ENGLISH

ITALIANO

ESPAÑOL

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards by

authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

Ceiling Suspended Air Conditioner

Original instruction (R32)

[Representative]

[Manufacturer] LG Electronics Tianjin Appliances Co.,Ltd.

LG Electronics Inc. EU Representative :

LG Electronics European Shared Service Center B.V.

Krijgsman 1, 1186 DM Amstelveen, The Netherlands

No.09,Jinwei Road,Beichen District,Tianjin,China

FRANÇAIS

DEUTSCH

ΕΛΛΗΝΙΚΆ

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

P/NO.:MFL70520304

REV.00_190904

www.lg.com

Copyright © 2018 - 2019 LG Electronics Inc. All Rights Reserved.

2

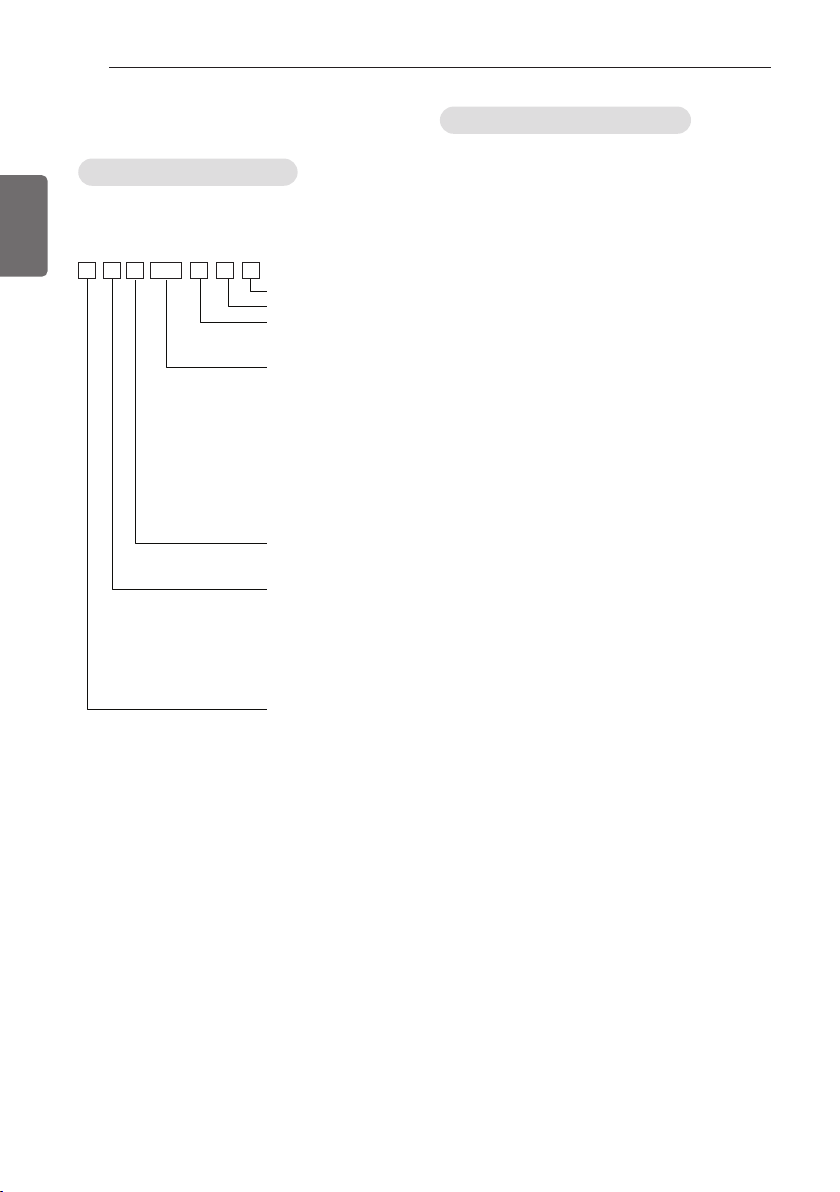

MODEL DESIGNATION

ENGLISH

MODEL DESIGNATION

- Product Name : Air conditioner

- Model Name :

- Additional Information : serial number is

refer to the barcode on the product.

- Max allowable pressure High side :

4.2 MPa / Low side : 2.4 MPa

- Refrigerant : R32

Product information

The A-weighted sound pressure emitted by

this product is below 70 dB.

** The noise level can vary depending on the

site.

The figures quoted are emission level and are

not necessarily safe working levels.

Whilst there is a correlation between the

emission and exposure levels, this cannot be

used reliably to determine whether or not further precautions are required.

Factor that influence the actual level of exposure of the workforce include the characteristics of the work room and the other sources

of noise, i.e. the number of equipment and

other adjacent processes and the length of

time for which an operator exposed to the

noise. Also, the permissible exposure level

can vary from country to country.

This information, however, will enable the

user of the equipment to make a better evaluation of the hazard and risk.

Airborne Noise Emission

SQSM N B 015

Serial number

Chassis name

Indoor Unit / Outdoor Units

N : Indoor Unit

U : Outdoor Unit

Detailed product type only

for M- series models

AQ : Wall mounted Libero-R

SQ : Wall mounted Libero-E

AH* : ARTCOOL

AW* : ART COOL Mirror

AH : Ceiling Cassette

AHL : Ceiling Concealed Duct

(Low Static)

Detailed product type for

U- / C- series models

L : Low Static

H : High COP

C : Econo

R : Refrigerant R32

Nominal Capacity

Ex) 7,000 Btu/h Class → '07',

18,000 Btu/h Class → '18'

Product type

S : Wall mounted /

ARTCOOL mirror

J : Wall mounted

A : ARTCOOL

T : Ceiling Cassette

B, M : Ceiling Concealed Duct

V : Ceiling Suspended & floor

Q : Console

P : Floor Standing

Connectable Outdoor unit type

M : Indoor units only for

Multi systems

U : Indoor units only for

Single A systems

C : Common Indoor Unit for

Multi and Single CAC

TIPS FOR SAVING ENERGY

3

ENGLISH

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Open windows regularly for ventilation as the indoor air quality may deteriorate if the air conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

TIPS FOR SAVING ENERGY

4

IMPORTANT SAFETY INSTRUCTIONS

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid

dangerous situations and ensure peak performance of your

product

WARNING

It can result in serious injury or death when the directions are

ignored

CAUTION

It can result in minor injury or product damage when the

directions are ignored

WARNING

• Installation or repairs made by unqualified persons can result in

hazards to you and others.

• Installation MUST conform with local building codes or, in the

absence of local codes, with the Nation Electrical Code NFPA

70/ANSI C1-1003 or current edition and Canadian Electrical

Code Part1 CSA C.22.1.

• The information contained in the manual is intended for use by

a qualified service technician familiar with safety procedures

and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this

manual can result in equipment malfunction, property damage,

personal injury and/or death.

• Compliance with national gas regulations shall be observed.

!

!

!

Read the precautions in this manual

carefully before operating the unit.

This appliance is filled with flammable refrigerant (R32)

This symbol indicates that the Operation Manual should be read carefully.

This symbol indicates that a service

personnel should be handling this

equipment with reference to the

Installation Manual.

IMPORTANT SAFETY INSTRUCTIONS

5

ENGLISH

Installation

• Always perform grounding. - Otherwise, it may cause electrical

shock.

• Don’t use a power cord, a plug or a loose socket which is

damaged. - Otherwise, it may cause a fire or electrical shock.

• For installation of the product, always contact the service

center or a professional installation agency. - Otherwise, it may

cause a fire, electrical shock, explosion or injury.

• Securely attach the electrical part cover to the indoor unit and

the service panel to the outdoor unit.

- If the electrical part cover of the indoor unit and the service

panel of the outdoor unit are not attached securely, it could

result in a fire or electric shock due to dust, water, etc.

• Always install an air leakage breaker and a dedicated switching

board. - No installation may cause a fire and electrical shock.

• Do not keep or use flammable gases or combustibles near the

air conditioner. - Otherwise, it may cause a fire or the failure of

product.

• Ensure that an installation frame of the outdoor unit is not

damaged due to use for a long time.

- It may cause injury or an accident.

• Do not disassemble or repair the product randomly. - It will

cause a fire or electrical shock.

• Do not install the product at a place that there is concern of

falling down. - Otherwise, it may result in personal injury.

• Use caution when unpacking and installing. - Sharp edges may

cause injury.

• The appliance shall be stored in a room without continuously

operating ignition sources (for example: open flames, an

operating gas appliance or an operating electric heater.)

• Two or more people must lift and transport the product. Avoid

personal injury.

• Do not use means to accelerate the defrosting process or to

clean, other than those recommended by the manufacturer.

• Do not pierce or burn refrigerant cycle part.

• Be aware that refrigerants may not contain an odour.

6

IMPORTANT SAFETY INSTRUCTIONS

ENGLISH

• Keep any required ventilation openings clear of obstruction.

• The appliance shall be stored in a well-ventilated area where

the room size corresponds to the room area as specified for

operation.

• Refrigerant tubing shall be protected or enclosed to avoid

damage.

• Flexible refrigerant connectors (such as connecting lines

between the indoor and outdoor unit) that may be displaced

during normal operations shall be protected against mechanical

damage.

• A brazed, welded, or mechanical connection shall be made

before opening the valves to permit refrigerant to flow

between the refrigerating system parts.

• Mechanical connections shall be accessible for maintenance

purposes.

Operation

• Do not share the outlet with other appliances. - It will cause an

electric shock or a fire due to heat generation.

• Do not use the damaged power cord. - Otherwise, it may

cause a fire or electrical shock.

• Do not modify or extend the power cord randomly.

- Otherwise, it may cause a fire or electrical shock.

• Take care so that the power cord may not be pulled during

operation. - Otherwise, it may cause a fire or electrical shock.

• Unplug the unit if strange sounds, smell, or smoke comes

from it. - Otherwise, it may cause electrical shock or a fire.

• Keep the flames away. - Otherwise, it may cause a fire.

• Take the power plug out if necessary, holding the head of the

plug and do not touch it with wet hands. - Otherwise, it may

cause a fire or electrical shock.

• Do not use the power cord near the heating tools. - Otherwise,

it may cause a fire and electrical shock.

• Do not open the suction inlet of the indoor/outdoor unit during

operation. - Otherwise, it may electrical shock and failure.

IMPORTANT SAFETY INSTRUCTIONS

7

ENGLISH

• Do not allow water to run into electrical parts. - Otherwise, it

may cause the failure of machine or electrical shock.

• Hold the plug by the head when taking it out. - It may cause

electric shock and damage.

• Never touch the metal parts of the unit when removing the

filter. - They are sharp and may cause injury.

• Do not step on the indoor/outdoor unit and do not put anything

on it. - It may cause an injury through dropping of the unit or

falling down.

• Do not place a heavy object on the power cord. - Otherwise, it

may cause a fire or electrical shock.

• When the product is submerged into water, always contact the

service center. - Otherwise, it may cause a fire or electrical

shock.

• Take care so that children may not step on the outdoor unit.

- Otherwise, children may be seriously injured due to falling

down.

• Use a vacuum pump or inert (nitrogen) gas when doing

leakage test or air purge. Do not compress air or oxygen, and

do not use flammable gases. Otherwise, it may cause fire or

explosion. - There is the risk of death, injury, fire or explosion.

• Do not turn on the breaker or power under condition that front

panel, cabinet, top cover, control box cover are removed or

opened. - Otherwise, it may cause fire, electric shock,

explosion or death.

• Turn off all devices that cause fire when the refrigerant leaks.,

ventilate the room (example : opening window or using

ventilation unit), and contact with dealer who you purchased

the unit.

• The installation of pipe-work shall be kept to a minimum.

• When mechanical connectors are reused indoors, sealing parts

shall be renewed.

• When flared joints are reused indoors, the flare part shall be refabricated.

8

IMPORTANT SAFETY INSTRUCTIONS

ENGLISH

CAUTION

Installation

• Install the drain hose to ensure that drain can be securely

done. - Otherwise, it may cause water leakage.

• Install the product so that the noise or hot wind from the

outdoor unit may not cause any damage to the neighbors.

- Otherwise, it may cause dispute with the neighbors.

• Always inspect gas leakage after the installation and repair of

product. - Otherwise, it may cause the failure of product.

• Keep level parallel in installing the product. - Otherwise, it may

cause vibration or water leakage.

• Any person who is involved with working on or breaking into a

refrigerant circuit should hold a current valid certificate from an

industry-accredited assessment authority, which authorises

their competence to handle refrigerants safely in accordance

with an industry recognised assessment specification.

• Wear adequate personal protection equipment (PPE) when

installing, maintaining or servicing the product.

Operation

• Avoid excessive cooling and perform ventilation sometimes.

- Otherwise, it may do harm to your health.

• Use a soft cloth to clean. Do not use wax, thinner, or a strong

detergent. - The appearance of the air conditioner may

deteriorate, change color, or develop surface flaws.

• Do not use an appliance for special purposes such as

preserving animals vegetables, precision machine, or art

articles.

- Otherwise, it may damage your properties.

• Do not place obstacles around the flow inlet or outlet.

- Otherwise, it may cause the failure of appliance or an

accident.

• The appliance shall be stored so as to prevent mechanical

damage from occurring.

!

IMPORTANT SAFETY INSTRUCTIONS

9

ENGLISH

• Servicing shall only be performed as recommended by the

equipment manufacturer. Maintenance and repair requiring the

assistance of other skilled personnel shall be carried out under

the supervision of the person competent in the use of

flammable refrigerants.

• Dismantling the unit, treatment of the refrigerant oil and

eventual parts should be done in accordance with local and

national standards.

• Periodic (more than once/year) cleaning of the dust or salt

particles stuck on the heat exchanger by using water.

• This equipment shall be provided with a supply conductor

complying with the national regulation.

• This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without

supervision.

• This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities

or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the

appliance by a person responsible for their safety. Children

should be supervised to ensure that they do not play with the

appliance.

10

TABLE OF CONTENTS

ENGLISH

2 MODEL DESIGNATION

3 TIPS FOR SAVING ENERGY

4 IMPORTANT SAFETY INSTRUCTIONS

11 PRODUCT PARTS

11 INSTALLATION TOOLS

12 INSTALLATION

12 Select the best Location

14 THE INDOOR UNIT INSTALLATION

15 Open side-cover

16 Mounting the anchor nut and bolt

18 Indoor unit drain piping

18 Drain piping

18 Drain test

19 Heat insulation

19 Flaring Work

22 Wiring Connection

23 TEST RUNNING

25 INSTALLATION INSTRUCTIONS

25 Installer Setting - How to enter installer setting mode

26 Installer Setting - Installer Setting Code Table

27 Installer Setting - Setting Address of Central Control

27 Installer Setting - Checking Address of Central Control

TABLE OF CONTENTS

PRODUCT PARTS

11

ENGLISH

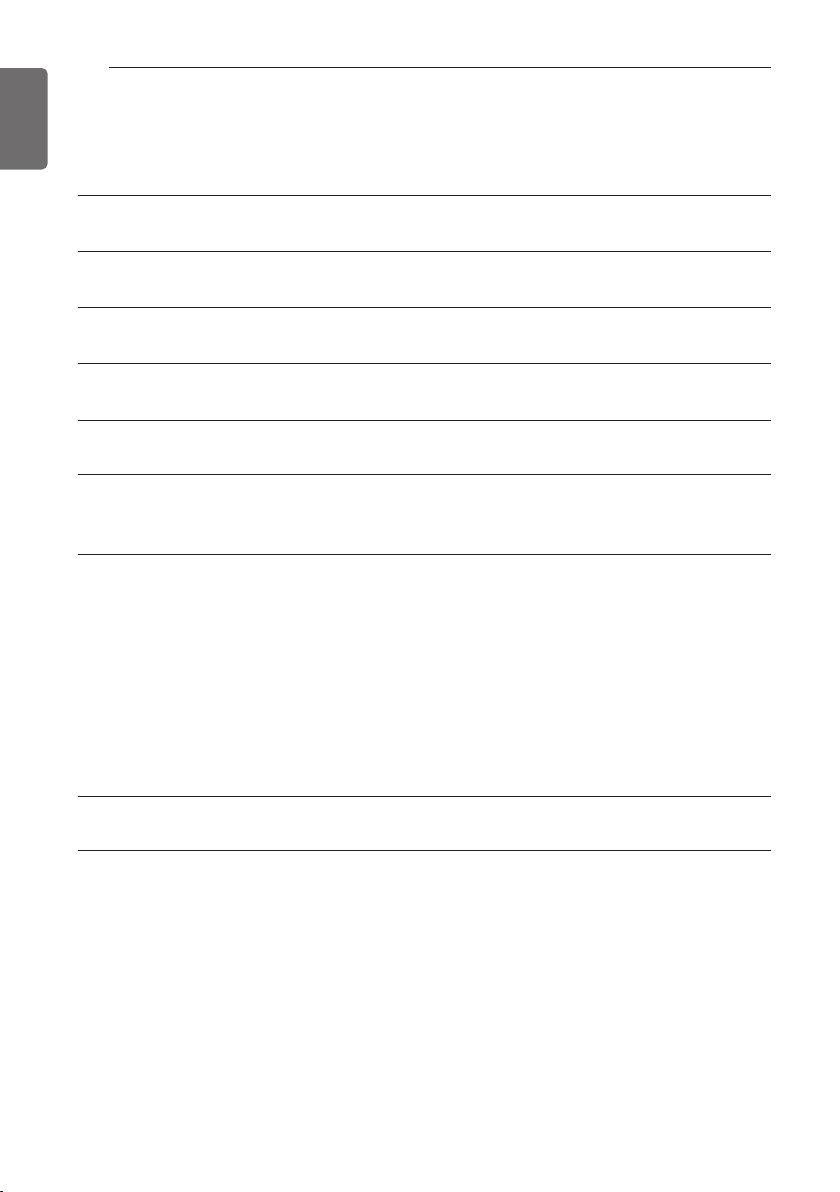

PRODUCT PARTS

INSTALLATION TOOLS

Right side cover

Air filters

(behind inlet grille)

Air inlet vent

(inlet grille)

Louver

Figure FigureName

Screw driver

Air outlet vent

Left side cover

Name

Multi-meter

Electric drill

Measuring tape, Knife

Hole core drill

Spanner

Torque wrench

Hexagonal wrench

Ammeter

Gas-leak detector

Thermometer,

Level

Flaring tool set

12

INSTALLATION

ENGLISH

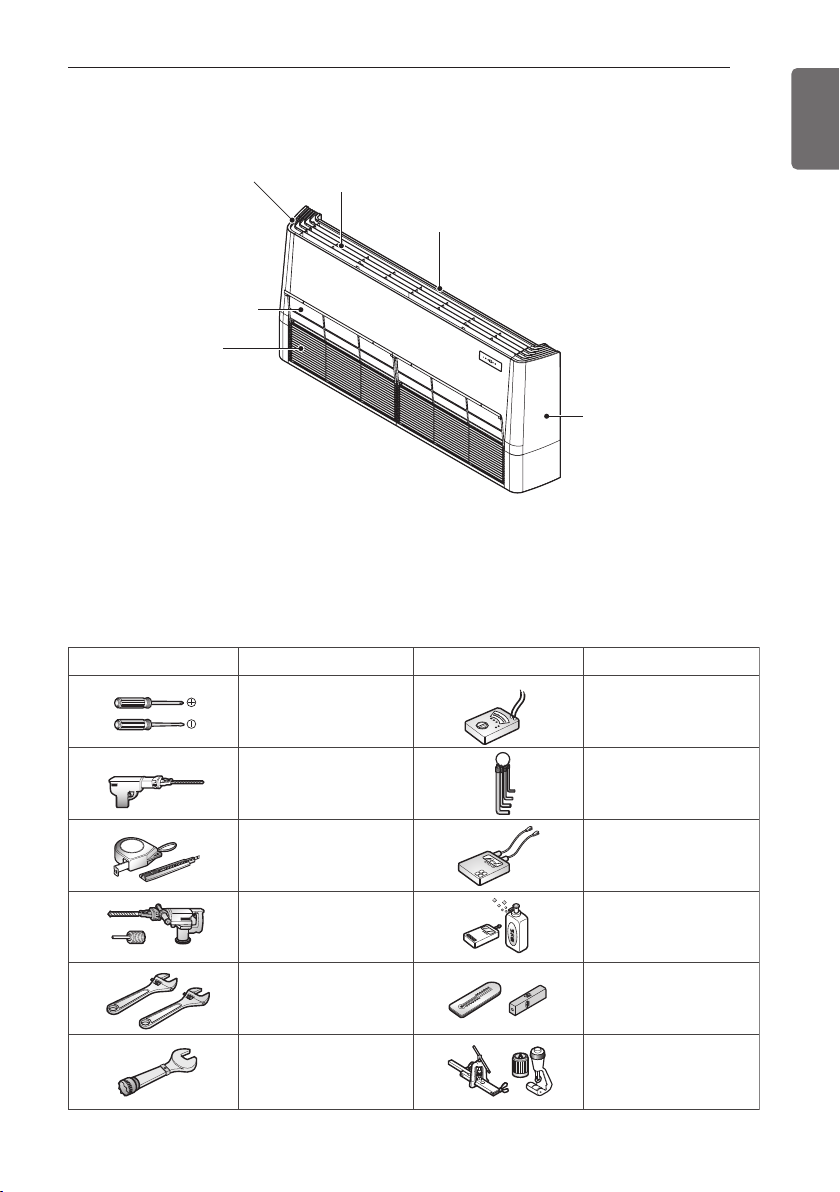

INSTALLATION

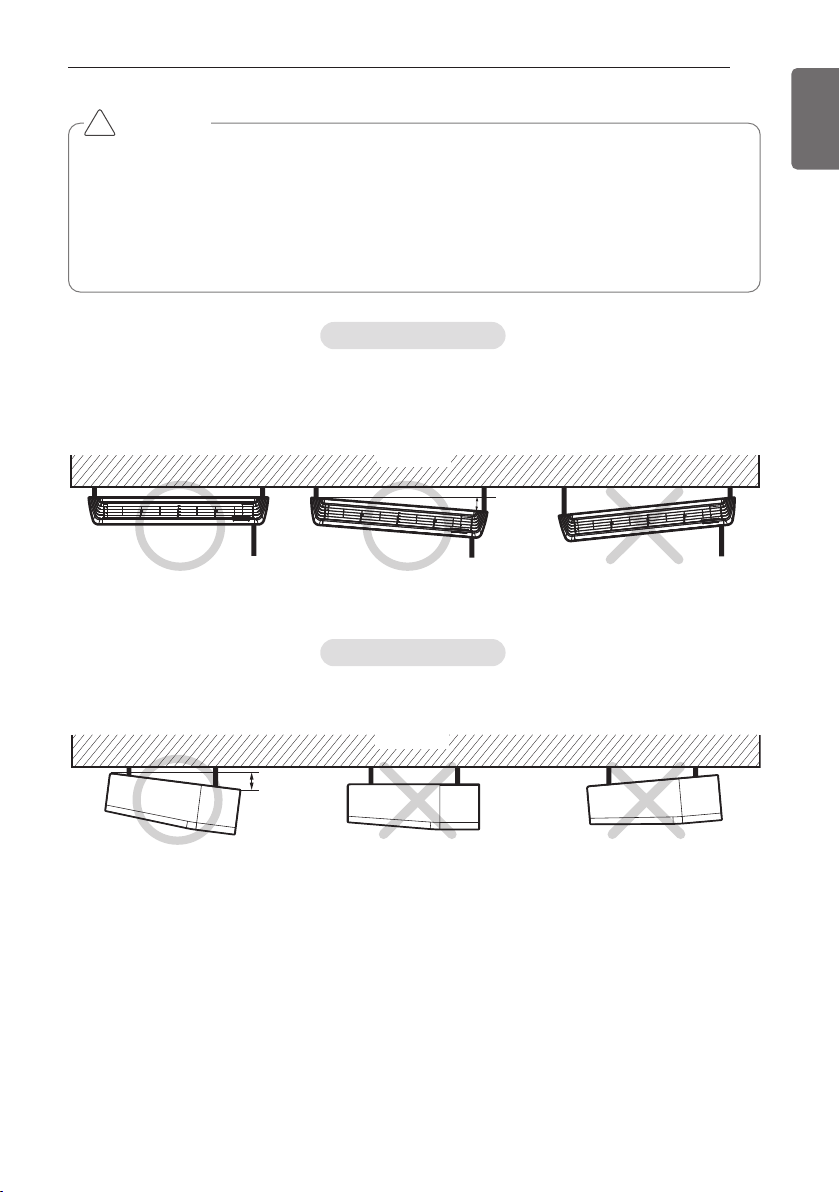

Indoor unit

Ceiling suspended type

- There should not be any heat source or steam near the unit.

- There should not be any obstacles to prevent the air circulation.

- A place where air circulation in the room will be good.

- A place where drainage can be easily obtained.

- A place where noise prevention is taken into consideration.

- Do not install the unit near the door way.

- Ensure the spaces indicated by arrows from the wall, ceiling, or other obstacles.

- The indoor unit must keep the maintenance space.

Unit: mm(inch)

10 (13/32)

or more

300 (11 – 13/16)

or more

2500 (98 – 3/7)

or more

Floor

700(27 – 9/16) or more 700(27 – 9/16) or more

INSTALLATION

13

ENGLISH

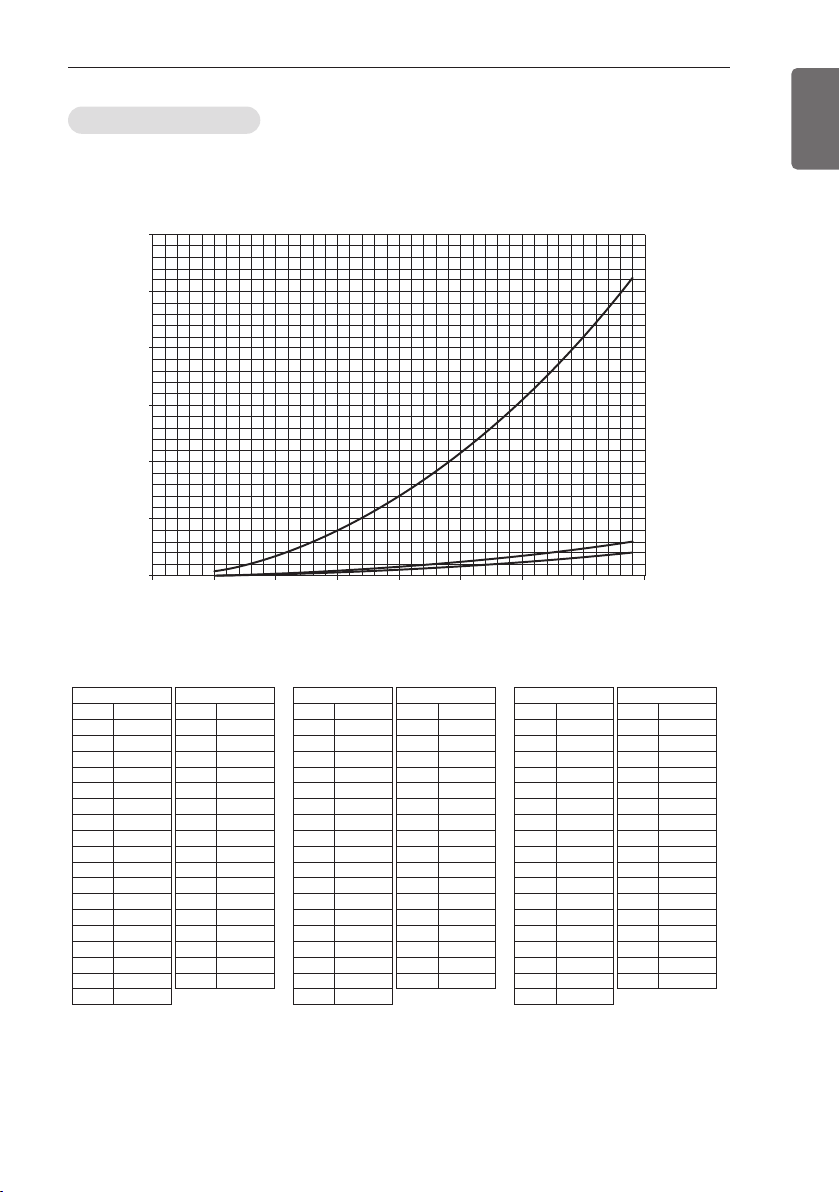

- The appliance shall be installed, operated and stored in a room with a floor area larger than the mini-

mum area.

- Use the graph of table to determine the minimum area.

- m : Total refrigerant amount in the system

- Total refrigerant amount : factory refrigerant charge + additional refrigerant amount

- Amin : minimum area for installation

Minimum floor area

0

100

200

300

400

500

600

Amin (m2)

m (kg)

0 1.224 2 3 4 5 6 7 8

Floor standing

Wall mounted

Ceiling mounted

Floor location

m (kg) Amin (m

2

)

4.6 181.56

4.8 197.70

5 214.51

5.2 232.02

5.4 250.21

5.6 269.09

5.8 288.65

6 308.90

6.2 329.84

6.4 351.46

6.6 373.77

6.8 396.76

7 420.45

7.2 444.81

7.4 469.87

7.6 495.61

7.8 522.04

Wall mounted

m (kg) Amin (m

2

)

4.6 20.17

4.8 21.97

5 23.83

5.2 25.78

5.4 27.80

5.6 29.90

5.8 32.07

6 34.32

6.2 36.65

6.4 39.05

6.6 41.53

6.8 44.08

7 46.72

7.2 49.42

7.4 52.21

7.6 55.07

7.8 58.00

Ceiling Mounted

m (kg) Amin (m

2

)

4.6 13.50

4.8 14.70

5 15.96

5.2 17.26

5.4 18.61

5.6 20.01

5.8 21.47

6 22.98

6.2 24.53

6.4 26.14

6.6 27.80

6.8 29.51

7 31.27

7.2 33.09

7.4 34.95

7.6 36.86

7.8 38.83

Floor location

m (kg) Amin (m

2

)

< 1.224 -

1.224 12.9

1.4 16.82

1.6 21.97

1.8 27.80

2 34.32

2.2 41.53

2.4 49.42

2.6 58.00

2.8 67.27

3 77.22

3.2 87.86

3.4 99.19

3.6 111.20

3.8 123.90

4 137.29

4.2 151.36

4.4 166.12

Wall mounted

m (kg) Amin (m

2

)

< 1.224 -

1.224 1.43

1.4 1.87

1.6 2.44

1.8 3.09

2 3.81

2.2 4.61

2.4 5.49

2.6 6.44

2.8 7.47

3 8.58

3.2 9.76

3.4 11.02

3.6 12.36

3.8 13.77

4 15.25

4.2 16.82

4.4 18.46

Ceiling Mounted

m (kg) Amin (m

2

)

< 1.224 -

1.224 0.956

1.4 1.25

1.6 1.63

1.8 2.07

2 2.55

2.2 3.09

2.4 3.68

2.6 4.31

2.8 5.00

3 5.74

3.2 6.54

3.4 7.38

3.6 8.27

3.8 9.22

4 10.21

4.2 11.26

4.4 12.36

14

THE INDOOR UNIT INSTALLATION

ENGLISH

THE INDOOR UNIT INSTALLATION

• Install the unit horizontally using a level

gauge.

• During the installation, care should be

taken not to damage electric wires.

• Select and mark the position for fixing

bolts and piping hole.

• Decide the position for fixing bolts

slightly tilted to the drain direction after

considering the direction of drain hose.

• Drill the hole for anchor bolt on the ceiling.

CAUTION

!

NOTE

!

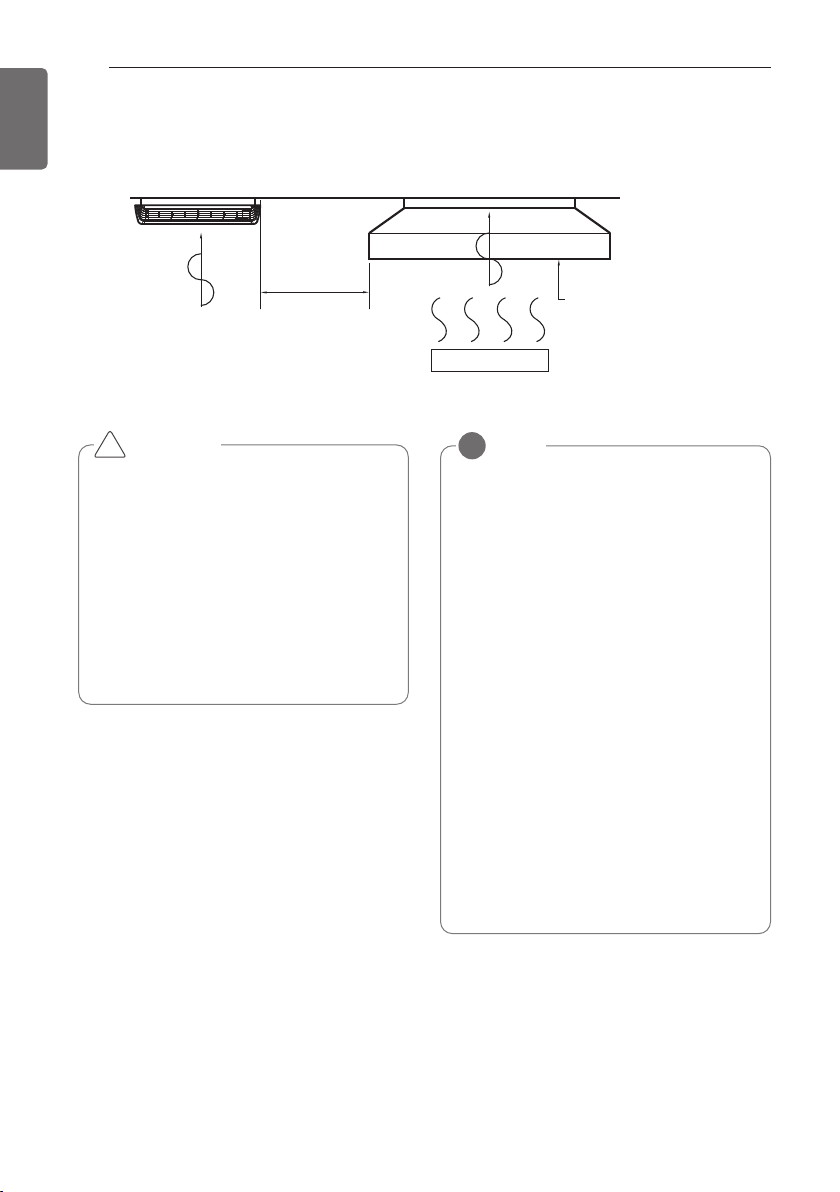

• Avoid the following installation location.

1. Such places as restaurants and kitchen

where considerable amount of oil

steam and flour is generated.

These may cause heat exchange efficiency reduction, or water drops, drain

pump mal-function.

In these cases, take the following

actions;

• Make sure that ventilation fan is enough

to cover all noxious gases from this

place.

• Ensure enough distance from the cook-

ing room to install the air conditioner in

such a place where it may not suck oily

steam.

2. Avoid installng air conditioner in such

places where cooking oil or iron powder is generated.

3. Avoid places where inflammable gas is

generated.

4. Avoid place where noxious gas is generated.

5. Avoid places near high frequency generators.

Air conditioner

Take enough

distance

Cooking table

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

THE INDOOR UNIT INSTALLATION

15

ENGLISH

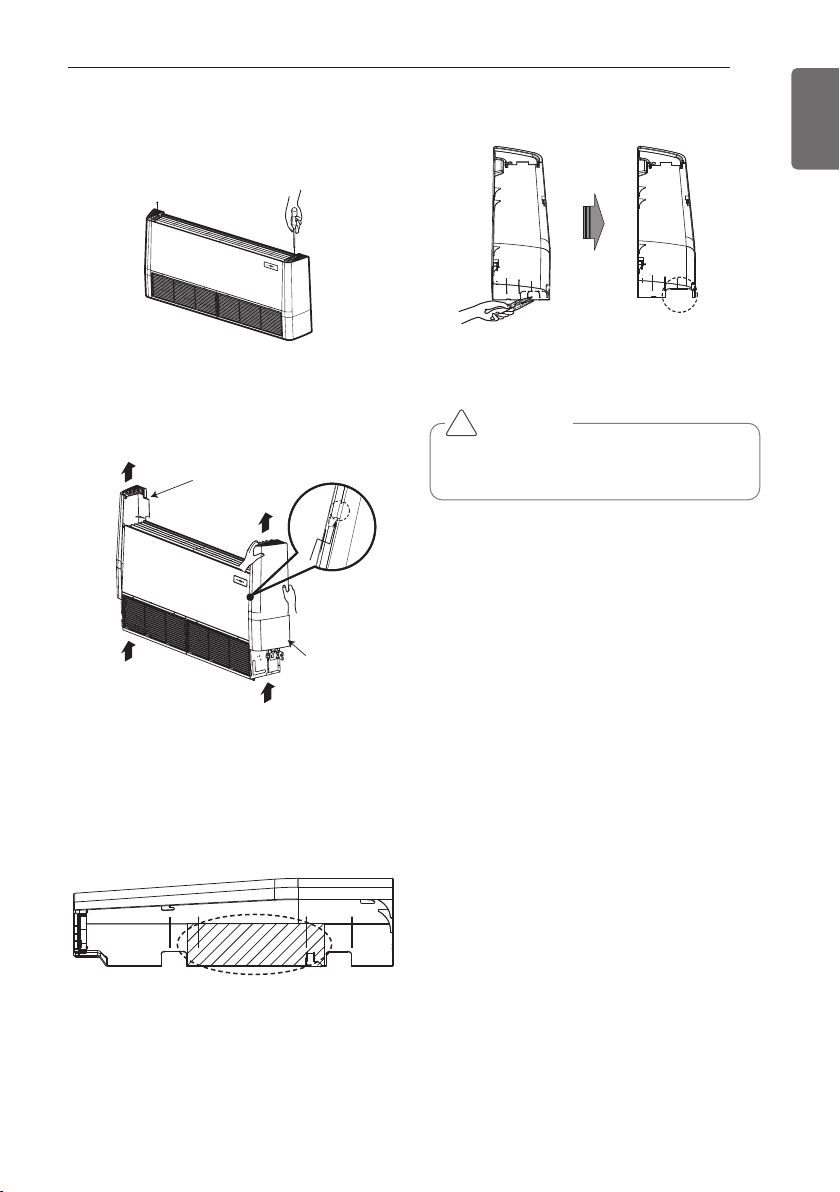

Open side-cover

Step 1

Backside

Right side cover

Backside

Left side

cover

Step 2

- Remove two screws from side-cover.

Step 3

Step 4

- Remove paper bracket from side-cover.

- Unlock side-cover from side-panel slightly

(Tap the side-cover with your palm on the

backside)

- Knock out the pipe hole from the left sidecover with nipper/plier.

Hold the side-cover with other hand while

tapping to prevent it to fall down.

CAUTION

!

16

THE INDOOR UNIT INSTALLATION

ENGLISH

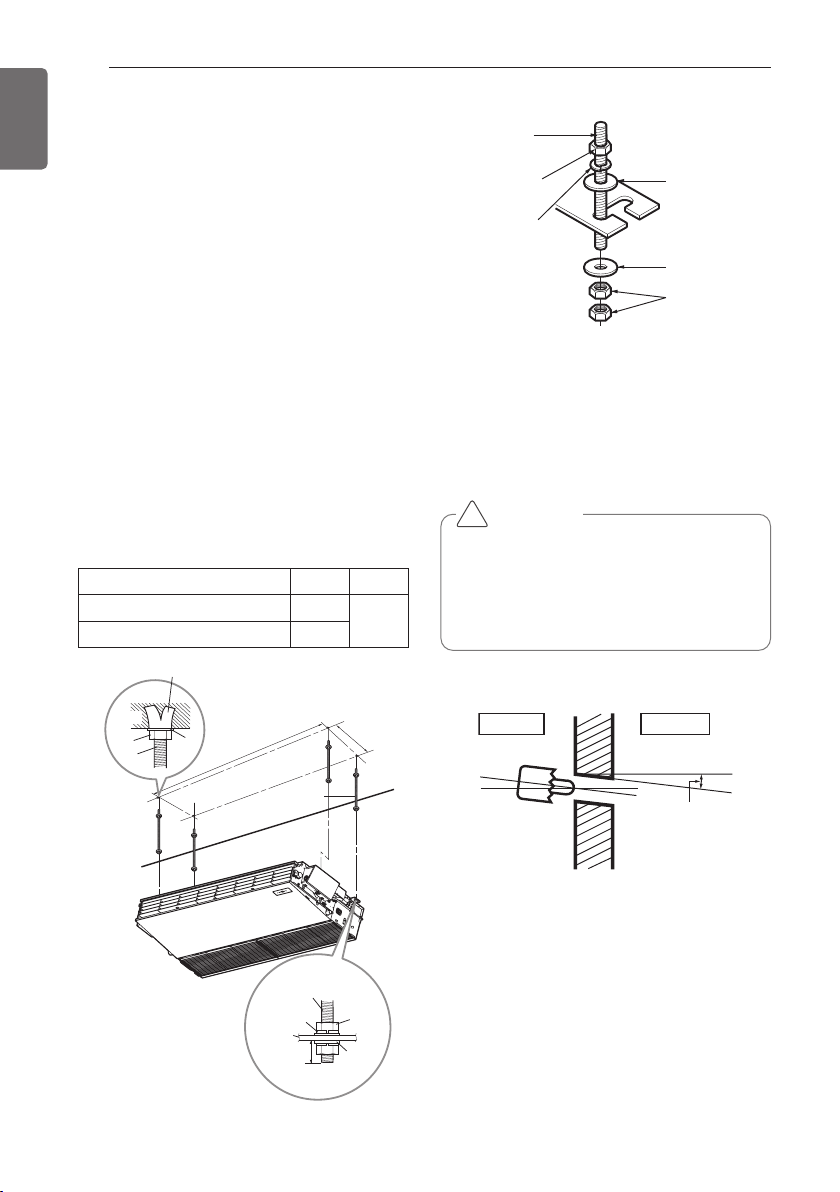

Mounting the anchor nut and

bolt

- Prepare 4 suspension bolts. (Each bolts

length should be same.)

- Measure and mark the position for the Suspension bolts and the piping hole.

- Drill the hole for anchor nut on the ceiling.

- Insert the nuts and washer onto the suspension bolts for locking the suspension bolts on

the ceiling.

- Mount the suspension bolts to the anchornuts firmly.

- Secure the hangers onto the Suspension

bolts (adjust level roughly.) using nuts, washers and spring washers.

- Adjust a level with a level gauge on the

direction of left-right, back-forth by adjusting

suspension bolts.

- Adjust a level on the direction of top-bottom

by adjusting supension bolts. Then the unit

will be declined to the bottomside so as to

drain well.

- The following parts is option.

Hanging Bolt - W 3/8 or M10

Nut - W 3/8 or M10

Spring Washer - M10

Plate Washer - M10

(Unit : mm)

Washer

Suspension

bolts

Model (kBtu/h) A B

18k/24k 1018

355

36k/42k/48k/60k 1418

Tighten the nut and bolt to prevent unit

from falling

• Drill the piping hole on the wall slightly

tilted to the outdoor side by using a

Ø 70 hole-core drill.

CAUTION

!

Anchor nut

Ceiling

Nut

Suspension

Suspension

bolts

bolts

Washer

Washer

A

Suspension bolt

B

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Spring washer

(M10)

Flat washer

for M10

(accessory)

Flat washer

for M10

(accessory)

Nut

(W3/8 or M10)

Wall

Indoor

Outdoor

Slope gradient for

drain Should be

1/50 ~ 1/100

Suspension

Spring

washer

Hangen

Max.

12mm

bolts

Nut

Washer

THE INDOOR UNIT INSTALLATION

17

ENGLISH

Installation information for declination

- Install declination of the indoor unit is very important for the drain of the convertible type air

conditioner.

- Minimum thickness of the insulation for the connecting pipe shall be 10 mm.

- If the Installation Plates are fixed to horizontal line, the indoor unit after installing will be

declined to the bottomside.

CAUTION

!

Front of view

- The unit must be horizontal or inclined at angle.

- The inclination should be less than or equal to 1° or in between 10 to 20 mm inclined in drain

direction as shown in fig.

Ceiling

10~20 mm

Side of view

- The unit must be inclined to the bottomside of the unit when finished installation.

Ceiling

5~10 mm

18

THE INDOOR UNIT INSTALLATION

ENGLISH

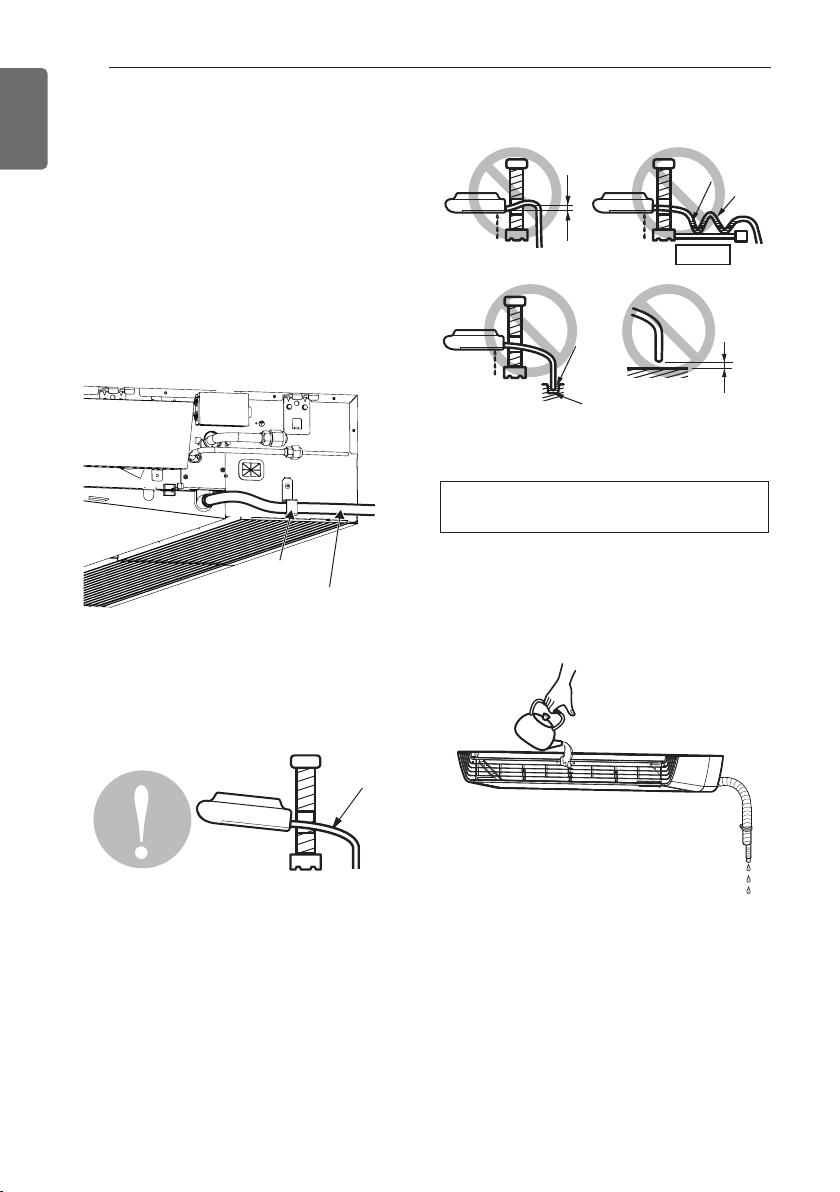

Indoor unit drain piping

- Drain piping must have down-slope (1/50 to

1/100): be sure not to provide up-and-down

slope to prevent reversal flow.

- During drain piping connection, be careful

not to exert extra force on the drain port on

the indoor unit.

- Remove the rubber stopple before connecting drain hose.

- Hook on the bracket after connecting the

drain hose as below.

Drain piping

- The drain hose should point downward for

easy drain flow.

- Do not make drain piping like the following.

- Be sure to execute heat insulation on the

drain piping.

Drain test

Use the following procedure to test the drain

pump operation:

- Set the air direction louvers up-and-down to

the position(horizontally) by hand.

- Pour a glass of water on the evaporator

using a kettle.

- Ensure the water flows through the drain

hose of the indoor unit without any leakage

and goes out the drain exit.

Drain hose

Bracket

Heat insulation material: Polyethylene foam

with thickness more than 8 mm.

Do not raise

Water

leakage

Tip of drain

hose dipped

in water

Water

leakage

Water

leakage

Ditch

Accumulated

drain water

Air

Waving

Less than

50 mm gap

Downward

slope

THE INDOOR UNIT INSTALLATION

19

ENGLISH

Heat insulation

Use the heat insulation material for the refrigerant piping which has an excellent heat-resistance (over 120 °C).

Precautions in high humidity circumstance:

This air conditioner has been tested according

to the "KS Standard Conditions with Mist" and

confirmed that there is not any default.

However, if it is operated for a long time in

high humid atmosphere (dew point temperature: more than 23 °C), water drops are liable

to fall. In this case, add heat insulation material according to the following procedure:

- Heat insulation material to be prepared...

Adiabatic glass wool with thickness 10 to 20

mm.

- Stick glass wool on all air conditioners that

are located in ceiling atmosphere.

Connecting cables to the indoor unit

- Remove the control box cover for electrical

connection between the indoor and out door

unit

- Use the cord clamper to fix the cord.

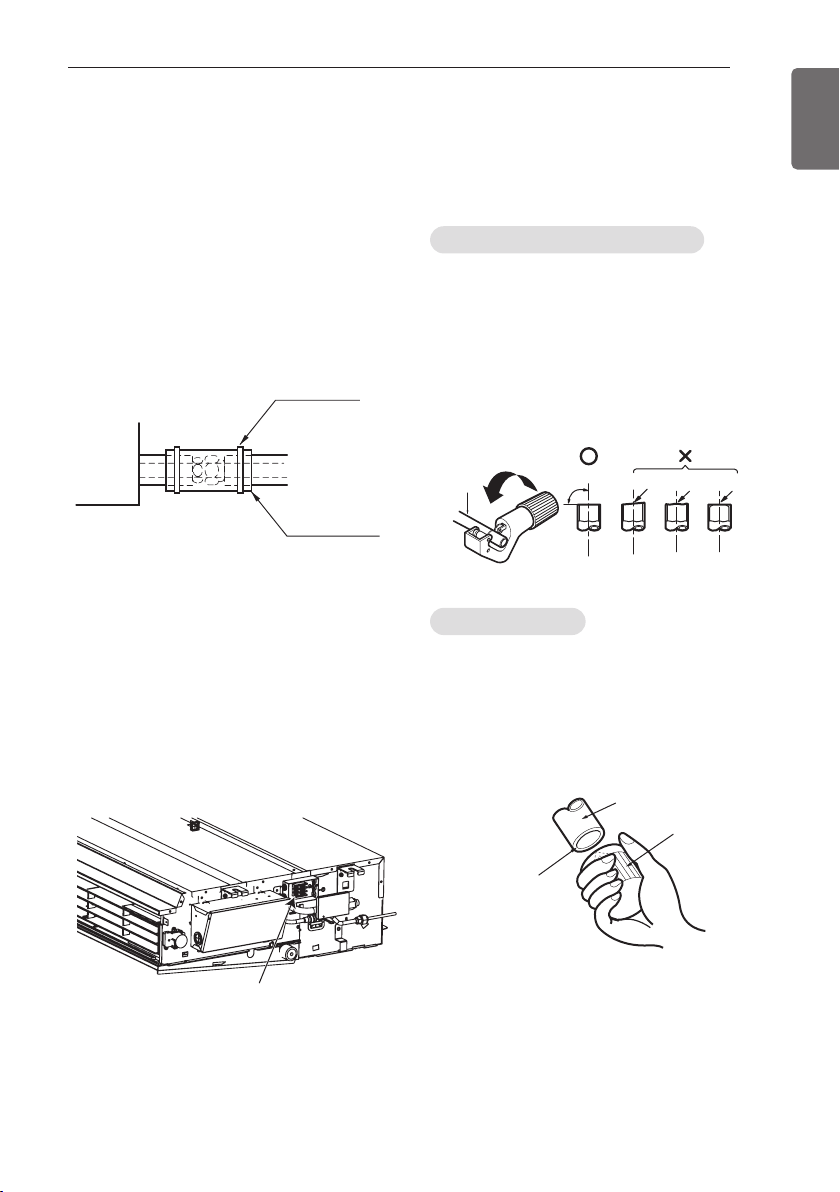

Flaring Work

Main cause for gas leakage is due to defect of

flaring work. Carry out correct flaring work in

the following procedure.

1 Use the piping kit accessory or the pipes

purchased locally.

2 Measure the distance between the indoor

and the outdoor unit.

3 Cut the pipes a little longer than measured

distance.

4 Cut the cable 1.5m longer than the pipe

length.

1. Completely remove all burrs from the cut

cross section of pipe/tube.

2. While removing burrs put the end of the

copper tube/pipe in a downward direction

while removing burrs location is also

changed in order to avoid dropping burrs

into the tubing.

Cut the pipes and the cable

Burrs removal

Pipe

Reamer

Point down

Control box cover

Fastening band

Refrigerant piping

Indoor unit

Thermal insulator

Copper

pipe

90°

Slanted Uneven Rough

20

THE INDOOR UNIT INSTALLATION

ENGLISH

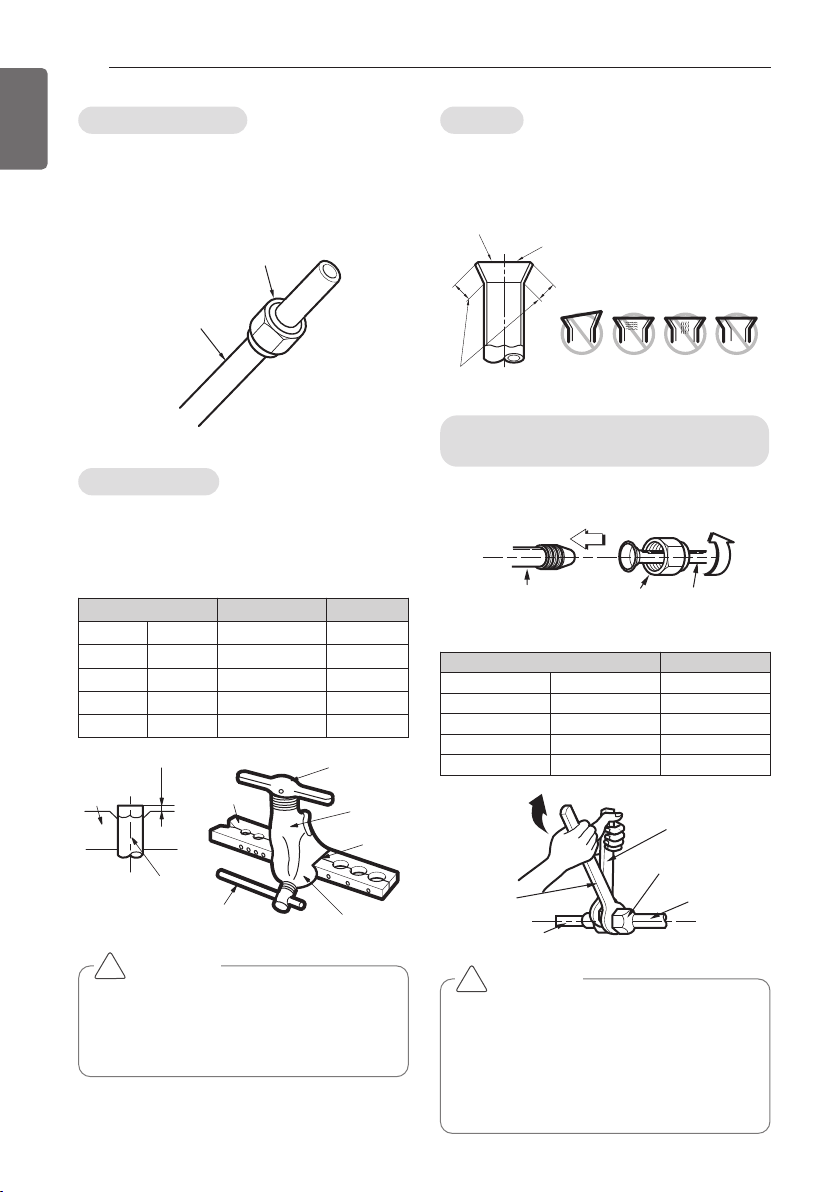

- Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after finishing

flare work)

1 Firmly hold copper pipe in a bar with the

dimension shown in below table table

below.

2 Carry out flaring work with the flaring tool.

1

Compare the flared work with the figure by.

2 If a flared section is defective, cut it off

and do flaring work again.

1 Align the center of the pipes and sufficient-

ly tighten the flare nut by hand

2 Tighten the flare nut with a wrench

Putting nut on

Flaring work

Outside diameter Temper grade A

mm inch Annealed(o) mm

Ø6.35 1/4 Annealed(o) 1.1~1.3

Ø9.52 3/8 Annealed(o) 1.5~1.7

Ø12.7 1/2 Annealed(o) 1.6~1.8

Ø15.88 5/8 Annealed(o) 1.6~1.8

Check

Connecting the installation pipe

and drain hose to the indoor unit.

Outside diameter Torque

mm inch kgf.m

Ø6.35 1/4 1.8~2.5

Ø9.52 3/8 3.4~4.2

Ø12.7 1/2 5.5~6.5

Ø15.88 5/8 6.3~8.2

CAUTION

• The installation of pipe-work shall be

kept to a minimum

• Flared joint shall be restricted to use

with annealed pipe only, and to pipe

sizes not exceeding a diameter of 20

mm outside diameter.

!

CAUTION

Copper in contact with refrigerants shall

be oxygen-free or de-oxidized, for example Cu-DHP as specified in EN 12735-1

and EN 12735-2

!

Flare nut

Copper tube

Bar

"A"

Copper pipe

Bar

Clamp handle

Handle

Yoke

Cone

Red arrow mark

Smooth all round

Even length

all round

Inside is shiny without scratches

= Improper flaring =

Surface

damaged

Cracked Uneven

Inclined

thickness

Indoor unit tubing Flare nut Pipes

Open-end wrench

(fixed)

Flare nut

Wrench

Indoor unit tubing

Connection

pipe

THE INDOOR UNIT INSTALLATION

21

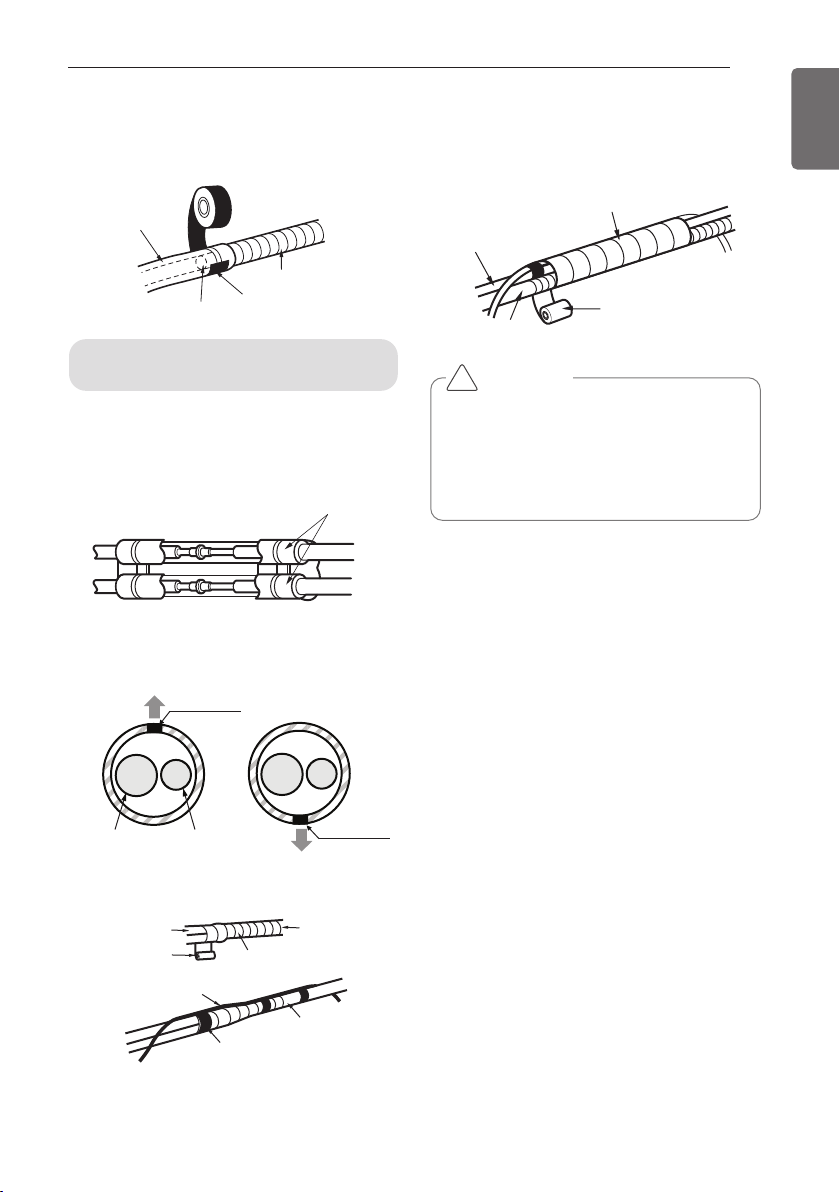

ENGLISH

3 When needed to extend the drain hose of

indoor unit, assembly the drain pipe as

shown on the drawing

1 Overlap the connection pipe insulation

material and the indoor unit pipe insulation

material. Bind them together with vinyl

tape so that there may be no gap.

2 Set the tubing cutting line upward.

Wrap the area which accommodates the

rear piping housing section with vinyl tape.

3 Bundle the piping and drain hose together

by wrapping them with vinyl tape sufficient

enough to cover where they fit into the

rear piping housing section.

Wrap the insulation material

around the connecting portion.

Gas Pipe

Liquid Pipe

Cutting Line

Cutting Line

Good Case Bad Case

* Tubing cutting line have to be upward.

Vinyl tape(narrow)

Connection pipe

Connecting cable

Vinyl tape (wide)

Wrap with vinyl tape

Indoor unit pipe

Pipe

CAUTION

• When mechanical connectors are

reused indoors, sealing parts shall be

renewed.

• When flared joints are reused indoors,

the flare part shall be re-fabricated.

!

Drain pipe

Indoor unit drain hose

Vinyl tape(narrow)

Adhesive

Insulation material

Wrap with vinyl tape

Pipe

Drain hose

Vinyl tape(wide)

22

ENGLISH

THE INDOOR UNIT INSTALLATION

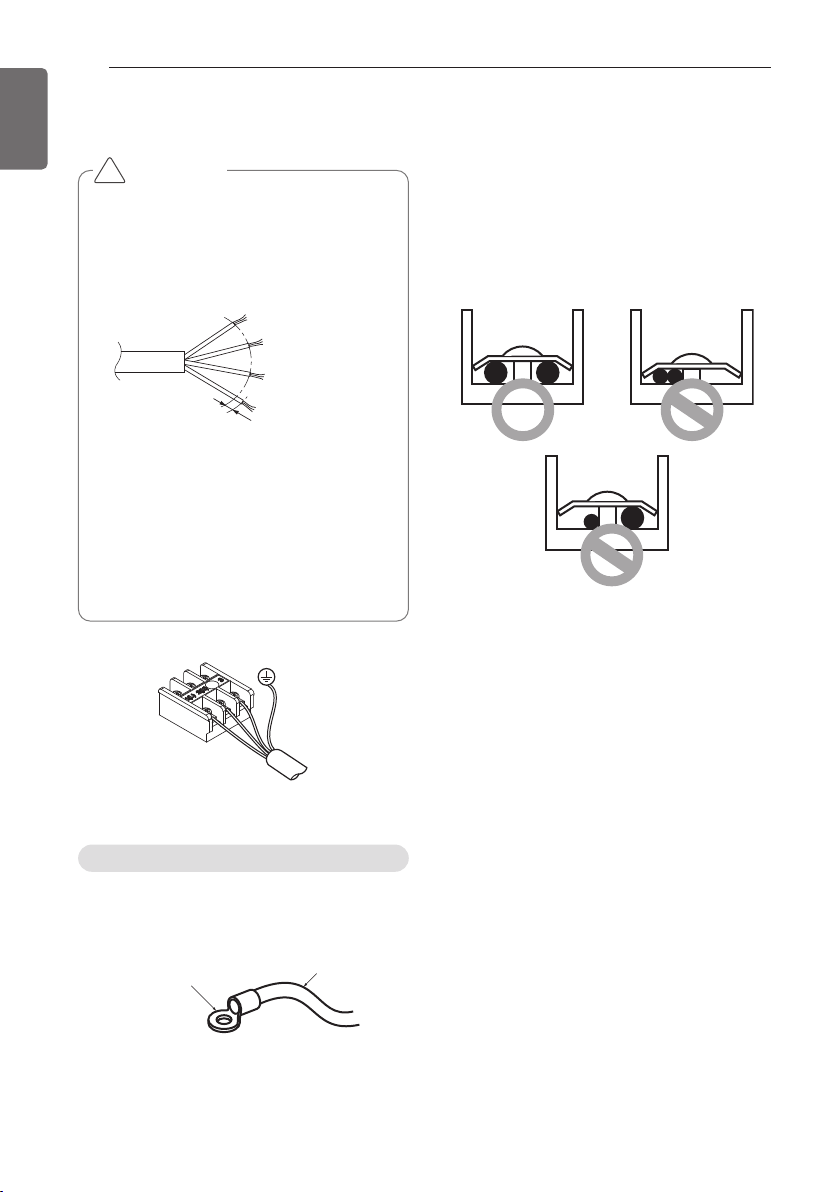

- For wiring, use the designated power wire and

connect firmly, then secure to prevent outside

pressure being exerted on the terminal block.

- Use an appropriate screwdriver for tightening

the terinal screws. A screwdriver with a small

head will strip the head and make proper

tighterning impossible.

- Over-tightening the terminal screws may break

them.

When none are available, follow the instructions below.

- Do not connect wiring of different thicknesses to the power terminal block. (Slack in the

power wiring may cause abnormal heat.)

- When connecting wiring which is the same

thickness, do as shown in the figure below.

Use round pressure terminals for connections

to the power terminal block.

Round pressure terminal

Power wire

CAUTION

The connecting cable connected to the

indoor and outdoor unit should be complied with the following specifications

(Rubber insulation, type H05RN-F

approved by HAR or SAA).

If the supply cord is damaged, it must be

replaced by a special cord or assembly

available from the manufacturer of its

service agent. When the connection line

between the indoor unit and outdooor

unit and outdoor unit is over 40 m, connect the telecommunication line and

power line separately.

!

20 mm

GN/YL

NORMAL

CROSS-SECTIONAL

AREA 0.75 mm

2

Precautions when laying power wiring

Wiring Connection

23

ENGLISH

TEST RUNNING

PRECAUTIONS IN TEST RUNNING

- The initial power supply must provide at least

90% of the rated voltage.

Otherwise, the air conditioner should not be

operated.

Check the following items when

installation is complete

After completing work, be sure to measure and

record trial run properties, and store measured

data, etc.

Measuring items are room temperature, outside

temperature, suction temperature, blow out

temperature, wind velocity, wind volume, voltage, current, presence of abnormal vibration and

noise, operating pressure, piping temperature,

compressive pressure.

As to the structure and appearance, check following items.

- Is the circulation of air adequate?

- Is the draining smooth?

- Is the heat insulation complete

(refrigerant and drain piping)?

- Is there any leakage of refrigerant?

- Is the remote controller switch operated?

- Is there any faulty wiring?

- Are not terminal screws loosened?

M4......118 N.cm{12 kgf.cm}

M5......196 N.cm{20 kgf.cm}

M6......245 N.cm{25 kgf.cm}

M8......588 N.cm{60 kgf.cm}

Connection of power supply

Connect the power supply cord to the independent power supply.

- Circuit breaker is required.

Operate the unit for fifteen minutes or more.

Evaluation of the performance

Measure the temperature of the intake and discharge air.

Ensure the difference between the intake temperature and the discharge one is more than 8°C

(Cooling) or reversely (Heating).

- To cancel the test run, press any button.

TEST RUNNING

CAUTION

• For test run, carry out the cooling operation firstly even during heating season.

If heating operation is carried out firstly,

it leads to the trouble of compressor.

Then attention must be paid.

• Carry out the test run more than 5 minutes without fail.

!

Thermometer

24

ENGLISH

TEST RUNNING

CAUTION

After the confirmation of the above conditions, prepare the wiring as follows:

• Never fail to have an individual power

specialized for the air conditioner. As for

the method of wiring, be guided by the

circuit diagram pasted on the inside of

control box cover.

• Provide a circuit breaker switch

between power source and the unit.

• The screw which fasten the wiring in

the casing of electrical fittings are liable

to come loose from vibrations to which

the unit is subjected during the course

of transportation. Check them and make

sure that they are all tightly fastened. (If

they are loose, it could give rise to

burnout of the wires.)

• Specification of power source.

• Confirm that electrical capacity is sufficient.

• Be sure that the starting voltage is maintained at more than 90 percent of the

rated voltage marked on the name plate.

• Confirm that the cable thickness is as

specified in the power sources specification. (Particularly note the relation

between cable length and thickness.)

• Never fail to equip a leakage breaker

where it is wet or moist.

• The following troubles would be caused

by voltage drop-down.

- Vibration of a magnetic switch, damage

on the contact point there of, fuse

breaking, disturbance to the normal

function of a overload protection

device.

- Proper starting power is not given to

the compressor.

• Use only 1 remote-controller contained

in indoor unit, when you combine to use

both cassette type indoor unit and different Indoor units combinations as

shown below.

!

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual

(air filter cleaning, temperature control, etc.).

25

ENGLISH

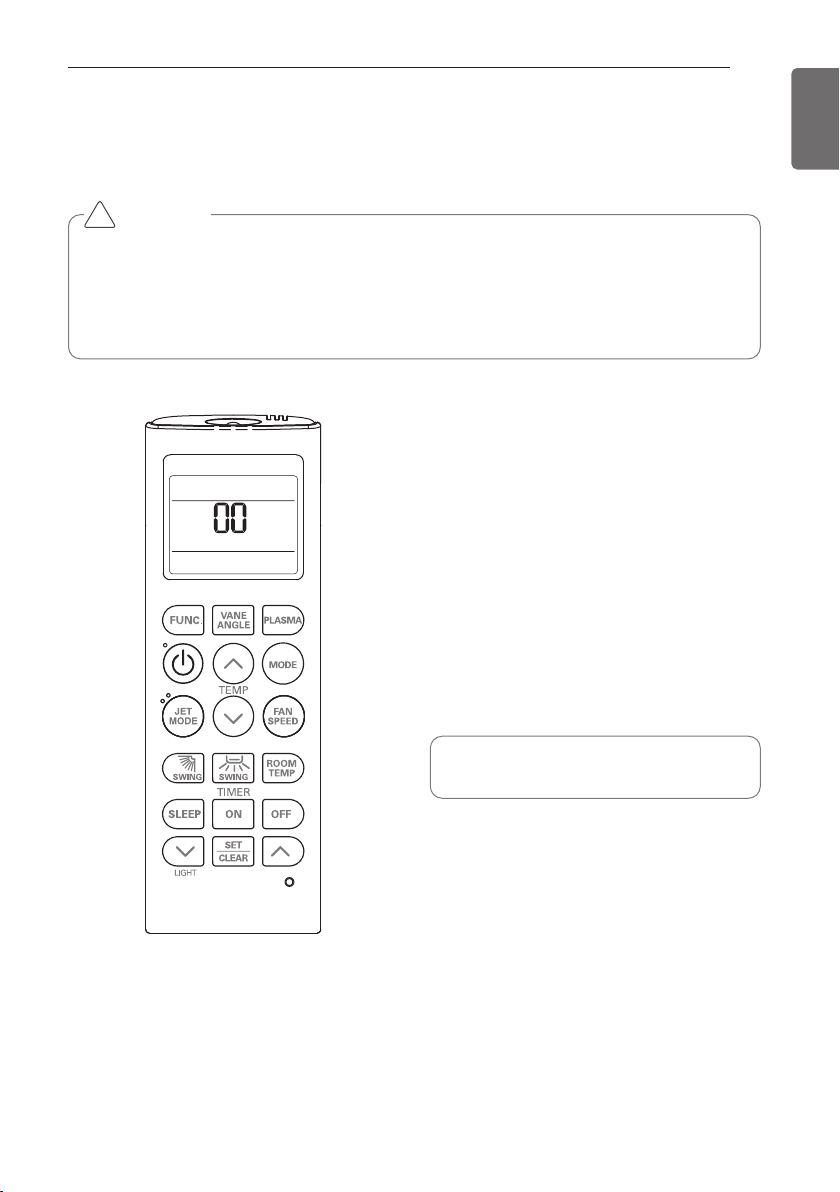

INSTALLATION INSTRUCTIONS

CAUTION

Installer setting mode is to set the detail function of the remote controller.

If the installer setting mode is not set correctly, it can cause problems to the product, user

injury or property damage. This must be set by an certificated installer, and any installation or

change that is carried out by a non-certificated person should be responsible for the results.

In this case, free service cannot be provided.

!

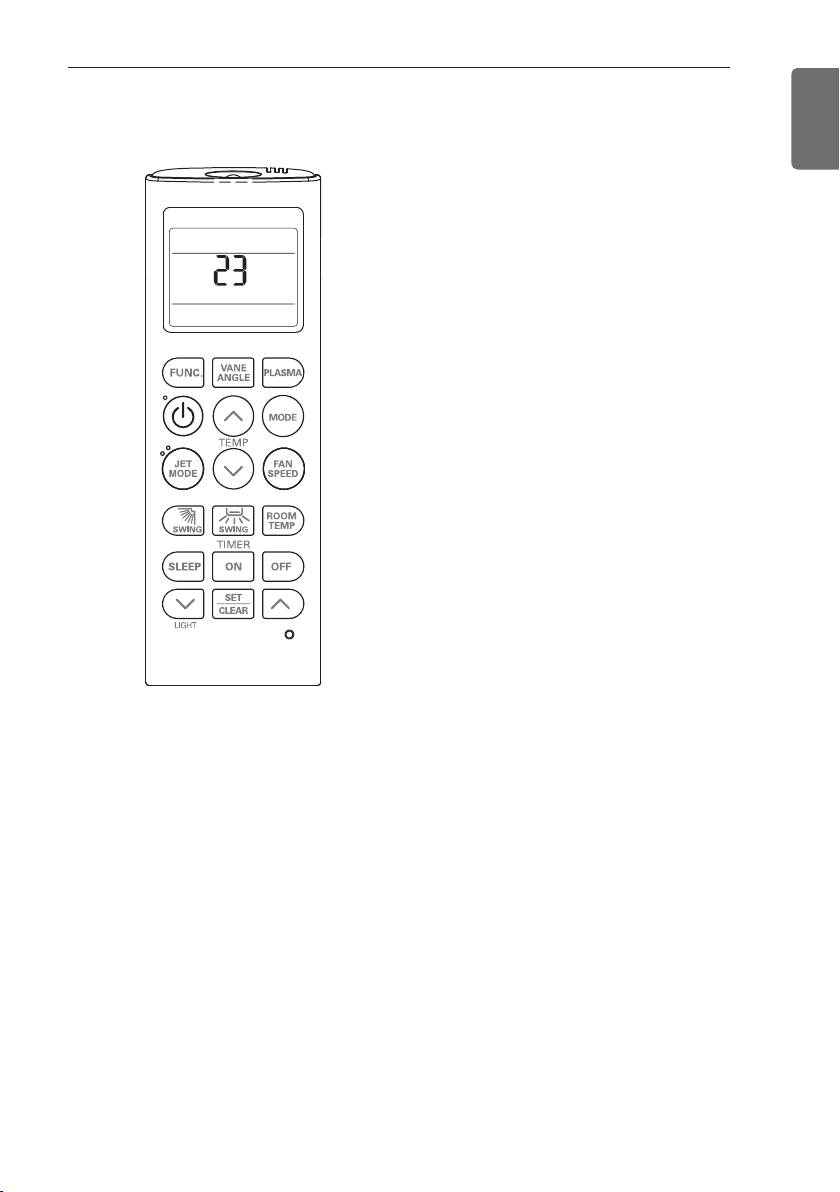

Refer to the Installer Setting Code Table

on the next page.

1. With the JET MODE button pressed, press

the RESET button.

2. By using the TEMPERATURE SETTING button, set function code and setting value.

(Please refer the Installer Setting Code Table.)

3. Press the ON/OFF button toward the indoor

unit 1 time.

4. Reset the remote controller to use the general

operation mode.

INSTALLATION INSTRUCTIONS

Installer Setting - How to enter installer setting mode

TIME (3 s)

°C/°F (5 s)

26

ENGLISH

INSTALLATION INSTRUCTIONS

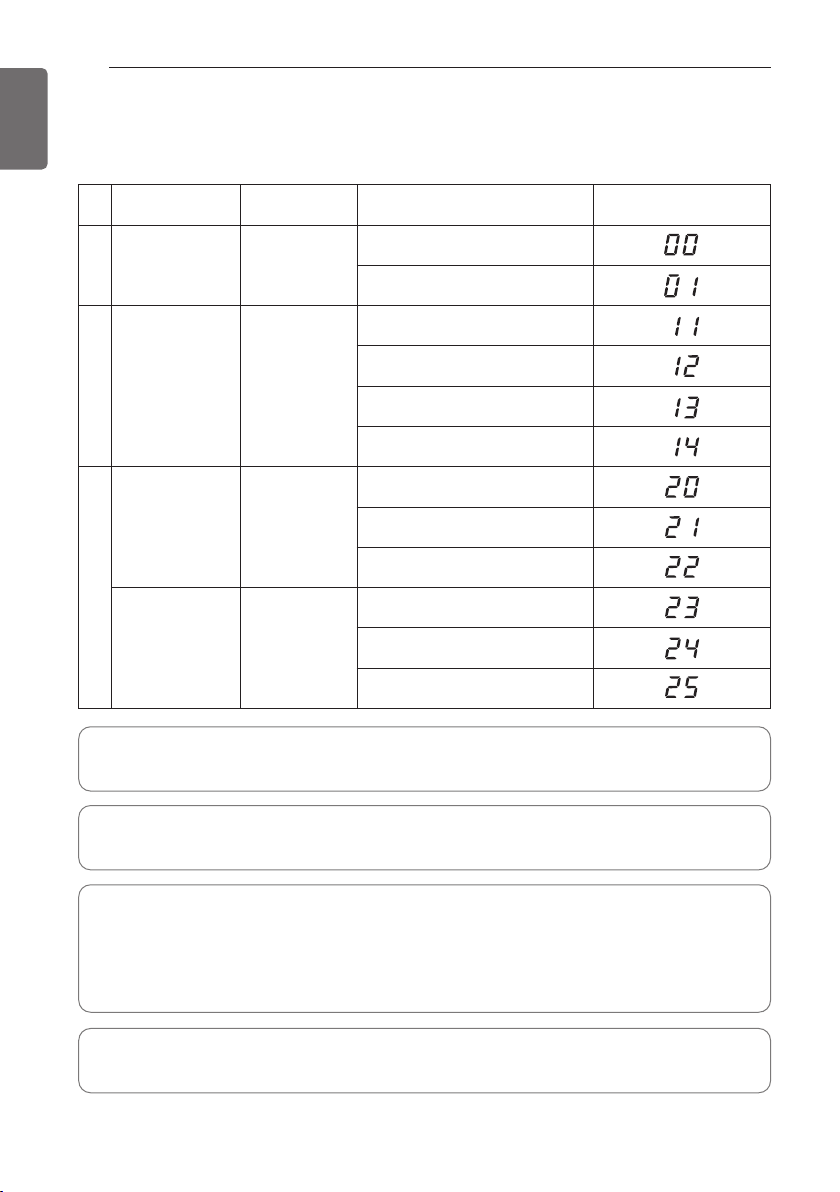

Installer Setting - Installer Setting Code Table

Installer Setting Code Table

No. Function Function code Setting value Remote controller LCD

0 Mode override

0

0 : Set to master

1 : Set to slave

1

Ceiling height

Selection

1

1 : Standard

2 : Low

3 : High

4 : Super high

2

Group control

2

0 : Set to master

1 : Set to slave

2 : Check master/slave

Auxiliary heater

2

3 : Set to auxiliary heater

4 : Cancel auxiliary heater

5 :

Check auxiliary heater Installation

Mode Override

This Function is only for Non-Auto Changeover H/P model.

Ceiling Height Selection

Indoor unit connected to wired remote controller operate as wired remote controller setting.

Auxiliary heater

This function is only applied to models with Auxiliary Heater function being activated.

Group Control (optional)

This function is only for group control. Please don’t set this function in case of non-group con-

trol.

After setting group control of the product, turn off the power then turn it back on after 1

minute.

27

ENGLISH

INSTALLATION INSTRUCTIONS

Installer Setting - Checking Address of Central Control

1. With the FUNC. button pressed, press the RESET button.

2. Press the ON/OFF button toward the indoor unit 1 time, and the indoor unit will display the set

address in the display window.

• The address display time and method can differ by the indoor unit type.

3. Reset the remote controller to use the general operation mode.

1. With the MODE button pressed, press the

RESET button.

2. By using the temperature setting button, set

the indoor unit address.

• Setting range : 00 ~ FF

3. After setting the address, press the ON/OFF

button toward the indoor unit 1 time.

4. The indoor unit will display the set address to

complete the address setting.

• The address display time and method can

differ by the indoor uint type.

5. Reset the remote controller to use the general

operation mode.

Installer Setting - Setting Address of Central Control

°C/°F (5 s)

TIME (3 s)

28

ENGLISH

MANUALE D’INSTALLAZIONE

CONDIZIONATORE

D'ARIA

Prima di installare il prodotto, leggere completamente questo manuale di installazione.

L'installazione deve essere eseguita in conformità con le norme nazionali per le connessioni

solo da parte di personale autorizzato.

Dopo avere letto il manuale di installazione conservarlo in un luogo sicuro per usarlo in

futuro.

Condizionatore a soffitto

Traduzione delle istruzioni originali (R32)

www.lg.com

Copyright © 2017 - 2018 LG Electronics Inc. All Rights Reserved.

ITALIANO

2

DESIGNAZIONE MODELLO

ITALIANO

DESIGNAZIONE MODELLO

- Nome prodotto : condizionatore d'aria

- Nome modello :

- Informazioni aggiuntive : il numero di serie si

riferisce al codice a barre presente sul prodotto

- Pressione max consentita lato Alto : 4,2 MPa

/ Lato basso : 2,4 MPa

- Refrigerante : R32

Informazioni prodotto

La pressione sonora ponderata emessa da questo prodotto è inferiore a 70 dB.

** Il livello di rumore può variare a seconda del

sito.

Le cifre riportate sono livelli di emissione e non

sono necessariamente i livelli di sicurezza di lavoro.

Mentre vi è una correlazione tra i livelli di emissione e di esposizione, questo non può essere

utilizzato in modo affidabile per determinare se

sono necessarie ulteriori precauzioni.

I fattori che influenzano il livello effettivo di esposizione del personale comprendono le caratteristiche della camera di lavoro e le altre fonti di

rumore, cioè il numero di apparecchiature e altri

processi adiacenti e il periodo di tempo in cui un

operatore è esposto al rumore. Inoltre, il livello di

esposizione consentito può variare da paese a

paese.

Tuttavia queste informazioni permetteranno all'utente dell'apparecchiatura di effettuare una migliore valutazione del pericolo e del rischio.

Emissione rumore aereo

SQSM N B 015

Numero di serie

Nome della struttura

Unità interna / Unità esterne

N : Unità interna

U : Unità esterna

Tipo di prodotto dettagliato

esclusivamente per modelli serie M

AQ : Montaggio a parete Libero-R

SQ : Montaggio a parete Libero-E

AH* : Raffreddamento artific.

AW* : Specchio per Raffreddamento artific.

AH : Cassetta per soffitto

AHL : Condotto per soffitto a scomparsa

(Bassa statica)

Tipo di prodotto dettagliato per

modelli serie U- / C

L : Bassa statica

H : COP elevato

C : Econo

R : Refrigerante R32

Capacità nominale

Es) 7.000 Btu/h Classe → '07',

18.000 Btu/h Classe → '18'

Tipo prodotto

S : Montaggio a parete /

ARTCOOL mirror

J : Montaggio a parete

A : ARTCOOL

T : Cassetta per soffitto

B, M : Condotto per soffitto a scomparsa

V : Sospensione a soffitto e pavimento

Q : Consolle

P : Montaggio a pavimento

Tipo di unità esterna collegabile

M : Unità interne esclusivamente per

sistemi Multi

U : Unità interne esclusivamente per

sistemi A Single

C : Unità interne comuni per CAC

Multiplo e Singolo

CONSIGLI PER IL RISPARMIO DI ENERGIA

3

ITALIANO

CONSIGLI PER IL RISPARMIO DI ENERGIA

Qui vi indichiamo alcuni consigli per ottenere un consumo di energia minimo quando usate il condizionatore d'aria. Potete usare il condizionatore d'aria con maggiore efficienza applicando le istruzioni indicate di seguito:

• Non raffreddare eccessivamente l'ambiente interno. Questo può essere pericoloso per la sa-

lute e può causare un consumo eccessivo di energia elettrica.

• Limitare al massimo la luce solare con schermi o tende quando si usa il condizionatore d'aria.

• Tenete porte e finestre ben chiuse quando utilizzate il condizionatore d'aria.

• Regolare la direzione del flusso d'aria verticalmente o orizzontalmente per far circolare l'aria in-

terna.

• Accelerare la velocità del ventilatore per raffreddare o riscaldare l'aria interna rapidamemte in

un breve periodo di tempo.

• Aprire le finestre regolarmente per la ventilazione quando la qualità dell'aria interna può peg-

giorare se il condizionatore d'aria viene usato per molte ore.

• Pulire il filtro dell'aria ogni 2 settimane. La polvere e le impurità accumulate nel filtro dell'aria

possono bloccare il flusso dell'aria e ridurre le funzioni di raffreddamento / deumidificazione.

Per le vostre registrazioni

Conservare con cura questa pagina nel caso che sia necessario provare la data di acquisto o per ottenere le prestazioni di riparazione in garanzia. Scrivere il numero del modello e il numero di serie qui:

Numero del modello:

Numero di serie:

Potete trovare questi dati su un'etichetta sul lato di ciascuna unità.

Nome del venditore:

Data di acquisto:

4

ITALIANO

ISTRUZIONI DI SICUREZZA IMPORTANTI

LEGGERE TUTTE LE ISTRUZIONI PRIMA DI USARE L'APPARECCHIO

Applicare sempre le precauzioni seguenti per evitare situazioni

pericolose e ottenere sicuramente la prestazione massima del vostro

prodotto.

ALLERTA

Si può provocare un ferimento grave o la morte se sono ignorate queste

istruzioni.

PRECAUZIONE

Si può provocare un ferimento o danno del prodotto limitato se sono

ignorate queste istruzioni.

ALLERTA

• L'installazione o le riparazioni eseguite da persone non qualificate

possono provocare pericoli a voi e ad altre persone.

• L'installazione DEVE essere conforme alle norme locali per la

costruzioni o in assenza delle norme locali deve essere conforme al

codice elettrico nazionale NFPA 70/ANSI C1-1003 o all'edizione attuale

del codice elettrico canadese parte 1^ CSA C.22.1.

• Le informazioni contenute nel manuale sono previste per l'uso da

parte di un tecnico di manutenzione qualificato che sia addestrato in

base alle norme di sicurezza e equipaggiato con gli attrezzi e strumenti

di controllo corretti.

• La mancanza della lettura e dell'applicazione precisa di tutte le

istruzioni di questo manuale può provocare un malfunzionamento

dell'apparecchio, danno per la proprietà, danno personale e/o la morte

delle persone.

!

!

!

ISTRUZIONI DI SICUREZZA IMPORTANTI

Leggere attentamente le precauzioni

contenute nel presente manuale prima di

avviare il funzionamento dell'apparecchio.

Questo elettrodomestico è pieno di

frigorigeno infiammabile (R32).

Questo simbolo indica che il Manuale di

istruzioni dovrebbe essere letto con

attenzione.

Questo simbolo indica che un tecnico

specializzato dovrebbe gestire

quest'attrezzatura facendo riferimento al

Manuale di installazione.

5

ITALIANO

ISTRUZIONI DI SICUREZZA IMPORTANTI

• Saranno rispettate le normative nazionali relative al gas

Installazione

• Collegare sempre l’apparecchio a terra. - In caso contrario, ci

potrebbero essere pericoli di scossa elettrica.

• Non usare cordoni d’alimentazione, spine, o prese elettriche

danneggiate o lasche. - Ciò comporterebbe pericoli di scossa elettrica

e di incendio.

• Per l’installazione del prodotto, rivolgersi sempre ad un centro di

assistenza qualificato o ad un’agenzia specializzata in installazioni.

- In caso contrario, ci potrebbero essere pericoli di scossa elettrica,

incendio, esplosione e infortuni.

• Collegare in modo sicuro ed affidabile la copertura delle parti elettriche

dell’unità interna e il pannello di servizio all’unità esterna. - Se la

copertura delle parti elettriche dell’unità interna e/o il pannello di

servizio non sono collegati in modo sicuro possono derivarne pericoli

di scossa elettrica a causa della polvere, dell’acqua, ... ecc.

• Installare sempre un sistema d’arresto delle fughe d’aria e un quadro

elettrico dedicato. - La loro non installazione può comportare rischi

d’incendio e di scossa elettrica.

• Non tenere o usare gas infiammabili vicino al condizionatore d’aria - In

caso contrario, ci potrebbero essere pericoli di incendio o di

malfunzionamento del prodotto.

• Assicurarsi che l’intelaiatura di installazione dell’unità esterna non sia

danneggiata a causa dell’usura del tempo. - Potrebbero esserci pericoli

di infortunio o di incidente.

• Non smontare o riparare il prodotto in modo casuale. - Ciò

comporterebbe pericoli di scossa elettrica e d’incendio.

• Non installare il prodotto in un luogo dove ci sono pericoli di caduta.

- In caso contrario, potrebbero esserci pericoli di infortuni.

• Usare le necessarie precauzioni quando si disimballa e si installa il

prodotto. - i bordi affilati potrebbero essere fonte di infortuni.

• L'apparecchio deve essere custodito in una stanza in cui non siano

presenti fonti di calore in continuo funzionamento (fonti di calore quali

ad esempio: fiamme libere, un apparecchio a gas o un riscaldatore

elettrico in funzionamento)

• Il prodotto va sollevato e trasportato da due persone o più. Evitare

lesioni personali.

6

ITALIANO

ISTRUZIONI DI SICUREZZA IMPORTANTI

• Non utilizzare significa accelerare il processo di sbrinamento o la

pulizia, processi diversi da quelli raccomandati dal produttore.

• Non forare o bruciare il sistema di circolo del refrigerante.

• Attenzione: i refrigeranti sono inodori.

• Mantenere libere le aperture di ventilazione

• L'apparecchio deve essere custodito in una stanza ben ventilata, nella

quale ci sia lo spazio necessario così come specificato per le

operazioni.

• I tubi refrigeranti dovranno essere protetti o avvolti per prevenire

danni.

• I connettori flessibili refrigeranti (come le linee di connessione tra

l'unità interna e quella esterna) che dovranno essere dislocati duranti

le normali operazioni, dovranno essere protetti da eventuali danni

meccanici.

• Sarà effettuato un collegamento brasato, saldato o meccanico prima di

aprire le valvole che consentiranno al frigorigeno di fluire tra le varie

parti del sistema di refrigerazione.

• I collegamenti meccanici saranno accessibili per motivi di

manutenzione.

Utilizzo

• Non collegare ad una presa di corrente condivisa con altri

elettrodomestici. - Questo potrebbe comportare pericoli di scossa

elettrica e d’incendio a causa del calore generato

• Non usare cordoni d’alimentazione danneggiati. - Ciò comporterebbe

pericoli di scossa elettrica e d’incendio.

• Non modificare o estendere in modo arbitrario la lunghezza del

cordone d’alimentazione. - Questo potrebbe comportare pericoli di

scossa elettrica e d’incendio.

• Prestare attenzione a che il cordone di alimentazione non venga tirato

durante il funzionamento operativo.

- Potrebbero esserci pericoli di scossa elettrica e d’incendio.

• Scollegare la spina elettrica di alimentazione del condizionatore

qualora da esso provenissero suoni anomali, strani odori, o fumo. - In

caso contrario, potrebbero esserci pericoli di scossa elettrica o

d’incendio.

• Tenere lontano da fiamme. - Altrimenti, ci potrebbero essere pericoli

d’incendio.

7

ITALIANO

ISTRUZIONI DI SICUREZZA IMPORTANTI

• Quando si vuole scollegare la spina elettrica, estrarla facendo presa

sul suo corpo, e non toccarla con le mani bagnate. - In caso contrario,

potrebbero esserci pericoli di scossa elettrica o d’incendio.

• Non usare il cordone d’alimentazione in prossimità di fonti di calore. Altrimenti, ci potrebbero essere pericoli di scossa elettrica e

d’incendio.

• Non aprire l’ingresso d’aspirazione dell’unità esterna/interna durante il

funzionamento. - Altrimenti, ci potrebbero essere pericoli di scossa

elettrica e di malfunzionamenti.

• Prestare attenzione a che l'acqua non scorra sulle parti elettriche. Questo potrebbe comportare malfunzionamenti del prodotto e pericoli

di scossa elettrica.

• Fare presa sul corpo della spina elettrica quando la si vuole scollegare

- Ci potrebbero pericoli di scossa elettrica o danneggiamenti.

• Non toccare mai le parti metalliche dell’unità quando si procede alla

rimozione del filtro. - Ci sono parti affilate che potrebbero causare

infortuni.

• Non salire sull’unità interna/esterna e non posare oggetti su di essa. Questo potrebbe causare infortuni dovuti a scivolamenti o caduta

dell’unità.

• Non collocare oggetti pesanti sul cordone d’alimentazione - Altrimenti,

ci potrebbero essere pericoli di

• Se il prodotto è stato immerso nell’acqua, consultare sempre un

centro di assistenza qualificato. - Altrimenti, ci potrebbero essere

pericoli di scossa elettrica e d’incendio.

• Prestare attenzione a che i bambini non salgano sull’unità esterna. - Ci

sono seri pericoli di infortuni dovuti a cadute.

• Usare una pompa a vuoto o gas inerte (azoto) quando si esegue il test

di perdita o lo spurgo di aria. Non comprimere l’aria o l’ossigeno e non

usare gas infiammabili. Altrimenti questa azione può provocare

incendio o esplosione. - Esiste il rischio di morte, ferimento, incendio

o esplosione.

• Non attivare il sezionatore o l’alimentazione elettrica nei casi in cui il

pannello anteriore, l’armadio, il coperchio superiore, il coperchio della

scatola dei comandi siano rimossi o aperti. - In caso contrario esiste il

rischio di incendio, shock elettrico, esplosione o morte.

8

ITALIANO

ISTRUZIONI DI SICUREZZA IMPORTANTI

• Spegnere tutti i dispositivi che potrebbero causare un incendio se vi

fossero perdite di frigorigeno, ventilare la stanza (es. aprendo la

finestra o utilizzando l’areazione), e contattare il distributore dal quale

avete acquistato l’unità.

• L'installazione delle tubature deve essere tenuta al minimo.

• Quando i collegamenti meccanici vengono riutilizzati all’interno, le parti

di tenuta dovranno essere rinnovate.

• Se vengono riutilizzati dei giunti svasati negli ambienti interni, la parte

svasata dovrà essere ricostruita.

PRECAUZIONE

Installazione

• Installare il tubo di scarico per assicurarsi che il deflusso avvenga in

modo insicuro. - Altrimenti, ci potrebbero essere perdite d’acqua.

• Installare il prodotto in maniera tale che il rumore o la corrente d’aria

calda provenienti dall’unità non possano danneggiare i vicini. Altrimenti, ci potrebbero essere delle dispute con i vicini.

• Controllare sempre l’eventuale presenza di perdite di gas dopo

l’installazione o la riparazione del prodotto.

- Altrimenti, ci potrebbero essere malfunzionamenti del prodotto.

• Mantenere il parallelismo dei livelli paralleli quando s’installa il

prodotto. - Altrimenti ci potrebbero essere vibrazioni o perdite d’acqua.

• Chiunque si trovi a lavorare o a intervenire su un circuito refrigerante

deve necessariamente essere in possesso di una certificazione in

corso di validità emessa dall'autorità competente del settore, con il

quale viene autorizzato a maneggiare i refrigeranti in condizioni di

sicurezza, in conformità alle norme specifiche del settore.

• Indossare sempre dispositivi di protezione adeguati (DPI) durante le

operazioni di installazione e manutenzione del prodotto.

Utilizzo

• Evitare il raffreddamento eccessivo e ventilare l’ambiente di tanto in

tanto. - Altrimenti, potrebbero esserci effetti dannosi per la vostra

salute.

• Usare panni soffici per le operazioni di pulizia. Non usare prodotti wax,

diluenti o detergenti forti. - L’aspetto generale del condizionatore

potrebbe deteriorarsi, cambiare colore, o subire graffiature superficiali.

!

ISTRUZIONI DI SICUREZZA IMPORTANTI

9

ITALIANO

• Non usare il condizionatore d’aria per scopi particolari diversi da quelli

specificati, quali preservare apparecchiature di precisione, vegetali,

animali, e oggetti d’arte. - Questo potrebbe danneggiare le parti

stesse.

• Non ostruire le aperture d’ingresso o d’uscita dell’aria. - Questo

potrebbe causare malfunzionamenti o incidenti.

• L'apparecchio deve essere custodito in un luogo in cui sia possibile

impedire il verificarsi di danni meccanici.

• Le operazioni di manutenzione devono essere fatte esclusivamente

seguendo le indicazioni del produttore delle attrezzature. La

manutenzione e la riparazione che richiedono l'assistenza di personale

tecnico abilitato devono avvenire sotto la supervisione di personale

competente nell'uso di refrigeranti infiammabili.

• Lo smontaggio dell'unità e il trattamento dell'olio refrigerante e di

eventuali parti sono operazioni da eseguirsi in conformità con le

normative standard locali e nazionali.

• Effettuare una pulizia periodica (più di una volta l’anno) relativa a

polvere e particelle accumulate sullo scambiatore di calore, utilizzando

acqua.

• Questo dispositivo sarà fornito con un conduttore di alimentazione che

risposta le normative nazionali.

• Questo elettrodomestico non è destinato all'utilizzo da persone

(inclusi bambini) con capacità fisiche, sensoriali o mentali ridotte, o

che manchino di esperienza e competenza, a meno che non sia

presente un supervisore o non siano fornite istruzioni relative

all'utilizzo dell'elettrodomestico da una persona responsabile per la

loro sicurezza. I bambini dovrebbero essere supervisionati per

assicurarsi che non giochino con l'elettrodomestico.

• Questo apparecchio può essere utilizzato da bambini di età pari o

superiore a 8 anni e persone con ridotte capacità fisiche, sensoriali o

mentali o mancanza di esperienza e conoscenza se hanno ricevuto

supervisione o istruzioni sull'uso dell'apparecchio in modo sicuro e

comprendono i pericoli. I bambini non devono giocare con

l'apparecchio. La pulizia e la manutenzione dell'utente non devono

essere eseguite da bambini senza supervisione.

10

INDICE DEI CONTENUTI

ITALIANO

INDICE DEI CONTENUTI

2 DESIGNAZIONE MODELLO

3 CONSIGLI PER IL RISPARMIO DI ENERGIA

4 ISTRUZIONI DI SICUREZZA IMPORTANTI

11 PARTI DEL DISPOSITIVO

11 ATTREZZI DI INSTALLAZIONE

12 INSTALLAZIONE

12 Scegliere la posizione migliore

14 INSTALLAZIONE DELL’UNITÀ INTERNA

15 Aprire il pannello laterale

16 Montare il dado e il bullone di ancoraggio

18 Tubazione di scarico dell’unità interna

18 Tubazione di scarico

18 Test di scarico

19 Isolamento termico

19 Svasatura

22 Cablaggi

23 PROVA DI FUNZIONAMENTO

25 ISTRUZIONI PER L'INSTALLAZIONE

25 Impostazioni di installazione - Come entrare nella modalità impostazioni di installazione

26 Impostazioni installazione - Tabella Impostazioni codice d’installazione

27 Impostazioni installazione - Impostare l’indirizzo del Controllo centralizzato

27 Impostazioni installazione - Controllare l’indirizzo del Controllo centralizzato

11

ITALIANO

PARTI DEL DISPOSITIVO

PARTI DEL DISPOSITIVO

ATTREZZI DI INSTALLAZIONE

Pannello laterale destro

Filtri dell’aria

(della griglia di

aspirazione)

Bocchetta di

aspirazione

(griglia di aspirazione)

Presa d’aria

Bocchetta di uscita dell’aria

Figura FiguraNome

Cacciavite

Trapano elettrico

Pannello laterale sinistro

Nome

Multimetro

Chiave esagonale

Nastro adesivo,

Taglierino

Trapano per carotaggio

Chiave

Coppia di serraggio

Amperometro

Rilevatore di

fughe di gas

Termometro, Livella

Set di strumenti

per svasatura

12

ITALIANO

INSTALLAZIONE

INSTALLAZIONE

Scegliere la posizione migliore

- Non deve esserci alcuna fonte di calore o vapore vicino all'unità.

- Non ci dovrebbero essere ostacoli che impediscano la circolazione dell'aria.

- Un luogo in cui ci sia una buona ventilazione.

- Un luogo in cui il drenaggio non provochi danni.

- Un luogo in cui sia presa in considerazione la prevenzione del rumore.

- Non installare l’unità vicino al vano della porta.

- Assicurarsi che lo spazio dalla parete, dal soffitto o da altri ostacoli rispettino quelli indicati dalle

frecce.

- L'unità interna deve poter garantire lo spazio di manutenzione.

Unità : mm(pollici)

10 (13/32)

o più

300 (11 – 13/16)

o più

2500 (98 – 3/7)

o più

A pavimento

700(27 – 9/16) o più 700(27 – 9/16) o più

13

ITALIANO

INSTALLAZIONE

- L'apparecchio deve essere installato, custodito e messo in funzione in una stanza nella quale la superficie del pavimento sia superiore all'area minima.

- Utilizzate il grafico della tabella per determinare l'area minima.

- m : Quantitativo totale di frigorigeno nel sistema

- Quantitativo totale di frigorigeno: ricarica di frigorigeno da fabbrica + quantitativo di frigorigeno addizionale

- Amin : area minima per l’installazione

Area del pavimento minima

A pavimento

m (kg) Amin (m

2

)

< 1.224

-

1.224 12.9

1.4 16.82

1.6 21.97

1.8 27.80

2 34.32

2.2 41.53

2.4 49.42

2.6 58.00

2.8 67.27

3 77.22

3.2 87.86

3.4 99.19

3.6 111.20

3.8 123.90

4 137.29

4.2 151.36

4.4 166.12

A pavimento

m (kg) Amin (m

2

)

4.6 181.56

4.8 197.70

5 214.51

5.2 232.02

5.4 250.21

5.6 269.09

5.8 288.65

6 308.90

6.2 329.84

6.4 351.46

6.6 373.77

6.8 396.76

7 420.45

7.2 444.81

7.4 469.87

7.6 495.61

7.8 522.04

A muro

m (kg) Amin (m

2

)

< 1.224

-

1.224 1.43

1.4 1.87

1.6 2.44

1.8 3.09

2 3.81

2.2 4.61

2.4 5.49

2.6 6.44

2.8 7.47

3 8.58

3.2 9.76

3.4 11.02

3.6 12.36

3.8 13.77

4 15.25

4.2 16.82

4.4 18.46

A muro

m (kg) Amin (m

2

)

4.6 20.17

4.8 21.97

5 23.83

5.2 25.78

5.4 27.80

5.6 29.90

5.8 32.07

6 34.32

6.2 36.65

6.4 39.05

6.6 41.53

6.8 44.08

7 46.72

7.2 49.42

7.4 52.21

7.6 55.07

7.8 58.00

A soffitto

m (kg) Amin (m

2

)

< 1.224

-

1.224 0.956

1.4 1.25

1.6 1.63

1.8 2.07

2 2.55

2.2 3.09

2.4 3.68

2.6 4.31

2.8 5.00

3 5.74

3.2 6.54

3.4 7.38

3.6 8.27

3.8 9.22

4 10.21

4.2 11.26

4.4 12.36

A soffitto

m (kg) Amin (m

2

)

4.6 13.50

4.8 14.70

5 15.96

5.2 17.26

5.4 18.61

5.6 20.01

5.8 21.47

6 22.98

6.2 24.53

6.4 26.14

6.6 27.80

6.8 29.51

7 31.27

7.2 33.09

7.4 34.95

7.6 36.86

7.8 38.83

Amin (m2)

600

500

400

300

200

100

0

0 1.224 2 3 4 5 6 7 8

Collocazione

a pavimento

Montaggio a parete

Montaggio a soffitto

m (kg)

14

INSTALLAZIONE DELL’UNITÀ INTERNA

ITALIANO

INSTALLAZIONE DELL’UNITÀ INTERNA

• Installare orizzontalmente l’unità usando

una livella.

• Durante l’installazione, fare attenzione a

non danneggiare i cavi elettrici.

• Scegliere e segnare la posizione per il

fissaggio dei bulloni e per l’imboccatura

del tubo.

• Stabilire una posizione leggermente inclinata verso lo scarico per fissare i bulloni, tenendo conto della direzione della

tubazione di scarico.

• Praticare il foro per il bullone di ancoraggio sul soffitto.

ATTENZIONE

!

NOTA

!

• Non installare nelle seguenti posizioni.

1. Luoghi come ristoranti e cucine, in cui

si producono grandi quantità di fumi

d’olio e farina. Questi possono penalizzare lo scambio di calore o causare perdite d’acqua e malfunzionamenti della

pompa di scarico. In questi casi, procedere come segue:

• Assicurarsi che l’impianto di aerazione

sia sufficiente per aspirare eventuali gas

nocivi dal luogo di installazione.

• Installare il condizionatore d’aria a una

distanza adeguata dalla cucina, affinché

non aspiri fumi d’olio.

2. Evitare luoghi dove si possono produrre

fumi d’olio di cottura o polvere di ferro.

3. Evitare luoghi dove si possono produrre

gas infiammabili.

4. Evitare luoghi dove si possono produrre

gas nocivi.

5. Evitare luoghi vicino a generatori ad alta

frequenza.

Condizionatore

Tenere una

distanza sufficiente

Usare un’impianto di

aerazione per cappe

aspiranti con sufficiente

Piano cottura

portata.

INSTALLAZIONE DELL’UNITÀ INTERNA

15

ITALIANO

Aprire il pannello laterale

Fase 1

Lato posteriore

Pannello laterale destro

Lato posteriore

Pannello

laterale sinistro

Fase 2

- Togliere due viti dal pannello laterale.

Fase 3

Fase 4

- Rimuovere la staffa di carta dal coperchio del

pannello.

- Togliere il coperchio dal pannello laterale.

(Picchiettare con il palmo sul lato posteriore

del pannello)

- Aprire nel coperchio il foro per il tubo con

l’aiuto di una pinza.

Stringere il coperchio con l’altra mano

mentre si picchietta per evitarne la caduta.

ATTENZIONE

!

16

ITALIANO

INSTALLAZIONE DELL’UNITÀ INTERNA

Montare il dado e il bullone di

ancoraggio

- Preparare 4 bulloni di sospensione. (I bulloni

devono essere della stessa lunghezza.)

- Prendere le misure e segnare la posizione

per i bulloni di sospensione e il foro per il

tubo.

- Praticare il foro per il bullone di ancoraggio

sul soffitto.

- Inserire i dadi e la rondella nei bulloni di

sospensione per agganciarli sul soffitto.

- Montare saldamente i bulloni di sospensione

al dado di ancoraggio.

- Fissare le piastre di installazione sui bulloni di

sospensione (regolare il livello a occhio) con

dadi, rondelle e rondelle elastiche.

- Correggere la posizione in direzione destrasinistra con una livella, avanti-indietro regolando i bulloni di sospensione.

- Correggere la posizione verso l’alto-basso

regolando i bulloni di sospensione. L’unità

sarà così inclinata verso il basso in modo da

favorire lo scarico.

- I seguenti elementi sono opzionali.

Bullone di montaggio - W 3/8 o M10

Dado – W 3/8 o M10

Rondella elastica - M10

Rondella piana - M10

[Unità: mm]

Rondella

Piastra di installazione

Rondella

Serrare il dado e il bullone per evitare la

caduta dell'unità.

• Praticare nella parete il foro per il tubo,

leggermente inclinato verso l’esterno,

con una fresa cilindrica di Ø 70.

ATTENZIONE

!

Modello (kBtu/h) A B

18k/24k 1018

355

36k/42k/48k/60k 1418

Dado di ancoraggio

Soffitto

Dado

Bulloni di

sospensione

Rondella

A

Bullone di sospensione

B

Bullone di montaggio

(W3/8 o M10)

Dado

(W3/8 o M10)

Rondella elastica

(M10)

Rondella piana

per M10

(facoltativa)

Rondella piana

per M10

(facoltativa)

Dado

(W3/8 o M10)

Wall

Indoor

Outdoor

Slope gradient for

drain Should be

1/50 ~ 1/100

Piastra di installazione

Piastra di installazione

Rondella

elastica

12mm

Bullone di

sospensione

Max.

Dado

Rondella

Rondella

17

ITALIANO

INSTALLAZIONE DELL’UNITÀ INTERNA

Informazioni di installazione per l’inclinazione

- L’inclinazione verso il basso dell’unità interna è essenziale per lo scarico dei condizionatori

d’aria a condotto.

- Lo spessore minimo dell'isolamento del tubo di collegamento deve essere 10 mm.

- Se le piastre di installazione sono fissate orizzontalmente, dopo l’installazione l’unità interna

sarà inclinata verso il basso.

ATTENZIONE

!

Vista frontale

- L’unità deve essere orizzontale o inclinata.

- L’inclinazione deve essere minore o uguale a 1° e non superare i 10-20 mm di pendenza in direzione dello scarico come mostrato nella fig.

Soffitto

10~20 mm

Vista laterale

- Al termine dell’installazione l’unità deve essere inclinata verso il basso.

Soffitto

5~10 mm

18

ITALIANO

INSTALLAZIONE DELL’UNITÀ INTERNA

18

Tubazione di scarico dell’unità

interna

- Le tubazioni di scarico devono avere una

pendenza verso il basso (da 1/50 a 1/100): assicurarsi che la pendenza non sia irregolare,

per prevenire l'inversione del flusso.

- Durante il collegamento delle tubazioni di

scarico, fare attenzione a non esercitare una

forza eccessiva sulla porta di scarico dell'unità interna.

- Rimuovere il tappo di gomma prima di collegare il tubo flessibile di scarico.

- Appendere alla staffa dopo aver collegato il

tubo flessibile di scarico come mostrato

sotto.

Tubazione di scarico

- Il tubo flessibile di scarico deve essere diretto verso il basso per facilitare il flusso di

drenaggio.

- Non montare la tubazione di scarico nel

modo seguente.

- Assicurarsi di installare l'isolamento termico

sul tubo di scarico.

Test di scarico

Attenersi alla seguente procedura per verificare il funzionamento della pompa di scarico:

- Regolare a mano le bocchette di aerazione in

posizione (orizzontale).

- Versare un bicchiere d’acqua nell’evaporatore con l’aiuto di una teiera.

- Accertarsi che l'acqua scorra attraverso il

tubo flessibile dell'unità interna senza perdite

ed esca dall'uscita di scarico.

Tubo flessibile di scarico

Staffa di supporto

Materiale termoisolante: Schiuma di polietilene con uno spessore superiore a 8 mm.

Non sollevare

Perdita di acqua

Perdita di acqua

Perdita di acqua

Estremità del

tubo flessibile

di scarico immersa

nell'acqua

Canalina di scarico

Acqua di scarico

accumulata

Aria

A onde

Meno di 50 mm

di spazio

Inclinazione

verso il basso

19

ITALIANO

INSTALLAZIONE DELL’UNITÀ INTERNA

Isolamento termico

Per la tubazione del refrigerante utilizzare materiale termoisolante che abbia un’eccellente

resistenza termica (oltre 120°C).

Precauzioni da adottare in ambienti ad alto

tasso di umidità: Questo condizionatore è

stato testato secondo gli “Standard Coreani in

Condizioni di Nebbia” ed è stato confermato

che non ha alcun difetto. Tuttavia, se viene utilizzato per un periodo prolungato in un ambiente estremamente umido (punto di

condensazione: superiore a 23°C), potrebbero

cadere delle gocce d’acqua. Se così fosse, aggiungere materiale termoisolante come indicato di seguito:

- Materiale isolante necessario...

Lana di vetro adiabatico con spessore da 10

a 20 mm.

- Incollare la lana di vetro su tutti i condizionatori posizionati sul soffitto.

Collegare i cavi all’unità interna

- Rimuovere il coperchio della scatola di controllo per effettuare il collegamento elettrico

tra l’unità interna e quella esterna.

- Utilizzare lo stringicavo per fissare il cavo.

Svasatura

La causa principale delle perdite di gas è

un’errata procedura di svasatura. Eseguire il lavoro di svasatura seguendo la procedura riportata di seguito:

1 Utilizzare tubazioni in rame ad uso frigori-

fero reperite da un rivenditore locale.

2 Misurare la distanza tra l’unità interna ed

esterna.

3 Tagliare i tubi un po’ più lunghi della di-

stanza misurata.

4 Tagliare il cavo 1,5 m più della lunghezza

del tubo.

1 Rimuovere ogni sbavatura dalla sezione ta-

gliata in trasversale del tubo.

2 Nel rimuovere le sbavature, posizionare

l’estremità del tubo in rame verso il basso

durante la rimozione delle sbavature per

evitare la caduta delle stesse nella tubatura.

Tagliare tubi e il cavo

Rimozione delle sbavature

Tubo

Alesatore

Punta verso

il basso

Coperchio scatola di controllo

Fascetta di fissaggio

Tubazione del

Unità interna

refrigerante

Isolante termico

Tubo in

rame

90°

Inclinato

Non uniforme

Grezzo

20

ITALIANO

INSTALLAZIONE DELL’UNITÀ INTERNA

- Rimuovere i dadi svasati fissati all’unità interna ed esterna, posizionarli sul tubo completamente privo di sbavature (non è

possibile montarli prima).

1 Tenere saldamente il tubo in rame in una

barra delle dimensioni indicate nella tabella

in basso.

2 Eseguire la svasatura con l’attrezzo appo-

sito.

1 Confrontare la svasatura con la figura in

basso.

2 Se la svasatura è difettosa, tagliare la se-

zione svasata e ripetere la svasatura.

1 Allineare il centro dei tubi e serrare

sufficientemente a mano il dado svasato.

2

Serrare il dado svasato con una chiave inglese.

Montaggio del dado

Montaggio del dado

Verifica

Collegamento del tubo di installazione e del tubo flessibile di scarico all’unità interna.

Diametro esterno Coppia

mm pollici kgf.m

Ø6.35 1/4 1.8~2.5

Ø9.52 3/8 3.4~4.2

Ø12.7 1/2 5.5~6.5

Ø15.88 5/8 6.3~8.2

Il rame a contatto con i refrigeranti sarà

privo di ossigeno o de-ossidato, per

esempio Cu-DHP come specificato in EN

12735-1 e EN 12735-2

ATTENZIONE

!

• L'installazione delle tubature deve essere tenuta al minimo.

• Lo snodo svasato sarà utilizzato unicamente con un tubo ricotto, e con misure

di tubature che non superino i 20 mm di

diametro esterno.

ATTENZIONE

!

Diametro

esterno

Grado di tem-

pratura

A

mm pollici Metallo ricotto(o) mm

Ø6.35 1/4 Metallo ricotto(o) 1.1~1.3

Ø9.52 3/8 Metallo ricotto(o) 1.5~1.7

Ø12.7 1/2 Metallo ricotto(o) 1.6~1.8

Ø15.88 5/8 Metallo ricotto(o) 1.6~1.8

Dado svasato

Tubo in rame

Barra

Tubo in rame

"A"

Barra

Maniglia di presa

Maniglia

Forcella

Cono

Contrassegno di

freccia rossa

Uniforme per tutta

la circonferenza

Lunghezza uniforme per

tutta la circonferenza

Interno privo di graffi

= Svasatura errata =

Inclinata

Superficie

danneggiata

Fessurata Spessore

non uniforme

Tubatura dell'unità interna Dado svasato Tubi

Chiave aperta (fissa)

Dado svasato

Chiave inglese

Tubatura dell'unità interna

Tubo di collegamento

21

ITALIANO

INSTALLAZIONE DELL’UNITÀ INTERNA

3 When needed to extend the drain hose of

indoor unit, assembly the drain pipe as

shown on the drawing