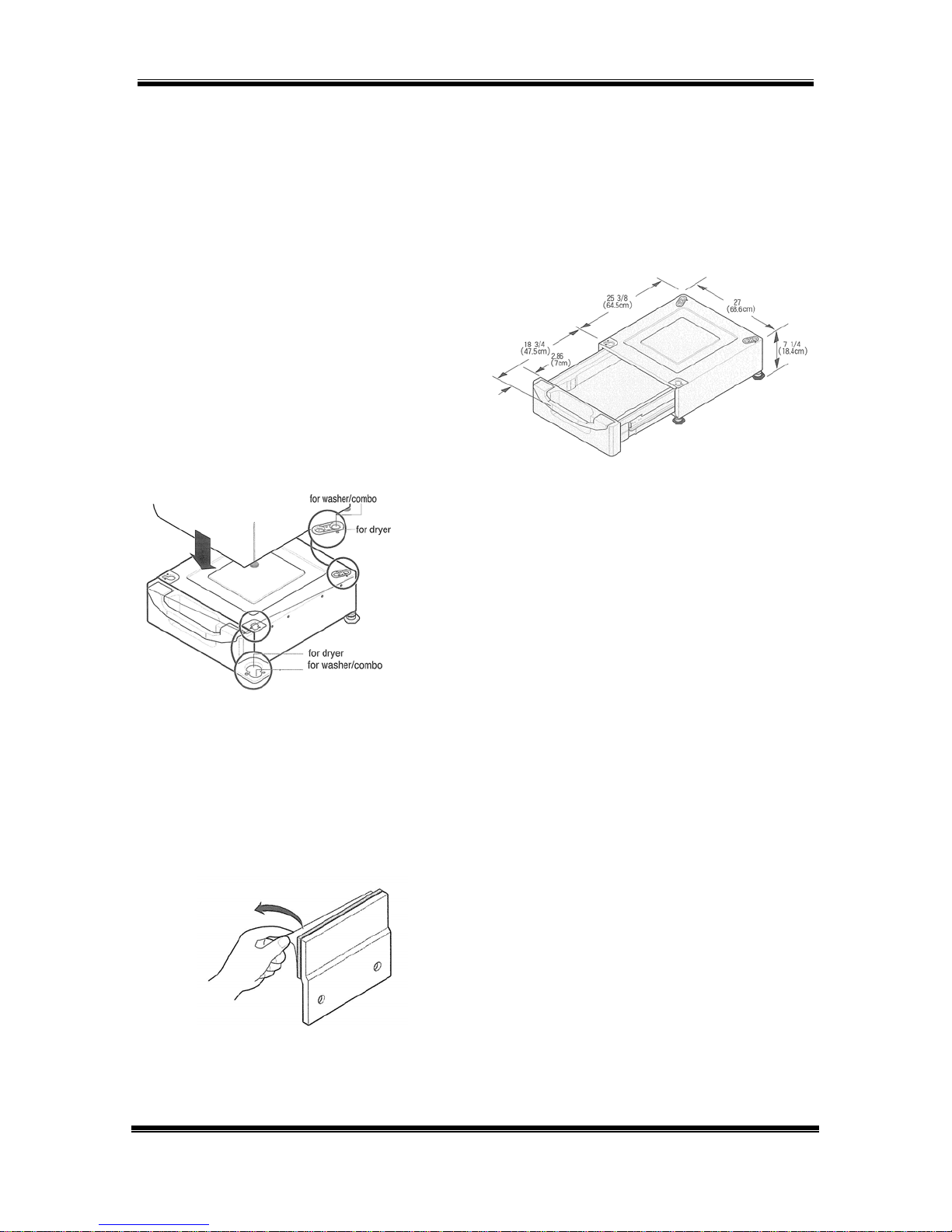

INSTALLATION (PEDESTAL KIT)

This procedure covers installing and leveling the 7½” and 13” pedestals for 27”

washers, dryers, and combos. If the products are stacked, the washer must be

below the dryer, and you’ll use only one pedestal.

1. Remove the pedestal,

installation hardware, and

instructions form the shipping

carton. Set the pedestal as close

to the installation position as

possible.

2. Level the pedestal on a flat, solid

floor before proceeding. Lock

down the rear adjusters but

leave the front ones free for now.

3. Note which holes are for the

washer and which are for the

dryer. If you are stacking the

appliances, the washer must

be on the bottom.

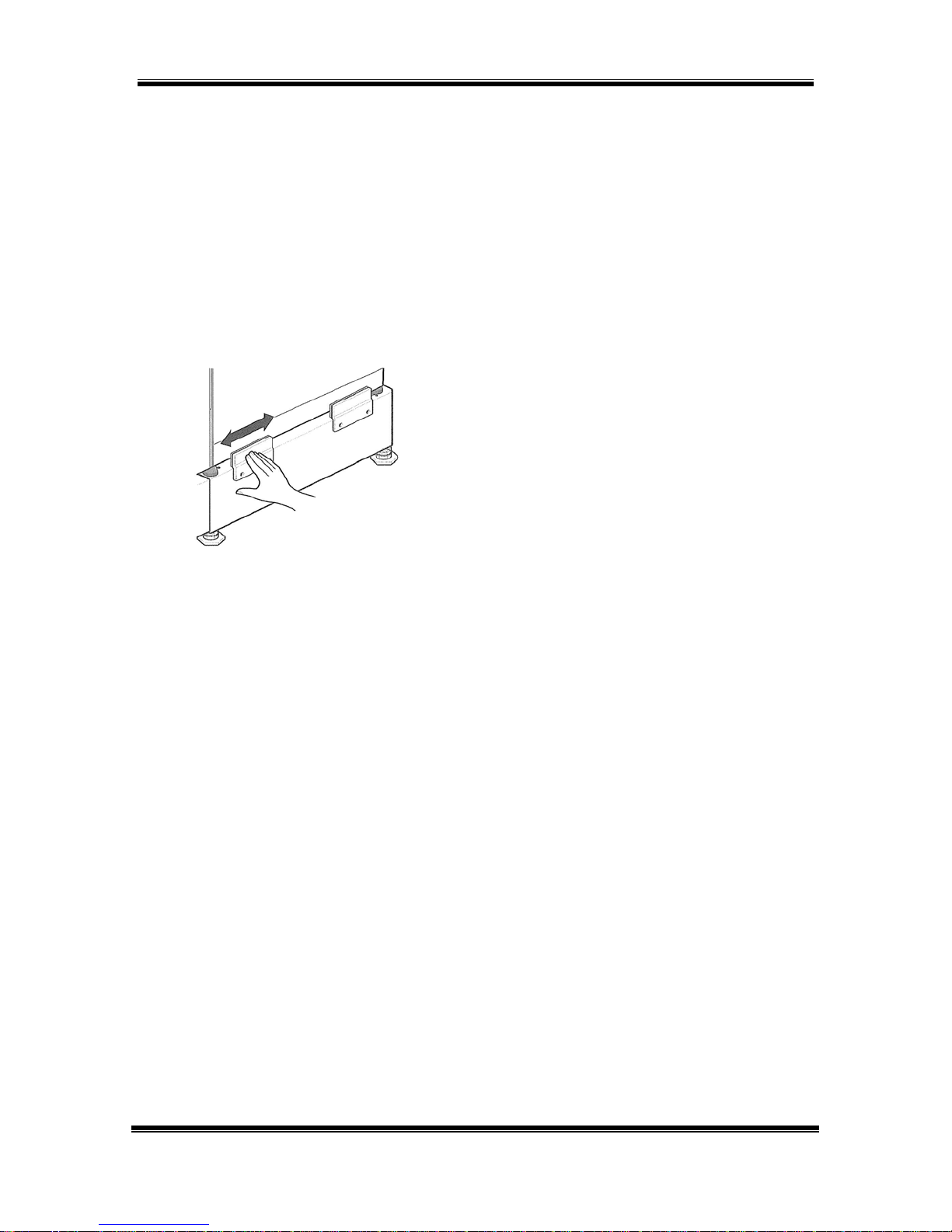

4. Remove the protective paper

from the adhesive surface of the

bracket. Be particularly careful,

because when the adhesive

makes contact, there is no

adjustment possible.

WM2496H*M Page 16 of 58 TRAINING MANUAL

PEDESTAL, continued

5. Depending upon the model, your

pedestal may have straight or

curved brackets. The curved

ones are to be used on the rear

positions when mounting a dryer

to a pedestal, but can also be

used in any other position on the

pedestal.

6. Holding the exposed adhesive

away from the appliance, insert

the screws and get them started.

Then press the brackets to the

appliance and tighten all the

screws. Rub the bracket from

side to side to ensure a

complete bond.

7. Use the wrench to turn each leg

of the appliance approximately

¼ turn to put a little pressure

between the appliance and the

pedestal. This will eliminate any

rattles.

8. It is usually easier to set the

pedestal and washer into place

and connect the water and drain

hoses before placing the dryer

on top of them.

WM2496H*M Page 17 of 58 TRAINING MANUAL

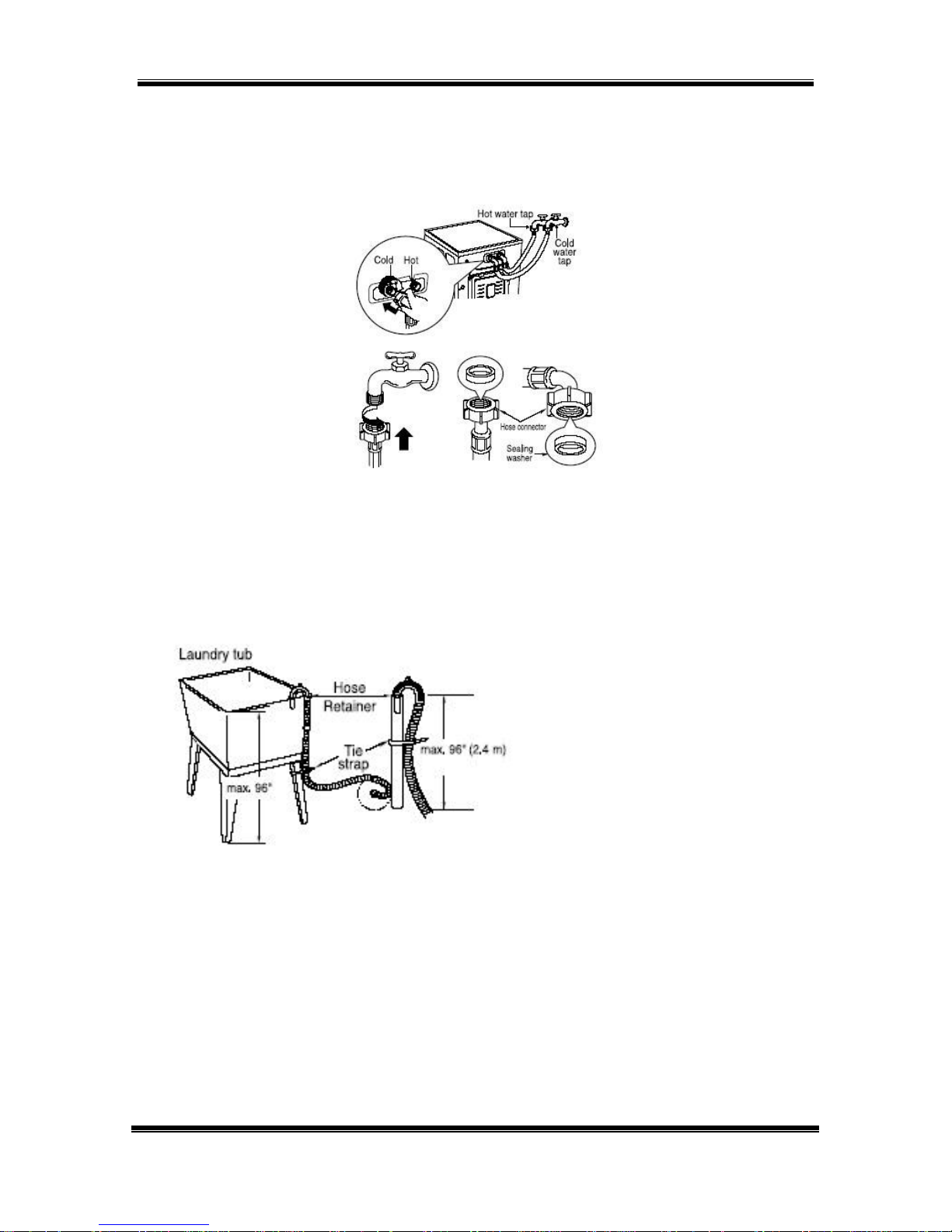

CONNECTIONS

WATER

Be sure the rubber washer is inside the hose end. Attach the hoses to the

washer (red is HOT, blue is COLD). Tighten them firmly but don’t strip the plastic

threads on the washer connections. The hoses may appear to be mechanically

identical, but the hot hose is rated at a higher temperature and burst strength.

DRAIN

The drain pipe should be firmly attached to the standpipe or the laundry tub or

sink where it drains. The pump has sufficient power to cause the pipe to move

around when the water is expelled. The pump can lift the drain water a maximum

of 96 inches (2.4 m), but there is no minimum height requirement. The vacuum

breaker in the drain line will prevent drainage by gravity or siphoning. The hose

can lay flat into a floor drain as long as the end of it is not submerged.

ELECTRICAL

The WM2496 washer requires a 120 VAC, 60 Hz., dedicated, 20-amp circuit.

WM2496H*M Page 18 of 58 TRAINING MANUAL

Loading...

Loading...