Page 1

ROBOTIC CLEANER

SERVICE MANUAL

MODEL : VR657* LVMP

VR657** LVMP

VR95** Ser

VR86** Ser

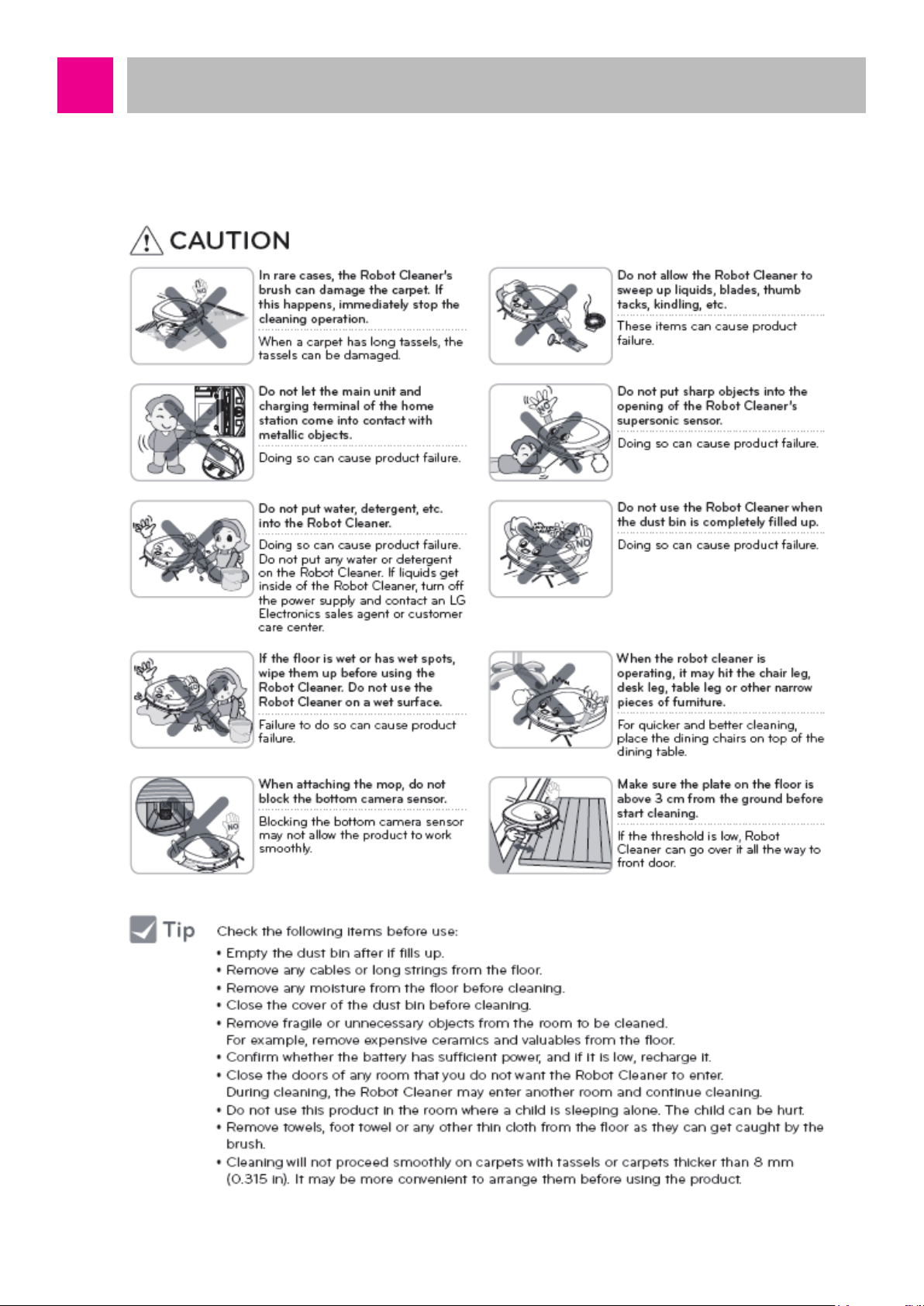

Caution

Please read the safety cautions of this booklet

before the maintenance of the product.

P/NO : MFL67646518

July, 2015

Printed in Korea

Page 2

Table of Contents

1. Product SPEC

2. Structure and Name of Each Part

3. Cautions and Methods during the Usage

4. How to Use Main Body Operation Buttons and Remote Controller

5. Technical Descriptions of the Parts

6. Safety Cautions and Verifications During the Repair

7. How to Disassemble/Assemble and Repair Major Parts

8. Cabling Diagram

9. Types of Defects and the Countermeasures

10. How to Use R-Manager RK diagnosis program

11. How to Use Black Box Viewer

12. Deal Drawing of the Structure and List of the Parts

-2-

Page 3

Product Specifications

■ Main Unit

ITEM LG Robot Cleaner

MODEL

Battery (Fully Charging)

Power Consumption

Charging Time

Use Time

Traveling Velocity

Cleaning Mode

Weight

External Dimensions

Accessary

Scheduled Cleaning / Error Displaying / Navigation / Auto/Manual Recharging /

Main Function

Spot Cleaning / Repeat Cleaning / My Space Cleaning / Cell by Cell cleaning /

VR657*LVMP / VR657**LVMP / VR95** Ser / VR86** Ser

Li ion, DC 16.8V

58W

3 hours

Approx. 100 minutes

(based on general wooden oor )

0.35 m/s

zigzag cleaning / Cell by Cell Cleaning / My Space Cleaning / Spot Cleaning

3kg

340mm x 340mm x 89mm

Home station / remote controller / Filter / Cleaning Brush / Brush

Turbo Mode / Learning Mode / Obstacle Sensing / Anti-Plunge function /

Corner Clean / Voice Messaging / Map Drawing /

Zigzag Cleaning /

■ Home Station

ITEM Home Station

Model

Rating

Power Consumption

Output Voltage/Current

■ Remote Controller

ITEM AKB73296002

Battery

Type

Operating Range

Size(WxLxH)

VR621

AC 220V, 60Hz

23W

DC 17.1V / 1.1A

DC 3V(AAA, 2ea)

Infra Red(38kHz)

5m

45 X 22 X 115 mm

-3-

Page 4

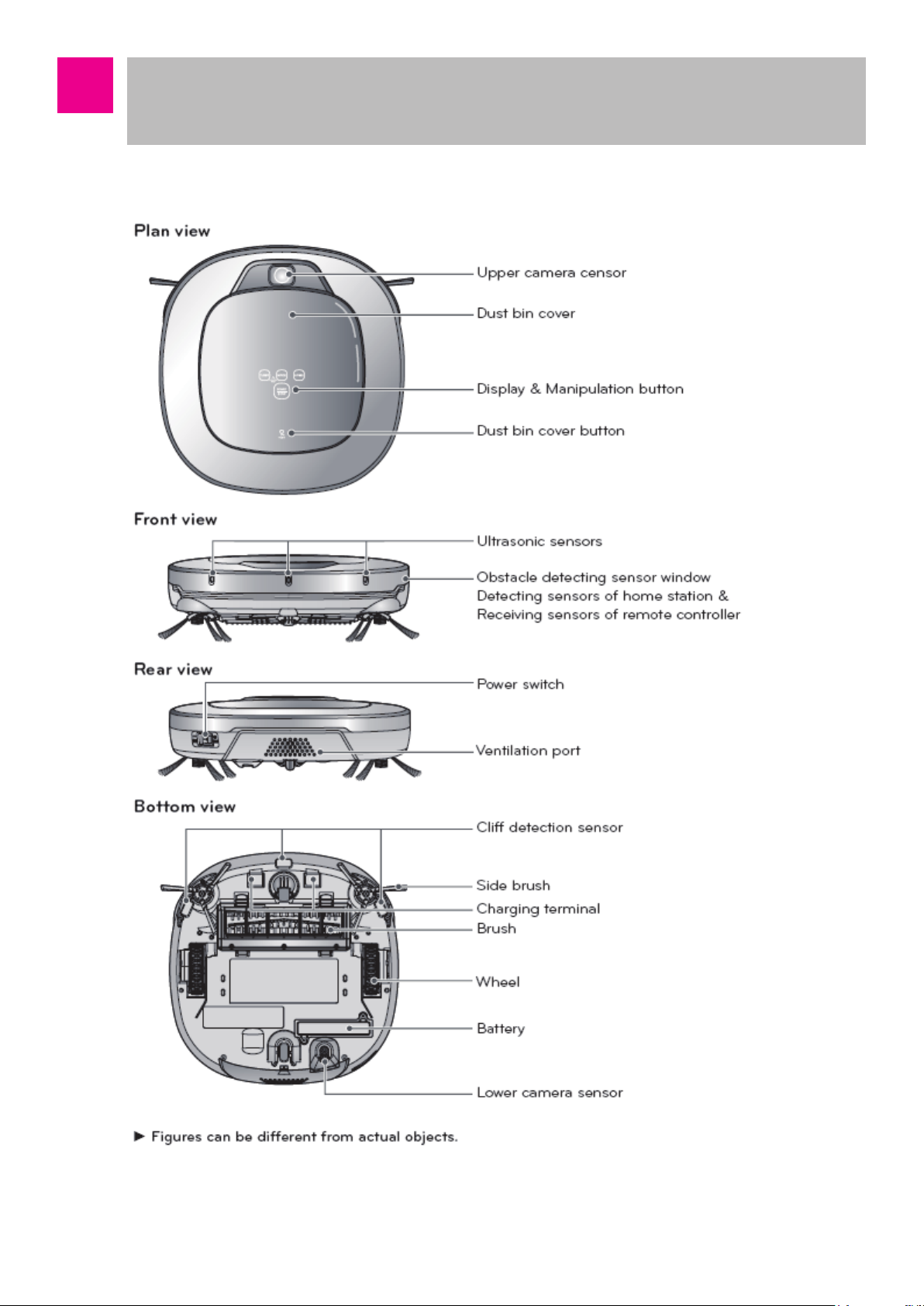

Structure and Name of Each Part

– Robot Cleaner

-4-

Page 5

Structure and Name of Each Part

– Robot Cleaner

-5-

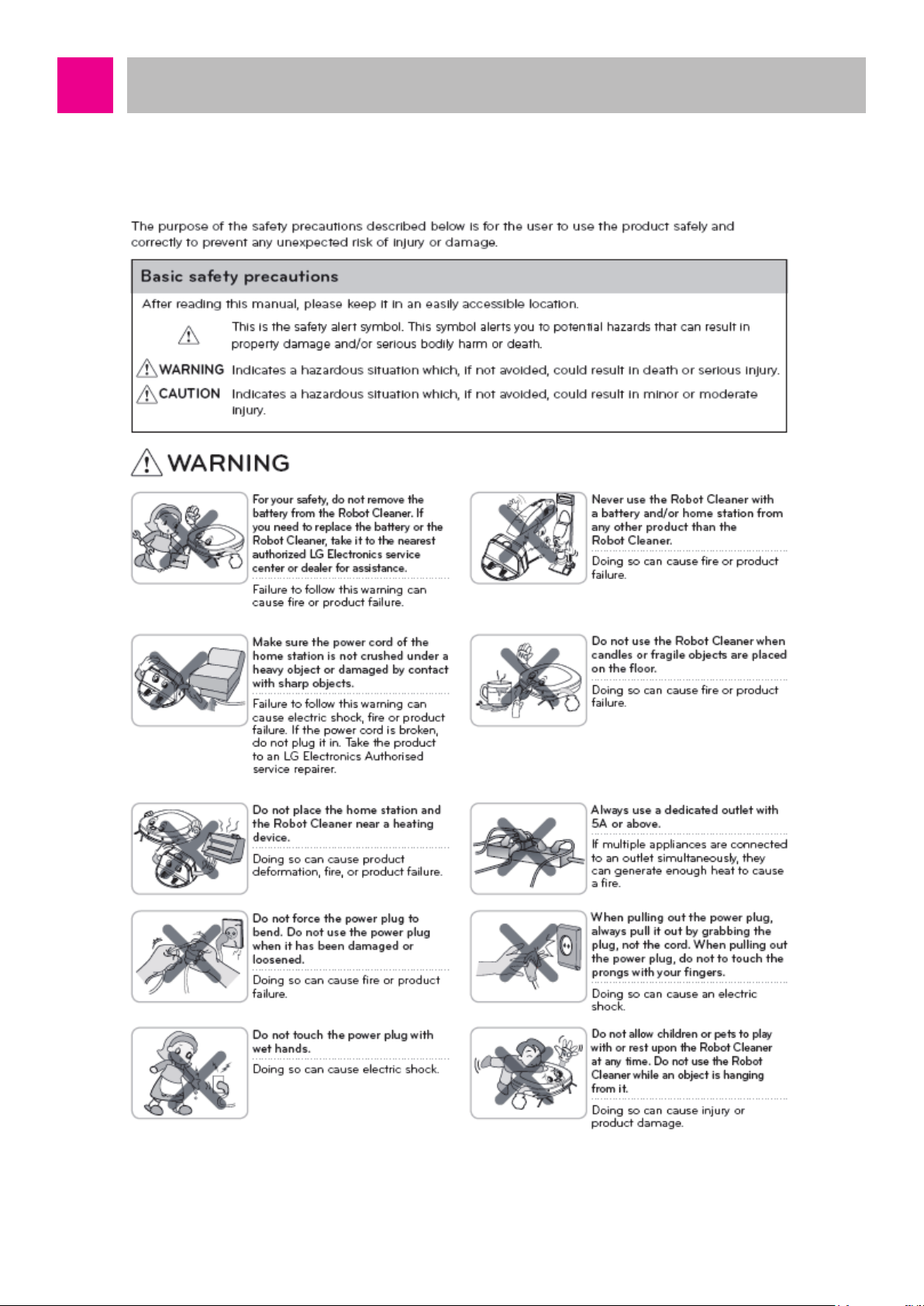

Page 6

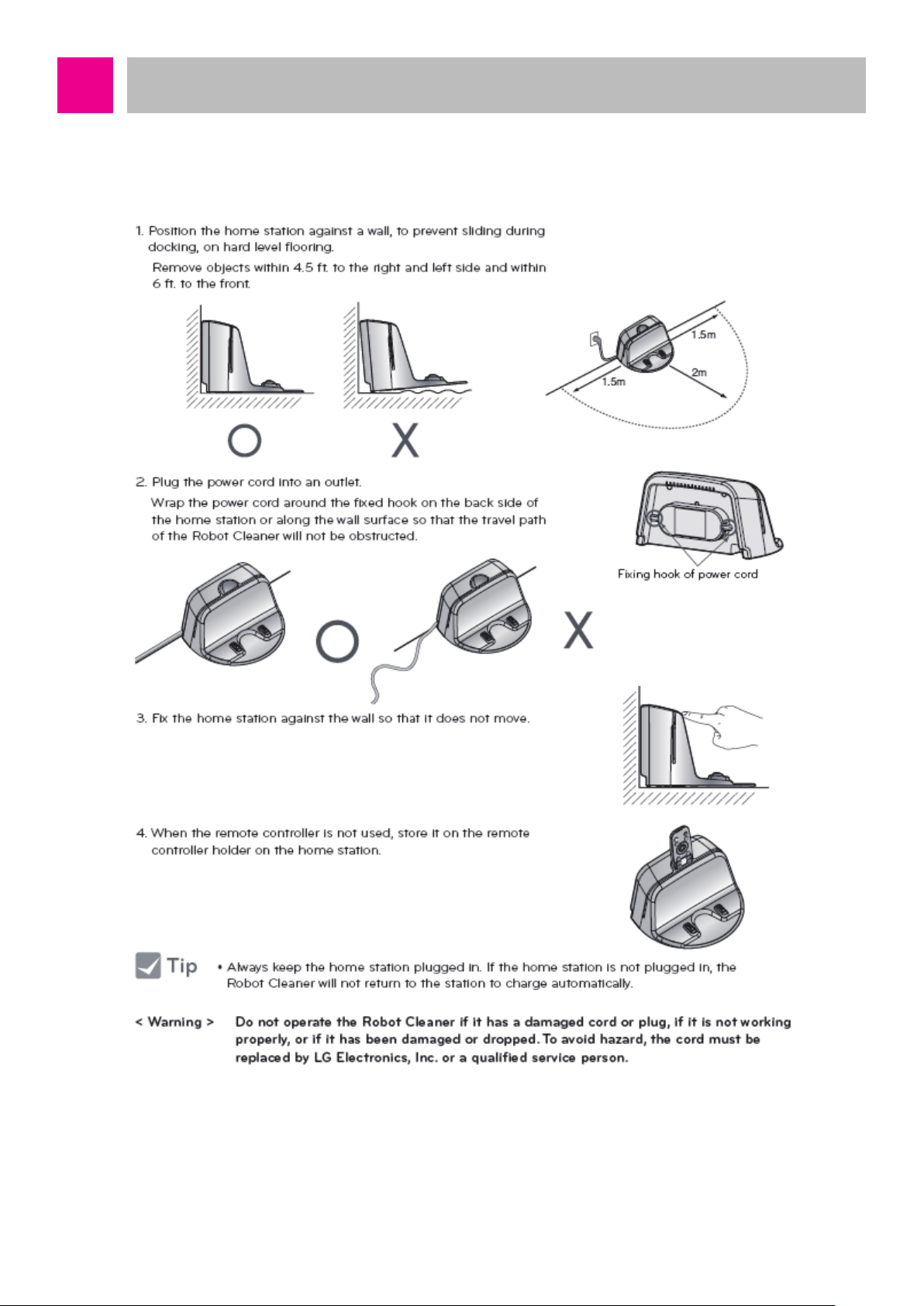

Cautions and Methods during the Usage

-6-

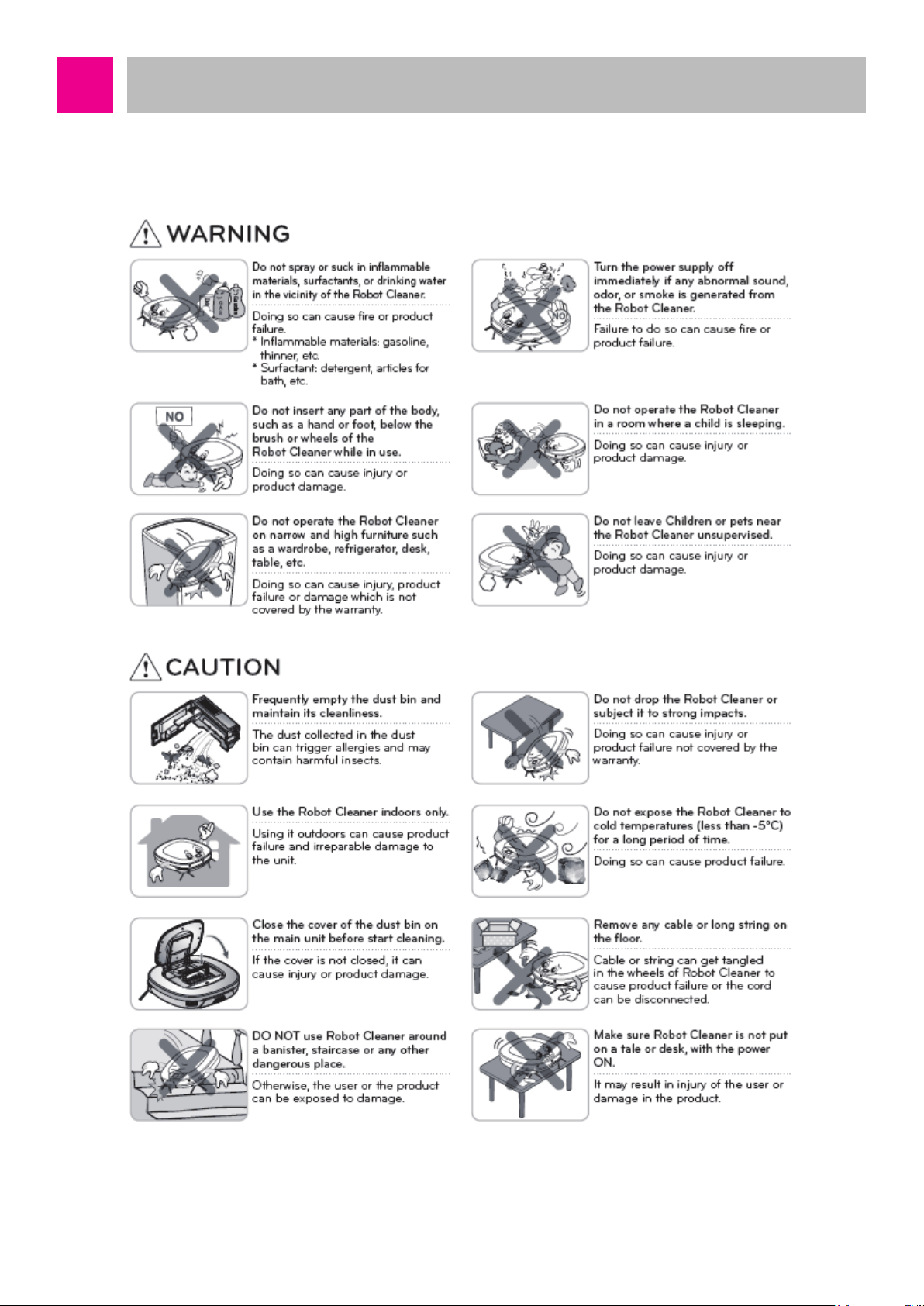

Page 7

Cautions and Methods during the Usage

-7-

Page 8

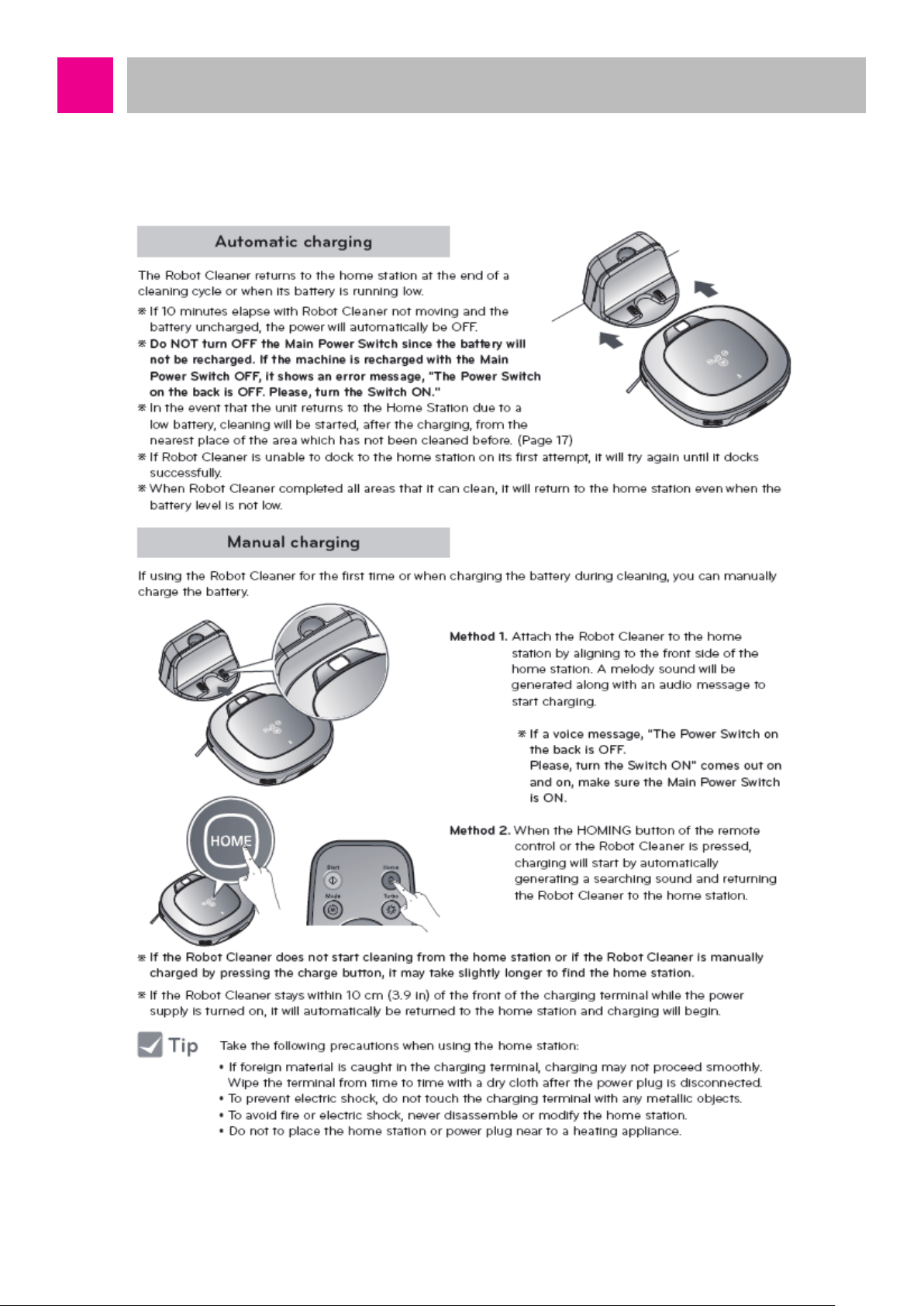

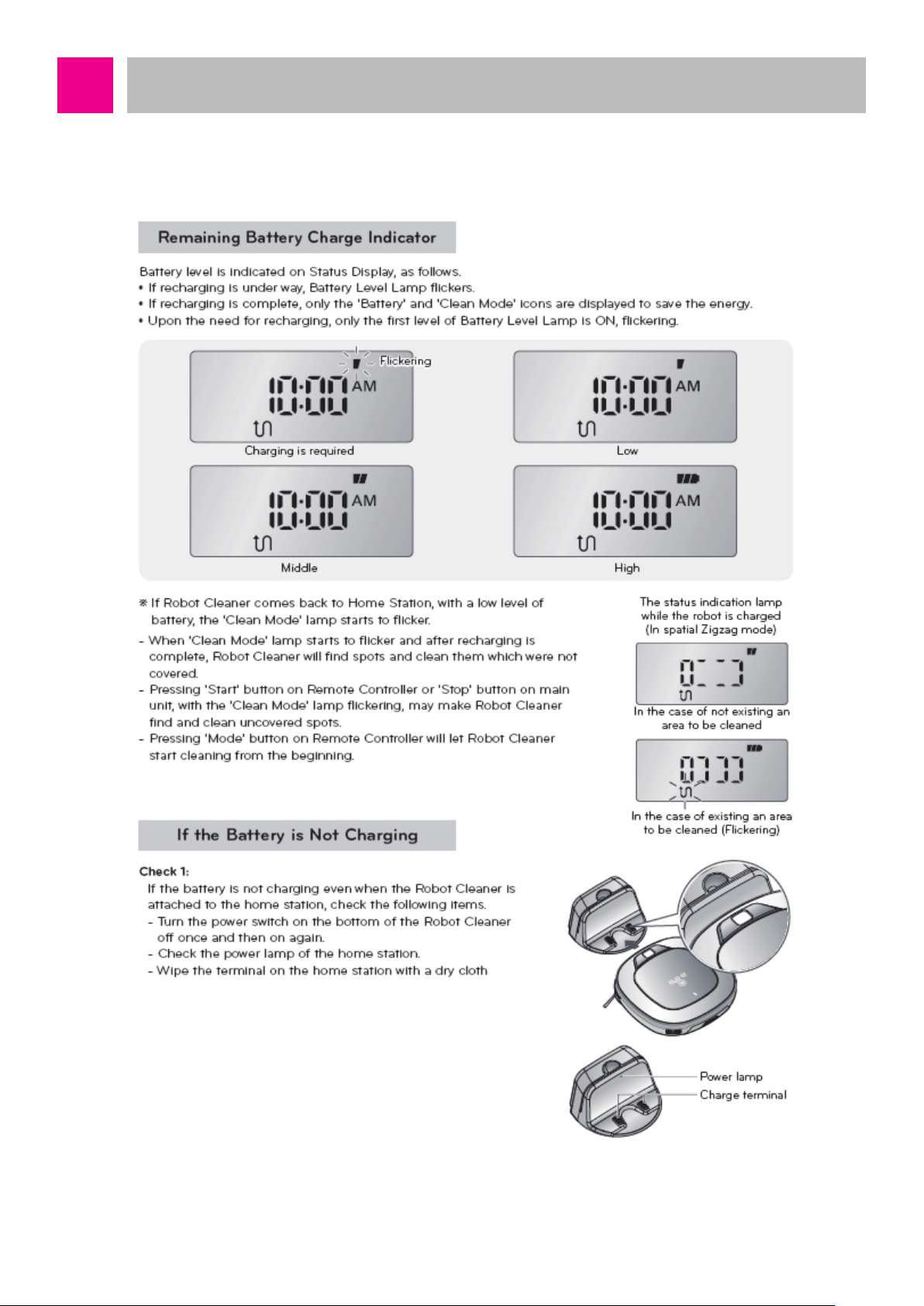

Cautions and Methods during the Usage

-8-

Page 9

Cautions and Methods during the Usage

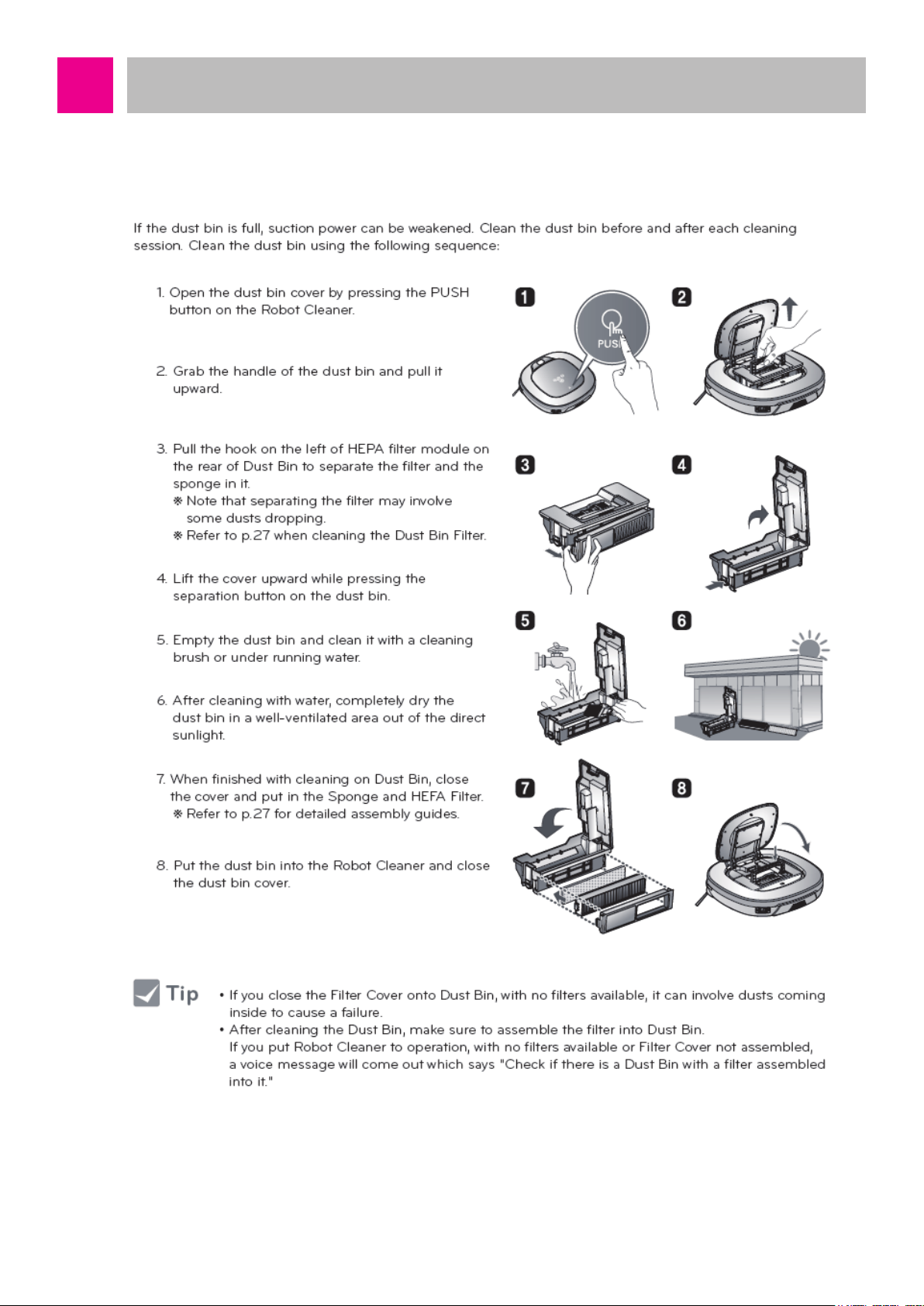

1. About Dust Bin

-9-

Page 10

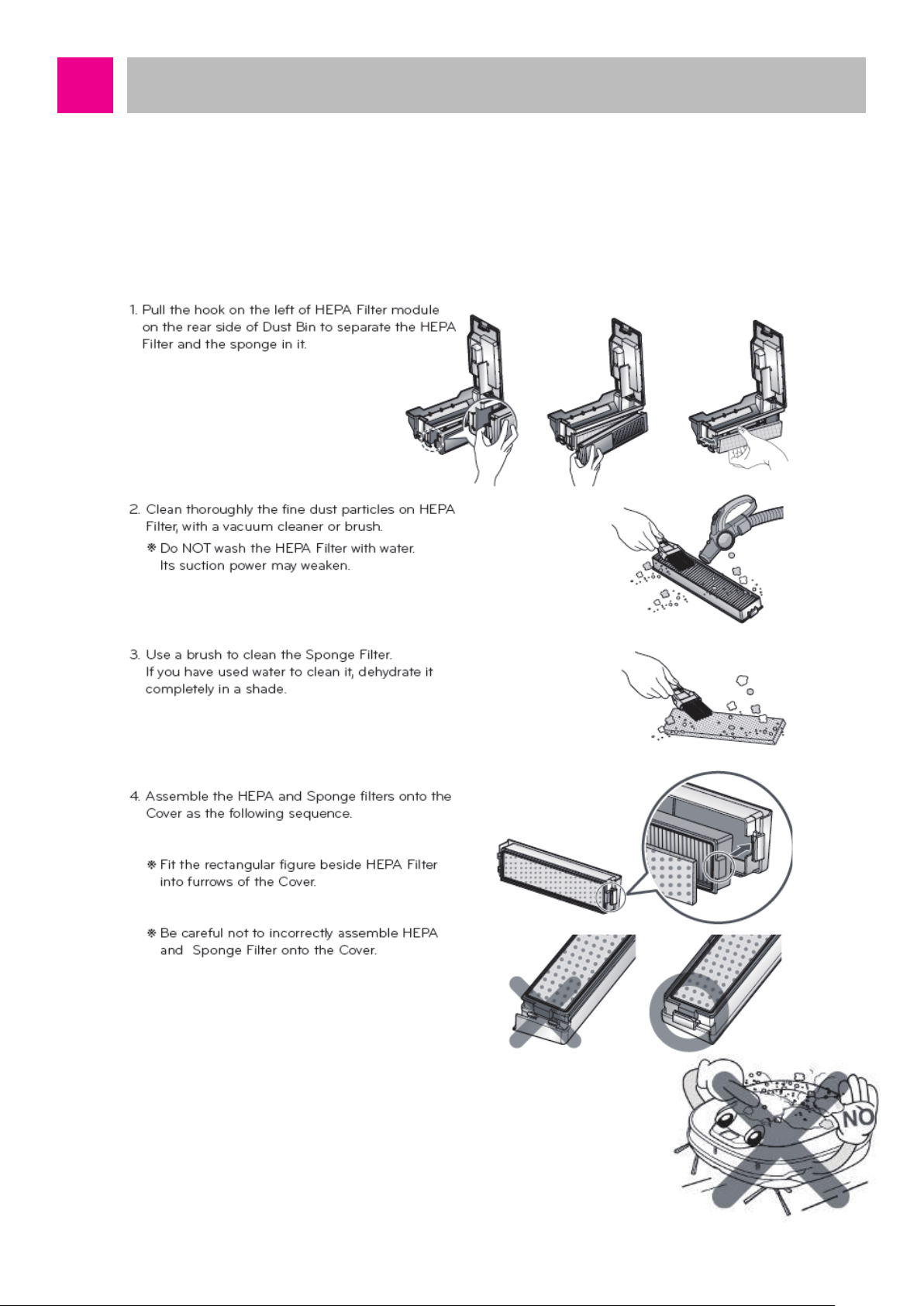

Cautions and Methods during the Usage

2. About Filter

■

Dust Bin Filter

It is recommended to clean the dust bin filter with HEPA 11 once a week. During the cleaning,

clean thoroughly with cleaning brush and the cleaner. Never clean the filter with water. When it

is washed with water, the cleaning performance will be degraded.

Make sure to install the dust bin filter (HEPA filter, sponge

filter) to the dust bin after the cleaning.

If the dust bin or dust bin filter is not installed, dust may enter

inside Roboking and cause disorder.

-10-

Page 11

Cautions and Methods during the Usage

3. About Agitator

If foreign object is stuck in the agitator, it decreases the rotation speed and degrades the

cleaning performance to cause disorder. Especially, after cleaning hair or hair of pets, make

sure to clean the agitator. Clean periodically after 10 usages in ordinary homes.

If the agitator stops by foreign object during the cleaning, a voice alarm of “check foreign object

in the agitator at the bottom” will sound. At this time, remove the foreign object stuck in the

agitator before the usage.

Side agitator rotates synchronized with the bottom agitator. If the bottom agitator does not

rotate, the side agitator will not rotate either.

-11-

Page 12

Cautions and Methods during the Usage

4. Cleaning the Side Brush

-12-

Page 13

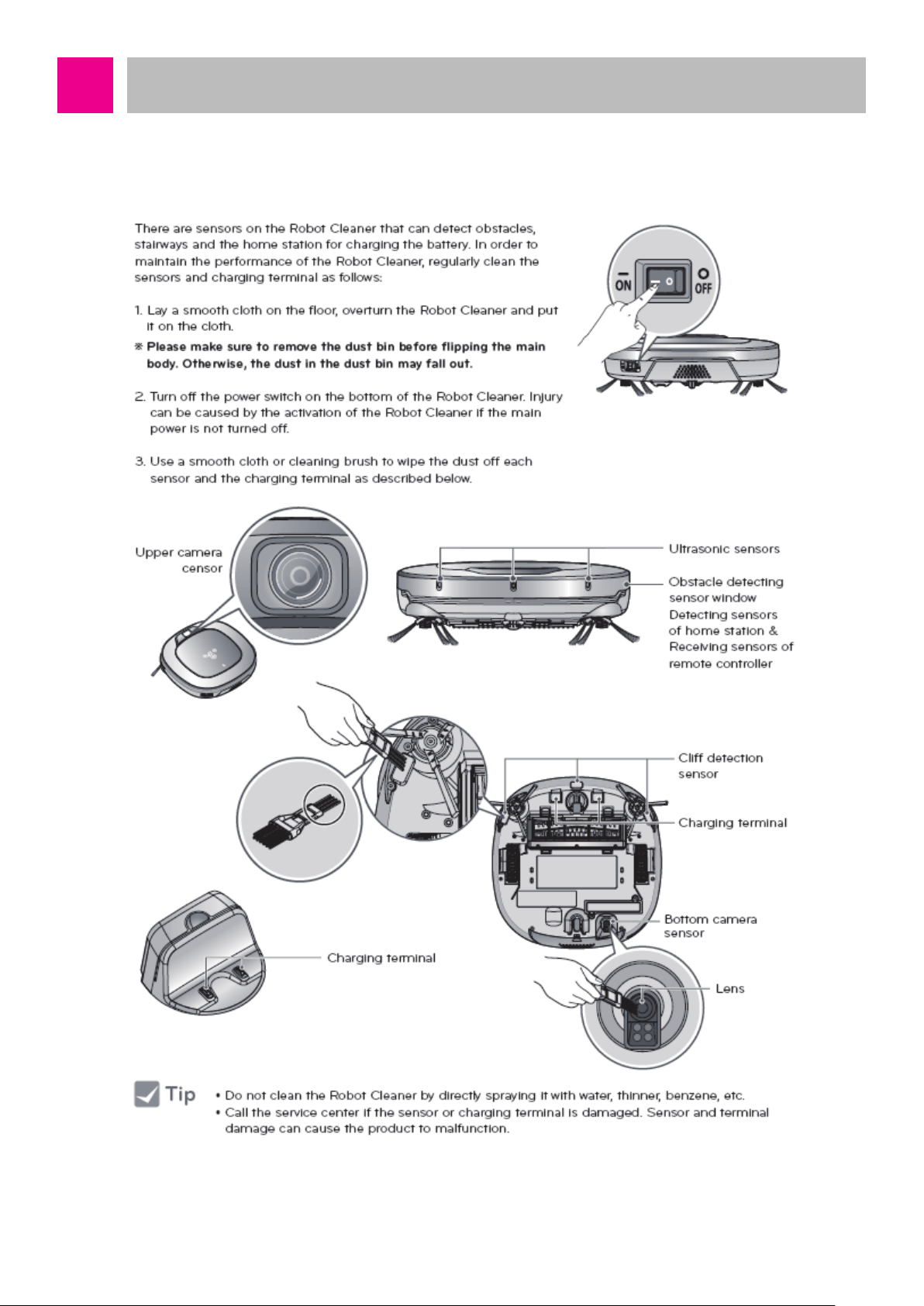

Cautions and Methods during the Usage

5. Cleaning the Sensor / Charging Terminal

-13-

Page 14

Cautions and Methods during the Usage

6. How to Install the Home Station

-14-

Page 15

Cautions and Methods during the Usage

7. How to Charge the Battery

-15-

Page 16

Cautions and Methods during the Usage

8. Remaining Battery Charge Indicator

-16-

Page 17

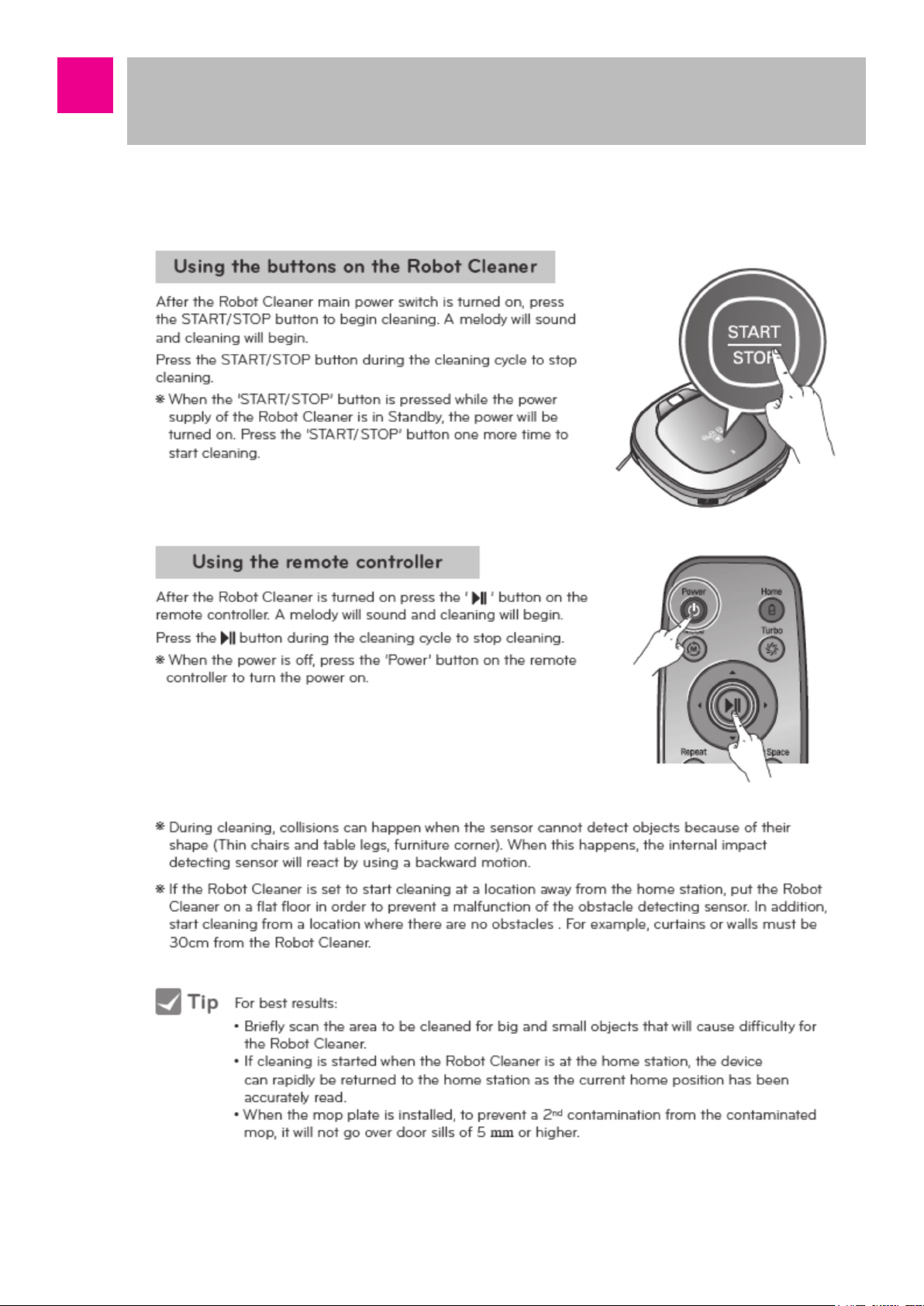

How to Use Main Body Operation Buttons

and Remote Controller

■ Turning ON/OFF the Power Button

The power switch at the left backside of the main body is connected between the battery and the Main circuit to

function to supply or block the power. Also, it is connected between the recharging connector of the main body

and the Main circuit to functions to supply or block the power of the recharging station.

When the main body power switch remains in ON state, the product can be turned on by pressing the button

on the main body, and recharge is possible. If the power is not turned ON even if the power button on the

main body is pressed, or if power is not turned on even if the main body is connected to the recharging

station, check the status of the main power switch at the left backside of the main body.

※ When you turn on the main power button, do not turn it on while pressing the button at the top of the cleaning

robot. Button operation may be delayed.

Even if the main body power switch is turned on, Micom does not operate, so there is no change is the status

indication window. To start Micom, press the start/stop button of the main body for 1 second after turning on

the main body power switch. Then, Micom will start, LED of the screen display window will be turned on, and

Booting will start. Booting time may be different for each model, and when the Booting is over, it converts to

standby state with a melody.

In the standby state, if the start/stop button of the main body is pressed for 2 seconds or longer, the power will

be turned off with the ending melody.

It is the state with the power off, but a small amount of electricity is used for button operation, so when it is left

alone for long period of time, the battery may be consumed and power may not be turned on. When it is not

used for long period of time, please store it with the power switch turned off.

-17-

Page 18

How to Use Main Body Operation Buttons

and Remote Controller

■ How to Start and Stop Cleaning

-18-

Page 19

How to Use Main Body Operation Buttons

and Remote Controller

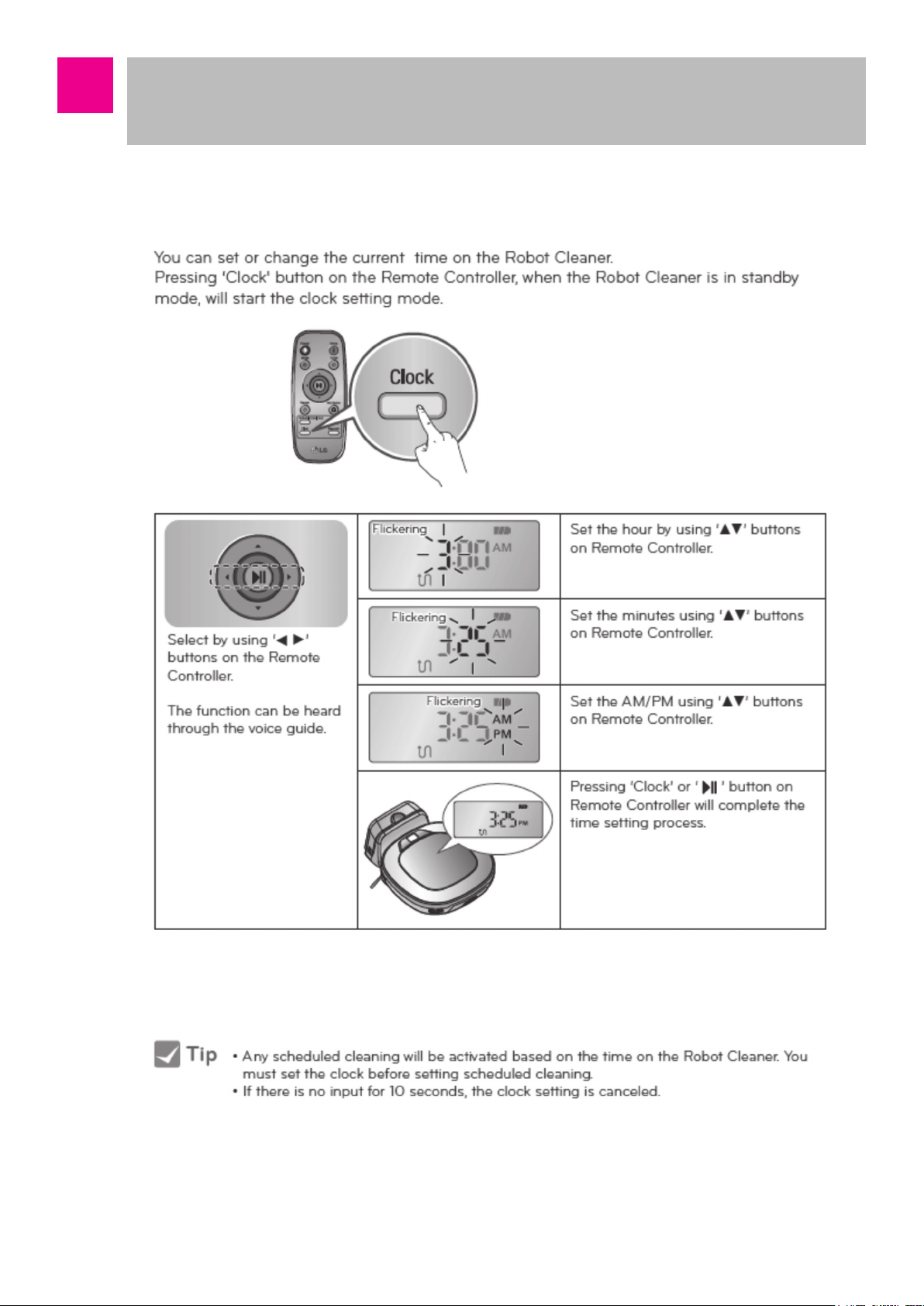

■ Time Setting

-19-

Page 20

How to Use Main Body Operation Buttons

and Remote Controller

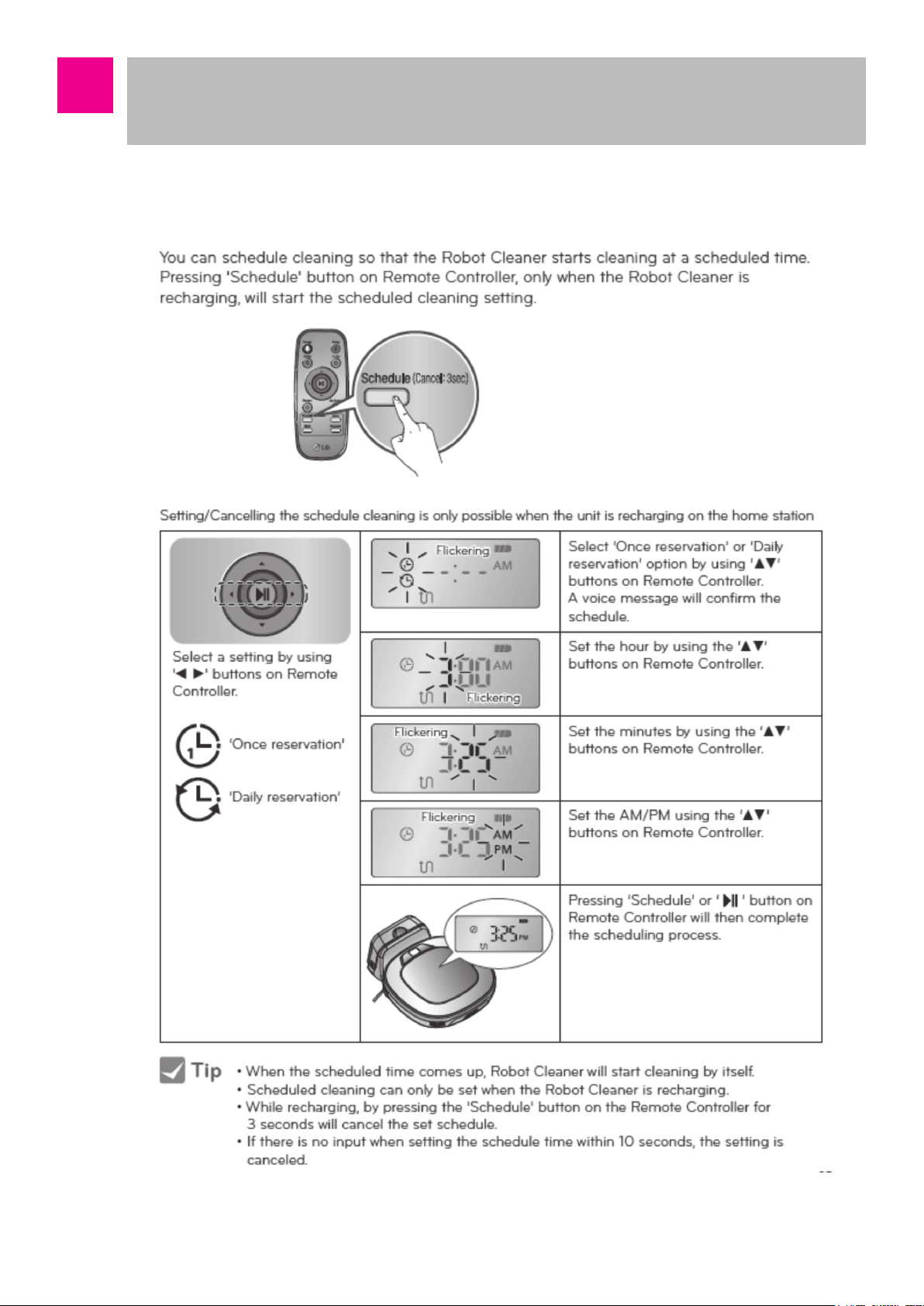

■ Schedule Cleaning

-20-

Page 21

How to Use Main Body Operation Buttons

and Remote Controller

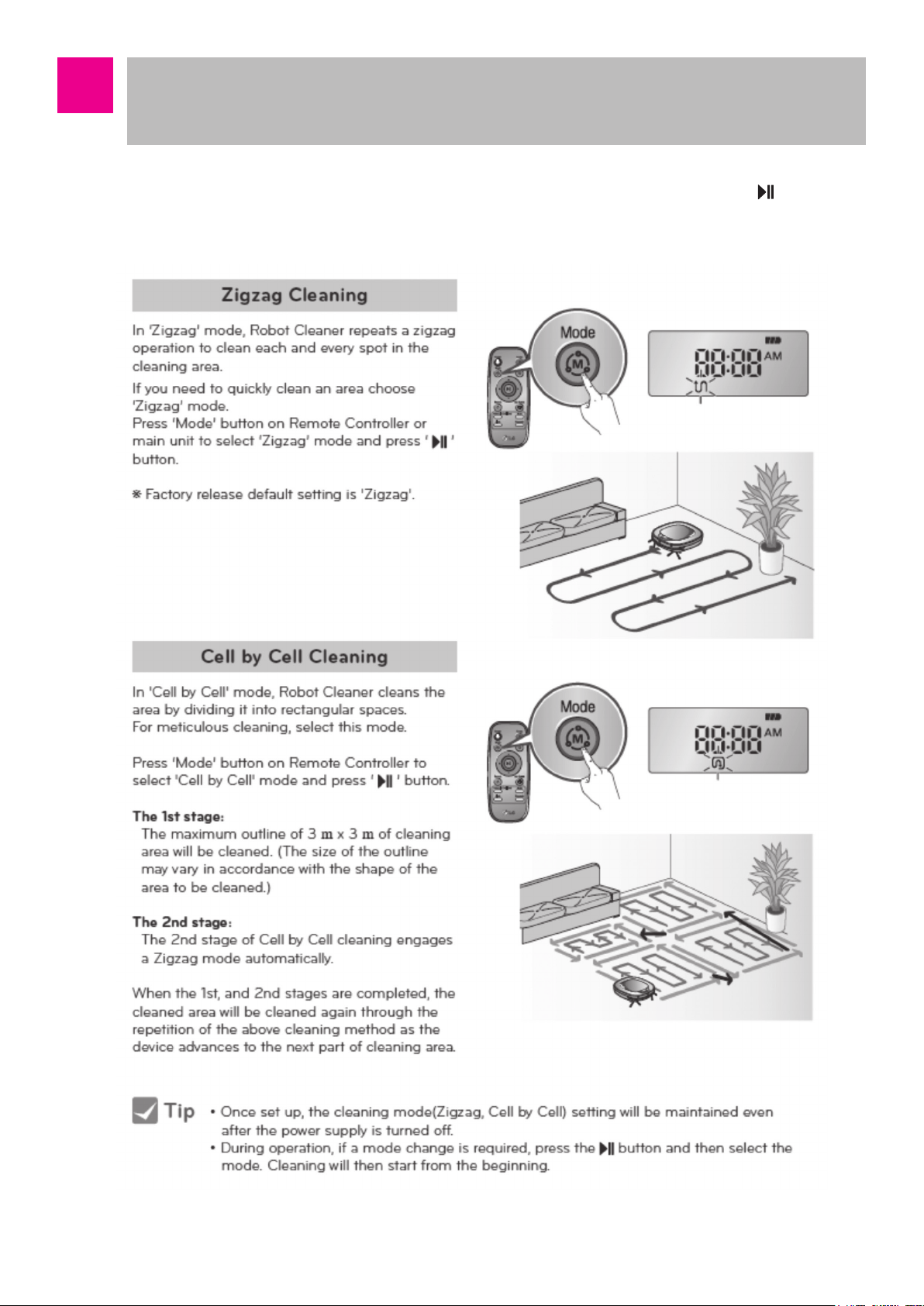

■ Cleaning Modes ※ If you want to change the mode during the operation, press and select

the mode.

-21-

Page 22

How to Use Main Body Operation Buttons

and Remote Controller

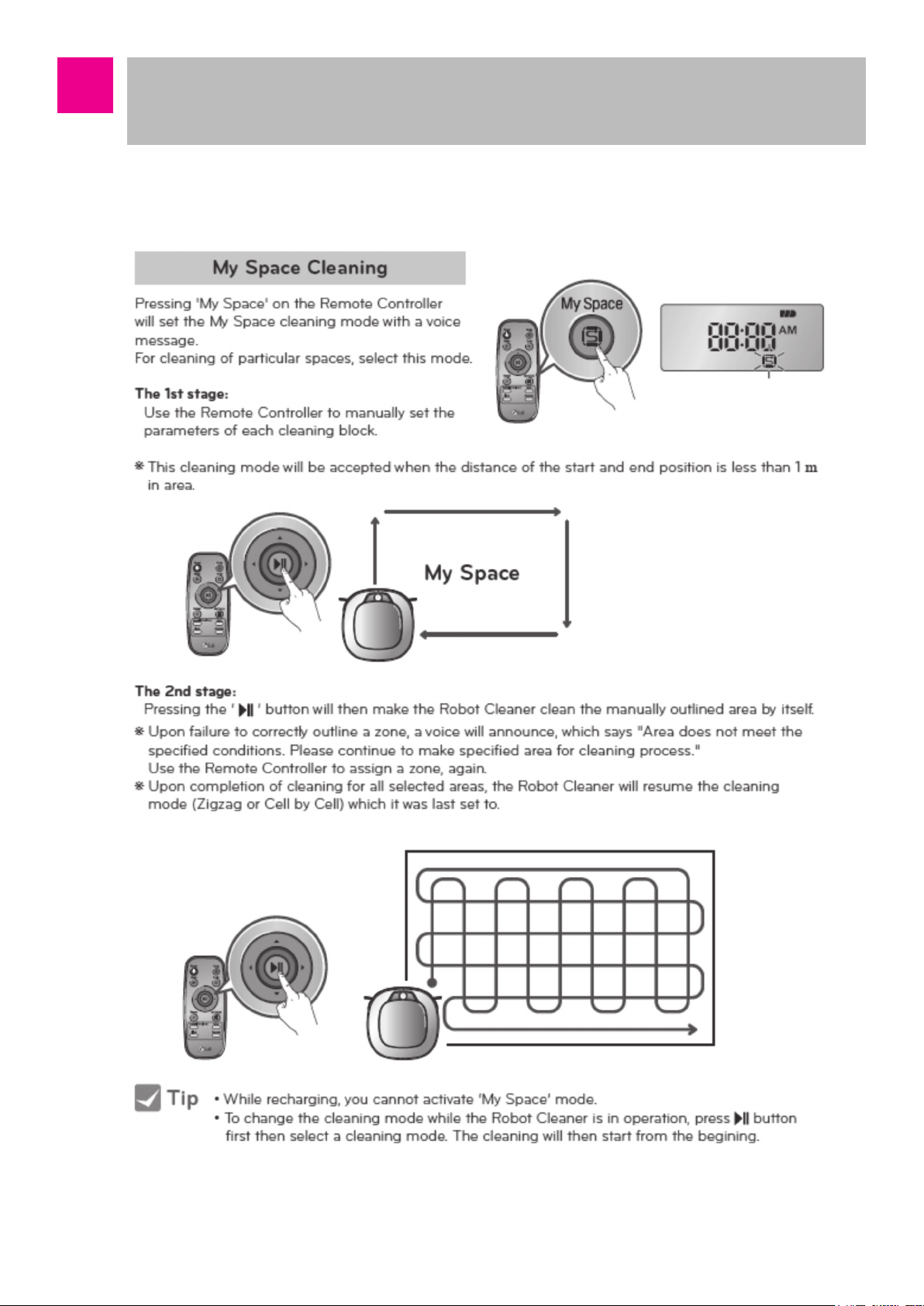

■ My space clean

-22-

Page 23

How to Use Main Body Operation Buttons

and Remote Controller

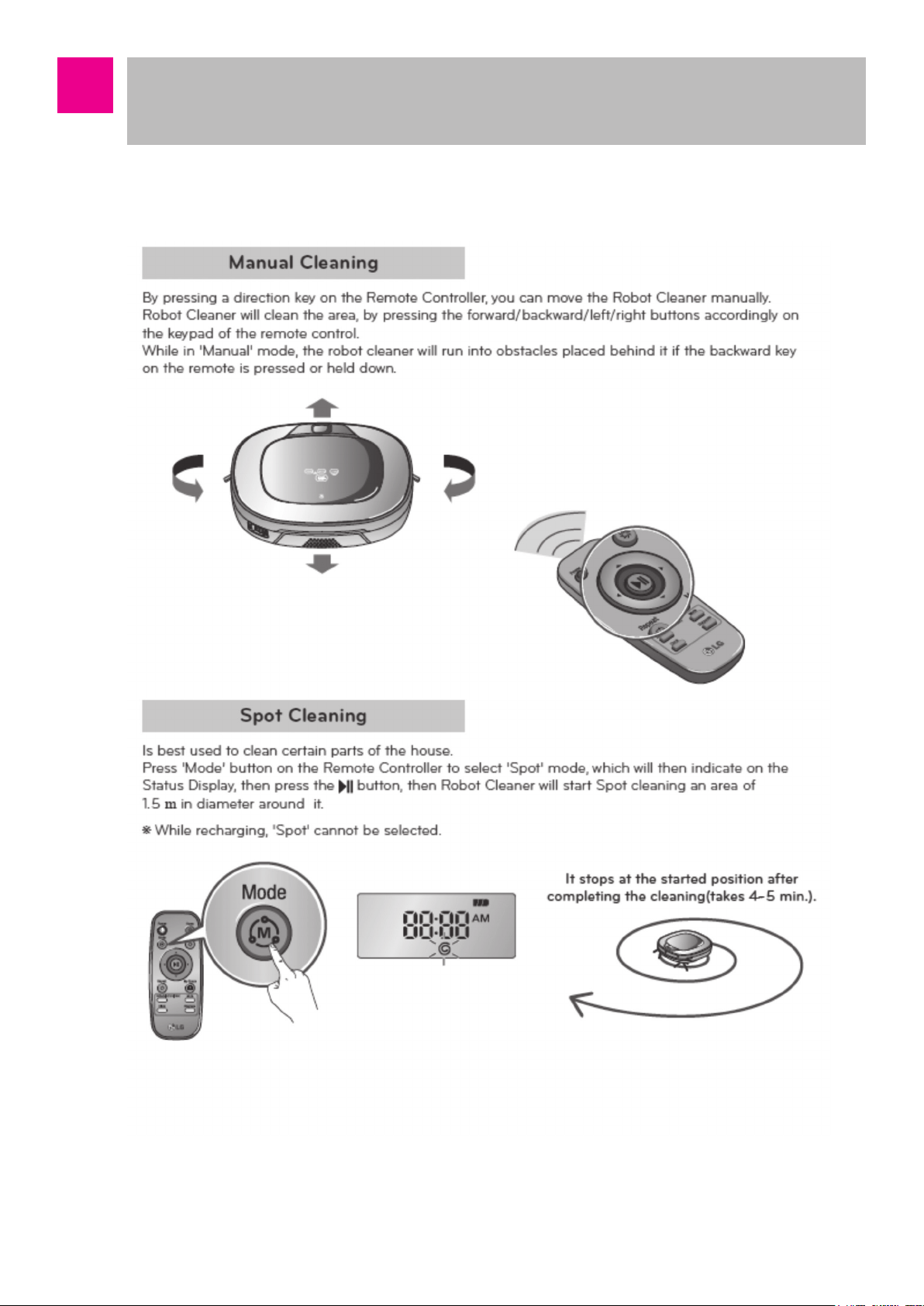

■ Manual Cleaning and Spot Cleaning

-23-

Page 24

How to Use Main Body Operation Buttons

and Remote Controller

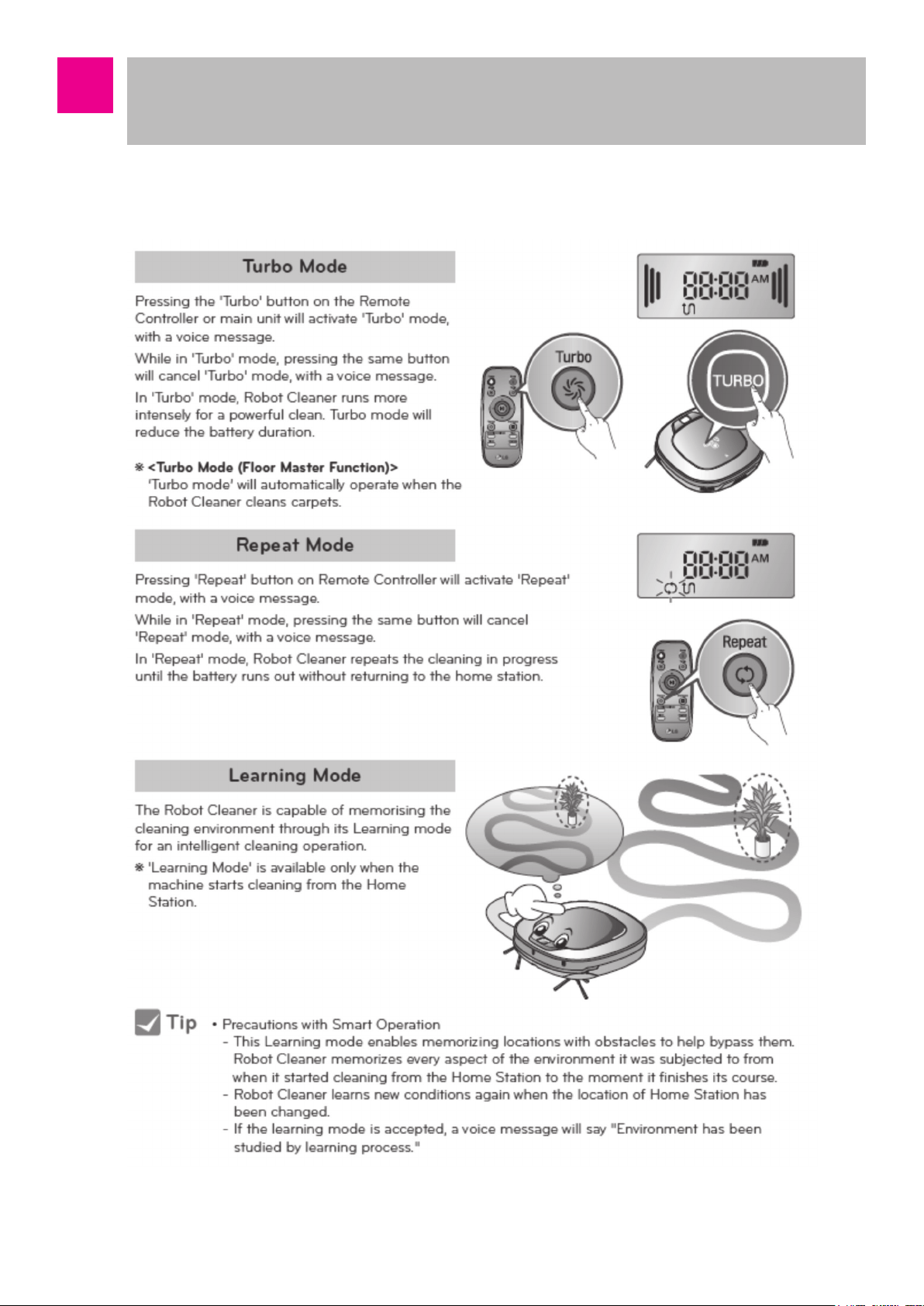

■ Turbo Mode, Repeat Mode and Learning Mode

-24-

Page 25

How to Use Main Body Operation Buttons

and Remote Controller

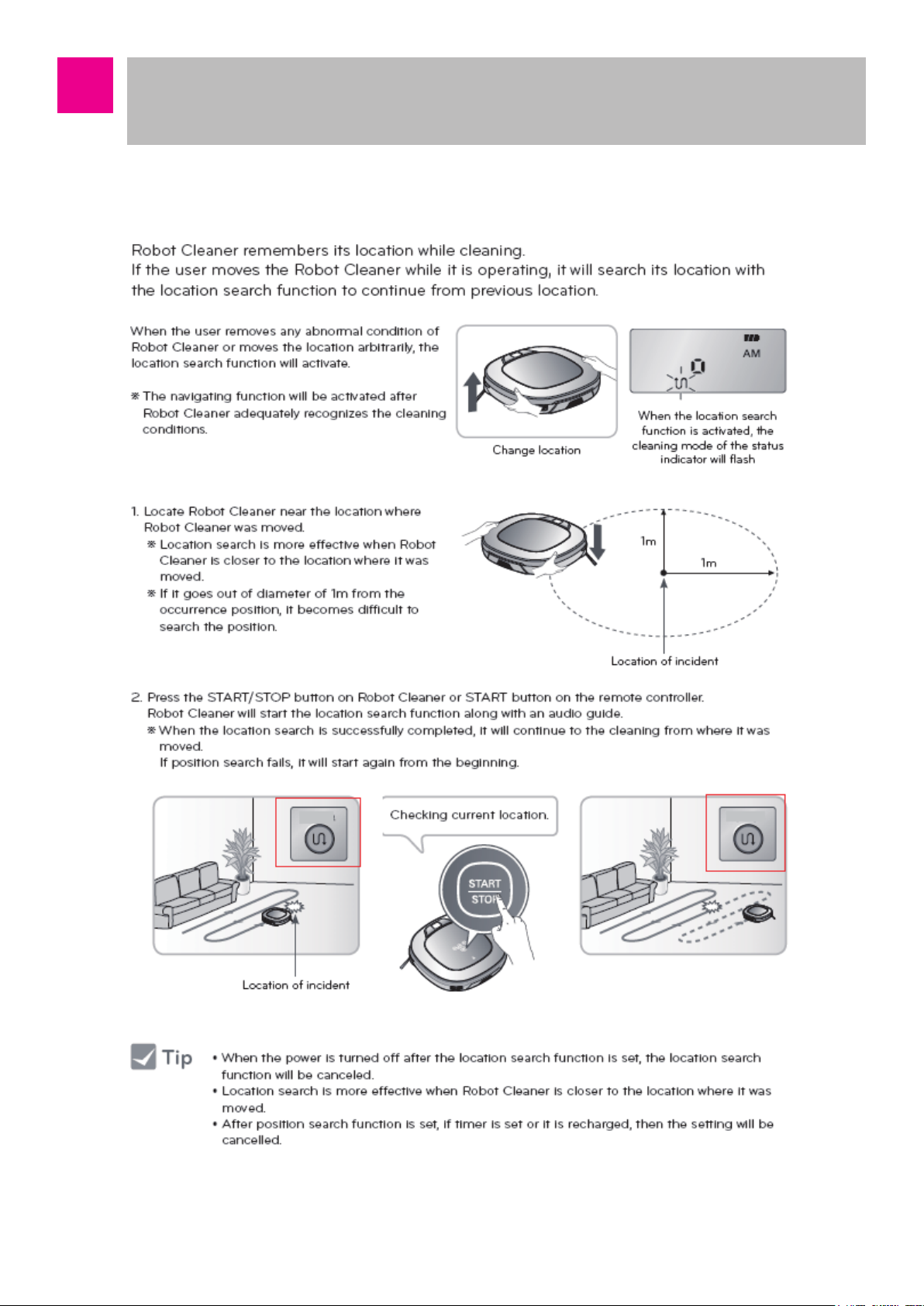

■ Location Search Function

-25-

Page 26

How to Use Main Body Operation Buttons

and Remote Controller

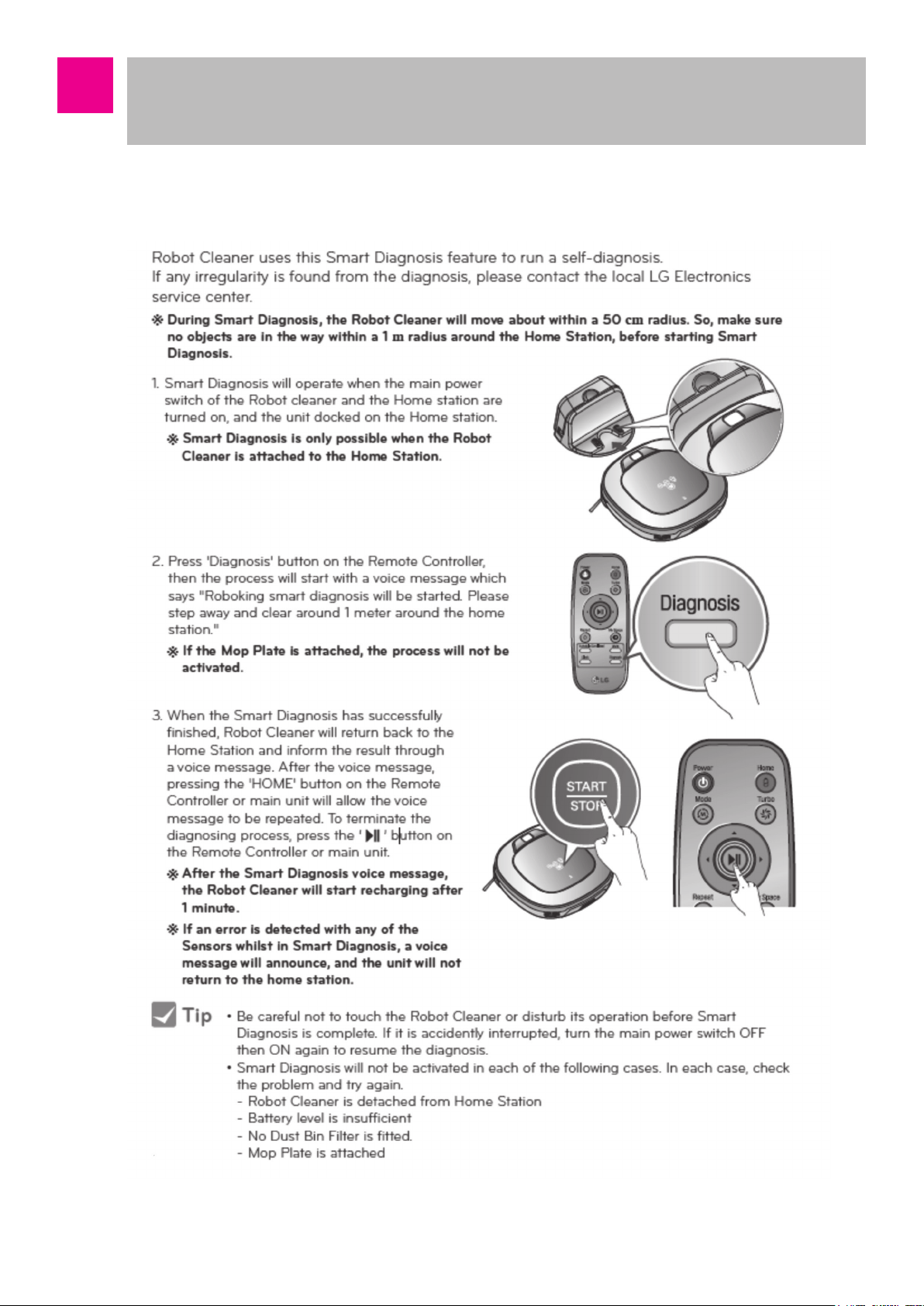

■ Smart Diagnosis

-26-

Page 27

How to Use Main Body Operation Buttons

and Remote Controller

■ Smart Diagnosis

-27-

Page 28

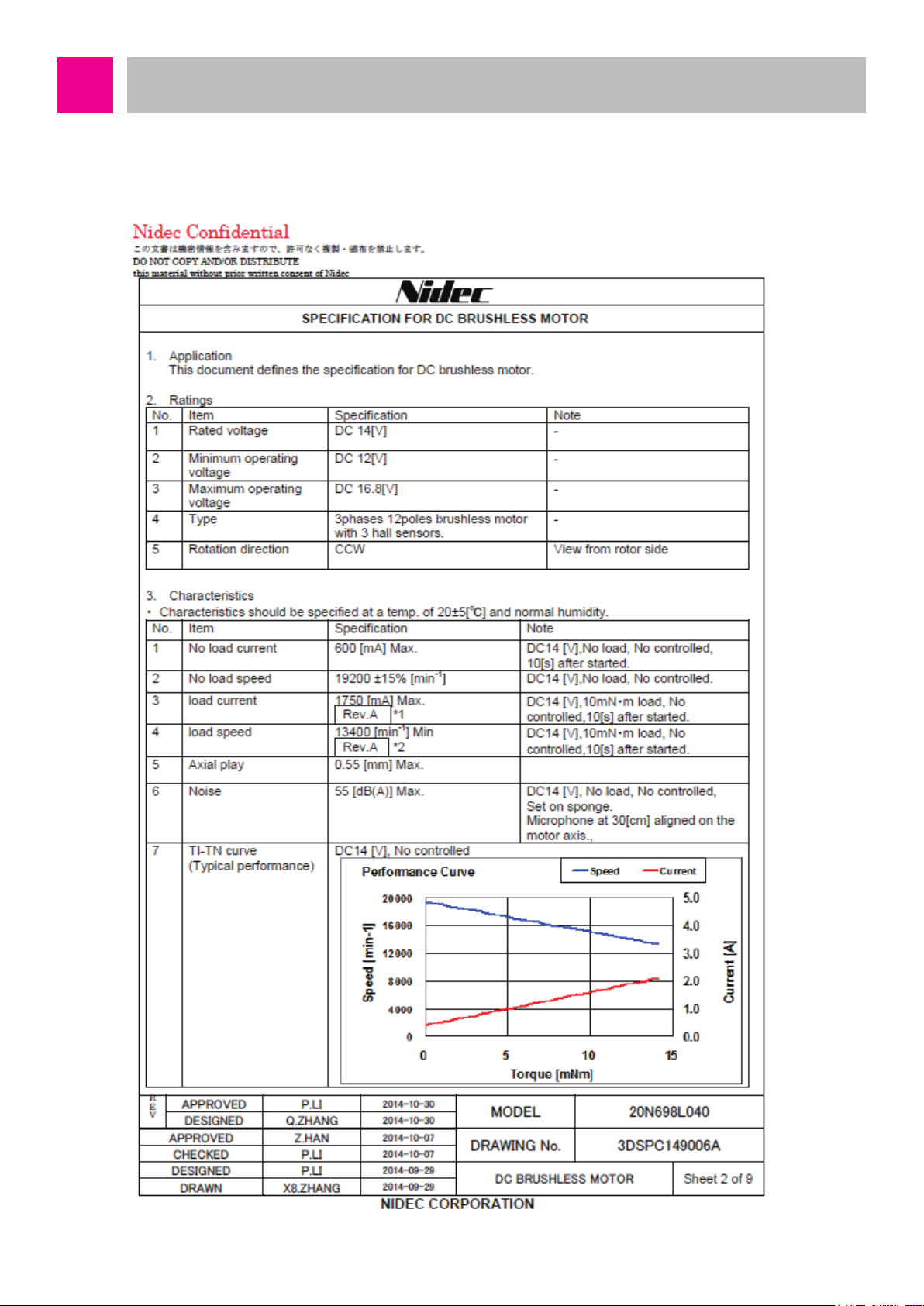

Technical Descriptions of the Parts

■ Suction Motor

Manufacturer: Nidec

-28-

Page 29

Technical Descriptions of the Parts

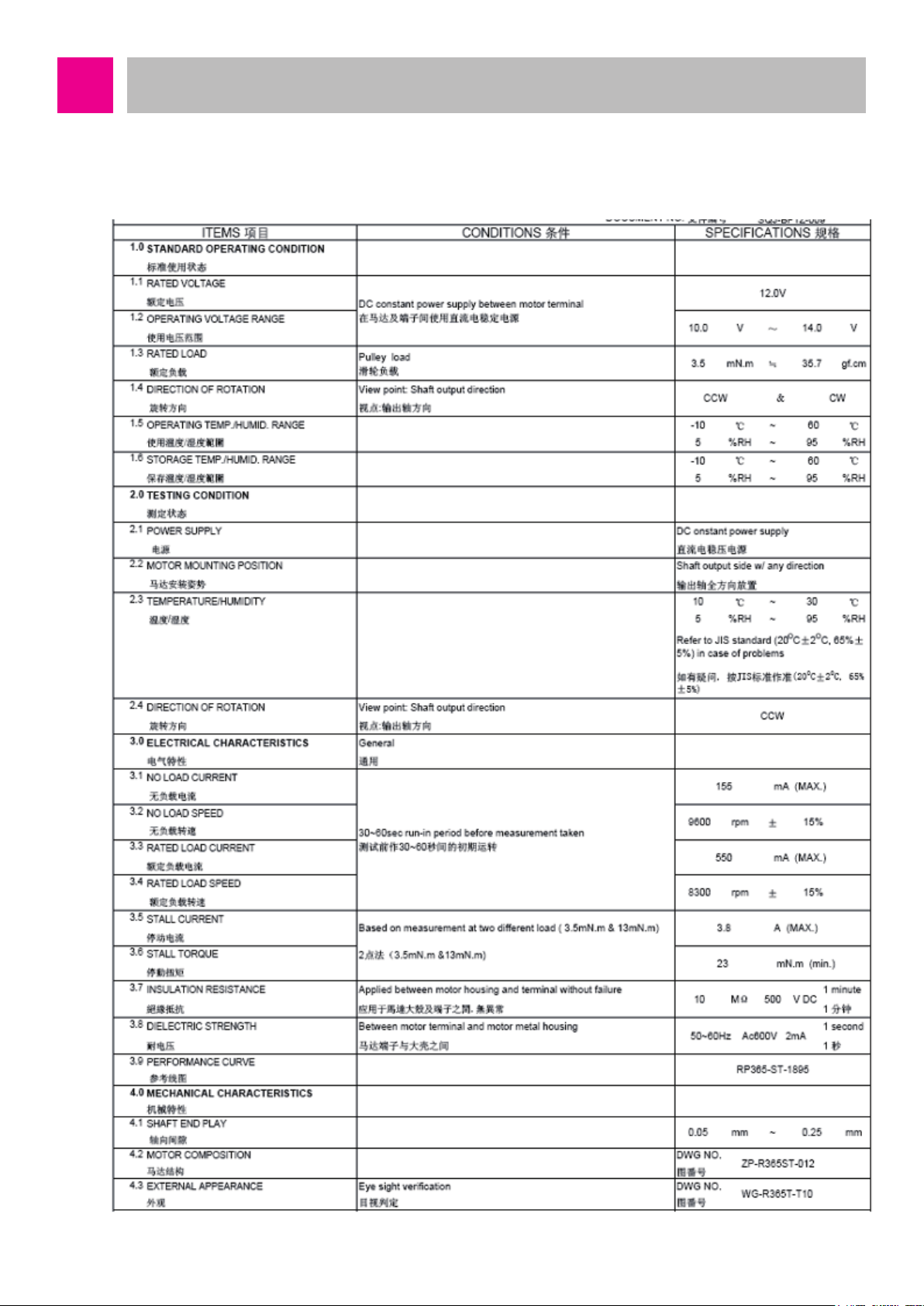

■ Agitator Motor

Manufacturer: STANDARD

-29-

Page 30

Technical Descriptions of the Parts

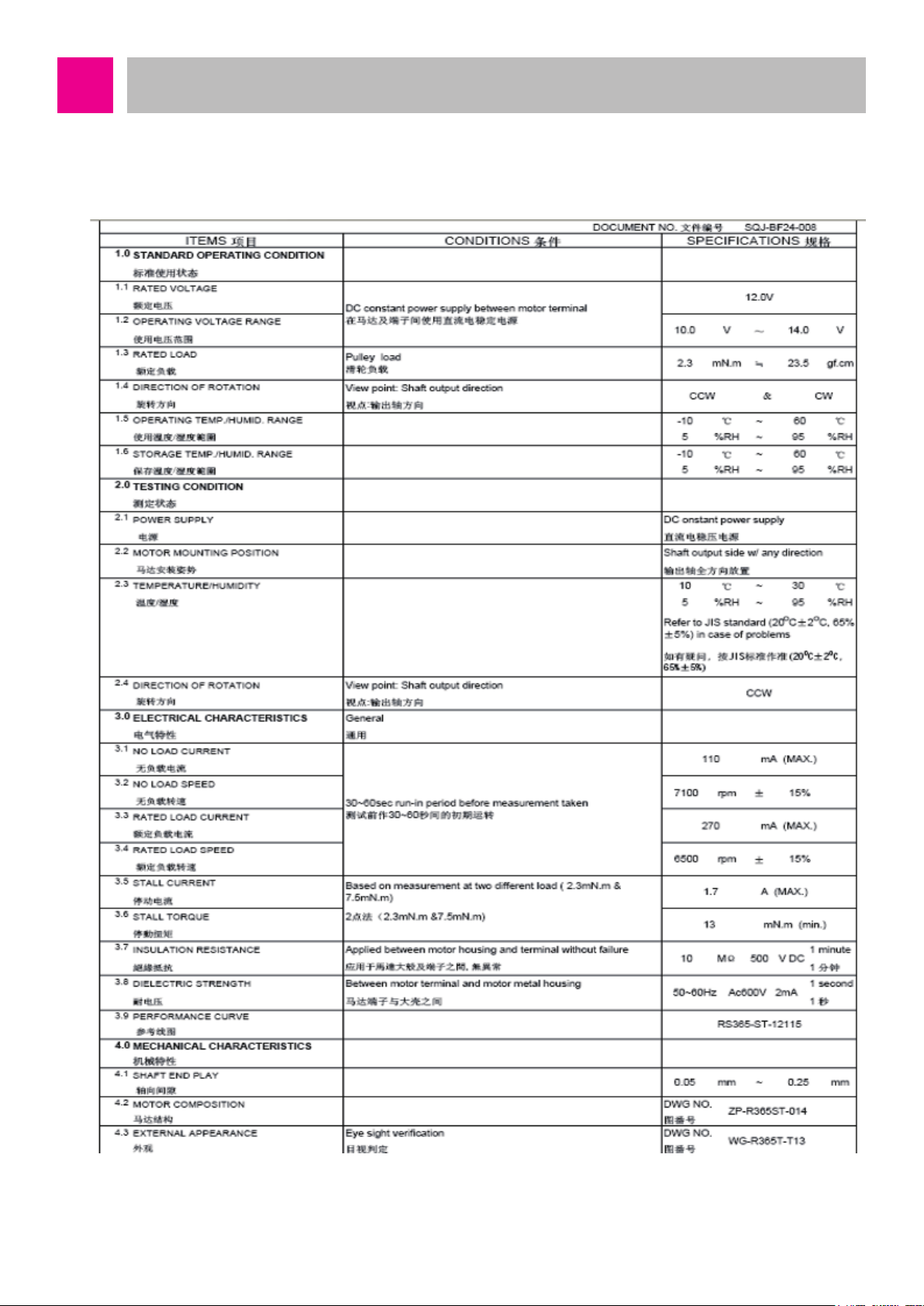

■ Wheel Motor

Manufacturer: SHARP

-30-

Page 31

Technical Descriptions of the Parts

■ Wheel Motor

Manufacturer: SHARP

Model Name

Operation Voltage

Measurable Distance

Connector Voltage Output (L=30)

Minimum/Maximum Distance

Voltage Difference

Average Current Supply

GP2Y051SK0F

DC 4.5V ~ 5.5V

2 ~ 15 cm

Min = 0.25 / Typ = 0.4 / Max = 0.55 (V)

Min = 1.95 / Typ = 2.25 / Max = 2.55 (V)

Typ = 12 / Max = 22 (mA)

-31-

Page 32

Technical Descriptions of the Parts

■ Wheel Motor

Manufacturer: SensorTech

Category Specication

Applied frequency

Transmission Sound Pressure Level

Reception Sensitivity

122.00 ~ 123.16

-58.06 ~ -54.54

Angle of Beam Spread

Capacitance

Max Input Voltage 20 Vrms

Operation Temperature Range -30 ~ 80

Storage Temperature Range -40 ~ 85

40 ± 1

90 ± 10°

2100 ± 20%

Remark

0dB = 0.02mPa, 10Vrms, 30cm

0dB = 10V/Pa, 30cm

-6 dB down angle

@1KHz

-32-

Page 33

Technical Descriptions of the Parts

■ Battery

Manufacturer: LG Chem.

-33-

Page 34

Technical Descriptions of the Parts

■ PCM(Protection Circuit Module)

Manufacturer: LG Chem.

-34-

Page 35

Technical Descriptions of the Parts

■ Battery

Manufacturer: LG Chem.

-35-

Page 36

Technical Descriptions of the Parts

■ PCM(Protection Circuit Module)

Handling and Cautions

8.1 Disassembly: Never disassemble the battery pack. If the pack is damaged and short

circuit is caused by conductive material inflow, overcurrent will flow and there is a risk

of device damage or heat generation.

8.2 Handling: It may cause the falling out of soldered area or welded area, so be careful

during the handling of the battery pack.

8.3 Short circuit: Be careful of the short circuit of the batter pack. If there is a short circuit

in the batter pack, over-current will flow and there is a risk of device damage or heat

generation. Do not expose it to heat.

8.4 Exposure to moist environment: Do not use the battery pack in a moist state. The

current leakage by the moist of the insulating material inside the pack may cause

degradation of the performance.

8.5 Recharging station: Use only the recharging station specified for this battery pack.

Using other recharging station other the specification may cause heat generation,

flame, or an explosion.

-36-

Page 37

Safety Cautions and Verifications During the Repair

1. Make sure to convert the power to “Off” state when you check, disassemble, or repair

the cleaning robot. (Turn off the power button at the left backside of the main body.)

2. The circuits used in the cleaning robot are sensitive to static electricity, so repair in an

environment without static electricity. (Wear antistatic gloves and sleepers.)

3. During the electricity applied inspection of the circuit, do not have pin or coin contact

with the recharging part.

4. Make sure to use the designated parts for replacement parts during the repair.

5. Use appropriate tools for repair.

6. Make sure to check the damage of the power cable, etc. before the repair. If the sheath

is peeled or if there is a short circuit, make sure to firmly connect it and wrap it with

insulation tape.

7. Check the parts with problems using the diagnosis program before and after the repair.

8. Check if the upper part and lower part of the main body are completely combined. (It

may cause degradation of the suction power or noise generation. Especially, check the

handling of the lead line.)

9. Make sure to carry out the insulation test of the motor. (It is OK if it is 5MΩ or more

between the impeller cover of the motor and the power connector.)

-37-

Page 38

How to Disassemble/Assemble Major Parts

g

■ Battery Disassembly

Make sure to disassemble the battery before the disassembly/assembly work. After

setting power switch to OFF, then unscrew two battery screws by using a (+) driver and

disassemble the battery.

Battery is at the bottom

when the main body is

flipped over

Disassemble the battery

by unscrewing the bolts

usin

a (+) driver

Hold the bottom part and lightly

hit the set to the table to take out

the battery

Take out the separated

battery out of the set

Separate by pressing the battery

connector hook with hand

-38-

Battery is completely

separated from the set

Page 39

How to Disassemble/Assemble Major Parts

■ Cover Assembly

Open cover by pressing the

pressing point

Separate dust bin

from the set

1. Open COVER 2. Take out Dust Bin

After lig htly pressing front

of the set with one hand

Insert (- )driver under

the hook to lift

The front hook of the

set is lifted with a tick

sound

3. Separate DÉCOR COVER 3. Separate DÉCOR COVER

Insert both hands into the

separatedgap

Separate left and right hook to

down direction

3. Separate DÉCOR COVER 3. Separate DÉCOR COVER

-39-

Page 40

Take out DÉCOR

COVER from the set

Remove 8 bolts

3. Separate DÉCOR COVER 3. Separate DÉCOR COVER

Lift BODY COVER

4. Separate BODY COVER

Main board

connector position

Insert hand under BODY

COVER to separate the

connector

4. Separate BODY COVER 5. After separating COVER

ASSEMBLY

-40-

Page 41

Separate 3 connectors

Separate 1 screw to

separate Usb pcb

6. Separate VISION BOARD wire 7. Separate USB PCB

Take out wire from

hook and separate

micro switch

Take out wire from hook

and separate speaker

8. Separate Dust Bin Sensor Switch 9. Separate Speaker

Lightly lift top

coverto take out

Remove 3 screws

WINDOW GLASS

10. Separate WINDOW GLASS 10. Separate WINDOW GLASS

-41-

Page 42

Take out vision board

Take out wire from hook

11. Separate VISION BOARD 12. Separate TOP COVER ASS’Y

Separate 6 screws

13. After TOP COVER ASS’Y is

14. Separate HOLDER

separated

Separte UI PCB

Separate wire

15. Separate UI PCB, wire 16. After INNER COVER is separated

-42-

Page 43

How to Disassemble/Assemble Major Parts

■ Cautions during Top Cover reassembly

Insert all wires

into the hook

Divide to 3 wires

each centered

around boss

During the assembly, wire may be

imprinted, so insert into the hook to divided

to groups of 3

Lift top cover while wire

is not pressed

Insert into wire

guide

If it is not inserted in to the guide, wire

may be pressed by the vision board and

disconnected

Insert into both sides

spring guides with (-)

driver

Arrange the wires not to be stuck in the top

cover and lock spring to top cover

Arrange the length and

shape so that the wire

can move well

Arrange well after top cover assembly so

that the wire can move well

Assembly by pressing the ends of both

springs using (-) driver

-43-

Page 44

How to Disassemble/Assemble Major Parts

■ Window viewing disassembly

Carefully separate

hook using narrow

(- ) driver

1. Separte left hoo

(Be careful not to break)

Carefully separate

hook using narrow

(- ) driver

2. Separate right hook

(Be careful not to break)

Separate hook

using narrow (-)

driver

3. Separate center hook 4. Separate WINDOW VIEWING (1)

(Be careful not to break)

Lock indicated eight

hooks with both

sides

Pull hard upward

5. Separate WINDOW VIEWING (2) 6. Reassemble WINDOW VIEWING

-44-

Page 45

How to Disassemble/Assemble Major Parts

■ Base Assembly

Lift by pressing the

hooks next to the both

side wheels

1. Shape of BASE ASSEMBLY 2. Separate WINDOW LED

Separate connector

to separa te

WINDOW LED

2. Separate WINDOW LED 2. After WINDOW LED is separated

Separate 2 PSD

Separate 4 IR PCB

3. Separate Ultrasonic Sensor 4. Separate IR PCB, PSD sensor

-45-

Page 46

Separate from hook

5. Separate SUCTION module 6. Separate both side WHEEL ASS’Y

Remove 3 screws to

separate main board

7. Separate main board connector 8. Separate main board

Spread the guide with

fingers to separate

micro switch

9. Separate MOP sensor wire 10. Separate CLIFF sensor wire

-46-

Page 47

Separate 3 CLIFF sensors

11. Separate CLIFF sensor 12. Separate OFS sensor

13. Separate recharging connector 14. Separate AIR guide

Lift by inserting dr iver

into the groove in the

caster

Lift by inserting

driver into the caster

15. Separate front caster 16. Separate rear caster

-47-

Page 48

How to Disassemble/Assemble Major Parts

■ Cautions during Base assembly reassembly

Be careful for dust prevention

cap not to be taken off

Assemble according to the

power switch ON/OFF

Assemble power switch according to the

assembly directions and be careful for the

dust prevention cap not to be taken off

during the assembly.

Recharging

connector (+)

line

CLIFF left line

CLILFF right

line

R / L directions are

marked

Connector CONTACT has R / L markings,

so assemble according to the directions

Assemble harness in the connector

CONTACT guide to prevent assembly

defect

First insert the connector, and then

assemble CLIFF to minimize the insufficient

insertion of the connector during the

assembly.

-48-

Page 49

Check CLIFF sensor assembly

direction and wire direction

(blue is right side)

Assemble both side CLIFF to have the

connector to be at the bottom, and the

central CLIFF to be at the left side

Check PSD sensor

assembly direction

Do not have wire passing

over the guide

If wire is over the guide, it may be pressed

by the main board during the assembly, and

it may cause short circuit.

Assemble PCB after wire

connection

First insert the connector, and assemble

both sides PSD for the connector to be at

the top

Be careful for IR wire not to

be inserted

During the assembly of WINDOW LED in

BASE, be careful not to have the rear IR

wire pressed

Assemble after inserting all connectors

before the assembly of front IR and

ultrasonic.

Insert TP sensor all

the way

Cover rubber after

assembly of wire

After pushing in wire into rubber, assemble

TP sensor fully in the guide, and insert

connector,

-49-

Page 50

Insert all the way

Assemble mop sensor wire

on the guide so that it

does not go over to motor

fan side

If it is not properly inserted, the mop sensor

function will not work properly, so check

whether it works after the assembly

The rubber gasket

shall not go out of

the support

If the wire touches the fan, it causes

abnormal noise, so firmly fix to the guide.

Assemble the marked part to face upward,

and assemble rubber gasket inside the

support

-50-

Page 51

How to Disassemble/Assemble Major Parts

■ Separate Wheel

Disassemble by

spreading the hook to

1. Separate harness and spring 2. Separate COVER WHEEL

Disassemble motor by

unscrewing 2 screws

3. Separate WHEEL 4. Disassemble Motor

5. When WHEEL is disassembled

-51-

Page 52

How to Disassemble/Assemble Major Parts

■ Cautions during the reassembly of the Wheel

Do not hold the

magnetize with hand

After inserting motor in the COVER, rotate

left and right to assemble according to the 3

holes of the motor and the COVER

Do not impose unnecessary force on motor

PCB or magnetize during the reassembly.

■ Cautions during the reassembly of the Wheel Wire

Insert wire into the

first guide with Ishaped way

Insert the wire into

first and second

guide with Ushaped way

First, insert 2-line wire into the guide after

assembly the micro switch

Insert IR signal wire into first and second

guide with u-shaped way and wheel cover

guide consecutively

-52-

Page 53

Insert NTC wire into wheel cover guide with

U-shaped way and then arrange the NTC

part.

Fasten the wire and NTC with attaching

EPDM not to be taken off from wheel

assembly

-53-

Page 54

How to Disassemble/Assemble Major Parts

■ Separate Agitator

1. Separate SIDE brush 2. Separate COVER DÉCOR

3. Separate BASE ASS’Y nozzle 4. Separate BASE ASS’Y nozzle

5. Separate agitator brush 6. Separate agitator motor ASS’Y

-54-

Page 55

How to Disassemble/Assemble Major Parts

7. Right side agitator motor ASS’Y 8. Left agitator motor ASS’Y

■ Cautions during the reassembly of Nozzle cover

First assemble the

yellow part of the brush

First insert the yellow part, push the bar all

the way to the right, and then assemble the

left part.

Slide in hook askew

to the hole

First assemble the left hook

Press or hit hard the

hook with palm

Assemble by pressing with finger

Assemble by pressing the upper side hook

with a finger

Assemble the hook by pressing hard the

right side hook with palm

-55-

Page 56

How to Disassemble/Assemble Major Parts

■ Separate TANK ASS’Y DUST

Lift by slightly pushing to

the right side

Open thecover completely and

urn until it is separated

1. Separate handle 2. Separate dust bin cover

Take out dust bin filter

from the hook with hand

3. Separate PLATE COVER 4. Disassemble dust bin filter

5. Dust bin deal drawing

-56-

Page 57

■ Cautions during reassembly of TANK ASS’Y DUST

Assemble by pressing the hook

part from the top

Place the cover on the dust bin, and

assemble by pressing the left part of the

cover with hand

■ Separate power switch ASS’Y

Press the guides on

both sides of the

switch using (-) driver

When you lightly hit the right part of the

cover, it will be inserted.

Take out of BASE with

finger

1. Separate power switch (1) 2. Separate power switch (2)

Power switch and

wires are connected

3. Separate power switch (3)

-57-

Page 58

Do not insert switch wire

into base hook

Off polar wire should not

be exposed to upper of

X

■ SUCTION module disassembly

switch assembly

Off polar wire should be

pushed and arranged

manually at the top of

the baseplane

Make sure polar direction

of switch

O

-58-

Page 59

How to Disassemble/Assemble Major Parts

■ Separate Charger Battery Assembly

During the disassembly of

the recharging station, pull

out the power cord

Being switch -applied, first

of all turn off the switch

1. Disassemble power cord from

2. Disassemble BODY BASE

Disassemble after removing

the screw

condenser

Disassemble after

removing 2 screws

Push up with both thumbs

3. Disassemble COVER BODY 4. Disassemble COVER FRONT

5. Separate connector 6. Separate wire

-59-

Push up lightly the

receptacle with (-)

driver

Page 60

While slowly rotating to one

direction, separate the spring

Separate the connector

7. Separate spring 8. Separate power cord (1)f

Pick out receptacles

Push top of holder,

pull and pick out

8. Separate power cord (2)

(switch-applied)

from switch pushing

8. Separate power cord (3)

(switch-applied)

Take out for wire

working part to be

facing to the right.

8. Separate power cord (4) 9. Separate PLATE GUIDE and PCB

-60-

Page 61

eparate stopper with

hands or equipments

eparate stopper

with hands or

equipment

10. Separate STOPPER(1) 10. Separate STOPER(2)

-61-

Page 62

Cabling Diagram

-62-

Page 63

Types of Defects and the Countermeasures

-63-

Page 64

Types of Defects and the Countermeasures

-64-

Page 65

Types of Defects and the Countermeasures

-65-

Page 66

Types of Defects and the Countermeasures

-66-

Page 67

Types of Defects and the Countermeasures

-67-

Page 68

Types of Defects and the Countermeasures

-68-

Page 69

Types of Defects and the Countermeasures

-69-

Page 70

Types of Defects and the Countermeasures

-70-

Page 71

Types of Defects and the Countermeasures

-71-

Page 72

Types of Defects and the Countermeasures

-72-

Page 73

Types of Defects and the Countermeasures

-73-

Page 74

Types of Defects and the Countermeasures

-74-

Page 75

Types of Defects and the Countermeasures

-75-

Page 76

How to Use R-Manager RK diagnosis program

-76-

Page 77

How to Use R-Manager RK diagnosis program

-77-

Page 78

How to Use R-Manager RK diagnosis program

-78-

Page 79

How to Use R-Manager RK diagnosis program

-79-

Page 80

How to Use R-Manager RK diagnosis program

-80-

Page 81

How to Use R-Manager RK diagnosis program

-81-

Page 82

How to Use R-Manager RK diagnosis program

-82-

Page 83

How to Use R-Manager RK diagnosis program

-83-

Page 84

How to Use R-Manager RK diagnosis program

-84-

Page 85

How to Use R-Manager RK diagnosis program

-85-

Page 86

How to Use R-Manager RK diagnosis program

-86-

Page 87

How to Use Black Box Viewer

-87-

Page 88

How to Use Black Box Viewer

-88-

Page 89

How to Use Black Box Viewer

-89-

Page 90

How to Use Black Box Viewer

-90-

Page 91

How to Use Black Box Viewer

-91-

Page 92

How to Use Black Box Viewer

-92-

Page 93

How to Use Black Box Viewer

-93-

Page 94

How to Use Black Box Viewer

Repeat Repeat

-94-

Page 95

M

W1

#EV#

Deal Drawing of the Structure and List of Parts

■ Base Assembly

ACS1

BBA1

BHS2

GJ185

BBU1

BPM1

BCS1

1

BHS9

BSN2

N2

ACS2

BBA2

BBB1

BHS5

BHS4

BAW1

BAA1

BSN1

BRL1

-95-

Page 96

#EV#

BSG1

SC02

BCD1

AAB1

BRB2

AAB2

BFC1

SC02

BAC1

BCD2

BSC2

BCB1

BSB1

BRB1

BBN1

-96-

Page 97

#EV#

BHS1

BHS1

BSC3

BWW1

BWH1

BMD1

BMD1

BWA1 BWA2

BWW2

BSC3

BWH1

BGT1

BHS3

BMD2

-97-

BGA1

BFF1

Page 98

#EV#

BCS2

BSN2

BPS1

BPS2

BSS1

BHS8

BHS6

BHS7

BWL1

-98-

Page 99

#EV#

Deal Drawing of the Structure and List of Parts

■ Cover Assembly

CCD1

CWA1

CPA2

CHD1

CWV1

CPB1

CGK1

CSP1

CCT1

CSP2

CLA1

CHS3

CCV1

CCC1

CPU1

CCI1

CSA1

CHS2

-99-

Page 100

#EV#

Deal Drawing of the Structure and List of Parts

■ Charger, Battery

ACB1

AAC1

ABB1

AHR1

APC1

APG1

ACF1

APP1

AAS1

CSW1

AAS2

AHS1

CCP1

-100-

ATC1

ASC1

Loading...

Loading...